Page 1

Feedback on the

Catalyst 8540 Chassis

Installation Guide

78-6134-01

Documentation Response Card

Feedback on the Catalyst 8540 Chassis Installation Guide, 78-6134-01.

Please respond to the following statements by checking a number from 1 to 5:

5 Strongly agree

4 Somewhat agree

3 Neutral

2 Somewhat disagree

1 Strongly disagree

Overall, I am satisfied with this document.

Strongly agree 54321 Strongly disagree

This document is accurate and free of errors.

Strongly agree 54321 Strongly disagree

Thank you for taking the time

to fill out this response card.

Your input is important to us

and helps us to provide you

with better documentation.

If you have comments

about this document,

please complete this

self-addressed response

card and mail it to us.

We also encourage you to

make copies of this blank

response card to complete and

send to us whenever you

have comments about this

document. You can mail

copies of this card to:

Cisco Systems, Inc.

Attn: Central

Documentation Services

170 West Tasman Drive

San Jose, CA 95134-9883

You can also send us your

comments by e-mail to

bug-doc@cisco.com, or fax

your comments to us at

(408) 527-8089.

You can also submit

comments electronically on

the World Wide Web. Click

Feedback in the toolbar and

select Documentation. After

you complete the form, click

Submit to send it to Cisco. We

appreciate your comments.

I can find the information I need in this document.

Strongly agree 54321 Strongly disagree

This document is complete and offers enough relevant information for me to do my job.

Strongly agree 54321 Strongly disagree

This document is written at the correct level of complexity for the subject matter.

Strongly agree 54321 Strongly disagree

This document is useful to me in doing my job.

Strongly agree 54321 Strongly disagree

Would you like us to contact you? Yes No

Additional Information

Mailing Information

Date

Company Name

Contact Name

Mailing Address

City State/Province

Zip/Postal Code Country

Phone ( ) Extension

Fax ( ) E-mail

Page 2

BUSINESS REPLY MAIL

FIRST-CLASS MAIL PERMIT NO. 4631 SAN JOSE CA

ATTN DOCUMENTATION

CISCO SYSTEMS INC

170 WEST TASMAN DRIVE

SAN JOSE CA 95134-9883

POSTAGE WILL BE PAID BY ADDRESSEE

UNITED STATES

IN THE

NO POSTAGE

NECESSARY

IF MAILED

Page 3

Catalyst 8540

Chassis Installation Guide

Corporate Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel:

408 526-4000

800 553-NETS (6387)

Fax:

408 526-4100

Customer Order Number: DOC-786134=

Text Part Number: 78-6134-01

Page 4

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT

NOTICE. ALL STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE

PRESENTED WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR

APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION

PACKET THAT SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO

LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency

energy. If it is not installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment

has been tested and found to comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These

specifications are designed to provide reasonable protection against such interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class A or

Class B digital devices. In that ev ent, your right to use the equipm ent may be limited by FCC regulations, and you may be required to correct any interference

to radio or television communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused b y the Cisco equipment

or one of its peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of

the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio

are on circuits controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of

UCB’s public domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE

PROVIDED “AS IS” WITH ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL

DAMAGES, INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR

INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

AccessPath, Any to Any, AtmDirector, the CCIE logo, CD-PAC, Centri, the Cisco Capital logo, CiscoLink, the Cisco Management Connection logo, the

Cisco NetWorks logo, the Cisco Powered Network logo, the Cisco Press logo, the Cisco Technologies logo, ClickStart, ControlStream, DAGAZ, Fast Step,

FireRunner, IGX, IOS, JumpStart, Kernel Proxy, LoopRunner, MGX, Natural Network Viewer, NetRanger, NetSonar, Packet, PIX, Point and Click

Internetworking, Policy Builder, RouteStream, Secure Script, SMARTnet, SpeedRunner, Stratm, StreamView, The Cell, TrafficDirector, TransPath,

VirtualStream, VlanDirector, Workgroup Director, and Workgroup Stack are trademarks; Changing the Way We Work, Live, Play, and Learn, Empowering

the Internet Generation, The Internet Economy, and The New Internet Economy are service marks; and BPX, Catalyst, Cisco, Cisco IOS, the Cisco IOS

logo, Cisco Systems, the Cisco Systems logo, Enterprise/Solver, E therChannel, FastHub, ForeSight, FragmentFree, IP/TV, IPX, Ligh tStream, MICA, Phase/

IP, StrataSphere, StrataView Plus, and SwitchProbe are registered trademarks of Cisco Systems, Inc. in the U.S. and certain other countries. All other

trademarks mentioned in this document are the property of their respective owners. (9810R)

Catalyst 8540 Chassis Installation Guide

Copyright © 1998, Cisco Systems, Inc.

All rights reserved.

