Page 1

Send documentation comments to mdsfeedback-doc@cisco.com

Cisco MDS 9200 Series Hardware

Installation Guide

October 2008

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Text Part Number: OL-17468-02

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required

to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency energy. If it is not

installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment has been tested and found to

comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These specifications are designed to provide reasonable

protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class A or Class B digital

devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference to radio or television

communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco equipment or one of its

peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio are on circuits

controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

CCDE, CCENT, Cisco Eos, Cisco Lumin, Cisco Nexus, Cisco StadiumVision, Cisco TelePresence, Cisco WebEx, the Cisco logo, DCE, and Welcome to the Human Network

are trademarks; Changing the Way We Work, Live, Play, and Learn and Cisco Store are service marks; and Access Registrar, Aironet, AsyncOS, Bringing the Meeting To

You, Catalyst, CCDA, CCDP, CCIE, CCIP, CCNA, CCNP, CCSP, CCVP, Cisco, the Cisco Certified Internetwork Expert logo, Cisco IOS, Cisco Press, Cisco Systems,

Cisco Systems Capital, the Cisco Systems logo, Cisco Unity, Collaboration Without Limitation, EtherFast, EtherSwitch, Event Center, Fast Step, Follow Me Browsing,

FormShare, GigaDrive, HomeLink, Internet Quotient, IOS, iPhone, iQuick Study, IronPort, the IronPort logo, LightStream, Linksys, MediaTone, MeetingPlace,

MeetingPlace Chime Sound, MGX, Networkers, Networking Academy, Network Registrar, PCNow, PIX, PowerPanels, ProConnect, ScriptShare, SenderBase, SMARTnet,

Spectrum Expert, StackWise, The Fastest Way to Increase Your Internet Quotient, TransPath, WebEx, and the WebEx logo are registered trademarks of Cisco Systems, Inc.

and/or its affiliates in the United States and certain other countries.

All other trademarks mentioned in this document or website are the property of their respective owners. The use of the word partner does not imply a partnership relationship

between Cisco and any other company. (0809R)

Any Internet Protocol (IP) addresses used in this document are not intended to be actual addresses. Any examples, command display output, and figures included in the

document are shown for illustrative purposes only. Any use of actual IP addresses in illustrative content is unintentional and coincidental.

Cisco MDS 9200 Series Hardware Installation Guide

© 2004–2008 Cisco Systems, Inc. All rights reserved.Send documentation comments to mdsfeedback-doc@cisco.com

Page 3

Send documentation comments to mdsfeedback-doc@cisco.com

CONTENTS

New and Changed Information vii

Preface xi

Audience xi

Organization xi

Conventions xii

Related Documentation xiv

Release Notes xiv

Compatibility Information xiv

Regulatory Compliance and Safety Information xiv

Hardware Installation xiv

Cisco Fabric Manager xiv

Command-Line Interface xv

Intelligent Storage Networking Services Configuration Guides xv

Troubleshooting and Reference xv

Installation and Configuration Note xv

CHAPTER

Obtaining Documentation, Obtaining Support, and Security Guidelines xv

1 Product Overview 1-1

Chassis 1-2

Cisco MDS Fibre Channel Bladeswitch for IBM Blade Center 1-5

Integrated Supervisor Modules 1-5

Cisco MDS 9222i Integrated Supervisor Module 1-6

Cisco MDS 9216i Integrated Supervisor Module 1-6

Cisco MDS 9216A Integrated Supervisor Module 1-7

LEDs on the Cisco MDS 9200 Series Integrated Supervisor Modules 1-9

Interface Modules 1-10

LEDs on the Interface Module 1-11

Cisco MDS 9000 Family Module Compatibility 1-12

Switching Modules 1-12

4/44-Port 8-Gbps Host-Optimized Fibre Channel Switching Module 1-13

48-Port 4-Gbps Fibre Channel Switching Module 1-13

24-Port 4-Gbps Fibre Channel Switching Module 1-14

12-Port 4-Gbps Fibre Channel Switching Module 1-15

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

i

Page 4

Contents

Send documentation comments to mdsfeedback-doc@cisco.com

4-Port 10-Gbps Fibre Channel Switching Module 1-16

LEDs on the Generation 2 Switching Modules 1-17

32-Port 2-Gbps Fibre Channel Switching Module 1-17

16-Port 2-Gbps Fibre Channel Switching Module 1-18

Switching Module Features 1-19

LEDs on the Generation 1 Switching Module 1-20

Services Modules 1-21

18/4-Port Multiservice Module 1-21

18/4-Port Multiservice Federal Information Processing Standards Module 1-22

LEDs on the 18/4-Port Multiservice Module 1-23

14/2-Port Multiprotocol Services Module 1-23

LEDs on the 14/2-Port Multiprotocol Services Module 1-25

IP Storage Services Modules 1-25

LEDs on IP Storage Services Module 1-27

32-Port Fibre Channel Storage Services Module 1-27

LEDs on the Storage Services Module 1-29

32-Port Fibre Channel Advanced Services Module 1-29

LEDs on the Fibre Channel Advanced Services Module 1-31

Caching Services Module 1-31

LEDs on the Caching Services Module 1-34

CHAPTER

Power Supplies 1-35

Fan Module 1-36

Supported Transceivers 1-36

X2 Fibre Channel Transceivers 1-37

Fibre Channel SFP Transceivers 1-37

Combination Fibre Channel/Gigabit Ethernet SFP Transceivers 1-37

CWDM Combination Fibre Channel/Gigabit Ethernet SFP Transceivers 1-38

Gigabit Ethernet SFP Transceivers 1-38

DWDM Fibre Channel SFP Transceivers 1-38

2 Installing the Cisco MDS 9200 Series 2-1

Preinstallation 2-2

Installation Options 2-2

Installation Guidelines 2-3

Required Equipment 2-4

Unpacking and Inspecting the Switch 2-4

Installing the Chassis in a Cabinet or Rack 2-5

Installing the Switch in a Cabinet with Insufficient Front Clearance 2-11

Installing Front Rack-Mount Brackets for Cabinets with 26 Inches or Greater of Rail Spacings 2-12

Cisco MDS 9200 Series Hardware Installation Guide

ii

OL-17468-02

Page 5

Contents

Send documentation comments to mdsfeedback-doc@cisco.com

Installing Front Rack-Mount Brackets for Cabinets with Less Than 26 Inches of Rail Spacings 2-14

Installing the Cisco MDS 9200 Series Rear-Facing into Cabinet 2-16

System Grounding 2-19

Proper Grounding Practices 2-19

Preventing Electrostatic Discharge Damage 2-21

Establishing the System Ground 2-23

Required Tools and Equipment 2-23

Grounding the Chassis 2-24

Starting Up the Switch 2-26

Removing and Installing Components 2-28

Removing and Installing Switching and Services Modules 2-28

Removing a Caching Services Module 2-31

Removing Other Switching or Services Modules 2-32

Installing a Switching or Services Module, Including Caching Services Modules 2-33

Verifying Installation of a Switching or Services Module 2-34

Maintaining a Caching Services Module 2-35

Maintaining the Batteries on the Caching Services Module 2-35

Maintaining the Disk Drives on the Caching Services Module 2-35

Removing and Installing Power Supplies 2-36

Removing a Power Supply 2-36

Installing a Power Supply 2-36

Removing and Installing the Fan Module 2-38

Removing a Fan Module 2-39

Installing a Fan Module 2-39

Removing the Cisco MDS 9200 Series 2-40

CHAPTER

OL-17468-02

3 Connecting the Cisco MDS 9200 Series 3-1

Preparing for Network Connections 3-2

Connecting to the Console Port 3-2

Connecting to the COM1 Port 3-4

Connecting to the MGMT 10/100 Ethernet Port 3-5

Connecting to a Fibre Channel Port 3-6

Removing and Installing X2 Transceivers 3-6

Installing an X2 Transceiver 3-8

Removing an X2 Transceiver 3-8

Removing and Installing SFP Transceivers 3-8

Installing an SFP Transceiver 3-9

Removing an SFP Transceiver 3-10

Removing and Installing Cables into SFP Transceivers 3-11

Cisco MDS 9200 Series Hardware Installation Guide

iii

Page 6

Contents

Send documentation comments to mdsfeedback-doc@cisco.com

Installing a Cable into an SFP Transceiver 3-11

Removing a Cable from an SFP Transceiver 3-12

Maintaining SFP Transceivers and Fiber-Optic Cables 3-13

APPENDIX

APPENDIX

A Cabinet and Rack Installation A-1

Cabinet and Rack Requirements A-1

General Requirements for Cabinets and Racks A-1

Requirements Specific to Perforated Cabinets A-2

Requirements Specific to Solid-Walled Cabinets A-3

Requirements Specific to Standard Open Racks A-3

Requirements Specific to telco Racks A-3

Cisco MDS 9000 Family telco and EIA Shelf Bracket A-4

Rack-Mounting Guidelines A-4

Before Installing the Shelf Brackets A-5

Required Equipment A-5

Installing the Shelf Bracket Kit into a Two-Post telco Rack A-6

Installing the Shelf Bracket Kit into a Four-Post EIA Rack A-7

Installing the Switch on the Shelf Brackets A-8

Removing the Shelf Bracket Kit (Optional) A-9

B Technical Specifications B-1

Switch Specifications B-1

iv

Module Specifications B-2

Weight of Modules B-3

Power Specifications B-4

Specifications for the Cisco MDS 9200 Series Power Supplies B-4

Component Power Requirements and Heat Dissipation Specifications B-5

X2 Transceiver Specifications B-7

Cisco 10-Gbps Fibre Channel X2 Transceivers B-7

General Specification for Cisco 10-Gbps Fibre Channel X2 Transceivers B-7

Environmental Conditions and Power Requirement Specifications for Cisco 10-Gbps Fibre

Channel X2 Transceivers

Cisco 10-Gbps Ethernet X2 Transceivers B-8

General Specification for Cisco 10-Gbps Ethernet X2 Transceivers B-9

Environmental and Power Requirements Specifications for Cisco 10-Gbps Ethernet X2

Transceiver

B-9

Cisco 10-Gbps Ethernet DWDM X2 Transceiver B-9

SFP and SFP+ Transceiver Specifications B-10

Cisco Fibre Channel SFP and SFP+ Transceivers B-10

Cisco MDS 9200 Series Hardware Installation Guide

B-8

OL-17468-02

Page 7

Contents

Send documentation comments to mdsfeedback-doc@cisco.com

General Specifications for Cisco 8-Gbps Fibre Channel SFP+ Transceivers B-11

Environmental and Power Requirements for Cisco 8-Gbps Fibre Channel SFP+

Transceivers

General Specifications for Cisco 4-Gbps Fibre Channel SFP Transceivers B-13

Environmental and Power Requirement for Cisco 4-Gbps Fibre Channel SFP Transceivers B-13

General Specifications for Cisco 2-Gbps Fibre Channel SFP Transceivers B-14

Environmental and Power Requirement for Cisco 2-Gbps Fibre Channel SFP Transceivers B-14

Maximum Environmental and Electrical Ratings for Cisco Fibre Channel SFP Transceivers B-15

Cisco Fibre Channel/Gigabit Ethernet Transceivers B-15

General Specifications for Cisco Fibre Channel/Gigabit Ethernet SFP Transceivers B-16

Environmental and Power Requirement Specifications for Cisco Fibre Channel/Gigabit Ethernet

SFP Transceivers

Cisco CWDM SFP Transceivers B-17

Environmental and Optical Specifications for Cisco 2-Gbps CWDM SFP Transceivers B-18

Environmental and Optical Specifications for Cisco 4-Gbps CWDM SFP Transceivers B-19

Cisco Gigabit Ethernet Transceivers B-21

General Specifications for Cisco Gigabit Ethernet Transceivers B-21

Environmental and Power Requirement Specifications for Cisco Gigabit Ethernet

Transceivers

DWDM SFP Transceivers B-22

B-11

B-16

B-21

APPENDIX

C Cable and Port Specifications C-1

Cables and Adapters Provided C-1

Console Port C-2

Console Port Pinouts C-2

Connecting the Console Port to a Computer Using the DB-25 Adapter C-2

Connecting the Console Port to a Computer Using the DB-9 Adapter C-3

COM1 Port C-3

COM1 Port Pinouts C-3

Connecting the COM1 Port to a Modem C-4

MGMT 10/100/1000 Ethernet Port C-4

MGMT 10/100 Ethernet Port C-6

Supported Power Cords and Plugs C-7

Power Cords C-7

Supported Plugs for 6000-W AC, 2500-W AC, and 1900-W AC Power Supplies C-8

Supported Plugs for the 4000-W AC Power Supply C-10

Jumper Power Cord C-11

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

v

Page 8

Contents

Send documentation comments to mdsfeedback-doc@cisco.com

APPENDIX

D Site Planning and Maintenance Records D-1

Site Preparation Checklist D-1

Contact and Site Information D-3

Chassis and Module Information D-4

vi

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 9

Send documentation comments to mdsfeedback-doc@cisco.com

New and Changed Information

The Cisco MDS 9200 Series Hardware Installation Guide applies to Cisco MDS NX-OS Release 4.1(1b)

and earlier Cisco MDS SAN-OS releases.

