CissiCissi

Cissi

CissiCissi

FF

F

FF

FF

F

FF

ModelsModels

Models

ModelsModels

FCCG FCFGFCCG FCFG

FCCG FCFG

FCCG FCFGFCCG FCFG

FCCD FCACFCCD FCAC

FCCD FCAC

FCCD FCACFCCD FCAC

oo

o

oo

inisherinisher

inisher

inisherinisher

rmrm

rm

rmrm

OWNER’S MANUOWNER’S MANU

OWNER’S MANU

OWNER’S MANUOWNER’S MANU

CISSELL MANUFACTURING COMPANYCISSELL MANUFACTURING COMPANY

CISSELL MANUFACTURING COMPANY

CISSELL MANUFACTURING COMPANYCISSELL MANUFACTURING COMPANY

HEADQUARTERSHEADQUARTERS

HEADQUARTERS PHONE: (502) 587-1292

HEADQUARTERSHEADQUARTERS

831 SOUTH FIRST ST. SALES FAX: (502) 585-3625

P.O. BOX 32270 SERVICE/PARTS FAX: (502) 681-1275

LOUISVILLE, KY 40232-2270

THIS MANUTHIS MANU

THIS MANU

THIS MANUTHIS MANU

MAN38 5/97MAN38 5/97

MAN38 5/97

MAN38 5/97MAN38 5/97

AL MUST BE GIVEN AL MUST BE GIVEN

AL MUST BE GIVEN

AL MUST BE GIVEN AL MUST BE GIVEN

Page 1Page 1

Page 1

Page 1Page 1

ALAL

AL

ALAL

TT

O O

THE EQUIPMENT OWNER.THE EQUIPMENT OWNER.

T

O

THE EQUIPMENT OWNER.

TT

O O

THE EQUIPMENT OWNER.THE EQUIPMENT OWNER.

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

The Cissell Manufacturing Company (Cissell) warrants all new equipment (and the original parts thereof)

to be free from defects in material or workmanship for a period of one (1) year from the date of sale thereof

to an original purchaser for use, except as hereinafter provided. With respect to non-durable parts normally

requiring replacement in less than one (1) year due to normal wear and tear, including, but not limited to,

cloth goods, valve discs, hoses, and iron cords, and with respect to all new repair or replacement parts for

Cissell equipment for which the one (1) year warranty period has expired, or for all new repair or

replacement parts for equipment other than Cissell equipment, the warranty period is limited to ninety (90)

days from date of sale. The warranty period on each new replacement part furnished by Cissell in fulfillment

of the warranty on new equipment or parts shall be for the unexpired portion of the original warranty period

on the part replaced.

With respect to electric motors, coin meters and other accessories furnished with the new equipment, but

not manufactured by Cissell, the warranty is limited to that provided by the respective manufacturer.

Cissell's total liability arising out of the manufacture and sale of new equipment and parts, whether under

the warranty or caused by Cissell's negligence or otherwise, shall be limited to Cissell repairing or replacing,

at its option, any defective equipment or part returned f.o.b. Cissell's factory, transportation prepaid, within

the applicable warranty period and found by Cissell to have been defective, and in no event shall Cissell be

liable for damages of any kind, whether for any injury to persons or property or for any special or

consequential damages. The liability of Cissell does not include furnishing (or paying for) any labor such

as that required to service, remove or install; to diagnose troubles; to adjust, remove or replace defective

equipment or a part; nor does it include any responsibility for transportation expense which is involved

therein.

The warranty of Cissell is contingent upon installation and use of its equipment under normal operating

conditions. The warranty is void on equipment or parts; that have been subjected to misuse, accident, or

negligent damage; operated under loads, pressures, speeds, electrical connections, plumbing, or conditions

other than those specified by Cissell; operated or repaired with other than genuine Cissell replacement

parts; damaged by fire, flood, vandalism, or such other causes beyond the control of Cissell; altered or

repaired in any way that effects the reliability or detracts from its performance, or; which have had the

identification plate, or serial number, altered, defaced, or removed.

No defective equipment or part may be returned to Cissell for repair or replacement without prior written

authorization from Cissell. Charges for unauthorized repairs will not be accepted or paid by Cissell.

