Page 1

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

First Published: 2018-02-12

Last Modified: 2018-07-18

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

©

2018 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

PREFACE

CHAPTER 1

CHAPTER 2

Preface vii

Audience vii

Documentation Conventions vii

Documentation Feedback viii

Obtaining Documentation and Submitting a Service Request viii

Overview 1

Overview 1

Preparing the Site 5

Temperature Requirements 5

Humidity Requirements 5

Altitude Requirements 5

Dust and Particulate Requirements 6

Minimizing Electromagnetic and Radio Frequency Interference 6

Shock and Vibration Requirements 7

CHAPTER 3

Grounding Requirements 7

Planning for Power Requirements 7

Airflow Requirements 9

Rack and Cabinet Requirements 9

Clearance Requirements 10

Installing the Switch Chassis 11

Safety 11

Installation Options with Racks and Cabinets 12

Airflow Considerations 12

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

iii

Page 4

Contents

Installation Guidelines 12

Unpacking and Inspecting the Switch 13

Installing the Switch 14

Grounding the Chassis 18

Starting the Switch 19

CHAPTER 4

CHAPTER 5

Connecting the Switch to the Network 23

Overview of Network Connections 23

Connecting a Console to the Switch 23

Creating the Initial Switch Configuration 25

Setting Up the Management Interface 26

Connecting Interface Ports to Other Devices 27

Uplink Connections 27

Downlink Connections 28

Replacing Components 29

Replacing a Fan Module 29

Removing a Fan Module 29

Installing a Fan Module 30

Replacing a Power Supply Module 30

Replacing an AC Power Supply 31

Replacing a High Voltage (HVAC/HVDC) Power Supply 32

APPENDIX A

APPENDIX B

iv

Replacing a DC Power Supply 33

Rack Specifications 35

Overview of Racks 35

General Requirements for Cabinets and Racks 35

Requirements Specific to Standard Open Racks 36

Requirements Specific to Perforated Cabinets 36

Cable Management Guidelines 36

System Specifications 37

Environmental Specifications 37

Switch Dimensions 37

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

Page 5

Switch and Module Weights and Quantities 38

Transceiver and Cable Specifications 38

Switch Power Input Requirements 38

Power Specifications 39

1100-W AC Power Supply Specifications 39

1100-W HVAC/HVDC Power Supply Specifications 40

Power Cable Specifications 40

AC Power Cables Supported by NX-OS Mode Switches 40

HVAC/HVDC Power Cables Supported by ACI-Mode and NX-OS Mode Switches 41

DC Power Cable Specifications 42

Regulatory Standards Compliance Specifications 42

Contents

APPENDIX C

APPENDIX D

APPENDIX E

LEDs 45

Switch Chassis LEDs 45

Fan Module LEDs 46

Power Supply LEDs 46

Additional Kits 47

Accessory Kit 47

Site Preparation and Maintenance Records 49

Site Preparation Checklist 49

Contact and Site Information 50

Chassis and Module Information 51

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

v

Page 6

Contents

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

vi

Page 7

Preface

• Audience, on page vii

• Documentation Conventions, on page vii

• Documentation Feedback, on page viii

• Obtaining Documentation and Submitting a Service Request, on page viii

Audience

This publication is for network administrators who install, configure, and maintain Cisco Nexus switches.

Documentation Conventions

Command descriptions use the following conventions:

bold

DescriptionConvention

Bold text indicates the commands and keywords that you enter literally

as shown.

Italic

[x | y]

{x | y}

[x {y | z}]

variable

Italic text indicates arguments for which the user supplies the values.

Square brackets enclose an optional element (keyword or argument).[x]

Square brackets enclosing keywords or arguments separated by a vertical

bar indicate an optional choice.

Braces enclosing keywords or arguments separated by a vertical bar

indicate a required choice.

Nested set of square brackets or braces indicate optional or required

choices within optional or required elements. Braces and a vertical bar

within square brackets indicate a required choice within an optional

element.

Indicates a variable for which you supply values, in context where italics

cannot be used.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

vii

Page 8

Documentation Feedback

Preface

DescriptionConvention

string

Examples use the following conventions:

italic screen font

!, #

Documentation Feedback

To provide technical feedback on this document, or to report an error or omission, please send your comments

to . We appreciate your feedback.

A nonquoted set of characters. Do not use quotation marks around the

string or the string will include the quotation marks.

DescriptionConvention

Terminal sessions and information the switch displays are in screen font.screen font

Information you must enter is in boldface screen font.boldface screen font

Arguments for which you supply values are in italic screen font.

Nonprinting characters, such as passwords, are in angle brackets.< >

Default responses to system prompts are in square brackets.[ ]

An exclamation point (!) or a pound sign (#) at the beginning of a line

of code indicates a comment line.

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, using the Cisco Bug Search Tool (BST), submitting a service

request, and gathering additional information, see What's New in Cisco Product Documentation at:

http://www.cisco.com/c/en/us/td/docs/general/whatsnew/whatsnew.html

Subscribe to What’s New in Cisco Product Documentation, which lists all new and revised Cisco technical

documentation as an RSS feed and delivers content directly to your desktop using a reader application. The

RSS feeds are a free service.

viii

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

Page 9

Overview

CHAPTER 1

Overview

• Overview, on page 1

The Cisco Nexus 93240YC-FX2 (N9K-C93240YC-FX2) is a 1.2-RU, fixed-port switch designed for deployment

in data centers. This switch has 48 1/10/25-Gigabit Ethernet SFP28 ports and 12 40/100-Gigabit Ethernet

QSFP28 ports. The ports on this switch can operate in multiple template configurations. This switch includes

the following user-replaceable components:

• Fan modules (five) with the following airflow choices:

• Port-side exhaust airflow with blue coloring (NXA-FAN-35CFM-PE)

• Port-side intake airflow with burgundy coloring (NXA-FAN-35CFM-PI)

• Power supply modules (two—one for operations and one for redundancy [1+1]) with the following

choices (do not mix AC and DC power sources and do not mix airflow directions):

• 1100-W AC power supply with port-side intake airflow (burgundy coloring) (NXA-PAC-1100W-PI2)

• 1100-W AC power supply with port-side exhaust airflow (blue coloring) (NXA-PAC-1100W-PE2)

• 1100-W DC power supply with port-side exhaust airflow (blue coloring) (NXA-PDC-1100W-PE)

• 1100-W HVAC/HVDC power supply with port-side intake airflow (burgundy coloring)

(NXA-PHV-1100W-PI)

• 1100-W HVAC/HVDC power supply with port-side exhaust airflow (blue coloring)

(NXA-PHV-1100W-PE)

