TIG WELDING TORCH

FOR USE WITH MODEL AT131/AT132/AT133/AT135

PART NO: 6012232

OPERATING & MAINTENANCE

INSTRUCTIONS

GC1216

INTRODUCTION

Thank you for purchasing this CLARKE Welding Torch. Assembly. It is ideal for

use with the CLARKE model AT161,162 & 165 ARC/TIG welders.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to your purchase

giving you long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission. This guarantee does not effect your

statutory rights.

GENERAL SAFETY PRECAUTIONS

IMPORTANT: In addition to the following precautions, you should read, and

fully comply with, all instructions and safety precautions that were supplied

with your TIG Welder. Please keep these instructions in a safe place for

future reference.

1. NEVER point the torch at any person or animal.

2. NEVER touch the nozzle unless the welder is switched OFF and the nozzle

has been allowed to cool off.

3. NEVER connect, disconnect, or attempt to service the torch, unless the

machine is switched OFF and disconnected from the mains supply.

4. NEVER allow the cables to become wrapped around the operator or

anyone in the vicinity.

5. When welding, users and bystanders must ALWAYS use a protective

headshield fitted with the correct shade of lens. Failure to do so can cause

serious damage to your eyes.

2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

INTRODUCTION

Unpack and lay out the components, checking against the following list. Any

damage which may have been incurred in transit should be reported to your

CLARKE dealer immediately.

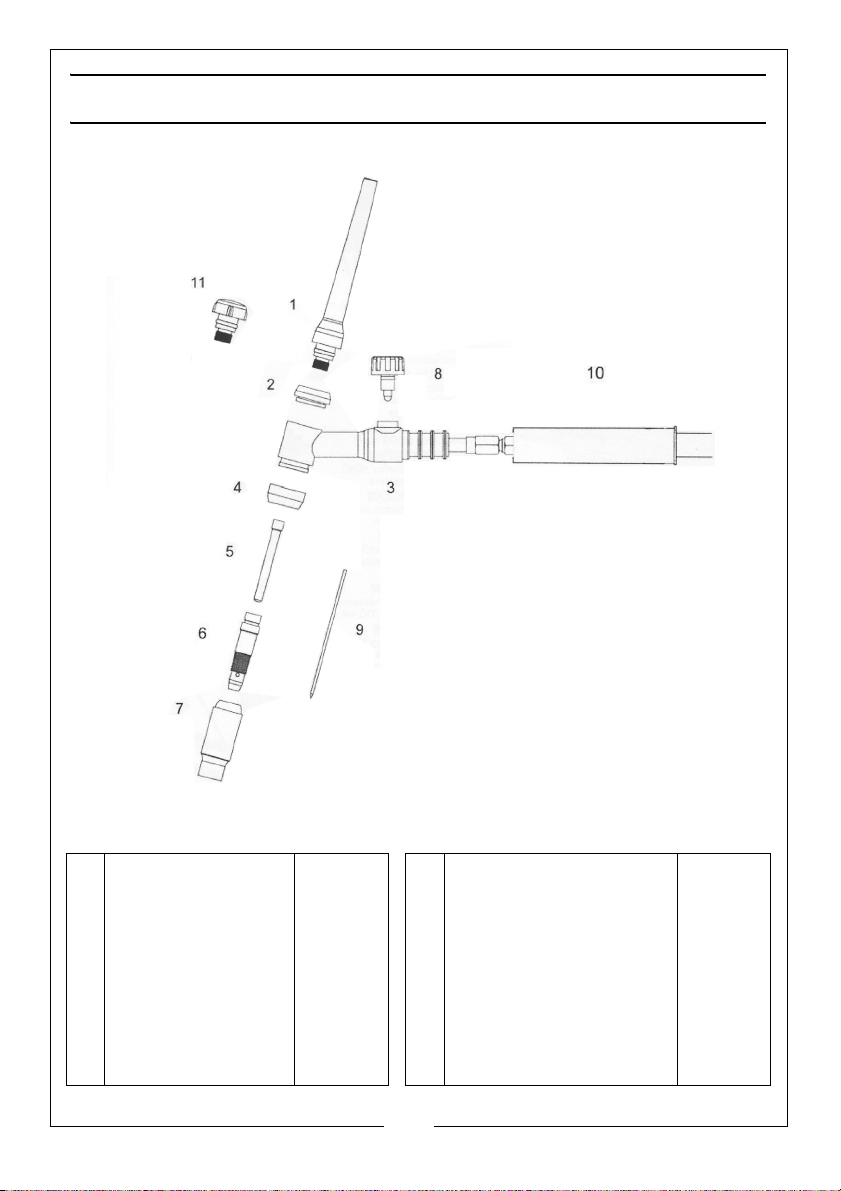

The welding torch comprises the following items: (Nos. in brackets refer to parts

diagram on page 7).

