Cissell FINTUNMAN67 User Manual

WARRANTY

The Cissell Manufacturing Company (Cissell) warrants all new equipment (and the original parts thereof)

to be free from defects in material or workmanship for a period of one (1) year from the date of sale thereof

to an original purchaser for use, except as hereinafter provided. With respect to non-durable parts normally

requiring replacement in less than one (1) year due to normal wear and tear, including, but not limited to,

cloth goods, valve discs, hoses, and iron cords, and with respect to all new repair or replacement parts for

Cissell equipment for which the one (1) year warranty period has expired, or for all new repair or

replacement parts for equipment other than Cissell equipment, the warranty period is limited to ninety (90)

days from date of sale. The warranty period on each new replacement part furnished by Cissell in fulfillment

of the warranty on new equipment or parts shall be for the unexpired portion of the original warranty period

on the part replaced.

With respect to electric motors, coin meters and other accessories furnished with the new equipment, but

not manufactured by Cissell, the warranty is limited to that provided by the respective manufacturer.

Cissell's total liability arising out of the manufacture and sale of new equipment and parts, whether under

the warranty or caused by Cissell's negligence or otherwise, shall be limited to Cissell repairing or replacing,

at its option, any defective equipment or part returned f.o.b. Cissell's factory, transportation prepaid, within

the applicable warranty period and found by Cissell to have been defective, and in no event shall Cissell be

liable for damages of any kind, whether for any injury to persons or property or for any special or

consequential damages. The liability of Cissell does not include furnishing (or paying for) any labor such

as that required to service, remove or install; to diagnose troubles; to adjust, remove or replace defective

equipment or a part; nor does it include any responsibility for transportation expense which is involved

therein.

The warranty of Cissell is contingent upon installation and use of its equipment under normal operating

conditions. The warranty is void on equipment or parts; that have been subjected to misuse, accident, or

negligent damage; operated under loads, pressures, speeds, electrical connections, plumbing, or conditions

other than those specified by Cissell; operated or repaired with other than genuine Cissell replacement

parts; damaged by fire, flood, vandalism, or such other causes beyond the control of Cissell; altered or

repaired in any way that effects the reliability or detracts from its performance, or; which have had the

identification plate, or serial number, altered, defaced, or removed.

No defective equipment or part may be returned to Cissell for repair or replacement without prior written

authorization from Cissell. Charges for unauthorized repairs will not be accepted or paid by Cissell.

CISSELL MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY, STATUTORY OR OTHERWISE,

CONCERNING THE EQUIPMENT OR PARTS INCLUDING, WITHOUT LIMITATION, A WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE, OR A WARRANTY OF MERCHANTABILITY. THE

WARRANTIES GIVEN ABOVE ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED. CISSELL NEITHER ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT,

ANY OTHER WARRANTY OR LIABILITY IN CONNECTION WITH THE MANUFACTURE, USE OR SALE

OF ITS EQUIPMENT OR PARTS.

For warranty service, contact the Distributor from whom the Cissell equipment or part was purchased. If

the Distributor cannot be reached, contact Cissell.

Page 1

TABLE OF CONTENTS

GENERAL INFORMATION PAGE

Warranty ........................................................................................................................... 1

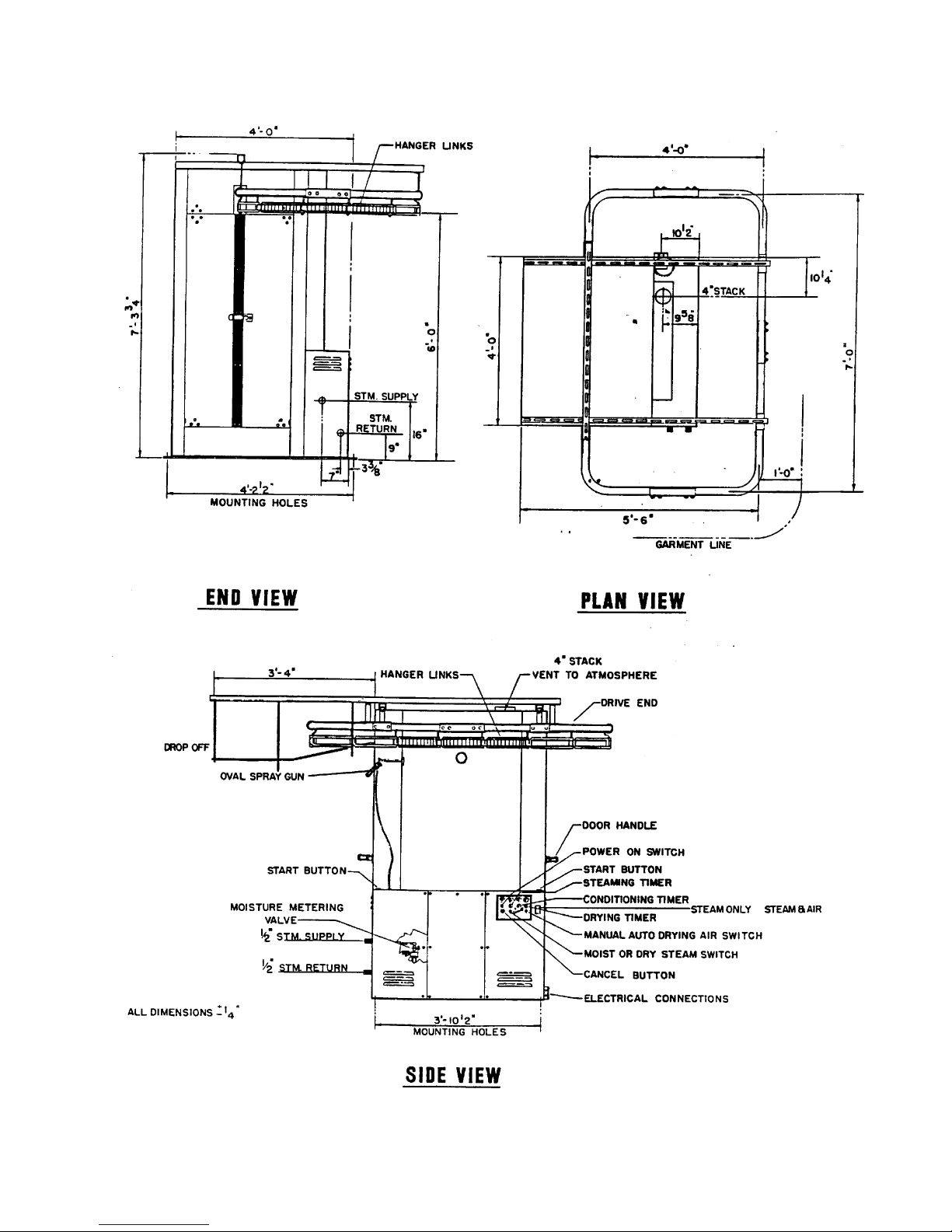

Outline Drawing.............................................................................................................. 3

