Cissell HD190 Owner's Manual

OWNER'S MANUAL

190 lb. HD LAUNDRY DRYER

Gas: Natural and LP

Steam

HD190

THIS MANUAL MUST BE GIVEN TO THE EQUIPMENT OWNER

MAN HD190 2/03

Cissell Manufacturing Co.

831 S. First St. - P.O.Box 32270 - Louisville, Ky. - 40232-2270

Tel: (502) 587-1292 - Fax: (502) 585-2333 Sales Fax: (502) 585-3625 - Service/Parts Fax: (502) 681-1275

Page 1

IMPORTANT NOTICESPLEASE READ

For optimum efficiency and safety, we recommend that you read the manual before operating the equipment. Store this manual in a

file or binder and keep for future reference.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion or to prevent property damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or

any other appliance.

- WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

WARNING: In the event the user smells gas odor, instructions on what to do must be posted in a

prominent location. This information can be obtained from the local gas supplier.

WARNING: Wear safety shoes to prevent injuries.

WARNING: Purchaser must post the following notice in a prominent location:

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WARNING: A clothes dryer produces combustible lint and should be exhausted outside the

building. The dryer and the area around the dryer should be kept free of lint.

WARNING: Be safe, before servicing machine, the main power should be shut off.

Page 2

WARNING: To avoid fire hazard, do not dry articles containing foam rubber or similar texture materials.

Do not put into this dryer flammable items such as baby bed mattresses, throw rugs,undergarments

(brassieres, etc.) and other items which use rubber as padding or backing. Rubber easily oxidizes causing

excessive heat and possible fire. These items should be air dried.

WARNING: Synthetic solvent fumes from drycleaning machines create acids when drawn through the

dryer. These fumes cause rusting of painted parts, pitting of bright or plated parts, and completely

removes the zinc from galvanized parts, such as the tumbler basket. If drycleaning machines are in the

same area as the tumbler, the tumbler's make-up air must come from a source free of solvent fumes.

WARNING: Do not operate without guards in place.

WARNING: Check the lint trap often and clean as needed but at least a minimum of once per day.

WARNING: Alterations to equipment may not be carried out without consulting with the factory and

only by a qualified engineer or technician. Only Manufacturer parts may be used.

WARNING: Remove clothes from dryer as soon as it stops. This keeps wrinkles from setting in and

reduces the possibility of spontaneous combustion.

WARNING: Be safe - shut main electrical power and gas supply off externally before attempting

service.

WARNING: Never use drycleaning solvents, gasoline, kerosene, or other flammable liquids in the dryer.

FIRE AND EXPLOSION WILL OCCUR. NEVER PUT FABRICS TREATED WITH THESE LIQUIDS

INTO THE DRYER. NEVER USE THESE LIQUIDS NEAR THE DRYER..

WARNING: Do not place items exposed to cooking oils in your dryer. Items contaminated with cooking

oils may contribute to a chemical reaction that could cause a load to catch fire.

WARNING: Never let children play near or operate the dryer. Serious injury could occur if a child

should crawl inside and the dryer is turned on.

WARNING: Never tumble fiberglass materials in the dryer unless the labels say they are machine

dryable. Glass fibers break and can remain in the dryer. These fibers cause skin irritation if they

become mixed with other fabrics.

WARNING: Before operating gas ignition system - purge air from natural gas or propane gas lines

per manufacturers instructions.

WARNING: To reduce the risk of electric shock, disconnect this appliance from the power supply

before attempting any user maintenance other than cleaning the lint trap. Turning the controls to the

OFF position does not disconnect this appliance from the power supply.

Page 3

ATTENTION: LACHETEUR DOIT PLACER LAVERTISSEMENT

SUIVANT DANS UN ENDROIT CLAIR ET VISIBLE:

AVERTISSEMENT. Assurez-vous de bien

suivre les instructions donnees dans cette

notice pour reduire au minimum le risque

dincendie ou dexplosion ou pour eviter tuot

dommage materiel, toute blessure ou la mort.

__ Ne pas entreposer ni utiliser dessence ni

dautres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

apparell.

__ QUE FAIRE SI VOUS SENTEZ UNE

ODEUR DE GAZ:

Ne pas tenter dallumer dapparell.

Ne touchez a aucun interrupteur. Ne pas

vous servir des telephones se trouvant dans

le batiment ou vous vous trouvez.

Evacuez la piece, le batiment ou la zone.

Appelez immediatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le service des incendies.

__ linstallation et lentretien doivent etre assures

par un installateur ou un service dentretien

qualifie ou par le fournisseur de gaz.

ATTENTION: LACHETEUR DOIT PLACER LAVERTISSEMENT

SUIVANT DANS UN ENDROIT CLAIR ET VISIBLE:

POUR VOTRE SECURITE

Ne pas entreposer ni utiliser d essence

ni dautres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de tout autre appareil.

Page 4

CISSELL DRYER WARRANTY

The Cissell Manufacturing Company (Cissell) warrants all new equipment (and the original parts thereof) to be free from

defects in material or workmanship for a period of three (3) years from the date of sale thereof to an original purchaser for

use, except as hereinafter provided. With respect to non-durable parts normally requiring replacement in less than three (3)

years due to normal wear and tear, and with respect to all new repair or replacement parts for Cissell equipment for which

the three (3) year warranty period has expired, or for all new repair or replacement parts for equipment other than Cissell

equipment, the warranty period is limited to ninety (90) days from date of sale. The warranty period on each new replacement

part furnished by Cissell in fulfillment of the warranty on new equipment or parts shall be for the unexpired portion of the

original warranty period on the part replaced.

With respect to electric motors, coin meters and other accessories furnished with the new equipment, but not manufactured

by Cissell, the warranty is limited to that provided by the respective manufacturer.

Cissells total liability arising out of the manufacture and sale of new equipment and parts, whether under the warranty or

caused by Cissells negligence or otherwise, shall be limited to Cissell repairing or replacing, at its option, any defective

equipment or part returned f.o.b. Cissells factory, transportation prepaid, within the applicable warranty period and found

by Cissell to have been defective, and in no event shall Cissell be liable for damages of any kind, whether for any injury to

persons or property or for any special or consequential damages. The liability of Cissell does not include furnishing (or

paying for) any labor such as that required to service, remove or install; to diagnose troubles; to adjust, remove or replace

defective equipment or a part; nor does it include any responsibility for transportation expense which is involved therein.

The warranty of Cissell is contingent upon installation and use of its equipment under normal operating conditions. The

warranty is void on equipment or parts; that have been subjected to misuse, accident, or negligent damage; operated under

loads, pressures, speeds, electrical connections, plumbing, or conditions other than those specified by Cissell; operated

or repaired with other than genuine Cissell replacement parts; damaged by fire, flood, vandalism, or such other causes

beyond the control of Cissell; altered or repaired in any way that effects the reliability or detracts from its performance,

or; which have had the identification plate, or serial number, altered, defaced, or removed.

No defective equipment or part may be returned to Cissell for repair or replacement without prior written authorization

from Cissell. Charges for unauthorized repairs will not be accepted or paid by Cissell.

CISSELL MAKES NO OTHER EXPRESSED OR IMPLIED WARRANTY, STATUTORY OR OTHERWISE,

CONCERNING THE EQUIPMENT OR PARTS INCLUDING, WITHOUT LIMITATION, A WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE, OR A WARRANTY OF MERCHANTABILITY. THE

WARRANTIES GIVEN ABOVE ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED. CISSELL NEITHER ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT,

ANY OTHER WARRANTY OR LIABILITY IN CONNECTION WITH THE MANUFACTURE, USE OR SALE OF

ITS EQUIPMENT OR PARTS.

