Page 1

Cisco UCS 5108 Server Chassis Installation Guide

First Published: June 10, 2009

Last Modified: October 08, 2013

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Text Part Number: OL-20035-05

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If the equipment causes interference to radio or television reception, which can be determined by turning the equipment off and on, users are

encouraged to try to correct the interference by using one or more of the following measures:

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•

Consult the dealer or an experienced radio/TV technician for help.

•

Modifications to this product not authorized by Cisco could void the FCC approval and negate your authority to operate the product

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public domain version

of the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED "AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: http://

www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

©

2009-2013 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

Preface

CHAPTER 1

Preface ix

Audience ix

Conventions ix

Related Cisco UCS Documentation xi

Obtaining Documentation and Submitting a Service Request xi

Overview 1

System Overview 1

Features and Benefits 2

Components 4

Cisco UCS 5108 Server Chassis 4

LEDs 4

Buttons 4

Connectors 4

Midplane 4

Blade Servers 5

Cisco UCS B200 Blade Servers 5

LEDs 6

Buttons 6

Connectors 6

Cisco UCS B200 M3 Blade Servers 7

LEDs 7

Buttons 7

Connectors 8

Cisco UCS B22 M3 Blade Servers 8

LEDs 8

Buttons 9

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 iii

Page 4

Contents

Connectors 9

Cisco UCS B230 Blade Servers 9

LEDs 10

Buttons 10

Connectors 10

Cisco UCS B250 Blade Servers 11

LEDs 11

Buttons 11

Connectors 12

Cisco UCS B440 Blade Servers 12

LEDs 12

Buttons 13

Connectors 13

Cisco UCS B420 M3 High Performance Blade Server 13

LEDs 14

Buttons 14

Connectors 14

Adapter Cards 14

Cisco UCS Virtual Interface Card 1280 14

Cisco UCS M81KR Virtual Interface Card 14

Cisco UCS 82598KR-CI 10 Gigabit Ethernet Adapter 15

Cisco UCS M71KR-E Emulex Converged Network Adapter 15

Cisco UCS M71KR-Q QLogic Converged Network Adapter 16

Cisco UCS 2104XP FEXes 17

LEDs 18

Buttons 18

Connectors 18

Cisco UCS 2200 Series FEXes 18

LEDs 20

Buttons 20

Connectors 20

Power Distribution Unit (PDU) 20

LEDs 20

Buttons 20

Connectors 20

Cisco UCS 5108 Server Chassis Installation Guide

iv OL-20035-05

Page 5

Contents

Fan Modules 21

LEDs 21

Buttons and Connectors 21

Power Supplies 21

LEDs 21

Buttons 21

Connectors 21

Power Supply Redundancy 21

Non-redundant Mode 22

N+1 Redundancy 22

Grid Redundancy 23

LEDs 23

CHAPTER 2

LED Locations 24

Interpreting LEDs 25

Installation 29

Installation Notes and Warnings for the Cisco UCS 5108 Server Chassis 29

Rack Requirements 30

Cable Management 30

Airflow Considerations 31

Moving Server Chassis 32

Installation Guidelines 32

Required Equipment 33

Unpacking and Inspecting the Chassis 33

Attaching the Round Hole Adapter Kit to the Rails (Optional) 34

Installing the Chassis 35

Installing the Rails 36

Installing the Round Hole Adapter Kit 39

Inserting the Chassis into the Rack 42

Connecting a DC Power Supply 44

Required Tools 44

DC Power Installation Procedure 44

Cabling Considerations for Fabric Port Channels 47

Proper FEX and Fabric Interconnect Port Connectivity 48

Removing the Chassis from a Rack 50

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 v

Page 6

Contents

Repacking the Chassis 51

SFP+ Transceivers 51

SFP+ Twinax Copper Transceivers 51

Optical SFP+ Transceivers 52

Replacing a Copper Twinax SFP+ Transceiver with an Optical SFP+ Transceiver 53

CHAPTER 3

Installing and Removing Components 55

Components 55

Installing and Removing a Blade Server 57

Installing and Removing a Blade Server Hard Drive 57

Installing a Blade Server Hard Drive 58

Removing a Blade Server Hard Drive 59

Installing and Removing Power Supplies 59

Installing a Power Supply 60

Removing a Power Supply 61

Installing and Removing a Power Distribution Unit (PDU) 62

Installing a PDU 62

Removing a PDU 63

Installing and Removing FEXes 63

FEX Upgrade Considerations 63

Removing a FEX 64

Installing a FEX 65

Installing and Removing a Fan Module 66

Installing a Fan Module 66

Removing a Fan Module 67

APPENDIX A

Technical Specifications 69

KVM Cable 69

Chassis Specifications 70

Environmental Specifications 71

Environmental Conditions and Power Requirement Specifications for Twinax SFP+

Transceivers 71

Specifications for the Cisco UCS 5108 Blade Server Chassis Power Supply Units 72

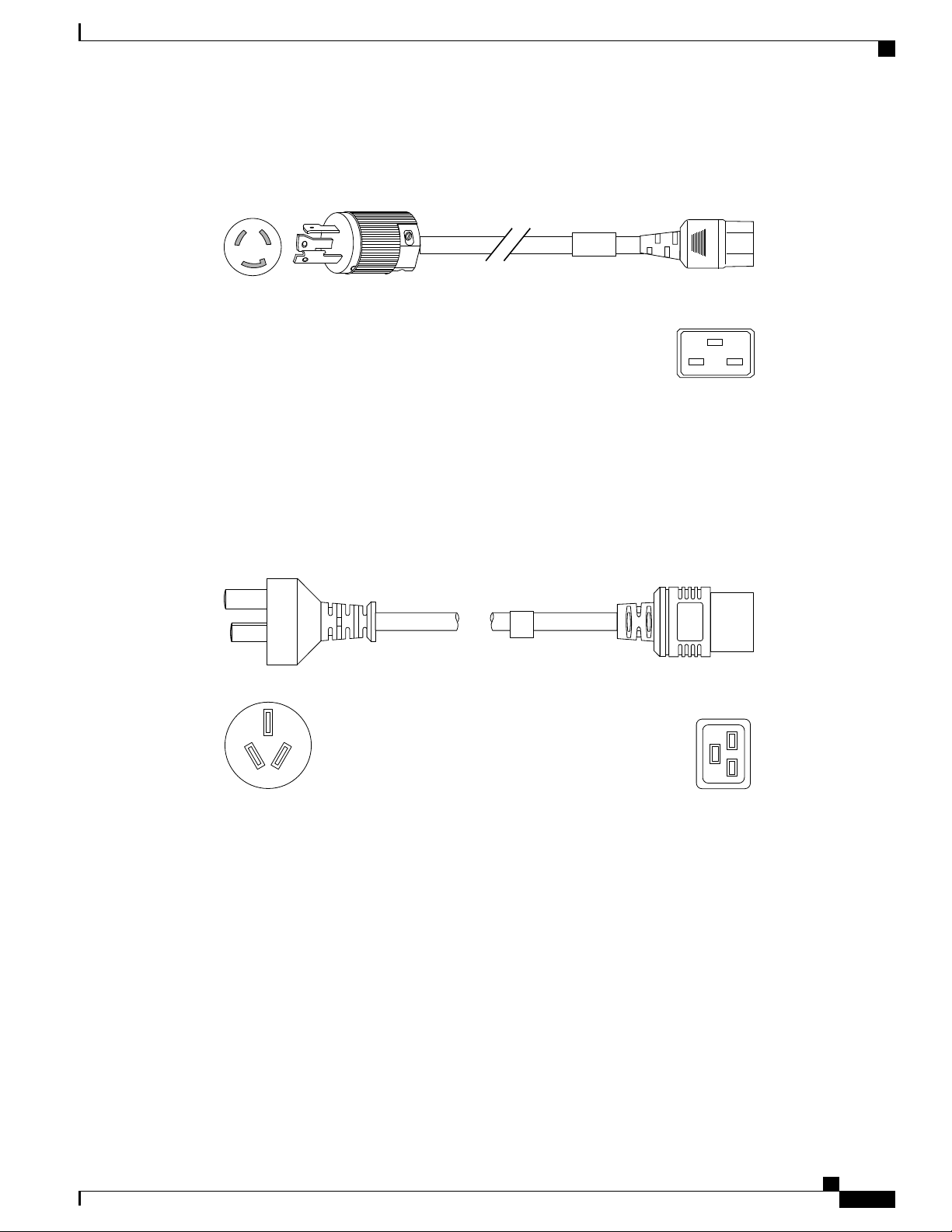

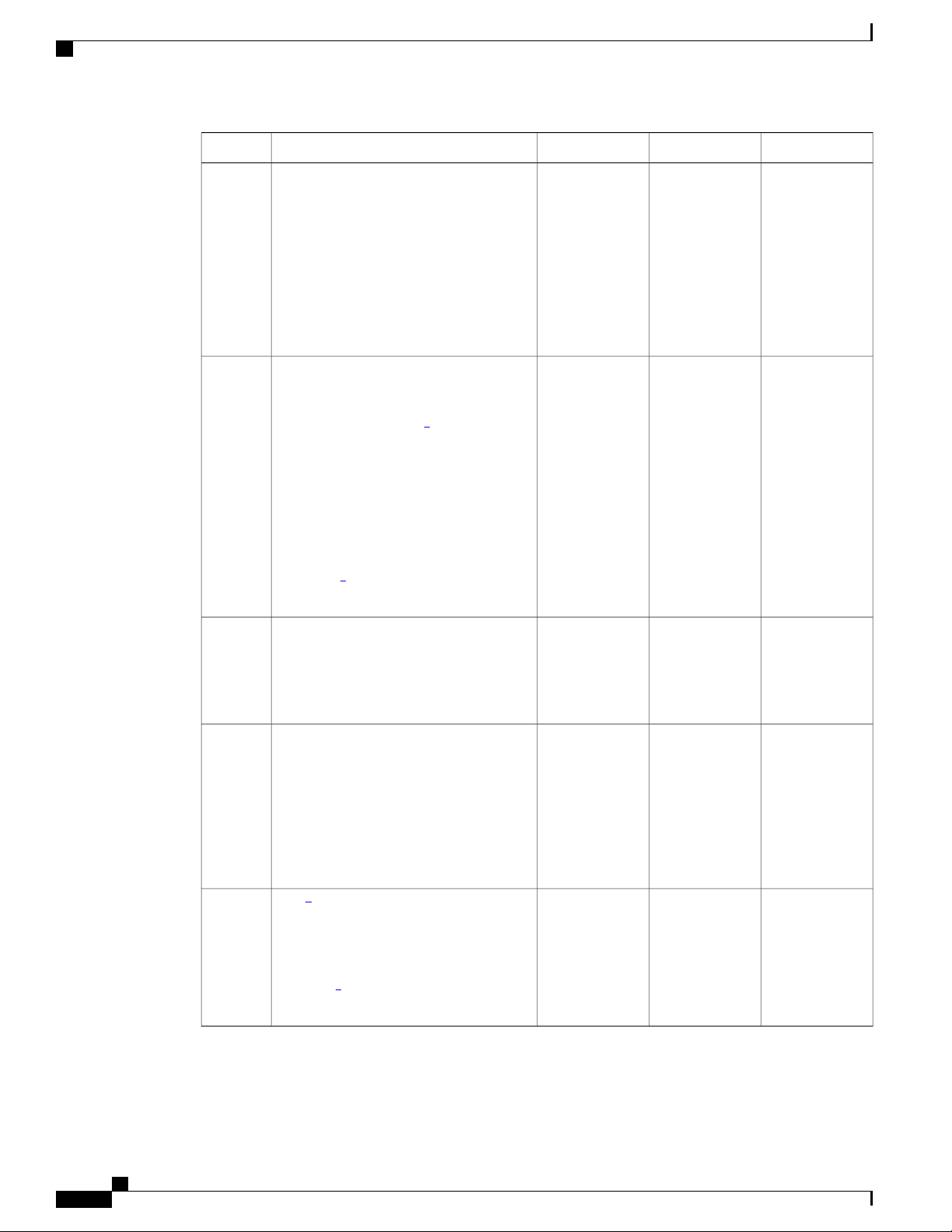

Supported AC Power Cords and Plugs 74

Australia and New Zealand 74

Cisco UCS 5108 Server Chassis Installation Guide

vi OL-20035-05

Page 7

Contents

Continental Europe 75

International 75

Israel 75

Japan and North America 76

Peoples Republic of China 77

Switzerland 77

Power Distribution Unit (PDU) 78

APPENDIX B

Site Planning and Maintenance Records 79

Site Preparation Checklist 79

Contact and Site Information 81

Chassis and Module Information 81

FEX Port Connection Record 83

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 vii

Page 8

Contents

Cisco UCS 5108 Server Chassis Installation Guide

viii OL-20035-05

Page 9

Audience

Preface

This preface includes the following sections:

Audience, page ix

•

Conventions, page ix

•

Related Cisco UCS Documentation, page xi

•

Obtaining Documentation and Submitting a Service Request, page xi

•

To use this installation guide, you must be familiar with electronic circuitry and wiring practices and preferably

be an electronic or electromechanical technician who has experience with electronic and electromechanical

equipment.

Only trained and qualified service personnel (as defined in IEC 60950-1 and AS/NZS60950) should install,

replace, or service the equipment. Install the system in accordance with the U.S. National Electric Code if

you are in the United States.

Conventions

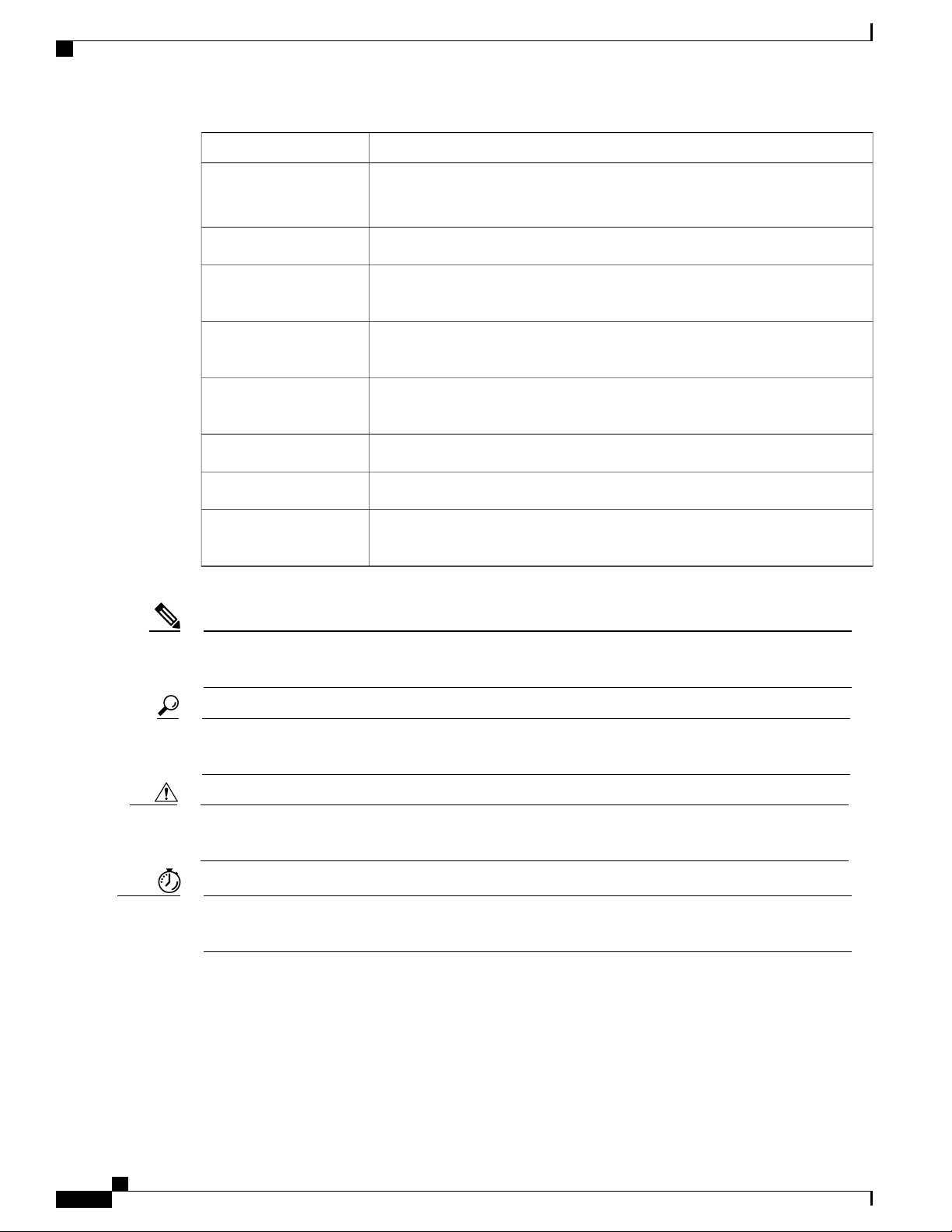

IndicationText Type

GUI elements

Document titles

System output

OL-20035-05 ix

GUI elements such as tab titles, area names, and field labels appear in this font.

Main titles such as window, dialog box, and wizard titles appear in this font.

Document titles appear in this font.

In a Text-based User Interface, text the system displays appears in this font.TUI elements

Terminal sessions and information that the system displays appear in this

font.

Cisco UCS 5108 Server Chassis Installation Guide

Page 10

Conventions

Preface

IndicationText Type

CLI commands

{x | y | z}

[x | y | z]

string

!, #

CLI command keywords appear in this font.

Variables in a CLI command appear in this font.

Elements in square brackets are optional.[ ]

Required alternative keywords are grouped in braces and separated by vertical

bars.

Optional alternative keywords are grouped in brackets and separated by vertical

bars.

A nonquoted set of characters. Do not use quotation marks around the string or

the string will include the quotation marks.

Nonprinting characters such as passwords are in angle brackets.< >

Default responses to system prompts are in square brackets.[ ]

An exclamation point (!) or a pound sign (#) at the beginning of a line of code

indicates a comment line.

Note

Tip

Caution

Timesaver

Means reader take note. Notes contain helpful suggestions or references to material not covered in the

document.

Means the following information will help you solve a problem. The tips information might not be

troubleshooting or even an action, but could be useful information, similar to a Timesaver.

Means reader be careful. In this situation, you might perform an action that could result in equipment

damage or loss of data.