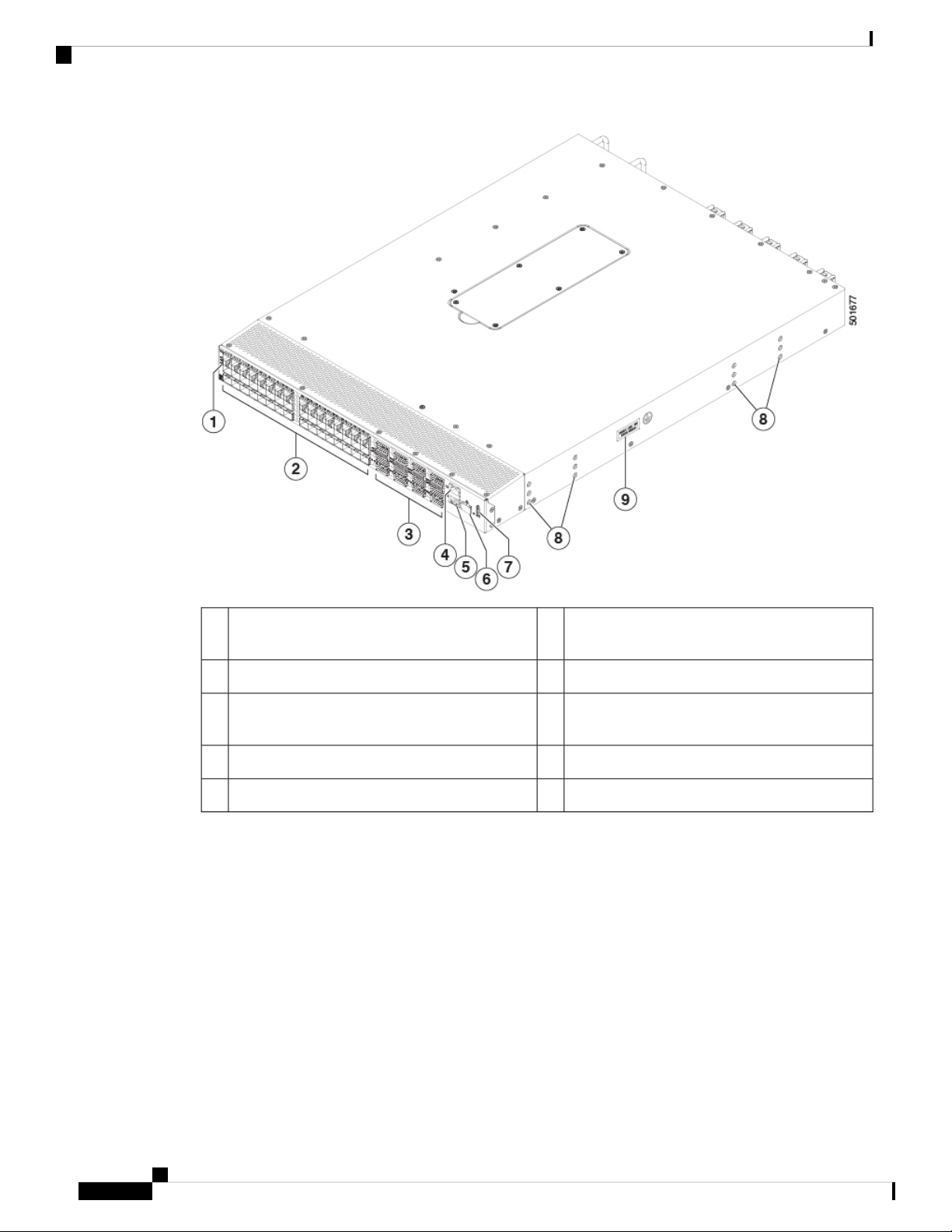

The following figure shows the hardware features seen from the port side of the chassis.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

1

Page 10

Overview

Overview

1

Management port (SFP+ port)6Chassis LEDs (Beacon [BCN], Status [STS], and

Environment [ENV])

USB port710-/25-Gigabit Ethernet SFP28 ports (48)2

Screw holes (6) for attaching rack mounting

840-/100-Gigabit Ethernet QSFP28 ports (12)3

brackets

Grounding pad9Console port (RS232 port)4

Management port (RJ-45 port)5

To determine which transceivers, adapters, and cables this switch supports, see the Cisco Transceiver Modules

Compatibility Information document.

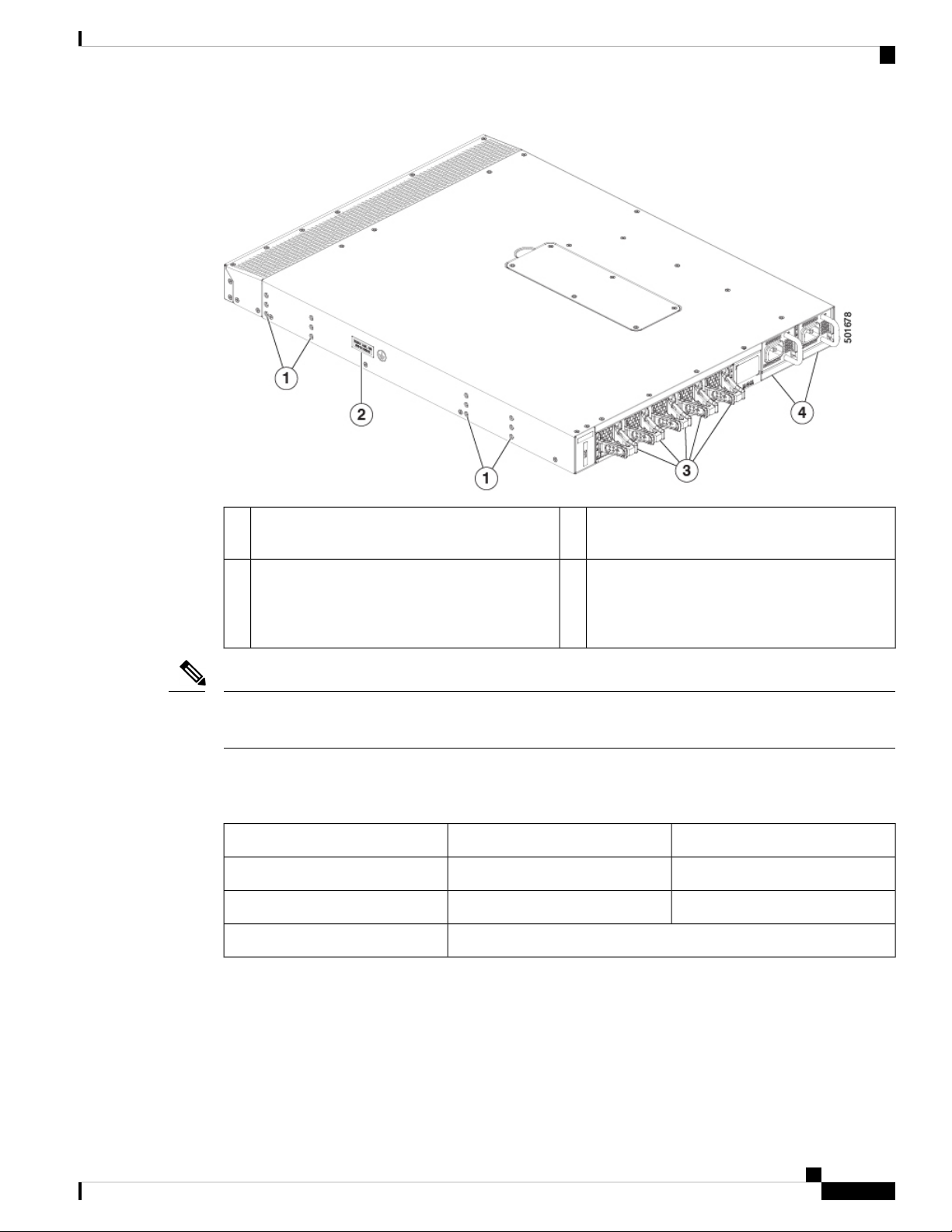

The following figure shows the hardware features seen from the power supply side of the chassis.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

2

Page 11

Overview

Overview

Fan modules (5) with fan slot 1 on the left and

1

brackets

3Screw holes (6) for attaching rack mounting

fan slot 5 on the right

Two power supplies (one used for operations and

4Grounding pad2

one used for redundancy) (AC power supplies

shown) with power supply slot 1 on the left and

slot 2 on the right

Note

USB support is limited to USB 2.0 devices that use less than 2.5 W (less than 0.5 A inclusive of surge current).

Devices, such as external hard drives, that instantaneously draw more than 0.5 A are not supported.

Depending on whether you plan to position the ports in a hot or cold aisle, you can order the fan and power

supply modules with port-side intake or port-side exhaust airflow. To determine the airflow direction of the

modules installed in your switch, see the following table.

Port-Side Exhaust Airflow ColoringPort-Side Intake Airflow ColoringReplaceable Modules

BlueBurgundyFans

BlueBurgundyAC power supplies

WhiteHVAC/HVDC power supplies

The fan and power supply modules are field replaceable. You can replace one fan module or one power supply

module during operations, so long as the other modules are installed and operating. If you have only one

power supply installed, you can install the replacement power supply in the open slot before removing the

original power supply.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

3

Page 12

Overview

Note

All of the fan and power supply modules must have the same direction of airflow. Otherwise, the switch can

overheat and shut down. If you are installing a dual-direction power supply, that module automatically uses

the same airflow direction as the other modules in the switch.

Overview

Caution

If the switch has port-side intake airflow (burgundy coloring for fan modules), you must locate the ports in

the cold aisle. If the switch has port-side exhaust airflow (blue coloring for fan modules), you must locate the

ports in the hot aisle. If you locate the air intake in a hot aisle, the switch can overheat and shut down.

The switch supports the Fabric Extenders (FEXs) listed at

https://www.cisco.com/c/en/us/td/docs/switches/datacenter/nexus9000/hw/interoperability/fexmatrix/fextables.html.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

4

Page 13

Preparing the Site

• Temperature Requirements, on page 5

• Humidity Requirements, on page 5

• Altitude Requirements, on page 5

• Dust and Particulate Requirements, on page 6

• Minimizing Electromagnetic and Radio Frequency Interference, on page 6

• Shock and Vibration Requirements, on page 7

• Grounding Requirements, on page 7

• Planning for Power Requirements, on page 7

• Airflow Requirements, on page 9

• Rack and Cabinet Requirements, on page 9

• Clearance Requirements, on page 10

Temperature Requirements

The switch requires an operating temperature of 32 to 104 degrees Fahrenheit (0 to 40 degrees Celsius). If

the switch is not operating, the temperature must be between –40 to 158 degrees Fahrenheit (–40 to 70 degrees

Celsius).

