Hydraulic

Booster

Maintenance Instructions

Trouble-Shooting

CISSELL MANUFACTURING COMPANY

HEADQUARTERS PHONE: (502) 587-1292

831 SOUTH FIRST ST. SALES FAX: (502) 585-3625

P.O. BOX 32270 SERVICE/PARTS FAX: (502) 681-1275

LOUISVILLE, KY 40232-2270

THIS MANUAL MUST BE GIVEN TO THE EQUIPMENT OWNER.

Information subject to change without notice.

MAN386 8/951C

Page 1

Information subject to change without notice.

Page 2

TROUBLE SHOOTING LIST OF THE HYDRAULIC BOOSTER

(see also “example of assembling” Fig. 1 to 8)

What to do if: 1. Press opens too slowly.

2. Booster gives no pressure.

3. Press looses pressure during cycle.

4. Loss of oil / Loss of pressure.

When disassembling the Booster, all Packings and O-Rings have to be replaced preferably. This is less expensive than disassembling resp. reassembling of Booster every

time.

At least once a year the Hydraulic Oil in the Booster has to be replaced, because the

Oil reduces its viscosity and could be penetrated with dust or dirt.

1. Press opens too slowly

a) BOOSTER NUT 893 (see Fig. 8) has been driven in, hindering back flow of oil.

If the Booster Nut is slightly driven in, it might be sufficient to adjust Booster

Valve 10306 somewhat higher (see Fig. 7).

Otherwise a new Booster Nut has to be mounted.

b) AIR BOOSTER SPRING 50092 is broken (see Fig. 8) or has not sufficient

tension anymore. Requires replacement.

2. Booster gives no pressure

Check whether Operating Valve in resting position allows air to pass to booster, so

that this valve is already worked out before operated.

3. Press loses pressure during cycle

a) Check if air supply line is leaky.

b) It may occur that there is a leakage between Check Valve Stem 30595 and Seat

(see Fig. 1). If necessary, replace Valve and adjust Seat. Former presses have

been equipped with a metallic Valve instead of a plastic one.

Such metallic Valve has to be tightened by means of an O-Ring. Old parts can

simply be replaced by 30595.

c) BACK-UP RING 30025 and O-RING 30029 (see Fig. 2) require replacement.

Damages on Back-Up Ring can be hardly located, because of small cracks.

Check also O-Ring 30032; after longer use this )-Ring can be damaged.

Information subject to change without notice.

Page 3

d) Check if seat between Plunger 10520 and Booster Valve 10306 is damaged (see

Fig. 7) (always to be replaced at the same time).

e) Check O-Ring 30081 (damages do not occur very often) (see Fig. 8).

f) Check O-Ring 30083 (see Fig. 5).

4. Loss of oil and eventual loss of pressure

a) CHECK VALVE STEM 30595 does not work, causing that oil cannot flow back.

Oil will then accumulate in the top of the Booster at PISTON ROD GUIDE 894

(see Fig. 1 and 4).

b) BACK-UP RING 30084 and O-RING 30082 let oil pass through, so that it can

enter into the air part. In most cases to be located by a greasy oil vapour, which

blows out of the Exhaust Valve during release of air part.

(The Exhaust Valve is mounted in front of air inlet of Booster.) Check also, if

PISTON ROD 1884 has been damaged. Sometimes this Rod can be repaired by

rubbing with very fine sandpaper in longitudinal direction (only slight damages)

(see Fig. 7 and 8).

5. Press slows down badly at closing

a. Refill oil on Booster (use only oil with Pantex No. 80022).

b. In case of loss of oil, see point 4.

Please note, when mounting the Booster between the shafts, that upper and lower

fastening points must be lined out absolutely vertically.

Information subject to change without notice.

Page 4

EXAMPLE OF ASSEMBLING HYDRAULIC BOOSTERS

This example of assembling is meant of those who have some technical insight in the

process of working of the above mentioned cylinders, like service technicians and similar persons.

The numbers indicated in this example of assembling may not be used for ordering

spare parts.

For this purpose you have to use the spare parts catalogue, which is delivered with

every machine.

Disassembling takes place in reversed order of succession.

The used auxiliary tools can be ordered as per the following list:

Auxiliary tools:

A. “O” Ring mounting tool 19 946

C. Chain tong 19 949

D. Auxiliary tool 19 943

E. “O” Ring mounting tool 19 945

F. Mounting Rod 19 941

H. “O” Ring mounting tool 19 944

J . “O” Ring adjusting tool 19 947

K. Special screw driver 19 950

M. Shaft clamp 19 948

N. Protection plate (2x) 19 942

Booster Revision Tools (complete set as described above) 117 847

For prices of these auxiliary tools, please see price list.

Information subject to change without notice.