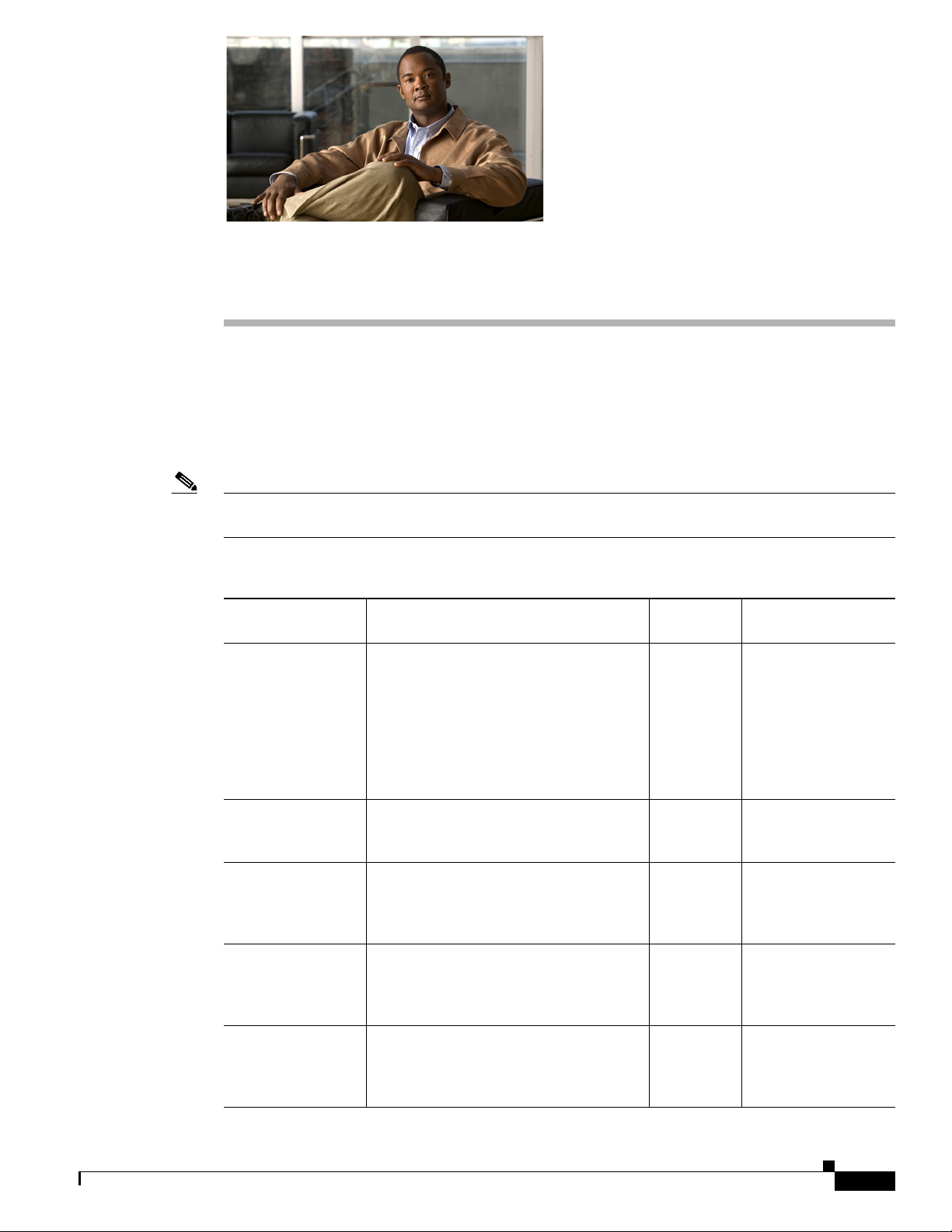

Table 1 lists the new and changed features available with each supported Cisco MDS NX-OS release and

SAN-OS release for the Cisco MDS 9500 Series, with the latest release first.

Note As of NX-OS Release 4.1(1b), SAN-OS has been changed to NX-OS. References to SAN-OS releases

before 4.1(1b) still apply.

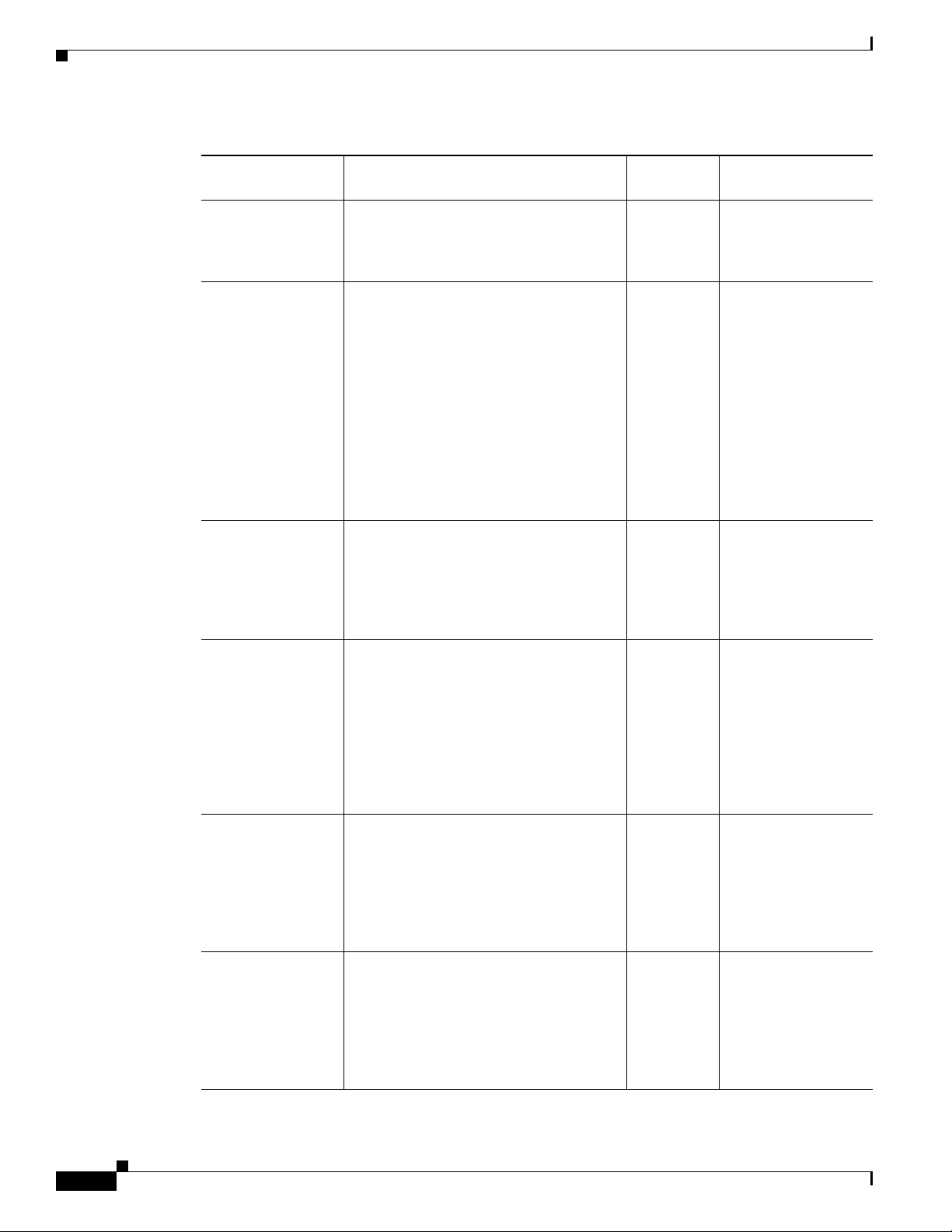

Table 1 Documented Features for the Cisco MDS 9200 Series

Changed in

Feature Description

4/44-port 8-Gbps

Host-Optimized

Fibre Channel

switching module

SFP+ Transceivers Added the SFP+ transceivers information. 4.1(1b) “Technical

Cisco MDS Fibre

Channel

Bladeswitch

overview

18/4-port

Multiservice

(MSM-18/4)

module

18/4-port

Multiservice

(MSM-18/4)

module

Added 4/44-port 8-Gbps Host-Optimized

Fibre Channel switching module. The

switching module offers 48 autosensing

1-, 2-, 4- and 8-Gbps Fibre Channel ports

and can be used in any of the Cisco MDS

9500 Series chassis and in the Cisco MDS

9222i Switches, when running NX-OS

4.1(1b).

Description of the Cisco MDS Fibre

Channel Bladeswitch for IBM

BladeCenter.

Added information on IPv6 support. 3.3(1a) The “1 8/4-Port

Added information on SAN extension

support.

Release Where Documented

4.1(1b) Product Overview

chapter.

Specifications”

section on page B-1

3.3(1a) Product Overview

chapter.

Multiservice Module”

section on page 1-21.

3.3(1a) The “1 8/4-Port

Multiservice Module”

section on page 1-21.

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

vii

Page 10

New and Changed Information

Send documentation comments to mdsfeedback-doc@cisco.com

Table 1 Documented Features for the Cisco MDS 9200 Series (continued)

Changed in

Feature Description

18/4-port

Multiservice

Added the Storage Media Encryption

information.

(MSM-18/4)

module

Cisco MDS 9222i

Mutiservice

Modular Switch

18/4-port

Multiservice

Added the new 18/4 Fibre Channel port

and 4 Gigabit Ethernet IP services port

Multiservice Modular Switch.

Added the new 18/4-port Multiprotocol

Services module.

(MSM-18/4)

module

18/4-port

Multiservice FIPS

Added the new 18/4-port Multiprotocol

Services FIPS module.

(MSFM-18/4)

module

48-port 4-Gbps

Fibre Channel

switching module

Added 48-port 4-Gbps Fibre Channel

switching module. The switching module

offers 48 autosensing 1-, 2-, and 4-Gbps

Fibre Channel ports and can be used in

any of the Cisco MDS 9500 Series chassis

and in the Cisco 9216i and 9216A

Switches.

24-port 4-Gbps

Fibre Channel

switching module

Added 24-port 4-Gbps Fibre Channel

switching module. The switching module

offers 24 autosensing 1-, 2-, and 4-Gbps

Fibre Channel ports and can be used in

any of the Cisco MDS 9500 Series chassis

and in the Cisco 9216i and 9216A

Switches.

Release Where Documented

3.2(1) The “1 8/4-Port

Multiservice Module”

section on page 1-21.

3.2(1) The “Product

Overview” section on

page 1-1, the

“Chassis” section on

page 1-2,

“Cisco MDS 9222i

Integrated Supervisor

Module” section on

page 1-6, and the

“Technical

Specifications”

section on page B-1.

3.2(1) The “1 8/4-Port

Multiservice Module”

section on page 1-21

and the “Technical

Specifications”

section on page B-1.

3.2(1) The “18/4-Port

Multiservice Federal

Information

Processing Standards

Module” section on

page 1-22 and the

“Technical

Specifications”

section on page B-1.

3.0(1) The “48-Port 4-Gbps

Fibre Channel

Switching Module”

section on page 1-13

and the “Technical

Specifications”

section on page B-1.

3.0(1) The “24-Port 4-Gbps

Fibre Channel

Switching Module”

section on page 1-14

and the “Technical

Specifications”

section on page B-1.

viii

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 11

New and Changed Information

Send documentation comments to mdsfeedback-doc@cisco.com

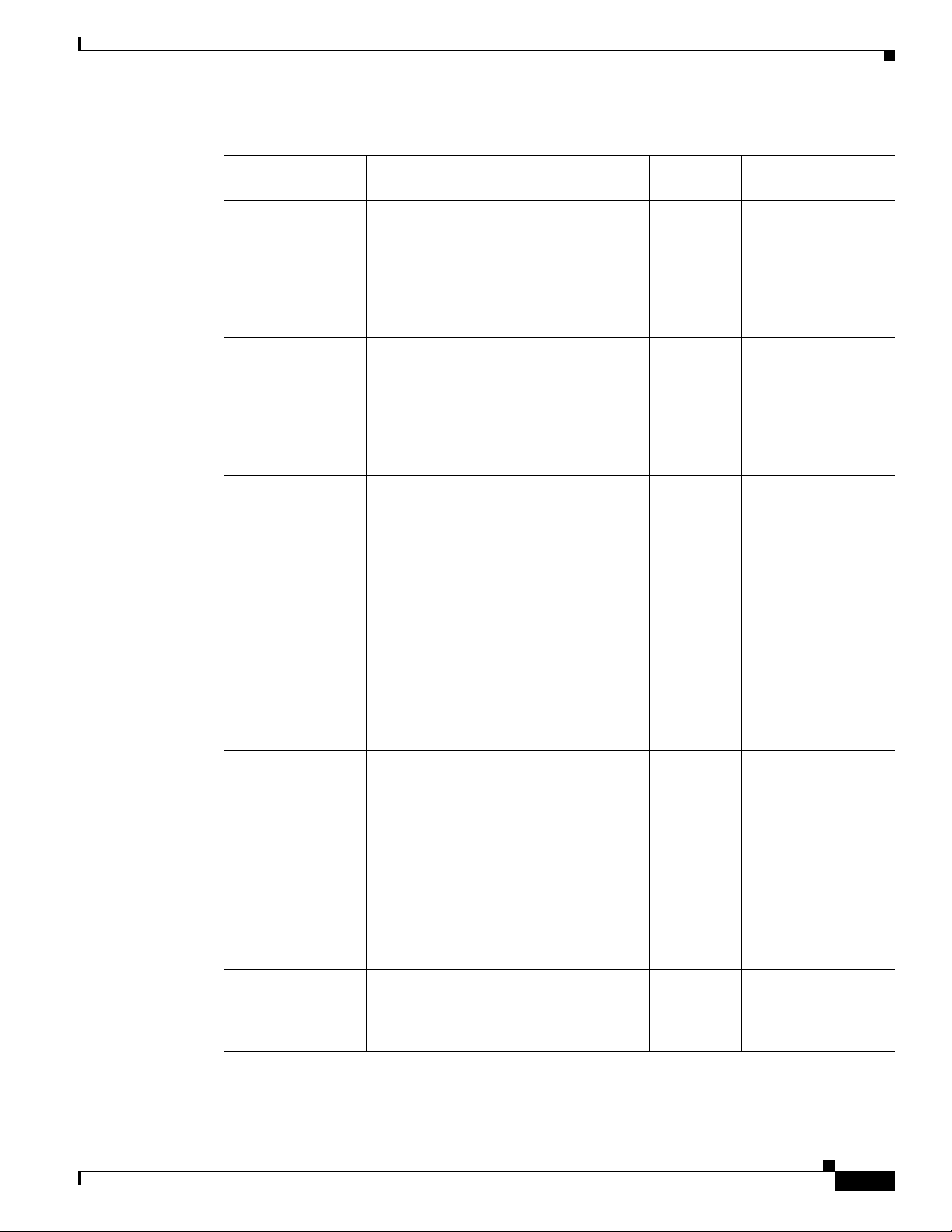

Table 1 Documented Features for the Cisco MDS 9200 Series (continued)

Changed in

Feature Description

12-port 4-Gbps

Fibre Channel

switching module

Added 12-port 4-Gbps Fibre Channel

switching module. The switching module

can be used in any of the Cisco MDS 9500

Series chassis and in the Cisco MDS

9216i and 9216A Switches.

