Page 1

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

May 24, 2013

Cisco Systems, Inc.

www.cisco.com

Cisco has more than 200 offices worldwide.

Addresses, phone numbers, and fax numbers

are listed on the Cisco website at

www.cisco.com/go/offices.

Text Part Number: OL-24619-02

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required

to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency energy. If it is not

installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment has been tested and found to

comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These specifications are designed to provide reasonable

protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class A or Class B digital

devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference to radio or television

communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco equipment or one of its

peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio are on circuits

controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this

URL: www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

Any Internet Protocol (IP) addresses used in this document are not intended to be actual addresses. Any examples, command display output, and figures included in the

document are shown for illustrative purposes only. Any use of actual IP addresses in illustrative content is unintentional and coincidental.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

© 2013 Cisco Systems, Inc. All rights reserved.

Page 3

Preface vii

CONTENTS

CHAPTER

CHAPTER

1 Introducing the Cisco Wide Area Virtualization Engine 594 and 694 1-1

Supported Products 1-1

Hardware Features 1-1

Front Panel Components and LEDs 1-2

Back Panel Components and LEDs 1-4

Location of Ports and Connectors 1-5

Connecting a Console Terminal 1-6

Cabling 1-6

Installing the Cisco USB Driver 1-6

2 Preparing to Install the WAVE-594 and WAVE-694 2-1

Safety Warnings and Cautions 2-1

Safety Guidelines 2-2

General Precautions 2-4

System Reliability Considerations 2-5

Protecting Against Electrostatic Discharge 2-5

Understanding the Environmental Requirements 2-5

Understanding the Power Requirements 2-6

CHAPTER

OL-24619-02

Understanding the Grounding Requirements 2-6

3 Installing the WAVE-594 and WAVE-694 3-1

Rack-Mounting Considerations, Parts, and Tools 3-1

Rack Mounting and Cabling the WAVE-594 and WAVE-694 3-2

Mounting in a 4-Post Rack 3-3

Front-Mounting in a 2-Post Rack 3-5

Cabling 3-7

Connecting Power and Booting the System 3-8

Checking the LEDs 3-8

Removing or Replacing a WAVE Appliance 3-9

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

iii

Page 4

Contents

CHAPTER

CHAPTER

4 Installing Hardware Options for the WAVE-594 and WAVE-694 4-1

Installing a Cisco WAVE Interface Module 4-1

Replacing a Hard Disk Drive/Solid State Drive 4-2

Replacing a Fan 4-4

Replacing a Power Supply 4-5

Installing Memory 4-6

Removing the Cover 4-6

Installing Memory Modules 4-7

5 WAVE Interface Modules 5-1

Interface Module Descriptions 5-1

Gigabit Ethernet Interface Module—Copper 5-1

Gigabit Ethernet Interface Module—Fiber Optic 5-2

10 Gigabit Ethernet Interface Module—Fiber Optic SFP+ 5-3

Inline Interface 5-4

Ports and LED Indicators 5-5

Network Adapter Cabling Requirements 5-8

Gigabit Ethernet—Copper 5-8

Gigabit Ethernet—Fiber Optic 5-10

CHAPTER

APPENDIX

APPENDIX

Installation Scenarios and Cabling Examples for Fast Ethernet Connections 5-10

6 Troubleshooting the System Hardware 6-1

Identifying System Problems 6-1

Checking Connections and Switches 6-2

Troubleshooting the Ethernet Controller 6-2

Network Connection Problems 6-3

Ethernet Controller Troubleshooting Chart 6-3

Undetermined Problems 6-4

Problem-Solving Tips 6-5

Error Symptoms 6-6

A WAVE-594 and WAVE-694 Hardware Specifications A-1

Appliance Specifications A-1

Interface Module Specifications A-3

B Maintaining the WAVE-594 and WAVE-694 B-1

iv

Maintaining Your Site Environment B-1

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 5

Temperature B-2

Humidity B-2

Altitude B-2

Dust and Particles B-3

Corrosion B-3

Electrostatic Discharge B-3

Electromagnetic and Radio Frequency Interference B-4

Magnetism B-4

Shock and Vibration B-4

Power Source Interruptions B-5

Using Power Protection Devices B-5

Surge Protectors B-6

Line Conditioners B-6

Uninterruptible Power Supplies B-6

Contents

I

NDEX

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

v

Page 6

Contents

vi

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 7

Preface

This preface describes the purpose of the Cisco Wide Area Virtualization Engine 594 and 694 Hardware

Installation Guide, who should read it, how it is organized, and its document conventions.

This preface contains the following sections:

• Purpose, page vii

Purpose

Audience

• Audience, page vii

• Organization, page viii

• Conventions, page viii

• Related Documentation, page xiii

• Obtaining Documentation and Submitting a Service Request, page xiv

This installation guide explains how to prepare your site for installation, how to install a Wide Area

Virtualization Engine 594 and 694 (WAVE-594 and WAVE-694) in an equipment rack, and how to

maintain and troubleshoot the system hardware. After completing the hardware installation procedures

covered in this guide, you will then use the appropriate related publications to configure your system.

(See the “Related Documentation” section on page xiii.)

To use this installation guide, you should be familiar with internetworking equipment and cabling, and

have a basic knowledge of electronic circuitry and wiring practices.

To complete the installation, including the software configuration for your WAVE-594 and WAVE-694

appliance and for the router that works with the WAVE-594 and WAVE-694 appliance, you should be

familiar with basic networking principles, router configuration, and web page protocols.

OL-24619-02

Warning

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

vii

Page 8

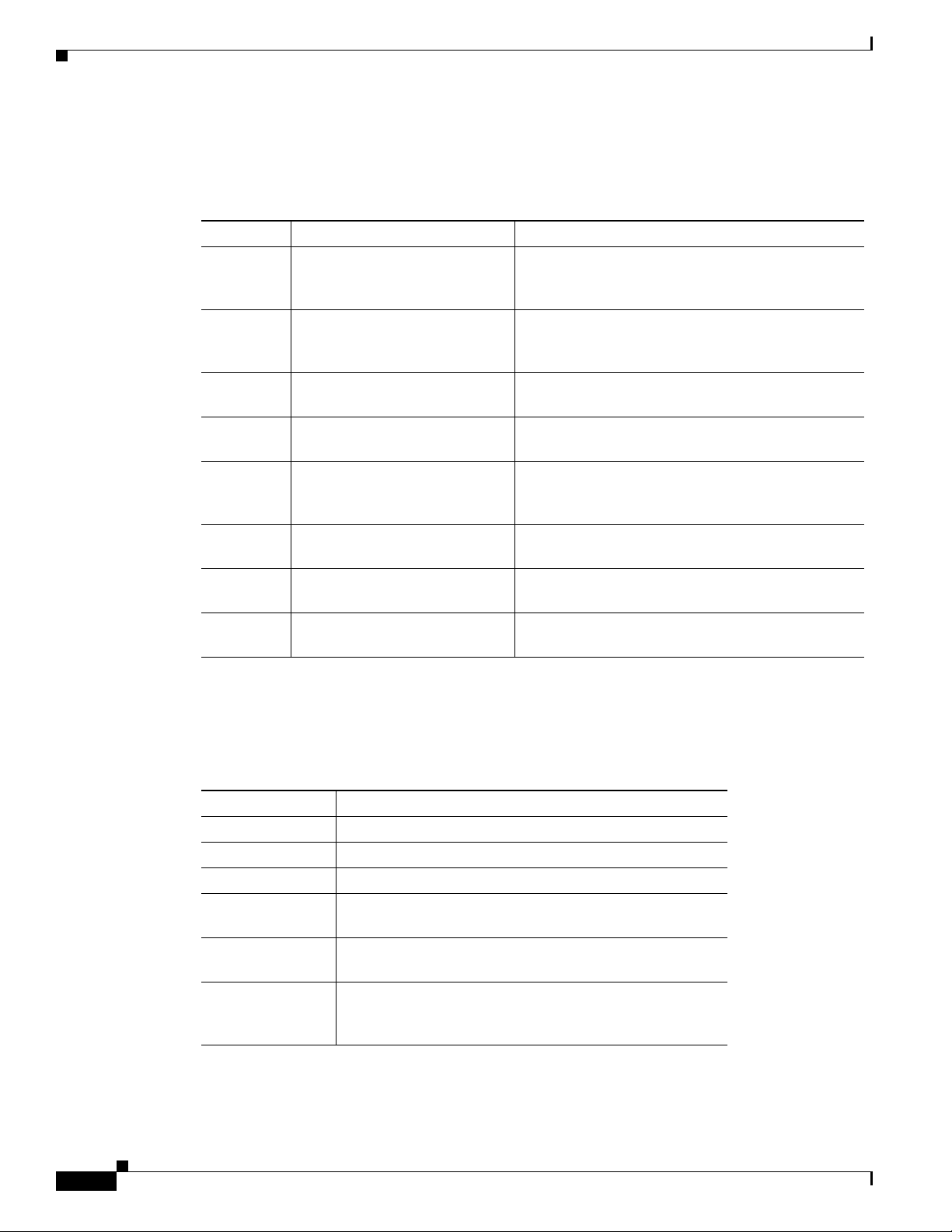

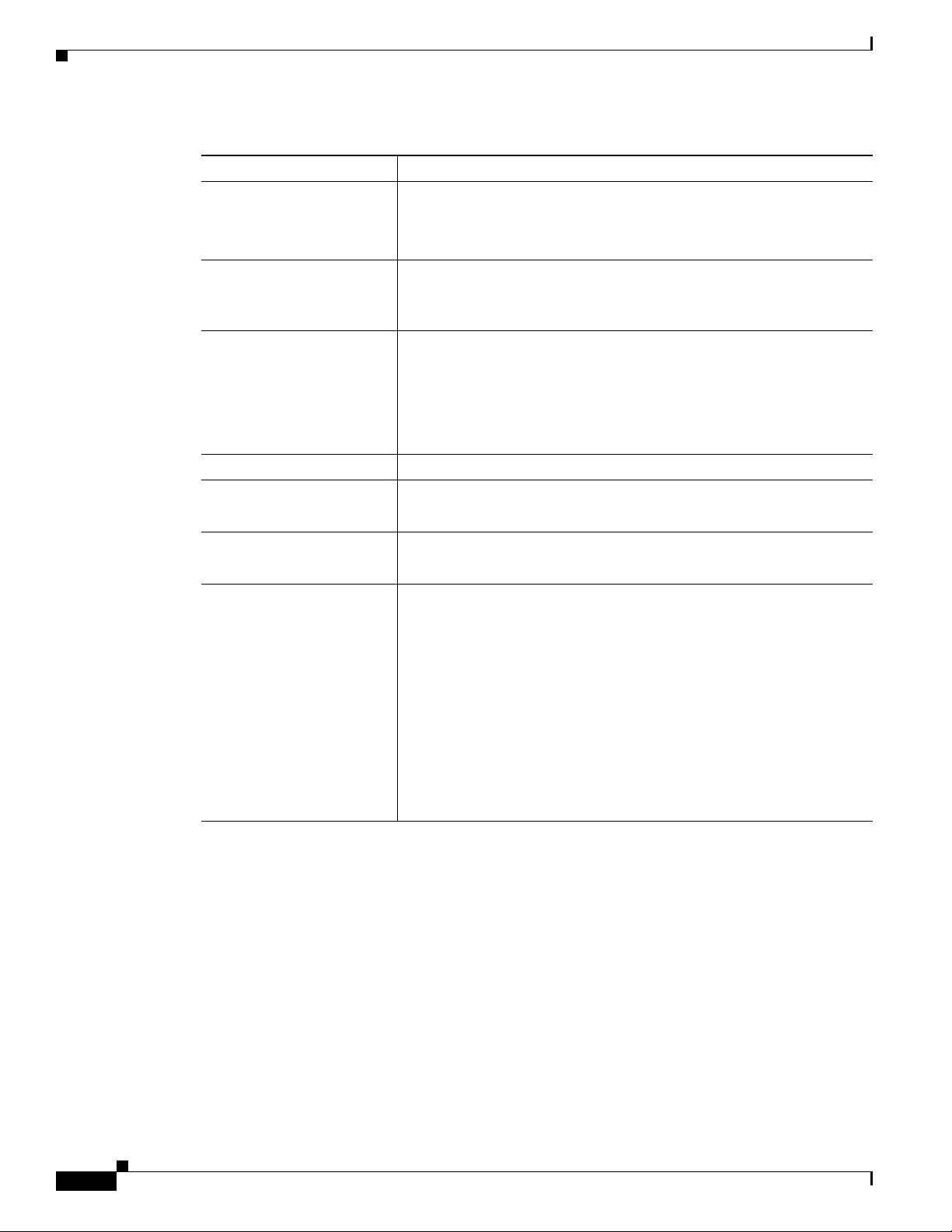

Organization

This guide is organized as follows:

Chapter Title Description

Chapter 1 Introducing the Cisco Wide Area

Chapter 2 Preparing to Install the

Chapter 3 Installing the WAVE-594 and

Chapter 4 Installing Hardware Options for

Chapter 5 WAVE Interface Modules Describes the features and cabling requirements of

Chapter 6 Troubleshooting the System

Appendix A WAVE-594 and WAVE-694

Appendix B Maintaining the WAVE-594 and

Virtualization Engine 594 and

694

WAVE-594 and WAVE-694

WAVE-694

the WAVE-594 and WAVE-694

Hardware

Hardware Specifications

WAVE-694

Describes the physical properties and provides a

functional overview of the WAVE-594 and

WAV E- 6 9 4.

Describes safety considerations and gives an

overview of the installation and procedures that you

should perform before the actual installation.

Describes how to install the hardware and connect

the external network interface cables.

Describes how to install Cisco Interface Modules,

hard disk drives, fans, power supplies, and memory.

the Cisco WAVE-594 and WAVE-694 Cisco

Interface Modules.

Describes troubleshooting procedures for the

hardware installation.

Gives a summary of the hardware features and

specifications.

Describes how to maintain the WAVE-594 and

WAV E- 6 9 4.

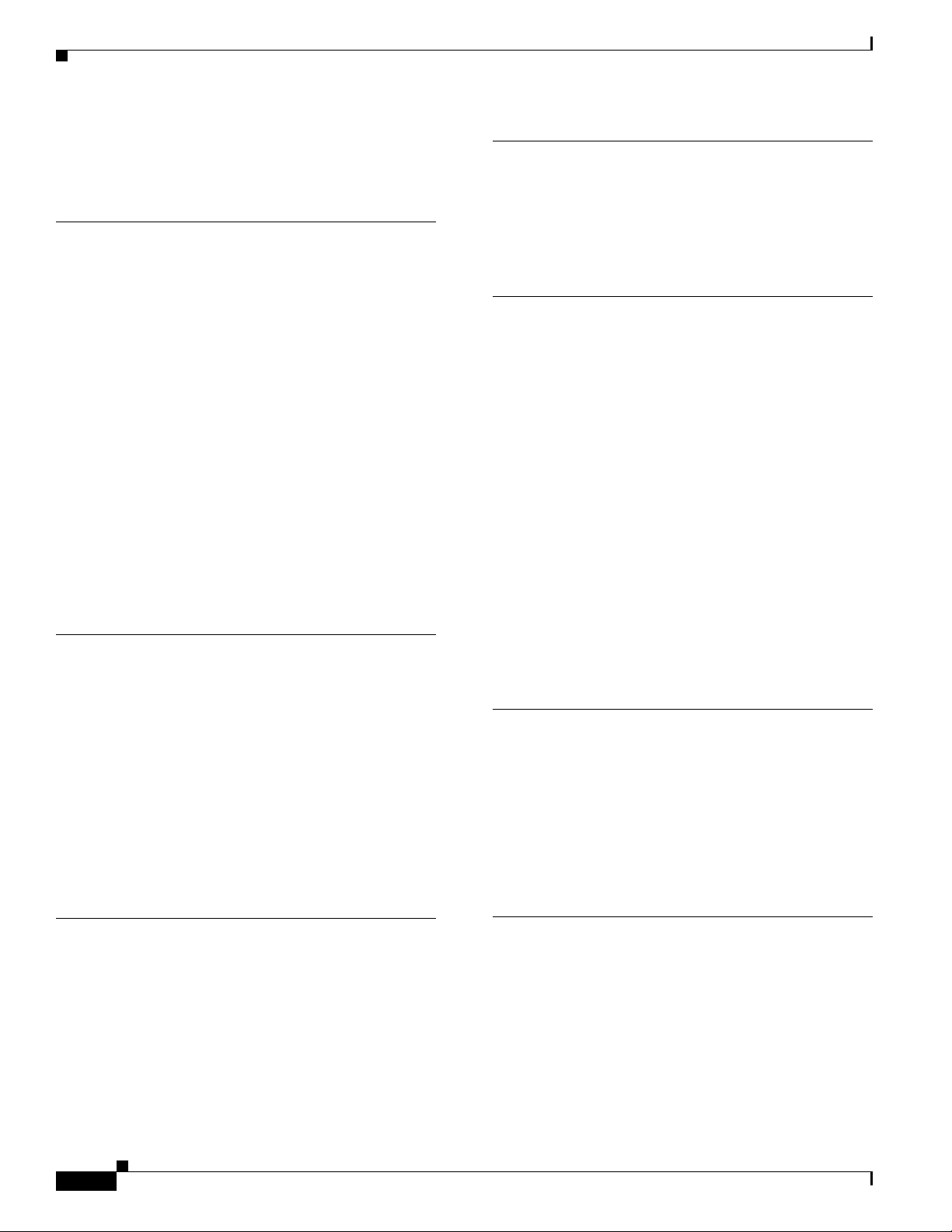

Conventions

Command descriptions use the following conventions:

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

viii

Convention Description

boldface font Commands and keywords are in boldface.

italic font Variables for which you supply values are in italics.

[ ] Elements in square brackets are optional.

{x | y | z} Alternative keywords are grouped in braces and separated

by vertical bars.

[x | y | z] Optional alternative keywords are grouped in brackets and

separated by vertical bars.

string A nonquoted set of characters. Do not use quotation marks

around the string, or the string will include the

quotation marks.

OL-24619-02

Page 9

Screen examples use the following conventions:

Convention Description

screen font Terminal sessions and information the system displays are

in

screen font.

boldface screen

font

italic screen

font

^ The symbol ^ represents the key labeled Control—for

< > Nonprinting characters, such as passwords, are in angle

[ ] Default responses to system prompts are in square brackets.

!, # An exclamation point (!) or a pound sign (#) at the

Information you must enter is in boldface screen font.

Variables for which you supply values are in italic screen

font.

example, the key combination ^D in a screen display means

hold down the Control key while you press the D key.

brackets.

beginning of a line of code indicates a comment line.

Notes, cautionary statements, and safety warnings use these conventions:

Note Means reader take note. Notes contain helpful suggestions or references to materials not contained in

this manual.

Caution Means reader be careful. You are capable of doing something that might result in equipment damage or

loss of data.

