Contents

1 General safety instructions ...........................................................................

2 Technical data and dimensions ....................................................................

Technical data .............................................................................................

Dimensions ..................................................................................................

3 Installation and connection ..........................................................................

Ground .........................................................................................................

Removing the transport brackets .................................................................

Water connection .........................................................................................

Water drain ..................................................................................................

Main power connection .................................................................................

Liquid soap connection ................................................................................

Connection of a central operating panel for coinmachines (option) ...............

Steam connection ........................................................................................

4 Operating instructions ..................................................................................

Machine with start button .............................................................................

Machine with coin or token operation............................................................

5 Standard programs .......................................................................................

6 Technical remarks.........................................................................................

Internal connection of the electrical heating .................................................

Tilt switch ....................................................................................................

Error messages ...........................................................................................

7 Maintenance of the machine ........................................................................

3

4

4

7

10

10

10

10

10

11

12

13

13

14

15

23

29

30

30

30

31

33

Code: 249/00078/01

10/06/2002

Content

General safety instructions

Ignoring any of the safety instructions can cause serious

personal injury and can also cause damage to the linen or the

machine

p

Read the installation and instruction manual carefully before connecting the

machine.

p

It is recommended that the machine be installed by qualified technicians.

p

The machine should be installed according to the installation instructions. (See

chapter 3)

p

The machine should be grounded according to the instructions in order to

eliminate the risk of electrocution.

Do not expose the machine to high humidity or extreme high or low temperatures.

p

Cut off all main water inlets, steam and electrical supplies at the end of each

p

operating day.

1

Before starting repairs or maintenance, shut off all power and water supplies.

p

To prevent fire and explosion:

p

Keep the area around the machine free from inflammable or combustible

products.

Do not put fabrics that are treated with inflammable products into the machine.

These fabrics should be hand-washed or air-dried first.

Always carefully read and follow the instructions on the packing of detergents.

p

Store these products out of the reach of children.

Always take into account the instructions on the labels of clothes.

p

Never allow children to play in the surroundings of a machine.

p

Remark:

These instructions surely cannot prevent all risks of accidents. It is up to the user to act with the

p

utmost precaution.

Do not hesitate to contact the dealer in case of a problem.

p

3

Technical data and dimensions

Technical data

2

HW55

HW55

Capacity (dry weight)

1/11 5 kg

1/10 5,5 kg

1/9 6,1 kg

Cylinder

Diameter 530 mm

Depth 250 mm

Volume 55 lit.

Cabinet

Height 1005 mm

Width 660 mm

Depth 708 mm

Front loading

Diameter door opening 300 mm

Door height 355 mm

To center 505 mm

Speed

Wash 10 - 50 tr/min

Distribution 85 tr/min

Spin 500 - 1250 tr/min

G-force

Low spin/High spin 74/462

Motor (3-phase)

4p. 1470 tr./min 550W

Drain valve

Depend-O-Drain 6/4"

Water supply

Hot + warm water 3/4"

Heating

Electrical 230/400 V 3 kW

Electrical 400V 6 kW

Steam X

Warm water (without additional heating) X

Warm water (with additional heating) X

Packing dimensions

(H x W x D) mm 1140x732x832

Weight

Net 197 kg

Gross 252 kg

4

HW64/72/75/94

2

HW 64 HW72 HW 75 HW94

Capacity (dry weight)

1/11 5,9 kg 6,6 kg 6,9 kg 8,6 kg

1/10 6,5 kg 7,3 kg 7,6 kg 9,5 kg

1/9 7,2 kg 8,1 kg 8,4 kg 10,5 kg

Cylinder

Diameter 530 mm 530 mm 530 mm 530 mm

Depth 295 mm 345 mm 345 mm 440 mm

Volume 65 Lit. 73 Lit. 76 Lit. 95 lit.