Page 5

Documentation Feedback xi

Who Should Read This Guide xii

How This Guide Is Organized xii

Related Documentation xiii

Document Conventions xiii

Cisco Connection Online xvi

Chapter 1 Product Overview 1-1

Chapter 2 Site Planning 2-1

Site Preparation Guidelines 2-1

Environmental Monitoring Functions 2-2

Site Requirements 2-3

AC and DC Power 2-3

Interference Considerations 2-4

Equipment Racks 2-4

Site Environment 2-8

Equipment Rack Ventilation 2-10

Power 2-11

Network Connections 2-11

CONTENTS

Chapter 3 Installing the Chassis 3-1

Safety Recommendations 3-2

Safely Lifting the Chassis 3-3

Ensuring Safety with Electricity 3-4

Preventing Electrostatic Discharge Damage 3-5

Tools for Installation 3-7

Rack-Mounting the Chassis 3-7

Contents iii

Page 6

System Ground Connection 3-13

Required Tools and Equipment 3-13

Connecting the System to the Grounding Pad 3-15

Installing the Power Supplies 3-15

Confirming the Installation 3-17

Chapter 4 Maintaining the Chassis 4-1

Removing and Installing Power Supplies 4-2

Power Supply LEDs 4-2

Overvoltage and Overtemperature Protection 4-3

Removing and Installing AC-Input Power Supplies 4-3

Tools Required 4-4

Removing AC-Input Power Supplies 4-4

Installing the AC-Input Power Supply 4-7

Connecting the AC-Input Power Supply 4-7

Connecting Redundant AC-Input Power Supply 4-7

Powering Up the AC-Input Power Supply 4-9

Removing and Installing DC-Input Power Supplies 4-9

Removing the DC-Input Power Supply 4-10

Installing the DC-Input Power Supply 4-13

Connecting the DC-Input Power Supply 4-13

Connecting the Redundant DC-Input Power Supply 4-15

Powering Up the DC-Input Power Supply 4-15

Replacing the Chassis Fan Assembly 4-15

Tools Required 4-17

Removing the Fan Assembly 4-17

Installing a New Fan Assembly 4-17

Appendix A Chassis and Power Supply Specifications A-1

Appendix B Translated Safety Warnings B-1

iv

Catalyst 8540 Chassis Installation Guide

Restricted Area Warning B-1

Disconnect Device Warning B-2

Overtemperature Warning B-3

TN Power Warning B-4

Page 7

Supply Circuit Warning B-5

Installation Warning B-6

Installation Warning B-6

Jewelry Removal Warning B-7

Stacking the Chassis Warning B-8

Ground Conductor Warning B-9

Lightning Activity Warning B-10

Chassis Warning—Rack-Mounting and Servicing B-11

Three Person Lifting and Chassis Handling Warning B-15

Backpane Voltage Warning B-17

Product Disposal Warning B-18

Power Disconnection Warning B-18

Faceplates and Cover Panel Requirement B-19

Main Disconnecting Device Warning B-21

Chassis Power Connection B-22

Ground Connection Warning B-23

DC Power Disconnection Warning B-24

Index

Contents v

Page 8

vi

Catalyst 8540 Chassis Installation Guide

Page 9

FIGURES

Figure 1-1 Catalyst 8540 Chassis 1-2

Figure 2-1 Chassis Footprint and Outer Dimensions 2-5

Figure 2-2 Installing the Chassis in the Rack 2-7

Figure 2-3 Internal Airflow 2-8

Figure 3-1 Unsafe Lifting Practice 3-4

Figure 3-2 Placement of Electrostatic Discharge Wrist Strap

3-6

Figure 3-3 Installing the Shelf Brackets 3-9

Figure 3-4 Attaching L Brackets and Cable Guides

3-10

Figure 3-5 Installing the Chassis in the Rack 3-12

Figure 3-6 System Ground Location 3-14

Figure 3-7 Handling a Power Supply 3-16

Figure 4-1 Power Supply 4-2

Figure 4-2 AC-Input Power Supply Switch, AC Connection, and Captive Screws 4-4

Figure 4-3 Power Supply Removal and Installation 4-5

Figure 4-4 Handling an AC-Input Power Supply 4-6

Figure 4-5 Power Cord Connections 4-8

Figure 4-6 DC-Input Power Supply Location 4-10

Figure 4-7 DC-Input Power Supply 4-11

Figure 4-8 Handling a DC-Input Power Supply 4-12

Figure 4-9 Power Switch and Terminal Block Connections 4-14

Figure 4-10 Chassis Fan Assembly 4-16

Figures vii

Page 10

viii

Catalyst 8540 Chassis Installation Guide

Page 11

Tab le 2- 1 Processor-Monitored Temperature Thresholds 2-2

Tab le 2- 2 Specifications for Operating and Nonoperating Environments 2-10

Tabl e A-1 Chassis and Power Supply Specifications A-1

TABLES

Tables ix

Page 12

x

Catalyst 8540 Chassis Installation Guide

Page 13

About This Guide

This preface describes who should read the Catalyst 8540 Chassis Installation Guide, how

it is organized, and its document conventions.

Cisco documentation and additional literature are available in a CD-ROM package, which

ships with your product. The Documentation CD-ROM, a member of the Cisco Connection

Family, is updated monthly. Therefore, it might be more up to date than printed

documentation. To order additional copies of the Documentation CD-ROM, contact your

local sales representative or call customer service. The CD-ROM package is available as a

single package or as an annual subscription. You can also access Cisco documentation on

the World Wide Web at http://www.cisco.com, http://www-china.cisco.com, or

http://www-europe.cisco.com.

Documentation Feedback

If you are reading Cisco product documentation on the World Wide Web, you can submit

comments electronically:

1 Click Feedback in the toolbar.

2 Select Documentation.

3 Complete the form, click Submit, and send it to Cisco Systems.

If you are reading printed documentation that contains a response card, you can complete

the card and mail it to Cisco Systems.

We appreciate your comments.

About This Guide xi

Page 14

Who Should Read This Guide

Who Should Read This Guide

To use this publication, you should be familiar with electronic circuitry and wiring practices

and preferably have experience as an electronic or electromechanical technician.

How This Guide Is Organized

The major sections of this guide are as follows:

Chapter 1 Product Overview Describes the physical properties of the chassis and chassis

components

Chapter 2 Site Planning Describes how to prepare your site for the installation

of the chassis

Chapter 3 Installing the

Chassis

Chapter 4 Maintaining the

Chassis

Appendix A Chassis and

Power Supply

Specifications

Appendix B Translated Safety

War ni ng s

Describes the procedures for rack-mounting, connecting the

power cables, and powering up the chassis at your site

Describes maintenance procedures

Describes the chassis specifications

Repeats the warnings in this guide and translates them into

different languages

xii

Catalyst 8540 Chassis Installation Guide

Page 15

Related Documentation

This document describes how to install the Catalyst 8540 chassis. There are two

Catalyst 8540 models: Catalyst 8540 Campus Switch Router (CSR) and Catalyst 8540

Multiservice ATM Switch Router (MSR.) The chassis is the same for both models.The

difference between the models depends on how the chassis is populated and which software

is installed. The chassis installation is the same, regardless of which model you have.

For more information about the Catalyst 8540 CSR software and hardware configuration,

refer to the following publications:

• Catalyst 8540 Campus Switch Router Processor and Line Module Installation Guide

• Catalyst 8540 Campus Switch Router Software Feature and Configuration Guide

• Interactive Quick Start: Catalyst 8540 Hardware Installation

http://www.cisco.com/mm/quickstart/8540/

For more information about the Catalyst 8540 MSR software and hardware configuration,

refer to the following publications:

• Catalyst 8540 MSR Preinstallation Guide

• Installing the Catalyst 8540

Related Documentation

• Catalyst 8540 MSR Quick Configuration Guide

• Catalyst 8540 MSR Software Configuration Guide

• Catalyst 8540 MSR Command Reference

Document Conventions

Notes use the following conventions:

Note Means reader take note. Notes contain helpful suggestions or references to material

not covered in the publication.

About This Guide xiii

Page 16

Document Conventions

Cautions use the following conventions:

Caution Means reader be careful. In this situation, you might do something that could

result in equipment damage or loss of data.

Warnings use the following conventions:

Warning This warning symbol means danger. You are in a situation that could cause

bodily injury. Before you work on any equipment, you must be aware of the hazards

involved with electrical circuitry and familiar with standard practices for preventing

accidents. To see translated versions of the warning, refer to the appendix “Translated

Safety Warnings.”

Waarschuwing Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie

die lichamelijk letsel kan veroorzaken. Voordat u aan enige apparatuur gaat werken, dient

u zich bewust te zijn van de bij elektrische schakelingen betrokken risico's en dient u op de

hoogte te zijn van standaard maatregelen om ongelukken te voorkomen. (Voor vertalingen

van de waarschuwingen die in deze publicatie verschijnen, kunt u het aanhangsel

“Translated Safety Warnings” (Vertalingen van veiligheidsvoorschriften) raadplegen.)

Varoitus Tämä varoitusmerkki merkitsee vaaraa. Olet tilanteessa, joka voi johtaa

ruumiinvammaan. Ennen kuin työskentelet minkään laitteiston parissa, ota selvää

sähkökytkentöihin liittyvistä vaaroista ja tavanomaisista onnettomuuksien

ehkäisykeinoista. (Tässä julkaisussa esiintyvien varoitusten käännökset löydät liitteestä

"Translated Safety Warnings" (käännetyt turvallisuutta koskevat varoitukset).

Attention Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une

situation pouvant causer des blessures ou des dommages corporels. Avant de travailler sur

un équipement, soyez conscient des dangers posés par les circuits électriques et

familiarisez-vous avec les procédures couramment utilisées pour éviter les accidents. Pour

obtenir les traductions des mises en garde figurant dans cette publication, veuillez consulter

l’annexe intitulée «Translated Safety Warnings » (Traduction des avis de sécurité).

Warnung Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die

zu einer Körperverletzung führen könnte. Bevor Sie mit der Arbeit an irgendeinem Gerät

beginnen, seien Sie sich der mit elektrischen Stromkreisen verbundenen Gefahren und der

Standardpraktiken zur Vermeidung von Unfällen bewußt. (Übersetzungen der in dieser

Veröffentlichung enthaltenen Warnhinweise finden Sie im Anhang mit dem Titel

“Translated Safety Warnings” (Übersetzung der Warnhinweise).)

xiv

Catalyst 8540 Chassis Installation Guide

Page 17

Document Conventions

Avvertenza Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe

causare infortuni alle persone. Prima di lavorare su qualsiasi apparecchiatura, occorre

conoscere i pericoli relativi ai circuiti elettrici ed essere al corrente delle pratiche standard

per la prevenzione di incidenti. La traduzione delle avvertenze riportate in questa

pubblicazione si trova nell’appendice, “Translated Safety Warnings” (Traduzione delle

avvertenze di sicurezza).