CISSELL MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY, STATUTORY OR OTHERWISE,

CONCERNING THE EQUIPMENT OR PARTS INCLUDING, WITHOUT LIMITATION, A WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE, OR A WARRANTY OF MERCHANTABILITY. THE

WARRANTIES GIVEN ABOVE ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED. CISSELL NEITHER ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT,

ANY OTHER WARRANTY OR LIABILITY IN CONNECTION WITH THE MANUFACTURE, USE OR SALE

OF ITS EQUIPMENT OR PARTS.

For warranty service, contact the Distributor from whom the Cissell equipment or part was purchased. If

the Distributor cannot be reached, contact Cissell.

Page 2Page 2

Page 2

Page 2Page 2

TT

ABLE OF CONTENTSABLE OF CONTENTS

T

ABLE OF CONTENTS

TT

ABLE OF CONTENTSABLE OF CONTENTS

GENERAL INFORMATION

Warranty ...................................................................................................................... 1

Cissi Form Finisher Features.....................................................................................3-4

SPECIFICATIONS

Motor, Steam Pressure, Weights.................................................................................. 4

Outline Dimensions..................................................................................................... 5

INSTALLATION AND OPERATION

Installation Instructions.............................................................................................. 6

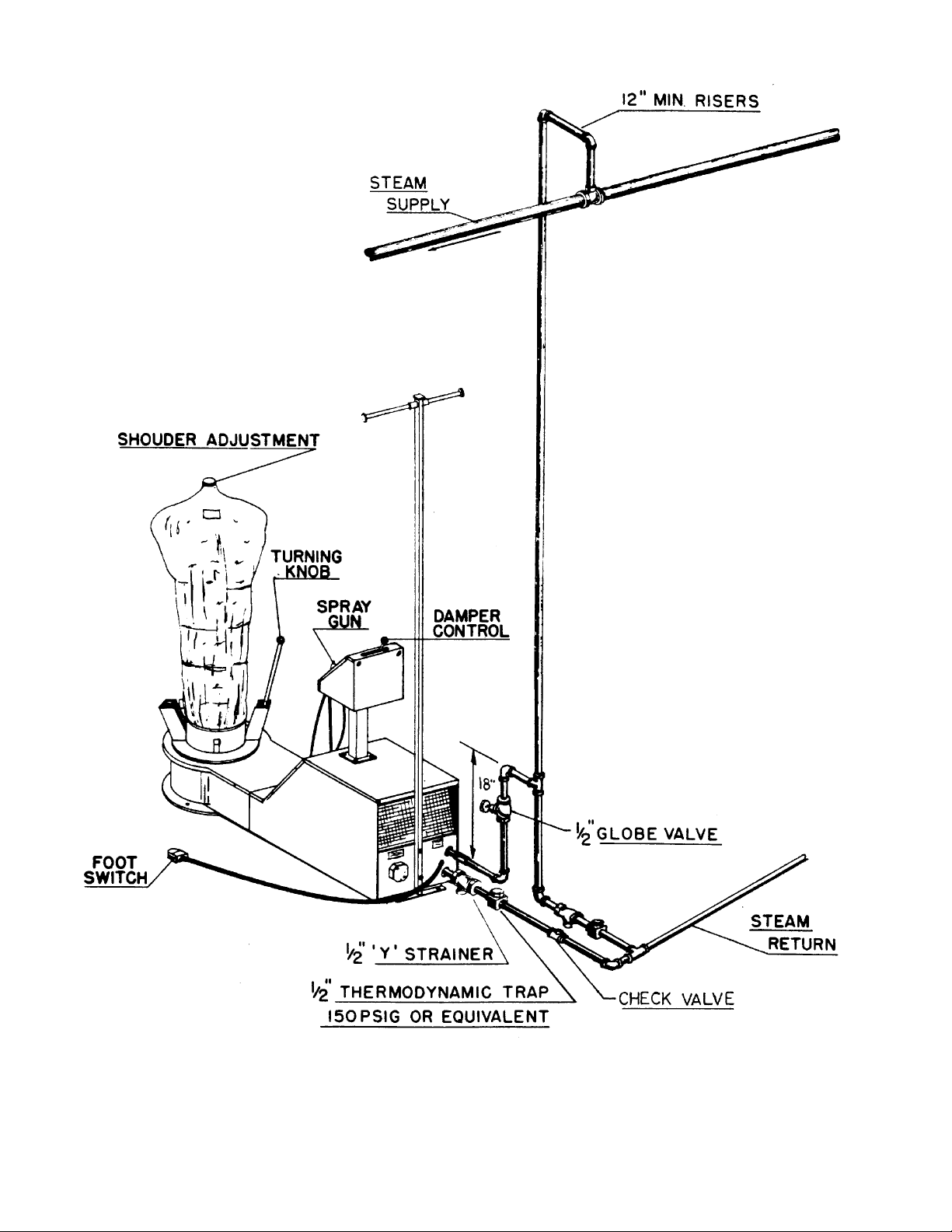

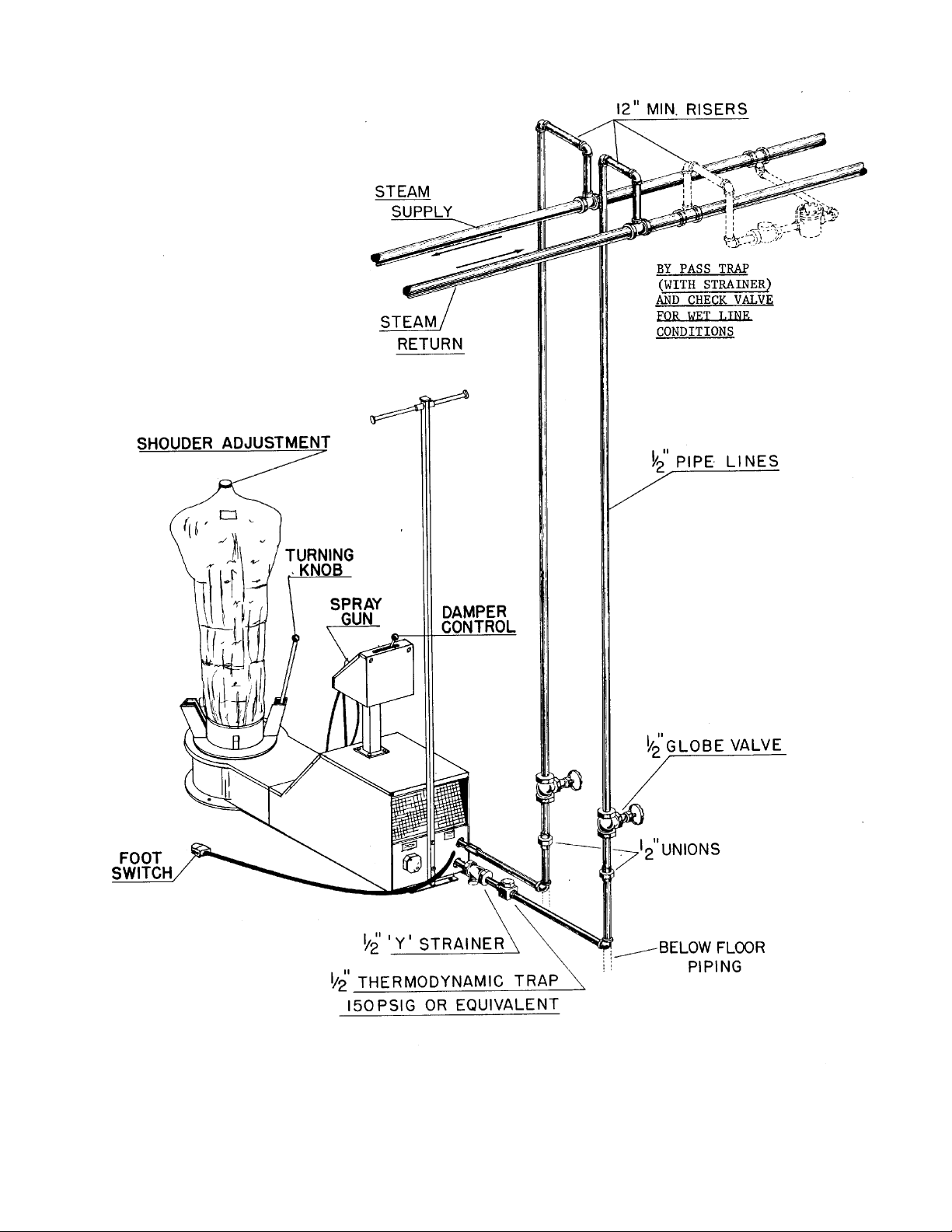

Steam Piping Illustrations .........................................................................................7-8

Operating Instructions ..............................................................................................9-10

