Page 1

PRIVATE CARS

XANTIA-XM-SYNERGIE

CAR 050008

Book 2

«The technical information contained in this document is intended for the exclusive use of the trained personnel of the

motor vehicle repair trade. In some instances, this information could concern the security and safety of the vehicle. The

information is to be used by the professional vehicle repairers for whom it is intended and they alone would assume full

responsibility to the exclusion of that of the manufacturer».

’’The technical information appearing in this brochure is subject to updating as the characteristics of each

model in the range evolve. Motor vehicle repairers are invited to contact the CITROËN network periodically

for further information and to obtain any possible updates».

2001

Page 2

PRESENTATION

THIS HANDBOOK summarises the characteristics, adjustments, checks and special features of CITROEN vehicles, not including COMMERCIAL

vehicles for which there exists a separate handbook.

The handbook is divided into the following groups representing the main functions :

GENERAL - ENGINE - INJECTION - IGNITION - CLUTCH, GEARBOX, DRIVESHAFTS - AXLES, SUSPENSION, STEERING - BRAKES -

HYDRAULICS - ELECTRICAL - AIR CONDITIONING.

In each section, the vehicles are dealt with in the following order : XANTIA-XM-SYNERGIE and all models where applicable.

The information given in this handbook is based on vehicles marketed in EUROPE.

Page 3

IMPORTANT

If you find that this handbook does not always meet your requirements, we invite you to send us your suggestions which we will take into account

when preparing future publications. For example :

– INSUFFICIENT INFORMATION

– SUPERFLUOUS INFORMATION

– NEED FOR MORE DETAILS

Please send your comments and suggestions to :

CITROEN U.K. Ltd.

221, Bath Road,

SLOUGH,

SL1 4BA.

U.K.

Page 4

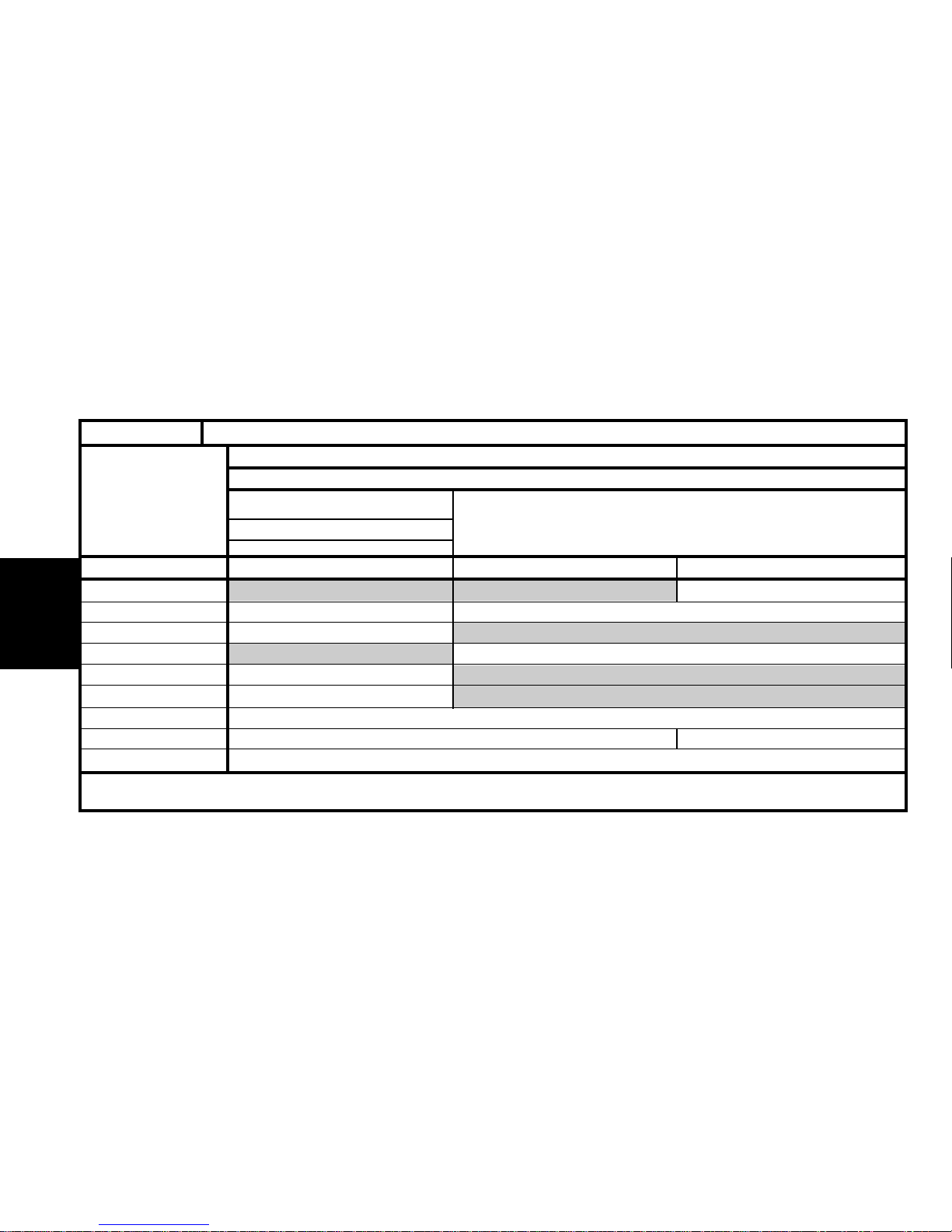

XANTIA

Parking brake 240 - 241

Bleed of brakes

242

XM

Parking brake

244

Bleed of brakes

245

SYNERGIE Parking brake 249

SUSPENSION

De-pressurising 250 - 260

HYDRAULICS

Pneumatic

XANTIA 261 - 265

units

XM 266 - 269

ELECTRICITY

Starter motors 270 - 272

Alternators 273 - 279

Charging circuit 280

Preheater plugs 281

AIR CONDITIONING

R 134 a quantities 282

Special features 283 - 288

Checking temperatures 289 - 290

Checking pressures 291

XANTIA 293 - 297

XM 298 - 301

SYNERGIE 302 - 303

INDEX

GENERAL

XANTIA 1 - 8

XM 9 - 13

SYNERGIE 14 - 15

XANTIA 17 - 18

XM 19

SYNERGIE 20

Lubricants 21 - 34

ENGINE

Specifications 36 - 38

Cyl. head marking and tightening 51 - 61

Auxiliary equipment drive belt 62 - 78

Checking and setting valve timing 83 - 84

Valve clearances 121

Oil pressure 122

Oil filter 125

INJECTION

Idling, anti-pollution 127

Petrol injection 128 - 129

Anti-pollution technical checks 130

Emission standards 131 - 137

LPG safety requirements 138 - 142

Identification

of vehicles

Capacities

Axle

geometry

Brake specifications

Aircon

system

HDi safety requirements 143 - 146

Checks: HDi fuel circuit 147 - 148

Checks: HDi air circuit 149

Checks: Turbo pressure 150 - 151

Checks: HDi exhaust gas recycling 152

DELPHI checking, timing 153 - 156

BOSCH checking, timing 157 - 163

IGNITION

Sparking plugs 164

CLUTCH-GEARBOX-DRIVESHAFTS

Speedometer 165

Clutch adjustments 169 - 176

Driveshafts 214

AXLES-SUSPENSION-STEERING

XANTIA 215 - 223

XM 224 - 230

SYNERGIE 231 - 236

BRAKES

XANTIA 237 - 238

XM 243

SYNERGIE 246

Page 5

PRESENTATION

THIS HANDBOOK summarises the characteristics, adjustments, checks and special features of CITROEN vehicles, not including COMMERCIAL

vehicles for which there exists a separate handbook.

The handbook is divided into the following groups representing the main functions :

GENERAL - ENGINE - INJECTION - IGNITION - CLUTCH, GEARBOX, DRIVESHAFTS - AXLES, SUSPENSION, STEERING - BRAKES -

HYDRAULICS - ELECTRICAL - AIR CONDITIONING.

In each section, the vehicles are dealt with in the following order : XANTIA-XM-SYNERGIE and all models where applicable.

The information given in this handbook is based on vehicles marketed in EUROPE.

Page 6

IMPORTANT

If you find that this handbook does not always meet your requirements, we invite you to send us your suggestions which we will take into account

when preparing future publications. For example :

– INSUFFICIENT INFORMATION

– SUPERFLUOUS INFORMATION

– NEED FOR MORE DETAILS

Please send your comments and suggestions to :

CITROEN U.K. Ltd.

221, Bath Road,

SLOUGH,

SL1 4BA.

U.K.