Advarsel Dette varselsymbolet betyr fare. Du befinner deg i en situasjon som kan føre til

personskade. Før du utfører arbeid på utstyr, må du vare oppmerksom på de faremomentene

som elektriske kretser innebærer, samt gjøre deg kjent med vanlig praksis når det gjelder å

unngå ulykker. (Hvis du vil se oversettelser av de advarslene som finnes i denne

publikasjonen, kan du se i vedlegget "Translated Safety Warnings" [Oversatte

sikkerhetsadvarsler].)

Aviso Este símbolo de aviso indica perigo. Encontra-se numa situação que lhe poderá

causar danos físicos. Antes de começar a trabalhar com qualquer equipamento, familiarizese com os perigos relacionados com circuitos eléctricos, e com quaisquer práticas comuns

que possam prevenir possíveis acidentes. (Para ver as traduções dos avisos que constam

desta publicação, consulte o apêndice “Translated Safety Warnings” - “Traduções dos

Avisos de Segurança”).

¡Advertencia! Este símbolo de aviso significa peligro. Existe riesgo para su integridad

física. Antes de manipular cualquier equipo, considerar los riesgos que entraña la corriente

eléctrica y familiarizarse con los procedimientos estándar de prevención de accidentes.

(Para ver traducciones de las advertencias que aparecen en esta publicación, consultar el

apéndice titulado “Translated Safety Warnings.”)

Varning! Denna varningssymbol signalerar fara. Du befinner dig i en situation som kan

leda till personskada. Innan du utför arbete på någon utrustning måste du vara medveten

om farorna med elkretsar och känna till vanligt förfarande för att förebygga skador. (Se

förklaringar av de varningar som förekommer i denna publikation i appendix "Translated

Safety Warnings" [Översatta säkerhetsvarningar].)

About This Guide xv

Page 18

Cisco Connection Online

Cisco Connection Online

Cisco Connection Online (CCO) is Cisco Systems’ primary, real-time support channel.

Maintenance customers and partners can self-register on CCO to obtain additional

information and services.

Available 24 hours a day, 7 days a week, CCO provides a wealth of standard and valueadded services to Cisco’s customers and business partners. CCO services include product

information, product documentation, software updates, release notes, technical tips, the

Bug Navigator, configuration notes, brochures, descriptions of service offerings, and

download access to public and authorized files.

CCO serves a wide variety of users through two interfaces that are updated and enhanced

simultaneously: a character-based version and a multimedia version that resides on the

World Wide Web (WWW). The character-based CCO supports Zmodem, Kermit,

Xmodem, FTP, and Internet e-mail, and it is excellent for quick access to information over

lower bandwidths. The WWW version of CCO provides richly formatted documents with

photographs, figures, graphics, and video, as well as hyperlinks to related information.

You can access CCO in the following ways:

• WWW: http://www.cisco.com

• WWW: http://www-europe.cisco.com

• WWW: http://www-china.cisco.com

• Telnet: cco.cisco.com

• Modem: From North America, 408 526-8070; from Europe, 33 1 64 46 40 82. Use the

following terminal settings: VT100 emulation; databits: 8; parity: none; stop bits: 1; and

connection rates up to 28.8 kbps.

For a copy of CCO’s Frequently Asked Questions (FAQ), contact cco-help@cisco.com.

For additional information, contact cco-team@cisco.com.

