Page 1

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

First Published: 2014-07-24

Last Modified: 2018-03-30

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB's public domain version

of the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: https:/

/www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1721R)

©

2016-2018 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

Preface

CHAPTER 1

CHAPTER 2

Preface xi

Audience xi

Documentation Conventions xi

Related Documentation xiii

Changes to This Document xiii

Obtaining Documentation and Submitting a Service Request xiii

Installation Roadmap 1

Installation Roadmap 1

Overview 3

About the Cisco NCS 6000 Fabric Card Chassis 3

Fabric Card Chassis Components 4

Slot Numbers 8

Cable Management 10

Safety Guidelines 10

CHAPTER 3

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics 13

About the Power Enclosure 13

Installing the Power Enclosure 14

Required Tools and Equipment 14

Steps 15

Installing the Power Trays 16

About the AC and DC Power Trays 16

Installing an AC or DC Power Tray 18

Prerequisites 18

Required Tools and Equipment 19

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

iii

Page 4

Contents

Steps 19

Installing the Exterior Cosmetics 20

Overview of the Exterior Cosmetics 21

Installing the Front Exterior Cosmetics 22

Prerequisites 23

Required Tools and Equipment 23

Steps 23

Installing the Rear Exterior Cosmetics 28

Prerequisites 28

Required Tools and Equipment 28

Steps 28

CHAPTER 4

Installing the Power Components 35

Power System Overview 35

Prerequisites 35

Installing the Fabric Card Chassis Ground Cable 35

Required Tools and Equipment 36

Steps 38

AC Power System 39

Overview of the AC Power System 39

Installing an AC Power Distribution Unit 39

Mounting the PDU 40

Installing the Tie-Down Bar 42

DC Power System 43

Installing the Power Modules and Input Power Cables 45

Installing an AC or DC Power Module 46

Prerequisites 48

Required Tools and Equipment 48

Steps 49

About the Power Module Status Indicators 50

Installing an AC or DC Power Module Slot Cover 52

Prerequisites 52

Required Tools and Equipment 52

Steps 53

Installing AC Input Power Cords 53

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

iv

Page 5

Contents

Prerequisites 53

Required Tools and Equipment 54

Steps 54

Installing DC Input Power Cables 55

Prerequisites 55

Required Tools and Equipment 55

Steps 56

Powering On and Powering Off the Fabric Card Chassis 57

Powering On the Fabric Card Chassis 57

Prerequisites 57

Required Tools and Equipment 58

Steps 58

CHAPTER 5

Powering Off the Fabric Card Chassis 59

Steps 59

Installing the Shelf Controller Cards and Fabric Cards 61

About Installing Cards and Associated Components 62

Preventing Electrostatic Discharge 62

Guidelines for Installing a Card 62

Steps for OIR Fabric Card Removal 63

About Cable Management Brackets 64

Installing and Removing an Impedance Carrier 66

Installing an S2 Fabric Card Impedance Carrier 67

Prerequisites 67

Required Tools and Equipment 67

Steps 68

Removing an S2 Fabric Card Impedance Carrier 68

Prerequisites 68

Required Tools and Equipment 68

Steps 68

About the SC and SC-SW Cards 69

Front Panel Ports 70

Installing an SC or SC-SW Card 71

Prerequisites 72

Required Tools and Equipment 72

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

v

Page 6

Contents

Steps 72

Verifying the Installation of an SC or SC-SW Card 74

Troubleshooting the SC or SC-SW Card 77

About the Fabric Cards 77

S2 Fabric Card 78

S13 and Universal Fabric Card 78

Installing the Fabric Cards 79

Installing an S2 Fabric Card 79

Prerequisites 79

Required Tools and Equipment 79

Steps 80

Verifying the Installation of an S2 Fabric Card 82

S2 Fabric Card LEDs 83

CHAPTER 6

Installing an S13 MC Fabric Card or Universal Fabric Card 85

Removing and Replacing Chassis Components 87

Removing the Exterior Cosmetics 87

Prerequisites 87

Required Tools and Equipment 87

Removing the Front Exterior Cosmetics 88

Removing the Rear Exterior Cosmetics 94

Removing the Power Components 96

Removing AC Input Power Cords 96

Prerequisites 96

Required Tools and Equipment 96

Steps 97

Removing DC Input Power Cables 97

Prerequisites 97

Steps 98

Replacing an AC or DC Power Tray 99

Prerequisites 99

Required Tools and Equipment 99

Steps 100

Removing a Power Module Slot Cover 101

Prerequisites 101

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

vi

Page 7

Contents

Steps 101

Removing an AC or DC Power Module 102

Prerequisites 102

Required Tools and Equipment 102

Steps 103

Removing the FCC Ground Cable 103

Prerequisites 104

Required Tools and Equipment 104

Steps 105

Replacing a Power Control Module 105

Required Tools and Equipment 106

Steps 106

Removing the Power Enclosure 108

Required Tools and Equipment 108

Steps 109

Replacing the Fan Trays and Air Filter 110

About the Fan Trays and Air Filter 110

About the Fan Trays 111

Fan Tray LEDs 111

About the Air Filter 112

Replacing the Fan Tray 112

Prerequisites 112

Required Tools and Equipment 112

Steps 113

Replacing the Air Filter 114

Steps 114

Removing the Shelf Controller Cards and Fabric Cards 115

Guidelines for Removing a Card 116

Removing an SC or SC-SW Card 116

Prerequisites 116

Required Tools and Equipment 117

Steps 118

Removing an S2 Fabric Card 120

Guidelines for Handling CXP2 Optical Modules 120

Prerequisites 122

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

vii

Page 8

Contents

Required Tools and Equipment 122

Steps 123

Removing an S13 Multi-Chassis Fabric Card 125

APPENDIX A

APPENDIX B

APPENDIX C

System Specifications 127

Fabric Card Chassis Specifications 127

Power Specifications 128

Environmental Specifications 129

Regulatory, Compliance, and Safety Specifications 130

System Product IDs 131

Component Product IDs 131

Fabric Card Product IDs 133

Cosmetic Product IDs 134

Accessory Product IDs 134

Optical Module IDs 135

Cabling a Multi-Chassis Configuration 137

About the Cisco NCS 6000 Multi-Chassis System 137

Prerequisites 138

Cabling Requirements 138

MPO-24 Cable Specifications 140

Required Tools and Equipment 142

Cabling Overview 143

Cable Routing Considerations 143

General Cabling Procedures 144

Safety Guidelines 144

Cabling the Ethernet Control Plane Network 145

Cabling the Control Plane for a 2+1 Multi-Chassis system 145

Cabling the Control Plane for a 2+2 Multi-Chassis System 147

Cabling the Fabric 149

Fabric Overview 150

Multi-Chassis 2+1 Configuration 155

Prerequisites 155

Configuring a 2+1 Configuration with Six S2 FCs 155

viii

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

Page 9

Contents

2+1 Software Configuration (Six S2 Fabric Cards) 158

Configuring a 2+1 Configuration with 12 S2 FCs 159

2+1 Software Configuration (12 S2 Fabric Cards) 162

Multi-Chassis 2+2 Configuration 163

Prerequisites 163

Configuring a 2+2 Configuration with 12 S2 Fabric Cards 163

2+2 Software Configuration (12 S2 Fabric Cards) 167

Configuring a 2+2 Configuration with 24 S2 Fabric Cards 168

2+2 Software Configuration (24 S2 Fabric Cards) 172

Multi-Chassis 4+2 Configuration 173

Prerequisites 173

Configuring a 4+2 Configuration with 12 S2 Fabric Cards 174

4+2 Software Configuration (12 S2 Fabric Cards) 181

Configuring a 4+2 Configuration with 24 S2 Fabric Cards 181

4+2 Software Configuration (24 S2 Fabric Cards) 188

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

ix

Page 10

Contents

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

x

Page 11

Audience

Preface

This document describes how to install a Cisco Network Convergence System (NCS) 6000 Fabric Card

Chassis and its components. The Cisco NCS 6000 Fabric Card Chassis (FCC) is a product in the Cisco

Network Convergence System 6000 Series family. The chassis specifications are included in Appendix A

“System Specifications.” The Cisco product IDs (PIDs) are listed in Appendix B “System Product IDs.”

Audience, page xi

•

Documentation Conventions, page xi

•

Related Documentation, page xiii

•

Changes to This Document, page xiii

•

Obtaining Documentation and Submitting a Service Request, page xiii

•

This guide is intended for chassis installers and Cisco installation partners who are responsible for installing

the Cisco NCS 6000 FCC and its components. The installers are expected to have installed networking hardware

in the past. No additional knowledge of routing or the Cisco IOS XR software is assumed.

Documentation Conventions

This document uses the following conventions:

Italic font

{x | y | z}

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

DescriptionConvention

Commands and keywords and user-entered text appear in bold font.bold font

Document titles, new or emphasized terms, and arguments for which you

supply values are in italic font.

Elements in square brackets are optional.[ ]

Required alternative keywords are grouped in braces and separated by

vertical bars.

xi

Page 12

Documentation Conventions

Preface

DescriptionConvention

Note

[x | y | z]

Optional alternative keywords are grouped in brackets and separated by

vertical bars.

string

A nonquoted set of characters. Do not use quotation marks around the

string or the string will include the quotation marks.

courier font

Terminal sessions and information the system displays appear in courier

font.

Indicates a variable for which you supply values, in context where italics

cannot be used.

Nonprinting characters such as passwords are in angle brackets.< >

Default responses to system prompts are in square brackets.[ ]

!, #

An exclamation point (!) or a pound sign (#) at the beginning of a line

of code indicates a comment line.

Means reader take note. Notes contain helpful suggestions or references to material not covered in the

manual.

Tip

Caution

Warning

Warning

Means the following information will help you solve a problem. The tips information might not be

troubleshooting or even an action, but could be useful information, similar to a Timesaver.

Means reader be careful. In this situation, you might perform an action that could result in equipment

damage or loss of data.

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Statements using this symbol are provided for additional information and to comply with regulatory and

customer requirements.

xii

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

Page 13

Preface

Related Documentation

For complete planning, installation, and configuration information, see the following documents that are

available on Cisco.com at the following URL:

http://www.cisco.com/c/en/us/support/routers/network-convergence-system-6000-series-router/products-installation-guides-list.html.

Cisco Network Convergence System 6000 Series Routers Site Planning Guide

•

Cisco Network Convergence System 6000 Series Routers Unpacking, Moving, and Securing Guide

•

Cisco Network Convergence System 6000 Series Routers Hardware Installation Guide

•

Regulatory Compliance and Safety Information for the Cisco Network Convergence System 6000 Series

•

Routers

Changes to This Document

Related Documentation

This table lists the technical changes made to this document since it was first created.

Table 1: Changes to This Document

SummaryDate

January 2018

September 2014

Added support for the 2nd generation S2 fabric card (NCS-F-FC2) and

CXP2 optics modules (ONS-CXP2-SR25).

Added Telercordia GR-63 requirements for air filter and other minor

updates.

This document introduces the Cisco NCS 6000 Fabric Card Chassis.July 2014

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, using the Cisco Bug Search Tool (BST), submitting a service

request, and gathering additional information, see What's New in Cisco Product Documentation, at: http://

www.cisco.com/c/en/us/td/docs/general/whatsnew/whatsnew.html.

Subscribe to What's New in Cisco Product Documentation, which lists all new and revised Cisco technical

documentation as an RSS feed and delivers content directly to your desktop using a reader application. The

RSS feeds are a free service, and Cisco currently supports RSS Version 2.0.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

xiii

Page 14

Obtaining Documentation and Submitting a Service Request

Preface

xiv

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

Page 15

Installation Roadmap

Installation Roadmap , page 1

•

Installation Roadmap

The following table lists the tasks to install the Cisco NCS 6000 Fabric Card Chassis (FCC) and its components

and prepare the system for operation. Use this table as a checklist to ensure that all components are properly

installed in the correct order. For information about a step, see the respective section of this installation guide.