Means the described action saves time. You can save time by performing the action described in the

paragraph.

Cisco UCS 5108 Server Chassis Installation Guide

x OL-20035-05

Page 11

Preface

Related Cisco UCS Documentation

Warning

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Related Cisco UCS Documentation

Documentation Roadmaps

For a complete list of all B-Series documentation, see the Cisco UCS B-Series Servers Documentation Roadmap

available at the following URL: http://www.cisco.com/go/unifiedcomputing/b-series-doc.

For a complete list of all C-Series documentation, see the Cisco UCS C-Series Servers Documentation Roadmap

available at the following URL: http://www.cisco.com/go/unifiedcomputing/c-series-doc.

Other Documentation Resources

An ISO file containing all B and C-Series documents is available at the following URL: http://www.cisco.com/

cisco/software/type.html?mdfid=283853163&flowid=25821. From this page, click Unified Computing

System (UCS) Documentation Roadmap Bundle.

The ISO file is updated after every major documentation release.

Follow Cisco UCS Docs on Twitter to receive document update notifications.

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information,

see the monthly What's New in Cisco Product Documentation, which also lists all new and revised Cisco

technical documentation.

Subscribe to the What's New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed

and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free

service and Cisco currently supports RSS version 2.0.

Follow Cisco UCS Docs on Twitter to receive document update notifications.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 xi

Page 12

Obtaining Documentation and Submitting a Service Request

Preface

Cisco UCS 5108 Server Chassis Installation Guide

xii OL-20035-05

Page 13

Overview

This chapter contains the following sections:

System Overview, page 1

•

Features and Benefits, page 2

•

Components, page 4

•

LEDs, page 23

•

System Overview

The Cisco UCS 5108 server chassis and its components are part of the Cisco Unified Computing System

(UCS), which uses the Cisco UCS 5108 server system with the two I/O modules and the Cisco UCS Fabric

Interconnects to provide advanced options and capabilities in server and data management. All servers are

managed via the GUI or CLI with Cisco UCS Manager.

The Cisco UCS 5108 server chassis system consists of the following components:

CHAPTER 1

• Cisco UCS 5108 server chassis–AC version (N20-C6508)

• Cisco UCS 5108 server chassis–DC version (UCSB-5108-DC)

• Cisco UCS 2104XP I/O Module (N20-I6584)—Up to two I/O modules, each providing four ports of

10-Gb Ethernet, Cisco Data Center Ethernet, and Fibre Channel over Ethernet (FCoE) connection to the

fabric interconnect

• Cisco UCS 2208XP I/O Module (UCS-IOM-2208XP)—Up to two I/O modules, each providing eight

universal ports configurable as a 10-Gb Ethernet, Cisco Data Center Ethernet, or Fibre Channel over

Ethernet (FCoE) connection to the fabric interconnect

• Cisco UCS 2204XP I/O Module (UCS-IOM-2204XP)—Up to two I/O modules, each providing four

universal ports configurable as a 10-Gb Ethernet, Cisco Data Center Ethernet, or Fibre Channel over

Ethernet (FCoE) connection to the fabric interconnect

A number of SFP+ choices using copper or optical fiber

•

• Power supplies (N20-PAC5-2500W, UCSB-PSU-2500ACPL or N20-DC-2500)—Up to four 2500 Watt

hot-swappable power supplies

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 1

Page 14

Features and Benefits

• Fan modules (N20-FAN5)—Eight hot-swappable fan modules

UCS B-series blade servers, including

•

◦ Cisco UCS B200 blade servers (N20-B6620-1 for M1 or N20-B6625-1 for M2)—Up to eight

half-width blade servers, each containing two CPUs and holding up to two hard drives capable of

RAID 0 or 1

◦ Cisco UCS B200 M3 blade servers (UCSB-B200-M3)—Up to eight half-width blade servers, each

containing two CPUs and holding up to two hard drives capable of RAID 0 or 1

◦ Cisco UCS B22 blade servers (UCSB-B22-M3)—Up to eight half-width blade servers, each

containing two CPUs and holding up to two hard drives capable of RAID 0 or 1

◦ Cisco UCS B230 blade servers (N20-B6730)—Up to eight half-width blade servers, each containing

two CPUs and holding up to two SDD drives capable of RAID 0 or 1

◦ Cisco UCS B250 blade servers (N20-B6620-2 for M1 or N20-B6625-2 for M2)—Up to four

full-width blade servers, each containing two CPUs and holding up to two hard drives capable of

RAID 0 or 1

◦ Cisco UCS B440 blade servers (N20-B6740-2)—Up to four full-width blade servers, each containing

four CPUs and holding up to four hard drives capable of RAID 0, 1, 5, and 6

Overview

◦ Cisco UCS B420 blade servers (UCSB-B420-M3)—Up to four full-width blade servers, each

containing four CPUs and holding up to four hard drives capable of RAID 0, 1, 5, and 10

Features and Benefits

The Cisco UCS 5108 revolutionizes the use and deployment of blade-based systems. By incorporating unified

fabric, integrated, embedded management, and fabric extender technology, the Cisco Unified Computing

System enables the chassis to have fewer physical components, no independent management, and to be more

energy efficient than traditional blade server chassis.

This simplicity eliminates the need for dedicated chassis management and blade switches, reduces cabling,

and enables the Cisco Unified Computing System to scale to 40 chassis without adding complexity. The Cisco

UCS 5108 chassis is a critical component in delivering the Cisco Unified Computing System benefits of data

center simplicity and IT responsiveness.

Table 1: Features and Benefits

Management by Cisco

UCS Manager

BenefitFeature

Reduces total cost of ownership by removing management modules from the

chassis, making the chassis stateless.

Provides a single, highly available management domain for all system chassis,

reducing administrative tasks.

Unified fabric

Cisco UCS 5108 Server Chassis Installation Guide

2 OL-20035-05

Decreases TCO by reducing the number of network interface cards (NICs), host

bus adapters (HBAs), switches, and cables needed.

Page 15

Overview

Features and Benefits

BenefitFeature

Support for one or two

Cisco UCS 2100 Series

or Cisco UCS 2200

FEXes

Auto discovery

High-performance

midplane

Redundant hot

swappable power

supplies and fans

Eliminates switches from the chassis, including the complex configuration and

management of those switches, allowing a system to scale without adding

complexity and cost.

Allows use of two I/O modules for redundancy or aggregation of bandwidth.

Enables bandwidth scaling based on application needs; blades can be configured

from 1.25 Gbps to 40 Gbps or more.

Requires no configuration; like all components in the Cisco Unified Computing

System, chassis are automatically recognized and configured by Cisco UCS

Manager.

Provides investment protection for new fabric extenders and future blade servers.

Supports up to 2x 40 Gigabit Ethernet for every blade server slot when used in

high-availability mode.

Provides 8 blades with 1.2 terabits (Tb) of available Ethernet throughput for future

I/O requirements.

Provides reconfigurable chassis to accommodate a variety of form factors and

functions.

Provides high availability in multiple configurations.

Increases serviceability.

Provides uninterrupted service during maintenance.

Available configured for AC or DC environments (mixing not supported)

servers and FEXes

Comprehensive

monitoring

airflow

Tool-free installation

Mixed blade

configurations

Provides uninterrupted service during maintenance and server deployment.Hot-pluggable blade

Provides extensive environmental monitoring on each chassis

Allows use of user thresholds to optimize environmental management of the

chassis.

Helps reduce power consumption and increase component reliability.Efficient front-to-back

Requires no specialized tools for chassis installation.

Provides mounting rails for easy installation and servicing.

Allows up to 8 half-width or 4 full-width blade servers, or any combination

thereof, for outstanding flexibility.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 3

Page 16

Components

Components

Cisco UCS 5108 Server Chassis

The Cisco UCS 5100 Series Blade Server Chassis is a scalable and flexible blade server chassis for today’s

and tomorrow’s data center that helps reduce total cost of ownership. It is available configured for AC

(N20-C6508) and DC (UCSB-5108-DC) power environments.

Is six rack units (6 RU) high and can mount in an industry-standard 19-inch rack with square holes (such as

the Cisco R Series Racks) or in round hole racks when an adapter is used. The chassis can house up to eight

half-width Cisco UCS B-Series Blade Servers and can accommodate both half- and full-width blade form

factors.

Four single-phase, hot-swappable AC or DC power supplies are accessible from the front of the chassis. These

power supplies can be configured to support nonredundant, N+1 redundant, and grid-redundant configurations.

The rear of the chassis contains eight hot-swappable fans, four power connectors (one per power supply), and

two I/O bays for I/O modules. A passive midplane provides up to an effective maximum of 20 Gbps of I/O

bandwidth per server slot and up to 40 Gbps of I/O bandwidth for two slots, the midplane is built to eventually

support 80 Gbps per slot.

Scalability is dependent on both hardware and software. For more information, see FEX Upgrade

Considerations, on page 63 and the appropriate UCS software release notes.

Overview

LEDs

Buttons

Connectors

Midplane

LEDs on the chassis indicate system connectivity and failure warnings. See LED Locations, on page 24 for

details. There is also a flashing blue Beaconing LED and button that can be triggered manually or remotely

from UCS Manager.

The beaconing function LED is also a feature on/off button. When triggered, beaconing of the server chassis

is observable remotely from UCS Manager.

There are no user connectors such as RJ-45 ports on the chassis itself.

The integral chassis midplane supports the following:

40 G total bandwidth to each of two I/O Modules

•

Auto-discover of all components

•

Redundant data and management paths

•

10 G Base-KR

•

Cisco UCS 5108 Server Chassis Installation Guide

4 OL-20035-05

Page 17

Overview

Blade Servers

Blade Servers

The midplane is an entirely passive device.

The Cisco UCS B-Series Blade Servers are based on industry-standard server technologies and provide the

following:

Up to two or four Intel multi-core processors, depending on the server

•

Front-accessible, hot-swappable hard drives or solid-state disk (SSD) drives

•

Depending on the server, support is available for up to three adapter card connections for up to 40 Gbps

•

of redundant I/O throughput

Industry-standard double-data-rate 3 (DDR3) memory

•

Remote management through an integrated service processor that also executes policy established in

•

Cisco UCS Manager software

Local keyboard, video, and mouse (KVM) and serial console access through a front console port on

•

each server

Out-of-band access by remote KVM, Secure Shell (SSH), and virtual media (vMedia) as well as Intelligent

•

Platform Management Interface (IPMI)

The Cisco UCS B-Series offers multiple blade server models. The supported processor family is indicated by

M1, M2, or M3 designations on the model.

Cisco UCS B200 Blade Servers

For full service and installation instructions, see the Cisco UCS B200 Blade Server Installation and Service

Note. You can install up to eight UCS B200 M1 or M2 Blade Servers to a chassis.