INSTALLATION AND ADJUSTMENTS

Installation Power Struts.............................................................................................. 4

Steam Piping Installation ........................................................................................... 5-6

Spray Gun Hose Connections....................................................................................... 7

Conveyor Interlock and Door Adjustment................................................................. 9

Conveyor Link Installation.......................................................................................... 10

Door Interlock Switch Adjustment............................................................................. 11

Installation of Switch of Foot Pedal........................................................................... 1 2

Disassembling Tunnel................................................................................................... 1 3

OPERATION

Control Panel Operation............................................................................................... 14

Tunnel Operation Instructions.................................................................................... 15

TROUBLE SHOOTING CHARTS ...................................................................... 16-17

ILLUSTRATED PARTS

Conveyor Struts........................................................................................................... 18-19

Jacket Assembly ............................................................................................................. 20

Blower Assembly............................................................................................................. 2 1

Door Actuator Parts .................................................................................................... 22-23

Dual Spray Gun and Hose ........................................................................................... 2 5

Control Panel .................................................................................................................. 26

Drop Off Assembly ......................................................................................................... 2 7

Electrical Wiring Diagram........................................................................................... 28

Foot Switch and Junction Boxes................................................................................. 29

Conveyor Drive End ................................................................................................... 30-31

Steam Coil and Piping - 50 Hz................................................................................. 32-33

Steam Coil and Piping - 60 Hz................................................................................. 34-35

Mixing Jet Assembly...................................................................................................... 3 6

Water Spray Gun - Overhead Type ............................................................................ 3 7

Conveyor Links............................................................................................................... 38

Electrical Control Schematic ....................................................................................... 3 9

Wiring Diagrams ......................................................................................................... 40-41

Page 2

Page 3

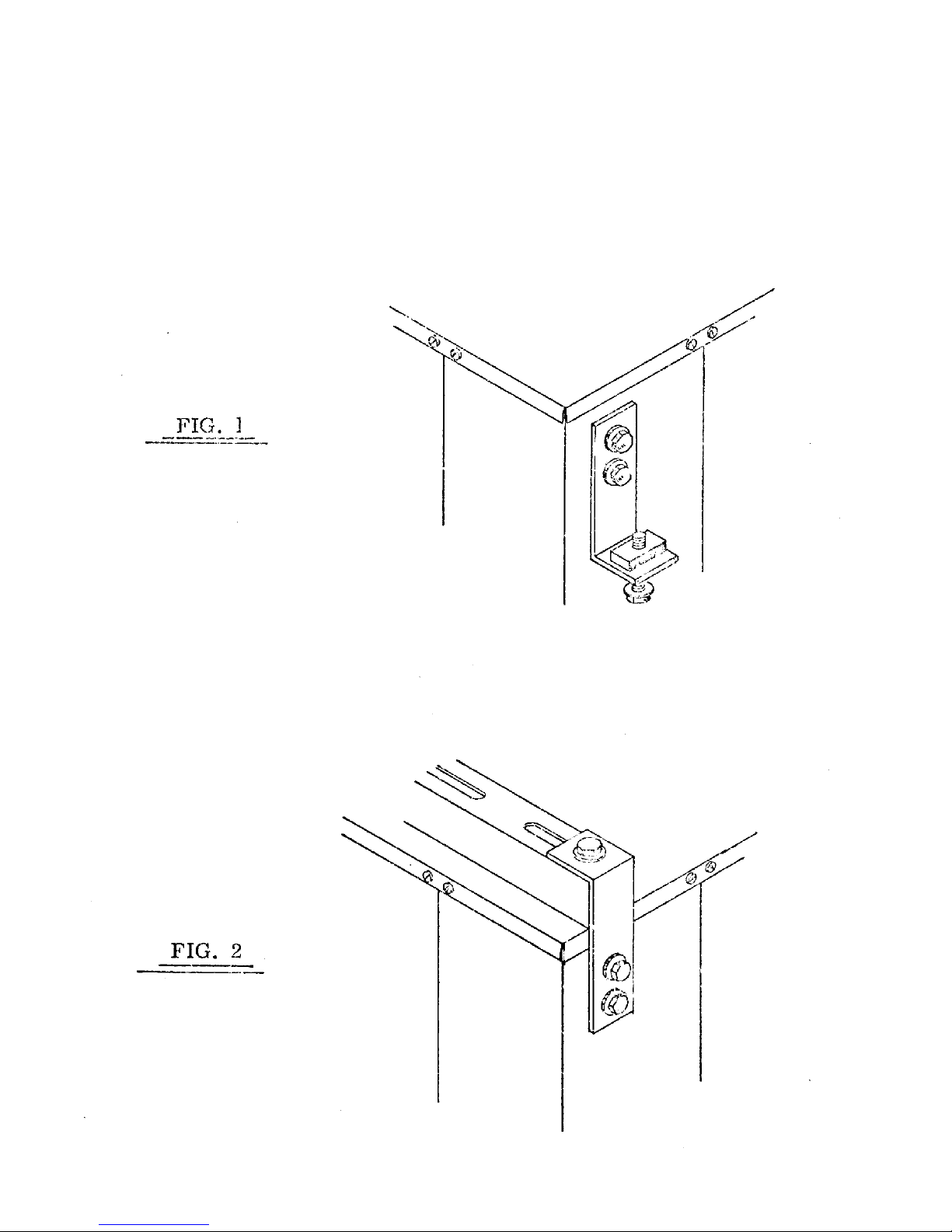

REAR POWER STRUT BRACKETS ARE MOUNTED UPSIDE DOWN FOR

SHIPPING PURPOSES. FIG. 1

WHEN INSTALLING POWER STRUTS, BE SURE TO INSTALL REAR BRACKETS

AS ILLUSTRATED IN FIG. 2.

