Page 1

Catalyst 2350 Switch

Hardware

February 2009

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Installation Guide

Text Part Number: OL-18479-01

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required

to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency energy. If it is not

installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment has been tested and found to

comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These specifications are designed to provide reasonable

protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class A or Class B digital

devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference to radio or television

communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco equipment or one of its

peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio are on circuits

controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

CCDE, CCENT, Cisco Eos, Cisco HealthPresence, the Cisco logo, Cisco Lumin, Cisco Nexus, Cisco StadiumVision, Cisco TelePresence, Cisco WebEx, DCE, and Welcome

to the Human Network are trademarks; Changing the Way We Work, Live, Play, and Learn and Cisco

Bringing the Meeting To You, Catalyst, CCDA, CCDP, CCIE, CCIP, CCNA, CCNP, CCSP, CCVP, Cisco, the Cisco

Cisco

Press, Cisco Systems, Cisco Systems Capital, the Cisco Systems logo, Cisco Unity, Collaboration Without Limitation, EtherFast, EtherSwitch, Event Center, Fast Step,

Follow Me Browsing, FormShare, GigaDrive, HomeLink, Internet Quotient, IOS, iPhone, iQuick Study, IronPort, the IronPort

MeetingPlace, MeetingPlace Chime Sound, MGX, Networkers, Networking Academy, Network Registrar, PCNow, PIX, PowerPanels, ProConnect, ScriptShare, SenderBase,

SMARTnet, Spectrum Expert, StackWise, The Fastest Way to Increase Your Internet Quotient, TransPath, WebEx, and the WebEx

Cisco

Systems, Inc. and/or its affiliates in the United States and certain other countries.

All other trademarks mentioned in this document or website are the property of their respective owners. The use of the word partner does not imply a partnership relationship

between Cisco and any other company. (0812R)

Catalyst 2350 Switch Hardware Installation Guide

©2009 Cisco Systems, Inc. All rights reserved.

Store are service marks; and Access Registrar, Aironet, AsyncOS,

IMPLIED, INCLUDING, WITHOUT

Certified Internetwork Expert logo, Cisco IOS,

logo, LightStream, Linksys, MediaTone,

logo are registered trademarks of

Page 3

CONTENTS

Preface vii

Audience vii

Purpose vii

Conventions vii

Related Publications viii

Obtaining Documentation and Submitting a Service Request ix

CHAPTER

1 Overview 1-1

Switch Models 1-1

Front Panel Description 1-1

10/100/1000 Ethernet Ports 1-2

10-Gigabit Ethernet Module Slots 1-2

SFP Modules 1-3

LEDs 1-3

Rear Panel Description 1-5

Power-Supply Modules 1-5

Fan Modules 1-6

Management Ports 1-7

Management Options 1-8

Network Configurations 1-8

Cisco TwinGig Converter Module 1-2

System LED 1-4

Port LEDs and Modes 1-4

Catalyst 2350 Switch Power-Supply Modules 1-6

CHAPTER

OL18479-01

2 Switch Installation 2-1

Preparing for Installation 2-1

Safety Warnings 2-1

Installation Guidelines 2-5

Box Contents 2-5

Tools and Equipment 2-6

Catalyst 2350 Switch Hardware Installation Guide

iii

Page 4

Contents

Installing the Switch 2-6

Rack-Mounting 2-6

Attaching the Rack-Mount Brackets 2-8

Mounting the Switch in a Rack 2-10

Table- or Shelf-Mounting 2-11

After Installing the Switch 2-11

Installing Devices in 10-Gigabit Ethernet Slots 2-12

Installing X2 Transceiver and Converter Modules 2-12

Removing an X2 Transceiver or Converter Module 2-14

Installing SFP Modules 2-14

Installing an SFP Module 2-15

Removing an SFP Module 2-16

Connecting Devices to the Ethernet Ports 2-16

10/100/1000 Ethernet Port Connections 2-16

Where to Go Next 2-17

CHAPTER

CHAPTER

3 Power Supply and Fan Module Installation 3-1

Installation Overview 3-1

Tools and Equipment 3-1

Installation Guidelines 3-1

Installing an AC-Power Supply 3-3

Installing a DC-Power Supply 3-4

Preparing for Installation 3-4

Grounding the Switch 3-5

Installing the DC Power Supply in the Switch 3-6

Wiring the DC-Input Power Source 3-7

Installing a Fan Module 3-8

4 Troubleshooting 4-1

Diagnosing Problems 4-1

Switch POST Results 4-1

Switch LEDs 4-1

Switch Connections 4-2

Bad or Damaged Cable 4-2

Ethernet and Fiber Cables 4-2

Link Status 4-2

SFP Module Issues 4-3

Interface Settings 4-3

iv

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 5

Ping End Device 4-3

Spanning Tree Loops 4-3

Switch Performance 4-3

Speed, Duplex, and Autonegotiation 4-3

Autonegotiation and Network Interface Cards 4-4

Cabling Distance 4-4

Clearing the Switch IP Address and Configuration 4-4

Finding the Switch Serial Number 4-5

Contents

APPENDIX

APPENDIX

APPENDIX

A Technical Specifications A-1

B Connector and Cable Specifications B-1

Connector Specifications B-1

10/100/1000 Ports B-1

10-Gigabit Ethernet Module Interfaces B-2

SFP Modules B-2

10/100 Ethernet Management Port B-3

Console Port B-4

Cable and Adapter Specifications B-4

10-Gigabit Ethernet X2 Transceiver Module Cable Specifications B-4

SFP Module Cable Specifications B-5

Four Twisted-Pair Cable Pinouts B-5

Two Twisted-Pair Cable Pinouts B-6

Identifying a Crossover Cable B-6

Console Port Adapter Pinouts B-7

C Configuring the Switch with the CLI-Based Setup Program C-1

I

NDEX

OL18479-01

Accessing the CLI C-1

Accessing the CLI Through Express Setup C-1

Accessing the CLI Through the Console Port C-1

Connecting to the Console Port C-2

Entering the Initial Configuration Information C-2

IP Settings C-2

Completing the Setup Program C-3

Catalyst 2350 Switch Hardware Installation Guide

v

Page 6

Contents

vi

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 7

Audience

Preface

This guide is for the networking or computer technician responsible for installing Catalyst 2350

switches. We assume that you are familiar with the concepts and terminology of Ethernet and local area

networking. If you are interested in more training and education in these areas, learning opportunities

including training courses, self-study options, seminars, and career certifications programs are available

on the Cisco Training & Events web page:

http://www.cisco.com/web/learning/index.html

Purpose

This guide documents the hardware features of the Catalyst 2350 switches. It describes the physical and

performance characteristics of the switch, explains how to install a switch, and provides troubleshooting

information.

This guide does not describe system messages that you might receive or how to configure your switch.

For more information, see the switch getting started guide, the switch software configuration guide, the

switch command reference, and the switch system message guide on the Cisco.com Technical Support

and Documentation home page. For information about the standard Cisco IOS Release

commands, see the Cisco

and Documentation > Documentation. On the Cisco Documentation home page, select Release 12.1

or 12.2 from the Cisco IOS Software drop-down list.

Conventions

This document uses the following conventions and symbols for notes, cautions, and warnings.

Translations of the warning statements in this document appear in the Regulatory Compliance and Safety

Information for the Catalyst

Note Means reader take note. Notes contain helpful suggestions or references to materials not contained in

this manual.

12.1 or 12.2

IOS documentation set from the Cisco.com home page at Technical Support

2350 Switch that ships with the switch.

OL18479-01

Caution Means reader be careful. In this situation, you might do something that could result in equipment

damage or loss of data.

Catalyst 2350 Switch Hardware Installation Guide

vii

Page 8

Preface

Warning

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar

with standard practices for preventing accidents. Use the statement number provided at the end of

each warning to locate its translation in the translated safety warnings that accompanied this device.