4-port 10-Gbps

Fibre Channel

switching module

Added 4-port 10-Gbps Fibre Channel

switching module. The switching module

offers four dedicated bandwidth Fibre

Channel ports running at 10 Gbps with no

oversubscription.

X2 transceiver Added X2 transceiver. The X2 transceiver

is a small form-factor pluggable

optimized for 10-Gbps applications.

Fibre Channel SFP

transceiver

Gigabit Ethernet

Added 4-Gbps Fibre Channel SFP trans-

ceiver.

Added Gigabit Ethernet SFP transceiver.

SFP transceiver

32-port Fibre

Channel Storage

Added 32-port Fibre Channel Storage

Services Module (SSM).

Services Module

(SSM)

14/2-port

Multiprotocol

Added 14/2-port Multiprotocol Services

module.

Services

(MPS-14/2) module

Release Where Documented

3.0(1) The “12-Port 4-Gbps

Fibre Channel

Switching Module”

section on page 1-15

and the “Technical

Specifications”

section on page B-1.

3.0(1) The “4-Port 10-Gbps

Fibre Channel

Switching Module”

section on page 1-16

and the “Technical

Specifications”

section on page B-1.

3.0(1) The “X2 Fibre

Channel

Transceivers” section

on page 1-37 and the

“X2 Transceiver

Specifications”

section on page B-7.

3.0(1) The “Fibre Channel

SFP Transceivers”

section on page 1-37

and the “Cisco Fibre

Channel SFP and

SFP+ Transceivers”

section on page B-10.

Not release

specific

The “Supported

Transceivers” section

on page 1-36 and the

“Cisco Gigabit

Ethernet

Transceivers” section

on page B-21.

2.0(2b) The “32-Port Fibre

Channel Storage

Services Module”

section on page 1-27.

2.0(1b) The “14/2-Port

Multiprotocol

Services Module”

section on page 1-23.

OL-8494-01

Cisco MDS 9200 Series Hardware Installation Guide

ix

Page 12

New and Changed Information

Send documentation comments to mdsfeedback-doc@cisco.com

Cisco MDS 9200 Series Hardware Installation Guide

x

OL-17468-02

Page 13

Send documentation comments to mdsfeedback-doc@cisco.com

Preface

This preface describes the audience, organization, and conventions of the

Cisco MDS 9200 Series Hardware Installation Guide. It also provides information on how to obtain

related documentation.

Audience

To use this installation guide, you must be familiar with electronic circuitry and wiring practices and

preferably be an electronic or electromechanical technician.

Organization

This guide is organized as follows:

Chapter Title Description

Chapter 1 Product Overview Provides an overview of the Cisco MDS 9200 Series and its

Chapter 2 Installing the Cisco

Chapter 3 Connecting the

Appendix A Cabinet and Rack

Appendix B Technical

Appendix CCable and Port

Appendix D Site Planning and

MDS 9200 Series

Cisco MDS 9200

Series

Installation

Specifications

Specifications

Maintenance

Records

components.

Describes how to install the Cisco MDS 9200 Series, and how to

install modules, power supplies, and fan assemblies.

Describes how to connect the Cisco MDS 9200 Series, including

the modules.

Provides guidelines for selecting an enclosed cabinet, the

procedure for installing a switch using the optional telco and

EIA Shelf Bracket Kit.

Lists specifications for the Cisco MDS 9200 Series switches and

components including modules, power, and transceivers.

Lists cable and port specifications for the Cisco MDS 9200

Series.

Provides site planning and maintenance records.

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

xi

Page 14

Preface

Send documentation comments to mdsfeedback-doc@cisco.com

Conventions

This document uses the following conventions for notes, cautions, and safety warnings.

Notes and Cautions contain important information that you should be aware of.

Note Means reader take note. Notes contain helpful suggestions or references to material that are not covered

in the publication.

Caution Means reader be careful. You are capable of doing something that might result in equipment damage or

loss of data.

Safety warnings appear throughout this publication in procedures that, if performed incorrectly, can

cause physical injuries. A warning symbol precedes each warning statement.

Warning

Waarschuwing

Varoitus

Attention

This warning symbol means danger. You are in a situation that could cause

bodily injury. Before you work on any equipment, be aware of the hazards

involved with electrical circuitry and be familiar with standard practices for

preventing accidents. Use the statement number provided at the end of each

warning to locate its translation in the translated safety warnings that

accompanied this device.

Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie die

lichamelijk letsel kan veroorzaken. Voordat u aan enige apparatuur gaat

werken, dient u zich bewust te zijn van de bij elektrische schakelingen

betrokken risico's en dient u op de hoogte te zijn van standaard maatregelen

om ongelukken te voorkomen. Voor vertalingen van de waarschuwingen die in

deze publicatie verschijnen, kunt u het document Regulatory Compliance and

Safety Information (Informatie over naleving van veiligheids- en andere

voorschriften) raadplegen dat bij dit toestel is ingesloten.

Tämä varoitusmerkki merkitsee vaaraa. Olet tilanteessa, joka voi johtaa

ruumiinvammaan. Ennen kuin työskentelet minkään laitteiston parissa, ota

selvää sähkökytkentöihin liittyvistä vaaroista ja tavanomaisista

onnettomuuksien ehkäisykeinoista. Tässä julkaisussa esiintyvien varoitusten

käännökset löydät laitteen mukana olevasta Regulatory Compliance and

Safety Information -kirjasesta (määräysten noudattaminen ja tietoa

turvallisuudesta).

Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une

situation pouvant causer des blessures ou des dommages corporels. Avant de

travailler sur un équipement, soyez conscient des dangers posés par les

circuits électriques et familiarisez-vous avec les procédures couramment

utilisées pour éviter les accidents. Pour prendre connaissance des

traductions d’avertissements figurant dans cette publication, consultez le

document Regulatory Compliance and Safety Information (Conformité aux

règlements et consignes de sécurité) qui accompagne cet appareil.

Statement 1071

xii

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 15

Preface

Send documentation comments to mdsfeedback-doc@cisco.com

Warnung

Avvertenza

Advarsel

Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die

zu einer Körperverletzung führen könnte. Bevor Sie mit der Arbeit an

irgendeinem Gerät beginnen, seien Sie sich der mit elektrischen

Stromkreisen verbundenen Gefahren und der Standardpraktiken zur

Vermeidung von Unfällen bewußt. Übersetzungen der in dieser

Veröffentlichung enthaltenen Warnhinweise finden Sie im Dokument

Regulatory Compliance and Safety Information (Informationen zu

behördlichen Vorschriften und Sicherheit), das zusammen mit diesem Gerät

geliefert wurde.

Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe

causare infortuni alle persone. Prima di lavorare su qualsiasi

apparecchiatura, occorre conoscere i pericoli relativi ai circuiti elettrici ed

essere al corrente delle pratiche standard per la prevenzione di incidenti. La

traduzione delle avvertenze riportate in questa pubblicazione si trova nel

documento Regulatory Compliance and Safety Information (Conformità alle

norme e informazioni sulla sicurezza) che accompagna questo dispositivo.

Dette varselsymbolet betyr fare. Du befinner deg i en situasjon som kan føre

til personskade. Før du utfører arbeid på utstyr, må du vare oppmerksom på de

faremomentene som elektriske kretser innebærer, samt gjøre deg kjent med

vanlig praksis når det gjelder å unngå ulykker. Hvis du vil se oversettelser av

de advarslene som finnes i denne publikasjonen, kan du se i dokumentet

Regulatory Compliance and Safety Information (Overholdelse av forskrifter og

sikkerhetsinformasjon) som ble levert med denne enheten.

Aviso

¡Advertencia!

Varning!

Este símbolo de aviso indica perigo. Encontra-se numa situação que lhe

poderá causar danos físicos. Antes de começar a trabalhar com qualquer

equipamento, familiarize-se com os perigos relacionados com circuitos

eléctricos, e com quaisquer práticas comuns que possam prevenir possíveis

acidentes. Para ver as traduções dos avisos que constam desta publicação,

consulte o documento Regulatory Compliance and Safety Information

(Informação de Segurança e Disposições Reguladoras) que acompanha este

dispositivo.

Este símbolo de aviso significa peligro. Existe riesgo para su integridad física.

Antes de manipular cualquier equipo, considerar los riesgos que entraña la

corriente eléctrica y familiarizarse con los procedimientos estándar de

prevención de accidentes. Para ver una traducción de las advertencias que

aparecen en esta publicación, consultar el documento titulado Regulatory

Compliance and Safety Information (Información sobre seguridad y

conformidad con las disposiciones reglamentarias) que se acompaña con

este dispositivo.

Denna varningssymbol signalerar fara. Du befinner dig i en situation som kan

leda till personskada. Innan du utför arbete på någon utrustning måste du vara

medveten om farorna med elkretsar och känna till vanligt förfarande för att

förebygga skador. Se förklaringar av de varningar som förkommer i denna

publikation i dokumentet Regulatory Compliance and Safety Information

(Efterrättelse av föreskrifter och säkerhetsinformation), vilket medföljer

denna anordning.

OL-8494-01

Cisco MDS 9200 Series Hardware Installation Guide

xiii

Page 16

Preface

Send documentation comments to mdsfeedback-doc@cisco.com

Related Documentation

The documentation set for the Cisco MDS 9000 Family includes the following documents. The

documentation set for the Cisco MDS 9000 Family includes the following documents. To find a

document online, use the Cisco MDS NX-OS Documentation Locator at:

http://www.cisco.com/en/US/products/ps5989/products_documentation_roadmap09186a00804500c1.html.

Release Notes

• Cisco MDS 9000 Family Release Notes for Cisco MDS NX-OS Releases

• Cisco MDS 9000 Family Release Notes for Storage Services Interface Images

• Cisco MDS 9000 Family Release Notes for Cisco MDS 9000 EPLD Images

Compatibility Information

• Cisco MDS 9000 NX-OS Hardware and Software Compatibility Information

• Cisco MDS 9000 Family Interoperability Support Matrix

• Cisco MDS Storage Services Module Interoperability Support Matrix

• Cisco MDS NX-OS Release Compatibility Matrix for Storage Service Interface Images

Regulatory Compliance and Safety Information

• Regulatory Compliance and Safety Information for the Cisco MDS 9000 Family

Hardware Installation

• Cisco MDS 9124 Multilayer Fabric Switch Quick Start Guide

• Cisco MDS 9500 Series Hardware Installation Guide

• Cisco MDS 9200 Series Hardware Installation Guide

• Cisco MDS 9100 Series Hardware Installation Guide

Cisco Fabric Manager

xiv

• Cisco MDS 9000 Family Fabric Manager Quick Configuration Guide

• Cisco MDS 9000 Family Fabric Manager Configuration Guide

• Cisco MDS 9000 Family Fabric Manager Database Schema

• Cisco MDS 9000 Family Data Mobility Manager Configuration Guide

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 17

Preface

Send documentation comments to mdsfeedback-doc@cisco.com

Command-Line Interface

• Cisco MDS 9000 Family Software Upgrade and Downgrade Guide

• Cisco MDS 9000 Family Storage Services Module Software Installation and Upgrade Guide

• Cisco MDS 9000 Family CLI Quick Configuration Guide

• Cisco MDS 9000 Family CLI Configuration Guide

• Cisco MDS 9000 Family Command Reference

Intelligent Storage Networking Services Configuration Guides

• Cisco MDS 9000 Family Data Mobility Manager Configuration Guide

• Cisco MDS 9000 Family Storage Media Encryption Configuration Guide

• Cisco MDS 9000 Family Secure Erase Configuration Guide - For Cisco MDS 9500 and 9200 Series

Troubleshooting and Reference

• Cisco MDS 9000 Family Troubleshooting Guide

• Cisco MDS 9000 Family MIB Quick Reference

• Cisco MDS 9000 Family SMI-S Programming Reference

• Cisco MDS 9000 Family System Messages Reference

Installation and Configuration Note

• Cisco MDS 9000 Family SSM Configuration Note

• Cisco MDS 9000 Family Port Analyzer Adapter Installation and Configuration Note

• Cisco 10-Gigabit X2 Transceiver Module Installation Note

• Cisco MDS 9000 Family CWDM SFP Installation Note

• Cisco MDS 9000 Family CWDM Passive Optical System Installation Note

Obtaining Documentation, Obtaining Support, and Security Guidelines

OL-8494-01

For information on obtaining documentation, submitting a service request, and gathering additional

information, see the monthly What’s New in Cisco Product Documentation, which also lists all new and

revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What’s New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed

and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free

service and Cisco currently supports RSS version 2.0.

Cisco MDS 9200 Series Hardware Installation Guide

xv

Page 18

Preface

Send documentation comments to mdsfeedback-doc@cisco.com

xvi

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 19

Send documentation comments to mdsfeedback-doc@cisco.com

CHAP T ER

1

Product Overview

The Cisco MDS 9200 Series of multilayer modular fabric switches supports storage area network (SAN)

applications. The Cisco MDS 9200 Series switches provide scalability, multitransport capability,

security, and manageability to enterprise SANs. The Cisco MDS 9200 Series shares a consistent

architecture with the Cisco MDS 9500 Series of multilayer directors, making it an intelligent and

flexible fabric switch series. The Cisco MDS 9200 Series includes the Cisco MDS 9222i Multiservice

Modular Switch, the Cisco MDS 9216i Multilayer Fabric Switch, and the Cisco MDS 9216A Multilayer

Fabric Switch.