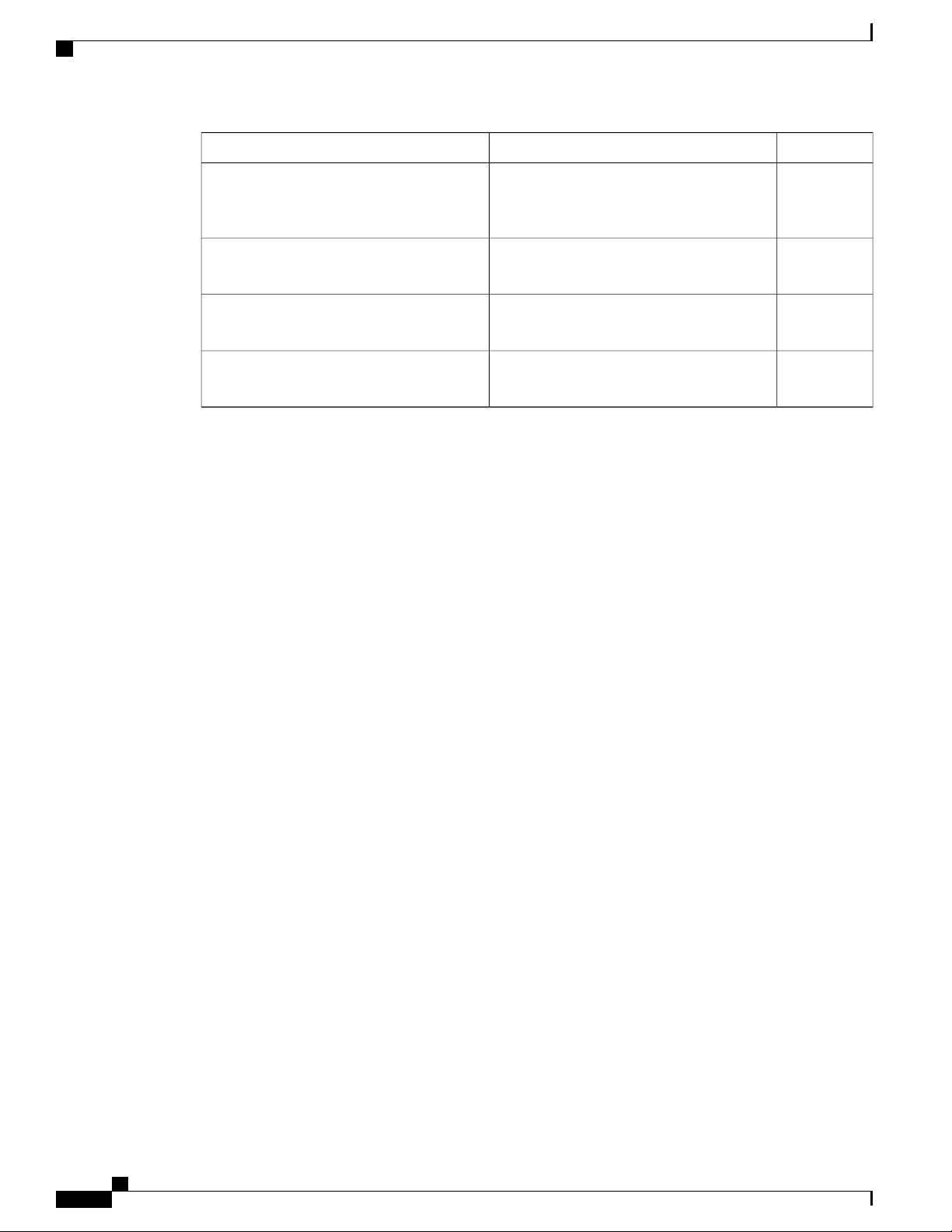

Table 2: Overview of Installation Steps

CHAPTER 1

CheckSeeStep

1. Verify that the FCC is securely bolted to

the floor.

2. Install the power enclosure.

3. Ground the FCC.

4. Install the power trays.

5. Install the external cosmetics on the front

of the FCC.

6. Install the external cosmetics on the rear

of the FCC.

7. Install power modules in the power trays.

Cisco Network Convergence System 6000

Series Routers Unpacking, Moving, and

Securing Guide

About the Power Enclosure, on page 13

section

Installing the Fabric Card Chassis Ground

Cable, on page 35 section

Installing an AC or DC Power Tray, on page

18 section

Installing the Front Exterior Cosmetics, on

page 22 section

Installing the Rear Exterior Cosmetics, on

page 28

Installing an AC or DC Power Module , on

page 46 section

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

1

Page 16

Installation Roadmap

Installation Roadmap

CheckSeeStep

8. Install either AC or DC input power

connections to the power trays.

9. Power on the FCC.

10. Install the shelf controller cards and fabric

cards in the FCC.

11. Connect the cabling for multi-chassis

configuration.

Installing AC Input Power Cords, on page

53 or Installing DC Input Power Cables , on

page 55 section

Powering On the Fabric Card Chassis , on

page 57 section

Installing the Shelf Controller Cards and

Fabric Cards , on page 61 section

Cabling a Multi-Chassis Configuration, on

page 137 section

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

2

Page 17

CHAPTER 2

Overview

This chapter provides an overview of the Cisco NCS 6000 Fabric Card Chassis.

About the Cisco NCS 6000 Fabric Card Chassis, page 3

•

Fabric Card Chassis Components, page 4

•

Slot Numbers, page 8

•

Cable Management , page 10

•

Safety Guidelines, page 10

•

About the Cisco NCS 6000 Fabric Card Chassis

The Cisco NCS 6000 Fabric Card Chassis is a highly scalable core routing platform designed for service

providers to build next generation multi-service networks that provide video, data and voice services. The

fabric card chassis, also known as a switch fabric chassis, is referred to in this document as the Cisco NCS

6000 FCC.

The Cisco NCS 6000 FCC is part of the Cisco NCS 6000 Multi-Chassis system that also includes the Cisco

NCS 6008 8-slot line card chassis (LCC). The system can expand from a single chassis to various multi-chassis

configurations for increased routing capacity and is capable of supporting up to 16 LCCs interconnected to

4 FCCs.

The Cisco NCS 6000 Multi-Chassis system scales by interconnecting up to 16 LCCs through up to four FCCs.

These connections are made from the LCC switch fabric cards to the FCC fabric cards through CXP or CXP2

optical interconnects. The NCS 6000 has a 3-stage switch fabric architecture. In a multi-chassis configuration,

the first and third stages are implemented by the S13 fabric cards on the LCC, and the second stage is performed

by the S2 fabric cards on the FCC. For an overview of the fabric system and multi-chassis cabling

configurations, see About the Cisco NCS 6000 Multi-Chassis System, on page 137.

The Cisco NCS 6000 FCC has an integrated rack and is bolted to the facility floor (no external rack is required).

The FCC contains its own power and cooling systems. Power systems are available using either AC or DC

power.

This installation guide provides the installation procedures for the FCC. For installation information about

the LCC, see the Cisco Network Convergence System 6000 Series Routers Hardware Installation Guide.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

3

Page 18

Fabric Card Chassis Components

Overview

Note

The installation of a Cisco NCS 6000 FCC may require space, floor loading, power, and cooling

modifications to a facility. Therefore, you should plan the site well in advance of the scheduled delivery

of the FCC. For site preparation information, see the Cisco Network Convergence System 6000 Series

Routers Site Planning Guide.