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

ix

Page 10

Warning

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause

bodily injury. Before you work on any equipment, be aware of the hazards

involved with electrical circuitry and be familiar with standard practices for

preventing accidents. Use the statement number provided at the end of each

warning to locate its translation in the translated safety warnings that

accompanied this device.

Statement 1071

SAVE THESE INSTRUCTIONS

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

x

OL-24619-02

Page 11

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

xi

Page 12

xii

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 13

Related Documentation

The WAVE-594 and WAVE-694 appliance supports the Cisco Wide Area Application Services software

(WAAS) and can function as either a WAAS Central Manager or as an Application Acceleration Engine.

The Cisco WAAS software document set includes the following documents:

• Release Note for Cisco Wide Area Application Services

• Cisco Wide Area Application Services Upgrade Guide

• Cisco Wide Area Application Services Quick Configuration Guide

• Cisco Wide Area Application Services Configuration Guide

• Cisco Wide Area Application Services Command Reference

• Cisco Wide Area Application Services API Reference

• Cisco Wide Area Application Services Monitoring Guide

• Cisco WAAS Installation and Configuration Guide for Windows on a Virtual Blade

• Cisco WAAS Troubleshooting Guide for Release 4.1.3 and Later

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

xiii

Page 14

The documentation for this product also includes the following hardware-related document:

• Regulatory Compliance and Safety Information for the Cisco Wide Area Virtualization Engines

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional

information, see the monthly What’s New in Cisco Product Documentation, which also lists all new and

revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What’s New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed

and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free

service and Cisco currently supports RSS version 2.0.

xiv

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 15

Introducing the Cisco Wide Area Virtualization Engine 594 and 694

This chapter provides a basic functional overview of the Cisco Wide Area Virtualization Engine 594 and

694 (WAVE-594 and WAVE-694) appliance and describes the hardware, major components, and front

and back panel indicators and controls.

This chapter contains the following sections:

• Supported Products, page 1-1

• Hardware Features, page 1-1

• Connecting a Console Terminal, page 1-6

Supported Products

CHAP T E R

1

The WAVE-594 and WAVE-694 appliance supports Cisco Wide Area Application Services (WAAS)

software version 4.4.1 and later releases.

Hardware Features

This section illustrates and describes the front and back panel controls, ports, and LED indicators on the

WAVE-594 and WAVE-694. It contains the following topics:

• Front Panel Components and LEDs, page 1-2

• Back Panel Components and LEDs, page 1-4

• Location of Ports and Connectors, page 1-5

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

1-1

Page 16

Hardware Features

246569

1 2 3 4

5

6

7

8 9

Cisco

W

ide

Ar

ea

Vir

t

ualiza

t

ion Engine

594

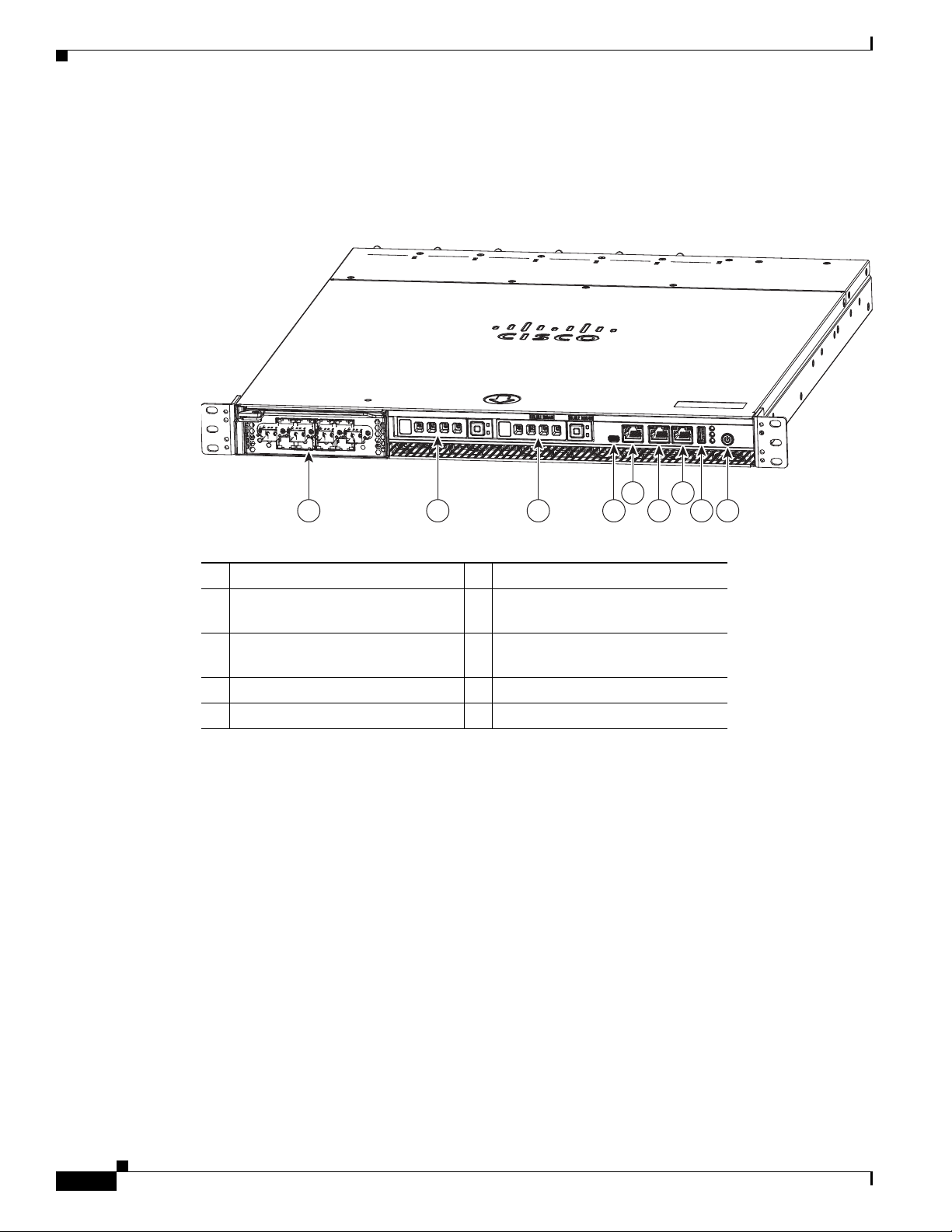

Front Panel Components and LEDs

Figure 1-1 shows the front panel components.

Figure 1-1 Front Panel

Chapter 1 Introducing the Cisco Wide Area Virtualization Engine 594 and 694

1 Interface Module slot 6 10/100/1000 GE 0/0 connector

2 Hard drive bay 1 (device number 0)7 10/100/1000 GE 0/1 connector

3 Hard drive bay 2 (device number 1)8 External USB port

4 Console port (mini-USB) 9 Power On button

5 Console port (RJ-45)

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

1-2

OL-24619-02

Page 17

Chapter 1 Introducing the Cisco Wide Area Virtualization Engine 594 and 694

246570

1 2 3 4 5 6

9

7

8

Cisco

W

ide

Ar

ea

Vir

t

ualiza

t

ion Engine

594

Figure 1-2 shows the front panel LEDs.

Figure 1-2 Front Panel LEDs

Hardware Features

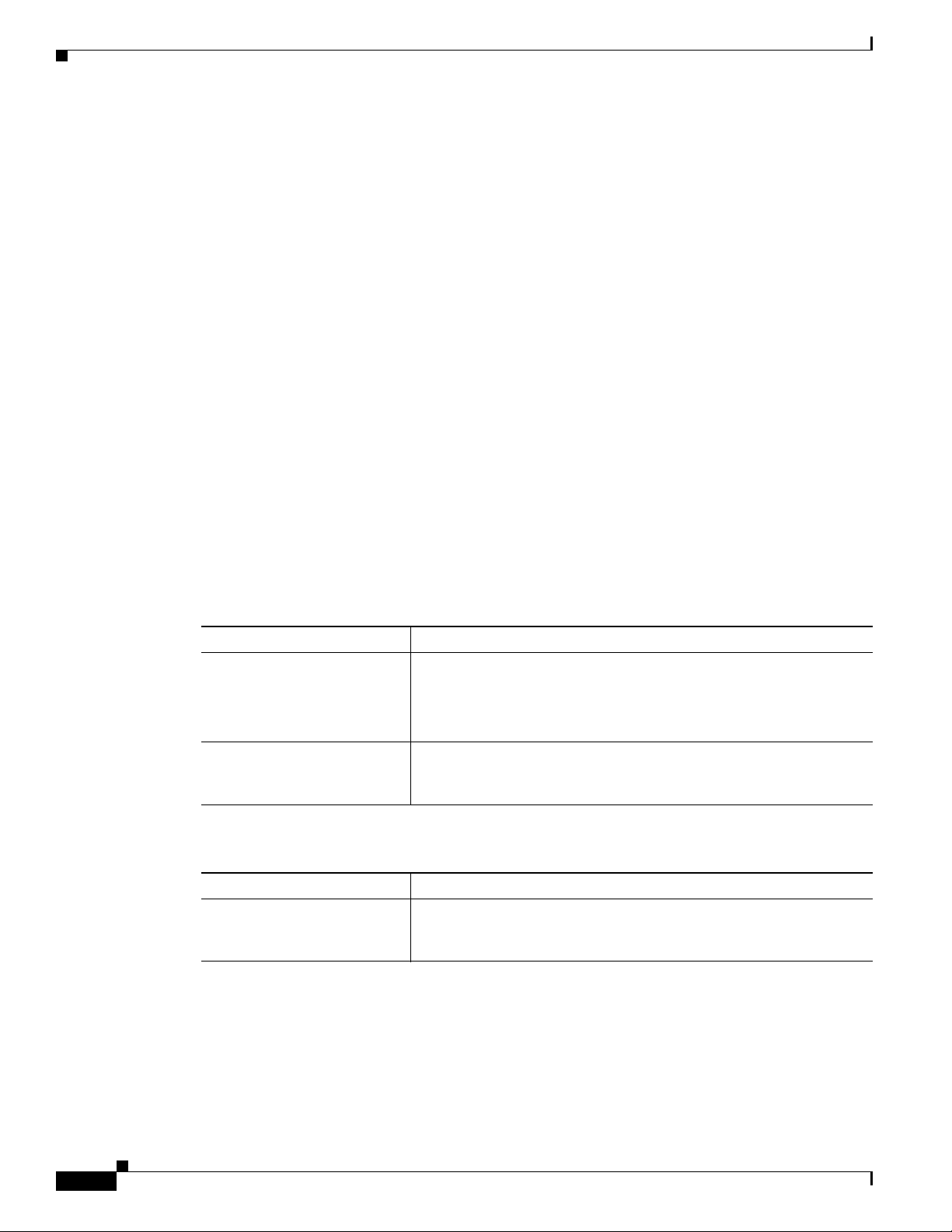

Table 1-1 describes the front panel LEDs and their functions.

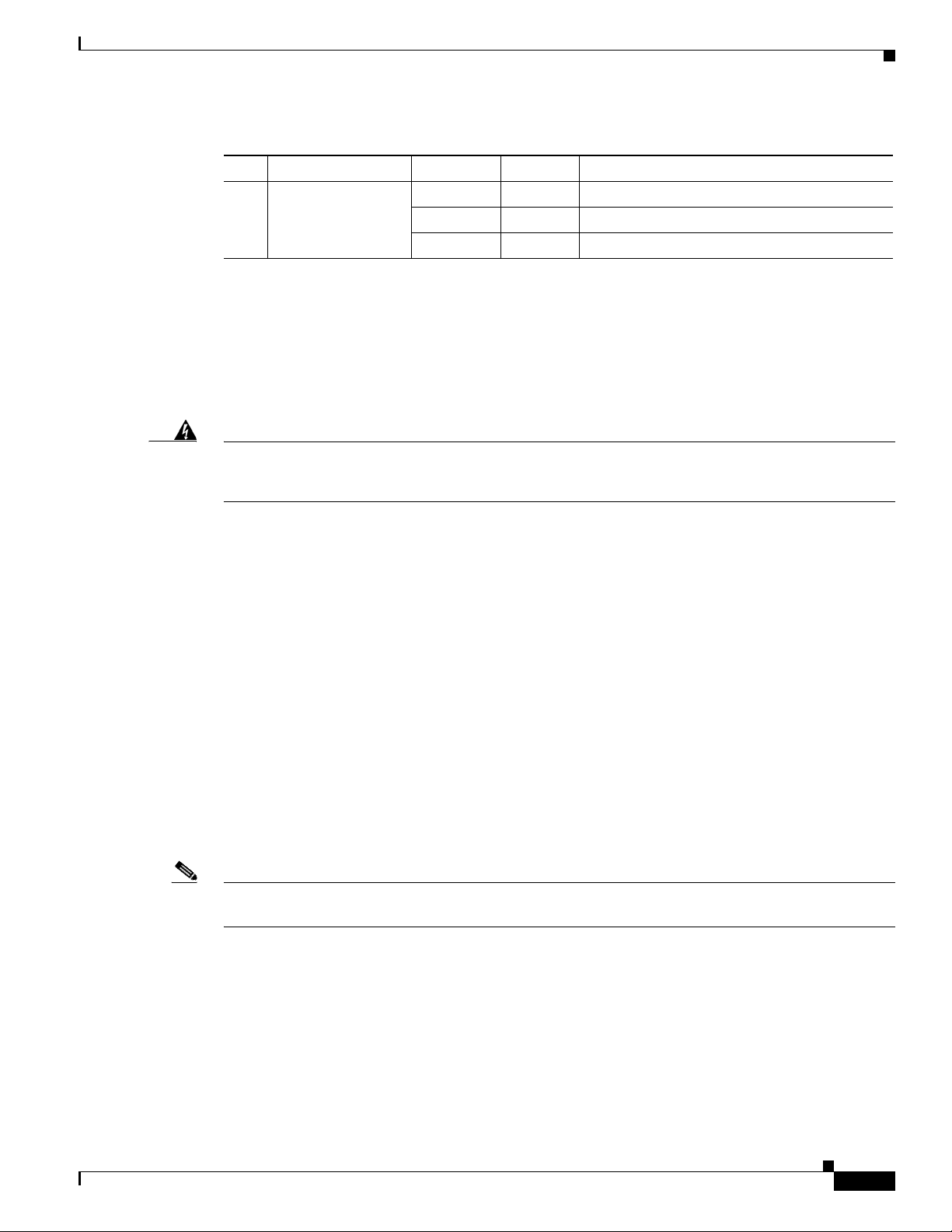

Table 1-1 Front Panel LEDs

LED Color State Description

1,3 Drive activity LED Green Blinking Drive activity is normal.

Green On Online.

Green Blinking

Drive locate.

1Hz

— Off No reading/writing, no activity.

5 NIC link/activity Green On Link exists.

Green Blinking Activity exists.

— Off No link detected.

6 NIC speed — Off 10Mbps connection.

Green On 100Mbps connection.

Yellow On 1000Mbps connection.

7 System power LED Green On System is on.

— Off Power cord is not attached or power supply

failure has occurred.

8 System fault LED Yellow On System has detected a fault. Refer to the

“Troubleshooting the System Hardware”

chapter for more information.

— Off System operation is normal.

9 Storage activity LED Green Blinking Drive activity is normal.

Orange On Drive failure has occurred.

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

1-3

Page 18

Hardware Features

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

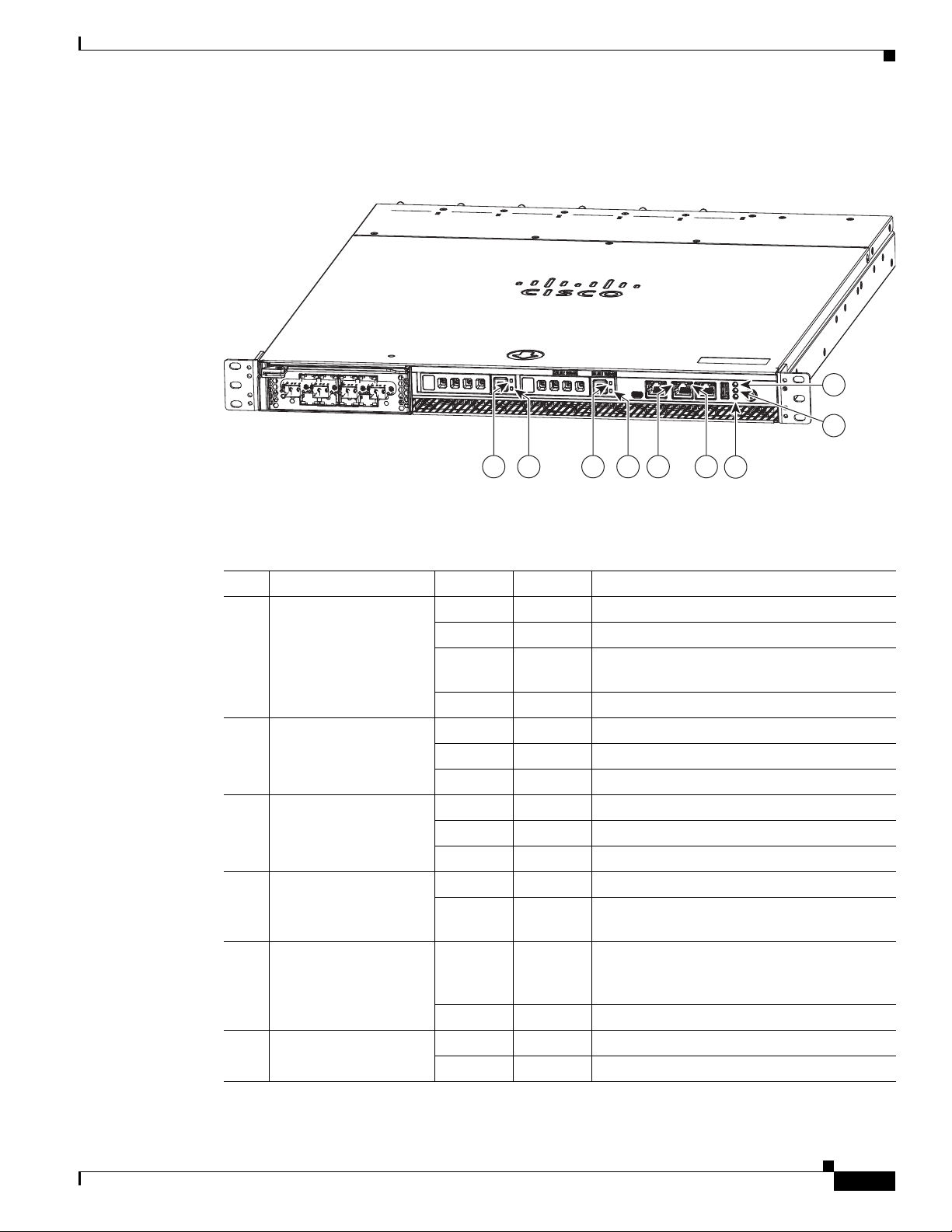

Back Panel Components and LEDs

Figure 1-3 shows the back panel components.