CHAPTER 2

Humidity Requirements

High humidity can cause moisture to enter the switch. Moisture can cause corrosion of internal components

and degradation of properties such as electrical resistance, thermal conductivity, physical strength, and size.

The switch is rated to withstand from 5- to 95-percent (non-condensing) relative humidity.

Buildings in which the climate is controlled by air-conditioning in the warmer months and by heat during the

colder months usually maintain an acceptable level of humidity for the switch equipment. However, if the

switch is located in an unusually humid location, you should use a dehumidifier to maintain the humidity

within an acceptable range.

Altitude Requirements

The following table lists the maximum altitude that this switch is tested to operate. This switch is rated to

operate at altitudes from 0 to 10,000 feet (0 to 3,048 meters). If you operate this switch at a higher altitude

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

5

Page 14

Dust and Particulate Requirements

(low pressure), the efficiency of forced and convection cooling is reduced and can result in electrical problems

that are related to arcing and corona effects. This condition can also cause sealed components with internal

pressure, such as electrolytic capacitors, to fail or to perform at a reduced efficiency.

Dust and Particulate Requirements

Exhaust fans cool power supplies and system fans cool switches by drawing in air and exhausting air out

through various openings in the chassis. However, fans also ingest dust and other particles, causing contaminant

buildup in the switch and increased internal chassis temperature. A clean operating environment can greatly

reduce the negative effects of dust and other particles, which act as insulators and interfere with the mechanical

components in the switch.

In addition to regular cleaning, follow these precautions to avoid contamination of your switch:

• Do not permit smoking near the switch.

• Do not permit food or drink near the switch.

Preparing the Site

Minimizing Electromagnetic and Radio Frequency Interference

Electromagnetic interference (EMI) and radio frequency interference (RFI) from the switch can adversely

affect other devices, such as radio and television (TV) receivers, operating near the switch. Radio frequencies

that emanate from the switch can also interfere with cordless and low-power telephones. Conversely, RFI

from high-power telephones can cause spurious characters to appear on the switch monitor.

RFI is defined as any EMI with a frequency above 10 kHz. This type of interference can travel from the switch

to other devices through the power cable and power source or through the air as transmitted radio waves. The

Federal Communications Commission (FCC) publishes specific regulations to limit the amount of EMI and

RFI that can be emitted by computing equipment. Each switch meets these FCC regulations.

To reduce the possibility of EMI and RFI, follow these guidelines:

• Cover all open expansion slots with a blank filler plate.

• Always use shielded cables with metal connector shells for attaching peripherals to the switch.

When wires are run for any significant distance in an electromagnetic field, interference can occur between

the field and the signals on the wires with the following implications:

• Bad wiring can result in radio interference emanating from the plant wiring.

• Strong EMI, especially when it is caused by lightning or radio transmitters, can destroy the signal drivers

and receivers in the chassis and even create an electrical hazard by conducting power surges through

lines into equipment.

Note

To predict and prevent strong EMI, you might need to consult experts in radio frequency interference (RFI).

The wiring is unlikely to emit radio interference if you use twisted-pair cable with a good distribution of

grounding conductors. If you exceed the recommended distances, use a high-quality twisted-pair cable with

one ground conductor for each data signal when applicable.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

6

Page 15

Preparing the Site

Shock and Vibration Requirements

Caution

If the wires exceed the recommended distances, or if wires pass between buildings, give special consideration

to the effect of a lightning strike in your vicinity. The electromagnetic pulse caused by lightning or other

high-energy phenomena can easily couple enough energy into unshielded conductors to destroy electronic

switches. You might want to consult experts in electrical surge suppression and shielding if you had similar

problems in the past.

Shock and Vibration Requirements

The switch has been shock- and vibration-tested for operating ranges, handling, and earthquake standards.

Grounding Requirements

The switch is sensitive to variations in voltage supplied by the power sources. Overvoltage, undervoltage,

and transients (or spikes) can erase data from memory or cause components to fail. To protect against these

types of problems, ensure that there is an earth-ground connection for the switch. You can connect the grounding

pad on the switch either directly to the earth-ground connection or to a fully bonded and grounded rack.

When you properly install the chassis in a grounded rack, the switch is grounded because it has a metal-to-metal

connection to the rack. Alternatively, you can ground the chassis by using a customer-supplied grounding

cable that meets your local and national installation requirements (we recommend 6-AWG wire for U.S.

installations) connected to the chassis with a grounding lug (provided in the switch accessory kit) and to the

facility ground.

Note

You automatically ground AC power supplies when you connect them to AC power sources. For DC power

supplies, you must connect a grounding wire when wiring the power supply to the DC power source.

Planning for Power Requirements

The switch includes two power supplies (1-to-1 redundancy with current sharing) in one of the following

combinations:

• Two 1100-W AC power supplies

• Two 1100-W DC power supplies

• Two 1100-W HVAC/HVDC power supplies

Note

Both power supplies must be the same type. Do not mix AC and DC power supplies in the same chassis.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

7

Page 16

Planning for Power Requirements

Note

For n+1 redundancy, you can use one or two power sources for the two power supplies. For n+n redundancy,

you must use two power sources and connect each power supply to a separate power source.

The power supplies are rated to output up to 1100 W, but the switch requires less than those amounts of power

from the power supply. To operate the switch you must provision enough power from the power source to

cover the requirements of both the switch and a power supply. Typically, this switch and a power supply

require about 367 W of power input from the power source, but you must provision as much as 777 W power

input from the power source to cover peak demand.

Note

Some of the power supply modules have Underwriter Labs (UL) rating capabilities that exceed the switch

requirements. When calculating power requirements, use the switch requirements to determine the amount

of power required for the power supplies.

To minimize the possibility of circuit failure, make sure that each power-source circuit used by the switch is

dedicated to the switch.

Preparing the Site

Note

Warning

Note

Warning

For AC input application, please refer to the statement below:

Statement 1005—Circuit Breaker

This product relies on the building's installation for short-circuit (overcurrent) protection. Ensure that the

protective devices are rated not greater than 20A (North America), 16A (Europe), and 13A (UK).

For DC input application, please refer to the statement below:

Statement 1005—Circuit Breaker

This product relies on the building's installation for short-circuit (overcurrent) protection.

• Ensure that the protective devices are rated not greater than 40A when the switch is powered with regular

DC power supplies (rated 48-60VDC).

• Ensure that the protective devices are rated not greater than 10A when the switch is powered with HVDC

power supplies (rated 240-350VDC).

Note

For the power cables to use with the power supplies, see Power Cable Specifications, on page 40.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

8

Page 17

Preparing the Site

Airflow Requirements

The switch is designed to be positioned with its ports in either the front or the rear of the rack depending on

your cabling and maintenance requirements. Depending on which side of the switch faces the cold aisle, you

must have fan and power supply modules that move the coolant air from the cold aisle to the hot aisle in one

of the following ways:

• Port-side exhaust airflow—Coolant air enters the chassis through the fan and power supply modules in

the cold aisle and exhausts through the port end of the chassis in the hot aisle.

• Port-side intake airflow—Coolant air enters the chassis through the port end in the cold aisle and exhausts

through the fan and power supply modules in the hot aisle.

You can identify the airflow direction of each fan and power supply module by its coloring as follows:

• Blue coloring indicates port-side exhaust airflow.

• Burgundy coloring indicates port-side intake airflow.

Airflow Requirements

Note

To prevent the switch from overheating and shutting down, you must position the air intake for the switch in

a cold aisle, and all of the fan and power supply modules must have the same direction of airflow (even if

their coloring is different). If you must change the airflow direction for the switch, you must shutdown the

switch before changing the modules.

Rack and Cabinet Requirements

You can install the following types of racks or cabinets for your switch:

• Standard perforated cabinets

• Solid-walled cabinets with a roof fan tray (bottom-to-top cooling)

• Standard open four-post Telco racks

Work with your cabinet vendors to determine which of their cabinets meet the following requirements or see

the Cisco Technical Assistance Center (TAC) for recommendations:

• Use a standard 19-inch (48.3-cm), four-post Electronic Industries Alliance (EIA) cabinet or rack with

mounting rails that conform to English universal hole spacing per section 1 of the ANSI/EIA-310-D-1992

standard.

• The depth of a four-post rack must be 24 to 32 inches (61.0 to 81.3 cm) between the front and rear

mounting rails (for proper mounting of the bottom-support brackets or other mounting hardware).