xvi

Catalyst 8540 Chassis Installation Guide

Page 19

CHAPTER

1

Product Overview

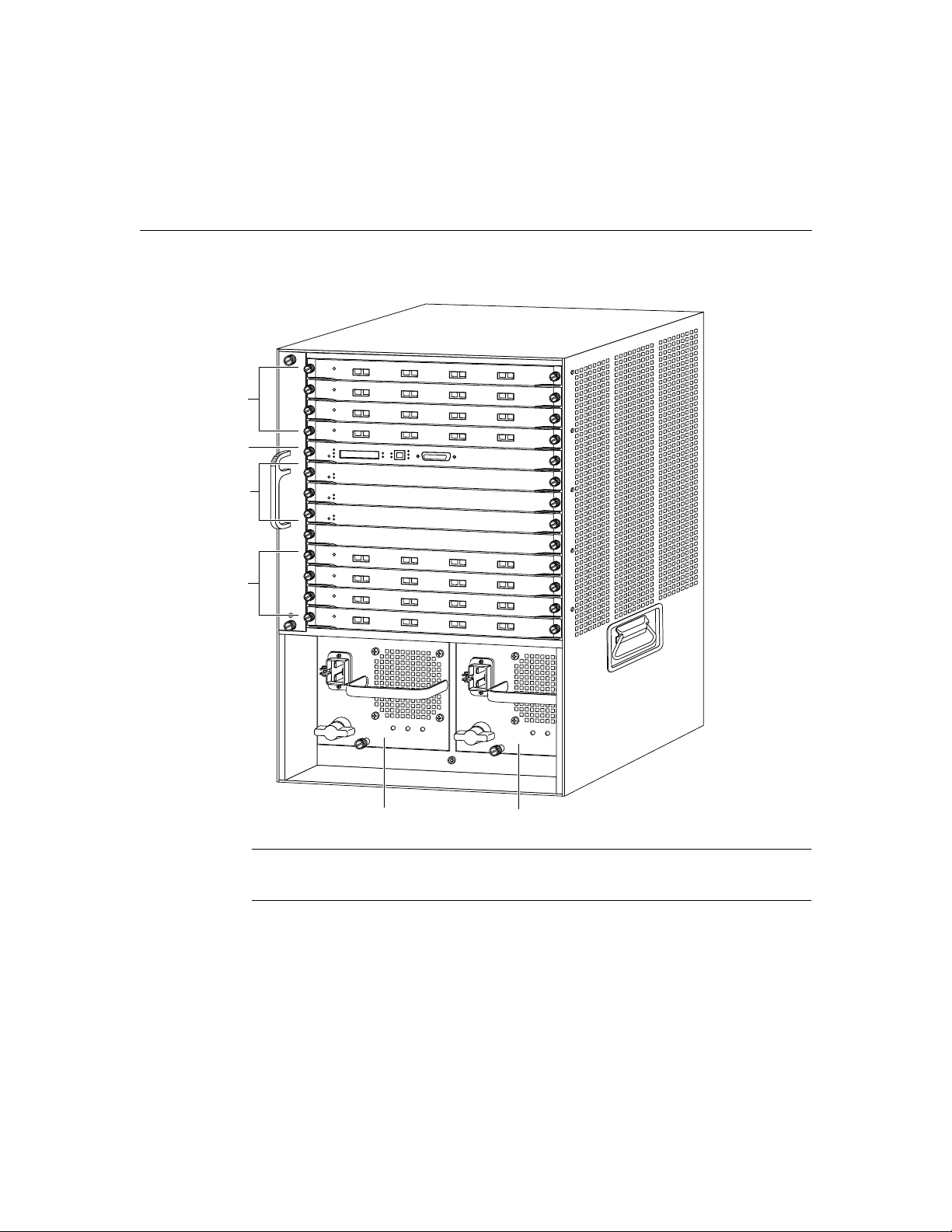

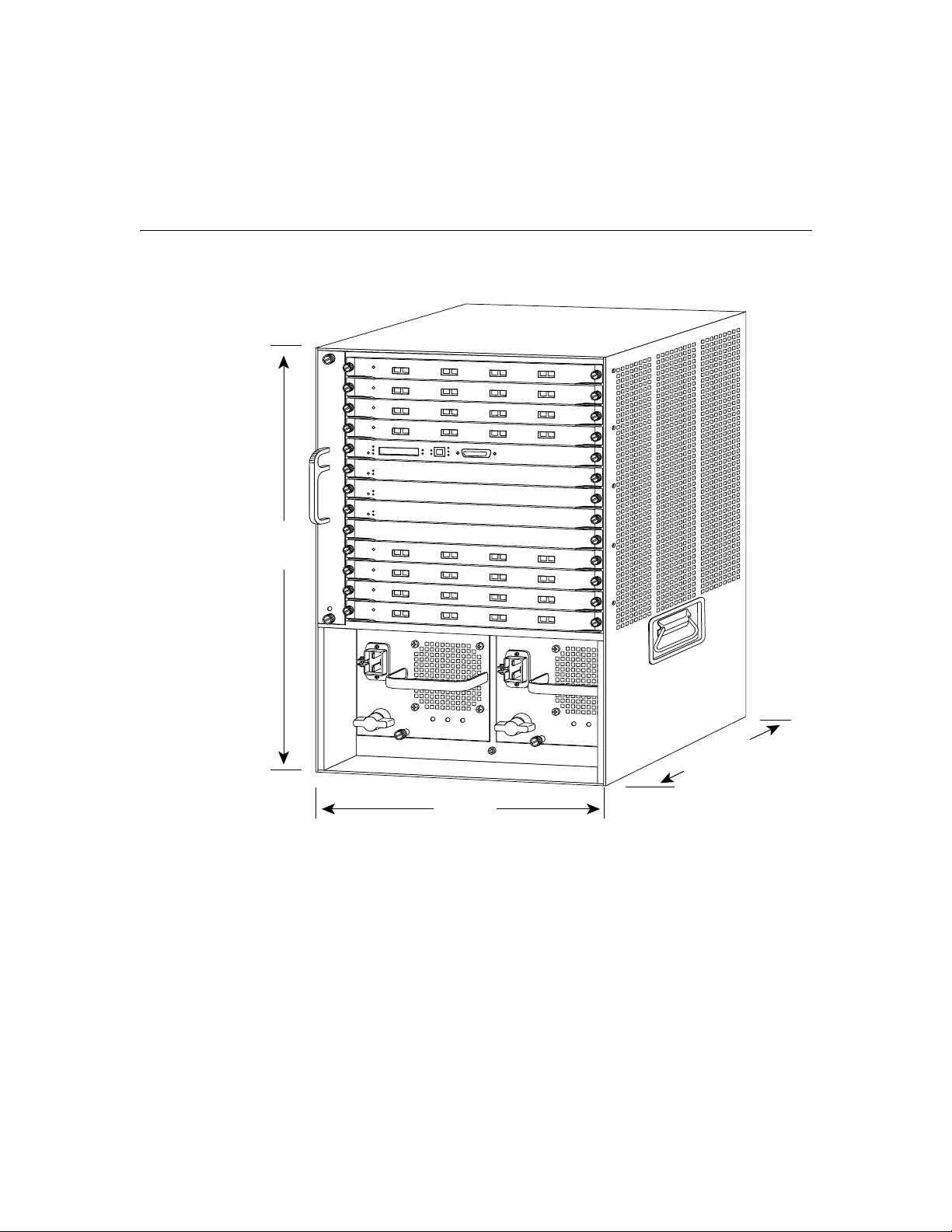

This chapter describes the Catalyst 8540 chassis and provides an overview of the chassis

components. The Catalyst 8540 is a 13-slot, modular chassis with optional dual,

fault-tolerant, load-sharing AC or DC power supplies. (See Figure 1-1.) In the event of a

failure of input power to one supply, or the failure of one power supply, the redundant

power option ensures uninterrupted operation.

The chassis can contain the following components:

• One route processor placed in slot 4 of the chassis.

• Up to eight hot-swappable line modules or port adapters placed in slots 0 through 3 and

slots 9 through 12.

• Up to three hot-swappable switch modules placed in slots 5 and 7. Slot 6 can contain a

switch module that acts as a backup if either module fails.

Product Overview 1-1

Page 20

Figure 1-1 Catalyst 8540 Chassis

y

Line modules/

Port adapters

Route processor

Switch modules

Line modules/

Port adapters

16781

1-2

Power suppl

0 Power supply 1

Note The chassis ships populated specific to your order. Figure 1-1 shows an example of

a fully populated chassis.

Catalyst 8540 Chassis Installation Guide

Page 21

Site Planning

This chapter describes how to prepare your site for installation of the chassis and discusses

the site environment requirements. This chapter contains the following sections:

• Site Preparation Guidelines

• Environmental Monitoring Functions

• Site Requirements

Site Preparation Guidelines

Planning the proper location and layout of your equipment rack or wiring closet is essential

for successful system operation. Equipment placed in an inadequately ventilated area can

cause system overtemperature conditions. In addition, poor equipment placement can make

chassis panels inaccessible and difficult to maintain. Follow these precautions when

planning your equipment locations and connections:

CHAPTER

2

• Keep the front of the chassis free from obstructions and away from the exhaust air of

other equipment. Remember that electrical equipment generates heat, and ambient room

temperature alone might not be adequate to cool equipment to acceptable operating

temperatures.

• Secure the placement of all chassis panels, modules, and any module slot fillers. The fan

assembly pulls cooling air across the line modules. A loose panel allows too much air

to escape and can redirect the airflow away from active line modules.

Site Planning 2-1

Page 22

Environmental Monitoring Functions

Warning This unit is intended for installation in restricted access areas. A

restricted access area is where access can only be gained by service personnel

through the use of a special tool, lock and key, or other means of security, and is

controlled by the authority responsible for the location.

Environmental Monitoring Functions

You can maintain normal system operation by identifying and resolving adverse conditions

before the system fails by using environmental monitoring and reporting functions.

Environmental monitoring functions constantly monitor the internal air temperature of the

chassis. Each power supply monitors its own voltage and shuts down if it detects a critical

condition within the power supply. The reporting functions retrieve and display the present

values of measured parameters. If any of the monitored parameters exceed defined

thresholds, the reporting functions display alarms on the console.

The environmental monitoring functions use two levels of status conditions to monitor the

system: normal and alarm. The processor monitors the temperature inside the module

compartment, and the power supplies use the normal and alarm levels to monitor voltages.

Table 2-1 lists temperature thresholds for the processor-monitored levels:

• Normal—All monitored parameters are within normal tolerances.

2-2

• Alarm—An out-of-tolerance temperature or voltage condition exists. The system might

not continue operation. If a voltage measurement reaches this level, the power supply

can shut down the system. Immediate action is required.

Table 2-1 Processor-Monitored Temperature Thresholds

Parameter Normal Alarm

Temperature 0–55°C> 55°C

The power supply monitors its own internal temperature and voltages. The power supply is

either within tolerance (normal) or out of tolerance (alarm). If an internal power supply

temperature or voltage reaches the alarm level, the output fail LED may be unreliable and

the power supply can shut down the system.

Catalyst 8540 Chassis Installation Guide

Page 23

Site Requirements

This section contains the following topics:

• AC and DC Power

• Interference Considerations

• Equipment Racks

• Site Environment

• Equipment Rack Ventilation

• Power

• Network Connections

AC and DC Power

The 1300W AC power supply uses a power factor corrector (PFC) that allows the power

supply to operate on input voltage and current within the ranges of 90 to 264 VAC and 50

to 60 Hz.

A second, identical power supply is also present in the chassis configured with an optional

redundant power supply. Table A-1 in the appendix “Chassis and Power Supply

Specifications” lists system power specifications, including input voltage and operating

frequency ranges.

Site Requirements

The Catalyst 8540 relies on protective devices in the building installation for protection

against short-circuit, overcurrent, and earth fault. Ensure that the protective devices in the

building installation are properly rated to protect the system, and that the protective devices

comply with national and local codes.

Site Planning 2-3

Page 24

Site Requirements

The following warnings apply to DC power supplies:

Warning A readily accessible two-poled disconnect device must be incorporated

in the fixed wiring.

Before connecting each unit, note its power consumption rating in Table A-1 in the

appendix “Chassis and Power Supply Specifications.”

Interference Considerations

When wires are run for any significant distance in an electromagnetic field, interference can

occur between the field and the signals on the wires. As a result:

• Bad plant wiring can result in radio frequency interference (RFI).

• Strong electromagnetic interference (EMI), especially when it is caused by lightning or

radio transmitters, can destroy the signal drivers and receivers in the chassis, and can

even create an electrical hazard by conducting power surges through lines and into

equipment.