Note To monitor the boot process in normal operation, use a console port.

Figure 1-3 Back Panel Components

1 Power supply 1 5 Fan 4

2 Power supply 0 6 Fan 3

3 Fan 6 7 Fan 2

4 Fan 5 8 Fan 1

Chapter 1 Introducing the Cisco Wide Area Virtualization Engine 594 and 694

Figure 1-4 shows the back panel LEDs.

Figure 1-4 Back Panel LEDs

Table 1-2 describes the back panel LEDs and their functions.

Table 1-2 Back Panel LEDs

LED Color State Description

1, 2 Power supply status — Off No AC power to all power supplies.

Red Blinking No AC power to this power supply.

Green Blinking AC power is present, only standby output on.

Green On Power supply DC outputs on and OK.

Red On Power supply failure. Refer to the

“Troubleshooting the System Hardware”

chapter for more information.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

1-4

OL-24619-02

Page 19

Chapter 1 Introducing the Cisco Wide Area Virtualization Engine 594 and 694

Table 1-2 Back Panel LEDs (continued)

LED Color State Description

3 - 8 Fan status Orange On Alarm.

Orange Blinking Alarm. Fan speed too low.

— Off Normal state.

Location of Ports and Connectors

The WAVE appliance supports two Ethernet connectors and two Console ports on the front of the

appliance.

Figure 1-3 shows the back panel ports and connectors.

Hardware Features

Warning

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-network

voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV circuits. Some

LAN and WAN ports both use RJ-45 connectors. Use caution when connecting cables.

This section contains the following topics:

• Ethernet Port Connectors

• Console Port Connector

Ethernet Port Connectors

Connect a Category 3, 4, or 5 unshielded twisted-pair cable to an Ethernet connector. 100BASE-TX and

1000BASE-T Fast Ethernet standards require Category 5 or higher cabling.

The WAVE-594 and WAVE-694 appliance has two Ethernet connectors that are attached to the Ethernet

controllers (see Figure 1-5). The Ethernet controllers are integrated on the system board. They provide

an interface for connecting to a 10-Mbps, 100-Mbps, or 1-Gbps network and provide full-duplex (FDX)

capability, which enables simultaneous transmission and reception of data on the network. If the

Ethernet ports in the server support auto negotiation, the controllers detect the data-transfer rate

(10BASE-T, 100BASE-TX, or 1000BASE-T) and duplex mode (full duplex or half duplex) of the

network and automatically operate at that rate and mode. You do not have to set any jumpers or configure

the controllers.

Note There is a third RJ45 connector on the front of the appliance (see Figure 1-1). This is a console port. Do

not connect this port to your network.

Statement 1021

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

1-5

Page 20

Connecting a Console Terminal

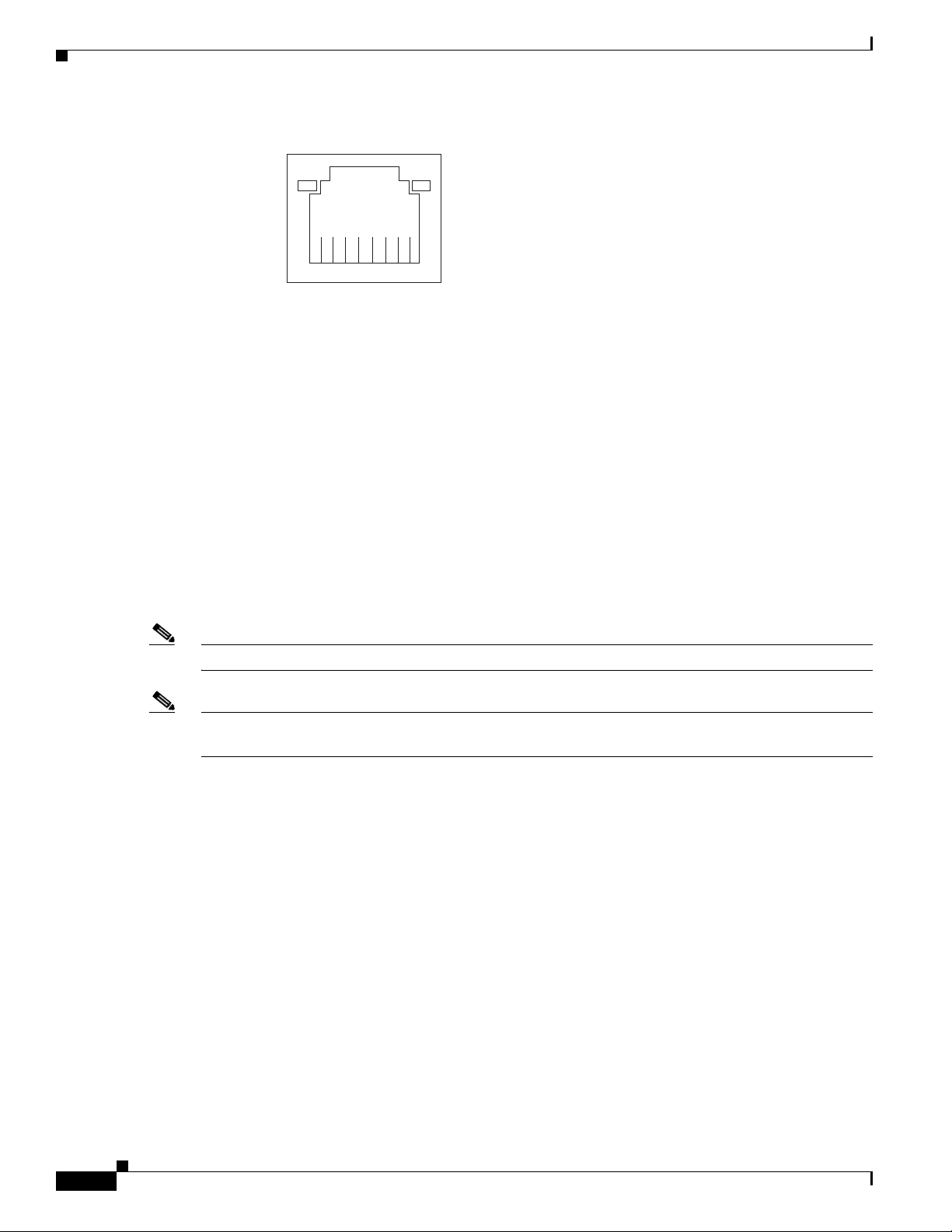

Figure 1-5 Ethernet Port Connector

Chapter 1 Introducing the Cisco Wide Area Virtualization Engine 594 and 694

Link/Activity

LED

8

1

Console Port Connector

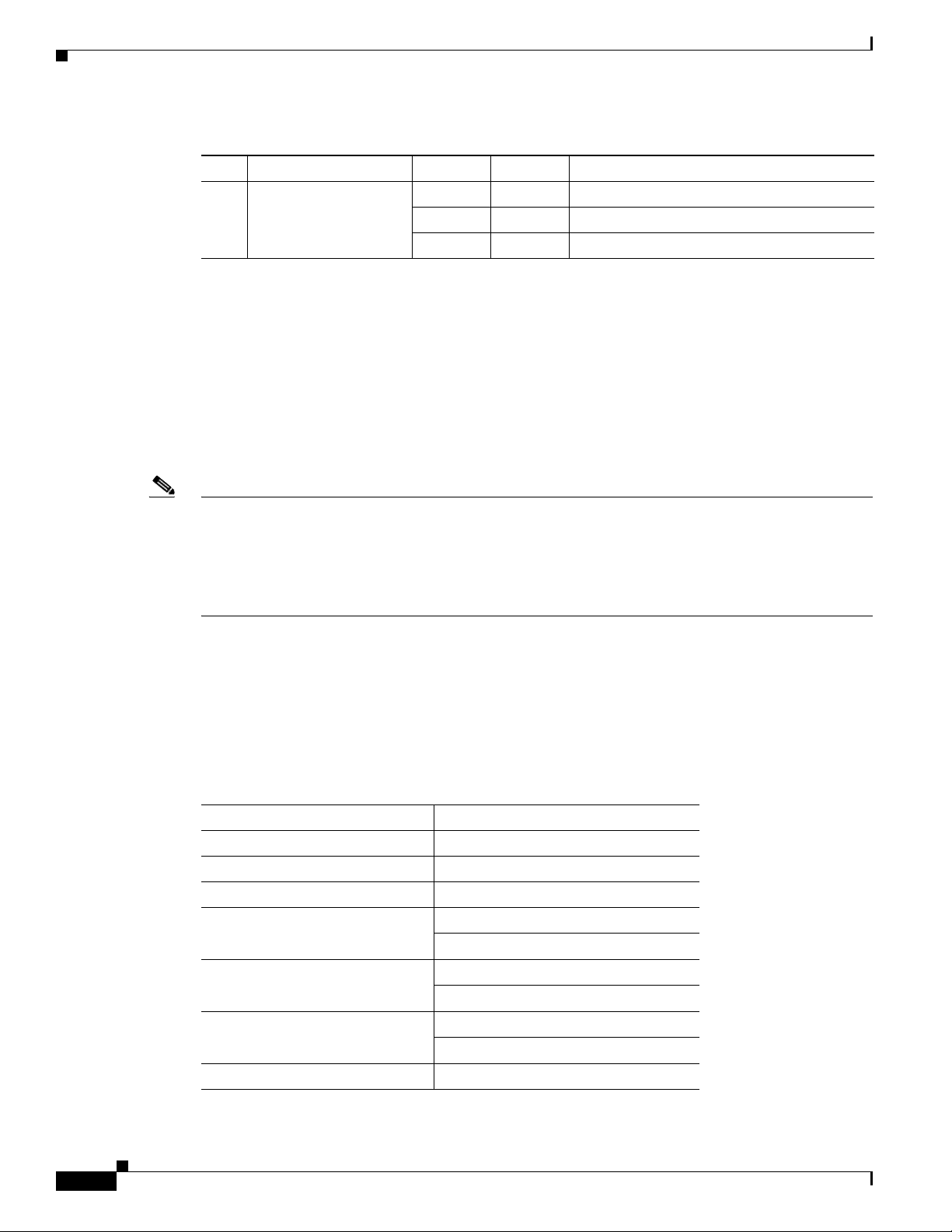

The WAVE-594 and WAVE-694 appliance has two console port connectors, serial and mini-USB (see

Figure 1-1). Use a console port connector to access the command-line interface (CLI) for controlling the

WAVE appliance.

For information on connecting a console terminal to the mini-USB console port, see the “Connecting a

Console Terminal” section on page 1-6.

Connecting a Console Terminal

The WAVE appliance has both serial and mini-USB console ports (see Figure 1-1). These ports provide

administrative access to your appliance with a console terminal or PC.

Speed LED

330210

Note You cannot use both ports at the same time. If both ports are connected, the mini-USB port takes priority.

Note When using the mini-USB port to connect to a Windows-based PC for the first time, you must install the

Windows USB driver on the PC first. See the “Installing the Cisco USB Driver” section on page 1-6.

Cabling

The following cables included with the WAVE appliance may be used for connecting the WAVE

appliance to a console terminal or PC:

• USB Console cable—5-pin USB to mini-USB Type A-B

• Serial Console cable— EIA RJ-45 to DB-9

Installing the Cisco USB Driver

When using the mini-USB port to connect a Microsoft Windows based PC as a console terminal to the

WAVE appliance, you must first install the Windows USB driver on the PC. Otherwise, the USB

interface may not function.

The following Windows operating systems are supported:

• Windows XP—32-bit and 64-bit

1-6

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 21

Chapter 1 Introducing the Cisco Wide Area Virtualization Engine 594 and 694

• Vista—32-bit, Business edition

• Vista—64-bit

• Windows 7—32-bit and 64-bit

To install the Cisco Microsoft Windows USB driver, perform the following steps:

Note Do not connect the cable from the Windows PC to the WAVE appliance until after the driver is installed.

Step 1 Load the DVD that came with your WAVE appliance and double-click the CUSBInst.exe file. The Cisco

Virtual Com InstallShield Wizard begins.

You can also access the driver from the WAAS software download area of Cisco.com located at:

http://www.cisco.com/cisco/pub/software/portal/select.html?&mdfid=280484571&catid=268437639&

softwareid=280836712

It’s located under release 4.4.1 and the filename is CUSBInst_Signed_18May2011.exe

Step 2 Click Next. The Ready to Install the Program window appears.

Step 3 Click Install. The InstallShield Wizard Completed window appears.

Step 4 Click Finish.

Step 5 Connect the USB cable to the PC USB port and WAVE appliance mini-USB console port. Within a few

moments, the Found New Hardware Wizard appears.

Connecting a Console Terminal

Follow the instructions to complete the installation of the driver.

Step 6 Once the installation is finished, the USB console is ready for use.

Note If the driver has been installed on the PC but does not get bound to the hardware, you can manually

browse the driver installation query to the location C:\Windows\tiinst\. The newly attached hardware will

appear in the Windows Device Manager as "TUSB3410 EECode Ser".

This solution also applies when connecting additional WAVE appliances to the same PC. Multiple WAVE

appliances can be independently administered by console sessions on the same PC.

Note You do not need to reinstall the driver if you change to a different USB port on your PC.

Note If you happen to install the driver multiple times, each time the driver is installed the virtual COM port

number assigned to the USB port gets incremented. This is expected behavior and may not get reset even

if you uninstall the driver.

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

1-7

Page 22

Connecting a Console Terminal

Chapter 1 Introducing the Cisco Wide Area Virtualization Engine 594 and 694

1-8

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 23

CHAP T E R

2

Preparing to Install the WAVE-594 and WAVE-694

This chapter contains important safety information that you should know before you work with the

WAVE-594 and WAVE-694. Use the guidelines in this chapter to ensure your own personal safety and

to help protect your appliance from potential damage.

This chapter contains the following sections:

• Safety Warnings and Cautions, page 2-1

• Safety Guidelines, page 2-2

• Understanding the Environmental Requirements, page 2-5

• Understanding the Power Requirements, page 2-6

• Understanding the Grounding Requirements, page 2-6

Note Read the Regulatory Compliance and Safety Information for Cisco Wide Area Virtualization Engines

document and the Site Preparation and Safety Guide that came with your appliance before you begin the

installation.

Safety Warnings and Cautions

Before you install the WAVE-594 and WAVE-694, observe the following safety warnings and cautions:

Warning

Warning

Warning

OL-24619-02

Read the installation instructions before connecting the system to the power source.

This unit is intended for installation in restricted access areas. A restricted access area can be

accessed only through the use of a special tool, lock and key, or other means of security.

Statement 1017

The plug-socket combination must be accessible at all times, because it serves as the main

disconnecting device.

Statement 1019

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

Statement 1004

2-1

Page 24

Safety Guidelines

Chapter 2 Preparing to Install the WAVE-594 and WAVE-694

Warning

Warning

Warning

Warning

Warning

Caution To properly ventilate the system, you must provide at least 7.6 cm (3.0 in) of clearance at the front and

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection

authority or an electrician if you are uncertain that suitable grounding is available.

This unit might have more than one power supply connection. All connections must be removed to

de-energize the unit.

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

This product requires short-circuit (overcurrent) protection, to be provided as part of the building

installation. Install only in accordance with national and local wiring regulations.

Installation of the equipment must comply with local and national electrical codes.

Statement 1028

Statement 1024

Statement 1045

Statement 1074

back of the WAVE appliance.

Caution To reduce the risk of electric shock or damage to the equipment:

- Do not disable the power cord grounding plug. The grounding plug is an important safety feature.

- Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all times.

- Unplug the power cord from the power supply to disconnect power to the equipment.

- Do not route the power cord where it can be walked on or pinched by items placed against it. Pay

particular attention to the plug, electrical outlet, and the point where the cord extends from the WAVE

appliance.

Caution To reduce the risk of personal injury or damage to the equipment:

- Observe local occupation health and safety requirements and guidelines for manual handling.

- Obtain adequate assistance to lift and stabilize the chassis during installation or removal. The WAVE

appliance is unstable when not fastened to the rails. When mounting the WAVE appliance in a rack,

remove the power supplies and any other removable module to reduce the overall weight of the product.

Safety Guidelines

To reduce the risk of bodily injury, electrical shock, fire, and damage to the equipment, observe the

precautions in this section.

This section contains the following topics:

• General Precautions, page 2-4

2-2

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 25

Chapter 2 Preparing to Install the WAVE-594 and WAVE-694

• System Reliability Considerations, page 2-5

• Protecting Against Electrostatic Discharge, page 2-5

Safety Guidelines

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

2-3

Page 26

Safety Guidelines

General Precautions

Observe the following general precautions for using and working with the WAVE-594 and WAVE-694:

• Observe and follow service markings. Do not service any Cisco product except as explained in your

system documentation. Opening or removing covers that are marked with the triangular symbol with

a lightning bolt may expose you to electrical shock. Components inside these compartments should

be serviced only by a trained and qualified service technician.

• If any of the following conditions occur, unplug the product from the electrical outlet and replace

the part or contact your customer service representative:

–

The power cable or plug is damaged.

–

An object has fallen into the product.

–

The product has been exposed to water.

–

The product has been dropped or damaged.

–

The product does not operate correctly when you follow the operating instructions.

• Keep your system components away from radiators and heat sources. Also, do not block cooling

vents.

• Do not spill food or liquids on your system components, and never operate the product in a wet

environment.

Chapter 2 Preparing to Install the WAVE-594 and WAVE-694

• Do not push any objects into the openings of your system components. Doing so can cause fire or

electric shock by shorting out interior components.

• Use the product only with other Cisco-approved equipment.

• Allow the product to cool before removing covers or touching internal components.

• Use the correct external power source. Operate the product only from the type of power source

indicated on the electrical ratings label. If you are not sure of the type of power source required,

consult your service representative or local power company.

• Use only approved power cables. If you have not been provided with a power cable for your WAVE

appliance or for any AC-powered option intended for your system, purchase a power cable that is

approved for use in your country. The power cable must be rated for the product and for the voltage

and current marked on the product’s electrical ratings label. The voltage and current rating of the

cable should be greater than the ratings marked on the product.

• To help prevent electric shock, plug the system components and peripheral power cables into

properly grounded electrical outlets. These cables are equipped with three-prong plugs to help

ensure proper grounding. Do not use adapter plugs or remove the grounding prong from a cable.

• Observe power strip ratings. Make sure that the total ampere rating of all products plugged into the

power strip does not exceed 80 percent of the power strip ampere ratings limit.

• Do not use appliance or voltage converters or kits sold for appliances with your product.

• To help protect your system components from sudden, transient increases and decreases in electrical

power, use a surge suppressor, line conditioner, or uninterruptible power supply (UPS).

• Position cables and power cords carefully; route cables and the power cord and plug so that they

cannot be stepped on or tripped over. Be sure that nothing rests on your system components’ cables

or power cord.

• Do not modify power cables or plugs. Consult a licensed electrician or your power company for site

modifications. Always follow your local or national wiring rules.