Additionally, you must have power receptacles located within reach of the power cords used with the switch.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

9

Page 18

Clearance Requirements

Preparing the Site

Warning

Statement 1048—Rack Stabilization

Stability hazard. The rack stabilizing mechanism must be in place, or the rack must be bolted to the floor

before you slide the unit out for servicing. Failure to stabilize the rack can cause the rack to tip over.

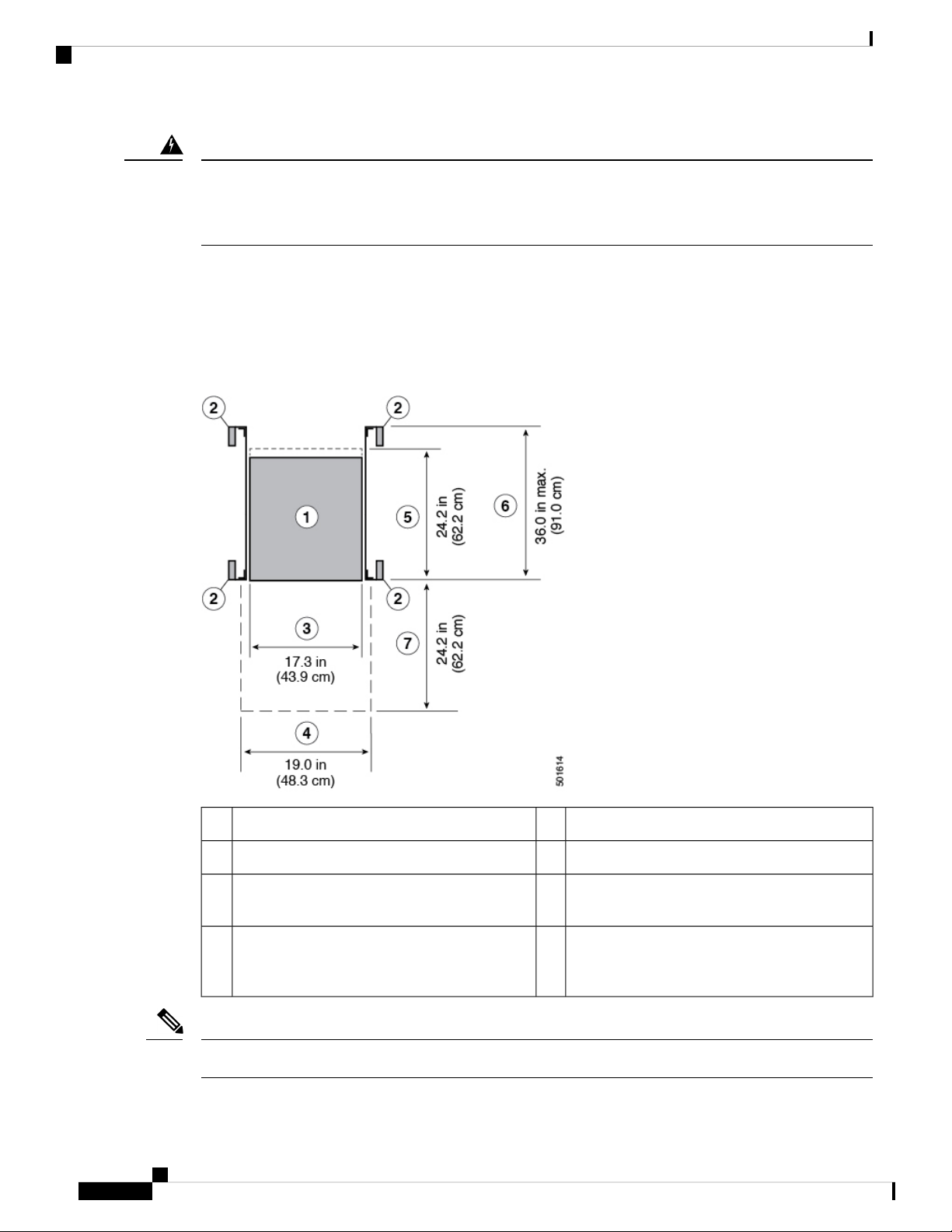

Clearance Requirements

You must provide the chassis with adequate clearance between the chassis and any other rack, device, or

structure so that you can properly install the chassis, route cables, provide airflow, and maintain the switch.

For the clearances required for an installation of this chassis in a four-post rack, see the following figure.

Depth of the chassis5Chassis1

Maximum extension of the bottom-support rails6Vertical rack-mount posts and rails2

Depth of the front clearance area (this equals the

7Chassis width3

depth of the chassis)

Width of the front clearance area (this equals the

4

width of the chassis with two rack-mount

brackets attached to it)

Note

Both the front and rear of the chassis must be open to both aisles for airflow.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

10

Page 19

Safety

CHAPTER 3

Installing the Switch Chassis

• Safety, on page 11

• Installation Options with Racks and Cabinets, on page 12

• Airflow Considerations, on page 12

• Installation Guidelines, on page 12

• Unpacking and Inspecting the Switch, on page 13

• Installing the Switch, on page 14

• Grounding the Chassis, on page 18

• Starting the Switch, on page 19

Before you install, operate, or service the switch, see the Regulatory, Compliance, and Safety Information for

the Cisco Nexus 3000 and 9000 Series for important Safety Information.

Warning

Warning

Statement 1071—Warning Definition

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you work

on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard

practices for preventing accidents. Use the statement number provided at the end of each warning to locate

its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Statement 1017—Restricted Area

This unit is intended for installation in restricted access areas. A restricted access area can be accessed only

through the use of a special tool, lock and key, or other means of security.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

11

Page 20

Installation Options with Racks and Cabinets

Installing the Switch Chassis

Warning

Statement 1030—Equipment Installation

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Installation Options with Racks and Cabinets

You can install the switch in the following types of racks using the rack-mount kit shipped with the switch:

• Open EIA rack

• Perforated EIA cabinet

The rack or cabinet that you use must meet the requirements listed in General Requirements for Cabinets and

Racks, on page 35.

The rack-mount kit enables you to install the switch into racks of varying depths. You can use the rack-mount

kit parts to position the switch with easy access to either the port connections end of the chassis or the end of

the chassis with the fan and power supply modules. For instructions on how to install the rack-mount kit, see

the Installing the Switch, on page 14.

Airflow Considerations

The switch comes with fan and power supply modules that have either port-side intake or port-side exhaust

airflow for cooling the switch. If you are positioning the port end of the switch in a cold aisle, make sure that

the switch has port-side intake fan modules with burgundy coloring. If you are positioning the fan and power

supply modules in a cold aisle, make sure that the switch has port-side exhaust fan modules with blue colorings.

All fan modules must have the same direction of airflow.

Installation Guidelines

When installing the switch, follow these guidelines:

• Record equipment and installation information in the forms presented in Chassis and Module Information

as you install and configure the switch.

• Ensure that there is adequate clearance space around the switch to allow for servicing the switch and for

adequate airflow.

• Ensure that you are positioning the switch in a rack so that it takes in cold air from the cold aisle and

exhausts air to the hot aisle. If there is blue coloring on the fan modules, the switch is configured for

port-side exhaust airflow and you must position the module side of the switch in a cold aisle. If there is

burgundy coloring on the fan modules, the switch is configured for port-side intake airflow and you must

position the port side of the switch in a cold aisle.

• Ensure that the chassis can be adequately grounded. If the switch is not mounted in a grounded rack, we

recommend connecting both the system ground on the chassis directly to an earth ground.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

12

Page 21

Installing the Switch Chassis

Unpacking and Inspecting the Switch

• Ensure that the site power meets the power requirements for the switch. If available, you can use an

uninterruptible power supply (UPS) to protect against power failures.

Caution

Avoid UPS types that use ferroresonant technology. These UPS types can become

unstable with the switch, which can have substantial current draw fluctuations

because of fluctuating data traffic patterns.

• Ensure that circuits are sized according to local and national codes. Typically, this often requires one or

both of the following:

• AC power supplies typically require at least a 15-A or 20-A AC circuit, 100 to 240 VAC, and a

frequency of 50 to 60 Hz.

• HVAC/HVDC power supplies require the following:

• HVAC input voltage range of 100 to 277 VAC with a frequency of 50 to 60 Hz

• HVDC input voltage range of -240 to -380 VDC

Caution

To prevent loss of input power, ensure the total maximum loads on the circuits

supplying power to the switch are within the current ratings for the wiring and

breakers.

Unpacking and Inspecting the Switch

Before you install the switch, be sure to unpack and inspect the switch for damage or missing components.

If anything is missing or damaged, contact your customer service representative immediately.

Tip

Keep the shipping container in case the chassis requires shipping at a later time.

