Cissell IPH100H Installation Manual

IPSO USA,

Part No. D0001

PO Box 188

Fort Mill, SC 29716

t: 803.548.8127

f: 803.548.8129

Ipso Installation Manual

(All Hard and Soft Mount Washer Extractors)

an company www.laundry-systems-group.com

Contents

WE Models

Electrical Specifications-----------------------Section 1

Breaker Chart-----------------------------------Section 1

Surface, Anchors and Mounting--------------Section 2

Clearances----------------------------------------Section 3

Warnings-----------------------------------------Section 3

Install Kits----------------------------------------Section 4

Bolt Hole Patterns-------------------------------Section 4

General Dimensions ----------------------------Section 5

Concrete Requirements-------------------------Section 5

HW Models

Electrical Specifications------------------------Section 6

Breaker Chart------------------------------------Section 6

Surface, Anchors and Mounting---------------Section 7

Clearances----------------------------------------Section 7

Bolt Hole Patterns-------------------------------Section 8

General Dimensions-----------------------------Section 8

HF Models

Electrical Specifications------------------------Section 9

Breaker Chart------------------------------------Section 9

Surface, Anchors and Mounting---------------Section 10

Clearances----------------------------------------Section 10

Bolt Hole Patterns-------------------------------Section 11

General Dimensions-----------------------------Section 12

IPH Models

Electrical Specifications------------------------Section 13

Breaker Chart------------------------------------Section 13

Surface, Anchors and Mounting---------------Section 14

Install Kits-----------------------------------------Section 14

Bolt Hole Patterns--------------------------------Section 16

General Dimensions and Clearances-----------Section 16

Electrical Specifications

Circuit Breakers

All Ipso machines are to be connected to individual common trip circuit breakers. Use

only UL 489 rated circuit breakers. Fuses are not to be used in any installations. (Fuses

may fail separately causing a single-phase voltage condition). A single-phase condition

will cause the other lines to have a considerable change in current draw suddenly, which

may cause the inverter or drive motor to fail. Do not install more than one machine per

breaker and do not install any other equipment on the breaker supplying the machine.

Grounding

All equipment should be grounded with a proven earth ground. Do not use water pipes or

electrical conduit as an earth ground path. All grounding and wiring must conform to

local and national electrical code.

Wire Size

Wire size must meet or exceed all codes for breaker size.

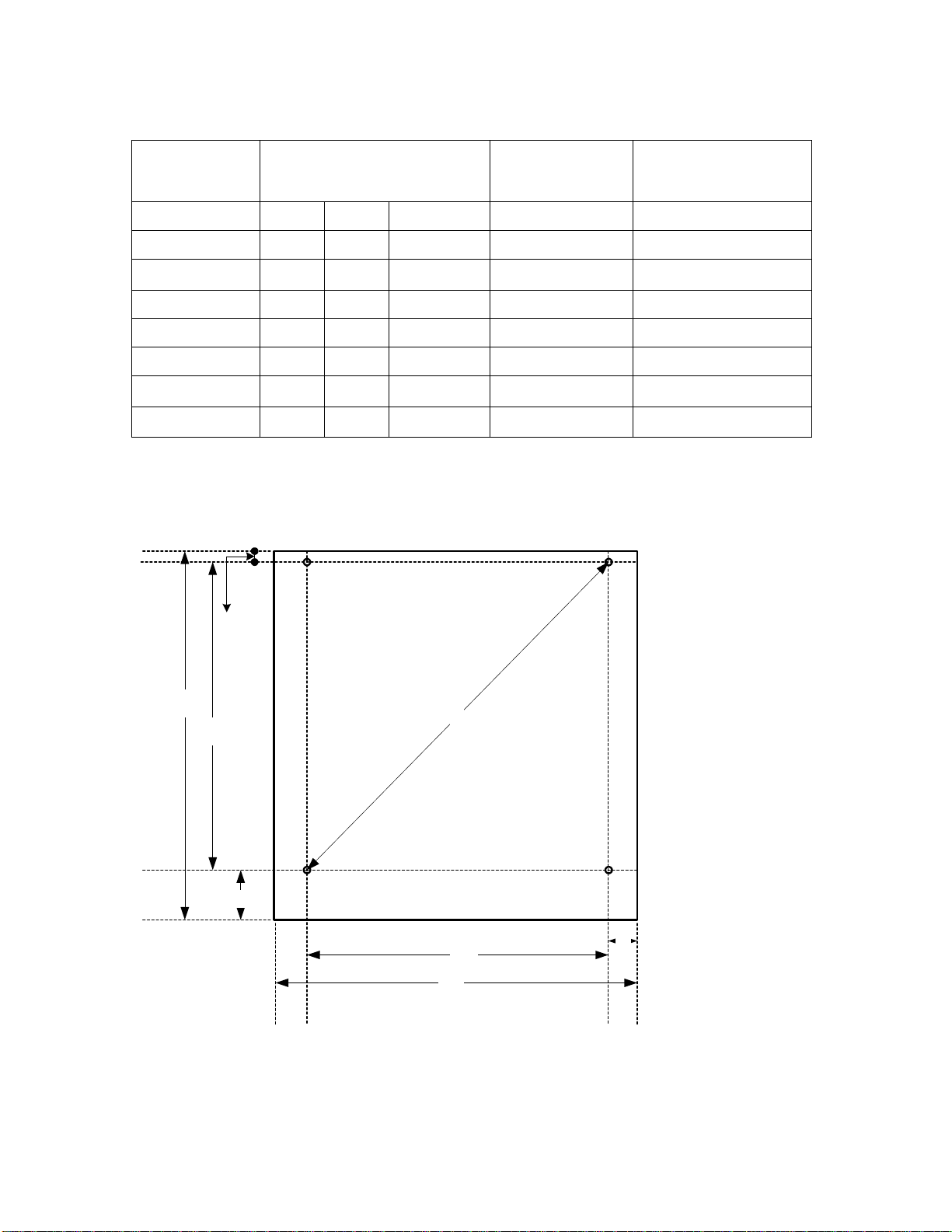

IPSO - WE, HW, HF MODELS

t

Electrical Breaker Char

Model Model

3 phase 208 / 60 / 3 240 / 60 / 3 480 / 60 / 3 Single Phase 115 / 60 / 1 208 / 60 / 1 240 / 60 / 1 480 / 60 / 1

Special Order Special Order

WE 73 15 AMP 15 AMP WE 73 30 AMP 20 AMP 20 AMP

WE 95 15 AMP 15 AMP WE 95 N/A 25 AMP 25 AMP

WE 165 20 AMP 20 AMP WE 165 N/A 30 AMP 30 AMP

WE 181 20 AMP 20 AMP WE 181 N/A 30 AMP 30 AMP

WE 233 N/A N/A WE 181 N/A 20 AMP *** 20 AMP ***

WE 234 WE 233 N/A 20 AMP*** 20 AMP***

WE 234 N/A N/A N/A

WE 304 N/A 20 AMP *** 20 AMP ***

HW 55 N/A N/A HW 55 N/A 15 AMP *** 15 AMP ***

HW 72 N/A N/A HW 72 N/A 15 AMP *** 15 AMP ***

HW 76 N/A N/A HW 76 N/A 15 AMP *** 15 AMP ***

HW 94 N/A N/A HW 94 N/A 15 AMP *** 15 AMP ***

HW 131 N/A N/A HW 131 N/A 15 AMP *** 15 AMP ***

HW 164 N/A N/A HW 164 N/A 15 AMP *** 15 AMP ***

HF 176 N/A N/A HF 176 N/A 20 AMP *** 20 AMP ***

HF234 N/A N/A HF234 N/A 20 AMP *** 20 AMP ***

HF 304 20 AMP *** 20 AMP *** HF 304 N/A N/A N/A

HF 455 30 AMP *** 30 AMP *** HF 455 N/A N/A N/A

HF 575 30 AMP *** 30 AMP *** HF 575 N/A N/A N/A

HF 730 40 AMP *** 40 AMP *** HF 730 N/A N/A N/A

3/22/2004

*** Inverter Drive

Installation Instructions For Ipso “WE” Models

Surface

These machines must be securely anchored on a solid, flat reinforced concrete surface

capable of withstanding the weight of the machine and the considerable forces generated

during the spin/extract cycle. Surface should be a high quality concrete (minimum

3000psi test strength) and at least 6” in thickness for the WE 73 thru the WE 165, and a

thickness of at least 8” for the WE181 thru the WE304. The surface shall be clean, flat

and free of irregularities.