2-4

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 27

Chapter 2 Preparing to Install the WAVE-594 and WAVE-694

System Reliability Considerations

To help ensure proper cooling and system reliability, make sure that the following occurs:

• Each of the hard drive bays has either a drive or a filler panel installed.

• The Interface Module bay has either a Cisco Interface Module or a filler panel installed.

• Each power supply bay has either a power supply of filler panel installed.

• For rack configurations, make sure that space is available around the appliance to enable the cooling

system to work properly. See the documentation that comes with the rack for additional information.

• A removed hot-swappable drive is replaced within 1 minute of removal.

• Cables for optional adapters are routed according to the instructions provided with the adapters.

• A failed fan is replaced within 48 hours.

Protecting Against Electrostatic Discharge

Static electricity can harm delicate components inside the appliance. To prevent static damage, discharge

static electricity from your body before you touch any of your system’s electronic components. You can

do so by touching an unpainted metal surface on the chassis.

You can also take the following steps to prevent damage from electrostatic discharge (ESD):

• When unpacking a static-sensitive component from its shipping carton, do not remove the

component from the antistatic packing material until you are ready to install the component in your

system. Just before unwrapping the antistatic packaging, be sure to discharge static electricity from

your body.

Understanding the Environmental Requirements

• When transporting a sensitive component, first place it in an antistatic container or packaging.

• Handle all sensitive components in a static-safe area. If possible, use antistatic floor pads and

workbench pads.

• Handle the appliance carefully, holding it by its edges or its frame.

• Do not touch solder joints, pins, or exposed printed circuitry.

• Do not leave the appliance where others can handle and possibly damage the appliance.

• Take additional care when handling appliances during cold weather, because heating reduces indoor

humidity and increases static electricity.

Understanding the Environmental Requirements

To ensure continued safe and reliable equipment operation, install or position the system in a

well-ventilated, climate-controlled environment.

For details about the WAVE-594 and WAVE-694 environmental requirements, see Appendix A,

“WAVE-594 and WAVE-694 Hardware Specifications” and the “Temperature” section on page B-2.

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

2-5

Page 28

Chapter 2 Preparing to Install the WAVE-594 and WAVE-694

Understanding the Power Requirements

Understanding the Power Requirements

Installation of this equipment must comply with local and regional electrical regulations governing the

installation of information technology equipment by licensed electricians. This equipment is designed

to operate in installations covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75,

1992 (code for Protection of Electronic Computer/Data Processing Equipment).

Warning

Caution Protect the WAVE appliance from power fluctuations and temporary interruptions with a regulating

Take care when connecting units to the supply circuit so that wiring is not overloaded.

uninterruptible power supply (UPS). This device protects the hardware from damage caused by power

surges and voltage spikes and keeps the system in operation during a power failure.

When installing more than one WAVE appliance, you may need to use additional power distribution

devices to safely provide power to all devices. Observe the following guidelines:

• Balance the WAVE appliance power load between available AC supply branch circuits.

• Do not allow the overall system AC current load to exceed 80 percent of the branch circuit AC

current rating.

• Do not use common power outlet strips for this equipment.

• Provide a separate electrical circuit for the WAVE appliance.

For details about the WAVE-594 and WAVE-694 power requirements, see Appendix A, “WAVE-594 and

WAVE-694 Hardware Specifications.”

Understanding the Grounding Requirements

To ensure proper operation and safety, you must properly ground the WAVE appliance. In the United

States, install the equipment in accordance with NFPA 70, 1999 Edition (National Electric Code),

Article 250, as well as any local and regional building codes. In Canada, you must install the equipment

in accordance with Canadian Standards Association, CSA C22.1, Canadian Electrical Code. In all other

countries, you must install the equipment in accordance with any regional or national electrical wiring

codes, such as the International Electrotechnical Commission (IEC) Code 364, parts 1 through 7.

Furthermore, you must be sure that all power distribution devices used in the installation, such as branch

wiring and receptacles, are listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple WAVE appliances connected to

the same power source, we recommend the use of a PDU that is either permanently wired to the

building’s branch circuit or includes a nondetachable cord that is wired to an industrial-style plug.

NEMA locking-style plugs or those complying with IEC 60309 are considered suitable for this purpose.

Using common power outlet strips for the WAVE appliance is not recommended.

Statement 1018

2-6

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 29

Warning

CHAP T E R

3

Installing the WAVE-594 and WAVE-694

This chapter describes how to install a WAVE-594 and WAVE-694 in an equipment rack. This chapter

contains the following sections:

• Rack-Mounting Considerations, Parts, and Tools, page 3-1

• Rack Mounting and Cabling the WAVE-594 and WAVE-694, page 3-2

• Connecting Power and Booting the System, page 3-8

• Checking the LEDs, page 3-8

• Removing or Replacing a WAVE Appliance, page 3-9

Before you begin the installation, read Chapter 2, “Preparing to Install the WAVE-594 and WAVE-694”

and the Regulatory Compliance and Safety Information for Cisco Wide Area Virtualization Engines

document.

Read the installation instructions before connecting the system to the power source.

Statement 1004.

Rack-Mounting Considerations, Parts, and Tools

To allow for servicing and adequate airflow, observe the following space and airflow requirements when

deciding where to install a rack:

• Leave a minimum clearance of 63.5 cm (25 in) in front of the rack.

• Leave a minimum clearance of 76.2 cm (30 in) behind the rack.

• Leave a minimum clearance of 121.9 cm (48 in) from the back of the rack to the back of another

rack or row of racks.

The WAVE-594 and WAVE-694 appliance draws in cool air through the front door and expels warm air

through the rear door. Therefore, the front and rear rack doors must be adequately ventilated to allow

ambient room air to enter the cabinet, and the rear door must be adequately ventilated to allow the warm

air to escape from the cabinet.

Caution To prevent improper cooling and damage to the equipment, do not block the ventilation openings.

When vertical space in the rack is not filled by a WAVE appliance or rack component, the gaps between

the components cause changes in airflow through the rack and across the WAVE appliances. Cover all

gaps with filler panels to maintain proper airflow.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

3-1

Page 30

Rack Mounting and Cabling the WAVE-594 and WAVE-694

Caution Always use filler panels to fill empty vertical spaces in the rack. This arrangement ensures proper

airflow. Using a rack without filler panels results in improper cooling that can lead to thermal damage.

• Observe the following additional requirements to ensure adequate airflow and to prevent damage to

the equipment:

–

Front and rear doors—If the 42U rack includes closing front and rear doors, you must allow

5,350 sq cm (830 sq in) of holes evenly distributed from top to bottom to permit adequate

airflow (equivalent to the required 64 percent open area for ventilation).

–

Side—The clearance between the installed rack component and the side panels of the rack must

be a minimum of 7 cm (2.75 in).

Note Rack-mounting the WAVE-594 and WAVE-694 appliance is supported for rear mount in a 4-post rack or

front mount in a 2-post rack.

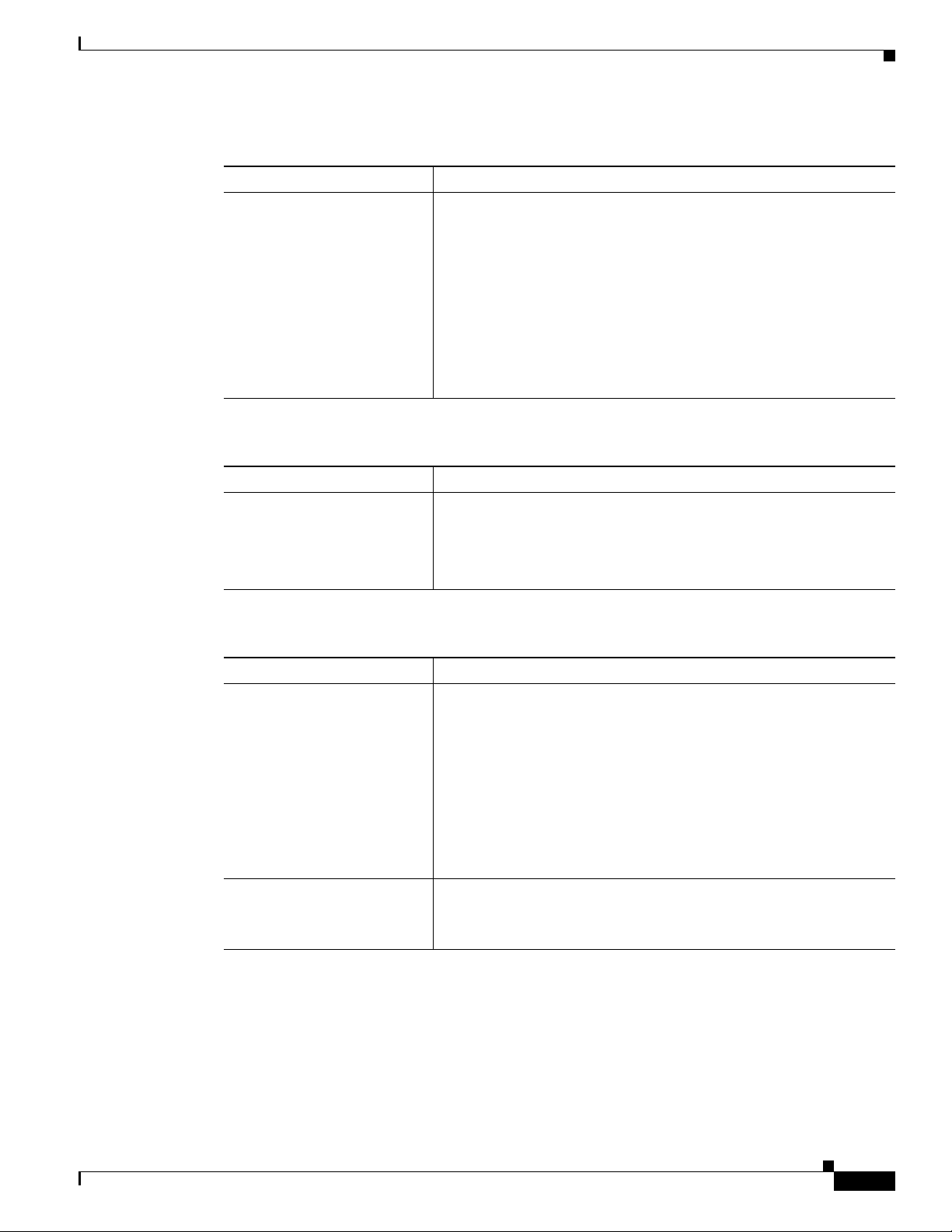

Table 3-1 lists the rack mounting hardware included in your shipping container. You will need a Phillips

screwdriver. Verify that you have received the following items for the installation:

Chapter 3 Installing the WAVE-594 and WAVE-694

Table 3-1 Rack Mount Hardware Provided

Rack Type

Item Name Description Qty

1 Front rack mount

Front rack mount L bracket 2 X X

2-post 4-post

bracket

2 Rear rack mount

Rear rack mount bracket holder 2 X

bracket holder

3 32” rear rack mount

Rear rack mount bracket (32 inch) 2 X

bracket

4 Front rack mount

bracket screw

5 Rear rack mount

bracket holder screw

6 Rack screw Rack screw, #10-32 x 0.50”, Truss Head, Phillips,

Front rack bracket screw, #6-32 x 0.30”, Wafer

Head, Phillips, Steel w/ Zinc and Black

Rear bracket holder screw, M4 x0.7 x 4.85 mm,

120º, Flat Head, Phillips, Steel w/ Zinc and Black

6X X

6X

8X X

Steel w/ Ni and Black

7 Rack screw Rack screw, M5 x 12.7 mm, Truss Head, Phillips,

8X

Steel w/ Ni and Black

Rack Mounting and Cabling the WAVE-594 and WAVE-694

3-2

There are two ways you can rack mount the WAVE appliance. The following topics are included in this

section:

• Mounting in a 4-Post Rack

• Front-Mounting in a 2-Post Rack

• Cabling

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 31

Chapter 3 Installing the WAVE-594 and WAVE-694

Rack Mounting and Cabling the WAVE-594 and WAVE-694

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you

must take special precautions to ensure that the system remains stable. The

following guidelines are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the

top with the heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting

or servicing the unit in the rack.

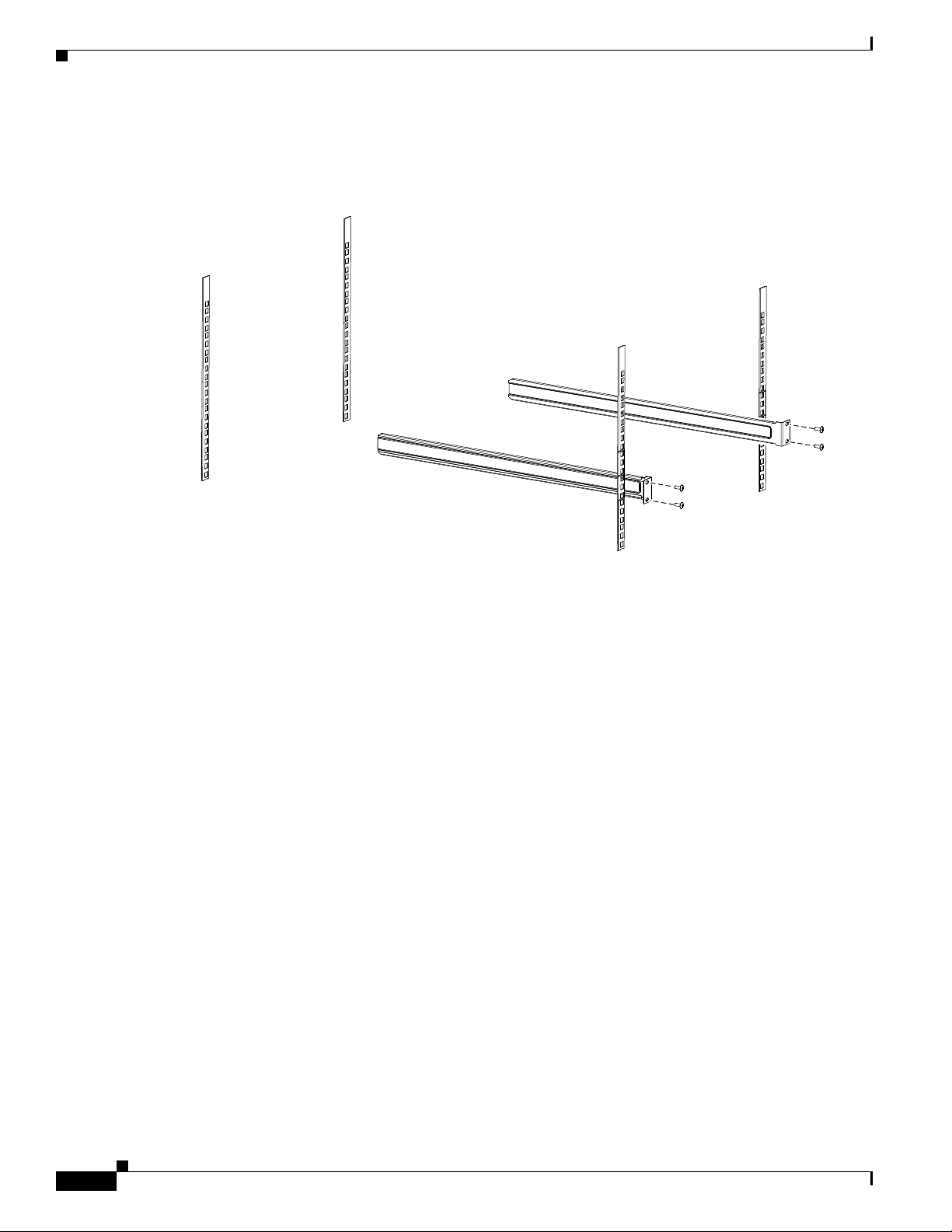

Mounting in a 4-Post Rack

Follow these steps to mount the WAVE appliance in a 4-post rack:

Step 1 Prepare for installation by reading the “Rack-Mounting Considerations, Parts, and Tools” section on

page 3-1) and verify that you have the correct tools and rack-mount hardware necessary for the

installation.

Step 2 Attach the front rack mount brackets (item #1 in Tab l e 3- 1 ) using the six front bracket screws (item #4

in Table 3 - 1). (See Figure 3-4.)

Step 3 Attach the rear rack mount holder brackets (item #2 in Table 3-1) using the six rear bracket holder screws

(item #5 in Table 3 -1).

Statement 1006

Note The front arrow must point toward the front of the chassis.

