TELESCOPIC BOTTLE JACK

MODEL NO: CBJ2B,3B,5B,8B,10B,12B,15B & 20B

PART NO: 7620006,7620008,7620012,7620022,7620027,7620032,7620034 & 7620037

OPERATION AND MAINTENANCE

INSTRUCTIONS

ORIGINAL INSTRUCTIONS GC1021 - rev 7

INTRODUCTION

Thank you for purchasing this CLARKE Bottle Jack.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to your purchase

giving you long and satisfactory service. Keep these instructions for future

reference.

MODEL SPECIFICATIONS

CBJ2B CBJ3B CBJ5B CBJ8B CBJ10B CBJ12B CBJ15B CBJ20B

Rated Load

(tonnes)

Min Height

of saddle

(mm)

Max Height

of saddle

(mm)

Oil capacity 0.65L 0.13L 0.175L 0.22L 0.255L 0.3L 0.34L 0.44L

Dimensions

(L x W x H)

mm

Handle

length (mm)

Weight

(kg)

235810121520

140 168 185 190 195 200 205 217

260 326 355 365 375 380 390 407

89 x

95 x

135

368 457 457 457 457 496 496 495

2.4 3.1 4.1 4.9 5.7 6.6 7.7 9.8

92 x

100 x

180

96 x

110 x

185

103 x

118 x

190

110 x

123 x

195

116 x

136 x

200

133 x

136 x

205

144 x

150 x

217

2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SAFETY PRECAUTIONS

1. Do not exceed the rated capacity of the jack.

2. Do not allow personnel to operate the jack unless they have read these

safety precautions.

3. Do not operate the jack if damaged.

4. Use the jack in a suitable, well lit work area.

5. Keep the work area clean and tidy and free from unrelated items.

6. Only use the jack on firm, level and solid ground, preferably concrete.

Avoid soft/unmade ground as the jack may sink in. or move.

7. Ensure non-essential persons keep a safe distance whilst the jack is in use.

8. Ensure there are no personnel or obstructions under the vehicle before

lowering.

9. Do not work under the vehicle until it is fully supported by axle stands.

10. Keep hands etc clear of the vehicle until lifting is complete.

11. Ensure that you can see the saddle and jacking point throughout the

jacking operation in case there is any relative movement.

12. Always ensure that the jack saddle is centred and stable on the lifting point

before lifting and position the jack to avoid operating it from under the

vehicle.

13. Check the vehicle weight and recommended lifting points by referring to

the vehicle owners manual. Ensure the lifting point is not corroded.

14. Never tamper with the jack or modify it in any way, as this could prove to

be dangerous and will invalidate the guarantee. Only use the jack for the

purpose for which it is intended.

15. Use appropriate safety equipment, such as protective footwear, when

using this jack.

16. Ensure that the jack is properly maintained and lubricated at all times, and

that no corrosion is allowed to weaken any part of it.

17. If the jack has been subjected to an abnormal load or shock, it should be

removed from service immediately and fully inspected by qualified

personnel, and passed as serviceable, before being used again.

18. When not in use, store the jack, fully lowered, in a safe, dry, childproof area.

19. Always inspect the jack before use. Ensure that all parts are in good

condition and operating smoothly, and that no cracks or distortion is

apparent. If in doubt do not use.

3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

20. Never push a vehicle off the jack or start the engine while supported only

by the jack.

21. Do not use if an oil leak is apparent. Consult the Clarke Service

Department.

22. If more than one jack is used in unison, they must all be of the same rating

and be raised at the same speed/height to reduce the possibility of the

load slipping.

SAFETY SYMBOLS

The following safety symbols may be found on the product.

Read the user manual before use.

LIFTING OPERATIONS AND LIFTING EQUIPMENT REGULATIONS 1998

This jack, depending on use, may fall within the scope of LOLER. It is the

owner’s responsibility to determine whether or not it does and, if so, to comply

with any applicable requirements in LOLER, for having the jack thoroughly

examined.

ENVIRONMENTAL PROTECTION

1. Take care to ensure that if hydraulic oil is spilt that it is cleaned away using

sand or treated with absorbent granules designed for the purpose.