Statement 1071

Related Publications

Before installing, configuring, or upgrading the switch, see the release notes on Cisco.com for the latest

information.

These documents provide complete information about the switch and are available from these

Cisco.com

http://www.cisco.com/en/US/products/ps10116/tsd_products_support_series_home.html

• Catalyst 2350 Switch Getting Started Guide

• Regulatory Compliance and Safety Information for the Catalyst 2350 Switch

• Release Notes for the Catalyst 2350 Switch

• Catalyst 2350 Switch Software Configuration Guide

• Catalyst 2350 Switch Command Reference

• Catalyst 2350 Switch System Message Guide

• Cisco Software Activation and Compatibility Document

sites:

• Installation Notes for the Power Supply Modules for the Catalyst 2350 Switch

• Installation Notes for the 60CFM Fan Module for the Catalyst 2350 Switch

• Installation Notes for the Cisco TwinGig Converter Module

• Device manager online help (available on the switch)

viii

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 9

Preface

These compatibility matrix documents are available from this Cisco.com site:

http://www.cisco.com/en/US/products/hw/modules/ps5455/products_device_support_tables_list.html

• Cisco Gigabit Ethernet Transceiver Modules Compatibility Matrix

• Cisco 100-Megabit Ethernet SFP Modules Compatibility Matrix

• Cisco Small Form-Factor Pluggable Modules Compatibility Matrix

• Compatibility Matrix for 1000BASE-T Small Form-Factor Pluggable Modules

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional

information, see the monthly What’s

revised Cisco

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What’s New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed

and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free

service and Cisco currently supports RSS

technical documentation, at:

New in Cisco Product Documentation, which also lists all new and

Ve r si o n 2.0.

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

ix

Page 10

Preface

Catalyst 2350 Switch Hardware Installation Guide

x

OL18479-01

Page 11

Overview

The Catalyst 2350 switch, also referred to as the switch, is an Ethernet switch to which you can connect

devices such as servers, routers, and other switches.

• Switch Models, page 1-1

• Front Panel Description, page 1-1

• Rear Panel Description, page 1-5

• Management Options, page 1-8

Switch Models

Note All switch models support the Cisco TwinGig Converter Module.

CHAP T ER

1

Ta b l e 1-1 Catalyst 2350 Switch Models

Model Description

WS-C2350-48TD-S 48 10/100/1000 Ethernet ports, 2 10-Gigabit

WS-C2350-48TD-SD 48 10/100/1000 Ethernet ports, 2 10-Gigabit

Front Panel Description

The switch front panel includes the 10/100/1000 Ethernet ports, the 10-Gigabit Ethernet module slots,

and the switch LEDs.

the AC-powered and DC-powered switches have similar components.

Figure 1-1 shows the Catalyst 2350 switch with AC power as an example. Both

Ethernet X2 module slots, AC power

Ethernet X2 module slots, DC power

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

1-1

Page 12

Front Panel Description

Figure 1-1 Catalyst 2350 Switch Front Panel

1

X

2

X

1

11

X

13

X

1

2

X

1

3

X

2

3

X

2

5X

2

4

X

2

6

X

3

5

X

3

7

X

3

6X

3

8

X

4

7X

4

8X

2

3

Chapter 1 Overview

273892

1 Mode button and switch LEDs 3 10-Gigabit Ethernet module slots

2 10/100/1000 Ethernet ports and port

LEDs

1. For use with the Cisco TwinGig Converter Modules and Cisco X2 transceiver modules.

10/100/1000 Ethernet Ports

The 10/100/1000 Ethernet ports use standard RJ-45 connectors with Ethernet pinouts. The maximum

cable length is 328 feet (100 meters). The 100BASE-TX and 1000BASE-T traffic requires Category

Category

5e, or Category 6 unshielded twisted pair (UTP) cable. The 10BASE-T traffic can use Category

3 or Category 4 UTP cable.

For more information about the 10/100/1000 Ethernet port connections and specifications, see the

“10/100/1000 Ethernet Port Connections” section on page 2-16 and Appendix B, “Connector and Cable

Specifications.”

10-Gigabit Ethernet Module Slots

The switch 10-Gigabit Ethernet module slots are used for uplink connection to other switches and

routers. The module slots operate in full-duplex mode and use the hot-swappable Cisco X2 transceiver

modules and the Cisco TwinGig Converter Module.

For the list of supported X2 transceiver modules, see the switch release notes on Cisco.com.

http://www.cisco.com/en/US/products/ps10116/tsd_products_support_series_home.html

1

5,

For more information about the 10-Gigabit Ethernet module slots, see the “Installing Devices in

10-Gigabit Ethernet Slots” section on page 2-12. For cable specifications, see Appendix B, “Connector

and Cable Specifications.”

Cisco TwinGig Converter Module

The Cisco TwinGig Converter Module, also known as the converter module, has two SFP module slots

that convert a 10-Gigabit slot into a dual SFP module interface to establish Gigabit uplinks to network

devices.

Catalyst 2350 Switch Hardware Installation Guide

1-2

OL18479-01

Page 13

Chapter 1 Overview

SFP Modules

Front Panel Description

For more information about the Cisco TwinGig Converter Module, see the “Installing X2 Transceiver

and Converter Modules” section on page 2-12. For cable specifications, see Appendix B, “Connector

and Cable Specifications.”

The Gigabit Ethernet SFP modules connect to other devices and provide uplink interfaces when inserted

in an SFP module slot. The SFP modules have LC connectors for fiber-optic connections or RJ-45

connectors for copper connections. You can use any combination of these field-replaceable modules:

• 1000BASE-SX

• 1000BASE-T

The Catalyst 2350 switch supports the SFP module patch cable, a 0.5-meter, passive copper cable with

SFP module connectors at each end. The patch cable can connect two Catalyst 2350 switches in a

cascaded configuration.

For more information about SFP modules, see your SFP module documentation and the “Installing SFP

Modules” section on page 2-14. For cable specifications, see Appendix B, “Connector and Cable

Specifications.”

LEDs

You can use the switch LEDs to monitor switch activity and its performance. Figure 1-2 shows the switch

LEDs and the Mode button that you use to select one of the port modes.

Figure 1-2 Catalyst 2350 Switch LEDs

273893

2 3 4 51

1 Mode button 4 Status LED

2 Speed LED 5 System LED

3 Duplex LED

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

1-3

Page 14

Front Panel Description

System LED

The System LED shows whether the system is receiving power and is functioning properly.

Ta b l e 1-2 System LED

Color System Status

Off System is not powered on.

Green System is operating normally.

Amber System is receiving power but is not functioning properly.

For information on the System LED colors during power-on self-test (POST), see the “Diagnosing

Problems” section on page 4-1.

Port LEDs and Modes

Each Ethernet port and 10-Gigabit Ethernet module slot has a port LED. These port LEDs, as a group or

individually, display information about the switch and about the individual ports. The port mode

determines the type of information displayed through the port LEDs.

Chapter 1 Overview

To select or change a mode, press the Mode button until the desired mode is highlighted. When you

change port modes, the meanings of the port LED colors also change.

Ta b l e 1-3 Port Mode LEDs

Mode LED Port Mode Description

STAT Port status The port status. This is the default mode.

DUPLX Port duplex mode The port duplex mode: full duplex or half duplex.

Note The 10/100/1000 ports operate only in full-duplex

mode.

SPEED Port speed The port operating speed: 10, 100, or 1000 Mb/s.

Ta b l e 1-4 Meanings of Switch LED Colors in Different Modes

Port Mode Port LED Color Meaning

STAT

(port status)

Off No link, or port was administratively shut down.

Green Link present.

Blinking green Activity. Port is sending or receiving data.