Page 4

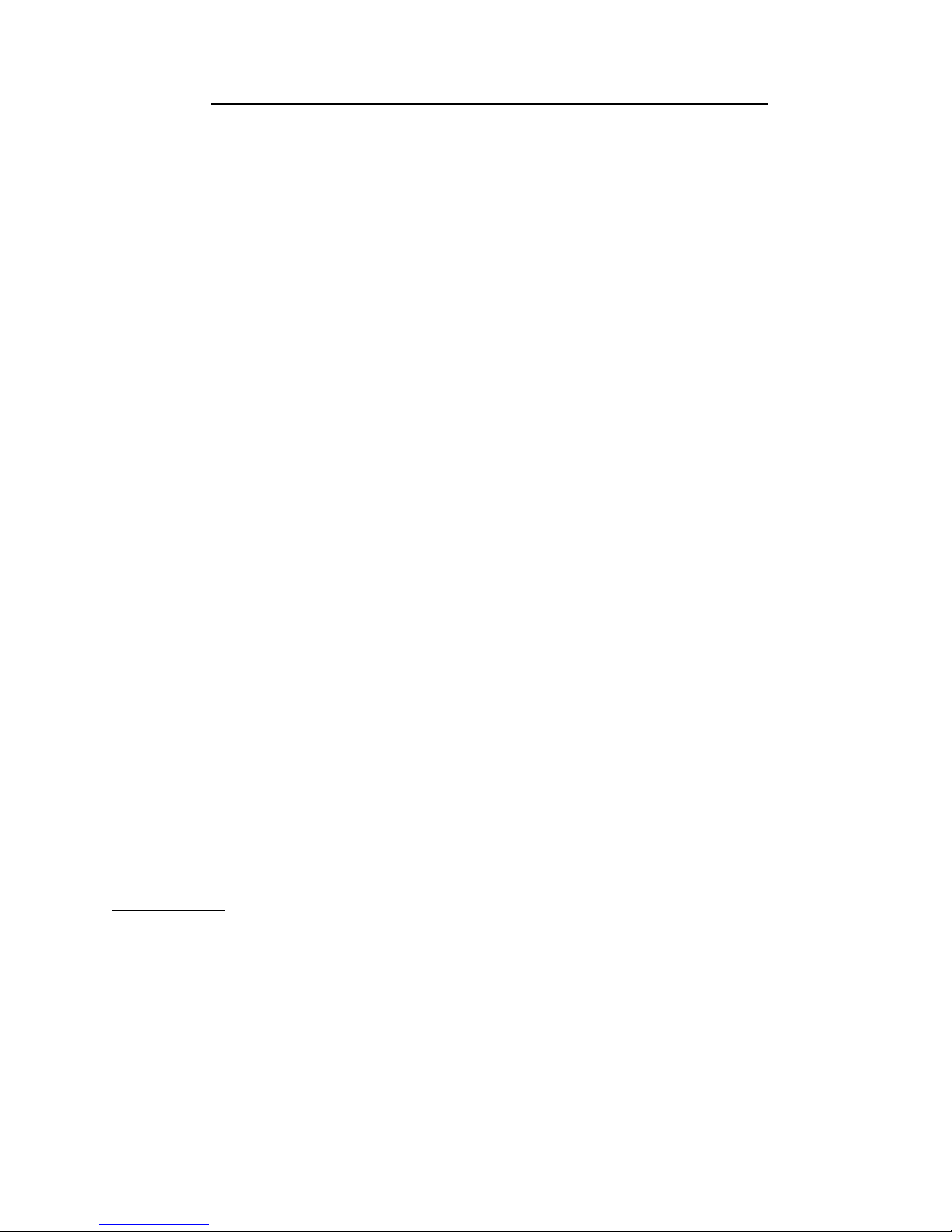

STEAM PIPING INSTALLATION INSTRUCTIONS

Refer to illustration on next page

IMPORTANT: INSTALL STEAM PIPING IN ACCORDANCE WITH

ALL LOCAL REGULATIONS AND REQUIREMENTS

1. Set and anchor Tunnel in position. Machine should be level to assure proper steam

circulation.

2. To prevent condensate draining from headers to Tunnel, piping should have a

minimum riser 12 above each respective header as illustrated. Do not make steam

connection to header with a horizontal or downwardly facing tee or elbow.

3. Whenever possible, horizontal runs of steam lines must drain, by gravity, to

respective steam header. Water pockets, or an improperly drained steam header

will provide wetsteam, causing improper operation of Tunnel. If pockets or

improper drainage cannot beeliminated, install a by-pass trap to drain condensate

from the low point in the steam supply header to the return.

4. In both the steam supply and steam return line, it is recommended that each have a

1/2 union and 1/2 globe valve. This will enable you to disconnect the steam

connections and service the Tunnel while your plant is in operation.

5. When Tunnel is on the end of a line of equipment extend headers at least 4 ft.

beyond Tunnel. Install globe valve, union, check valve and by-pass trap at end of

line. If gravity return to boiler, omit trap.

6. Insulate steam supply and return line for safety of operator and safety while

servicing Tunnel.

7. Keep Tunnel in good working condition. Repair or replace any worn or defective

parts.

8. If steam is dirty, it may be advisable to install a filter or blow-down ahead of tunnel.

Maintenance

The interior of the tunnel will turn white as the protective zinc oxide coating forms.

Do not try to remove this coating.

Do remove lint, dust, and boiler compound or red rust which is entrained by the steam.

Touch-up scratches and chips in the paint.