For warranty service, contact the Distributor from whom the Cissell equipment or part was purchased. If the Distributor

cannot be reached, contact Cissell.

IDENTIFICATION NAMEPLATE

The Identification Nameplate is located on the rear wall of the dryer. It contains the dryer serial number, product number, model

number, electrical specifications and other important data that may be needed when servicing and ordering parts, wiring diagrams,

etc. Do not remove this nameplate.

Page 5

TABLE OF CONTENTS

175 LB. LAUNDRY DRYER

PAGE

Model Numbers & Company Address................................................................................. 1

Important Notices ............................................................................................................. 2-4

Dryer Warranty ................................................................................................................... 5

Table of Contents ................................................................................................................ 6

Warnings, Cautionary Notes and Symbols ........................................................................ 7-8

Unpacking and General Installation ................................................................................ 9-10

Dryer Specifications .................................................................................................... 11-17

Main Drive Motor List ...................................................................................................... 18

Gas Pipe Size Chart .......................................................................................................... 19

Gas Piping Installation ................................................................................................. 20-21

Steam Piping Installation .............................................................................................. 22-23

Dryer Installation with Multiple Exhaust ......................................................................24-26

Dryer Installation with Separate Exhaust .......................................................................... 27

Exhaust and Venting .......................................................................................................... 28

Link Belts .......................................................................................................................... 29

Rules for Safe Operation of Your Dryer ...................................................................... 30-31

Service Savers ..................................................................................................................32

Troubleshooting Charts ................................................................................................ 33-37

Two Timer Models ...................................................................................................... 38-39

Direct Spark Ignition Operation ................................................................................... 40-41

General Maintenance .................................................................................................... 42-43

Shimming the Basket and Spider Assembly .................................................................. 44-46

Air Switch Adjustment ...................................................................................................... 47

Pulley and Belt Maintenance ............................................................................................. 48

Front of Dryer - Parts ........................................................................................................ 49

Rear of Dryer - Parts .................................................................................................... 50-51

Front Panel and Door Assembly........................................................................................ 52

Lint Door Assembly........................................................................................................... 53

DMP Control Assembly ............................................................................................... 54-55

Two Timer Control Box Assembly .............................................................................. 56-57

PROHC Control Panel Assembly ...................................................................................... 58

DMP Sensor Assembly ..................................................................................................... 59

Two Timer Sensor Assembly ............................................................................................ 60

PRO Sensor Assembly ...................................................................................................... 61

PROHC Sensor Assembly ................................................................................................. 62

Fan Assembly ....................................................................................................................63

Basket/Spider Assembly ................................................................................................... 64

Reversing Control Panel Assembly ................................................................................... 65

Gas Bonnet Assembly ....................................................................................................... 66

Steam Bonnet Assembly .................................................................................................... 67

Air Switch Assembly ........................................................................................................ 68

Parts- Temperature Assembly ........................................................................................... 69

Orifice Information ............................................................................................................ 70

Ordering Overload Heaters for Overload Relays ........................................................ 71-72

Minimum Dryer Make-up Air Requirements ..................................................................... 74

Recommended Spare Parts

Page 6

SYMBOLS

The following symbols are used in this manual and/or on the machine.

Symbol Description

NOTE!

Hot! Do Not Touch

Heib! Nicht Beruhren

Haute temperature! Ne pas toucher

Caliente! no tocar

Heet! Niet Aanraken

dangerous voltage

tension dangereuse

Gafahrliche elektrische Spannung

tension peligrosa

on

marche

Ein

conectado

off

arrêt

Aus

desconectado

start

demarrage

Start

arranque de un movimiento

emission of heat in general

êmission de chaleur en general

Warmeabgabe allgemein

emisión de calor

cooling

refroidissement

Kuhlen

enfriamiento

Page 7

SYMBOLS

The following symbols are used in this manual and/or on the machine.

Symbol Description

rotation in two directions

rotation dans les deux sens

Drehbewigung in zwei Richtungen

movimiento rotativo en los dos sentidos

direction of rotation

sens de mouvement continu de rotation

Drehbewegung in Pfeilrichtung

movimiento giratorio o rotatorio

en el sentido de la flecha

End of Cycle

caution

attention

Achtung

atencion; precaucion

Page 8

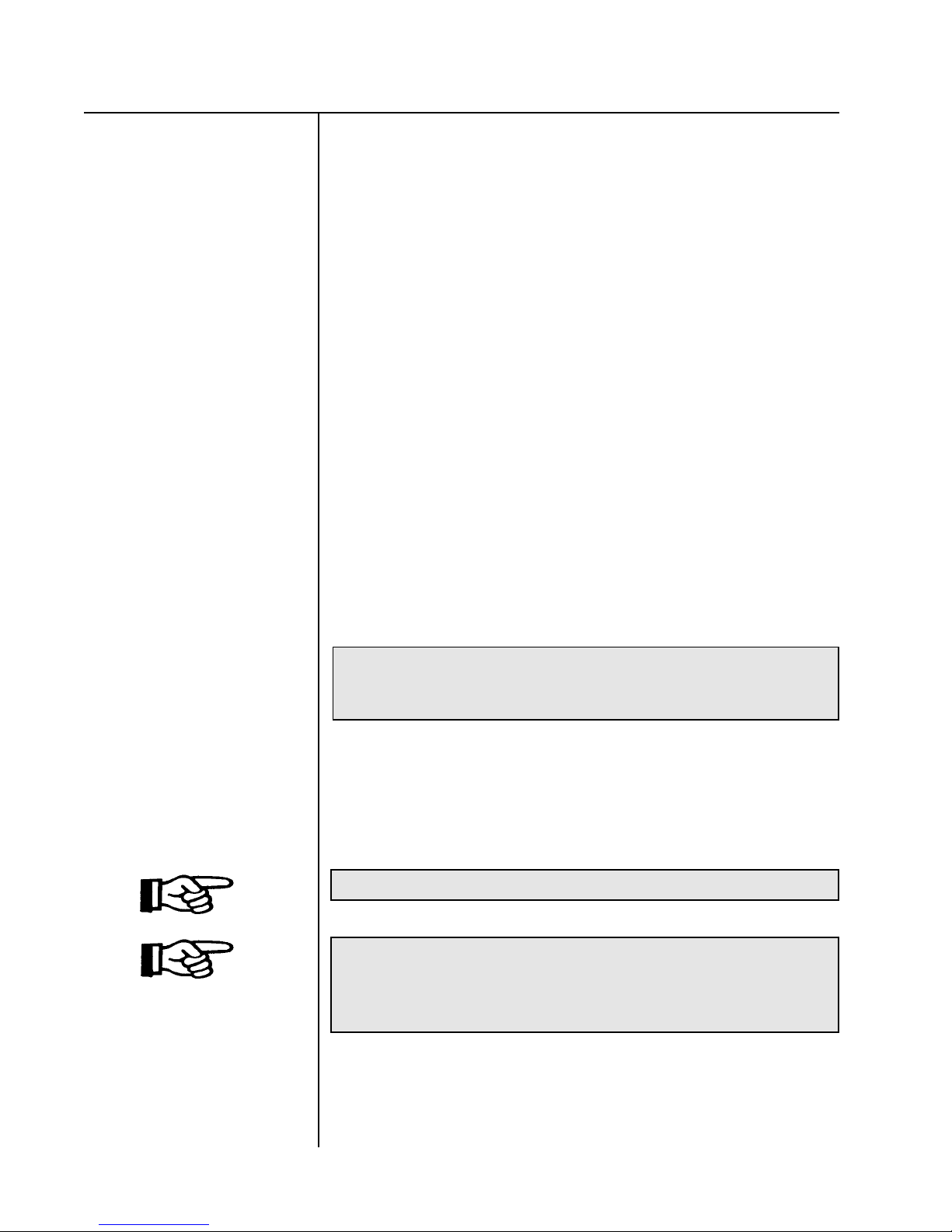

Unpacking/General Installation (All Dryers)

UNPACKING

GENERAL

INSTALLATION

(ALL DRYERS)

This dryer is packed in a large (heavy-duty) protective wooden crate.

