Cissell IPSO RI Installation Manual

IPSO - LSG n.v.

Nieuwstraat 146 - B-8560 Wevelgem (België)

Tel. 056/41 20 54 - Fax 056/41 86 74

Technical specifi cations

Installation instructions

Operating instructions

Maintenance

Instruction manual

IPSO RI 800-16

Part No. D0163

General Information

Dear Customer,

Please read the instructions for use before first using your ironing machine. These

instructions provide important information on safety, use and maintenance of your appliance.

They will protect you and prevent damage to the appliance. Keep these instructions for use in

a safe place and pass them on to any subsequent owners.

This ironer is a domestic appliance and is not intended for commercial industrial use.

Transport damages

Check the appliance for transport damages immediately. If the appliance has been damaged,

do not put the appliance into operation in case of doubt, but contact the dealer or supplier.

Disposal of the transport packaging

The packaging protects the appliance from transport damages. Environmental compatibility

and waste disposal are taken into account when selecting the packaging material; it is

therefore recyclable. Recycling the packaging saves on raw materials and reduces waste.

Please contact your local council for information on your nearest disposal point; otherwise,

your specialist dealer will also accept the packaging.

Disposal of your old appliance

The old appliance must be made unusable before scrapping, in other words, the power supply

cord must be removed.

All plastic parts are marked with standard international abbreviations, allowing easy sorting

and environmentally-aware recycling when disposing of the appliance. Please contact your

local council for information on your nearest disposal point; otherwise, your specialist dealer

will also accept the old appliance.

Technical assistance

In the event of queries and requests for technical information and in the event of faults or if

you need a spare part for your appliance, please contact the service point specified in the

warranty documents.

Please state the precise appliance designation and the serial number, to enable us to help

you quickly.

The cotton cover of the ironing roller and the pilot light in the main switch are so-called

wearing parts and are not included in the warranty.

2

DESCRIPTION

The ironer can iron and press. During ironing the roll turns, during pressing the roll is stationary.

The footswitch has two working functions and one stationary fonction.

In the working position, the ironing plate is swung in, so you can iron or press.

In the idle position, the ironing plate is swung away and the roll is stationary.

The roller has a complete forwards free movement.

The roller is hung up at one side and free at the other.

The rotation of the roll is driven by an electric motor.

The ironing plate is installed on the pressure arm, which by pressing the footswitch moves towards

the roll and by releasing away from the roll.

The movement of the ironing plate is operated by a motor and a gearwheel drive.

The motor for rotating the roller is installed in the head of the roll.

The motor for the tension and releasing is put in in the baseplate.

At the left side of the finger guard, a microswitch is installed for the automati swining away of the

ironing plate.

The footswitch has two microswitches to command the printed circuit board which is installed in the

head of the roll.

In the baseplate you can find two switches to command the roll to swing in and out.

On the ironinghead there is a button to regulate the speed of the rotation.