Overbag ....................................................................................................................... 11

ADJUSTMENTS AND SERVICE

Changing Bag ...........................................................................................................12-13

Adjustment of Revolving Form Height ...................................................................... 14

Solenoid Linkage Adjustment.................................................................................... 15

Motor Mounting Dimensions ..................................................................................... 16

Trouble Shooting Charts ..........................................................................................17-20

ILLUSTRATED P ARTS

Revolving Form ........................................................................................................... 21

Foot Switch.................................................................................................................. 22

Tower of Power Parts .................................................................................................. 23

Rear Base Assembly ................................................................................................... 24

Shallow Base............................................................................................................... 25

Valve Parts .................................................................................................................. 26

Blower, Motor, and Motor Mount................................................................................ 27

Jacket and Filter......................................................................................................... 28

Damper Control Assembly.......................................................................................... 29

Condenser Assembly and Tubing............................................................................... 30

Water Spray Gun ........................................................................................................ 31

Condenser ................................................................................................................... 32

Rear and Front Paddle Assemblies............................................................................ 33

WIRING DIAGRAMS

Schematic .................................................................................................................... 34

Rear Base .................................................................................................................... 35

Control Box ................................................................................................................. 36

Page 3Page 3

Page 3

Page 3Page 3

CISSI FORM FINISHERCISSI FORM FINISHER

CISSI FORM FINISHER

CISSI FORM FINISHERCISSI FORM FINISHER

Loving Care for GarmentsLoving Care for Garments

Loving Care for Garments

Loving Care for GarmentsLoving Care for Garments

CISSELL FINISHERCISSELL FINISHER

CISSELL FINISHER

CISSELL FINISHERCISSELL FINISHER

HELPS GIVE ORIGINAL LOOKHELPS GIVE ORIGINAL LOOK

HELPS GIVE ORIGINAL LOOK

HELPS GIVE ORIGINAL LOOKHELPS GIVE ORIGINAL LOOK

TT

O O

ANY GARMENTANY GARMENT

T

O

ANY GARMENT

TT

O O

ANY GARMENTANY GARMENT

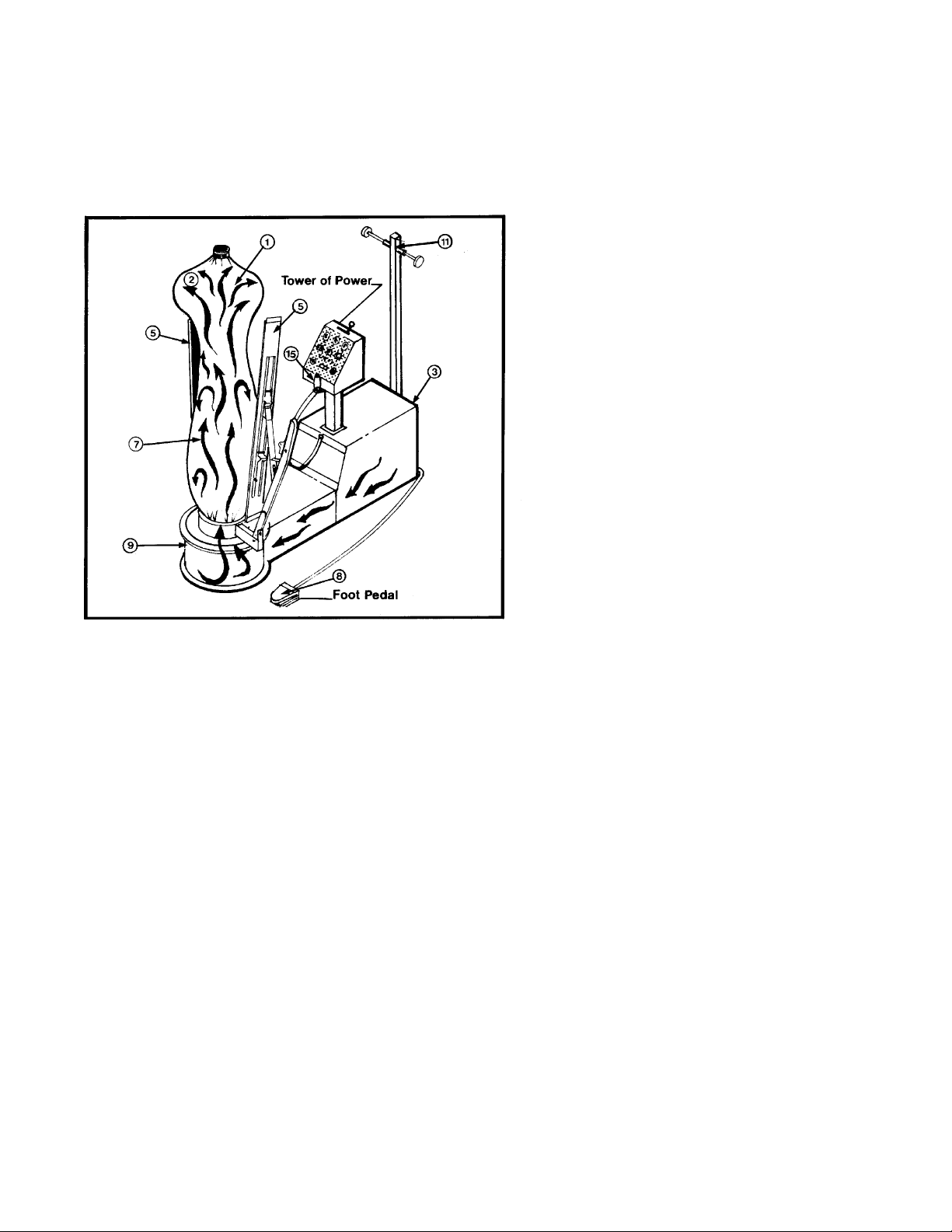

(1) Sturdy, stainless steel, rust-resistant frame. (2) Controlled porosity

nylon bag for better steam and air

distribution. (3) Cleanable inlet air

filter reduces bag replacement; helps

keep garments clean. (4) Flow of air

shapes garment whether heavy or light

material. (5) Clamps. (6) Easily

adjustable steaming; conditioning and

drying controls. (7) Steam evenly

distributed throughout entire form. (8)

Easy to use foot pedal for starting. (9)

Low base makes entire form easy for

short operators to use. (10) Form

revolves 360 degrees. (11) Clothes rack

for hanging finished garments. (12)

Vent clamps. (13) Net overbag. (14)

Hand pad. (15) Water spray gun. (16)

Sleevers.

All parts quickly accessible for ease in

maintenance.

*Numbers 12, 13, 14 and 16 are not illustrated.

MODELSMODELS

MODELS

MODELSMODELS

CISSI BASE (FC);CISSI BASE (FC);

CISSI BASE (FC);

CISSI BASE (FC);CISSI BASE (FC);

FCFG with Geni Revolving Assembly

FCAF with Aire Form Revolving Assembly

FCCD with Form Finisher Revolving Assembly

FCCG with Finisher 6” Taller Revolving Assembly

Base can also be used with ANY Cissell Garment Manufacturer’s model revolving

assembly.

Buy the Cissi with your choice of assembly chosen from above; or, buy the Base only - to

use with any Cissell revolving assembly you have now.