Upon arrival of the equipment, any damage in shipment should be reported to

the carrier immediately.

Upon determining permanent location of a unit, care should be taken in

movement and placement of equipment. To move dryer through doorways, you

may need to remove the top of the machine. Follow instructions for disassembling.

See outline clearance diagrams for correct dimensions.

Remove all packing material such as: tape, manuals, skid, etc.

Check voltage and amperes on rating plate before installing the dryer.

Leveling: Use spirit level on top of dryer. The use of shims are acceptable for

this procedure.

IMPORTANT

Before installing or operating this dryer, thoroughly read the

owner's manual for correct instructions concerning electric

connections, exhaust ducting, gas piping, steam connections,

make-up air, etc.

IMPORTANT

Read the warnings in this manual.

IMPORTANT

Do not install this dryer in an area where it will be exposed to

water and/or weather.

IMPORTANT

Failure to follow these instructions and warnings may create a

safety hazard and may affect the warranty.

IMPORTANT

Follow all local codes.

IMPORTANT

If you have any installation questions, consult the factory

Service Department.

Page 9

General Installation (All Dryers)

GENERAL

INSTALLATION

(ALL DRYERS)

GENERAL

Position dryer for the least amount of exhaust piping and elbows,

and allow free access to the rear of dryer for future servicing of

belts, pulleys and motors. Installation clearance from all

combustable material for gas dryers is 24 ceiling clearance, 24

rear clearance, and 0 side clearance. Installation clearance from

all combustable material for steam dryers is 24 ceiling clearance,

24 rear clearance, and 0 side clearance.

Before operating dryer, open basket door and remove blocking

between front panel and basket. Read the instruction tags, owner's

manual, warnings, etc.

The dryer is so designed that when an operator opens the dryer

door, the basket and exhaust fan stop. Hot, dry air is properly and

effectively moved through the basket and exhausted through a lint

trap to the venting and eventually to the atmosphere. The lint

accumulates in the collector and should be removed as needed,

minimum once daily.

IMPORTANT

REPLACEMENT PARTS

IMPORTANT

Provide adequate clearance for air openings into the combustion

chamber.

Replacement parts for this dryer are available from your distributor

or by contacting the factory at the address or phone number printed

on the cover of this manual.

WARNING Unit is heavy!

NOTE

The gas installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1 or the CAN/CGA-B149, Installation Codes.

