Page 1

2003

CAR 050016

«The technical information contained in this document is intended for the exclusive use of the trained personnel of the

motor vehicle repair trade. In some instances, this information could concern the security and safety of the vehicle. The

information is to be used by the professional vehicle repairers for whom it is intended and they alone would assume full

responsibility to the exclusion of that of the manufacturer».

«The technical information appearing in this brochure is subject to updating as the characteristics of each model in the

range evolve. Motor vehicle repairers are invited to contact the CITROËN network periodically for further information and

to obtain any possible updates».

Page 2

PRESENTATION

THIS HANDBOOK summarises the specifications, adjustments, checks and special features of the CITROEN C2.

The handbook is divided into nine groups representing the main functions :

GENERAL - ENGINE - INJECTION - IGNITION - CLUTCH, GEARBOX, DRIVESHAFTS - AXLES, SUSPENSION, STEERING - BRAKES - ELECTRICAL

AIR CONDITIONING.

Page 3

GENERAL

1

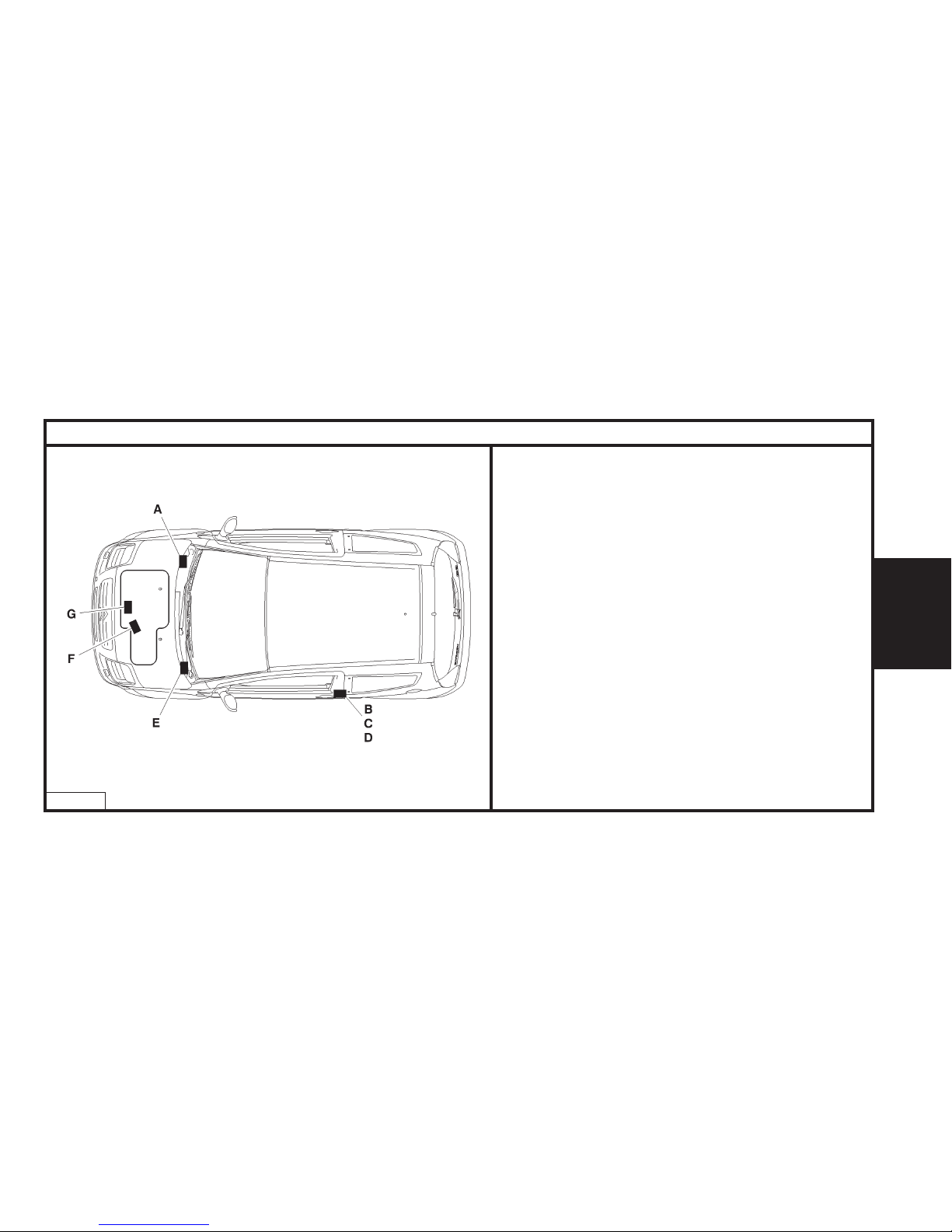

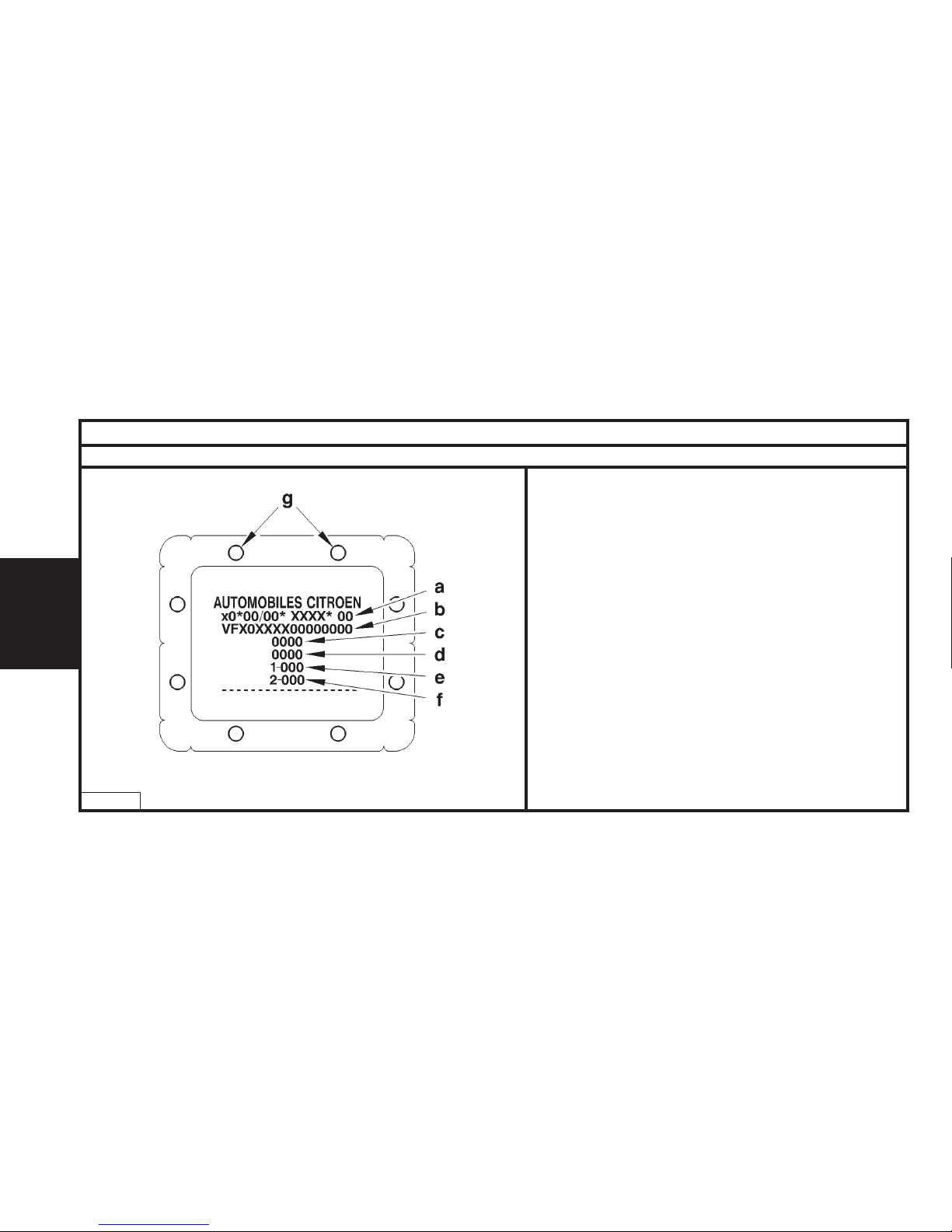

IDENTIFICATION OF VEHICLES

E1AP0C3D

A: Cold stamp

(Cold stamp engraved on the bodywork).

B : Manufacturer’s name plate

(On the LH centre pillar)

C : AS/RP No. and RP paint code.

(On the LH centre pillar)

D : Tyre pressures and tyre type.

(On the LH centre pillar)

E : Serial number on bodywork.

F : Gearbox ident. reference – Factory serial no.

G : Engine legislation type– Factory serial no.