Anchors

We recommend the use of “Hilti” brand, or equivalent expansion bolt, chemical adhesive

anchor, or “J” bolts for installing Ipso washer extractors.

Mounting

On Base

If a metal base is to be used on the concrete to raise machine, position metal base in

location that the machine will be installed, being sure to follow clearance guidelines.

Mark and drill holes as dictated by the anchoring method and the anchors types being

used, in the concrete surface at the places provided in the metal base. Re-position metal

base over the holes. Raise the metal base ½” – ¾” to allow for grouting. Install anchors in

place but do not tighten. Using a high quality machinery grout, force grout between the

concrete surface and the metal base until all voids are filled. Before grout has set and

become stiff, carefully lower the base into the wet grout. When grout is fully hardened,

install lock washers and nuts on anchors. Tighten the nuts in even increments using a

diagonal pattern. Place machine on metal base and shim as needed to ensure solid contact

between base and machine frame. There should be no gap between the base and the

frame. To achieve this place, thin sheet metal shims between the base and the frame

lengthwise from bolt to bolt. (* Note all bolt holes must be used to anchor machines. On

WE 233, WE 234, and WE 304 models, pay particular attention to the mounting holes in

the center cross brace.) After machine has been in place and operated for one day

retighten anchors in same manner as before.

On Concrete

If the machine is to be mounted directly on the concrete floor, position the machine being

sure to allow for clearances. Mark and drill holes as dictated by anchoring method and

anchor types used. Reposition machine over the holes. Raise the machine ½” – ¾” to

allow for grouting. Install anchors in place but do not tighten. Using a high quality

machinery grout, force grout between the concrete surface and the base until all voids are

filled. Before grout has set and become stiff, carefully lower machine into the wet grout.

When grout is fully hardened, install lock washers and nuts on anchors. Tighten the nuts

in even increments using a diagonal pattern. After machine has been in place and

operated for one day retighten anchors in same manner as before.

Clearances

For easy maintenance it is recommended to keep a minimum of 24” between the wall and

the back of the machine. If several machines are placed next to each another, there should

be a minimum of 1” between each machine.

Warnings

Always mount these machines on a solid, stable, ground floor.

Never install a hard mount washer-extractor on an above ground floor or over a

basement.

Any failure to follow all guidelines may result in the void of all warranties.

WE INSTALL KITS

WE73 & WE95-TIMER CONTROLLED

CWE73/95 NON COMP INSTALL KIT NUMBER 1 PER MACHINE

INSTALL KIT CONTAINS:

C6242 BOLTS 5/8X6 ANCHOR BOLTS 4 EACH

C5/8 LOCK WASHER 5/8 LOCK WASHERS 4 EACH

C5/8-WASHER 5/8 FLAT WASHERS 25 EACH

CH-101 INLET HOSE 5’X3/8 2 EACH

CGSW-300 WASHER INLET HOSE 4 EACH

WE73 & W395-MICROPROCESSOR

CWE73/95 COMPUTER INSTALL KIT NUMBER 1 PER MACHINE

INSTALL KIT CONTAINS:

C6242 BOLTS 5/8X6 ANCHOR BOLTS 4 EACH

C5/8 LOCK WASHER 5/8 LOCK WASHERS 4 EACH

C5/8-WASHER 5/8 FLAT WASHERS 25 EACH

CH-101 INLET HOSE 5’X3/8 3 EACH

CGSW-300 WASHER INLET HOSE 6 EACH

WE165 & WE181-TIMER CONTROLLED

CWE165 NON COMP INSTALL KIT NUMBER 1 PER MACHINE

INSTALL KIT CONTAINS:

C7565 BOLT ¾ X81/2 ANCHOR BOLTS 4 EACH

C3/4 LOCK WASHER ¾ LOCK WASHERS 4 EACH

C3/4-WASHER ¾ FLAT WASHERS 25 EACH

CH-102 INLET HOSE 5’X1/2 2 EACH

CGSW-300 WASHER INLET HOSE 4 EACH

WE165 & WE181-MICROPROCESSOR

CWE165 COMPUTER INSTALL KIT NUMBER 1 PER MACHINE

INSTALL KIT CONTAINS:

C7565 BOLT ¾ X81/2 ANCHOR BOLTS 4 EACH

C3/4 LOCK WASHER ¾ LOCK WASHERS 4 EACH

C3/4-WASHER ¾ FLAT WASHERS 25 EACH

CH-102 INLET HOSE 5’X1/2 3 EACH

CGSW-300 WASHER INLET HOSE 6 EACH

WE234 & WE304-TIMER CONTROLLED

CWE234/304 NO COMP INSTALL KIT NUMBER 1 PER MACHINE

INSTALL KIT CONTAINS:

C7565 BOLT ¾ X8 ½ ANCHOR BOLTS 6 EACH

C3/4 LOCK WASHER ¾ LOCK WASHERS 6 EACH

C3/4-WASHER ¾ FLAT WASHERS 25 EACH

CH-102 INLET HOSE 5’X1/2 2 EACH

CGSW-300 WASHER INLET HOSE 4 EACH

WE234 & WE304-MICROPROCESSOR

CWE234/304 COMP INSTALL KIT NUMBER 1 PER MACHINE

INSTALL KIT CONTAINS:

C7565 BOLT ¾ X8 ½ ANCHOR BOLTS 6 EACH

C3/4 LOCK WASHER ¾ LOCK WASHERS 6 EACH

C3/4-WASHER ¾ FLAT WASHERS 25 EACH

CH-102 INLET HOSE 5’X1/2 3 EACH

CGSW-300 WASHER INLET HOSE 6 EACH

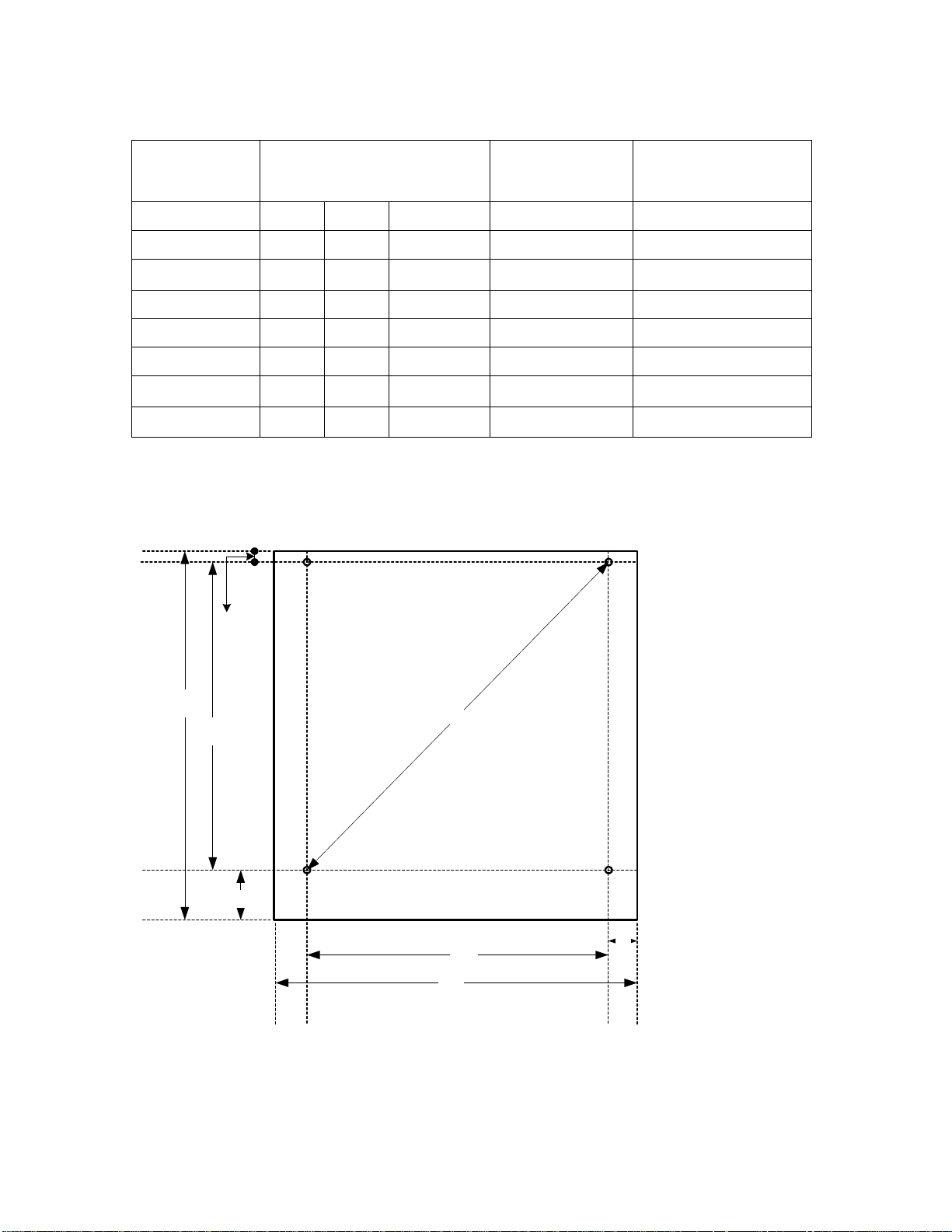

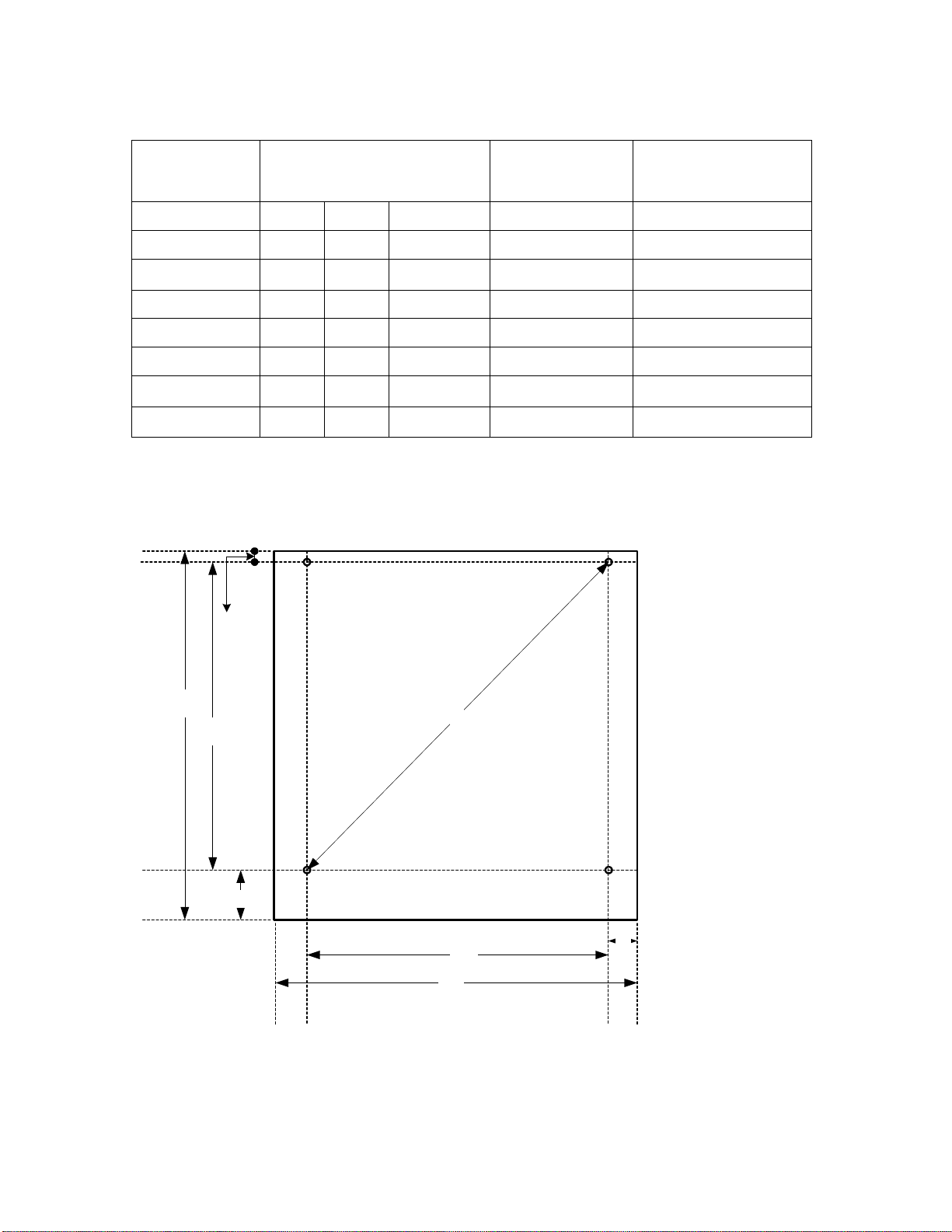

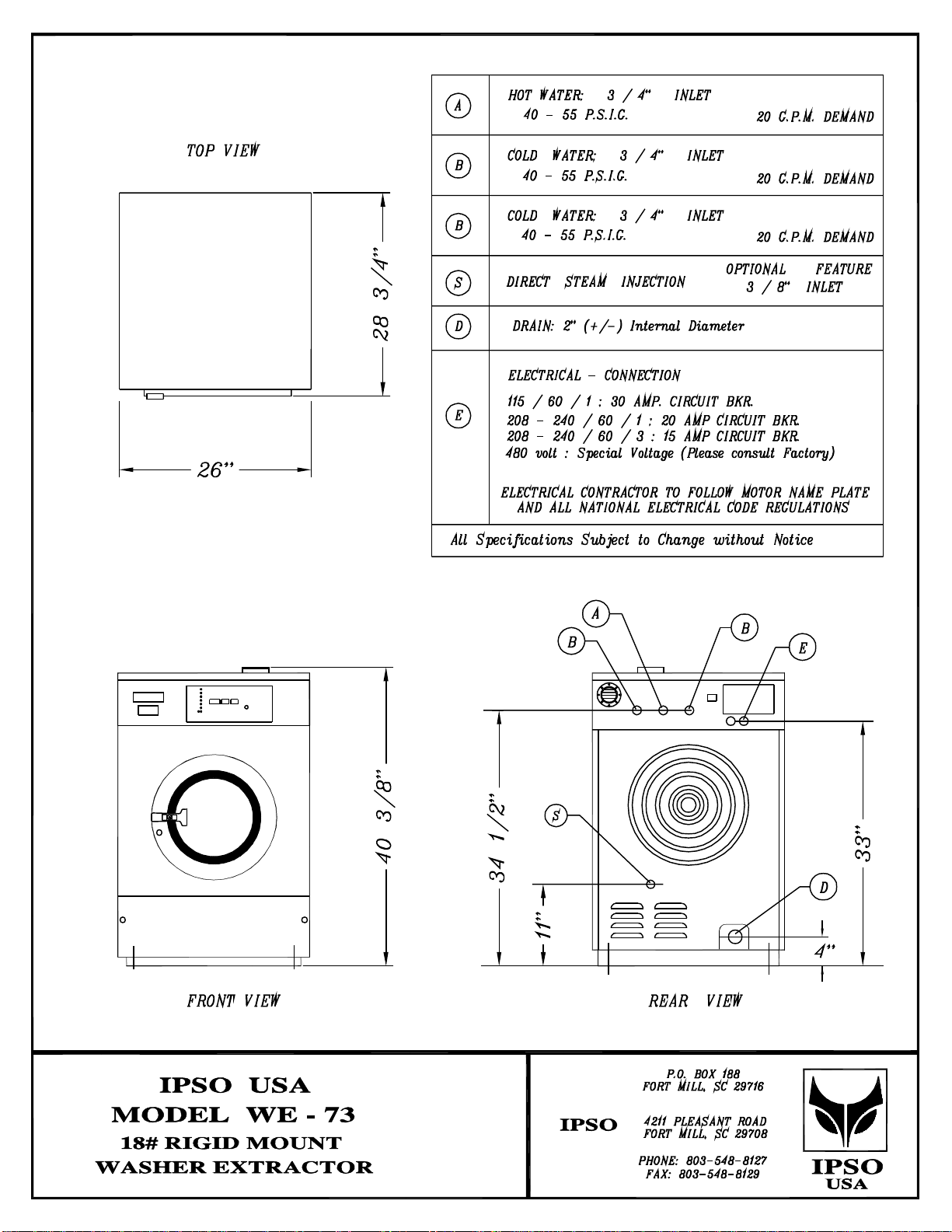

B Model : WE 73

Measurement

Location

A

B

C

D

E

F

G

H

Standard

Measure

Ft In Fraction

Metric

Measure

Inches / Decimals

2 1 31/32 660 mm 25.9843

1 9 21/32 550mm 21.6535

2 5/23 55 mm 2.1654

2 2 3/8 670 mm 26.3780

1 10 1/16 560 mm 22.0472

3 3/8 86 mm 3.3858

1 5/16 24 mm 0.9448

2 6 29/32 785 mm 30. 906