The Cisco MDS 9200 Series provides the following features:

• An interface module providing local and remote management interfaces for the supervisor module.

• A spare slot for an optional hot-swappable switching or services module.

• Redundant and hot-swappable power supplies and fan modules.

• Power and cooling management and environmental monitoring.

• Switch module port interfaces that support field-replaceable, hot-swappable X2 transceivers.

• Switch module port interfaces that support field-replaceable, hot-swappable small form-factor

pluggable (SFP) and Enhanced small form-factor pluggable (SFP+) transceivers.

• Nondisruptive code load and activation.

OL-17468-02

• Redundant and self-monitoring system clocks.

The Cisco MDS 9222i Multiservice Modular Switch provides an 18-port Fibre Channel switching and

4-port Gigabit Ethernet IP services module, and a modular expansion slot to host Cisco MDS 9000

Family Switching and Services modules.

The Cisco 9216i Switch includes a nonremovable supervisor module with an integrated 14-port Fibre

Channel and 2-port Gigabit Ethernet switching module. The integrated supervisor module supports IP

services on the 2 Gigabit Ethernet ports. It also provides switching and local and remote management.

The Cisco 9216A Switch includes a nonremovable supervisor module with an integrated 16-port Fibre

Channel switching module. The integrated supervisor module provides switching and local and remote

management.

The Cisco MDS 9200 Series enhances the Cisco MDS 9216 Switch with a flexible backplane that is

designed to meet the requirements of future modules in the Cisco MDS 9000 Family, while maintaining

backward compatibility with all existing modules. The Cisco MDS 9200 Series is also compatible with

all existing Cisco MDS 9216 power supplies and fan trays, and provides a COM1 port interface that is

compatible with a standard RJ-45 to DB-9 adapter.

For information on how to configure the Cisco MDS 9200 Series, see the Cisco MDS 9000 Family CLI

Configuration Guide and the Cisco MDS 9000 Family Fabric Manager Configuration Guide.

Cisco MDS 9200 Series Hardware Installation Guide

1-1

Page 20

Chapter 1 Product Overview

Chassis

Send documentation comments to mdsfeedback-doc@cisco.com

Note The Cisco MDS 9200 Series requires Cisco MDS SAN-OS Release 2.x, 3.x, and NX-OS 4.1(1b). The

Cisco MDS 9222i Switch requires MDS SAN-OS Release 3.x and NX-OS 4.1(1b).

The following hot-swappable, field-replaceable modules are supported by the Cisco MDS 9200 Series:

• 4/44-port 8-Gbps Host-Optimized Fibre Channel switching module (DS-X9248-48K9)

• 48-port 4-Gbps Fibre Channel switching module (DS-X9148)

• 24-port 4-Gbps Fibre Channel switching module (DS-X9124)

• 12-port 4-Gbps Fibre Channel switching module (DS-X9112)

• 4-port 10-Gbps Fibre Channel switching module (DS-X9704)

• 32-port 2-Gbps Fibre Channel switching module (DS-X9032)

• 16-port 2-Gbps Fibre Channel switching module (DS-X9016)

• 18/4-port Multiservice (MSM-18/4) module (DS-X9304-18K9)

• 18/4-port Multiservice FIPS (MSFM-18/4) module (DS-X9304-18FK9

• 14/2-port Multiprotocol Services (MPS-14/2) module (DS-X9302-14K9)

• 8-port IP Storage Services (IPS-8) module (DS-X9308-SMIP)

• 4-port IP Storage Services (IPS-4) module (DS-X9304-SMIP)

Chassis

• Storage Services Module (SSM) (DS-X9032-SSM)

• Advanced Services Module (ASM) (DS-X9032-SMV)

• Caching Services Module (CSM) (DS-X9560-SMC)

This chapter includes the following sections:

• Chassis, page 1-2

• Cisco MDS Fibre Channel Bladeswitch for IBM Blade Center, page 1-5

• Integrated Supervisor Modules, page 1-5

• Interface Modules, page 1-10

• Cisco MDS 9000 Family Module Compatibility, page 1-12

• Switching Modules, page 1-12

• Services Modules, page 1-21

• Fan Module, page 1-36

• Supported Transceivers, page 1-36

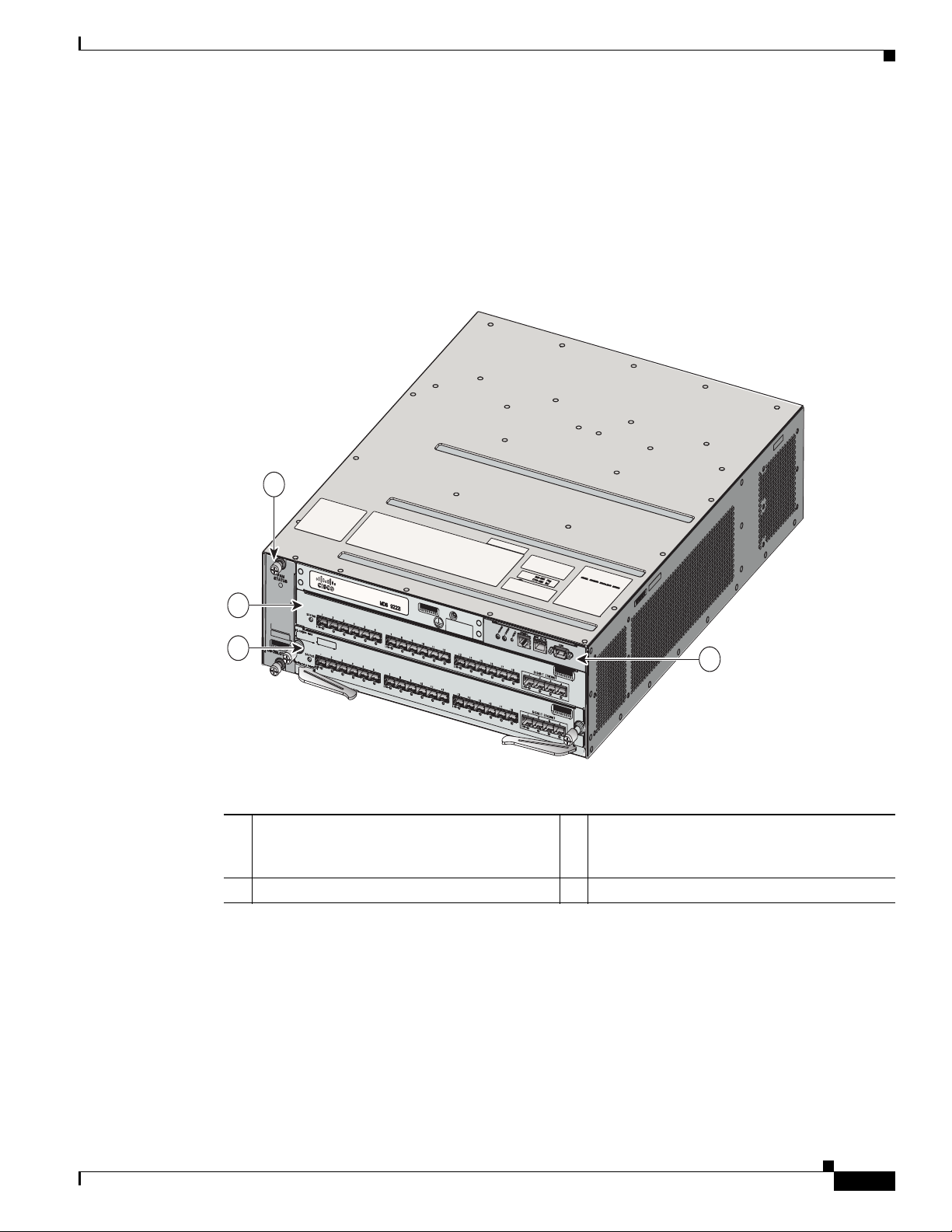

The Cisco MDS 9200 Series switches have a two-slot chassis. The Cisco MDS 9222i (see Figure 1-1)

has a nonremovable supervisor module (in slot 1) with an integrated 18-port Fibre Channel switching

and 4-port Gigabit Ethernet IP services module, and a modular expansion slot to host Cisco MDS 9000

Family Switching and Services modules. See the “Cisco MDS 9222i Integrated Supervisor Module”

section on page 1-6.

1-2

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 21

Chapter 1 Product Overview

Chassis

Send documentation comments to mdsfeedback-doc@cisco.com

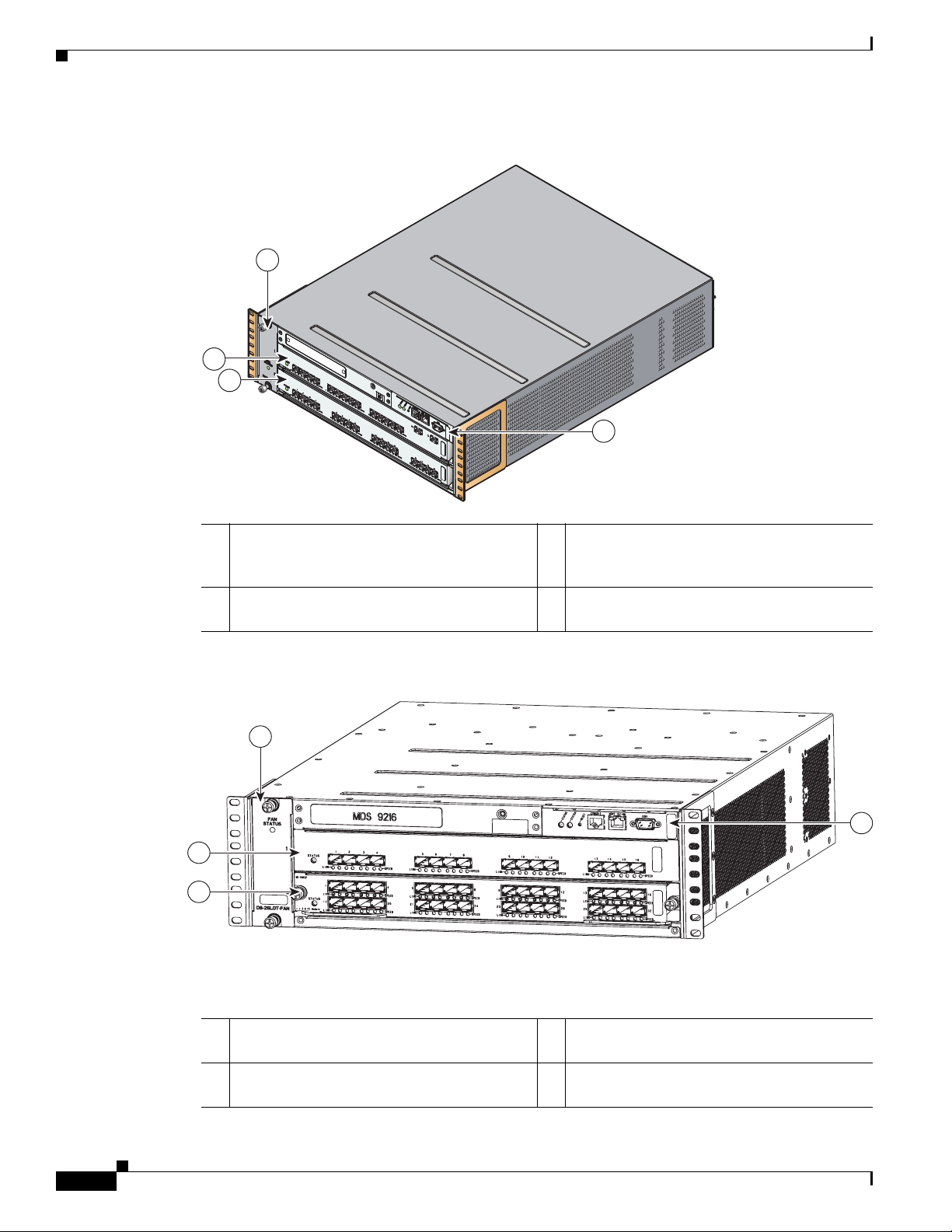

The Cisco MDS 9216i (see Figure 1-2) has a nonremovable supervisor module (in slot 1) with an

integrated 14-port Fibre Channel and 2-port Gigabit Ethernet switching module. See the “Cisco MDS

9216i Integrated Supervisor Module” section on page 1-6.

The Cisco MDS 9216A (see Figure 1-3) has a nonremovable supervisor module (in slot 1) with an

integrated 16-port Fibre Channel switching module. See the “Cisco MDS 9216A Integrated Supervisor

Module” section on page 1-7.

Figure 1-1 Cisco MDS 9222i Chassis

1

3

2

1 Fan module 3 Supervisor module with integrated 18-port

Fibre Channel switching and 4-port Gigabit

Ethernet IP Storage Services module

2 Switching module or the services module 4 Interface module

4

184704

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

1-3

Page 22

Chapter 1 Product Overview

240805

1

4

3

2

Chassis

Send documentation comments to mdsfeedback-doc@cisco.com

Figure 1-2 Cisco MDS 9216i Chassis

1

M

DS

3

2

9216

1

2

i

3

4

5

6

7

8

9

1

0

1

1

12

1

3

14

L

I

N

K

G

E

1

L

IN

K

G

E

2

4

116888

1 Fan module 3 Supervisor module with integrated 14-port

Fibre Channel and 2-port Gigabit Ethernet

switching module

2 Switching module or Services module (such

4 Interface module

as the IPS module)

Figure 1-3 Cisco MDS 9216A Chassis

1 Fan module 3 Supervisor module with integrated 16-port

Fibre Channel switching module

2 Switching module or Services module (such

4 Interface module

as the IPS module)

Cisco MDS 9200 Series Hardware Installation Guide

1-4

OL-17468-02

Page 23

Chapter 1 Product Overview

Cisco MDS Fibre Channel Bladeswitch for IBM Blade Center

Send documentation comments to mdsfeedback-doc@cisco.com

The Cisco MDS 9200 Series supports the following additional modules:

• The nonremovable interface module (located above the integrated supervisor module), provides the

console port (COM1 port) and the MGMT 10/100 Ethernet port for the integrated supervisor

module. See the “Interface Modules” section on page 1-10.

