AireAire

Aire

AireAire

FF

F

FF

ModelModel

Model

ModelModel

AF1AF1

AF1

AF1AF1

OWNER’S MANUOWNER’S MANU

OWNER’S MANU

OWNER’S MANUOWNER’S MANU

ormorm

orm

ormorm

ALAL

AL

ALAL

CISSELL MANUFACTURING COMPANYCISSELL MANUFACTURING COMPANY

CISSELL MANUFACTURING COMPANY

CISSELL MANUFACTURING COMPANYCISSELL MANUFACTURING COMPANY

HEADQUARTERSHEADQUARTERS

HEADQUARTERS PHONE: (502) 587-1292

HEADQUARTERSHEADQUARTERS

831 SOUTH FIRST ST. SALES FAX: (502) 585-3625

P.O. BOX 32270 SERVICE/PARTS FAX: (502) 681-1275

LOUISVILLE, KY 40232-2270

MAN60MAN60

MAN60

MAN60MAN60

THIS MANUTHIS MANU

THIS MANU

THIS MANUTHIS MANU

4/954/95

4/95

4/954/95

AL MUST BE GIVEN AL MUST BE GIVEN

AL MUST BE GIVEN

AL MUST BE GIVEN AL MUST BE GIVEN

TT

O O

THE EQUIPMENT OWNER.THE EQUIPMENT OWNER.

T

O

THE EQUIPMENT OWNER.

TT

O O

THE EQUIPMENT OWNER.THE EQUIPMENT OWNER.

Page 1Page 1

Page 1

Page 1Page 1

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

The Cissell Manufacturing Company (Cissell) warrants all new equipment (and the original parts thereof)

to be free from defects in material or workmanship for a period of one (1) year from the date of sale thereof

to an original purchaser for use, except as hereinafter provided. With respect to non-durable parts normally

requiring replacement in less than one (1) year due to normal wear and tear, including, but not limited to,

cloth goods, valve discs, hoses, and iron cords, and with respect to all new repair or replacement parts for

Cissell equipment for which the one (1) year warranty period has expired, or for all new repair or

replacement parts for equipment other than Cissell equipment, the warranty period is limited to ninety (90)

days from date of sale. The warranty period on each new replacement part furnished by Cissell in fulfillment

of the warranty on new equipment or parts shall be for the unexpired portion of the original warranty period

on the part replaced.

With respect to electric motors, coin meters and other accessories furnished with the new equipment, but

not manufactured by Cissell, the warranty is limited to that provided by the respective manufacturer.

Cissell's total liability arising out of the manufacture and sale of new equipment and parts, whether under

the warranty or caused by Cissell's negligence or otherwise, shall be limited to Cissell repairing or replacing,

at its option, any defective equipment or part returned f.o.b. Cissell's factory, transportation prepaid, within

the applicable warranty period and found by Cissell to have been defective, and in no event shall Cissell be

liable for damages of any kind, whether for any injury to persons or property or for any special or

consequential damages. The liability of Cissell does not include furnishing (or paying for) any labor such

as that required to service, remove or install; to diagnose troubles; to adjust, remove or replace defective

equipment or a part; nor does it include any responsibility for transportation expense which is involved

therein.

The warranty of Cissell is contingent upon installation and use of its equipment under normal operating

conditions. The warranty is void on equipment or parts; that have been subjected to misuse, accident, or

negligent damage; operated under loads, pressures, speeds, electrical connections, plumbing, or conditions

other than those specified by Cissell; operated or repaired with other than genuine Cissell replacement

parts; damaged by fire, flood, vandalism, or such other causes beyond the control of Cissell; altered or

repaired in any way that effects the reliability or detracts from its performance, or; which have had the

identification plate, or serial number, altered, defaced, or removed.

No defective equipment or part may be returned to Cissell for repair or replacement without prior written

authorization from Cissell. Charges for unauthorized repairs will not be accepted or paid by Cissell.

CISSELL MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY, STATUTORY OR OTHERWISE,

CONCERNING THE EQUIPMENT OR PARTS INCLUDING, WITHOUT LIMITATION, A WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE, OR A WARRANTY OF MERCHANTABILITY. THE

WARRANTIES GIVEN ABOVE ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED. CISSELL NEITHER ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT,

ANY OTHER WARRANTY OR LIABILITY IN CONNECTION WITH THE MANUFACTURE, USE OR SALE

OF ITS EQUIPMENT OR PARTS.

For warranty service, contact the Distributor from whom the Cissell equipment or part was purchased. If

the Distributor cannot be reached, contact Cissell.