Note To predict and remedy strong EMI, you might need to consult RFI experts.

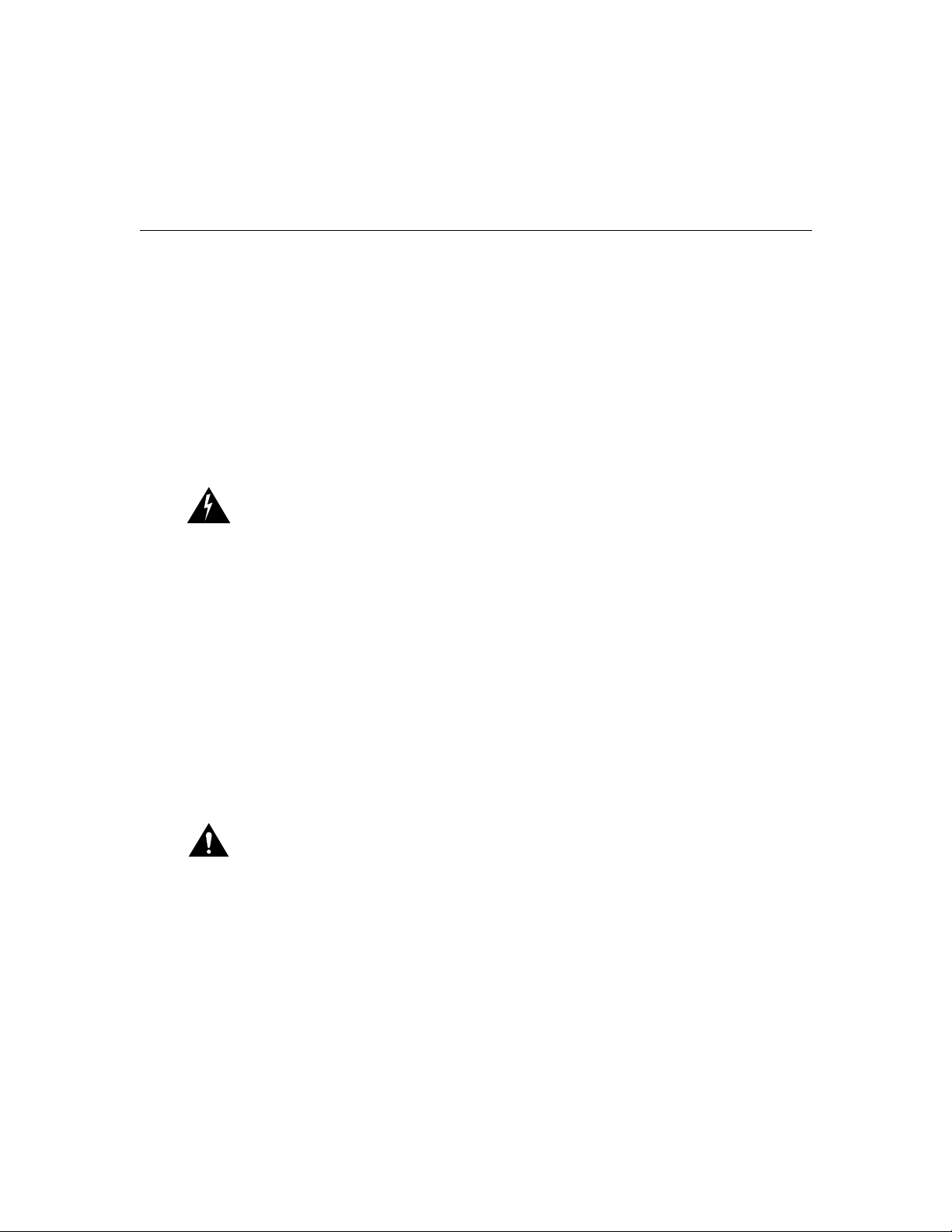

Equipment Racks

A rack-mount kit is provided for mounting the chassis in a standard 19-inch (48 cm)

equipment rack. The rack-mount kit is not suitable for racks with obstructions (such as a

power strip) that could impair access to the processor and power supplies. Figure 2-1 shows

the chassis footprint and outer dimensions.

2-4

Catalyst 8540 Chassis Installation Guide

Page 25

Figure 2-1 Chassis Footprint and Outer Dimensions

25"

(62.5 cm)

Equipment Racks

17104

19.75"

(48.2 cm)

17.75"

(43.13 cm)

To use the rack-mount kit, your equipment rack must meet the following requirements:

• The width of the rack, between the two front mounting strips or rails, must be

17.75 inches (43.13 cm).

• The depth of the rack, between the front and rear mounting strips, must be at least

19.25 inches (48.2 cm) but not more than 32 inches (80 cm).

Site Planning 2-5

Page 26

Site Requirements

• The height of the chassis is approximately 25 inches (62.5 cm). The rack must have

sufficient vertical clearance to allow insertion of the chassis.

When planning your rack installation, follow these guidelines:

• Allow at least 3 feet (1 m) of clearance in front of the rack for maintenance and removal

of the route processor, line modules, power supplies, and the fan assembly.

• Note that the ports for cooling air are located on the front, rear, and both sides of the

chassis, so multiple chassis can be rack-mounted with little or no vertical clearance.

However, avoid placing the chassis in an overly congested rack.

Warning To prevent overheating the chassis, do not operate it in an area that

exceeds the maximum recommended ambient temperature of 104°F (40°C). To

prevent airflow restriction, allow at least 3 inches (7.6 cm) of clearance around the

ventilation openings.

• Consider the equipment and cabling already installed in the rack. Ensure that cables

from other equipment do not obstruct the airflow through the chassis or impair access

to the power supplies or line modules. Route cables away from field-replaceable

components to avoid having to disconnect cables unnecessarily to perform equipment

maintenance or upgrades.

2-6

• Install heavier equipment in the lower half of the rack to maintain a low center of

gravity.

• Ensure that the shelf you place the chassis on can support the weight and dimensions of

the chassis. Use the chassis footprint, shown in Figure 2-1 if you are designing a

customized shelf.

Caution Never install the chassis in an enclosed rack that is not properly

ventilated or air-conditioned.

Catalyst 8540 Chassis Installation Guide

Page 27

Equipment Racks

Follow these guidelines to help ensure your safety:

• Mount the chassis at the bottom of the rack.

• If the rack has stabilizing devices, install the stabilizers before mounting or servicing

the unit in the rack.

• The chassis must always be mounted horizontally, as shown in Figure 2-2.

In addition to the preceding guidelines, review the precautions in the section “Equipment

Rack Ventilation” later in this chapter.

Figure 2-2 Installing the Chassis in the Rack

Cable

guide

L bracket

17105

Site Planning 2-7

Page 28

Site Requirements

Site Environment

The chassis operates as a standalone system mounted in a rack in a secure wiring closet.

The environment must be dry, clean, well-ventilated, and air-conditioned. An internal fan

assembly pulls cooling air through the chassis from the front and right side (intake) to the

rear and left side (exhaust). (See Figure 2-3.) The flow of ambient air must be maintained

to ensure normal operation. If the airflow is blocked or restricted, or if the intake air exceeds

104°F, an overtemperature condition can occur. Under extreme conditions, the

environmental monitor can shut down the system to protect the system components.

Figure 2-3 Internal Airflow

Fan

assembly

2-8

17106

To ensure normal operation and avoid unnecessary maintenance, plan your site

configuration and prepare your site before installation. After installation, make sure that the

site maintains an ambient temperature of 32 to 104°F (40°C), and that the area around the

chassis is free of dust.

Catalyst 8540 Chassis Installation Guide

Page 29

Site Environment

If the room temperature exceeds 104°F (40°C), the air temperature inside the chassis could

overheat the unit. Any of the following can inhibit airflow and cause overheating:

• The wiring closet or rack in which the chassis is mounted is not properly ventilated.