Before you begin

Before you unpack the switch and before you handle any switch components, be sure that you are wearing a

grounded electrostatic discharge (ESD) strap. To ground the strap, attach it directly to an earth ground or to

a grounded rack or grounded chassis (there must be a metal-to-metal connection to the earth ground).

Step 1 Compare the shipment to the equipment list provided by your customer service representative and verify that you have

received all items, including the following:

• Accessory Kit

Note

For the contents of these kits, see the Additional Kits.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

13

Page 22

Installing the Switch Chassis

Installing the Switch

Step 2 Check for damage and report any discrepancies or damage to your customer service representative. Have the following

information ready:

• Invoice number of shipper (see packing slip)

• Model and serial number of the damaged unit

• Description of damage

• Effect of damage on the installation

Step 3 Check to be sure that each of the power supply and the fan tray modules have the expected direction of airflow as follows:

• Port-side intake airflow modules

• Burgundy (fan modules and power supplies)

• Port-side exhaust airflow modules

• Blue (fan modules and power supplies)

Note

All power supplies and fan modules must have the same direction of airflow.

Installing the Switch

To install the switch, you must attach front and rear mounting brackets to the switch, install slider rails on the

rear of the rack, slide the switch onto the slider rails, and secure the switch to the front of the rack. Typically,

the front of the rack is the side easiest to access for maintenance.

Note

You must supply the eight 10-32 or 12-24 screws required to mount the slider rails and switch to the rack.

Before you begin

• You have inspected the switch shipment to ensure that you have everything ordered.

• Make sure that the switch rack-mount kit includes the following parts:

• Front rack-mount brackets (2)

• Rear rack-mount brackets (2)

• Slider rails (2)

• M4 x 0.7 x 8-mm Phillips countersink screws (12)

• The rack is installed and secured to its location.

Step 1 Install two front-mount brackets to the switch as follows:

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

14

Page 23

Installing the Switch Chassis

a) Determine which end of the chassis is to be located in the cold aisle as follows:

• If the switch has port-side intake modules (fan modules with burgundy coloring), position the switch so that its

ports will be in the cold aisle.

• If the switch has port-side exhaust modules (fan modules with blue coloring), position the switch so that its fan

and power supply modules will be in the cold aisle.

b) Position a front-mount bracket so that four of its screw holes are aligned to the screw holes on the side of the chassis.

Installing the Switch

Note

You can align any four of the holes in the front rack-mount bracket to four of the six screw holes on the

side of the chassis (see the two ways to mount these brackets on a typical chassis, in following figure). The

holes that you use depend on the requirements of your rack and the amount of clearance required for interface

cables (3 inches [7.6 mm] minimum) and module handles (1 inch [2.5 mm] minimum).

1

the chassis

2

chassis

3

the chassis

4

chassis

Front rack-mount bracket aligned to the module end

5Front rack-mount bracket aligned to the port end of

of the chassis

Four M4 screws used to attach the bracket to the

6Four M4 screws used to attach the bracket to the

chassis

Two M4 screws used to attach the bracket to the

7Rear rack-mount guide aligned to the module end of

chassis

Rear rack-mount guide aligned to the port end of the

8Two M4 screws used to attach the bracket to the

chassis

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

15

Page 24

Installing the Switch Chassis

Installing the Switch

c) Secure the front-mount bracket to the chassis using four M4 screws and tighten each screw to 12 in-lb (1.36 N·m)

of torque.

d) Repeat Step 1 for the other front rack-mount bracket on the other side of the switch and be sure to position that bracket

the same distance from the front of the switch.

Step 2 Install the two rear rack-mount brackets on the chassis as follows:

a) Align the two screw holes on a rear rack-mount bracket to the middle two screw holes in the remaining six screw

holes on a side of the chassis. If you are aligning the guide to holes that are near the port connections end of the

chassis, see Callout 3 in the previous figure. Otherwise, see Callout 7 in the previous figure.

b) Attach the guide to the chassis using two M4 screws (see Callout 4 or 8 in the previous figure). Tighten the screws

to 12 in-lb (1.36 N·m) of torque.

c) Repeat Step 2 for the other rear rack-mount bracket on the other side of the switch.

Step 3 If you are not installing the chassis into a grounded rack, you must attach a customer-supplied grounding wire to the

chassis as explained in Grounding the Chassis, on page 18. If you are installing the chassis into a grounded rack, you

can skip this step.

Step 4 Install the slider rails on the rack or cabinet as follows:

a) Determine which two posts of the rack or cabinet you should use for the slider rails. Of the four vertical posts in the

rack or cabinet, two will be used for the front mount brackets attached to the easiest accessed end of the chassis, and

the other two posts will have the slider rails.

b) Position a slider rail at the desired level on the back side of the rack and use two 12-24 screws or two 10-32 screws,

depending on the rack thread type, to attach the rails to the rack (see the following figure). Tighten 12-24 screws to

30 in-lb (3.39 N·m) of torque and tighten 10-32 screws to 20 in-lb (2.26 N·m) of torque.

Two customer-supplied 12-24 or 10-32 screws used

1

rack

2Slider rail with screw holes aligned to screw holes in

to attach each slider rail to the rack

c) Repeat Step 3 to attach the other slider rail to the other side of the rack.

To make sure that the slider rails are at the same level, you should use a level tool, tape measure, or carefully count

the screw holes in the vertical mounting rails.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

16

Page 25

Installing the Switch Chassis

Step 5 Insert the switch into the rack and attach it as follows:

a) Holding the switch with both hands, position the two rear rack-mount brackets on the switch between the rack or

cabinet posts that do not have slider rails attached to them (see the following figure).

Installing the Switch

1

Front-mount brackets.3Align the two rear rack-mount bracket guides with

the slider rails installed in the rack.

2

Mounting rails on rack or cabinet posts.4Slide the rack-mount guides onto the slider rails until

the front rack-mount brackets come in contact with

the front rack-mount rails.

b) Align the two rear rack-mount guides on either side of the switch with the slider rails installed in the rack. Slide the

rack-mount guides onto the slider rails, and then gently slide the switch all the way into the rack until the front

rack-mount brackets come in contact with two rack or cabinet posts.

Note

If you attached a grounding cable to the chassis, you will need to bend one of the rack-mount rails slightly

to allow the grounding lug to go behind the rail.

c) Holding the chassis level, insert two screws (12-24 or 10-32, depending on the rack type) in each of the two front

rack-mount brackets (using a total of four screws) and into the cage nuts or threaded holes in the vertical rack-mounting

rails (see the following figure).

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

17

Page 26

Grounding the Chassis

Installing the Switch Chassis

1

12-24 or 10-32 screws on each side.

Front-mount bracket.2

d) Tighten the 10-32 screws to 20 in-lb (2.26 N·m) or tighten the 12-24 screws to 30 in-lb (3.39 N·m).

Step 6 If you attached a grounding wire to the chassis grounding pad, connect the other end of the wire to the facility ground.

Mounting rails on rack or cabinet posts.3Fasten the chassis to the front of the rack with two

Grounding the Chassis

The switch chassis is automatically grounded when you properly install the switch in a grounded rack with

metal-to-metal connections between the switch and rack.

You can alternatively ground the chassis (this is required if the rack is not grounded) by attaching a

customer-supplied grounding cable to the chassis grounding pad and the facility ground.

Warning

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence

of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician

if you are uncertain that suitable grounding is available.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

18

Page 27

Installing the Switch Chassis

Starting the Switch

Warning

Step 1 Use a wire-stripping tool to remove approximately 0.75 inch (19 mm) of the covering from the end of the grounding

wire.

Step 2 Insert the stripped end of the grounding wire into the open end of the grounding lug, and use a crimping tool to crimp

the lug to the wire (see Callout 2 in the following figure). Verify that the ground wire is securely attached to the grounding

lug by attempting to pull the wire out of the crimped lug.

Statement 1046—Installing or Replacing the Unit

When installing or replacing the unit, the ground connection must always be made first and disconnected last.

Before you begin

Before you can ground the chassis, you must have a connection to the earth ground for the data center building.

3Chassis grounding pad1

2

Step 3 Secure the grounding lug to the chassis grounding pad with two M4 screws (see Callouts 1 and 3 in the previous figure),

and tighten the screws to 11 to 15 in-lb (1.24 to 1.69 N·m) of torque.

Step 4 After you install the chassis, prepare the other end of the grounding wire and connect it to an appropriate grounding point

in your site to ensure an adequate earth ground for the switch.

Grounding cable, with 0.75

in. (19 mm) of insulation

stripped from one end,

inserted into the grounding

lug and crimped in place

2 M4 screws used to secure

the grounding lug to the

chassis

Starting the Switch

You start the switch by connecting it to its dedicated power source. If you need n+1 redundancy, you must

connect each of the power supplies to one or two power sources. If you need n+n redundancy, you must

connect each power supply in a switch to a different power source.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

19

Page 28

Starting the Switch

Installing the Switch Chassis

Before you begin

• The switch must be installed and secured to a rack or cabinet.