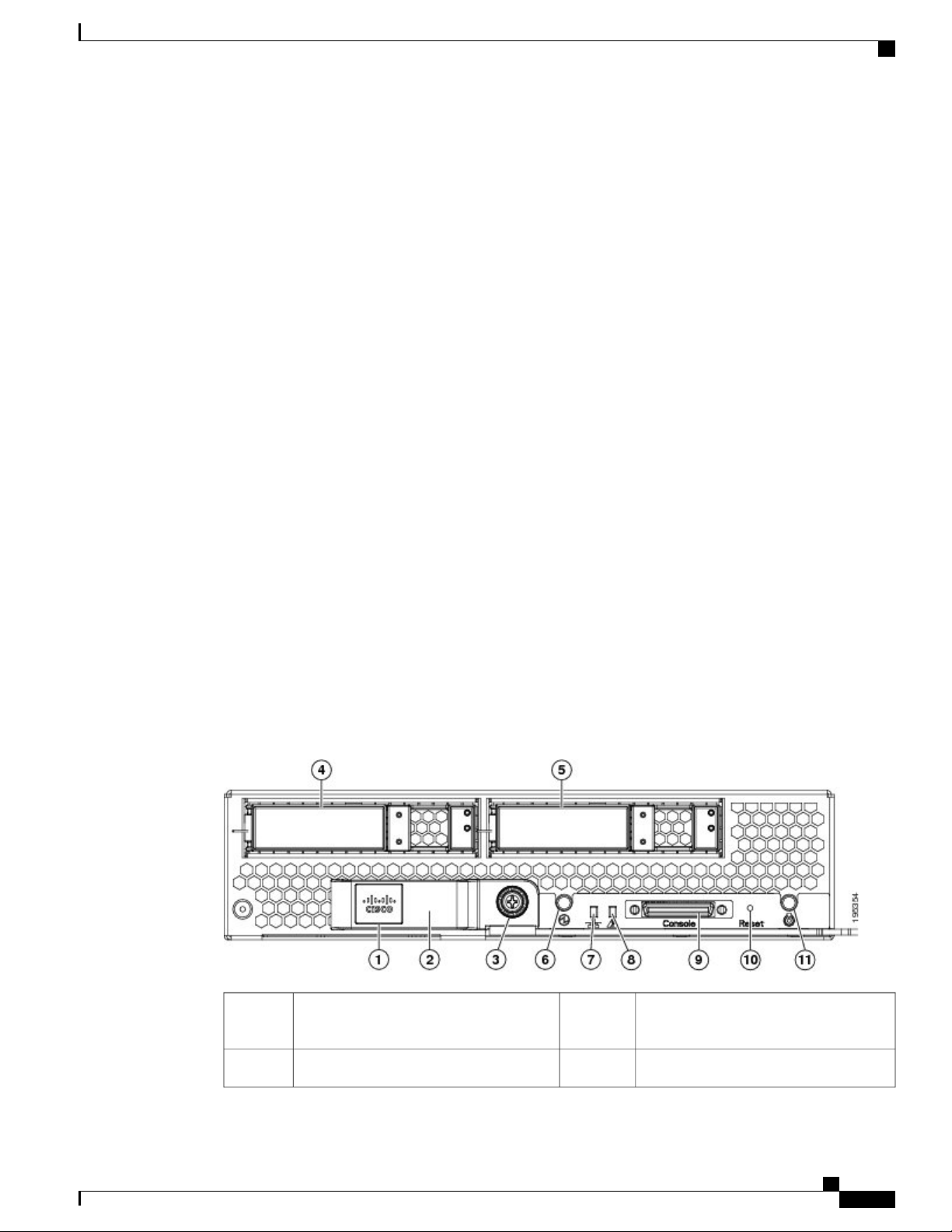

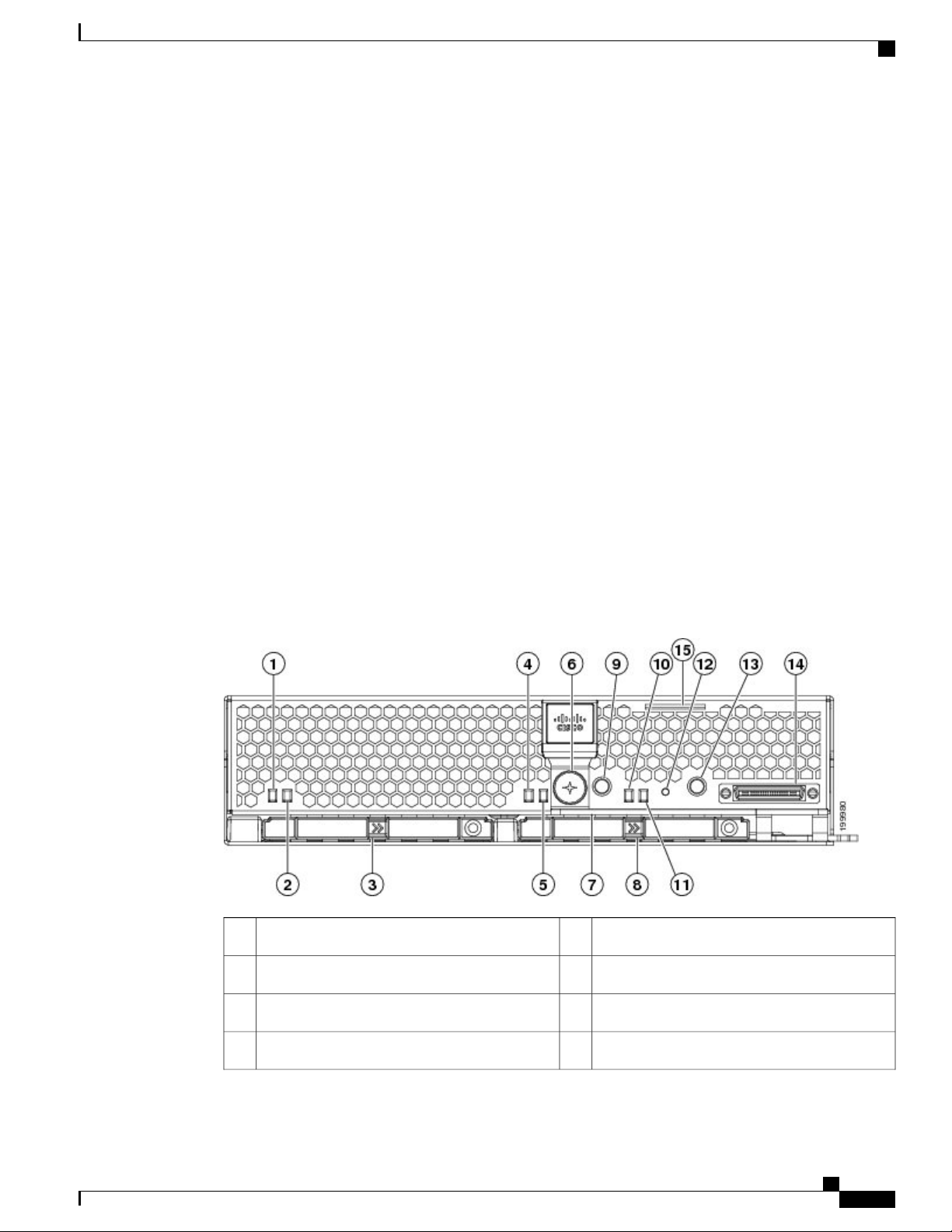

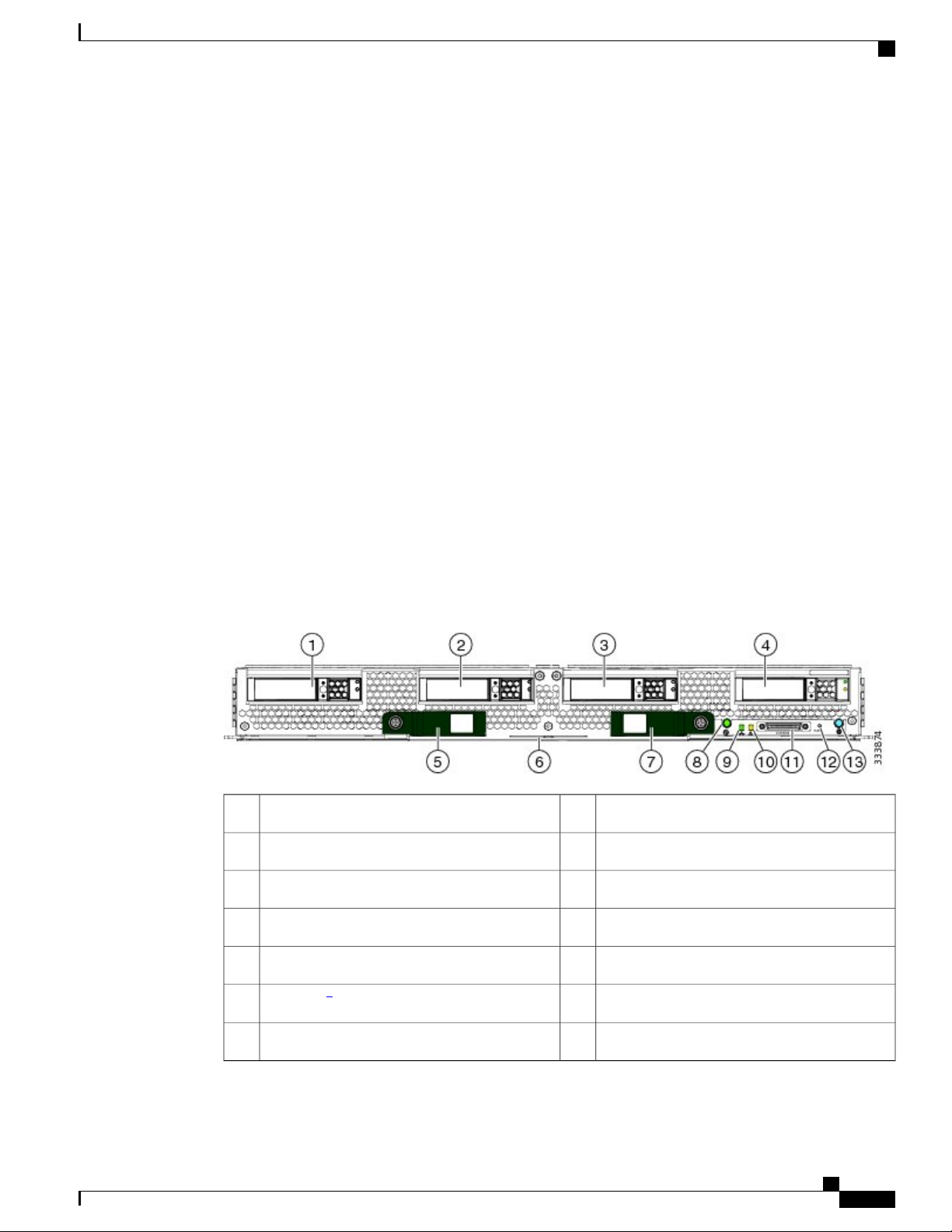

Figure 1: Cisco UCS B200 M1 and M2

1

numbers

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 5

Network link status LED7Paper tab for server name or serial

Blade health LED8Blade ejector handle2

Page 18

Blade Servers

LEDs

Overview

Console connector9Ejector captive screw3

Reset button access10Hard drive bay 14

Beaconing LED and button11Hard drive bay 25

Power button and LED6

The LED indicators indicate whether the blade server is in active or standby mode, the status of the network

link, the over all health of the blade server, and whether the server is set to give a flashing blue beaconing

indication. See Interpreting LEDs, on page 25 for details.

The removable hard disks also have LEDs indicating hard disk access activity and hard disk health.

Buttons

Connectors

The Reset button is just inside the chassis and must be pressed using the tip of a paper clip or a similar item.

Hold the button down for five seconds and then release it to restart the server if other methods of restarting

are not working.

The beaconing function for an individual server may get turned on or off by pressing the combination button

and LED. See Interpreting LEDs, on page 25 for details.

The power button and LED allows you to manually take a server temporarily out of service but leave it in a

state where it can be restarted quickly.

A console port gives a direct connection to a blade server to allow operating system installation and other

management tasks to be done directly rather than remotely. The port uses the KVM dongle device included

in the chassis accessory kit. See KVM Cable, on page 69 for more information.

Cisco UCS 5108 Server Chassis Installation Guide

6 OL-20035-05

Page 19

Overview

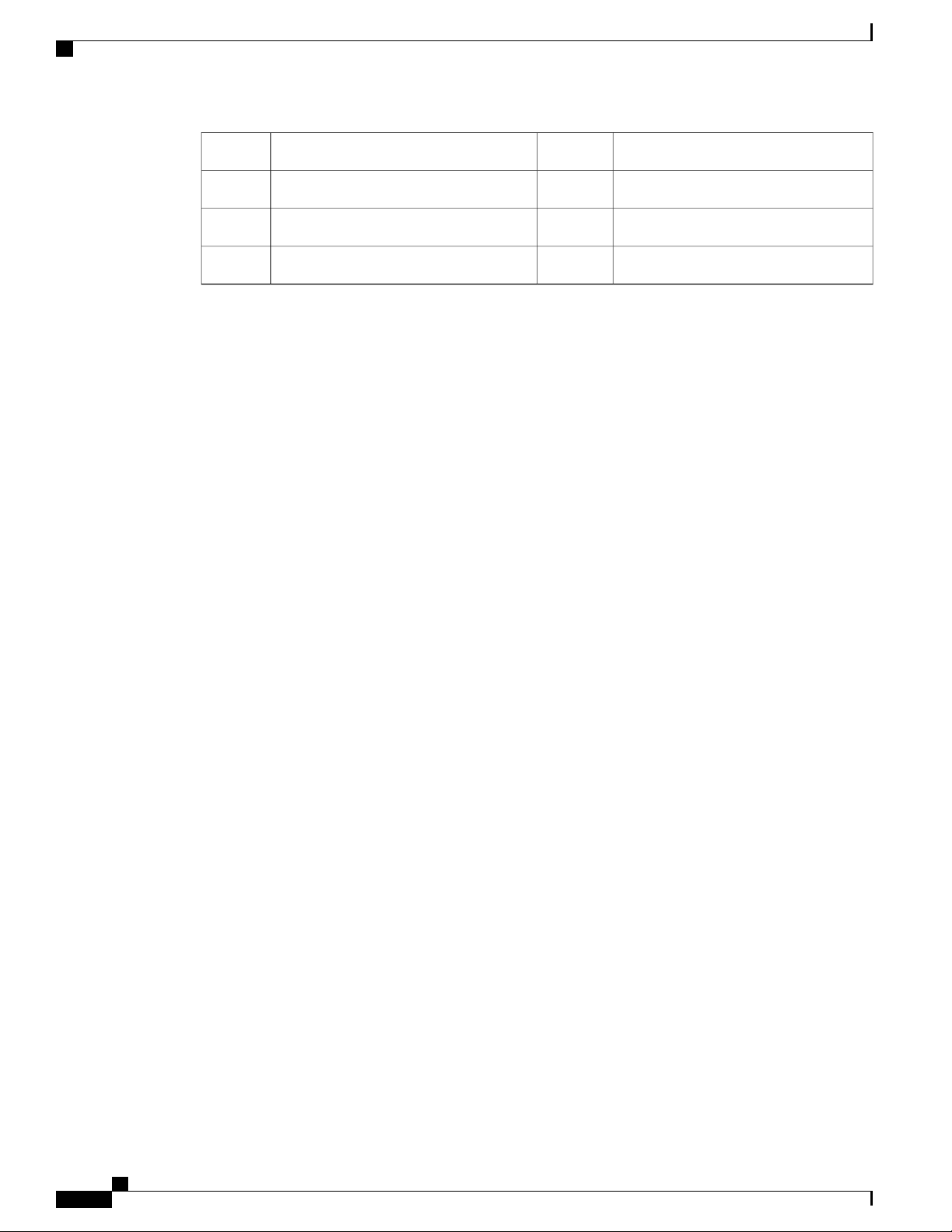

Cisco UCS B200 M3 Blade Servers

For full service and installation instructions, see the Cisco UCS B200 M3 Blade Server Installation and Service

Note. You can install up to eight UCS B200 M3 Blade Servers to a chassis.

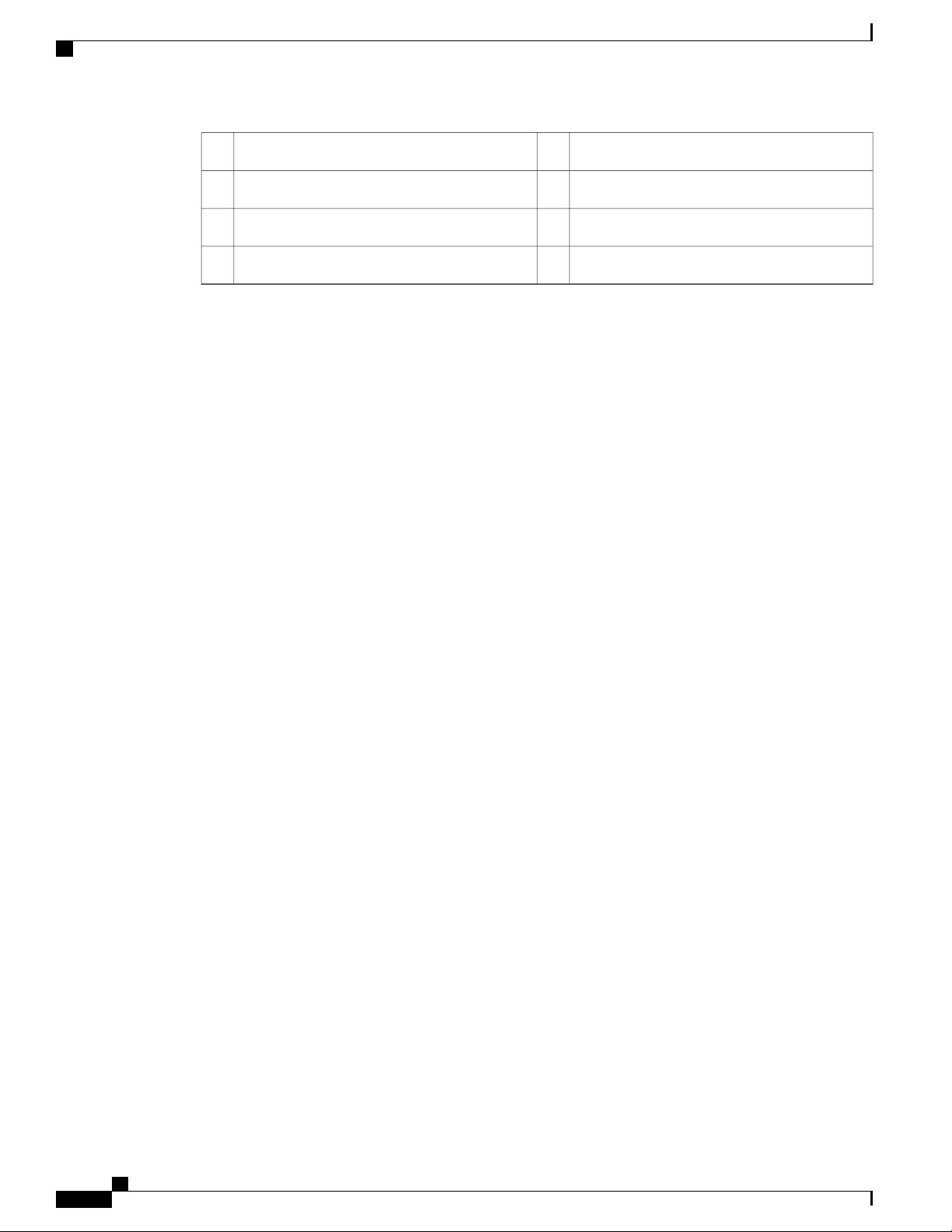

Figure 2: Cisco UCS B200 M3

Blade Servers

1

1

Network link status LED7Asset Tag

Blade health LED8Blade ejector handle2

Console connector9Ejector captive screw3

Reset button access10Hard drive bay 14

Beaconing LED and button11Hard drive bay 25

Power button and LED6

1

Each server has a blank plastic tag that pulls out of the front panel which is provided so that you can add your own asset tracking label without interfering with

the intended air flow.

LEDs

The LED indicators indicate whether the blade server is in active or standby mode, the status of the network

link, the over all health of the blade server, and whether the server is set to give a flashing blue beaconing

indication. See Interpreting LEDs, on page 25 for details.

The removable hard disks also have LEDs indicating hard disk access activity and hard disk health.

Buttons

The Reset button is just inside the chassis and must be pressed using the tip of a paper clip or a similar item.

Hold the button down for five seconds and then release it to restart the server if other methods of restarting

are not working.

The beaconing function for an individual server may get turned on or off by pressing the combination button

and LED. See Interpreting LEDs, on page 25 for details.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 7

Page 20

Blade Servers

The power button and LED allows you to manually take a server temporarily out of service but leave it in a

state where it can be restarted quickly.

Connectors

A console port gives a direct connection to a blade server to allow operating system installation and other

management tasks to be done directly rather than remotely. The port uses the KVM dongle device included

in the chassis accessory kit. See KVM Cable, on page 69 for more information.

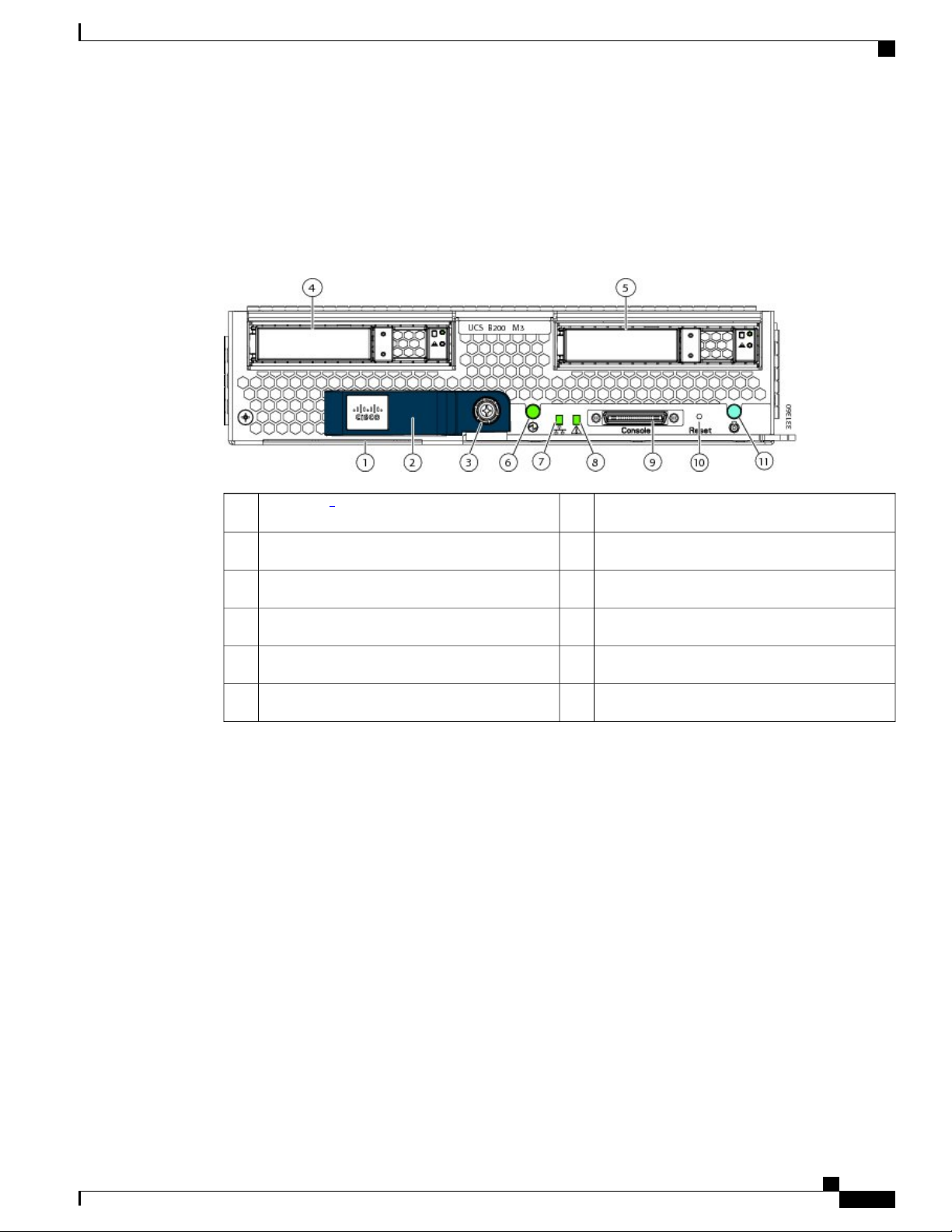

Cisco UCS B22 M3 Blade Servers

For full service and installation instructions, see the Cisco UCS B22 Blade Server Installation and Service

Note. You can install up to eight UCS B22 M3 Blade Servers to a chassis.

