Lay Down Sleever

LDS/CMMSL

Installation/Operation

WARNING

Read and understand these instructions

before operating or servicing these machines.

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

An LSG Company

831 South First Street, P.O. Box 32270

Louisville, KY 40232-2270

Phone: (502) 587-1292

Sales Fax: (502) 585-3625

Service/Parts Fax: (502) 681-1275 www.cissellmfg.com

CAB1812C

CAB1812C

Part No. AJ0852R1

June 2002

Table of

Contents

Safety.................................................................................................... 3

Installation........................................................................................... 5

Front View............................................................................................ 5

Rear View ............................................................................................. 6

Dimensions and Specifications ............................................................. 7

Electrical Requirements........................................................................ 7

Electrical Data.................................................................................. 7

Motor Data ....................................................................................... 7

Overall Dimensions and Connecting Data ........................................... 8

Required Materials................................................................................ 9

Receiving Inspection ............................................................................ 9

Location Requirements......................................................................... 10

Foundation Requirements..................................................................... 10

Uncrating .............................................................................................. 10

Installing Anchor Bolts and Leveling Finisher..................................... 10

Connecting Steam Supply and Returns ................................................ 10

Connecting Air Service......................................................................... 11

Connecting Electrical Service............................................................... 12

Final Preparation for Use...................................................................... 12

Final Check-Out Procedure .................................................................. 12

Operation............................................................................................. 15

Operating Controls................................................................................ 15

Pre-Operating Services......................................................................... 16

Finisher Operation ................................................................................ 16

Long Sleeve Shirts ........................................................................... 16

Short Sleeve Shirts........................................................................... 21

Post-Operating Services........................................................................ 22

Maintenance ........................................................................................ 23

Periodic Inspections.............................................................................. 23

Cleaning Airline Filter ..................................................................... 25

Cleaning Steam Strainer .................................................................. 25

Cleaning Customer-Furnished Steam Traps .................................... 25

Lubrication............................................................................................ 26

Adjusting Air Line Lubricator Flow Rate........................................ 27

Filling Air Line Lubricator .............................................................. 27

Quality Troubleshooting....................................................................... 28

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

AJ0852

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0852

Safety

Danger indicates the presence of a hazard

that WILL cause SEVERE personal injury,

death, or substantial property damage if the

danger is ignored.

DANGER

Warning indicates the presence of a hazard

that CAN cause SEVERE personal injury,

death, or substantial property damage if the

warning is ignored.

WARNING

Caution indicates the presence of a hazard

that WILL or CAN cause MINOR personal

injury or property damage if the caution is

ignored.

CAUTION

Safe operating and maintenance practices presented in

this manual are emphasized with special safety

messages. These messages are categorized as

DANGER, WARNING and CAUTION. Explanations

of these categories are listed below.

These safety messages are used throughout this

manual to identify safe practices. Signal words are

placed with descriptions or steps where the need to

maintain safe conditions is critical.

Safety signs and labels are also placed on the finisher.

Those signs and labels are limited messages. Where

needed, further explanations are provided in the

manual. These signs are to be inspected for readability

and replaced when missing, damaged or unreadable.

Refer to Maintenance section of this manual for

inspections process. Refer to parts manual for ordering

information.

DANGER

To avoid possible serious injury, ensure

that air and steam supply systems have

adequate RELIEF VALVE PROTECTION or

have the pressures sufficiently limited at

the sources for safe operating pressures

as specified for this equipment.

W333

WARNING

To AVOID possible serious injury, BEFORE

performing maintenance or repair tasks:

• Shut off and lock out ALL electric power

to the unit.

• Shut off and lock out ALL air service to

the unit.

• Shut off and lock out ALL steam service

to the unit.

• Allow heated surfaces to cool.

W399

• Failure to install, maintain, and/or operate this machine according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death, and/or

property damage.

• Do not repair or replace any part of the machine or attempt any servicing unless specifically

recommended or published in the service manual and that you understand and have the

skills to carry out.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded and to reduce the risk of fire,

electric shock, serious injury, or death.