Fabric Card Chassis Components

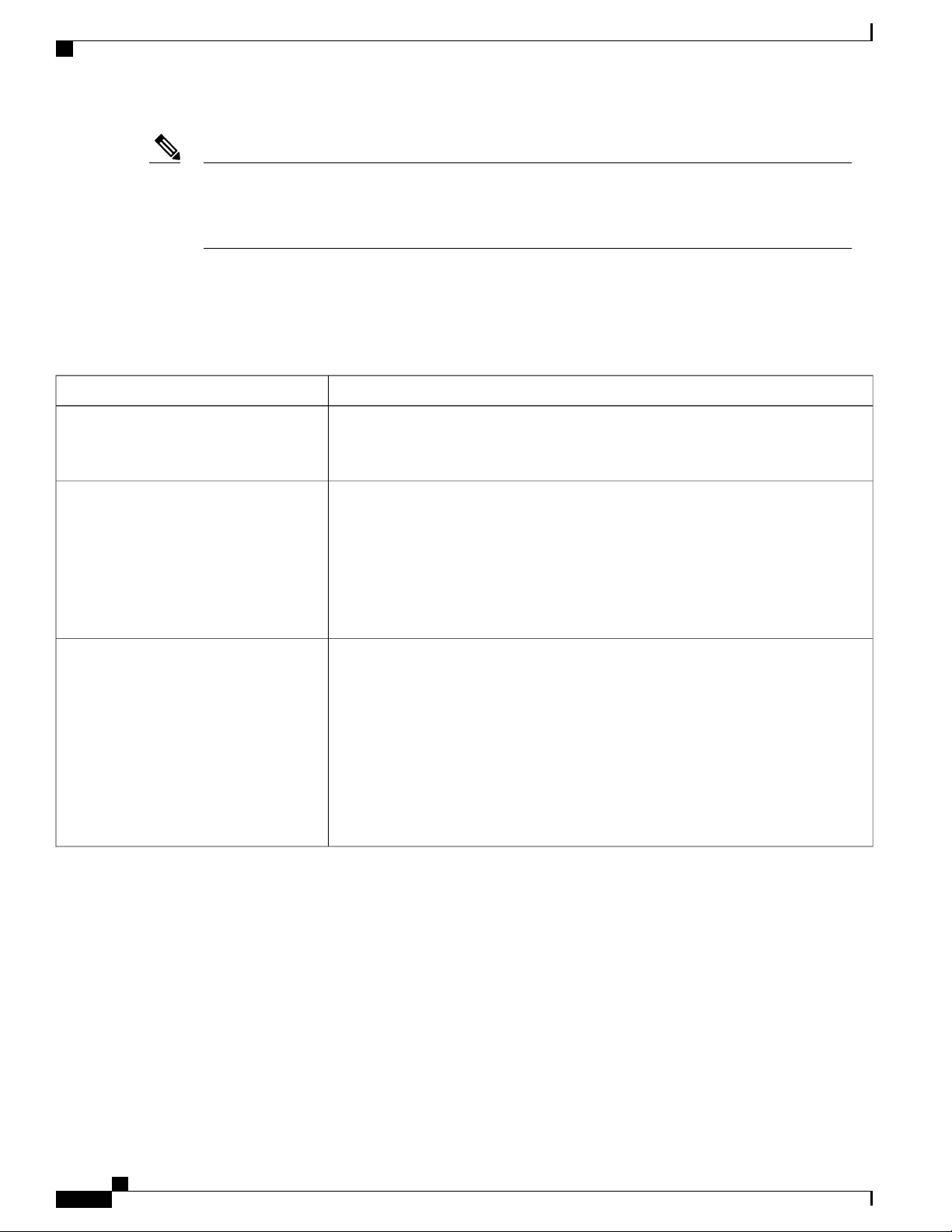

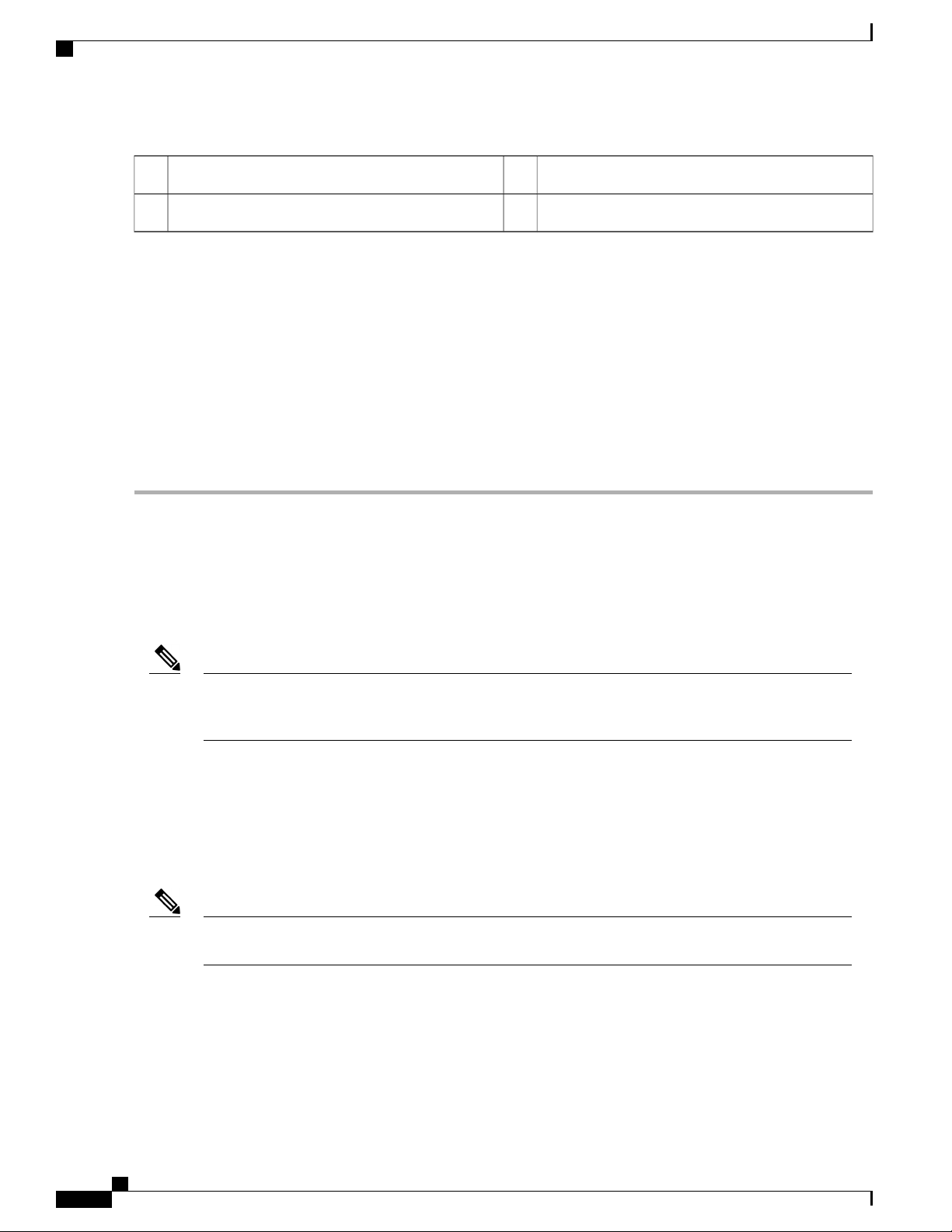

Table 3: Main Components of the Cisco NCS 6000 FCC

DescriptionComponent

Chassis midplane

S2 Fabric Cards (FCs)

The chassis midplane distributes power and provides interconnections for other

components in the system. Each S2 FC is connected through the midplane to the FCC.

The midplane is not a field-replaceable unit (FRU).

The FCC has 12 FC slots: Six FC slots on the front side of the FCC (three slots on the

upper cage and three slots on the lower cage) and six FC slots on the rear side of the

FCC (three slots on the upper cage and three slots on the lower cage). See Figure 3:

Cisco NCS 6000 FCC Slot Numbers. For an overview of the fabric, see Fabric

Overview, on page 150.

Each S2 FC supports up to 32 CXP modules. Each S2 FC2 supports up to 32 CXP2

modules.

CXP/CXP2 optical modules and connectors

The connections between the LCC and the FCC are implemented through a number of

bi-directional optical links. Pluggable CXP/CXP2 optics are used for these interconnects.

In 1T multi-chassis (MC) mode, CXP optical modules connect the S2 FC and S13

•

FC together.

In 2T MC mode, CXP2 optical modules connect the S2 FC2 and UFC together.

•

The CXP module (CXP-100G-SR12) and the CXP2 module (ONS-CXP2-SR25) use

a 24-fiber MPO connector that supports 12 bi-directional optical links up to 100 meters

of OM-4 multi-mode fiber.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

4

Page 19

Overview

Fabric Card Chassis Components

DescriptionComponent

Shelf Controller Cards

Power enclosure

The Cisco NCS 6000 FCC offers two types of shelf controller cards: the SC card and

the SC-SW card.

The SC-SW card is a 56-port combination card that integrates a shelf controller

•

and switch for the NCS 6000 Control Ethernet into one physical card. The shelf

controller (SC) portion controls the route processing and management functions

for the FCC and its components. The switch (SW) portion interconnects all the

route processors (RPs) and SCs in a multi-chassis system. The LEDs on the SC-SW

indicate active alarm conditions.

The SC card is a shelf-controller-only card.

•

For detailed information about the SC-SW and SC cards, see About the SC and SC-SW

Cards, on page 69.

The FCC ships with two shelf controller cards, either two SC-SW cards or a combination

of one SC-SW card and one SC card pre-installed in the FCC. The cards are inserted

into two dedicated slots on the front of the FCC. One SC-SW or SC card installs into

slot SC0 on the upper card cage and the other SC-SW or SC card installs into slot SC1

on the lower card cage (Figure 3: Cisco NCS 6000 FCC Slot Numbers). Both the upper

and lower card slots are identical. The secondary card is installed for redundancy, so

that the loss or removal of a single card does not bring down the FCC. At least one

SC-SW or SC card must be operational for the FCC to function.

Note

In a multi-chassis system with more than one FCC, we recommend that the

SC-SW cards are not installed in the same FCC.

The power enclosure is a separate unit that is installed at the top of the FCC (Figure 5:

FCC Power Enclosure—Front and Rear Views). The enclosure has four slots for AC

or DC power trays, and two power control modules (PCMs). Each set of power trays

has a PCM with its own I/O power switch.

Fan trays

Air filter

Each AC power tray has three slots for power modules (PMs). Each DC power

•

tray has four slots for PMs.

Mixing AC and DC power supplies in the FCC is not supported.

•

The AC and DC power trays are field-replaceable (after power down). The PMs are

hot-swappable.

Two redundant fan trays are inserted into the rear of the FCC (Figure 2: Rear View of

the Cisco NCS 6000 FCC ). Each fan tray contains four axial fans. The fans pull cooling

air through the FCC from the front to the back of the FCC.

A removable air filter is located below the lower cable management bracket and inside

the front air intake on the front of the FCC (Figure 1: Front View of the Cisco NCS

6000 FCC ).

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

5

Page 20

Fabric Card Chassis Components

Overview

DescriptionComponent

Cable management brackets

Cable troughs

Craft panel display

The FCC has cable management features on the front and rear sides of the FCC. These

brackets organize the interface cables entering and exiting the different cards, keeping

them out of the way and free of sharp bends that may damage the cables.

Four horizontal cable management brackets are preinstalled on the FCC (two on the

front side and two on the rear side of the FCC (Figure 1: Front View of the Cisco NCS

6000 FCC and Figure 2: Rear View of the Cisco NCS 6000 FCC ). Each side of the

FCC has one cable management bracket above the upper card cage and one cable

management bracket below the lower card cage.

Four vertical cable troughs are supplied for cable management, two on the front side

of the FCC and two on the rear side of the FCC.

A temperature sensor is located on the lower rear side of the FCC.Temperature sensor assembly

A craft panel display, located on the front of the FCC (Figure 1: Front View of the

Cisco NCS 6000 FCC ), consists of an LCD touch-screen display and LEDs used to

indicate system alarms. The craft panel has a basic interface used to monitor the operation

of the FCC.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

6

Page 21

Overview

Fabric Card Chassis Components

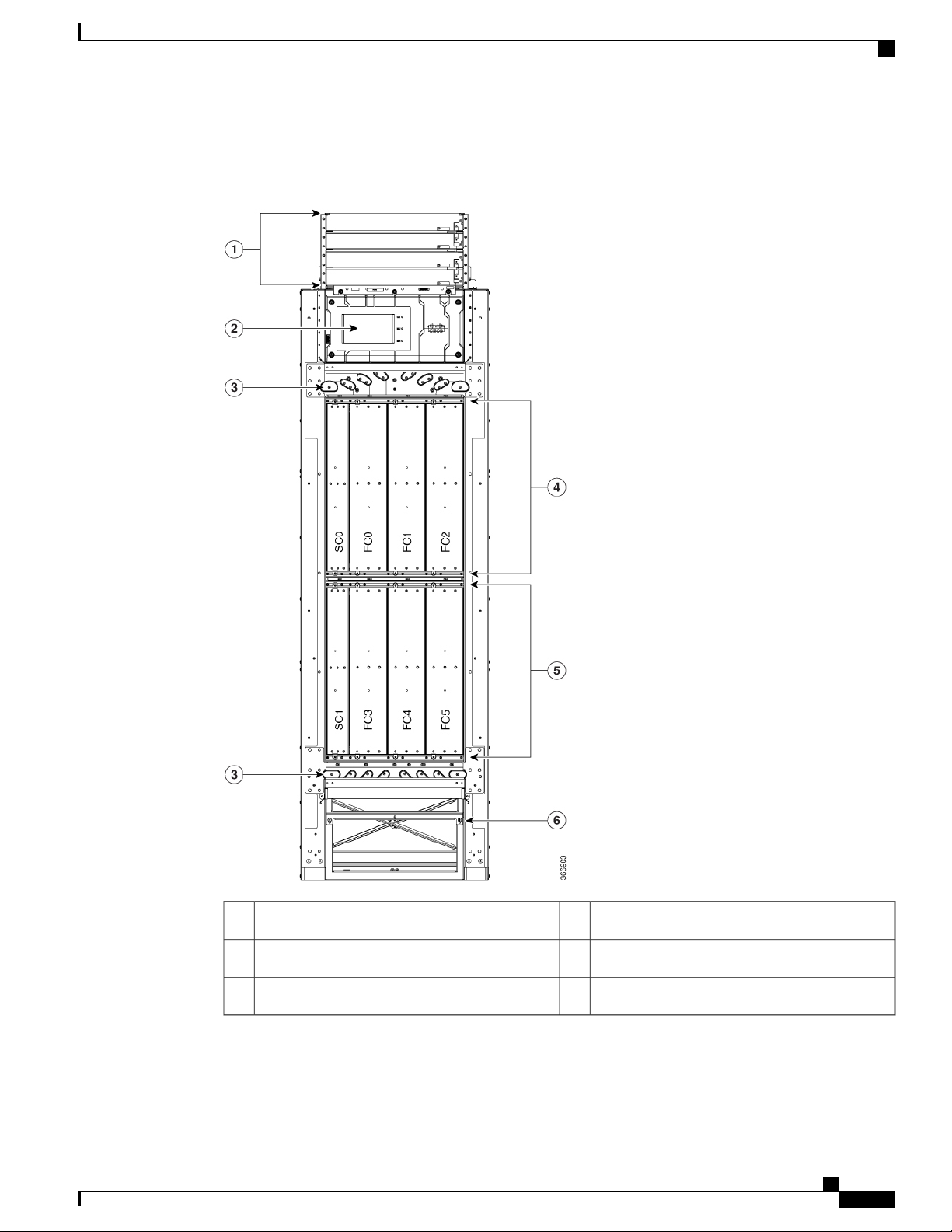

The following figure shows the front view of the Cisco NCS 6000 FCC.