• The exhaust of one device is placed so it enters the air intake vent of the chassis.

• The chassis is the top unit in an unventilated rack.

Multiple chassis can be rack-mounted with no clearance above and below the chassis.

When mounting a chassis in a rack with other equipment or when placing a chassis on the

floor adjacent to other equipment, ensure that the exhaust from other equipment does not

blow into the intake vent (lower front panel) of the chassis.

Table 2-2 lists the operating and nonoperating environmental site requirements. To

maintain normal operation and ensure high system availability, maintain an ambient

temperature at your site. The chassis operates in the ranges listed in Table 2-2; however, a

measurement that is approaching the minimum or maximum of a range indicates a potential

problem. You can maintain normal operation by anticipating and correcting environmental

anomalies before they exceed the maximum operating range.

Site Planning 2-9

Page 30

Site Requirements

Table 2-2 Specifications for Operating and Nonoperating Environments

Minimum Maximum

Temperature, ambient operating 32°F (0°C) 104°F (40°C)

Temperature, ambient

nonoperating and storage

Humidity (RH), ambient

(noncondensing) operating

Humidity (RH), ambient

(noncondensing) nonoperating and

storage

Altitude, operating and

nonoperating

Vibration, operating 5 to 200 Hz, 0.5 g

Vibration, nonoperating 5 to 200 Hz, 1 g (1 octet/min)

–4°F (–20°C) 149°F (65°C)

10% 90%

5% 95%

Sea level 6,500 ft. (2000 m)

(1 octet/min)

200 to 500 Hz, 2 g

(1 octet/min)

Equipment Rack Ventilation

If you plan to install the chassis in an equipment rack, follow these precautions and

guidelines that are provided in the section “Equipment Racks” earlier in this chapter to

avoid overtemperature conditions:

• Install the chassis in an enclosed rack only if it has adequate ventilation or an exhaust

fan. Use an open rack whenever possible.

• Note that a ventilation system that is too powerful in a closed rack might prevent cooling

by creating negative pressure around the chassis and redirecting the air away from the

chassis intake vent. If necessary, operate the chassis with the rack open.

• Use baffles inside the enclosed rack to assist in cooling the chassis.

• Do not place equipment near the bottom of a rack, because it might generate excessive

heat that is drawn upward and into the intake ports of equipment above, leading to

overtemperature conditions in the chassis at or near the top of the rack.

2-10

Catalyst 8540 Chassis Installation Guide

Page 31

Power

Follow these precautions when planning power connections to the chassis:

Warning The device is designed to work with TN power systems.

• Install proper grounding to avoid damage from lightning and power surges.

• Connect redundant power supplies to separate input power lines. Install a second source

for redundant power if a separate line is not already in place.

Warning Care must be given to connecting units to the supply circuit so that wiring is not

overloaded.

Network Connections

When preparing your site for network connections to the chassis, consider these factors

related to each type of interface:

• Type of cabling required for each type (fiber-optic, coaxial, or twisted-pair cabling)

Power

• Distance limitations for each signal type

• Specific cables you need to connect each interface

• Any additional interface equipment you need, such as transceivers, modems, channel

service units (CSUs), or data service units (DSUs)

Before installing the chassis, make sure all the additional external equipment and cables are

on hand.

Site Planning 2-11

Page 32

Site Requirements

2-12

Catalyst 8540 Chassis Installation Guide

Page 33

CHAPTER

Installing the Chassis

This chapter describes how to install the chassis, connect the cables, and power up the

chassis at your site. This chapter contains the following sections:

• Safety Recommendations

• Tools for Installation

• Rack-Mounting the Chassis

• System Ground Connection

Caution Before installing the chassis in a rack, read the section “Safety

Recommendations” in this chapter to become familiar with the proper site and

environmental conditions. Failure to read and follow these guidelines can lead to

an unsuccessful installation and possible damage to the system and components.

3

Warning Read the installation instructions before you connect the system to its

power source.

Installing the Chassis 3-1

Page 34

Safety Recommendations

Safety Recommendations

The following guidelines ensure your safety and protect the equipment. This list is not

inclusive of all potentially hazardous situations that you may be exposed to as you install

the chassis, so be alert:

Warning Only trained and qualified personnel should be allowed to install,

replace, or service this equipment.

• Do not lift the chassis by yourself; for safety guidelines to use when lifting, see the

section “Safely Lifting the Chassis.”

• Turn all power supplies off (the position marker should be at zero) and unplug all power

cords before installing or removing a chassis.

• Keep the chassis area clear and free of dust during and after installation.

• Keep tools and chassis components away from walk areas.

• Do not wear loose clothing, jewelry (including rings and chains), or other items that

could get caught in the chassis. Fasten your tie or scarf and sleeves.

3-2

Warning Before working on equipment that is connected to power lines, remove

jewelry (including rings, necklaces, and watches). Metal objects will heat up when

connected to power and ground and can cause serious burns or weld the metal

object to the terminals.

Install the equipment in compliance with the following national codes:

• United States—National Fire Protection Association (NFPA) 70; United States

Electrical Code

• Canada—Canadian Electrical Code, Part I, CSA C22.1

• Other countries—International Electrotechnical Commission (IEC) 364, Parts 1–7 and

any applicable national electrical codes of countries where the product is installed.

Catalyst 8540 Chassis Installation Guide

Page 35

Safely Lifting the Chassis

The chassis weighs 70 pounds (31.7 kg) when empty (no modules or power supplies

installed) and 160 pounds (72.5 kg) with two power supplies and all modules installed. The

chassis is not intended to be moved frequently. Before you install the chassis, verify that

your site is properly prepared to avoid having to move the chassis later to accommodate

power sources and network connections.

Three people are required to lift the chassis. Whenever you lift the chassis or any heavy

object, follow these guidelines:

• Do not lift the chassis by yourself. The size and weight of the chassis requires three

people to safely lift and move it without causing injury and without damaging the

equipment.

• Grasp the bottom of the chassis exterior with both hands.

• Ensure that your footing is solid, and balance the weight of the chassis between your

feet.

• Do not move suddenly or twist your body as you lift. Lift the chassis slowly.

• Keep your back straight and lift with your legs, not your back. If you must bend down

to lift the chassis, bend at the knees, not at the waist, to reduce the strain on your lower

back muscles. (See Figure 3-1.)

Safely Lifting the Chassis

Installing the Chassis 3-3

Page 36

Safety Recommendations

Figure 3-1 Unsafe Lifting Practice

• Leave line modules, power supplies, switch modules, and fan assembly installed.

• Disconnect all external cables before lifting or moving the chassis.

Warning Do not stack the chassis on any other equipment. If the chassis falls, it

can cause severe bodily injury and equipment damage.

H1369a

Ensuring Safety with Electricity

Follow theses guidelines when working with any electrical equipment:

• Locate the emergency off switch for the room in which you are working before

beginning any procedures requiring access to the chassis interior.

• Disconnect all power and external cables before installing or removing a chassis.

• Work with at least one other person when potentially hazardous conditions exist.

• Disconnect the power from a circuit.

3-4

Catalyst 8540 Chassis Installation Guide

Page 37

Preventing Electrostatic Discharge Damage

• Do not perform any action that creates a potential hazard to people or makes the

equipment unsafe.

• Examine your work area for possible hazards such as moist floors, ungrounded power

extension cables, and missing safety grounds.

Warning Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate

electrical inspection authority or an electrician if you are uncertain that suitable

grounding is available.

In addition, use the guidelines that follow when working with any equipment that is

disconnected from a power source but still connected to telephone wiring or other network

cabling.

Warning Do not work on the system or connect or disconnect cables during

periods of lightning activity.

• Do not install telephone jacks near water unless the jack is specifically designed for wet

locations.

• Do not touch uninsulated telephone wires or terminals unless the telephone line was

disconnected at the network interface.

• Use caution when installing or modifying telephone lines.