Back of Machine

G

D

E

F

H

B

A

Front of Machine

C

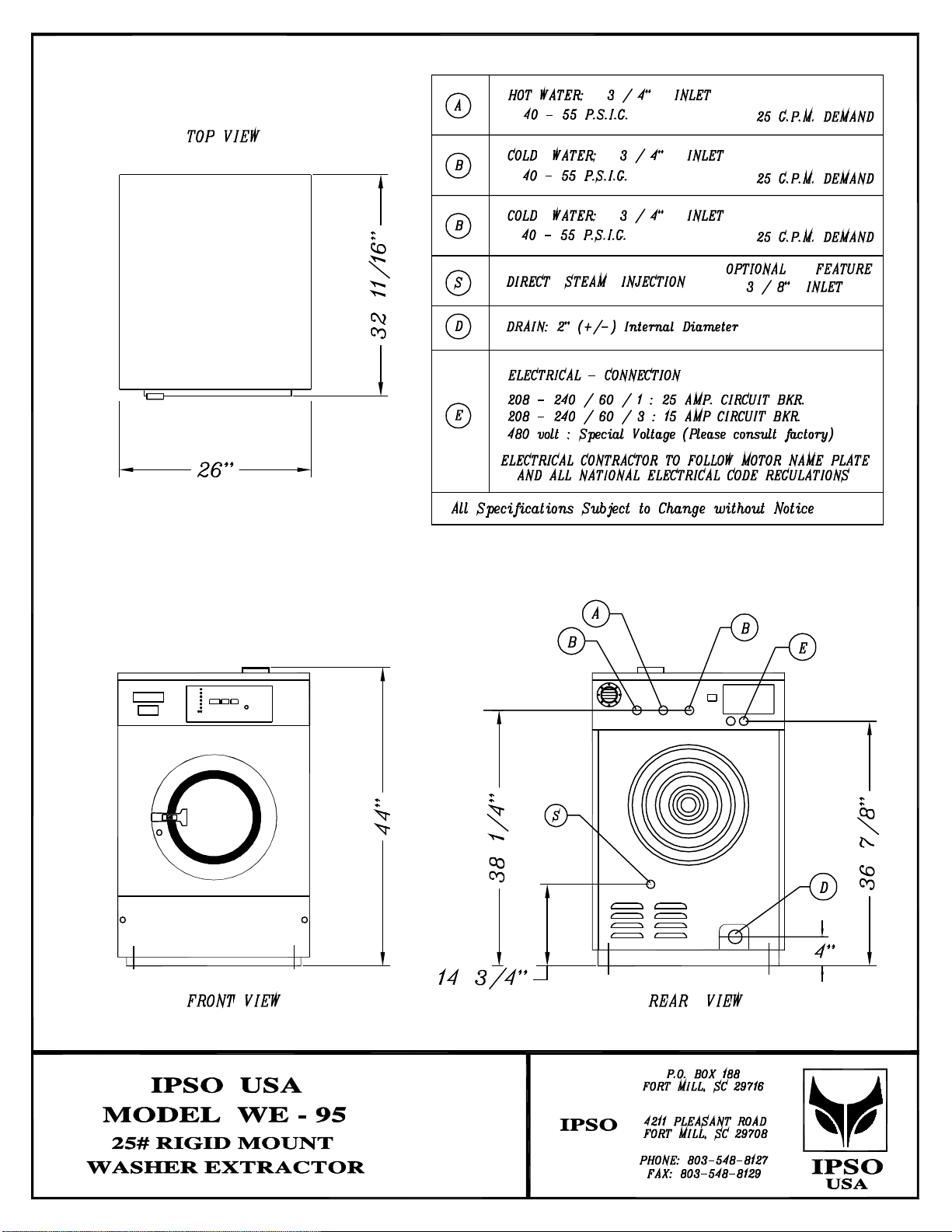

Model : WE 95

Measurement

Location

A

B

C

D

E

F

G

H

Standard

Measure

Ft In Fraction

Metric

Measure

Inches / Decimals

2 1 31/32 660 mm 25.9843

1 9 21/32 550mm 21.6535

2 5/23 55 mm 2.1654

2 6 5/16 770 mm 30.3150

1 10 1/16 560 mm 22.0472

7 5/16 186 mm 7.3228

1 5/16 24 mm 0.9448

2 6 29/32 785 mm 30. 906

Back of Machine

G

D

E

F

H

B

A

Front of Machine

C

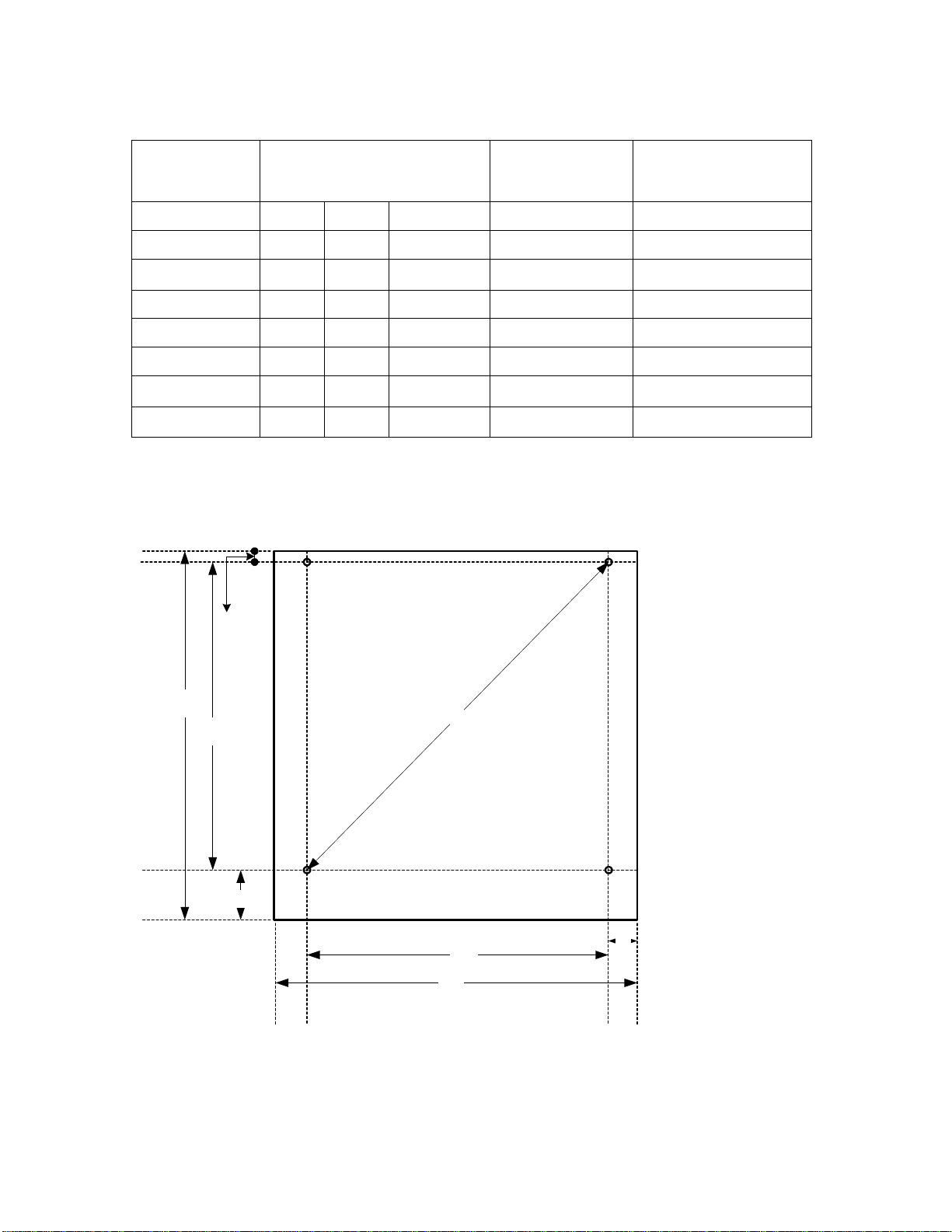

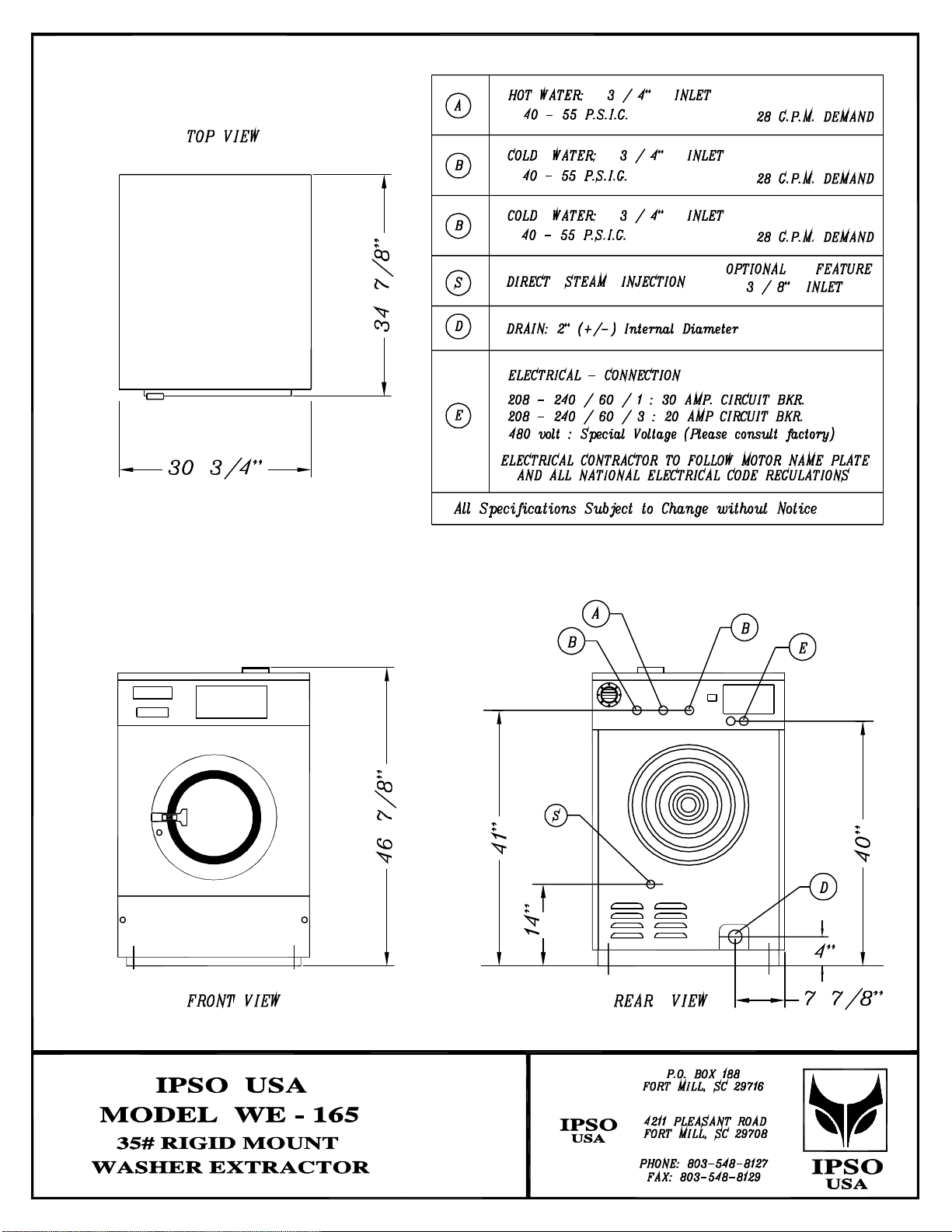

Model : WE 165

Measurement

Location