Figure 1: Front View of the Cisco NCS 6000 FCC

Upper card cage4Power enclosure1

Lower card cage5Craft panel display2

Removable air filter6Cable management brackets3

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

7

Page 22

Slot Numbers

Overview

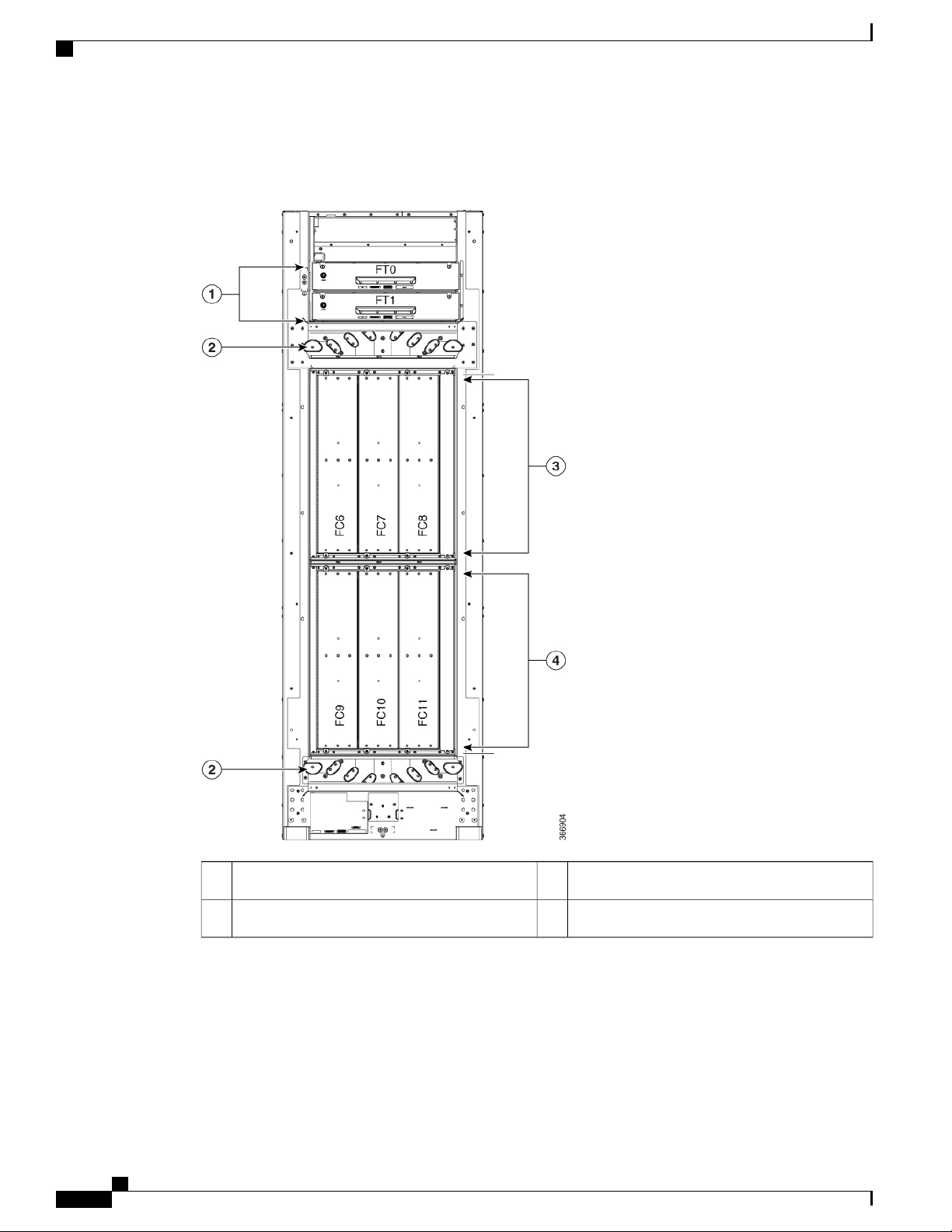

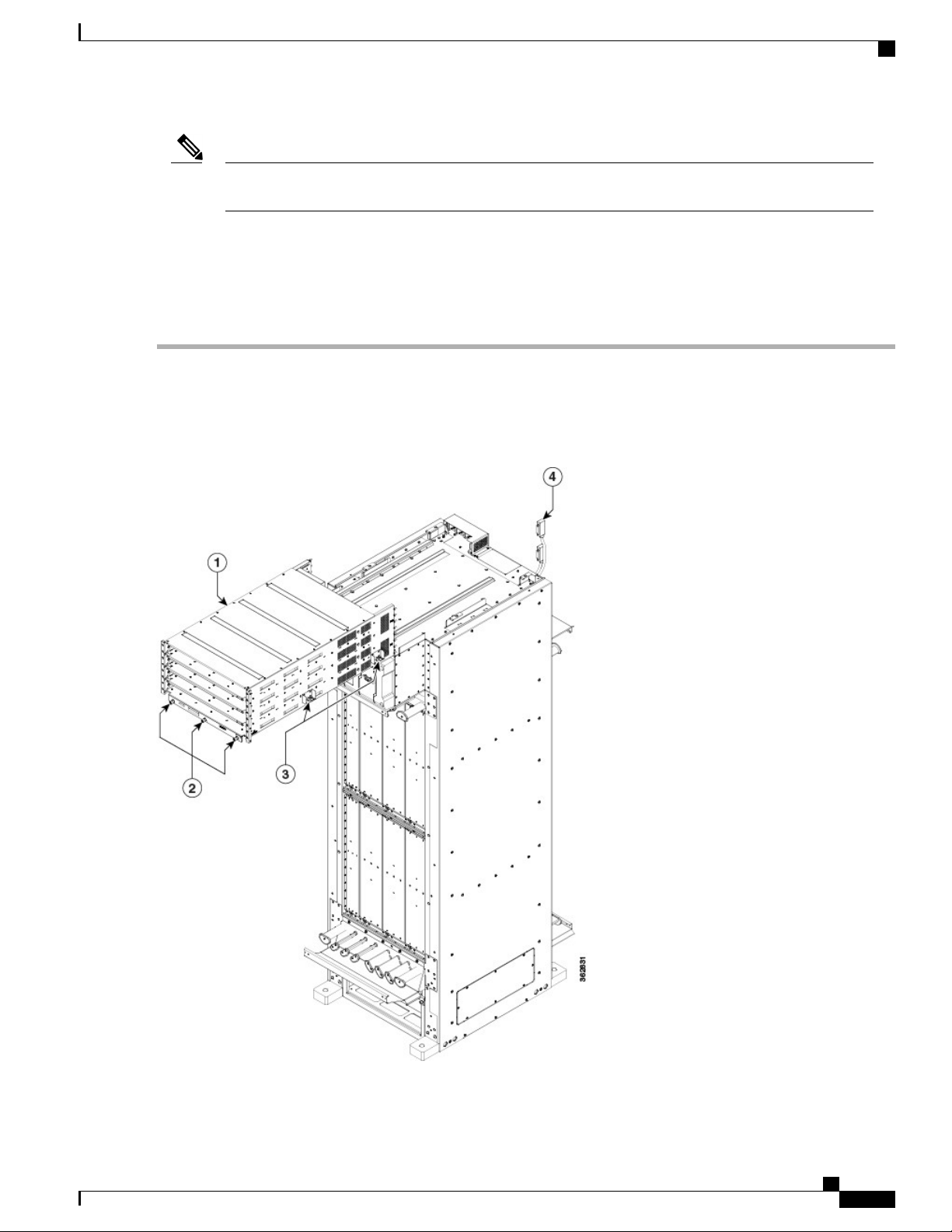

The following figure shows the rear view of the Cisco NCS 6000 FCC.

Figure 2: Rear View of the Cisco NCS 6000 FCC

Slot Numbers

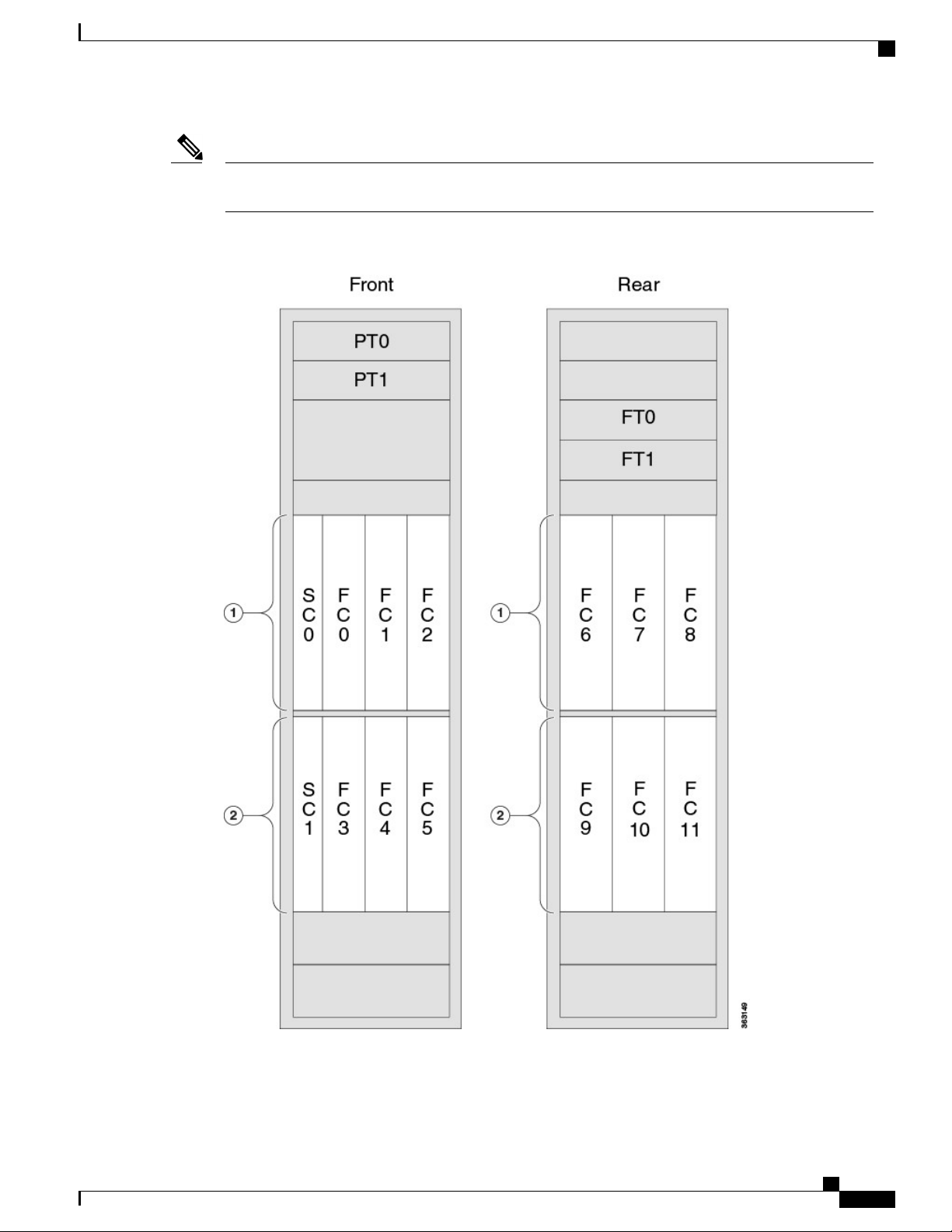

This section identifies the location and slot numbers for system components that plug into the Cisco NCS

6000 FCC. The following figure shows the slot number locations on the front and rear of the LCC.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

8

Upper card cage3Two fan trays1

Lower card cage4Cable management brackets2

Page 23

Overview

Slot Numbers

Note

The four power trays slots (PT0–PT3) are part of the power enclosure described in the About the Power

Enclosure, on page 13 section.