Page 10

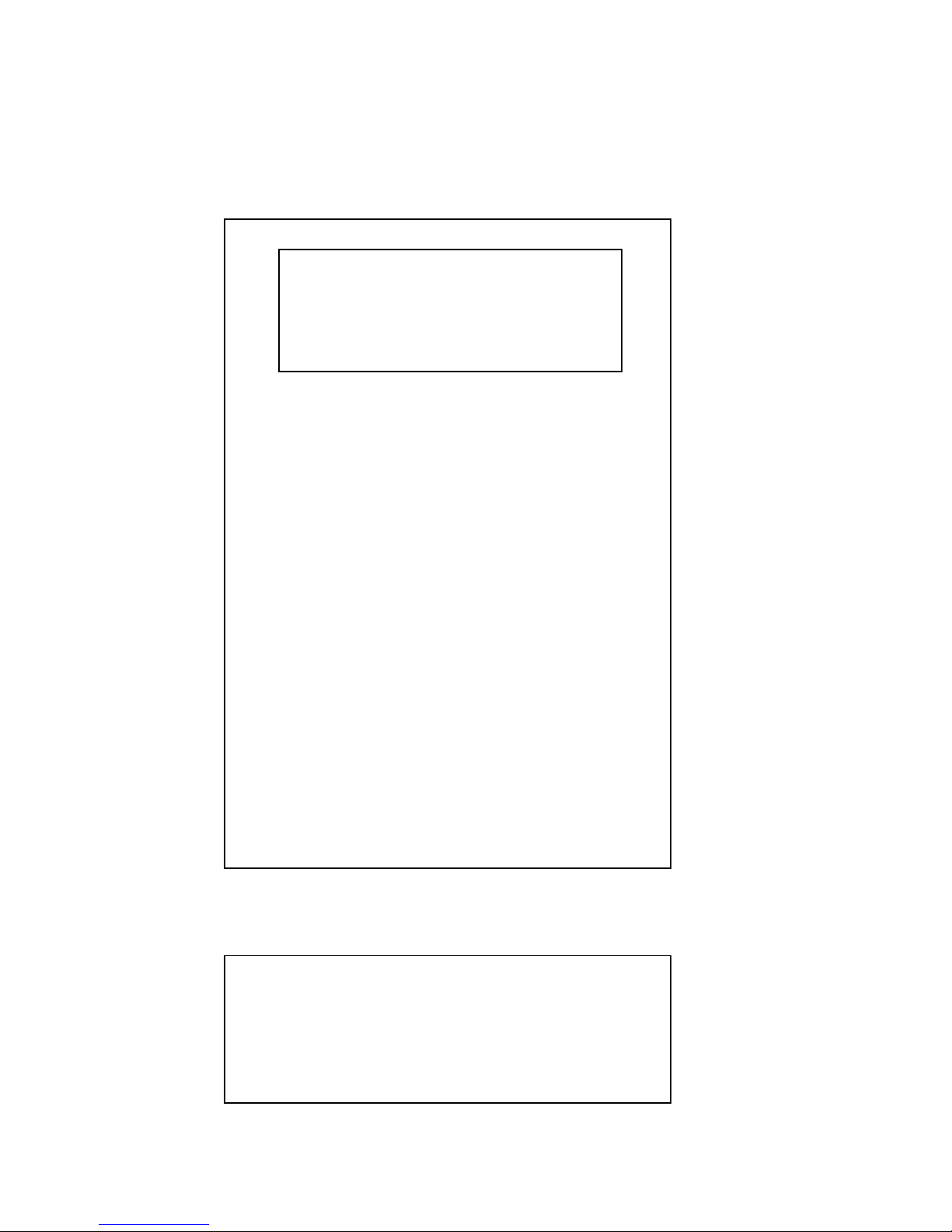

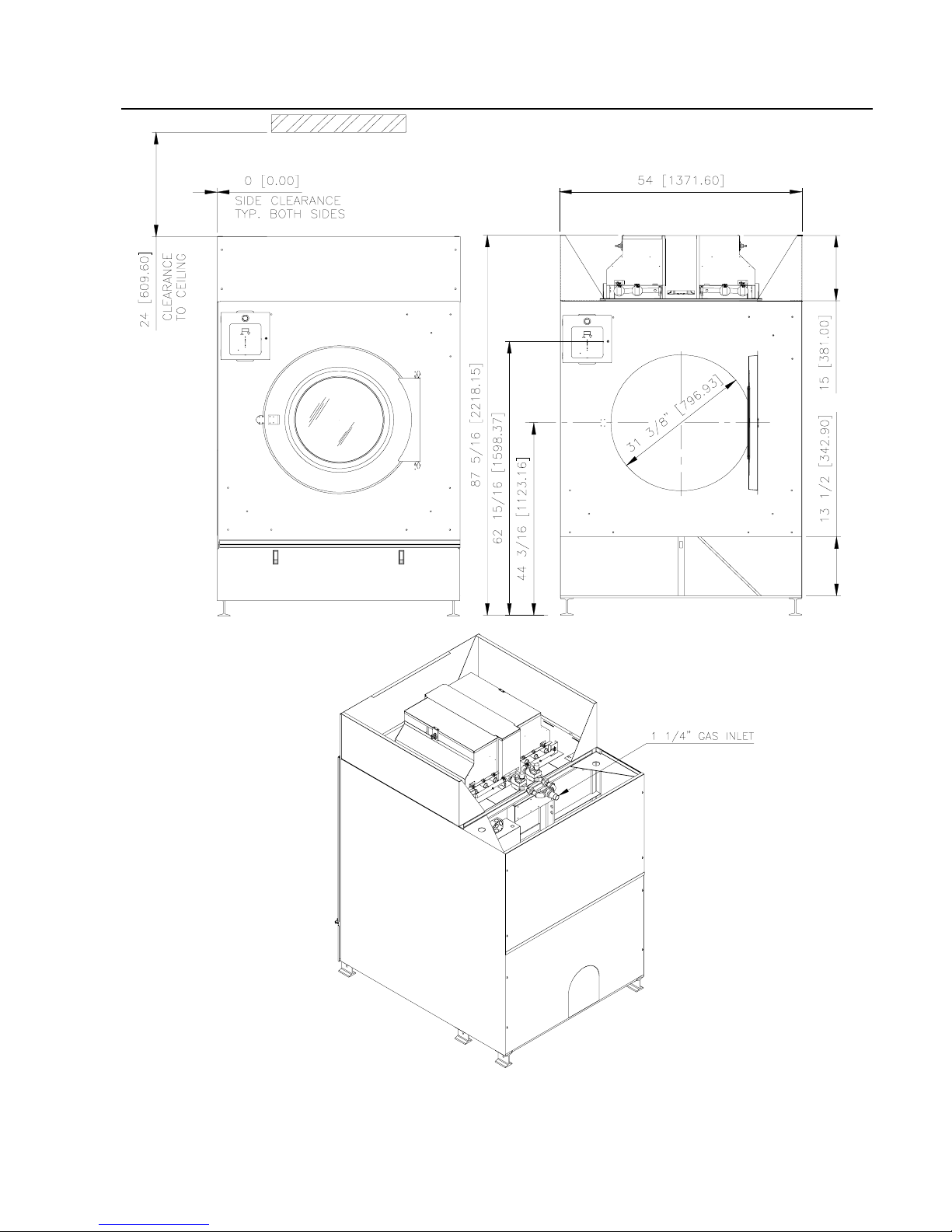

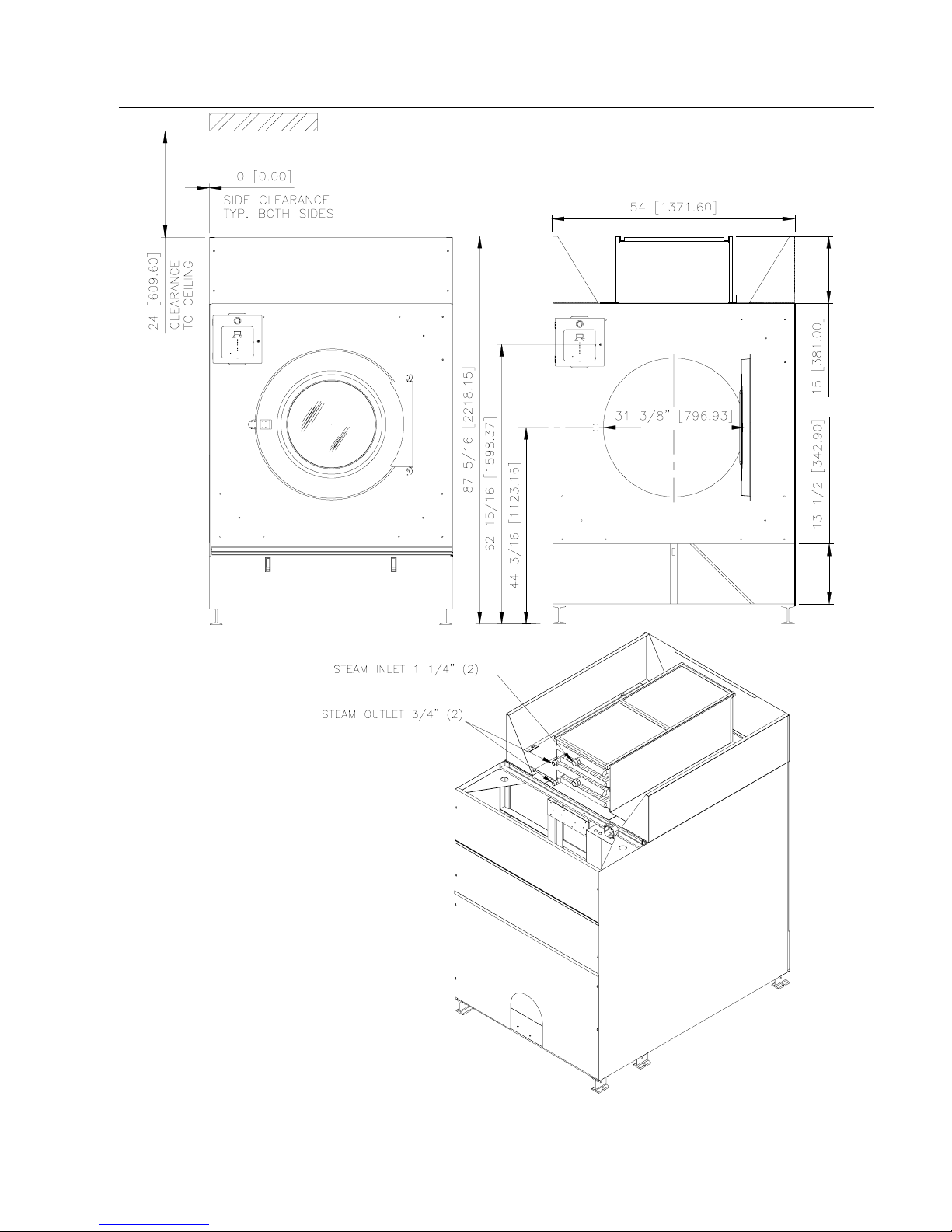

190 LB. GAS DRYER SPECIFICATIONS (ILLUSTRATION)

REAR VIEW

ALL DIMENSIONS ARE +/- 1/4 (6.4 MM) AND ARE SUBJECT TO CHANGE WITHOUT NO-

TICE

Page 11

190 LB GAS DRYER SPECIFICATIONS (ILLUSTRATION)

TOP VIEW DIMENSIONS

REAR VIEW DIMENSIONS

REAR COVER

NOT SHOWN

ALL DIMENSIONS ARE +/- 1/4 (6.4 MM) AND ARE SUBJECT TO CHANGE WITHOUT NO-

TICE

Page 12

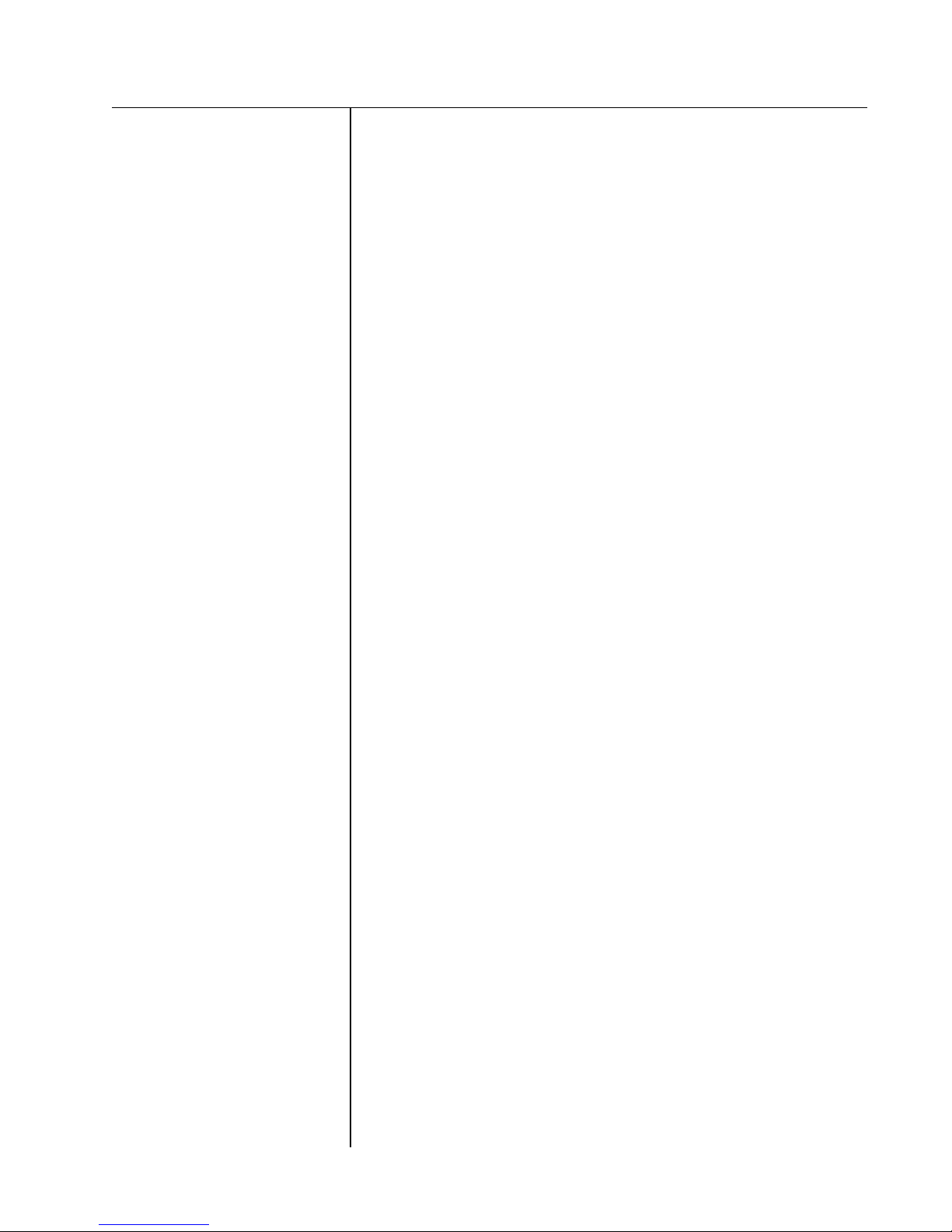

190LB. STEAM DRYER SPECIFICATIONS (ILLUSTRATION)

REAR VIEW

ALL DIMENSIONS ARE +/- 1/4 (6.4 MM) AND ARE SUBJECT TO CHANGE WITHOUT NO-

TICE

Page 13

190 LB. STEAM DRYER SPECIFICATIONS (ILLUSTRATION)

TOP VIEW DIMENSIONS

REAR VIEW DIMENSIONS

REAR COVER

NOT SHOWN

ALL DIMENSIONS ARE +/- 1/4 (6.4 MM) AND ARE SUBJECT TO CHANGE WITHOUT NO-

TICE

Page 14

Specifications for 190 lb. Gas Heated Dryer

GENERAL

SPECIFICATIONS FOR

190 lb. GAS HEATED

DRYERS

Basket Capacity.........................................190 lb (86.2 kg) Dryweight

Electrical Specifications .......................... 208-240/60/3, 480/60/3,

220-380/50/3

Motor Size: Basket .................................. 2 Hp (1.49 kW)

Motor Size: Fan .......................................5 Hp (3.73 kW)

Floor Space ...............................................89 H x 54 W x 71 15/16 D

...................................................................(2261 x 1372 x 1651 mm)

Door Opening............................................31-1/4 (794 mm)

Basket ........................................................ 52 dia. x 48 deep

................................................................... (1321 x 1220 mm)

Basket RPM: Reversing........................... 30 rpm (w/ 3.2 reversals per minute)

Non-Reversing ..........................................30 rpm

