Page 1

Cisco StrataCom

BPX Service Node Installation

Release 8.5

Corporate Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

World Wide Web URL:

http://www.cisco.com

Tel:

408 526-4000

800 553-NETS (6387)

Fax:

408 526-4100

Customer Order Number: DOC-SCBPXIG-8.5=

Text Part Number: 78-4688-01

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT

NOTICE. ALL STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE

PRESENTED WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR

APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION

PACKET THAT SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO

LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency

energy. If it is not installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment

has been tested and found to comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These

specifications are designed to provide reasonable protection against such interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco equipment

or one of its peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of

the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio

are on circuits controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The following third-party software may be included with your product and will be subject to the software license agreement:

CiscoWorks software and documentation are based in part on HP OpenView under license from the Hewlett-Packard Company. HPOpenView is a

trademark of the Hewlett-Packard Company. Copyright © 1992, 1993 Hewlett-Packard Company.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of

UCB’s public domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

Network Time Protocol (NTP). Copyright © 1992, David L. Mills. The University of Delaware makes no representations about the suitability of this

software for any purpose.

Point-to-Point Protocol. Copyright © 1989, Carnegie-Mellon University. All rights reserved. The name of the University may not be used to endorse or

promote products derived from this software without specific prior written permission.

The Cisco implementation of TN3270 is an adaptation of the TN3270, curses, and termcap programs developed by the University of California, Berkeley

(UCB) as part of UCB’s public domain version of the UNIX operating system. All rights reserved. Copyright © 1981-1988, Regents of the University of

California.

Cisco incorporates Fastmac and TrueView software and the RingRunner chip in some Token Ring products. Fastmac software is licensed to Cisco by Madge

Networks Limited, and the RingRunner chip is licensed to Cisco by Madge NV. Fastmac, RingRunner, and TrueView are trademarks and in some

jurisdictions registered trademarks of Madge Networks Limited. Copyright © 1995, Madge Networks Limited. All rights reserved.

XRemote is a trademark of Network Computing Devices, Inc. Copyright © 1989, Network Computing Devices, Inc., Mountain View, California. NCD

makes no representations about the suitability of this software for any purpose.

The X Window System is a trademark of the X Consortium, Cambridge, Massachusetts. All rights reserved.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE

PROVIDED “AS IS” WITH ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

Page 3

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL

DAMAGES, INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR

INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

AccessPath, AtmDirector, Cache Director System, CD-PAC, CiscoIOS, the CiscoIOS logo, CiscoLink, the Cisco Powered Network logo, ClickStart,

ControlStream, Fast Step, FragmentFree, IGX, JumpStart, LAN

2

LAN Enterprise, LAN2LAN Remote Office, MICA, NetBeyond, NetFlow, Netsys

Technologies, Packet, PIX, Point and Click Internetworking, RouteStream, SMARTnet, StrataSphere, StrataSphere BILLder, StrataSphere Connection

Manager, StrataSphere Modeler, StrataSphere Optimizer, Stratm, StreamView, SwitchProbe, TheCell, TokenSwitch, TrafficDirector, VirtualStream,

VlanDirector, Workgroup Director, Workgroup Stack, and XCI are trademarks; The Network Works. No Excuses. is a service mark; and BPX, Catalyst,

Cisco, CiscoSystems, the CiscoSystems logo, EtherChannel, FastHub, FastPacket, ForeSight, IPX, LightStream, OptiClass, Phase/IP, StrataCom, and

StrataView Plus are registered trademarks of CiscoSystems,Inc. in the U.S. and certain other countries. All other trademarks mentioned in this document

are the property of their respective owners.

Cisco StrataCom BPX Service Node Installation

Copyright © 1997, Cisco Systems, Inc.

All rights reserved. Printed in USA.

