Cissell FFMAN57, FFCD, FFCG Owner's Manual

FF

Form

Finisher

Models

FFCD

FFCG

OWNERS MANUAL

CISSELL MANUFACTURING COMPANY

HEADQUARTERS PHONE: (502) 587-1292

831 SOUTH FIRST ST. SALES FAX: (502) 585-3625

P.O. BOX 32270 SERVICE/PARTS FAX: (502) 681-1275

LOUISVILLE, KY 40232-2270

THIS MANUAL MUST BE GIVEN TO THE EQUIPMENT OWNER.

MAN57 8/98

Page 1

WARRANTY

The Cissell Manufacturing Company (Cissell) warrants all new equipment (and the original parts thereof) to be free from

defects in material or workmanship for a period of one (1) year from the date of sale thereof to an original purchaser for

use, except as hereinafter provided. With respect to non-durable parts normally requiring replacement in less than one (1)

year due to normal wear and tear, including, but not limited to, cloth goods, valve discs, hoses, and iron cords, and with

respect to all new repair or replacement parts for Cissell equipment for which the one (1) year warranty period has expired,

or for all new repair or replacement parts for equipment other than Cissell equipment, the warranty period is limited to

ninety (90) days from date of sale. The warranty period on each new replacement part furnished by Cissell in fulfillment

of the warranty on new equipment or parts shall be for the unexpired portion of the original warranty period on the part

replaced.

With respect to electric motors, coin meters and other accessories furnished with the new equipment, but not manufactured

by Cissell, the warranty is limited to that provided by the respective manufacturer.

Cissell's total liability arising out of the manufacture and sale of new equipment and parts, whether under the warranty or

caused by Cissell's negligence or otherwise, shall be limited to Cissell repairing or replacing, at its option, any defective

equipment or part returned f.o.b. Cissell's factory, transportation prepaid, within the applicable warranty period and found

by Cissell to have been defective, and in no event shall Cissell be liable for damages of any kind, whether for any injury to

persons or property or for any special or consequential damages. The liability of Cissell does not include furnishing (or

paying for) any labor such as that required to service, remove or install; to diagnose troubles; to adjust, remove or replace

defective equipment or a part; nor does it include any responsibility for transportation expense which is involved therein.

The warranty of Cissell is contingent upon installation and use of its equipment under normal operating conditions. The

warranty is void on equipment or parts; that have been subjected to misuse, accident, or negligent damage; operated under

loads, pressures, speeds, electrical connections, plumbing, or conditions other than those specified by Cissell; operated

or repaired with other than genuine Cissell replacement parts; damaged by fire, flood, vandalism, or such other causes

beyond the control of Cissell; altered or repaired in any way that effects the reliability or detracts from its performance,

or; which have had the identification plate, or serial number, altered, defaced, or removed.

No defective equipment or part may be returned to Cissell for repair or replacement without prior written authorization

from Cissell. Charges for unauthorized repairs will not be accepted or paid by Cissell.

CISSELL MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY, STATUTORY OR OTHERWISE, CONCERNING

THE EQUIPMENT OR PARTS INCLUDING, WITHOUT LIMITATION, A WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE, OR A WARRANTY OF MERCHANTABILITY. THE WARRANTIES GIVEN ABOVE ARE EXPRESSLY IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. CISSELL NEITHER ASSUMES, NOR AUTHORIZES

ANY PERSON TO ASSUME FOR IT, ANY OTHER WARRANTY OR LIABILITY IN CONNECTION WITH THE

MANUFACTURE, USE OR SALE OF ITS EQUIPMENT OR PARTS.

For warranty service, contact the Distributor from whom the Cissell equipment or part was purchased. If the Distributor

cannot be reached, contact Cissell.