AJ0852

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

WARNING

W335

3

Notes

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT AJ0852

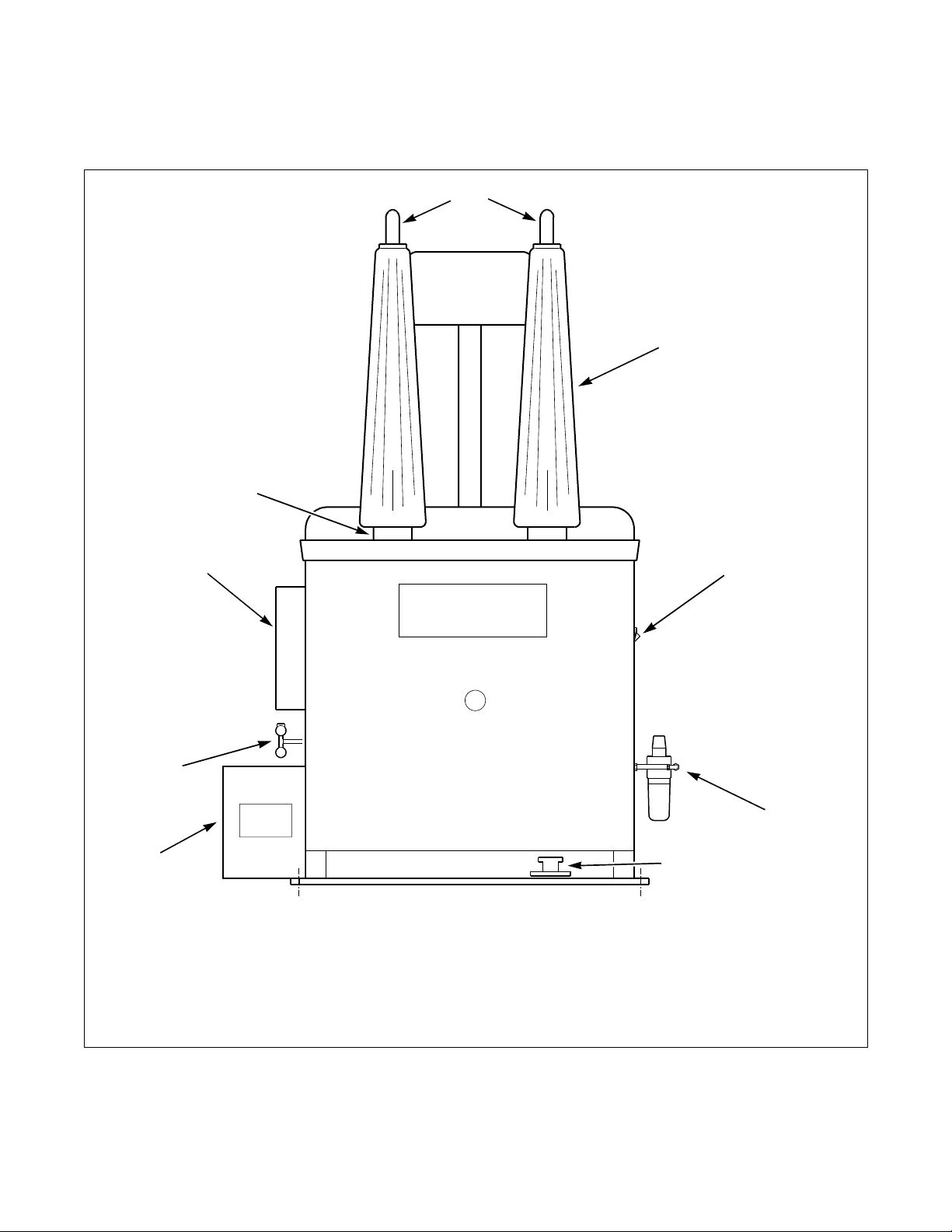

Front View

Installation

1

2

9

8

7

6

1 Cuff Clamps 6 Transformer Box (Units over 230 Volts)

2 Air Bags 7 Steam Inlet/Return Manifold

3 Power ON/OFF Switch 8 Air Filter

4 Air Inlet Filter/Regulator/Lubricator 9 Buck Weldment

5 Foot Pedal

5

3

4

CAB33N

AJ0852

Figure 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

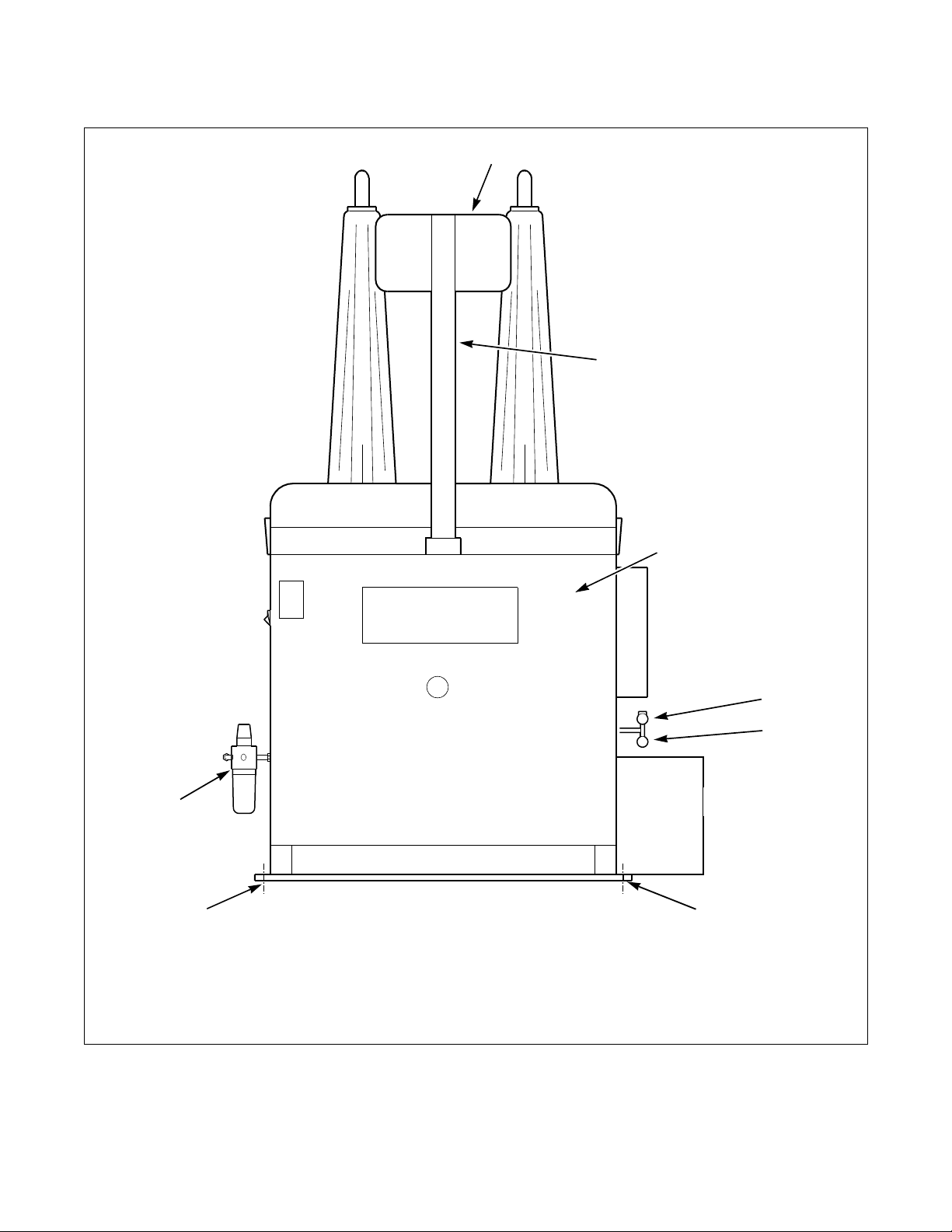

Installation

Rear View

1

2

3

7

6

1 Cuff Gusset Press Plates 5 Buck Steam Outlet

2 Gusset Arm 6 Anchor Bolt Holes

3 Rear Cover 7 Air Inlet

4 Steam Inlet

4

5

6

CAB40N

Figure 2

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

AJ0852

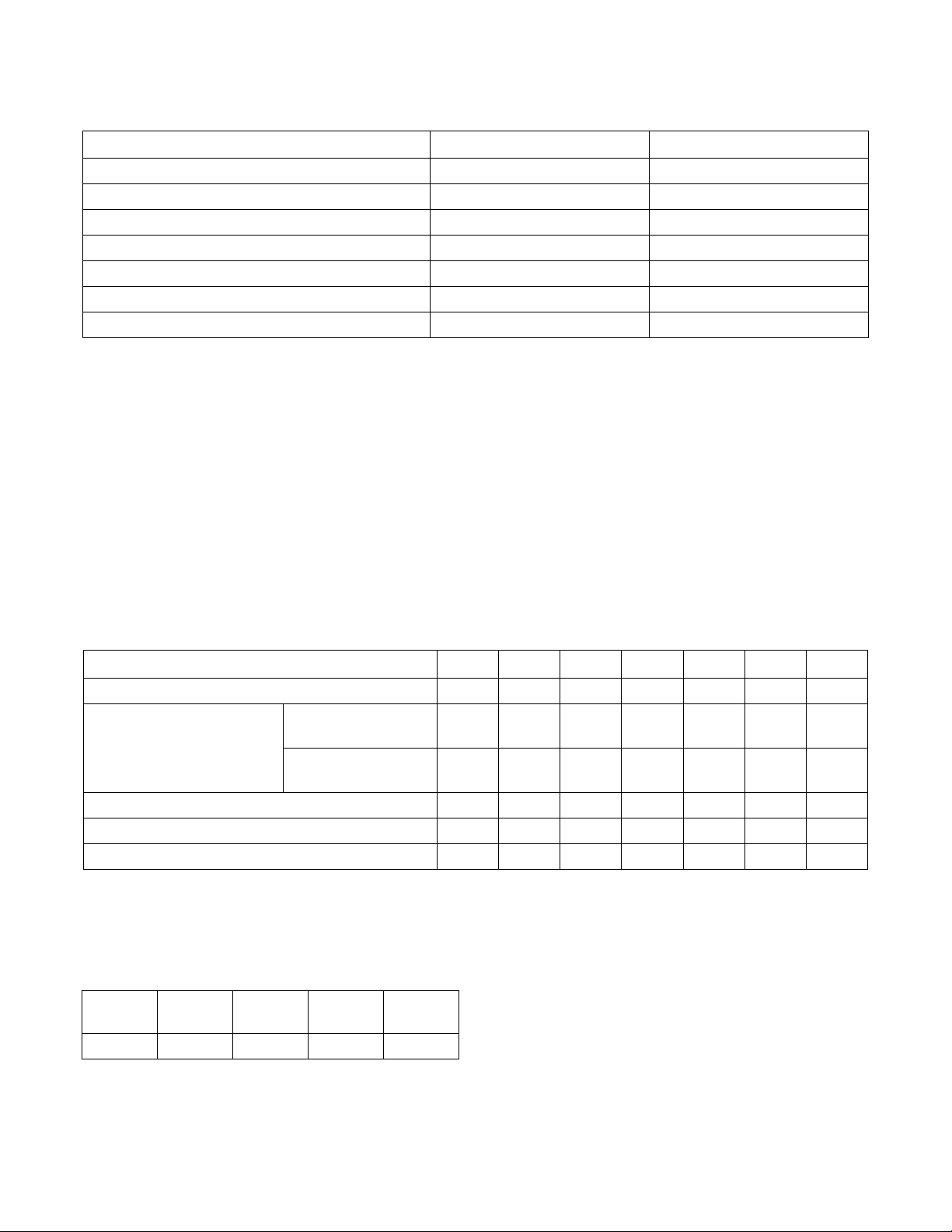

Dimensions and Specifications