978R

Page 4

Page 5

What’s in This Publication?xv

Related Documentationxvii

Conventionsxvii

Chapter 1 Introduction1-1

Introduction1-1

Installation Sequence1-1

Support1-2

Chapter 2 Installation, Preliminary2-1

Site Preparation2-1

Parts Checklist2-2

Safety Requirements2-4

Laser Safety Guidelines2-4

Power and Grounding2-5

CEPT Requirements2-5

EMI Requirements2-5

TABLE OF CONTENTS

Mechanical Installation2-6

Installing a BPX Shelf, Preliminary Steps2-9

Chapter 3 Installation, with STRATM Cabinet3-1

Installing a BPX Shelf, Rear-Rail Setback at 19.86 Inch3-1

Preliminary Procedure:3-3

Chapter 4 Installation, with Customer Cabinet4-1

Installing a BPX Shelf, Rear Rail Setback at 30-Inch4-1

Preliminary Procedure:4-1

Chapter 5 Installation, DC Shelf Initial Setup5-1

DC Power Input Connections5-1

Card Slot Fuses5-4

Fan Power Fuses5-4

Chapter 6 Installation, AC Shelf Initial Setup6-1

Installing an AC Power Supply Tray6-1

Installing an AC Power Supply6-8

AC Power Input Connections6-10

Card Slot Fuses6-13

Fan Power Fuses6-13

Chapter 7 Finishing the Installation7-1

Installing the BPX Cards7-2

Table of Contentsv

Page 6

Installing Front Cards7-4

Installing Back Cards7-6

Verifying 9.6 or 19.2 Gbps Backplane7-7

Making T3 or E3 Connections7-9

Making an ASI-155 or BNI-155 Connection7-12

Making a BXM OC3 or OC12 Connection7-12

Making a BXM T3/E3 Connection7-14

Alarm Output Connections7-16

Attaching Peripherals7-17

Connecting a terminal or NMS to the Control Port7-17

LAN Connection for the Network Management Station7-20

Connecting a Network Printer to the BPX7-21

Connecting Modems7-23

Making External Clock Connections7-24

Initial Startup of the BPX7-26

BPX Startup Diagnostic7-26

BPX Management7-29

Initial Node Configuration Summary7-30

Adding Nodes, Adding Trunks, Shelves, etc.7-30

IP Setup and IP Relay Configuration7-32

Installing StrataView Plus and Associated Applications7-33

Configure StrataView Plus Workstation (example)7-33

Configuring the LAN Port7-34

7-38

Configuring the AXIS for StrataView Plus NMS Operation (example)7-39

Adding Virtual Trunks7-40

Provisioning the BPX Service Node7-41

Chapter 8 T3/E3 Cable Management Tray8-1

Installation of Cable Management Tray8-2

Installing Tray Brackets8-2

Installing Tray8-3

Raising Tray for Access to PEMs8-5

Installing BXM T3/E3 Cable Bracket8-6

Connecting Cables to BXM T3/E3 Cards8-7

Routing Cables from Cards through Cable Management Tray8-9

Tray Raised with Cables in Place8-10

Appendix A STRATM Cabinet DimensionsA-1

vi BPX Service Node Installation, Release 8.5

Page 7

STRATM Cabinet and Component HeightsA-2

STRATM CabinetA-3

Cable ManagementA-4

Examples of BPX System ConfigurationsA-5

Examples of IGX System ConfigurationsA-12

Appendix B BPX Cabling SummaryB-1

Trunk CablingB-1

Power CablingB-1

AC Powered NodesB-1

DC Powered NodesB-2

LM-BCC CablingB-2

Auxiliary and Control Port CablingB-2

LAN Port CablingB-3

Modem CablingB-3

External Clock Input CablingB-4

T1 Clock CablingB-4

E1 Clock CablingB-5

External Alarm CablingB-6

Standard BPX CablesB-6

Redundancy “Y” CableB-7

Appendix C BPX PeripheralsC-1

Network ManagementC-1

StrataView Plus TerminalC-1

Control Port, Local ControlC-1

PrinterC-2

DIP Switch Settings for Okidata 184C-2

Modems, Dial-In and Dial-OutC-4

Motorola V.34R BPX Dial-In ConfigurationC-4

BPX Auto-Answer (Dial-In to BPX)C-4

IPX Auto-Dial to Customer ServiceC-6

Table of Contentsvii

Page 8

viii BPX Service Node Installation, Release 8.5

Page 9

LIST OF FIGURES

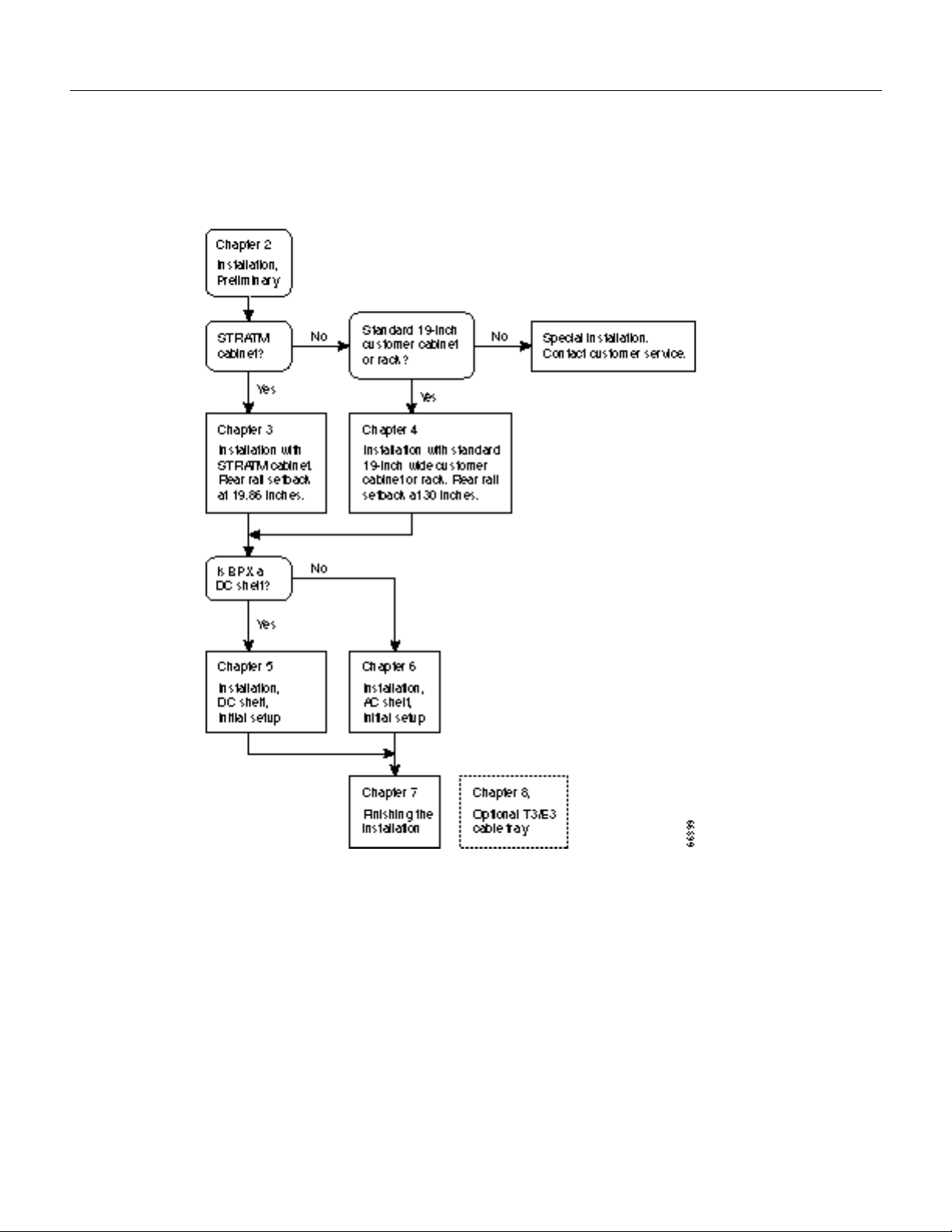

Figure1-1 Installation Sequence1-2

Figure2-1 Laser Information Label2-4

Figure2-2 Cabinet Mounting Options for the BPX Shelf2-7

Figure2-3 BPX Shelf and T-Rail (Open Rack) or Equivalent Mounting Options2-8

Figure2-4 Removing an Air Intake Grille2-10

Figure2-5 Rack Mounting Dimensions, DC Powered Shelf2-11

Figure2-6 Rack Mounting Dimensions, AC Powered Shelf2-12

Figure2-7 Temporary Spacer Bracket and Support Bracket Installation2-13

Figure2-8 BPX Shelf Aligned with Temporary Support Brackets and Bar2-13

Figure3-1 Location of DC Power Entry Module(s), Cabinet Rear View3-2

Figure3-2 BPX Shelf Aligned with Temporary Support Brackets and Bar3-3

Figure3-3 BPX Shelf with Rear Rail Mounting at Setback of 19.86 inches3-5

Figure3-4 Rear Mounting Brackets, with 19.86 Inch Rear Rail Setback (DC Systems)3-6

Figure3-5 Rear Mounting Brackets, 19.86 Inch Rear Rail Setback (AC-Systems)3-6

Figure4-1 BPX Cabinet Aligned with Temporary Support Brackets and Bar4-2

Figure4-2 BPX Shelf with Rear Rail Mounting at Setback of 30 Inches4-3

Figure4-3 Rear Mounting Brackets, Detail4-3

Figure4-4 Rear Mounting Brackets, with 30 Inch Rear Rail Setback (DC Systems)4-4

Figure4-5 Rear Mounting Brackets, 30 Inch Rear Rail Setback (AC-Powered Systems)4-4

Figure5-1 DC Power5-2

Figure5-2 DC Power Connections—With Conduit Box5-3

Figure5-3 DC Power Connections—Without Conduit Box5-4

Figure6-1 Temporary Spacer Bracket and Support Bracket Installation6-2

Figure6-2 Power Supply Tray aligned with Temporary Support Brackets and Bar6-3

Figure6-3 Removing an Air Intake Grille6-4

Figure6-4 Securing AC Power Supply Tray, 30-Inch Rail Setback6-5

Figure6-5 Securing an AC Power Supply Tray, 19.86 inch Rear Rail Setback6-6

Figure6-6 AC Power Supply Tray with Redundant AC Inputs (view from rear)6-7

Figure6-7 Removing an Air Intake Grille6-8

Figure6-8 AC Power Supply Installation6-9

Figure6-9 AC Power Supply Connections (Dual and Single Versions Shown)6-11

Figure6-10 AC Power6-12

Figure7-1 BPX Shelf (front view)7-3

List of Figuresix

Page 10

Figure7-2 BPX Shelf (rear view, DC shelf shown)7-3

Figure7-3 Removing an Air Intake Grille7-5

Figure7-4 Laser Information Label7-6

Figure7-5 Installing a Back Card7-7

Figure7-6 Connecting T3 Cables to BPX LM-T3 (BNI T3 backcard)7-10

Figure7-7 Connecting Y-Cable Adapters to a T3 Port7-11

Figure7-8 Connecting Y-Cables to an OC3-SMF Backcard7-13

Figure7-9 BXM T3/E3 Cable Connector Detail7-14

Figure7-10 Y-Cable for BXM T3/E3 Cards7-15

Figure7-11 Alarm Output Connector7-16

Figure7-12 Connections to NMS (Single BCC), LM-BCC Backcard Shown7-18

Figure7-13 NMS Connections via Control Port (Redundant BCCs), LM-BCCs Shown7-19

Figure7-14 LAN Connections to BCC Backcards, LM-BCCs Shown7-20

Figure7-15 Connections to a Network Printer, LM-BCC Shown7-22

Figure7-16 Connecting Modems to the BPX, LM-BCC Shown7-23

Figure7-17 Synchronizing a Local IPX to BPX Node, LM-BCCs Shown7-25

Figure7-18 Successful Power-Up Diagnostic Screen7-27

Figure7-19 On-Line Screen7-28

Figure7-20 SV+ Physical LAN and IP Relay Network7-32

Figure7-21 Configuring a Node’s Control Port (Gateway Router Example)7-35

Figure7-22 SV+ LAN Connection via Gateway Router to a BPX Node7-36

Figure7-23 Configuring the IP Relay Parameters (Required for each node)7-37

Figure7-24 dsplan after SV+ Startup (Gateway Router Example)7-37

Figure7-25 SV+ LAN Connection to an IPX Node (no gateway)7-38

Figure7-26 Virtual Trunks across a Cisco StrataCom ATM Cloud7-40

Figure8-1 Installation of Cable Management Tray Brackets8-2

Figure8-2 Sliding Cable Management Tray over Brackets8-3

Figure8-3 Cable Management Tray in Lowered Home Position8-4

Figure8-4 Cable Management Tray in Raised Position8-5

Figure8-5 Installing BXM T3/E3 Cable Bracket8-6

Figure8-6 Connecting Cables to T3/E3 Card8-7

Figure8-7 T3/E3 SMB Connector Detail8-8

Figure8-8 Cables Routed through Cable Management Tray in Lowered Position8-9

Figure8-9 Tray Raised with Cables in Place8-10

x BPX Service Node Installation, Release 8.5

Page 11

FigureA-1 Back View of Empty STRATM CabinetA-3

FigureA-2 Typical Cable Management, IGX-32 in STRATM CabinetA-4

FigureA-3 Single BPX, DC and AC SystemsA-5

FigureA-4 Single BPX and AXIS, DC and AC SystemsA-6

FigureA-5 BPX, AXIS, and INS, DC and AC SystemsA-7

FigureA-6 BPX With 2 INS and 3 AXIS, DC SystemA-8

FigureA-7 Six AXIS, DC SystemA-9

FigureA-8 BPX With Three AXIS, DC SystemA-10

FigureA-9 Mounting Brackets (BPX), Standard ConfigurationA-11

FigureA-10 IGX 32, DC and AC SystemsA-12

FigureA-11 Single IGX 16, DC and AC SystemsA-13

FigureA-12 Single IGX 8, DC and AC SystemsA-14

FigureC-1 Dial-Modem Cabling for Auto Answer (Dial-In to BPX)C-6

FigureC-2 Dial Modem Cabling for Auto Dial (dial-out to customer service)C-8

List of Figuresxi

Page 12

xii BPX Service Node Installation, Release 8.5

Page 13

TableA-1 Table of STRATM Cabinet and Component HeightsA-2

TableB-1 Trunk CablesB-1

TableB-2 AC Power CablesB-2

TableB-3 DC Power WiringB-2

TableB-4 Auxiliary and Control Port CablingB-2

TableB-5 Auxiliary and Control Port Pin AssignmentsB-3

TableB-6 LAN Port CablingB-3

TableB-7 LAN Port Pin AssignmentsB-3

TableB-8 External Clock CablingB-4

TableB-9 T1 Connection to XFER TMG on BCC-bcB-4

TableB-10 T1 Connection to EXT TMG on BCC-bcB-4

TableB-11 T1 Connection to EXT 1 or EXT 2 on BCC-3-bcB-4

TableB-12 E1 Connector Pin Assignments for External ClockB-5

LIST OF TABLES

TableB-13 E1 Connection 75 Ohm to EXT TMG on BCC-bc or BCC-3-bcB-5

TableB-14 E1 Connection 100/120 Ohm to EXT TMG on BCC-bcB-5

TableB-15 E1 Connection 100/120 Ohm to EXT 1 or EXT 2 on BCC-3-bcB-5

TableB-16 External Alarm CablingB-6

TableB-17 Network Alarm Pin AssignmentsB-6

TableB-18 Standard Cables Available from CiscoB-7

TableB-19 Redundancy Y-CablesB-7

TableC-1 Control Port Parameters for Local Control (pc or workstation)C-2

TableC-2 Auxiliary Port Parameters for OkiData 184 PrinterC-2

TableC-3 Switch A Settings—Okidata 184 PrinterC-2

TableC-4 Switch 1 Settings—Okidata 184 PrinterC-3

TableC-5 Switch 2 Settings—Okidata 184 PrinterC-3

TableC-6 Modem Interface RequirementsC-4

TableC-7 V.34R Modem Configuration for Auto-Answer (Dial-in to BPX)C-5

TableC-8 V.34R Auto-Dial Configuration (dial-out to customer service)*C-7

TableC-9 V.34R with talk/data, Auto-Dial Configuration (dial-out to customer service)*C-7

List of Tablesxiii

Page 14

xiv BPX Service Node Installation, Release 8.5

Page 15

About this Publication

This publication provides installation instructions for the BPX.

Cisco documentation and additional literature are available in a CD-ROM package, which ships with

your product. The Documentation CD-ROM, a member of the Cisco Connection Family, is updated

monthly. Therefore, it might be more up to date than printed documentation. To order additional

copies of the Documentation CD-ROM, contact your local sales representative or call customer

service. The CD-ROM package is available as a single package or as an annual subscription. You

can also access Cisco documentation on the World Wide Web at http://www.cisco.com,

http://www-china.cisco.com, or http://www-europe.cisco.com.