A

B

C

D

E

F

G

H

Standard

Measure

Ft In Fraction

Metric

Measure

Inches / Decimals

2 6 23/32 780 mm 30.7087

2 1 3/16 640 mm 25.1968

2 3/4 70 mm 2.7559

2 9 27/32 860 mm 33.8583

2 6 5/16 770 mm 30.3150

2 9/16 65 mm 2.5591

31/32 25 mm 0.9843

3 3 7/16 1002 mm 39.4418

Back of Machine

G

D

E

F

H

B

A

Front of Machine

C

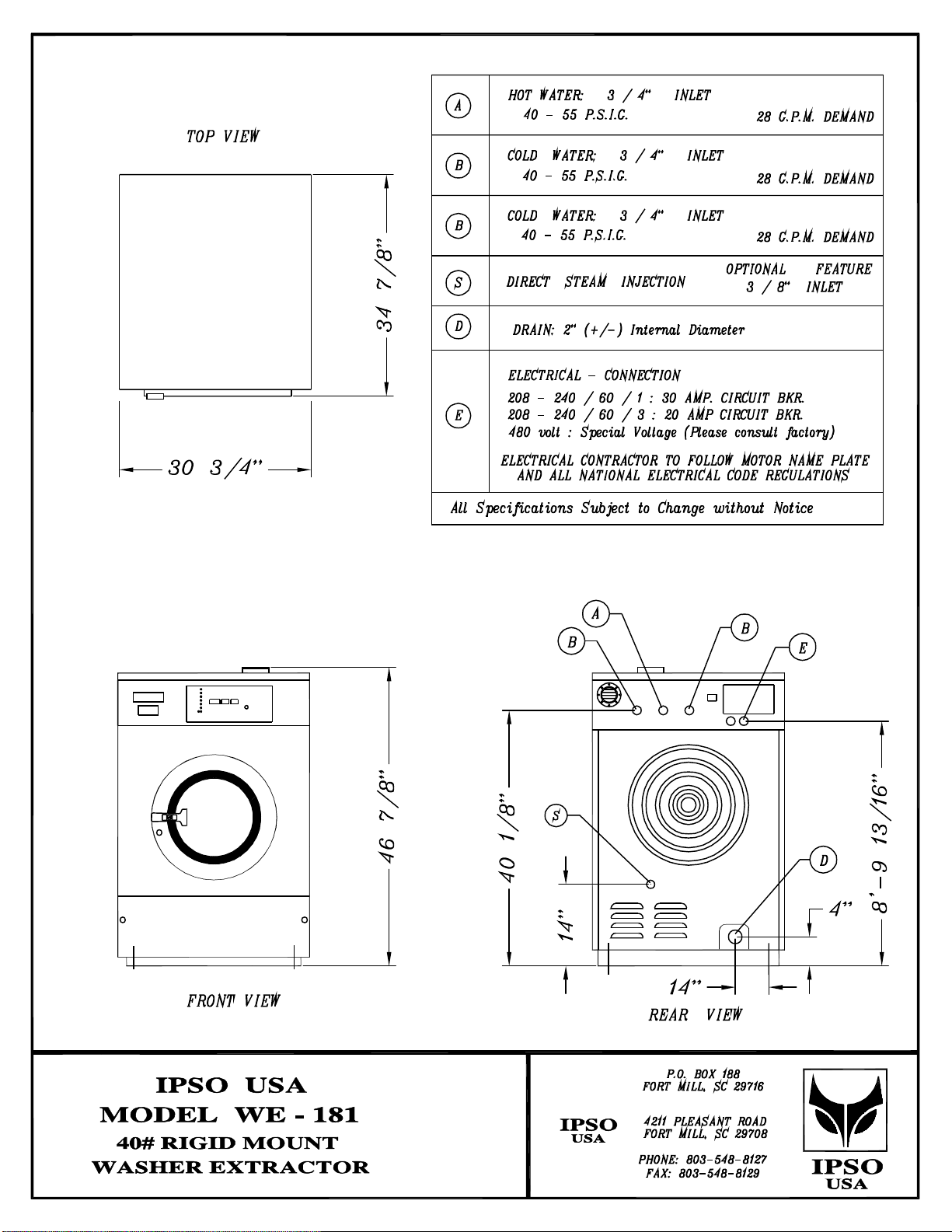

Model : WE 181

Measurement

Location

A

B

C

D

E

F

G

H

Standard

Measure

Ft In Fraction

Metric

Measure

Inches / Decimals

2 6 23/32 780 mm 30.7087

2 1 3/16 640 mm 25.1968

2 3/4 70 mm 2.7559

2 9 27/32 860 mm 33.8583