Figure 3: Cisco NCS 6000 FCC Slot Numbers

The FCC has the following slots:

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

9

Page 24

Cable Management

Front of the FCC

Four power trays for redundancy. The upper two power trays (PT0 and PT1) are referred to as power

•

shelf 0 (PS0) and the lower two power trays (PT2 and PT3) are referred to as power shelf 1 (PS1).

Two SC slots for redundancy (for SC and SC-SW cards) and six FC slots.

•

Upper card cage: (left to right: SC0, FC0, FC1, FC2)

◦

Lower card cage: (left to right: SC1, FC3, FC4, FC5)

◦

Rear of the FCC

Two fan trays for redundancy.

•

Upper fan tray: FT0

◦

Lower fan tray: FT1

◦

Six FC slots

•

Overview

Upper card cage: (left to right: FC6, FC7, FC8)

◦

Lower card cage: (left to right: FC9, FC10, FC11)

◦

Cable Management

The distribution of the slot locations on the Cisco NCS 6000 FCC allows for the large number of optic fiber

cables required for a fully-loaded routing system. Splitting the FCs front and back maximizes the space around

each connector and simplifies cable management.

The NCS 6000 FCC cable management features include:

Front and rear cable management brackets: One cable management bracket is located above the upper

•

card cage and one cable management bracket below the lower card cage (Figure 1: Front View of the

Cisco NCS 6000 FCC and Figure 2: Rear View of the Cisco NCS 6000 FCC ).

Vertical cable troughs: Four troughs, two on the front side of the FCC, and two on the rear side of the

•

FCC (Figure 14: Front Door Trough Hinges, Latches, and Retention Brackets and Figure 17: Rear Door

Trough Hinges, Latches, and Retention Brackets).

Safety Guidelines

Before performing any installation procedures, review the safety guidelines in this section to avoid injuring

yourself or damaging the equipment.

Note

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

10

Review the safety warnings listed in Regulatory Compliance and Safety Information for the Cisco Network

Convergence System 6000 Series Routers before installing, configuring, or troubleshooting any installed

card.

Page 25

Overview

Safety Guidelines

Note

Power off the PCM output switch and the power to the associated two power trays prior to removing a

power tray.

The following guidelines are for your safety and to protect equipment. The guidelines do not include all

hazards. Be alert.

Never attempt to lift an object that might be too heavy for you to lift by yourself.

•

Keep the work area clear and dust-free during and after installation. Do not allow dirt or debris to enter

•

into any laser-based components.

Keep tools and FCC components away from walk areas.

•

Do not wear loose clothing, jewelry, and other items that could get caught in the FCC while working

•

with the FCC and its components.

Use Cisco equipment in accordance with its specifications and product-usage instructions.

•

Do not work alone if potentially hazardous conditions exist.

•

Make sure your installation follows national and local electrical codes:

•

In the United States, National Fire Protection Association (NFPA) 70, United States National

◦

Electrical Code; in Canada, Canadian Electrical Code, part I, CSA C22.1.

In other countries, International Electrotechnical Commission (IEC) 60364, part 1 through part 7.

◦

Connect only a DC power source that follows the safety extra-low voltage (SELV) requirements in

•

UL/CSA/IEC/EN 60950-1 and AS/NZS 60590 to the DC input power system.

Make sure that you have a readily accessible two-poled disconnect device incorporated in the fixed

•

configuration wiring of a DC input power system.

Make sure that you provide short-circuit (overcurrent) protection as part of the building installation.

•

Preventing Electrostatic Discharge

Electrostatic discharge (ESD) damage, which can occur when electronic cards or components are improperly

handled, results in complete or intermittent failures. We recommend use of an ESD-preventive wrist strap

whenever you handle network equipment or one of its components.

To prevent ESD damage:

Always use an ESD-preventive wrist or ankle strap, and ensure that it makes good skin contact. Connect

•

the equipment end of the connection cord to an ESD jack or a bare metal surface on the FCC (ensure

that the FCC is grounded).

Handle a card by its ejector levers, when applicable, or its metal carrier only; avoid touching the board

•

or connector pins.

Place a removed card board side up on an antistatic surface or in a static-shielding bag. If you plan to

•

return the component to the factory, immediately place it in a static-shielding bag.

Avoid contact between a card and clothing. The wrist strap protects the board from only ESD voltage

•

on the body; ESD voltage on clothing can still cause damage.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

11

Page 26

Safety Guidelines

Overview

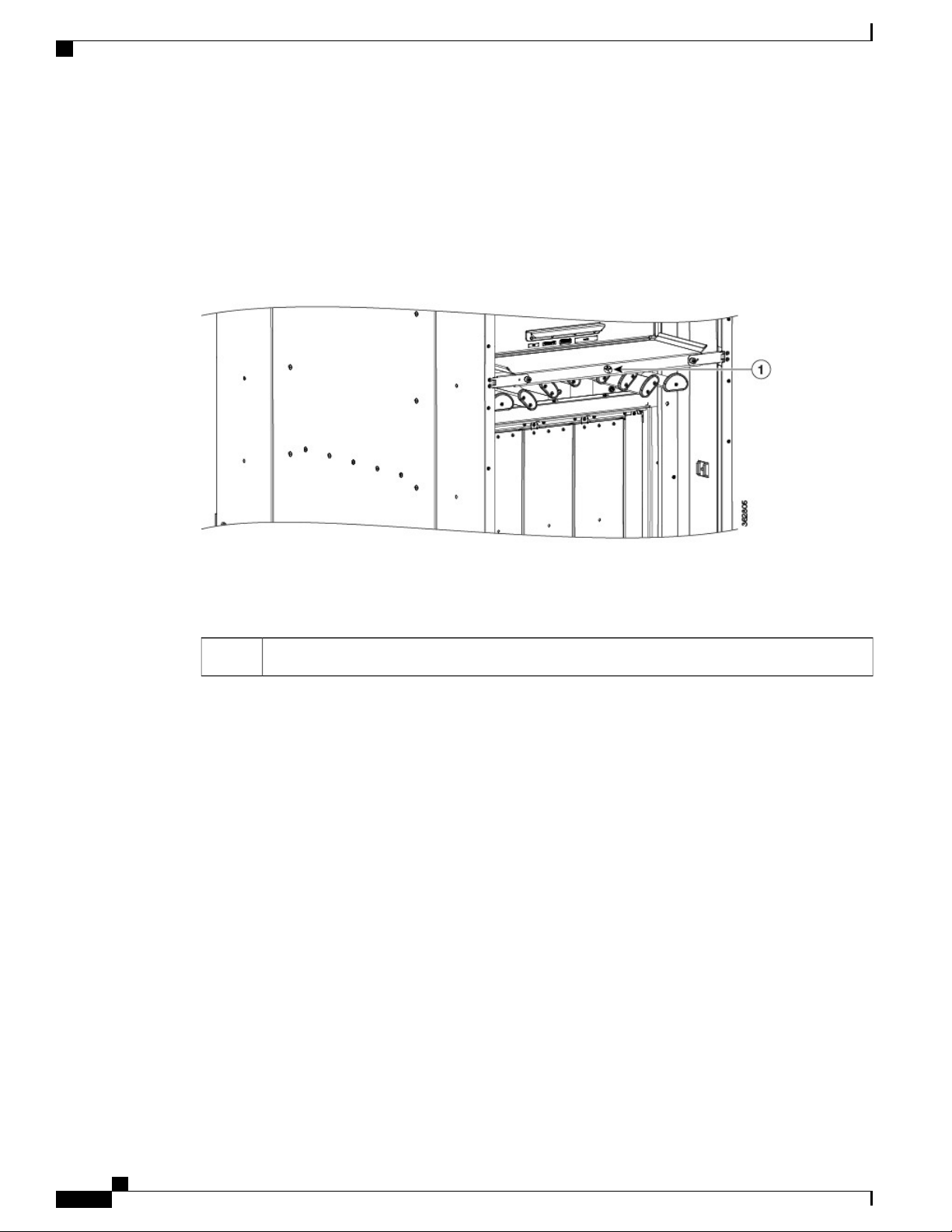

The following figure shows an example of the ESD jack on the FCC. An ESD jack is located directly above

the upper and lower cable management brackets on both sides of the FCC.

Figure 4: ESD Jack

ESD jack (two on each side of the FCC)1

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

12

Page 27

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

This chapter provides instructions on installing the Cisco NCS 6000 Fabric Card Chassis power enclosure,

power trays, and exterior cosmetics.

About the Power Enclosure, page 13

•

Installing the Power Trays, page 16

•

Installing the Exterior Cosmetics, page 20

•

About the Power Enclosure

The Cisco NCS 6000 FCC ships with a separate empty power enclosure (Cisco PID NCS-F-PWR-SHELF).

The power enclosure consists of one power shelf, four slots for AC or DC power trays, and two power control

modules (PCMs).

The upper two power trays (PT0 and PT1) are referred to as power shelf 0 (PS0), and the lower two power

trays (PT2 and PT3) are referred to as power shelf 1 (PS1) Figure 3: Cisco NCS 6000 FCC Slot Numbers.

Each set of power trays has a power control module (PCM) with its own I/O power switch. Three AC power

modules or four DC power modules can be installed in each power tray. See the Installing an AC or DC Power

Module , on page 46 section.

CHAPTER 3

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

13

Page 28

Installing the Power Enclosure

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Note

Usually, it is not necessary to remove the power enclosure although it is field-serviceable. For information

about removing the power enclosure components, see the Replacing an AC or DC Power Tray, on page

99 section.

Figure 5: FCC Power Enclosure—Front and Rear Views

Two PCMs2

Installing the Power Enclosure

This section describes how to install the power enclosure in the Cisco NCS 6000 FCC.

Required Tools and Equipment

6-inch, Number-2 Phillips screwdriver

•

Power enclosure (Cisco PID NCS-F-PWR-SHELF)

•

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

14

PCM I/O power switches (one per PCM)3Four power tray slots for AC or DC power trays1

Page 29

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Installing the Power Enclosure

Step 1

Note

The power enclosure weighs approximately 30 pounds and sits on top of the FCC. To prevent injury, we

recommend that you use a ladder and use two people when installing the power shelf.

Steps

Follow these steps to attach the power enclosure to the FCC:

Lift and place the power enclosure (busbar facing back) at the top of the FCC.

Caution

Figure 6: Attaching the Power Enclosure to the FCC

Handle the power shelf by lifting it at the sides and along the bottom of the shelf when installing it into the

FCC. Avoid lifting the shelf from the center bottom.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

15

Page 30

Installing the Power Trays

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Side captive screws (two per side)3Power enclosure1

D-Sub connector cables (one per PCM)4Three front captive screws2

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Position and align the two rails on each side of the underside of the power enclosure with the two rails at the top of the

FCC. When the shelf is aligned properly, it will easily slide in place.

Slowly push the power enclosure forward until the front flange with the three captive screws engages with the front of

the FCC.

Loosely tighten the captive screws (two per side) on the power enclosure, and then loosely tighten the three captive

screws on the front flange.

Repeat Step 4, tightening all captive screws to firmly attach the power enclosure to the FCC.

Attach the two D-Sub connector cables to the two PCM connectors on back of the power enclosure and tighten the captive

screws on each cable connector. The individual PCMs are labeled PCM0 and PCM1.

Tighten the captive screws on each cable connector.

Installing the Power Trays

This section describes how to install an AC or DC power tray in the power enclosure and includes the following

topics:

Note

Although there are differences between AC and DC power trays, they are installed by using the same

procedures described in this section. Once they are installed into an FCC that is properly grounded, external

grounding to the power tray is not needed.

About the AC and DC Power Trays

The Cisco NCS 6000 FCC power enclosure supports either four AC power trays or four DC power trays. An

AC power tray houses up to three AC power modules, while a DC power tray houses up to four DC power

modules. See the Installing an AC or DC Power Module , on page 46 section.