What’s in This Publication?

This publication is organized as follows:

Chapter1 Introduction

Provides a brief introduction to the document, including a flow diagram that

shows which procedures are applicable to the various options, Stratm

Cabinet or Customer Cabinet, ac cabinet or dc cabinet

Chapter2 Installation, Preliminary

Provides preliminary installation instructions for the BPX .

Chapter3 Installation, with STRATM Cabinet

This chapter provides installation steps for the mechanical placement of a

BPX shelf in a standard STRATM cabinet. This cabinet provides rear rails at

a 19.86 inch (50.5 cm) setback from the front of the cabinet.

Chapter4 Installation, with Customer Cabinet

This chapter provides installation steps for the mechanical placement of a

BPX shelf in a standard 19-inch customer supplied equipment cabinet or

rack with a rear rail setback at 30 inches.

Chapter5 Installation, DC Shelf Initial Setup

This chapter describes how to make the DC power connections.

About this Publication xv

Page 16

What’s in This Publication?

Chapter6 Installation, AC Shelf Initial Setup

Chapter7 Finishing the Installation

Chapter8 T3/E3 Cable Management Tray

AppendixA STRATM Cabinet Dimensions

This chapter explains how to install the AC power supply tray, power

supplies, and make AC power connections.

This chapter explains how to install the BPX cards, connect line and trunk

cables, connect peripherals, connect to a network management station, initial

power up, and initial configuration.

This appendix provide details on the peripherals used with the BPX

including printers and modems.

Illustrates typical cable management and space requirements for various

system configurations in the STRATM cabinet. It also lists the height of

StrataCom components in inches, centimeters, and rack-mount units

(RMUs).

AppendixB BPX Cabling Summary

This appendix provides details on the cabling required to install the BPX

node.

AppendixC BPX Peripherals

This appendix provide details on the peripherals used with the BPX

including printers and modems.

xviBPX Service Node Installation, Release 8.5

Page 17

Related Documentation

• StrataView Plus Operations Guide providing for procedures for using the StrataView Plus

network management system.

• StrataSphere Network Design Tools providing procedures for modeling networks.

• Release 8.4 of the IGX/IPX/BPX Documentation set, including:

— BPX Reference providing a general description and technical details of the BPX broadband

node.

— IPX Reference providing a general description and technical details of the IPX narrowband

node.

— IPX Installation providing installation instructions for the IPX.

— IGX Reference providing a general description and technical details of the IGX node.

— IGX Installation providing installation instructions for the IGX.

— AXIS Reference providing a general description and technical details of the AXIS node.

— AXIS Command Reference providing detailed information for AXIS command line usage.

— Command Reference providing detailed information on operating the BPX, IGX, and IPX

systems through their command line interfaces.

Related Documentation

Conventions

This publication uses the following conventions to convey instructions and information.

Command descriptions use these conventions:

• Commands and keywords are in boldface .

• Arguments for which you supply values are in italics.

• Elements in square brackets ([ ]) are optional.

• Alternative but required keywords are grouped in braces ({ }) and are separated by vertical bars ( | ).

Examples use these conventions:

• Terminal sessions and information the system displays are in screen font.

• Information you enter is in boldface screen font.

• Nonprinting characters, such as passwords, are in angle brackets (< >).

• Default responses to system prompts are in squarebrackets ([ ]).

NoteMeans reader take note. Notes contain helpful suggestions or references to materials not contained in this

manual.

— SuperUser Command Reference providing detailed information on their command line

interfaces special commands requiring SuperUser access authorization.

TimesaverMeans the described action saves time. You can save time by performing the action described in the

paragraph.

About this Publication xvii

Page 18

Conventions

CautionMeans reader be careful. In this situation, you might do something that could result in equipment

damage or loss of data.

WarningThis warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, you must be aware of the hazards involved with electrical circuitry and familiar with

standard practices for preventing accidents. (To see translated versions of this warning, refer to the Regulatory

Compliance and Safety Information that accompanied your equipment.)

xviiiBPX Service Node Installation, Release 8.5

Page 19

Introduction

CHAPTER

Introduction

This document provides installation instructions for the BPX.

For additional information on the BPX, including card descriptions and additional information on

configuration, refer to the BPX Service Node Reference. For a description of the commands used to

operate a BPX, refer to the Command Reference. Refer to the System Overview for system and

network information. Refer to the StrataView Plus manuals for information on network

management.

1

Installation Sequence

Figure1-1 shows the sequence of operations followed during the installation of the BPX. A

summary of this sequence is as follows:

— Chapter2, Introduction, provides preliminary setup instructions for the mechanical

installation of a BPX shelf. Depending on the type of rack or cabinet, the installer is then

directed to either:

— Chapter3, Installation, with STRATM Cabinet with rear rail setback at 19.86 inches, or

— Chapter4, Installation, with Customer Cabinet that is 19 inches wide with a rear rail setback

of 30 inches.

— Otherwise, the installation is non-standard and requires that Customer Service be contacted.

The BPX shelves are either AC or DC powered. At the completion of the procedures in Chapter3 or

Chapter4, the installer is directed to the appropriate power setup and connection chapter:

— Chapter5, Installation, DC Shelf Initial Setup, or

— Chapter6, Installation, AC Shelf Initial Setup.

The remaining procedures are common and the installer is directed to the final setup and

configuration procedures in:

— Chapter7, Finishing the Installation

An optional cable management tray and optional BXM T3/E3 cable management brackets are

available for use with T3/E3 BXM cards. The brackets are for use with cards set up as non-redundant

(single cables rather than Y-cabling). The tray is designed primarily for use in a mid-mount open rack

configuration. Instructions for installing the optional tray are provided in:

— Chapter8, T3/E3 Cable Management Tray

Introduction1-1

Page 20

Support

Figure1-1 Installation Sequence

Support

Contact Customer Service for more information. In North America, call Customer Support toll free

at 800-553-6387. International customers should contact your local Cisco sales office or call

408-526-400 and ask for Customer Service.

1-2 BPX Service Node Installation, Release 8.5

Page 21

CHAPTER

Installation, Preliminary

This chapter provides preliminary installation steps for the BPX, including the mechanical

installation of the BPX shelf in a STRATM cabinet or vendor supplied standard 19 inch (48.25 cm)

equipment rack.

This chapter contains the following sections:

Site Preparation

Parts Checklist

Safety Requirements

2

Mechanical Installation

WarningInstallation should be performed by authorized personnel only.

Site Preparation

The BPX has the following site preparation requirements.

• Space

Each BPX shelf requires floor space of 22 inches (55.9 cm) wide and 80 inches (203.2 cm) deep

to assure sufficient clearance around the cabinet to allow access to the front and back of the unit.

• Power

An AC or DC power source must be available within 6 feet (2 m.) of the rear of the BPX shelf.

A maximum configuration for an AC powered BPX may require up to 2333 VA (13 A at 180 VAC,

10 A at 230 VAC). A maximum configuration for a DC powered BPX may require up to 1680

Watts (40 A at –42 VDC, 35 A at -48 VDC).

• Cooling

The site must be capable of maintaining an ambient temperature of 40°C maximum

(recommended range 20°C to 30°C) while the system is operating. A fully loaded BPX may

dissipate up to 7200 BTUs. It is extremely important that the BPX is positioned to assure an

unrestricted air flow through the enclosure.

Installation, Preliminary2-1

Page 22

Parts Checklist

Parts Checklist

Before proceeding, go through this parts checklist to verify that all the parts you ordered are present,

and that they are all in good condition. If there is anything missing or damaged, report it to your

Cisco Order Administration representative.

Plug-in cards may be shipped installed or under separate cover. The exact number of cards will vary

from site to site, depending on the selected configuration. The BPX is shipped with all unused slots

covered by backplane inserts which prevent radio frequency emissions from the equipment. The unit

must not be operated with any unused slots left uncovered.

2-2 BPX Service Node Installation, Release 8.5

Page 23

Parts Checklist

Refer to the list below and check the number and type of cards shipped against the number and type

of card you ordered.

If a DC version, the correct number of Power Entry modules.

If an AC version, the unit has the correct number of power supplies (1 or 2).

For non- redundant configuration, one Broadband Controller Card. This can be a

BCC-4, BCC-3, or a BCC-32 depending on system configuration

For a non-redundant configuration, one Broadband Controller backcard. For a

BCC-4 or BCC-3 front card, a BCC-3-bc backcard must be used. For a BCC-32

front card, a BCC-bc backcard must be used.

For a redundant configuration, two Broadband Controller Cards. These can be two

BCC-3s or two BCC-32s.

For a redundant configuration, two Broadband Controller backcards. For BCC-4 or

BCC-3 front cards, these must be BCC-3-bc backcards. For BCC-32 front cards,

these must be BCC-bc backcards.

One ASM card.

One LM-ASM card.

Correct number of BXM cards.

Correct number of BNI cards.

Correct number of ASI cards.

One line module backcard for each BXM, as applicable (e.g., BPX-T3/E3-BC,

MMF-155-4, SMF-155-4, SMFLR-155-4, MMF-155-8, SMF-155-8,

SMFLR-155-8, SMF-622, SMFLR-622, SMF-622-2, or SMFLR-622-2).

One line module backcard (e.g., BPX-T3-BC, BPX-E3-BC, MMF-2-BC,

SMF-2-BC, or SMFLR-2-BC) for each BNI, as applicable.

One line module backcard (e.g., BPX-T3-BC, BPX-E3-BC, MMF-2-BC,

SMF-2-BC, or SMFLR-2-BC) for each ASI, as applicable.

NoteAn inventory of the installed cards is taped to the BPX stating each card's serial number,

All cables specified in the order.

revision number, and slot number (serial and revision numbers are also found on the component side

of each card).

Installation, Preliminary 2-3

Page 24

Safety Requirements

Safety Requirements

The following paragraphs contain safety information for system planners, installers, and

maintenance personnel. The mechanical design of the BPX prevents any access to exposed voltages

without the use of tools. When installed properly, all front and rear cards are held captive

mechanically.

WarningFor protection against shock hazard, verify all power cords or cables are disconnected

before servicing unit (there may be more than one). The highest voltage that may be present in the

node when powered up is 264 VAC (AC systems) or 56 VDC (DC systems).

Laser Safety Guidelines

The optical ports contain an information label as shown in Figure2-1.