Cabinet

Height 1005 mm 1005 mm 1005 mm 1005 mm

Width 660 mm 660 mm 660 mm 660 mm

Depth 670 mm 670 mm 670 mm 770 mm

Front loading

Diameter door opening 300 mm 300 mm 300 mm 300 mm

Door height 355 mm 660 mm 355 mm 355 mm

To center 505 mm 505 mm 505 mm 505 mm

Speed

Wash 10 - 50 tr/min

Distribution 85 tr/min

Low spin 250 - 500 tr/min

High spin 500 - 1000 tr/min

G-force

Low spin/High spin 74/296

Motor (3-phase)

4p. 1470 tr./min 750W

Drain valve

Depend-O-Drain 6/4"

Water supply

Hard, soft, warm water and cool-down 3/4"

Steam connection

Steam connection 3/8"

Heating

Electrical 230/400 V 4,2/6/9 kW

Electrical 400V 12 kW

Steam X

Warm water (without additional heating) X

Warm water (with additional heating) X

Packing dimensions

(H x W x D) mm 1140x732x832 1240x732x950

Weight

Net 197 kg 210 kg 210 kg 212 kg

Gross 252 kg 265 kg 265 kg 268 kg

5

HW131/164

2

HW 131 HW 164

Capacity (dry weight)

1/11 12 kg 15 kg

1/10 13,2 kg 16,5 kg

1/9 14,5 kg 18,3 kg

Cylinder

Diameter 650 mm 650 mm

Depth 400 mm 400 mm

Volume 132 Lit. 165 Lit.

Cabinet

Height 1170 mm 1170 mm

Width 780 mm 780 mm

Depth 760 mm 860 mm

Front loading

Diameter door opening 300 mm 300 mm

Door height 455 mm 455 mm

To center 605 mm 605 mm

Speed

Wash 50 tr/min

Distribution 100 tr/min

Low spin 250--500 tr/min

High spin 500--1000 tr/min

G-force

Low spin/High spin 88/363

Motor (3-phase)

4p. 1470 tr./min 1500W

Drain valve

Depend-O-Drain 6/4"

Water supply

Hard, soft, warm water and cool-down 3/4"

Steam connection

Steam connection 3/8"