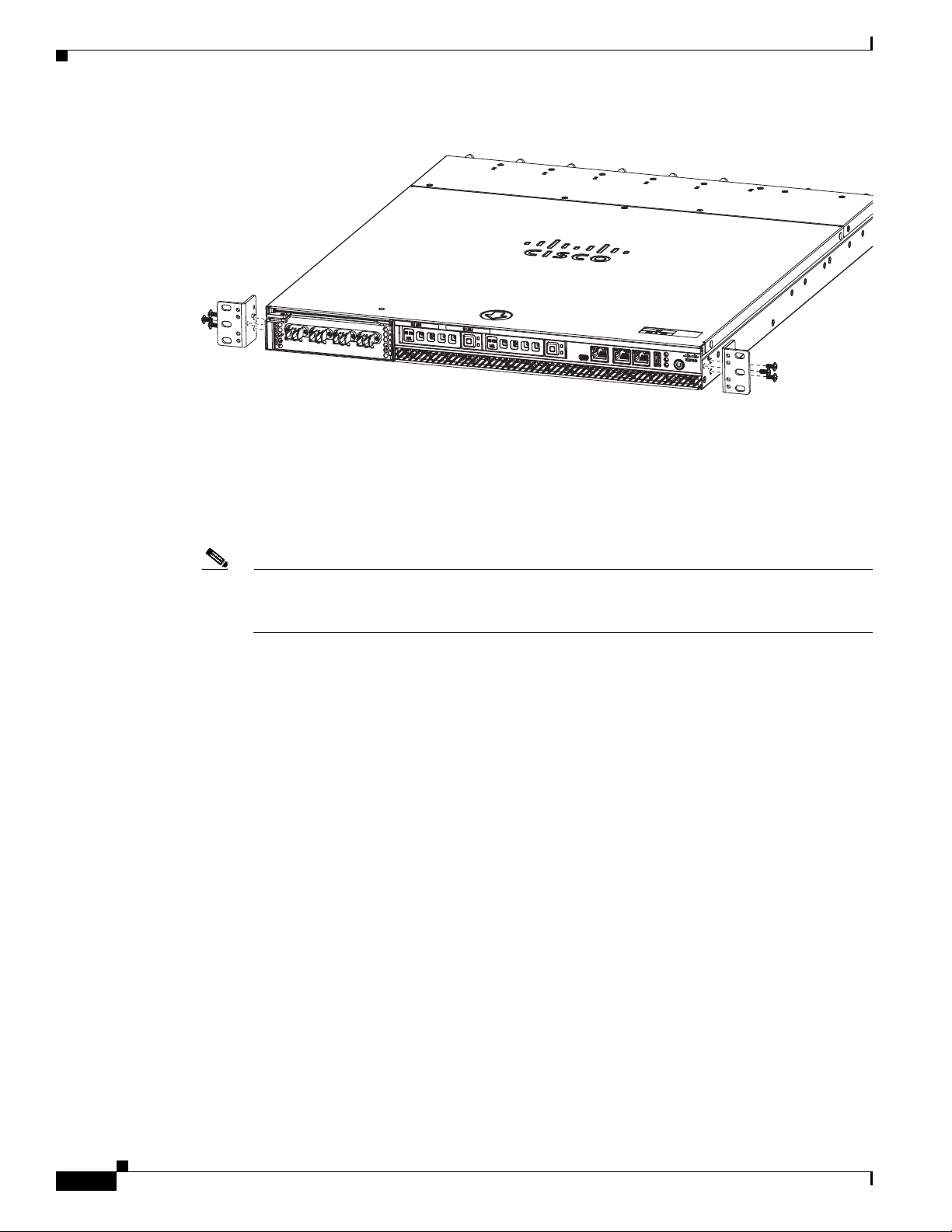

Figure 3-1 Attaching the Brackets

330144

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

3-3

Page 32

Rack Mounting and Cabling the WAVE-594 and WAVE-694

330142

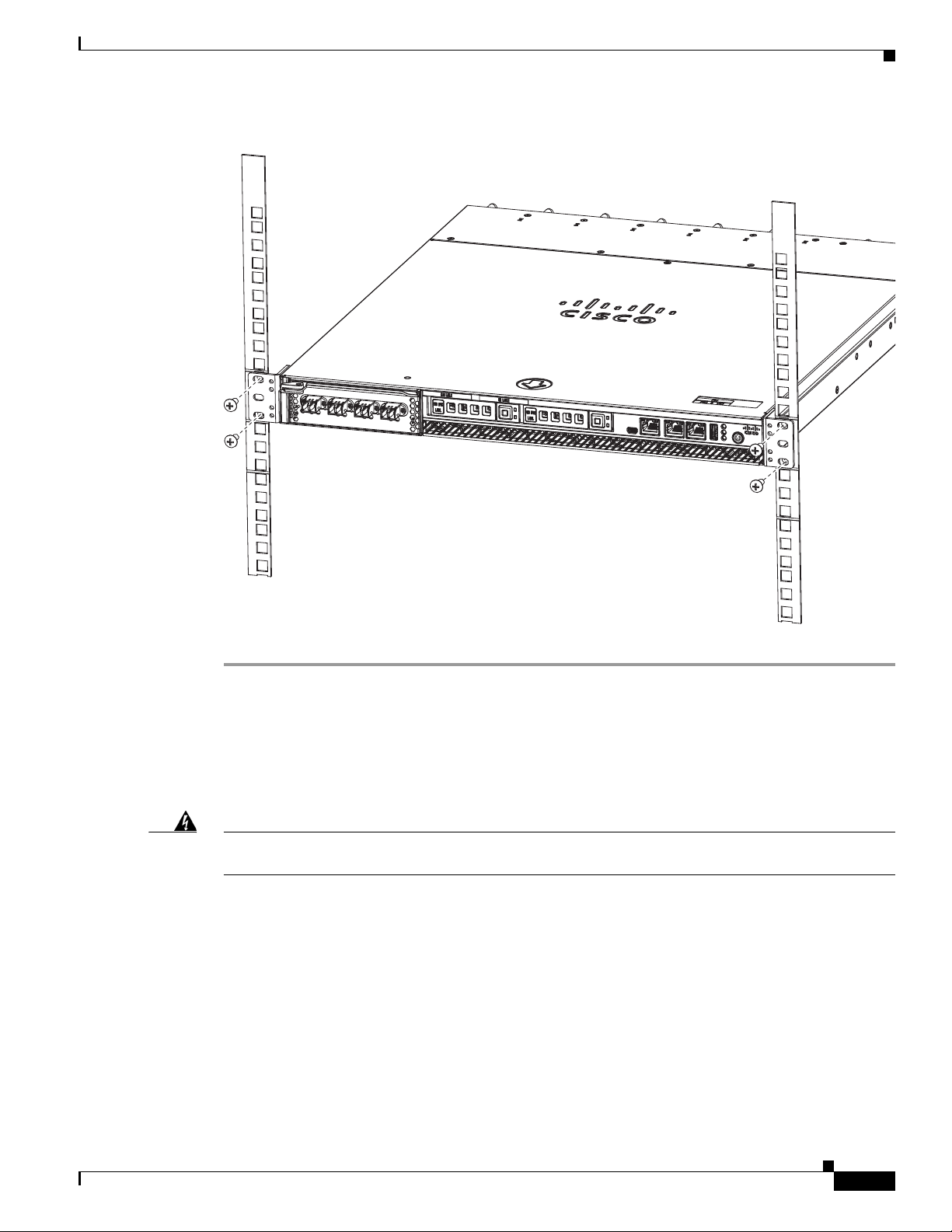

Step 4 Attach the rear mount bracket holders (item #3 in Tabl e 3 - 1) to the rear rack posts using four appropriate

rack screws (item #6 or #7 in Table 3-1). (see Figure 3-2)

Figure 3-2 Attaching Rear Rack Mount to the Rack

Chapter 3 Installing the WAVE-594 and WAVE-694

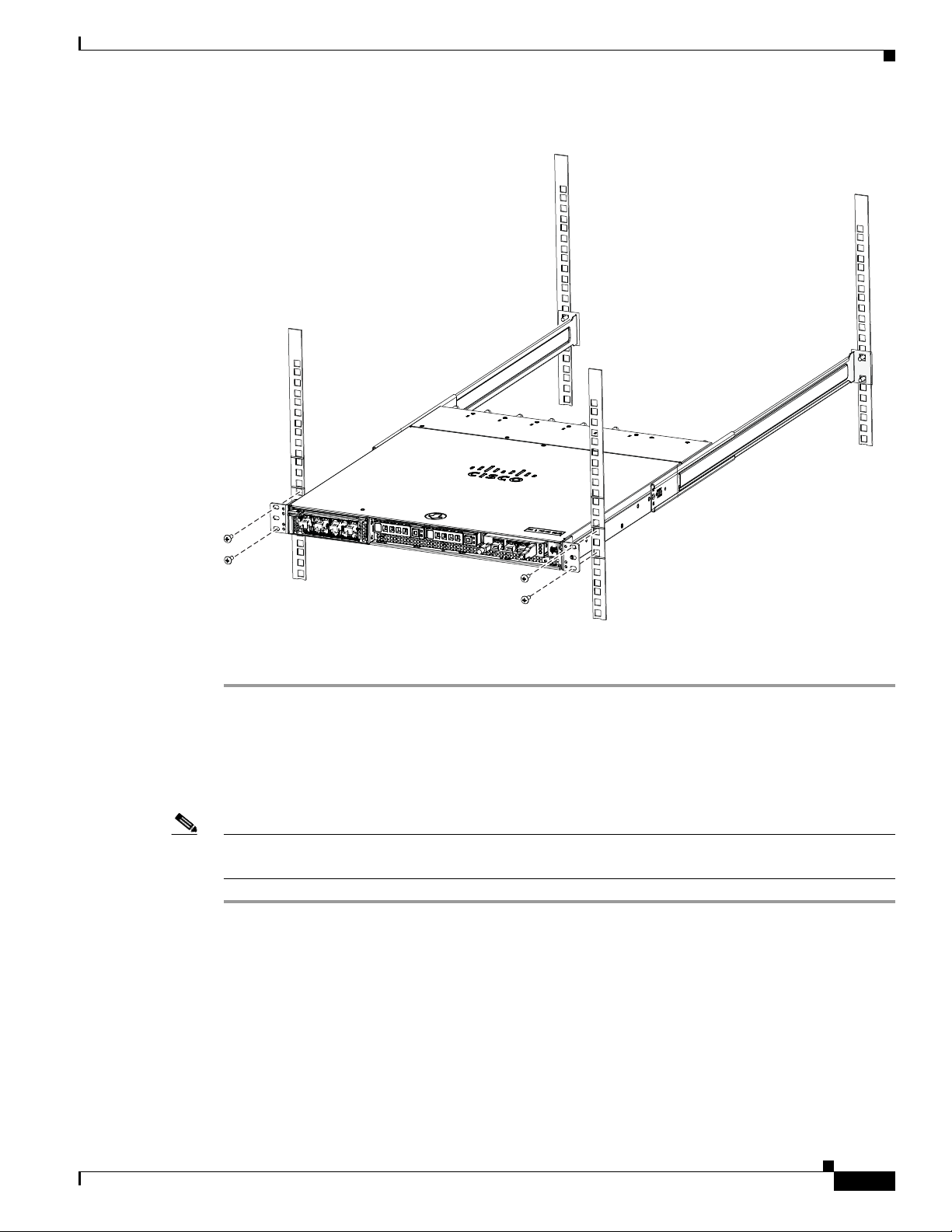

Step 5 Insert the chassis between the mounting posts and secure (see Figure 3-3):

a. Insert the chassis into the rack with the rear rack mount holders sliding into the rear rack mount

brackets.

b. Align the mounting holes in the front brackets with the mounting holes in the equipment rack.

c. Secure the chassis using four (two on each side) rack screws (item #6 or #7 in Table 3 - 1) through

the holes in the front brackets and into the threaded holes in the mounting post.

3-4

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 33

Chapter 3 Installing the WAVE-594 and WAVE-694

Figure 3-3 Rack-Mounting the Chassis

Rack Mounting and Cabling the WAVE-594 and WAVE-694

Step 6

Verify that the chassis is securely installed in the rack.

Front-Mounting in a 2-Post Rack

Follow these steps to front-mount the WAVE appliance in a 2-post rack:

Note There must be an empty 1RU space in the rack directly below the chassis to allow space for the back

edge to sag. A sag of up to 1/2RU (7/8”) is acceptable.

Step 1 Prepare for installation by reading the “Rack-Mounting Considerations, Parts, and Tools” section on

page 3-1) and verify that you have the correct tools and rack-mount hardware necessary for the

installation.

Step 2 Attach the front rack mount brackets (item #1 in Tab l e 3- 1 ) using the six front bracket screws (item #4

in Table 3 - 1). (See Figure 3-4.)

330145

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

3-5

Page 34

Rack Mounting and Cabling the WAVE-594 and WAVE-694

Figure 3-4 Attaching the Front Brackets

Chapter 3 Installing the WAVE-594 and WAVE-694

Step 3

Insert the chassis between the mounting posts and secure (see Figure 3-5):

a. Align the mounting holes in the front brackets with the mounting holes in the equipment rack.

b. Secure the chassis using four (two on each side) rack screws (item #6 or #7 in Table 3 - 1) through

the holes in the front brackets and into the threaded holes in the mounting post.

c. Use a tape measure and level to ensure that the chassis is installed straight and level.

Note Since the chassis is secured in the rack by the front edge only, there must be an empty 1RU space

in the rack directly below the chassis to allow space for the back edge to sag. A sag of up to

1/2RU (7/8”) is acceptable.

3-6

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 35

Chapter 3 Installing the WAVE-594 and WAVE-694

Figure 3-5 Rack-mounting the Chassis

Rack Mounting and Cabling the WAVE-594 and WAVE-694

Cabling

Step 4 Verify that the chassis is securely installed in the rack.

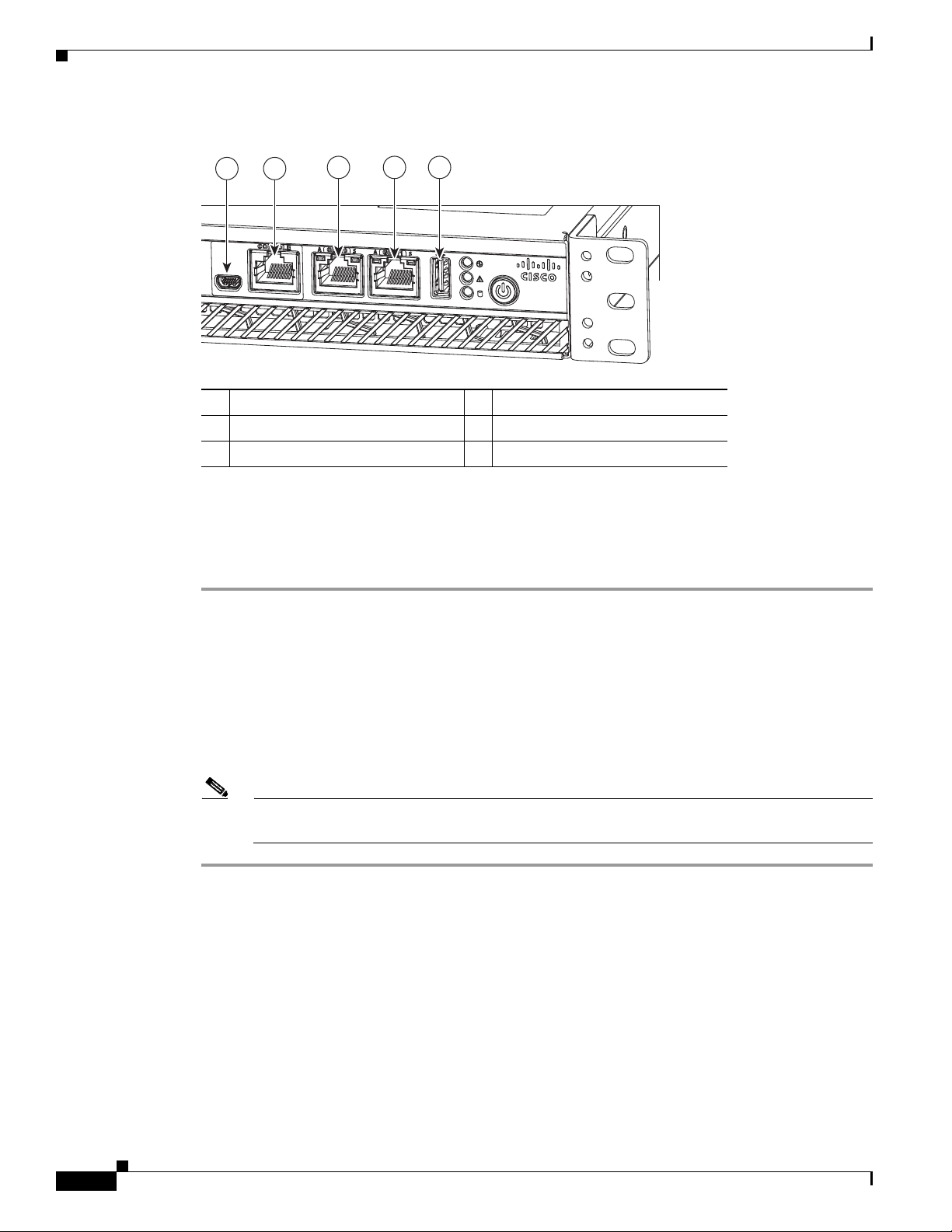

Use the following information (see Figure 3-6) when connecting peripheral cables to the WAVE

appliance.

Warning

To reduce the risk of electric shock, fire, or damage to the equipment, do not plug telephone or

telecommunications connectors into RJ-45 connectors.

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

3-7

Page 36

Connecting Power and Booting the System

1 2

3 4 5

Figure 3-6 Cable Connections—Front

1 Console port (mini-USB) 4 10/100/1000 GE 0/1 connector

2 Console port (RJ-45) 5 External USB port

3 10/100/1000 GE 0/0 connector

Chapter 3 Installing the WAVE-594 and WAVE-694

Connecting Power and Booting the System

To connect power to your system, follow these steps:

Step 1 Review the information in the “Safety Guidelines” section on page 2-2.

Step 2 Plug a power cord into the power cord receptacle on the back of the WAVE appliance.

Step 3 Connect the other end of the power cord to a power source at your installation site.

Step 4 Power up all externally connected devices.

Step 5 Press the power control button on the front of the WAVE appliance.

The system should begin booting. Once the operating system boots, you are ready to initialize the basic

software configuration. (See the software configuration guide for details.)

Note While the WAVE appliance is powering up, the green power-on LED on the front of the

appliance is on.

Checking the LEDs

3-8

When the WAVE-594 and WAVE-694 is up and running, observe the front panel LEDs (see Figure 1-1

and Table 1-1) to verify that your system is operating properly.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

To troubleshoot using the LEDs, see Chapter 6, “Troubleshooting the System Hardware.”

OL-24619-02

Page 37

Chapter 3 Installing the WAVE-594 and WAVE-694

Removing or Replacing a WAVE Appliance

To remove a WAVE appliance from your network, power it down, disconnect the power cords and

network cables, and physically remove the chassis from the rack.

The WAVE appliance is in constant communication with the router on your network. When the router

notices that the WAVE appliance is no longer responding to it, the router stops sending requests to the

WAVE appliance. This action is transparent to users. If other WAVE appliances are attached to the router,

the router continues sending requests to the other WAVE appliances.

When you remove a WAVE appliance, the pages that were cached on that appliance are no longer

available to the router or other WAVE appliances. You might see an increase in outgoing web traffic that

might have otherwise been fulfilled by the WAVE appliance that you are removing. However, after a

time, the router and other WAVE appliances redistribute the load of web traffic.

If you remove the last WAVE appliance from your network, you can also disable WAVE support on the

router. However, this action is not necessary because leaving WAVE support enabled when there are no

WAVE appliances attached has no effect on the router’s performance.

To replace a WAVE appliance, remove it from the network, and then install a new WAVE appliance and

configure it using the same configuration parameters (IP address and so forth) that you used for the

removed WAVE appliance.

Removing or Replacing a WAVE Appliance

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

3-9

Page 38

Removing or Replacing a WAVE Appliance

Chapter 3 Installing the WAVE-594 and WAVE-694

3-10

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 39

CHAP T E R

4

Installing Hardware Options for the WAVE-594 and WAVE-694

This chapter provides basic instructions for installing hardware options in your WAVE-594 and

WAVE-694. These instructions are intended for technicians who are experienced with setting up Cisco

WAVE-594 and WAVE-694 hardware.

This chapter contains the following sections:

• Installing a Cisco WAVE Interface Module, page 4-1

• Replacing a Hard Disk Drive/Solid State Drive, page 4-2

• Replacing a Fan, page 4-4

• Replacing a Power Supply, page 4-5

• Installing Memory, page 4-6

Installing a Cisco WAVE Interface Module

In addition to the two onboard Gigabit Ethernet ports, the WAVE-594 and WAVE-694 can accommodate

one optional Interface Module network module:

• 4-port Gigabit Ethernet Copper Bypass Interface Module

• 8-port Gigabit Ethernet Copper Bypass Interface Module

• 4-port Gigabit Ethernet Fiber Optic Bypass Interface Module

• 2-port 10 Gigabit Ethernet Fiber Optic SPF+ Interface Module

For information on the features of the Cisco WAVE Interface Modules and cabling requirements, see

Chapter 5, “WAVE Interface Modules.”