Alternating

green-amber

Link fault. Error frames can affect connectivity, and errors such as

excessive collisions, CRC errors, and alignment and jabber errors

are monitored for a link-fault indication.

Amber Port is blocked by Spanning Tree Protocol (STP) and is not

forwarding data.

After a port is reconfigured, the port LED can remain amber for up

to 30 seconds as STP tests the switch for possible loops.

Blinking amber Port is blocked by STP and is sending or receiving packets.

1-4

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 15

Chapter 1 Overview

Table 1-4 Meanings of Switch LED Colors in Different Modes (continued)

Port Mode Port LED Color Meaning

DUPLX

(duplex)

SPEED

Off Port is operating in half duplex.

Green Port is operating in full duplex.

10/100/1000 ports

Off Port is operating at 10 Mb/s.

Green Port is operating at 100 Mb/s.

Blinking green Port is operating at 1000 Mb/s.

10-Gigabit Ethernet module slots

Off Port is not operating.

Blinking green Port is operating at up to 10 Gb/s.

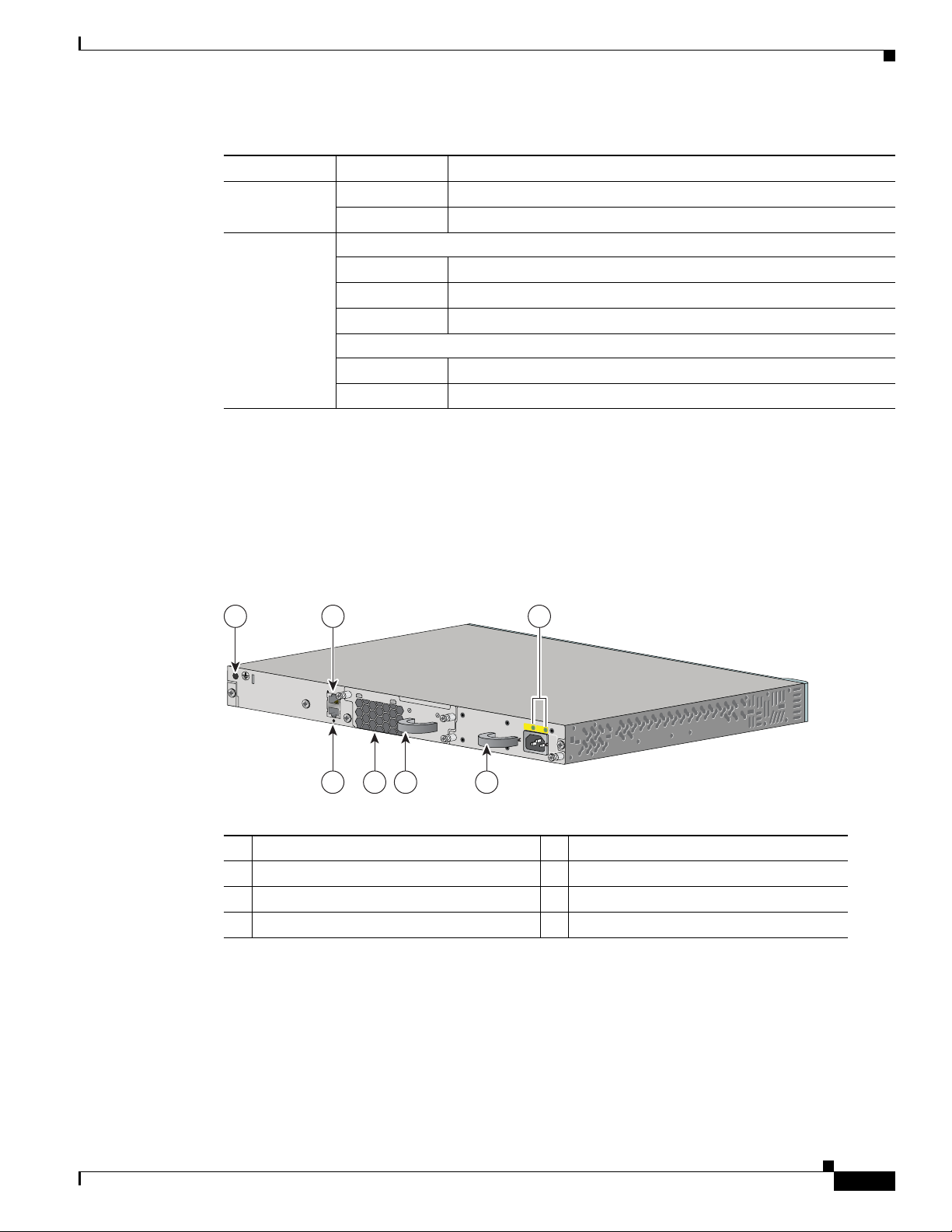

Rear Panel Description

Rear Panel Description

The switch rear panels have a ground location, a console port, a power-supply module, a fan module, and

a 10/100 management port.

Figure 1-3 shows the switch with AC power as an example. Both switches

have similar components.

Figure 1-3 Catalyst 2350 Switch Rear Panel

1 2

3

AC OK

PS OK

1

00-

~

2

4

0

V

1

.

0

-5A

5

0-6

0

H

Z

273894

567 4

1 Ground location 5 Fan module

2 Console port 6 Fan exhaust

3 Power-supply LEDs 7 Ethernet management port and LED

4 Power-supply module

Power-Supply Modules

The Catalyst 2350 switches are powered through an internal power-supply module. See the

“Catalyst 2350 Switch Power-Supply Modules” section on page 1-6 and Table 1-5.

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

1-5

Page 16

Rear Panel Description

Catalyst 2350 Switch Power-Supply Modules

The switches have one internal 265-W power-supply module (Tabl e 1-5). The 265-W AC-power-supply

module is an autoranging unit that supports input voltages between 100 and 240 VAC. The

DC-power-supply module has dual input feeds (A and B) and supports input voltages between 36 and 72

VDC.

The AC-power-supply module uses an 18-AWG power cord for connection to an AC power outlet. The

DC-power-supply module requires wiring to a DC-power source.

Ta b l e 1-5 Power-Supply Modules for the Catalyst 2350 Switch

Power-Supply Module WS-C2350-48TD-S WS-C2350-48TD-SD

C3K-PWR-265WAC= Spare or primary Not allowed

C3K-PWR-265WDC= Not allowed Primary or spare

The power-supply modules have two status LEDs.

Ta b l e 1-6 Power-Supply Module LEDs

Chapter 1 Overview

Fan Modules

AC-Power-Supply Module LEDs

AC OK Description PS OK Description

Off No AC input power. Off Power supply failure.

Green AC input power present. Green Power output to switch active.

DC-Power-Supply Module LEDs

DC IN Description PS OK Description

Off No DC input power. Off Power supply failure.

Green DC input power present. Green Power output to switch active.

For more information about replacing a power-supply module, wiring a DC-power-supply module, and

for module specifications, see

“Technical Specifications.”

The switch models has an internal hot-swappable 12-V fan module that inserts in the switch rear panel.

The air circulation system consists of the fan module and the power supply modules. The airflow patterns

vary depending on the power supply configuration.

Chapter 3, “Power Supply and Fan Module Installation,” and Appendix A,

1-6

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 17

Chapter 1 Overview

1

X

2

X

11

X

1

2

X

1

3

X

1

3

X

2

3

X

2

4

X

2

5

X

2

6

X

3

5

X

3

6

X

3

7

X

3

8

X

4

7

X

4

8

X

273895

The blue arrow shows cool air flow, and the red arrow shows warm air flow.

Figure 1-4 Catalyst 2350 Switch Airflow Patterns

For more information about installing a fan module and the module specifications, see Chapter 3,

“Power Supply and Fan Module Installation,” and Appendix A, “Technical Specifications.”