GENERAL

Page 4

2

GENERAL

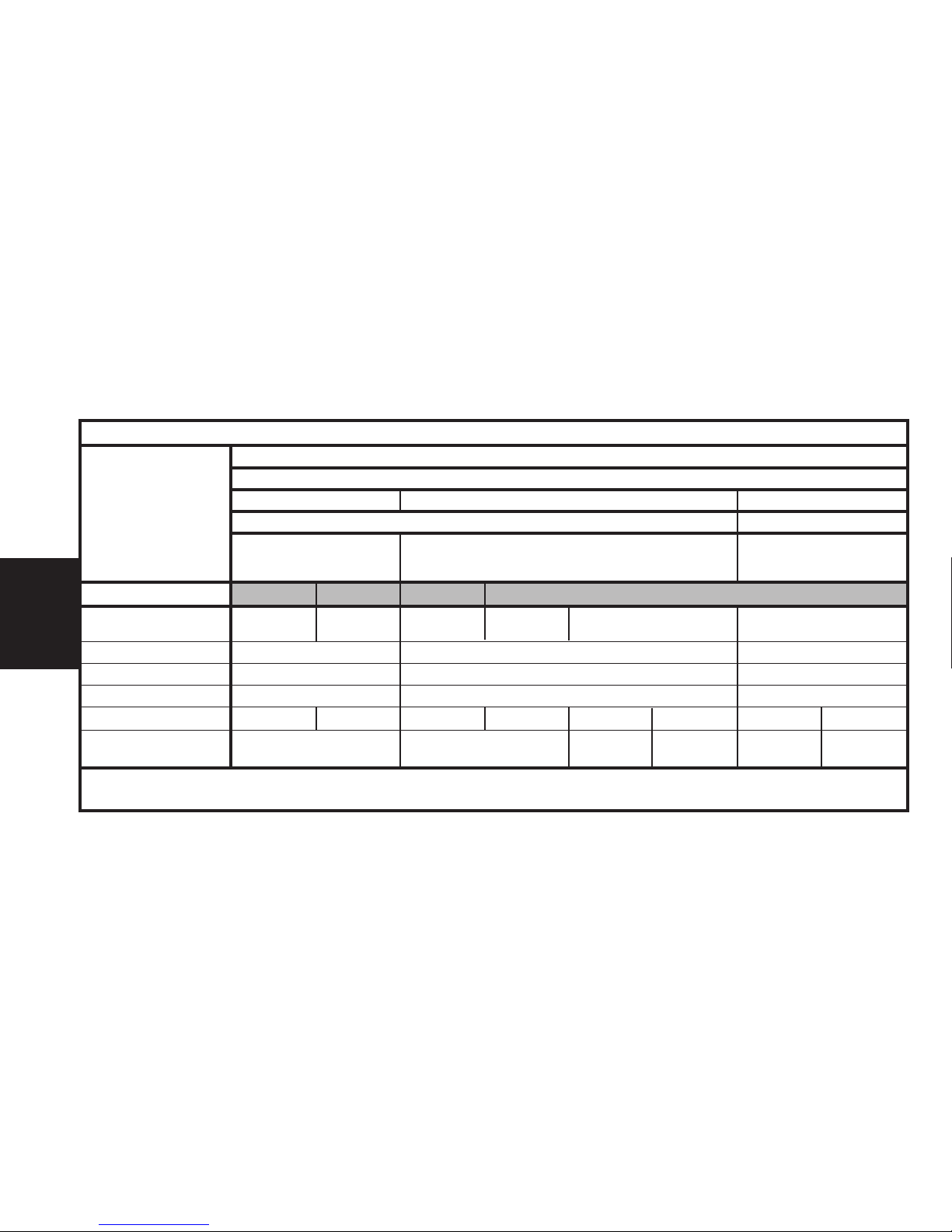

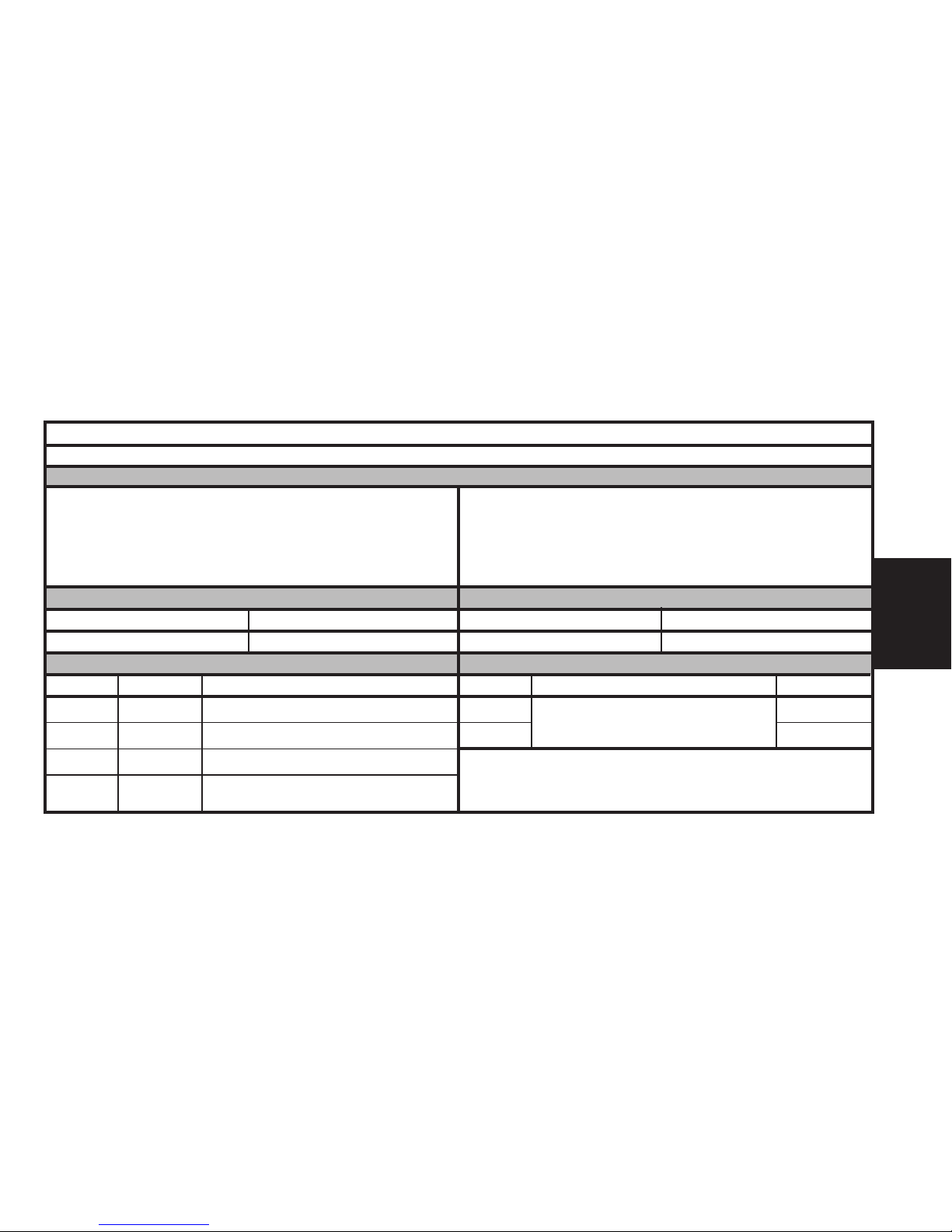

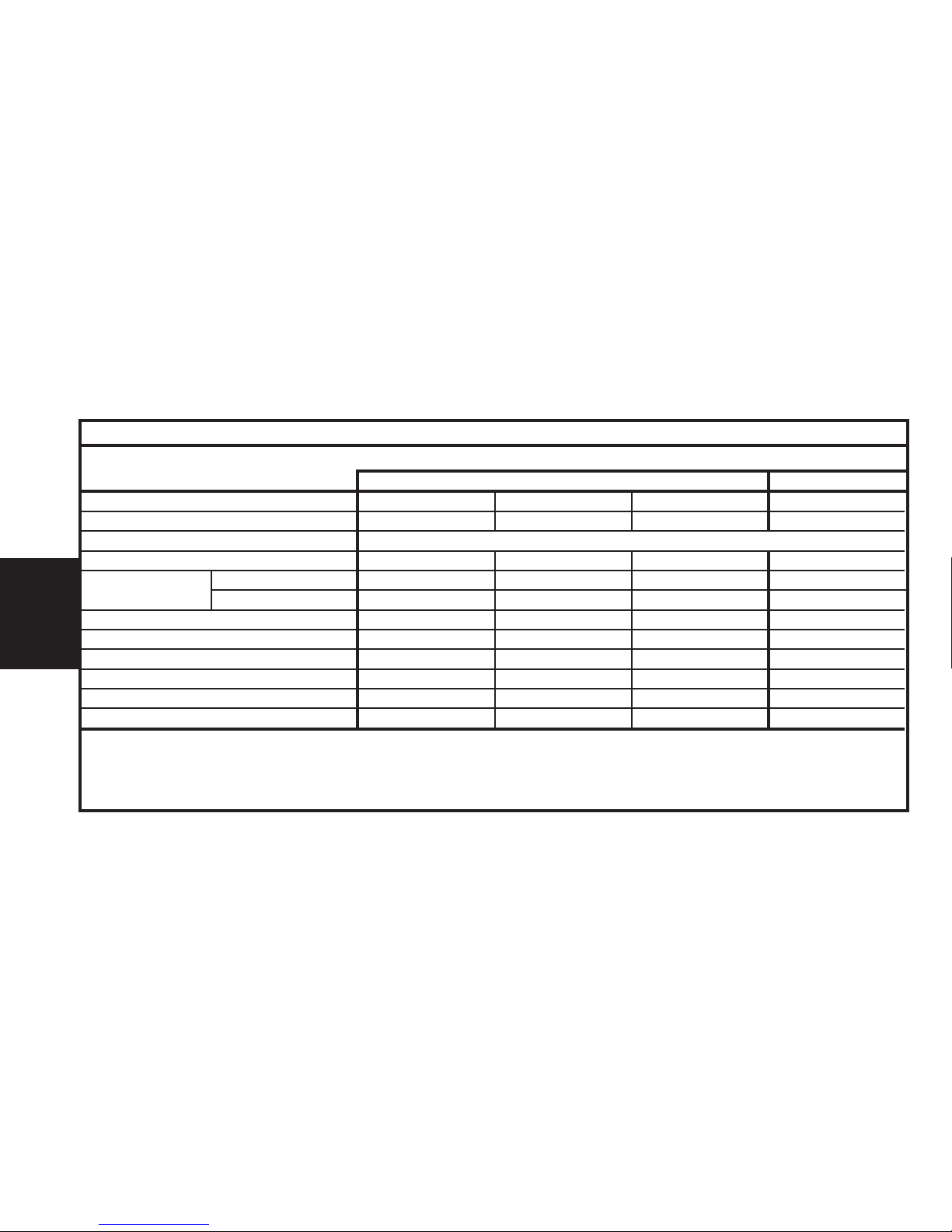

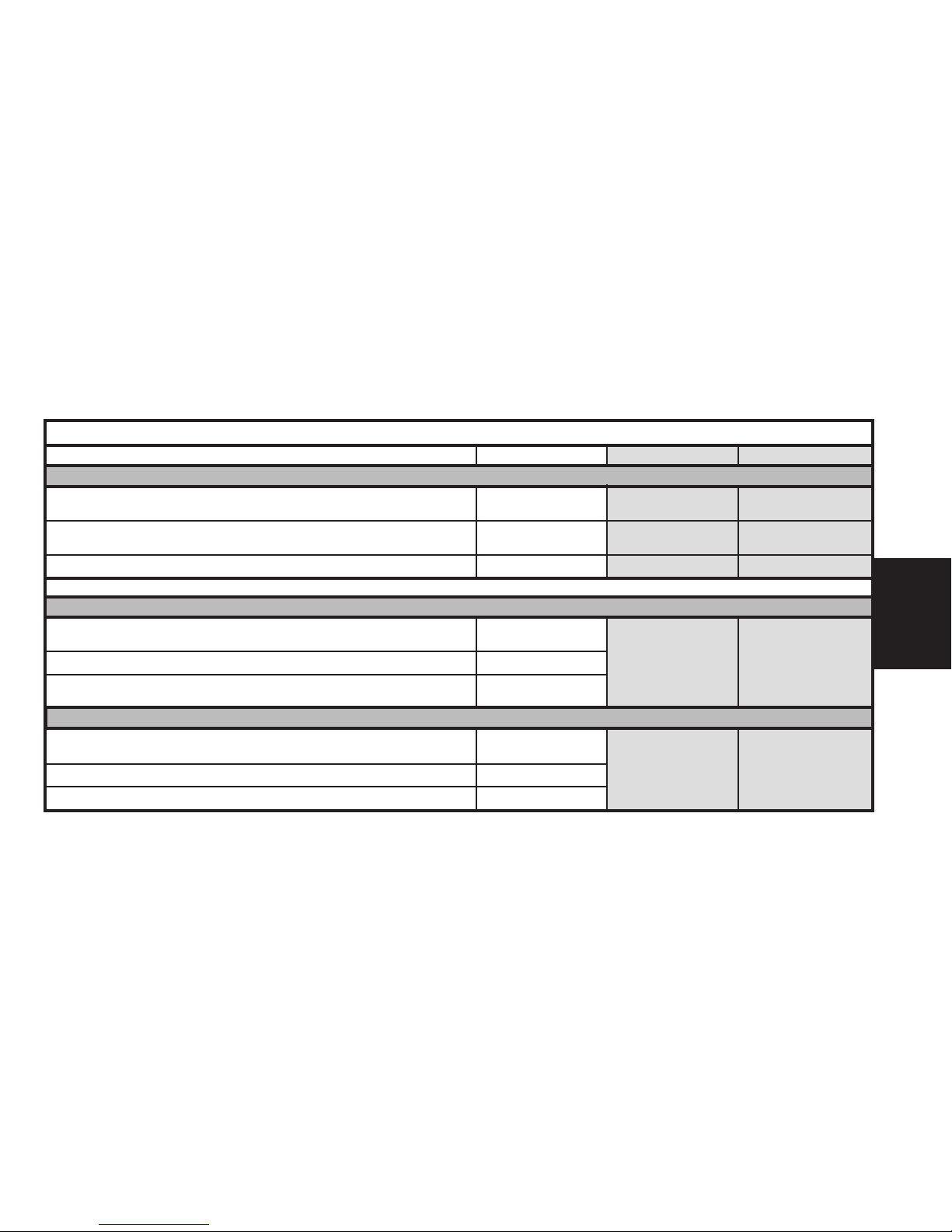

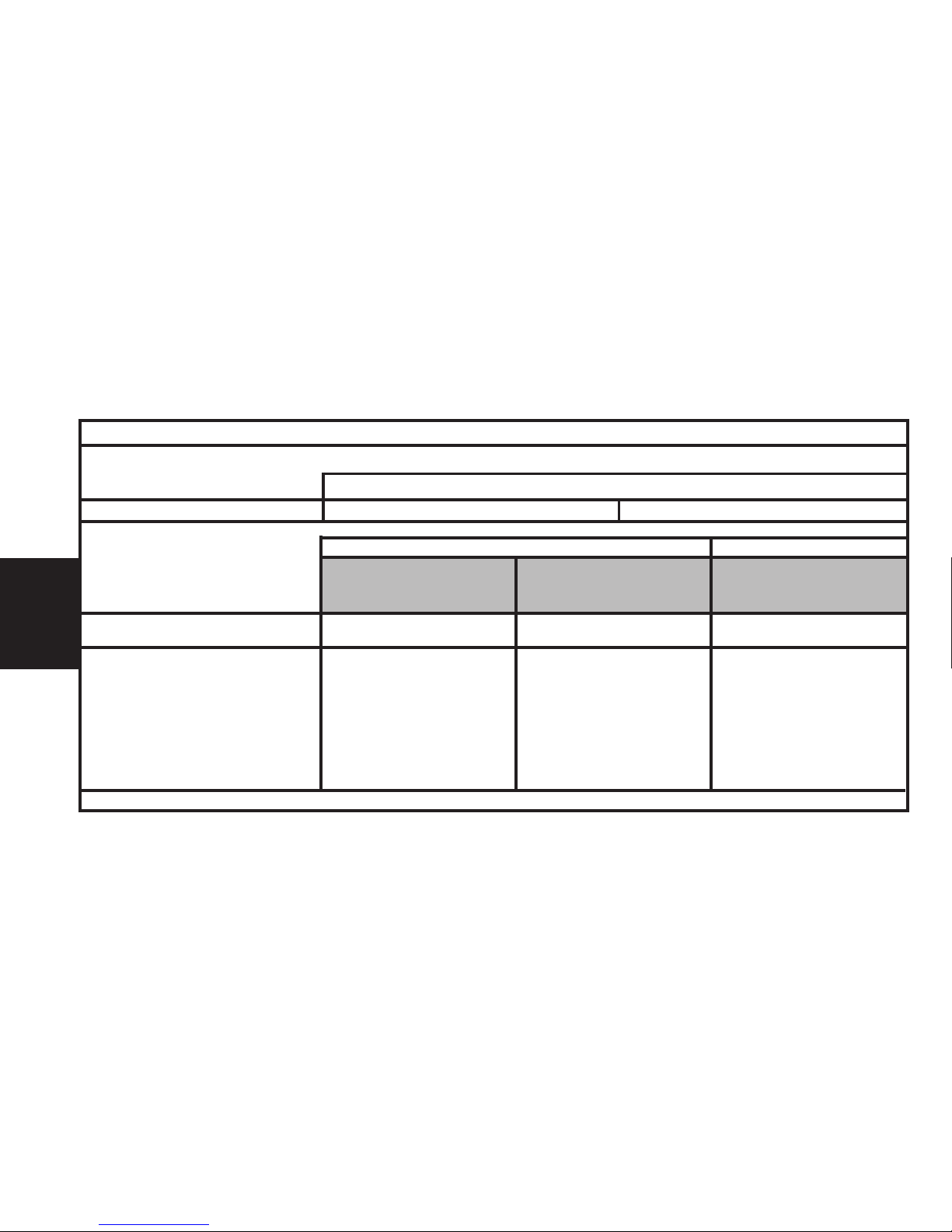

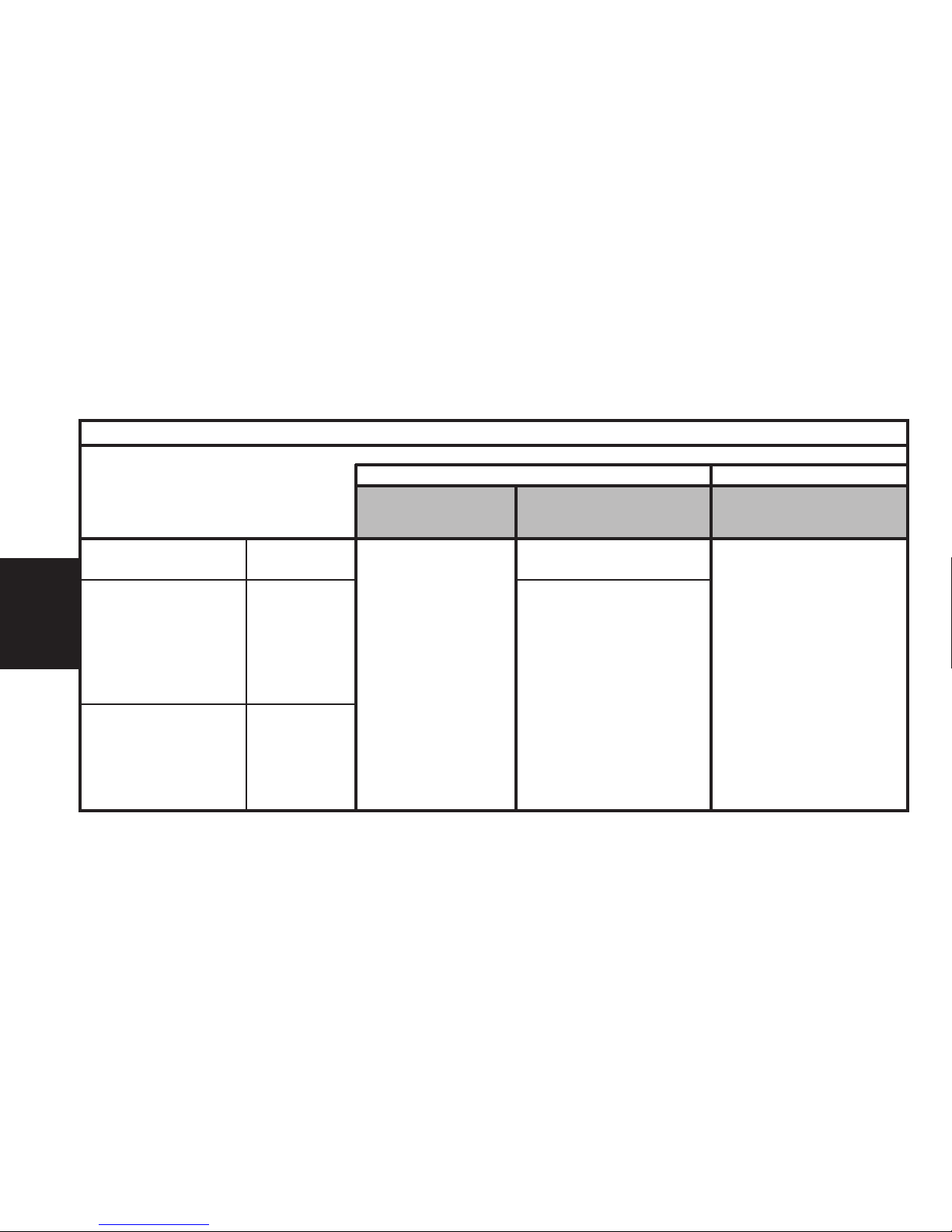

Emission standard L4 IFL5 L4 IFL5

Type code JM HFXB

JM JM JM

JM KFVC/IF (*) JM NFUC/IF (*)

HFXC/IF (*) KFVC/P KFVC/PIF (**)

Engine type HFX KFV NFU

Cubic capacity (cc) 1124 1360 1585

Fiscal rating (hp) 456

Gearbox type MA5 MA5 MA5 MA5 MA5 MA5 MA5 MA5

Gearbox ident. plate 20 CF 20 (mp) (3) 20 CF 21 (m) (4)

20 CF 25 20 CF 16 20 CN 48 20 CN 50

(1) (m) (4)

(2) (m) (4) (mp) (3) (mp) (3)