2. Always make every effort to contain any spillage and prevent ingress into

the local water course.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights

4

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

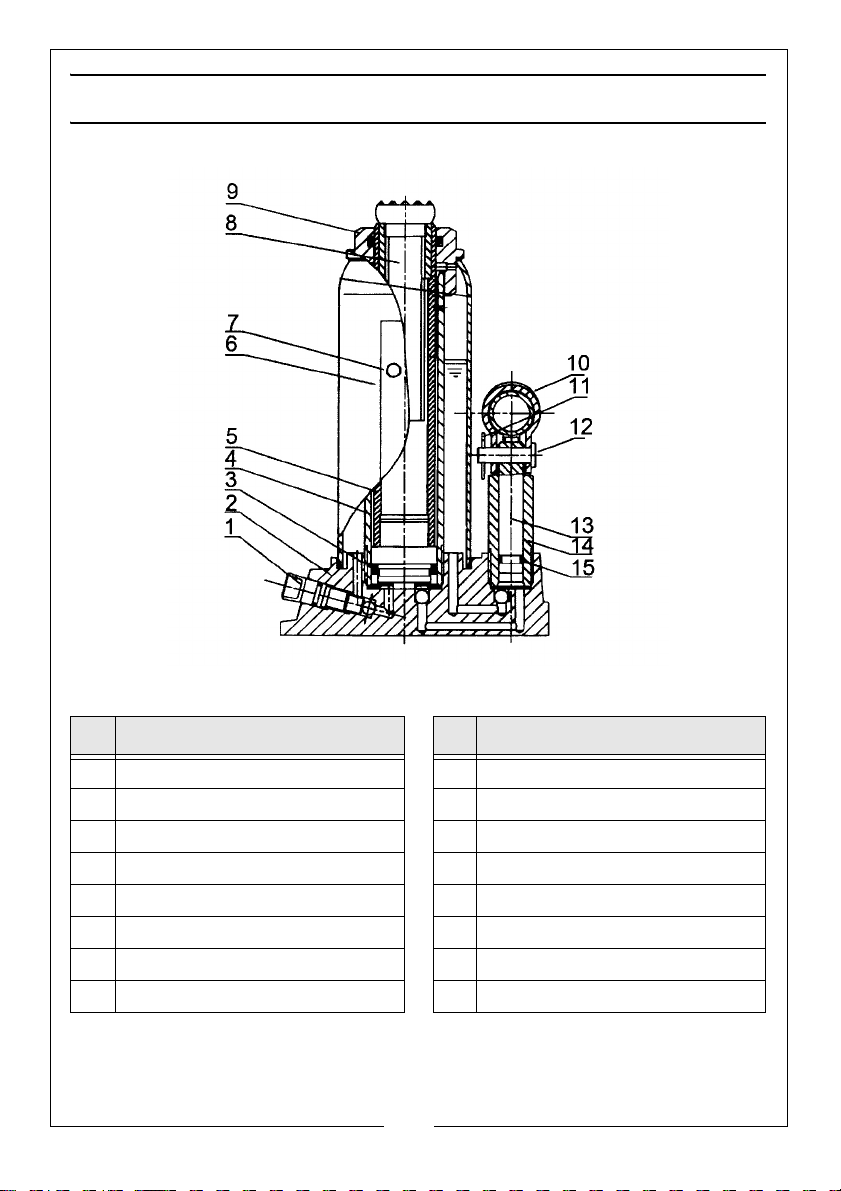

PRODUCT FEATURES

(CBJ5B shown)

1 Handle Tubes

2Ram

3 Screw Extension

4 Oil Filler Plug

5Actuating Lever

6 Release Valve

7 Safety Valve (non-adjustable)

UNPACKING

During transit or storage, it is possible that an air pocket may have developed

within the hydraulic ram, and the ram action may therefore appear to be

‘spongy’. In this case the jack may require purging as described on page 8.

If the ram does not reach its full height, the oil level may require topping up, as

described in the Maintenance section.

5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

OPERATION

WARNING: ENSURE THE SAFETY PRECAUTIONS ARE STRICTLY FOLLOWED.

NO RESPONSIBILITY CAN BE ACCEPTED FOR INCORRECT USE OF THE

JACK

RAISING A VEHICLE

1. Ensure the vehicle is stable and is on firm level ground with the wheels

chocked before positioning the jack so that is directly beneath the lifting

point. DO NOT rely upon the vehicle handbrake alone to prevent vehicle

movement.

2. Ensure the jack is on solid ground. If not, place a suitable piece of solid

wood of sufficient size to provide adequate support beneath the jack.

3. Consult the vehicle owners manual to ascertain the location of suitable

jacking points and position the jack beneath the designated lifting point.

4. Locate the oval end of the jack handle on to the release valve and turn

fully clockwise to close the valve.