Page 7

XANTIA

Parking brake 240 - 241

Bleed of brakes

242

XM

Parking brake

244

Bleed of brakes

245

SYNERGIE Parking brake 249

SUSPENSION

De-pressurising 250 - 260

HYDRAULICS

Pneumatic

XANTIA 261 - 265

units

XM 266 - 269

ELECTRICITY

Starter motors 270 - 272

Alternators 273 - 279

Charging circuit 280

Preheater plugs 281

AIR CONDITIONING

R 134 a quantities 282

Special features 283 - 288

Checking temperatures 289 - 290

Checking pressures 291

XANTIA 293 - 297

XM 298 - 301

SYNERGIE 302 - 303

INDEX

GENERAL

XANTIA 1 - 8

XM 9 - 13

SYNERGIE 14 - 15

XANTIA 17 - 18

XM 19

SYNERGIE 20

Lubricants 21 - 34

ENGINE

Specifications 36 - 38

Cyl. head marking and tightening 51 - 61

Auxiliary equipment drive belt 62 - 78

Checking and setting valve timing 83 - 84

Valve clearances 121

Oil pressure 122

Oil filter 125

INJECTION

Idling, anti-pollution 127

Petrol injection 128 - 129

Anti-pollution technical checks 130

Emission standards 131 - 137

LPG safety requirements 138 - 142

Identification

of vehicles

Capacities

Axle

geometry

Brake specifications

Aircon

system

HDi safety requirements 143 - 146

Checks: HDi fuel circuit 147 - 148

Checks: HDi air circuit 149

Checks: Turbo pressure 150 - 151

Checks: HDi exhaust gas recycling 152

DELPHI checking, timing 153 - 156

BOSCH checking, timing 157 - 163

IGNITION

Sparking plugs 164

CLUTCH-GEARBOX-DRIVESHAFTS

Speedometer 165

Clutch adjustments 169 - 176

Driveshafts 214

AXLES-SUSPENSION-STEERING

XANTIA 215 - 223

XM 224 - 230

SYNERGIE 231 - 236

BRAKES

XANTIA 237 - 238

XM 243

SYNERGIE 246

Page 8

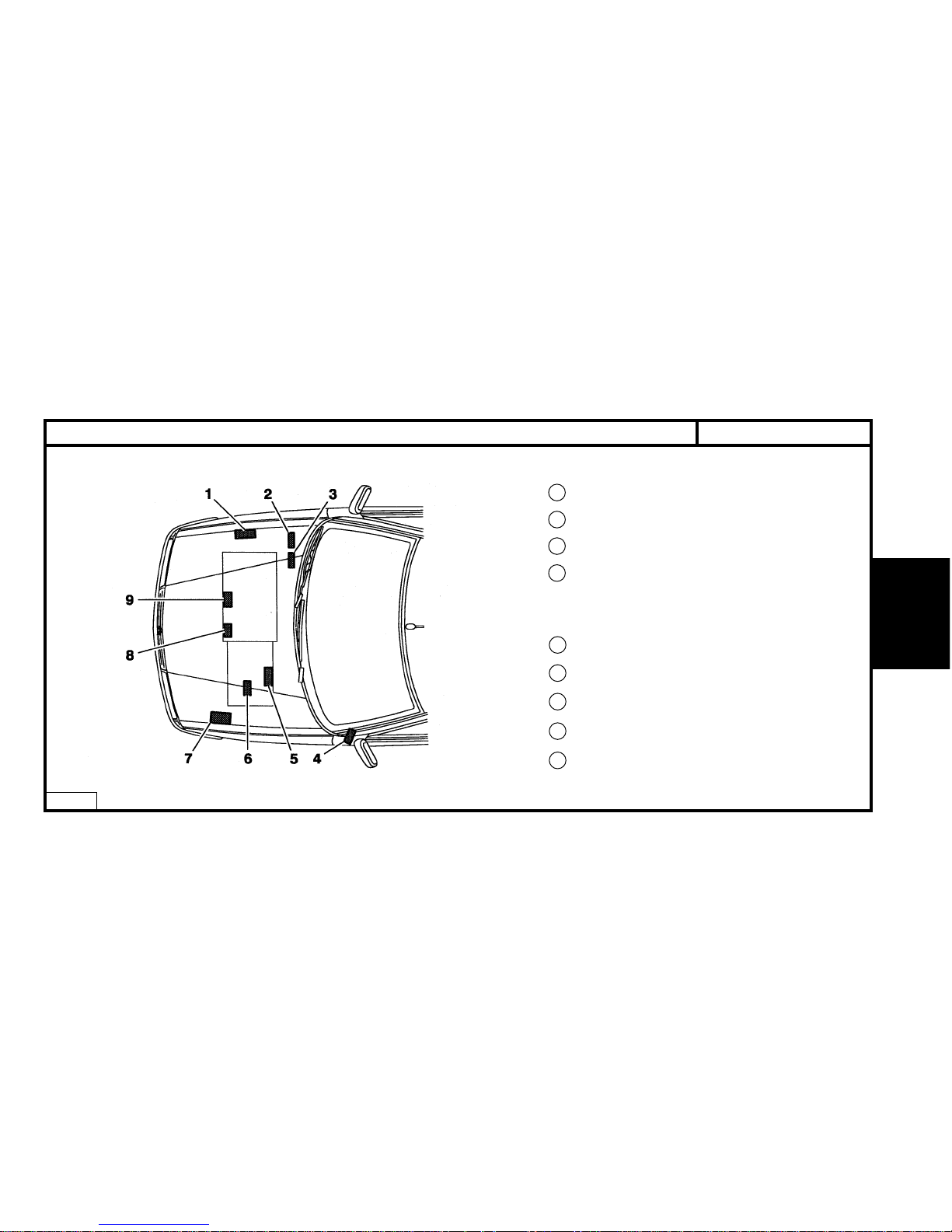

GENERALGENERAL

1

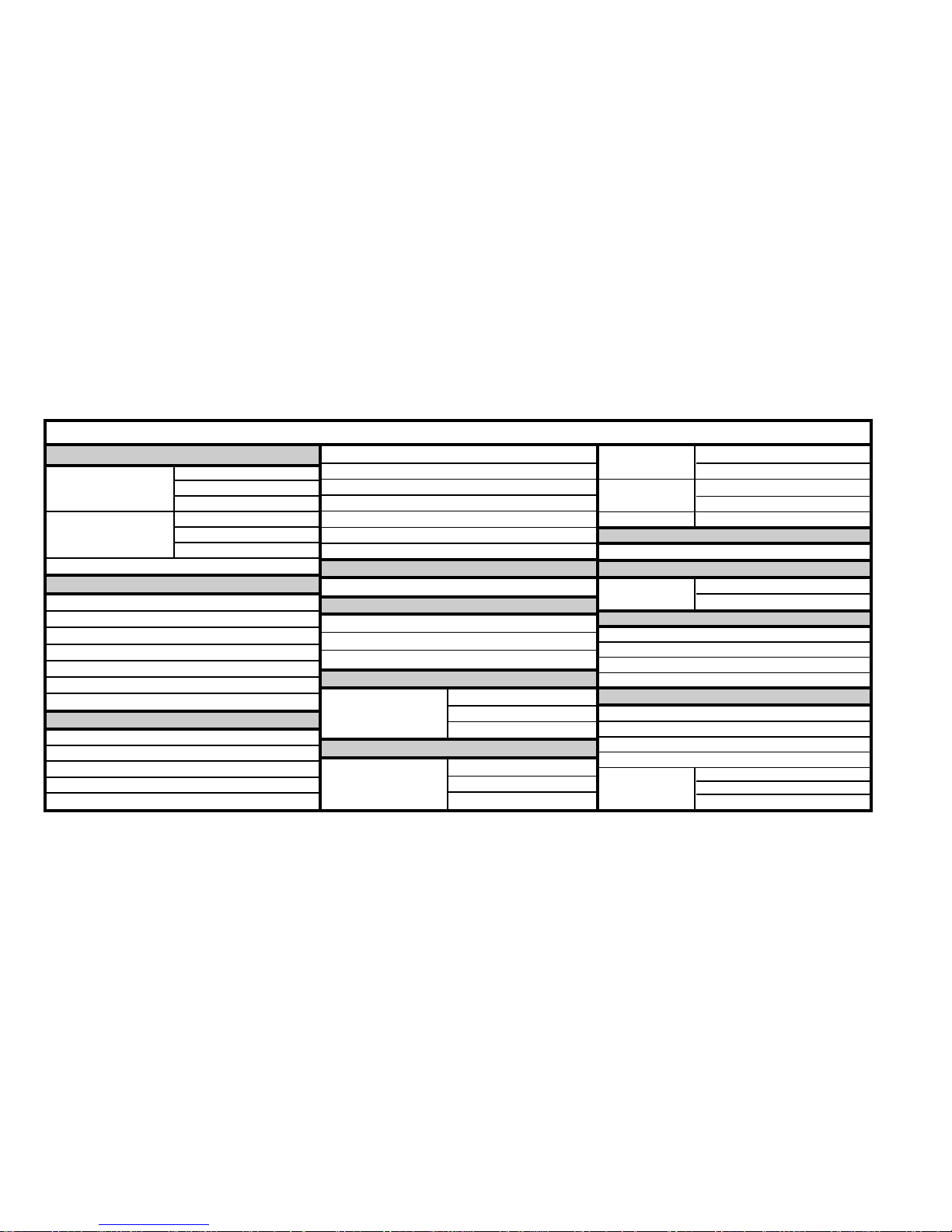

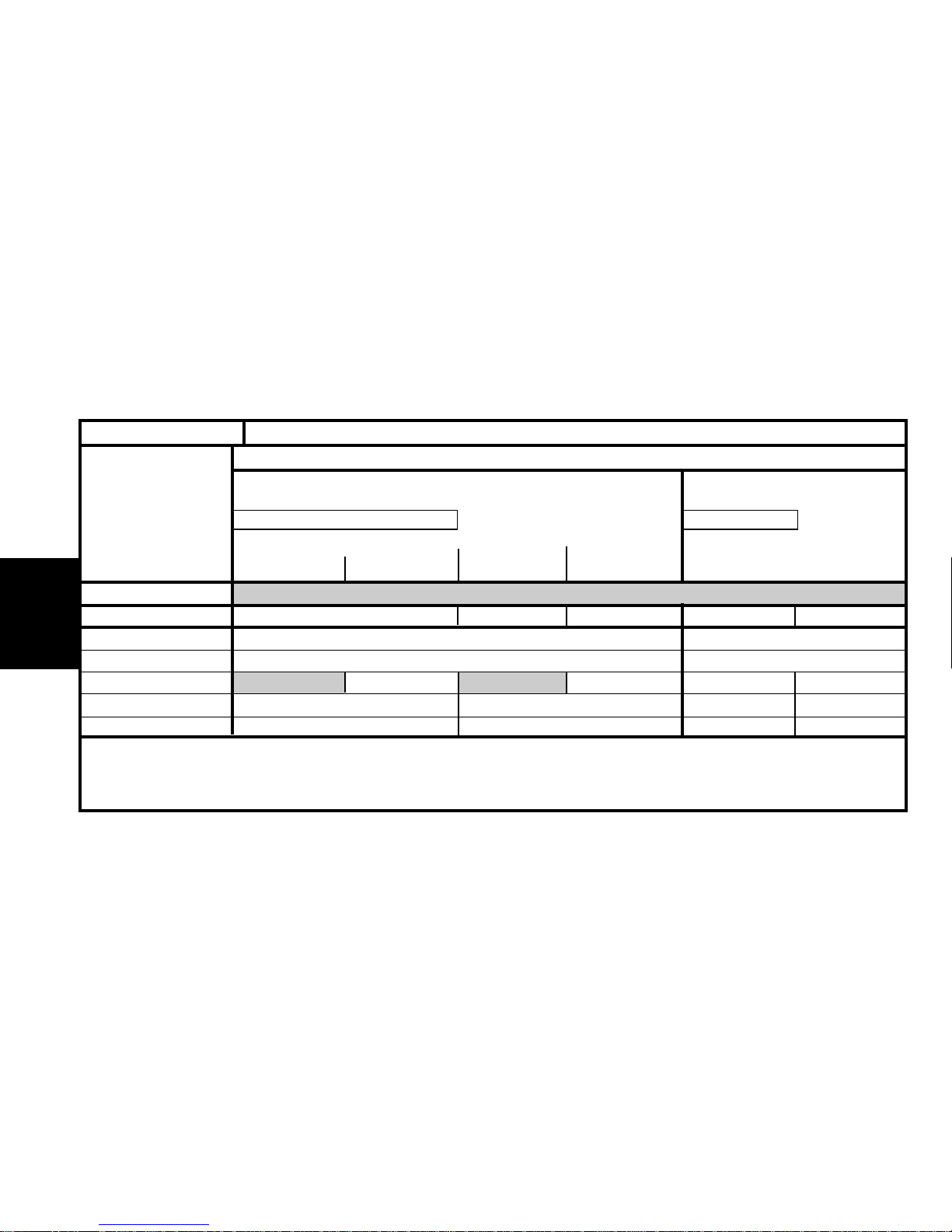

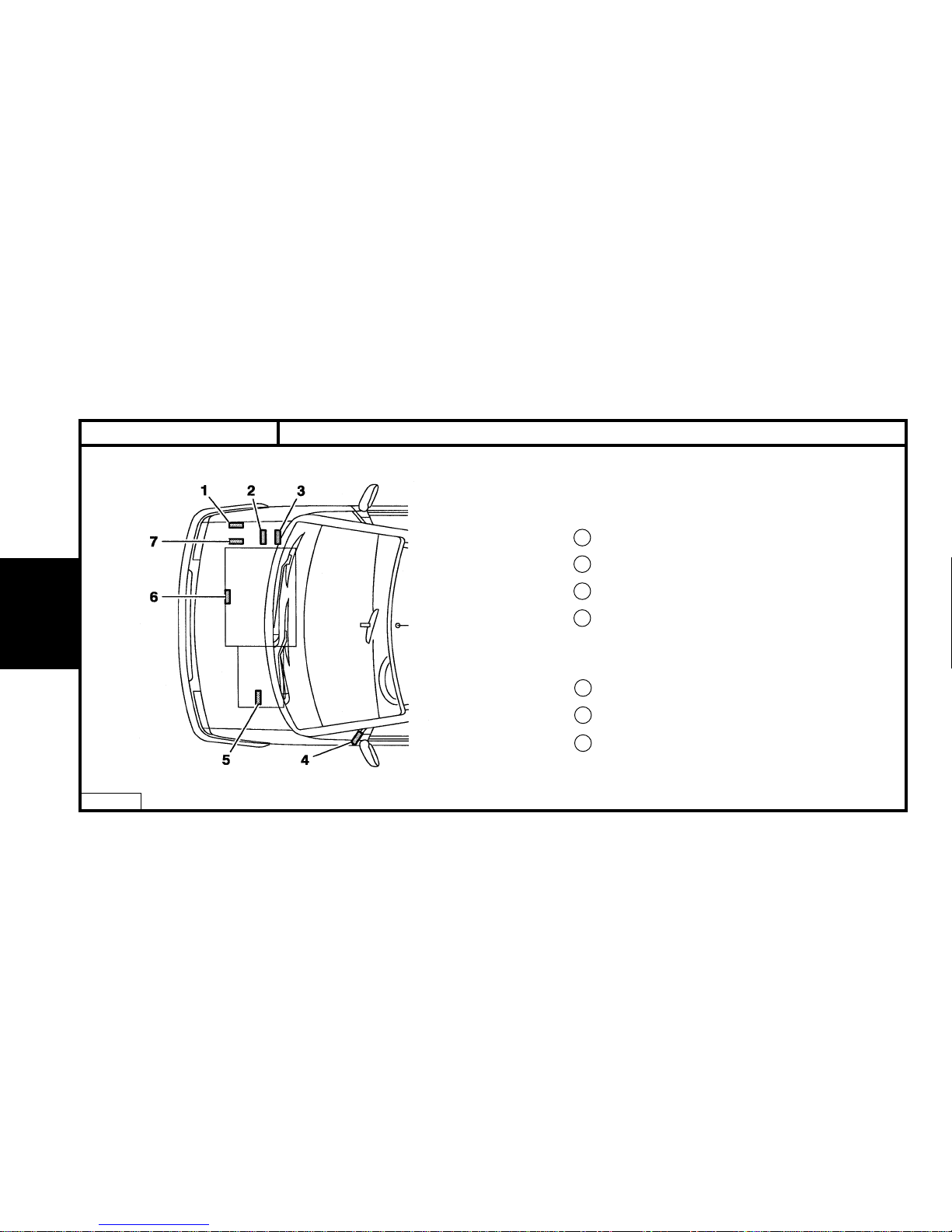

XANTIA - All TypesIDENTIFICATION OF VEHICLES

E1AP07ED

1 Manufacturer’s cold stamp.

2 R.P. organisation N°.

3 Paint code.

4 01/02/99 # Label :

- Pression de gonflage.

- N° organisation P.R.

- Code peinture

5 Automatic gearbox identification ref.

6 Manual gearbox identification ref.

7 Manufacturer’s name plate.

8 XU5 - XU7 - ES9J4 engine plate.

9 XU10 - XUD engine plate.

Page 9

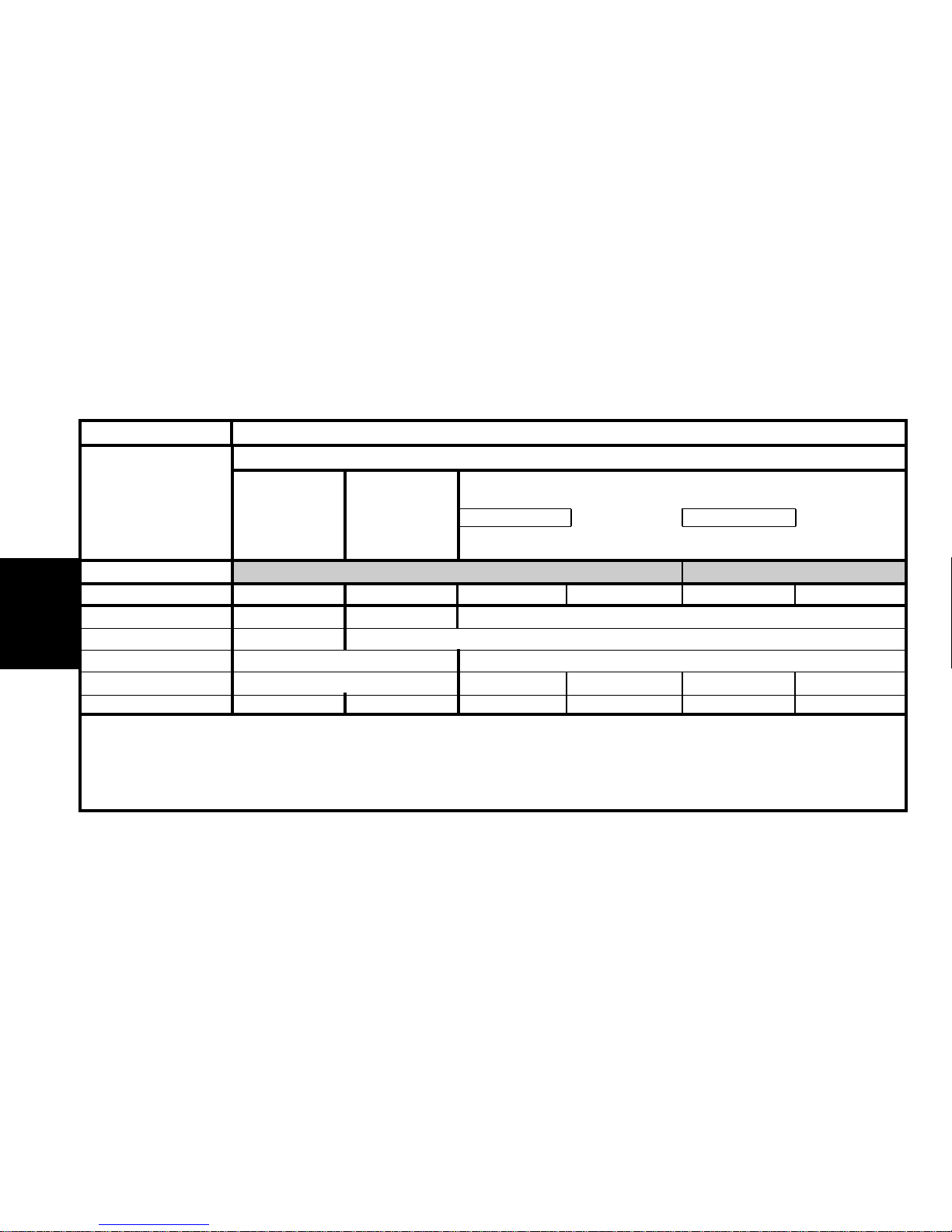

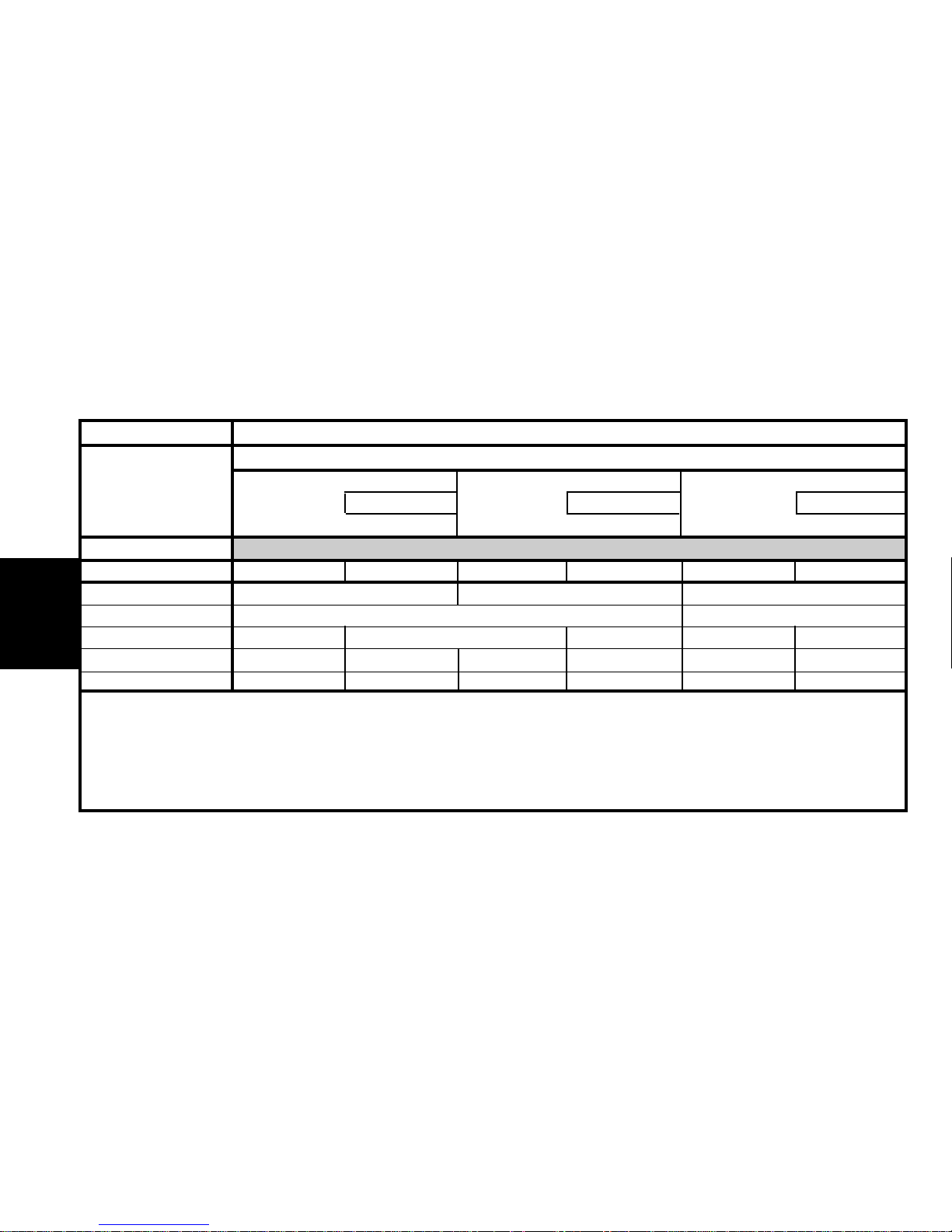

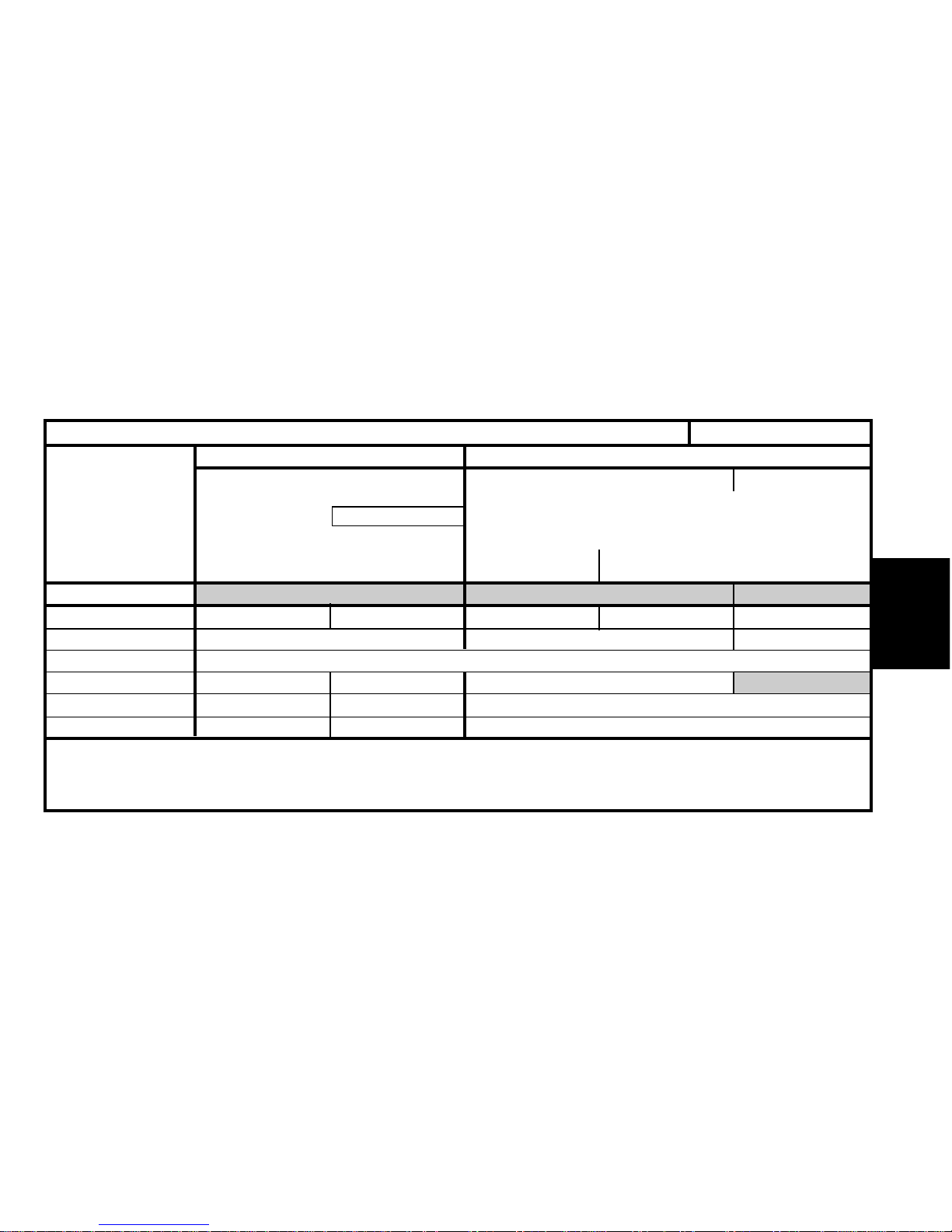

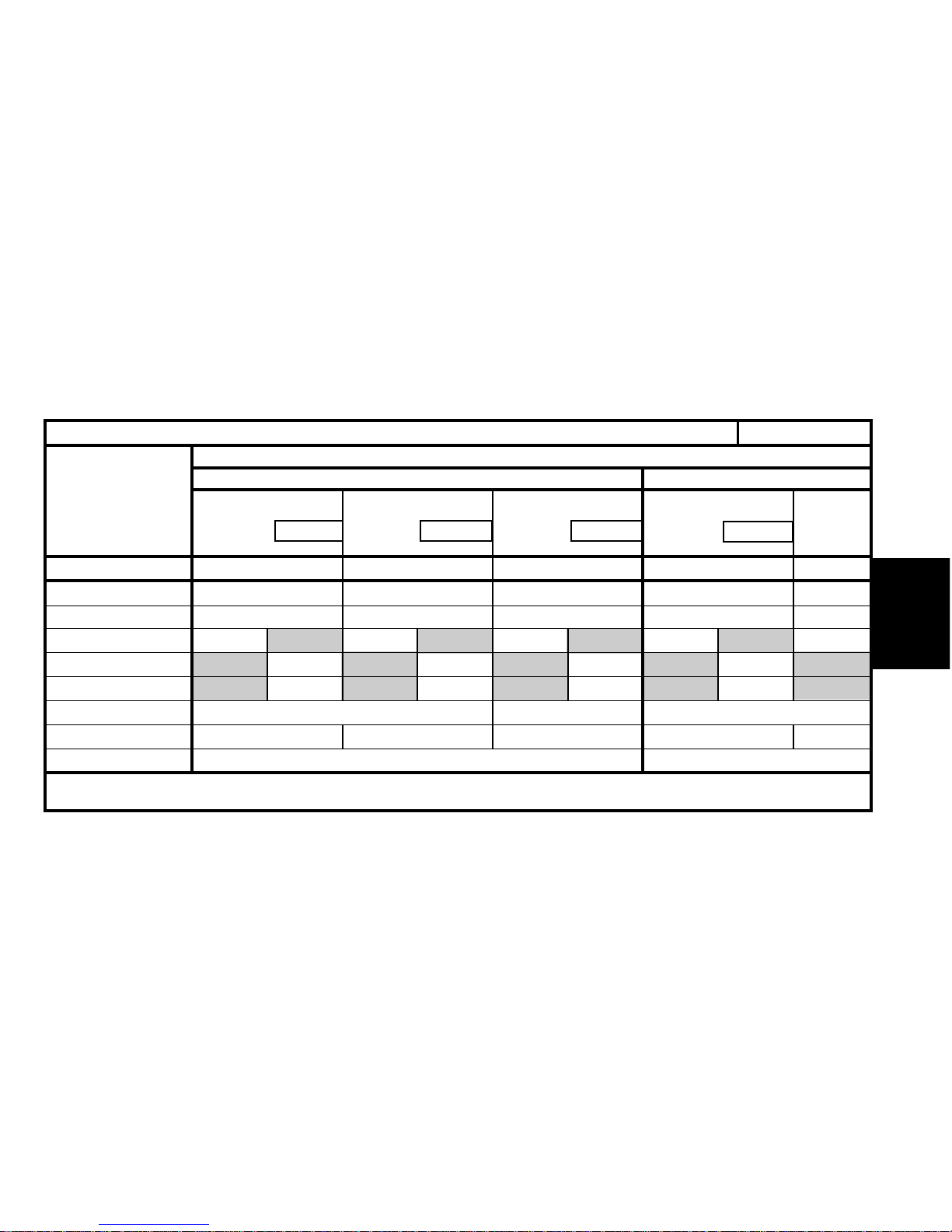

GENERAL

X1 BFZF X1 BFXF X1 LFYM X1 LFYF X1 LFYN X1 LFYB

BFZ BFX LFY

1580 1761

78

BE3/5 AL4 BE3/5 AL4 BE3/5

20 TE 00 20 TE 35 20 TP 52 20 TE 35 (*) 20 TP 52 20 TE 36

Emission standard L3 L4

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

2

XANTIA - All Types

IDENTIFICATION OF VEHICLES

PETROL SALOON

SX SX

1.6 i 1.8 i

SX

1.8 i 16 V

Auto.