IDENTIFICATION OF VEHICLES

Petrol

TU

135

JP4JP

1.1i 1.4i 1.6i 16 V

A - X - SX - SX Pack SX - SX Pack - VTR VTR

(1) = Europe

(2) = Export

(3) mp = Piloted manual gearbox

(4) m = Manual gearbox

(*) = IF : Fiscal incentive

(**) = PIF: Power fiscal incentive

Page 5

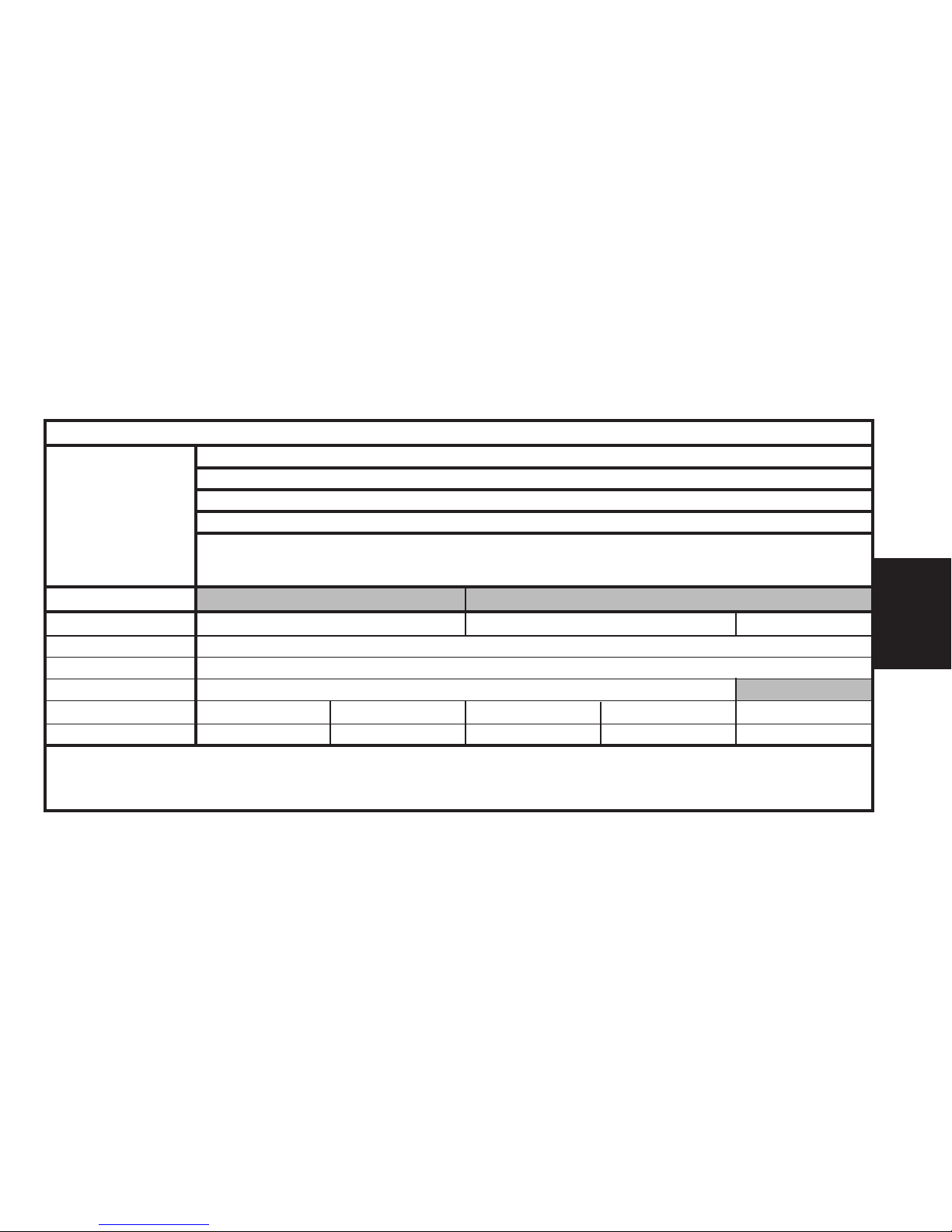

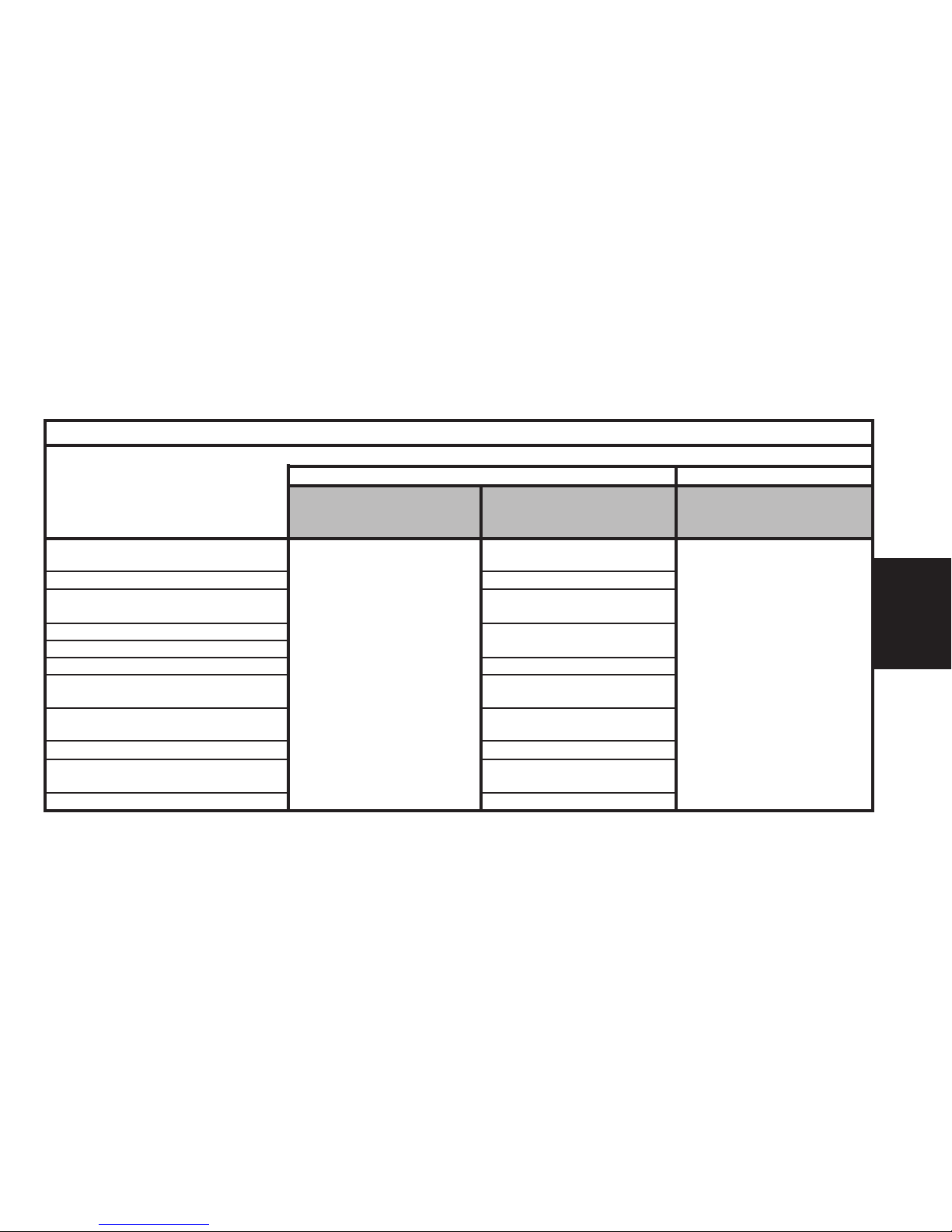

3

GENERAL

IDENTIFICATION OF VEHICLES

Diesel

DV

4

TD

1.4 HDi

X - SX – SX Pack - VTR

Emission standard L4 IFL5

Type code JM 8HXB JM 8HXC/IF (*) JM 8HXC/PIF (**)

Engine type 8HX

Cubic capacity (cc) 1398

Fiscal rating (hp) 4

Gearbox type MA5 MA5 MA5 MA5 MA5

Gearbox ident. plate 20 CN 51 (1) (m) (4) 20 CN 33 (2) (m) (4) 20 CN 51 (1) (m) (4) 20 CN 33 (2) (m) (4) 20 CN 49 (mp) (3)

(1) = Europe

(2) = Export

(3) mp = Piloted manual gearbox

(4) m = Manual gearbox

(*) = IF : Fiscal incentive

(**) = PIF: Power fiscal incentive

Page 6

4

GENERAL

IDENTIFICATION OF VEHICLES

Manufacturer’s plate.

E1AP09JC

The manufacturer’s plate carries the following information :

(a) Type approval number (*).

(b) Type serial number (VIN).

(c) Gross vehicle weight (*).

(d) Gross vehicle weight (*).

(e) Maximum weight on front axle (*).

(f) Maximum weight on rear axle (*).

(g) Manufacturer identification.

(*) = according to marketing country.

Page 7

5

GENERAL

IDENTIFICATION OF VEHICLES

Factory code.

Structure

The factory code is composed of 6 figures or letters.

J = Vehicle family. HFX = Engine.

M = Body shape. C = Version.

Body shape

Ref. Body shape

3-door saloon (4-seater)

M

Version (Gearbox and emission standard)

Ref. Gearbox

Manual

5-speed gearbox

Emissions

EURO/3

IF EURO/4

B

C

Example : JM HFXC

Family

Ref.

J

Engine

Ref.

HFX

KFV

NFU

8HX

Capacity

1124

1360

1587

1398

Engine type

TU1JP/EURO/3/IF EURO /4

TU3JP/ EURO /3/IF EURO /4

TU5JP4/IF EURO /4

DV4TD EURO/3

EURO/4

Family

CITROËN C2

Page 8

6

GENERAL

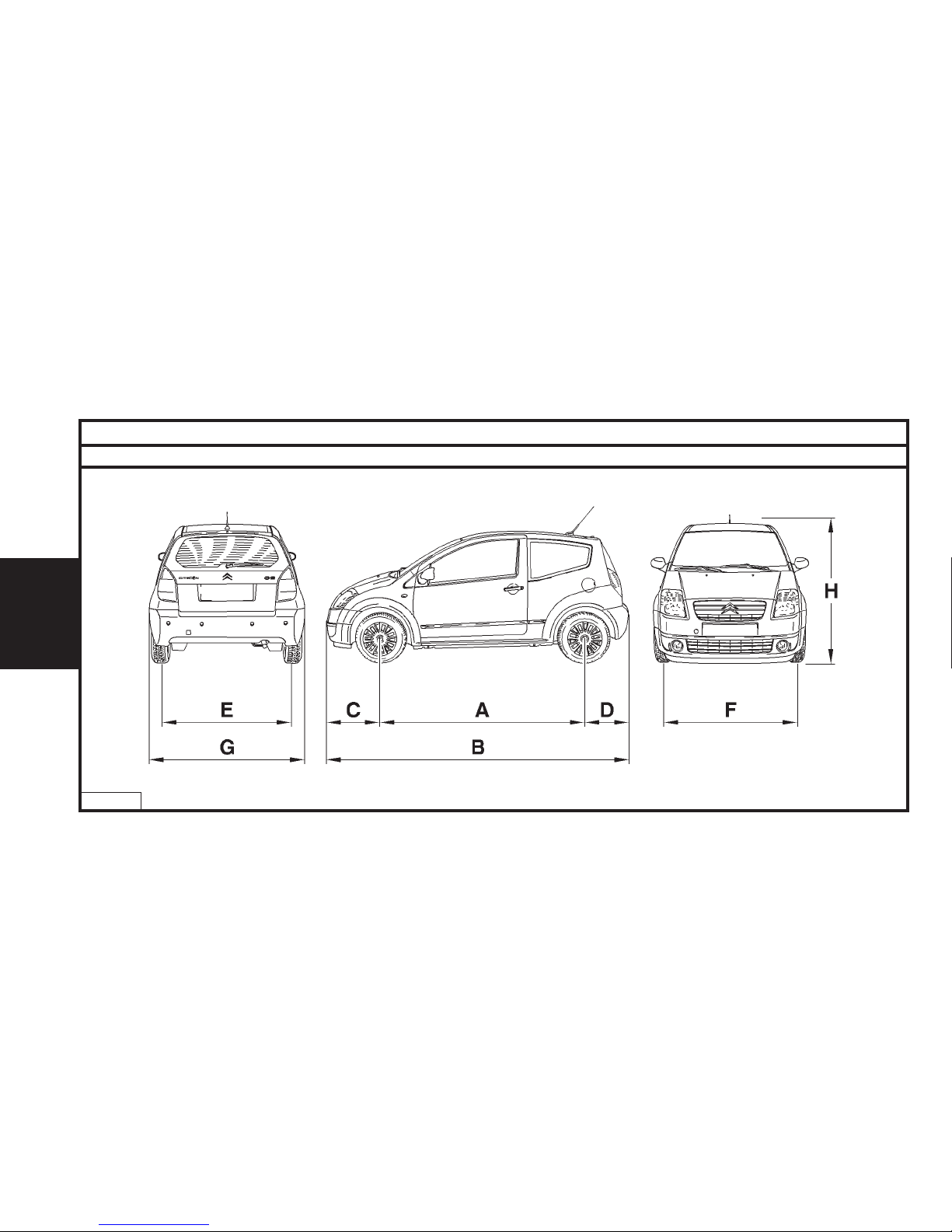

GENERAL SPECIFICATION : DIMENSIONS

E1AP0C4D

Exterior dimensions

Page 9

Exterior dimensions (mm)

7

GENERAL

GENERAL SPECIFICATION : DIMENSIONS

Interior dimensions and volumes (mm)

Vehicles All types

Wheelbase A 2315

Length overall B 3666

Front overhang C 760

Rear overhang D 591

Rear track * E 1435

Front track * F 1438

Width overall G 1660

Height overall * H 1462

(*) = Vehicle in running order (vehicle empty, levels topped up).

(*) = Boot floor with adjustable configuration.

Elbow width, front 1406

Elbow width, rear 1402

Height of boot below parcel shelf 585

Minimum floor width 1040

Depth of bootspace at floor level 660

Volume of boot below parcel shelf (dm

3

) 305

Volume in dm3 of boot below Moduboard (*) 282

Page 10

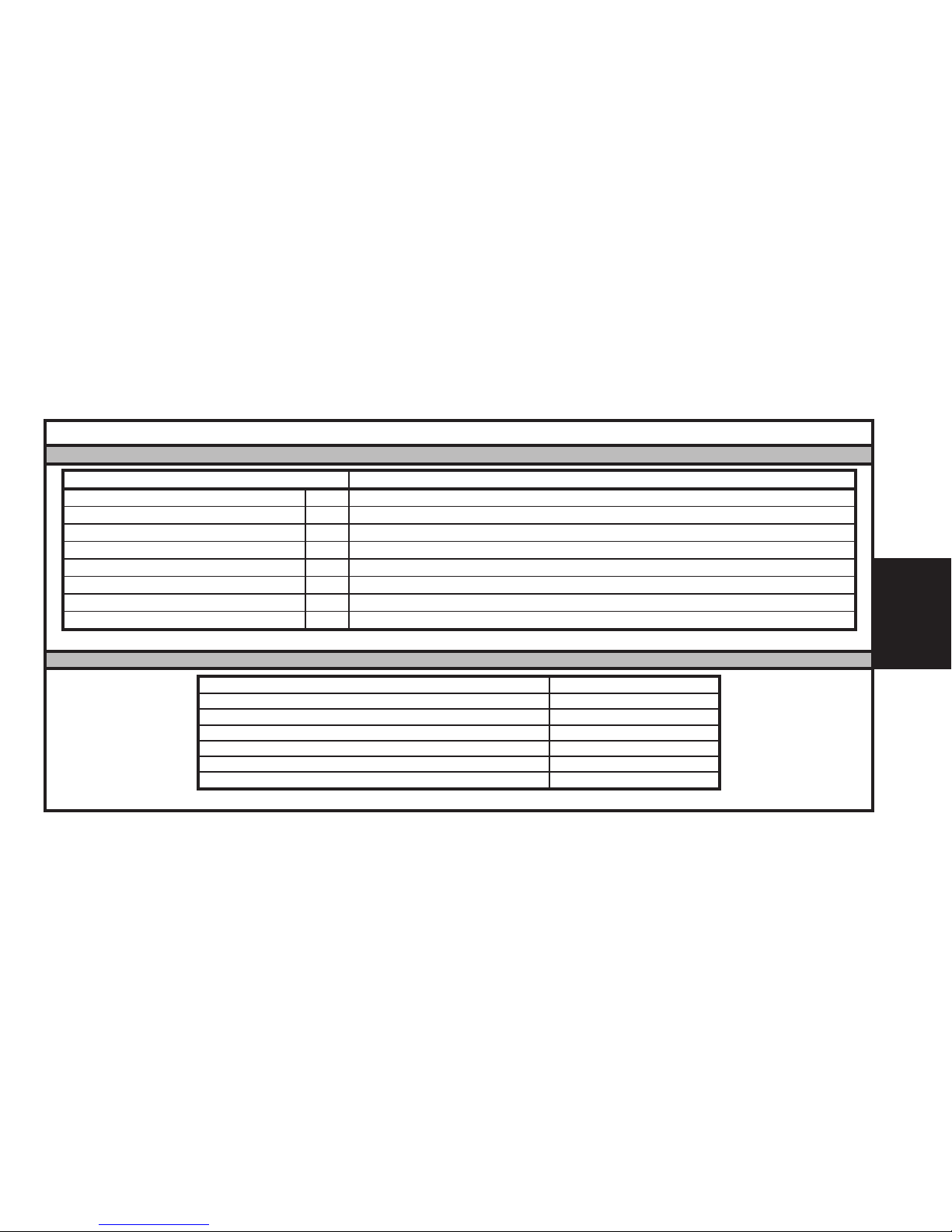

8

GENERAL

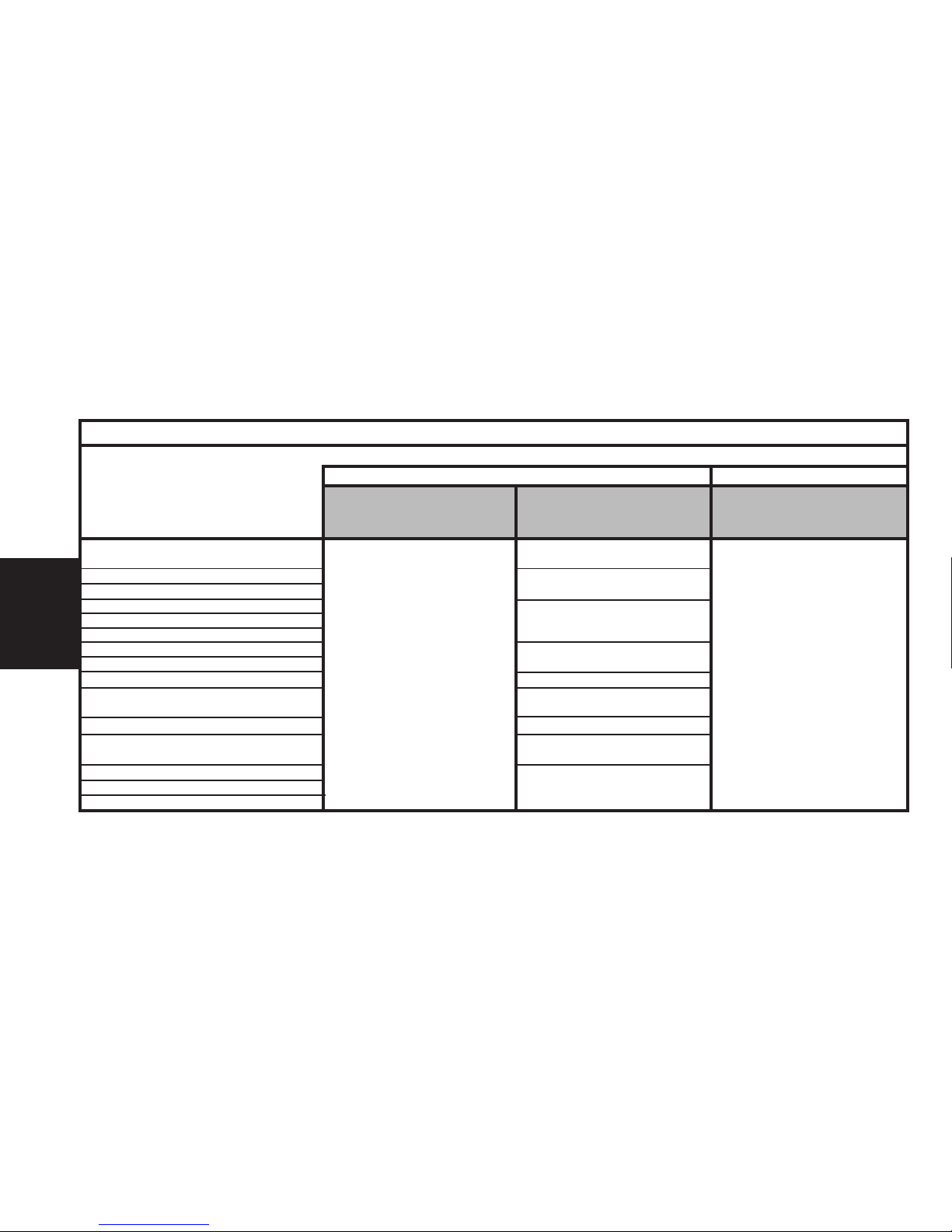

Versions 1.1i 1 4i 1.6i 16V 1.4 HDi

Engine type HFX KFV NFU 8HX

Gearbox type MA

Payload 485 465 467 479

Weight empty Without options 1053 1080 1133 1097

in running order With all options 1138 1147 1200 1177

Gross vehicle weight 1463 1470 1525 1501

Gross train weight 2113 2370 2425 2401

Maximum trailer weight without brakes 926 1174 1176 1175

Maximum trailer weight with brakes 526 540 566 548

Incline 12% 38 47 48 47

Maximum nose weight 60 60 60 60

GENERAL SPECIFICATION : WEIGHTS

Petrol Diesel

Page 11

9

GENERAL

OPERATIONS TO BE CARRIED OUT AFTER A REPAIR

IMPERATIVE : All these operations are to be performed following a reconnection of the battery.