Figure2-1 Laser Information Label

Warning

multi-mode products when no fiber cable is connected. Avoid exposure and do not look into open

apertures. (For translated versions of this warning, refer to the Regulatory Compliance and Safety

Information that accompanied your equipment).

WarningClass 1 laser product. (For translated versions of this warning, refer to the Regulatory

Compliance and Safety Information that accompanied your equipment).

WarningLaser radiation when open. (For translated versions of this warning, refer to the

Regulatory Compliance and Safety Information that accompanied your equipment).

Invisible laser radiation may be emitted from the optical ports of the single-mode or

2-4 BPX Service Node Installation, Release 8.5

Page 25

Power and Grounding

Step1 In order for the BPX to function safely and correctly, along with peripheral equipment,

Step2 Certain BPX nodes are supplied with two power feeds (cords). Before commencing

Step3 Ensure that the BPX frame is attached to an isolated ground connection (connection

Step4 A conduit hookup box is factory-installed on each DC Power Entry Module for sites

Step5 For an AC system, verify that the node is powered from a dedicated AC branch circuit.

Safety Requirements

use only the power cords, cables, and connectors specified for the attached peripheral

equipment, and make sure they are in good condition.

installation or maintenance inside the cabinet, be sure both power feeds are disconnected

from their respective sources.

attached directly to ground through an uninterrupted line).

requiring wiring to be enclosed in conduit. A plastic terminal block cover is also provided

for installations that do not require conduit hookup. Install one or the other as protection

for the DC input.

The circuit shall be protected by a dedicated 2-pole circuit breaker sized such that the

rated current and the trip delay is higher and longer than the BPX circuit breaker. A

dedicated 20A, 2-pole AC circuit breaker with a long trip delay is recommended for

installation.

NoteThe BPX uses a 15A (or in newer models a 20_A), 2-pole AC circuit breaker with a medium

trip delay on each AC input. The circuit breaker manufacture is either Carlingswitch (p/n

CA2-B0-34-615-121-C) or Heinemann (p/n AM2-A3-A-0015-02E).

Step6 For a DC system, verify that the node is powered from a dedicated DC branch circuit. The

NoteThe BPX uses a 50A, 1-pole DC circuit breaker with medium trip delay on the -48V input.

The circuit breaker manufacture is Heinemann (p/n AM1S-B3-A-0050-02-H).

Step7 An insulated grounding conductor that is identical in size to the grounded and

CEPT Requirements

All apparatus (e.g., 48 VDC power supplies) connected to the BPX must comply with BS6301 or

EN60950

circuit shall be protected by a dedicated circuit breaker sized such that the rated current

and the trip delay is higher and longer than the BPX circuit breaker. A dedicated 50A,

1-pole DC circuit breaker with a long trip delay is recommended for installation.

ungrounded branch circuit supply conductors, but is green with yellow stripes, is to be

installed as part of the branch circuit that supplies the unit.

EMI Requirements

Compliance with emission regulations depends upon adherence to the installation steps in this

manual, including installation of faceplates for all slots and the use of shielded cables between

systems.

Installation, Preliminary 2-5

Page 26

Mechanical Installation

Mechanical Installation

Weight

A fully loaded, AC-version, BPX node can weigh up to 213 pounds (97 Kgs). A fully-loaded

DC-version BPX may weigh up to 163 pounds (74 Kgs).

Cooling

CautionIf the BPX is to be mounted in an enclosed cabinet, assure that a free flow of air in and out

of the enclosure is provided. Contact Customer Service for further information.

Horizontal Positioning

BPX shelves are designed to be mounted to two sets of vertical mounting rails in either a STRATM

cabinet or a standard 19-inch equipment rack with unrestricted front to rear air flow. When installed

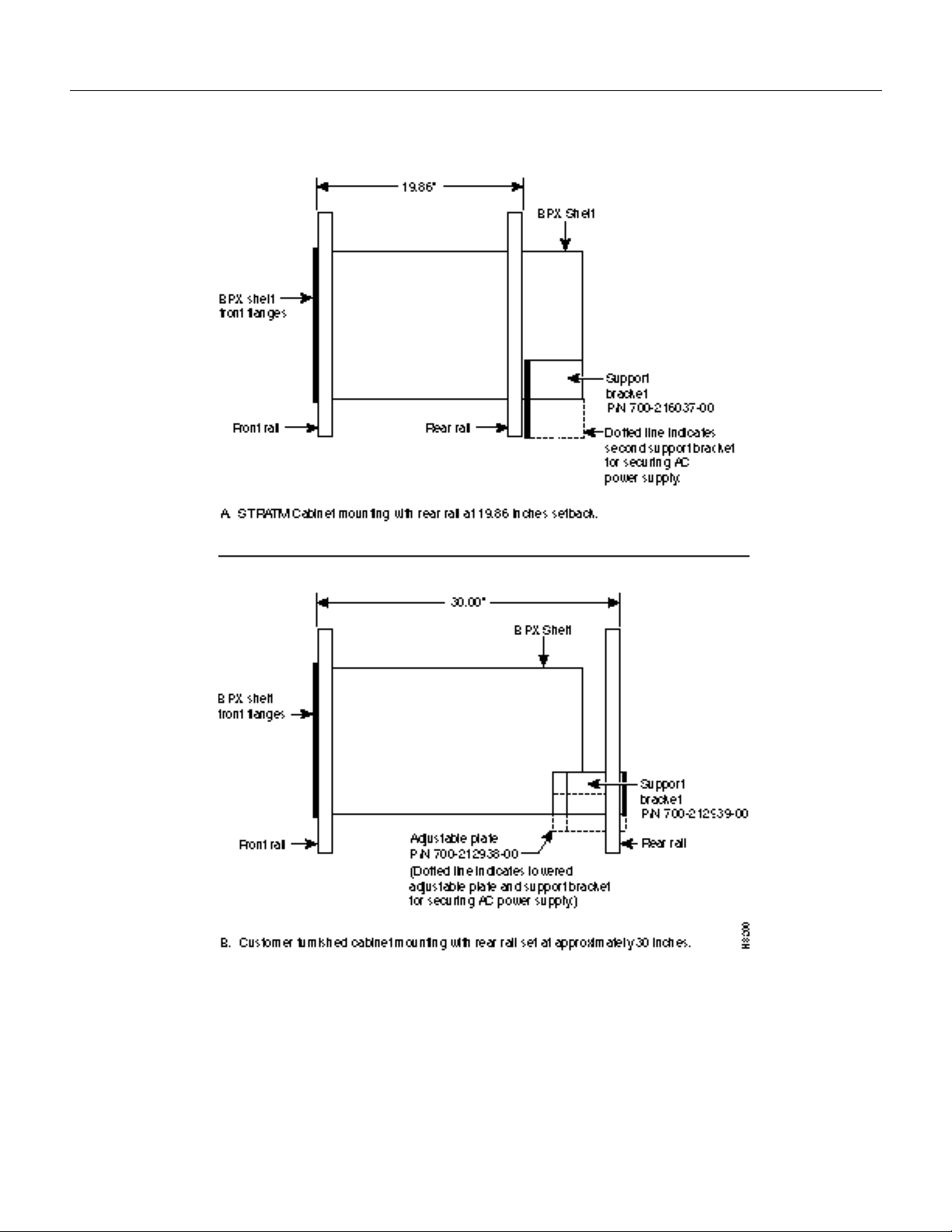

in a STRATM cabinet (Figure2-2), the front flanges of the BPX are secured to the front rails of the

STRATM cabinet. In factory installations, rear support is provided by rear mounting rails in the

cabinet at a setback of 19.86 inches. As an option, a rear set of rails located at a setback of

approximately 30 inches may be used for rear support.

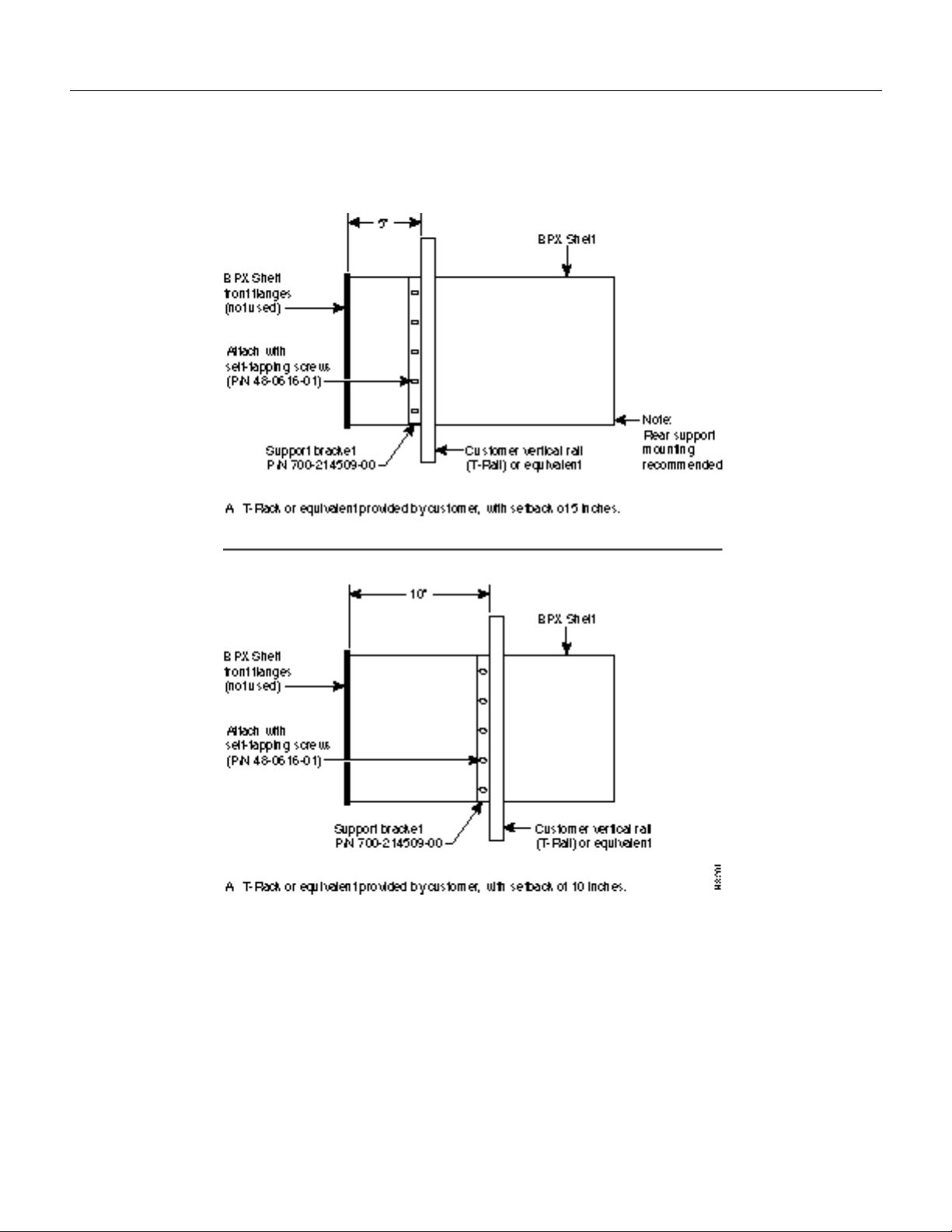

BPX shelves can also be mid-mounted to an open T-Rail type rack (Figure2-3) with unrestricted

front to rear air flow. To facilitate this type of installation, brackets may be fastened to the BPX shelf

at a 5 or 10 inch setback for supporting the front of the BPX shelf. Additional rear mounting support

is also recommended. Contact Customer Service for further information.