Page 2Page 2

Page 2

Page 2Page 2

Page 3Page 3

Page 3

Page 3Page 3

INSTINST

INST

INSTINST

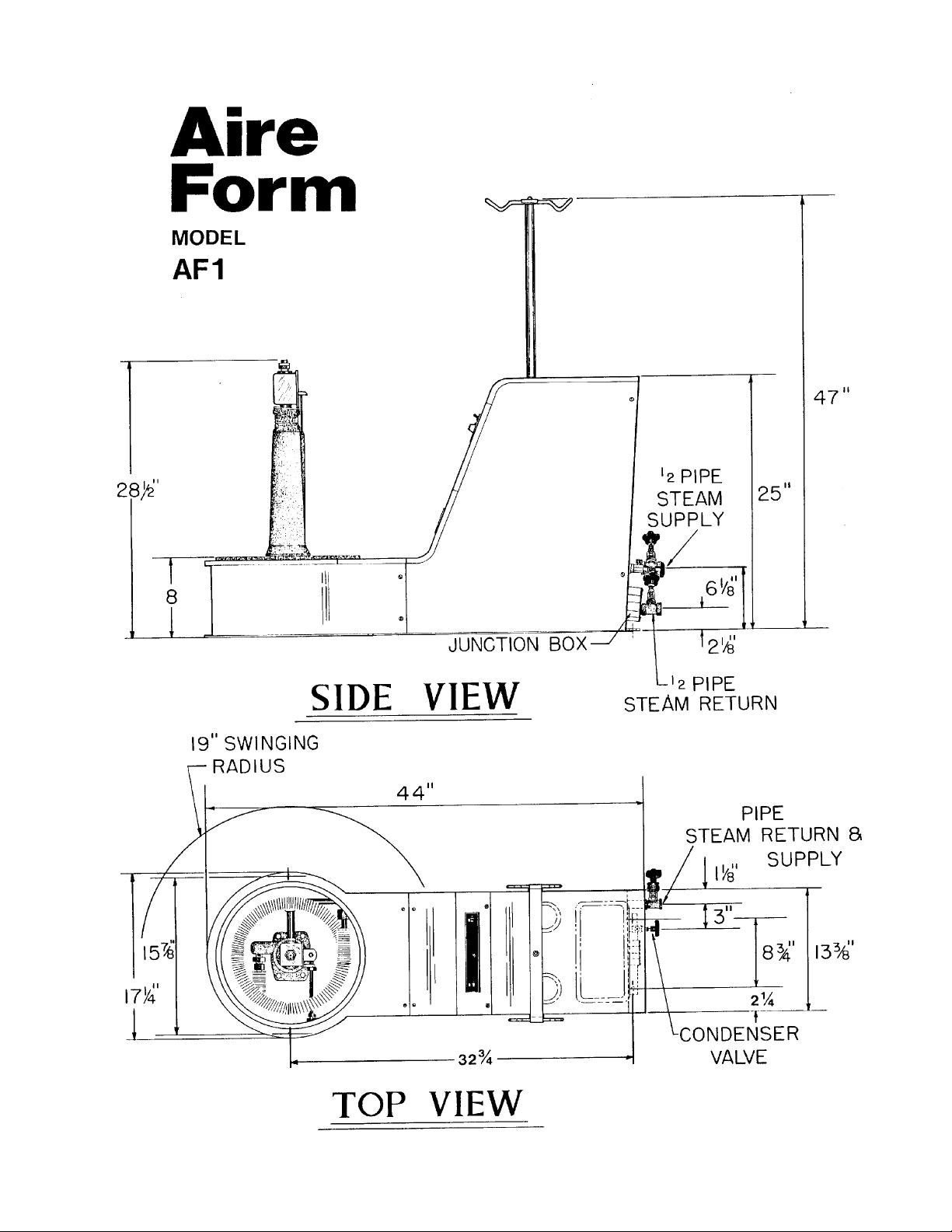

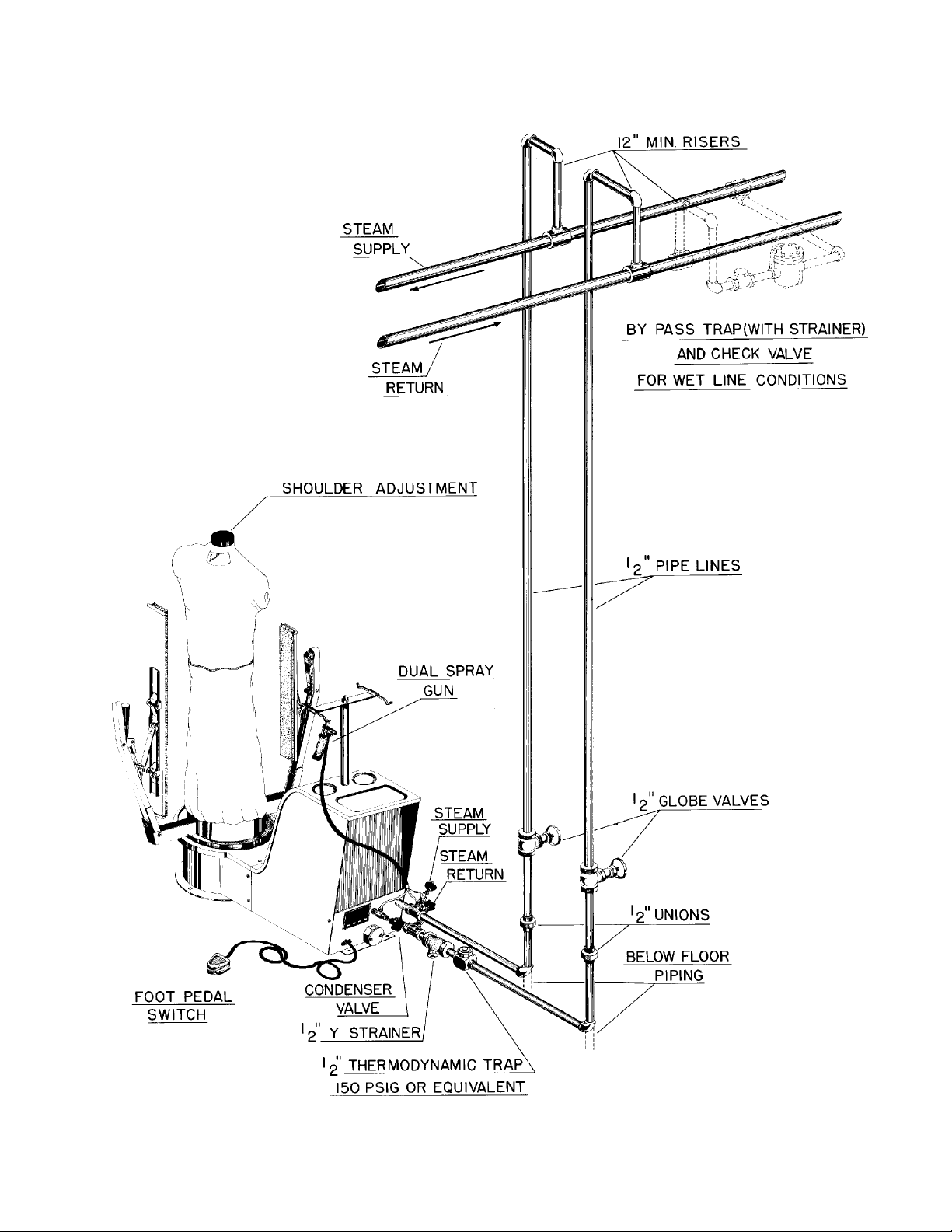

Refer to illustration sheet

(1) UNCRATE MACHINE. Check the nameplate voltage and current, making sure it

is the same as the supply voltage and current.

(2) SET MACHINE IN POSITION.

(3) REMOVE THE REVOLVING FORM by holding the turning knob and the oppo-

site weight “bucket” and lifting approximately 22”.

(4) CONNECT STEAM SUPPLY LINE as shown on next page.