Note Interface Modules are not hot-swappable therefore it is necessary to power the system down before

installing or replacing.

Caution To maintain proper system cooling, do not operate the appliance for more than 1 minute without either

an Interface Module or a filler panel installed in the bay.

To install a Cisco Interface Module in the Interface Module slot, follow these steps:

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

4-1

Page 40

Replacing a Hard Disk Drive/Solid State Drive

246553

1

2

Step 1 Review the information in the “Safety Warnings and Cautions” section on page 2-1 and the “Safety

Guidelines” section on page 2-2.

Step 2 Power down the appliance.

Note You must power down the appliance before installing or removing an Interface Module. Interface

Modules are not hot-swappable.

Step 3 Locate the Interface Module slot in the appliance chassis and slide the Cisco Interface Module into the

slot until the ejector lever is seated.

To remove an Interface Module, first use the ejector lever to unlatch and then pull out the Interface

Module. (See Figure 4-1.)

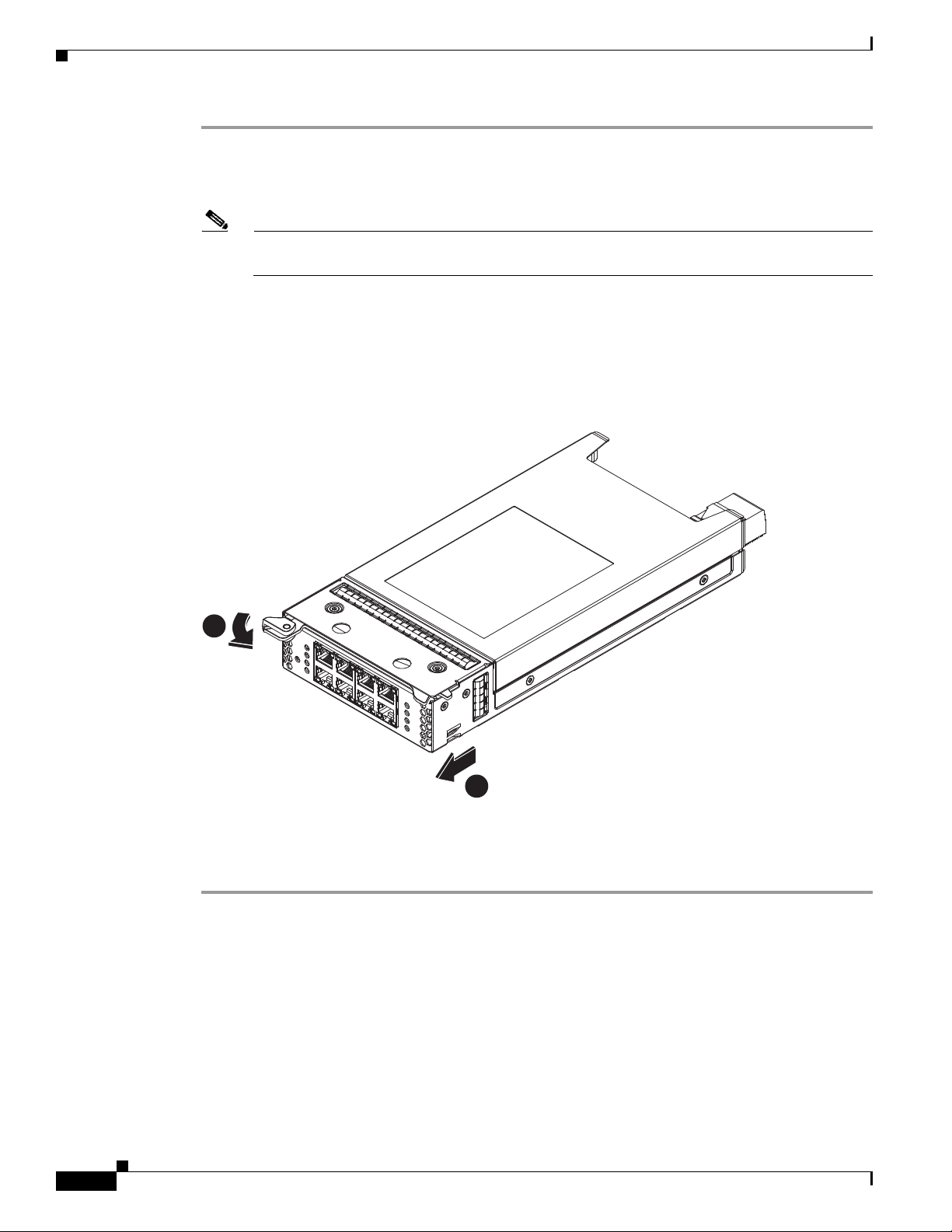

Figure 4-1 Interface Module—Removal

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

Step 4 Power on the appliance.

Step 5 For information about connecting cables to the Cisco WAVE Interface Module ports, see Chapter 5,

“WAVE Interface Modules.”

Replacing a Hard Disk Drive/Solid State Drive

The WAVE appliance supports as many as two 2.5-inch (Small Form Factor) hard drives. The WAVE-594

supports SATA drives and the WAVE-694 supports SAS drives.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

4-2

OL-24619-02

Page 41

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

246552

1

2

3

Note The WAVE-594 supports both Solid State Drives and Hard Disk Drives. You cannot mix HDD and SSD

in the same chasis.

For details about the WAVE-594 appliance specifications, see Appendix A, “Appliance Specifications”.

Hard drives are hot-swappable therefore it is not necessary to power the system down before installing

or replacing.

When removing hard drives from the WAVE appliance, observe the following general guidelines:

• The system automatically sets all drive numbers.

• Drives must be the same capacity to provide the greatest storage space efficiency when drives are

grouped together into the same drive array.

Note All hard disk drives being used in the appliance must be identical.

Caution To maintain proper system cooling, do not operate the appliance for more than 1 minute without either

a hard disk drive or a filler panel installed in each bay.

Replacing a Hard Disk Drive/Solid State Drive

To replace a hard disk drive in a bay, follow these steps:

Step 1 Review the information in the “Safety Warnings and Cautions” section on page 2-1 and the “Safety

Guidelines” section on page 2-2.

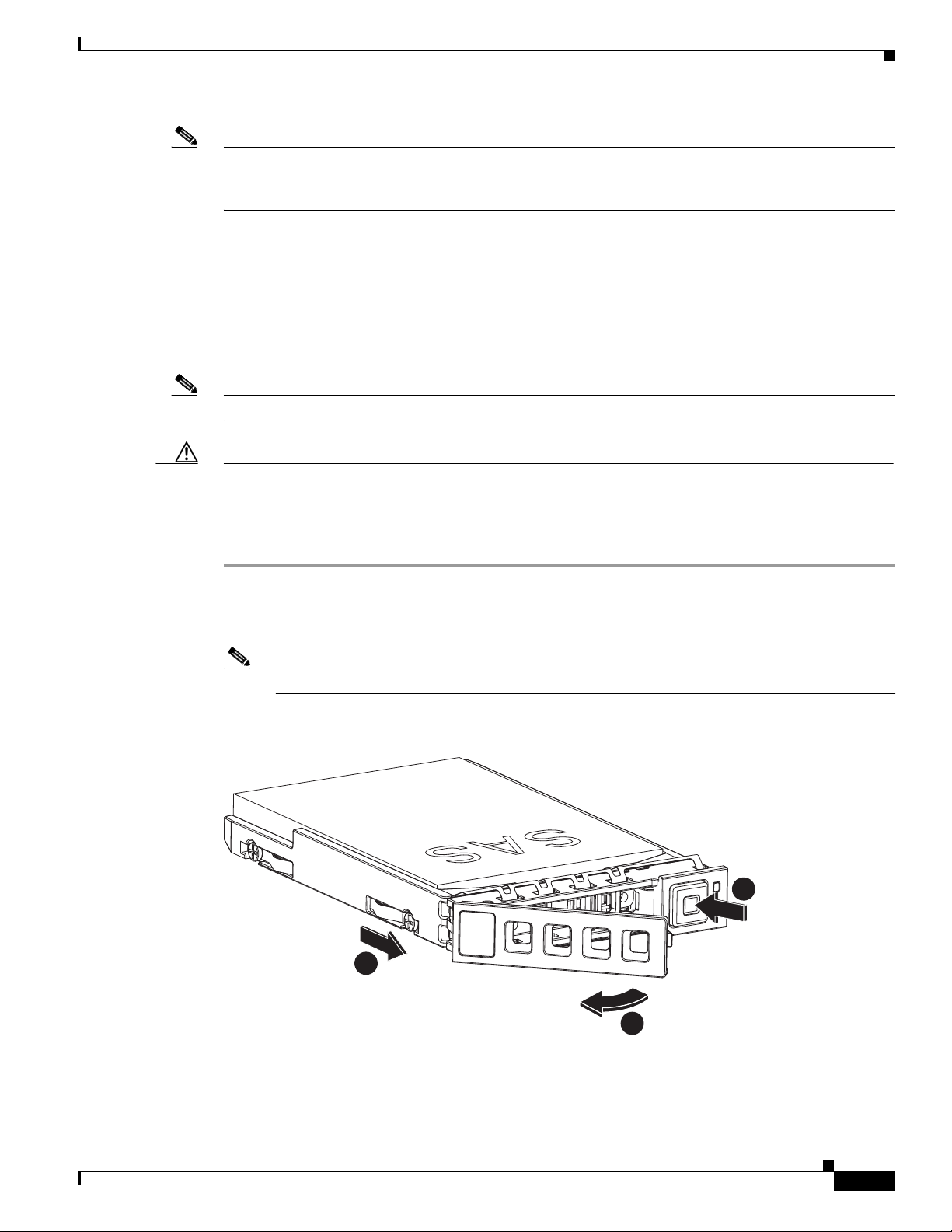

Step 2 Press the button and swing the handle out. (See Figure 4-2).

Note Wait 5 seconds before removing to let the disk spin down.

Figure 4-2 Removing a Hard Disk Drive

OL-24619-02

Step 3

After waiting 5 seconds, pull the handle to remove the drive assembly from the bay.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

4-3

Page 42

Replacing a Fan

Step 4 Within one minute, insert the new drive into the same slot by aligning the replacement drive assembly

Step 5 Close the drive handle.

Step 6 Check the hard disk drive status LED after the system has booted to verify that the hard disk drive is

Step 7 Wait 1 minute and then verify that the replaced disk drive is in the Rebuilding state by using the show

Step 8 Wait until the rebuild operation is complete. A disk rebuild operation may take several hours. You can

Step 9 Use the show disk tech command in EXEC mode to verify that the firmware and BIOS information is

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

with guide rails in the bay and sliding the drive assembly into the bay until it stops. Make sure that the

drive is properly seated in the bay.

operating correctly. If the amber hard disk drive status LED for a drive is lit continuously, that drive is

faulty and must be replaced. If the green hard disk drive activity LED is flashing, the drive is being

accessed.

disks details command in EXEC mode.

Note The system automatically starts the rebuild operation when it detects the removal and reinsertion

of a drive that is part of the logical RAID drive.

check if the rebuild operation is complete by using the show disk details command in EXEC mode. The

physical drive state will be Online and the RAID logical drive state will be Okay after the rebuild

operation is completed.

correct for both hard drives.

If you have multiple disk failures and your RAID-1 logical status is Offline, you must recreate the

RAID-1 array. For more information on disk removal and replacement procedures, see the Cisco Wide

Area Application Services Configuration Guide chapter named “Maintaining Your WAAS System.”

Replacing a Fan

The WAVE appliance supports six fan assemblies that are hot-swappable.

Fan assemblies can only be inserted in one orientation.

Note Fan assemblies must be inserted and can only function with the surface marked “TOP” facing up.

Caution To maintain proper system cooling, do not operate the appliance for more than 1 minute without a fan

installed in each bay.

To replace a fan assembly, follow these steps:

Step 1 Review the information in the “Safety Warnings and Cautions” section on page 2-1 and the “Safety

Guidelines” section on page 2-2.

Step 2 Disengage the fan latch and pull the fan out by the handle (see Figure 4-3).

4-4

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 43

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

246554

1

2

Figure 4-3 Fan Assembly

Replacing a Power Supply

Step 3

Within one minute, insert the new fan with the surface marked “TOP” facing up and verify that the latch

is engaged.

Step 4 Check the power LED to verify that the new fan is receiving power.

Note If a fan alarm occurs and you power down the WAVE appliance to replace the fan, you must use the clear

bmc event-log global configuration command and then reboot to clear the alarm.

Replacing a Power Supply

The WAVE appliance supports two power supply assemblies that are hot-swap capable.

Power supply assemblies can only be inserted in one orientation.

Note Power supply assemblies must be inserted and can only function with the surface marked “TOP” facing

up.

Caution To maintain proper system cooling, do not operate the appliance for more than 1 minute without either

a power supply or a filler panel installed in each bay.

OL-24619-02

To replace a power supply assembly, follow these steps:

Step 1 Review the information in the “Safety Warnings and Cautions” section on page 2-1 and the “Safety

Guidelines” section on page 2-2.

Step 2 Remove the power cord from the power supply.

Note When more than one power supply assembly is present, load-sharing is supported. If one loses

power, the second power supply takes over.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

4-5

Page 44

Installing Memory

Step 3 Disengage the latch and pull the power supply out by the handle. (See Figure 4-4.)

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

Figure 4-4 Power Supply Assembly

246692

Step 4

Within one minute, insert the new power supply with the surface marked “TOP” facing up and verify

that the latch is engaged.

Step 5 Insert the power cord into the replacement power supply.

Step 6 Check the power LED to verify that the new power supply is receiving power.

Note If a power supply alarm occurs and you power down the WAVE appliance to replace the power supply,

you must use the clear bmc event-log global configuration command and then reboot to clear the alarm.

Installing Memory

This section provides basic instructions for installing memory in your WAVE-594 and WAVE-694. It

contains the following topics:

• Removing the Cover, page 4-6

• Installing Memory Modules, page 4-7

Removing the Cover

4-6

Warning

Caution To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system

Before working on a system that has an on/off switch, turn OFF the power and unplug the power cord.

Statement 1

components to cool before touching them.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 45

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

Caution Do not operate the WAVE appliance with the access panel open or removed. Operating the WAVE

appliance in this manner results in improper airflow and improper cooling that can lead to thermal

damage.

To remove the appliance cover, follow these steps:

Step 1 Review the information in the “Safety Warnings and Cautions” section on page 2-1 and the “Safety

Guidelines” section on page 2-2.

Step 2 Power off the appliance and all attached devices and disconnect all external cables and power cords.

Step 3 Remove the WAVE appliance from the rack.

Step 4 Loosen the screw on the top that secures the access panel to the WAVE appliance.

Step 5 Slide the access panel toward the front of the WAVE appliance, then lift it from the WAVE appliance.

Installing Memory

Installing Memory Modules

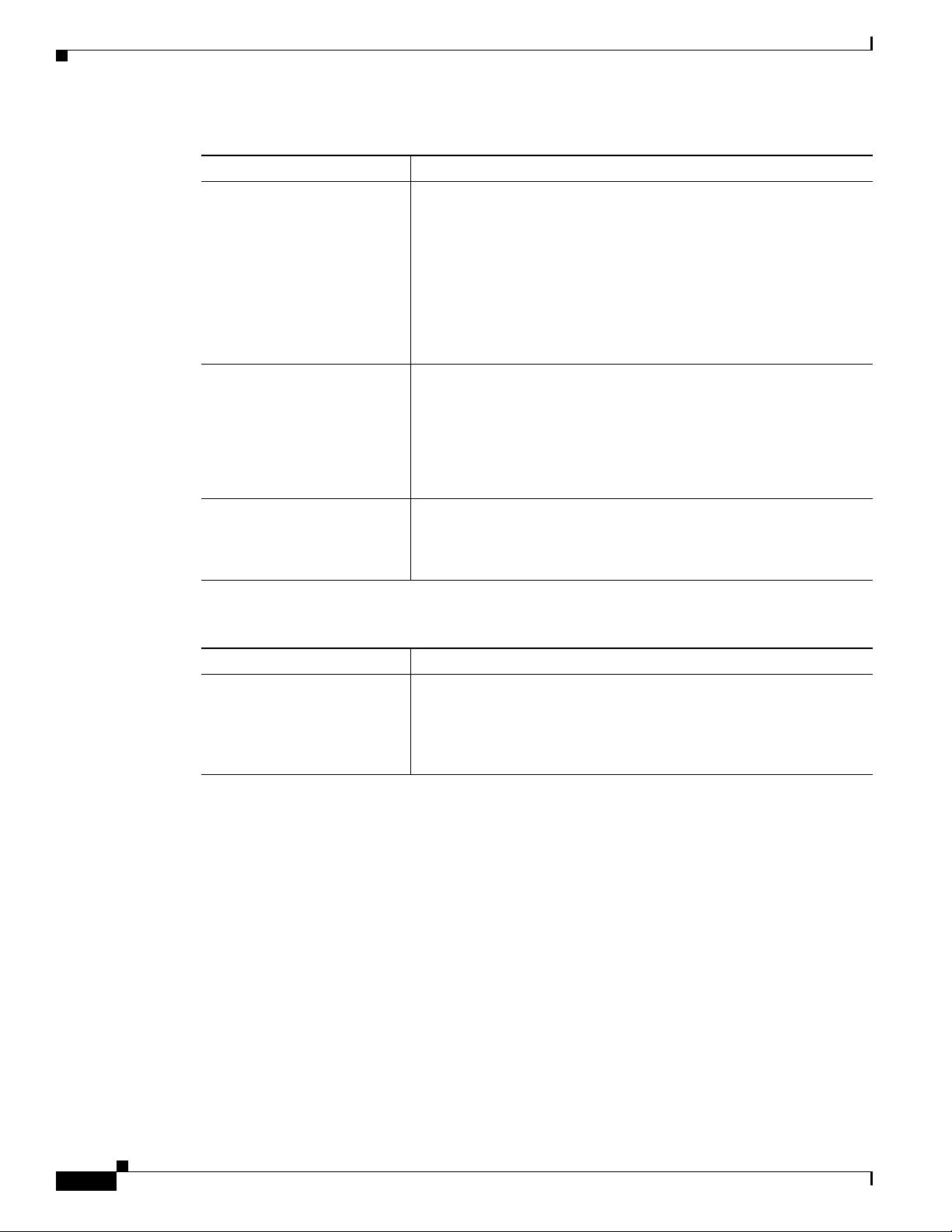

The WAVE-594 appliance supports either 8 GB or 12 GB of memory using 2-GB RDIMM memory

modules. The WAVE-694 appliance supports either 16 GB or 24 GB of memory using 4-GB RDIMM

memory modules.

Observe the following guidelines when installing additional memory:

• Use only Cisco memory upgrades in your appliance.

• BIOS detects the DIMM population and sets the system to dual-bank interleaved mode (DIMMs

installed in both banks with equal bank capacities).