Heating

Electrical 230/400 V 12/15/18 kW

Electrical 400V 21/24 kW

Steam X

Warm water (without additional heating) X

Warm water (with additional heating) X

Packing dimensions

(H x W x D) 1310x850x1000mm 1310x850x1100mm

Weight

Net 287 kg 347 kg

Gross 349 kg 417 kg

6

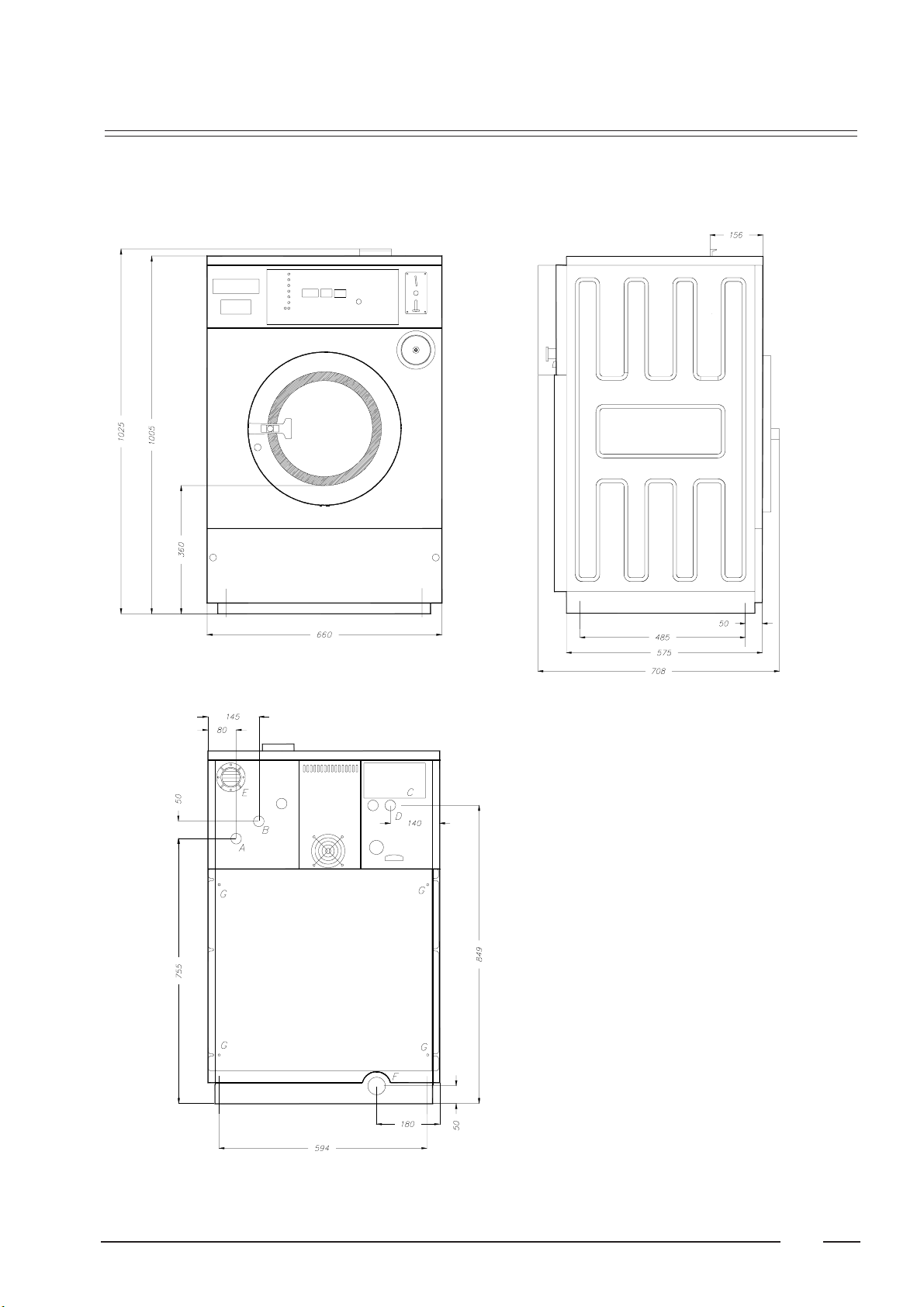

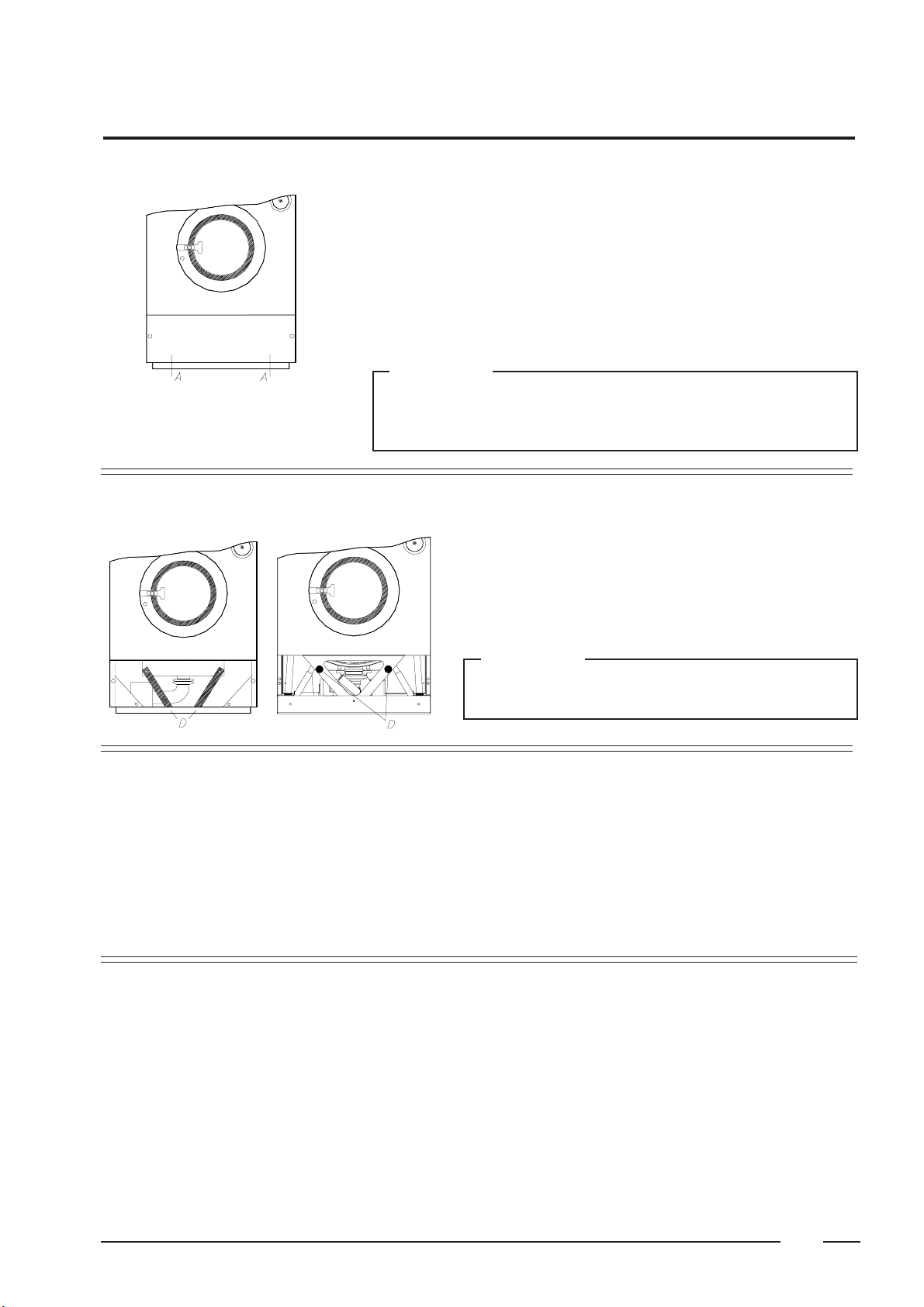

Dimensions

HW55

2

2

A. Hard water connection 3/4"

B. Warm water connection 3/4"

C. Input electrical supply

D. Electrical connection clamps

E. Ventilation soap dispenser

F. Water drain

G. Bolt pattern for fixation of the machine

7

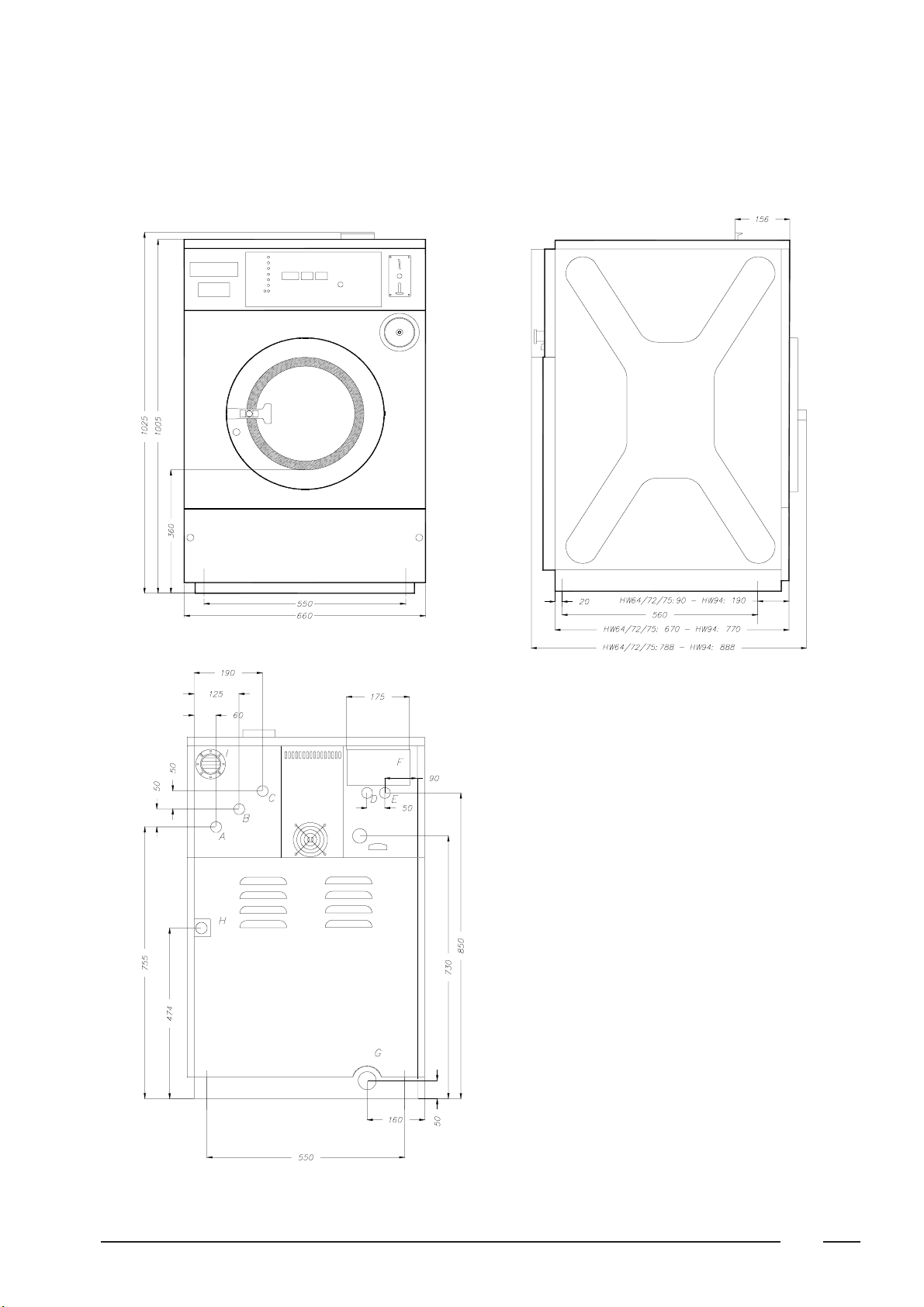

HW64/72/75/94

2

A. Hard water connection 3/4"

p

B. Warm water connection 3/4"

p

C. Soft water connection 3/4"

p

D. Output connection steam valve

p

E. Input electrical supply

p

F. Electrical connection clamps

p