(5) CONNECT RETURN LINE as shown on next page.

NOTE: Before final return line connection is made, open the steam supply valve

and blow all foreign matter out of the steam lines and chamber. Failure

to do so will cause trap to leak.

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

(6) MAKE ELECTRICAL CONNECTIONS in 3” junction box on rear of the machine,

according to applicable electric codes. Connections should include a fused

disconnect switch or circuit breaker with “slo-blow” characteristics and be

capable of carrying 15 amps 115 volts or 8 amps 230 volts.

(7) TURN ON ELECTRICAL POWER AND TEST THE MACHINE.

Replace the revolving assembly, remove the plastic protective bag, and open the

return and steam lines.

Page 4Page 4

Page 4

Page 4Page 4

Page 5Page 5

Page 5

Page 5Page 5

AIRE FORM OPERAAIRE FORM OPERA

AIRE FORM OPERA

AIRE FORM OPERAAIRE FORM OPERA

On the front panel of unit, set timers for required cycle. (Preferred is 5 seconds steam; 10

seconds air).

NOTE: A toggle switch on the control panel may be set to give steam followed by air (AUTO).

Set timers switches as described above. Or you may give air only (ON). Most fabrics

will finish better with the Auto cycle.

Where possible, perform all touc h-up of sleeves, collars, trim, etc., prior to finishing on the Aire

Form. In this way, differences in sheen will be eliminated from the garment.

TING INSTRUCTIONSTING INSTRUCTIONS

TING INSTRUCTIONS

TING INSTRUCTIONSTING INSTRUCTIONS

OPERAOPERA

OPERA

OPERAOPERA

1. Place overbag on the form.

2. Position garment on form and adjust shoulders. A knob on top of the form is used to adjust

the form shoulder width. Turn knob clockwise to increase shoulder width.

3. Step on foot switch to activate the automatic cycle.

4. Remove garment from form.

GENERAL SUGGESTIONS:GENERAL SUGGESTIONS:

GENERAL SUGGESTIONS:

GENERAL SUGGESTIONS:GENERAL SUGGESTIONS:

To finish coats and other open front garments, use front paddle clamp to hold front of garment

in place. Use the hand vent clamps to hold rear vent or pleat.

When additional moisture is needed for hard set wrinkles, use the water spray gun, spraying

into the steam from a distance of approximately 15”. Rotate the garment to the spray gun,

using the turning knob on the revolving assembly.

TION INSTRUCTIONS FOR TION INSTRUCTIONS FOR

TION INSTRUCTIONS FOR

TION INSTRUCTIONS FOR TION INSTRUCTIONS FOR

(Machine can be operated from either side)

““

AIRE”AIRE”

“

AIRE”

““

AIRE”AIRE”

FORM FINISHER FORM FINISHER

FORM FINISHER

FORM FINISHER FORM FINISHER

Keep the nylon bag clean and in good repair. A vacuum cleanable air filter is provided to help

keep the bag clean. Vacuum clean the filter weekly. Remove nylon bag (see detailed instructions) and wet clean as required. Repair holes or worn spots. To obtain proper characteristics

of cloth porosity, bag size, and control strings, use only genuine Cissell replacement bags.

Page 6Page 6

Page 6

Page 6Page 6

NET OVERBAG FOR CISSELL STEAM-AIR FINISHERNET OVERBAG FOR CISSELL STEAM-AIR FINISHER

NET OVERBAG FOR CISSELL STEAM-AIR FINISHER

NET OVERBAG FOR CISSELL STEAM-AIR FINISHERNET OVERBAG FOR CISSELL STEAM-AIR FINISHER

This overbag is for use ONLY when finishing sweaters or other soft garments that do

not require bag contact for proper finishing.

DO NOT use overbag with hard fabrics or heavy garments. Hard set wrinkles will not

be removed when using the overbag.

The Cissell overbag holds the form to a narrow size, thereby spreading steam and

gentle diffused air throughout the garment to eliminate distortion.

THE NET OVERBAG IS EASY THE NET OVERBAG IS EASY

THE NET OVERBAG IS EASY

THE NET OVERBAG IS EASY THE NET OVERBAG IS EASY

1. Place the net bag over the form so that it fully covers the standard nylon bag.

2. Place the garment on the form and operate the machine per standard instructions,

using “large size” setting for faster drying.

In general, garments including bonded knits and wool dresses can be finished without

the overbag.

When ordering additional net overbags, specify F816.