• Torch body (3) with front/rear cup gaskets (2 & 4)

• End cap complete with O-ring (1)

• Valve stem complete with O-ring (8)

• Tungsten Electrodes - 1.6 and 2.4mm (9)

• Collet bodies 1.6 mm and 2.4mm (6)

• Collets 1.6 and 2.4 mm (5)

• Ceramic nozzles size 5 and size 6 (7)

• Handle and Hose Assembly (10)

• Instruction Manual (this document)

3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

ASSEMBLY

A complete torch assembly with

electrode, is supplied, and is

assembled as follows:

1. Screw the collet body into the

head of the torch, (Fig.1) and

tighten finger tight.

2. Screw on the ceramic nozzle

insulator (Fig 2).

NOTE: Before assembly, file or grind

the tip of the electrode to a

point (from 40

this will give optimum

performance.

3. Pass the electrode through the

collet from the shoulder end and

insert the collet into the collet

body through the rear of the

torch, with its shoulder facing the

rear as in Fig 3.

4. Pass the electrode through, so

that it protrudes from the nozzle

by approx.10mm and screw on

the rear end cap.

If welding space is likely to be

restricted, the short end cap should

be used in conjunction with an

electrode of reduced length.

Otherwise use the long end cap and

standard electrode.

5. As the end cap tightens, the

electrode will be gripped and

secured in position. Whilst it is still

possible for the electrode to

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

o

to 60o), as

4

move, adjust it so that it protrudes from the nozzle by 4 - 5mm and then

tighten the end cap against the rubber O-ring. The electrode will now be

secured in position.

Your torch assembly is now ready for use.

GAS SUPPLY

it will be necessary to procure a supply of pure ARGON gas and a suitable gas

regulator.

Attach the gas hose to the pressure regulator, securing with a worm drive clip

and the pressure regulator to the gas bottle, ensuring the connection is

perfectly gas tight. Pressure is regulated by turning the control knob on the

regulator.

ALWAYS release the pressure from the regulator when not in use, and

remember to turn OFF the gas supply as soon as you have finished welding.

ALWAYS close the cylinder valve before attempting to change an empty

cylinder.