• An optional module in the open slot (slot 2).

• Two power supplies that are redundant by default and can be configured to be combined if desired.

• A hot-swappable fan module with four fans provides redundancy. See the “Fan Module” section on

page 1-36.

Cisco MDS Fibre Channel Bladeswitch for IBM Blade Center

The Cisco MDS Fibre Channel Bladeswitch for IBM BladeCenter is designed for IBM BladeCenter

environments. The Cisco MDS Fibre Channel Bladeswitch is based on the Cisco MDS 9000 Family SAN

switching technology, which integrates the Cisco MDS 9000 Family of switches and directors into a

blade-switch architecture. The advanced architecture of the Cisco MDS Fibre Channel Bladeswitch for

IBM BladeCenter, along with 4-GB technology, provides outstanding performance between

Bladeswitches and the rest of the Fibre Channel infrastructure.

The Cisco MDS Fibre Channel Bladeswitch for IBM BladeCenter provides 4-GB Fibre Channel

performance to blade-server switching. It also provides network intelligence features such as virtual

SANs (VSANs), quality of service (QoS), and N-port interface virtualization (NPIV). It also offers

nondisruptive software upgrades and on-demand port activation and is the most complete embedded

Fibre Channel switching available for the IBM BladeCenter, BladeCenter-T, and BladeCenter-H

platforms.

The Cisco MDS Fibre Channel Bladeswitch for IBM BladeCenter provides up to 20 nonblocking 1-, 2-,

and 4-GB Fibre Channel ports that are available in two configurations: 7 internal ports and 3 external

ports, or 14 internal ports and 6 external ports. Each port provides line-rate performance up to 4-GB

without any performance loss for integrated features such as VSANs, QoS, or Network Address

Translation (NAT). The Cisco MDS Fibre Channel Bladeswitch for IBM BladeCenter supports up to 16

VSANs per blade switch.

Each external port on the Cisco MDS FC Bladeswitch for IBM BladeCenter also provides line-rate

performance up to 4-GB for Inter-Switch Links (ISLs) or additional device connectivity such as storage

or host bus adapters (HBAs).

The Cisco NX-OS software provides role-based access control (RBAC) for management access of the

Cisco Fibre Channel Bladeswitch for IBM BladeCenter command-line interface (CLI) and Simple

Network Management Protocol (SNMP). For more information, see the Cisco 9000 Family Command

Reference.

Integrated Supervisor Modules

The Cisco MDS 9200 Series switches have nonremovable integrated supervisor modules in each chassis.

These modules include the following:

• Cisco MDS 9222i Integrated Supervisor Module, page 1-6

• Cisco MDS 9216i Integrated Supervisor Module, page 1-6

• Cisco MDS 9216A Integrated Supervisor Module, page 1-7

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

1-5

Page 24

Chapter 1 Product Overview

184706

1

2

4

3

Integrated Supervisor Modules

Send documentation comments to mdsfeedback-doc@cisco.com

Cisco MDS 9222i Integrated Supervisor Module

The nonremovable Cisco MDS 9222i integrated supervisor module provides the control and

management functions of the Cisco MDS 9222i Switch, and it includes an integrated 18-port Fibre

Channel switching and 4-port Gigabit Ethernet IP services module. The Cisco MDS 9222i integrated

supervisor module provides multiple communication and control paths to avoid a single point of failure.

Note For description of the integrated 18/4-port Multiservice and the 18/4-port Multiservice FIPS module and

their capabilities, see the “1 8/4-Port Multiservice Module” section on page 1-21 and the “18/4-Port

Multiservice Federal Information Processing Standards Module” section on page 1-22.

Figure 1-4 shows the Cisco MDS 9222i integrated supervisor module with an integrated 18-port Fibre

Channel and 4-port Gigabit Ethernet module.

Figure 1-4 Cisco MDS 9222i Supervisor Module with Integrated 18-Port Fibre Channel and 4-Port

Gigabit Ethernet Module

1 Status LED 3 Gigabit Ethernet ports

2 4-Gbps Fibre Channel ports 4 Link LEDs

The Cisco MDS 9222i integrated supervisor module has a PowerPC PowerQUICC III class processor,

1 GB of DRAM, and an internal CompactFlash card that provides 1 GB of storage for software images.

Cisco MDS 9216i Integrated Supervisor Module

The nonremovable Cisco MDS 9216i integrated supervisor module provides the control and

management functions for the Cisco MDS 9216i Switch, and it includes an integrated 14-port Fibre

Channel switching and 2-port Gigabit Ethernet with IP services module. The Cisco MDS 9216i

integrated supervisor module provides multiple communication and control paths to avoid a single point

of failure.

Note For a description of the integrated 14/2-port Multiprotocol Services module and its capabilities, see the

Cisco MDS 9200 Series Hardware Installation Guide

1-6

“14/2-Port Multiprotocol Services Module” section on page 1-23.

OL-17468-02

Page 25

Chapter 1 Product Overview

—SPEED LINK—

LINK-

—SPEEDLINK—

STATUS

1 56789

LINK— —SPEED

10 11 12 13 14234

12

LINK-

GIGABIT E THERNET

116889

1 6

2 4

3 5

Integrated Supervisor Modules

Send documentation comments to mdsfeedback-doc@cisco.com

Figure 1-5 shows the Cisco MDS 9216i integrated supervisor module with an integrated 14-port Fibre

Channel and 2-port Gigabit Ethernet module.

Figure 1-5 Cisco MDS 9216i Supervisor Module with Integrated 14-Port Fibre Channel and 2-Port

Gigabit Ethernet Module

1 Status LED 4 Gigabit Ethernet ports

2 1-Gbps/2-Gbps Fibre Channel ports 5 Link LEDs

3 Link LEDs (under ports, on left) and Speed

LEDs (under ports, on right)

6 Asset tag

The Cisco MDS 9216i integrated supervisor module has a Pentium III class processor, 1 GB of DRAM,

and an internal CompactFlash card that provides 256 MB of storage for software images.

Cisco MDS 9216A Integrated Supervisor Module

The nonremovable Cisco MDS 9216A integrated supervisor module provides the control and

management functions for the Cisco MDS 9216A Switch, and it includes an integrated 16-port switching

module. The Cisco MDS 9216A integrated supervisor module provides multiple communication and

control paths to avoid a single point of failure.

Note For a description of the integrated 16-port switching module and its capabilities, see the “16-Port 2-Gbps

Fibre Channel Switching Module” section on page 1-18.

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

1-7

Page 26

Chapter 1 Product Overview

91670

1 43

LINK- -SPEED LINK- -SPEED LINK- -SPEED LINK- -SPEED

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

2

Integrated Supervisor Modules

Send documentation comments to mdsfeedback-doc@cisco.com

Figure 1-6 shows the Cisco MDS 9216A supervisor module with an integrated 16-port Switching

module.

Figure 1-6 Cisco MDS 9216A Supervisor Module with Integrated 16-Port Switching Module

1 Status LED 3 Link LEDs (under ports, on left) and Speed

LEDs (under ports, on right)

2 1-Gbps/2-Gbps Fibre Channel ports 4 Asset tag

The Cisco MDS 9216A integrated supervisor module has a Pentium III class processor, 1 GB of DRAM,

and an internal CompactFlash card that provides 256 MB of storage for software images.

1-8

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 27

Chapter 1 Product Overview

Integrated Supervisor Modules

Send documentation comments to mdsfeedback-doc@cisco.com

LEDs on the Cisco MDS 9200 Series Integrated Supervisor Modules

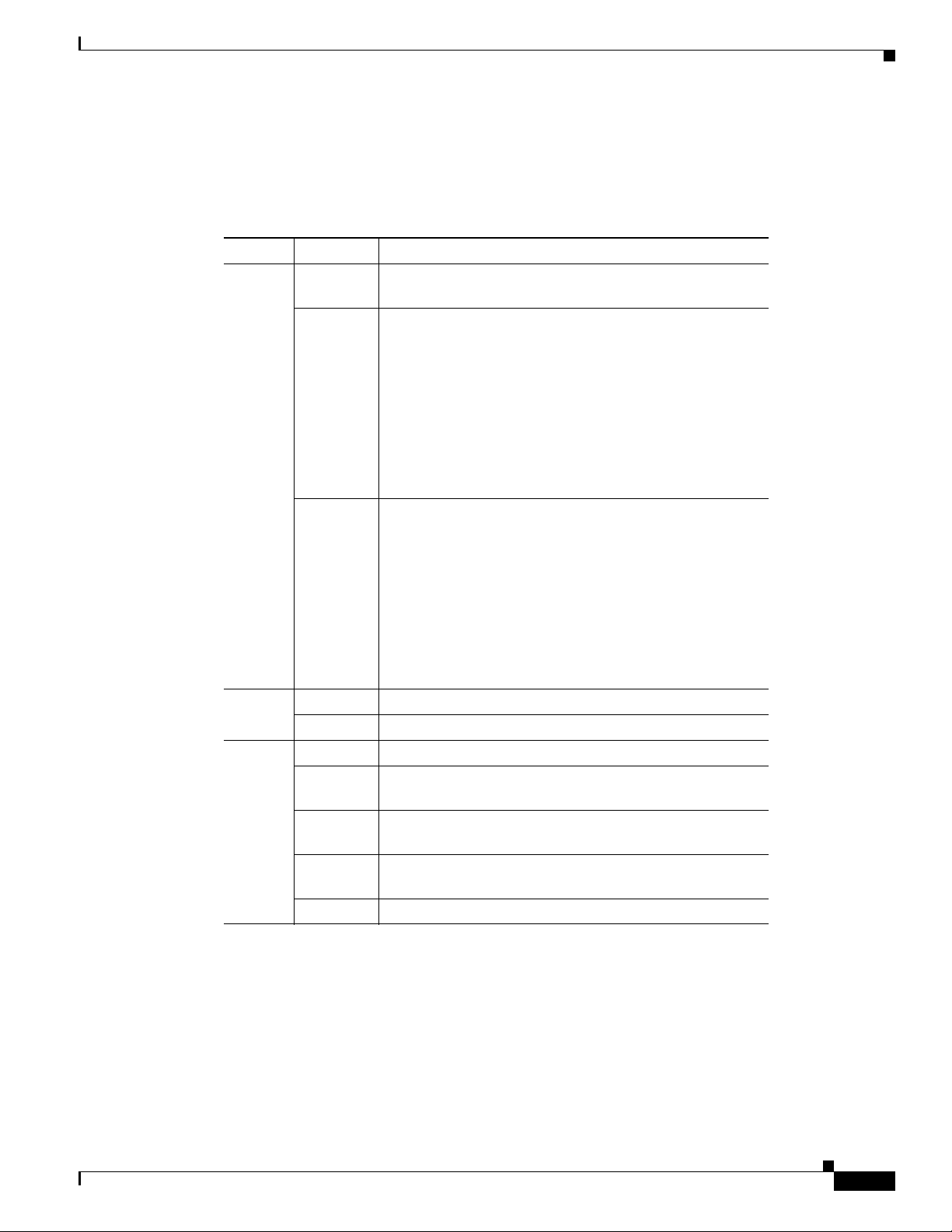

Table 1-1 describes the LEDs for the Cisco MDS 9200 Series integrated supervisor modules.

Table 1-1 LEDs for the Cisco MDS 9200 Series Integrated Supervisor Modules

LED Status Description

Status Green All diagnostics pass. The module is operational (normal

initialization sequence).

Orange One of the following occurs or occurred:

• The module is booting or running diagnostics (normal

initialization sequence).

• The inlet air temperature of the system exceeded the

maximum system operating temperature limit (a minor

environmental warning). To ensure maximum product

life, you should immediately correct the

environmental temperature and restore the system to

normal operation.

Red One of the following occurred:

• The diagnostic test failed. The module is not

operational because a fault occurred during the

initialization sequence.

• The inlet air temperature of the system exceeded the

safe operating temperature limits of the card (a major

environmental warning). The card shut down to

prevent permanent damage. The system will be shut

down after two minutes if this condition is not cleared.

1

Speed

On 2-Gbps mode.

Off 1-Gbps mode.

Link Solid green Link is up.

Flashing

Link is up (beacon used to identify port).

green

Solid

Link is disabled by software.

yellow

Flashing

A fault condition exists.

yellow

Off No link.

1. The Speed LEDs are available only on Cisco MDS 9216i and Cisco MDS 9216A Supervisor

Modules.