2 6 5/16 770 mm 30.3150

2 9/16 65 mm 2.5591

31/32 25 mm 0.9843

3 3 7/16 1002 mm 39.4488

Back of Machine

G

D

E

F

H

B

A

Front of Machine

C

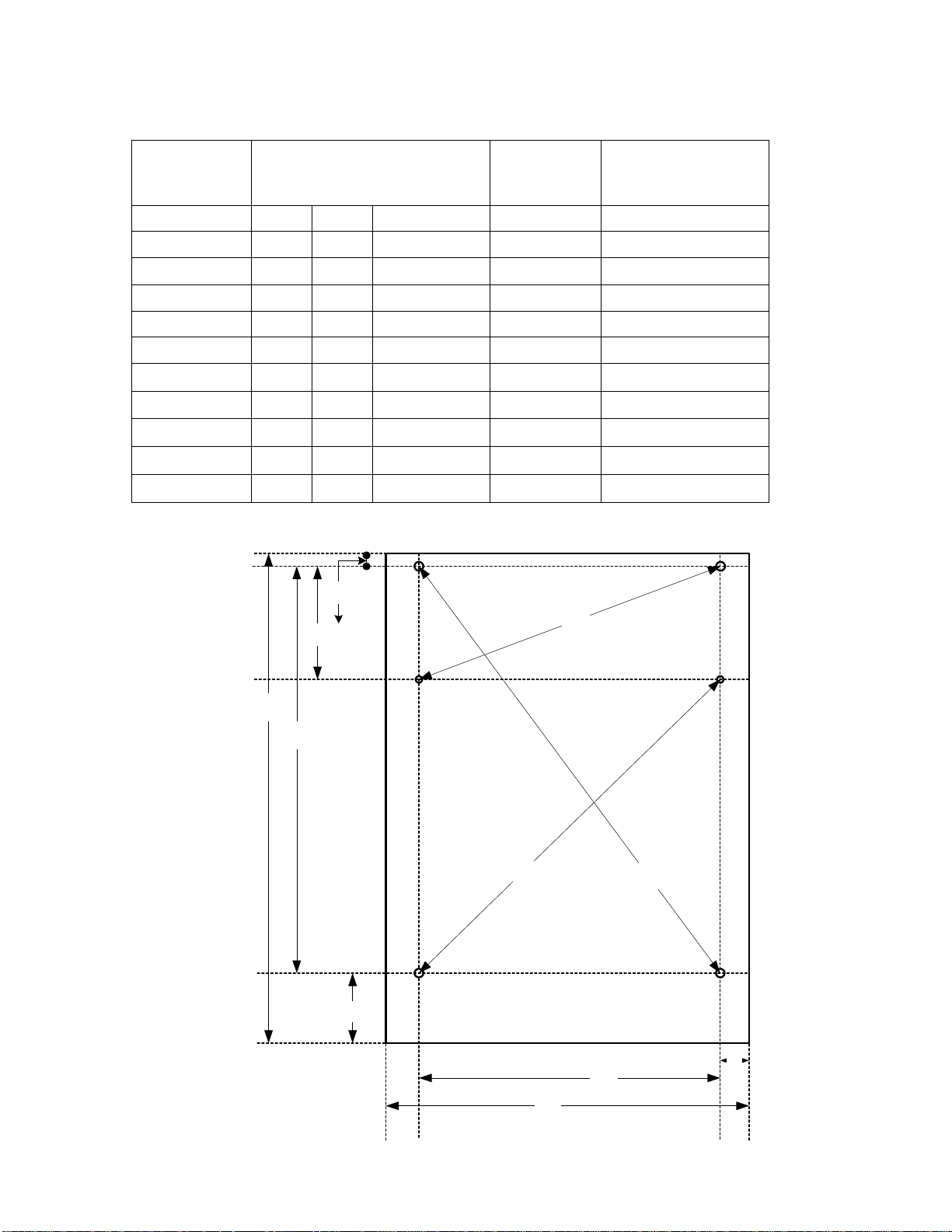

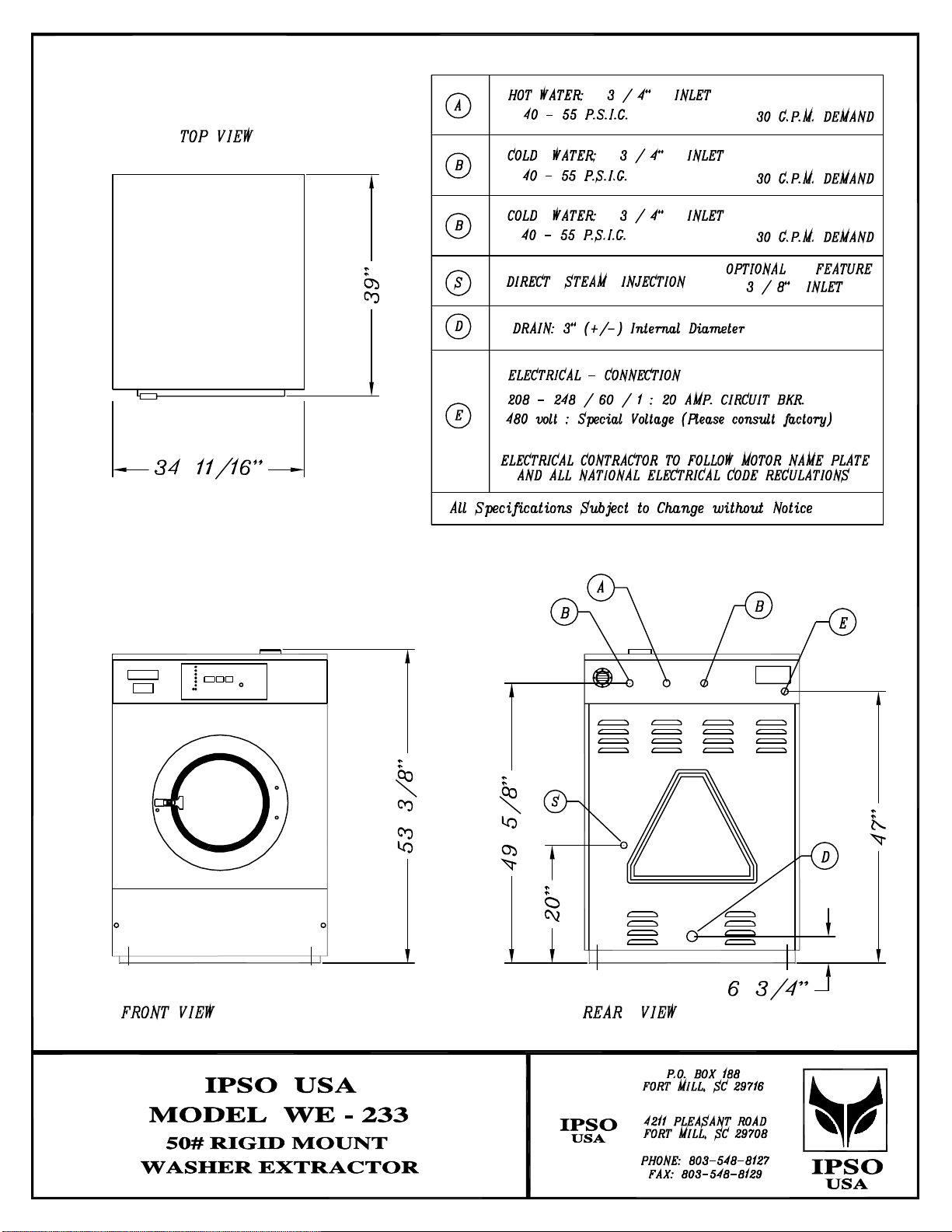

Model: WE 233

Measurement

Location

A

B

C

D

E

F

G

H

I

J

K

Standard

Measure

Metric

Measure

Inches / Decimals

FT In. Fraction

2 9 27/32 860 mm 33.8582

2 2 25/32 680 mm 26.7716

3 17/32 90 mm 3.5433

3 9/16 929 mm 36.5748

2 7 1/2 800 mm 31.4961

11 3/32 282 mm 11.1023

1 31/32 50 mm 1.9685

3 1/8 79 mm 3.1102

2 4 31/32 736 mm 28.9763

3 5 11/32 1050 mm 41.3385