A good car wax will extend life of the painted surface.

Page 5

Page 6

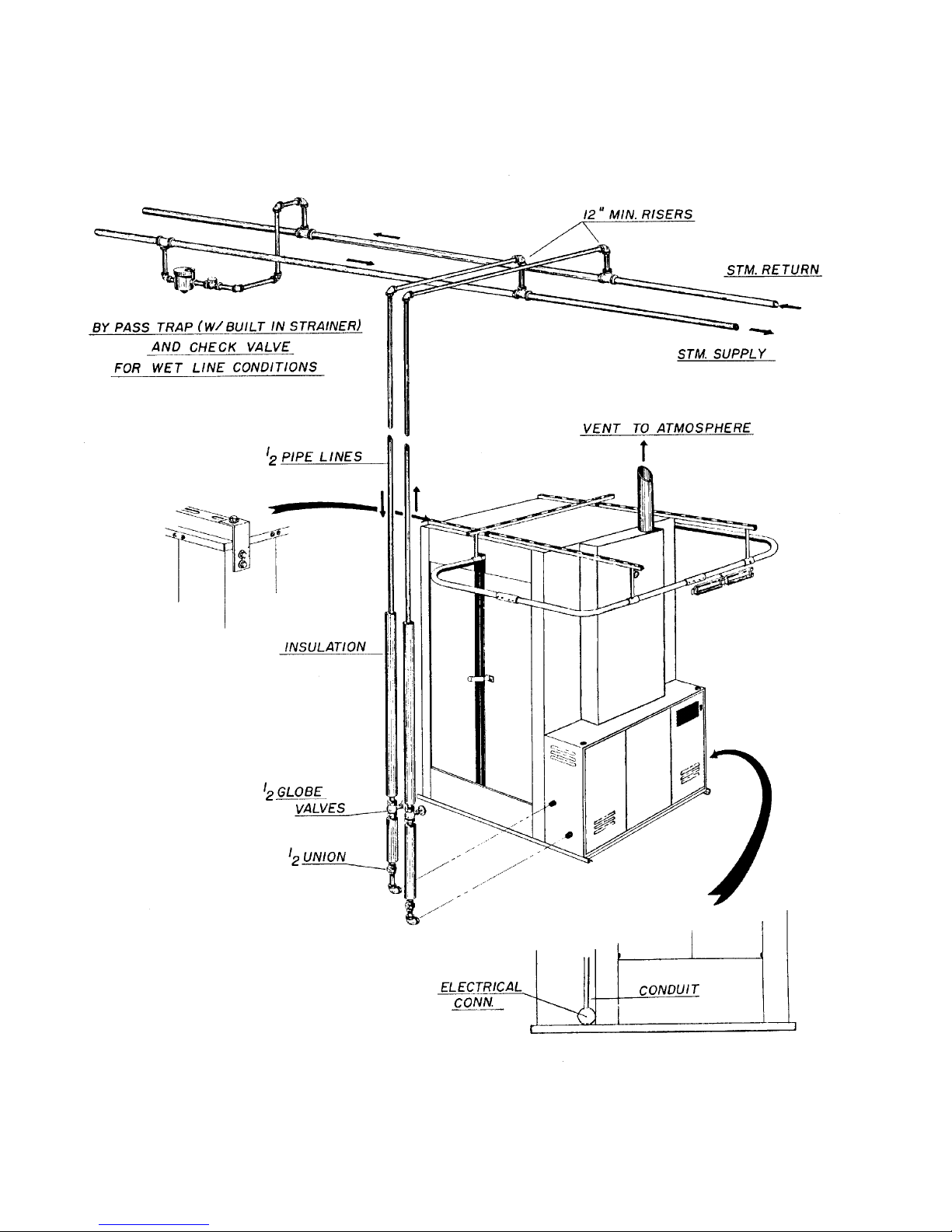

*

NOTE: This connection works best in most installations. Should there be excessive

condensate in the spray, reverse these two connections. Use the configuration that

has the best results.