5. Set the screw extension in contact with the lifting point. Pump the handle

and raise the ram so that the jack and lifting point are in full contact.

Before proceeding further, make one final check to ensure that:

• the jack is completely vertical and stable.

• there are no obstructions to the lift and that the handle can move

freely up and down.

• all personnel are in a safe position, well away from the underneath

of the vehicle.

6. When satisfied, continue to pump the handle and lift the load to the height

required.

7. Never allow anyone to get beneath the load until it is firmly supported on

suitable, properly rated axle stands.

LOWERING THE VEHICLE

WARNING: ALWAYS LOWER IN A SLOW AND CONTROLLED MANNER, AND

CHECK THAT THERE ARE NO OBSTACLES IN THE PATH OF THE LOAD’S

DESCENT. BE EXTREMELY CAREFUL WHEN LOWERING HEAVY LOADS.

1. The lowering speed is controlled by the amount you turn the release valve.

With the axle stands removed, check to ensure that there are no personnel

6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

in the immediate vicinity before removing the handle from its housing, and

engaging it with the release valve.

2. Very slowly turn the handle anticlockwise to open the release valve, and

allow the jack to lower the load, under complete control. NEVER, under

any circumstances, jerk the valve open.

MAINTENANCE

IMPORTANT: Only fully qualified personnel should attempt to repair the jack.

INSPECTION

1. Always visually inspect the jack before use, to ensure that all parts are

correctly located and secure. Check for hydraulic leaks, signs of damage

or worn parts. Do not use the jack unless it is perfectly serviceable.

• A slight dampness on the ram is normal, but where leakage is found,

the ram seals must be renewed by your Clarke Service Department.

2. The jack should be fully inspected annually as follows:

• Check for cracks and deformation of components.

• Check operation and top up the oil level. (see below).

• Remove completely, any rust or corrosion and repaint to prevent

further corrosion..

3. After use, store the jack with the ram in its lowest position. This not only

relieves the hydraulic ram, but also prevents any possibility of corrosion to

the ram.

4. Do not leave the jack in the open, exposed to the weather. Keep under

cover. If stored for long periods, inspect before use, clean, and re-oil. For

servicing, contact your CLARKE dealer or CLARKE Service dept.

TOPPING UP THE OIL

It may be necessary from time to time to top up the hydraulic oil level.

Proceed as follows.

1. Turn the release valve anti-clockwise and allow the ram to retract to its

lowest position.

• It may be necessary to apply force to the saddle for lowering

without any weight on the jack.

2. With the jack in the level position, remove the filler plug and stand upright.

• The oil should be level with the bottom of the oil filler hole.

3. If below this, top up.

7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

4. Do not overfill. Only use the correct type of oil such as Clarke hydraulic oil

(part number 3050830).

5. Replace the filler plug.

6. Check the jack for correct operation and purge any air from the system as

described below.

PURGING AIR FROM THE JACK

1. Turn the release valve counterclockwise one full turn to open.

2. Pump the handle eight full strokes.

3. Turn the release valve clockwise to close the valve.

4. Pump the handle until the ram reaches maximum height and continue to

pump several times to remove trapped air.

5. Turn the release valve counterclockwise one full turn and lower the ram to

its lowest position. Apply pressure if necessary.

6. Turn the release valve clockwise to the closed position and check for

correct operation. It may be necessary to perform the procedure more

than once to evacuate all the air.

TROUBLESHOOTING

Problem Check Solution

Jack will not lift to full

height

Jack will not hold load Release valve not closing

Jack piston will not

lower

Jack feels spongy

when lifting

Low oil level Check oil level

Contact Clarke Service

Hydraulic oil contaminated

Pump valves not sealing

Cylinder ram binding

Cylinder ram binding

Parts warn

Internal damage

Lift arm linkage bent or

binding

See Air Purging section See air purging

Department

Contact Clarke Service

Department

procedure above

8

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

COMPONENT PARTS

No Description No Description

1 Release valve assembly 9 Top Cap

2 Base Casting 10 Actuating Arm

3 O-ring 11 Spring Clip

4 Hydraulic Cylinder 12 Hinge Pin

5 Piston 13 Pump Plunger

6 Oil Reservoir 14 Pump Body

7 Filler Plug 15 O-ring

8 Extension Screw

Please contact the Clarke Spares Department for availability of seal kits,

handle or other component parts.

9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

ALSO AVAILABLE FROM CLARKE

10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

DECLARATION OF CONFORMITY

11

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Loading...

Loading...