Management Ports

Rear Panel Description

You can connect the switch to a host such as a Windows workstation or a terminal server through the

10/100

Ethernet management port or the console port (shown in Figure 1-3). The 10/100 Ethernet

management port connection uses a standard RJ-45 crossover or straight-through cable. The console port

connection uses the supplied RJ-45-to-DB-9 female cable.

Ta b l e 1-7 Ethernet Management Port LED

Color Description

Green Active link to PC

Off Inactive link

Amber POST failure

For more information about the switch management ports, see the switch software configuration guide

and the command reference on Cisco.com and the

“Connector and Cable Specifications” section on

page B-1.

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

1-7

Page 18

Management Options

Management Options

• Device manager

You can use the device manager, which is in the switch memory, to manage the switch. This web

interface offers quick configuration and monitoring. You can access the device manager from

anywhere in your network through a web browser. For more information, see the getting started

guide and the device manager online help.

• Cisco IOS CLI

The switch CLI is based on Cisco IOS software and is enhanced to support desktop-switching

features. You can fully configure and monitor the switch from the CLI. You can access the CLI either

by connecting your management station directly to the switch management port or a console port or

by using Telnet from a remote management station. See the switch command reference on

Cisco.com for more information.

• CiscoWorks application

The CiscoWorks LAN Management Solution (LMS) is a suite of management tools for configuring,

administering, monitoring, and troubleshooting Cisco networks. For more information, see the

CiscoWorks LMS documentation on Cisco.com:

Chapter 1 Overview

http://www.cisco.com/en/US/products/sw/cscowork/ps2425/tsd_products_support_series_home.ht

ml

• Cisco Network Assistant

Cisco Network Assistant is a PC-based network management GUI application that enables

centralized management of Cisco switches. Cisco Network Assistant is available at no cost and can

be downloaded from this URL:

http://www.cisco.com/go/networkassistant

For information on starting the Network Assistant application, see the Getting Started with Cisco

Network Assistant guide on Cisco.com.

Network Configurations

See the switch software configuration guide on Cisco.com for network configuration concepts and

examples of using the switch to create dedicated network segments and interconnecting the segments

through Gigabit Ethernet connections.

1-8

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 19

CHAP T ER

2

Switch Installation

Read the topics and perform the procedures in this order:

• Preparing for Installation, page 2-1

• Installing the Switch, page 2-6

• Installing Devices in 10-Gigabit Ethernet Slots, page 2-12

• Installing SFP Modules, page 2-14

• Connecting Devices to the Ethernet Ports, page 2-16

• Where to Go Next, page 2-17

For initial switch setup, how to assign the switch IP address, and for powering information, see the

switch getting started guide on Cisco.com.

http://www.cisco.com/en/US/docs/switches/lan/catalyst2350/hardware/quick/guide/18478.html

Preparing for Installation

• Safety Warnings, page 2-1

• Installation Guidelines, page 2-5

• Box Contents, page 2-5

• Tools and Equipment, page 2-6

Safety Warnings

This section provides the basic installation caution and warning statements. Translations of the warning

statements appear in the Regulatory Compliance and Safety Information for the Catalyst

document that shipped with the switch and online at Cisco.com. Read this section before you start the

installation procedure.

Warning

To prevent the switch from overheating, do not operate it in an area that exceeds the maximum

recommended ambient temperature of 113•F (45•C). To prevent airflow restriction, allow at least

3 inches (7.6 cm) of clearance around the ventilation openings.

2350 Switch

Statement 17B

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

2-1

Page 20

Preparing for Installation

Chapter 2 Switch Installation

Warning

Warning

Warning

Warning

Warning

Warning

Before working on equipment that is connected to power lines, remove jewelry (including rings,

necklaces, and watches). Metal objects will heat up when connected to power and ground and can

cause serious burns or weld the metal object to the terminals.

Statement 43

Do not stack the chassis on any other equipment. If the chassis falls, it can cause severe bodily injury

and equipment damage.

Statement 48

An exposed wire lead from a DC-input power source can conduct harmful levels of electricity. Be sure

that no exposed portion of the DC-input power source wire extends from the terminal block plug.

Statement 122

Ethernet cables must be shielded when used in a central office environment.

Statement 171

Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed

circuitry could constitute an energy hazard.

Statement 206

Read the wall-mounting instructions carefully before beginning installation. Failure to use the

correct hardware or to follow the correct procedures could result in a hazardous situation to people

and damage to the system.

Statement 378

Warning

Warning

Warning

Do not work on the system or connect or disconnect cables during periods of lightning activity.

Statement 1001

Before performing any of the following procedures, ensure that power is removed from the DC circuit.

Statement 1003

Read the installation instructions before connecting the system to the power source.

Statement 1004

2-2

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 21

Chapter 2 Switch Installation

Preparing for Installation

Warning

Warning

Warning

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special

precautions to ensure that the system remains stable. The following guidelines are provided to

ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest

component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in

the rack.

Class 1 laser product.

Statement 1006

Statement 1008

This unit is intended for installation in restricted access areas. A restricted access area can be

accessed only through the use of a special tool, lock and key, or other means of security.

Statement 1017

The plug-socket combination must be accessible at all times, because it serves as the main

disconnecting device.

Statement 1019

Warning

Warning

Warning

Warning

Warning

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection

authority or an electrician if you are uncertain that suitable grounding is available.

Statement 1024

This unit might have more than one power supply connection. All connections must be removed to

de-energize the unit.

Statement 1028

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

Ultimate disposal of this product should be handled according to all national laws and regulations.

Statement 1040

For connections outside the building where the equipment is installed, the following ports must be

connected through an approved network termination unit with integral circuit protection: 10/100/1000

Ethernet.

Statement 1044

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

2-3

Page 22

Preparing for Installation

Chapter 2 Switch Installation

Warning

Warning

When installing or replacing the unit, the ground connection must always be made first and

disconnected last.

Installation of the equipment must comply with local and national electrical codes.

Statement 1046

Statement 1074

Statement 371—Power Cable and AC Adapter

Caution To comply with the Telcordia GR-1089 Network Equipment Building Systems (NEBS) standard for

electromagnetic compatibility and safety, connect the Ethernet cables only to intrabuilding or

nonexposed wiring or cabling.

Caution To comply with the Telcordia GR-1089 NEBS standard, PoE or non-PoE 10/100/1000 Ethernet port

cables that exit from either the left side or right side of the switch should be routed and tied to the nearest

rack metal hardware.

Note The grounding architecture of this product is DC-isolated (DC-I).

2-4

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 23

Chapter 2 Switch Installation

Installation Guidelines

Before installing the switch, verify that these guidelines are met:

• Clearance to front and rear panels is such that

–

Front-panel indicators can be easily read.

–

Access to ports is sufficient for unrestricted cabling.

–

AC power cord can reach from the AC power outlet to the connector on the switch rear panel.

–

The X2-10GB-CX4 transceiver module minimum bend radius and connector length is met. See

the X2 transceiver module documentation for more information.

• If you do not have access to the rear panel, you should cable the switches before you rack-mount

them.

• Tighten the captive screws on power-supply modules and fan modules before moving the switch.

• When connecting or disconnecting the power cord on a switch that is installed above or below a

1150-W power supply-equipped switch, you might need to remove the module from the switch to

access the power cord.

• Cabling is away from sources of electrical noise, such as radios, power lines, and fluorescent

lighting fixtures. Make sure that the cabling is safely away from other devices that might damage

the cables.

Preparing for Installation

• For copper connections on Ethernet ports, cable lengths from the switch to connected devices can

be up to 328 feet (100

• For cable requirements for X2 module connections, see the “Cable and Adapter Specifications”

meters).

section on page B-4. Each port must match the wave-length specifications on the other end of the

cable, and the cable must not exceed the required cable length.

• Operating environment is within the ranges listed in Appendix A, “Technical Specifications.”

• Airflow around the switch and through the vents is unrestricted.