Antiscanning function.

It is necessary to wait 1 minute after the battery has been disconnected in order to be able to start the vehicle.

Tailgate.

The opening of the tailgate is deactivated on reconnection of the battery.

Perform locking/unlocking to activate the opening of the tailgate.

Overspeed check.

The vehicle’s overspeed values have to be re-initialised.

The button on the wiper stalk (multifunction display B or C ) or the button on the dashboard (multifunction display A or clock) operates the following

functions:

- Activation of the vehicle’s overspeed function.

- Programming of the overspeed alert.

Electric windows

It may be necessary to re-initialise the sequential and anti-pinch functions.

NOTE : If the window is open at the time the battery is reconnected, action the window switch several times to close it, then re-initialise.

Open the window fully.

Action and release the window switch until the window is completely closed.

This operation has to be carried out on each electric window.

Page 12

10

GENERAL

OPERATIONS TO BE CARRIED OUT AFTER A REPAIR

Sun roof.

The anti-pinch function has to be re-initialised.

Place the sun roof switch in the maximum tilt position.

Keep the sun roof switch pressed until the sun roof ceases its movement.

Release the sun roof switch within 5 seconds.

Keep the sun roof switch pressed until the end of the sun roof opening sequence.

Multifunction screen.

It is necessary to adjust the date, time and outside temperature.

Adjust the display language of the multifunction screen if necessary.

NOTE : The default display language of the multifunction screen is French.

Navigation.

Warning, the vehicle has to be in the open air (on switching on the ignition, the ECU searches for satellites).

Vehicle location is only effective after some ten minutes.

Reprogramme the customer parameters.

Radio.

Reprogramme the radio stations.

Radiotelephone RT3.

Reprogramme the radio stations.

Page 13

11

GENERAL

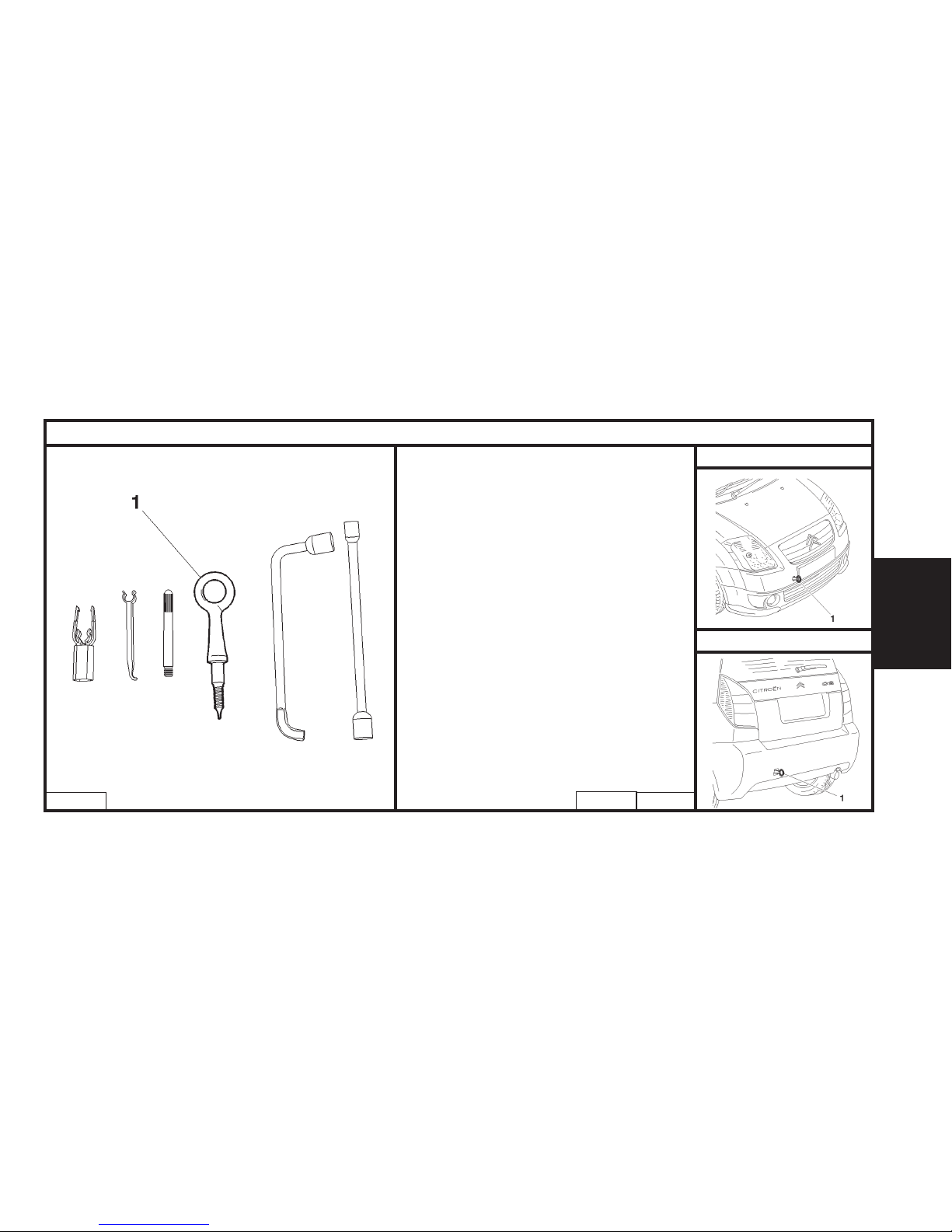

GENERAL SPECIFICATION : TOWING THE VEHICLE

Front towing

Rear towing

WARNING : When the engine is not running,

steering and braking are no longer power-assisted.

Towing eye

(1) Towing eye

The towing eye (1) is to be found in the vehicle

toolkit located under one of the front seats.

E2AP029C

E2AP02AC

E2AP02BC

Page 14

12

GENERAL

GENERAL SPECIFICATION : TOWING THE VEHICLE

Vehicle towing : Precautions to be taken

Manual gearbox Piloted manual gearbox

ESSENTIAL : Never tow the vehicles with wheels hanging

(towing by the wheels).

IMPERATIVE : It is necessary to lift the front of the vehicle in

order to tow it, after having positioned the gear lever in neutral.

WARNING : Whether the ignition is switched on or not, an action on

the gear selector will move the clutch fork and the gear engagement

lever.

If a gear is engaged, there is more than one way to free it :

- Engage «N», with the aid of a diagnostic tool

- Engage «N», without the diagnostic tool

Essential : Never swap two gearbox ECUs between two vehicles.

IMPERATIVE : If a gear is engaged and it is not possible to free it,

The vehicle must be towed with the front wheels raised.

Page 15

13

GENERAL SPECIFICATION : TOWING THE VEHICLE

GENERAL

Vehicle towing : Precautions to be taken

Piloted manual gearbox

Engagement of «N», using a diagnostic tool.

Preliminary operation :

- Battery voltage higher than 12 Volts.

- Ignition switched on.

- Connect the diagnostic tool to the vehicle’s diagnostic socket.

Using the menus of the diagnostic tool, select :

- «DIAGNOSIS»

- MA piloted manual gearbox.

- Actuator tests.

- Gearbox actuator test.

- Gear engagement test.

- N (Neutral).

NOTE : The letter «N» should appear on the instrument panel. If this

does not happen, see the following solution:

- Engagement of «N», without using a diagnostic tool.

Engagement of «N», without a diagnostic tool.

In this configuration, the gearbox actuator is blocked, gear engaged.

IMPERATIVE : This recovery solution is to be used solely in a case

where the methods for setting the gearbox actuators using the

diagnostic tool have failed (destruction of the gearbox actuator)

Page 16

14

GENERAL

GENERAL SPECIFICATION : TOWING THE VEHICLE

Vehicle towing : Precautions to be taken

Piloted manual gearbox

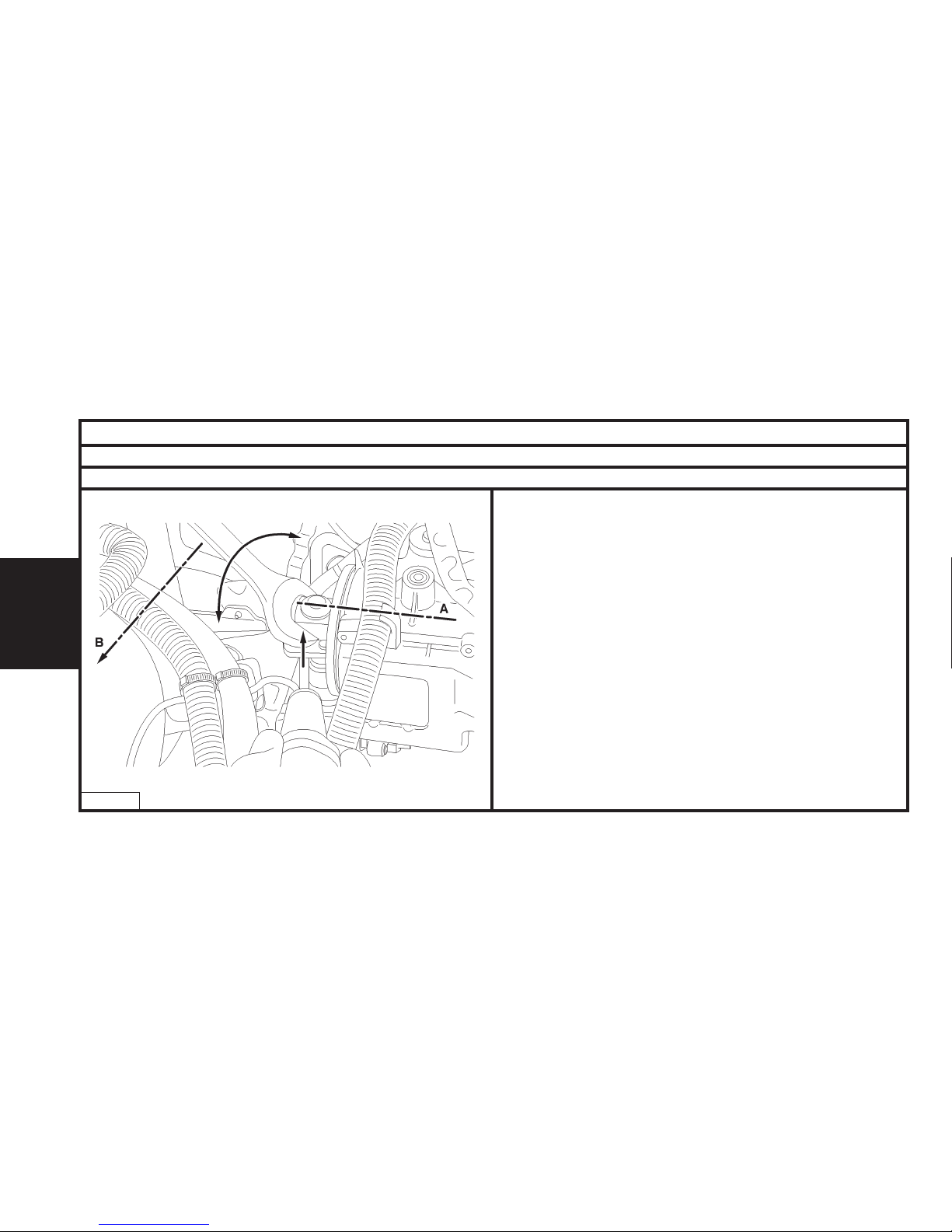

Preliminary operations:

- Disconnect the battery negative terminal.

- Remove the air filter.

- Position a 22 mm flat spanner.

- Lift the gear engagement lever as far as possible (in the direction of

the arrow); use a screwdriver to hold it in this position.

- Turn the spanner until the axis of the gear engagement lever (A) is at

right angles to the axis (B).

- When this position is attained, position «N» is engaged.

Moving the vehicle.

IMPERATIVE : Never be towed with the ignition switched on.

Never attempt to push-start the vehicle (impossible with a piloted manual

gearbox).