Figure 4-5 shows the memory slot mapping on the system board.

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

4-7

Page 46

Installing Memory

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

Figure 4-5 Memory Slot Mapping

A3

A2 A1 B3 B2 B1

330139

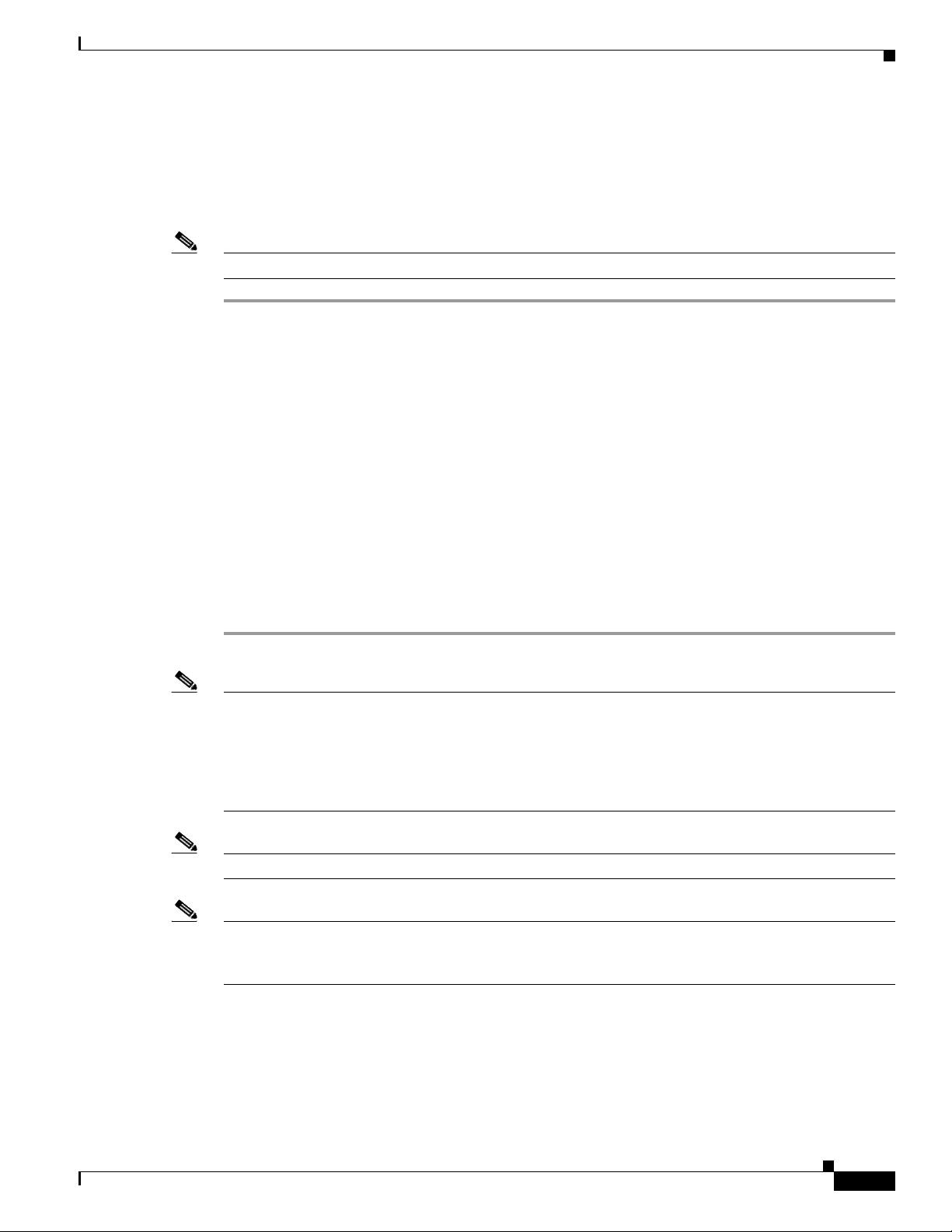

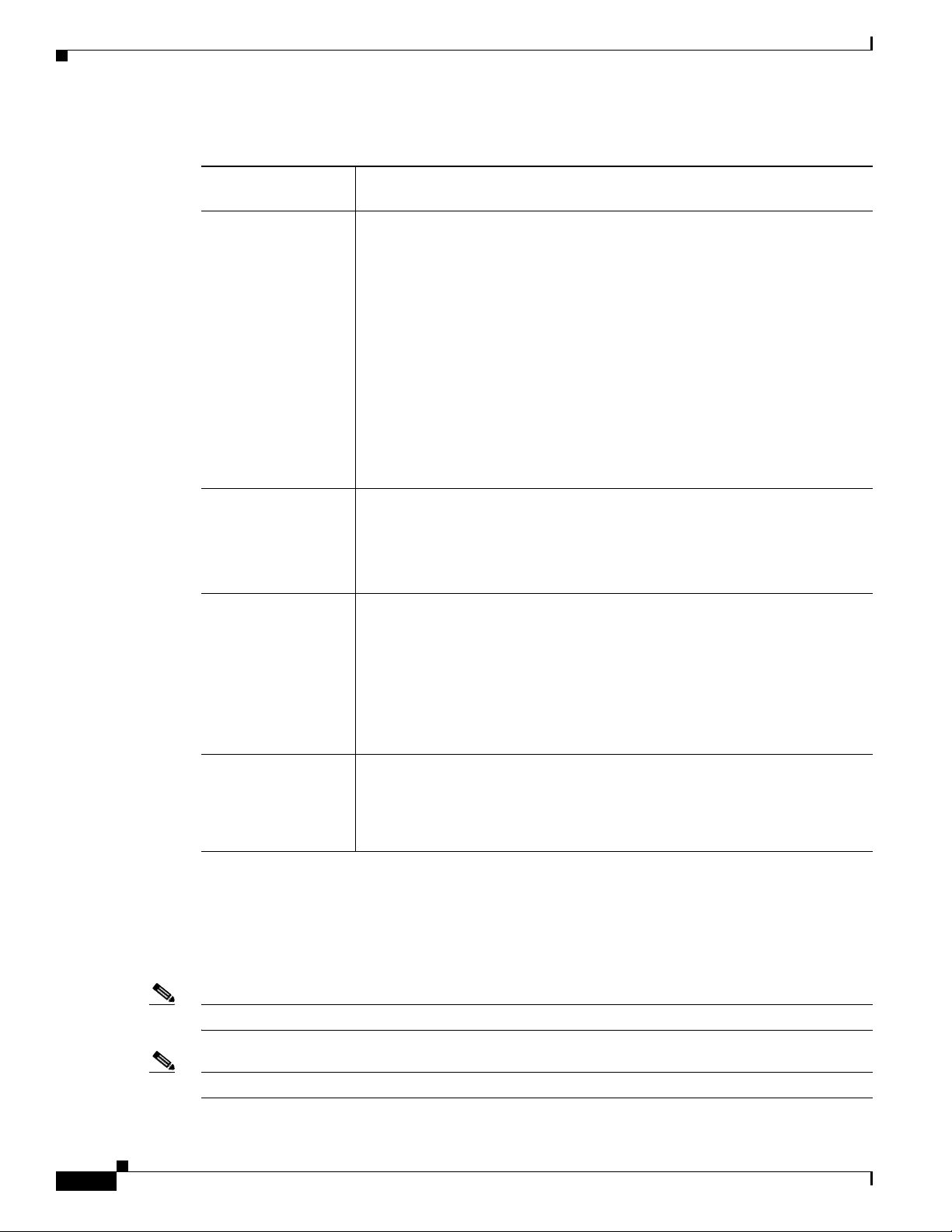

Table 4-1 and Tab l e 4-2 list the RDIMM configurations available for the WAVE-594 and WAVE-694

appliance.

Table 4-1 WAVE-594 RDIMM Configurations

Slot A3 Slot A2 Slot A1 Slot B3 Slot B2 Slot B1

8 GB Memory

12 GB Memory

Table 4-2 WAVE-694 RDIMM Configurations

— 2-GB 2-GB — 2-GB 2-GB

2-GB 2-GB 2-GB 2-GB 2-GB 2-GB

Slot A3 Slot A2 Slot A1 Slot B3 Slot B2 Slot B1

16 GB Memory

24 GB Memory

— 4-GB 4-GB — 4-GB 4-GB

4-GB 4-GB 4-GB 4-GB 4-GB 4-GB

4-8

To install a Cisco memory upgrade on the WAVE-594 from 8 GB to 12 GB or on the WAVE-694 from

16 GB to 24 GB, follow these steps:

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 47

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

330140

1

2

2

Step 1 Power down the WAVE appliance.

Step 2 Remove the WAVE appliance from the rack.

Step 3 Remove the primary access panel (See the “Removing the Cover” section on page 4-6).

Step 4 Open the DIMM slot latches for slots A1, A2, B1, and B2 and remove the existing memory modules.

Note All existing memory must be removed and replaced by the RDIMMS contained in the Cisco

upgrade kit.

Step 5 Open the DIMM slot latches for slots A3 and B3.

Step 6 To upgrade from 8 GB to 12 GB on a WAVE-594, install a 2-GB RDIMM memory module into all six

slots. (See Figure 4-6.)

To upgrade from 16 GB to 24 GB on a WAVE-694, install a 4-GB RDIMM memory module into all six

slots. (See Figure 4-6.)

Figure 4-6 Installing an RDIMM

Installing Memory

OL-24619-02

Step 7

Step 8 Install the access panel.

Check to make sure that the DIMM latches are fully engaged in the notches.

a. Lower the access panel onto the WAVE appliance and then slide the access panel toward the back of

the WAVE appliance.

b. Tighten the screw on the top that secures the access panel to the WAVE appliance.

Step 9 Install the WAVE appliance into the rack.

For complete rack installation and removal instructions, see Chapter 3, “Installing the WAVE-594 and

WAV E -6 9 4 .”

Caution Install the appliance only in a rack cabinet with perforated doors.

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

4-9

Page 48

Installing Memory

Caution Do not leave open spaces above or below an installed appliance in the rack cabinet. To help prevent

Step 10 Connect the cables and power cords. For information on connecting cables and power cords, see the

Step 11 Reboot the WAVE appliance.

Step 12 Use the show memory EXEC mode command to verify that the memory you installed is recognized by

Step 13 Repartition the disks, using the disk delete-data-partitions command, and reload.

Chapter 4 Installing Hardware Options for the WAVE-594 and WAVE-694

damage to appliance components, always install a filler panel to cover the open space and to help ensure

proper air circulation. See the documentation that comes with your rack cabinet for more information.

“Rack Mounting and Cabling the WAVE-594 and WAVE-694” section on page 3-2.

the WAVE appliance.

Note Repartitioning the disks deletes all data, including all virtual blades on the hardware.

Note Repartitioning the disks is required after adding memory to reset the DRE space allocation.

4-10

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 49

WAVE Interface Modules

This chapter describes Cisco WAVE Interface Modules and contains the following sections:

• Interface Module Descriptions, page 5-1

• Ports and LED Indicators, page 5-5

• Network Adapter Cabling Requirements, page 5-8

• Installation Scenarios and Cabling Examples for Fast Ethernet Connections, page 5-10

For information on installing an inline adapter in your WAVE-594 and WAVE-694, see the “Installing a

Cisco WAVE Interface Module” section on page 4-1.

For adapter specifications, see Table A- 2 in Appendix A.

Interface Module Descriptions

CHAP T E R

5

The WAVE appliance supports one optional 4-port Copper Gigabit Ethernet Interface Module, 8-port

Copper Gigabit Ethernet Interface Module, 4-port Fiber Optic Gigabit Ethernet Interface Module, or

2-port SFP+ Fiber Optic 10 Gigabit Ethernet Interface Module.

This section contains the following topics:

• Gigabit Ethernet Interface Module—Copper

• Gigabit Ethernet Interface Module—Fiber Optic

• 10 Gigabit Ethernet Interface Module—Fiber Optic SFP+

• Inline Interface

Gigabit Ethernet Interface Module—Copper

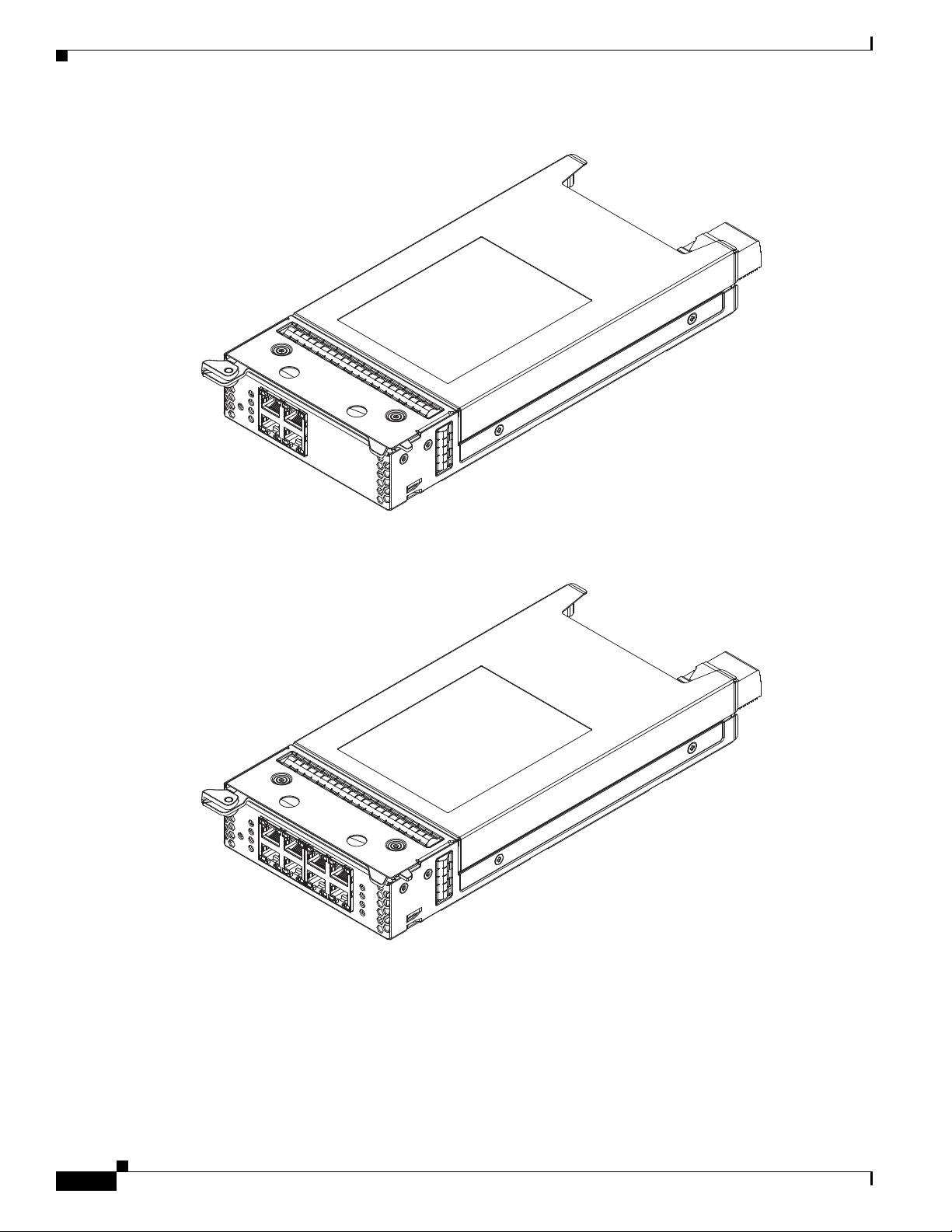

The copper Gigabit Ethernet Interface Module is available in 4 or 8 ports. Both models support bypass.

(See Figure 5-1 and Figure 5-2.)