Page 2

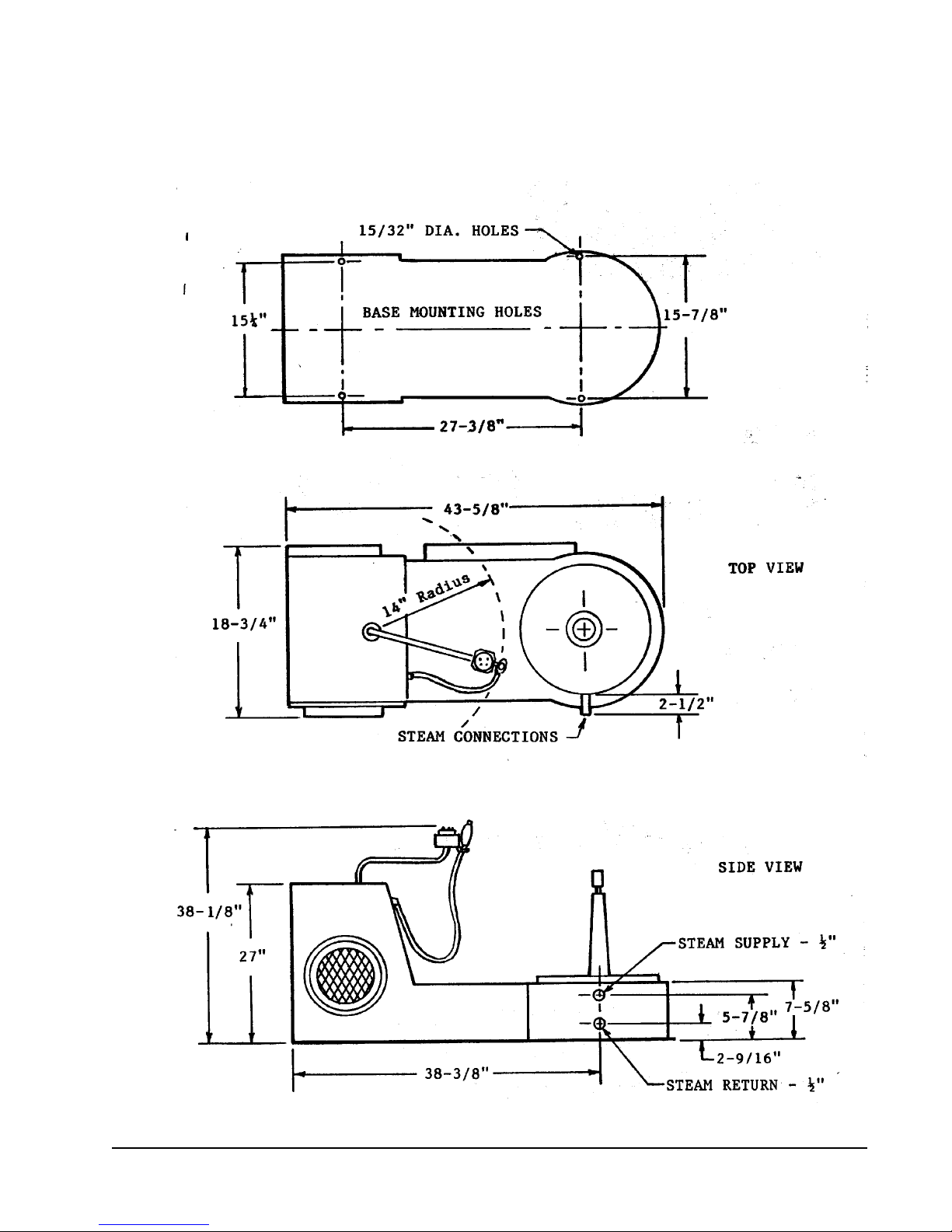

FF FORM FINISHER

LOW BASE OVERALL DIMENSIONS

Page 3

SPECIFICATIONS

Cissell Form Finisher includes one set of #11 Sleevers, one set of #24 Sleevers, and two

Cissell Vent Clamps. Electric Motor: 1/3 (250 w) HP, 1725 RPM, 115 or 230 Volt, 60

Cycle, AC, Single Phase. Other voltages and currents available.