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

1-9

Page 28

Chapter 1 Product Overview

S

T

A

T

U

S

S

Y

S

T

E

M

R

E

S

E

T

CONSOLE

MGMT 10/100

MDS 9216i

9

3

1

5

6

42

116890

COM1

7

8

Interface Modules

Send documentation comments to mdsfeedback-doc@cisco.com

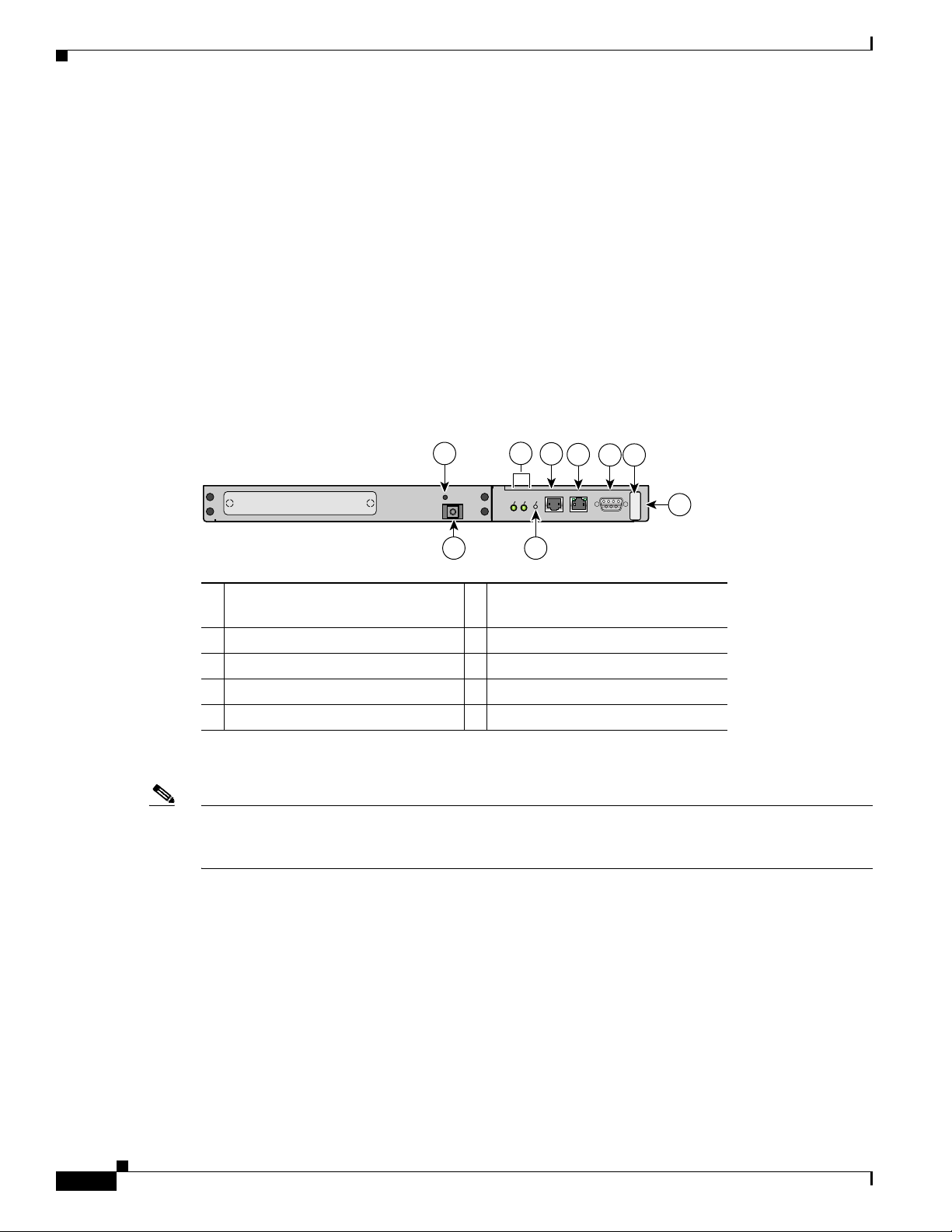

Interface Modules

The nonremovable interface module is located above slot 1 (see Figure 1-7) and is identical for all Cisco

MDS 9200 Series switches. It provides the following local and remote management interfaces:

• RS-232 (EIA/TIA-232) console port with an RJ-45 connection that you can use to:

–

Configure the switch from the CLI.

–

Monitor network statistics and errors.

–

Configure SNMP agent parameters.

• MGMT 10/100 Ethernet port with an RJ-45 connection that provides network management

capabilities.

• RS-232 COM1 port with a DB-9 connector that can be attached to a modem.

Figure 1-7 Nonremoveable Interface Module of the Cisco MDS 9200 Series

1 ESD socket (for ESD strap) 6 MGMT 10/100 Ethernet port (with

integrated Link and Activity LEDs)

2 Grounding pad (beneath tape) 7 COM1 port

3 Status and System LEDs 8 Asset tag

4 Reset button 9 Interface module

5 Console port

The clock module is also part of the interface module.

Note The system clocks in the Cisco MDS 9200 Series have a field-measured mean time between failures

(MTBF) of approximately 3.2 million hours or 365 years. In the event of a clock module failure, the

system generates an error message.

1-10

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 29

Chapter 1 Product Overview

Interface Modules

Send documentation comments to mdsfeedback-doc@cisco.com

LEDs on the Interface Module

Table 1-2 describes the LEDs for the Cisco MDS 9200 Series interface module.

Table 1-2 LEDs on the Cisco MDS 9200 Series Interface Module

LED Status Description

Status Green All diagnostics pass. The module is operational

(normal initialization sequence).

Orange One of the following occurs or occurred:

• The module is booting or running diagnostics

(normal initialization sequence).

• The inlet air temperature of the system exceeded

the maximum system operating temperature limit

(a minor environmental warning). To ensure

maximum product life, you should immediately

correct the environmental temperature and

restore the system to normal operation.

Red One of the following occurred:

• The diagnostic test failed. The module is not

operational because a fault occurred during the

initialization sequence.

• The inlet air temperature of the system exceeded

the safe operating temperature limits of the card

(a major environmental warning). The card shut

down to prevent permanent damage.

System Green All chassis environmental monitors are reporting OK.

Orange One of the following occurs or occurred:

• The power supply failed or the power supply fan

failed.

• Incompatible power supplies are installed.

• The redundant clock failed.

Red The temperature of the supervisor module exceeded

the major threshold.

MGMT 10/100

Ethernet Link

LED

MGMT 10/100

Ethernet

Activity LED

Green Link is up.

Off No link.

Green Traffic is flowing through port.

Off No link or no traffic.

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

1-11

Page 30

Chapter 1 Product Overview

Cisco MDS 9000 Family Module Compatibility

Send documentation comments to mdsfeedback-doc@cisco.com

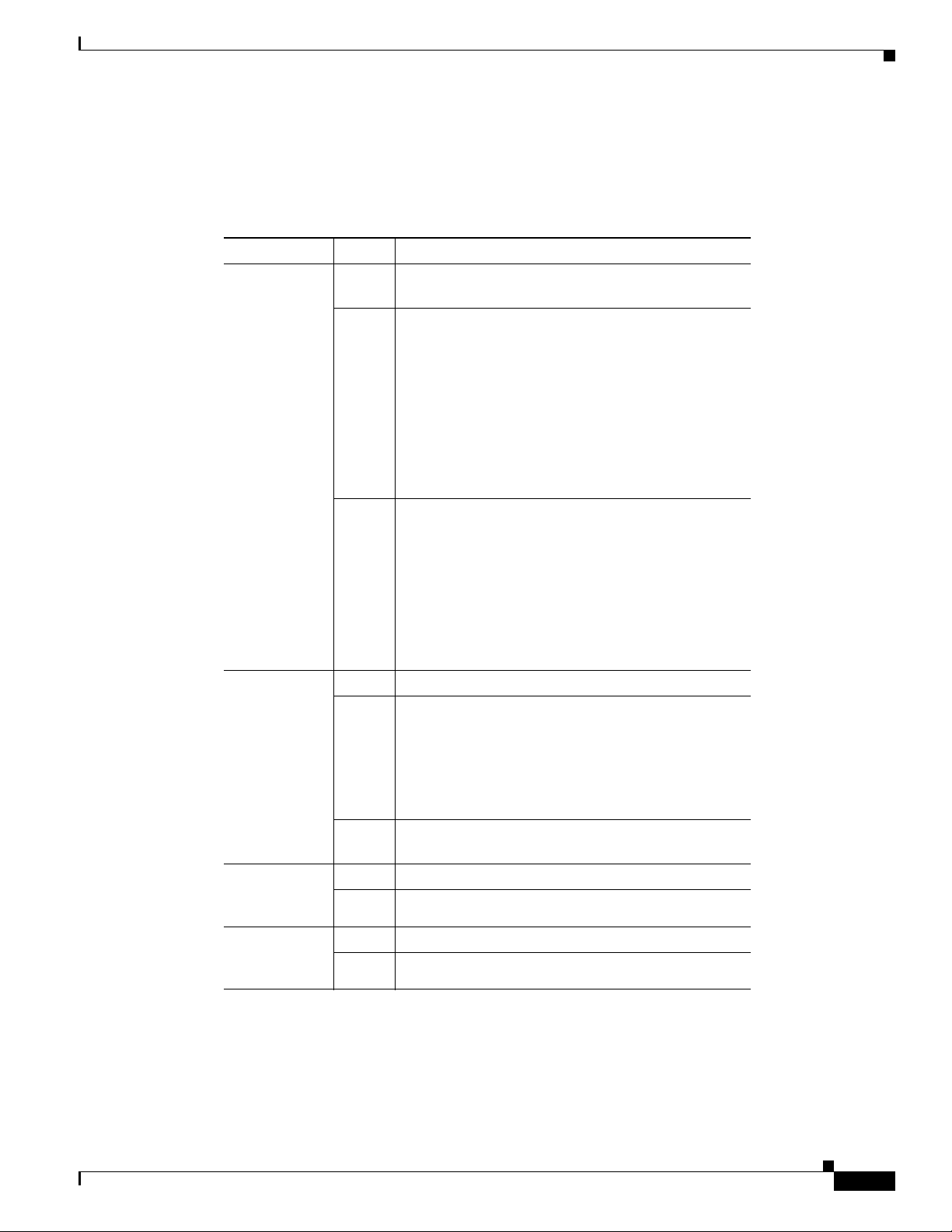

Cisco MDS 9000 Family Module Compatibility

Table 1-3 lists the hardware modules available and the chassis compatibility associated with them.

Table 1-3 MDS 9000 Modules and Platform Compatibility Matrix

Module 9513 9509 9506 9222i 9216A 9216i 9216

Supervisor-2 module X X X

Supervisor-1 module X X

4/44-port 8-Gbps Host-Optimized Fibre Channel switching

module

48-port 4-Gbps Fibre Channel switching module XXXXXX

24-port 4-Gbps Fibre Channel switching module XXXXXX

12-port 4-Gbps Fibre Channel switching module XXXXXX

4-port 10-Gbps Fibre Channel switching module XXXXXX

32-port 1-Gbps/2-Gbps Fibre Channel module X X X X X X

16-port 1-Gbps/2-Gbps Fibre Channel module X X X X X X

8-port Gigabit Ethernet IP Storage Services module XXXXXXX

4-port Gigabit Ethernet IP Storage Services module X X X X X X

32-port Fibre Channel Advanced Services Module (ASM) X X X X X

32-port 1-Gbps/2-Gbps Fibre Channel Storage Services

Module (SSM)

Caching Services Module (CSM) X X X X X

18-port Fibre Channel /4-port Gigabit Ethernet Multiservice

(MSM-18/4) module

18-port Fibre Channel /4-port Gigabit Ethernet Multiservice

FIPS (MSFM-18/4) module

14-port Fibre Channel/2-port Gigabit Ethernet Multiprotocol

Services (MPS-14/2) module

XXXX

XXXXXXX

XXXXXX

XXXXXX

XXX XXX

Switching Modules

The Cisco MDS 9200 Series supports the following hot-swappable Fibre Channel switching modules:

• Generation 3 Modules

–

4/44-Port 8-Gbps Host-Optimized Fibre Channel Switching Module

• Generation 2 Modules

–

48-Port 4-Gbps Fibre Channel Switching Module

–

24-Port 4-Gbps Fibre Channel Switching Module

–

12-Port 4-Gbps Fibre Channel Switching Module

–

4-Port 10-Gbps Fibre Channel Switching Module

• Generation 1 Modules

Cisco MDS 9200 Series Hardware Installation Guide

1-12

OL-17468-02

Page 31

Chapter 1 Product Overview

Switching Modules

Send documentation comments to mdsfeedback-doc@cisco.com

–

32-Port 2-Gbps Fibre Channel Switching Module

–

16-Port 2-Gbps Fibre Channel Switching Module

The Cisco MDS 9200 Series supports one hot-swappable switching or services module in addition to the

integrated module that is part of the supervisor module.

The Fibre Channel switching modules provide system-wide power management and autonegotiation,

which allows ports to negotiate for speed at the other end of the link. Each module has temperature

sensors and an EEPROM that stores serial number and model number information.

The Fibre Channel port interfaces support hot-swappable Fibre Channel SFP and SFP+ transceivers,

which can be short wavelength (SWL) or long wavelength (LWL). The port interfaces also support

coarse wavelength-division multiplexing (CWDM) and dense wavelength-division multiplexing

(DWDM) SFP transceivers, which can be used for extended long wavelength (ELWL) transmission or

for coarse wavelength-division multiplexing (CWDM) and dense wavelength-division multiplexing

(DWDM). See the “Supported Transceivers” section on page 1-36.

Note The internal bootflash installed on the modules are not field-replaceable units. Do not remove or replace

internal bootflash on the modules. Modifying the factory-installed bootflash is not supported.

4/44-Port 8-Gbps Host-Optimized Fibre Channel Switching Module

The 4/44-port 8-Gbps Host-Optimized Fibre Channel switching module offers 48 autosensing 1-, 2-,

4-and 8-Gbps Fibre Channel ports and can be used in any of the Cisco MDS 9500 Series chassis and in

the Cisco MDS 9222i Switches. The 4/44-port switching module can be configured in one of two

operational modes: shared bandwidth mode (default) and dedicated bandwidth mode.