Auto.

(*) = Long gearbox.

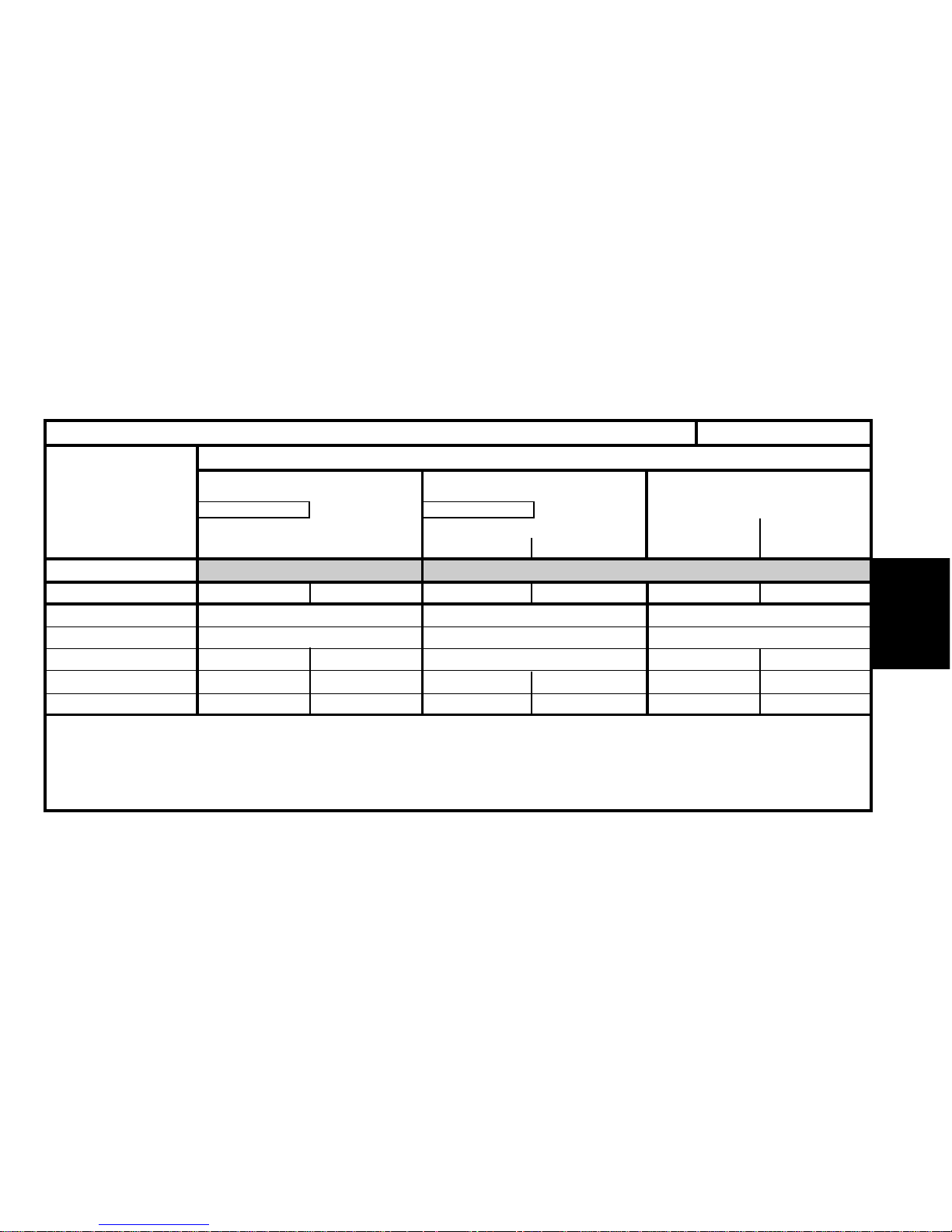

Page 10

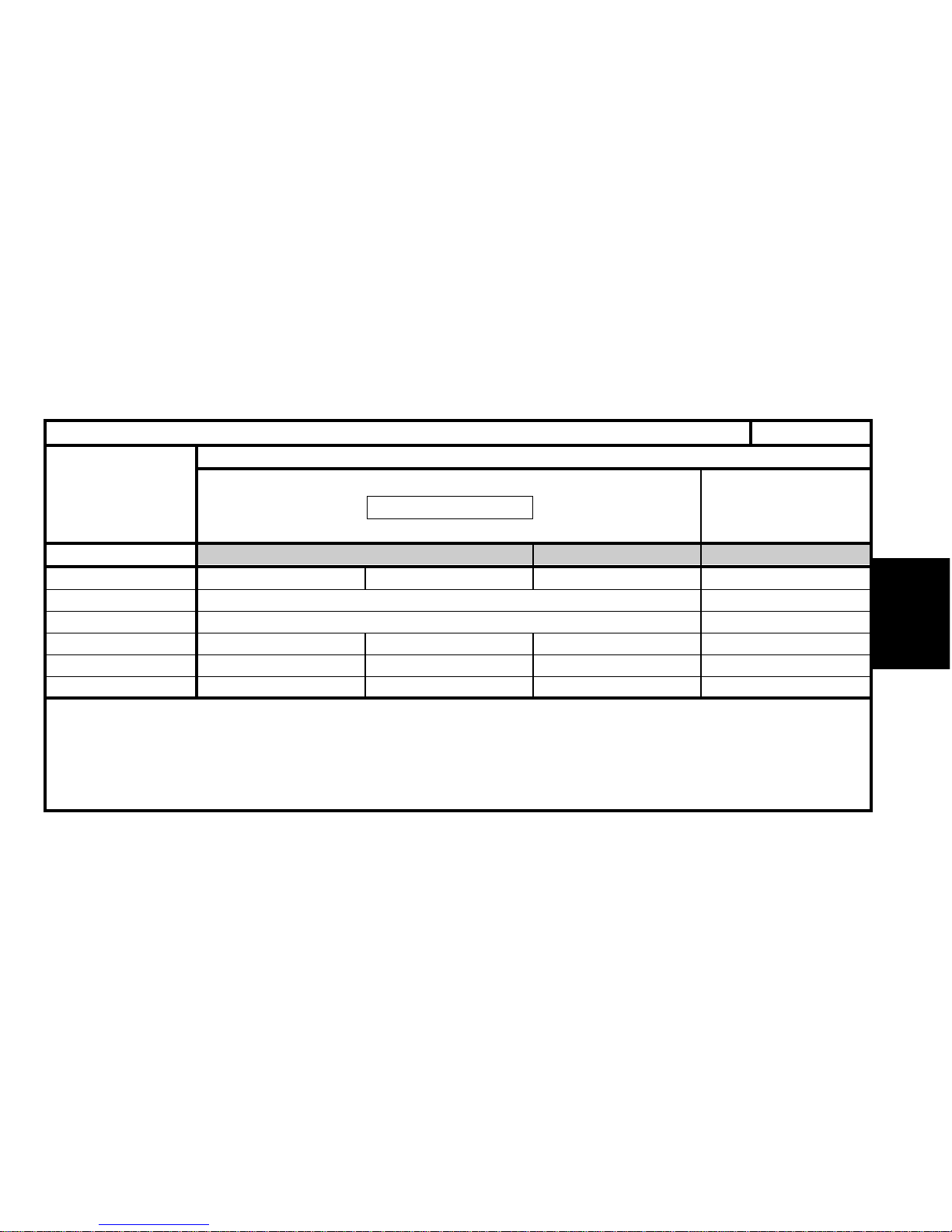

GENERALGENERAL

Emission standard L4 L3

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

3

X1 LFYN/IF (*) X1 LFYB/IF (*) X1 RFVM X1 RFVF X7 XFZF X7 XFZM

LFY RFV XFZ

1761 1998 2946

91314

AL4 BE3/5 AL4 BE3/5 ML/5 4HP20

20 TP 52 20 TE 36 20 TE 53 20 TE 37 20 LE 89 20 HZ XX

XANTIA - All TypesIDENTIFICATION OF VEHICLES

PETROL SALOON

1.8i 16 V

SX SX

Exclusive Activa

SX

Exclusive

2.0i 16 V 30.i V6

(*) = IF = Fiscal incentive.

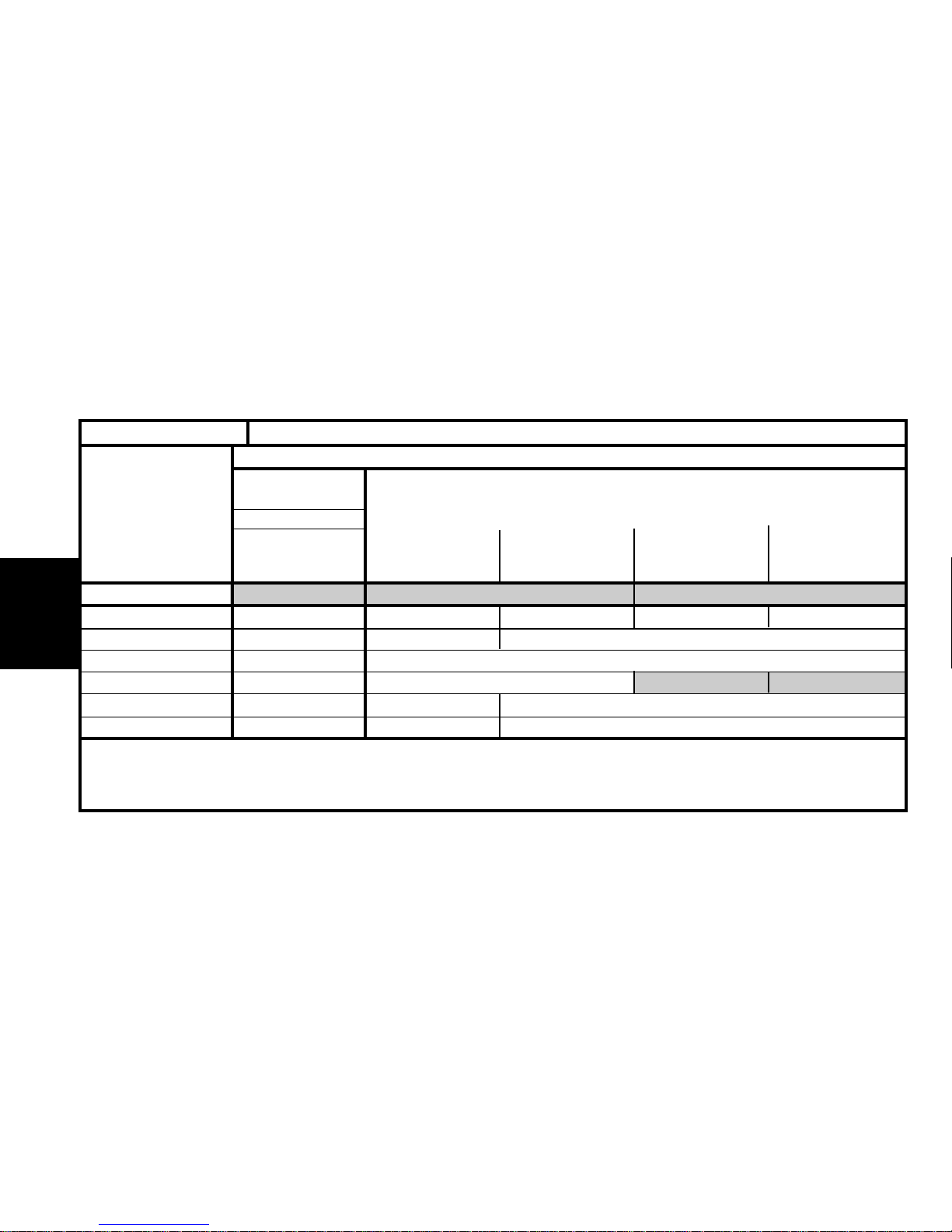

Page 11

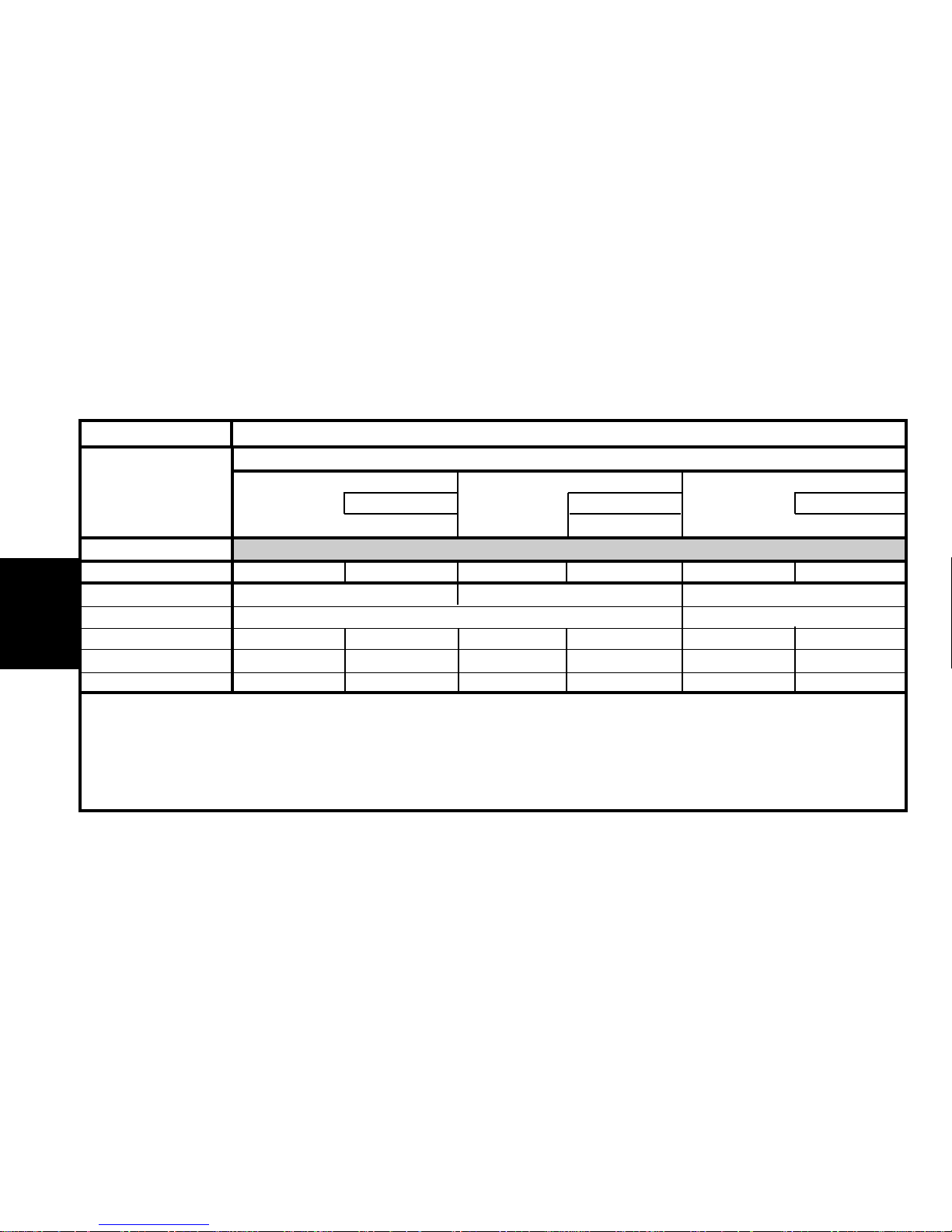

GENERAL

4

Emission standard L3 L3 L4

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

X1 DHXM X1 RFYF X1 RHZF X1 RHZB X7 RHZB

DHX RHY RHZ

1905 1997

76

AL4 BE3/5 ML/5

20 TP 50 20 TE 40 20 LE 84

IDENTIFICATION OF VEHICLESXANTIA - All Types

DIESEL SALOON

2.0 HDi (1)

SX

Activa

SX - SX Aircon Pack

Exclusive

Activa

SX

Exclusive

1.9 D

Auto.