Vertical Positioning

For recommended typical equipment configurations in a STRATM cabinet, refer to AppendixA,

STRATM Cabinet Dimensions.

2-6 BPX Service Node Installation, Release 8.5

Page 27

Figure2-2 Cabinet Mounting Options for the BPX Shelf

Mechanical Installation

Installation, Preliminary 2-7

Page 28

Mechanical Installation

Figure2-3 BPX Shelf and T-Rail (Open Rack) or Equivalent Mounting Options

2-8 BPX Service Node Installation, Release 8.5

Page 29

Installing a BPX Shelf, Preliminary Steps

The BPX is designed for mounting in a standard 19-inch (48.25 cm.) equipment rack such as the

standard STRATM cabinet. A minimum width between rails of 17.750 inches (44.45 cm) is required

(Figure2-5 and Figure2-6). Mounting flanges are permanently attached to the front edge of the BPX

shelf. It is recommended that the shelf be mounted with all plug-in cards temporarily removed to

lessen the weight.

There are two types of BPX shelves, AC powered and DC powered. When an AC powered BPX shelf

is installed, an AC Power Supply Tray is installed directly below it. The DC Powered BPX Shelf

contains factory installed DC power entry modules (PEMs) within the shelf itself.

A temporary support bracket and spacer bracket is furnished to ease installation. The pallet tray part

of the shipping container is used in the installation of the BPX. This wooden pallet tray that is

shipped under the BPX chassis is used to lift, align, and support the chassis during installation in a

rack.

The following instructions are for BPX Shelf installation in a STRATM cabinet which has rear rails

at 19.86 inches (50.5 cm) or in a customer supplied standard 19-inch (48.25 cm)_ equipment rack

with rear rails at a 30 inch (76.2 cm) setback.

NoteInstallation in a non-STRATM cabinet or T-Rail type rack is similar to installation in a

STRATM cabinet. Contact Customer Service for recommended rear support details.

Mechanical Installation

To install the BPX in a rack proceed as follows:

Step1 Position the shipping container and pallet in front of the cabinet with the rear of the

chassis towards the cabinet. Remove the foam strips on the sides, front, and rear.

Step2 Remove the card retaining bracket from the front of the chassis by unscrewing the four

Phillips screws. This bracket is used to retain the boards during shipping.

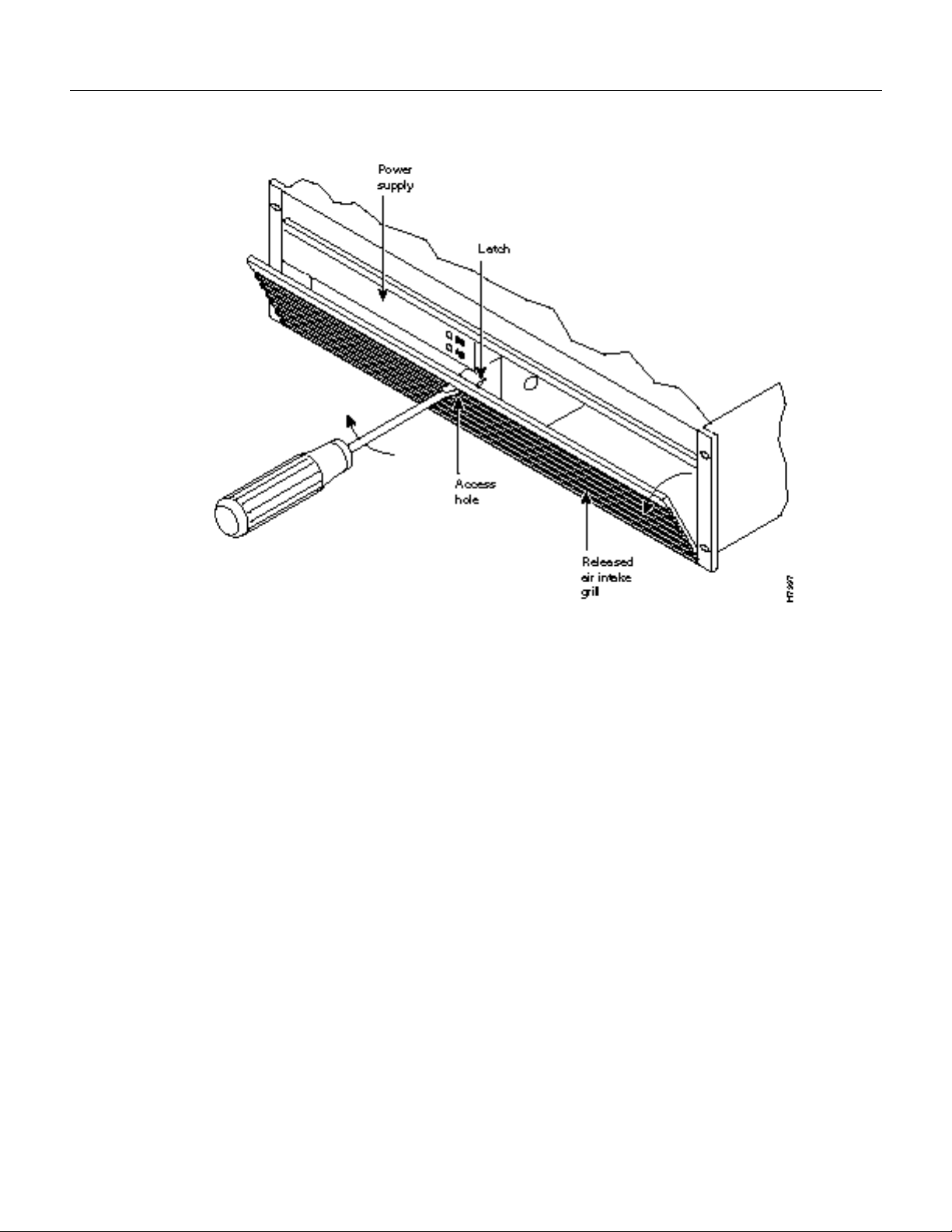

Step3 Remove the Air Intake Grill and all front and rear cards from the shelf and temporarily

set aside as follows:

(a) Locate the small access hole in the top center of the front Air Intake Grille below the

card slots (see Figure2-4 for location).

(b) Insert a small slotted blade screwdriver (0.20/0.25 inch blade width) into the access

hole until it stops (approximately 1 inch).

(c) Carefully rotate the screwdriver approximately a quarter turn in either direction. The

top of the Air Intake Grille should spring out.

(d) Remove Air Intake Grille.

CautionGround yourself before handling BPX cards by placing a wrist strap on your wrist and

clipping the strap lead to the cabinet.

(e) To remove the cards, rotate the extractor handles at the top and bottom of each card

to release the card and slide it out.

Installation, Preliminary 2-9

Page 30

Mechanical Installation

Figure2-4 Removing an Air Intake Grille

Step4

Decide where the BPX is to be located. Refer to Figure2-2 through Figure2-6 for typical

mounting dimensions. Also, for typical mounting configuration examples, refer to

AppendixA, STRATM Cabinet Dimensions. The appendix lists dimensions in inches,

centimeters, and rack mounting units (RMUs). The top of the spacer bracket should be

temporarily installed in the rack 22.75" (57.8 cm.) below the location selected for the top

of the BPX chassis.

Step5 Install the temporary support brackets and spacer bracket (shipped with the unit). Use two

mounting screws to attach each temporary support bracket and two screws to attach the

temporary spacer bracket to the rack (Figure2-7 and Figure2-8).

2-10 BPX Service Node Installation, Release 8.5

Page 31

Figure2-5 Rack Mounting Dimensions, DC Powered Shelf

Mechanical Installation

Installation, Preliminary 2-11

Page 32

Mechanical Installation

Figure2-6 Rack Mounting Dimensions, AC Powered Shelf

2-12 BPX Service Node Installation, Release 8.5

Page 33

Figure2-7 Temporary Spacer Bracket and Support Bracket Installation

Mechanical Installation

Figure2-8 BPX Shelf Aligned with Temporary Support Brackets and Bar

Installation, Preliminary 2-13

Page 34

Mechanical Installation

NoteIt is recommended that all BPX systems use a set of vertical support rails to provide additional

support for the rear of the chassis. In the STRATM cabinet these are located at a 19.86 inch setback

from the front in factory installations.

Step6 If the BPX Shelf is being installed in a STRATM cabinet and is using factory installed

Step7 If the BPX Shelf is being installed in a customer supplied cabinet using rear rail mounting

rear rails located at a 19.86 inch setback from the front, go to Chapter3, Installation, with

STRATM Cabinet.

support brackets located at a setback of approximately 30 inches from the front, go to

Chapter4, Installation, with Customer Cabinet.

2-14 BPX Service Node Installation, Release 8.5

Page 35

CHAPTER

Installation, with STRATM Cabinet

This chapter provides installation steps for the mechanical placement of a BPX shelf in a standard

STRATM cabinet. This cabinet provides rear rails at a 19.86 inch (50.5 cm) setback from the front

of the cabinet.