B2CP3L8D

Page 17

15

GENERAL

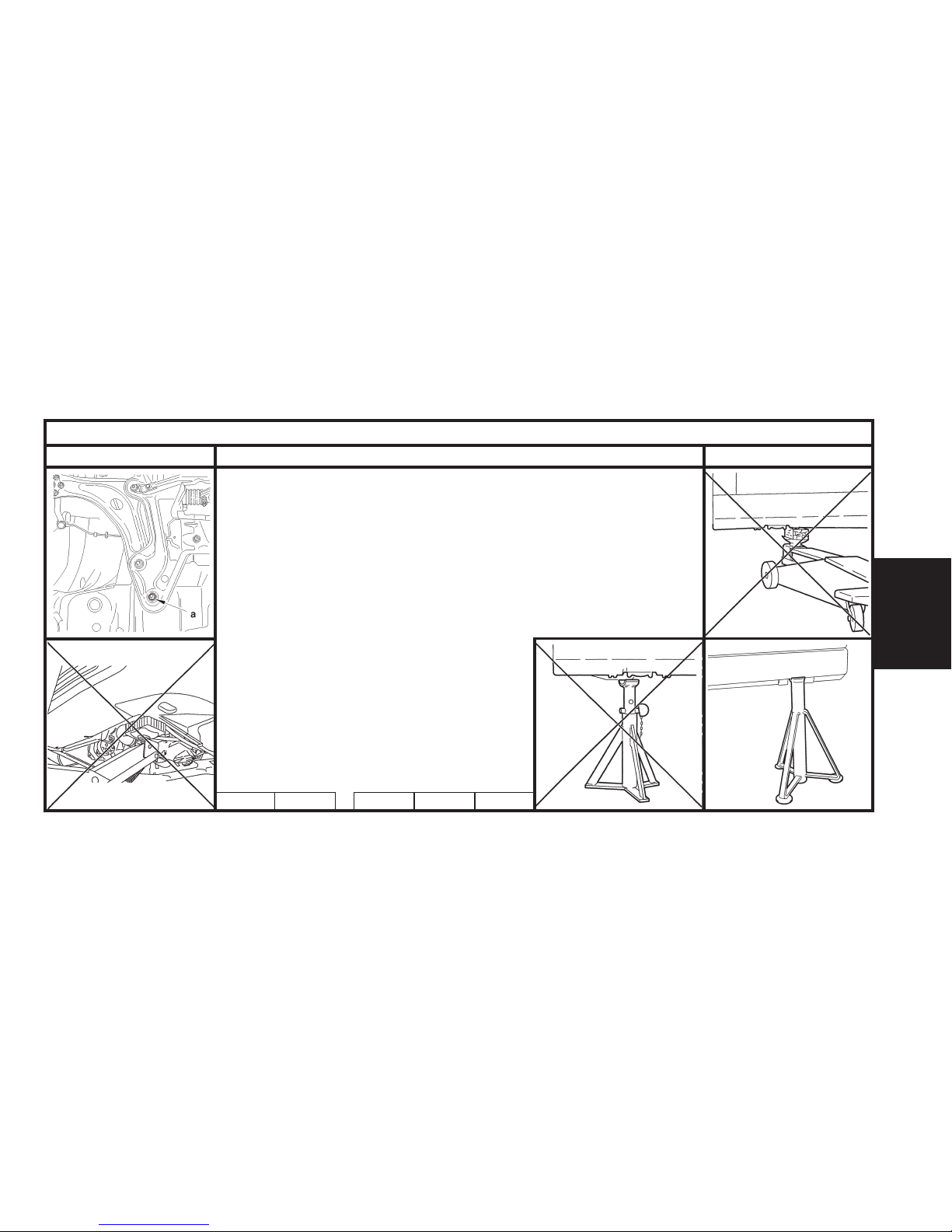

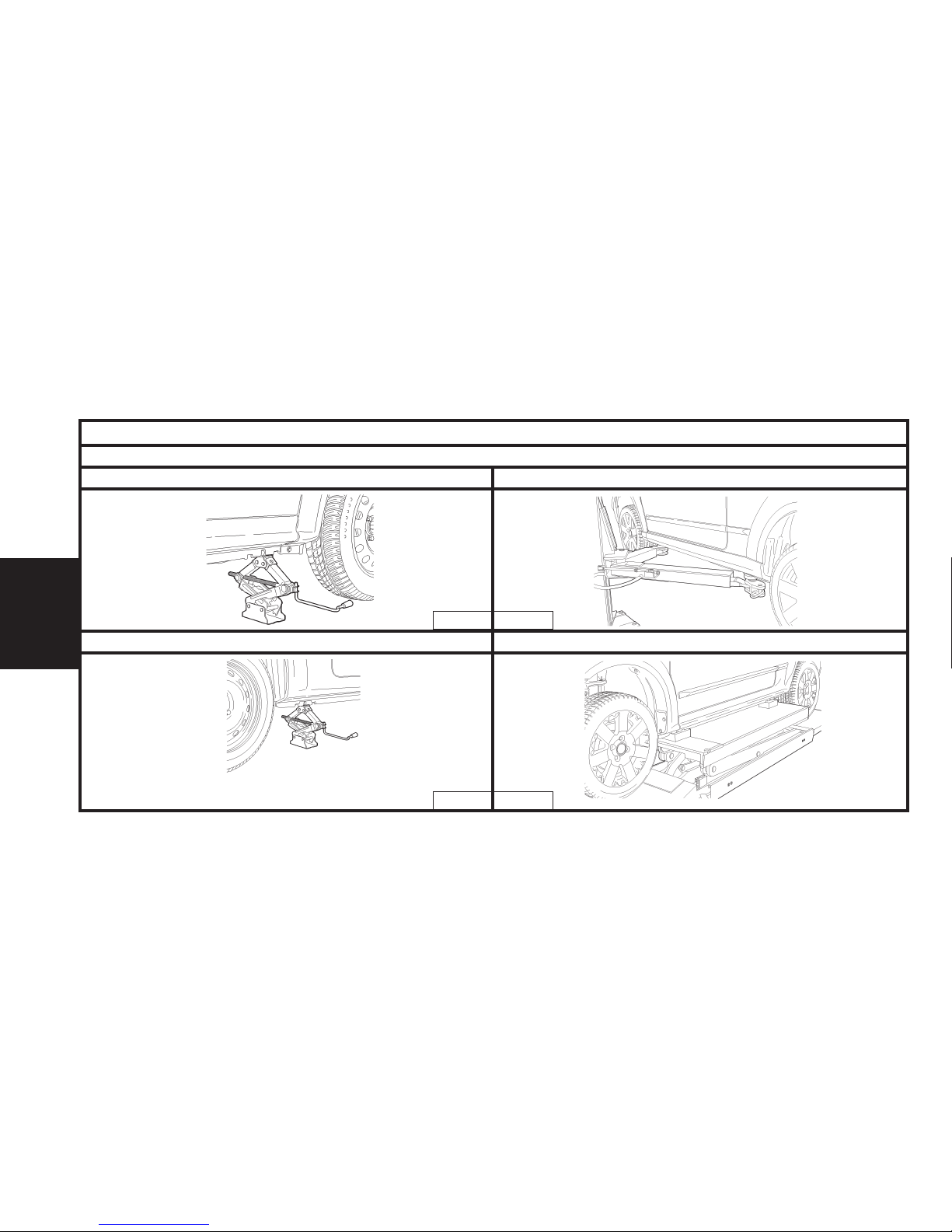

Lifting and supporting the vehicle Side liftingFront lifting

Front of the vehicle.

The authorised lifting points at the front of the vehicle are on the rear fixing bolts of

the subframe at «a».

For front lifting, take weight at the two lifting points at «a», using a crossbeam equipped

with blocks.

For front lifting from the side, take weight at the lifting point at «a».

ESSENTIAL : Never attempt to lift by the front

panel mountings.

Side lifting

Always ensure the jack is correctly positioned at the

lifting points.

Do not place the axle stands under the jack contact

lugs.

Lifting from the rear.

IMPERATIVE : Do not lift the vehicle by the rear.

Position of the axle stand.

B3CP07KC E2AP016C E2AP00GCE2AP018CE2AP017C

GENERAL SPECIFICATION: LIFTING AND SUPPORTING THE VEHICLE

Page 18

16

GENERAL

GENERAL SPECIFICATION: LIFTING AND SUPPORTING THE VEHICLE

Lifting and supporting the vehicle (continued)

Lifting with the handle jack at the front

Lifting with the handle jack at the rear

Lifting on a two-column lift using the jack supports

Lift accessory with blocks on the jack supports

E2AP026C E2AP028D

E2AP025C E2AP027D

NOTE : The handle jack is specific to the vehicle, do not use

it for any other purposes.

Page 19

17

GENERAL

CAPACITIES (in litres)

Draining method.

The oil capacities are defined according to the following methods.

1/ Vehicle on level surface (in high position, if equipped with hydropneumatic suspension).

2/ Engine warm (oil temperature 80°C).

3/ Draining of the oil sump + removal of the cartridge (duration of draining + dripping = 15 min).

4/ Refit plug + cartridge.

5/ Engine filling.

6/ Engine starting (allowing the cartridge to be filled).

7/ Engine stopped (stationary for 5 min).

ESSENTIAL : Systematically check the oil level using the oil dipstick.

Page 20

18

GENERAL

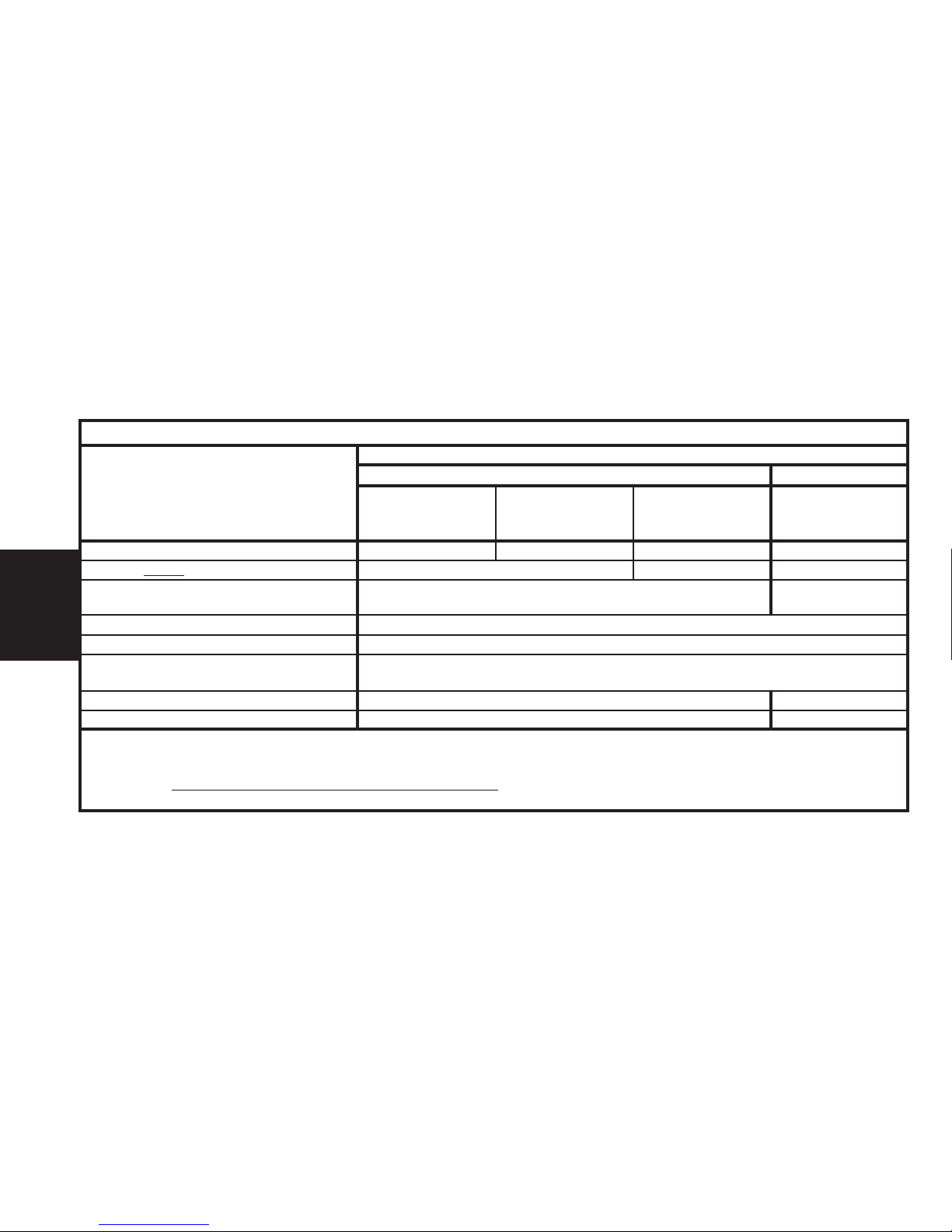

1.1i 1.4i 1.6i 16V 1.4 HDi

Engine type HFX KFV NFU 8HX

Drain by gravity : engine with filter change 3 3.25 3.75

Between Min. and Max. 1.5

1.8

9

RPO 9844)

1.5 (RPO 9845 9)

MA5 5-speed gearbox 2

MA5 piloted 5-speed gearbox 2 ± 0.15

Braking circuit

0.7 Litre version with front calipers Ø 48 / rear drums

0.8 Litre version with front calipers Ø 54 / rear discs

Cooling system 7 5.6

Fuel tank capacity 40 45

CAPACITIES (in litres)

Petrol

C2

Diesel

ESSENTIAL : Systematically check the oil level using the oil dipstick.

Page 21

19

GENERAL

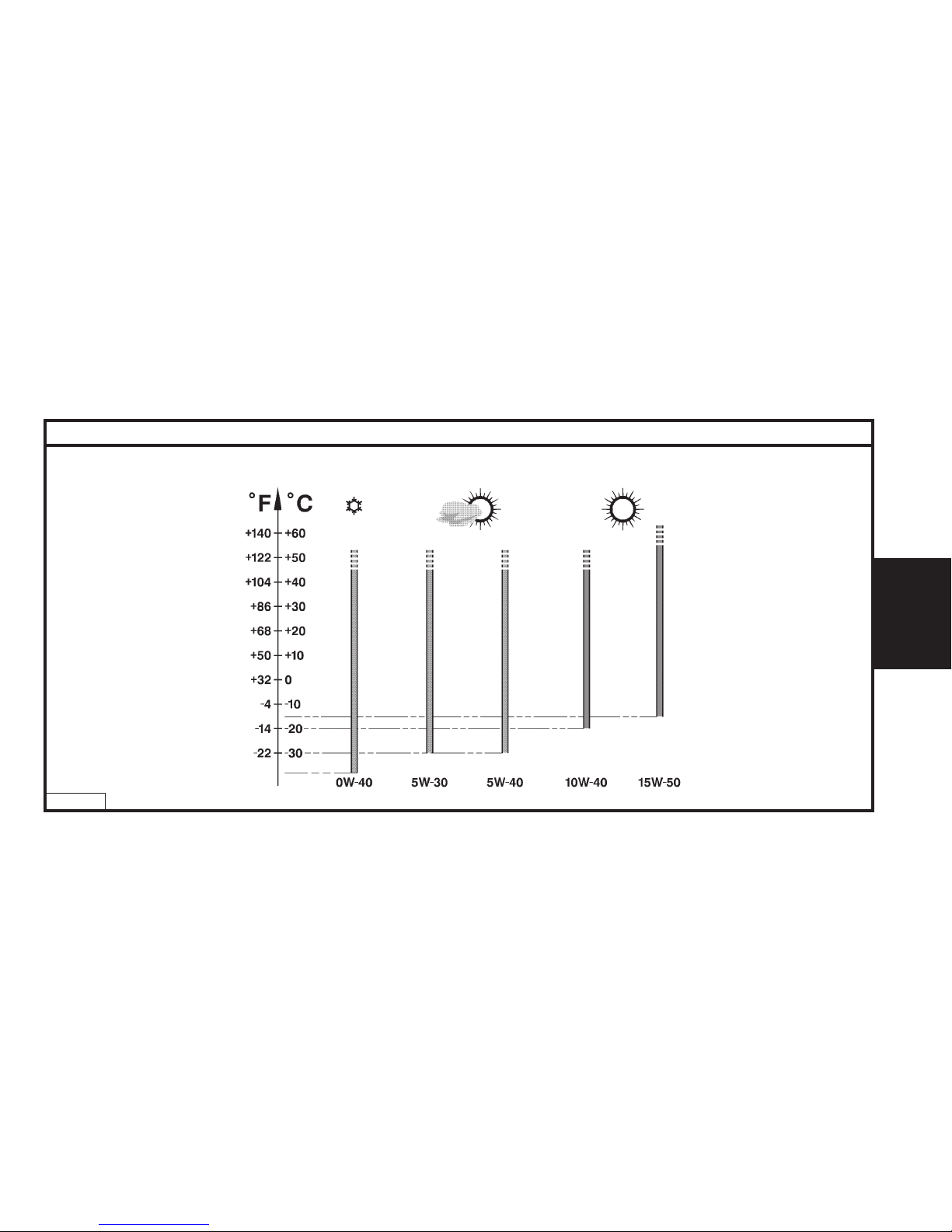

LUBRICANTS - TOTAL recommended oils

S.A.E. Norm - Table for selection of engine oil grade

E4AP006D

Page 22

LUBRICANTS – TOTAL recommended oils

20

GENERAL

Factory evolutions in 2001 model year

CITROËN engines are lubricated at the factory with TOTAL oil of

grade S.A.E.5W-30.

TOTAL oil of grade S.A.E.5W-30 allows improved fuel economies

(approx 2.5%).

Features of CITROËN C5 :

2.0 and 2.2 HDi engines have a particle filter.

The maintenance interval for normal operation

is 30,000 km (20,000 miles) for petrol engines.

WARNING : HDi engines are high technology engines which

imperatively require use of quality SYNTHETIC OILS : TOTAL

ACTIVA or TOTAL QUARTZ 5W40.

To maintain engine performances, all countries in Europe

should observe this requirement.

NOTE : Only PORTUGAL and GREECE may use 10W40 semisynthetic oil.

ESSENTIAL : For all vehicles with a 30,000 km (20,000 miles)

maintenance interval, use exclusively TOTAL ACTIVA/QUARTZ

7000 or 9000 or any other oils offering identical specifications to

these.

These oils offer specifications that are superior to those defined

by norms ACEA A3/98 or API SJ.

Failing this, it is essential to adhere to the maintenance programmes covering severe operating conditions.

5W30 cannot be used in the following engines:

XU10J4RS : XSARA VTS 2.0i 16V (3 doors).

SOFIM : RELAY 2.8 D and 2.8 TD.

1580 SPI : DISPATCH 1.6i.

2.0 and 2.2 HDi engines equipped with particle filter.

WARNING : CITROËN engines prior to model year 2000 do not

have to be lubricated with oils adhering to the norms ACEA A198/B1-98 and API SJ/CF EC.

Page 23

21

GENERAL

LUBRICANTS – TOTAL recommended oils

Selection of engine oil grades recommended for climatic conditions in countries of distribution

ACEA Norms

The first letter corresponds to the type of engine concerned :

A : petrol and dual fuel petrol / LPG engines.

B : diesel engines.

The figure following the first letter corresponds to the type of oil.

1 : highly fluid oils, for reducing friction and lowering fuel

consumption.

3 : high performance oils.

The number after that (96 or 98) corresponds to the year of

creation of the norm.

NOTE : From 01/03/2000, all engine oils must comply with ACEA-98

norms.

Example :

ACEA A1-98 / B1-98 : Blended oils for all engines, permitting fuel

economy (complying with ACEA 98 norms).

API Norms

The first letter corresponds to the type of fuel used by the engine :

S : petrol and dual fuel petrol / LPG engines.

C : diesel engines.

The second letter corresponds to the degree of evolution, in ascending

order.

Example : The norm SJ is more severe than the norm SH and corresponds to a higher level of performance.

The adding of the letters EC indicates that the engine oil concerned is

an oil which permits fuel economy.

EC : Energy Conserving, reduction in fuel consumption.

Examples :

API SJ / CF : Blended oils for all engines.

engines API CF / EC: Oils specifically for diesel engines, permitting fuel

economy.

API SJ / CF / EC : Blended oils for all engines, permetting fuel economy.

Page 24

22

GENERAL

LUBRICANTS – TOTAL recommended oils

Engine oil norms.

Norms in force.

These engine oils have been classified by the following recognised organisations:

S.A.E. : Society of Automotive Engineers.

API : American Petroleum Institute.

ACEA : Association des Constructeurs Européens d’Automobiles.

Recommendations.

Denominations of TOTAL oils, according to country of marketing:

TOTAL ACTIVA (France only).

TOTAL QUARTZ (Outside France).

Summary

Engine oil norms to be respected in 2001 model year

(*) = It is essential not to use engine oils respecting these norms for the following engine-types .

XU10J4RS. 1580 SPI. SOFIM 2.8 D and SOFIM 2.8 TD.

ESSENTIAL : To preserve engine performances, all engines fitted in CITROEN vehicles must be lubricated with high

quality oils (synthetic or semi-synthetic)

Model year Types of engine ACEA norms API norms

Petrol and dual fuel petrol /

LPG engines

A3-98 or A1-98 (*) SJ or SJ / EC (*)

AM 2001

Diesel engines B3-98 or B1-98 (*) CF or CF / EC (*)

Page 25

23

GENERAL

S.A.E. grades SPI norms ACEA norms

Blended oils for all engines (petrol, dual-fuel petrol / LPG and diesel)

TOTAL ACTIVA 9000

TOTAL QUARTZ 9000

5W-40 SJ / CF A3-98 / B3-98

TOTAL ACTIVA 9000. (*)

TOTAL QUARTZ 9000. (*)

5W-30 SJ / CF EC A1-98 / B1-98

TOTAL ACTIVRAC 10W-40 SJ / CF A3-98 / B3-98

(*) = Blended oils for all engines, permitting fuel economy.