SX

SX Aircon Pack

SX

SX Aircon Pack

(1) HDi = High pressure Diesel injection

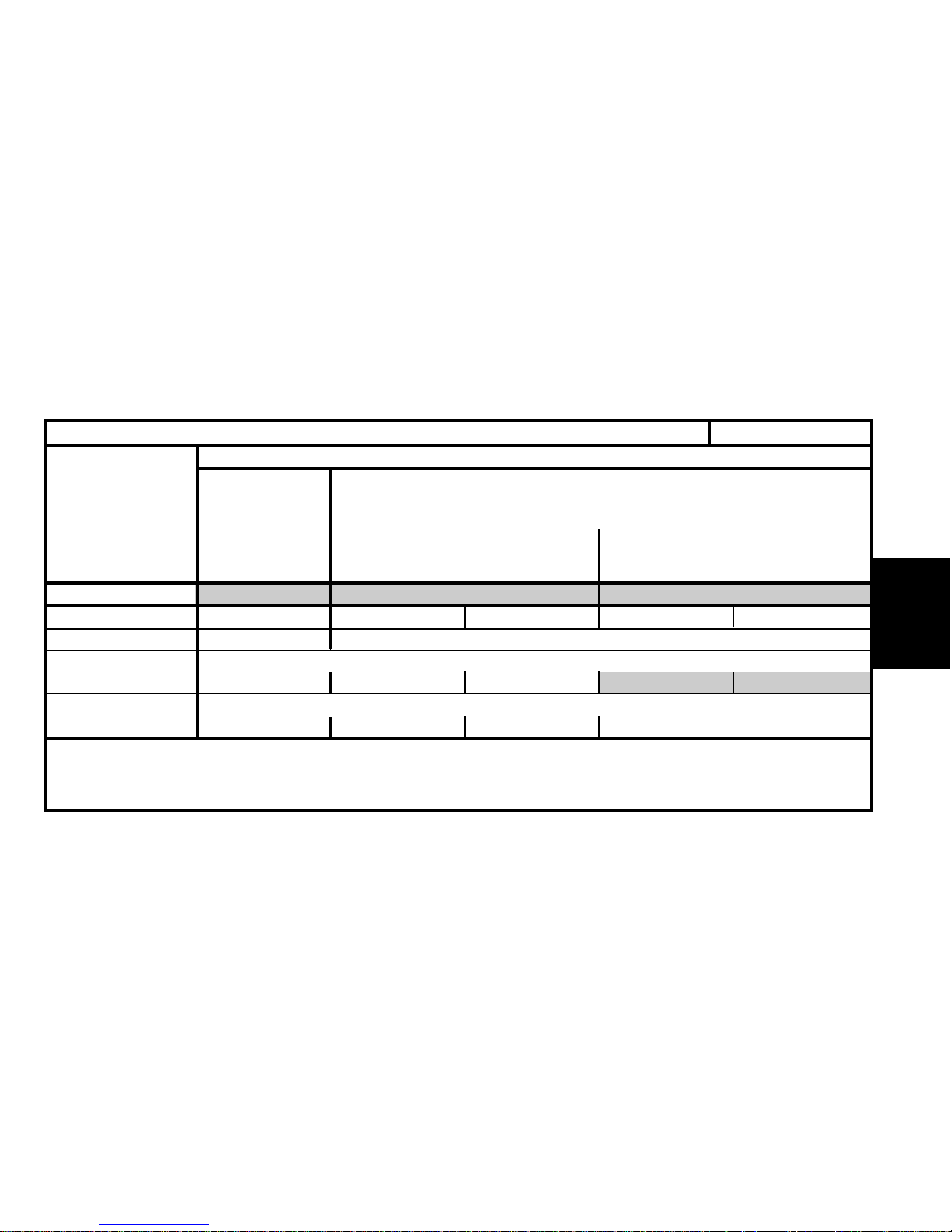

Page 12

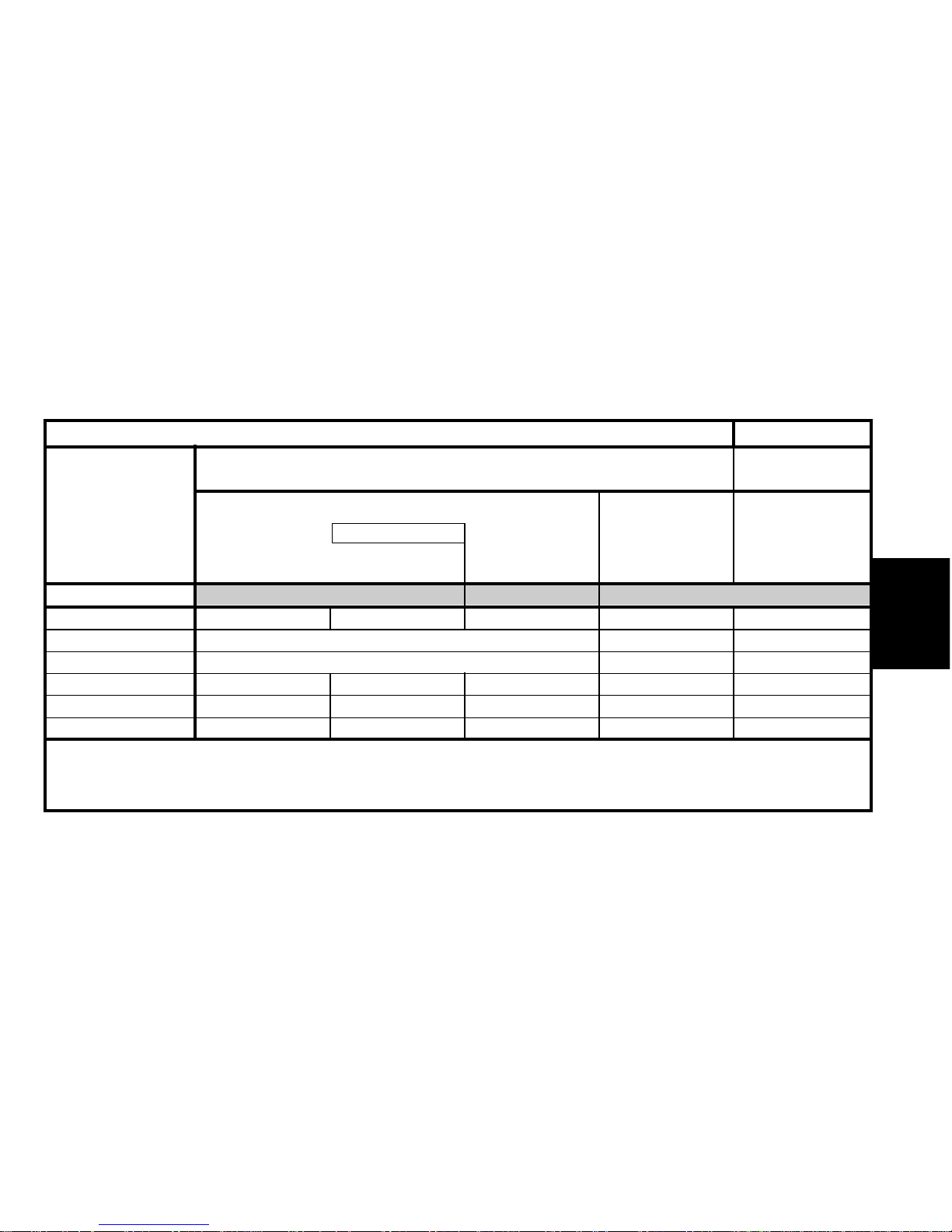

GENERALGENERAL

5

Emission standard L3 L3 L4

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

X2 LFXF X2 LFYF X2 LFYC X2 LFYB/IF (*) X2 LFYB

LFX LFY

1761

787

BE3/5

20TE 35 20 TE 36 20 TE 35 20 TE 36

IDENTIFICATION OF VEHICLES XANTIA - All Types

PETROL ESTATE

1.8i 16V

SX

1.8i

SX

(*) = IF = Fiscal incentive.

SX - SX Aircon Pack

Page 13

GENERAL

6

X2 RFVM X2 RFVF X2 RFVM X2 XFZF X7 XFZM

RFV XFZ

1998 2946

9 9 14 13

AL4 BE3/5 4HP20 ML/5

20 TP 53 20 TE 37 20 HZ XX 20 LE 89

Emission standard L3

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

XANTIA - All Types

IDENTIFICATION OF VEHICLES

PETROL ESTATE

3.0i V6

SX Aircon Pack

Exclusive Exclusive

SX

2.0i 16V

Auto.

Auto.

SX Aircon Pack

Exclusive

SX

Page 14

GENERALGENERAL

7

L3 L3 L4

X2 DHXM X2 RHYF X2 RHZF X2 RHZB

DHX RHY RHZ

1905 1997

76

AL4 BE3/5 ML/5

20 TP 50 20 TE 40 20 LE 84

XANTIA - All Types

IDENTIFICATION OF VEHICLES

DIESEL ESTATE

1.9 TD

2.0 HDi (*)

SX

SX Aircon Pack

SX

SX Aircon Pack

SX - SX Aircon Pack

Exclusive

SX

Exclusive

Auto.

Emission standard

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

(1) HDi = High pressure Diesel injection

Page 15

GENERAL

Petrol

8

Emission standard L3 L3

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

X1 RHYF X1 RHZF X2 RHYF/T (3) X1 LFYC/GPL X1 LFYC/GPL X2 LFYC/GPL

RHY RHZ RHY LFY/GPL

1997 1761

67

BE3/5 ML/5 BE3/5 BE3/5

20 TE 40 20 LE 84 20 TE 40 20 TE 36 20 TE 35

XANTIA - All Types

IDENTIFICATION OF VEHICLES

DUAL FUEL PETROL/LPG (1)COMMERCIAL VERSIONS ALL TYPES

Estate

2.0HDi (2)

SX Ambulance

SX Company

SX Entreprise SX

SX

SX Aircon Pack

X - SX Company

Diesel

Saloon Saloon

1.8i 16V

Estate

(1) = Liquid Petroleum Gas.

(2) HDi = High pressure Diesel injection.

(3) /T = Can be converted.

Page 16

GENERALGENERAL

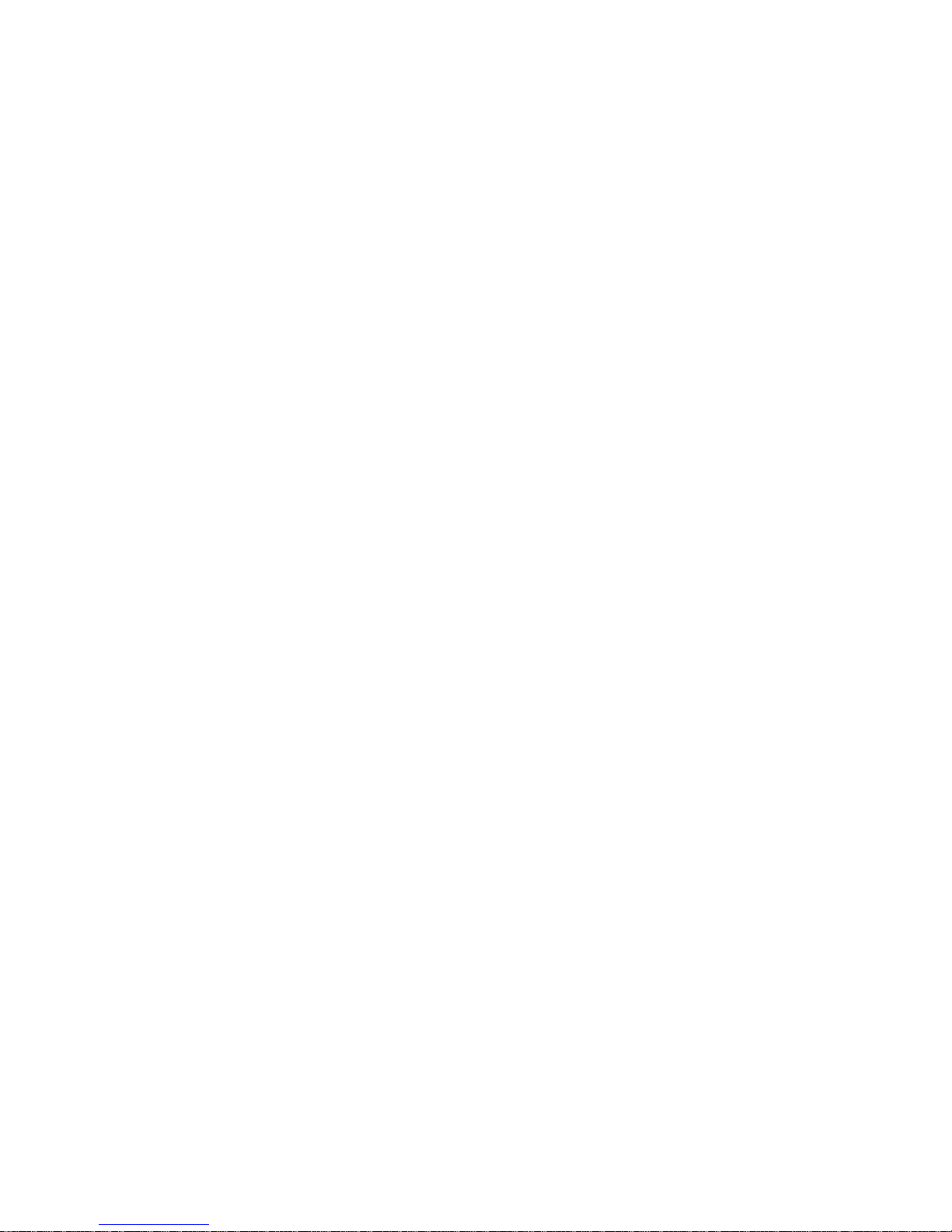

9

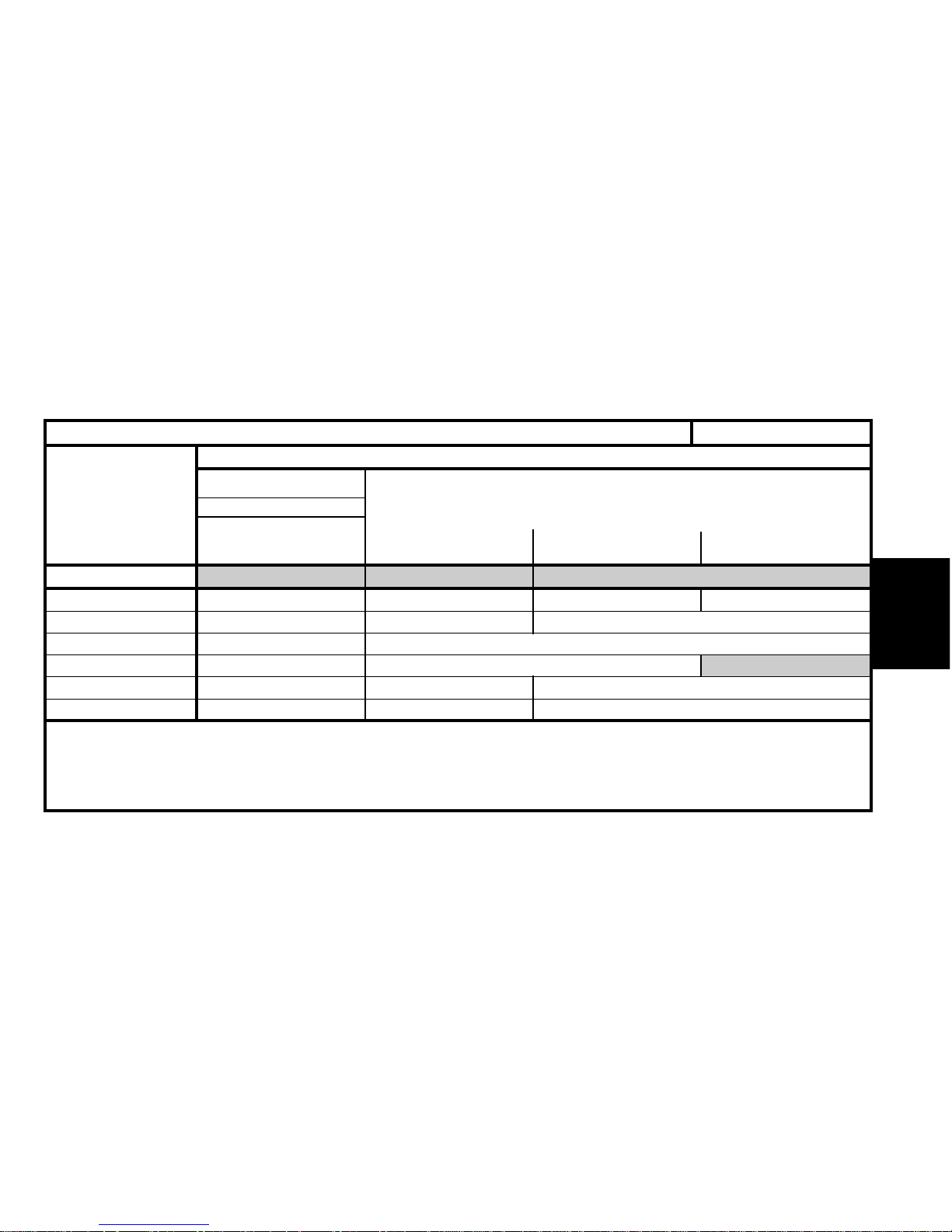

5 R.P. organisation N°. # 01/02/99 (

*

)

6 BE3 gearbox ident.

7 4HP 18 gearbox ident.

8 MG gearbox ident.

9 ME5T gearbox ident.

10 Paint code # 01/02/99 (*)

11 Manufacturer’s plate

12 4 cyl. engine plate

XM - All Types

IDENTIFICATION OF VEHICLES

1 Bodyshell N°

2 Manufacturer’s cold stamp

3 6 cyl. engine plate

4 R.P. organisation N°. (*) 01/02/1999 #

Label :

- Tyre pressures.

- R.P. organisation N°.

- Paint code

E1AP07FD

(*) : Applicable only to 1999 model year saloons

Page 17

GENERAL

3.0i V6

10

Emission standard L3

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

Y4-CZ Y4-TV Y4-GG Y4-TT Y4-WG Y4-WH

RFV RGX XFZ

1998 2946

910 111314

BE3/5 4 HP 18 ME/5 4 HP 18 ML/5 4 HP20

20 TD 01 20 GZ 5G 20 GM 32 20 GZ 1G 20 LE 59 20 HZ YY

IDENTIFICATION OF VEHICLES

PETROL SALOON

2.0i 16 V

Auto.

Auto. Auto.

SX SX

SX - Exclusive

2.0i Turbo CT

XM - All Types

Page 18

GENERALGENERAL

L3 L4 L3

Y4-GZ Y4-RN Y4-WE Y4-NZ

P8C THY

2088 2446

78 79

ME/5 4 HP 18 ME/5 MG/5

20 GM 31 20 GZ 5D 20 GM 31 20 KM 70

11

XM Diesel

IDENTIFICATION OF VEHICLES

DIESEL SALOON

2.1 TD 2.5 TD

SX - ExclusiveSX

Auto.

Emission standard

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

Page 19

GENERAL

12

Emission standard L3

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

Y4-GB Y4-TU Y4-GM Y4-TS Y4-WJ Y4-TN

RFV RGX XFZ

1998 2946

9 10 9 10 13 14

BE3/5 4 HP 18 ME/5 4 HP 18 ML/5 4 HP 20

20 GM 36 20 GZ 5G 20 GM 33 20 GZ 1G 20 LE 59 20 HZ YY

XM - All Types IDENTIFICATION OF VEHICLES

PETROL ESTATE

2.0i 2.0i Turbo CT 3.0i V6

Auto.Auto.Auto.

SX SXSX-Commerce

SX

Page 20

GENERALGENERAL

Emission standard L3 L4 L3

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

13

Y4-MZ Y4-CW Y4-WF Y4-RM Y4-GZ

P8C THY P8C

2088 2446 2088

787 97

ME/5 4 HP 18 ME/5 MG/5 ME/5

20 GM 31 20 GZ 5D 20 GM 31 20 KM 70 20 GM 31

IDENTIFICATION OF VEHICLES XM - All Types

Commercial EstateDIESEL ESTATE

2.1 TD

SX

Ambulance

2.5 TD

SX

Commerce

2.1 TD

Auto.