Page 7

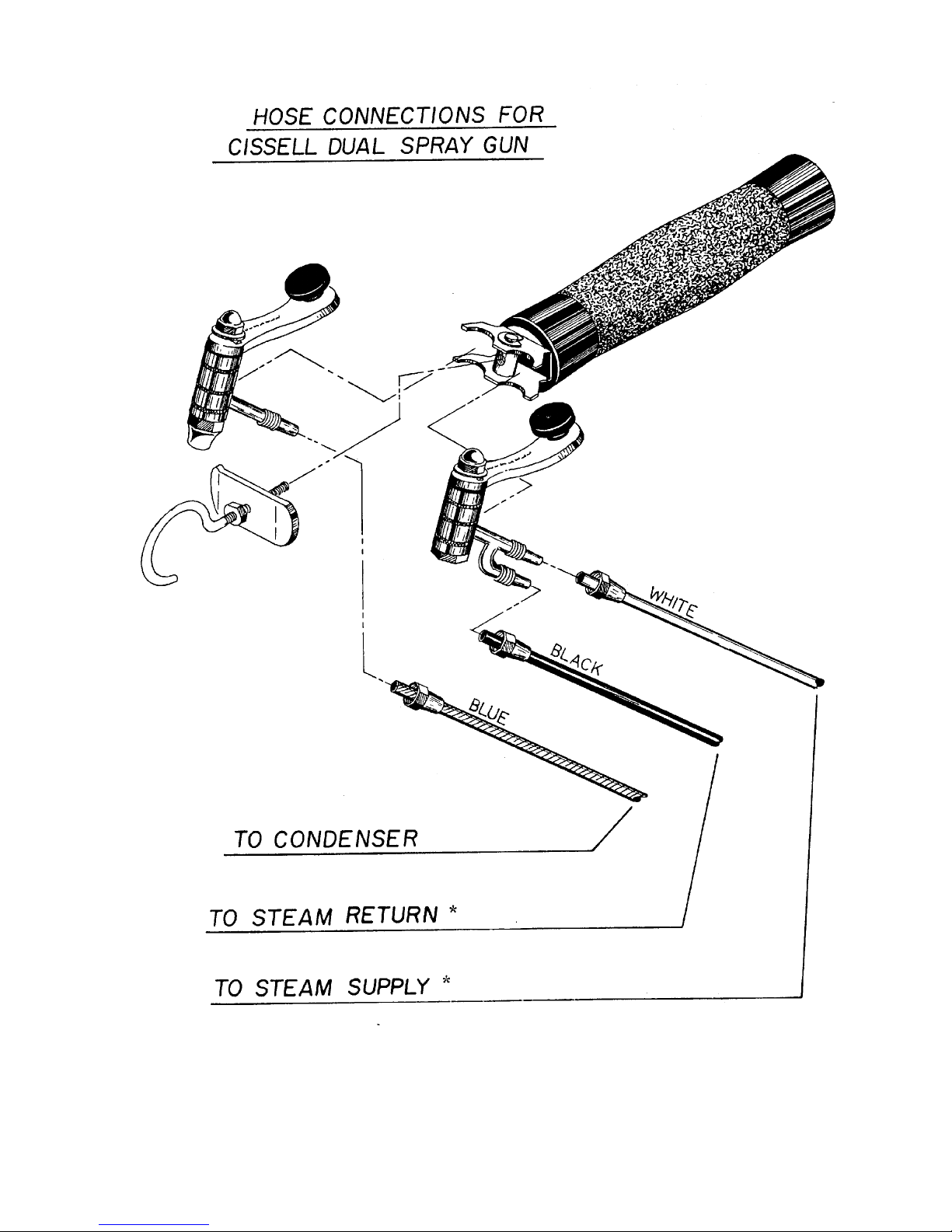

ADJUSTING DROP-OFF

IMPORTANT!

1. Warning! When placing hanger on conveyor, open end of hanger must point toward cabinet.

A hanger placed on the conveyor backwards may result in a damaged garment.

2. Any make of wire hanger with sufficient clearance may be used on the automatic tunnel

conveyor, but all hangers should be the same to insure proper drop-off.

3. Adjust drop-off so that it barely misses the conveyor links by adjusting nuts on the bracket

inside of tunnel as illustrated above in A of Figure 1.

4. Using the selected hanger, then adjust the height of the drop-off as illustrated above in B of

Figure 1.

5. Adjust lower end of drop-off to desired height for proper sliding of garment and for proper

feed to screw conveyor if used (C of Figure 1).

6. Run a few garments through the tunnel and check to be sure that there is clearance at the

top of hanger, and that drop-off operation is smooth. If hanger does not have enough

clearance perhaps a change in hanger is needed. If the drop-off is not smooth, repeat steps

3 through 5 above.

Page 8

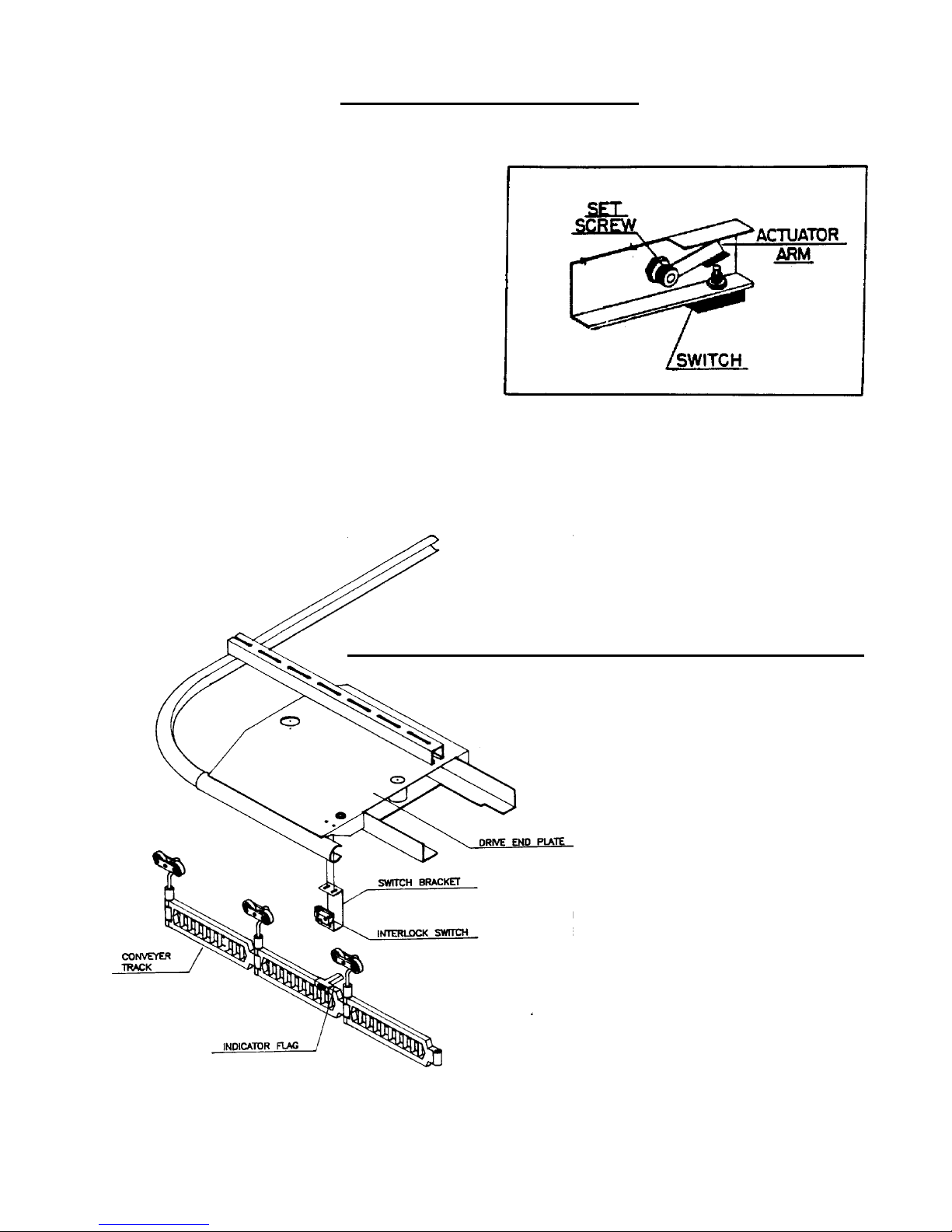

ADJUSTMENT OF DOORS

1. Loosen the set screws that hold the

Actuator arm onto the door lever.