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

5-1

Page 50

Interface Module Descriptions

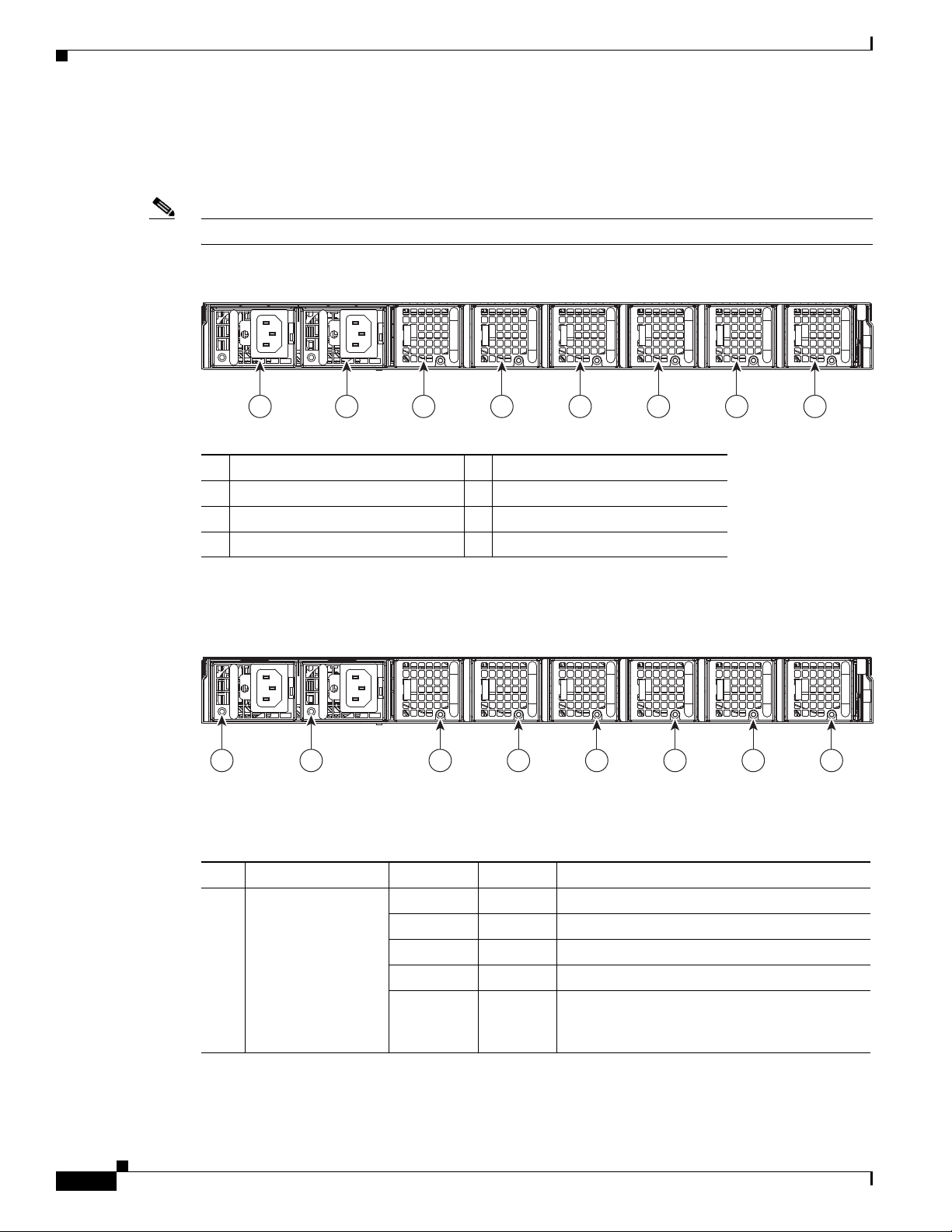

Figure 5-1 Gigabit Ethernet Interface Module—4-Port Copper

Chapter 5 WAVE Interface Modules

246685

Figure 5-2 Gigabit Ethernet Interface Module—8-Port Copper

Gigabit Ethernet Interface Module—Fiber Optic

246687

5-2

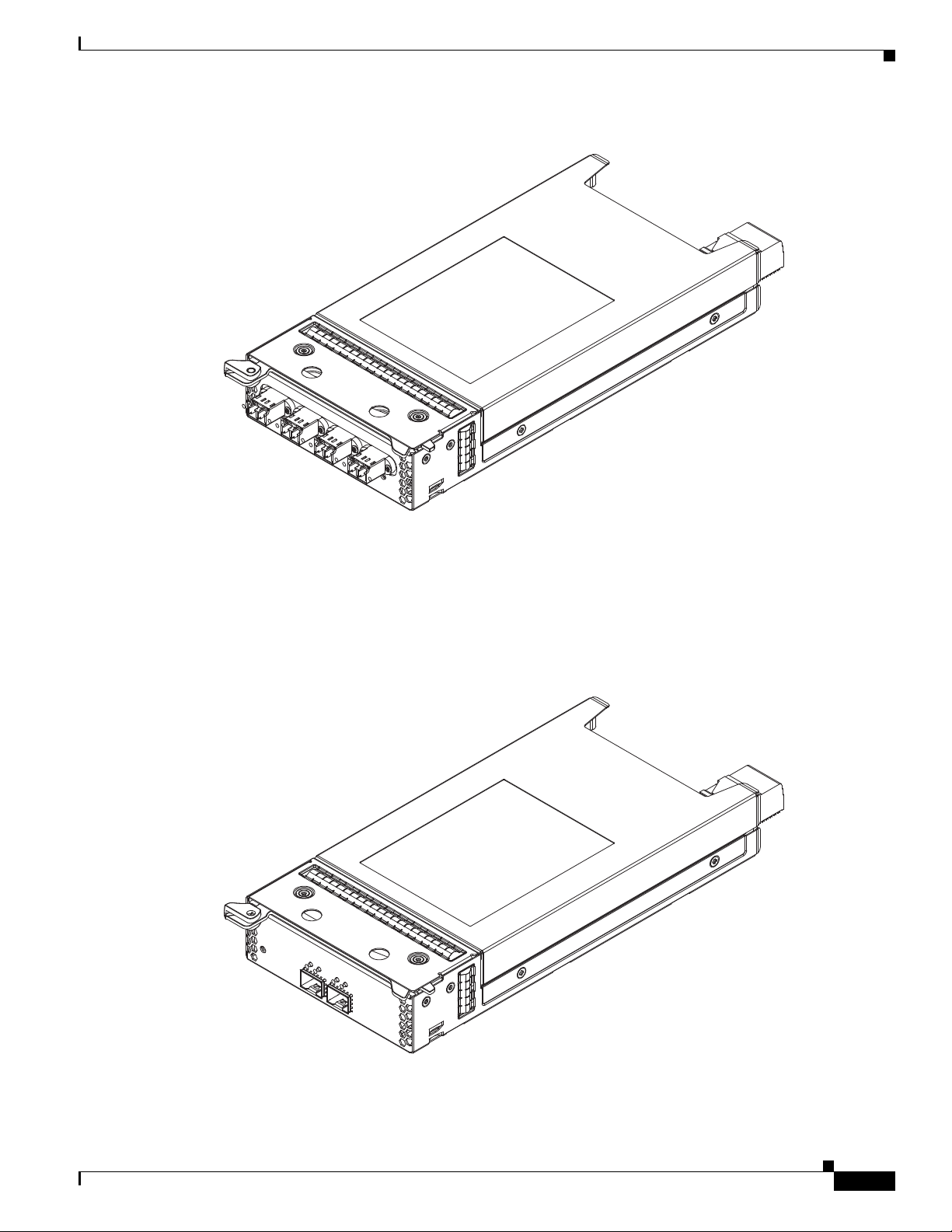

The fiber optic Gigabit Ethernet Interface Module is available in 4 ports. This model supports bypass.

(See Figure 5-3.)

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 51

Chapter 5 WAVE Interface Modules

Figure 5-3 Gigabit Ethernet Interface Module—4-Port Fiber Optic

Interface Module Descriptions

246686

10 Gigabit Ethernet Interface Module—Fiber Optic SFP+

The fiber optic Gigabit Ethernet Interface Module is available in 2 ports. This model does not support

bypass. (See Figure 5-4.)

Figure 5-4 Gigabit Ethernet Interface Module—2-Port Fiber Optic

246684

OL-24619-02

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

5-3

Page 52

Interface Module Descriptions

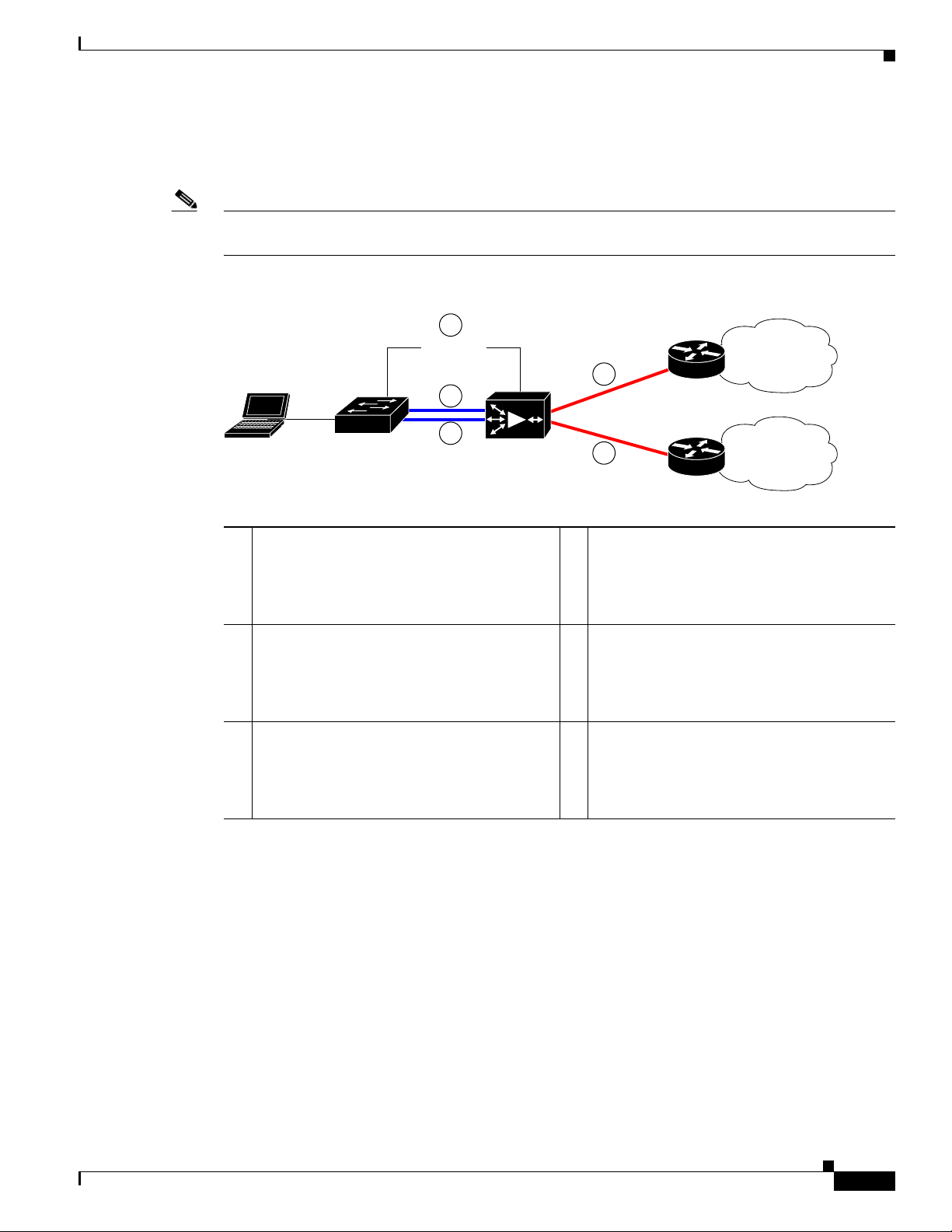

Inline Interface

When you configure the WAVE appliance for inline interception mode, you can set attributes to control

which interfaces are to be used over which VLANs. By default, the module operates on all inline-capable

interfaces and VLANs. You can configure the inline redirection feature using the WAAS CLI or the

WAAS Central Manager GUI.

Note Throughout this section, we refer to a WAVE appliance configured for inline interception mode as a

WAVE inline appliance.

The WAAS software defines two interface types: A group interface that represents an inline pair

grouping and a port interface that represents the individual port. These interfaces are referred to as

inlineGroup and inlinePort.

InlineGroup interfaces are numbered using the format slot/group. The slot number is the slot in which

the adapter is inserted. Since there is only one slot, the slot number is always 1.

The group number starts from 0 and can go up to 4 on 8-port Interface Modules. For 4-port Interface

Modules, the groups are numbered 0 and 1. Groups are numbered from left to right.

InlinePort interfaces are numbered slot/group/lan or slot/group/wan. The last attribute is the LAN or

WAN designator.

For copper Interface Modules, the top row consists of WAN ports and the bottom row consists of LAN

ports. For fiber Interface Modules, the ports are designated as WAN and LAN form left to right. For

example, the four ports on the 4-port fiber Interface Module are designated as “W0 L0 W1 L1” in inline

mode:

Chapter 5 WAVE Interface Modules

• W0—InlineGroup 1/0/WAN

• L0—InlineGroup 1/0/LAN

• W1—InlineGroup 1/1/WAN

• L1—InlineGroup 1/1/LAN

The inline network adapter also includes an onboard programmable watch dog timer (WDT) controller

that allows you to set the time to wait after a failure event, such as a power outage or a kernel crash,

before the unit begins to operate in mechanical bypass mode. This can be configured using the inline

failover timeout global configuration command:

(config)# inline failover timeout ?

<1-1> 1 second

<25-25> 25 seconds

<5-5> 5 seconds

In mechanical bypass mode, the traffic is bridged between the LAN and WAN ports of each group.

Mechanical bypass mode prevents the WAVE appliance from becoming a single point of failure and

allows traffic to continue to flow between the router and the client while it passes through an

unresponsive WAVE appliance without being processed.

For more information about configuring the inline network adapter, see the Cisco Wide Area Application

Services Configuration Guide.

5-4

Cisco Wide Area Virtualization Engine 594 and 694 Hardware Installation Guide

OL-24619-02

Page 53

Chapter 5 WAVE Interface Modules

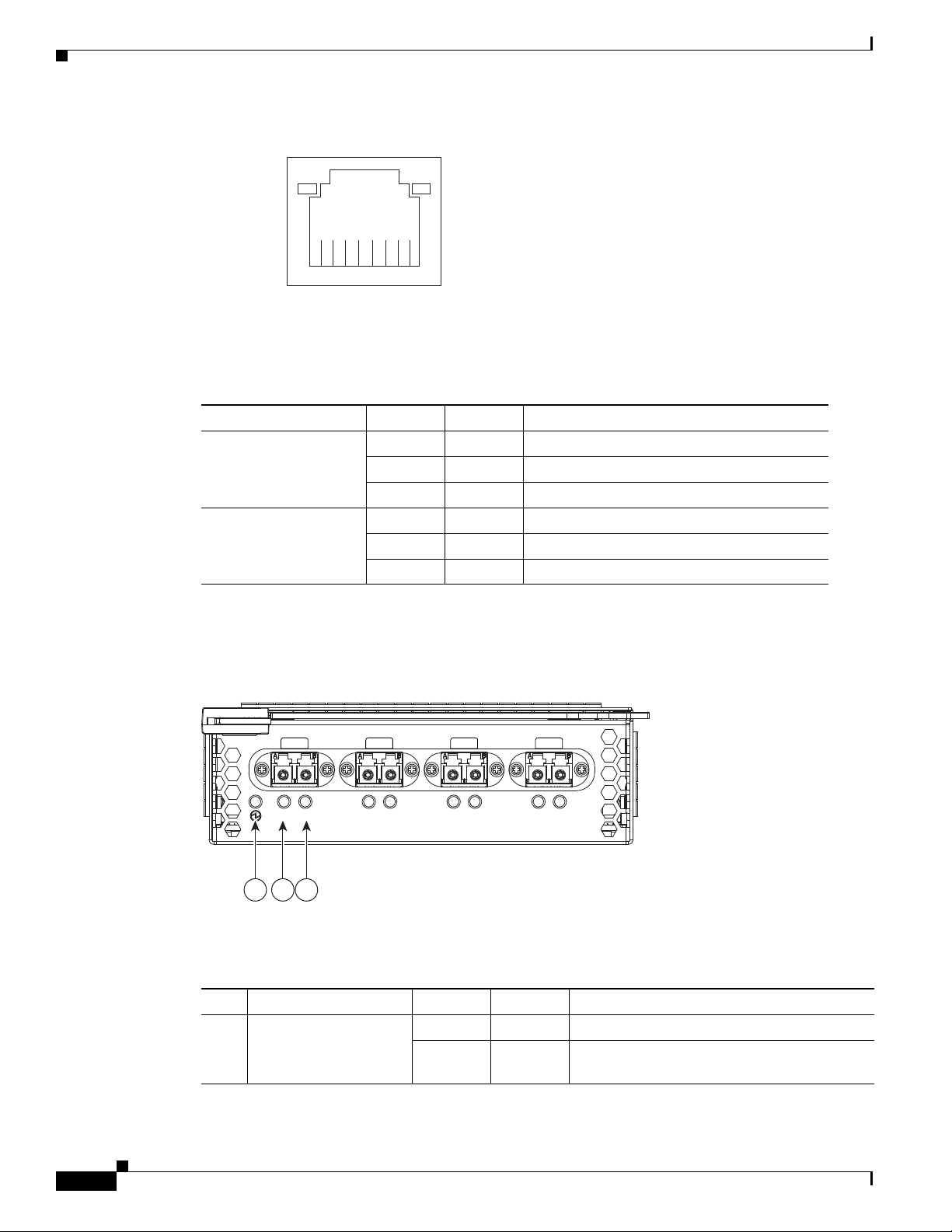

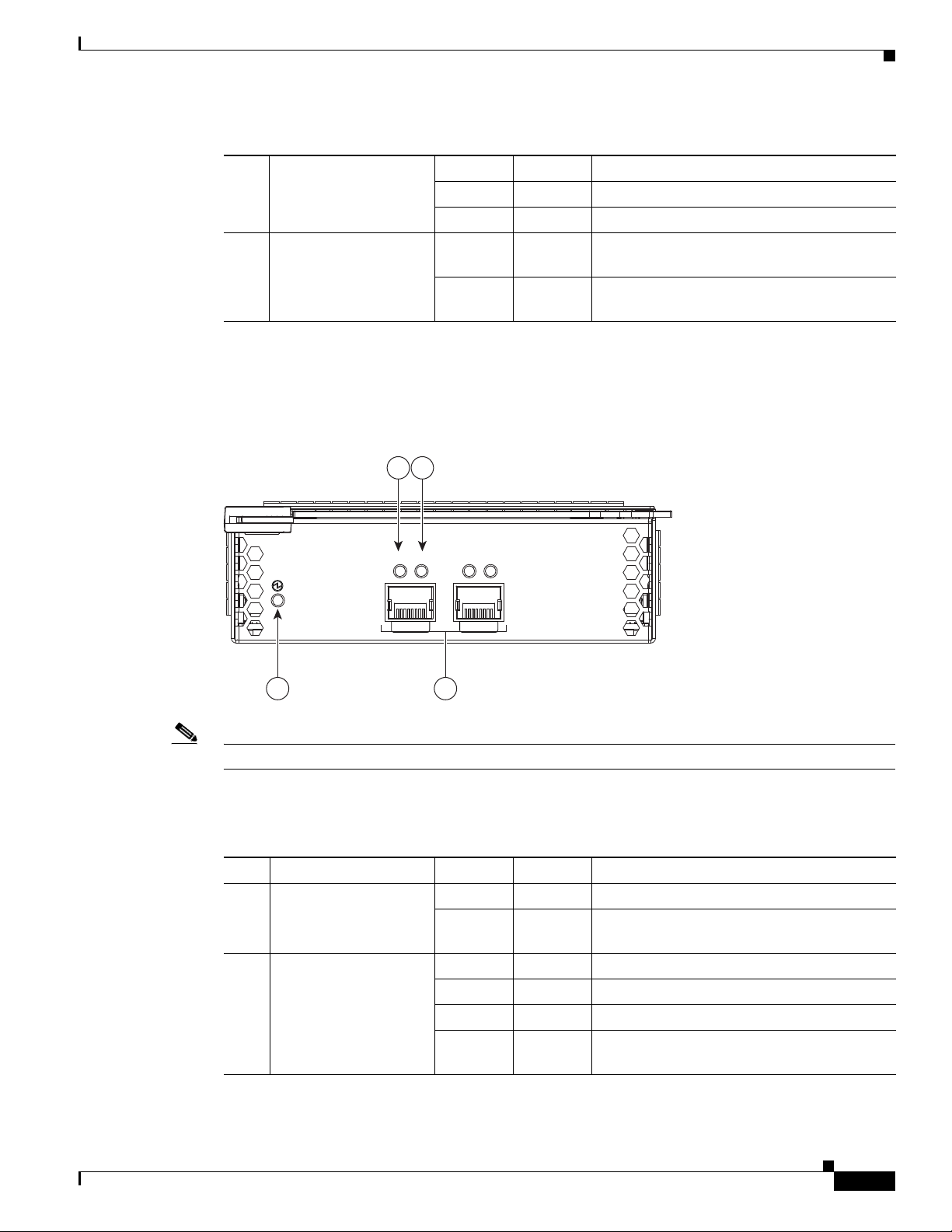

Ports and LED Indicators

Figure 5-5 shows the 4-port Copper Gigabit Ethernet Interface Module port numbers, interface

designations, and LEDs. Figure 5-6 shows the same information for the 8-port adapter.

Figure 5-5 4-Port Copper Gigabit Ethernet Interface Module—Port Numbering and LEDs

4 PORT BYPASS

0

1

2

3

Status

1 2

GE 0/1

GE 2/3

Ports and LED Indicators

246548