TT

O USEO USE

T

O USE

TT

O USEO USE

Page 7Page 7

Page 7

Page 7Page 7

TT

O REMOVE BAGO REMOVE BAG

T

O REMOVE BAG

TT

O REMOVE BAGO REMOVE BAG

TT

O REPLACE BAGO REPLACE BAG

T

O REPLACE BAG

TT

O REPLACE BAGO REPLACE BAG

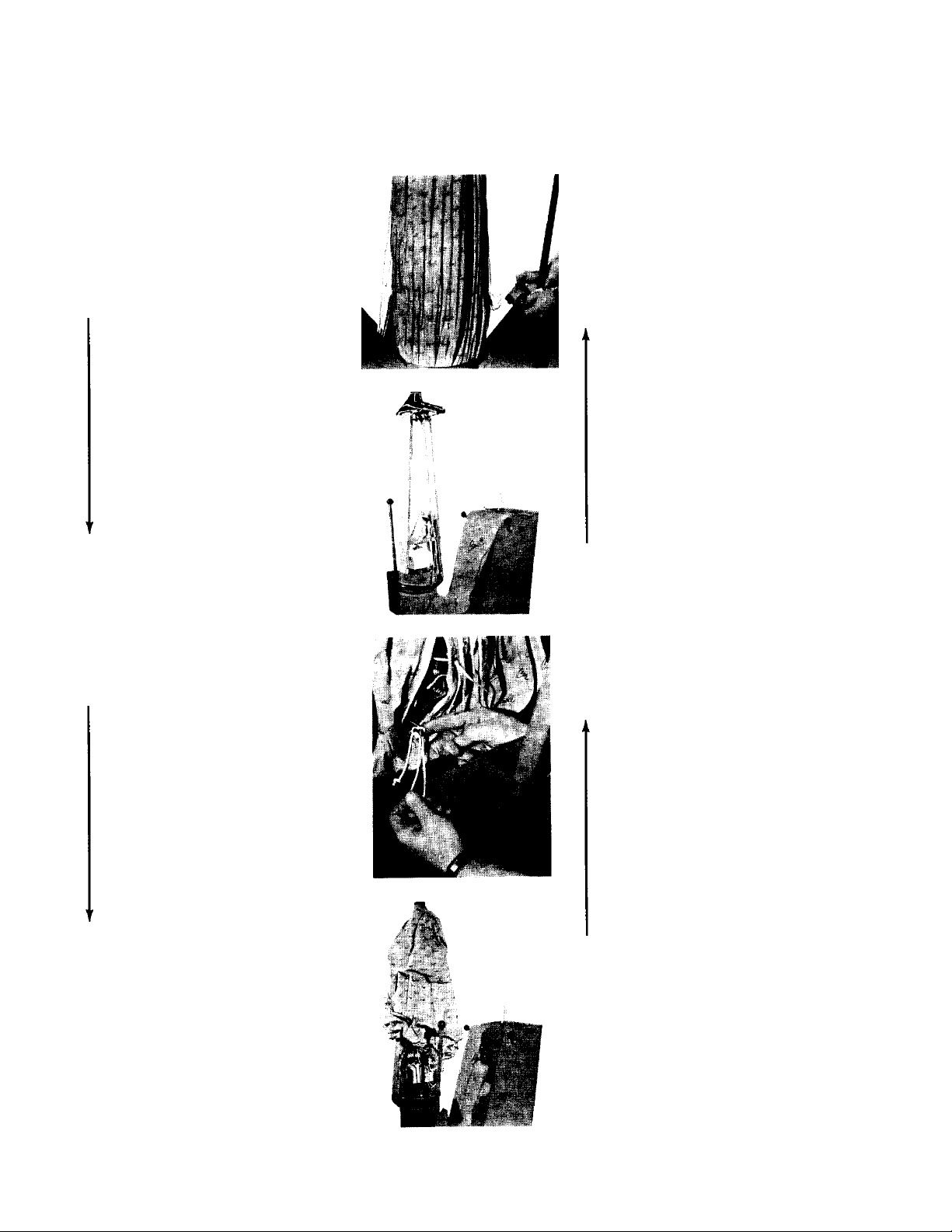

(1) Remove yellow

weights, 1 each

side.

(2) Raise the lower

control ring (inside

bag).

(3) Open zipper and

untie bottom string.

(4) Replace yellow

weights, one each

side, on end of

control strings.

(3) Lower the control

ring inside bag.

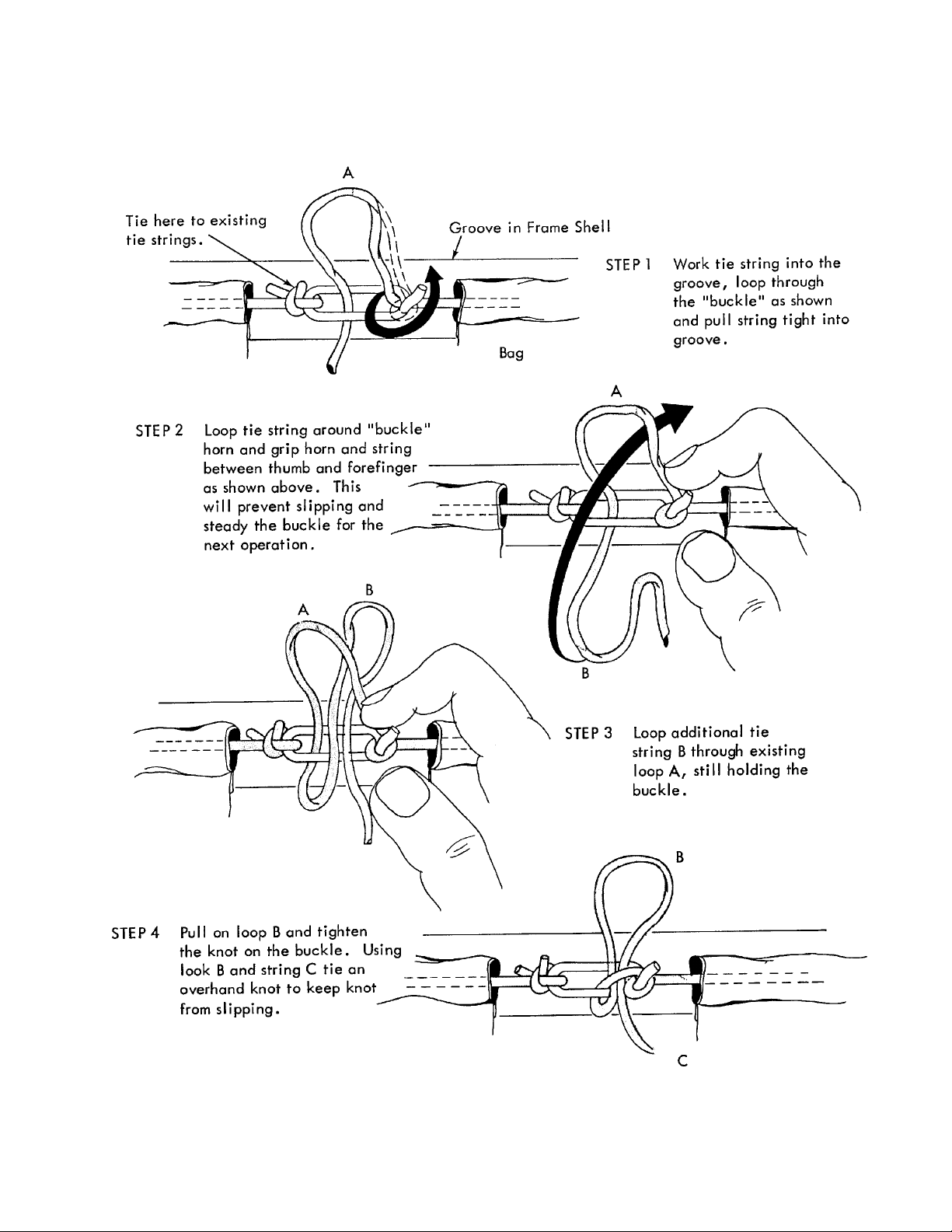

(2) Tie bottom string in

groove and close

zipper. Refer to

instructions on next

page for proper knot

when tying string.