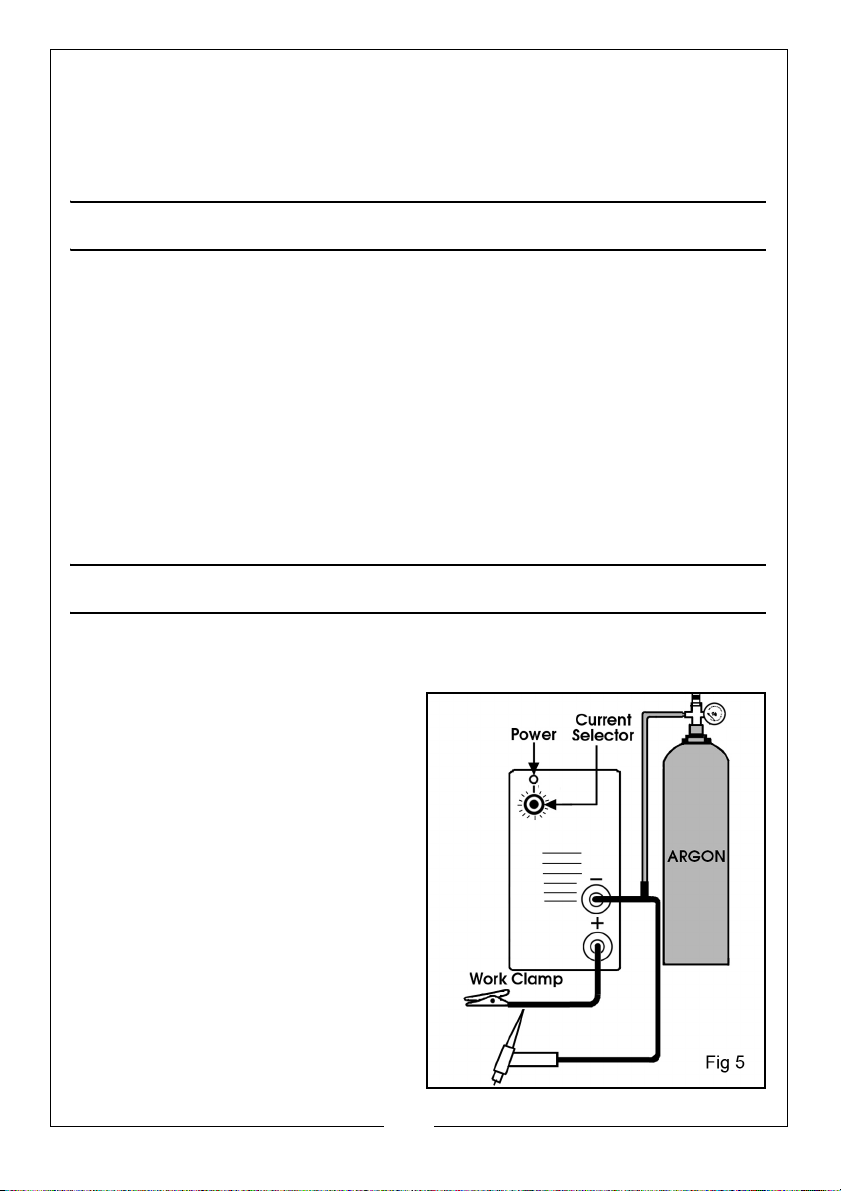

CONNECTIONS

Before connecting the torch to the welder, ensure the welder is switched OFF,

and disconnected from the mains supply.

It is important to note that the torch

cable male DIN connector, is

plugged into the NEGATIVE terminal

of the welder, as shown in Fig 5,

otherwise the tungsten electrode will

melt.

The earth clamp cable is connected

to the POSITIVE terminal.

Connect the earth clamp from the

welder to the workpiece choosing an

area of bare metal, free from rust,

paint or oil etc.

Fig 5 illustrates a typical connection.

5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

OPERATION

There are three methods generally employed for producing the initial arc for

TIG welding.

On smaller, DIY machines, a ‘scratch arc‘ method is used where the electrode

is ‘scratched’ against the workpiece to strike an arc, similar to normal arc

welding. Other machines employ a ‘lift arc’ method, which is similar to scratch

arc in that the electrode must touch the workpiece, but a far greater degree

of control is available. Others are fitted with a High Frequency unit which

allows the arc to form once the electrode is brought to within a specified

distance from the workpiece.

If you are unfamiliar with TIG welding, you should consult the manual supplied

with your TIG welder, where full details of its operation should be given.

MAINTENANCE

The torch and cable should be inspected before use, to ensure it is

undamaged. Replace any part which is suspect and ensure all connections

are firmly secured before switching on the welder.

Consumable parts (electrodes, nozzles etc) are listed in the parts list on page

7.

Do not dispose of welding products with general household waste. All tools,

accessories and packaging should be sorted, taken to a recycling centre and

disposed of appropriately.

ACCESSORIES

Regulator Part No: 8134140

Argon (60 bar) Part No: 6000661

Argon (110 bar) Part No: 6000663

6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

COMPONENT PARTS

No Description Part No No Description Part No

1 End Cap c/w O-ring GWWK01 7 Ceramic Nozzle GWWK07

2 Rear Cup Gasket GWWK02 8 Twist Valve c/w O-ring GWWK08

3 Torch Body GWWK03 9 Tungsten Electrode1.6/

2.4 mm

4 Front Cup Gasket GWWK04 10 Hose & protective sleeve GWWK10

5 Collet GWWK05 11 Short end cap & O-ring GWWK11

6 Collet Body GWWK06

7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

GWWK09

Loading...

Loading...