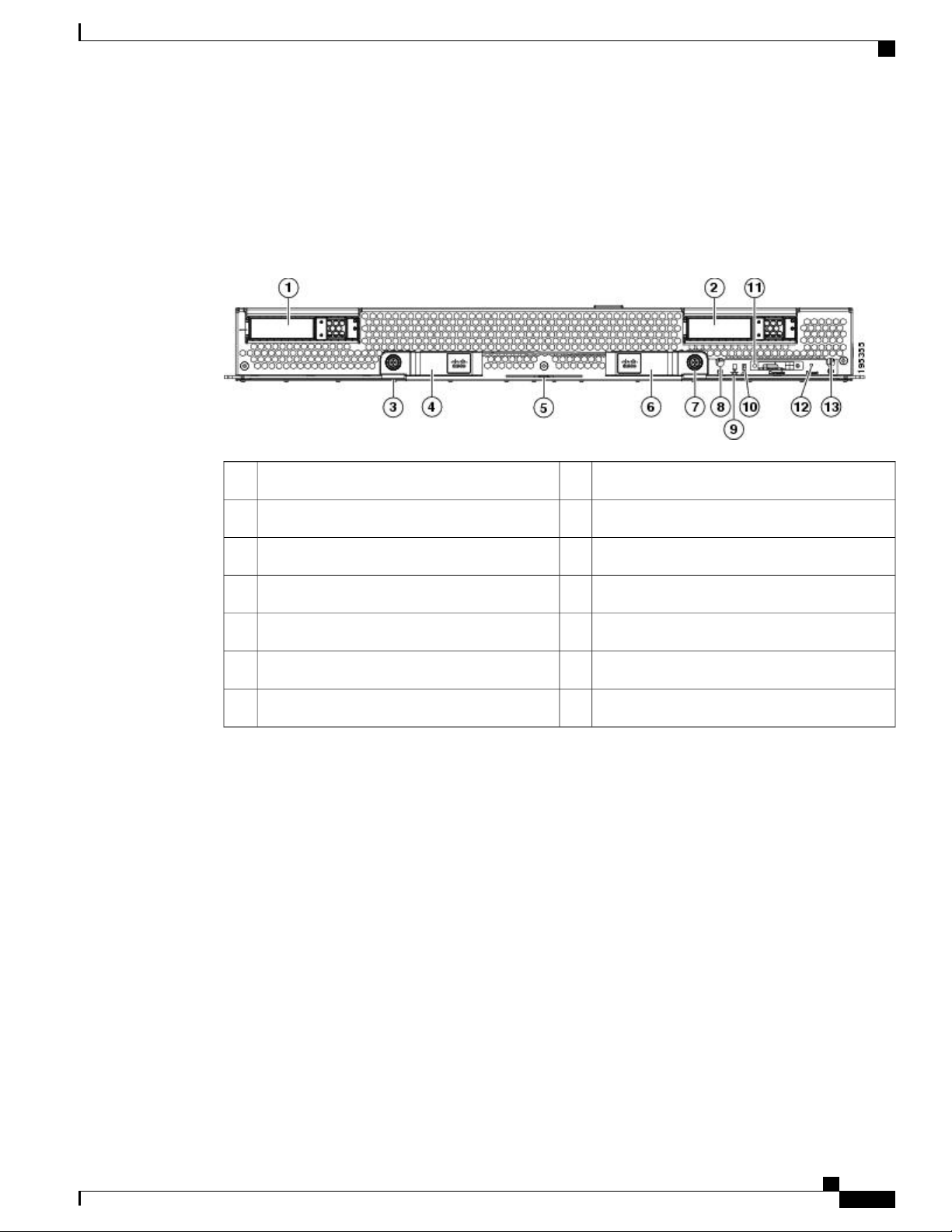

Figure 3: Cisco UCS B22 M3

Overview

1

2

Network link status LED7Asset tag

Blade health LED8Blade ejector handle2

Console connector9Ejector captive screw3

Reset button access10Hard drive bay 14

Beaconing LED and button11Hard drive bay 25

Power button and LED6

2

Each server has a blank plastic asset tag that pulls out of the front panel, provided so you can add your own asset tracking label without interfering with the

intended air flow.

LEDs

The LED indicators indicate whether the blade server is in active or standby mode, the status of the network

link, the over all health of the blade server, and whether the server is set to give a flashing blue beaconing

indication. See Interpreting LEDs, on page 25 for details.

Cisco UCS 5108 Server Chassis Installation Guide

8 OL-20035-05

Page 21

Overview

Buttons

Connectors

Blade Servers

The removable hard disks also have LEDs indicating hard disk access activity and hard disk health.

The Reset button is just inside the chassis and must be pressed using the tip of a paper clip or a similar item.

Hold the button down for five seconds and then release it to restart the server if other methods of restarting

are not working.

The beaconing function for an individual server may get turned on or off by pressing the combination button

and LED. See Interpreting LEDs, on page 25 for details.

The power button and LED allows you to manually take a server temporarily out of service but leave it in a

state where it can be restarted quickly.

A console port gives a direct connection to a blade server to allow operating system installation and other

management tasks to be done directly rather than remotely. The port uses the KVM dongle device included

in the chassis accessory kit. See KVM Cable, on page 69 for more information.

Cisco UCS B230 Blade Servers

For full service and installation instructions, see the Cisco UCS B230 Blade Server Installation and Service

Note. You can install up to eight UCS B230 Blade Servers to a chassis.

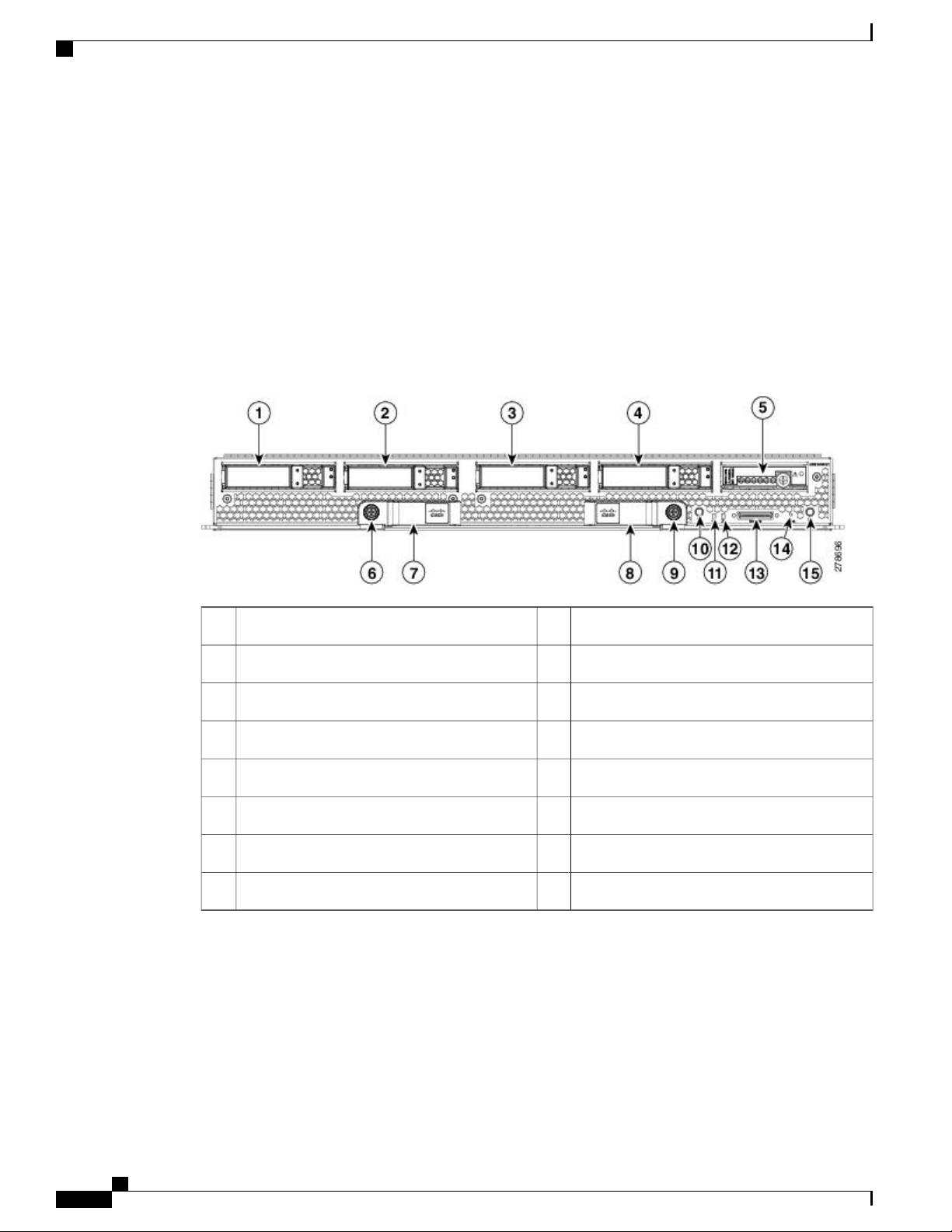

Figure 4: Cisco UCS B230 (N20-B6730) Front Panel

Beaconing LED and button9SSD 1 Activity LED1

System Activity LED10SSD 1 Fault/Locate LED2

Blade health LED11SSD sled in Bay 13

Reset button access12SSD 2 Activity4

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 9

Page 22

Blade Servers

LEDs

Overview

Power button and LED13SSD 2 Fault LED5

Console connector14Ejector lever captive screw6

Asset tag15Ejector lever7

SSD sled in Bay 18

The LED indicators indicate whether the blade server is in active or standby mode, the status of the network

link, the over all health of the blade server, and whether the server is set to give a flashing blue beaconing

indication. See Interpreting LEDs, on page 25 for details.

The removable hard disks also have LEDs indicating hard disk access activity and hard disk health.

Buttons

Connectors

The Reset button is just inside the chassis and must be pressed using the tip of a paper clip or a similar item.

Hold the button down for five seconds and then release it to restart the server if other methods of restarting

are not working.

The beaconing function for an individual server may get turned on or off by pressing the combination button

and LED. See Interpreting LEDs, on page 25 for details.

The power button and LED allows you to manually take a server temporarily out of service but leave it in a

state where it can be restarted quickly.

A console port gives a direct connection to a blade server to allow operating system installation and other

management tasks to be done directly rather than remotely. The port uses the KVM dongle device included

in the chassis accessory kit. See KVM Cable, on page 69 for more information.

Cisco UCS 5108 Server Chassis Installation Guide

10 OL-20035-05

Page 23

Overview

Cisco UCS B250 Blade Servers

For full service and installation instructions, see the Cisco UCS B250 Blade Server Installation and Service

Note.

Figure 5: Cisco UCS B250

Blade Servers

Power button and LED8Hard drive bay 11

LEDs

Buttons

Network link status LED9Hard drive bay 22

Blade health LED10Left ejector captive screw3

Console connector11Left blade ejector handle4

Reset button access12Paper tab for server name or serial numbers5

Beaconing LED and button13Right blade ejector handle6

Right ejector captive screw7

The LED indicators indicate whether the blade server is in active or standby mode, the status of the network

link, the over all health of the blade server, and whether the server is set to give a flashing blue beaconing

indication. See Interpreting LEDs, on page 25 for details.

The removable hard disks also have LEDs indicating hard disk access activity and hard disk health.

The Reset button is just inside the chassis and must be pressed using the tip of a paper clip or a similar item.

Hold the button down for five seconds and then release it to restart the server if other methods of restarting

are not working.

The beaconing function for an individual server may get turned on or off by pressing the combination button

and LED. See Interpreting LEDs, on page 25 for details.

The power button and LED allows you to manually take a server temporarily out of service but leave it in a

state where it can be restarted quickly.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 11

Page 24

Blade Servers

Connectors

A console port gives a direct connection to a blade server to allow operating system installation and other

management tasks to be done directly rather than remotely. The port uses the KVM dongle device included

in the chassis accessory kit. See KVM Cable, on page 69 for more information.

Cisco UCS B440 Blade Servers

For full service and installation instructions, see the Cisco UCS B440 High Performance Blade Server

Installation and Service Note.

Figure 6: Cisco UCS B440

Overview

LEDs

Right ejector thumbscrew9Hard drive bay 11

Power button and LED10Hard drive bay 22

Network link status LED11Hard drive bay 33

Blade health LED12Hard drive bay 44

Local console connection13RAID battery backup module (BBU)5

Reset button access14Left ejector thumbscrew6

Locate button and LED15Left ejector handle7

Right ejector handle8

The LED indicators indicate whether the blade server is in active or standby mode, the status of the network

link, the over all health of the blade server, and whether the server is set to give a flashing blue beaconing

indication. See Interpreting LEDs, on page 25 for details.

The removable hard disks also have LEDs indicating hard disk access activity and hard disk health.

Cisco UCS 5108 Server Chassis Installation Guide

12 OL-20035-05

Page 25

Overview

Buttons

Connectors

Cisco UCS B420 M3 High Performance Blade Server

The Reset button is just inside the chassis and must be pressed using the tip of a paper clip or a similar item.

Hold the button down for five seconds and then release it to restart the server if other methods of restarting

are not working.

The beaconing function for an individual server may get turned on or off by pressing the combination button

and LED. See Interpreting LEDs, on page 25 for details.

The power button and LED allows you to manually take a server temporarily out of service but leave it in a

state where it can be restarted quickly.

A console port gives a direct connection to a blade server to allow operating system installation and other

management tasks to be done directly rather than remotely. The port uses the KVM dongle device included

in the chassis accessory kit. See KVM Cable, on page 69 for more information.

Cisco UCS B420 M3 High Performance Blade Server

For full service and installation instructions, see the Cisco UCS B420 M3 High Performance Blade Server

Installation and Service Note. You can install up to four UCS B420 M3 High Performance Blade Servers to

a chassis.

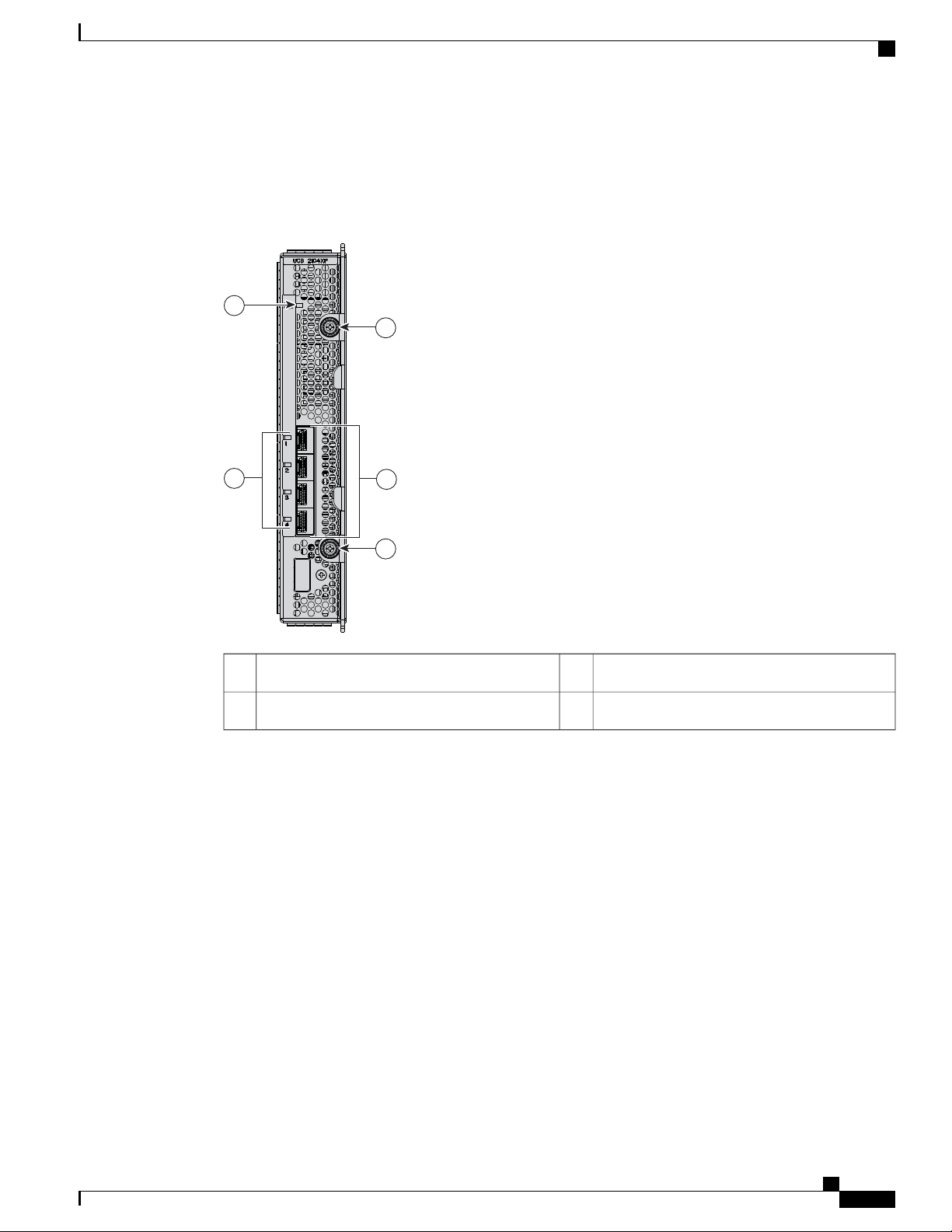

Figure 7: Cisco UCS B420 M3

Power button and LED8Hard drive bay 11

Network link status LED9Hard drive bay 22

Blade health LED10Hard drive bay 33

Console connector11Hard drive bay 44

Reset button access12Left ejector handle5

6

3

Beaconing LED and button13Asset tag

Right ejector handle7

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 13

Page 26

Overview

Adapter Cards

3

Each server has a blank plastic asset tag that pulls out of the front panel, provided so you can add your own asset tracking label without interfering with the

intended air flow.

LEDs

The LED indicators indicate whether the blade server is in active or standby mode, the status of the network

link, the over all health of the blade server, and whether the server is set to give a flashing blue beaconing

indication. See Interpreting LEDs, on page 25 for details.

The removable hard disks also have LEDs indicating hard disk access activity and hard disk health.

Buttons

The Reset button is just inside the chassis and must be pressed using the tip of a paper clip or a similar item.

Hold the button down for five seconds and then release it to restart the server if other methods of restarting

are not working.

The beaconing function for an individual server may get turned on or off by pressing the combination button

and LED. See Interpreting LEDs, on page 25 for details.

The power button and LED allows you to manually take a server temporarily out of service but leave it in a

state where it can be restarted quickly.

Connectors

A console port gives a direct connection to a blade server to allow operating system installation and other

management tasks to be done directly rather than remotely. The port uses the KVM dongle device included

in the chassis accessory kit. See KVM Cable, on page 69 for more information.