SX

SX

Commerce

Page 21

GENERAL

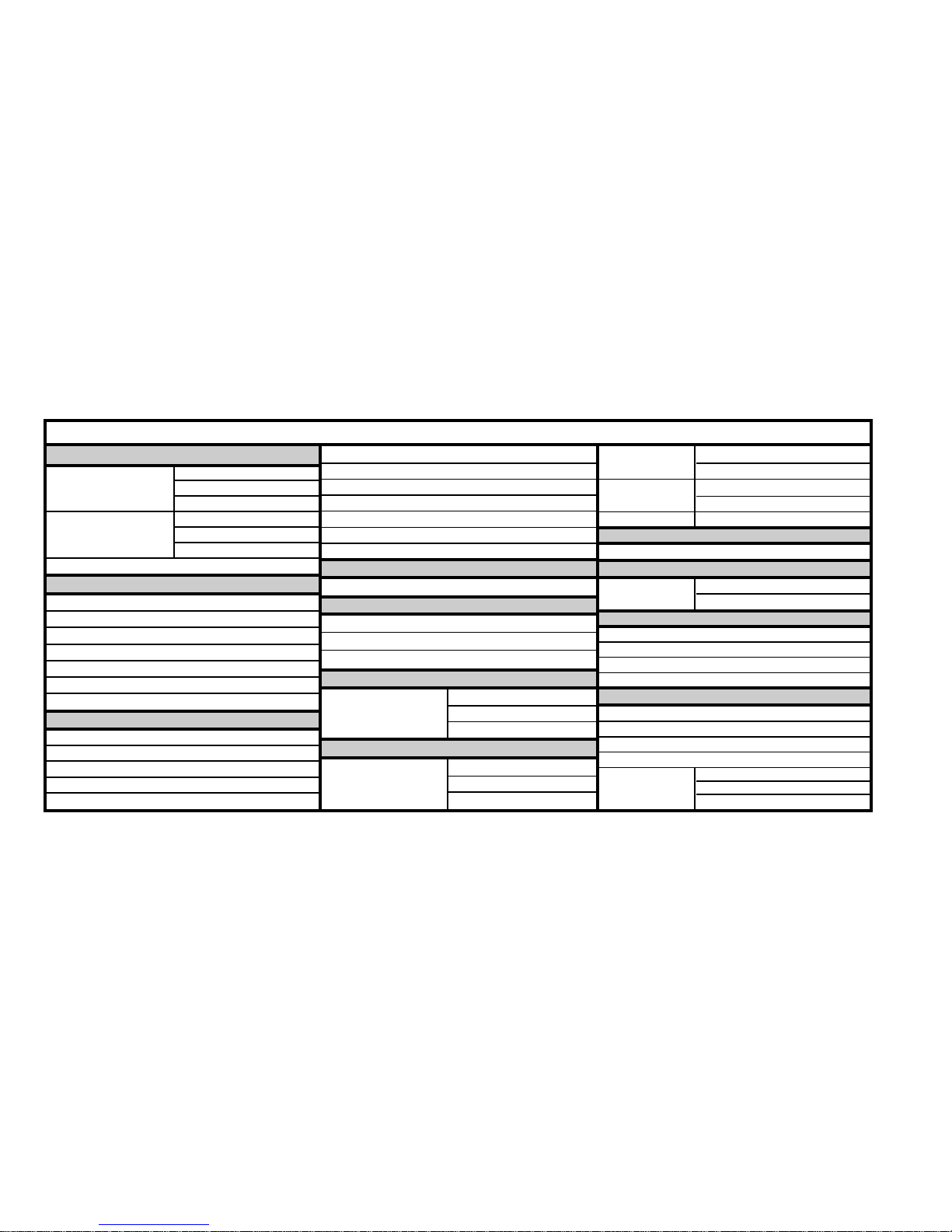

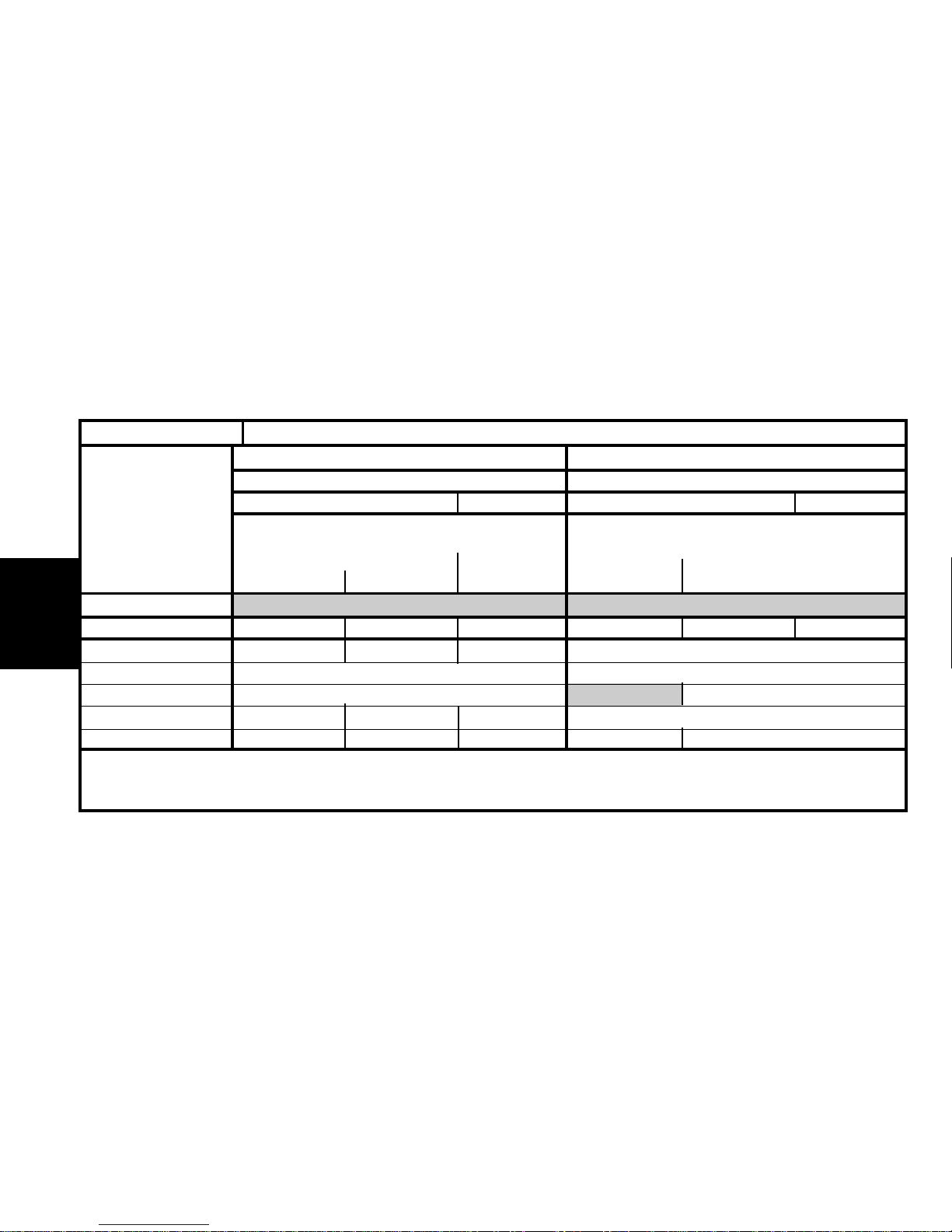

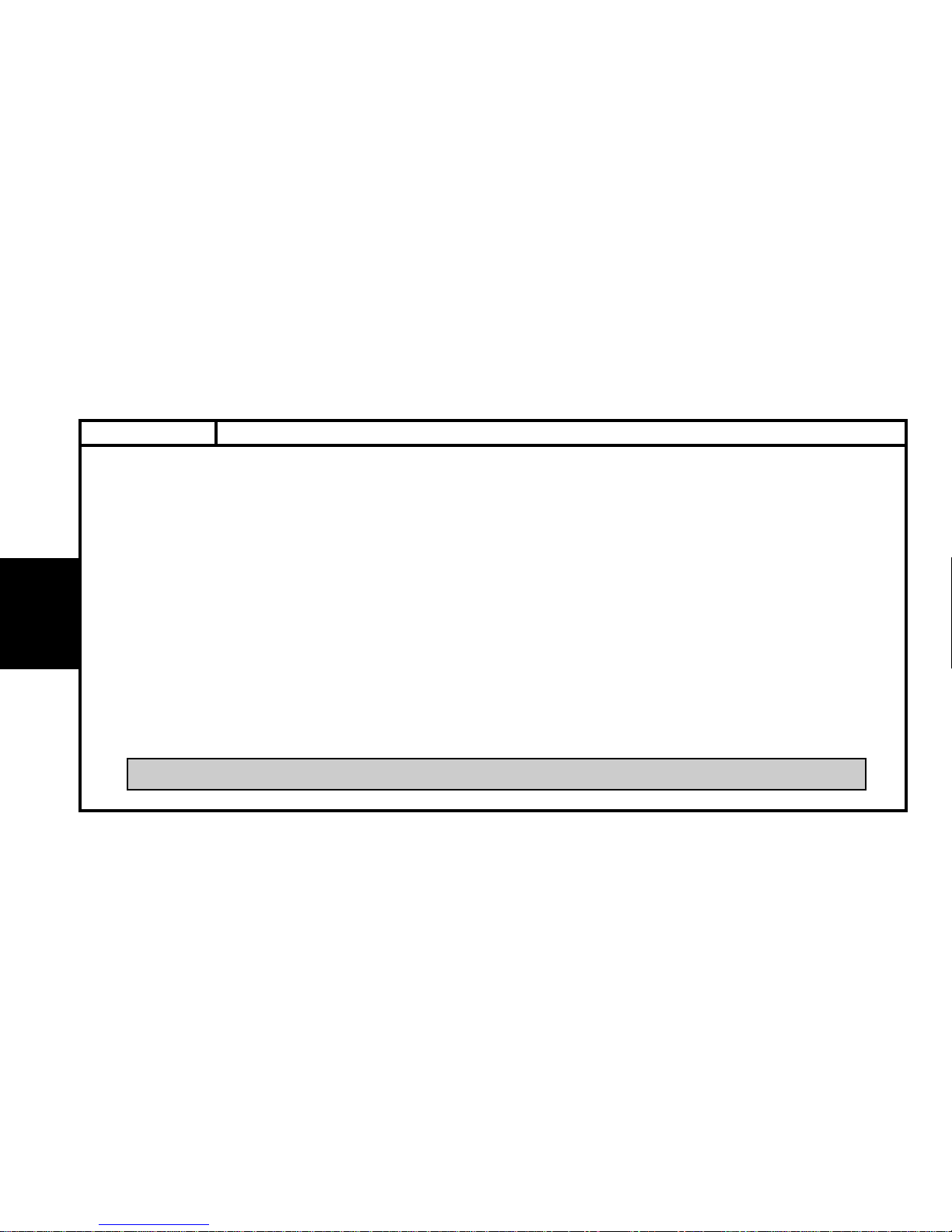

14

IDENTIFICATION OF VEHICLES

1 Manufacturer’s cold stamp

2 R.P. organisation No.

3 Paint code

4 01/02/99 # Label :

- Tyre pressures.

- R.P. Organisation No.

- Paint code.

5 Gearbox ident.

6 Engine plate

7 Manufacturer’s plate

SYNERGIE - All Types

E1AP07GD

Page 22

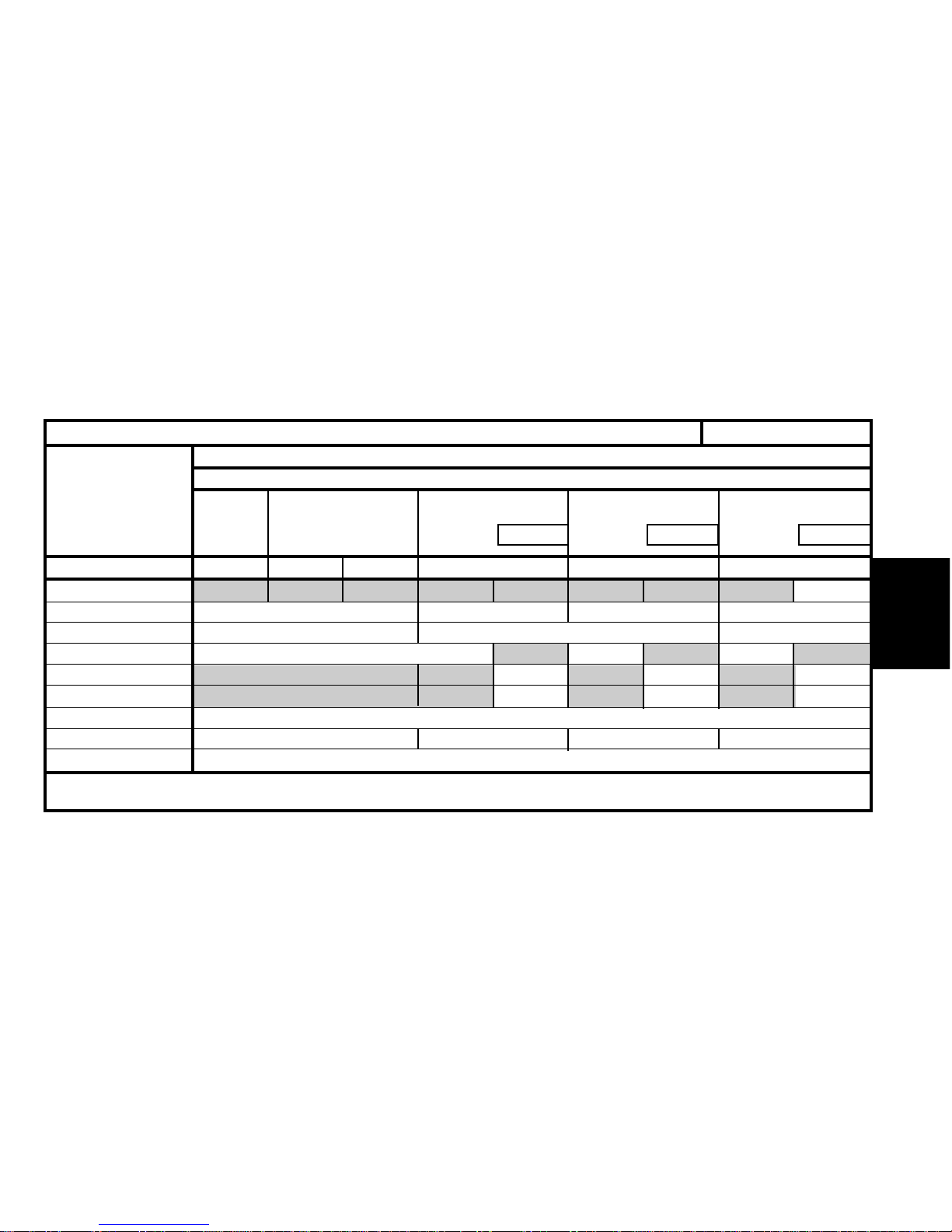

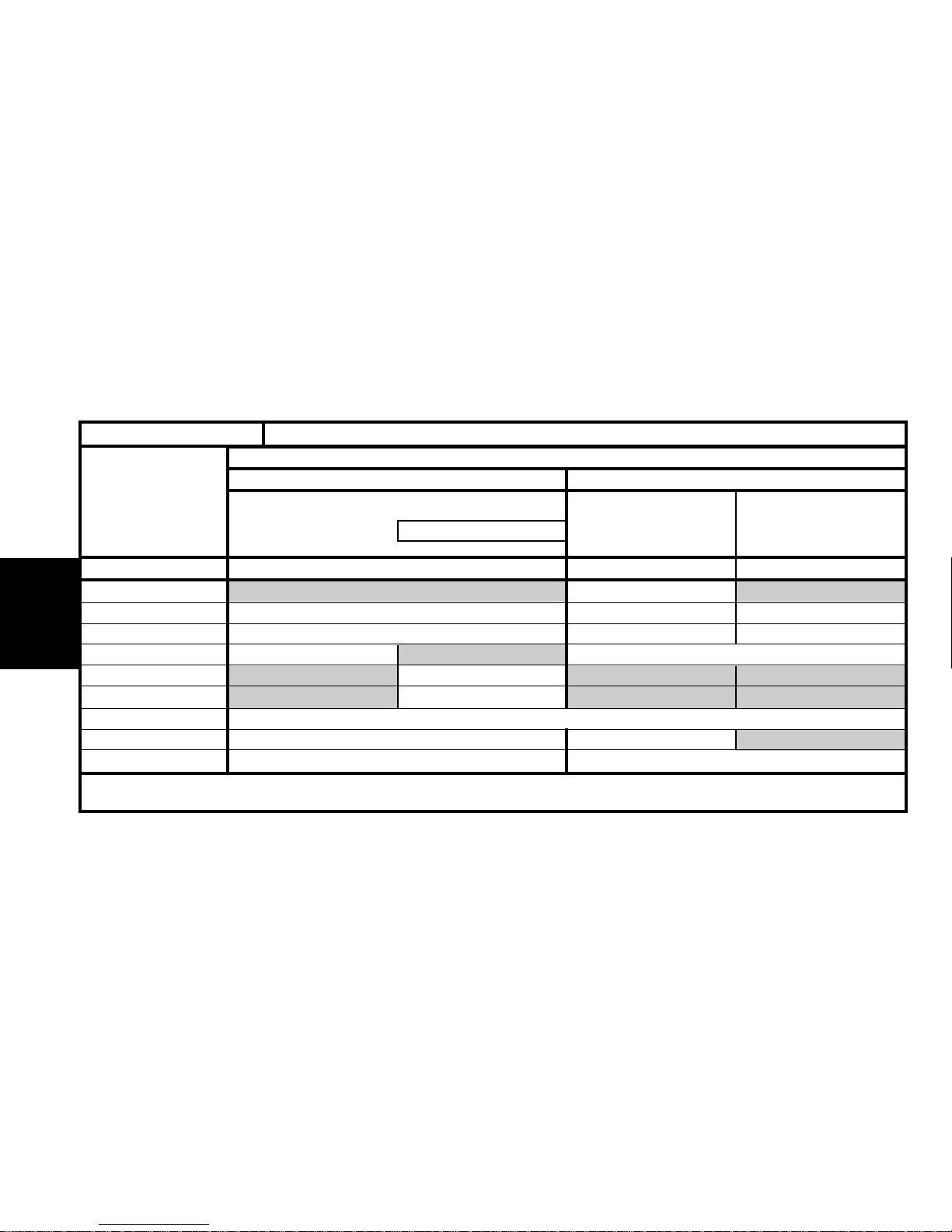

15

GENERALGENERAL

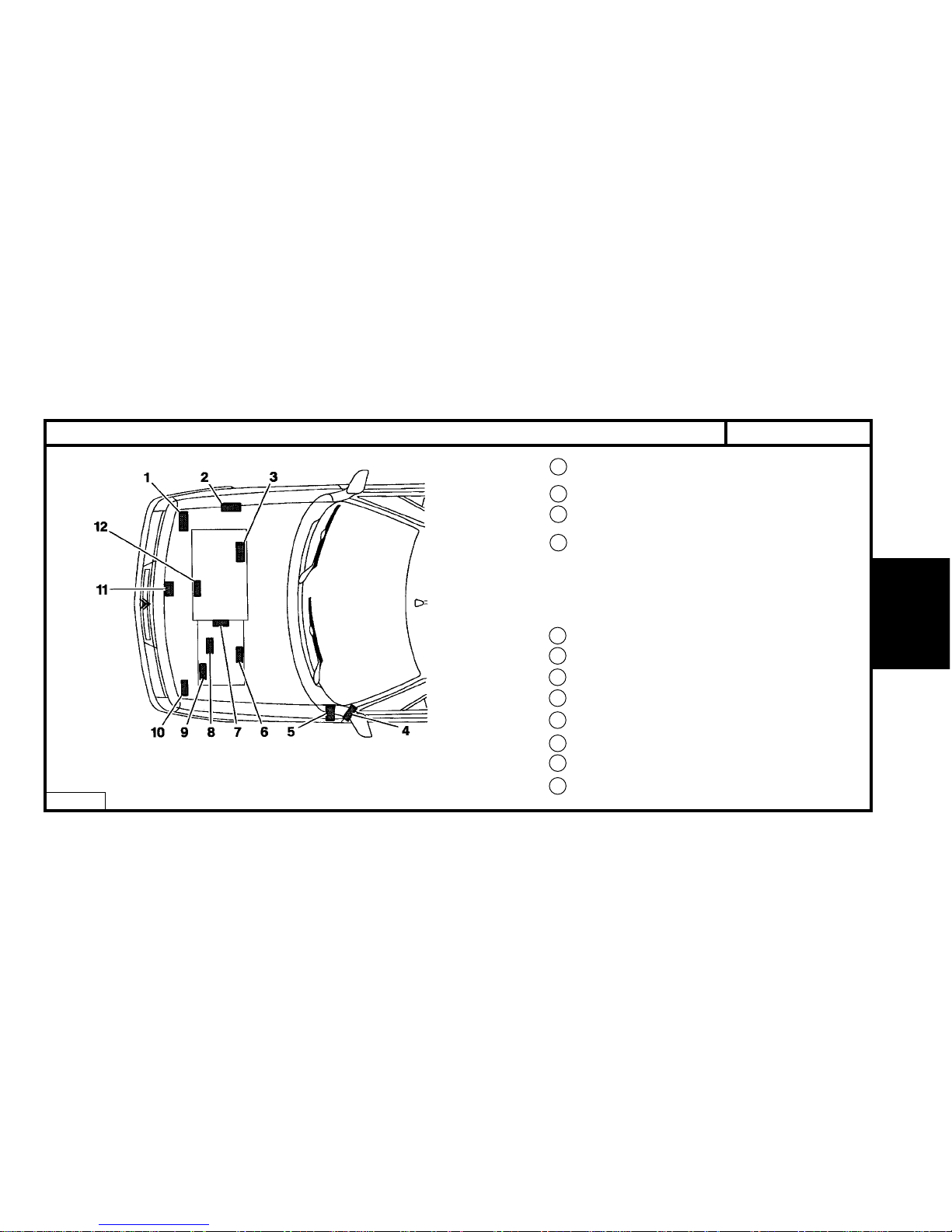

Emission standard IF L5 (*) L3 L4

Type code

Engine type

Cubic capacity (cc)

Fiscal rating (hp)

Gearbox type

Gearbox ident. plate

AF RFNC/IF AF RFNF/IF AF RHZA/T AF RHZA AF RHWB

RFN RHZ RHW

1997

910 6

BE4/5 AL4 ML5

DL26 - DL27 20 TP 31 20 LE 91

IDENTIFICATION OF VEHICLES

SYNERGIE - All Types

2.0 16 V HDi

2.0 HDi

X – SX

X Taxi – SX

Exclusive

2.0i 16 V

X – SX

Exclusive

DIESELPETROL

Auto.