Oils specifically for petrol and dual-fuel petrol / LPG engines

TOTAL ACTIVA 7000

TOTAL QUARTZ 7000

10W-40

TOTAL QUARTZ 9000 0W-40 SJ A3-98

TOTAL ACTIVA 7000

TOTAL QUARTZ 7000

15W-50

Oils specifically for diesel engines

TOTAL ACTIVA DIESEL 7000

TOTAL QUARTZ DIESEL 7000

10W-40

TOTAL ACTIVA DIESEL 7000

15W-50

CF B3-98

TOTAL ACTIVA DIESEL 9000 5W-40

LUBRICANTS – TOTAL recommended oils

Page 26

24

GENERAL

FRANCE

Metropolitan FRANCE

Metropolitan FRANCE

New Caledonia

Guadeloupe

Saint-Martin

La Réunion

Martinique 9000 5W-40 7000 15W-50 7000 15W-50

Guyana

Tahiti

Mauritius

Mayotte

LUBRICANTS – TOTAL RECOMMENDED OILS

Blended oils for all engines, supplied in bulk

TOTAL ACTIVRAC S.A.E : 10W-40 Norms

TOTAL ACTIVA

9000 5W-40

9000 5W-30 (*)

7000 10 W-40

7000 10W-40

9000 5W-40

TOTAL ACTIVA DIESEL

Blended oils for all engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically for diesel

engines

(*) = Blended oils for all engines, permitting fuel economy.

Page 27

25

GENERAL

EUROPE

Germany

Austria

Belgium

Bulgaria

Cyprus

Croatia

Denmark

Spain

Estonia

Finland

Great Britain

LUBRICANTS – TOTAL RECOMMENDED OILS

TOTAL QUARTZ TOTAL QUARTZ DIESEL

Blended oils for all engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically for diesel

engines

9000 5W-40

9000 5W-30 (*)

(*) = Blended oils for all engines,

permitting fuel economy

7000 10W-40

9000 0W-40

7000 10W-40

7000 10W-40

9000 0W-40

7000 10W-40

7000 15W50

7000 10W-40

7000 10W-40

9000 0W-40

7000 10W-40

7000 15W-50

7000.10W-40

7000 10W-40

9000 0W-40

7000 10W-40

7000 10W-40

Page 28

26

GENERAL

Oils specifically for diesel

engines

EUROPE (continued)

Greece

Holland

Hungary

Italy

Irland

Iceland

Latvia

Lithuania

Macedonia

Malta

Moldova

Norway

Poland

Portugal

Slovak Republic

LUBRICANTS – TOTAL recommended oils

TOTAL QUARTZ TOTAL QUARTZ DIESEL

Blended oils for all engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

(*) = Blended oils for all engines,

permitting fuel economy

9000 5W-40

9000 5W-30 (*)

7000 10W-40

7000 10W-40

7000 15W-50

7000 10W-40

9000 0W-40

7000 10W-40

7000 10W-40

9000 0W-40

7000 10W-40

7000 10W-40

7000 15W-50

7000 10W-40

7000 10W-40

9000 0W-40

7000 10W-40

Page 29

27

GENERAL

EUROPE (continued)

Czech Republic

7000 10W-40

9000 0W-40

Roumania

7000 10W-40

7000 15W-50

Russia

7000 10W-40

9000 0W-40

Slovenia 7000 10W-40

Sweden

7000 10W-40

9000 0W-40

Switzerland 7000 10W-40

7000 10W-40

Turkey 7000 15W-50

9000 0W-40

Ukraine

7000 10W-40

9000 0W-40

Yugoslavia 7000 10W-40

LUBRICANTS – TOTAL recommended oils

Oils specifically for diesel

engines

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Blended oils for all engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

(*) = Blended oils for all engines, per-

mitting fuel economy

9000 5W-40

9000 5W-30 (*)

7000 10W-40

Page 30

28

GENERAL

Oils specifically for diesel

engines

Australia

New-Zealand

Ivory Coast

Egypt

Gabon

Madagascar

Morocco

Senegal

Tunisia

Argentina

Brazil, Chile

Cuba

Mexico

Paraguay

Uruguay

LUBRICANTS – TOTAL recommended oils

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Blended oils for all

engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

OCEANIA

AFRICA

CENTRAL

AND SOUTH

AMERICA

9000 5W-40

7000 10W-40

7000 15W-50

7000 10W-40

Page 31

29

GENERAL

Oils specifically for diesel

engines

China

South Korea

Hong-Kong

India

Indonesia

Japan

Malaysia

Pakistan

Philippines

Singapore

Taiwan

Thailand

Vietnam

LUBRICANTS – TOTAL recommended oils

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Blended oils for all

engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

SOUTH EAST

ASIA

9000 5W-40

9000 5W-40

9000 5W-30

9000 5W-40

7000 10W-40

7000 15W-50

7000 10W-40

7000 15W-50

7000 10W-40

7000 15W-50

7000 15W-50

7000 10W-40

7000 15W-50

7000 15W-50

7000 10W-40

(*) = Blended oils for all engines,

permitting fuel economy

Page 32

30

GENERAL

Oils specifically for diesel

engines

LUBRICANTS – TOTAL recommended oils

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Blended oils for all engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

MIDDLE

EAST

9000 5W-40 7000 15W-50 7000 10W-50

Saudi Arabia

Bahrain

Dubai

United Arab Emirates

Iran

Israel

Jordan

Kuwait

Lebanon

Oman

Qatar

Yemen

Page 33

31

GENERAL

Manual gearbox

TOTAL TRANSMISSION BV

Norms S.A.E 75W-80

Special oil distributed by CITROËN

(Part No. 9730 A2)

MB3 automatic gearbox

All countries

TOTAL FLUIDE ATX ou

TOTAL FLUIDE AT 42.

Special oils distributed by CITROËN

(Part No. 9730 A3)

4 HP 20 and AL4 automatic gearboxes

Special oil distributed by CITROËN

(Part No. 9736 22)

Transfer box and rear axle TOTAL TRANSMISSION X 4

All countries TOTAL FLUIDE ATX

Power- assisted steering TOTAL FLUIDE DA

Very cold countries Special oil distributed by CITROËN

(Part No. 9730 A1)

LUBRICANTS – TOTAL recommended oils

Gearbox oils

Power steering oils

Page 34

32

GENERAL

Engine coolant fluid

LUBRICANTS – TOTAL recommended oils

Packs

CITROEN reference

GLYSANTIN G 33 REVCOGEL 2000

CITROEN Fluid 2 litres 9979 70 9979 72

All countries

Protection : - 35°C 5 litres 9979 71 9979 73

20 litres 9979 76 9979 74

210 litres 9979 77 9979 75

Synthetic brake fluid

Packs CITROEN reference

All countries

CITROEN Fluid

0.5 litre 9979 05

1 litre 9979 06

5 litres 9979 07

CITROEN hydraulic circuit fluid

Norme Packs CITROEN reference

TOTAL LHM PLUS

ISO 7308-7309

ZCP 830 095

Green in colour 1 litre 9979.20 (Scandinavia)

All countries

TOTAL FLUIDE LDS Orange in colour 9979.6

WARNING: TOTAL LDS fluid cannot be blended with TOTAL LHM PLUS

WARNING: CITROËN C5 : Use only TOTAL FLUIDE LDS suspension fluid.

Hydraulic circuit rinsing fluid- green in colour

All countries TOTAL HYDRAURINCAGE

Page 35

33

GENERAL

Packs CITROEN reference

Concentrated : 250 ml 9980 33 ZC 9875 953 U 9980 56

All countries

Liquid ready to use: 1 litre 9980 06 ZC 9875 784 U

Liquid ready to use: 5 litres 9980 05 ZC 9885 077 U ZC 9875 279 U

Grease

Norms NLGI (1)

TOTAL MULTIS EP2 2

All countries TOTAL MULTIS COMPLEX EP2 2

TOTAL MULTIS N4128 1

TOTAL PETITES MECANIQUES

(1) NLGI = National Lubricating Grease Institute.

Wash/wipe fluid

LUBRICANTS – TOTAL recommended oils

Page 36

34

ENGINE OIL CONSUMPTION

I-Oil consumption depends on :

- the engine type.

- how run-in or worn it is.

- the type of oil used.

- the driving conditions.

II - An engine can be considered RUN-IN after:

- 3,000 miles (5,000 km) for a PETROL engine.

- 6,000 miles (10,000 km) for a DIESEL engine.

III - MAXIMUM PERMISSIBLE oil consumption for a RUN-IN engine.

- 0.5 litres per 600 miles (1,000 km) for a PETROL engine.

- 1 litre per 600 miles (1,000 km) for a DIESEL engine.

DO NOT WORK BELOW THESE VALUES.

IV - OIL LEVEL : The level should NEVER be above the MAX. mark on the dipstick after changing or topping up the oil.

- This excess oil will be used up rapidly.

- It will reduce the engine output and adversely affect the operation of the air circuits and gas recycling.

GENERAL

Page 37

35

ENGINE SPECIFICATIONS

DieselPetrol

1.1i 1.4i 1.6i 16V 1.4 HDi

Engine type

Cubic capacity (cc)

Bore / Stroke

Compression ratio

Power ISO or EEC KW - rpm

Power DIN (HP - rpm)

Torque ISO or EEC (m.daN - rpm)

Torque DIN (mkg-rpm)

HFX KFV NFU 8HX

1124 1360 1587 1398

72/69 75/77 78/82 73/82

10.5/1 11/1 17.9/1

44-5500 54-5400 80-5800 50-4000

61-5500 75-5400 110-5800 70-4000

9.4-3400 12-3400 14.7-4000 15-2000

9.8-3400 12.5-3400 15.3-4000 15.6-2000

ENGINE

Page 38

36

ENGINE SPECIFICATIONS

Engines : HFX - KFV - NFU

Engine identification

B1BP10JC B1BP2GKC

A=Engines : HFX - KFV

B = Engine : NFU

Compulsory engine identification

in zone « a »:

- Component reference.

- Engine legislation type.

- Factory serial no.

ENGINE

Page 39

37

CYLINDER HEAD

Engines : HFX - KFV - NFU

Identification of cylinder head gasket

Engine types

HFX

KFV

NFU

Thicknesses

(Standard)

1.2 ± 0.1

0.66 ± 0.04

Thicknesses (repair)

1.4 ± 0.1

Thickness references

2

1

4

ENGINE

References

1.2.3.4 = Type of engine.

A,B,D = Suppliers.

C = Gasket material.

R = Repair.

B1BP10KC

Page 40

38

CYLINDER HEAD

Engines : HFX - KFV - NFU

Cylinder head tightening (m.daN) Cylinder head bolts

X = MAXIMUM reusable length

Tightening 2 ± 0.2

Angular tightening 240° ± 5°

(In the order 1 to 10)

Tightening 2 ± 0.2

Angular tightening 260° ± 5°

(In the order 1 to 10)

NOTE : Oil the threads and

under the heads of the bolts.

(Use engine oil or Molykote G

Rapid Plus).

B1BP1DVC

NFU

HFX - KFV

HFX - KFV

175.5 ± 0.5 122 ± 0.3

NFU

B1DP05BC

NOTE : Retightening of the cylinder head

after a completed repair is prohibited.

ENGINE

Page 41

39

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Crankshaft

Accessories drive pulley 2.5 ± 0.2

Pinion fixing on crankshaft

- Tightening 4 ± 0.4

- Angular tightening 45° ± 4°

Cylinder block

Sump 0.8 ± 0.2

Timing belt tensioner roller 2.1 ± 0.2

Accessories belt tensioner roller 2.5 ± 0.2

Accessories belt guide roller 2.5 ± 0.2

Alternator support 2.5 ± 0.2

Alternator TU1JP-TU3JP

- Pre-tightening 1 ±

- Tightening 3.7 ± 0.3

Alternator TU5JP4

- Pre-tightening 1 ±

- Tightening

4 ± .04

Aircon compressor support 2.2 ± 0.2

Aircon compressor 2.3 ± 0.2

ENGINE

Page 42

40

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Cylinder head

Coolant outlet housing

- in plastic 0.8 ± 0.2

- in aluminium 0.8 ± 0.2

Camshaft bearing caps (TU1JP-TU3JP)

- Tightening 2 ± 0,2

- Angular tightening 44 °± 4°

Camshaft bearing caps (TU5JP4)

- Tightening 2 ± 0,2

- Angular tightening 50° ± 5°

Inlet manifold 0.8 ± 0.,2

Exhaust manifold 1.8 ± 0.4

Valve rockers adjusting screw 1.75 ± 0.25

Sparking plugs 3

Camshaft pulley screw (TU1JP-TU3JP) 3.7 ± 0.2

Camshaft pulley screw (TU5JP4) 4.5 ± 0.5

ENGINE

Page 43

41

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Flywheel - Clutch

Engine flywheel 6.7 ± 1 (LOCTITE FRENETANCH)

Oil pressure mechanism 2 ± 0.2

Lubrication circuit

Oil pressure switch 3.5 ± 0.5

Oil pump 0.9 ± 0.1

Cooling circuit

Coolant pump 1.6 ± 0.2

ENGINE

Page 44

42

TIGHTENING TORQUES : POWER UNIT SUSPENSION

Engines : HFX - KFV - NFU

(1) : 6 ± 0.6

(2) : 6 ± 0.6

(3) : 4.5 ± 0.4

(4) : 6 ± 0.6

(5) : 6 ± 0.6

(6) : 8.5 ± 0.8

(7) : 6 ± 0.6

(8) : 3 ± 0.3

(9) : 6 ± 0.6

(10) : 5.5 ± 0.5

B1BP2Y3P

ENGINE

Page 45

43

ENGINE

ENGINE SPECIFICATIONS

Engine : 8HX

Engine identification

"a" Engine legislation type.

"b"Component reference.

"c" Factory serial no.

B1CP0BKD

Page 46

44

ENGINE

CYLINDER HEAD

Engine : 8HX

Cylinder head tightening (m.daN) Cylinder head bolts

X = MAXIMUM reusable length

Pre-tightening 2 ± 0.2 m.daN

Tightening 4 ± 0.4 m.daN

Angular tightening 230° ± 5°

(In the order 1 to 10)

NOTE :

- The bolts should have been thoroughly cleaned and dried with a

dry metal brush.

- Oil the threads and under the

heads of the bolts. (Use engine

oil or Molykote G Rapid Plus).

- Pass a tap into the holes in the

cylinder block.

8HX

8HX

X = 149 mm

B1DP1CLC

B1DP1DBC

NOTE : Retightening of the cylinder head

after a completed repair is prohibited.

The cylinder head gasket is dry-fitted.

Page 47

45

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Crankshaft mobile

Bearing cap fixing screws

Pre-tightening 1 ± 0.2

Slackening 180°

Tightening 3 ± 0.3

Angular tightening 140°

Con rod screws

Tightening 1 ± 0.1

Angular tightening 100° ± 5°

Accessories drive pulley

Pre-tightening 3 ± 0.3

Angular tightening 180° ± 5°

Cylinder block

Sump 1.3 ± 0.1

Timing belt guide roller 2.3 ± 0.2

Timing belt tensioner roller 3.7 ± 0.3

ENGINE

Page 48

46

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Cylinder head

Camshaft bearing covers

Pre-tightening 0.3 ± 0.1

Tightening 1 ± 0.1

Fixing of camshaft sub-assemblies on cylinder head

Pre-tightening 0.3 ± 0.1

Tightening 1 ± 0.1

Exhaust manifold 3 ± 0.3

Camshaft pulley

Pre-tightening 0.3 ± 0.1

Tightening 4.3 ± 0.4

Engine flywheel

Flywheel

Pre-tightening 1.7 ± 0.2

Tightening 70° ± 5°

Clutch mechanism 2 ± 0.2

ENGINE

Page 49

47

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Lubrication circuit

Oil pump assembly

Pre-tightening 0.5 ± 0.1

Tightening 0.9 ± 0.1

Coolant/oil heat exchanger 1 ± 0.1

Diesel injection circuit

Spherical-base screws for diesel injection fixing fork 2.5 ± 0.2

Fuel high pressure common injection rail on engine block 2.2 ± 0.2

Unions on fuel high pressure common injection rail 2.5 ± 0.2

Diesel injection pump on support 2.2 ± 0.2

Union on diesel injection 2.5 ± 0.2

Diesel injection pump pulley 5 ± 0.5

Union on diesel high pressure pump 2.5 ± 0.2

Cooling circuit

Coolant pump

Pre-tightening 0.3 ± 0.1

Tightening 0.9 ± 0.1

Coolant outlet housing

Pre-tightening 0.3 ± 0.1

Tightening 0.7 ± 0.1

ENGINE

Page 50

48

TIGHTENING TORQUES : POWER UNIT SUSPENSION

Engine : 8HX

(1) : 6 ± 0.6

(2) : 6 ± 0.6

(3) : 6 ± 0.6

(4) : 6 ± 0.6

(5) : 3 ± 0.3

(6) : 6 ± 0.6

(7) : 5.5± 0.5

(8) : 5.7 ± 0.9

B1BP2Y1P

ENGINE

Page 51

49

Tools

BELT TENSION/SEEM UNITS CORRESPONDENCE TABLE

! 4099-T (C.TRONIC.105)

4122-T (C.TRONIC.105.5) !

!

!