Exhaust Duct .............................................12 (3048 mm) dia.

Maximum Air Displacement .................... 2,780 cfm (4726 m3/h)

Recomm. Oper. Range..............................2,300 cfm (3910 m3/h)

Gas Net Weight ........................................2,075 lb (941 kg)

Steam Net Weight..................................... 2,205 lb (1000 kg)

Gas Shipping Weight ................................2,225 lb (1009 kg)

Steam Shipping Weight ............................2,355 lb ( 1068 kg)

Shipping Dimensions ................................89 1/2 H x 58 W x 84 1/2 D

(2273 x 1473 x 2146 mm)

Crating Volume ......................................... 232 ft³ ( 6.57m³)

Gas Supply................................................. 1 1/4 (DN32) pipe connection

(1 1/4 SPT)

Input Rating ............................................... 525,000 Btu/h

(132,300 kcal/h)

Recommended Make-up Air..................... 4.0 sq. ft. (576 sq. in.,

3,744 sq. cm)

Page 15

Specifications for 190 lb. Steam Heated Dryer

GENERAL

SPECIFICATIONS FOR

190 lb. STEAM HEATED

DRYERS

Basket Capacity.........................................190 lb (86.2 kg)

Electrical Specifications .......................... 208-240/60/3, 480/60/3,

220-380/50/3

Motor Size: Basket .................................. 2 Hp (1.49 kW)

Motor Size: Fan .......................................5 Hp (3.73 kW)

Floor Space ...............................................89 H x 54W x 71 15/16 D

( 2261 x 1372 x 1828 mm)

Door Opening............................................31-1/4 (794 mm)

Basket ........................................................ 52 dia. x 48 deep (59 cu. ft.)

(1321 x 1220 mm, 3600 liters)

Basket RPM: Reversing...........................30 rpm (w/ 3.2 reversals

per minute)

Non-Reversing ..........................................30 rpm

Exhaust Duct .............................................12 (3048 mm) dia.