_________________________________________________________________________________________

Rotary ironer RI800-16 Technical data for customer service 04/2005

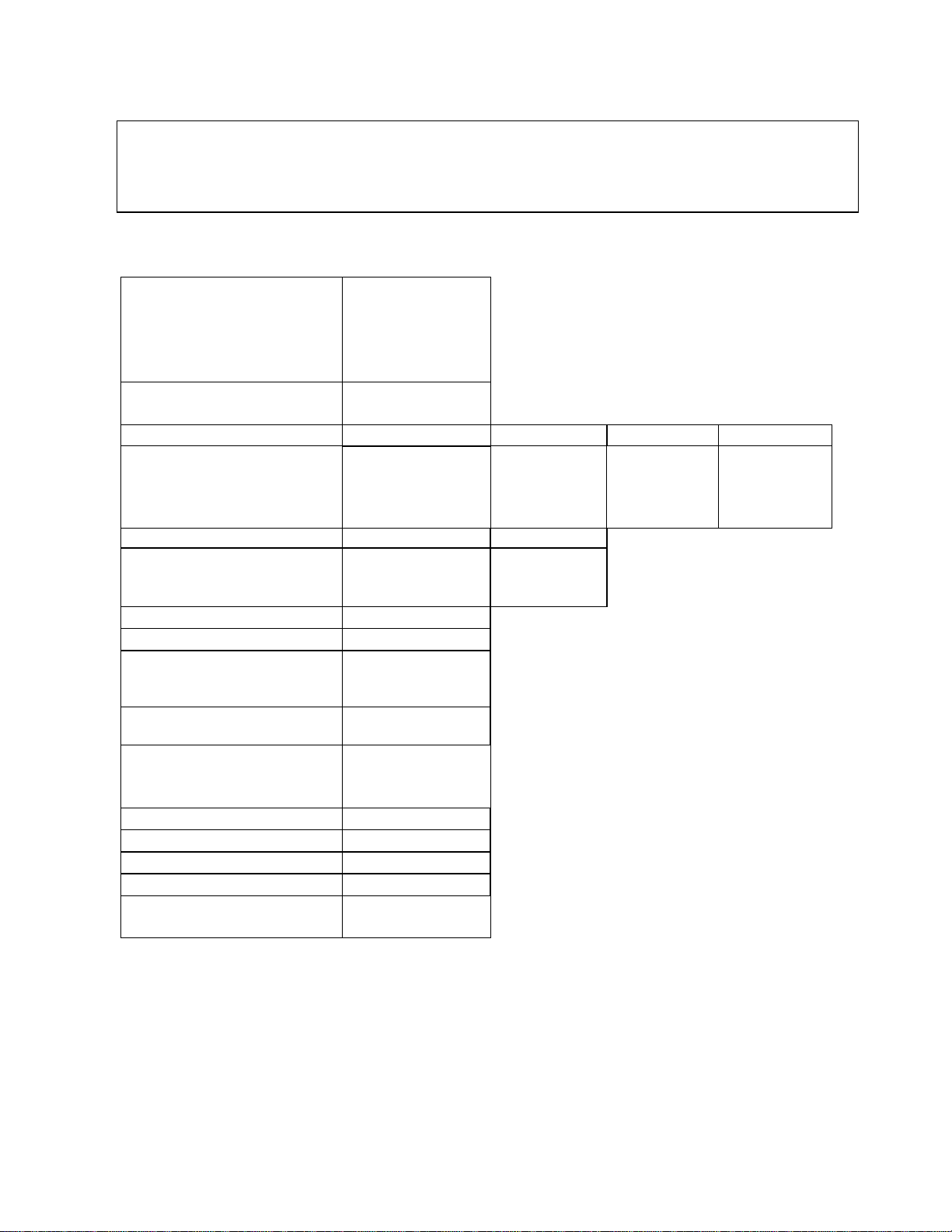

TECHNICAL INFORMATION

Standards EN60335-2-44

EN55014-1

EN55014-2

EN61000-3-2

EN61000-3-3

Characteristics VDE-GS

VDE-EMC

Electrical connection 2780 Watt 220-240V 50 Hz 16 A

Dimensions Total height Total depth Total length

Working position ca 1020 mm ca 390 mm ca 980 mm

Folded ca 1060 mm ca 390 mm ca 590 mm

Weigth ca 46 Kg

Height (up to the lower part of

the base plate)

Roller Length ca 855 mm

Roller Diameter ca 160 mm

Roller Pressure ca 17.5kg + 0.5kg

Rotation Min 8 – max 15

Distance between 35 - 40 mm

Ironing plate and roller

(swung away)