• Temperature around the unit does not exceed 113°F (45°C). If the switch is installed in a closed or

multirack assembly, the temperature around it might be greater than normal room temperature.

• Cisco Ethernet Switches are equipped with cooling mechanisms, such as fans and blowers. However,

these fans and blowers can draw dust and other particles, causing contaminant buildup inside the

chassis, which can result in system malfunction. You must install this equipment in an environment

as free from dust and foreign conductive material (such as metal flakes from construction activities)

as is possible.

These standards provide guidelines for acceptable working environments and acceptable levels of

suspended particulate matter:

–

Network Equipment Building Systems (NEBS) GR-63-CORE

–

National Electrical Manufacturers Association (NEMA) Type 1

–

International Electrotechnical Commission (IEC) IP-20

Box Contents

OL18479-01

The box contents are described in the switch getting started guide. If any item is missing or damaged,

contact your Cisco representative or reseller for support.

Catalyst 2350 Switch Hardware Installation Guide

2-5

Page 24

Installing the Switch

Tools and Equipment

You need to supply a number-2 Phillips screwdriver to rack-mount the switch.

Installing the Switch

• Rack-Mounting, page 2-6

• Table- or Shelf-Mounting, page 2-11

• After Installing the Switch, page 2-11

The illustrations shown in this section show the Catalyst 2350 switch with AC power as an example. You

can install both models of the Catalyst

Rack-Mounting

To install the switch in a 19-inch rack, follow the instructions described in this section.

Chapter 2 Switch Installation

2350 switch following the same procedures.

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special

precautions to ensure that the system remains stable. The following guidelines are provided to

ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest

component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in

the rack.

Statement 1006

2-6

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 25

Chapter 2 Switch Installation

Installing the switch in other rack types requires an optional bracket kit not included with the switch.

Figure 2-1 shows the standard 19-inch brackets and optional mounting brackets and part numbers.

Figure 2-1 Rack-Mounting Brackets

1

2

Installing the Switch

3

4

1 19-inch brackets, part number RCKMNT-E-1RU=

2 23-inch brackets, part number RCKMNT-E-MISC=

3 24-inch brackets, part number RCKMNT-E-MISC=

4 ETSI brackets, part number RCKMNT-E-MISC=

202363

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

2-7

Page 26

Installing the Switch

Attaching the Rack-Mount Brackets

You must first remove the screws from the switch chassis so that the mounting brackets can be attached.

For a front-mounting position, remove two Phillips truss-head screws from the switch side panels

(

Figure 2-2). For a mid-mounting position, remove one screw. For a rear-mounting position, remove two

screws.

Figure 2-2 Removing Screws from the Switch

Chapter 2 Switch Installation

47X

48X

205608

2-8

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 27

Chapter 2 Switch Installation

AC OK

PS OK

100-240V

~

1.0-5A

50-60 HZ

Use four Phillips flat-head screws to attach the long side of the brackets to the switch for front- or

rear-mounting (

Figure 2-3 Attaching Brackets for 19-inch Racks

Installing the Switch

Figure 2-3). Use three screws to attach the brackets for mid-mounting.

1

47X

48X

2

3

47X

48X

2

4

205609

2

1 Front-mounting position 3 Mid-mounting position

2 Number-8 Phillips flat-head screws 4 Rear-mounting position

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

2-9

Page 28

Installing the Switch

1X

2X

11X

12X

13X

13X

23X

24X

25X

26X

35X

36X

37X

38X

47X

48X

1X

2X

11X

12X

13X

13X

23X

24X

25X

26X

35X

36X

37X

38X

47X

48X

AC OK

PS OK

100-240V

~

1.0-5A

50-60 HZ

205610

2 3

5

4

6

4

4

1

Mounting the Switch in a Rack

After the brackets are attached to the switch, use the four supplied Phillips machine screws to attach the

brackets to the rack (

left or right bracket.

When you complete the switch installation, see the “After Installing the Switch” section on page 2-11

for more information switch configuration.

Figure 2-4 Mounting the Switch in a Rack

Chapter 2 Switch Installation

Figure 2-4). Use the black Phillips machine screw to attach the cable guide to the

1 Phillips machine screw, black 4 Number-12 Phillips machine screws

2 Cable guide 5 Mid-mounting position

3 Front-mounting position 6 Rear-mounting position

2-10

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 29

Chapter 2 Switch Installation

Table- or Shelf-Mounting

Locate the adhesive strip with the rubber feet in the mounting-kit envelope. Attach the four rubber feet

to the recessed areas on the bottom of the chassis.

Remove two Phillips truss-head screws from the switch side panels and use those screws to attach the

brackets to the switch (

hardware.

Caution Do not use the 19-inch brackets to wall-mount the switch. The brackets are not suitable for

wall-mounting.

Figure 2-5 Attaching the 19-inch Brackets for Table- or Shelf-Mounting

Installing the Switch

Figure 2-5). Secure the brackets to the table or shelf with the appropriate

1

1 User-supplied screws 2 Phillips truss-head screws

When you complete the switch installation, see the “After Installing the Switch” section on page 2-11

for more information switch configuration.

After Installing the Switch

You might need to:

• Configure the switch by running Express Setup to enter the initial switch configuration. For

instructions, see the switch getting started guide that shipped with the switch and also on Cisco.com.

• Use the CLI setup program to enter the initial switch configuration. See Appendix C, “Configuring

the Switch with the CLI-Based Setup Program.”

• Connect to the front-panel ports. See the “Installing Devices in 10-Gigabit Ethernet Slots” section

on page 2-12 and the “Connecting Devices to the Ethernet Ports” section on page 2-16.

AC OK

P

S OK

1

0

0

~

2

4

0

V

1

.

0

-5A

5

0

-60

H

Z

273897

2

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

2-11

Page 30

Installing Devices in 10-Gigabit Ethernet Slots

Installing Devices in 10-Gigabit Ethernet Slots

These sections describe how to install and remove X2 transceiver converter modules.

Use only Cisco X2 transceiver modules, converter modules, and SFP modules with the switch. Each

Cisco module has an internal serial EEPROM that is encoded with security information. This encoding

provides a way for Cisco to identify and validate that the module meets the requirements for the switch.

For more information about installing, removing, cabling, and troubleshooting X2 transceiver modules,

see the module documentation that shipped with your device. For module cable specifications, see

Appendix B, “Connector and Cable Specifications.”

Installing X2 Transceiver and Converter Modules

• When you install or remove the converter module, the mode on the switch changes from 10-Gigabit

Ethernet to Gigabit Ethernet or the reverse. During this mode change, data traffic on the other switch

uplink ports (X2 transceiver or SFP module ports) might temporarily stop. When you install or

remove an X2 transceiver or SFP module, traffic delay does not occur.

• Do not remove the EMC plug from the 10-Gigabit Ethernet slot until you are ready to install an X2

transceiver or a converter module. Either a module or an EMC plug must be installed in the slot at

all times.

• Do not remove the dust plugs from the fiber-optic X2 transceiver modules or the rubber caps from

the fiber-optic cable until you are ready to connect the cable. The plugs and caps protect the module

ports and cables from contamination and ambient light.

• Removing and installing an X2 module can shorten its useful life. Do not remove and insert any X2

module more often than is absolutely necessary.

Chapter 2 Switch Installation

• To prevent ESD damage, follow your normal board and component handling procedures when

connecting cables to the switch and other devices.

Step 1 Attach an ESD-preventive wrist strap to your wrist and to a bare metal surface.

Step 2 Remove the module from the protective packaging.

Step 3 Remove the 10-Gigabit Ethernet module slot EMC plug and save.

Caution Verify the correct orientation of your module before inserting it into the slot. Incorrect insertion can

damage the module.