2 9 21/32 855 mm 33.6614

Back of Machine

G

D

F

I

E

K

J

H

C

B

A

Front of Machine

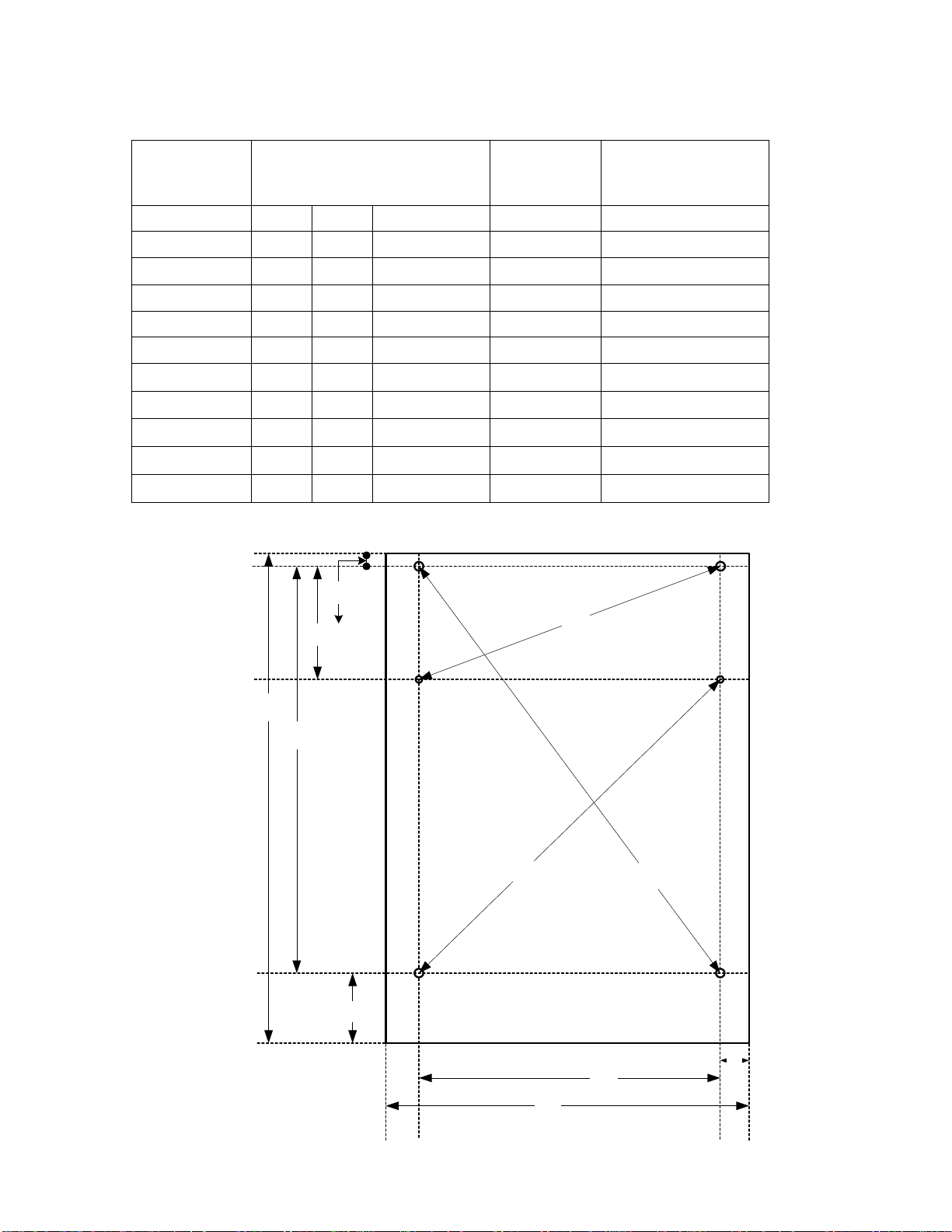

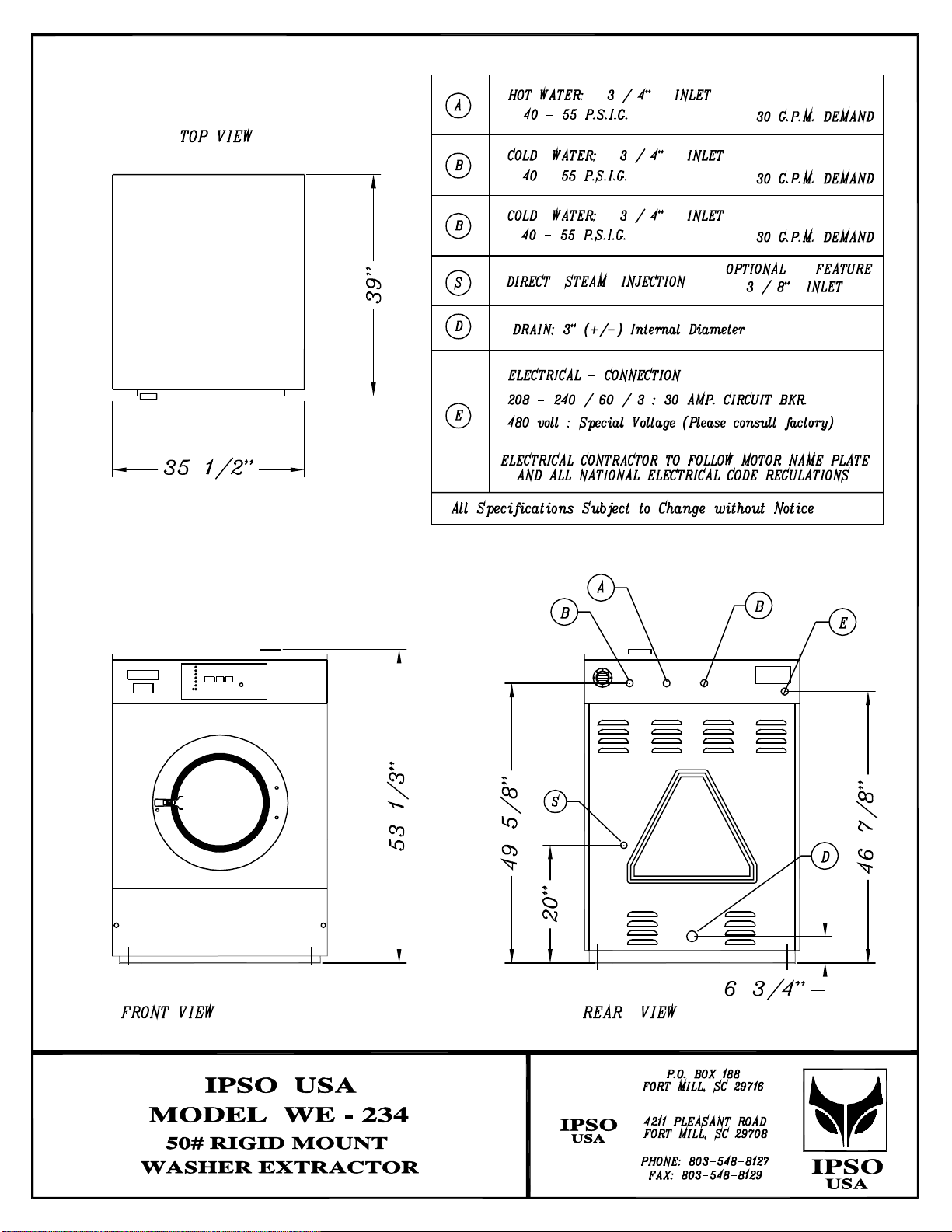

Model: WE 234

Measurement

Location

A

B

C

D

E

F

G

H

I

J

K

Standard

Measure

Metric

Measure

Inches / Decimals

FT In. Fraction

2 11 7/16 900 mm 35.4331

2 2 25/32 680 mm 26.7716

4 11/32 110 mm 4.3307

3 9/16 929 mm 36.5748

2 7 1/2 800 mm 31.4961

11 3/32 282 mm 11.1023

1 31/32 50 mm 1.9685

3 1/8 79mm 3.1102

2 4 31/32 736 mm 28.9763

3 5 11/32 1050 mm 41.3385

2 9 21/32 855 mm 33.6614

Back of Machine

G

D

F

I

E

K

J