Operating Steam Pressure ............................................... 100 P.S.I.G. Max. (6.9 bars)

Boiler HP Approx. 2 (1.5 kw) Depth ............................................... 57 (145 cm)

Steam Sply. & Ret. .... 1/2 (1.27 cm) Height ............................................ 61 (155 cm)

Swinging Radium 19 (48 cm) Width.................................................... 22 (56 cm)

Net Weight .............................................................................................. 245 lbs. (111 kg)

Approximate Shipping Weights: Domestic ....................................... 290 lbs. (132 kg)

Export.............................................. 435 lbs. (197 kg)

Export Shipping

Diminsions ................................................... 61 (155 cm) x 30 (76 cm) x 44 (112 cm)

Cubic Feet Export Crating ....................................................................... 46.6 (1.32 m3)

When ordering specify voltage desired.

CISSELL FORM FINISHER - with Taller Revolving Assembly which differs from specifications for standard model given above:

Height ............................................................................................................... 67 (170 cm)

Net Weight Approx. ................................................................................. 250 lbs. (113 kg)

Approximate Shipping Weight: Domestic ......................................... 295 lbs. (134 kg)

Export.......................................... 435 lbs. (197 kg)

Export Shipping

Dimensions ........................................ 61 (175 cm) x 30 (76 cm) x 44 (112 cm)

Cubic Feet Export Crating ..................................................... Approx. 46.6 (1.32 m3)

THE CISSELL FORM FINISHER IS MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING PATENTS: 2,459,962; 2,736,471;

2,736,472; 2,805,009; 2,998,171; 2,889,969; 2,895,659; 2,948,443; 3,006,516; 3,033,429; 3,051,358; 3,058,635; 3,140,830. OTHER PATS. APPLIED

FOR.

NOTE: All dimensions are approximate and may vary with adjustment

or the addition of optional equipment. Information in this manual is

subject to change without prior notice.

Page 4

CISSELL FORM FINISHER

GENERAL INFORMATION

UNCRATE FINISHER. Check voltage and current on name plate of motor before installing machine.

Electrical Specification of Relay and Solenoid (within junction box on Finisher) must be the same as

the motor. Do not remove the plastic protective cover on the Nylon Form until the machine is ready to

be placed in operation.

INSTALLATION

SET FINISHER IN POSITION. Grip handle of front and rear clamps and lift revolving form about

22 to remove from base.