Straighten bag until

control strings are at

the sides.

(4) Lift bag off over

revolving assembly

shoulder form.

Page 8Page 8

Page 8

Page 8Page 8

(1) Place bag over

revolving assembly

shoulder form, with

front of bag toward

front of form.

Page 9Page 9

Page 9

Page 9Page 9

CISSELL FORM FINISHERCISSELL FORM FINISHER

CISSELL FORM FINISHER

CISSELL FORM FINISHERCISSELL FORM FINISHER

INSTRUCTIONS FOR ADJUSTING HEIGHT OR REVOLVING FORM

Should the revolving form “drag” on the Form Finisher base rather than turn freely, the form

must be raised.

Conversely, if the revolving form rides too high above the Form Finisher base, permitting steam

to escape from the space between the form and base, the form must be lowered.

WHEN AN ADJUSTMENT MUST BE MADE, REMOVE REVOLVING FORM BY SIMPLY

LIFTING IT SRAIGHT UP OFF THE FORM FINISHER BASE

PROBLEM: Revolving Form “drags” on base of Form Finisher

TO CORRECT: Loosen F-286 Bearing Lock Nut. Turn F-287 Bearing Adjustment Screw

COUNTER-CLOCKWISE.

CHECK ADJUSTMENT: Replace revolving form on Form Finisher base. Rotate form. If

perfectly adjusted, form will rotate freely and snugly on felt seal around top of base. If form is

still too low...or too high...repeat adjustment until it is correct.

PROBLEM: Revolving Form rides too high above Form Finisher base.

TO CORRECT: Loosen F-286 Bearing Lock Nut. Turn F-287 Bearing Adjustment Screw

CLOCKWISE.

CHECK ADJUSTMENT: Replace revolving form on Form Finisher base. Rotate form. If

perfectly adjusted, form will rotate freely and snugly on felt seal around top of base. If form is

still too high...or too low...repeat adjustment until it is correct.

Page 10Page 10

Page 10

Page 10Page 10

F517 - Adjustable Shoulder Assembly

Consists of 1-10, 18, 19, 20.

AIR FORM REVOLAIR FORM REVOL

AIR FORM REVOL

AIR FORM REVOLAIR FORM REVOL

AF115 - Revolving Form w/Front & Rear Clamps

AF181 - Revolving Form w/o Clamps

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

1 TU3478 #8 x 1/2” Screw

2 F381 Shoulder Adjustment Rod,

3 F49 Shoulder Lever Pin

4 F192 Insulating Gskt.

5 F492 Neck Form w/4 Bolts,

6 F493 Shoulder Extension

7 F336 Shoulder Connecting Link

8 F494 Bearing Plate w/Scrs.

9 F197 Shldr. Tension Sprg.

10 F317 Shoulder Lever

11 AF113 Frame Assm. w/Hdwe.

12 AF121WH Rear Paddle Clmp. Asm.

13 AF176WH Front Paddle Clmp. Asm.

14 F1060 Bearing Assy.

16 AF207 Collar

17 AF153 Form Assembly

18 TU3477 #10 - 24 x 1/2 Screw

19 FB187 #10 Lockwasher (pkg. 6)

20 FB185 #10 Nut (pkg. 6)

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

VING FORMVING FORM

VING FORM

VING FORMVING FORM

DescriptionDescription

Description

DescriptionDescription

Knob, & Pin

(2 required)

Nuts & Washers

*

*

AF114 Replacement Bag

(not shown)

*See Separate Page for Exploded View

Painted parts furnished in white unless

otherwise specified

Page 11Page 11

Page 11

Page 11Page 11

FRONT PFRONT P

FRONT P

FRONT PFRONT P

REAR PREAR P

REAR P

REAR PREAR P

ADDLE CLAMP ADDLE CLAMP

ADDLE CLAMP

ADDLE CLAMP ADDLE CLAMP

ADDLE CLAMP ADDLE CLAMP

ADDLE CLAMP

ADDLE CLAMP ADDLE CLAMP

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

Y - Y -

Y -

Y - Y -

Y - Y -

Y -

Y - Y -

AF176AF176

AF176

AF176AF176

AF121AF121

AF121

AF121AF121

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

1 FG135 Handle Weldment

2 AF157 Trigger Release w/Rodhinge, Pin,

3 F218 Clamp Leaf Spring w/Hardware

4 F267 Pivot Pin w/”E” Rings

5 F240 Clamp Slide Supp. Pin

6 FG443 Clamp Latch Rod

7 F243 Slide Spring Clip

8 F237 Clamp Slide

9 F215 Set Collar

10 F197 Spring

11 F949 Pin

12 FG288 Pin

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

FG450 Latch Pin

F489 “E” Rings

DescriptionDescription

Description

DescriptionDescription

“E” Rings

Painted parts furnished in white unless otherwise specified

Page 12Page 12

Page 12

Page 12Page 12

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

13 FG277 Stud

14 F63 Springs w/Hardware (Set of 2)

15 F11 No. 11 Sleevers (Set of 2)

16 F432 Front Paddle Channel

17 F433 Sponge for Front Paddle

18 AF165 Sponge for Rear Paddle

19 AF168 Rear Paddle Channel

20 F904 Sponge Pad (Set 6/F842)

21 F842 Vent Clamp

22 F24 No. 24 Sleevers

23 TU4787 Hex Nut

24 F888 “E” Rings

25 F901 #10-24 x 3/8 Screw

26 FB187 #10 Lockwasher

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

DescriptionDescription

Description

DescriptionDescription

AIRE FORM JAIRE FORM J

AIRE FORM J

AIRE FORM JAIRE FORM J

ACKETACKET

ACKET

ACKETACKET

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

1 AF120 Gun Support Bracket

2 AF117 Locating Plug

3 PU47 Shaft

4 AF152 Tube Cover

5 AF102 Removable Air Filter

6 AF104 Frame Weldment

7 AF103 Filter Screen

9 AF144 Ja cket Weldment

10 FG344 Speed Nut

11 TU8013 Cissell Nameplate

12 AF161 Control Panel Assembly

13 FG343 Screw w/Wear Washer

14 FG345 Retaining Washer

Painted parts furnished in white unless otherwise specified

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

Page 13Page 13

Page 13

Page 13Page 13

DescriptionDescription

Description

DescriptionDescription

(See Separate Page)

CONTROL PCONTROL P

CONTROL P

CONTROL PCONTROL P

ANEL - ANEL -

ANEL -

ANEL - ANEL -

AF161AF161

AF161

AF161AF161

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

1 FG235 Relay - 115V/50-60 Hz.

2 FG453 Timer - 115-230V

3 AF185 Toggle Switch

4 AF162 Panel

5 AF100 Nameplate

6 PT118 Timer Knob

7 C196 Set Screw

8 LB291 #6-32 x 3/8 Rd. Hd. Screw

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

FG234 Relay - 230V/50-60 Hz.