Before proceeding to this chapter, the procedures should be completed, in:

— Chapter2, Installation, Preliminary

3

Installing a BPX Shelf, Rear-Rail Setback at 19.86 Inch

The steps in this procedure apply to a BPX Shelf that is being installed in a STRATM cabinet and

using factory installed rear rails located at 19.86 inches from the front.

If the BPX shelf is DC-powered, the DC Power Entry Modules are factory-installed in the lower

portion of the rear of the BPX shelf (Figure3-1). Locate the DC Power Entry Module(s) and make

sure it/they are equipped as ordered. If the BPX shelf is AC-powered, an AC Power Tray is installed

below it as part of the installation process.

Installation, with STRATM Cabinet3-1

Page 36

Installing a BPX Shelf, Rear-Rail Setback at 19.86 Inch

Figure3-1 Location of DC Power Entry Module(s), Cabinet Rear View

3-2 BPX Service Node Installation, Release 8.5

Page 37

Preliminary Procedure:

Proceed as follows to install either an AC or DC powered BPX shelf, referring to Figure3-2 and

Figure3-3 and to either Figure3-4 for DC powered systems or Figure3-5 for AC powered systems:

Step1 Locate the two rear support brackets (P/N 700-216037-00) in the miscellaneous parts kit.

Step2 Secure one each support bracket to the back of the rear rail located at 19.86 inches from

NoteEuropean installation may use a size M6 metric screw.

WarningAn empty BPX enclosure weighs 75 pounds (34 Kgs.) and requires a 2 or 3-person lift to

move into place.

Step3 With one person on each side of the BPX shelf, lift the pallet tray and BPX chassis

Installing a BPX Shelf, Rear-Rail Setback at 19.86 Inch

the front flange of the STRATM cabinet using #10-32 machine screws and flat washers.

positioning the slots at the rear of the pallet tray over the locating tabs on the spacer

bracket (Figure3-2).

Step4 Slide the BPX shelf back over the temporary support brackets and into place.

Figure3-2 BPX Shelf Aligned with Temporary Support Brackets and Bar

Step5

Step6 Attach the BPX shelf to the previously installed support brackets by inserting 8 each

Attach the BPX shelf to the cabinet front rail using 8 each # 10-32 screws.

#10-32 machine screws and flat washers from inside the back of the BPX shelf.

Installation, with STRATM Cabinet 3-3

Page 38

Installing a BPX Shelf, Rear-Rail Setback at 19.86 Inch

Step7 Remove the temporary support brackets and spacer bracket.

Step8 If this is a DC powered shelf, proceed to Chapter5, Installation, DC Shelf Initial Setup.

Step9 If this is an AC powered shelf, proceed to Chapter6, Installation, AC Shelf Initial Setup.

3-4 BPX Service Node Installation, Release 8.5

Page 39

Installing a BPX Shelf, Rear-Rail Setback at 19.86 Inch

Figure3-3 BPX Shelf with Rear Rail Mounting at Setback of 19.86 inches

Installation, with STRATM Cabinet 3-5

Page 40

Installing a BPX Shelf, Rear-Rail Setback at 19.86 Inch

Figure3-4 Rear Mounting Brackets, with 19.86 Inch Rear Rail Setback (DC Systems)

Figure3-5 Rear Mounting Brackets, 19.86 Inch Rear Rail Setback (AC-Systems)

3-6 BPX Service Node Installation, Release 8.5

Page 41

Installation, with Customer Cabinet

This chapter provides installation steps for the mechanical placement of a BPX shelf in a standard

19-inch customer supplied equipment cabinet or rack with a rear rail setback at 30 inches.

Before proceeding to this chapter, the procedures should be completed, in:

— Chapter2, Installation, Preliminary

Installing a BPX Shelf, Rear Rail Setback at 30-Inch

The steps in this procedure apply to a BPX shelf that is being installed in a customer supplied cabinet

with rear vertical rails located at a setback of approximately 30 inches from the front.

CHAPTER

4

If the BPX shelf is DC-powered, the DC Power Entry Modules are factory-installed in the lower

portion of the rear of the BPX shelf itself. Locate the DC Power Entry Module(s) and make sure

it/they are equipped as ordered. If the BPX shelf is AC-powered, an AC Power Assembly will be

installed below it.

Figure4-2 shows the location of the rear located third rails in a customer supplied cabinet and of the

corresponding adjustable plates and support brackets on the BPX shelf.

Preliminary Procedure:

Proceed as follows to install the BPX shelf, referring to Figure4-1 through Figure4-3, and to either

Figure4-4 for DC powered systems or Figure4-5 for AC powered systems.

Step1 With one person on each side of the BPX shelf, lift the pallet tray and BPX shelf

Step2 Slide the BPX shelf back over the support brackets and into place.

Step3 Secure the BPX shelf to the front rail using 8 each #10-32 screws.

NoteEuropean installation may use a size M6 metric screw.

Step4 Locate the two rear support brackets and adjustable plates in the miscellaneous parts kit.

positioning the slots at the rear of the pallet tray over the locating tabs on the spacer

bracket (Figure4-1).

Step5 Position the adjustable plates with the tabs in the three punchouts facing up as shown in

Figure4-3.

Installation, with Customer Cabinet4-1

Page 42

Installing a BPX Shelf, Rear Rail Setback at 30-Inch

Figure4-1 BPX Cabinet Aligned with Temporary Support Brackets and Bar

Step6

Align the top and bottom holes in the adjustable plates with corresponding holes in the

side panel of the BPX shelf. (The bottom of the plates should be approximately aligned

with the bottom of a DC powered BPX shelf. They should be extended below the bottom

of an AC powered BPX shelf so that the AC Power Supplies can be secured to the shelf.)

Step7 Secure one each adjustable plate to each side of the BPX shelf using (2) each #10-32

machine screws and flat washers.

Step8 Attach a rear support bracket to each one of the adjustable plates with 2 each 10-32 screws

and washers. Do not tighten yet.

Step9 Secure the support brackets to the rear located vertical rails using 2 each #10-32 screws

(or up to M6 metric screws). You may have to lift the BPX shelf slightly to align the holes

in the bracket to the holes in the rack.

Step10 Tighten the screws attaching the support bracket to the adjustable plate.

Step11 Slide a cable strap over each of the three tabs on the support brackets.

Step12 Remove the temporary support bracket and spacer bracket from the front of the cabinet.

Step13 If this is a DC powered shelf, proceed to Chapter5, Installation, DC Shelf Initial Setup.

Step14 If this is an AC powered shelf, proceed to Chapter6, Installation, AC Shelf Initial Setup.

4-2 BPX Service Node Installation, Release 8.5

Page 43

Installing a BPX Shelf, Rear Rail Setback at 30-Inch

Figure4-2 BPX Shelf with Rear Rail Mounting at Setback of 30 Inches

Figure4-3 Rear Mounting Brackets, Detail

Installation, with Customer Cabinet 4-3

Page 44

Installing a BPX Shelf, Rear Rail Setback at 30-Inch

Figure4-4 Rear Mounting Brackets, with 30 Inch Rear Rail Setback (DC Systems)

Figure4-5 Rear Mounting Brackets, 30 Inch Rear Rail Setback (AC-Powered Systems)

4-4 BPX Service Node Installation, Release 8.5

Page 45

CHAPTER

Installation, DC Shelf Initial Setup

This chapter describes how to make the DC power connections.

Before proceeding to this chapter, the procedures should be completed, in either:

— Chapter3, Installation, with STRATM Cabinet, or

— Chapter4, Installation, with Customer Cabinet.

This chapter contains the following sections:

DC Power Input Connections

5

Card Slot Fuses

Fan Power Fuses

DC Power Input Connections

There are two versions of the DC-powered BPX cabinet as follows:

• Single DC Power Entry Module, single power feed.

• Dual DC Power Entry Module, dual power feed.

For DC systems, the wiring is connected from a 48 VDC power source to one or two DC Power Entry

Modules (Figure5-1). This wiring is provided by the installer. A metallic conduit box that meets all

electrical codes for attaching electrical conduit is factory-installed Figure5-2. A simple plastic cover

is also enclosed for customers who do not require conduit protection for the input power leads

Figure5-3. Use conduit if required by local electrical code.

To make DC power connections to the BPX:

Step1 Locate the conduit terminating box, one for each Power Entry Module. (Figure5-2).

Remove the two cover screws and lift off the cover. If conduit is required, proceed to step

2. If conduit is not required, proceed to step 3.

Step2 Determine which knockout to remove (rear or bottom). Remove knockout and install

conduit fitting.

Step3 If conduit is not required, remove the conduit box by removing the two screws, one above

the terminal block and one below it.

Step4 Run three wires from the DC terminal block to a source of 48 VDC. Use 8 AWG wire

(ormetric equivalent for E1 systems). Use a #10 screw ring lug designed for 8 AWG wire

° lug if using conduit box) to terminate the wires.

(90

Installation, DC Shelf Initial Setup5-1

Page 46

DC Power Input Connections

CautionEnsure that polarity of the DC input wiring is correct! Connections with reversed polarity

may damage the equipment.

WarningRemember that this is a positive ground system. Connect the positive lead to the +RTN

terminal. Connect the negative lead to the –48V terminal. Connect the earth ground to the middle

terminal labeled SAFETY GROUND. See Figure5-1, Figure5-2 and Figure5-3. For personnel

safety, the green/yellow wire must be connected to safety (earth) ground at both the equipment and

at the supply side of the dc wiring.

Figure5-1 DC Power

Step5

Terminate the DC input wiring to a DC source capable of supplying at least 50 amperes.

A 50A dc circuit breaker is required at the 48 VDC facility power source. An easily

accessible disconnect device should be incorporated into the facility wiring. Be sure to

connect the ground wire/conduit to a solid office (earth) ground.

NotePrimary overcurrent protection is provided by the building circuit breaker. In North America,

this breaker should protect against excess currents, short circuits, earth faults in accordance with

NEC/CEC.

Step6 If the system is equipped with dual power feed, repeat steps 1 through 6 for the second

power feed.

Step7 Either replace the cover on the conduit terminating box(es) or attach the plastic cover

plate(s) to the terminal block with screws into the two terminal block standoffs. See

Figure5-2 and Figure5-3.

Step8 Proceed to Chapter7, Finishing the Installation.