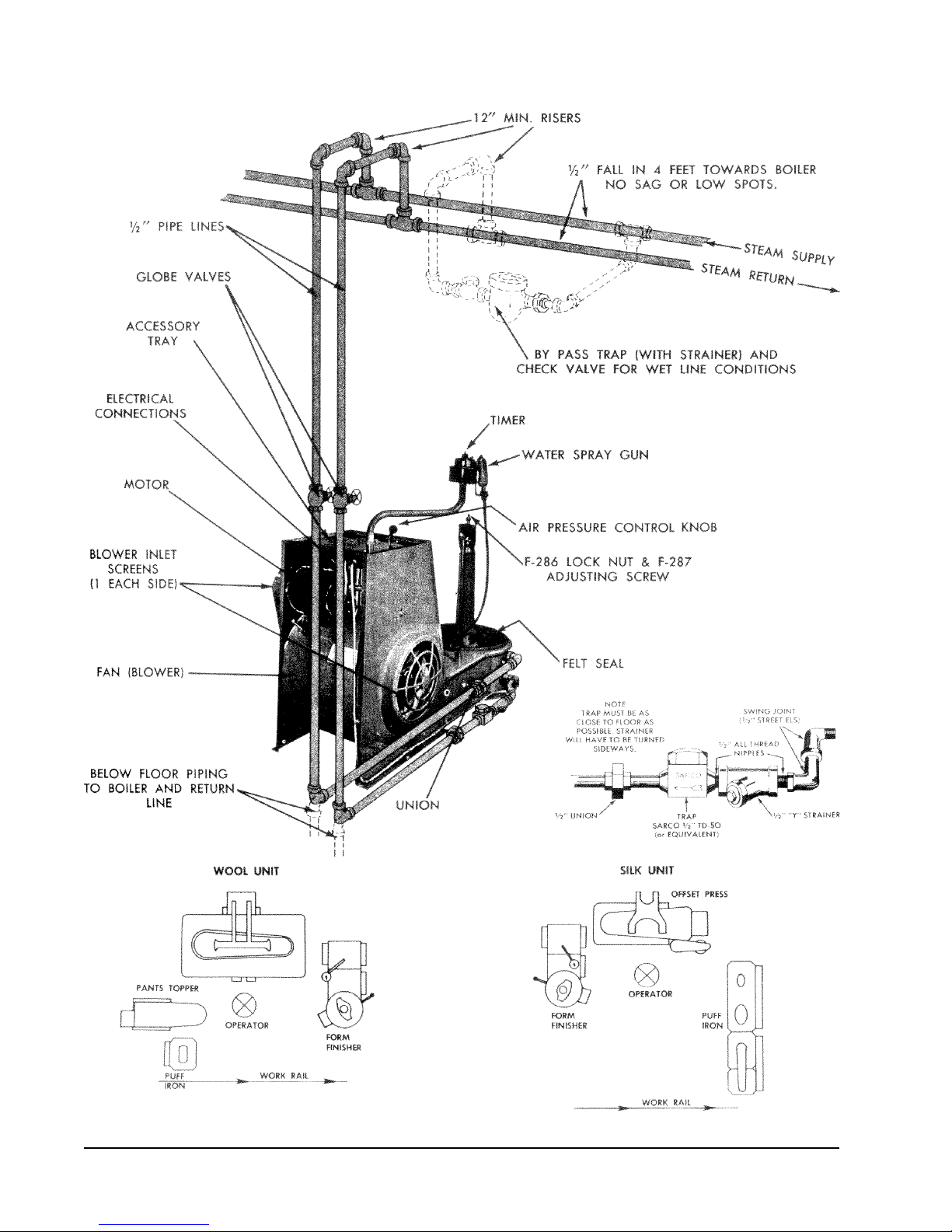

STEAM SUPPLY line must fall towards machine (without water pockets.) Connect Finisher to steam

supply line with union, globe valve and 12 (or more) riser, as illustrated on reverse side. If Finisher

is located at the end of stream line, extend line at least 4 feet beyond machine, and install a by-pass

trap and check valve as illustrated in dotted lines; if gravity return, omit trap.

STEAM RETURN line must fall towards boiler (without water pockets). Connect Finisher to steam

return line with a swing connection, unions, strainer, trap, check valve and 12 (or more) riser as

illustrated on reverse side. Inspect trap carefully for inlet and outlet markings and install swing

connection, trap, and check valve as close to machine as possible with trap as close to floor as

practical.

Use a separate trap for the Finisher; keep it clean and in good working condition for best performance. If steam line is gravity returned to boiler, omit trap.

IMPORTANT: Before installing trap and connecting steam return line, open globe valve in steam

supply connection and flush pipe dope, borings and other foreign matter, from steam connections and

steam chamber within Finisher. Failure to do this may later cause trap trouble.

THE STANDARD Cissell Form Finisher has single phase motors and controls.

MAKE ELECTRICAL CONNECTIONS as indicated on wiring diagram attached to inside cover of

electrical junction box on Finisher. Voltage and current of power line must be the same as the Electrical Specifications of the motor, relay and solenoid.

FOR SINGLE PHASE CURRENT (120V), connect the black and white power leads of the Finisher to

an approved fused disconnect switch in the power line.