Page 5

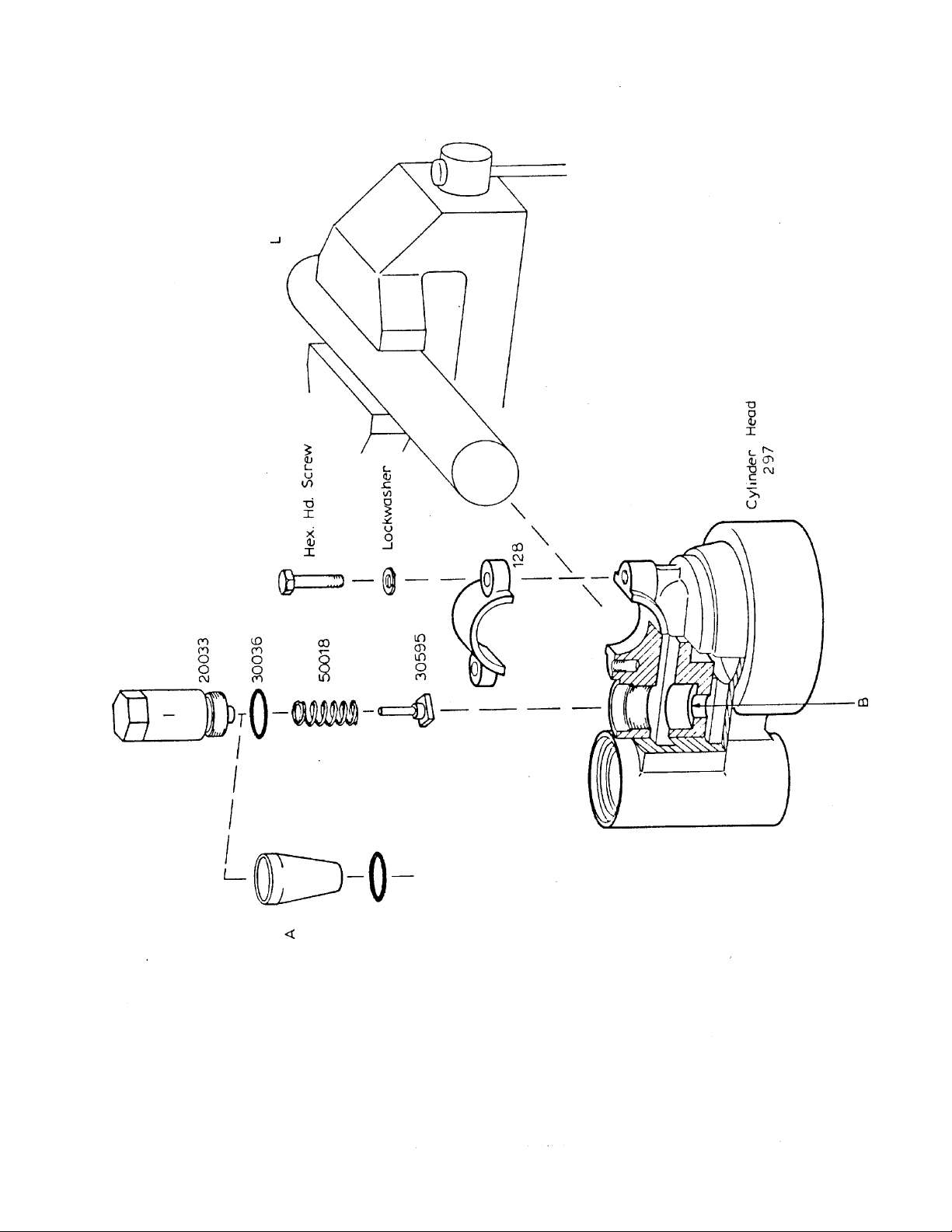

PRELIMINARY ASSEMBLING OF CYLINDER HEAD

(Figure 1)

Pinch tool “L” in a bench screw and fix to it CYLINDER HEAD 297 by means of PIVOT

CLAMP 128 and the fastening bolts.

Fix O-RING 30036 after greasing by means of special tool “A” round the CHECK

VALVE CAP 20033.

Check whether there is a sharp edging at point “B” in the CYLINDER HEAD 297; if

there is, remove it. This prevents damage to the valve.

Fix successively CHECK VALVE STEM 30595, CHECK VALVE CAP SPRING 50018,

and the already preliminary assembled CHECK VALVE.

Instead of a plastic CHECK VALVE STEM a metal one is used in older executions, on

which an extra O-RING 30036 has been mounted.

Both old parts CHECK VALVE STEM and O-RING can be replaced by the new

CHECK VALVE STEM 30595.

Information subject to change without notice.

Page 6

Information subject to change without notice.

Figure 1

Page 7

PRELIMINARY ASSEMBLING OF PISTON ROD

HYDRAULIC PART (Figure 2)

Mount NEEDLE BEARING 80011 into ROD HEAD 114 and screw this on to PISTON

ROD 10087.

Assemble successively on the PISTON ROD;

CHECK SPRING _____________________ 50 016

CHECKING RING____________________ 10 088

HYDRAULIC PISTON ________________ 20 697

BACK-UP RING ______________________ 30 025

O-RING______________________________ 30 029

PISTON PACKING RING _____________ 10 094 (check if it is damaged)

SPRING _____________________________ 50 019

PISTON ROD NUT ___________________ 10 095

After tightening the PISTON ROD NUT 10095 the hole at the bottom of PISTON ROD

10087 may be deformed somewhat. Please note, that this will not cause any difficulties

when assembling CHECKING DISC ASSY 110029 (see Figure 3).

This only appears on replacing the PISTON ROD 10087 and not on disassembling and

assembling in the normal way.

Information subject to change without notice.

Page 8

Loading...

Loading...