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) damage, which occurs when electronic modules or

components are improperly handled, can result in complete or intermittent failures. The

route processor, switch modules, and line modules each consist of a printed circuit card that

is fixed in a metal carrier. Electromagnetic interference (EMI) shielding and connectors are

integral components of the carrier. Handle the carriers by the carrier edges only; never

touch the modules or connector pins. Although the metal carrier helps to protect the

modules from ESD, use a preventive antistatic strap whenever you handle the route

processor, switch modules, or line modules.

Installing the Chassis 3-5

Page 38

Safety Recommendations

Follow these guidelines to prevent ESD damage:

• Use an ESD-preventive wrist or ankle strap and ensure that it makes good skin contact.

• When removing any module, connect the equipment end of the ESD strap to the ESD

strap connection. (See Figure 3-2.)

• Handle carriers by the faceplates and carrier edges only; avoid touching the card or any

connector pins.

• When removing a module, place the removed module component side up on an

antistatic surface or in a static shielding bag. If the line module is to be returned to the

factory, immediately place it in a static shielding bag.

• Avoid contact between the line modules and clothing. The wrist strap only protects the

card from ESD voltages on the body; ESD voltages on clothing can still cause damage.

For safety, periodically check the resistance value of the antistatic strap. The measurement

should be between 1 and 10 megohms (Mohms).

Figure 3-2 Placement of Electrostatic Discharge Wrist Strap

3-6

16785

ESD

Catalyst 8540 Chassis Installation Guide

Page 39

Tools for Installation

You need the following tools and equipment to install the chassis:

• Number 1 and number 2 Phillips screwdrivers to tighten the captive installation screws

on most systems

• A 3/16-inch flat-blade screwdriver for the captive installation screws on the route

processor and line modules

• An antistatic mat or antistatic foam if you need to remove modules to troubleshoot the

installation

• Your own ESD grounding strap or the disposable ESD strap included with the system

If you are installing the chassis in a rack, you also need the following:

• A rack-mount kit

• A tape measure and a level

Rack-Mounting the Chassis

To install the chassis in a rack, follow these steps:

Tools for Installation

Warning To prevent the chassis from overheating, do not operate it in an area

that exceeds the maximum recommended ambient temperature of 104°F (40°C).

To prevent airflow restriction, allow at least 3 inches (7.6 cm) of clearance around

the ventilation openings.

Step 1 Prepare for installation as follows:

(a) Remove the rubber feet from the chassis, if needed, to ensure a better fit in

the rack. Place the chassis face down on a flat surface. Remove the screw

that holds each foot.

(b) Place the chassis on the floor or on a sturdy table as close as possible to the

rack. Leave enough clearance so that you can move around the chassis.

Installing the Chassis 3-7

Page 40

Rack-Mounting the Chassis

Caution If the rack is on wheels, ensure that the brakes are engaged or that the

rack is otherwise stabilized.

Warning To prevent bodily injury when mounting or servicing this unit in a rack, you

must take special precautions to ensure that the system remains stable. The following

guidelines are provided to ensure your safety:

—This unit should be mounted at the bottom of the rack if it is the only

(c) Use a tape measure to measure the depth of the rack. Measure from the

outside of the front mounting posts to the outside of the rear mounting

strip. The depth must be at least 19.25 inches (48.9 cm) but not greater than

32 inches (81.3 cm).

(d) Measure the space between the inner edges of the left front and right front

mounting posts to ensure that it is 17.75 inches (45.09 cm) wide. (The

chassis is 17.25 inches [43.8 cm] wide and must fit between the mounting

posts.)

(e) Open the rack-mount kit.

unit in the rack.

3-8

—When mounting this unit in a partially filled rack, load the rack from the

bottom to the top with the heaviest component at the bottom of the

rack.

—If the rack is provided with stabilizing devices, install the stabilizers

before mounting or servicing the unit in the rack.

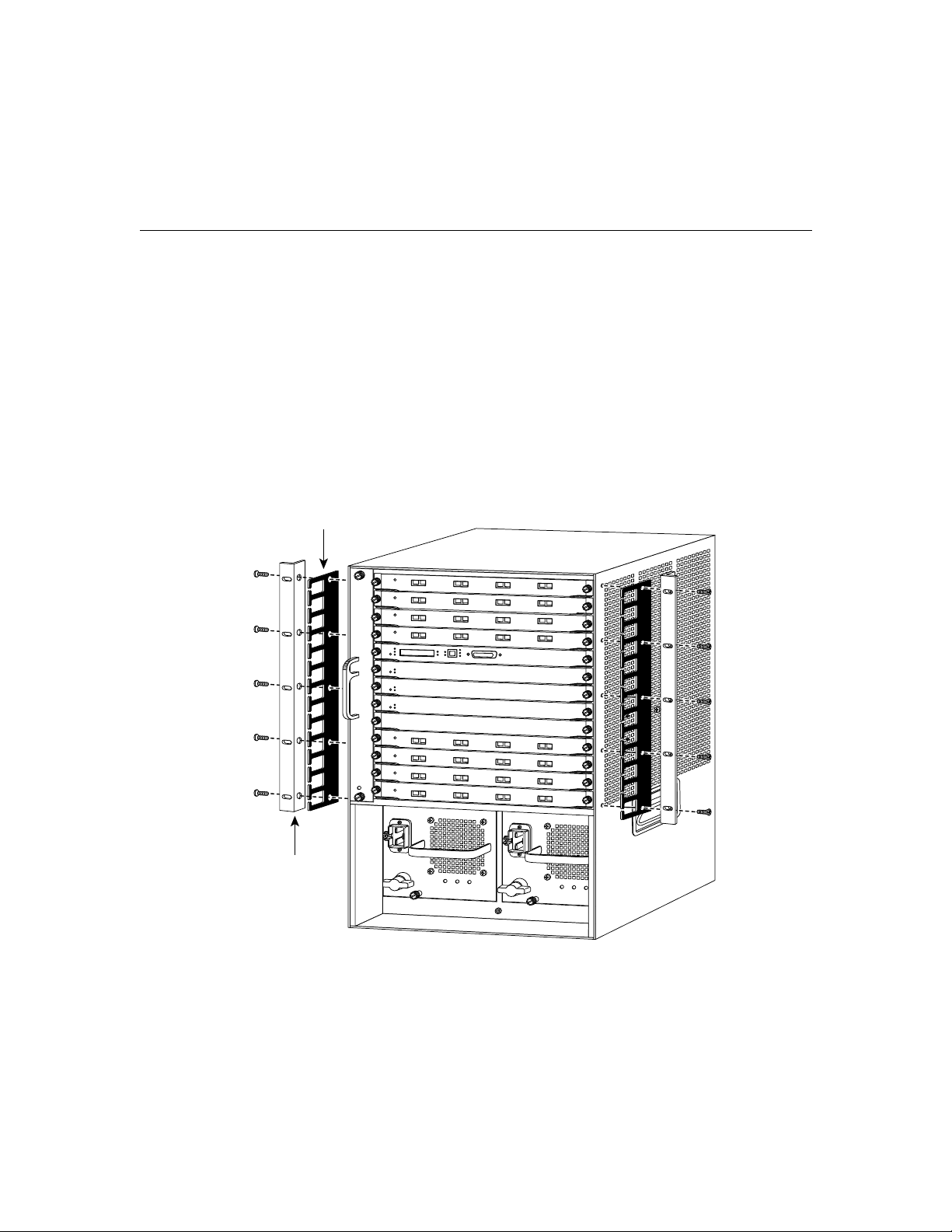

Step 2 Install the shelf brackets as follows:

(a) Position the shelf brackets in the rack. (See Figure 3-3.)

(b) Secure the shelf brackets by using six (three per side) 12 –24 or 10–32

screws.

(c) Attach the crossbar bracket to the back of the shelf brackets using two M3

screws.

Catalyst 8540 Chassis Installation Guide

Page 41

Rack-Mounting the Chassis

Note No shelf is required with this assembly; the shelf brackets support the chassis in the

rack.