Maximum Air Displacement .................... 2780 cfm ( 4726 m³/h)

Recomm. Oper. Range.............................. 2300 cfm (3910 m³/h)

Net Weight ................................................ 1800 lb (816 kg)

Shipping Weight ........................................ 1950 lb (885 kg)

Shipping Dimensions ................................89 1/2 H x 58 W x 84 1/2 D

...................................................................(2273 x 1473 x 2146 mm)

Crating Volume ......................................... 232 ft³ ( 6.57 m³)

Input Rating ............................................... 15.7 BHP ( 132,000 kcal/h)

Pressure .................................................... 125 psi max

Steam Supply Connection.........................1 1/4 SPT (DN32)

Steam Return Connection......................... 3/4 SPT (DN20)

Page 16

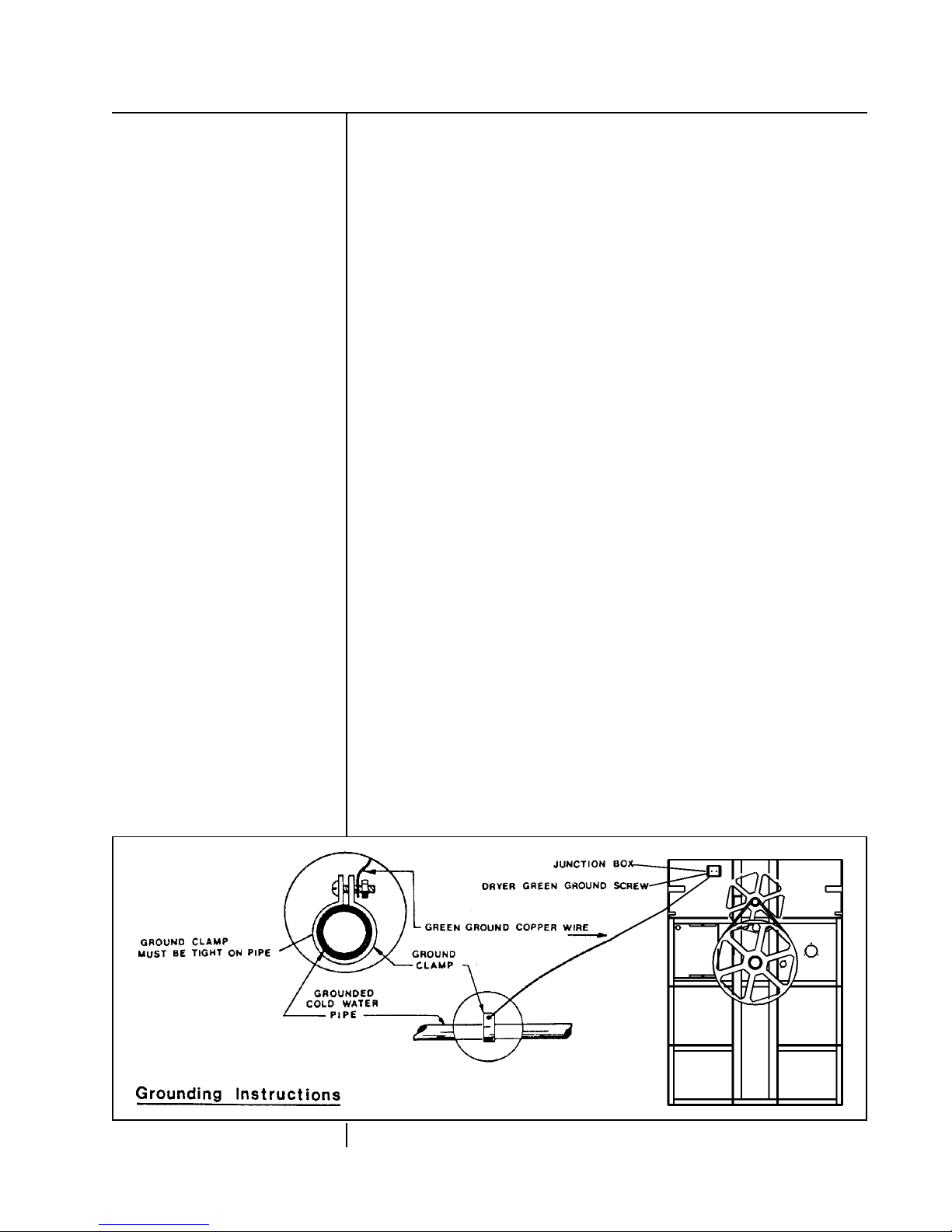

190 lb. Steam Heated Laundry Dryers - Specifications

ELECTRICAL

CONNECTIONS

(ALL DRYERS)

Dryers must be electrically grounded by a separate #14 or larger

green wire from the grounding terminal within the service connection

box to a cold water pipe. In all cases, the grounding method must

comply with local electrical code requirements; or in the absence of

local codes, with the National Electrical Code, ANSI/NFPA 70 or

the Canadian Electrical Code, CA C22.1.

See wiring diagram furnished with dryer. Your dryer is completely

wired at the factory and it is only necessary for the electrician to

connect the power leads to the wire connectors with the service

connection box on the rear of the dryer. Do not connect the dryer to

any voltage or current other than that specified on the dryer rating

plate. (Wiring diagram is located on rear wall of dryer.)

All panels must be in position before operation of dryer.

CAUTION: Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper operation.

Attention. Lors des opérations dentretien des commandes,

ètiqueter tous les fils avant de les dèconnecter. Toute erreur de

câblage peut être une source de danger et de panne.

(ILLUSTRATION)