G. Water drain

p

H. Steam connection

p

I. Ventilation soap dispenser

p

8

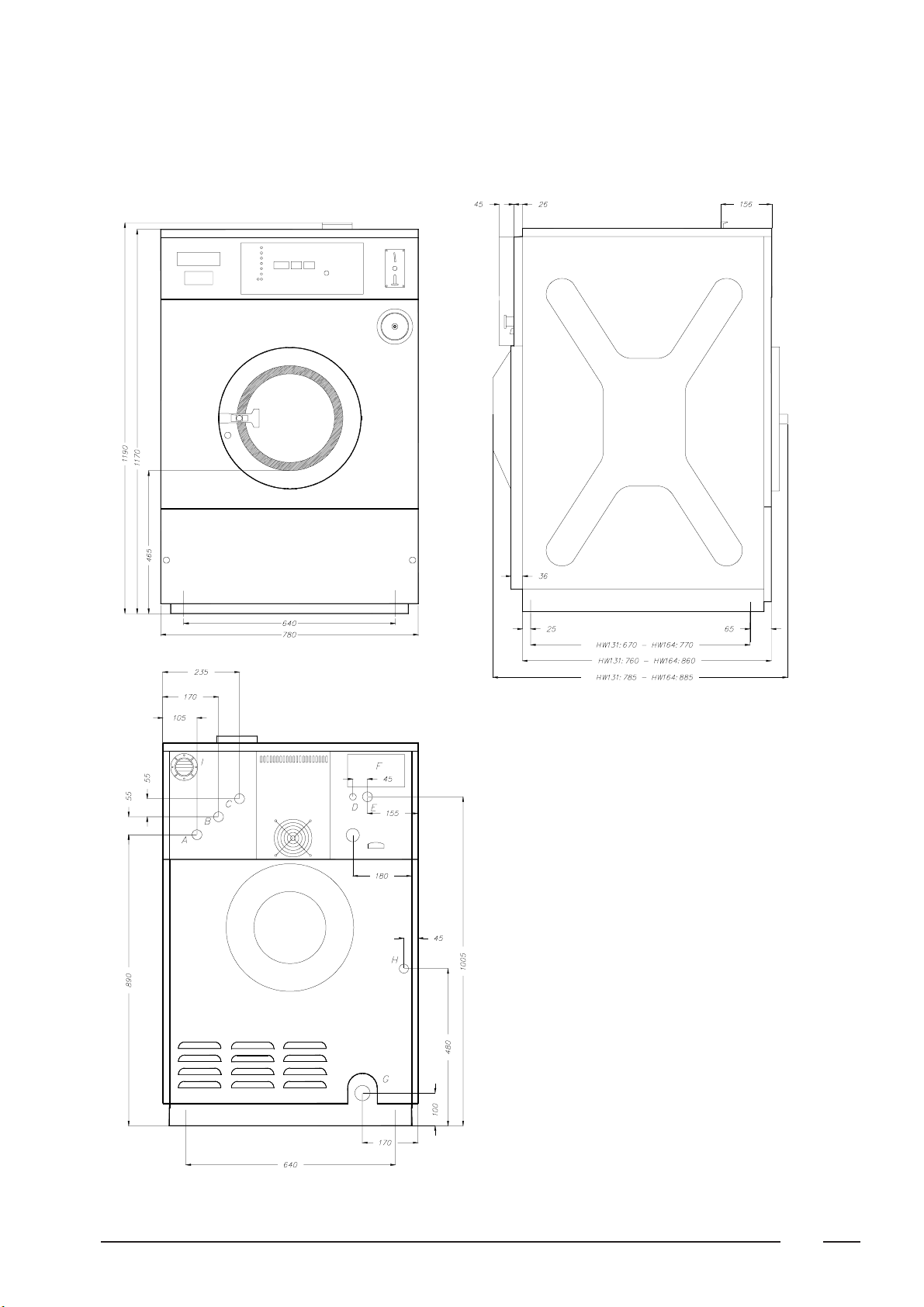

HW131/164

2

A. Hard water connection 3/4"

p

B. Warm water connection 3/4"

p

C. Soft water connection 3/4"

p

D. Output connection steam valve

p

E. Input electrical supply

p

F. Electrical connection clamps

p

G. Water drain

p

H. Steam connection

p

I. Ventilation soap dispenser

p

9

Installation and connection

Ground

The machine must be placed on a flat, solid surface (metal base, concrete or solid

ground). It is recommended that the machine be anchored (bolts M10) on the

provided places (A) in the base, especially in case of a plint (see Dimensions 2).

The machine must be placed entirely level. For easy maintenance it is recommended to keep a minimal distance of 600 mm between the wall and the back of the

machine.