B1EP135D

ENGINE

Page 52

50

Engine type HFX KFV NFU 8HX

C2 X X X X

See pages : 50 to 52 53 to 55

AUXILIARY EQUIPMENT DRIVE BELT

Petrol Diesel

TU DV

1354

JP JP4 TD

ENGINE

Page 53

51

AUXILIARY EQUIPMENT DRIVE BELT

Engines : HFX - KFV - NFU

B1BP2LSC B1BP2LTC

Tools.

[1] Pliers for removing plastic pegs : 7504-T.

[2] Belt tension measuring instrument : 4122-T.

Vehicle without air conditioning.

Refit.

Refit the belt.

Respect the following sequence:

- Crankshaft pinion.

- Alternator pulley.

Place tool [2] on the belt.

Tighten screw (1) to achieve a tension of:

55 ± 3 unités SEEM.

Tighten:

- Screw (3).

- Screw (2).

Remove tool [2] and complete the refitting.

Remove.

Slacken:

- Screw (2).

- Screw (3).

- Tensioning screw (1).

Push the alternator back towards the engine.

Remove the belt.

ENGINE

Page 54

52

AUXILIARY EQUIPMENT DRIVE BELT

Engines : HFX - KFV - NFU

B1BP10XC

Vehicle with air conditioning.

Remove

Slacken:

- Screws (6), (4) and (5).

- Fully detension the belt by acting on the tensioner roller.

- Remove the accessories drive belt.

Refit.

Respect the following sequence:

- Crankshaft pinion.

- Aircon compressor pulley.

- Guide roller.

- Alternator pulley.

- Tensioner roller.

Place tool [2] on the belt.

- Tighten screw (5) to achieve a belt tension of:

120 ± 3 SEEM units.

- Tighten screws (4) and (6).

- Remove tool [2].

- Complete the refitting.

ENGINE

B1BP10VC

Page 55

53

AUXILIARY EQUIPMENT DRIVE BELT

Engine : 8HXWith compressor and alternator

B1BP2MKC

B1BP2MJD

Tools

[1] Pliers for removing plastic pegs : 7504-T.

[2] Tensioner roller compression lever : (-).0194.E.

[3] Tensioner roller setting peg Ø4 mm : (-).0194.F.

Removing.

Disconnect the battery negative cable.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel.

Move aside the splash-shield, using tool [1].

IMPERATIVE : In the case of belt re-use, mark the direction of rotation of the belt. If the index on the tensioner

roller is outside the marks, change the auxiliary equipment drive belt.

Remove :

The alternator (1).

The aircon compressor (2).

Detension the auxiliary belt tensioner roller, using tool [2].

Position the peg [3]. Remove the auxiliary drive belt.

ENGINE

Page 56

54

AUXILIARY EQUIPMENT DRIVE BELT

Engine : 8HX

Markings on the dynamic tensioner roller

.

«a» Position of «maximum wear» of the auxiliary drive belt.

«b» Normal position.

Refitting

NOTE : Check that the tensioner roller moves freely (no tight spot). If this is not the

case, replace the tensioner roller.

Respect the direction of fitting of the drive belt.

Complete the setting of the belt, of both sides, by means of the tensioner roller.

Make sure that the drive belt is correctly positioned in the «V» grooves of the

various pulleys.

Move the tool [2] on the tensioner roller to remove the peg [3].

ENGINE

B1EP18UD

Page 57

55

AUXILIARY EQUIPMENT DRIVE BELT

Engine : 8HY

B1BP2MYD B1BP2MZC

Tools.

[1a] Dynamic tensioner roller lever : (-).0194-E1.

[1b] Lever extension : (-).0194-E2.

[2] Accessories belt roller locking peg Ø 4 mm : (-).0194-F

Removing

Pivot the tensioner roller support (1) (clockwise), using tools [1a] and [1b] at «a».

Remove the belt.

Immobilise the support (1) of the tensioner roller, using tool [2].

Remove the auxiliary drive belt (2).

IMPERATIVE : Ensure that the tensioner rollers turn freely

(no play, no tight spot).

Refitting

Refit the belt.

Move the tool [1] on the tensioner roller to remove the peg [2].

ESSENTIAL: Make sure that the belt is correctly positioned in the various pulley

grooves.

ENGINE

Page 58

56

ENGINE

Engine type HFX KFV NFU 8HX

C2 X X X X

See pages : 57 to 66 67 to 83

CHECKING AND SETTING THE VALVE TIMING

Petrol Diesel

TU DV

1354

JP JP4 TD

Page 59

57

CHECKING AND SETTING THE VALVE TIMING

Engines : HFX - KFV - NFU

B1BP2M7C B1BP2M9CB1BP2M8C

Tools.

[1] Engine flywheel peg : 4507-T.A

[2] Camshaft pulley peg : 4507-T.B

[3a] Camshaft peg : 4533-TA.C1

[3b] Camshaft peg : 4533-TA.C2

[4] Dynamic tensioner roller pin : 4200-T.H

[5] Belt retaining pin : 4533-T.AD

[6] Pliers for removing plastic pins : 7504-T.

Checking the valve timing.

Raise and support the front RH side of the vehicle.

Disconnect the battery positive terminal.

Engage 5th gear.

Remove the oil filter (1).

HFX - KFV engine

Remove :

The timing top casing (2).

Turn the wheel to rotate the engine (normal direction of rotation).

Peg the camshaft pulley, using tool [2].

ENGINE

Page 60

58

CHECKING AND SETTING THE VALVE TIMING

Engine : NFU

B1BP2MAC

Checking the timing (continued)

Engine: NFU

Place a jack under the engine, peg the engine.

Remove:

- The engine support (4) complete.

- The timing casing (3).

- The sparking plugs (eases engine rotation).

Turn the wheel to rotate the engine (normal direction of rotation).

Position the pegs [3a] and [3b].

Peg the flywheel, using tool [1].

If the setting is not correct, recommence the operation.

Remove the tools [1], [2], [3a] and [3b].

Complete the refitting.

B1BP2MBC

ENGINE

B1EP18MC

Page 61

59

CHECKING AND SETTING THE VALVE TIMING

Engines : HFX - KFV

B1BP2MBCB1BP2M9C B1BP2MDC

Setting the timing

Preliminary operation.

Lift and support the vehicle, wheels hanging.

Disconnect the battery.

Remove:

- The front RH wheel.

- The splash-shield, using tool [6]

- The accessories belt (See corresponding operation).

- The crankshaft pulley.

- The oil filter.

Place a jack under the engine, peg the engine.

Removing.

HFX - KFV engine

Turn the engine by means of screw (1). (normal direction of rotation).

Remove the timing casings.

Peg the camshaft pinion, using tool [2].

Peg the flywheel, using tool [1].

Remove:

- The fixing screws (2).

- The upper engine support (3).

ENGINE

B1BP2MCC

Page 62

60

CHECKING AND SETTING THE VALVE TIMING

Engines : HFX - KFV

B1BP2MEC B1EP18NC

Setting the timing (continued)

HFX - KFV engines

Slacken the screws (4) without removing them.

Remove the bottom engine support assembly (5), and the fixing screws (4).

Slacken the nut (6).

Completely detension the belt by acting on the tensioner roller (7).

Remove the timing belt.

IMPERATIVE : Check that the tensioner roller turns freely (no tight spot).

ENGINE

Page 63

61

CHECKING AND SETTING THE VALVE TIMING

Engine : NFU

B1BP2MBC

NFU engine.

Setting the timing (continued)

Remove:

The bottom plastic casing.

The engine support (9).

The middle support.

The timing cover (8);

Peg the flywheel, using tool [1].

Position the tools [3a] and [3b].

ENGINE

B1BP2MFC B1EP18MC

Page 64

62

CHECKING AND SETTING THE VALVE TIMING

Engine : NFU

B1EP18PC

Setting the timing (continued)

NFU engine.

Slacken the tensioer roller.

Turn the tensioner roller so as to be able to position the tool [4], with the aid of an Allen key placed at «a».

Turn the tensioner roller towards the right to bring it to the index «c» in position «b».

Peg the tensioner roller in this position in order to slacken the timing belt to the maximum.

IMPERATIVE : Never make the dynamic tensioner roller turn by a complete rotation.

Remove the timing belt (8).

Check that the rollers (9) and (10) turn freely (no tight spot).

ENGINE

B1EP18QC

Page 65

63

CHECKING AND SETTING THE VALVE TIMING

Engines : HFX - KFV

B1EP18QC

Setting the timing (continued)

HFX - KFV engines

Refit.

WARNING: Respect the direction of fitting of the belt: (the arrows «d» indicate the direction of rotation of

the crankshaft).

Refit the timing belt.

Position the timing belt, belt «e» well tensioned, in the following order:

Crankshaft pinion, hold the belt using tool [5].

Camshaft pulley.

Coolant pump pulley.

Tensioner roller.

Remove the pegs [1] and [2].

ENGINE

Page 66

64

CHECKING AND SETTING THE VALVE TIMING

Engines : KFX - KFV - NFU

Setting the timing (continued)

HFX - KFV engines

Refitting.

NOTE : Check that the pegs [1] and [2] are in place.

WARNING: Respect the direction of fitting of the timing belt, the arrows «d» indicate the direction of rotation

of the crankshaft.

Refit the timing belt.

Position the timing belt, belt «e» well tensioned, in the following order:

Crankshaft pinion, hold the belt using tool [5].

- Camshaft pulley.

- Coolant pump pulley.

- Tensioner roller.

Remove the tools [1], [2].

NFU engine.

Fit the timing belt in position in the following order:

- Inlet camshaft pulley.

- Exhaust camshaft pulley.

- Guide roller.

- Crankshaft pulley.

Position tool [5].

- Coolant pump pulley.

- Dynamic tensioner roller.

Remove the tools [1], [3] and [5].

ENGINE

B1EP18RC

Page 67

65

CHECKING AND SETTING THE VALVE TIMING

Engines : KFX - KFV - NFU

B1EP18SD

Timing belt overtensioned:

A: Engine HFX - KFV.

B : Engine NFU

Turn the tensioner roller (7) with the aid of a hexagonal spanner at «a».

Bring the index «c» to position «f», to tension the belt to the maximum of the

interval indicated.

Hold the tensioner roller (7), using tool [4].

Tighten the fixing nut of the tensioner roller, tightening to 1 ± 0,1 m.daN

Turn the crankshaft by 4 rotations (normal direction of rotation).

IMPERATIVE : Never make the crankshaft rotate backwards.

Make sure that the timing is correctly set by refitting the tools [1], [2] and [3].

Remove the tools [1], [2] and [3].

ENGINE

Page 68

66

CHECKING AND SETTING THE VALVE TIMING

Engines : HFX - KFV - NFU

B1EP18TD

Adjusting the fitting tension of the timing belt

A:Engine HFX - KFV.

B : Engine NFU

Slacken the nut while maintaining the position of the tensioner roller, with the aid of

a hexagonal spanner at «a».

Next bring the index «c» to its adjusting position «a».

The index «c» should not go beyond the notch «g».

WARNING: The index «c» must not go beyond the notch «g». If it should do this,

restart the timing belt tensioning operation.

Hold the tensioner roller (7) in this position, with the aid of a hexagonal spanner.

Tighten the tensioner roller fixing nut to :

2 ± 0.2 m.daN. (HFX - KFV engines)

2.2 ± 0.2 m.daN. (NFU engines)

IMPERATIVE : The tensioner roller must not rotate during the tightening of its

fixing. If it does, restart the timing belt tensioning operation.

Complete the refitting.

ENGINE

Page 69

67

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HX

B1BP2LXC

Tools.

[1] Pliers for removing plastic pegs : 7504-T.

[2] Lever for detensioning the dynamic tensioner roller : (-).0194.E

[3] Engine flywheel setting peg : (-).0194.C

[4] Camshaft setting peg : (-).0194.B.

[5] Crankshaft and high pressure pump setting peg : (-).0194.A.

Preliminary operations.

Remove:

- The front RH wheel.

- The front RH splash-shield, using tool [1].

- The clips of the electrical harness on the upper timing cover.

- The accessories belt, using tool [2] (see corresponding operation).

Check ing the setting.

Disconnect the battery negative cable.

Remove the upper timing cover (1).

Rotate the engine using the screw (2) of the crankshaft pulley.

NOTE : The locking hole is located under the crankshaft bearing cap cover.

Undo the screw (2).

Detension the auxiliary drive belt dynamic tensioner roller, using tool [2].

ENGINE

Page 70

68

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HX

B1EP18EC

Checking the setting (continued)

Remove:

- the accessories drive belt.

- the accessories drive pulley.

- the lower timing cover (3).

IMPERATIVE : The magnetic track should show no signs of

damage and should not be approached by any other source of

magnetism.

Reposition the screw (2).

Remove tool [3].

Rotate the engine by means of the crankshaft pinion screw (2)

(clockwise), to bring it to the pegging position.

Position the tool [4].

Peg the crankshaft pinion (1), using tool [5].

Peg the high pressure pump pinion, using tool [5]

NOTE: Index «a» of the roller tensioner must be centred within the

area «b».

Check the correct positioning of index «a».

Remove tools [4] and [5].

Rotate the engine ten times.

Fit the tools [4] and [5].

If pegging is not possible, carry out the operation to remove/refit the

timing belt. (See corresponding operation).

B1JP03SC

B1EP18DC

B1EP18FC

ENGINE

Page 71

69

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HX

B1EP18GC

Setting the timing.

Remove the upper timing cover (1).

Rotate the engine by means of the crankshaft screw (2).

NOTE : The pegging hole is located under the crankshaft bearing cap cover.

Peg the engine flywheel, using tool [3].

Remove the lower timing cover (3).

Uncouple the exhaust line from the manifold.

IMPERATIVE : Uncouple the exhaust line in order to avoid damaging the front flexible pipe. Twisting,

pulling and bending the front flexible pipe reduces its life.

Remove:

- The engine speed sensor (6).

- The belt retaining stop (5).

- The screw (2).

- The crankshaft pinion (4) (with its magnetic track «a»).

IMPERATIVE : The magnetic track should show no signs of damage and should not be approached

by any other source of magnetism. Should this not be adhered to, it is essential to replace the

crankshaft pinion.

Refit the screw (2).

ENGINE

B1BP2LXC

Page 72

70

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HX

Setting the timing (continued).

Remove the tool [3].

Rotate the engine by means of the crankshaft pinion screw (2)

(clockwise), to bring it to the pegging position.

Peg the camshaft pulley, using tool [4].

Peg :

- The crankshaft pinion (6), using tool [5].

- The high pressure pump pinion, using tool [5].

Support the engine with the aid of a roller jack equipped with a

chock.

Remove:

- The RH engine support (7).

- The intermediate engine support (right hand side) (8).

B1JP03SC B1EP18DC B1EP195C B1BP2LYC

ENGINE

Page 73

71

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HX

B1EP18HC

Setting the timing (continued).

Hold the tensioner roller, using a hexagonal spanner at «b».

Slacken the screw (9).

Remove the timing belt (10).

Refitting.

IMPERATIVE : Check that both the tensioner roller and the fixed roller turn

freely (no tight spots). If this is not the case, replace the rollers.

Fitting of the pulleys.

- Camshaft pulley : Tighten to 4,3 ± 0,4 m.daN.

- Fuel high pressure pump pulley : Tighten to 5 ± 0,5 m.daN.

The crankshaft pinion is located without a screw at the end of the crankshaft.

Fitting of the rollers.

IMPERATIVE : Check that the tensioner roller turns freely (no tight spot).

Otherwise, replace the rollers.

- Guide roller : Tighten to 4,5 ± 0,4 m.daN

- Tensioner roller : Pre-tighten to 0,1 m.daN

Check the condition of the seals at the camshaft and at the crankshaft pinion.

ENGINE

Page 74

72

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HX

B1EP18JD

Setting the timing (continued).

NOTE : Screw (9) slackened.

Position the timing belt (10) observing the following sequence:

Crankshaft pinion (4).

Guide roller (12).

Camshaft pulley (11), (check that the belt is held correctly against the roller).

Coolant pump pinion (13).

Fuel high pressure pump pulley (15).

Tensioner roller (14).

ENGINE

Page 75

73

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HX

B1EP18KC

Setting the timing (continued).

Turn the tensioner roller to the right to bring the index «c» to position «d», using a

hexagonal spanner.

Tighten the screw (9) of the tensioner roller, tighten to 3 ± 0,3 m.daN.

Remove the tools [4] and [5].

Rotate the engine ten times (check that the timing pinion is correctly up against the

crankshaft).

Check:

The pegging of the camshaft.

The crankshaft pinion.

The fuel high pressure pump pinion (15).

The correct positioning of the index of the dynamic tensioner.

If these are not correct, repeat the operation to position the timing belt.

Refit:

The engine speed sensor (6).

The belt retaining stop (5), tighten to 0,7 m.daN.

Page 76

74

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HX

B1EP18LC B1BP2LZC

Setting the timing (continued).

Refit:

The intermediate RH engine support, tighten the screws (16) to 5,5 ± 0,5 m.daN.

The RH engine support, tighten the screws (17) to 4,5 ± 0,4 m.daN.

The bottom timing cover (3).

Immobilise the engine flywheel, using tool [3].

Remove the screw (2).

Refit the accessories drive pulley and tighten to:

Pre-tighten to : 3 ± 0,3 m.daN.

Angular tighten to : 180° ± 1,8°

Remove tool [3]

Refit:

The top cover (1).

The accessories belt (see corresponding operation).

The exhaust line (see corresponding operation).

The front RH splash-shield.

The front RH wheel.

ENGINE

Page 77

75

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1BP2N0C

Tools.

[1] Engine flywheel peg Ø 12 mm : (-).0194-C.

[2] Camshaft pulley peg Ø 8 mm : (-).0194-B.