AF203 Wiring Harness (not shown)

AF216 Resistor, 200VL w/Piggy Back End & Black Insulation

AF217 Resistor, 500VL w/Piggy Back End & Black Insulation

DescriptionDescription

Description

DescriptionDescription

Page 14Page 14

Page 14

Page 14Page 14

AIR FORM REAR BASEAIR FORM REAR BASE

AIR FORM REAR BASE

AIR FORM REAR BASEAIR FORM REAR BASE

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

1 FG274 1/2” Pipe 30” Long

2 SGV13 Supply Valve

3 SGV40 Return Valve

4 AF124 Rear Base Weldment

5 SB170 Junction Box Cover

6 PIU94 Nameplate

7 F739 Solenoid - 115V

F738 Solenoid - 230V

8 TU3549 Rubber Bumper

9 FG175 Rod Extension

DescriptionDescription

Description

DescriptionDescription

Painted parts furnished in white unless otherwise specified

Page 15Page 15

Page 15

Page 15Page 15

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

10 F520 Seal Spring

11 F519 Nylon Seal

12 AF128 Damper

13 OP296 1/2” Pipe 5” Long

14 FG273 1/2” Pipe 28 - 1/2” Long

15 OP306 Tee - 1/2” x 1/2” x 3/8”

16 FG143 Tee - 1/2” x 1/2” x 1/4”

17 M155 Strain Relief

18 RC385 Round Head Screw

19 M263 Sheet Metal Screw

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

DescriptionDescription

Description

DescriptionDescription

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

DescriptionDescription

Description

DescriptionDescription

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

DescriptionDescription

Description

DescriptionDescription

1 F149 Steam Valve Pull Rod

2 FG320 Extension Bar

3 F215 Set Collar, 2 req’d

4 FG275 Steam Valve Lever Ass’y

5 TU49 Delrin Bearing (Pkg. 2)

6 F539 Stm. Chamber

7 TU4593 1/2” x 90º Pipe Elbow

8 LB20 1/2” Pipe Nipple 3” Long

9 FG319 Stm. Coil Adapter

10 F357 Felt Air Seal

11 FG321 Steam Manifold

12 FG322 Steam Coil

13 FG323 Shallow Base Welded Ass’y

Page 16Page 16

Page 16

Page 16Page 16

14 ------ See Separate Parts Sheet

15 F122 1/4” - 28 Brass Nut

16 RC349 1/4” Lockwasher

17 V02 1/16” x 1/2” Cotter Pin

18 IB139 3/8” x 1-1/4” Hex. Hd. Scw.

19 VSB134 3/8” Split Lockwasher

20 IB140 3/8” Flat Washer

21 F819 5/16” - 18-5/8” Sq. Hd. Set Scw.

22 P126 1/4” - 20 x 1/4” Set Scw.

23 TU3210 5/16” - 18 x 5/8” Hex. Scw.

24 TU2814 5/16” Split Lockwasher

25 TU2793 #8 x 5/8” S.M.S.

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

1 F287 Bearing Adjustment Scr.

2 F286 Bearing Locknut

3 F285 Bearing Support Box

4 FV101 Valve Lever

5 OP547 Locknut

6 FV106 Collar Retainer

7 F18 Steam Spreader

FV110 Valve Ass’y CONSISTS OF

10 FV100 Valve Body

11* V36 Valve Seat

12* P103 Gasket

13 F359 “E” Ring

14* FV103 Valve Stem

15* V15 Small Locknut

16* V16 Teflon Disc

17 FV104 Valve Disc Holder

18* V330 30 Lb. Spring

19 FV105 Spring Retainer

20* F358 “E” Ring

*K451 Repair Kit for FV110 Valve

DescriptionDescription

Description

DescriptionDescription

REF. NO. 10-20

Page 17Page 17

Page 17

Page 17Page 17

CONDENSER PCONDENSER P

CONDENSER P

CONDENSER PCONDENSER P

SGC9 - Condenser Only (Consists of Ref. Nos. 2, 3, 4, 5, 6)

ARTSARTS

ARTS

ARTSARTS

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

1 F578 Plug

2 SGC6 Upper Section

3 SG116 Taptite Bolts

4 SG77 “O” Ring

5 SG79 Strainer

6 SGC8 Lower Section

7 OP225 Straight Connector

8 FG340 Copper Tube - 24”

9 FG159 Elbow

10 OP305 Bushing 3/8 x 1/4

11 BR61 Bushing 1/4 x 1/8

12 SB88 Straight Connector

13 AF142 Tube - 16”

14 V63 Small Pack Nut

15 PU8 Bead

16 SGV12 Valve

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

Page 18Page 18

Page 18

Page 18Page 18

DescriptionDescription

Description

DescriptionDescription

BLOWER & MOBLOWER & MO

BLOWER & MO

BLOWER & MOBLOWER & MO

TT

OR MOUNTOR MOUNT

T

OR MOUNT

TT

OR MOUNTOR MOUNT

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

1 FG292 Blower Wheel

2 FG226 Inlet Cone

3 AF131 Motor Bracket w/Hardware (7, 8, 9)

4 AF130 Mounting Hardware (3 sets/pkg.)

5 FG148 Harness Clamp

6 MTR88 Motor - 110-120/220-240/50/60/1

7 FB124 Cap Screw

8 TU2814 Split Lockwasher

9 C249 Hex Nut

10 TU2793 Sheet Metal Screw

11 M263 Sheet Metal Screw

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

Consult factory for other voltages

Page 19Page 19

Page 19

Page 19Page 19

DescriptionDescription

Description

DescriptionDescription

FOOFOO

FOO

FOOFOO

T PEDAL SWITCH T PEDAL SWITCH

T PEDAL SWITCH

T PEDAL SWITCH T PEDAL SWITCH

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

Y - PT527Y - PT527

Y - PT527

Y - PT527Y - PT527

INSTINST

INST

INSTINST

ALLAALLA

ALLA

ALLAALLA

FOR FOR

FOR

FOR FOR

1. Turn switch to upside down

2. Lift off base plate pad.

3. Remove two (2) screws marked (B)

4. Remove two (2) washers, plate,

insulation and switch.