Page 23

GENERAL

CAPACITIES

16

Draining method.

The oil capacities are defined according to the following methods.

1) - Vehicle on level surface (in high position, if equipped with hydropneumatic suspension).

2) - Engine warm (oil temperature 80°C).

3) - Draining of the oil sump + removal of the cartridge (duration of draining + dripping = 15 mm).

4) - Refit plug + cartridge.

5) - Engine filling.

6) - Engine starting (allowing the cartridge to be filled).

7) - Engine stopped (stationary for 5 mm).

ESSENTIAL : Systematically check the oil level using the oil dipstick.

ALL TYPES

Page 24

GENERALGENERAL

BFZ BFX LFX LFY RFV XFZ

30°

4.75 4.75 - 4.25 (1) 4.25 5.25

1.3 1 2

1.8 1.8 1.8

6 6 8.3

3 3 5.3

5.8

7 - 8.3 (2) 7.5 7.5 - 8.5 (2) 10

65

Engine type

Engine angle

Engine with filter change

Between Min. and Max.

5-speed gearbox

Automatic gearbox

after oil change

Hydraulic or brake circuit

Cooling system

Fuel tank capacity

CAPACITIES (in litres) XANTIA - All Types

17

XANTIA

Petrol

1.6i 1.8i 1.8i 16V 2.0i 16V 3.0i 6V

Auto.

Auto. Auto.

(1) Air conditioning (2) Depending on equipment - NOTE : Engine, systematically check the oil level using the oil dipstick.

Page 25

18

GENERAL

DHX RHY RHZ

30°

4.25 - 4 (1) 4.5 - 4.25 (1)

1.5

1.8

8

3

5.8

9 8.5 - 11 (1)

65

CAPACITIES (in litres)

XANTIA - All

Engine type

Engine angle

Engine with filter change

Between Min. and Max.

5-speed gearbox

Automatic gearbox

after oil change

Hydraulic or brake circuit

Cooling system

Fuel tank capacity

XANTIA

Diesel

1.9 D 2.0 HDi

(1) Air conditioning - NOTE : Engine, systematically check the oil level using the oil dipstick.

Auto.

Page 26

GENERALGENERAL

Engine type

Engine with filter change (a)

Between Min. and Max. (b)

5-speed gearbox

Automatic gearbox

after oil change

Hydraulic or brake circuit

Cooling system

Fuel tank capacity

RGX RFV XFZ P8C THY

4.75 - 4.5 (1) 4.25 5.25 5 - 4.5 (1) 8

1.4 - 1.2 (1) 1 2 1.45 - 1.25 (1) 3

1.9 1.9 1.8 1.85 2.2

7.5 7.5 8.3 7.5

2.4 2.4 5.3 2.4

5.4 5 5.4

10.8 - 11.3 (2) 8.8 - 11.5 (2) 9.4 11.4 - 12 (2) 13.2

80 80

19

CAPACITIES (in litres) XM - All Types

XM

Petrol Diesel

2.0i Turbo CT 2.0i 16 V 3.0i 2.1 TD 2.5 TD

Auto.

Auto. Auto.

Auto.

(1) Air conditioning (2) Depending on equipment - NOTE : Engine, systematically check the oil level using the oil dipstick.

Page 27

20

GENERAL

RFN RHZ RHW

21°

4.25 4.5 4.75

1.7 1.4 1.9

1.8 1.8

8

3

Sans ABR : 0.47 - Avec ABR : 0.52

7 8.5

80 80

CAPACITIES (in litres)

SYNERGIE - All Types

Engine type

Engine angle

Engine with filter change

Between Min. and Max.

5-speed gearbox

Automatic gearbox

after oil change

Hydraulic or brake circuit

Cooling system

Fuel tank capacity

SYNERGIE

Petrol Diesel

2.0i 16V 2.0 HDi 2.0 HDi 16V

(1) Air conditioning - NOTE : Engine, systematically check the oil level using the oil dipstick.

Auto.

Page 28

21

GENERALGENERAL

ALL TYPES

LUBRICANTS - TOTAL recommended oils

S.A.E. Norm - Table for selection of engine oil grade

Factory evolutions in 2000 model year

CITROËN engines are lubricated at the factory with TOTAL oil of

grade S.A.E.5W-30.

TOTAL oil of grade S.A.E.5W-30 allows improved fuel economies

(approx. 2.5%).

This oil is not used in the following engines :

- XU10 4 RS – XSARA VTS 2.0i 16V (3-door)

- SOFIM – RELAY 2.8 D and 2.8 TD.

Engine oil norms

These engine oils have been classified by the following recognised

organisations:

SAE : Society of Automotive Engineers.

API : American Petroleum Institute.

ACEA : Association des Constructeurs Européens

d'Automobiles

E4AP006D

Page 29

22

GENERAL

ALL TYPES

Selection of engine oil grades recommended for climatic conditions in countries of distribution

ACEA Norms

The first letter corresponds to the type of engine concerned :

A : petrol and dual fuel petrol / LPG engines.

B : diesel engines.

The figure following the first letter corresponds to the type of oil.

1 : highly fluid oils, for reducing friction and lowering fuel

onsumption.

3 : high performance oils.

The number after that (96 or 98) corresponds to the year of creation of

the norm.

NOTE : From 01/03/2000, all engine oils must comply with ACEA-

98 norms.

Example :

ACEA A1-98 / B1-98 : Blended oils for all engines, permetting fuel eco-

nomy (complying with ACEA 98 norms).

API Norms

The first letter corresponds to the type of fuel used by the engine :

S : petrol and dual fuel petrol / LPG engines.

C : diesel engines.

The second letter corresponds to the degree of evolution, in ascending order.

Example : The norm SJ is more severe than the norm SH and corresponds to a higher level of performance.

The adding of the letters EC indicates that the engine oil concerned is an

oil which permits fuel economy.

EC : Energy Conserving, reduction in fuel consumption.

Examples :

API SJ / CF : Blended oils for diesel and dual fuel petrol / LPG engines

API CF / EC :Oils specifically for diesel engines, permitting fuel economy.

API SJ / CF / EC : Blended oils for all engines, permetting fuel economy.

LUBRICANTS - TOTAL recommended oils

Page 30

23

GENERALGENERAL

LUBRICANTS - TOTAL recommended oils

ALL TYPES

Recommendations.

Denominations of TOTAL oils, according to country of marketing :

TOT ALACTIVA (France only).

TOT ALQUARTZ (outside France).

IMPERATIVE : From 1999 model year, to preserve engine performance, all engines fitted in CITROEN vehicles must be

lubricated with high quality oils (synthetic or semi-synthetic)

These oils must comply with the following norms :

Petrol and dual fuel petrol / LPG engines: ACEA A3-98 and API SJ.

Diesel engines: ACEA B3-98 and API CF.

ATTENTION : Engines fitted in CITROEN vehicles prior to 2000 model year must not be lubricated with oil complying

with

standards ACEA A1-98 / B1-98 and API SJ/CF EC.

Summary

Engine oil norms to be respected in 2001 model year.

Model year

2001 model year

Petrol and dual fuel petrol /

LPG engines

A3-98 or A1-98 (*) SJ or SJ / EC (*)

CF or CF / EC (*)B3-98 or B1-98 (*)Diesel engines

Types of engine ACEAnorms API norms

Page 31

24

GENERAL

LUBRICANTS - TOTAL recommended oils

ALL TYPES

S.A.E. grades SPI norms ACEA norms

Blended oils for all engines (petrol, dual-fuel petrol / LPG and diesel)

TOTAL ACTIVA 9000

TOTAL QUARTZ 9000

5W-40 SJ / CF A3-98 / B3-98

TOTAL ACTIVA 9000 (*)

TOTAL QUARTZ 9000 (*)

5W-30 SJ / CF EC A1-98 / B1-98

TOTAL ACTIVRAC 10W-40 SJ / CF A3-98 / B3-98

(*) = Blended oils for all engines, permitting fuel economy.

Oils specifically for petrol and dual-fuel petrol / LPG engines

TOTAL ACTIVA 7000

TOTAL QUARTZ 7000

10W-40

TOTAL QUARTZ 9000 0W-40 SJ A3-98

TOTAL ACTIVA 7000

TOTAL QUARTZ 7000

15W-50

Oils specifically for diesel engines

TOTAL ACTIVA DIESEL 7000

TOTAL QUARTZ DIESEL 7000

10W-40

TOTAL ACTIVA DIESEL 7000

TOTAL QUARTZ DIESEL 7000

15W-50 CF B3-98

TOTAL ACTIVA 9000 5W-40

Page 32

25

GENERALGENERAL

FRANCE

Metropolitan FRANCE

Metropolitan FRANCE

New Caledonia

Guadeloupe

Saint-Martin

La Réunion

9000 5W-40 7000 15W-50 7000 15W-50

Martinique

Guyana

Tahiti

Mauritius

Mayotte

LUBRICANTS - TOTAL recommended oils

ALL TYPES

Blended oils for all engines

TOTAL ACTIVRAC S.A.E : 10W-40 Norms

TOTAL ACTIVA

Blended oils for all engines

900 5W-40

9000 5W-30 (*)

7000 10 W-40

7000 10 W-40

9000 5W-40

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically

for diesel engines

TOTAL ACTIVA DIESEL

(*) = Blended oils for all engines, permitting fuel economy.

Page 33

26

GENERAL

EUROPE

Germany

7000 10W-40

9000 0W-40

Austria 7000 10W-40

Belgium

7000 10W-40

9000 0W-40

Bulgaria 7000 10W-40

Cyprus

7000 15W-50

Croatia 7000 10W-40

Denmark

7000 10W-40

9000 0W-40

Spain

7000 10W-40

7000 15W-50

Finland

7000 10W-40

9000 0W-40

Great Britain 7000 10W-40

LUBRICANTS - TOTAL recommended oils

ALL TYPES

TOTAL QUARTZ TOTAL QUARTZ DIESEL

Blended oils for all engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically

for diesel engines

7000 10W-40

7000 10W-40

7000 15W-50

7000 10W-40

7000 10W-40

7000 15W-50

7000 10W-40

9000 5W-40

9000 5W-30 (*)

(*) = Blended oils for all engines,

permitting fuel economy

Page 34

27

GENERALGENERAL

LUBRICANTS - TOTAL recommended oils ALL TYPES

TOTAL QUARTZ TOTAL QUARTZ DIESEL

Blended oils for all engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically

for diesel engines

9000 5W-40

9000 5W-30 (*)

(*) = Blended oils for all engines,

permitting fuel economy

EUROPE (continued)

Greece

7000 10W-40 7000 10W-40

7000 15W-50 7000 15W-50

Holland 7000 10W-40

Hungary 9000 0W-40

Italy 7000 10W-40

7000 10W-40

Latvia 7000 10W-40

Lithuania 9000 0W-40

Macedonia 7000 10W-40

Malta

7000 10W-40 7000 10W-40

7000 15W-50 7000 15W-50

Norway

7000 10W-40

9000 0W-40

Poland

7000 10W-40

Portugal 7000 10W-40

Slovak Republic

Page 35

28

GENERAL

EUROPE (continued)

Czech Republic

7000 10W-40

7000 10W-40

9000 0W-40

Romania

7000 10W-40 7000 10W-40

7000 15W-50 7000 15W-50

Russia

7000 10W-40

9000 0W-40

Slovenia 7000 10W-40

7000 10W-40

Sweden

7000 10W-40

9000 0W-40

Switzerland 7000 10W-40

Turkey

7000 10W-40

7000 10W-40

7000 15W-50

7000 15W-50

9000 0W-40

Ukraine

7000 10W-40

7000 10W-40

9000 0W-40

LUBRICANTS - TOTAL recommended oils

ALL TYPES

TOTAL QUARTZ TOTAL QUARTZ DIESEL

Blended oils for all engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically

for diesel engines

9000 5W-40

9000 5W-30 (*)

(*) = Blended oils for all engines,

permitting fuel economy

Page 36

29

GENERALGENERAL

Australia

New Zealand

OCEANIA 9000 5W-40 7000 10W-40 7000 10W-40

Angola - Ivory Coast

Egypt - Ecuador - Gabon

Madagascar - Morocco AFRICA 9000 5W-40 7000 15W-50 7000 15W-50

Dominican Republic

Senegal - Tunisia

Argentina - Brazil - Chile

Colombia - Cuba

SOUTH

Guatemala - Paraguay

AMERICA

9000 5W-40 7000 15W-50 7000 15W-50

Peru - El Salvador

Uruguay

LUBRICANTS - TOTAL recommended oils ALL TYPES

TOTAL QUARTZ TOTAL QUARTZ DIESEL

Blended oils for all

engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically

for diesel engines

Page 37

30

GENERAL

LUBRICANTS - TOTAL recommended oilsALL TYPES

China

7000 10W-40

7000 15W-50

South Korea 7000 10W-40

Hong Kong - India

Indonesia

7000 15W-50

Japan

7000 10W-40

7000 15W-50

SOUTH & EAST 7000 15W-50

Malaysia ASIA

9000 5W-40

7000 15W-50

Singapore

Taiwan

7000 10W-40

7000 15W-50

Thaïland

7000 15W-50

Vietnam

TOTAL QUARTZ TOTAL QUARTZ DIESEL

Blended oils for all

engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically

for diesel engines

Page 38

31

GENERALGENERAL

Saudi Arabia

Bahrain

Dubai

United Arab Emirates

Israel MIDDLE

9000 5W-40 7000 15W-50 7000 15W-50

Jordan EAST

Kuwaït

Lebanon

Qatar

Yemen

LUBRICANTS - TOTAL recommended oils

ALL TYPES

TOTAL QUARTZ TOTAL QUARTZ DIESEL

Blended oils for all

engines

Oils specifically for petrol and

dual-fuel petrol / LPG engines

Oils specifically

for diesel engines

Page 39

32

GENERAL

Manual gearbox

Europe TOTAL TRANSMISSION

Overseas France (new formula)

Asia Norms S.A.E 75W-80

TOTAL FLUIDE ATX ou

TOTAL FLUIDE AT 42.

Automatic gearbox MB3

Special oil distributed by CITROEN

(Part No. : 9730 94).

TOTAL FLUIDE AT 42 ou

Automatic gearbox 4 HP 14 et 4 HP 18 All countries

Special oil distributed by CITROEN

(Part No. : 9730 94).

Automatic gearbox 4 HP 20 et AL4

Special oil distributed by CITROEN

(Part No. : 9736 22).

Transfer box and differential TOTAL TRANSMISSION X 4

C MATIC gearbox TOTAL FLUIDE T

Power-assisted steering All countries TOTAL FLUIDE ATX

LUBRICANTS - TOTAL recommended oils

ALL TYPES

Gearbox oils

Oils for power-assisted steering

Page 40

33

GENERALGENERAL

Engine coolant

LUBRICANTS - TOTAL recommended oils

ALL TYPES

Packs

CITROEN Reference

GLYSANTIN G 33 REVCOGEL 2000

CITROEN Fluid 2 litres 9979 70 9979 72

All countries

Protection : - 35°C 5 litres 9979 71 9979 73

20 litres 9979 76 9979 74

210 litres 9979 77 9979 75

Synthetic brake fluid

Packs CITROEN Reference

All countries

CITROEN Fluid

0.5 litre 9979 05

1 litre 9979 06

5litres 9979 07

CITROEN hydraulic circuit fluid

Mineral fluid for hydraulic circuit – green colour

TOTAL LHM PLUS Packs CITROEN Reference

All countries Norms ISO 7308-7309 1 litre ZCP 830 095

Hydraulic circuit rinsing fluid – green colour

TOTAL HYDRAURINCAGE

Page 41

34

GENERAL

CITROEN Reference

Concentrate : 250 ml 9980 33 ZC 9875 953 U 9980 56

All countries Liquid ready to use : 1 litre 9980 06 ZC 9875 784 U

Liquid ready to use : 5 litres 9980 05 ZC 9885 077 U ZC 9875 279 U

Grease

Norms NLGI (1)

All countries TOTAL MULTIS EP2 2

TOTAL MULTIS COMPLEX EP2 2

TOTAL MULTIS N4128 1

TOTAL SMALL MECHANISMS

(1) NLGI = National Lubrificating Grease Institute.

Wash / wipe fluid

LUBRICANTS - TOTAL recommended oils

ALL TYPES

Page 42

I-Oil consumption depends on :

- the engine type.

- how run-in or worn it is.

- the type of oil used.

- the driving conditions.

II - An engine can be considered RUN-IN after:

- 3,000 miles (5,000 km) for a PETROL engine.

- 6,000 miles (10,000 km) for a DIESEL engine.

III - MAXIMUM PERMISSIBLE oil consumption for a RUN-IN engine.

- 0.5 litres per 600 miles (1,000 km) for a PETROL engine

- 1 litre per 600 miles (1,000 km) for a DIESEL engine.

DO NOT WORK BELOW THESE VALUES.

IV - OIL LEVEL : The level should NEVER be above the MAX. mark on the dipstick after changing or topping up the oil.

- This excess oil will be used up rapidly.

- It will reduce the engine output and adversely affect the operation of the air circuits and gas recycling.