H

C

B

A

Front of Machine

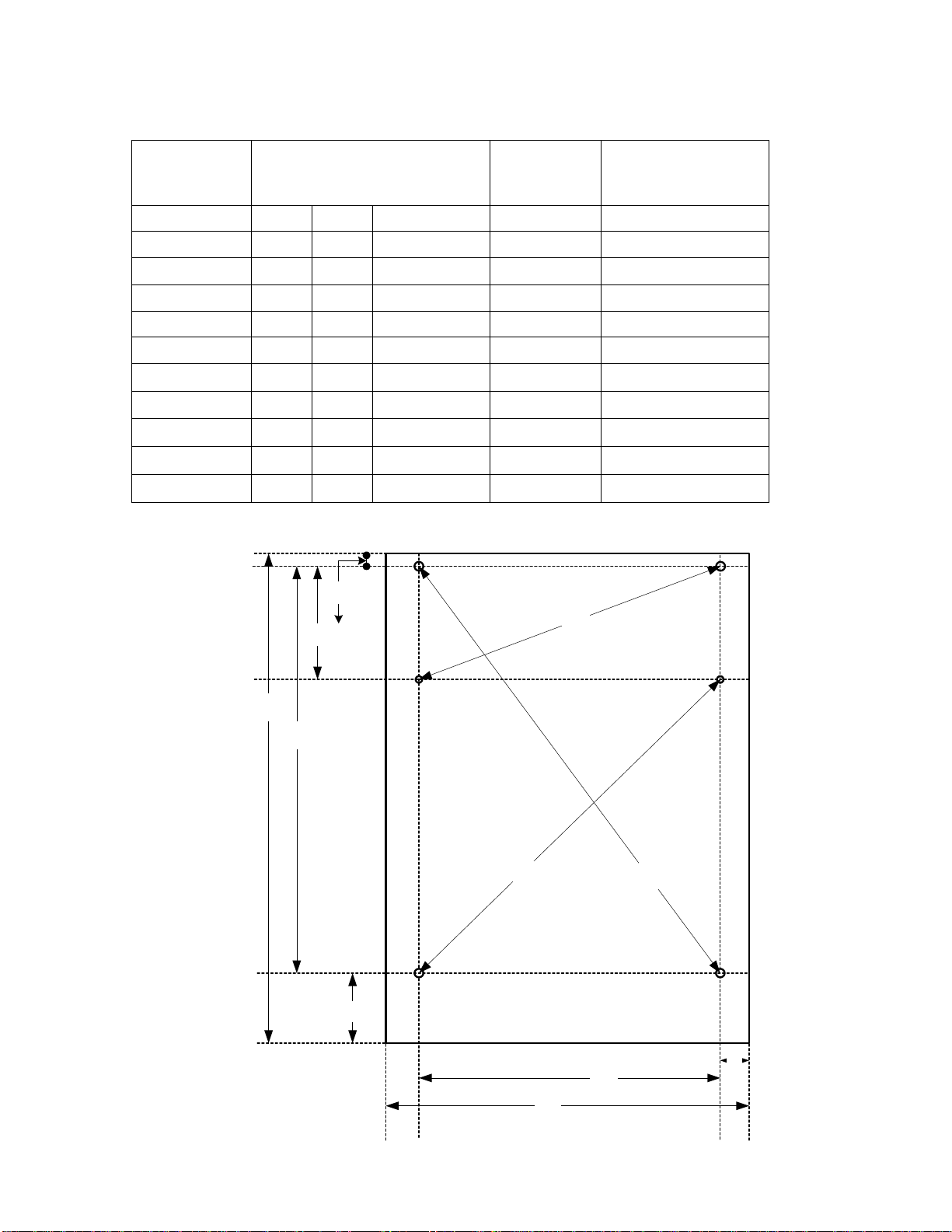

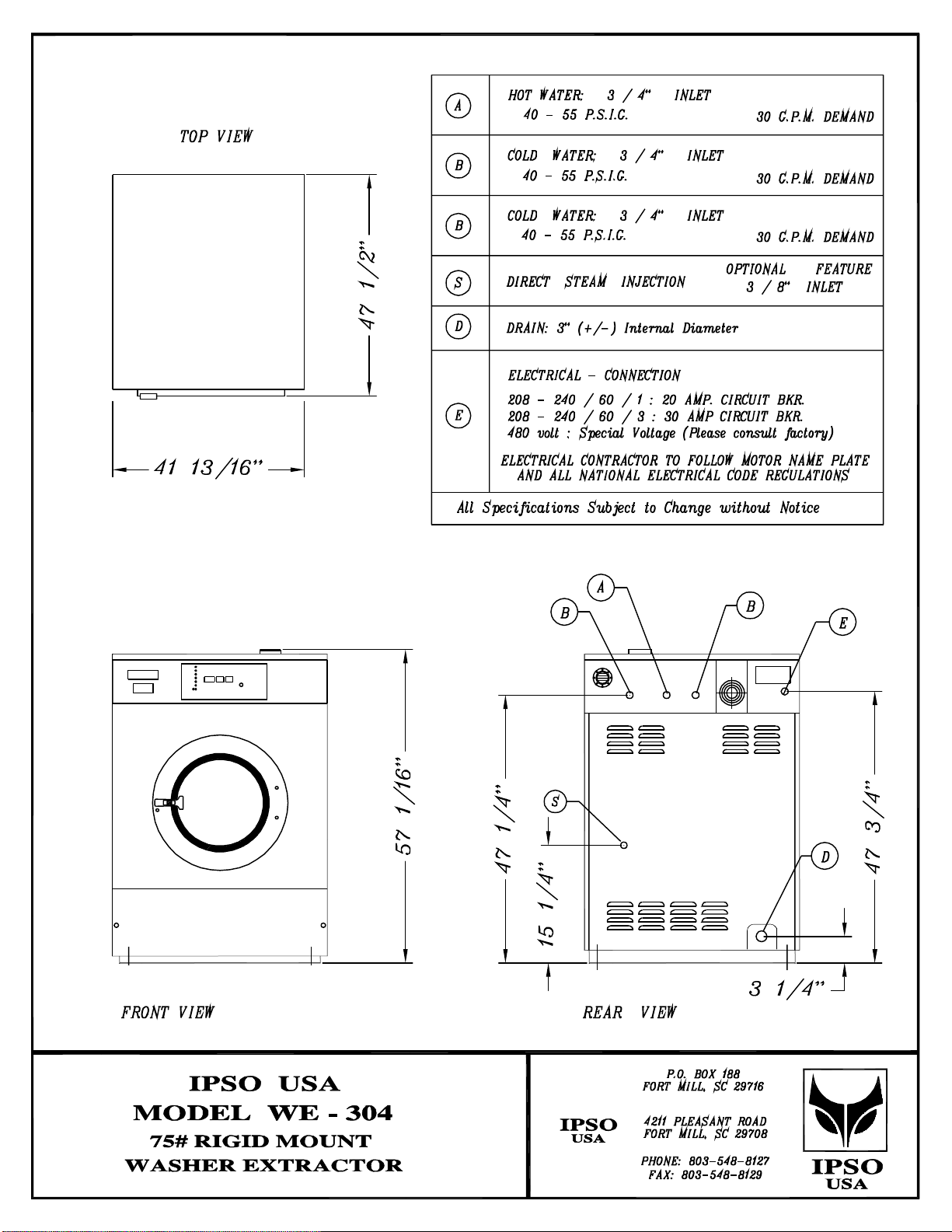

Model: WE 304

Measurement

Location

A

B

C

D

E

F

G

H

I

J

K

Standard

Measure

Metric

Measure

Inches / Decimals

FT In. Fraction

3 5 23/32 1060 mm 41.7323

2 8 3/32 815 mm 32.0866

4 13/16 122.5 mm 4.8228

3 5 23/32 1060 mm 41.7323

2 10 27/32 885 mm 34.8425

1 19/32 320 mm 12.5984

1 9/16 40 mm 1.5748

5 5/16 135 mm 5.3114

2 10 1/2 876 mm 34.4881

3 11 3/8 1203 mm 47.3622

3 3 1/16 992 mm 39.0551

Back of Machine

G

D

F

I

E

K

J

H

C

B

A

Front of Machine

Loading...

Loading...