Page 4Page 4

Page 4

Page 4Page 4

TT

OWER FEAOWER FEA

T

OWER FEA

TT

OWER FEAOWER FEA

TURESTURES

TURES

TURESTURES

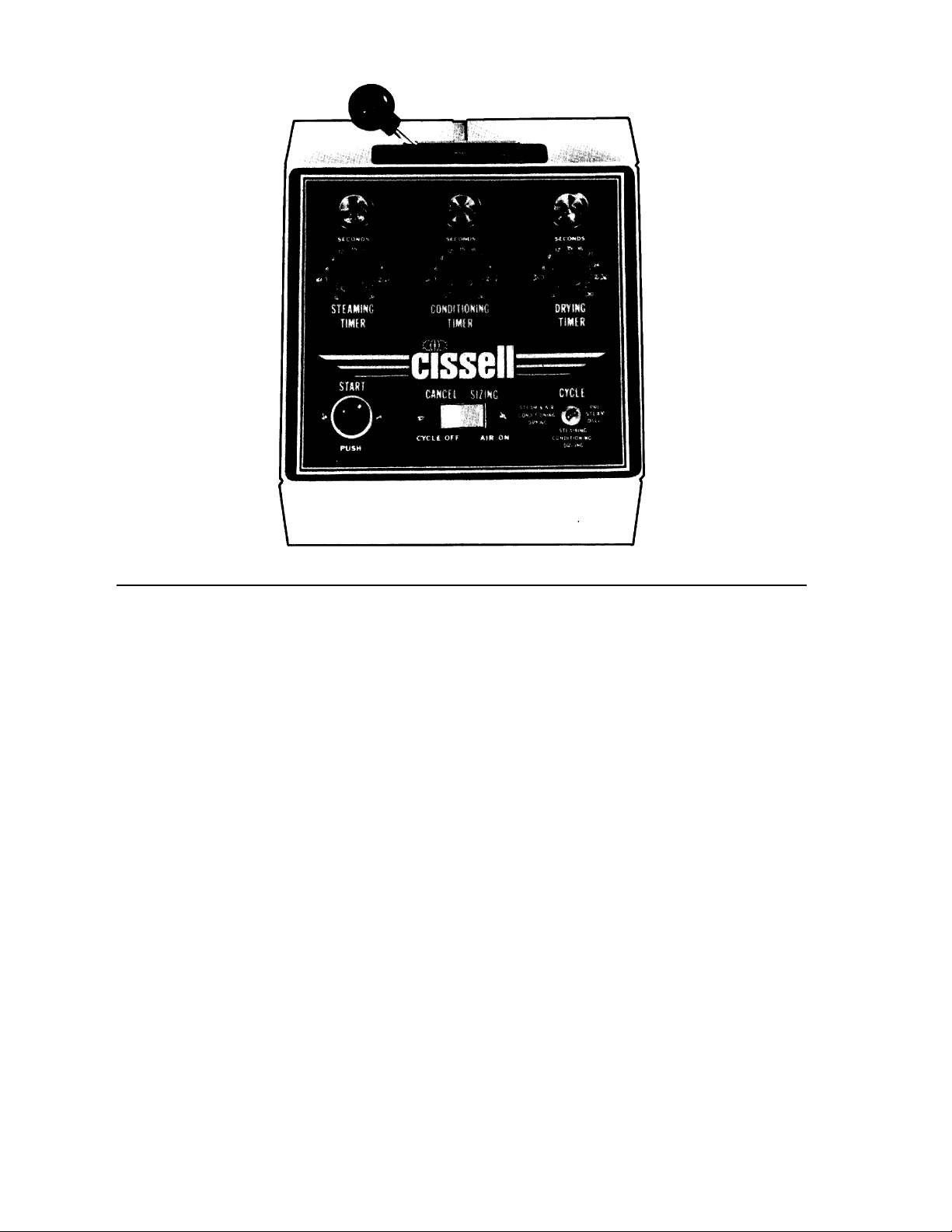

• Steaming Timer w/Light

• Conditioning Timer w/Light

• Drying Timer w/Light

• Push Button Start Switch

• 3 Position Cycle Switch:

1. Steam and Air Conditioning, Drying;

2. Steaming, Conditioning, Drying;

3. Pre-steam Only

• Combination Sizing and Cancel Rocker Switch

• Water Spray Gun

• Air Damper Control

The flexibility of these controls on the new model Form Finisher permits the proper

steam/air cycles to quickly and efficiently finish heavy, or hard-woven, badly wrinkled

garments.

But cycle control is not the only new feature on the Form Finisher. Remember! This

Finisher offers the option of multiple revolving assemblies as noted on front side. The

choice is yours!

Electric Motor: 1/2 HP,

1725 RPM, 115 Volt, 60

cycle, single phase 1/2 HP,

1425 RPM, 230 Volt, 50

cycle, Single Phase

Fully guaranteed for one year against manufacturer’s defects.

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

Operating Steam Pressure 60 to

100 Pounds

Boiler HP: Approx. 2

Steam Supply Line: 1/2”

Steam Return Line: 1/2”