• The switch must be adequately grounded.

• The rack must be close enough to the dedicated power source so that you can connect the switch to the

power source by using a designated power cables.

• You have the designated power cables for the power supplies that you are connecting to the dedicated

power sources.

Note

Depending on the outlet receptacle on your AC power distribution unit, you might

need an optional jumper power cord to connect the switch to your outlet receptacle.

• The switch is not connected to the network (this includes any management or interface connections).

• The fan and power supply modules are fully secured in their chassis slots.

All of the fan slots must be filled with fan modules and the power supply slots must be filled with the

same types of power supplies (do not mix AC and DC power supplies).

Step 1 For each AC power supply, do the following:

a) Using the recommended AC power cable for your country or region, connect one end to the AC power supply.

b) Connect the other end of the power cable to the AC power source.

Step 2 For each HVAC/HVDC power supply, connect it to a power source as follows:

a) Using the recommended high voltage power cable for your country or region, connect the Anderson Power Saf-D-Grid

connector on the power cable to the power receptacle on the power supply. Make sure that the connector clicks when

fully pushed into the receptacle.

b) Connect the other end of the power cable to a power source.

• When connecting to an HVAC power source, insert the C14 or LS-25 plug in a receptacle for the HVAC power

source.

• When connecting to an HVDC power source, do the following:

1. Verify that the power is turned off at a circuit breaker for the power source terminals.

2. Remove the nuts from each of the terminal posts for the power supply.

3. Place the power cable negative-wire terminal ring on the negative terminal for the power source and secure

them with a terminal nut.

4. Place the power cable positive-wire terminal ring on the positive terminal for the power source and secure

them with a terminal nut.

5. Place the power cable ground-wire terminal ring on the ground terminal for the power source and secure

them with a terminal nut.

6. If there is a safety cover for the power source terminals, place and secure it over the terminals to avoid an

electrical shock hazard.

7. Turn on the power at the power source circuit breaker.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

20

Page 29

Installing the Switch Chassis

Step 3 For each DC power supply, do the following:

a) Turn off the circuit breaker for the power source to avoid an electrical shock hazard.

b) Verify that the power cable wires from the power source are connected to a connector block.

c) Insert the connector block into the receptacle on the power supply. Make sure that the connector block clicks when

fully inserted in the receptacle and does not pull out.

d) If there is a safety cover for the terminals, place and secure it over the terminals to avoid an electrical shock hazard.

e) Turn on the power at the circuit breaker for the DC power source.

Step 4 Verify that the power supply LED is on and green.

Step 5 Listen for the fans; they should begin operating when the power supply is powered.

Step 6 After the switch boots, verify that the following LEDs are lit:

• On the fan modules, the Status (STA or STS) LED is green.

If a fan module Status LED is not green, try reinstalling the fan module.

• After initialization, the switch chassis Status (labeled as STA or STS) LED is green.

Step 7 Verify that the system software has booted and the switch has initialized without error messages.

Step 8 Complete the worksheets provided in Site Preparation and Maintenance Records for future reference.

Starting the Switch

Note

A setup utility automatically launches the first time that you access the switch and guides you through the basic

configuration. For instructions on how to configure the switch and check module connectivity, see the appropriate Cisco

Nexus configuration guide.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

21

Page 30

Starting the Switch

Installing the Switch Chassis

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

22

Page 31

Connecting the Switch to the Network

• Overview of Network Connections, on page 23

• Connecting a Console to the Switch, on page 23

• Creating the Initial Switch Configuration, on page 25

• Setting Up the Management Interface, on page 26

• Connecting Interface Ports to Other Devices, on page 27

• Uplink Connections, on page 27

• Downlink Connections, on page 28

Overview of Network Connections

After you install the switch in a rack and power it up, you are ready to make the following network connections:

• Console connection—This is a direct local management connection that you use to initially configure

the switch. You must make this connection first to initially configure the switch and determine its IP

address, which is needed for the other connections.

• Management connection—After you complete the initial configuration using a console, you can make

this connection to manage all future switch configurations.

CHAPTER 4

• Uplink and downlink interface connections—These are connections to hosts and servers in the network.

Each of these connection types is explained in one of the sections that follow.

Note

When running cables in overhead or subfloor cable trays, we strongly recommend that you locate power cables

and other potential noise sources as far away as practical from network cabling that terminates on Cisco

equipment. In situations where long parallel cable runs cannot be separated by at least 3.3 feet (1 meter), we

recommend that you shield any potential noise sources by housing them in a grounded metallic conduit.

Connecting a Console to the Switch

Before you create a network management connection for the switch or connect the switch to the network, you

must create a local management connection through a console terminal and configure an IP address for the

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

23

Page 32

Connecting a Console to the Switch

switch. You also can use the console to perform the following functions, each of which can be performed

through the management interface after you make that connection:

• Configure the switch using the command-line interface (CLI).

• Monitor network statistics and errors.

• Configure Simple Network Management Protocol (SNMP) agent parameters.

• Download software updates.

You make this local management connection between the asynchronous serial port on a supervisor module

and a console device capable of asynchronous transmission. Typically, you can use a computer terminal as

the console device. On the supervisor modules, you use the console serial port.

Note

Before you can connect the console port to a computer terminal, make sure that the computer terminal supports

VT100 terminal emulation. The terminal emulation software makes communication between the switch and

computer possible during setup and configuration.

Connecting the Switch to the Network

Before you begin

• The switch must be fully installed in its rack, connected to a power source, and grounded.

• The necessary cabling for the console, management, and network connections must be available.

• An RJ-45 rollover cable provided in the switch accessory kit.

• Network cabling should already be routed to the location of the installed switch.

Step 1 Configure the console device to match the following default port characteristics:

• 9600 baud

• 8 data bits

• 1 stop bit

• No parity

Step 2 Connect an RJ-45 rollover cable to the console port on the switch.

You can find this cable in the accessory kit.

Step 3 Route the RJ-45 rollover cable to the console or modem.

Step 4 Connect the other end of the RJ-45 rollover cable to the console or to a modem.

What to do next

You are ready to create the initial switch configuration (see Creating the Initial Switch Configuration, on page

25).

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

24

Page 33

Connecting the Switch to the Network

Creating the Initial Switch Configuration

You must assign an IP address to the switch management interface so that you can then connect the switch

to the network.

When you initially power up the switch, it boots up and asks you a series of questions to configure the switch.

To enable you to connect the switch to the network, you can use the default choices for each configuration

except the IP address, which you must provide. You can perform the other configurations at a later time as

described in the Cisco Nexus 9000 Series NX-OS Fundamentals Configuration Guide.

Note

You should also know the unique name needed to identify the switch among the devices in the network.

Before you begin

• A console device must be connected with the switch.

Creating the Initial Switch Configuration

• The switch must be connected to a power source.

• Determine the IP address and netmask needed for the Management (Mgmt0) interface.

Step 1 Power up the switch by connecting each installed power supply to an AC circuit.

If you are using the combined or power-supply (n+1) power mode, connect all of the power supplies to the same AC

circuit. If you are using the input-source (n+n) power mode, connect half of the power supplies to one AC circuit and the

other half to another AC circuit.

The Input and Output LEDs on each power supply light up (green) when the power supply units are sending power to

the switch, and the software asks you to specify a password to use with the switch.

Step 2 Enter a new password to use for this switch.

The software checks the security strength of your password and rejects your password if it is not considered to be a strong

password. To increase the security strength of your password, make sure that it adheres to the following guidelines:

• At least eight characters

• Minimizes or avoids the use of consecutive characters (such as "abcd")

• Minimizes or avoids repeating characters (such as "aaabbb")

• Does not contain recognizable words from the dictionary

• Does not contain proper names

• Contains both uppercase and lowercase characters

• Contains numbers as well as letters

Examples of strong passwords include the following:

• If2CoM18

• 2004AsdfLkj30

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

25

Page 34

Setting Up the Management Interface

• Cb1955S21

Connecting the Switch to the Network

Note

Tip

If you enter a strong password, the software asks you to confirm the password.

Step 3 Enter the same password again.

If you enter the same password, the software accepts the password and begins asking a series of configuration questions.

Step 4 Until you are asked for an IP address, you can enter the default configuration for each question.

Repeat this step for each question until you are asked for the Mgmt0 IPv4 address.

Step 5 Enter the IP address for the management interface.

The software asks for the Mgmt0 IPv4 netmask.

Step 6 Enter a network mask for the management interface.