2. Open the doors until they are wide

enough for garment travel; hold in

place.

3. Press Actuator arm onto door switch

so that switch is completely depressed.

Tighten set screws onto door lever.

ADJUSTMENT OF CONVERTER INTERLOCK

1. Interlock switch should be positioned so

that when a flag indicator activates the

conveyor interlock switch, a load of

garments are completely inside the

tunnel.

2. If the adjustment is off, loosen the screws

on the conveyor interlock switch bracket

and slide bracket until properly

positioned.

Page 9

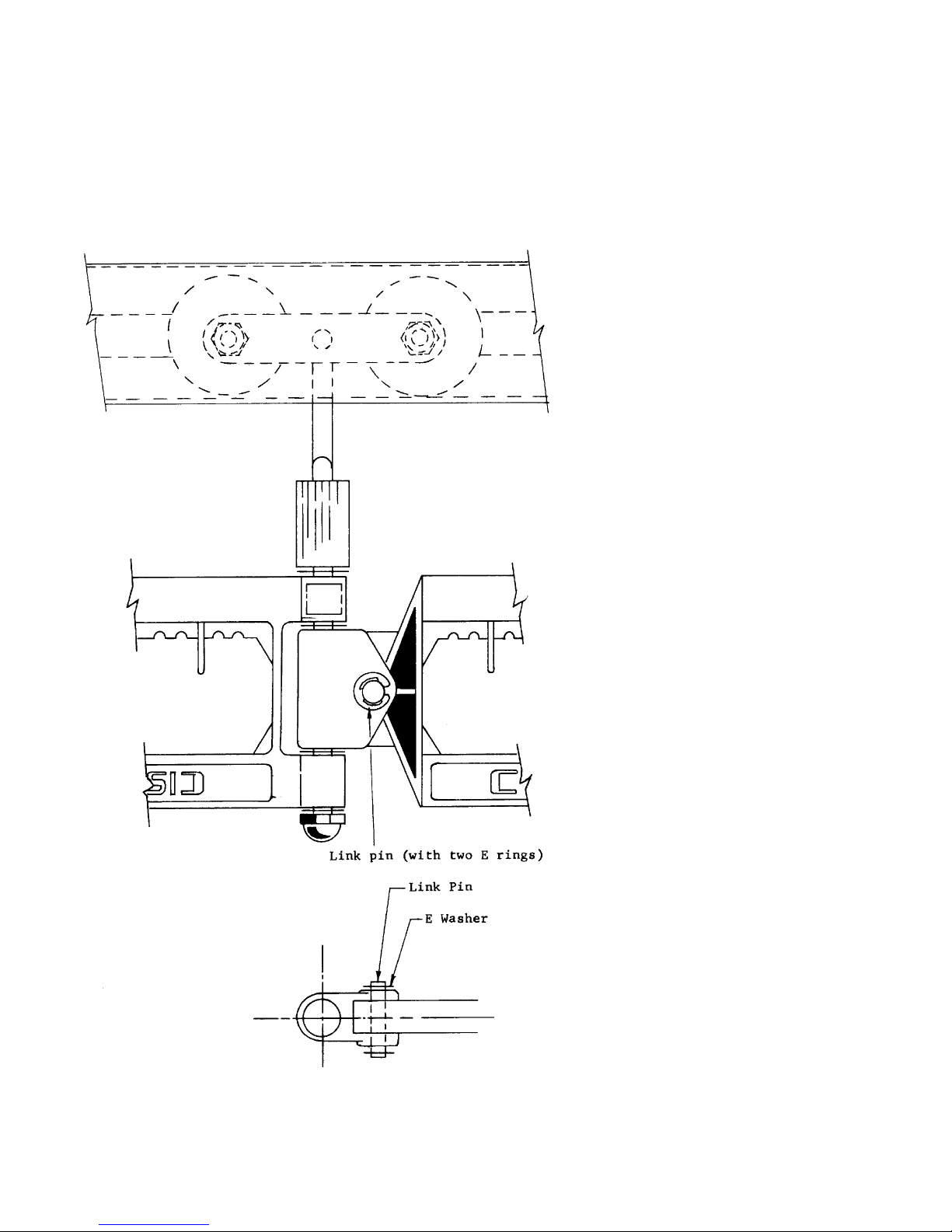

INSTALLATION INSTRUCTIONS

For Connecting Floor Model Link Sections on Conveyor

1. Move connecting link

preferably to a straight

portion of the track.

2. Insert the connecting pin

(as illustrated) and replace

the E ring in the Groove

of the pin.

NOTE: Inspect E ring to

be certain that it has

snapped securely into the

groove of the pin.