Adapter Cards

Depending on the model of server in question, one to three adapter cards will reside in each blade server,

providing failover connectivity to each FEX in the chassis. The following models are available, and others

are released on an ongoing basis:

Cisco UCS Virtual Interface Card 1280

The Cisco UCS Virtual Interface Card 1280 (UCS-VIC-M82-8P) is an eight-port 10 Gigabit Ethernet, Fibre

Channel over Ethernet (FCoE)-capable mezzanine card designed exclusively for Cisco UCS B-Series Blade

Servers. The card enables a policy-based, stateless, agile server infrastructure that can present up to 256 PCIe

standards-compliant interfaces to the host that can be dynamically configured as either network interface cards

(NICs) or host bus adapters (HBAs). In addition, the Cisco UCS Virtual Interface Card 1280 supports Cisco

Virtual Machine Fabric Extender (VM-FEX) technology, which extends the Cisco UCS Fabric Interconnect

ports to virtual machines, simplifying server virtualization deployment.

Cisco UCS M81KR Virtual Interface Card

The Cisco UCS M81KR Virtual Interface Card is a virtualization-optimized Fibre Channel over Ethernet

(FCoE) adapter card. The virtual interface card is a dual-port 10 Gigabit Ethernet adapter card that supports

Cisco UCS 5108 Server Chassis Installation Guide

14 OL-20035-05

Page 27

Overview

Adapter Cards

up to 128 Peripheral Component Interconnect Express (PCIe) standards-compliant virtual interfaces that can

be dynamically configured so that both their interface type (network interface card [NIC] or host bus adapter

[HBA]) and identity (MAC address and worldwide name [WWNN]) are established using just-in-time

provisioning. In addition, the Cisco UCS M81KR supports network interface virtualization and Cisco VN-Link

technology.

The Cisco UCS M81KR is designed for both traditional operating system and virtualization environments. It

is optimized for virtualized environments, for organizations that seek increased mobility in their physical

environments, and for data centers that want reduced TCO through NIC, HBA, cabling, and switch reduction.

The Cisco UCS M81KR presents up to 128 virtual interfaces to the operating system on a given blade. The

128 virtual interfaces can be dynamically configured by Cisco UCS Manager as either Fibre Channel or

Ethernet devices. Deployment of applications using multiple Ethernet and Fibre Channel interfaces is no

longer constrained by the available physical adapters. To an operating system or a hypervisor running on a

Cisco UCS B-Series Blade Server, the virtual interfaces appear as regular PCIe devices.

The Cisco UCS M81KR has built-in architectural support enabling the virtual machine to directly access the

adapter. I/O bottlenecks and memory performance can be improved by providing virtual machines direct

access to hardware I/O devices, eliminating the overhead of embedded software switches.

The Cisco UCS M81KR also brings adapter consolidation to physical environments. The adapter can be

defined as multiple different NICs and HBAs. For example, one adapter card can replace two quad-port NICs

and two single-port HBAs, resulting in fewer NICs, HBAs, switches, and cables.

Cisco UCS 82598KR-CI 10 Gigabit Ethernet Adapter

The Cisco UCS 82598KR-CI 10 Gigabit Ethernet adapter is based on the Intel 82598 10 Gigabit Ethernet

controller, which is designed for efficient high-performance Ethernet transport. It provides a solution for data

center environments that need low-latency 10 Gigabit Ethernet transport capability, and a dual-port connection

to the midplane of the blade server chassis.

The Cisco UCS 82598KR-CI supports Intel Input/Output Acceleration Technology (I/OAT) as well as virtual

queues for I/O virtualization. The adapter is energy efficient and can also help reduce CPU utilization by

providing large segment offload (LSO) and TCP segmentation offload (TSO). The Cisco UCS 82598KR-CI

uses Intel Virtual Machine Device Queue (VMDq) technology for the efficient routing of packets to the

appropriate virtual machine.

Cisco UCS M71KR-E Emulex Converged Network Adapter

The Cisco UCS M71KR-E Emulex Converged Network Adapter (CNA) is an Emulex-based Fibre Channel

over Ethernet (FCoE) adapter card that provides connectivity for Cisco UCS B-Series Blade Servers in the

Cisco Unified Computing System.

Designed specifically for the Cisco UCS blades, the adapter provides a dual-port connection to the midplane

of the blade server chassis. The Cisco UCS M71KR-E uses an Intel 82598 10 Gigabit Ethernet controller for

network traffic and an Emulex 4-Gbps Fibre Channel controller for Fibre Channel traffic all on the same

adapter card. The Cisco UCS M71KR-E presents two discrete Fibre Channel host bus adapter (HBA) ports

and two Ethernet network ports to the operating system.

The Cisco UCS M71KR-E provides both 10 Gigabit Ethernet and 4-Gbps Fibre Channel functions using

drivers from Emulex, providing:

Compatibility with current Emulex adapter-based SAN environments and drivers

•

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 15

Page 28

Adapter Cards

Consolidation of LAN and SAN traffic over the same adapter card and fabric, reducing the overall

•

number of network interface cards (NICs), HBAs, cables, and switches

Integrated management with Cisco UCS Manager

•

Cisco UCS M71KR-Q QLogic Converged Network Adapter

The Cisco UCS M71KR-Q QLogic Converged Network Adapter (CNA) is a QLogic-based Fibre Channel

over Ethernet (FCoE) adapter card that provides connectivity for Cisco UCS B-Series Blade Servers in the

Cisco Unified Computing System.

Designed specifically for the Cisco UCS blades, the adapter provides a dual-port connection to the midplane

of the blade server chassis. The Cisco UCS M71KR-Q uses an Intel 82598 10 Gigabit Ethernet controller for

network traffic and a QLogic 4-Gbps Fibre Channel controller for Fibre Channel traffic, all on the same adapter

card. The Cisco UCS M71KR-Q presents two discrete Fibre Channel host bus adapter (HBA) ports and two

Ethernet network ports to the operating system.

The Cisco UCS M71KR-Q provides both 10 Gigabit Ethernet and 4-Gbps Fibre Channel functions using

drivers from QLogic, providing:

Overview

Compatibility with current QLogic adapter-based SAN environments and drivers

•

Consolidation of LAN and SAN traffic over the same adapter card and fabric, reducing the overall

•

number of network interface cards (NICs), HBAs, cables, and switches

Integrated management with Cisco UCS Manager

•

Cisco UCS 5108 Server Chassis Installation Guide

16 OL-20035-05

Page 29

4

4

1

2

3

237201

Overview

Cisco UCS 2104XP FEXes

Figure 8: Cisco UCS 2104 IO Module

Cisco UCS 2104XP FEXes

Connection ports (to the fabric interconnect)3Fabric extender status indicator LED1

Captive screws for the insertion latches4Link status indicator LEDs2

Cisco UCS 2100 Series FEXes bring the unified fabric into the blade server enclosure, providing 10 Gigabit

Ethernet connections between blade servers and the fabric interconnect, simplifying diagnostics, cabling, and

management.

The Cisco UCS 2104 (N20-I6584) extends the I/O fabric between the fabric interconnects and the Cisco UCS

5100 Series Blade Server Chassis, enabling a lossless and deterministic Fibre Channel over Ethernet (FCoE)

fabric to connect all blades and chassis together. Because the FEX is similar to a distributed line card, it does

not do any switching and is managed as an extension of the fabric interconnects. This approach removes

switching from the chassis, reducing overall infrastructure complexity and enabling the Cisco Unified

Computing System to scale to many chassis without multiplying the number of switches needed, reducing

TCO and allowing all chassis to be managed as a single, highly available management domain.

The Cisco 2100 Series also manages the chassis environment (the power supply and fans as well as the blades)

in conjunction with the fabric interconnect. Therefore, separate chassis management modules are not required.

Cisco UCS 2100 Series FEXes fit into the back of the Cisco UCS 5100 Series chassis. Each Cisco UCS 5100

Series chassis can support up to two FEXes, enabling increased capacity as well as redundancy.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 17

Page 30

1

2

4

4

3

237200

Cisco UCS 2200 Series FEXes

LEDs

There are port activity LEDs and an LED that indicates connectivity to the servers in the chassis.

Buttons

No buttons are on the FEX.

Connectors

I/O ports support SFP+ 10 Gb Ethernet connections. There is also a console connection for use by Cisco

diagnostic technicians. It is not intended for customer use.

Cisco UCS 2200 Series FEXes

Overview

Figure 9: Cisco UCS 2208 FEX (UCS-IOM-2208XP)

Connection ports (to the fabric interconnect)3Fabric extender status indicator LED1

Captive screws for the insertion latches4Link status indicator LEDs2

18 OL-20035-05

Cisco UCS 5108 Server Chassis Installation Guide

Page 31

4

4

1

2

3

237201

Overview

Cisco UCS 2200 Series FEXes

Figure 10: Cisco UCS 2204XP FEX

Connection ports (to the fabric interconnect)3Fabric extender status indicator LED1

Captive screws for the insertion latches4Link status indicator LEDs2

Cisco UCS 2200 Series FEXes bring the unified fabric into the blade server enclosure, providing 10 Gigabit

Ethernet connections between blade servers and the fabric interconnect, simplifying diagnostics, cabling, and

management.

The Cisco UCS 2200 Series extends the I/O fabric between the fabric interconnects and the Cisco UCS 5100

Series Blade Server Chassis, enabling a lossless and deterministic Fibre Channel over Ethernet (FCoE) fabric

to connect all blades and chassis together. Because the FEX is similar to a distributed line card, it does not

do any switching and is managed as an extension of the fabric interconnects. This approach removes switching

from the chassis, reducing overall infrastructure complexity and enabling the Cisco Unified Computing System

to scale to many chassis without multiplying the number of switches needed, reducing TCO and allowing all

chassis to be managed as a single, highly available management domain.

The Cisco 2200 Series also manages the chassis environment (the power supply and fans as well as the blades)

in conjunction with the fabric interconnect. Therefore, separate chassis management modules are not required.

Cisco UCS 2200 Series FEXes fit into the back of the Cisco UCS 5100 Series chassis. Each Cisco UCS 5100

Series chassis can support up to two FEXes, enabling increased capacity as well as redundancy.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 19

Page 32

Power Distribution Unit (PDU)

LEDs

There are port activity LEDs and an LED that indicates connectivity to the servers in the chassis.

Buttons

No buttons are on the FEX.

Connectors

I/O ports support SFP+ 10 Gb Ethernet connections. There is also a console connection for use by Cisco

diagnostic technicians. It is not intended for customer use.

Power Distribution Unit (PDU)

The AC PDU (N01-UAC1) provides load balancing between the installed power supplies, as well as distributing

power to the other chassis components. DC versions of the chassis use a different PDU with appropriate

connectors. The PDU is not field-serviceable, and converting an AC chassis to a DC chassis by swapping the

PDU is not supported, as the PDU is not separately orderable.

Overview

LEDs

Buttons

Connectors

No LEDs are on the PDU.

No buttons are on the PDU.

The AC version of the PDU has four power connectors rated for 15.5 A, 200-240V @ 50-60 Hz. Only use

Cisco approved power cords, different power cords are available for many countries and applications. See for

more information about the supported power cords. See Supported AC Power Cords and Plugs, on page 74

for more information.

The DC version of the PDU has eight dual-post lug power connections, four positive and four negative. A

single dual-post lug grounding connection is also provided.

The AC version of the PDU has four power connectors rated for 15.5 A, 200-240V @ 50-60 Hz. Only use

Cisco approved power cords, different power cords are available for many countries and applications. See for

more information about the supported power cords. See Supported AC Power Cords and Plugs, on page 74

for more information.

The DC version of the PDU has eight dual-post lug power connections, four positive and four negative. A

single dual-post lug grounding connection is also provided.

Cisco UCS 5108 Server Chassis Installation Guide

20 OL-20035-05

Page 33

Overview

Fan Modules

The chassis can accept up to eight fan modules (N20-FAN5). A chassis must have filler plates in place if no

fan will be installed in a slot for an extended period.

LEDs

There is one LED indication of the fan module’s operational state. See Interpreting LEDs, on page 25 for

details.

Buttons and Connectors

No buttons or connectors are on a fan module.

Power Supplies

Fan Modules

Different power supplies are available to work with the AC (N20-PAC5-2500W) or DC

(UCSB-PSU-2500DC48) versions of the chassis. To determine the number of power supplies needed for a

given configuration, use the Cisco UCS Power Calculator tool.

LEDs

Two LEDs indicate power connection presence, power supply operation, and fault states. See Interpreting

LEDs, on page 25 for details.

Buttons

There are no buttons on a power supply.

Connectors

The power connections are at the rear of the chassis on the PDU, with different types for AC or DC input.

Four single-phase, hot-swappable power supplies are accessible from the front of the chassis. These power

supplies can be configured to support non-redundant, N+1 redundant, and grid-redundant configurations.

Power Supply Redundancy

Power supply redundancy functions identically for AC and DC configured systems. When considering power

supply redundancy you need to take several things into consideration:

Power supplies are all single phase and have a single input for connectivity to customer power source

•

(a rack PDU such as the Cisco RP Series PDU or equivalent).

The number of power supplies required to power a chassis varies depending on the following factors:

•

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 21

Page 34

Power Supplies

To configure redundancy, see the Configuration Guide for the version of Cisco UCS Central that you are

using. The configuration guides are available at the following URL: http://www.cisco.com/en/US/products/

ps12502/products_installation_and_configuration_guides_list.html.

Non-redundant Mode

In a non-redundant or combined mode, all installed power supplies are turned on and balance the load evenly.

Smaller configurations (requiring less than 2500 W) can be powered by a single power supply when the system

is using Cisco UCS Release 1.3(1) or earlier releases. However, a single power supply cannot provide

redundancy and if either the power input or power supply fail, the system immediately shuts down. More

common configurations require two or more power supplies (if requirements are between 2500 and 5000 W

peak) in non-redundant mode.

When using Cisco UCS Release 1.4(1) and later releases, the chassis requires a minimum of 2 power supplies.

Overview

The total "Maximum Draw" required to power all the components configured within that

◦

chassis—such as I/O modules, fans, blade servers (CPU and memory configuration of the blade

servers).

The Desired Power Redundancy for the chassis. The supported power configurations are

◦

non-redundant, N+1 redundancy (or any requirement greater than N+1), and grid redundancy.

Note

N+1 Redundancy

In a non-redundant system, power supplies can be in any slot. Installing less than the required number of

power supplies results in undesired behavior such as server blade shutdown. Installing more than the

required amount of power supplies may result in lower power supply efficiency. At most, this mode will

require two power supplies.

The N+1 redundancy configuration implies that the chassis contains a total number of power supplies to satisfy

non-redundancy, plus one additional power supply for redundancy. All the power supplies that are participating

in N+1 redundancy are turned on and equally share the power load for the chassis. If any additional power

supplies are installed, Cisco UCS Manager recognizes these “unnecessary” power supplies and places them

on standby.

If a power supply should fail, the surviving supplies can provide power to the chassis. In addition, UCS

Manager turns on any "turned-off" power supplies to bring the system back to N+1 status.

To provide N+1 protection, the following number of power supplies is recommended:

Three power supplies are recommended if the power configuration for that chassis requires greater than

•

2500 W or if using UCS Release 1.4(1) and later releases

Two power supplies are sufficient if the power configuration for that chassis requires less than 2500 W

•

or the system is using UCS Release 1.3(1) or earlier releases

Adding an additional power supply to either of these configurations will provide an extra level of protection.

Cisco UCS Manager turns on the extra power supply in the event of a failure and restores N+1 protection.