5. Remove wires from old switch and

6. Reinstall switch, insulation, plate,

TION INSTRUCTIONTION INSTRUCTION

TION INSTRUCTION

TION INSTRUCTIONTION INSTRUCTION

AF 177 SWITCHAF 177 SWITCH

AF 177 SWITCH

AF 177 SWITCHAF 177 SWITCH

position and remove two (2)

screws marked (A) as illustrated.

as shown.

install wires on new switch and

tighten securely.

washers and screws and tighten

securely.

Page 20Page 20

Page 20

Page 20Page 20

7. Reinstall base-plate-pad and

screws and tighten securely.

SPRASPRA

SPRA

SPRASPRA

Y GUN Y GUN

Y GUN

Y GUN Y GUN

VV

V

VV

ALAL

AL

ALAL

VE PVE P

VE P

VE PVE P

ARTSARTS

ARTS

ARTSARTS

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

10 SGV47 Valve Spring

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

1 SGV38 Valve Pin

2 SGV41 Hose Adapter

3 SGV37 Teflon Ball

4 SGV56 Valve Body

5 V30 Small Pack Ring

6 SGV46 Piston

7 V73 Control Knob Asy.

8 SGV56 Valve Body

9 SGV57 Valve Body

DescriptionDescription

Description

DescriptionDescription

Page 21Page 21

Page 21

Page 21Page 21

DUDU

AL SPRAAL SPRA

DU

AL SPRA

DUDU

AL SPRAAL SPRA

SG146 - Complete Gun & Hose SG146 - Complete Gun & Hose

SG146 - Complete Gun & Hose

SG146 - Complete Gun & Hose SG146 - Complete Gun & Hose

Y GUN & HOSE Y GUN & HOSE

Y GUN & HOSE

Y GUN & HOSE Y GUN & HOSE

SG147 - Dual Spray Gun Only

SKD147 - Repair Kit-Includes parts marked (*).

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

AssemblyAssembly

Assembly

AssemblyAssembly

Parts to repair one Dual Spray Gun.

YY

Y

YY

SG148 - Hose SG148 - Hose

SG148 - Hose

SG148 - Hose SG148 - Hose

Ref.Ref.

Ref.

Ref.Ref.

No.No.

No.

No.No.

1 SG122 Tube Adapter

2 SG136 Set of 3 Tubes (Black, White,

3 SG11 Tube Connection Nut

4 SG126 Tube Connector

5 SG25 Hose Gasket

6 SG137 Tube Cover Assembly

7 AF123 Hose Clamp (Not part

PP

P

PP

No.No.

No.

No.No.

SG200 Blue Tube Only

SG201 Black Tube Only

SG202 White Tube Only

Assembly OnlyAssembly Only

Assembly Only

Assembly OnlyAssembly Only

artart

art

artart

DescriptionDescription

Description

DescriptionDescription

& Blue)

of Assembly)

Page 22Page 22

Page 22

Page 22Page 22

HOSE CONNECTIONS FORHOSE CONNECTIONS FOR

HOSE CONNECTIONS FOR

HOSE CONNECTIONS FORHOSE CONNECTIONS FOR

CISSELL DUCISSELL DU

CISSELL DU

CISSELL DUCISSELL DU

AL SPRAAL SPRA

AL SPRA

AL SPRAAL SPRA

Y GUNY GUN

Y GUN

Y GUNY GUN

* NOTE: This connection works best in most installations. Should there be excessive condensate in the

spray, reverse these two connections and use the configuration that has the best results.

Page 23Page 23

Page 23

Page 23Page 23

TT

O O

ADJUST STEAM ADJUST STEAM

T

O

ADJUST STEAM

TT

O O

ADJUST STEAM ADJUST STEAM

1. Set steam valve extension bar and solenoid lever at 90º as shown and tighten set screw.

2. Adjust steam valve adjusting nuts until 1/32” to 1/16” gap is obtained as shown

above and lock adjusting nuts tightly together.

VV

V

VV

ALAL

AL

ALAL

VE VE

AND SOLENOID LINKAGE:AND SOLENOID LINKAGE:

VE

AND SOLENOID LINKAGE:

VE VE

AND SOLENOID LINKAGE:AND SOLENOID LINKAGE:

Page 24Page 24

Page 24

Page 24Page 24

Page 25Page 25

Page 25

Page 25Page 25

Page 26Page 26

Page 26

Page 26Page 26

PROBLEMPROBLEM

PROBLEM

PROBLEMPROBLEM

(1) No Steam

(2) Blower motor will start,

steam won’t start

(3) Leaking steam valve

(4) Wet steam

CACA

USEUSE

CA

USE

CACA

USEUSE

1A Steam supply valve

off.

1B Electric power “Off”

2A Loose wires

2B Incorrect voltage of

electrical parts

2C Defective start switch

2D Defective solenoid

2E Defective solenoid

linkage

3A Solenoid linkage

adjusted incorrectly

3B Loose valve seat

3C Worn valve

4A Trap not operating

4B Trap installed

incorrectly

4C Check valve installed

wrong or sticking

REMEDYREMEDY

REMEDY

REMEDYREMEDY

Open valve in steam supply

line.

Inspect electric service for

blown fuses & loose connections. Turn main disconnect

“ON”.

Inspect and replace any loose

wires.

Inspect nameplate voltage and

voltage on electrical parts,

especially the solenoid. Replace

switch if necessary.

Check switch to see that it

operates and will carry current.

Replace switch if necessary.

Inspect solenoid. Replace if

necessary.

Check linkage between solenoid

and steam valve for broken or

loose parts. Repair or replace

as required. (See adjustment

instructions.)

Inspect linkage and adjust

according to instructions.