GROUNDING

INSTRUCTIONS

Page 17

Main Drive Motors

Motor No. Voltage Hz. Phase HP Amps RPM B/F

MTR290 208/240 60 3 2 6.2 - 6.0 1725 Basket

MTR290 480 60 3 2 3.0 1725 Basket

MTR296 380 60 3 2 4.2 - 4.6 1725 Basket

MTR292 220/380 50 3 2 6.4/3.7 1425 Basket

MTR292 240/415 50 3 2 6.4/3.7 1425 Basket

MTR309 208/240 60 3 5 13.0 3450 Fan

MTR291 480 60 3 5 7.1 1725 Fan

MTR298 240 50 3 5 8.4 1425 Fan

MTR298 380 60 3 5 17.2 - 16.8 1725 Fan

MTR293 220/380 50 3 5 6.05/12.1 1425 Fan

MTR293 240/415 50 3 5 6.05/12.1 1425 Fan

Page 18

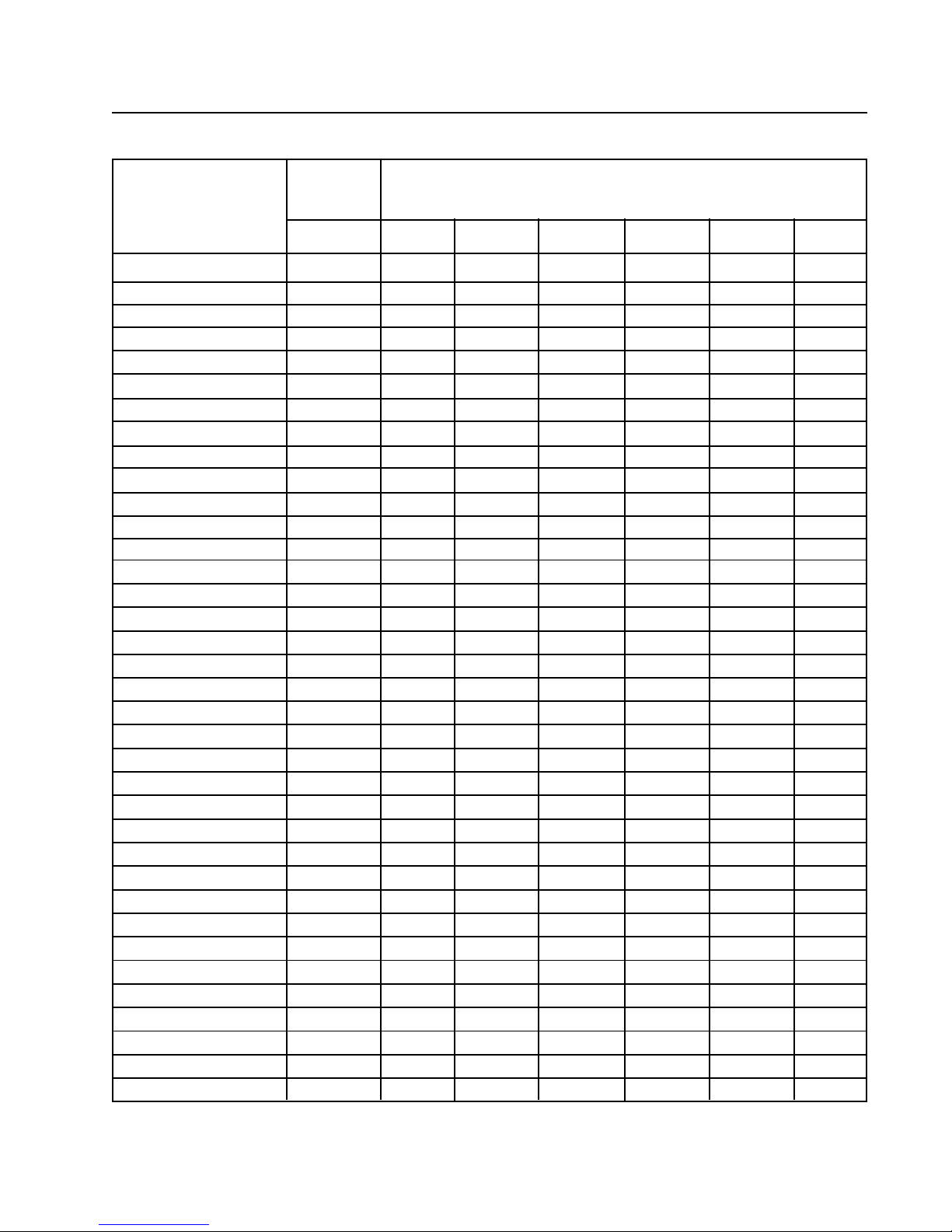

Gas Pipe Size Chart

TOTAL BTU/HR

(for LP Gas correct

total BTU/HR below by

multiplying by .6)

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

300,000

400,000

500,000

600,000

700,000

800,000

900,000

1,000,000

1,100,000

1,200,000

1,300,000

1,400,000

1,500,000

1,600,000

1,700,000

1,800,000

1,900,000

2,000,000

2,200,000

2,400,000

2,600,000

2,800,000

3,000,000

3,200,000

3,400,000

3,600,000

3,800,000

4,000,000

TOTAL

KCAL

HOUR

15000

20000

25200

30200

35200

40300

45300

50400

75600

100800

126000

151200

176400

202000

230000

250000

270000

300000

330000

350000

380000

400000

430000

450000

480000

504000

550000

605000

650000

705000

750000

806000

850000

907000

960000

1000000

(25 ft.)

7,62 m

3/4

3/4

3/4

3/4

3/4

3/4

1

1

1

1 1/4

1 1/4

1 1/2

1 1/2

1 1/2

2

2

2

2

2

2

2

2

2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

3

3

3

3

3

GAS PIPE SIZE FOR 1000 BTU (250 KCAL) NATURAL GAS

In figuring total length of pipe, make allowance for tees and elbows.

(50 ft.)

15,24 m

3/4

3/4

3/4

1 1/4

1 1/4

1 1/2

1 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

3 1/2

3 1/2

3 1/2

3 1/2

AT 7 (17.8 CM) W.C. PRESSURE

(75 ft.)

22,86 m

3/4

3/4

1

1

1

1

1

1

2

2

2

2

2

2

3

3

3

3

3

3

1

1

1

1

1 1/4

1 1/4

1 1/2

1 1/2

2

2

2

2

2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

3

3

3

3

3

3

3

3 1/2

3 1/2

3 1/2

3 1/2

3 1/2

3 1/2

(100 ft.)

30,48 m

3/4

1

1

1

1

1 1/4

1 1/4

1 1/4

1 1/2

1 1/2

2

2

2

2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

3

3

3

3

3

3

3

3 1/2

3 1/2

3 1/2

3 1/2

3 1/2

3 1/2

4

4

(125 ft.)

38,1 m

3/4

1

1

1

1

1 1/4

1 1/4

1 1/4

1 1/2

1 1/2

2

2

2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

3

3

3

3

3

3

3

3 1/2

3 1/2

3 1/2

3 1/2

3 1/2

3 1/2

4

4

4

4

(150 ft.)

45,72 m

3/4

1

1

1

1 1/4

1 1/4

1 1/4

1 1/2

1 1/2

2

2

2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

2 1/2

3

3

3

3

3

3

3

3 1/2

3 1/2

3 1/2

3 1/2

3 1/2

4

4

4

4

4

4

Page 19

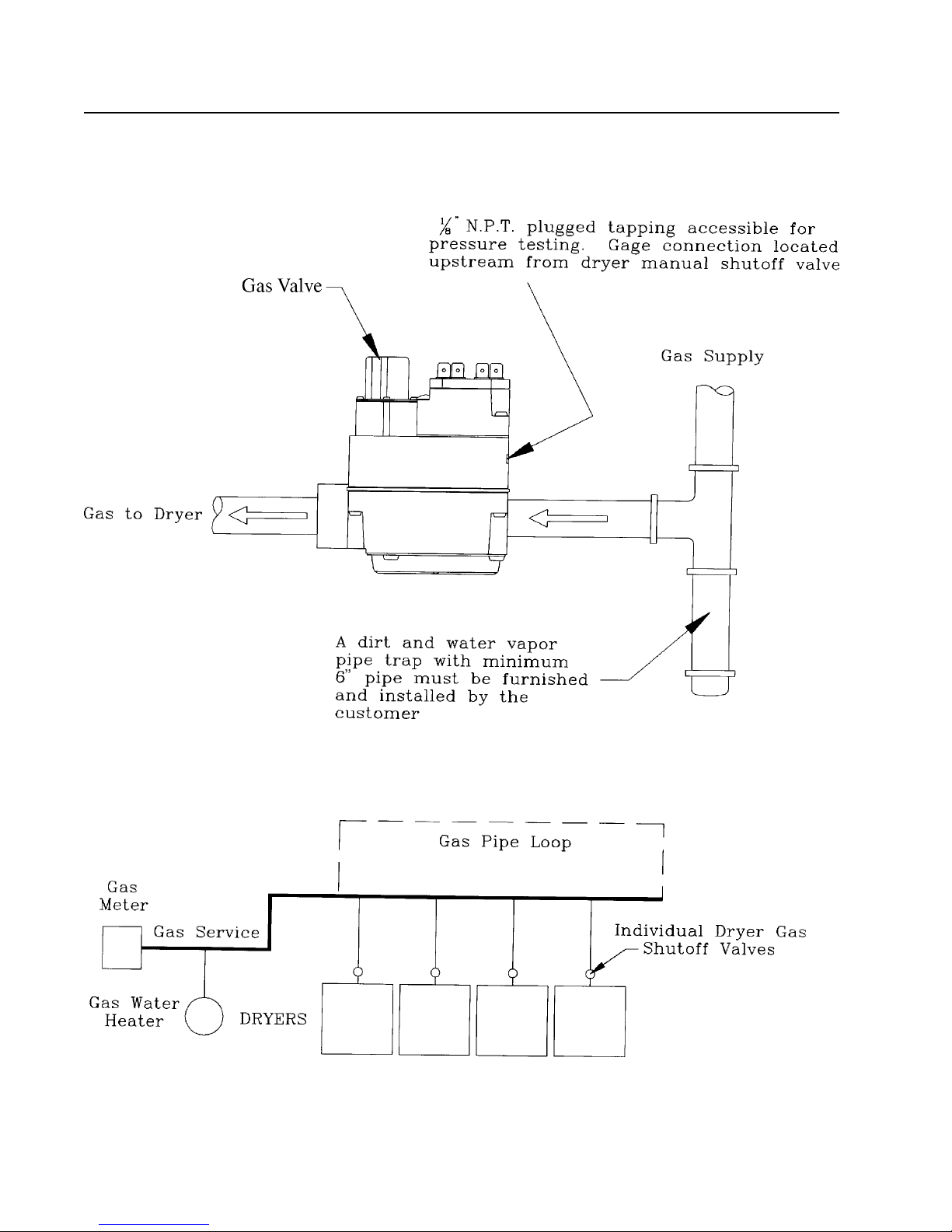

Gas Piping Installation (Illustration)

Page 20

Gas Piping Installation

GAS PIPING

INSTALLATION

1. Gas service installation must conform with local codes, or in

the absence of local codes with the National Fuel Gas Code,

ANSI Z223.1 or the CAN/CGA-B149, Installation Codes.