Cisco UCS 5108 Server Chassis Installation Guide

22 OL-20035-05

Page 35

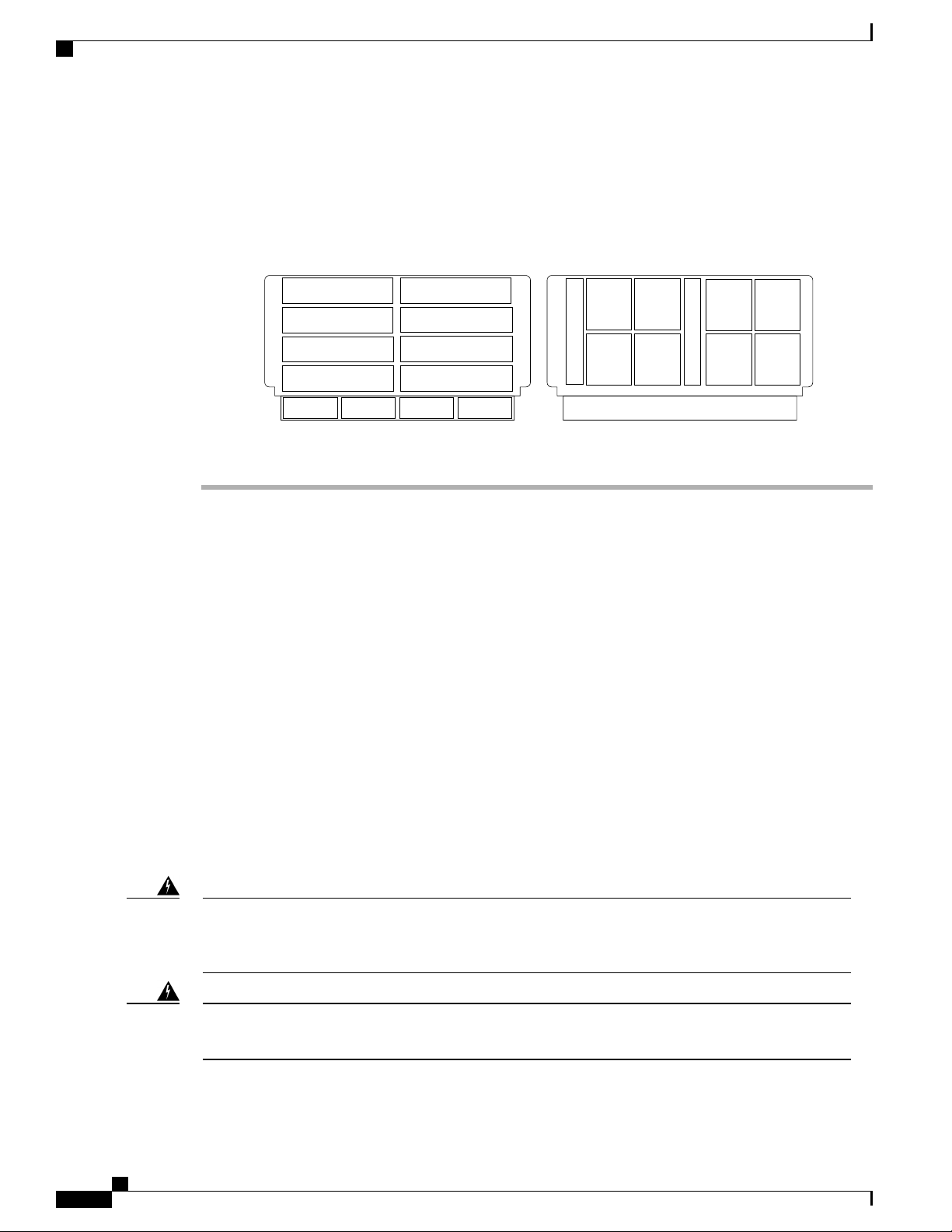

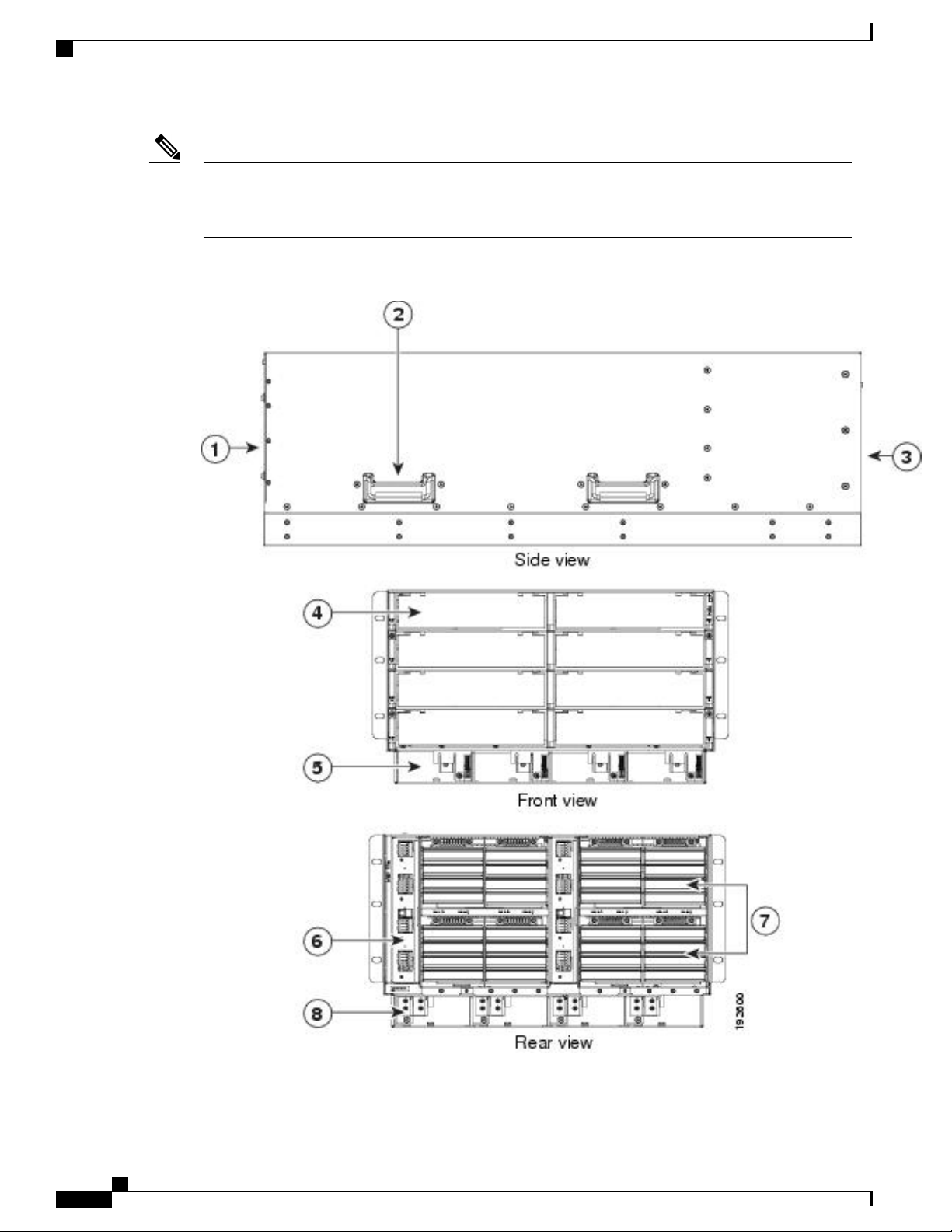

PS 1

PS 2

PS 3

PS 4

Server Slot 1

Server Slot 2

Server Slot 3

Server Slot 5

Server Slot 7

Server Slot 4

Server Slot 6

Server Slot 8

Front

Fan 1

Fan 2

I/O Module Slot 1

I/O Module Slot 2

Connector

PS 4

Connector

PS 3

Connector

PS 2

Connector

PS 1

Fan 6

Fan 5

Fan 4

Fan 3

Fan 8

Fan 7

Rear

279770

Overview

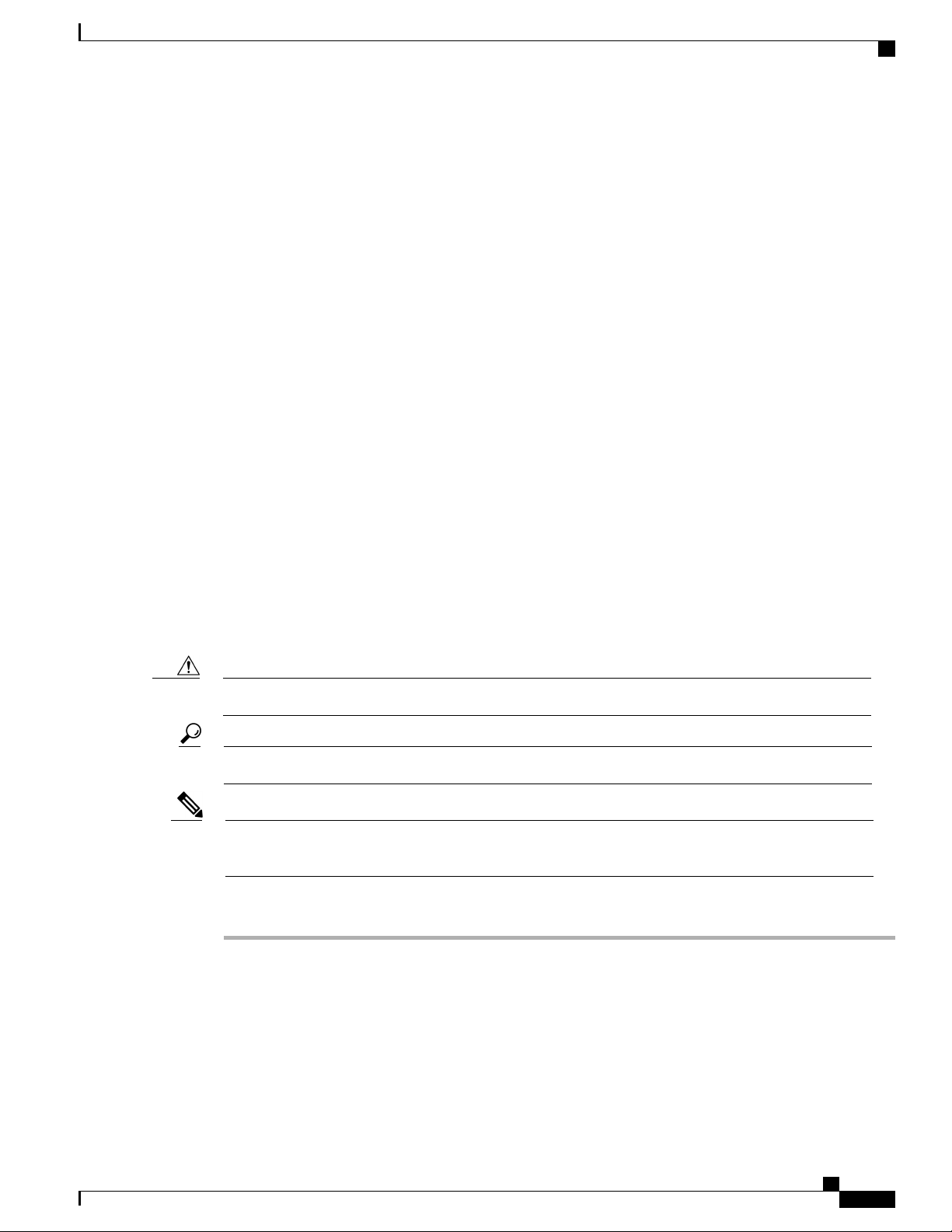

Grid Redundancy

LEDs

An n+1 redundant system has either two or three power supplies, which may be in any slot.Note

The grid redundant configuration is sometimes used when you have two power sources to power a chassis or

you require greater than N+1 redundancy. If one source fails (which causes a loss of power to one or two

power supplies), the surviving power supplies on the other power circuit continue to provide power to the

chassis. A common reason for using grid redundancy is if the rack power distribution is such that power is

provided by two PDUs and you want the grid redundancy protection in the case of a PDU failure.

To provide grid redundant (or greater than N+1) protection, the following number of power supplies is

recommended:

Four power supplies are recommended if the power configuration for that chassis requires greater than

•

2500W or if using Cisco UCS Release 1.4(1) and later releases

Two power supplies are recommended if the power configuration for that chassis requires less than

•

2500W or the system is using Cisco UCS Release 1.3(1) or earlier releases

LEDs

Note

Both grids in a power redundant system should have the same number of power supplies. If your system

is configured for grid redundancy, slots 1 and 2 are assigned to grid 1 and slots 3 and 4 are assigned to

grid 2. If there are only two power supplies (PS) in the a redundant mode chassis, they should be in slots

1 and 3. Slot and cord connection numbering is shown below.

Figure 11: Power Supply Bay and Connector Numbering

LEDs on both the chassis and the modules installed within the chassis identify operational states, both separately

and in combination with other LEDs.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 23

Page 36

192744

LED Locations

LED Locations

Overview

Figure 12: LEDs on a Cisco UCS 5108 Server Chassis—Front View

Figure 13: LEDs on the Cisco UCS 5108 Server Chassis—Rear View

Cisco UCS 5108 Server Chassis Installation Guide

24 OL-20035-05

Page 37

192743

Overview

Interpreting LEDs

Interpreting LEDs

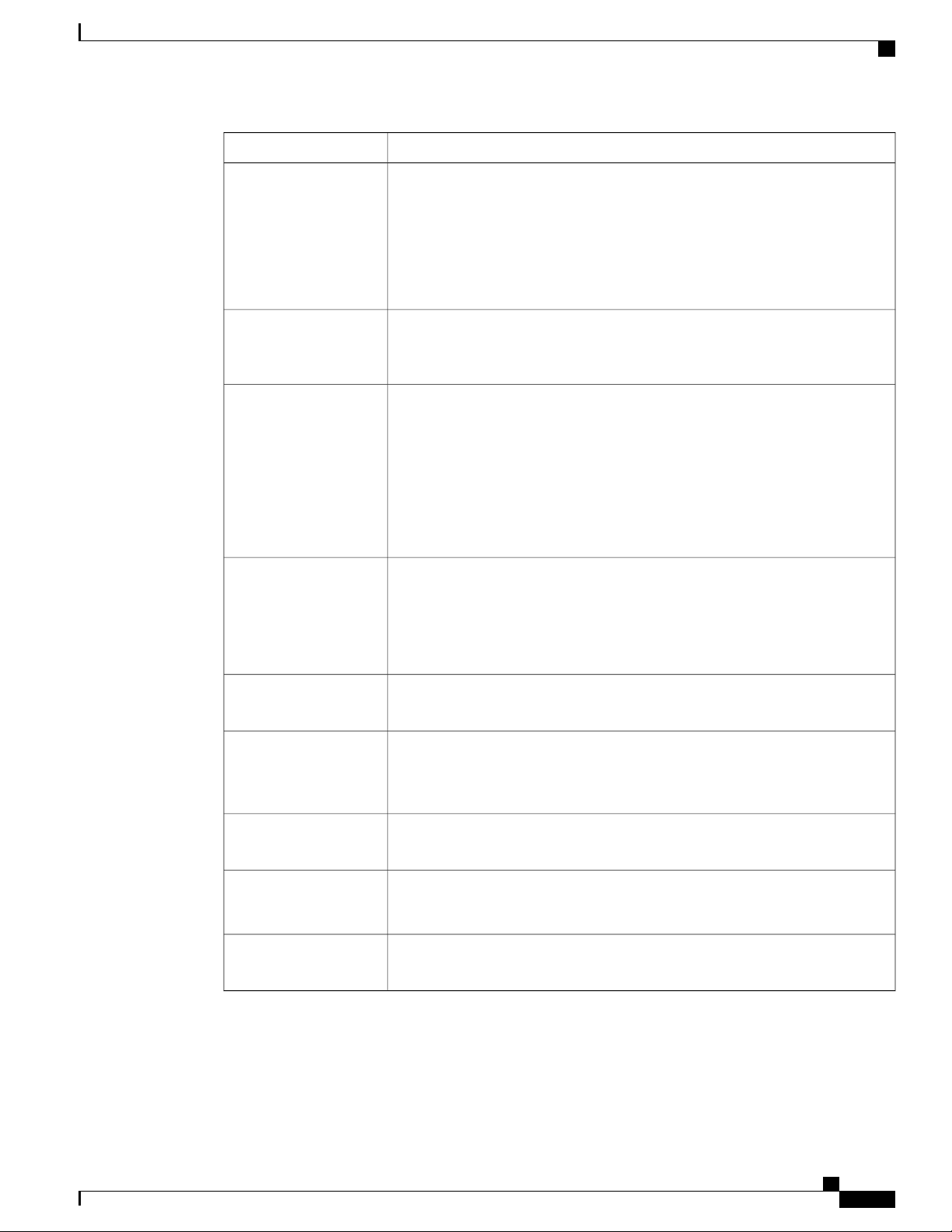

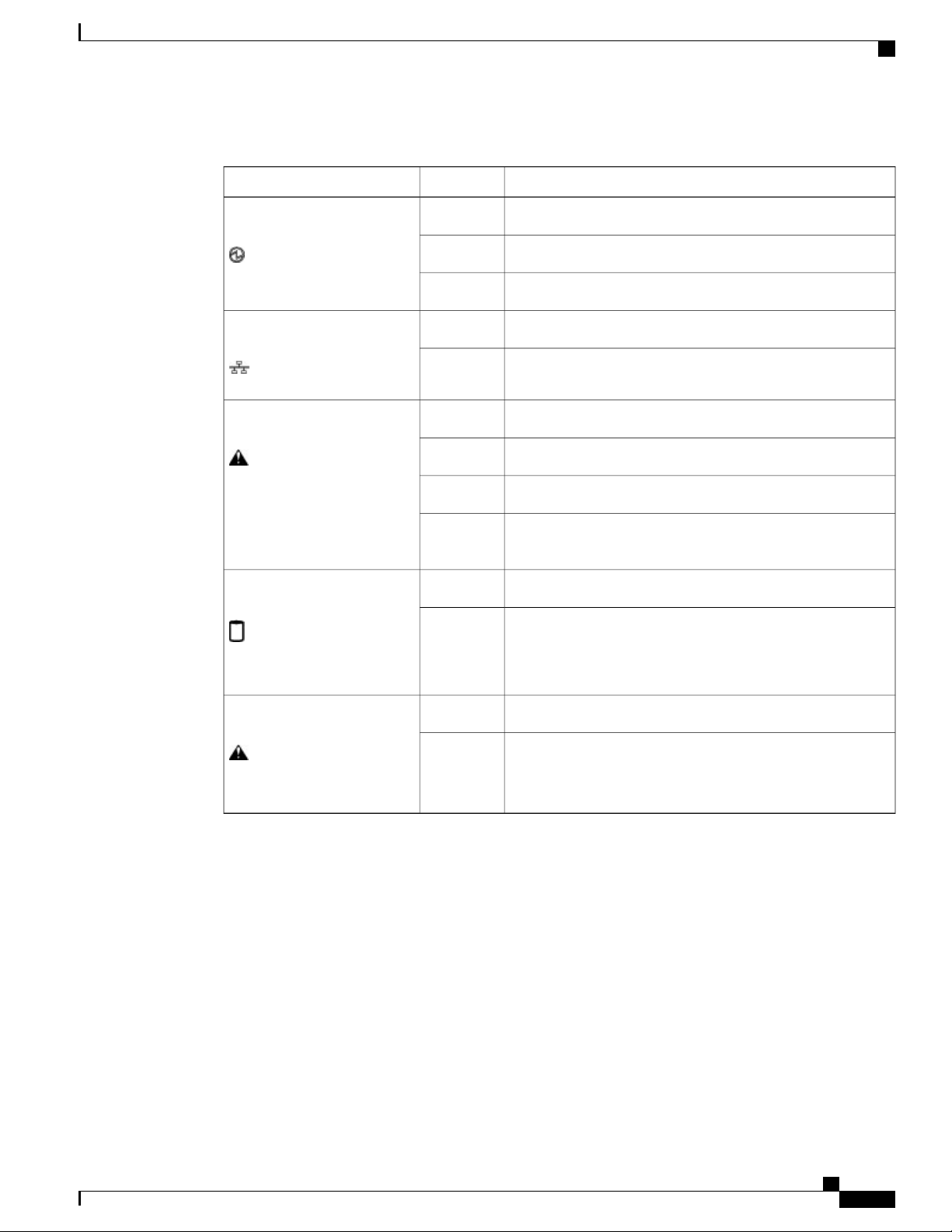

Table 2: Chassis, Fan, and Power Supply LEDs

LED and button

Blinking blue 1 Hz

Amber

Blinking amberChassis health

DescriptionColorLED

Beaconing not enabled.OffBeaconing

Beaconing to locate a selected chassis—If the LED

is not blinking, the chassis is not selected. You

can initiate beaconing in UCS Manager or with

the button.

No power.OffChassis connections

No I/O module is installed or the I/O module is

booting.