Tighten all lock nuts and set

screws.

Inspect and tighten seat if

required.

Inspect valve parts. Replace

worn parts as required.

Check size and operation of

trap. Repair or replace if

required.

Check to see that direction of

flow in trap is correct and that

trap is in or below machine

return line.

Check to see that direction of

flow is correct and valve not

sticking.

Page 27Page 27

Page 27

Page 27Page 27

PROBLEMPROBLEM

PROBLEM

PROBLEMPROBLEM

(4) Wet steam (Cont.)

(5) Water accumulates in

base

(6) Excessive noise or

vibration

(7) Blower motor won’t

start, machine won’t

steam

CACA

USEUSE

CA

USE

CACA

USEUSE

4D Strainer clogged

4E Return line turned off

4F Steam Cycle too long

4G Improperly installed

steam lines

4H Heavy condensate in

supply line

4I Machine not

individually trapped

4J Back pressure in return

line

5A Steam too wet

5B Leak in finned tube or

pipe fitting

5C Leaking steam valve

6A Foreign object in blower

wheel

6B Blower wheel out of

balance

6C Motor bearings bad

6D Motor mount bent

6E Blower wheel loose on

motor shaft

7A No electrical power

REMEDYREMEDY

REMEDY

REMEDYREMEDY

Inspect strainer and clean if

necessary.

Open valve in condensate

return line.

Reduce amount of time set on

steam timer.

Check steam line installation to

see that “risers” are installed,

as shown on installation

illustration.

Install a by-pass trap from

supply header to by-pass

condensate to return line.

Install a separate trap for each

machine.

Inspect all traps to see if one is

stuck open, or improperly

installed. Perform steps necessary to make return line drain

by gravity to condensate return

tank. See that return tank is

adequately vented.

See wet steam above.

Inspect machine and repair or

replace any leaking parts.

See leaking steam valve (3).

Inspect wheel and remove any

foreign objects & lint.

Inspect wheel for loose balance

weights, out of round or damage, replace if necessary.

Inspect motor to see if bearings

are tight and motor free

turning. Replace motor if

necessary.

Inspect motor mount to see if

machine has been dropped in

transit, bending the mount,

letting the blower wheel hit the

housing. If so, inspect blower

wheel for damage. Replace

either or both if necessary.

Check to see that wheel is

mounted in center of housing,

key is in keyway if used, and

both set screws tight.

Check electrical service and be

sure main switch is “ON” all

wires are tight and fuses are

good.

Page 28Page 28

Page 28

Page 28Page 28

PROBLEMPROBLEM

PROBLEM

PROBLEMPROBLEM

(7) Blower motor won’t

start, machine won’t

steam (Cont.)

(8) Blower motor won’t

start, machine steams

continuously after air

switch is operated.

(9) Blower motor will start,

machine steams only

while control knob is

pushed

CACA

USEUSE

CA

USE

CACA

USEUSE

7B Incorrect supply voltage

7C Air timer set at 0 time

7D Defective blower relay

7E Defective blower motor

7F Loose wires

8 Defective start switch

9A Steam timer set at 0

time

9B Defective steam timer

9C Defective steam relay

REMEDYREMEDY

REMEDY

REMEDYREMEDY

Check power source. Voltage

phase and frequency must be

the same as specified on machine nameplate.

Timer knob may slip on the

shaft and leave the timer set at

0 time. Tighten knob set screw

and set timer and knob to suit,

approx. 20 seconds.

Check to see if the blower relay

will operate. If not, replace

relay.

Check motor to see if it will

operate on normal nameplate

electrical power. If not, replace

the motor.

Check to see that all wires and

connections are tight. If not,

replace the wires and tighten

connections.

Check switch to see that it

operates and will carry current.

Replace switch if necessary.

Timer knob may slip on the

shaft and leave the timer set at

0 time. Tighten knob set screw

and set timer and knob to suit,

approx. 8 seconds.

Check timer operation. See if

timer switch operates properly.

If not, replace timer.

Check to see if relay will

operate on rated current and if

contacts will carry current. If

not, replace relay.

Page 29Page 29

Page 29

Page 29Page 29

PROBLEMPROBLEM

PROBLEM

PROBLEMPROBLEM

(10) Inadequate steam flow

(11) Blower motor will start,

steam starts but won’t

stop

(12) Blower Motor won’t

stop

CACA

USEUSE

CA

USE

CACA

USEUSE

10A Steam valve linkage not

properly adjusted

10B Steam time set too

short

11 Defective steam timer

12A Defective Air timer

12B Defective blower relay

REMEDYREMEDY

REMEDY

REMEDYREMEDY

Adjust linkage according to

adjustment instructions.

Tighten all set screws and lock

nuts.

Set steam timer for longer time.

Tighten knob set screw if

necessary.

Check timer operation. See if

timer switch operates properly.

If operation is not correct,

replace the timer.

Check timer operation. See if

timer switch operates properly.

If operation is not correct,

replace the timer.

Check to see if relay operates

properly on rated current. If

contacts are stuck or welded

shut, or relay does not operate

properly, replace it.

Aire FAire F

Aire F

Aire FAire F

orm orm

orm

orm orm

PP

artart

P

art

PP

artart

No.No.

No.

No.No.

F218 Clamp Leaf Spring

F267 Pivot Pin w/”E” Rings

F63 Covered Spring Asm.

F11 Set No. 11 Sleevers

F433 Sponge for Front Paddle

AF165 Sponge for Rear Paddle

F904 Foam Rubber Pads, Vent Clamp

F357 Felt Air Seal

F287 Bearing Adjust Screw

F18 Steam Spreader Asm.

F739H Solenoid

F738H Solenoid

V30 Pack Ring

TU13224 RBM Relay, 115V

TU13225 RBM Relay, 230V

FG453 Timer

AF185 Toggle Switch

AF102 Air Filter

SKD147 Repair Kit for SG147 Gun

SG148 Teflon Hose Assy. for SG147

K451 Repair Kit for FV110 Valve

AF1 Suggested Spare PAF1 Suggested Spare P

AF1 Suggested Spare P

AF1 Suggested Spare PAF1 Suggested Spare P

DescriptionDescription

Description

DescriptionDescription

artsarts

arts

artsarts

Page 30Page 30

Page 30

Page 30Page 30

Loading...

Loading...