Note

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

16

Only one type of power tray can be installed in the power enclosure. You cannot mix AC and DC power

trays.

Page 31

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

About the AC and DC Power Trays

Note

For a DC power tray, the rear input LED starts to light up when the input voltage reaches -20 VDC, gets

brighter as the voltage increases, and is fully lit when the input voltage reaches -48 VDC.

Figure 7: AC Power Tray—Front View

Figure 8: AC Power Tray—Rear View (Clear Plastic Safety Cover Removed)

Figure 9: DC Power Tray—Front View

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

17

Page 32

Installing an AC or DC Power Tray

Figure 10: DC Power Tray—Rear View (Clear Plastic Safety Cover Removed)

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Installing an AC or DC Power Tray

This section describes how to install an AC or DC power tray in the Cisco NCS 6000 FCC.

Note

Prerequisites

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

18

For information about removing a power tray, see the Replacing an AC or DC Power Tray, on page 99

section.

Before you install an AC or DC power tray, do the following:

Remove the top grilles from both the front and rear sides of the FCC, if installed.

•

Ensure the power tray you are about to install is empty. Do not install a power tray into the FCC with

•

the PMs installed in the power tray.

Page 33

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Required Tools and Equipment

Four M4 x 10 mm screws per power tray

•

6-inch, Number-2 Phillips screwdriver

•

Number-2 Phillips torque screwdriver with torque rated up to 55 in-lb (6.2 N-m)

•

AC or DC power tray

•

AC power tray (Cisco PID NCS-AC-PWRTRAY)

◦

DC power tray (Cisco PID NCS-DC-PWRTRAY)

◦

Steps

To install an AC or DC power tray, follow these steps:

Installing an AC or DC Power Tray

Step 1

Step 2

Using two people, one to support the power tray underneath and the other to keep it steady, lift the power tray up and

slide it partially into a power tray slot on the power enclosure.

Caution

Because of the weight of a power tray, 20 lb (9 kg), and the height at which a power tray is installed in the

FCC, be especially careful while removing and carrying a power tray. To prevent injury, avoid sudden twists

or lateral moves.

Grasping both handles simultaneously, push both the left and right handles in at the same time to push the tray into the

power enclosure. Slide the tray all the way into the enclosure until both power tray handles engage the slots.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

19

Page 34

Installing the Exterior Cosmetics

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Caution

Figure 11: Installing a Power Tray into the Power Enclosure—DC Power Tray Shown

Use care not to bend the

handles.

Step 3

Step 4

Use the screwdriver to loosely tighten the four M4 x 10 mm screws that attach the power tray to the power enclosure.

Use the torque screwdriver to tighten the four screws to a torque value of 15 in-lb (1.69 N-m) to 20 in-lb (2.26 N-m).

The screws that attach a power tray to the power shelf are relied upon for power tray bonding and grounding.Note

Installing the Exterior Cosmetics

This section describes how to install the exterior cosmetics on the Cisco NCS 6000 FCC and includes the

following topics:

For information about removing the external cosmetics, see the Removing the Exterior Cosmetics , on page

87 section.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

20

Page 35

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Overview of the Exterior Cosmetics

The Cisco NCS 6000 FCC is shipped with exterior cosmetics for the front side and rear side of the FCC.

Figure 12: Exterior Cosmetics—Front Side of the FCC

Overview of the Exterior Cosmetics

Bottom grille3Top grille1

Front door2

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

21

Page 36

Installing the Front Exterior Cosmetics

Figure 13: Exterior Cosmetics—Rear Side of the FCC

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Rear exhaust air deflector1

Rear door2

Installing the Front Exterior Cosmetics

This section describes how to install the front side exterior cosmetics on the Cisco NCS 6000 FCC. We

recommend that you install the exterior cosmetics in the order outlined in this section.

Note

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

22

Before performing these tasks, you must first unpack and secure the chassis. See the Cisco Network

Convergence System 6000 Series Routers Unpacking, Moving, and Securing Guide.

Page 37

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Prerequisites

Installing the Power Enclosure , on page 14

Required Tools and Equipment

8-inch, Number-1 Phillips screwdriver (magnetic head preferable)

•

Two vertical cable troughs (left and right troughs are interchangeable)

•

Three door hinges

•

Three door latches

•

Four trough retention brackets

•

Front door

•

Door grounding cable

•

Installing the Front Exterior Cosmetics

Step 1

Step 2

Craft panel cover

•

Front top grille

•

Front bottom grille

•

For information on the cosmetic PID numbers, see Cosmetic Product IDs, on page 134.

Steps

To install the front exterior cosmetics, follow these steps:

Remove the upper and lower horizontal cable management brackets (preinstalled on the FCC) by loosening and removing

the eight pan-head screws (four per bracket). One bracket is located above the upper card cage and the other bracket is

below the lower card cage.

Attach the left and right vertical cable troughs to the front of the FCC. The two vertical cable troughs are installed inverted

from each other. Each trough is marked FRONT to ensure that you install the trough on the correct side of the FCC.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

23

Page 38

Installing the Front Exterior Cosmetics

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Note

We recommend that you use two people to attach the vertical cable troughs; one person to hold the vertical

cable troughs in place while the other person inserts and tightens the screws.

Figure 14: Front Door Trough Hinges, Latches, and Retention Brackets

1

Trough retention brackets (two per trough)4Vertical cable troughs (one per side), each attached

to the FCC with eight pan-head screws

Two horizontal cable management brackets

5Three door hinges2

(preinstalled)

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

24

Page 39

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Installing the Front Exterior Cosmetics

Step 3

Step 4

Step 5

3

Craft panel display cover6Three door latches:

Door stop latch, top and bottom (700-39150-01)

Door latch, middle (700-46854-01)

For each vertical cable trough

Align the guide pins on the rear of the vertical cable trough with the positioning holes on the front of the FCC.

1

Loosely insert eight pan-head screws, and then use the screwdriver to tighten them clockwise to attach the vertical

2

cable troughs firmly to the front of the FCC. You might need to use a ladder to reach the upper screws.

Attach two trough retention brackets to each vertical trough with two 8-32 flat-head screws (two per trough).

3

Using the captive screw, insert the trough retention brackets into each upper and lower horizontal cable troughs (two

4

screws per side).

Reattach the upper and lower horizontal cable management brackets by inserting and tightening the eight pan-head

screws (four per bracket).

Attach the three door hinges and the three door latches by using two pan-head screws each.

Align the front door (see the following figure) with the three door hinges on the FCC. The door will then drop into

position onto the hinge attachment pins.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

25

Page 40

Installing the Front Exterior Cosmetics

We recommend that you use two people to lift the door onto the FCC.Note

Figure 15: Attaching the Front Door

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Grounding cable3Front door1

Door hinges2

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

26

Page 41

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Installing the Front Exterior Cosmetics

Step 6

Step 7

Attach the grounding cable to the front door.

a) Insert and tighten one pan-head screw to attach one end of the ground cable to the inside of the door.

b) Insert and tighten one pan-head screw to attach the other end of the ground cable to the vertical cable trough.

Attach the grilles to the troughs (see the following figure).

a) Attach the top grille by carefully inserting the bottom tabs into the slots on the bottom of the grille Press the grille

firmly against the troughs until the snap joiners on the top of the grill snap into place.

b) Attach the bottom grille by carefully inserting the top tabs into the slots on the top of the grille. Press the grille firmly

against the troughs until the snap joiners on the bottom of the grille snaps into place.

Figure 16: Front Grilles

Front bottom grille2Front top grille1

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

27

Page 42

Installing the Rear Exterior Cosmetics

Installing the Rear Exterior Cosmetics

This section describes how to install the rear side exterior cosmetics on the Cisco NCS 6000 FCC. We

recommend that you install the exterior cosmetic components in the order outlined in this section.

Prerequisites

Installing the Power Enclosure , on page 14

Installing the Front Exterior Cosmetics, on page 22

Required Tools and Equipment

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Step 1

Step 2

8-inch, Number-1 Phillips screwdriver (magnetic head preferable)

•

Two vertical cable troughs (left and right are interchangeable)

•

Three door hinges

•

Three door latches

•

Four trough retention brackets

•

Exhaust plenum bracket

•

Rear door

•

Door grounding cable

•

Rear exhaust air deflector

•

Steps

To install the rear exterior cosmetics, follow these steps:

Remove the upper and lower horizontal cable management brackets (preinstalled on the FCC) by loosening and removing

the eight pan-head screws (four per bracket). One bracket is located above the upper card cage and the other bracket is

below the lower card cage.

Attach the left and right vertical cable troughs to the rear of the FCC. The two vertical cable troughs are inverted from

each other. Each trough is marked REAR to ensure that you install the trough on the correct side of the FCC.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

28

Page 43

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Installing the Rear Exterior Cosmetics

Note

We recommend that you use two people to attach the vertical cable troughs; one person to hold the vertical

cable troughs in place while the other person inserts and tightens the screws

Figure 17: Rear Door Trough Hinges, Latches, and Retention Brackets

1

to the FCC with eight pan-head screws

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

Trough retention brackets (two per trough)4Vertical cable troughs (one per side), each attached

Two horizontal cable troughs (preinstalled)5Three door hinges2

29

Page 44

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Installing the Rear Exterior Cosmetics

Three door latches:

3

Door stop latch, top and bottom (700-39150-01)Door

latch, middle (700-46854-01)

For each vertical cable trough:

a) Align the guide pins on the rear of the vertical cable trough with the positioning holes on the rear of the chassis.

b) Loosely insert eight pan-head screws, and then use the screwdriver to tighten them clockwise to attach the vertical

cable troughs firmly to the front of the FCC. You might need to use a ladder to reach the upper screws .

c) Attach the trough retention brackets to each vertical trough with two 8-32 flat-head screws (two per trough).

d) Using the captive screw, insert the trough retention brackets into each upper and lower horizontal cable troughs on

the FCC (two screws per side).

Step 3

Step 4

Reattach the upper and lower horizontal cable management brackets by inserting and tightening the eight pan-head

screws (four per bracket).

Attach the side filler panels.

For each filler panel:

a) Align the guide pins on the filler panel with the positioning holes on top of the FCC.

b) Insert the filler panel into the FCC and slide it down until it is fully seated.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

30

Page 45

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

c) Loosely attach the filler panel to the FCC with two 8-32 screws.

Figure 18: Side Filler Panels

Installing the Rear Exterior Cosmetics

Two 8-32 screws3Side filler panel (one each side)1

Guide pins2

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

31

Page 46

Installing the Rear Exterior Cosmetics

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Step 5

Step 6

Attach the exhaust plenum bracket to the FCC (cutouts facing up) using six pan-head screws, three screws each side.

Before installing the bracket, remove the topmost screw on each of the vertical troughs.

Tighten the two 8-32 screws on the filler panel (that you previously installed) securely to the FCC.

Figure 19: Exhaust Plenum Bracket

Six pan-head screws (three per side)2Exhaust plenum bracket1

Step 7

Step 8

Step 9

Attach the three door hinges and the three door latches by using two pan-head screws each (Figure 17: Rear Door Trough

Hinges, Latches, and Retention Brackets).

Align the rear door with the three door hinges on the FCC (Figure 15: Attaching the Front Door). The door will then

drop into position onto the hinge attachment pins.

We recommend that you use two people to lift the door onto the FCC.Note

Attach the grounding cable to the rear door (step 7).

a) Insert and tighten one pan-head screw to attach one end of the ground cable to the inside of the door.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

32

Page 47

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

b) Insert and tighten one pan-head screw to attach the other end of the ground cable to the vertical cable trough.

Installing the Rear Exterior Cosmetics

Step 10

Attach the exhaust air deflector by carefully inserting its mounting tabs into the exhaust plenum brackets. Press the

deflector firmly against the vertical cable troughs until it snaps on.