Normal operation.Green

Indicates a component failure or a major

over-temperature alarm.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 25

Page 38

Interpreting LEDs

Overview

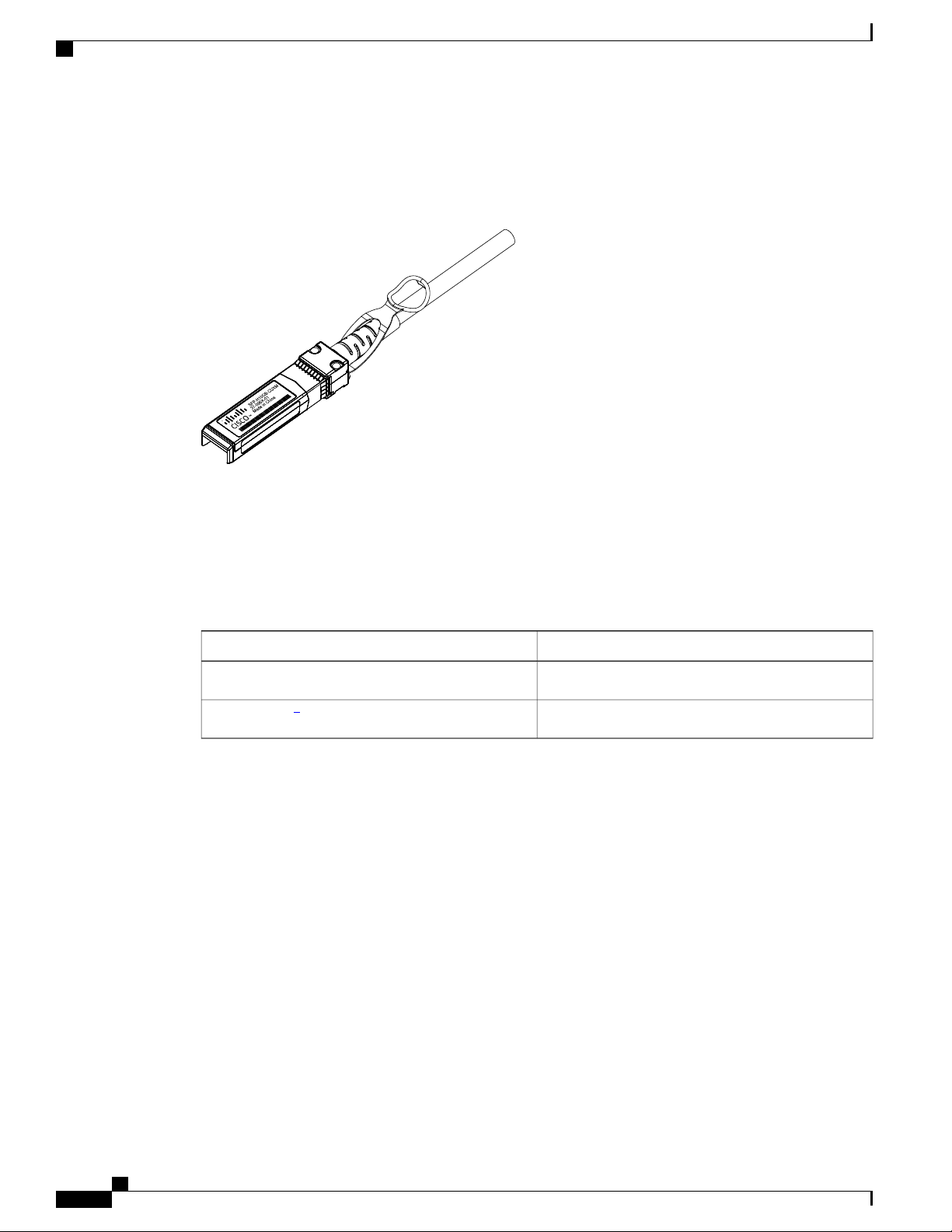

DescriptionColorLED

Power Supply

Table 3: I/O Module LEDs

OffFan Module

Blinking green

No power to the chassis or the fan module was

removed from the chassis.

Fan module restarting.Amber

Normal operation.Green

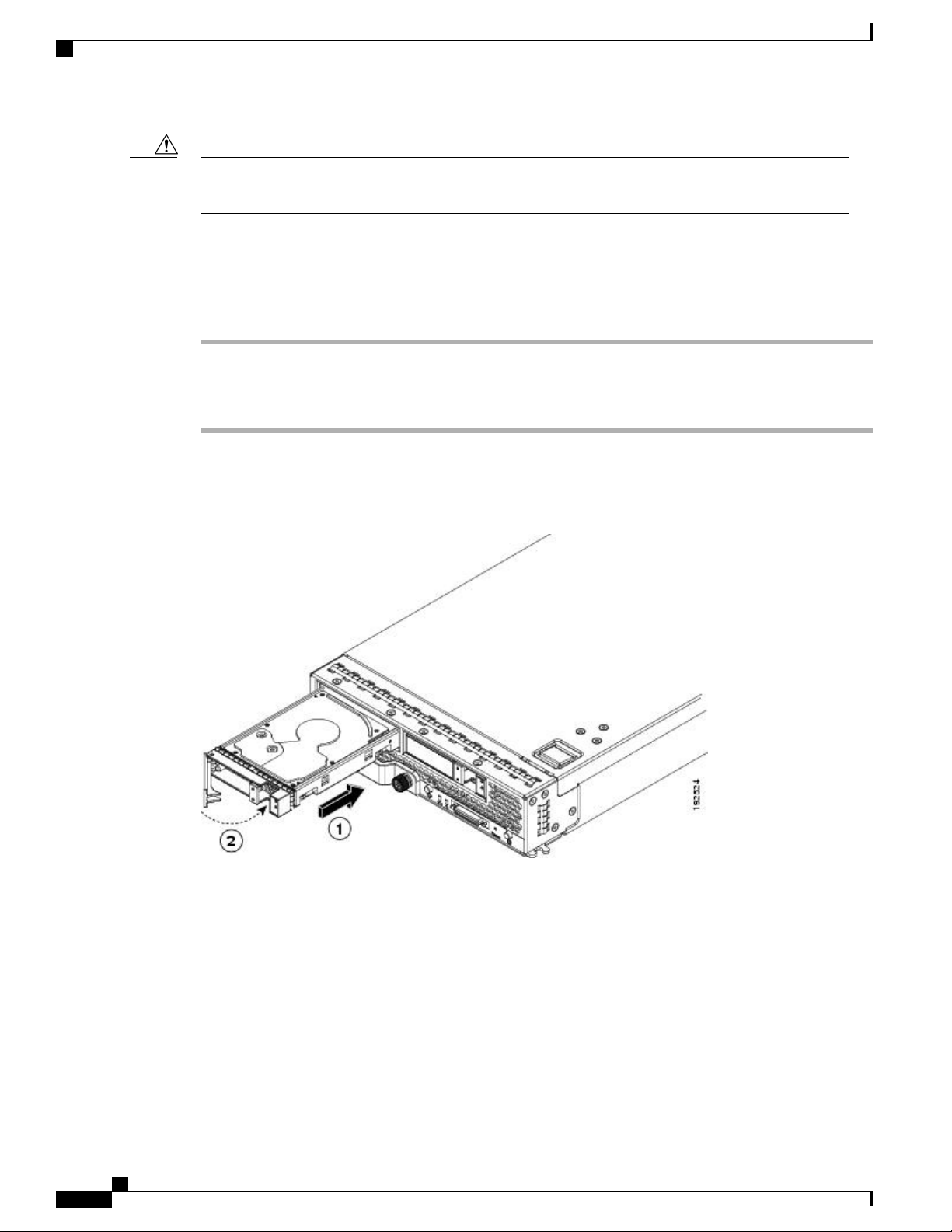

The fan module has failed.Blinking amber

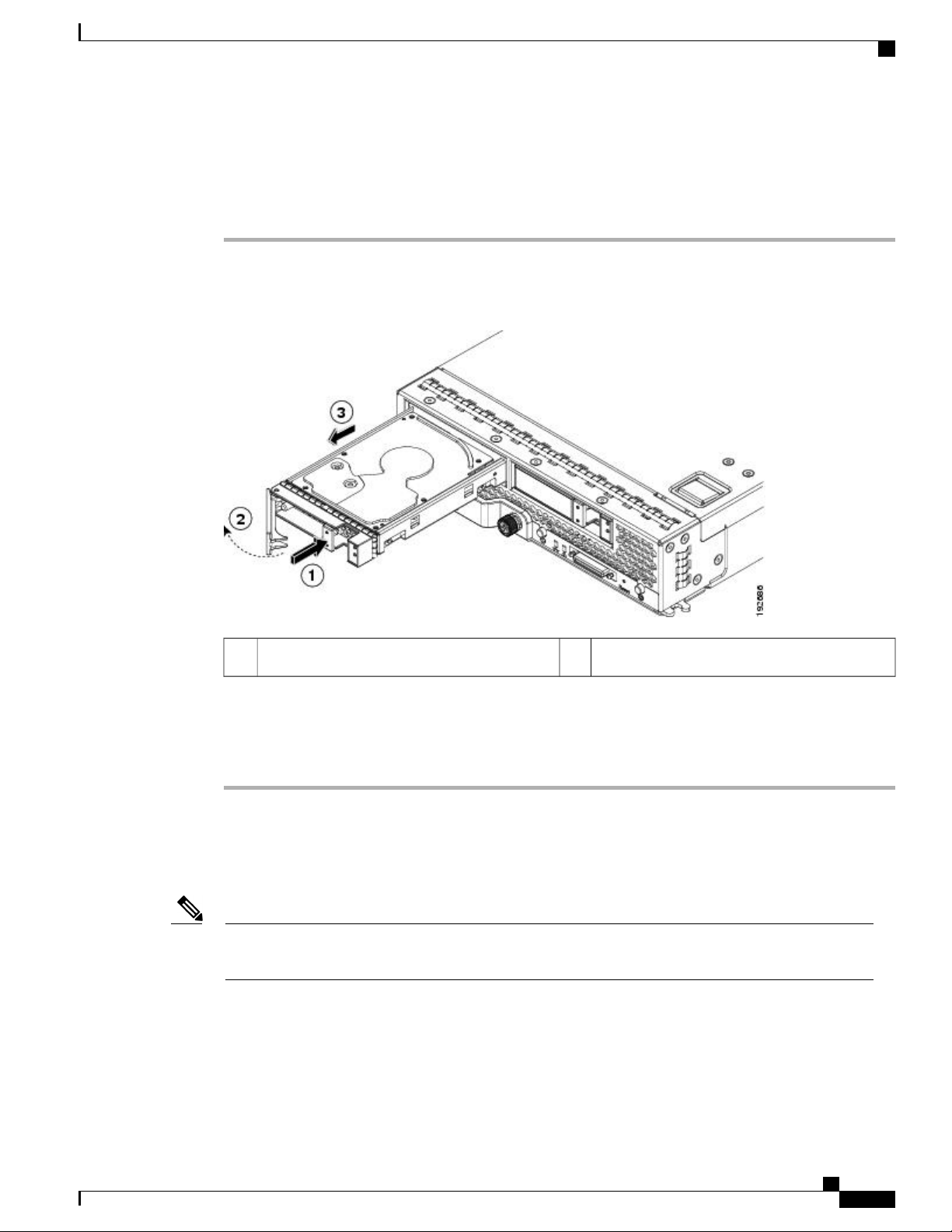

No power to the slot.OffOK

Normal operation.Green

AC power is present but the PS is either in

redundancy standby mode or is not fully seated.

Normal operation.OffFail

Over-voltage failure or over-temperature alarm.Amber

DescriptionColorLED

No power.OffBody

Normal operation.Green

Booting or minor temperature alarm.Amber

POST error or other error condition.Blinking amber

Link down.OffPort 1-4

Link up and operationally enabled.Green

Link up and administratively disabled.Amber

POST error or other error condition.Blinking amber

Cisco UCS 5108 Server Chassis Installation Guide

26 OL-20035-05

Page 39

Overview

Interpreting LEDs

Table 4: Blade Server LEDs

DescriptionColorLED

Power off.OffPower

Normal operation.Green

Standby.Amber

None of the network links are up.OffLink

At least one network link is up.Green

Power off.OffHealth

Normal operation.Green

(Disk Drive)

(Disk Drive)

Minor error.Amber

Critical error.Blinking

Amber

Inactive.OffActivity

Outstanding I/O to disk drive.Green

No fault.OffHealth

Some fault.Amber

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 27

Page 40

Interpreting LEDs

Overview

Cisco UCS 5108 Server Chassis Installation Guide

28 OL-20035-05

Page 41

CHAPTER 2

Installation

This chapter contains the following sections:

Installation Notes and Warnings for the Cisco UCS 5108 Server Chassis, page 29

•

Installing the Chassis, page 35

•

Repacking the Chassis, page 51

•

SFP+ Transceivers, page 51

•

Installation Notes and Warnings for the Cisco UCS 5108 Server Chassis

The following notes and warnings apply to all installation tasks:

Note

Warning

Warning

OL-20035-05 29

Before you install, operate, or service the system, see the Regulatory Compliance and Safety Information

for Cisco UCS for important safety information.

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device. Statement 1071

SAVE THESE INSTRUCTIONS

This unit is intended for installation in restricted access areas. A restricted access area can be accessed

only through the use of a special tool, lock and key, or other means of security. Statement 1017

Cisco UCS 5108 Server Chassis Installation Guide

Page 42

Rack Requirements

Installation

Warning

Only trained and qualified personnel must be allowed to install, replace, or service this equipment.

Statement 1030

Rack Requirements

This section provides the requirements for installing in a standard open rack, assuming an external ambient

air temperature range of 50 to 95°F (10 to 35°C):

Note

Do not use racks that have obstructions. These obstructions could impair access to field-replaceable units

(FRUs).

The Cisco R Series Racks are an ideal choice. If other racks will be used, the rack must be of the following

type:

Standard 19-inch (48.3 cm) four-post EIA rack, a minimum of 39.4 inches (100 cm) deep, with mounting

•

rails that conform to English universal hole spacing per section 1 of ANSI/EIA-310-D-1992.

The mounting holes of the rails in the rack must be square (unless the optional round hole adapter kit is

•

used).

The tool-less rack-mount kit shipped with the chassis is required. The adjustable rack rails shipped with

•

each enclosure extend from 29 inches (73.66 cm) to 35 inches (88.9 cm)

• Front and rear doors—If your server rack includes closing front and rear doors, the doors must have 65

percent open perforated area evenly distributed from top to bottom to permit adequate airflow.

Caution

The rack must also meet the following requirements:

The minimum available vertical rack space per chassis must be six RU (rack units), equal to 10.5 inches

•

(26.7 cm).

Cable Management

To help with cable management, allow additional space in the rack above and below the chassis to make it

easier to route copper cables (plus up to eight copper cables per Cisco UCS 5108 server chassis) through the

rack.