Step 4 Position the module face up to install in the upper module slot (slot 1). Position the module face down

to install in the lower module slot (slot 2). Slide the module into the opening until the back of the module

faceplate is flush with the switch faceplate.

Caution Do not insert or remove an X2 transceiver module with fiber-optic cables still attached. An X2 module

interface might change to error disabled when a module is inserted or removed with the fiber-optic cables

still connected. If the interface is error disabled, you can re-enable the interface by using the shutdown

and no shutdown interface configuration commands.

2-12

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 31

Chapter 2 Switch Installation

47X

48X

273998

1

2

47X

48X

273999

1

2

Figure 2-6 Installing X2 Transceiver Modules in Catalyst 2350 Switches

1 Module inserted face up 2 Module inserted face down

Installing Devices in 10-Gigabit Ethernet Slots

Caution Do not install the converter module with SFP modules or cables connected. Always remove any cables

and modules before installing the converter module in the slot.

Figure 2-7 Installing Converter Modules in Catalyst 2350 Switches

1 Module inserted face up 2 Module inserted face down

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

2-13

Page 32

Installing SFP Modules

Removing an X2 Transceiver or Converter Module

Step 1 Attach an ESD-preventive wrist strap to your wrist and to a bare metal surface.

Caution Do not insert or remove an X2 transceiver module with fiber-optic cables still attached. An X2 module

interface might change to error disabled when a module is inserted or removed with the fiber-optic cables

still connected. If the interface is error disabled, you can re-enable the interface by using the shutdown

and no shutdown interface configuration commands.

Step 2 For X2 transceiver modules, disconnect the cables from the module. For fiber-optic modules, install the

optical bore dust plugs.

Caution Do not remove the converter module with SFP modules or cables installed. Always remove any cables

and modules before removing the converter module from the slot.

Step 3 For converter modules, disconnect the cables from the SFP module. Remove the SFP modules from the

converter module.

Step 4 Carefully pull on the X2 module sleeve, or pinch the tabs on the converter module to disengage it from

the slot. Grasp the edges of the module, and carefully slide it out of the slot.

Chapter 2 Switch Installation

Step 5 Reinstall a replacement module or an EMC plug in the 10-Gigabit Ethernet slot.

Step 6 Place the module in an antistatic bag or other protective environment.

Installing SFP Modules

This section describes how to install and remove SFP modules in the switch and the Cisco TwinGig

Converter Module slots. To use SFP modules, you must have a converter module installed in a 10-Gigabit

Ethernet slot.

See the “SFP Modules” section on page 1-3 and the switch release notes on Cisco.com for the list of

supported SFP modules. Use only Cisco SFP modules on the switch. Each Cisco module has an internal

serial EEPROM that is encoded with security information. This encoding provides a way for Cisco to

identify and validate that the module meets the requirements for the switch.

For more information about installing, removing, cabling, and troubleshooting SFP modules, see the

module documentation that shipped with your device. For module cable specifications, see

“Connector and Cable Specifications.”

Appendix B,

2-14

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 33

Chapter 2 Switch Installation

47X

48X

Installing an SFP Module

Observe these general precautions:

• Do not remove the dust plugs from the SFP modules or the rubber caps from the fiber-optic cable

until you are ready to connect the cable. The plugs and caps protect the module ports and cables

from contamination and ambient light.

• Removing and installing an SFP module can shorten its useful life. Do not remove and insert any

SFP module more often than is absolutely necessary.

• To prevent ESD damage, follow your normal board and component handling procedures when

connecting cables to the switch and other devices.

Step 1 Attach an ESD-preventive wrist strap to your wrist and to a bare metal surface.

Caution To avoid damage to the converter module, first install the converter module in the switch 10-Gigabit

Ethernet slot before installing the SFP modules.

Step 2 For switches without SFP module slots, install a converter module in the 10-Gigabit Ethernet module

slot as described in the

Step 3 Find the send (TX) and receive (RX) markings that identify the top of the SFP module.

Installing SFP Modules

“Installing X2 Transceiver and Converter Modules” section on page 2-12.

On some SFP modules, the send and receive (TX and RX) markings might be replaced by arrows that

show the direction of the connection, either send or receive (TX or RX).

Step 4 If the SFP module has a bale-clasp latch, move it to the open, unlocked position.

Step 5 Position the SFP module face up to install in the upper converter module slot (slot 1). Position the

module face down to install in the lower converter module slot (slot 2). See

Step 6 If the module has a bale-clasp latch, close it to lock the SFP module in place.

Step 7 Remove the SFP module dust plugs and save.

Step 8 Connect the SFP module cables.

Figure 2-8 Converter Module with SFP Modules Installed in Catalyst 2350 Switch

Figure 2-8.

3 4

2

1

274000

4 3

OL18479-01

1 Converter modules 3 Send (TX) optical bore

2 SFP modules

1. Lower SFP modules are inverted (face down).

1

4 Receive (RX) optical bore

Catalyst 2350 Switch Hardware Installation Guide

2-15

Page 34

Connecting Devices to the Ethernet Ports

Removing an SFP Module

Step 1 Attach an ESD-preventive wrist strap to your wrist and to a bare metal surface.

Step 2 Disconnect the cable from the SFP module. For reattachment, note which cable connector plug is send

(TX) and which is receive (RX).

Step 3 Insert a dust plug into the optical ports of the SFP module to keep the optical interfaces clean.

Step 4 If the module has a bale-clasp latch, pull the bale out and down to eject the module. If the bale-clasp

latch is obstructed and you cannot use your index finger to open it, use a small, flat-blade screwdriver

or other long, narrow instrument to open the bale-clasp latch.

Step 5 Grasp the SFP module, and carefully remove it from the module slot.

Step 6 Place the SFP module in an antistatic bag or other protective environment.

Connecting Devices to the Ethernet Ports

Chapter 2 Switch Installation

• 10/100/1000 Ethernet Port Connections, page 2-16

• Where to Go Next, page 2-17

Caution Category 5e and Category 6 cables can store high levels of static electricity. Always ground the cables

to a suitable and safe earth ground before connecting them to the switch or other devices.

10/100/1000 Ethernet Port Connections

The 10/100/1000 Ethernet ports use standard RJ-45 connectors with Ethernet pinouts. The maximum

cable length is 328 feet (100 meters). The 100BASE-TX and 1000BASE-T traffic requires Category

Category

The autonegotiation feature is enabled by default. The switch ports configure themselves to operate at

the speed of an attached device. If the device does not support autonegotiation, you can explicitly set the

switch port speed and duplex parameters. To maximize performance, either let the ports autonegotiate

both speed and duplex, or set the port speed and duplex parameters on both ends of the connection.

The automatic medium-dependent interface crossover (auto-MDIX) feature is enabled by default. The

switch detects the required cable type for copper Ethernet connections and configures the interface

accordingly. You can use either a crossover or a straight-through cable for connections to a switch

10/100/1000 Ethernet port, regardless of the type of connected device.

See the switch software configuration guide or the switch command reference on Cisco.com for more

information about enabling or disabling autonegotiation and auto-MDIX.

If auto-MDIX is disabled, use Tabl e 2-1 to select the correct cable for connecting the switch 10/100/1000

Ethernet ports to other devices. See the “Cable and Adapter Specifications” section on page B-4 for

cable-pinout descriptions.

5e, or Category 6 UTP cable. The 10BASE-T traffic can use Category 3 or Category 4 cable.

5,

2-16

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 35

Chapter 2 Switch Installation

Ta b l e 2-1 Recommended Ethernet Cables When Auto-MDIX is Disabled

Where to Go Next

Device Crossover Cable

Switch to switch Ye s No

Switch to hub Yes No

Switch to computer or server No Ye s

Switch to router No Ye s

1. 100BASE-TX and 1000BASE-T traffic requires twisted four-pair, Category 5, Category 5e, or

Category 6 cable. 10BASE-T traffic uses Category 3 or Category 4 cable.