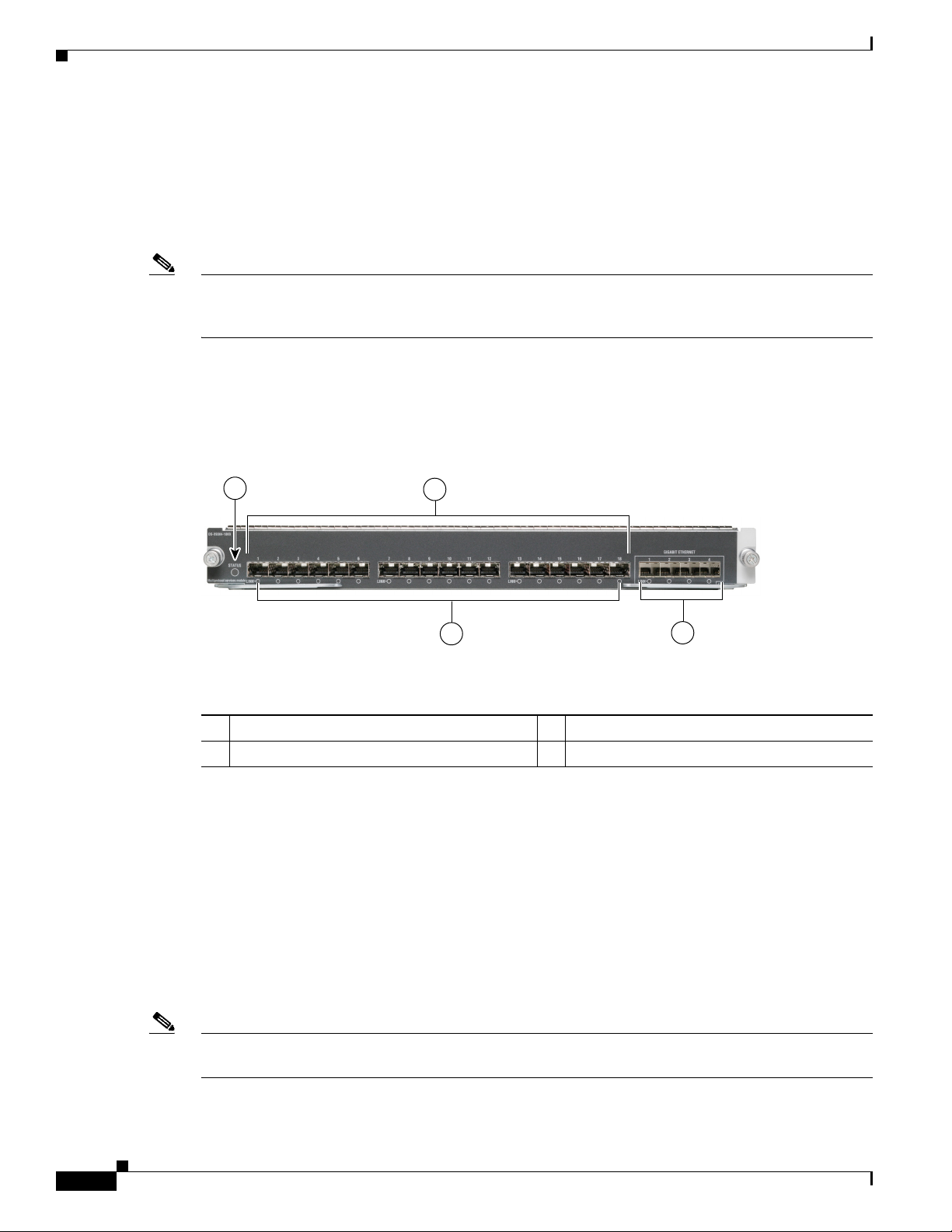

Figure 1-8 shows a 4/44-port 8-Gbps Host-Optimized Fibre Channel switching module. The front panel

connectors support standard modular SFP and SFP+ transceivers and the speed detection is autosensing.

Figure 1-8 4/44-port 8-Gbps Host-Optimized Fibre Channel Switching Module

48-Port 4-Gbps Fibre Channel Switching Module

The 48-port 4-Gbps Fibre Channel switching module offers 48 autosensing 1-, 2-, and 4-Gbps Fibre

Channel ports and can be used in any of the Cisco MDS 9500 Series chassis and in the Cisco MDS 9222i,

9216i, and 9216A Switches. The 48-port switching module can be configured in one of two operational

modes: shared bandwidth mode (default) and dedicated bandwidth mode.

Figure 1-9 shows a 48-port 4-Gbps Fibre Channel switching module. The front panel connectors are

standard modular SFP and the speed detection is autosensing.

188657

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

1-13

Page 32

Chapter 1 Product Overview

144474

144809

1

2

3

Switching Modules

Send documentation comments to mdsfeedback-doc@cisco.com

Figure 1-9 48-Port 4-Gbps Fibre Channel Switching Module

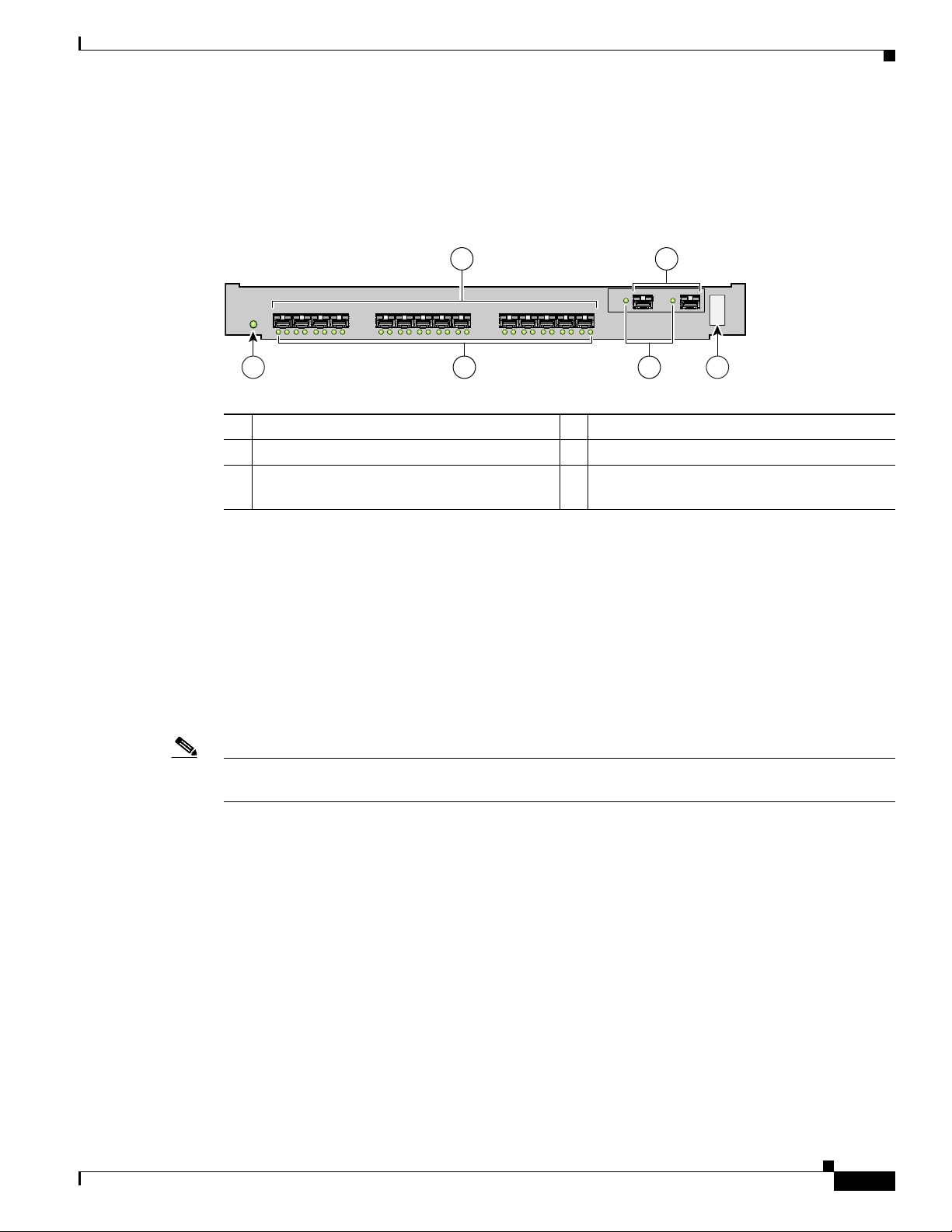

Figure 1-10 shows the port numbering and LEDs on the 48-port 4-Gbps Fibre Channel switching

module.

Figure 1-10 48-Port 4-Gbps Fibre Channel Switching Module LEDs

1 Status LED 3 Fibre Channel ports

2 Link LEDs

24-Port 4-Gbps Fibre Channel Switching Module

The 24-port 4-Gbps Fibre Channel switching module offers 24 autosensing 1-, 2-, and 4-Gbps Fibre

Channel ports and can be used in any of the Cisco MDS 9500 Series chassis and in the Cisco MDS 9216i

and 9216A Switches. The 24-port switching module can be configured in one of two operational modes:

shared bandwidth mode (default) and dedicated bandwidth mode.

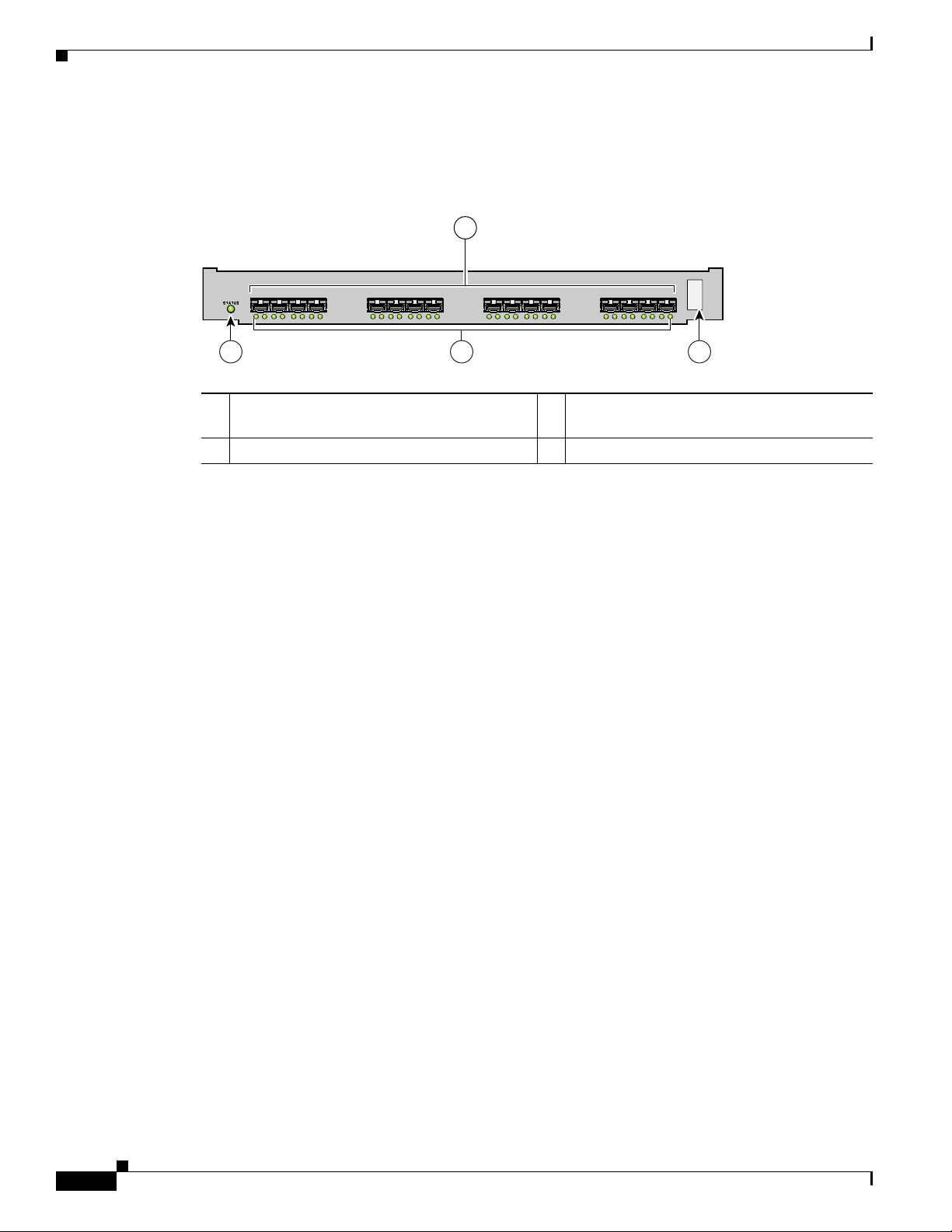

Figure 1-11 shows a 24-port 4-Gbps Fibre Channel switching module. The front panel connectors are

standard modular SFP and the speed detection is autosensing.

1-14

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 33

Chapter 1 Product Overview

144471

2

34

1

144470

3

2

1

Switching Modules

Send documentation comments to mdsfeedback-doc@cisco.com

Figure 1-11 24-Port 4-Gbps Fibre Channel Switching Module

1 Status LED 3 Fibre Channel ports

2 Link LEDs 4 Port Group

12-Port 4-Gbps Fibre Channel Switching Module

The 12-port 4-Gbps Fibre Channel switching module can be used in any of the Cisco MDS 9500 Series

chassis and in the Cisco MDS 9216i and 9216A Switches. The 12-port 4-Gbps switching module is a

full-rate mode module providing 12 SFP-based Fibre Channel interfaces. Each interface can support fullline rate operation at 4 Gbps interface speed. The module delivers a sustained data rate of up to 4-Gbps

in each direction, on all ports simultaneously, and up to 96 Gbps of continuous, aggregate bandwidth

when attached to high-performance servers and storage subsystems.

Figure 1-12 shows a 12-port 4-Gbps Fibre Channel switching module. The front panel connectors are

standard modular SFP and the speed detection is autosensing.