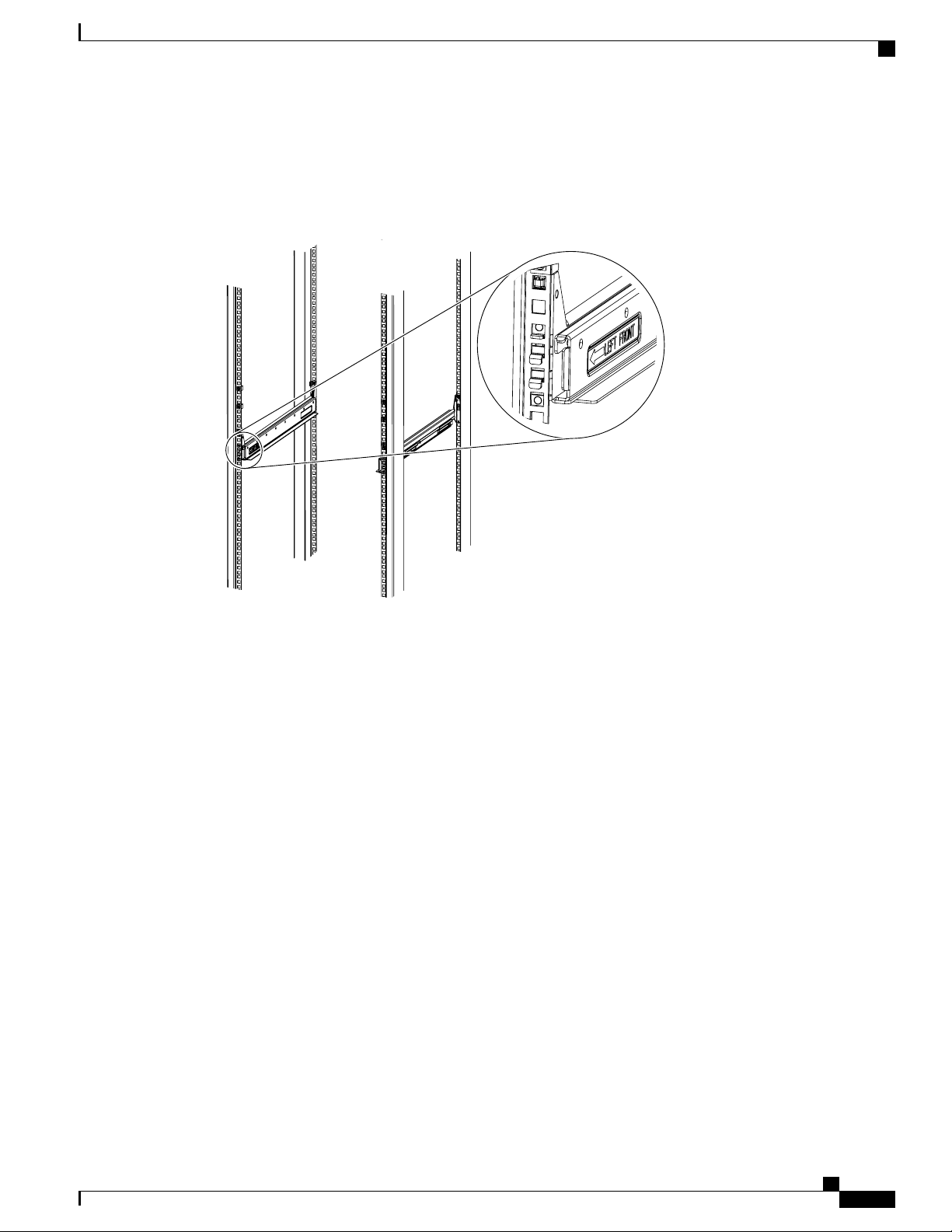

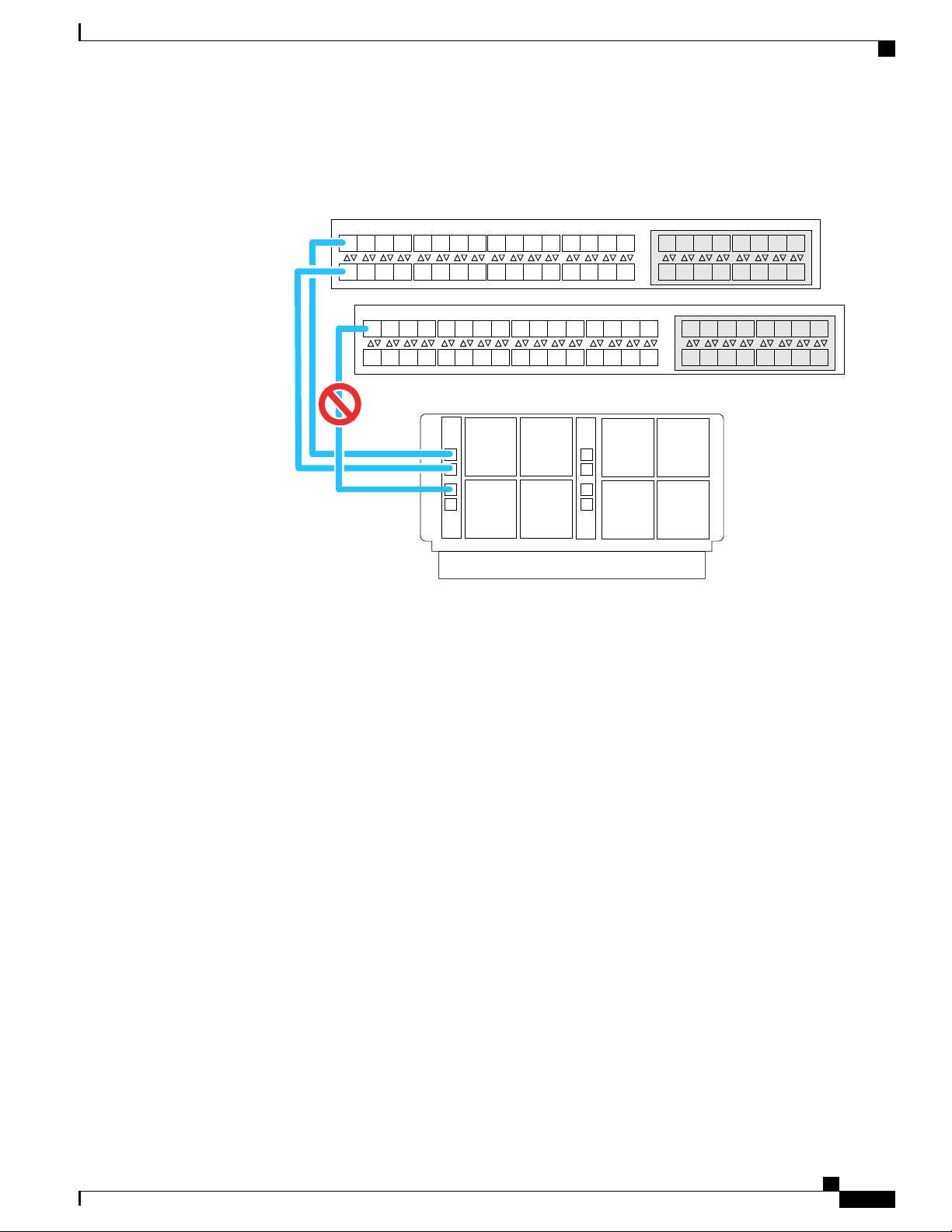

Cable management can be an important factor in preventing overheating issues. In the following figure, the

“before“ illustration shows cables blocking the rear of the chassis, and preventing the fans from exhausting

warm air from the chassis. This situation causes failed DIMMs in the blade servers, and seemingly random

Always use blanking panels to fill all remaining empty front panel U-spaces in the rack.

This arrangement ensures proper airflow. Using a rack without blanking panels results

in improper cooling that can lead to thermal damage.

Cisco UCS 5108 Server Chassis Installation Guide

30 OL-20035-05

Page 43

253898

Before

After

Installation

Airflow Considerations

server shutdowns when internal temperatures exceed specification. Use cable ties and other wiring practices

to keep the rear of the chassis unobstructed as shown in the “after“ illustration.

Figure 14: Cable Management

Airflow Considerations

Airflow through the chassis is from front to back. Air enters the chassis through the blade servers and power

supply grills at the front of the chassis and exits through the fan modules on the back of the chassis. To ensure

proper airflow, follow these guidelines:

Maintain ambient airflow throughout the data center to ensure normal operation.

•

Consider the heat dissipation of all equipment when determining air-conditioning requirements. Do not

•

allow the exhaust of one system to be the intake for another system.

When evaluating airflow requirements, take into consideration that the hot air generated by equipment

•

at the bottom of the rack can be drawn in the intake of the equipment above.

Make sure that the exhaust at the rear of the chassis is unobstructed for at least 24 in. (61 cm). This

•

includes obstruction due to messy cabling practices.

Some blade servers ship with internal shrouds that are placed over the DIMMs and CPUs. They are used

•

to channel airflow to where it is needed the most. If a shroud can be used a given model, it should be

used.

If an enclosed rack is used, the front door must be 65 percent perforated to ensure adequate airflow to

•

the servers.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 31

Page 44

Moving Server Chassis

Moving Server Chassis

When lifting the chassis, be aware of its weight, and follow these guidelines:

Installation

Caution

Do not try to lift the chassis using the handles on the side. These handles are intended only for moving

and adjusting the chassis position.

• Never lift the chassis alone—Always use two people to lift the chassis. If available, use a scissor jack

or other lifting device designed for installing heavy equipment into data center racks.

Disconnect all power and external cables before lifting the chassis.

•

Remove all FEXes, power supplies, fans, and servers from the chassis before lifting.

•

Ensure that your footing is solid and the weight of the system is evenly distributed between your feet.

•

Lift the system slowly, keeping your back straight. Lift with your legs, not with your back. Bend at the

•

knees, not at the waist.

Do not remove the Power Distribution Unit (PDU) located at the back of the chassis.Caution

Installation Guidelines

When installing the chassis, follow these guidelines:

Plan your site configuration and prepare the site before installing the chassis. See Site Planning and

•

Maintenance Records, on page 79 for the recommended site planning tasks. For details, see the Cisco

UCS Site Preparation Guide.

Record the information listed in Site Planning and Maintenance Records, on page 79 as you install and

•

configure the chassis.

Ensure that there is adequate space around the chassis to allow for servicing the chassis and for airflow.

•

Ensure that the air-conditioning meets the heat dissipation requirements listed in Technical Specifications,

•

on page 69

Ensure that the cabinet or rack meets the requirements listed in Rack Requirements, on page 30.

•

Note

Ensure that the site power meets the power requirements listed in Technical Specifications, on page

•

69. We recommend that you use a UPS to protect the UCS system. Using an unprotected supply exposes

you to a risk of system failure due to input supply voltage variations or failures.

Cisco UCS 5108 Server Chassis Installation Guide

32 OL-20035-05

Jumper power cords are available for use in a rack. See Specifications for the Cisco

UCS 5108 Blade Server Chassis Power Supply Units, on page 72.

Page 45

Installation

Avoid UPS types that use ferroresonant technology. These UPS types can become unstable with systems

such as the Cisco UCS, which can have substantial current draw fluctuations due to fluctuating data

traffic patterns.

Ensure that circuits are sized according to local and national codes. For North America, the power supply

•

requires a 20 A circuit.

To prevent loss of input power, ensure that the total maximum loads on the circuits supplying power to

the chassis are within the current ratings for the wiring and breakers.

Use the following torque values when installing the chassis:

•

Required Equipment

Before you begin the installation, ensure that you have the following items:

Number 1 and number 2 Phillips-head screwdrivers with torque measuring capabilities

•

10-32 screws: 20 in-lb

◦

Required Equipment

Tape measure and level

•

ESD wrist strap or other grounding device

•

Antistatic mat or antistatic foam

•

Unpacking and Inspecting the Chassis

When handling chassis components, wear an ESD strap and handle modules by the carrier edges only.Caution

Keep the shipping container in case the chassis requires shipping in the future.Tip

Note

The chassis is thoroughly inspected before shipment. If any damage occurred during transportation or any

items are missing, contact your customer service representative immediately.

Procedure

Step 1

Step 2

OL-20035-05 33

Remove the chassis from its cardboard container. Save all packaging material.

Compare the shipment to the equipment list provided by your customer service representative and verify that

you have received the following items:

Any printed documentation

•

• Tool-less rack-mount kit (N20-CRMK2=)—mounting rails can be installed in a rack without the use of

tools. The optional round hole adapter kit (N20-CRMK2-RHA=) does require tools.

Cisco UCS 5108 Server Chassis Installation Guide

Page 46

279771

1

2

3

Attaching the Round Hole Adapter Kit to the Rails (Optional)

ESD wrist strap

•

Cables with connectors (including the N20-BKVM=, which is the KVM/local I/O console dongle)

•

Any optional items ordered

•

Installation

Step 3

Verify that all unused blade slots and power supply bays have blank covers.

Attaching the Round Hole Adapter Kit to the Rails (Optional)

Note

Step 1

Step 2

Step 3

The chassis tool-less rails are designed for racks that have square mounting holes. You must use the round

hole adapters (N20-CRMK2-RHA=) to install the chassis in racks that have round mounting holes.

This round hole adapter kit allows you to adapt the rail kit (N20-CRMK2=) to install into rack (front and/or

rear) posts that use either threaded or non-threaded round holes. Four adapters in the kit are for adapting the

rail kit to install into rack posts with threaded round holes, and the other four adapters in the kit are for adapting

the rail kit to install into rack posts with non-threaded round holes. You can use a combination of adapters

based on the type of holes in the rack posts. Various sizes and lengths of screws are also included in the kit.

Procedure

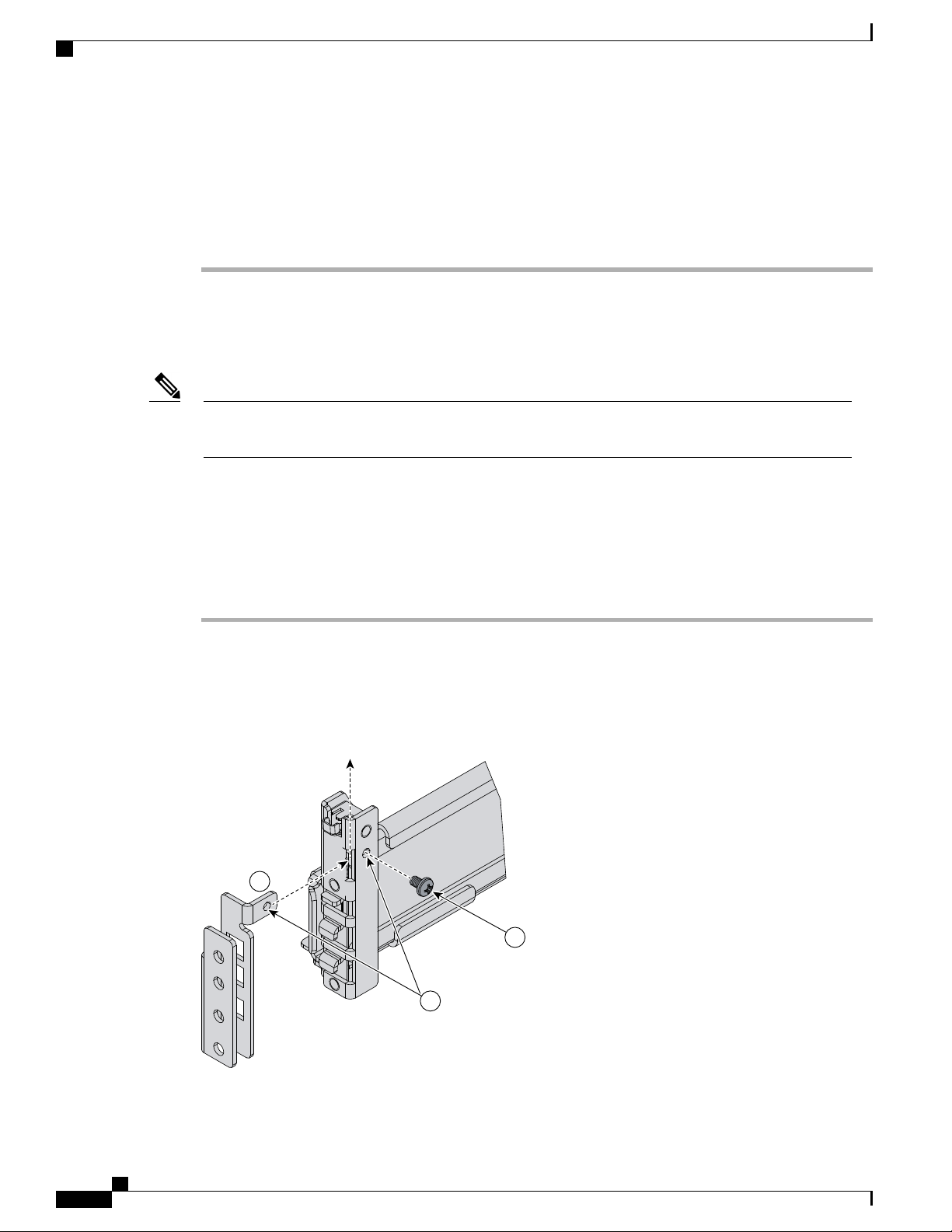

Insert the adapter tab into the mounting rail as shown in callout 1.

Slide the adapter up to lock it into position as shown in callout 2.

Secure the adapter into place using the provided pan-head screw as shown in callout 3.

Figure 15: Attaching the Round Hole Adapter (Optional)

Cisco UCS 5108 Server Chassis Installation Guide

34 OL-20035-05

Page 47

Installation

Installing the Chassis

Step 4

Repeat steps 1to 3 for the other three adapters.

Installing the Chassis

This section describes how to install the chassis. This two part process consists of installing the rails into the

rack and then installing the chassis into the rack and on to the rails.

Caution

Caution

Never attempt to lift the chassis by using an installed module’s handle as a grip point. only use the handles

on the sides of the chassis.

If the rack has wheels, ensure that the brakes are engaged, the stabilizing pads are extended, or that the

rack is otherwise stabilized.

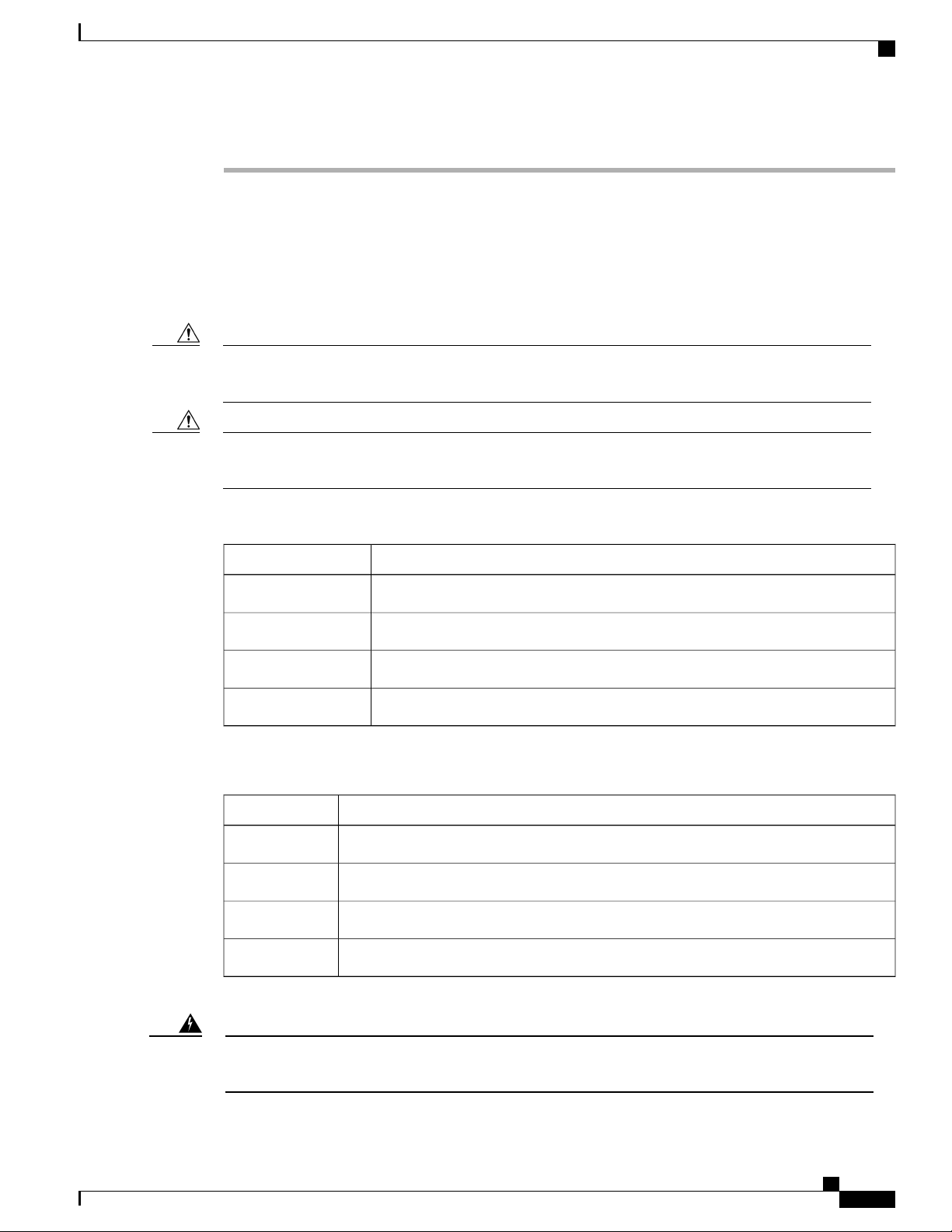

Table 5: Contents of the Cisco UCS 5108 Server Chassis Rack-Mount Kit (N20-CRMK2=)

Part DescriptionQuantity

Left tool-less rack mount rail1

Warning

Right tool-less rack mount rail1

10-32 X 0.75 Phillips round washer head screws6

10-32 X 0.125 cage nuts6

Table 6: Contents of the Cisco UCS 5108 Server Round Hole Adapter Kit (N20-CRMK2-RHA=)

Part DescriptionQuantity

Round hole adapters (threaded)4

Round hole adapters (un-threaded)4

Adapter securing screws4

Phillips head screws for securing the rails to the rack16

The plug-socket combination must be accessible at all times, because it serves as the main disconnecting

device. Statement 1019

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 35