Page 10

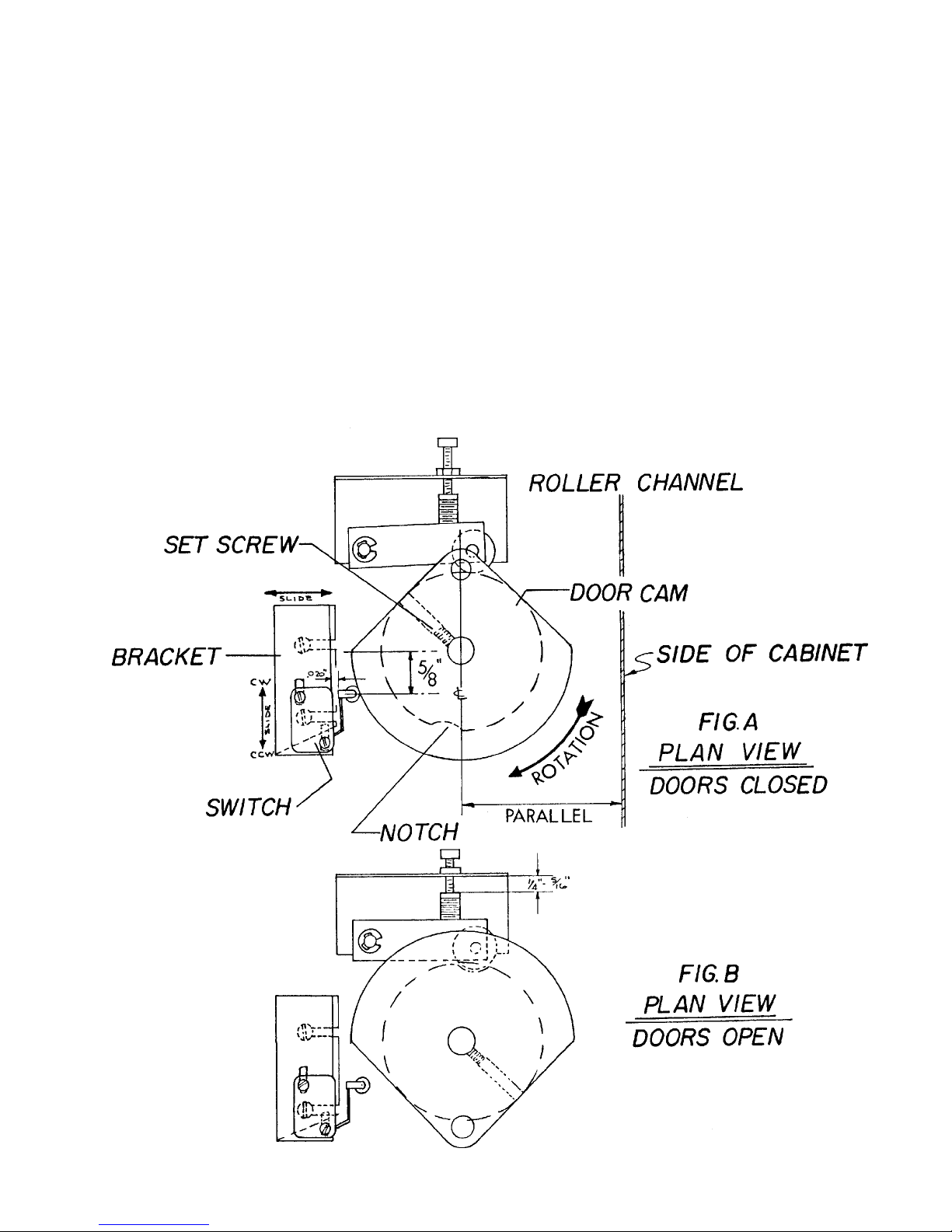

DOOR INTERLOCK

SWITCH ADJUSTMENT

1. With doors in closed position the switch should be set as shown in Figure A.

2. Figure B shows correct cam and roller alignment with doors in open position. To

check cam and roller alignment press start button and when the doors stop in the

open position, turn off main power switch. Check to see that the roller is centered

in the notch on the cam hub. If the cam has not rotated a full 180º to allow roller to

drop into notch, adjust the switch clockwise (up) approximately 1/16. If the cam

has rotated more than 180º, adjust the switch counter clockwise (down)

approximately 1/16. Repeat until roller drops into notch.