2. Check rating plate located on rear wall of dryer, for type of

gas to equip the dryer and the altitude (elevation).

3. Check with the gas supplier for the gas pressure and the

proper gas supply line installation.

NOTE: The dryer and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing

of that system at test pressures in excess of 1/2 psi (3.5 kPa).

The dryer must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to or greater

than 1/2 psi (3.5 kPa).

CAUTION: Low gas pressure and intermittent gas will cause gas

ignition problems. This will cause inadequate drying of the clothes

load.

NATURAL GAS ONLY

NATURAL GAS ONLY: Check the gas pressure inlet supply to the

dryer, 11 inches WC pressure maximum. Check the manifold pressure,

3.5 inches WC pressure inside the dryer.

CAUTION: Gas loop piping must be installed as shown on the previous page, to maintain equal pressure for all dryers connected to a

single gas service. Install other gas appliances upstream from the

loop.

Specific gas pipe size should be obtained from your supplier or refer to the

Gas Pipe Size Chart in this manual.

Page 21

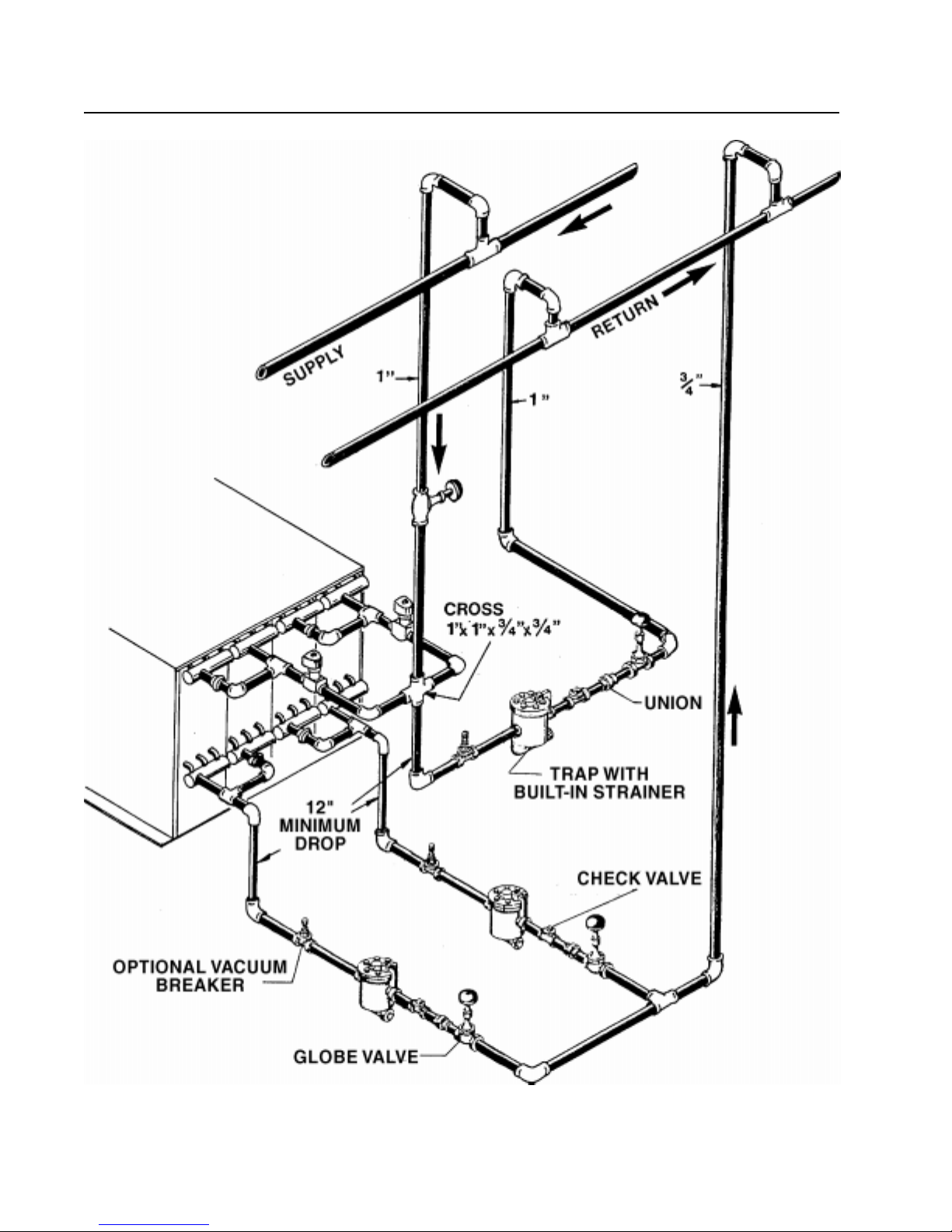

Steam Piping Installation (Illustration)

INDIVIDUALLY TRAPPED COILS ARE RECOMMENDED RATHER THAN MANFOLDING RETURN

INTO ONE TRAP.

Page 22

Steam Piping - Installation Instructions

STEAM PIPING

INSTALLATION

INSTRUCTIONS

1. Set and anchor dryer in position. Machine should be level to assure

proper steam circulation.

2. To prevent condensate draining from headers to dryer, piping should have

a minimum 12 above respective header. Do not make steam connection

to header with a horizontal or downwardly facing tee or elbow.

3. Whenever possible, horizontal runs of steam lines must drain, by gravity,

to respective steam header. Water pockets, or an improperly drained

steam header will provide wet steam, causing improper operation of dryer.

If pockets or improper drainage cannot be eliminated, install a by-pass

trap to drain condensate from the low point in the steam supply header to

the return.

4. In both steam supply and steam return line, it is recommended that each

have a union and a globe valve. This will enable you to disconnect the

steam connections and service the dryer whole your plant is in operation.

5. Before connecting trap and check valve to dryer, open globe valve in

steam supply line and allow steam to flow through dryer to flush out any

dirt and scale from dryer. This will assure proper operation of trap when

connected.

6. After flushing system, install bucket trap (with built-in strainer) and check

valve. For successful operation of dryer, install trap 18 below coil and as

near to the dryer as possible. Inspect trap carefully for inlet and outlet

markings and install according to trap manufacturer's instructions. If

steam is gravity returned to boiler, omit trap but install check valve in

return line near dryer.

PIPING

RECOMMENDATIONS

7. Install union and globe valve in return line and make final pipe connections to return header.

1. Trap each dryer individually. Always keep the trap clean and in good

working condition.

2. When dryer is on the end of a line of equipment, extend header at least 4

feet beyond dryer. Install globe valve, union, check valve and by-pass trap

at end of line. If gravity return to boiler, omit trap.

3. Insulate steam supply and return line for safety of operator and safety

while servicing dryer.

4. Keep dryer in good working condition. Repair or replace any worn or

defective parts.

Page 23

Loading...

Loading...