Quantity of thermostats 2 pcs

Heating element 1 x 2580 W

Motor load 150 W / 130 W

Transmission 1 : 422 / 1 : 85

On/Off switch (rocker switch) 0 - 1 with

red pilot light

ca 640 mm

per mm laundry

thickness

r/pm

_________________________________________________________________________________________

Rotary ironer RI800-16 Technical data for customer service 04/2005

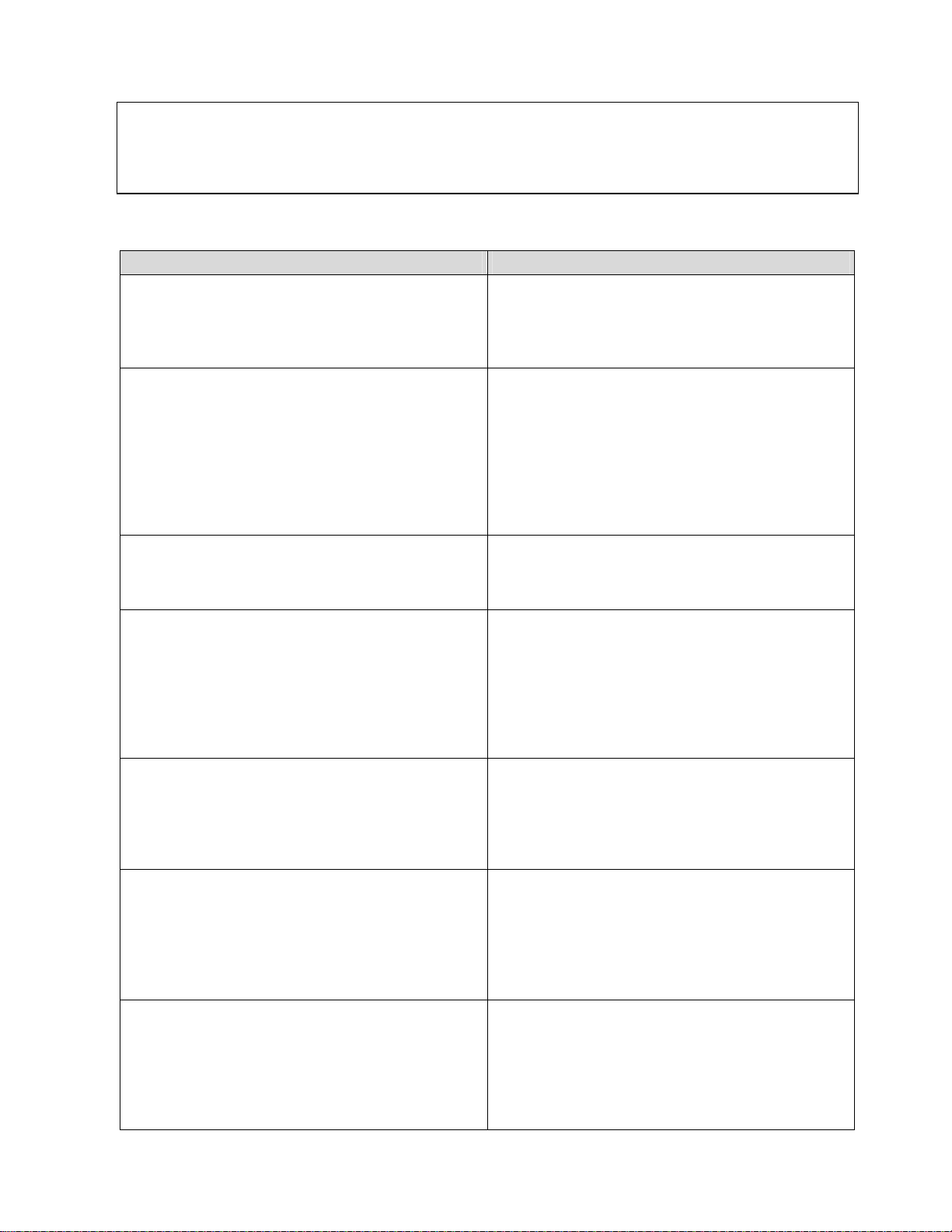

FAULTS

FAULT SOURCE

The temperature of the ironing plate does not

correspond with the indicators on the temperature

selectors

The ironing plate does not heat up

Does not iron equally along the whole length

The pressure of the ironingplate is too low.

During ironing, the roll is too noisy

The roll does not rotate during ironing

Ironing plate does not close

_________________________________________________________________________________________

Rotary ironer RI800-16 Technical data for customer service 04/2005

1. Thermostat defect – to be replaced

2. Temperature sensor is not close enough

to the ironing plate.

1. The thermostat is on "cold“

2. The rocker switch is set to "0“

3. The electrical connection is interrupted

4. Rocker switch defect – to be replaced

5. Thermostat defect – to be replaced

6. Heating element defect

7. Fuse defect – to be replaced

1. Check the tension of the ironing plate and

the parallelism with the roll

1. Check the adjustment of the ironing plate

and the parallelism with the roll

2. Motor for swinging the ironing plate is

defect

3. Microswitch on the pressure arm switches

to soon

1. Rollermotor defect

2. Check correct placement of the roller

3. Bearing in the roller defect

4. Gearwheeldrive defect

1. Check roll and fixation of the roll.

2. Microswitch in footswitch does not function

3. Check the connections on the PCB

4. Check the gearwheeldrive

5. Bearing the roll defect

1. Microswitch of the fingerguard is defect

2. Finger guard does not lay on the

microswitch in resting position

3. Check the connection on the printed circuit

board

The closing of the ironingplate does not function

when the footswitch is activated.

Roller rotates even when the footswitch is not

activated.

The ironingplate rests against the roll when the

footswitch is not activated.