(continued)

Page 5

Page 6

TO CONNECT STANDARD, SINGLE PHASE MACHINE TO THREE PHASE CURRENT, connect

the black and white power leads of the Finisher to any two terminals of an approved fused disconnect

switch in the three phase power line.

IMPORTANT: Consult your local electrical code, before making any electrical connections, and be

certain that the electrical installation conforms with all local requirements.

Always check wiring before closing the disconnect switch.

Operate the Steam Cycle a couple of times before installing the Revolving Assembly.

OPEN SLEEVE ZIPPERS ON EACH SIDE OF FORM; insert hand through zipper openings, and

remove paper between shoulder form and nylon form, which is a

protective covering for shipping only. Remove paper covering on front and rear clamps; grip handles

of front and rear clamps, and replace revolving form on base. Finisher is now ready for operation.

REMOVE NYLON FORM from finisher at frequent intervals for cleaning, as determined by its soiled

condition. WET clean only ... do NOT dryclean. After wet cleaning, the nylon form should be extracted and blown dry on a wind whip. KEEP NYLON FORM CLEAN. Nylon Fabric acts as a filter

in operation, collecting dust and lint, etc., which clogs pores of fabric, greatly reducing its efficient

operation. FAILURE to keep form clean may cause transfer of soil from form to lining of garments.

REPAIR HOLES OR WORN SPOTS in nylon form to extend its useful life; REPLACE when holes or

worn spots are beyond repair. A defective or worn nylon form will cause the machine to operate

unsatisfactorily.

CAUTION

Use only genuine CISSELL FD10 or FG10 replacement Nylon Forms for best results. The fabric for

Cissell Nylon Forms is especially woven (and cut to an exact pattern) to give the correct porosity for

proper steaming and drying. Remember, your CISSELL Form Finisher depends entirely on the Nylon

Form for proper operation.

Page 7

CISSELL FORM FINISHER

MECHANICAL ADJUSTMENTS

ADJUSTABLE LEVERS - Move back and forth to regulate size of nylon form at waist, hip and

lower positions. Markings on Index plates enable operator to re-set levers to the exact adjustments

for a known garment style or size. Rotate knob on lever clockwise to lock; counter-clockwise 1/4

to 1/2 turn to unlock; move knob

forward to increase size of form, reverse movement to decrease. Avoid excessive tightening or

loosening of knob as this will delay

adjustments and retard production.

WAIST CONTROL - Regulates expansion at waist line --- for finishing short jackets and childrens

garments.

HIP CONTROL - Regulates expansion at hip line --- for finishing sack coats,

medium length jackets, blouses, etc.

LOWER CONTROL - Regulated expansion at bottom --- for finishing topcoats,

overcoats, raincoats, etc.

ARM ZIPPERS (on both sides) - Open, for sleeved garments; close, for sleeveless; or adjust

between open and closed positions to provide required amount of steam and air within sleeves.

FRONT CLAMP - For clamping front edges of sack coats, jackets, overcoats, housecoats, robes,

front-buttoned dresses and blouses, etc.; - raises 5 for smallest childs garment. Front edges must

overlap at least 3 with buttons on outside. (Push lever to lock, squeeze trigger to unlock.)

BACK CLAMP - For clamping rear vent of sack coats, jackets, topcoats, raincoats, overcoats, etc.,

or center kick-pleat in rear panel of skirt. (Push lever to lock, squeeze trigger to unlock.) Separate

vent clamp furnished for holding rear vent of extremely short garments.

FORM - Rotates 360o (in either direction) to obtain the most convenient loading position. The back

clamp has two open positions. In the extreme open position, the handle of the back clamp will

strike the timer assembly, when rotated 360o. To avoid this, move clamp to intermediate position.

Avoid rotating form for each garment, as this is tiresome and will greatly reduce production. It is

best for the operator to step from front to rear, as required.