35

GENERALGENERAL

ENGINE OIL CONSUMPTION

ALL TYPES

Page 43

ENGINE

Engine type

Cubic capacity (cc)

Bore / Stroke

Compression ratio

Power ISO or EEC KW-rpm

Power DIN (HP-rpm)

Torque ISO or EEC (m.daN-rpm)

Torque DIN (mkg-rpm)

Max. speed (rpm)

BFZ BFX LFX LFY LFY/GPL

1580 1761

83/73 83/81.4

9.25/1 9.5/1 10.4/1

65-6000 66-5000 81-5500 79-5500

89-6000 90-5000 112-5500 109-5500

13-2600 14.7-2600 15.5-4250

13.5-2600 15.3-2600 16.1-4250

6800 6300 6400

36

ENGINE SPECIFICATIONS

ALL TYPES

Engines : BFZ BFX LFX LFY

Petrol

All Types

1.6i 1.8 i 1.8 i 16 V

Dual fuel

Page 44

ENGINE

37

Engine type

Cubic capacity (cc)

Bore / Stroke

Compression ratio

Power ISO or EEC KW-rpm

Power DIN (HP-rpm)

Torque ISO or EEC (m.daN-rpm)

Torque DIN (mkg-rpm)

Max. speed (rpm)

RGX RFN RFV XFZ

1998 1997 1998 2946

86/86 85/88 86/86 87/82.6

7.9/1 10.8/1 10.4/1 10.5/1

108-5300 99-6000 97.4-5500 140-5750

150-5300 136-6000 135-5500 194-5750

23.5-2500 19-4600 18-4200 26.7-4000

24.5-2500 19.8-4600 18.7-4200 27.7-4000

6300 6800 6520

ENGINE SPECIFICATIONS

ALL TYPES

Engines : RGX RFN RFV XFZ

Petrol

2.0I TURBO CT

2.0i 16V

3.0i V6

Page 45

ENGINE

Engine type

Cubic capacity (cc)

Bore / Stroke

Compression ratio

Power ISO or EEC KW-rpm

Power DIN (HP-rpm)

Torque ISO or EEC (m.daN-rpm)

Torque DIN (mkg-rpm)

Max. speed (rpm)

DHX RHZ RHY RHW P8C THY

1905 1997 2088 2445

83/88 85/88 85/88 95/92 92/92

21.8/1 17.6/1 18/1 21.5/1 22/1

66-4000 80-4000 66-4000 80-4000 80-4300 94.5-4300

90-4000 110-4000 90-4000 110-4000 110-4300 130-4300

19.6-2250 25-1750 20.5-1750 27-1750 25-2000 28.5-2000

20.5-2250 26-1750 21.3-1750 -1750 26-2000 30-2000

4500 5300 4300 5100

38

ENGINE SPECIFICATIONS

ALL TYPES

Engines : DHX - RHZ – RHY - RFW - P8C - THY

Diesel

All Types

1.9 TD 2.0 HDi

2.1 TD2.0 HDi 16V

2.5 TD

Page 46

ENGINE

in Bars

XUD 7 / 9 25 to 30 20

XUD 11 19 to 21 15

5

DW10 30 ± 5

DK5 25 to 30 20

39

COMPRESSION RATIO - DIESEL ENGINES ALL TYPES

ENGINE

COMPRESSION

RATIO

MINIMUM VALUE

(- 20 ‰)

MAX. SPACING

BETWEEN CYLINDERS

Page 47

ENGINE

40

Engine type

BFZ BFX LFX LFY RFV RGX

Maximum permissible bow 0.05

Gasket surface regrinding - 0.20

TIGHTENING TORQUES (m.daN)

Crankshaft bearing screws :

- Pre-tightening --

- Tightening 5.5 ± 0.5 7 ± 0.7

- Angular tightening -Connecting rod screws

- Pre-tightening

4±0.4

- Tightening 2±0.2

- Angular tightening 70°±7°

Flywheel screw 5

Crankshaft pulley screw 12

Pulley screw at end of camshaft 5.5±0.5 7.5±0.7 5.5±0.5

XANTIA - XM SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

Engines : BFZ – BFX - LFX - LFY - RFV - RGX

CYLINDER HEAD (mm)

WARNING : After removing the crankshaft pulley, carry out the following operations :

- Clean the thread (Tap 14X150) - Fit a NEW washer

- Fit a NEW screw. - Tighten (see table above)

Page 48

41

ENGINE

SYNERGIESPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

Maximum permissible bow

0.05

Gasket surface regrinding

- 0.20

Crankshaft

Engine : RFN

Bearing cap screws.

- Pre-tightening 2 ± 0.1 Camshaft pulley hubs 7.5 ± 0.7

- Angular tightening 60° ± 6°

Con-rod cap screws. Engine flywheel

- Tightening - Pre-tightening 2 ± 0.2

- Untightening - Tightening 21° ± 3°

- Tightening 2.3 ± 0.2

- Angular tightening 46° + 2° - 4°

Con-rod nuts.

- Pre-tightening Clutch plate 2 ± 0.2

- Angular tightening

Accessories drive pulley

- Tightening 2.1 ± 0.1

- Angular tightening

Accessories drive pulley hub

- Pre-tightening 4 ± 0.4

- Angular tightening (Sintered washer) 40°±4°

- Angular tightening (Steel washer) 53°±5°

Page 49

42

ENGINE

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

Engines : LFY - RFV

CYLINDER HEAD COVER

XM - XANTIA

LFY - RFV

- Pre-tighten :0.5

- Tighten :1±0.1

B1DP01YD

XANTIA - XM

Page 50

43

ENGINE

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN ) XANTIA - XM - V6

Engine : XFZ

(1) Compact coil unit 1 ± 0.1

(9) Flywheel

- Tightening 1

- Angular tightening 60°± 6°

(11) Connecting rod caps

- Tightening 2±

- Angular tightening 74°±7

(12) Crankshaft hub

- Tightening 4 ± 0.4

- Angular tightening 80°±8°

(13) Crankshaft pulley 2.5 ± 0.2

B1BP1HAP

Page 51

ENGINE

44

XANTIA - XM - V6

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

Engine : XFZ

- 2 Cylinder head cover (A) Front cyl. head - (B) Rear cyl. head

WARNING : Tighten screw by screw in the order shown.

- Pre-tighten 0.5

- Tighten 1 ± 0.1

- Pre-tighten 0.2

- Tighten 0.8

- 3 Bearing caps housing (A) Front cyl. head - (B) Rear cyl. head

B1DP08UD B1DP08TD

Page 52

ENGINE

45

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

XANTIA - XM - V6

Engine : XFZ

- 5 Air inlet manifold

WARNING : Tighten screw by screw in the order shown.

- Pre-tighten 1 ± 0.1

- Tighten 2 ± 0.2

- Pre-tighten 1 ± 0.1

- Tighten 2.5 ± 0.2

- 6 Lower manifold (A) Front cyl. head - (B) Rear cyl. head

B1HPOLJC

B1DP097C

Page 53

46

ENGINE

XANTIA - XM - V6

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

Engine : XFZ

- 7 Exhaust manifold (NEW seal)

WARNING : Tighten screw by screw in the order shown.

- Pre-tighten 1 ± 0.1

- Tighten 3 ± 0.3

- Pre-tighten 0.5 ±

- Tighten 0.8 ±

- 10 Oil sump

B1BP1GZDB1BP1GXD

Page 54

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

XANTIA - XM - V6

Engine : XFZ

- 8 Crankshaft bearing

B1BP1GYD

- Clean the threads of the screws with a brush.

- Refit the screws with a coating of grease ( MOLYKOTE G RAPID PLUS ).

- Check that the 8 centring pins are in place.

Maximum length under the heads of the screws :

- M11 = 131.5 mm.

- M8 = 119 mm.

- Pre-tighten the M11 screws to 3 m.daN ± 0,3 (1 to 8).

- Pre-tighten the M8 screws to 1 m.daN ± 0,1 (A to H).

- Tighten the M6 screws to 1 m.daN ± 0,1 (a to m).

- Slacken the M11 and M8 screws (screw by screw).

- Tighten the M11 screws to 3 m.daN ± 0,3 (1 to 8).

- Tighten the M8 screws to 1 m.daN ± 0,1 (A to H).

ENGINE

47

Page 55

ENGINE

ENGINE

48

XANTIA - XM - V6 SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

Engine : XFZ

B1BP1HBD

(14) Water pump

- Pre-tighten 0.5

- Tightening 0.8

(15) Oil pump

- Pre-tighten 0.5

- Tightening 0.8

(16) Guide roller 8 ± 0.8

(17) Tensioner roller 8 ± 0.8

(18) Camshaft hubs

- Pre-tighten 2 ± 0.2

- Tightening 57°±5°

(19) Camshaft pulley 1 ± 0.1

Page 56

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

XANTIA - XM - V6

B1BP1H1D

WARNING : Tighten screw by screw in the order shown.

- Pre-tighten 0.5 ±

- Tightening 1 ± 0.1

Engine : XFZ

- 20 Oil fumes recovery unit.

ENGINE

49

Page 57

50

ENGINE

DIESEL - All Types

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN )

Engine type

DHX P8C RHY RHZ RHW THY

Maximum permissible bow

0.07 0.05 0.03 0.05

Gasket surface regrinding

- 0.20 - 0.40

Crankshaft bearing screws :

- Pre-tightening

1.5 ± 0.1 2.5 ± 0.2 2 ± 0.2

- Tightening ---

- Angular tightening 60°±6° 60 ±6° 60°±6°

Connecting rod screws :

- Pre-tightening

2 ± 0.2 2 ± 0.2

- Angular tightening 70°±7° 65°±6°

Flywheel screw 5 ± 0.5

Crankshaft pulley screw :

- Pre-tightening

4 ± 0.4 7 ± 0.7 4 ± 0.4 7 ± 0.7

- Angular tightening 51°±5° 60°±6° 51°±5° 51°±5°

Pulley screw at end of camshaft 4.5 ± 0.4 4.3 ± 0.4

Engines : DHX - P8C - RHY - RHZ - RHW - THY

CYLINDER HEAD (mm)

TIGHTENING TORQUES (m.daN)

WARNING : After removing the crankshaft pulley, carry out the following operations : (Except for THY engines).

- Clean the thread (Tap 14X150) - Fit a NEW washer

-Fit a NEW screw. - Tighten (see table above)

Page 58

CYLINDER HEAD XANTIA - XM

Engines : BFZ – BFX - LFX - LFY - RGX - RFV

IDENTIFICATION OF THE CYLINDER HEAD GASKET

Engine types

Identification marks

(Notch on cylinder head gasket)

*

BFZ BFX LFX LFY RGX RFV

A

1

B

0

C

0

D

0

E

0

A

00

0

1

0

0

0

0

0

0

1

1

B

10

C

01

D

00

E

00

CURTY

MEILLOR

Suppliers

*

0 = Without notch

1 = One notch

B1BP004C

ENGINE

51

Page 59

ENGINE

52

XANTIA - XM

CYLINDER HEAD (continued)

Engines : BFZ – BFX - LFX - LFY - RGX - RFV

Cylinder head tightening (m.daN) Cylinder head bolts

X = MAXIMUM reusable length

Note : Oil the threads

and under the heads of

the cylinder head bolts.

(Use engine oil or

Molykote G Rapid Plus).

- Pre-tightening 3.5

- Loosening NO

- Tightening 7

- Angular tightening 160°

- Pre-tightening 6

- Loosening YES

- Tightening 2

- Angular tightening 300°

B1DP13PC

B1DP05BC

RGX – RFV

BFZ – BFX - LFX – LFY

BFZ - BFX

LFX

171.5 mm 160.5 mm 122 mm 112 mm

LFY

RGX RFV

Page 60

ENGINE

53

Nominal dimension Repair dimension

Marking zone

"d"

4 - 5 2 - 4 - 5

Marking zone

"e"

R1 R2

Gasket thickness

(mm)

0.8 1.1 1.4

Supplier MEILLOR

CYLINDER HEAD

Engine : RFN

Identification of the cylinder head gasket

SYNERGIE

B1DP183D

Multilayer metallic gasket

Page 61

54

ENGINE

Engine : RFN

X = MAXIMUM reusable length

A = Washer thickness : 4 ± 0.2 mm.

X = Length under heads of new bolts = 144.5 ± 0.5 mm.

Note : Oil the threads and

under the heads of the cylinder

head bolts. (Use engine oil or

Molykote G Rapid Plus).

Pre-tightening 1.5 ± 0.1

Tightening 5 ± 0.1

Loosening 360° ± 2°

Tightening 2 ± 0.75

Angular tightening 285° ± 5°

B1DP05BC

RFN

RFN

X = 147 mm

Cylinder head tightening (m.daN) Cylinder head bolts

SYNERGIE

CYLINDER HEAD (continued)

B1DP16FC

Page 62

ENGINE

55

CYLINDER HEAD

XANTIA - XM

Engine : XFZ

IDENTIFICATION OF THE CYLINDER HEAD GASKET

B1DP09TC

Supplier

ERLING 1.45 ± 0.04 Centre tab

Thickness

(mm)

Ident. marks

(1) and (2)

Rear

Front

Page 63

ENGINE

56

XANTIA - XM

CYLINDER HEAD (continued)

Engine : XFZ

X = MAXIMUM reusable length

Note : Oil the threads and under the

heads of the cylinder head bolts.

(Use engine oil or Molykote G Rapid

Plus).

- Pre-tighten 2

- Loosen YES

- Tightening 1.5

- Angular tightening 225°

B1DP09VC

B1DP09UC

XFZ

149.5 mm

Cylinder head tightening (m.daN) Cylinder head bolt

Rear

Front

Page 64

ENGINE

57

0.56 to 0.67 1.36

0.68 to 0.71 1.40

0.72 to 0.75 1.44

0.76 to 0.79 1.48

0.80 to 0.83 1.52

Engine Ident. (A) Ident. (B)

DHX 3 notches

XANTIA

CYLINDER HEAD

IDENTIFICATION OF THE CYLINDER HEAD GASKET

Marking

(B)

Thickness

(mm)

± 0.06

Engine type

Piston

stand-proud (mm)

DHX

(A) = Engine identification.

(B) = Thickness identification.

DHX

1 to 5 notches

B1BP10TC

Engine : DHX

Page 65

ENGINE

58

ENGINE

XM CYLINDER HEAD (continued)

IDENTIFICATION OF THE CYLINDER HEAD GASKET

Position of

hole(s)

Ident.

Thickness

(mm)

Engine type

Piston stand-proud

(mm)

0.65 to 0.76 1.52 B - A1

0.77 to 0.81 1.57 B - A2

0.82 to 0.86 1.62 B - A3 (A) and (B)

0.87 to 0.91 1.67 B - A4

0.92 to 0.96 1.72 B - A5

Reconditioning B - A1 - A5

P8C

B1BP1DTC

Engine : P8C

Page 66

ENGINE

59

XANTIA - SYNERGIE

CYLINDER HEAD

IDENTIFICATION OF THE CYLINDER HEAD GASKET

No. of notches

at A

Thickness

(mm)

Engine

type

Piston stand-

proud (mm)

0.47 to 0.605 1.30 ± 0.06 1

0.605 to 0.655 1.35 ± 0.06 2

0.655 to 0.705 1.40 ± 0.06 3

0.705 to 0.755 1.45 ± 0.06 4

0.755 to 0.83 1.50 ± 0.06 5

RHZ

RHY

B1DP15AD

Engine : RHZ - RHY

Page 67

ENGINE

60

XANTIA - XM - SYNERGIE

CYLINDER HEAD

Engines : DHX - RHZ - RHY - P8C

X = MAXIMUM reusable length

Note : Oil the threads and under the heads of the cylinder

head bolts. (Use engine oil or Molykote G Rapid Plus).

- Pre-tightening 2

- Tightening 6

- Angular tightening 220°

- Pre-tightening 2

- Tightening 6

- Angular tightening 180°

B1DP13PC B1DP15EC

B1DP05BC

DHX - RHZ - RHY

P8C

DHX P8C RHZ - RHY

150.5 mm 151.5 mm 133.3 mm

Cylinder head tightening (m.daN) Cylinder head bolts

RHZ - RHYDHX - P8C

Page 68

ENGINE

61

XM

CYLINDER HEAD

Engine : THY

Identification of the cylinder head gasket

Engine type

THY 1.6 None

Thickness

(mm)

Ident.

X = MAXIMUM reusable length

Bolt Ø 12 Bolt Ø 10

153.5 mm 162.5 mm

Cylinder head bolts

Cylinder head tightening ( m.daN)

Note : Oil the threads and under

the heads of the cylinder head

bolts. (Use engine oil or

Molykote G Rapid Plus).

B1DP03XC

Pre-tightening the bolts :

- 1 à 14 (Bolt Ø 12) 5

- 15 à 22 (Bolt Ø 10) 3.5

Angular tightening :

- 1 à 22 (Bolt Ø 12 and 10) 120° ± 5°

B1DP15EC

Page 69

ENGINE

Tools

ALL TYPES

BELT TENSION/SEEM UNITS CORRESPONDENCE TABLE

! 4099-T (C.TRONIC.105)

4122-T (C.TRONIC.105.5)

!

!

!

B1EP135D

62

Page 70

63

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

ALL TYPES

Engines : All Types Petrol and Diesel

TOOL

- Belt tension measuring instrument : 4122 - T. (C.TRONIC 105.5)

- WARNING : If using tool 4099-T (C.TRONIC 105) refer to the correspondence table on page 62.

ESSENTIAL

- Before refitting the auxiliary equipment drive belt, check that :

1) The roller(s) rotate freely (no play or stiffness)

2) The belt is correctly engaged in the grooves of the various pulleys.

Page 71

ENGINE

64

XANTIA - XM

AUXILIARY EQUIPMENT DRIVE BELT

[1] Belt tension measuring instrument : 4122-T

- (3) and (5) Roller support fixing screws.

- (6) Tensioning screw.

- Tighten the belt, by loosening the screw (6) to : In SEEM units

- Tighten the screws (3) and (5).

- Rotate the crankshaft by 4 turns (direction of rotation).

- Loosen the screws (3) and (5).

- Tension the belt, by slackening the screws (6) to : In SEEM units.

- Tighten the screws (3) and (5) to 2 m.daN.

Without air conditioning

B1BP00IC

B1BP00HC

Engines : BFZ - LFX - LFY - RFV - RGX

BFZ-LFX

100 ± 10 120 ± 10 100 ± 10

LFY RFV-RGX

BFZ-LFX

115 ± 5 120 ± 10 105 ± 10

LFY RFV-RGX

Page 72

ENGINE

65

AUXILIARY EQUIPMENT DRIVE BELT XANTIA - XM

- Loosen :

- The screws (4) of the tensioner roller (13 mm angle spanner).

- The screw (3).

- Tension the belt using the screw (3) to obtain :

- New belt : 120 SEEM units.

- Reused belt : 90 SEEM units.

- Tighten the screws (4) to 2 m.daN.

- Rotate the crankshaft by 4 turns (direction of rotation).

- Adjust the belt tension (if necessary).

With air conditioning

B1EP05FC

Engines : BFZ - LFX - LFY - RFV - RGX (Continued)

Page 73

ENGINE

66

XANTIA - XM

AUXILIARY EQUIPMENT DRIVE BELT

- Fit the drive belt.

- The tensioner roller (1).

- Tighten the screws (3) to 2 m.daN.

- Turn the tensioner roller (1) using the tool (9.52 mm square drive (3/8)) at (2), in order to remove

the tool or locking peg (Ø 4 mm) at (4).

- Slowly release the tensioner roller (1) so that the roller (5) presses against the belt

With air conditioning

B1BP1HJC

Engines : BFZ - LFX - LFY - RFV - RGX (Continued)

Page 74

ENGINE

67

AUXILIARY EQUIPMENT DRIVE BELT SYNERGIE

Engine : RFN

Without air conditioning With air conditioning

Tools

[1] Plyers for removing plastic pegs 7504-T

Remove the belt.

- Detension the belt (3) by turning the screw (2) of the tensioner roller (1)

(anti-clockwise).

- The screw (2) (WARNING : not left hand screw).

- Remove the belt (3), while keeping the tensioner roller (1) tight.

Refit the belt.

- Refit the belt (3), while keeping the tensioner roller (1) tight.

- Release the tensioner roller (1).

B1BP23PC B1BP23QC B1BP23PC B1BP23RC

Page 75

ENGINE

AUXILIARY EQUIPMENT DRIVE BELTXANTIA - XM

68

Removal :

- Release the bolt (3).

- Keep the dynamic tensioner (1) tensioned by holding the hexagonal fixture «a».

- Release the shoulder of the screw (2) from the oblong hole of the dynamic tensioner.

- Release the dynamic tensioner (1) using the hexagonal fixture «a».

- Remove the belt.

Refitting :

- Locate the dynamic tensioner (1) in its operating position using the hexagonal fixture «a».

(The tensioner (1) will automatically tension it).

- Tighten the screws (2) and (3) to 2.5 m.daN.

With air conditioning

B1BP1EXC

Engine : XFZ

Page 76

ENGINE

XANTIA - XM

69

AUXILIARY EQUIPMENT DRIVE BELT

Engines : DHX - P8C

Without air conditioning

[2] Belt tension measuring instrument 4122-T

- Tighten the belt, by loosening the screw (4) to obtain:

- 115 ± 10 SEEM units.

- Tighten the screws (1) and (3).

- Rotate the crankshaft by 4 turns (Direction of rotation).

- Loosen the screws (1) and (3).

- Tighten the belt to :

- 115 ± 10 SEEM units (if necessary).

- Tighten the screws (1) and (3) to 2 m.daN.

B1BP10GC B1BP10HC

Page 77

ENGINE

70

XANTIA

AUXILIARY EQUIPMENT DRIVE BELT

Engines : DHX

With air conditioning

- Loosen the screws (1).

- Tighten or loosen the screw (2) until holes «a» and «b» are superimposed.

- Locate the peg [1] : (in the hole «a»).

DHX peg 7019-T.

- Tighten the screw (2) until it stops..