Figure 20: Exhaust Air Deflector—Rear of the Chassis

Exhaust air deflector1

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

33

Page 48

Installing the Rear Exterior Cosmetics

Installing the Power Enclosure, Power Trays, and Exterior Cosmetics

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

34

Page 49

Installing the Power Components

This chapter provides an overview of the AC and DC power systems and how to install the power modules

and input power cables into the Cisco NCS 6000 Fabric Card Chassis (FCC). For information about removing

power components, see the Removing the Power Components, on page 96 section.

Power System Overview, page 35

•

Installing the Power Modules and Input Power Cables, page 45

•

Powering On and Powering Off the Fabric Card Chassis, page 57

•

Power System Overview

The Cisco NCS 6000 FCC can be configured with either an AC input power system or a DC input power

system. Site power requirements differ, depending on the source voltage used.

For information about power safety requirements, see the Regulatory Compliance and Safety Information for

the Cisco Network Convergence System 6000 Series Routers.

CHAPTER 4

Prerequisites

Follow these precautions and recommendations when planning power connections to the FCC:

Check the power at your site before installation to ensure that you are receiving clean power (free of

•

spikes and noise). Install a power conditioner, if necessary.

Install proper grounding to avoid damage from lightning and power surges.

•

Installing the Fabric Card Chassis Ground Cable

The FCC has two safety earth ground connections. You can connect the central office ground system or interior

equipment grounding system to either of these grounding points on the rear side of the FCC. One chassis

ground is located near the top of the FCC and one chassis ground is located at the bottom of the FCC. These

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

35

Page 50

Installing the Fabric Card Chassis Ground Cable

grounding points are also referred to as Network Equipment Building System (NEBS) bonding and grounding

point, and are provided to satisfy the Telcordia NEBS safety requirements.

Figure 21: NEBS Bonding and Grounding Points—Rear Side of the FCC

Installing the Power Components

Do not remove the FCC ground cable unless the FCC is being replaced.Caution

Required Tools and Equipment

You will need to provide the following tools and equipment:

Number-2 Phillips screwdriver

•

Ground lug

•

Ground cable

•

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

36

NEBS bonding and grounding point (lower)2NEBS bonding and grounding points (upper)1

Page 51

Installing the Power Components

•

•

To ensure a satisfactory ground connection:

•

•

•

Installing the Fabric Card Chassis Ground Cable

Crimping tool and lug specific die

3/8-inch drive torque wrench rated to include 30 in-lb (3.39 N-m)

One 180-degree angle (straight) grounding lug that has two M6 bolt holes with 0.63 inch (16 mm)

spacing center to center between them, and a wire receptacle able to accept a 2-6-AWG multistrand

copper wire.

Two M6 bolts with integrated square cone locking washers (shipped pre-installed on the FCC, two at

each grounding point).

2-6-AWG multistrand copper ground cable. This cable is not available from Cisco; it is available from

any commercial cable vendor such as Panduit (see http://www.panduit.com). The cable should be sized

according to local and national installation requirements.

Note

The DC return of this system should remain isolated from the system frame and FCC (DC-I: Isolated DC

Return).

Figure 22: 180-Degree Angle Straight Barrel Grounding Lug

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

37

Page 52

Installing the Fabric Card Chassis Ground Cable

Steps

To attach the ground cable to the FCC, follow these steps:

Installing the Power Components

Step 1

Step 2

Use the crimping tool mandated by the lug manufacturer to crimp the lug to the ground cable.

Use the socket wrench to attach the lug and ground cable to one the NEBS grounding point (Figure 21: NEBS Bonding

and Grounding Points—Rear Side of the FCC ).

Figure 23: Attaching the Ground Cable to a NEBS Bonding and Grounding Point

Step 3

Step 4

38

Use the torque wrench to tighten the bolts to a torque of 30 in-lb (3.39 N-m).

Connect the other end of the ground cable to a grounding point at your site, according to site requirements.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

Page 53

Installing the Power Components

AC Power System

Overview of the AC Power System

An AC-powered Cisco NCS 6000 FCC contains four AC power trays that are part of the FCC power enclosure

(Figure 5: FCC Power Enclosure—Front and Rear Views). The upper two power trays (PT0 and PT1) are

referred to as PS0, and the lower two power trays (PT2 and PT3) are referred to as PS1. Figure 3: Cisco NCS

6000 FCC Slot Numbers. Each set of power trays has a power control module (PCM) with its own I/O power

switch.

Each AC power tray has three slots for PMs. The AC power trays are field-replaceable (after power down),

however the PMs are hot-swappable.

Each inserted AC PM requires a single-phase, 50 to 60 Hz, 200 to 240 VAC input. Input current is variable

and based on facility minimum voltage. For N+N redundancy, power feeds A must power the upper two AC

power trays and power feeds B must power the lower two AC power trays (not all of the power module bays

need to be filled). This allows the system to balance its load across each set of power trays and across the

power modules within each tray.

The AC power system requires single-phase AC input power to each inserted PM. If you have a 3-phase AC

Delta or AC Wye at your equipment, a Cisco NCS power distribution unit (PDU) is required to convert

3-phase AC input power to single-phase AC input power system.

AC Power System

Note

Note

If you plan to use a three-phase AC PDU we recommend that you install three AC PMs in each AC power

tray to maintain a balanced three-phase power load.

We recommend that you use appropriate short-circuit protection in compliance with national and local

electrical codes.

Installing an AC Power Distribution Unit

The AC PDU converts three-phase AC input power to single-phase AC input power that connects directly to

the rear of each PM. The AC PDU includes either an AC Delta (Cisco PID NCS-PDU-DELTA) or AC Wye

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

39

Page 54

AC Power System

Installing the Power Components

(Cisco PID NCS-PDU-WYE) power interface, and has power input and power output cords entering and

exiting the box.

Figure 24: Cisco NCS-PDU

For detailed information on AC PDUs, see the Cisco CRS 3-Phase AC Power Distribution Unit Installation

Guide.

Mounting the PDU

The AC PDU mounting bracket holds two AC PDUs. The mounting bracket can be attached to both sides of

the FCC by using the existing screws that hold the side panels on (Figure 25: AC PDU Bracket Attached to

the Side of the FCC). The PDUs are attached to the mounting brackets with four M5 screws per AC PDU.

Output cord4Rack mounting ears1

Two PDUs5Rack tray2

Input cord3

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

40

Page 55

Installing the Power Components

Optionally, you can mount the AC PDU in an external 19-inch rack by using six pan-head screws (Figure 26:

Rack Mounting the AC PDU in a 19-Inch Rack).

Figure 25: AC PDU Bracket Attached to the Side of the FCC

AC Power System

PDU bracket (chassis mount)2AC PDUs (one each side)1

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

41

Page 56

AC Power System

Installing the Power Components

Figure 26: Rack Mounting the AC PDU in a 19-Inch Rack

Installing the Tie-Down Bar

A 19-inch tie-down bar can be used to add strain relief for input power cables from the AC PDUs or cables

routed from a raised floor. The following figure shows holes for two 10-32 x 0.50 inch screws that are

pre-drilled on the FCC for attaching a tie-down bar.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

42

Page 57

Installing the Power Components

DC Power System

Note

The 19-inch tie-down bar and screws are not supplied by Cisco. You can order these parts from a

commercial vendor such as Panduit.

Figure 27: 19-Inch Tie-Down Bar

DC Power System

A DC-powered Cisco NCS 6000 FCC contains four DC power trays that are part of the FCC power enclosure

(Figure 5: FCC Power Enclosure—Front and Rear Views). The upper two power trays (PT0 and PT1) are

referred to as power shelf 0 (PS0), and the lower two power trays (PT2 and PT3) are referred to as power

shelf 1 (PS1). Figure 3: Cisco NCS 6000 FCC Slot Numbers. Each set of power trays has a power control

module (PCM) with its own I/O power switch.

The DC power tray has four slots for PMs. The DC power trays are field-replaceable (after power down),

however the PMs are hot-swappable.

For N+N redundancy, “A” power feeds must power the upper two DC power trays and “B” power feeds must

power the lower two DC power trays (not all of the PM bays need to be filled). This allows the system to

balance its load across the two set of power trays and across the power modules within each tray.

The following table lists the DC input current and voltage specifications.

Tie-down bar1

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

43

Page 58

DC Power System

Installing the Power Components

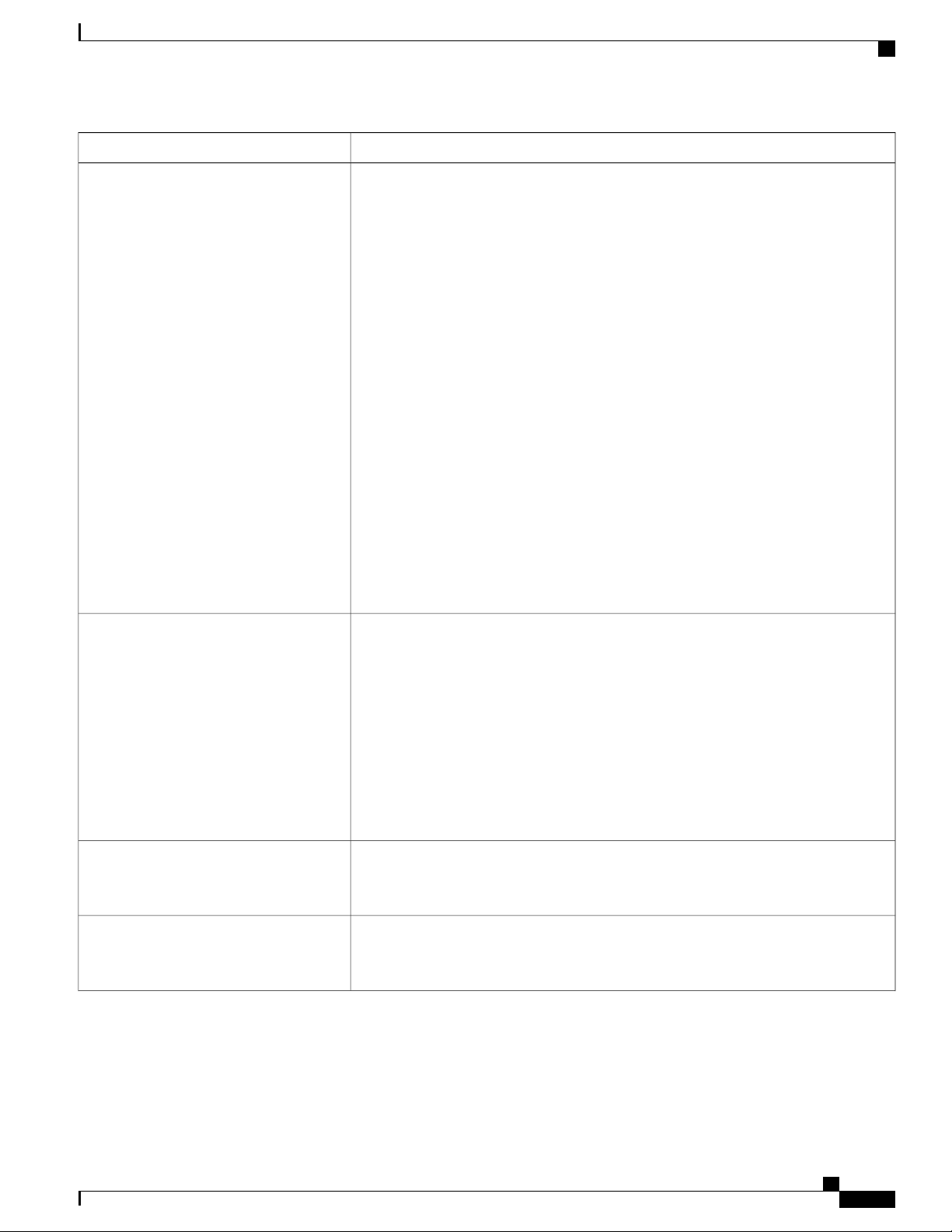

Table 4: DC Input Current and Voltage Information

Note

Nominal input voltage

Input line current

–48 VDC or –60 VDC (tolerance range: –40 to –72 VDC)

50 A maximum at –48 VDC

40 A maximum at –60 VDC

60 A maximum at –40 VDC

Each wiring block on the DC power tray contains two sets of terminals, one positive and one negative, and

is covered by a plastic terminal block cover that is secured by a screw to a torque of 5 to 7 in-lb (0.56 to 0.79

N-m). Each DC power cable is connected to a power tray with a torque of 45 to 55 in-lb (5.1 to 6.2 N-m).