SHOULDER ADJUSTMENT - For adjusting width of shoulder to size of garment. (Rotate knob

clockwise to increase width; counter-clockwise to decrease).

Page 8

CISSELL FORM FINISHER

(Operating Instructions)

Read General Information on Preceding Pages Before Reading Operating Instructions below.

-IMPORTANT-

For best performance, and maximum production, avoid unnecessary adjustments. Finish, in sequence,

garments of same size and type. This will eliminate adjusting waist, hip, or lower controls for each

garment; increase production, and provide maximum life for the nylon form. Time can also be saved

by finishing small garments first, then progressively moving from group to group, until largest size and

type is reached.

Selection from unfinished garments may be made by the operator directly from the incoming speed

rail, without separate sorting, classifying or grouping. It is best to REDUCE FORM TO ITS SMALLEST SIZE WITH AIR OFF, or with AIR CONTROL in Minimum Setting. Controls can be released

easily to allow air to expand form to size of garment with AIR ON.

AIR CONTROL

AIR PRESSURE - can be adjusted, at front of machine, from maximum to minimum, or to any intermediate stage. Markings 1-2-3 help operator to identify air pressure for repeat operations of similar

garments.

FOR HEAVY GARMENTS, keep air in maximum position, or adjust to any lower pressure

desired during step number 2 under finishing instructions.

FOR SHEER, delicate fabrics, reduce air to minimum or adjust to any higher pressure desired

during step number 2 under finishing instructions.

COAT FINISHING

Open Arm Zippers in Nylon Form for All Garments With Sleeves; Keep Closed for Sleeveless Garments.

1. PLACE COAT ON FORM FINISHER. With each hand, grasp front edges of coat lapels just

below gored seams. Swing coat over and around form and place coat to hang evenly. STRAIGHTEN

COAT - pocket flaps, collar lapels, etc.

Pull two front edges of coat forward; overlap front edges at least 3 from bottom of coat to

lapels with buttons on outside; close front clamp. Front clamp raises or lowers 5 to permit proper

positioning for long or short coats. Close back clamp on rear vent of topcoats, raincoats, or overcoats.

(Place separate vent clamp on rear vent of extremely short garments.)

Page 9

2. ADJUST FORM. Set Timer for continuous operation of air, move air control to

minimum setting. Adjust waist, hip, and lower controls as required. Never allow

nylon form to be larger than garment. It is unnecessary to adjust hip and lower

controls for childrens garments or very short jackets; or to adjust the lower

control for sack coats or medium length jackets. The control governing the width of

the form immediately below the lower edges of the garment is the important

adjustment; the control governing the width of the form within the garment is

next. Insert expanding sleever in one sleeve - POSITION CORRECTLY. Before inserting

second sleever, step No. 3 may be started.

3. STEAM AND DRY COAT. Move Air Control to obtain required pressure. Set Timer for

automatic steaming and drying. With Steam on, operator may proceed immediately with touchup of garment previously removed from form, as steaming and drying is fully automatic.

4. REMOVE COAT. With AIR OFF, withdraw sleevers, relieving spring tension while

withdrawing. Release front and rear clamps. (Remove coat, and place on hanger or press for

touch-up.) If next garment is a smaller size, reduce form to its smallest size with air off. It is

unnecessary to make repeated adjustments for successive garments when they are approximately

the same size and type.

PRODUCTION HINTS

In many instances, the nylon form can be expanded only to the inner lining of a garment, when it is

smaller than the garment. To solve this problem, adjust hip and lower width controls to the lining, or

as large as possible, whichever comes first. Then, during the steam cycle, pull the lower edges of the

garment until the entire garment is progressively brought into contact with the form for steaming; then

follow with normal drying procedure.

When the front clamp is used on full-nap soft fabrics, interchange the lapels after the initial steaming

period and resteam. During the drying cycle, release front (and rear) clamps slowly to avoid impression marks.

Page 10

Loading...

Loading...