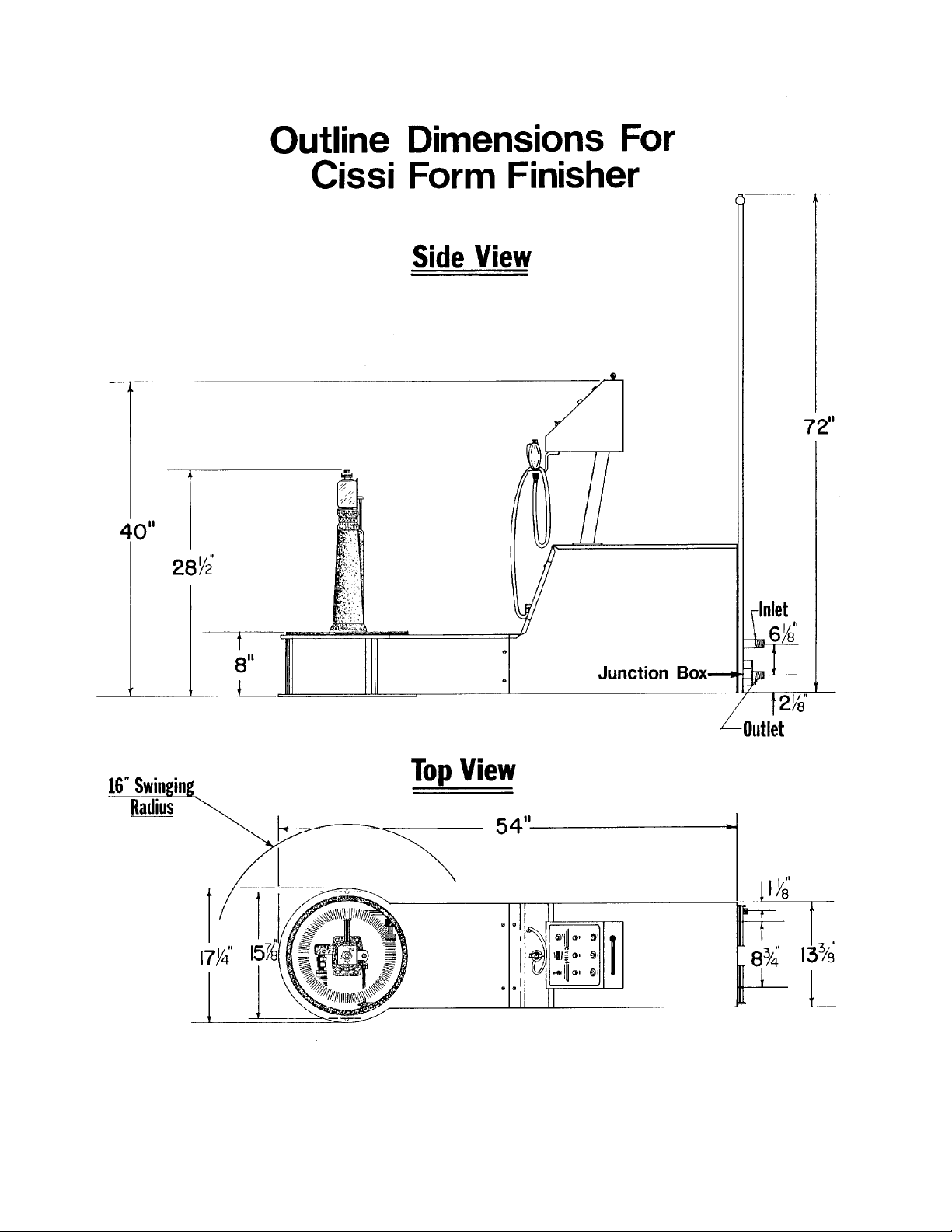

Depth: 54”

Height: 17” (to top of cabinet)

72” (to top of clothes rack)

36” (to top of controls)

TIONSTIONS

TIONS

TIONSTIONS

Width: 17”

Net Weight: 226 Lbs. (approx.)

SHIPPING WEIGHTS:

Domestic: 300 pounds (approx.)

Export: (500 pounds (approx.)

Export: Shipping Dimensions:

66” (H); 71” (L); 25” (W)

Cubic Feet Export Crating:

67.8 (approx.)

Page 5Page 5

Page 5

Page 5Page 5

Page 6Page 6

Page 6

Page 6Page 6

CISSICISSI

CISSI

CISSICISSI

Installation InstructionsInstallation Instructions

Installation Instructions

Installation InstructionsInstallation Instructions

Refer to illustration sheet

(1) UNCRATE MACHINE. Check the nameplate voltage and current, making sure

it is the same as the supply voltage and current.

(2) SET MACHINE IN POSITION .

(3) REMOVE THE REVOLVING FORM by holding the turning knob and the

opposite weight “bucket” and lifting approximately 22”.

(4) CONNECT STEAM SUPPLY LINE as shown on next page.

(5) CONNECT RETURN LINE as shown on next page.