Where to Go Next

If the default configuration is satisfactory, the switch does not need further configuration. You can use

any of these management options to change the default configuration:

• Start the device manager, which is in the switch memory, to manage individual and standalone

switches. This is a web interface that offers quick configuration and monitoring. You can access the

device manager from anywhere in your network through a web browser. For more information, see

the switch getting started guide and the device manager online help.

• Use the CLI to configure the switch from the console. See the switch command reference on

Cisco.com for information on using the CLI with the switch.

• Use CiscoWorks LAN Management Solution (LMS), a suite of management tools for configuring,

administering, monitoring, and troubleshooting Cisco networks. For more information, see the

CiscoWorks LMS documentation on Cisco.com.

• Start the Network Assistant application, which is described in the Getting Started with Cisco

Network Assistant guide. Through this GUI, you can configure and monitor one or more switches.

1

Straight-Through Cable

1

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

2-17

Page 36

Where to Go Next

Chapter 2 Switch Installation

2-18

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 37

Power Supply and Fan Module Installation

• Installation Overview, page 3-1

• Installing an AC-Power Supply, page 3-3

• Installing a DC-Power Supply, page 3-4

• Installing a Fan Module, page 3-8

Installation Overview

• Tools and Equipment, page 3-1

• Installation Guidelines, page 3-1

Tools and Equipment

CHAP T ER

3

• Ratcheting torque screwdriver with a number-2 Phillips head that exerts up to 15 pound-force inches

(lbf-in) or 240 ounce-force inches (ozf-in) of pressure.

• Power-supply power-cord retainer assembly in the switch accessory kit.

Installation Guidelines

Table 1-5 lists the compatible power-supply modules.

• Do not force the power supply or fan module into the slot. This can damage the pins on the switch

if they are not aligned with the module.

• A power supply or fan module that is only partially connected to the switch can disrupt the system

operation.

• Remove power from the power-supply module before removing or installing the module.

• The switch supports hot swapping of a fan module. When replacing a fan, you should complete the

replacement procedure within 2 minutes to avoid overheating the switch.

• Make sure that all power supply and fan module captive screws are tightened before moving the

switch.

• When replacing the switch 750-W power supply, verify that you are using the correct power cord

(CAB-16AWG-AC, only in North America).

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

3-1

Page 38

Installation Overview

Chapter 3 Power Supply and Fan Module Installation

Warning

Warning

Warning

Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed

circuitry could constitute an energy hazard.

Statement 206

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

Do not work on the system or connect or disconnect cables during periods of lightning activity.

Statement 1001

3-2

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 39

Chapter 3 Power Supply and Fan Module Installation

AC O

K

PS OK

100-

240V

~

1.

0-

5A

50-

60 HZ

273900

Installing an AC-Power Supply

Step 1 Turn off the power at its source.

Step 2 If used, detach the power cord retainer assembly from the power cord.

Step 3 Remove the power cord from the power connector.

Step 4 Use a Phillips screwdriver to loosen the two captive screws at the lower edge of the module that secure

it to the switch chassis (

Step 5 Remove the power-supply module from the power slot by pulling on the extraction handle.

Step 6 Insert the new power supply into the power-supply slot, and gently push it in (Figure 3-1). When

correctly inserted, the power supply is flush with the switch rear panel.

Figure 3-1 Inserting the AC-Power Supply in Catalyst 2350 Switches

Figure 3-1).

Installing an AC-Power Supply

273899

A

C

OK

P

S

OK

100

~

2

4

0

V

1.05

A

50-

60

H

Z

Step 7 Align the two captive screws with the screw holes. Using a ratcheting torque screwdriver, torque each

screw to 7

lbf-in (112 ozf-in).

Step 8 (Optional) Assemble the AC power cord retainer with the large end of the plastic bushing facing away

from the switch. Position the assembly on the power cord, and insert the wire bales into the slots on the

switch rear panel (

Figure 3-2 AC-Power Supply with Power Cord Retainer

Step 9 Connect the power cord to the power supply and to an AC-power outlet. Turn on the power at the power

source. Confirm that the power supply AC OK LED is green. See

Figure 3-2).

Table 1-6 for a description of the

module LEDs.

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

3-3

Page 40

Installing a DC-Power Supply

Installing a DC-Power Supply

1. Preparing for Installation, page 3-4

2. Grounding the Switch, page 3-5

3. Installing the DC Power Supply in the Switch, page 3-6

4. Wiring the DC-Input Power Source, page 3-7

Chapter 3 Power Supply and Fan Module Installation

Warning

Warning

Warning

Warning

Note The grounding architecture of this product is DC-isolated (DC-I)

An exposed wire lead from a DC-input power source can conduct harmful levels of electricity. Be sure

that no exposed portion of the DC-input power source wire extends from the terminal block plug.

Statement 122

Before connecting or disconnecting ground or power wires to the chassis, ensure that power is

removed from the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel

board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch

handle of the circuit breaker in the OFF position. Use a voltmeter to test for 0 (zero) voltage at the

power terminals on the chassis.

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that

the protective device is rated not greater than: 15 A.

A readily accessible two-poled disconnect device must be incorporated in the fixed wiring.

Statement 1022

Statement 196

Statement 1005

Preparing for Installation

• Ratcheting torque screwdriver with a number-2 and a number-1 Phillips head that exerts up to

15

pound-force inches (lbf-in) or 240 ounce-force inches (ozf-in) of pressure.

• Panduit crimping tool with optional controlled-cycle mechanism (model CT-720, CT-920,

CT-920CH, CT-930, or CT-940CH).

• Wire-stripping tools.

• 12-gauge copper ground wire (insulated or noninsulated) when using the single-ground connection.

• 6-gauge copper ground wire (insulated or noninsulated) when using the dual-ground connection.

• Ground lug screw and lug ring in the switch accessory kit. For a dual-ground connection, also use

the dual-ground adaptor and dual-hole lug from the DC power supply accessory kit.

• Four leads of 16-gauge copper wire.

• Four round eyelet terminals or four fork-type terminals from the DC power supply accessory kit.

Catalyst 2350 Switch Hardware Installation Guide

3-4

OL18479-01

Page 41

Chapter 3 Power Supply and Fan Module Installation

Insulation

Wire lead

0.5 in. (12.7 mm) ± 0.02 in. (0.5 mm)

60528

200044

Grounding the Switch

To make sure that the equipment is reliably connected to earth ground, follow the grounding procedure

instructions and observe these warnings:

Installing a DC-Power Supply

Warning

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection

Warning

authority or an electrician if you are uncertain that suitable grounding is available.

When installing or replacing the unit, the ground connection must always be made first and

disconnected last.

Statement 1046

Statement 1024

Follow any grounding requirements at your site.

Step 1 Locate the ground lug screw and the lug ring in the switch accessory kit. For a dual-ground connection,

locate the dual-ground adaptor and dual-hole lug that ships with the DC-power-supply module.

Step 2 If your ground wire is insulated, use a wire stripping tool to strip the 12-gauge or 6-gauge ground wire

to 0.5

inch (12.7 mm) ± 0.02 inch (0.5 mm) (Figure 3-3). Use 12-gauge copper ground wire for the

single-ground connection. Use 6-gauge copper ground wire for the dual-ground connection.

Figure 3-3 Stripping the Ground Wire

Step 3 Slide the open end of the ground lug over the exposed area of the wire.

Step 4 Using a Panduit crimping tool, crimp the ground lug to the wire (Figure 3-4).

Figure 3-4 Crimping the Ground Lug

Step 5 Use the ground screw to attach the single-ground lug and the wire assembly or the dual-ground adaptor

to the switch rear panel. For a dual-ground adaptor, attach the dual-hole lug and the wire assembly to the

adaptor with the supplied nuts (

OL18479-01

Figure 3-5).