The software asks if you need to edit the configuration.

Step 7 Enter no to not edit the configuration.

The software asks if you need to save the configuration.

Step 8 Enter yes to save the configuration.

Clear text passwords cannot include the dollar sign ($) special character.

If a password is trivial (such as a short, easy-to-decipher password), the software will reject your password

configuration. Be sure to configure a strong password as explained in this step. Passwords are case sensitive.

What to do next

You can now set up the management interface for each supervisor module on the switch.

Setting Up the Management Interface

The RJ-45 and SFP management ports provide out-of-band management, which enables you to use the

command-line interface (CLI) to manage the switch by its IP address. You can use one of these ports depending

on the cable and connecters that you are using to connect the management interface to the network.

Before you begin

• The switch must be powered on.

• The switch must be initially configured using a console.

Step 1 Connect the management cable into the management port on the switch. For shorter connections, you can use a cable

with RJ-45 connectors. For longer connections, you can use an optical cable with SFP transceivers (LH or SX type).

Note

Use only one of these management ports—the switch does not support the use of both management ports.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

26

Page 35

Connecting the Switch to the Network

Connecting Interface Ports to Other Devices

Step 2 Connect the other end of the cable to a 10/100/1000 or SFP port on a network device.

What to do next

You are ready to connect the interface ports on each of the line cards to the network.

Connecting Interface Ports to Other Devices

After you perform the initial configuration for the switch and create a management connection, you are ready

to connect the interface ports on the switch to other devices. Depending on the types of interface ports on the

switch, you will need to use interface cables with QSFP28, QSFP+, SFP+, or SFP transceivers or RJ-45

connectors to connect the switch to other devices.

Note

If you need to use SFP+ or SFP transceivers in a QSFP+ or QSFP28 uplink port, install a QSFP-to-SFP

adapter, such as the CVR-QSFP-SFP10G adapter, in the QSFP port and then install the SFP+ or SFP transceiver.

The switch automatically sets the port speed to the speed of the installed transceiver.

If the transceivers that you are using can be separated from their optical cables, install the transceivers without

their cables before inserting the cables into the transceivers. This helps to prolong the life of both the transceiver

and cables. When removing transceivers from the switch, it is best to remove the optical cable first and then

remove the transceiver.

Uplink Connections

The 18 uplink ports support 40- and 100-Gigabit Ethernet using QSFP28 transceivers.

For a list of transceivers and cables used by this switch for uplink connections, see

http://www.cisco.com/c/en/us/support/interfaces-modules/transceiver-modules/products-device-support-tables-list.html.

By default, the 40-Gigabit uplink ports operate at 40 Gbps, but you can use the speed-group 10000 command

to change the administrative speed to 10 Gbps. If you change the speed, you must also use a QSFP-to-SFP

adapter and a supported SFP+ transceiver in each of the converted SFP+ ports. All of the ports in a group of

ports must operate at the same speed or you will see an error with a "check speed-group config" message.To

return the administrative speed to 40 Gigabits, use the no speed-group 10000 command.

Warning

Statement 1051—Laser Radiation

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or

view directly with optical instruments.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

27

Page 36

Downlink Connections

Downlink Connections

The Cisco Nexus 92240YC-FX2 switch has 48 downlink ports that connect to servers. Each of these ports

supports 1-Gigabit, 10-Gigabit, and 25-Gigabit speeds over 10-Gigabit optical cables using SFP+ transceivers.

For a listing of the transceivers and cables that the optical downlink ports support, see

http://www.cisco.com/c/en/us/support/interfaces-modules/transceiver-modules/products-device-support-tables-list.html

Connecting the Switch to the Network

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

28

Page 37

Replacing Components

• Replacing a Fan Module, on page 29

• Replacing a Power Supply Module, on page 30

Replacing a Fan Module

You can replace one of the four fan modules at a time while the switch is operating so long as you perform

the replacement within one minute. If you cannot perform the replacement within one minute, leave the original

fan module in the chassis to maintain the designed airflow until you have the replacement fan module on hand

and can perform the replacement.

CHAPTER 5

Caution

If you are replacing a module during operations, be sure that the replacement fan module has the correct

direction of airflow, which means that it has the same airflow direction as the other modules in the chassis.

Also, be sure that the airflow direction takes in air from a cold aisle and exhausts to a hot aisle. Otherwise,

the switch can overheat and shutdown.

If you are changing the airflow direction of all the modules in the chassis, you must shutdown the switch

before replacing all the fan and power supply modules with modules using the other airflow direction. During

operations, all of the modules must have the same direction of airflow.

Removing a Fan Module

Warning

Step 1 On the fan module that you are removing, press the two sides of the fan module handle next to where it connects to the

fan module and pull on the handles enough to unseat it from its connectors.

Step 2 Holding the handle, pull the module out of the chassis.

Statement 263—Fan Warning

The fans might still be turning when you remove the fan assembly from the chassis. Keep fingers, screwdrivers,

and other objects away from the openings in the fan assembly's housing.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

29

Page 38

Installing a Fan Module

Replacing Components

Caution

Do not touch the electrical connectors on the back side of the module and prevent anything else from coming

into contact with and damaging the connectors.

Installing a Fan Module

Before you begin

• A fan slot must be open and ready for the new fan module to be installed.

• You must have a new fan module on hand and ready to install within one minute of removing the original

fan module if the switch is operating.

• The new fan module must have the same airflow direction as the other fan and power supply modules

installed in the switch.

Step 1 Holding the fan module by its handle, align the back of the fan module (the side with the electrical connectors) to the

open fan slot in the chassis.

Step 2 Slide the fan module into the slot until it clicks in place.

Step 3 Verify that the Status (STS) LED turns on and becomes green.

Replacing a Power Supply Module

The switch requires two power supplies for redundancy. With one power supply providing the necessary

power for operations, you can replace the other power supply during operations so long as the new power

supply has the same airflow direction as the other modules in the chassis.

You can replace a power supply with another supported power supply that has the same power source type

(AC, DC, HVAC, or HVDC) and the same wattage rating as the other installed power supply. Additionally,

the airflow direction of the power supply must match the airflow direction of the installed fan modules.

• NXA-PAC-1100W-PE2 (1100-W, port-side exhaust (blue latch) power supply requiring AC power

source providing at least 16 A)

• NXA-PAC-1100W-PI2 (1100-W, port-side intake (burgundy latch) power supply requiring AC power

source providing at least 16 A)

• N9K-PHV-1100W-PE (1100-W, port-side exhaust (blue latch) high-voltage AC/DC power supply

requiring a high-voltage AC or DC power source)

• N9K-PHV-1100W-PI (1100-W, port-side intake (burgundy latch) high-voltage AC/DC power supply

requiring a high-voltage AC or DC power source)

• NXA-PDC-1100W-PE (1100-W, port-side exhaust (blue latch) power supply requiring DC power source

providing at least 16 A)

• NXA-PDC-1100W-PI (1100-W, port-side intake (burgundy latch) power supply requiring DC power

source providing at least 16 A)

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

30

Page 39

Replacing Components

Replacing an AC Power Supply

You can replace an AC power supply during operations so long as the other power supply provides to the

switch.

Before you begin

• The replacement power supply must have the same wattage and airflow direction as the power supply

being replaced.

Note

You can determine the airflow direction by looking at the coloring of the latch

on each power supply. AC power supplies with burgundy latches have port-side

intake airflow direction, and power supplies with blue latches have port-side

exhaust airflow direction.

• An AC power source must be within reach of the power cable that will be used with the replacement

power supply. If you are using n+n power redundancy, there must be a separate power source for each

power supply installed in the chassis.

Replacing an AC Power Supply

• There must be an earth ground connection to the chassis that you are installing the replacement module.

AC power supplies connected to AC power sources are automatically grounded through their power

cable.

Step 1 Remove an AC power supply as follows:

a) Holding the plug for the power cable, pull the plug out from the power receptacle on the power supply and verify

that both power supply LEDs are off.

b) Grasp the power supply handle while pressing the colored release latch towards the power supply handle.

c) Place your other hand under the power supply to support it while you slide it out of the chassis.

Caution

Do not touch the electrical connections on the back side of the module and prevent anything else from

coming into contact with and damaging the connectors.

Step 2 Install the replacement power supply as follows:

a) Holding the replacement power supply with one hand underneath the module and the other hand holding the handle,

turn the power supply so that its release latch is on the right side and align the back end of the power supply (the end

with the electrical connections) to the open power supply slot before carefully sliding the power supply all the way

into the slot until it clicks into place.

Note

If the power supply does not fit into the open slot, turn the module over before sliding it carefully into the

open slot.

b) Test the installation by trying to pull the power supply out of the slot without using the release latch.