If several machines are placed next to each another, there should be a minimal

distance of 30 mm between each machine.

Important

The bolt pattern for the fixation of the HW 55 machine is foreseen in the back

panel of the cabinet. Put this panel on the floor and indicate the holes (see page

7).

Removing the transport brackets

3

To prevent damage during transportation, the machine has been

equipped with two red transport brackets (D) to eliminate every

possible movement of the tub.

After the machine has been placed level, take off the service panel

and remove these transport brackets.

Water connection

Water drain

Important

The machine must never be activated before removing

these transport brackets.

The machine is delivered with hoses with 3/4" connections. These hoses fit the

water inlet valves of the machine and the main water inlet taps. To ensure the

optimal functioning of the water inlet valves, the water pressure on the inlet

should be between 0,5 and 10 kg/cm² (7 and 145 psi). If the pressure is too low,

the cycle time will increase considerably.

In case of boiler fed machines, a minimum of hot water of 90°C should

be available: HW55: 46l. HW64: 55 l. H W 75: 65 l. H W94: 80l.

HW131: 100l. HW164: 120l.

The machine is equipped with a drain valve with 6/4" outer diameter (50 mm). This

drain valve should be connected to the drain by means of the drain elbow which

is delivered with the machine.

The diameter of the main drain should be adapted to the water flow and the

p

number of machines. It should be sufficient to handle at least 80L/min. per

machine.

It is necessary to connect the main drain at least on one side to an open air-

p

brake to allow ventilation.

10

Loading...

Loading...