General Specifications Standard Metric

Air Pressure @ Inlet 80-100 psi 5.52-6.90 bar

Consumption @ psig 0.3 ft

Maximum Steam Pressure 115 psig 6.90 bar

Suggested Operating Steam Pressure 105-115 psig 7.24-7.93 bar

Steam Consumption (Condensed) 30 lbs./hr 14 kg/hr

Net Machine Weight (Approximate) 400 lbs. 181 kg

Domestic Crated Weight (Approximate) 480 lbs. 217 kg

Table 1

3

free air/cycle 0.008 m3 per cycle

Electrical Requirements

200 Volt/60 Hertz/3 Phase/7.7 Full Load Amperes

230 Volt/60 Hertz/3 Phase/7.6 Full Load Amperes

460 Volt/60 Hertz/3 Phase/4.1 Full Load Amperes

575 Volt/60 Hertz/3 Phase/3.3 Full Load Amperes

Installation

220 Volt/50 Hertz/3 Phase/7.4 Full Load Amperes

380 Volt/50 Hertz/3 Phase/4.1 Full Load Amperes

415 Volt/50 Hertz/3 Phase/4.3 Full Load Amperes

Electrical Data

Nominal Voltage/Hertz/Phase* 200/3/60 230/3/60 460/3/60 575/3/60 220/3/50 380/3/50 415/3/50

Minimum Supply Circuit Conductor Ampacity** 9.4 9.3 5.0 4.0 9.1 4.9 5.1

Maximum Rating of

Protection Device**

Full Load Amperes (FLA) 7.7 7.6 4.1 3.3 7.4 4.1 4.3

Average Running Amperes 6.2 6.1 3.3 2.6 5.9 3.3 3.4

Quantity of Primary Power Connections 3 + grd 3 + grd 3 + grd 3 + grd 3 + grd 3 + grd 3 + grd

* The voltages listed are rated machine voltages. The currents listed are rated for system voltage ranges of 5%.

** Conductor ampacity and protection devices are determined in accordance with NATIONAL ELECTRICAL CODE.

Installer must comply with all local codes and ordinances related to installation.

Dual Element Time

Delay Fuse

Inverse Time Delay

Circuit Breaker

12A 12A 6A 5A 12A 6A 6A

20A 20A 10A 10A 20A 10A 10A

Motor Data

Motor

Blower 2.5 3450 1.85 2850

AJ0852

60 Hertzhp60 Hertz

RPM

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

50 Hertzhp50 Hertz

RPM

7

Loading...

Loading...