[3] Crankshaft pulley peg Ø 5 mm : (-).0194-A.

Preliminary operations.

Remove:

- The front RH wheel.

- The front RH splash-shield.

- The accessories belt (see corresponding operation).

Uncouple:

- The supply unions (1).

- The air/air heat exchanger inlet/outlet pipes (3).

- The exhaust line (at the flexible pipe).

Disconnect the connector (2).

Support the engine by means of a roller jack equipped with a chock.

Remove the engine supports (4) and (5).

ENGINE

Page 78

76

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1BP2N1C B1BP2N2C

Checks.

Rotate the engine to engage it (normal direction of rotation).

Immobilise the engine flywheel at «a», using tool [1].

Move aside the harness (6).

Remove:

- The engine support (7).

- The screw (8).

- The pulley (9).

- The lower timing cover (10).

- The upper timing cover (11).

- The tool [1].

ENGINE

Page 79

77

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1EP18YD

Checks (continued).

Refit the screw (8).

Rotate the crankshaft six times (clockwise).

IMPERATIVE : Never rotate the engine backwards.

Peg :

- The camshaft, using tool [2]. (Oil the pegs.)

- The fuel high pressure pump pulley (14), using tool [3] at «c».

WARNING: The magnetic track should show no signs of damage and should not

be approached by any source of magnetism.

Peg the crankshaft at «b», using tool [3].

IMPERATIVE: Should it be impossible to peg the camshaft, check that the offset between the hole in the camshaft pinion and the pegging hole is not

greater than 1 mm.

Otherwise repeat the operation to position the timing belt. (See corresponding

operation).

ENGINE

Page 80

78

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1EP18ZC

Checks (continued).

NOTE : The index «e» of the dynamic tensioner roller should be centred within the area «d».

Check the correct positioning of the index «e».

If it is not correct, repeat the operation to tension the timing belt (see corresponding operation).

Refitting.

Refit the tool [1] at «a».

Remove the screw (8).

Refit:

- The upper timing cover (11).

- The lower timing cover (10).

- The accessories drive pulley (9).

- The screw (8).

Tightening torque:

- Screw (8) :

Pre-tighten to : 3 ± 0,3 m.daN.

Angular tightening : 180° ± 5°.

Remove the tool [1].

ENGINE

Page 81

79

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1BP2N0C

Checks (continued).

Refit :

- The engine support (7), tighten to 1,5 ± 0,4 m.daN.

- The engine support (4), tighten to 6,1 ± 0,6 m.daN.

- The engine support (5), tighten to 6 ± 0,6 m.daN.

- The electrical harness (6).

Couple:

- The exhaust line, tighten the collar to : 2,5 ± 0,3 m daN

- The fuel supply unions (1).

- The air/air heat exchanger inlet/outlet pipes (3).

Connect the connector (2).

Refit :

- The accessories belt (see corresponding operation).

- The front RH splash-shield (see corresponding operation).

- The front RH road wheel, tighten to 9 ± 1 m.daN.

Reconnect the battery.

ENGINE

Page 82

80

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1EP18VD

Setting the timing.

Perform the preliminary operations for checking the timing up to removing tool [1] at «a» for immobiling the

engine flywheel.

Refit screw (8).

Rotate the crankshaft to bring the camshaft towards its pegging point.

Peg the camshaft, using tool [2]. (Oil the pegs).

WARNING: Do not press or damage the track which is the target for the engine speed

sensor (14).

Peg the crankshaft at «b», using tool [3].

Remove:

- The timing protector (13).

- The engine speed sensor (14).

Slacken the screw (12) of the tensioner roller, keeping it slack with the aid of a hexagonal spanner at «c».

Detension the belt by pivoting the tensioner roller (clockwise).

Remove the timing belt, commencing with the coolant pump pinion.

Peg the pulley (15), using a 5 mm diameter peg at «d».

ENGINE

Page 83

81

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1EP18WD

Setting the timing (continued).

Checking the setting.

IMPERATIVE : Just prior to refitting, carry out the following tests:

Check that:

- the rollers and the coolant pump operate freely

(no play and no tight spot).

- there are no traces of oil

(from the crankshaft and camshaft sealing rings).

- there is no leak of coolant fluid (from the coolant pump).

- the target track of the engine speed sensor (14) is not damaged or scratched.

(If necessary replace the defective components).

Refitting

Fit the timing belt on the crankshaft pinion.

Position the belt on the guide roller, with the belt well tensioned.

Refit:

- The timing protector (13).

- The sensor (14).

ENGINE

Page 84

82

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1EP18XC

Setting the timing (continued).

Checks (continued).

Reposition the timing belt, belt at «e» well tensioned, in the following order:

- Guide roller (17).

- Camshaft pulley (16).

- Fuel high pressure pump pulley (15).

- Coolant pump pinion (18).

- Tensioner roller (19).

Remove the 5 mm diameter peg at «d».

Adjusting the fitting tension of the belt.

Action the tensioner roller (19) to align the marks «f» and «g» , avoiding detensioning the timing belt,

with the aid of a male hexagonal spanner, at «c».

If this is not successful, repeat the operation to tension the belt.

Hold the tensioner roller in position (19).

Tighten the tensioner roller, tightening to 3,7 ± 0,3 m.daN.

Check the position of the tensioner roller (the alignment of the marks «f» and «g» should be correct).

Remove tools [2] and [3].

Turn the crankshaft six rotations (clockwise).

ENGINE

Page 85

83

CHECKING AND SETTING THE VALVE TIMING

Engine : 8HY

B1EP18XC

Adjusting the timing belt tension (continued).

IMPERATIVE : Never rotate the engine backwards.

WARNING : Do not touch or damage the track of the target of the engine speed sensor (14).

Peg the crankshaft, using tool [3].

Check the position of the tensioner roller (the alignment of the marks «f» and «g» should be correct).

If this is not the case, repeat the operation to tension the belt.

Peg the camshaft pulley, using tool [2].

IMPERATIVE : Should it be impossible to peg the camshaft, check that the offset between the

camshaft hole and the pegging hole is not more than 1 mm. If the offset is too great, repeat the

operation.

Remove the pegs [2] and [3].

Refit tool [1] at «a».

Remove the screw (8).

Complete the refitting.

ENGINE

Page 86

84

EXHAUST SPECIFICATIONS

Engines: HFX - KFV (Depollution L4)

B1JP03TD

ENGINE

«a» Cutting zone

Page 87

85

EXHAUST SPECIFICATIONS

Engines: HFX - KFV (Depollution IFL5)

B1JP04RD

«a» Cutting zone

ENGINE

Page 88

86

EXHAUST SPECIFICATIONS

Engine: NFU (Depollution IFL5)

B1JP04TD

«a» Cutting zone

ENGINE

Page 89

87

EXHAUST SPECIFICATIONS

Engine: HFX (Depollution L4 and IFL5)

(1) (2) (3) (4) (5) (6)

(1) (2) (3) (4) (5) (6)

(1)

(2)

(3) (4)

(5)

Engine type

Upstream

oxygen sensor

Tightening (m.daN)

Tightening (m.daN)

4.7 ± 0.5 TR PSA K179

TR PSA K208

TR PSA K181

4.7 ± 0.5

4.7 ± 0.5

4.7 ± 0.5

PSA 4173

PSA 4174

PSA 4176

PSA 4175

PSA 4175

PSA 96 362 494 80

PSA 96 362 494 80

0.8 ± 0.2

0.8 ± 0.2

HFX

KFV

NFU

Engine: KFV (Depollution L4 and IFL5)

Catalytic

converter

Downstream

oxygen sensor

Front silencer Rear silencer Air to exhaust injection valve

Upstream

oxygen sensor

Catalytic

converter

Downstream

oxygen sensor

Front silencer Rear silencer Air to exhaust injection valve

Engine type

Tightening (m.daN) Tightening (m.daN)

4.7 ± 0.5

Engine : NFU (Depollution IFL5)

Engine type

ENGINE

Tightening (m.daN)

Tightening (m.daN)

Upstream

oxygen sensor

Catalytic converter

Downstream oxygen

sensor

Front silencer

Rear silencer

Tightening (m.daN) Tightening (m.daN)

4.7 ± 0.5

Page 90

88

EXHAUST SPECIFICATIONS

Engine : 8HX

ENGINE

«a» Flexible pipe

«b» Cutting zone (marked by burrs)

«c» Silencer fixing strap

B1JP03PD

Page 91

89

EXHAUST SPECIFICATIONS

Engine : 8HX

8HX

TR PSA K278

Tightening (m.daN) 2.5 ± 0.3 Tightening (m.daN) 2.5 ± 0.3 Tightening (m.daN) 2.5 ± 0.3

Engine types

Catalytic converter

(1)

Strap

(2)

Intermediate pipe

(3)

Rear silencer

(4)

PSA 4177

ENGINE

Page 92

90

HFX KFV NFU 8HX

7 litres 5.7 Litres

16 dm

3

1.4 bar 1.4 bar

89°C Start of opening 101°C Opening complete 83° C

100W (without aircon) 300W (with aircon) 1 x 300 W

97° C

115 °C

118°C

105°C 6 minutes

COOLING SYSTEM SPECIFICATIONS

Engines : HFX - KFV - NFU - 8HX

Engine type

Capacity

Radiator surface

Pressurisation

Opening of thermostatic

regulator

Cooling fan

1st speed

2nd speed

Aircon cut-off

Warning

Post-cooling

1.4i. 1.6i 16V 1.4 HDi1.1i

Temperature sensor : Tighten to 1,7 ± 0,4 m.daN.

ENGINE

Page 93

91

COOLING SYSTEM SPECIFICATIONS

Engines : HFX - KFV - NFU

(1) Venting chamber

(2) Coolant pump

(3) Bleed screw of heater matrix

B1GP0AXP

ENGINE

Page 94

92

ENGINE

COOLING SYSTEM SPECIFICATIONS

Engine : 8HX

(1) Bleed screw (with or without aircon)

B1GP09MP

Page 95

93

Petrol

Diesel

OIL FILTERS

TU

1

JP

1.1i

HFX KFV NFU

X

FILTRAUTO

XX

1.4i 1.6i 16V

35

JP4

DV

TD

1.4 HDi

8HX

X

MALHEX

4

ENGINE

Page 96

94

CHECKING THE OIL PRESSURE

Engine type

Temperature (°C)

Pressure (Bars)

Rpm

Engine type

Diesel engines

1.1i

HFX KFV NFU

90°C

3

2000

1.4i

1.6i 16V

1.4 HDi

8HX

90°C

> 1.3

1000

Petrol engines

Temperature (°C)

Pressure (Bars)

Rpm

Tools :

Pressure gauge : 2279-T.Bis Toolkit 4103-T.

Flexible pipe

Engine oil pressure take-off union (TU engine) : 7001-T Toolkit 4103-T.

Oil pressure take-off union (DV engine) : 9780-80-T

NOTE : Tightening of the oil pressure switch 2 ± 0,2. (New seal).

IMPERATIVE : Respect the safety and cleanliness requirements.

ENGINE

Page 97

95

VALVE CLEARANCES

The valve clearances should be checked with the engine cold.

● Inlet

HFX - KFV

NFU

8HX

0.20 mm ± 0.05

Exhaust

0.40 mm ± 0.05

1 mm ± 0.05

Hydraulic adjustment

1 mm ± 0.05

Rocking

Adjust

1 ● 1

3 ● 3

4 ● 4

2 ● 2

4 ● 4

2 ● 2

1 ● 1

3 ● 3

Inlet

●

Admission

Rocking

Valves

fully

open

Adjust

1

3

4

2

3 ● 4

4 ● 2

2 ● 1

1 ● 3

Fully open (Exhaust)

POSSIBLE METHODS

On engines: 4 cylinders in line (1-3-4-2 )

Engines without hydraulic

adjustment : the clearance (J)

should be checked opposite

the cam.

B1DP13QC

ENGINE

Page 98

96

FILLING AND BLEEDING THE COOLING CIRCUIT

HFX-KFV-NFU

8HX

Tools

[1] Filling cylinder : 4520-T

[2] Adaptor for filling cylinder : 4222-T.

[3] Pliers for removing-refitting elastic clips : 9029-T

Draining.

Perform the operation with the engine cold.

Remove the air filter housing.

Open the expansion chamber cap.

Uncouple bottom hose (1), using tool [3] and bottom hose (2) of the radiator.

Open :

The bleed screw on the coolant outlet housing.

The bleed screw on the heater matrix.

The cylinder block drain plug.

Allow the coolant to flow out.

Before any refilling, rinse the cooling circuit with clean water.

Couple the bottom hose (1) and (2).

B1BP2LUC B1GP0AQD

ENGINE

Page 99

97

ENGINE

FILLING AND BLEEDING THE COOLING CIRCUIT

Filling and bleeding.

Fit the filling cylinder [1], with the adaptor [2] on the filling aperture.

Slowly fill the circuit with the coolant fluid.

Reclose the bleed screws when the liquid starts to flow out continuously without air bubbles.

NOTE : The filling cylinder [1] should be filled to the «1 Litre» mark to purge the heater matrix correctly.

Refit the air filter housing.

Start the engine.

Maintain an engine speed of 1500 to 2000 rpm, until the end of the second cooling cycle.

(Starting and stopping of the cooling fan).

Keep the filling cylinder full to the «1 Litre» mark.

Stop the engine after the second cooling cycle.

Remove the filling cylinder [1] with the adaptor [2].

Refit the expansion chamber cap.

B1GP09KC

Page 100

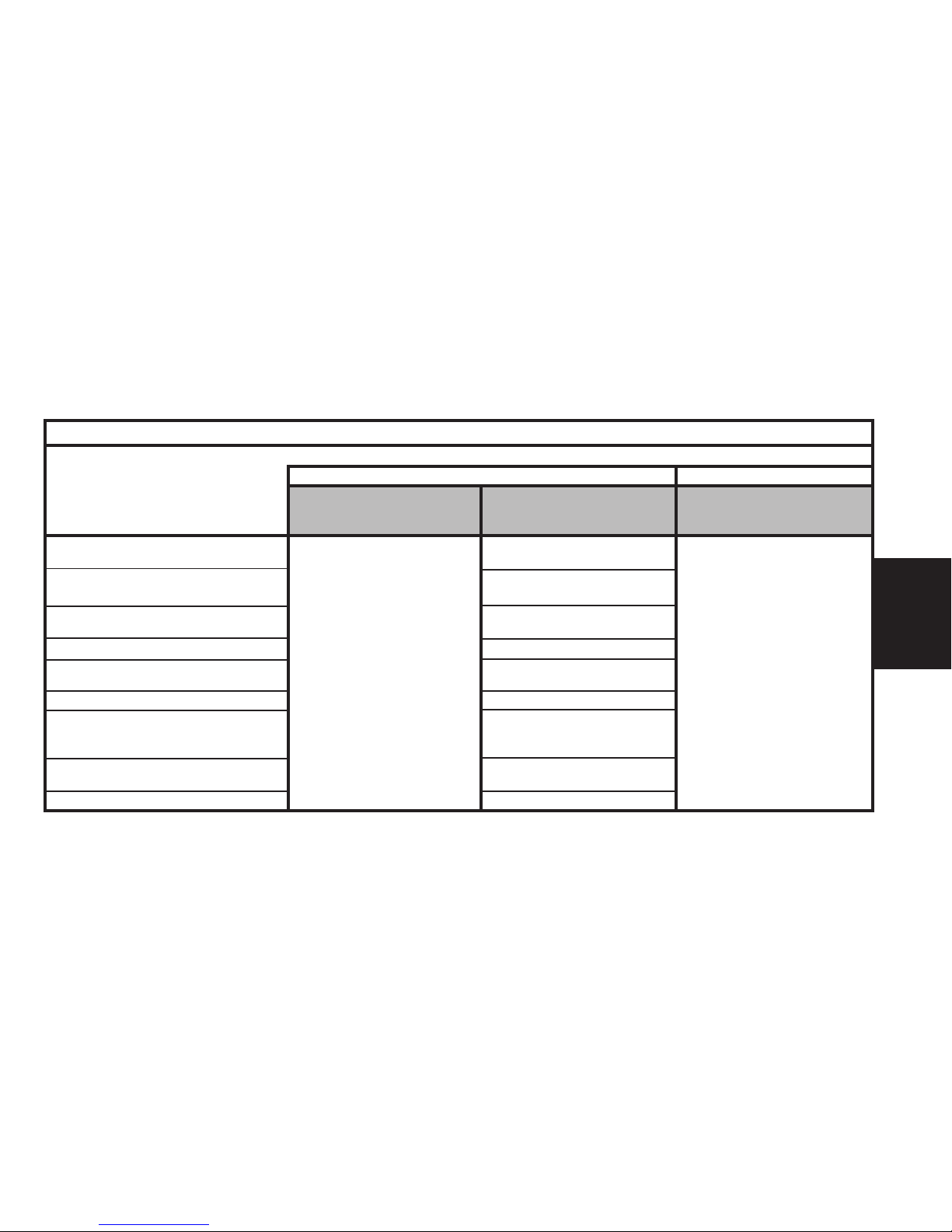

IDLING - DEPOLLUTION

Vehicles Engine type

Emission

standard

L4

MAGNETTI MARELLI

48P

SAGEM S2000

BOSCH

M 7.4.4.

850

< 0.5 > 9

HFX

KFW

NFU

1.1 i

1.4 i

1.6 i 16V

IF/L5

L4

IF/L5

L4

Make - Injection type

% Content

CO CO2

Idling speed

(± 50 rpm)

Manual

gearbox

Auto. gearbox: N

gear engaged

C2

98

INJECTION

Loading...

Loading...