5-2 BPX Service Node Installation, Release 8.5

Page 47

Figure5-2 DC Power Connections—With Conduit Box

DC Power Input Connections

Installation, DC Shelf Initial Setup 5-3

Page 48

Card Slot Fuses

Figure5-3 DC Power Connections—Without Conduit Box

Card Slot Fuses

Fuses for each card slot have been added to the backplane of later versions of the BPX to protect

against catastrophic backplane damage in the event of a shorted connector power pin. Backplane

fuses should rarely, if ever, need replacement. The card slot fuses are designated F4 through F18,

corresponding to card slot numbers 1 through 15, respectively.

Refer to the BPX Service Node Reference document, Repair and Replacement chapter, for

instructions on replacement of these fuses, and contact Cisco Customer Service for assistance

regarding their replacement.

CautionFor continued protection against risk of fire, replace only with the same type and rating of

fuse. Fuses should only be replaced after all power to the BPX has been turned off.

Fan Power Fuses

Fan fuses are located on the backplane of the BPX to protect against catastrophic backplane damage

in the event of a shorted fan cable. Backplane fuses should rarely, if ever, need replacement. The

fuses are designated F1 through F3, corresponding to fans 1 through 3.

5-4 BPX Service Node Installation, Release 8.5

Page 49

Fan Power Fuses

CautionRefer to the BPX Service Node Reference document, Repair and Replacement chapter, for

instructions on replacement of these fuses, and contact Cisco Customer Service for assistance

regarding their replacement.

WarningFor continued protection against risk of fire, replace only with the same type and rating

of fuse. Replace fuses only after all power to the BPX has been turned off.

Installation, DC Shelf Initial Setup 5-5

Page 50

Fan Power Fuses

5-6 BPX Service Node Installation, Release 8.5

Page 51

CHAPTER

Installation, AC Shelf Initial Setup

This chapter explains how to install the AC power supply tray, power supplies, and make AC power

connections.

Before proceeding to this chapter, the procedures should be completed, in either:

— Chapter3, Installation, with STRATM Cabinet, or

— Chapter4, Installation, with Customer Cabinet.

This chapter contains the following sections:

6

Installing an AC Power Supply Tray

Installing an AC Power Supply

AC Power Input Connections

Card Slot Fuses

Fan Power Fuses

Installing an AC Power Supply Tray

The AC Power Supply Assembly is shipped separately and must be mounted directly below the BPX

shelf. It consists of a Power Supply Tray and one or two AC power supplies. The power supplies are

shipped separately from the AC Power Supply Tray and are installed after the BPX shelf is mounted

in place.

All AC-powered systems are required to use a set of rear support brackets to provide additional

support for the rear of the Power Supply Tray. To install the AC Power Supply Tray proceed as

follows:

Step1 Use two screws to attach each of two temporary support brackets and a temporary spacer

bar to the rack (Figure6-1 and Figure6-2).

Step2 Locate the small access hole in the top center of the front Air Intake Grille on the Power

Supply Tray (Figure6-3).

Step3 Insert a slotted blade screwdriver (0.20/0.25 inch blade width) into the access hole until

it stops (approximately 1 inch).

Step4 Carefully rotate the screwdriver approximately a quarter turn in either direction. The top

of the Air Intake Grille should spring out.

Step5 Remove the Air Intake Grille.

Installation, AC Shelf Initial Setup6-1

Page 52

Installing an AC Power Supply Tray

Figure6-1 Temporary Spacer Bracket and Support Bracket Installation

6-2 BPX Service Node Installation, Release 8.5

Page 53

Installing an AC Power Supply Tray

Figure6-2 Power Supply Tray aligned with Temporary Support Brackets and Bar

Installation, AC Shelf Initial Setup 6-3

Page 54

Installing an AC Power Supply Tray

Figure6-3 Removing an Air Intake Grille

6-4 BPX Service Node Installation, Release 8.5

Page 55

Installing an AC Power Supply Tray

Step6 Slide the Power Supply Tray in the rack between the BPX shelf and the temporary support

brackets and spacer bar (Figure6-2). If cables are attached, use care to avoid damaging

them.

Step7 Install screws and washers to loosely secure power supply assembly to the front of the

BPX shelf. Align the front flanges of the Power Supply Tray with the flanges on the BPX

shelf and tighten screws. There should be approximately 1/16” clearance between the

BPX shelf and the Power Supply Tray to provide sufficient clearance for inserting power

supplies.

Step8 Secure the Power Supply Tray to the rear support bracket (plate) using one #10-32 screw

and flat washer on each side. Use the lower hole in the brackets. Figure6-4 shows the

setup for a configuration with the vertical rails at a 30 inch setback.

For a configuration with vertical rails at a 19.86 inch rail setback, attach one #10-32 screw

and flat washer to the single bracket on each side. Use the lower hole in the brackets.

Figure6-5 shows the bracket configuration only; the power supply tray position is the

same as shown for in Figure6-4.

Figure6-4 Securing AC Power Supply Tray, 30-Inch Rail Setback

Installation, AC Shelf Initial Setup 6-5

Page 56

Installing an AC Power Supply Tray

Figure6-5 Securing an AC Power Supply Tray, 19.86 inch Rear Rail Setback

Step9 Connect and secure a power supply interconnect cable (Cable A in Figure6-6) between

the primary AC Power Supply and the BPX backplane power connector.

Step10 Connect and secure a second power supply interconnect cable (Cable B in Figure6-6)

between the redundant AC Power Supply and the BPX backplane power connector.

Step11 Remove the temporary support bracket and spacer bracket from the front of the cabinet.

6-6 BPX Service Node Installation, Release 8.5

Page 57

Installing an AC Power Supply Tray

Figure6-6 AC Power Supply Tray with Redundant AC Inputs (view from rear)

Installation, AC Shelf Initial Setup 6-7

Page 58

Installing an AC Power Supply

Installing an AC Power Supply

The AC Power Supply is an assembly consisting of an AC-DC Converter, cooling fan, LED bezel,

and mounting frame. The AC Power Supply is installed and removed as an integral unit. There may

be one or two AC Power Supplies depending on node configuration. They are housed in the Power

Supply Tray.

Proceed as follows to remove and reinstall an AC Power Supply in the Power Supply Tray:

Step1 First install the Power Supply Tray in a rack (see “Installing an AC Power Supply Tray”

section).

Step2 Set the circuit breaker(s) at the rear of the Power Supply Tray to OFF.

Step3 If not already removed, remove the Power Supply Tray front Air Intake Grille. Locate the

small access hole in the top, center of the front Air Intake Grille for the Power Supply

Tray (Figure6-7).

Figure6-7 Removing an Air Intake Grille

Step4

Insert a small slotted blade screwdriver (0.20/0.25 inch blade width) into the access hole

until it stops, approximately 1 inch (2.5 cm).

Step5 Carefully rotate the screwdriver approximately a quarter turn in either direction. The top

of the Air Intake Grille should spring out.

Step6 Loosen the captive screw in the center of the power supply retainer and rotate the hinged

retainer frame down (Figure6-7).

6-8 BPX Service Node Installation, Release 8.5

Page 59

Figure6-8 AC Power Supply Installation

Installing an AC Power Supply

Step7

Align the power supply in the PS-A slots at the bottom of the Power Supply Tray and

gently slide it in part way (Figure6-8).

Step8 Continue to slide the power supply in until it mates with the rear connector.

Step9 When the power supply is completely seated in its connector, the pin plunger on the left

side of the supply will engage with a hole in the tray. If not, push firmly on the front edge

until the power supply assembly seats in the connector.

Step10 Screw the right-hand thumbscrew in finger tight.

Step11 When a second power supply is provided, install it in the PS-B slot in the same manner

after removing the Blank Panel from Slot B.

Step12 Rotate the power supply retainer up and tighten the center captive screw.

Step13 Install the Air Intake Grille. Press on the top center until the latch snaps into place.

Installation, AC Shelf Initial Setup 6-9

Page 60

AC Power Input Connections

AC Power Input Connections

There are three configurations of the AC-powered BPX cabinet as follows:

• Single power supply, single AC power feed.

• Dual power supplies, single AC power feed.

• Dual power supplies, dual AC power feed.

ft. (3 m.) power cord is supplied with each AC Power Supply Assembly. To make AC power

An 8

connections to the BPX:

Step1 Plug the power cord(s) into the applicable IEC connector(s) as shown in Figure6-9 and

tighten the cord retainers. A separate power cord connects to each of one or two IEC

connectors depending on the version of power supply shelf provided.

Step2 Plug the BPX cord into a 220 to 240 VAC, single-phase, wall outlet capable of supplying

15A. The building circuit should be protected with a 20A circuit breaker.

Step3 For the dual power feed version, plug each power cord into receptacles on separate

building circuits to provide protection against a power feed failure. Each building circuit

should be protected with a 20A circuit breaker.

6-10 BPX Service Node Installation, Release 8.5

Page 61

AC Power Input Connections

Figure6-9 AC Power Supply Connections (Dual and Single Versions Shown)

Installation, AC Shelf Initial Setup 6-11

Page 62

AC Power Input Connections

Step4 The ground (green/yellow) wire of the AC power cord provides the safety ground to the

Figure6-10 AC Power

.

Step5 As applicable, provide a convenience AC outlet strip, with at least four outlets, near the

BPX via the grounding prong on the three-prong connectors. Make sure the building AC

receptacle is also properly grounded (Figure6-10).

BPX node to power optional modems, CSU, or DSUs, test equipment, etc. There is no

accessory AC outlet supplied on the BPX. This outlet strip should be connected to a

source of AC voltage normal for the region (e.g., 115 VAC for domestic US use).

Step6 Proceed to Chapter7, Finishing the Installation.

6-12 BPX Service Node Installation, Release 8.5

Page 63

Card Slot Fuses

Fuses for each card slot have been added to the backplane of later versions of the BPX to protect

against catastrophic backplane damage in the event of a shorted connector power pin. Backplane

fuses should rarely, if ever, need replacement. The card slot fuses are designated F4 through F18,

corresponding to card slot numbers 1 through 15, respectively.

Refer to the BPX Service Node Reference document, Repair and Replacement chapter, for

instructions on replacement of these fuses, and contact Customer Service for assistance regarding

their replacement.

CautionFor continued protection against risk of fire, replace only with the same type and rating of

fuse. Fuses should only be replaced after all power to the BPX has been turned off.

Fan Power Fuses

Fan fuses are located on the backplane of the BPX to protect against catastrophic backplane damage

in the event of a shorted fan cable. Backplane fuses should rarely, if ever, need replacement. The

fuses are designated F1 through F3, corresponding to fans 1 through 3.