Catalyst 2350 Switch Hardware Installation Guide

3-5

Page 42

Installing a DC-Power Supply

Step 6 Using a ratcheting torque screwdriver, torque the ground-lug screws to 60 lbf-in (960 ozf-in)

(

Figure 3-5).

Step 7 Connect the other end of the grounding wire to an appropriate grounding point at your site or to the rack.

Figure 3-5 Attaching the Ground Lug and Wire Assembly on Catalyst 2350 Switches

Chapter 3 Power Supply and Fan Module Installation

1

2

273901

1 Single-ground screw and lug ring.

Used with AC power supply.

Installing the DC Power Supply in the Switch

Step 1 Turn off power at the DC circuits. Locate the circuit breakers for the DC circuits, switch the circuit

breakers to the OFF position, and tape the circuit-breaker switches in the OFF position.

Step 2 Use a number-2 Phillips screwdriver to remove the plastic safety cover from the power supply terminal

blocks.

Step 3 Use a number-1 Phillips screwdriver to remove the DC-input power wires from the power terminals.

Step 4 Use a Phillips screwdriver to loosen the two captive screws at the lower edge of the module that secure

it to the switch chassis.

Step 5 Remove the power-supply module from the power slot by pulling on the extraction handle.

Step 6 Insert the new power supply into the power-supply slot, and gently push it in (Figure 3-6). When

correctly inserted, the power supply is flush with the switch rear panel.

2 Dual-ground adaptor and dual-hole lug.

Used with DC power supply.

3-6

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 43

Chapter 3 Power Supply and Fan Module Installation

B+

157718

B-

+

A+

A-

+

Figure 3-6 Inserting the DC-Power Supply in Catalyst 2350 Switches

Installing a DC-Power Supply

Step 7 Align the two captive screws with the screw holes. Using a ratcheting torque screwdriver, torque each

screw to 7 lbf-in (112 ozf-in).

Step 8 Connect the input power as described in the “Wiring the DC-Input Power Source” section.

Wiring the DC-Input Power Source

Step 1 Using a wire-stripping tool, strip each of the four wires coming from the DC-input power source to the

appropriate length for either the round eyelet or the fork-type terminals.

Step 2 Using a Panduit crimping tool, crimp the terminals to the 16-gauge DC-power input wires.

Step 3 Connect the DC-input power terminals to the terminal blocks as shown in Figure 3-7. Make sure to

match the polarity (negative to negative, positive to positive) when connecting the wires to the terminal

blocks.

Figure 3-7 DC Source A Isolated From Source B with No Common Ground, Catalyst 2350

Switches

FRU C

273902

D

C

IN

C 2

6

5

W

A

PS

OK

A

+

I

NP

UT

+

-3

6

to

-72

V

/

1

2

A

O

UT

P

UT

2

6

5

W

MAX

/

2

2

A

Step 4 Torque all terminal block screws to 5 lbf-in (80 ozf-in).

Step 5 Replace the terminal block plastic safety cover. Torque the safety-cover screw to 10 lbf-in (160 ozf-in).

Step 6 Move the DC-power source circuit-breaker handles to the ON position.

Step 7 Confirm that the power-supply DC OK LED is green. See Tab l e 1-6 for a description of the module

OL18479-01

LEDs.

Catalyst 2350 Switch Hardware Installation Guide

3-7

Page 44

Installing a Fan Module

A

C

OK

PS

OK

1

0

0-

2

4

0

V

~

1

.

0

-5A

5

0

60

HZ

273903

Installing a Fan Module

Step 1 Use a number-2 Phillips screwdriver to loosen the two captive screws that secure the fan module to the

switch chassis.

Caution You should replace the fan module within 2 minutes to avoid overheating the switch.

Step 2 Remove the fan module by pulling on the extraction handle.

Step 3 Insert the new fan module into the fan slot, and gently push it in (Figure 3-8). When correctly inserted,

the fan module is flush with the switch rear panel.

Step 4 Align the two captive screws with the screw holes in the switch rear panel. Using a ratcheting torque

screwdriver, torque each screw to 5 lbf-in (80 ozf-in).

Chapter 3 Power Supply and Fan Module Installation

Warning

Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed

circuitry could constitute an energy hazard.

Statement 206

Figure 3-8 Inserting the Fan Module in Catalyst 2350 Switches

3-8

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01

Page 45

Troubleshooting

• Diagnosing Problems, page 4-1

• Clearing the Switch IP Address and Configuration, page 4-4

• Finding the Switch Serial Number, page 4-5

Diagnosing Problems

The LEDs on the front panel provide troubleshooting information about the switch. They show POST

failures, port-connectivity problems, and overall switch performance. You can also get statistics from the

device manager, from the CLI, or from an SNMP workstation. See the software configuration guide, the

switch command reference guide on Cisco.com, or the documentation that came with your SNMP

application for details.

CHA P T ER

4

Switch POST Results

As the switch powers on, it begins the power-on self-test (POST), a series of tests that runs automatically

to ensure that the switch functions properly. It might take several minutes for the switch to complete

POST.

When the switch begins POST, the switch status LEDs turn green. The System LED blinks green, and

the other LEDs remain solid green.

When POST completes successfully, the System LED stays green. The other LEDs turn off and return

to their operating status. If the switch fails POST, the System LED is amber.

Note POST failures are usually fatal. Contact your Cisco technical support representative if your switch does

not pass POST.

Switch LEDs

If you have physical access to the switch, look at the port LEDs for troubleshooting information about

the switch. See the

“LEDs” section on page 1-3 for a description of the LED colors and their meanings.

OL18479-01

Catalyst 2350 Switch Hardware Installation Guide

4-1

Page 46

Diagnosing Problems

Switch Connections

Bad or Damaged Cable

Always examine the cable for marginal damage or failure. A cable might be just good enough to connect

at the physical layer, but it could corrupt packets as a result of subtle damage to the wiring or connectors.

You can identify this situation because the port has many packet errors or the port constantly flaps (loses

and regains link).

• Examine or replace the copper or fiber-optic cable with a known, good cable.

• Look for broken or missing pins on cable connectors.

• Rule out any bad patch panel connections or media convertors between the source and the

destination. If possible, bypass the patch panel, or eliminate faulty media convertors

(fiber-optic-to-copper).

• Try the cable in another port or interface, if possible, to see if the problem follows the cable.

• Remove and inspect the stack cable and stack port for bent pins or damaged connectors. If the cable

is bad, replace it with a known good cable.

Chapter 4 Troubleshooting

Ethernet and Fiber Cables

Make sure that you have the correct cable type for the connection:

• For Ethernet, use Category 3 copper cable for 10 Mb/s UTP connections. Use either Category 5,

Category 5e, or Category 6 UTP for 10/100 or 10/100/1000 Mb/s connections.

• For fiber-optic connectors, verify that you have the correct cable for the distance and port type. Make

sure that the connected device ports both match and use the same type encoding, optical frequency,

and fiber type.

• For copper connections, determine if a crossover cable was used when a straight-through was

required or the reverse. Enable auto-MDIX on the switch, or replace the cable. See the

recommended Ethernet cables.

Link Status

Verify that both sides have link. A single broken wire or one shutdown port can cause one side to show

link, but the other side does not have link.

A port LED does not guarantee that the cable is fully functional. The cable might have encountered

physical stress that causes it to function at a marginal level. If the port LED does not turn on:

• Connect the cable from the switch to a known good device.

• Make sure that both ends of the cable are connected to the correct ports.

• Verify that both devices have power.

• Verify that you are using the correct cable type. See Appendix B, “Connector and Cable

Specifications” for more information.

Table 2-1 for

4-2

• Look for loose connections. Sometimes a cable appears to be seated, but is not. Disconnect the cable

and then reconnect it.

Catalyst 2350 Switch Hardware Installation Guide

OL18479-01