The terminal block supports 4-6-AWG input wire.

The cable should be sized according to local and national installation requirements. Use only copper cable.

An “allpole” separation of the power source is not required. The DC PM is an isolated DC/DC converter

with no galvanic connection between “L+” and the FCC. In addition, the “L+” potentials of each PM are

isolated from each other.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

44

Page 59

Installing the Power Components

The power supply terminal posts are centered 0.63 inches (16 mm) apart and are 1/4-20 thread. We recommend

that you use an appropriately sized 90-degree angle, industry-standard, dual-hole, standard barrel compression

lug.

Figure 28: 90-Degree Angle Standard Barrel Compression Lug

Installing the Power Modules and Input Power Cables

Installing the Power Modules and Input Power Cables

This section describes how to install the power modules and AC and DC power cables in the Cisco NCS 6000

FCC. We recommend that you perform the installation in the order outlined in this section.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

45

Page 60

Installing an AC or DC Power Module

Installing the Power Components

Note

Ensure that the ground cable is installed on the FCC before you install the power modules and input power

cables. See the Installing the Fabric Card Chassis Ground Cable, on page 35.

Installing an AC or DC Power Module

This section describes how to install an AC or DC power module (PM) into the power trays in the Cisco NCS

6000 FCC. Although there are differences between the AC and DC PMs, they are installed by using the same

procedures.

Note

An AC-powered FCC supports up to 12 AC PMs (three per power tray). A DC-powered FCC supports

up to 16 DC PM (four per power tray).

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

46

Page 61

Installing the Power Components

Each PM has three status LEDs located on the front left side of its faceplate (Figure 34: AC and DC Power

Module Power Module Status Indicators). See Table 5: Power Module LED Status Indicator Lights for the

meaning of each status LED.

Figure 29: AC Power Module—Front View

Installing an AC or DC Power Module

Figure 30: AC Power Module—Rear View

Figure 31: DC Power Module—Front View

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

47

Page 62

Installing an AC or DC Power Module

Figure 32: DC Power Module—Rear View

Installing the Power Components

Prerequisites

Installing the Exterior Cosmetics, on page 20

•

Installing the Fabric Card Chassis Ground Cable, on page 35

•

Caution

Do not install a power module into an AC or DC power tray until the power tray is securely screwed into

the power enclosure.

Required Tools and Equipment

ESD-preventive wrist strap

•

6-inch, Number1 Phillips-head screwdriver

•

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

48

Page 63

Installing the Power Components

•

•

Steps

Power modules are keyed to prevent incorrect insertion into the power tray.Note

To install a PM into a power tray, follow these steps:

Installing an AC or DC Power Module

Torque screwdriver with Number-1 Phillips bit and rated torque at 5.5 in-lb (0.62 N-m)

AC or DC PM

AC PM (Cisco PID PWR-3KW-AC-V2)

◦

DC PM (Cisco PID PWR-2KW-DC-V2)

◦

Step 1

Step 2

Attach the ESD-preventive wrist strap to your wrist and connect its leash to the ESD jack on the front side of the FCC

(see Preventing Electrostatic Discharge, on page 11). You can also connect the ESD-preventive wrist strap leash to any

bare metal surface on the FCC.

Use two hands to support and guide the PM, and then slide it into the power tray.

Note

Though a PM can be inserted into any empty PM bay in any power tray, during the initial installation, install a

PM into PM0 in PT0 first. Next, install PMs in ascending order into the remaining PM bays in PT0. Then, install

PMs in ascending order into the remaining power trays.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

49

Page 64

About the Power Module Status Indicators

Installing the Power Components

Step 3

Step 4

Rotate the ejector lever upwards to seat the PM into the power tray.

Tighten the ejector lever screw to a nominal installation torque of 5.5 in-lb (0.62 N-m). Do not exceed a maximum

installation torque of 10 in-lb (1.13 N-m).

Figure 33: Installing a Power Module into a Power Tray—DC Power Tray Shown

Ejector lever2

Step 5

Step 6

Fill the power tray, in PM ascending order, to the required configuration.

If necessary, repeat these steps for the remaining power trays.

About the Power Module Status Indicators

The input-power-present LED on the AC and DC power modules provide a visual indication that voltage is

present across the input terminal connection.

For DC power modules, the DC input LED lights up when the input voltage reaches within the acceptable

•

range.

For AC power modules, the AC Input LED lights up when the input voltage reaches within the acceptable

•

range.

Ejector lever screw3Power module1

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

50

Page 65

Installing the Power Components

Always disconnect power servicing the input power connection.Note

About the Power Module Status Indicators

Caution

If the input voltage polarity is reversed, or if the LED circuit fails, the LED will not light. In this case,

service personnel should check for hazardous voltages before working on the system.

Figure 34: AC and DC Power Module Power Module Status Indicators

Fault LED3Input OK LED1

Output OK LED2

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

51

Page 66

Installing an AC or DC Power Module Slot Cover

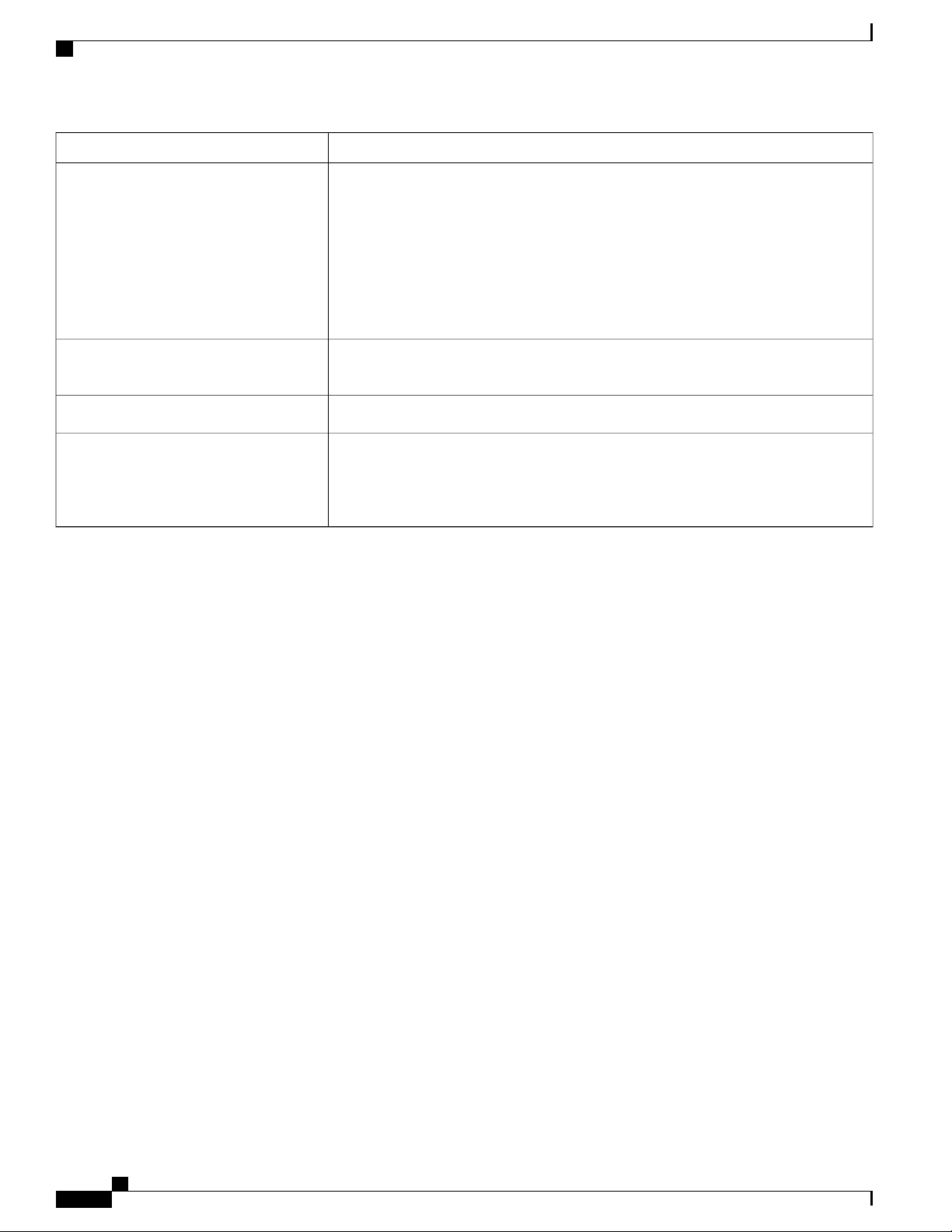

Table 5: Power Module LED Status Indicator Lights

Installing the Power Components

MeaningColorLED Name

GreenInput OK

GreenOutput OK

RedFault

On: The input voltage is present and within regulation range.

Blinking: The input voltage is present but out of regulation range.

Off: The input voltage is not present.

On: The output voltage is on.

Blinking: The PM is in a power limit or Over Current condition.

Off: The output voltage is off.

On: An internal fault is detected within the PM.

Off: No internal faults detected on the PM.

Installing an AC or DC Power Module Slot Cover

This section describes how to install a PM slot cover into an empty PM slot on an AC or DC power tray.

Prerequisites

Before performing this task, you must remove the cosmetic grilles and install the PMs to the required

configuration in each power tray.

Required Tools and Equipment

ESD-preventive wrist strap

•

AC or DC PM slot cover (Cisco PID A9K-PEM-V2-FILR)

•

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

52

Page 67

Installing the Power Components

Steps

To install a PM slot cover in an AC or DC power tray, follow these steps:

Installing AC Input Power Cords

Step 1

Step 2

Step 3

Step 4

Attach the ESD-preventive wrist strap to your wrist and connect its leash to the ESD jack on the front side of the FCC

(see Preventing Electrostatic Discharge, on page 11). You can also connect the ESD-preventive wrist strap leash to any

bare metal surface on the FCC.

Align the PM slot cover with the empty PM slot in the power tray.

Insert the two tabs on the top of the PM slot cover into the two holes on the top of the PM slot.

Push in the top of the PM slot cover gently until it clicks into place.

Figure 35: PM Slot Cover on the Front of a Power Tray—DC Power Tray Shown

Installing AC Input Power Cords

This section describes how to connect the AC input power cords to the power modules and includes the

following topics:

Prerequisites

Ensure that there is a readily accessible disconnect device incorporated in the building's installation wiring.

Caution

Before connecting AC input power cords to the power system, make sure that the input power cords are

not energized.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

53

Page 68

Installing AC Input Power Cords

Installing the Power Components

Caution

The circuit breaker and fuse lockout procedures should follow the rules and regulations in the National

Electrical Code (NEC) and any local codes.

Note

The AC power system requires single-phase AC input power to each PM. If you have 3-phase AC Delta

or AC Wye at your equipment, a Cisco NCS 6000 Series power distribution unit (PDU) is required to

convert 3-phase AC input power to single-phase AC input power (Cisco PID NCS-PDU-DELTA or Cisco

PID NCS-PDU-WYE). For more information, see the Cisco CRS 3-Phase AC Power Distribution Unit

Installation Guide.

Required Tools and Equipment

6-inch, Number 1 Phillips-head screwdriver

•