Card Slot Fuses

CautionRefer to the BPX Service Node Reference document, Repair and Replacement chapter, for

instructions on replacement of these fuses, and contact Customer Service for assistance regarding

their replacement.

CautionFor continued protection against risk of fire, replace only with the same type and rating of

fuse. Replace fuses only after all power to the BPX has been turned off.

Installation, AC Shelf Initial Setup 6-13

Page 64

Fan Power Fuses

6-14 BPX Service Node Installation, Release 8.5

Page 65

CHAPTER

Finishing the Installation

This chapter explains how to install the BPX cards, check for a 9.6 or 19.2 Gbps backplane, connect

line and trunk cables, connect peripherals, connect to a network management station, initial power

up, and initial configuration.

Before proceeding to this chapter, the procedures should be completed, in either:

— Chapter5, Installation, DC Shelf Initial Setup, or

— Chapter6, Installation, AC Shelf Initial Setup.

This chapter contains the following sections:

7

• Installing the BPX Cards

• Verifying 9.6 or 19.2 Gbps Backplane

• Making T3 or E3 Connections

• Making an ASI-155 or BNI-155 Connection

• Making a BXM OC3 or OC12 Connection

• Making a BXM T3/E3 Connection

• Alarm Output Connections

• Attaching Peripherals

• LAN Connection for the Network Management Station

• Connecting a Network Printer to the BPX

• Connecting Modems

• Making External Clock Connections

• Initial Startup of the BPX

• BPX Management

• Initial Node Configuration Summary

• IP Setup and IP Relay Configuration

• Configuring the LAN Port

• Configuring the AXIS for StrataView Plus NMS Operation (example)

• Adding Virtual Trunks

• Provisioning the BPX Service Node

Finishing the Installation7-1

Page 66

Installing the BPX Cards

Installing the BPX Cards

CautionGround yourself before handling BPX cards by placing a wrist strap on your wrist and

clipping the strap lead to the cabinet, or use the wrist strap that is connected to the cabinet.

The card shelf in the BPX has card slots numbered from 1 to 15, as viewed from left to right from

the front of the cabinet. Front and rear views of the BPX card shelf are shown in Figure7-1 and

Figure7-2, respectively. The configuration rules for the BPX are summarized as follows.

• For non-redundant nodes, either a Broadband Controller Card BCC-4, BCC-3, or BCC-32 is used

in front slot number 7.

• For non-redundant nodes, a BCC-3-bc backcard must be used in back slot number 7 with a

BCC-4 or BCC-3 front card, or a BCC-bc (also known as BCC backcard) must be used in back

slot number 7 with a BCC-32 front card.

• For redundant nodes, two Broadband Controller Cards, a pair of BCC-4s, BCC-3s, or BCC-32s

are used in front slot numbers 7 and 8.

• For redundant nodes, BCC-3 bc backcards must be used in back slot numbers 7 and 8 with BCC-4

or BCC-3 front cards, or BCC-c (also known as BCC backcards) backcards must be used in back

slot numbers 7 and 8 with BCC-32 front cards.

NoteIn some cases it may be possible to operate two of the three types of BCCs with their proper

backcards temporarily for maintenance purposes, i.e., replacing a failed controller card. Contact

Customer Service for assistance.

• ASM in front slot number 15.

• LM -ASM in back slot number 15.

• BNI-3T3, BNI-3E3, BNI-155 in any other front slot than 7, 8, or 15.

• LM -3T3, LM-3E3, 2OC3-SMF, 2OC3-MMF in all back slots with a BNI in the corresponding

front slot

• ASI-2T3, ASI-2E3, ASI-155 in any other front slot than 7, 8, or 15.

• LM -2T3, LM-2E3, 2OC3-SMF, 2OC3-MMF in all back slots with an ASI in the front other than

7, 8, or 15.

7-2 BPX Service Node Installation, Release 8.5

Page 67

Figure7-1 BPX Shelf (front view)

Installing the BPX Cards

Figure7-2 BPX Shelf (rear view, DC shelf shown)

Finishing the Installation 7-3

Page 68

Installing the BPX Cards

Installing Front Cards

CautionGround yourself before handling BPX cards by placing a wrist strap on your wrist and

clipping the strap lead to the cabinet, or use the wrist strap that is connected to the cabinet.

CautionBlank Front Card and Rear Face Plates must be used to fill/cover empty card slots to

eliminate Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI) and to ensure

correct air flow through the card cage.

Systems may be shipped with empty shelves, with filler cards or with plug-in cards installed. If filler

cards are installed in each slot, some of them may need to be replaced with functional cards. The

front cards are held captive mechanically by the Air Intake Grille and can not be removed until the

lower Air Intake Grille is released.

CautionDo not attempt to remove a front card from the BPX cabinet until the Air Intake Grille is

released and lowered or the Air Intake Grille and/or card extractors may be damaged.

Proceed as follows to remove/install a front card.

CautionBefore any card is installed, always examine the chassis backplane and card cage guides

for any signs of loose or misplaced EMI gasketing. Examine the backplane connectors for bent or

damaged connection or pre-power pins.

Step1 Turn off all power to the BPX.

NoteWhile it is a good idea to turn off power when initially installing cards, when replacing cards,

on an operating BPX, it is not necessary to turn off power as the cards are hot pluggable replaceable.

Step2 Locate the small access hole in the top center of the front Air Intake Grille below the card

slots (see Figure7-3 for location).

7-4 BPX Service Node Installation, Release 8.5

Page 69

Figure7-3 Removing an Air Intake Grille

Installing the BPX Cards

Step3

Insert a small slotted blade screwdriver (0.20/0.25 inch blade width) into the access hole

until it stops (approximately 1 inch).

Step4 Carefully rotate the screwdriver approximately a quarter turn in either direction. The top

of the Air Intake Grille should spring out.

Step5 Remove Air Intake Grille.

Step6 To remove a card, rotate the extractor handles at the top and bottom of the card to release

the card and slide it out.

Step7 To insert a new card, position the rear card guides over the appropriate slots at the top and

bottom of the card cage.

Step8 Gently slide the card in all the way to the rear of the slot and seat the board by fully seating

both extractor handles. The handles should snap back to a vertical position when seated.

NoteThe card should slide in with slight friction on the adjacent board’s EMI gaskets. Investigate

any binding. Do not use excessive force.

Finishing the Installation 7-5

Page 70

Installing the BPX Cards

Installing Back Cards

CautionGround yourself before handling BPX cards by placing a wrist strap on your wrist and

clipping the strap lead to the cabinet, or use the wrist strap that is connected to the cabinet.

The optical ports contain an information label as shown in Figure7-4.

Figure7-4 Laser Information Label

Warning

Invisible laser radiation may be emitted from the optical ports of the single-mode or

multi-mode products when no fiber cable is connected. Avoid exposure and do not look into open

apertures. (For translated versions of this warning, refer to the Regulatory Compliance and Safety

Information that accompanied your equipment).

WarningClass 1 laser product. (For translated versions of this warning, refer to the Regulatory

Compliance and Safety Information that accompanied your equipment).

WarningLaser radiation when open. (For translated versions of this warning, refer to the

Regulatory Compliance and Safety Information that accompanied your equipment).

Proceed as follows to install back cards:

Step1 Locate the card to remove.

Step2 For existing installations, remove any cable(s) that may be attached and tag them so they

may be replaced in the same location.

Step3 Loosen the captive mounting screws on both top and bottom of the line module faceplate

with a slotted blade screwdriver (Figure7-5)

Step4 Lift the extractor handles at the top and bottom, and slide out the line module.

Step5 To re-insert the line module, locate the corner edges of the card into the appropriate guide

slots at the top and bottom of the card cage. Gently slide the card in all the way to the rear

of the slot and push to seat the card in the connector.

NoteThe card should slide in easily. Investigate any binding. Do not use excessive force.

Step6 Screw in the captive screws.

Step7 Replace any cables that may have been removed in step 2.

7-6 BPX Service Node Installation, Release 8.5

Page 71

Figure7-5 Installing a Back Card

Verifying 9.6 or 19.2 Gbps Backplane

Verifying 9.6 or 19.2 Gbps Backplane

In order to operate the BPX Service Node at 19.2 Gbps the following is required:

• A 19.2 Gbps backplane

• BCC-4 or later controller cards

• One or more BXM cards

• Release 8.4.00 or later switch software

• A backplane NOVRAM that is programmed to identify the backplane as a 19.2 Gbps backplane.

Switch software will not allow node operation at 19.2 Gpbs unless it can read the backplane

NOVRAM to verify that the backplane is a 19.2 Gbps backplane.

The 19.2 backplane can be visually identified by the small white card slot fuses at the bottom rear of

the backplane. These fuses are approximately 1/4 inch high and 1/8 inch wide. The 9.6 Gbps

backplane does not have these fuses. If the BPX Service Node is a late model, then a 19.2 Gbps

backplane is installed. This can be verified by running the dspbpnv command which will display

“Word #2 =0001” if the backplane NOVRAM has been programmed. If anything else is displayed,

you’ll have to visually check the backplane for the fuses.

Finishing the Installation 7-7

Page 72

Verifying 9.6 or 19.2 Gbps Backplane

If the backplane is a 19.2 Gbps backplane, but the backplane NOVRAM has not been set to display

Word #2 =0001, then the cnfbpnw command may be used to program the NOVRAM as follows:

Step1 Enter cnfbpnv, and the response should be:

Are you sure this is a new backplane (y/n).

Step2 Enter y

Step3 Confirm that the change has been made by entering dspbpnv to confirm the response:

Word #2 =0001

NoteIf for some reason the change does not take place, it will be necessary to change the backplane

NOVRAM. Contact customer service.

Step4 Enter switchcc in order for the change to be recognized by the switch software.

If the backplane is not a 19.2 Gbps backplane, then it will be necessary to install a 19.2 Gbps

backplane to obtain 19.2 Gbps operation. Contact Customer Service.

7-8 BPX Service Node Installation, Release 8.5

Page 73

Making T3 or E3 Connections

Each LM-3T3 and LM-3E3 line module (BNI backcard) provides three ports with a BNC connector

each for the XMT trunk output and for the RCV trunk input. Each LM-2T3 and LM-2E3 line module

(ASI backcard) provides two ports with a BNC connector each for the XMT line output.and for the

RCV line input.Make the T3/E3 connections to each port as follows.

Step1 Bring each cable through the opening at the bottom of the cabinet at the back and route

them up the side.