Figure 1-12 12-Port 4-Gbps Fibre Channel Switching Module

1 Status LED 3 Link LEDs

2 Fibre Channel ports

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

1-15

Page 34

Chapter 1 Product Overview

144473

2

3

1

Switching Modules

Send documentation comments to mdsfeedback-doc@cisco.com

4-Port 10-Gbps Fibre Channel Switching Module

The 4-port 10-Gbps Fibre Channel switching module offers four dedicated bandwidth Fibre Channel

ports running at 10 Gbps with no oversubscription. This module can be used in any of the Cisco MDS

9500 Series chassis and in the Cisco MDS 9216i and 9216A Switches. The module delivers a sustained

data rate of up to 10 Gbps in each direction, on all ports simultaneously, and up to 80 Gbps of continuous,

aggregate bandwidth.

Figure 1-13 shows a 4-port 10-Gbps switching module. The front panel connectors are standard modular

X2 interfaces and the speed is fixed at 10 Gbps.

Figure 1-13 4-Port 10-Gbps Fibre Channel Switching Module

1 Status LED 3 Link LED

2 X2 port interfaces

Cisco MDS 9200 Series Hardware Installation Guide

1-16

OL-17468-02

Page 35

Chapter 1 Product Overview

Switching Modules

Send documentation comments to mdsfeedback-doc@cisco.com

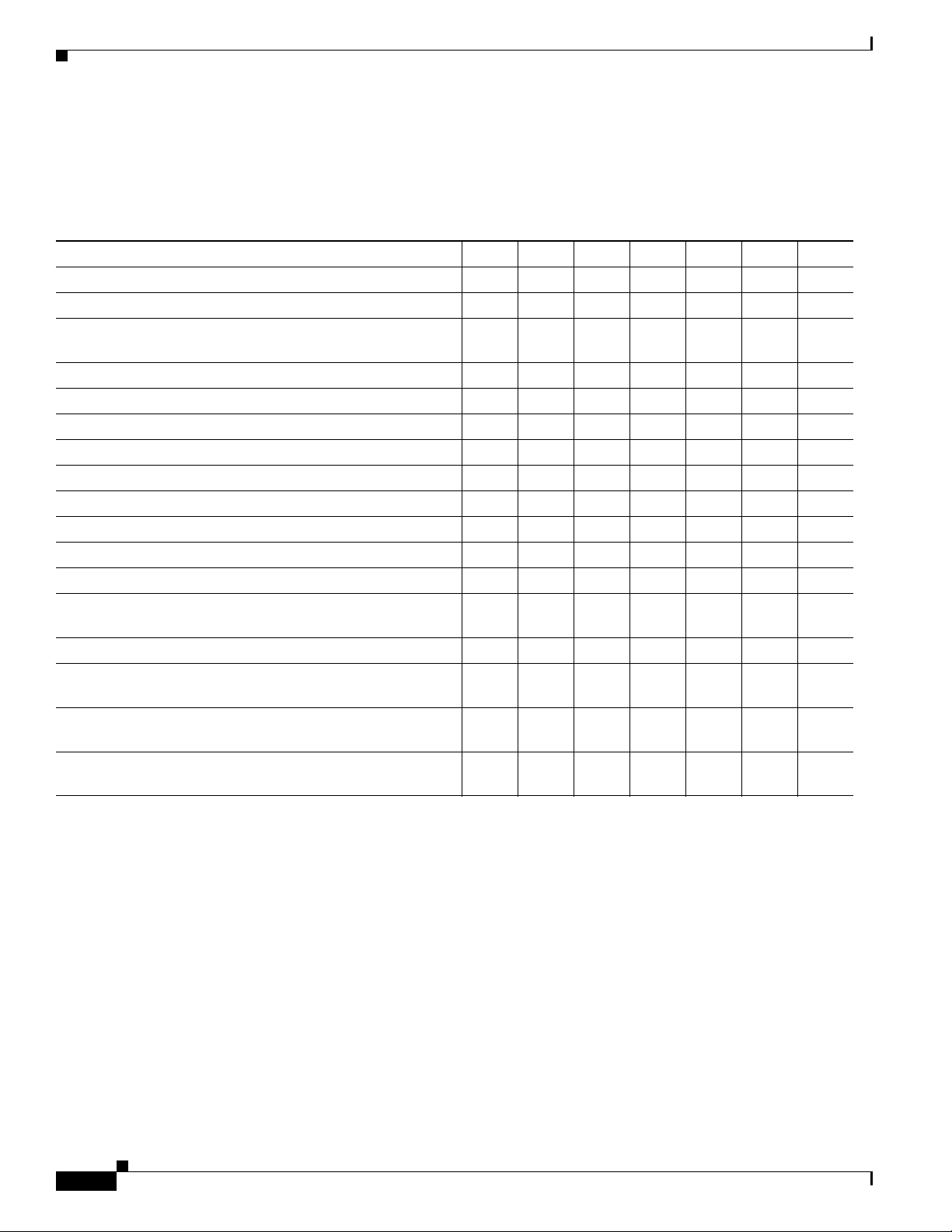

LEDs on the Generation 2 Switching Modules

Table 1-4 describes the LEDs for the 48-port, 24-port, and 12-port 4-Gbps Fibre Channel Switching

Modules and the 4-port 10-Gbps Fibre Channel Switching Module.

Table 1-4 LEDs for the Cisco MDS 9000 Family Generation 2 Fibre Channel Switching Modules

LED Status Description

Status Green All diagnostics pass. The module is operational

(normal initialization sequence).

Orange One of the following occurs or occurred:

• The module is booting or running diagnostics

(normal initialization sequence).

• The inlet air temperature of the system has

exceeded the maximum system operating

temperature limit (a minor environmental

warning). To ensure maximum product life, you

should immediately correct the environmental

temperature and restore the system to normal

operation.

Red One of the following occurs or occurred:

• The diagnostic test failed. The module is not

operational because a fault occurred during the

initialization sequence.

• The inlet air temperature of the system has

exceeded the safe operating temperature limits of

the card (a major environmental warning). The

card has been shut down to prevent permanent

damage.

Link Solid green Link is up.

Intermittent

flashing green

Solid yellow Link is disabled by software.

Flashing

yellow

Off No link.

Link is up (traffic on port).

A fault condition exists.

32-Port 2-Gbps Fibre Channel Switching Module

The 32-port 2-Gbps Fibre Channel switching module can be used to allocate bandwidth optimally. The

module is organized into eight four-port groups. Only the first port in each four-port group can be an

ISL. If the first port is an ISL, the other three ports in the group are disabled. The four ports within a port

group share a single internal channel resulting in a subscription ratio of approximately 3.2:1. The 32-port

2-Gbps switching module provides more ports at a lower price per port. Figure 1-14 shows a 32-port

switching module.

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

1-17

Page 36

Chapter 1 Product Overview

91673

2

1 4

3

17 20

4

DS-X9032

5

21 24

89

25 28

12 13

29 32

16

91672

4

3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

2

1

Switching Modules

Send documentation comments to mdsfeedback-doc@cisco.com

Tip For a full 2-Gbps bandwidth between two hosts, connect one host to the first port group and the second

host to the second port group.

Figure 1-14 Cisco MDS 9000 Family 32-Port 1-Gbps/2-Gbps Switching Module

1 Status LED 3 Link LED (to left of port) and

Speed LED (to right of port)

2 1-Gbps/2-Gbps Fibre Channel port

group

4 Asset tag

16-Port 2-Gbps Fibre Channel Switching Module

The 16-port 2-Gbps switching module is best used for applications requiring high bandwidth; for

example, Inter-Switch Link (ISL) connections between switches and high-performance host or storage

controllers. The 16-port switching module supports a sustained data rate of up to 2 Gbps in each

direction, on all ports simultaneously. Figure 1-15 shows a 16-port 2-Gbps switching module.

The autosensing 1-Gbps/2-Gbps ports of the 16-port Fibre Channel switching module deliver up to

64 Gbps of continuous, aggregate bandwidth when attached to high-performance servers and storage

subsystems.

Figure 1-15 Cisco MDS 9000 Family 16-Port 2-Gbps Switching Module

1 Status LED 3 Link LED (to left of port) and

Speed LED (to right of port)

2 1-Gbps/2-Gbps Fibre Channel

ports

4 Asset tag

Cisco MDS 9200 Series Hardware Installation Guide

1-18

OL-17468-02

Page 37

Chapter 1 Product Overview

Switching Modules

Send documentation comments to mdsfeedback-doc@cisco.com

Switching Module Features

Each switching module draws its power from the 42 V supplied on the backplane with local DC/DC

power converters and regulators.

The control processor on the switching module provides power-on, offline, and online diagnostics. The

control processor can be used to configure devices on the switching module and to gather statistical data

from each port.

The control processor can determine which slot it is plugged into, and it can monitor its DC/DC power

source and temperature. The control processor signals the supervisor module and displays an alarm on

its front panel when a problem is detected.

The front panel on the switching module provides basic status information, such as power-on, self-test

running, self-test passed, alarm, and ready.

The binary image for the switching module is downloaded from the supervisor module. Prior to the

image download, the control processor on the switching module runs from code stored on its local

CompactFlash card.

Note Routine software downloads are not required.

The integrated supervisor module can force a reset on the switching module and controls whether power

is applied to the switching module.

If a single component or a set of components on the switching module fails, this does not disable other

switching modules if that is the only failure in the system.

Each switching module has a hardware watchdog timer to detect most component failures. The watchdog

timer resets the card if it is not serviced periodically.

OL-17468-02

Cisco MDS 9200 Series Hardware Installation Guide

1-19

Page 38

Chapter 1 Product Overview

Switching Modules

Send documentation comments to mdsfeedback-doc@cisco.com

LEDs on the Generation 1 Switching Module

Table 1-5 describes the LEDs for the 16-port and 32-port switching modules.

Table 1-5 LEDs for the Cisco MDS 9000 Family Generation 1 Fibre Channel Switching Modules

LED Status Description

Status Green All diagnostics pass. The module is operational

(normal initialization sequence).

Orange One of the following occurs or occurred:

• The module is booting or running diagnostics

(normal initialization sequence).

• The inlet air temperature of the system has

exceeded the maximum system operating

temperature limit (a minor environmental

warning). To ensure maximum product life, you

should immediately correct the environmental

temperature and restore the system to normal

operation.

Red One of the following occurs or occurred:

• The diagnostic test failed. The module is not

operational because a fault occurred during the

initialization sequence.

• The inlet air temperature of the system has

exceeded the safe operating temperature limits of

the card (a major environmental warning). The

card has been shut down to prevent permanent

damage.

Speed On 2-Gbps mode.

Off 1-Gbps mode.

Steady

Link is up (beacon used to identify port).

1

flashing green

Link Solid green Link is up.

Intermittent

Link is up (traffic on port).

flashing green

Solid yellow Link is disabled by software.

Flashing

A fault condition exists.

yellow

Off No link.

1. The flashing green light turns on automatically when an external loopback is detected that causes

the interfaces to be isolated. The flashing green light overrides the beacon mode configuration.

The state of the LED is restored to reflect the beacon mode configuration after the external

loopback is removed.

1-20

The Fibre Channel switching modules provide auto-configuring Fibre Channel ports that support Fibre

Channel speeds of 1.0625 Gbps and 2.125 Gbps.

Cisco MDS 9200 Series Hardware Installation Guide

OL-17468-02

Page 39

Chapter 1 Product Overview

Services Modules

Send documentation comments to mdsfeedback-doc@cisco.com

Services Modules

The Cisco MDS 9200 Series supports the following hot-swappable services modules:

• 1 8/4-Port Multiservice Module

• 18/4-Port Multiservice Federal Information Processing Standards Module

• 14/2-Port Multiprotocol Services Module

• IP Storage Services Modules

• 32-Port Fibre Channel Storage Services Module

• 32-Port Fibre Channel Advanced Services Module

• Caching Services Module

The Cisco MDS 9200 Series supports one hot-swappable switching or services module in addition to the

integrated module that is part of the supervisor module. Each module has temperature sensors and an

EEPROM that stores serial number and model number information.

Note The internal bootflash installed on the modules are not field-replaceable units. Do not remove or replace

internal bootflash on the modules. You cannot modify the factory installed bootflash.

18/4-Port Multiservice Module

The Cisco MDS 9000 Family 18/4-Port Multiservice (MSM-18/4) module provides 18 autosensing

1-, 2-, and 4-Gbps Fibre Channel ports and four Gigabit Ethernet IP services ports. The MSM-18/4

module provides multiprotocol capabilities such as Fibre Channel, Fibre Channel over IP (FCIP), Small

Computer System Interface over IP (iSCSI), IBM Fiber Connectivity (FICON), and FICON Control Unit

Port (CUP) management.

The MSM-18/4 module provides 18 4-Gbps Fibre Channel interfaces for high-performance SAN and

mainframe connectivity and four Gigabit Ethernet ports for FCIP and iSCSI storage services. Individual

ports can be configured with hot-swappable short wavelength, long wavelength, extended-reach, coarse

wavelength-division multiplexing (CWDM) or dense wavelength-division multiplexing (DWDM) Small

Form-Factor Pluggables (SFPs) for connectivity up to 125 miles (200 km).

The MSM-18/4 module can minimize latency for disk and tape through FCIP write acceleration and

FCIP tape write and read acceleration. The MSM-18/4 module provides up to 16 virtual Inter-Switch

Link (ISL) connections on the four 1-Gigabit Ethernet ports through tunneling, and provides up to 4095

buffer-to-buffer credits that can be assigned to a single Fibre Channel port.

The MSM-18/4 supports hardware-based encryption and it is required to run the Storage Media

Encryption (SME), which is a part of the Cisco NX-OS. For more information on SME, see the Cisco

MDS Storage Media Encryption Guide.

The MSM-18/4 supports SAN extension over IP and is compatible with current SAN extension products,

such as, MPS-14/2, 9216i, and IPS. The MSM-18/4 provides an integrated next generation 4-Gbps FC