- Loosen the screw (2), so the peg [1] can be removed.

- Tighten the screws (1) to 2 m.daN.

B1BP1HHC

Page 78

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

XM

71

With air conditioning

Engines : P8C

- Engage the square drive tool [2] (9.52 mm - 3/8), in its location in the tensioner

arm (b).

- Compress the damper (1) using the tool [2].

- Peg the damper (1) at «a» using the tool [3] 7019- T.

(Tensioner in locking position).

- Remove the tool [2] and loosen the screw (2) of the roller (3).

- Position the belt on :

The crankshaft, the tensioner roller, the high pressure pump, the eccentric roller,

the air conditioning compressor.

- Tighten the belt, roller (3) tool [4] 5711- T.E.

NOTE : Tighten the screw (2) of the roller (3) when the tool [3] slides freely into its

pegging location.

- Tighten the screw (2) to 5 m.daN.

B1BP1HFC B1BP1HEC B1BP1HDC B1BP1HCC

Page 79

ENGINE

72

XANTIA - SYNERGIE AUXILIARY EQUIPMENT DRIVE BELT

Engine : RHY - RHZ

Without air conditioning

B1BP1YKD

Tools

[1] Belt tension adjusting square : (-).0188 J2

[2] Ø 4 mm peg : (-).0188.Q1

[3] Ø 2 mm peg : (-).0188.Q2

[4] Dynamic tensioner compression lever : (-).0188.Z

Removal.

Re-use of belt

WARNING : Mark the direction the belt was fiited in case of re-use of the same belt.

- Compress the tensioner roller (2) by action at «a» (in anti-clockwise direction), tool [4].

- Keep the tensioner roller (2) compressed and remove the belt.

No re-use of belt.

- Compress the tensioner roller (2) by action at «a» (in anti-clockwise direction), tool [4].

- Peg using tool [2], at «b».

- Hold the tensioner roller (2) compress and remove the belt.

- Loosen the screw (1).

Page 80

ENGINE

73

XANTIA - SYNERGIE

AUXILIARY EQUIPMENT DRIVE BELT

Engine : RHY - RHZ

Without air conditioning (continued)

Refit.

Re-used belt.

- Compress the tensioner roller (2) by action at «a» (in anti-clockwise direction), tool [4].

- Refit the belt.

WARNING : Respect the direction belt was fitted.

- Remove the tool [4].

New belt.

- Refit the belt.

- Turn the eccentric roller (3), tool[1] (clockwise) to free the tool [2]from its pegging at «b».

- Hold the eccentric roller (3), tool [1], and tighten the screw (1) to 4.3 m.daN.

- Remove the tool [2].

- Rotate the crankshaft 4 times in the direction of rotation.

- Check that it is possible to peg at «b», tool [3].

- If not possible to peg, restart the adjustment.

B1BP1YMD

Page 81

ENGINE

74

XANTIA - SYNERGIE AUXILIARY EQUIPMENT DRIVE BELT

Engine : RHY - RHZ

With air conditioning

B1BP1YLD

Tools

[1] Belt tension adjusting square : (-).0188 J2

[2] Ø 4 mm peg : (-).0188.Q1

[3] Ø 2 mm peg : (-).0188.Q2

[4] Dynamic tensioner compression lever : (-).0188.Z

Remove

Re-use of belt

WARNING : Mark the direction the belt was fitted in case of re-use of the same belt.

- Compress the tensioner roller (7) by moving it at «c» (in anti-clockwise direction),

tool [4].

- Hold the tensioner roller (7) compressed and remove the belt.

No re-use of belt.

- Compress the tensioner roller (7) by moving it at «c»(in anti-clockwise direction), tool [4].

- Peg using tool [2], at «d».

- Loosen the screw (6).

- Bring the eccentric roller (5) towards the rear.

- Tighten the screw (6) by hand.

- Remove the belt.

Page 82

ENGINE

75

XANTIA - SYNERGIEAUXILIARY EQUIPMENT DRIVE BELT

Engine : RHY - RHZ

With air conditioning (continued)

Refit.

Re-used belt.

- Compress the tensioner roller (7) by action at «c» (in anti-clockwise direction), tool [4].

- Refit the belt.

WARNING : Respect the direction belt was fitted.

Remove the tool [4].

New belt.

- Refit the belt.

- Turn the eccentric roller (5), tool [1] (clockwise) to free the tool [2]from its pegging at «d».

- Hold the eccentric roller (5), tool [1], and tighten the screw (6) to 4.3 m.daN.

- Remove the tool [2].

- Rotate the crankshaft 4 times in the direction of rotation.

- Check that it is possible to peg at «d», tool [3].

- If not possible to peg, restart the adjustment.

B1BP1YND

Page 83

ENGINE

76

XM

AUXILIARY EQUIPMENT DRIVE BELT

Engine : THY

With air conditioning

WORN BELT.

- Loosen the screw (2) using tool [2] 5714-T.R (6 mm across the flats).

- Move the roller (3), using tool [3] 5714-T.S (6 mm across the flats) until tool [1] 5714 - T.Q.

(Ø 4 mm) fits in the hole (5) of the automatic tensioner (4).

NOTE :If there is insufficient roller movement (3), move the tensioner (4) using a ratchet wrench (9.52 mm) plus

extension, so that the tool [1] (Ø 4 mm) fits in the hole (5).

- Remove the belt.

BROKEN BELT.

- Move the tensioner (4) using a ratchet wrench (9.52 mm) plus extension so that the tool [1] 5714-T.Q (Ø 4 mm)

fits in the hole (5).

B1BP051C B1BP052C

Page 84

ENGINE

77

XM

AUXILIARY EQUIPMENT DRIVE BELT

Engine : THY

With air conditioning (continued)

NEW BELT.

- ove the roller (3), with tool [3] 5714-T.S (6 mm across the flats) until tool [1] 5714-T.Q (Ø 4 mm) is released.

- Hold the roller (3) in this position and tighten the screw (2) using tool [2]. Tighten to 3.2 m.daN.

- Rotate the crankshaft by 5 turns (Direction of rotation) = 1 turn of the belt.

- Check the tension by inserting the tool [1] (Ø 2 mm) in the hole (5) of the automatic tensioner (4).

- If the tension is not correct, repeat the tensioning procedure.

B1BP051C

Page 85

ENGINE

78

XM

AUXILIARY EQUIPMENT DRIVE BELT

Engine : THY

With air conditioning (continued)

REUSED BELT

- Continue in the same way as for a new belt.

NOTE : In certain cases the roller (3) is in its maximum stop position, and it is not possible to remove the tool

[1] 5714-T.Q (Ø 4 mm) .

- Move the roller (4) using a ratchet wrench (9.52 mm) plus extension to release the tool [1].

- Rotate the crankshaft by 5 turns (Direction of rotation) = 1 turn of the belt.

Measure distance X :

- If measurement X is less than 98 mm, the belt is correctly tensioned.

- If measurement X is more than 98 mm, the belt must be replaced.

B1BP054C

Page 86

ENGINE

79

XM

BALANCE SHAFT BELT

Engine : THY

TOOLS

- [5] Belt tension measuring instrument : 4122-T

- [1] Flywheel locating peg : 7014-T.J. Tool kit 7004-T

- [2] Camshaft pinion locating peg : 5711-T.A.

- [3] Injection pump peg : 5711-T.B.

Tool kit 5711-T

- [4] Balance shaft peg : 5711-T.D.

- [6] Tensioning lever : 5711-T.E.

Removal

- The auxiliary equipment and timing belt (See pages 76 to 78 and 115 to 117).

- Peg the balance shafts using the tools [4].

- Remove the guide roller (1).

- Loosen the screw (2) (freeing the roller).

- Remove the balance shaft belt.

B1BP04QC

Page 87

ENGINE

80

XM

BALANCE SHAFT BELT

Engine : THY (continued)

Refitting

- Check that the rollers work properly.

- The balance shaft belt.

- Remove the tool [4].

- Fit the tool [5] to the belt.

- Pre-adjust the tension using the tool [6]. (Placed in the square locating hole of the tensioner roller).

Adjust the tension to :

- New belt 70 SEEM units.

- Reused belt 51 SEEM units.

- Tighten the roller to 4.5 m.daN.

Checking the fitting pre-tensioning.

- Remove and refit the tool [5]. ( Make any necessary corrections).

Fit :

- The guide roller (1), tighten to 4.5 m.daN.

- The timing belt (See pages 115 to 117).

- Pre-tension, then tension the timing belt (See pages 115 to 117).

B1BP04RC

Page 88

ENGINE

81

BALANCE SHAFT BELT

Engine : THY (continued)

NOTE : Rotate the crankshaft by 10 turns (if this wasn’t carried ort when refitting the timing belt).

- Loosen the screw (2) to release the tensioner roller.

- Fit the tool [5].

- Adjust the belt tension using the tool [6]. (Inserted in the square hole in the tensioner roller).

Adjust the tension to :

- New belt 31 SEEM units.

- Reused belt 26 SEEM units.

- Tighten the tensioner roller to 4.5 m.daN.

CHECKING THE FITTING TENSION

- Remove and refit the tool [5]. (Make any necessary corrections).

- Remove the tool [5].

CHECKS

- Rotate the crankshaft by 2 turns.

- Peg the flywheel, (behind the engine) using the tool [1].

- To check that a tooth hasn’t been missed, visually check the pegging of the following components :

- the injection pump.

- the camshaft.

- the balance shafts.

- Remove the tool [1].

B1BP04SC

DK5 - All Types

Page 89

ENGINE

82

XM

WATER PUMP BELT

Engine : THY

Removal

- Loosen the screw (19).

- Turn the screw (20) in the same direction as if tightening in order to slacken the belt.

- Remove the belt (21).

Refitting

- Refit the belt (21).

- Fit the measuring instrument [2] 4122-T to the belt.

- Loosen the screw (20) to tighten the belt.

•

NEW belt = 46 SEEM units.

•

Reused belt = 38 SEEM units.

- Remove the tool [2].

- Rotate the crankshaft by 3 turns (direction of rotation).

- Fit the tool [2].

- Check the belt tension:

•

NEW belt = 46 SEEM units.

•

Reused belt = 38 SEEM units.

- Retighten the screw (19).

- Remove the tool [2].

B1GP016C

Page 90

Engine type BFZ LFX

LFY LFY

RGX

RFV RFV

RFN XFZ

# 11/97 11/97 ## 11/97 11/97 #

XANTIA XXX X XX X

XM XXX X

SYNERGIE X

See pages : 85 to 86 87 to 91 82 to 96 85 to 86 87 to 91 92 to 96 97 to 101 102 to 106

ENGINE

83

CHECKING AND SETTING THE VALVE TIMING

XU ES

JP

1.6 i 1.8 i 1.8 i 16 V

2.0 i

Turbo CT

2.0 i 16 V 3.0 i

JB JP

JP4 J2TE J4R J4

57 10

9

ALL TYPES

EW

Page 91

ENGINE

84

CHECKING AND SETTING THE VALVE TIMING (continued)

XUDDWXUD DK

BTF

1.9 TD

9

TD

2.0 HDi

1110

ATED4ATED BTE

2.1 TD2.0 HDi 16V

5

ATE

2.5 TD

ALL TYPES

Engine type DHX RHY RHZ RHW P8C THY

XANTIA XXX

XM XX

SYNERGIE XX

See pages : 107 108 to 112 113 to 114 115 to 117

Page 92

ENGINE

85

CHECKING AND SETTING THE VALVE TIMING

Engine : BFZ - LFX - RGX

TOOLS

- Belt tension measuring instrument : 4099-T or 4122-T

- Camshaft pulley locating peg : 7004-T.G.

- Crankshaft locating peg : 7014-T.N. Tool kit 7004-T

- Square drive : 7017-T.W.

CHECKING THE VALVE TIMING

- Remove the protective covers.

- Peg the camshaft pulley at «a» using the tool 7004 - T.G.

- Peg the crankshaft at «b» using the tool 7014 - T.N.

SETTING THE VALVE TIMING

- Check that the pegs can be engaged correctly at «a» and «b».

- Fit the belt in the following order : camshaft pulley, crankshaft pinion, water pump pinion,

tensioner roller.

- Peg the camshaft pulley at «a» and the crankshaft at «b».

- Remove the peg at «b» only.

- Bring the tensioner roller (2) into contact with the belt.

B1EP07RC

Page 93

ENGINE

86

CHECKING AND SETTING THE VALVE TIMING

Engines : BFZ - LFX - RGX (continued)

SETTING THE VALVE TIMING

- Fit the tension measuring tool to the middle of the belt strip «c».

- Turn the tensioner roller (2) (anti-clockwise direction) using the tool 7017-T.W to obtain the following

measurements :

- Engines : LFZ - LFW : 30 ± 2 SEEM units.

- Engines : RGX - RFU : 16 ± 2 SEEM units.

- Tighten the screw (1) to 2m.daN.

- Remove the tools.

- Rotate the crankshaft by two turns (do not turn backwards).

- Check the setting by positioning the pegs at «a» and «b».

- Remove the pegs.

CHECKING THE TENSION

- Rotate the crankshaft by two turns (do not turn backwards).

- Peg the camshaft pulley at «a».

- Fit the tension measuring tool on the belt strip at «c».

- The tension measurement should be 44 ± 2 SEEM units.

(If the measurement is not correct, repeat the tensioning procedure).

- Remove the tools.

B1EP07SC

Page 94

ENGINE

87

CHECKING AND SETTING THE VALVE TIMING

Engine : LFY - RFV # 11/97

TOOLS

- Belt tension measuring instrument. : 4099-T or 4122-T

- Crankshaft locating peg : 7014-T.N.

- Camshaft pulley locating peg. : 9041-T.Z. Tool kit 7004-T

- Tensioning tool : 7017-T.W.

- Toothed sector for locking the flywheel XM : 6012-T

- Toothed sector for locking the flywheel XANTIA : 9044-T

CHECKING THE SETTING

- Turn the engine by the crankshaft screw (1).

- Ensure that the slot (a) for pegging the camshaft hubs can be seen (Conformity of hubs).

- Turn the engine by the screw (1) and peg the crankshaft at (2).

ESSENTIAL : Check that the crankshaft DAMPERS pulley is in good condition.

If the hub/pulley markings do not line up, the crankshaft pulley must be replaced.

- Peg the camshaft pulleys at (3). (The locating pegs should slide in easily).

If this is not the case :

- Check that the crankshaft pegs can be engaged correctly.

-Slacken the six screws (4) of pulleys (7) and (8).

-Peg the hubs at (3). (If necessary, turn the camshaft by the screw (5)).

-Tighten the screws (4) to 1 m.daN.

-Remove the pegs.

B1EP08KCB1EP08JC

Page 95

ENGINE

88

CHECKING AND SETTING THE VALVE TIMING

Engines : LFY - RFV # 11/97 (continued)

SETTING THE VALVE TIMING

- Peg the crankshaft at (2).

- Peg the camshaft pulleys at (3).

- Loosen the tensioner roller (6).

- Remove the belt..

PREPARATION

- Loosen the three screws (4) of pulleys (7) and (8).

- Ensure that the pulleys (7) and (8) move freely on the hubs.

If this is not the case :

- Remove the pulleys (7) and (8).

- Clean the contact faces of pulleys (7) and (8) and of the camshaft hubs at (b).

- Fit the pulleys (7) and (8) onto the hubs, without tightening them.

NOTE : Pulleys (7) and (8) are identical.

(Timing angles, see pages: 118 (LFY) - 119 (RFV)

LFY and RFV engines = The camshaft hubs are different.

REFITTING THE TIMING BELT

- Fit the belt on the pulley (7).

- Fit a plastic clamping collar (c) to hold it in place.

- Wind the belt around the : pulley (8), roller (9), pinion (10), water pump (11) and

tensioner roller (6).

B1EP08LC

B1EP08UCB1EP11UC

LFY

RFV

Page 96

ENGINE

PRE-TENSIONING THE TIMING BELT

- Fit the tool 4122-T.

- Turn the roller (6) with the tool 7017-T.W.

Pre-tension to :

- Tighten the roller (6) to 2 m.daN, and the six screws (4) to 1 m.daN.

- Remove the tool 4122-T, the pegs (3)and the plastic clamp at “c”.

- Fit the timing cover (12), the pulley (13), the screw (1) (LOCTITE

E6 on the threading, tighten to 12 m.daN).

89

CHECKING AND SETTING THE VALVE TIMING

Engines : LFY - RFV # 11/97 (continued)

LFY RFV

B1EP11VC B1EP08VC

Engines LFY - RFV

45 SEEM unitsNew belt

Page 97

ENGINE

90

CHECKING AND SETTING THE VALVE TIMING

Engines : LFY - RFV # 11/97 (continued)

RFVLFY

B1EP11WC B1EP08WC

TENSIONING THE TIMING BELT

- Rotate :

Engines LFY - RFV = 2 turns of the crankshaft.

- Peg the crankshaft at (2).

- Loosen the six screws (4) of pulleys (7) and (8).

- Peg the hubs at (3).

(If necessary, turn the camshaft by the screw (5)).

- Desserrer le galet (6).

- Poser l’ortil 4122-T.

- Effectuer une tension de :

- Tighten the roller (6) to 2 m.daN.

- Remove the tools.

Engines LFY - RFV

26 SEEM unitsNew belt

Page 98

ENGINE

91

CHECKING AND SETTING THE VALVE TIMING

Engines : LFY - RFV # 11/97 (continued)

SETTING THE VALVE TIMING (Cont.)

- Rotate the crankshaft by 2 turns.

- Peg the crankshaft at (2).

- Loosen the screws (4).

- Peg the hubs of pulleys (7) et (8) at (3).

(If necessary, turn the camshaft using the screw (5)).

- Tighten the screws (4) to 1 m.daN.

- Remove the pegs.

CHECKING THE BELT TENSION

- Rotate the crankshaft by 1/4 turn to align the locating peg hole (2) of the pulley (13), with the screw (14).

(Do not turn backwards).

- The tension measurements must be between:

If the measurements are different, repeat the tensioning procedure.

B1EP08KCB1EP08XC

Engines LFY - RFV

36

±4 SEEM unitsNew belt

Page 99

ENGINE

92

CHECKING AND SETTING THE VALVE TIMING

Engine : LFY - RFV 11/97 #

TOOLS

- [1] Belt tension measuring instrument : 4122-T

- [2] Camshaft locating peg : 9041-T.Z

- [3] Crankshaft locating peg : 7014-T.N

Tool kit 7004-T

- [4] Camshaft pulley locking peg : 4200-T.G

- [5] Tensioning tool : 7017-T.W

- [6] Toothed sector for locking the flywheel : 9044-T

CHECKING THE SETTING

- Turn the engine using the crankshaft screw (1).

- Peg the crankshaft using the tool [3].

ESSENTIAL : Check that the crankshaft DAMPERS pulley is in good condition.

If the hub/pulley markings do not line up, the crankshaft pulley must be replaced.

- Peg the camshafts using the tool [2].

(The locating pegs [2] should slide in easily).

- If this is not the case, set the timing.

NOTE : Camshaft hubs (See page 120).

B1EP12GCB1EP12FC

Page 100

ENGINE

93

CHECKING AND SETTING THE VALVE TIMING

Engines : LFY - RFV 11/97 # (continued)

SETTING THE VALVE TIMING.

- Peg the crankshaft using tool [3].

- Peg the camshaft pulleys using tool [2].

- Lock the flywheel using the tool [6].

REMOVE :

- The peg [3].

- The screw (4) (Brush the screw thread).

- The pulley (5).

- The lower cover (6).

REFIT :

- The pulley (5).

- The screw (4) (Tighten moderately).

- The peg [3].

REMOVE :

- The tool [6].

- The studs (8).

- Fit the tool [4].

- Loosen the screws (10).

- Remove the tool [4].

- Slacken the tensioner roller (7).

- Remove the belt (9).

B1EP11XC

B1EP11ZCB1EP120C

RFVLFY

Loading...

Loading...