Page 11

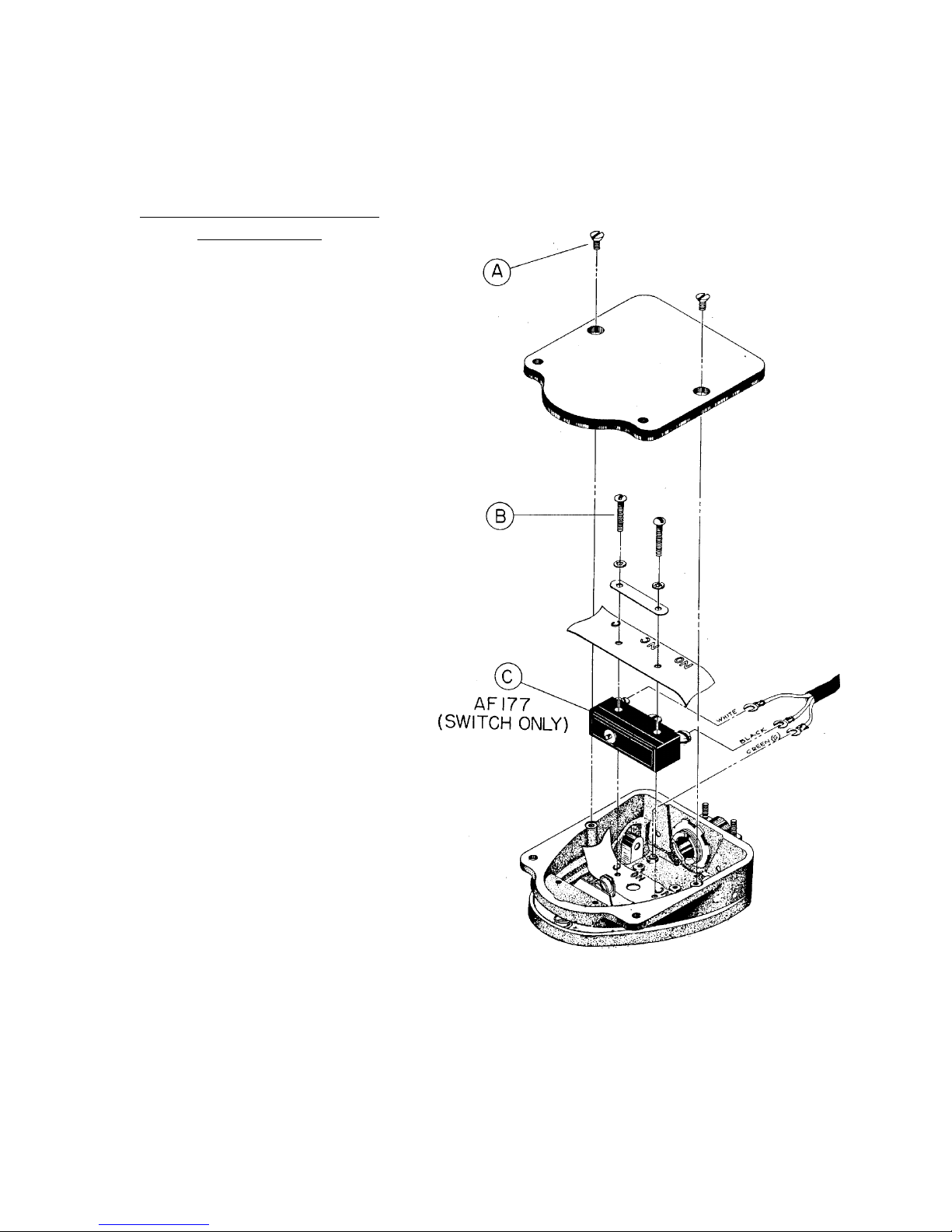

INSTALLATION INSTRUCTIONS

FOR AF177 MICRO SWITCH

PT527 Foot Pedal Complete

w/3-Wire Cord

1. Turn switch to inverted position and

remove screws (A) as illustrated.

2. Lift off base plate pad.

3. Remove screws marked (B) as

shown.

4. Remove washers, plate, insulation

and switch.

5. Remove wires from old switch.

Reinstall wires on new switch (C)

and tighten securely.

6. Reinstall switch, insulation, plate,

washers and screws. Tighten

securely.

7. Reinstall base-plate-pad and screws.

Tighten securely.

Page 12

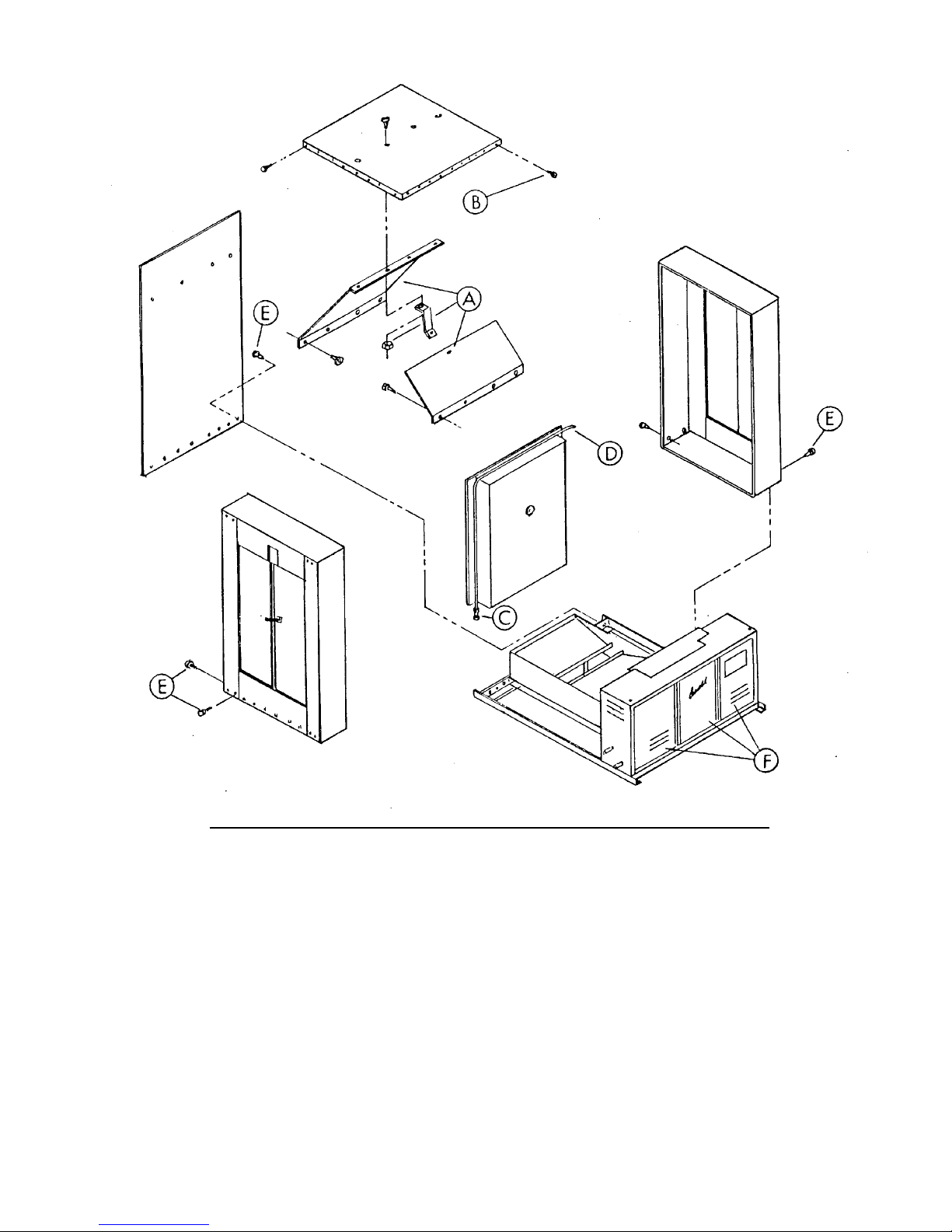

INSTRUCTIONS FOR DISASSEMBLING TUNNEL

1. Remove nuts, bolts, and screws holding Drip Pans (A) in place and remove Drip

Pan.

2. Remove screws (B) around the top and remove top.

3. Remove Center Door and open End Doors (F).

4. Remove Thermometer Bulb by loosening clip that holds it.

5. Break Union (C) and disconnect Copper Tube (D) to Condenser.

6. Remove Upper Linkage between Doors and remove Door Spring.

7. Remove Screws (E) located around the bottom of the Tunnel and the top of Controls

Section.

8. Remove End Sections and Side Panels.

9. To reassemble, follow procedure in reverse.

Page 13

Loading...

Loading...