1. Rocker switch on “0“

2. The electrical connection is interrupted

3. Microswitch in footswitch defect

4. Check connection of the cable in the

footswitch and the rollerhead.

5. Motor in ironing plate defect

6. Gearwheel drive defect

7. Lever on the pressure arm defect

1. Microswitch on the pressure arm defect

2. Footswitch defect

3. Printed circuit board defect

1. Spring on the pressure arm is defect

_________________________________________________________________________________________

Rotary ironer RI800-16 Technical data for customer service 04/2005

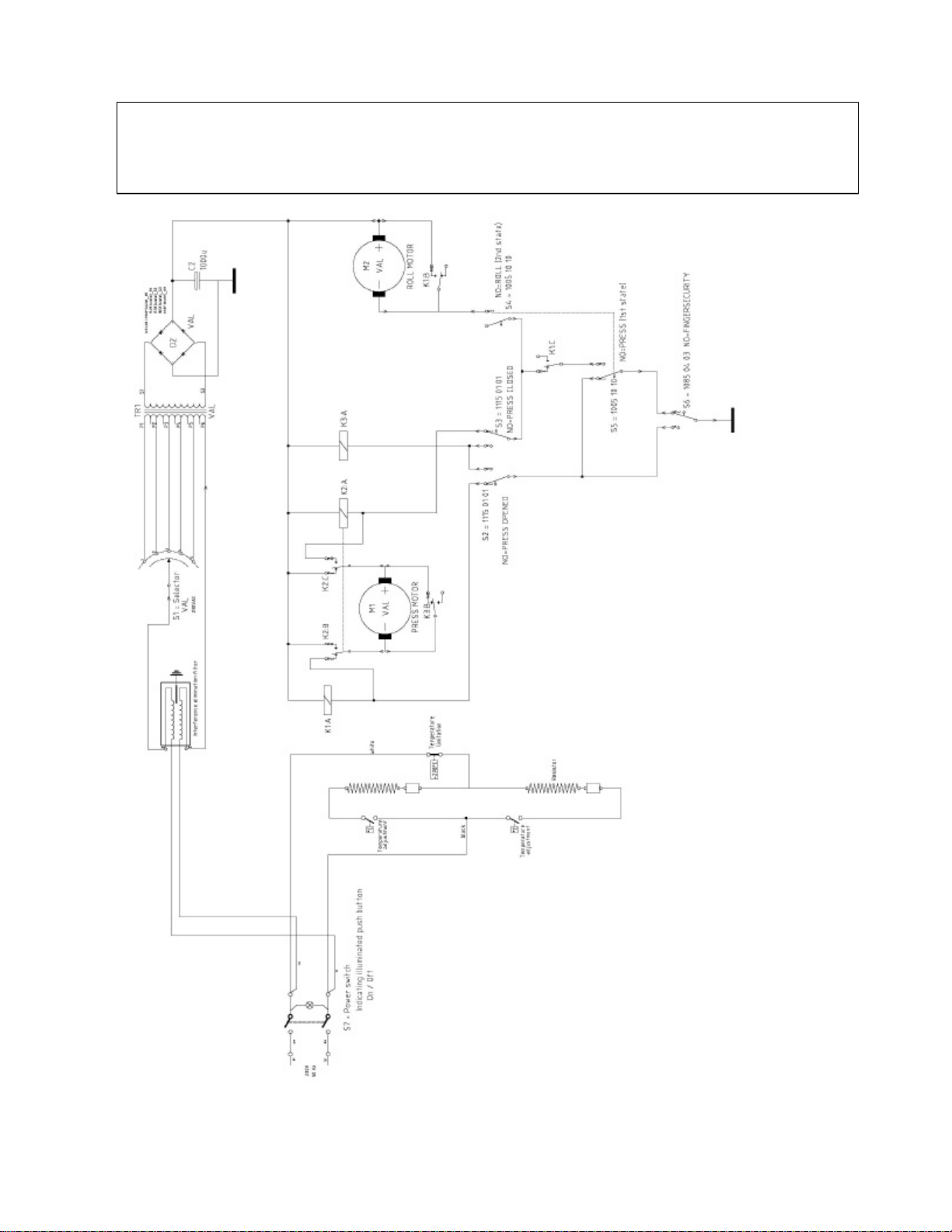

ELECTRICAL DIAGRAM

_________________________________________________________________________________________

Rotary ironer RI800-16 Technical data for customer service 04/2005

Loading...

Loading...