If the power supply does not move out of place, it is secured in the slot. If the power supply moves, carefully press

it all the way into the slot until it clicks in place.

c) Attach the power cable to the electrical outlet on the front of the power supply.

d) Make sure that the other end of the power cable is attached to the appropriate power source for the power supply.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

31

Page 40

Replacing a High Voltage (HVAC/HVDC) Power Supply

Replacing Components

Note

Depending on the outlet receptacle on your power distribution unit, you might need the optional jumper

cable to connect the switch to your outlet receptacle.

e) Verify that the power supply is operational by making sure that the power supply LED is green. For information

on what the power supply LEDs indicate, see Power Supply LEDs, on page 46.

Replacing a High Voltage (HVAC/HVDC) Power Supply

You can replace an HVACHVDC power supply during operations so long as the other power supply provides

power to the switch.

Before you begin

• The replacement power supply must have the same wattage and airflow direction as the power supply

being replaced.

Note

You can determine the airflow direction by looking at the coloring of the latch

on each power supply. The high voltage power supplies have either burgundy

latches for port-side intake airflow or they have blue latches for port-side exhaust

airflow.

• An HVAC/HVDC power source must be within reach of the power cable that will be used with the

replacement power supply. If you are using n+n power redundancy, there must be a separate power source

for each power supply installed in the chassis.

• There must be an earth ground connection to the chassis in which you are installing the replacement

power supply. HVAC/HVDC power supplies connected to AC power sources are automatically grounded

by their power cable when connected to the power supply and AC power source. HVAC/HVDC power

supplies connected to DC power sources have Saf-D-Grid power cables with three connectors on the

power source end--you connect one of those connectors to the earth ground.

Step 1 Remove an HVAC/HVDC power supply as follows:

a) Turn off the circuit breaker for the power feed to the power supply that you are replacing.

Be sure that the LEDs turn off on the power supply that you are removing.

b) Remove the power cable from the power supply by pressing the tab on the top of the Anderson Power SAF-D-Grid

connector and pull the cable and connector out of the power supply.

c) Grasp the power supply handle while pressing the colored release latch towards the power supply handle.

d) Place your other hand under the power supply to support it while you slide it out of the chassis.

Caution

Do not touch the electrical connections on the back side of the module and prevent anything else from

coming into contact with and damaging the connectors.

Step 2 Install the replacement power supply as follows:

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

32

Page 41

Replacing Components

a) Holding the replacement power supply with one hand underneath the module and the other hand holding the handle,

turn the power supply so that its release latch is on the right side and align the back end of the power supply (the end

with the electrical connections) to the open power supply slot before carefully sliding the power supply all the way

into the slot until it clicks into place.

Replacing a DC Power Supply

Note

If the power supply does not fit into the open slot, turn the module over before sliding it carefully into the

open slot.

b) Test the installation by trying to pull the power supply out of the slot without using the release latch.

If the power supply does not move out of place, it is secured in the slot. If the power supply moves, carefully press

it all the way into the slot until it clicks in place.

c) Attach the Saf-D-Grid end of the power cable to the electrical outlet on the front of the power supply.

d) Make sure that the other end of the power cable is attached to the appropriate power source for the power supply.

• For an HVAC power source, plug the other end of the power cable into the power source.

• For a HVDC power source, verify that the circuit breaker is turned off and then connect each of the three cable

connectors to the appropriate DC and grounding terminals on the power source. If there is a cover plate for the

DC terminals, install the plate to prevent accidental contact with the terminals.

e) If using an HVDC power source, turn on the circuit breaker for the power source.

f) Verify that the power supply is operational by making sure that the power supply LED is green. For information

on what the power supply LEDs indicate, see Power Supply LEDs, on page 46.

Replacing a DC Power Supply

You can replace an DC power supply during operations so long as the other power supply provides power to

the switch.

Before you begin

• The replacement power supply must have the same wattage and airflow direction as the power supply

being replaced.

Note

You can determine the airflow direction by looking at the coloring of the latch

on each power supply. AC power supplies with burgundy latches have port-side

intake airflow direction, and power supplies with blue latches have port-side

exhaust airflow direction.

• An DC power source must be within reach of the power cables that will be used with the replacement

power supply. If you are using n+n power redundancy, there must be a separate power source for each

power supply installed in the chassis.

• There must be an earth ground connection to the chassis in which you are installing the replacement

power supply. DC power supplies connected to DC power sources have three power cables (two for DC

power and one for grounding).

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

33

Page 42

Replacing a DC Power Supply

Step 1 Remove a DC power supply as follows:

a) Turn off the circuit breaker for the power feed to the power supply that you are replacing.

Be sure that the LEDs turn off on the power supply that you are removing.

b) Remove the DC power connector block from the power supply by doing the following:

1. Push the orange plastic button on the top of the connector block inward toward the power supply.

2. Pull the connector block out of the power supply.

c) Grasp the power supply handle while pressing the release latch towards the power supply handle.

d) Place your other hand under the power supply to support it while you slide it out of the chassis.

Replacing Components

Caution

Do not touch the electrical connections on the back side of the module and prevent anything else from

coming into contact with and damaging the connectors.

Step 2 Install the replacement power supply as follows:

a) Holding the replacement power supply with one hand underneath the module and the other hand holding the handle,

turn the power supply so that its release latch is on the right side and align the back end of the power supply (the end

with the electrical connections) to the open power supply slot before carefully sliding the power supply all the way

into the slot until it clicks into place.

Note

If the power supply does not fit into the open slot, turn the module over before sliding it carefully into the

open slot.

b) Test the installation by trying to pull the power supply out of the slot without using the release latch.

If the power supply does not move out of place, it is secured in the slot. If the power supply moves, carefully press

it all the way into the slot until it clicks in place.

c) Attach the power connector block end of the power cable to the electrical outlet on the front of the power supply.

d) Turn on the circuit breaker for the power source.

e) Verify that the power supply is operational by making sure that the power supply LED is green. For information

on what the power supply LEDs indicate, see Power Supply LEDs, on page 46.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

34

Page 43

Rack Specifications

• Overview of Racks, on page 35

• General Requirements for Cabinets and Racks, on page 35

• Requirements Specific to Standard Open Racks, on page 36

• Requirements Specific to Perforated Cabinets, on page 36

• Cable Management Guidelines, on page 36

Overview of Racks

You can install the switch in the following types of cabinets and racks, assuming an external ambient air

temperature range of 0 to 104°F (0 to 40°C):

• Standard perforated cabinets

• Solid-walled cabinets with a roof fan tray (bottom to top cooling)

• Standard open racks

APPENDIX A

Note

If you are selecting an enclosed cabinet, we recommend one of the thermally validated types, either standard

perforated or solid-walled with a fan tray.

Note

We do not recommend that you use racks that have obstructions (such as power strips), because the obstructions

could impair access to field-replaceable units (FRUs).

General Requirements for Cabinets and Racks

The cabinet or rack must also meet the following requirements:

• Standard 19-inch (48.3 cm) (four-post EIA cabinet or rack, with mounting rails that conform to English

universal hole spacing per section 1 of ANSI/EIA-310-D-1992). For more information, see Requirements

Specific to Perforated Cabinets, on page 36.

Cisco Nexus 93240YC-FX2 NX-OS Mode Switch Hardware Installation Guide

35

Page 44

Requirements Specific to Standard Open Racks

• The minimum vertical rack space requirement per chassis is .

• The width between the rack-mounting rails must be at least 17.75 inches (45.0 cm) if the rear of the

device is not attached to the rack. For four-post EIA racks, this measurement is the distance between the

two front rails.

Four-post EIA cabinets (perforated or solid-walled) must meet the following requirements:

• The minimum spacing for the bend radius for fiber-optic cables should have the front-mounting rails of

the cabinet offset from the front door by a minimum of 3 inches (7.6 cm).

• The distance between the outside face of the front mounting rail and the outside face of the back mounting

rail should be 23.0 to 30.0 inches (58.4 to 76.2 cm) to allow for rear-bracket installation.

Requirements Specific to Standard Open Racks

If you are mounting the chassis in an open rack (no side panels or doors), ensure that the rack meets the

following requirements:

Rack Specifications

• The minimum vertical rack space per chassis must be .

• The distance between the chassis air vents and any walls should be 2.5 inches (6.4 cm).

Requirements Specific to Perforated Cabinets

A perforated cabinet has perforations in its front and rear doors and side walls. Perforated cabinets must meet

the following requirements:

• The front and rear doors must have at least a 60 percent open area perforation pattern, with at least 15

square inches (96.8 square cm) of open area per rack unit of door height.

• The roof should be perforated with at least a 20 percent open area.