NOTE: Before final return line connection is made, open the steam supply

valve and blow all foreign matter out of the steam lines and

chamber. Failure to do so will cause trap to leak.

(6) MAKE ELECTRICAL CONNECTIONS in 3” junction box on rear of the

machine, according to applicable electric codes. Connections should include a

fused disconnect switch or circuit breaker with “slo-blow” characteristics and be

capable of carrying 15 amps 115 volts or 8 amps 230 volts.

(7) MAKE SURE THE CONDENSER VALVE IS OPEN (condenser located behind

the air filter) before connecting clothes tree.

(8) CONNECT CLOTHES TREE TO REAR OF BASE by the two 1/4” bolts.

(9) TURN ON ELECTRICAL POWER AND TEST THE MACHINE. Replace the

revolving assembly, remove the plastic protective bag, and open the return and

steam lines.

Page 7Page 7

Page 7

Page 7Page 7

Page 8Page 8

Page 8

Page 8Page 8

Page 9Page 9

Page 9

Page 9Page 9

OPERAOPERA

OPERA

OPERAOPERA

1. Position garment on form and adjust shoulders. A knob on top of the form is used to

adjust the form shoulder width. Turn knob clockwise to increase shoulder width.

Turn knob clockwise to increase shoulder width.

2. Press white switch to “air on” to size the bag by moving the damper control on top of

the tower.

3. Set the time on each timer. Recommended is:

Steam: 6-9 seconds

Conditioning: 4-9 seconds

Drying: 12-16 seconds.

4. Either presteam or not; whatever your demands require.

5. Position the cycle switc h for whatever cycle you desire. Recommend steaming,

conditioning, drying the central position of the switch.

TION INSTRUCTIONS FOR TION INSTRUCTIONS FOR

TION INSTRUCTIONS FOR

TION INSTRUCTIONS FOR TION INSTRUCTIONS FOR

(Machine can be operated from either side).

“CISSI”“CISSI”

“CISSI”

“CISSI”“CISSI”

FORM FINISHER FORM FINISHER

FORM FINISHER

FORM FINISHER FORM FINISHER

6. Push the push-to-start switch or step on the foot switch and the cycle will

automatically sequence.

7. If you desire to cancel that cycle at any time, push the white switch toward the cycle

off location.

Page 10Page 10

Page 10

Page 10Page 10

CISSI FORM FINISHERCISSI FORM FINISHER

CISSI FORM FINISHER

CISSI FORM FINISHERCISSI FORM FINISHER

The “Tower of Power” is at your fingertips for all of the finishing combinations you will

ever need. All three timers (steaming, conditioning, drying) are adjustable from 0 to 30

seconds. The cycle switch provides (presteam only, steaming-conditioning-drying,

steam & air-conditioning-drying) which ever is required. The white switch allows you

to have air only for sizing and provides a cancel position to terminate the cycle at any

time. The automatic push-to-start switch is available on the tower or by the foot

switch. The lights will glow whenever you are in any of the timer periods. Damper

control lever is on top of tower.

Where possible, perform all touch-up of sleeves, collars, trim, etc., prior to finishing on

the Genie. In this way, differences in sheen will be eliminated from the garment.

GENERAL SUGGESTIONSGENERAL SUGGESTIONS

GENERAL SUGGESTIONS

GENERAL SUGGESTIONSGENERAL SUGGESTIONS

When finishing knits or soft unlined woolens, place net overbag on form before positioning garment. After garment is positioned on form, repeat Step #2 in Operating

Instructions. Push damper knob all the way to obtain full air pressure and repeat step

6 to start cycle.

To finish coats and other open front garments, use front paddle clamp to hold front of

garment in place. Use the hand vent clamps to hold rear vent or pleat.

When additional moisture is needed for hard set wrinkles, use the water spray gun,

spraying into the steam from a distance of approximately 15”. Rotate the garment to

the spray gun, using the turning knob on the revolving assembly.

Keep the nylon bag clean and in good repair. A vacuum cleanable air filter is provided

to help keep the bag clean. Vacuum clean the filter weekly. Remove nylon bag (see

detailed instructions) and wet clean as required. Repair holes or worn spots. To obtain

proper characteristics of cloth porosity, bag size, and control strings, use only genuine

Cissell replacement bags.

Page 11Page 11

Page 11

Page 11Page 11

Loading...

Loading...