Figure 3-3 Installing the Shelf Brackets

Shelf bracket Shelf bracket

12-24 x 3/4-inch

or

10-32 x 3/4-inch screw (6x)

H9466

Step 3 Install the L brackets by attaching the left and right L brackets using the ten M3

Phillips countersunk-head screws provided in the rack-mount kit.

(See Figure 3-4.)

Note Some equipment racks provide a power strip along the length of one of

the rear posts. If your rack has this feature, consider the position of the strip

when planning fastener points. Before you install the L brackets on the chassis,

determine whether you will install the chassis from the front or the rear of the

rack.

Installing the Chassis 3-9

Page 42

Rack-Mounting the Chassis

Figure 3-4 Attaching L Brackets and Cable Guides

Fan

assembly

Note If you are installing cable guides, place the cable guides inside the L

brackets, between the L bracket and the chassis. Secure the cable guides to the

chassis using the same screws (and chassis holes) as the L brackets. (See

Figure 3-4.) The cable guides and screws are provided in the cable management

kit.

3-10

17106

Catalyst 8540 Chassis Installation Guide

Page 43

Rack-Mounting the Chassis

Step 4 Install the chassis in the rack as follows:

Warning Three people are required to lift the chassis. Grasp the chassis

underneath the lower edge and lift with both hands. To prevent injury, keep your

back straight and lift with your legs, not your back. To prevent damage to the

chassis and components, never attempt to lift the chassis with the handles on the

power supplies or on the interface processors, or by the plastic panels on the front

of the chassis. These handles were not designed to support the weight of the

chassis.

(a) With one person standing at each side of the chassis, grasp the bottom edge

of the chassis with one hand near the front and the other near the back.

Slowly lift the chassis in unison. To prevent injury, avoid sudden twists or

moves.

(b) Position the chassis in the rack as follows (see Figure 3-5):

If the front of the chassis (front panel) is at the front of the rack, insert the

rear of the chassis between the mounting posts.

If the rear of the chassis is at the front of the rack, insert the front of the

chassis between the mounting posts.

(c) Place the chassis on the shelf brackets.

(d) Align the mounting holes in the L bracket with the mounting holes in the

equipment rack.

(e) A third person should install the ten (five per side) 12–24 or 10–32 screws

through the elongated holes in the L bracket and into the threaded holes in

the mounting post.

(f) Use a tape measure and level to ensure that the chassis is installed straight

and level.

Step 5 Check the release levers to ensure that all modules are installed securely.

Step 6 Tighten any loose captive installation screws on all modules.

Installing the Chassis 3-11

Page 44

Rack-Mounting the Chassis

Figure 3-5 Installing the Chassis in the Rack

t

3-12

Crossbar bracket

Catalyst 8540 Chassis Installation Guide

H9467

Shelf bracket

Page 45

System Ground Connection

Note The system ground connection must be connected to a suitable ground. The power

supply ground connection must also be connected to a suitable ground.

This section describes how to connect a system (earth) ground to the switch. Two

grounding holes are provided on the chassis frame for the grounding hole location. See

Figure 3-6.

Note The earth ground should be used on both AC- and DC-powered systems.

Required Tools and Equipment

To connect the switch to an earth ground, you need the following tools and materials:

Note Materials are not provided; contact any commercial cable vendor for the required

parts.

System Ground Connection

• Grounding lug—The grounding lug must have two M4 screw holes.

• Two M4 (metric) hex-head screws with locking washers.

• One grounding wire—The length and size of the grounding wires depends on the

proximity of the switch to proper grounding facilities, national and local ones.

• Number 2 Phillips head screwdriver.

• Crimping/wire-stripping tool.

Installing the Chassis 3-13

Page 46

System Ground Connection

Figure 3-6 System Ground Location

F

A

S

F

A

S

U

T

U

T

T E

T

H

E

R

T

E

T

H

E

R

SWITCH/PROCESSOR

SWITCH/PROCESSOR

C

8

5

M

RO

UTE

OC3/STM1 M

P

P

G

I

G

A

B

I

T

E

T

H

E

R

N

E

T

1

6K

LL-

FU

RX

DUPLEX

CDM

T

TX

OP-DE

RX-SEC

OC

T-1

2 A

TM SMF

-IR

256

k

X

M

T

R

A

L

A

X

R

D

/

X

T

X

R

C

S

1

2

TU

STA

N

E

T S

W

IT

C

H

IN

G

M

O

D

U

L

E

1

STATUS

N

E

T

S

W

I

T

C

H

I

N

G

M

O

D

U

L

E

FAN

PS2

STATUS

S1

P

AN

F

S2

P

STATUS

S1

P

S

-1

8F

-O

C

3

M

M

TX

X

STATUS

R

K

SW

IT

IN

CH MO

DULE

L

1

M

F

0

TX

TX

RX

RX

UTP3

0

TX

TX

TX

RX

RX

RX

UTP3

UTP3

4

3

4

5

2

3

3

4

5

X

T 2

T

O

SL

ESET

R

SLOT 2

RX

T 1

LO

K

S

OT 1

LIN

SL

t

IA

ne

C

E

M

PC

X

T

SET

E

R

LOT 2

S

X

R

OT 1

L

LINK

S

IA

net

C

E

CM

X

T

X

R

K

IN

L

1

UTP3

1

UTP3

P

X

T

X

T

X

T

X

T

X

T

X

R

K

IN

2

L

3

X

T

X

X

R

X

R

X

R

X

R

K

R

K

IN

K

L

IN

4

K

L

IN

5

K

L

IN

6

L

7

LIN

2

3

TX

TX

RX

RX

UTP3

UTP3

2

3

TX

TX

RX

RX

UTP3

UTP3

LEX

G

IG

A

B

IT

E

T

H

E

R

N

E

T

16

K

FULL

RX

DM

DUP

C

TX

OP-DET

RX-SEC

GGIGA

BIT EHT

ERN

ET 16

K

FULL-

LINK

DUPLEX

RX

OP-DET

RX-SYNC

TX

X

T

X

R

6

7

8

9

10

11

12

6

7

8

9

10

11

12

UX

A

T

EJEC

UX

A

T

JEC

E

X

T

TX

X

T

X

T

X

T

X

R

K

IN

8

9

L

TX

RX

U

T

P

U

T

P

TX

RX

U

T

P

U

T

P

X

T

X

R

K

LIN

1

0

0

UTP3

0

UTP3

X

X

T

X

R

K

IN

1

L

1

1

TX

RX

UTP3

1

TX

RX

UTP3

T

X

R

K

IN

1

2

L

X

T

X

X

R

X

R

X

R

X

R

K

R

K

IN

K

L

IN

1

3

K

L

1

4

K

IN

LIN

1

5

L

IN

1

6

L

2

3

TX

TX

RX

RX

UTP3

UTP3

2

3

TX

TX

RX

RX

UTP3

UTP3

3-14

IN

P

U

T

IN

P

U

T

O

K

O

K

Grounding

pad

Wire

Grounding lug

Screws (M4)

Catalyst 8540 Chassis Installation Guide

F

A

N

O

U

T

P

U

T

F

A

N

O

U

T

P

U

T

O

K

F

A

IL

O

K

F

A

IL

IN

P

U

T

F

A

N

O

U

T

P

U

T

O

K

O

K

F

A

IL

45787

Grounding

pad location

Page 47

Connecting the System to the Grounding Pad

Connecting the System to the Grounding Pad

You must complete this procedure before connecting the system power or turning on the

switch.

To attach the grounding lug and cable to the grounding pad, perform these steps:

Step 1 Use a wire-stripping tool to remove approximately 0.75 inch (19 mm) of the

covering from the end of the grounding wire.

Step 2 Insert the stripped end of the grounding wire into the open end of the grounding

lug.

Step 3 Use a crimping tool to secure the grounding wire in place in the grounding lug.

Step 4 Locate the grounding pad on the switch (See Figure 3-6.).

Step 5 Remove the label that covers the grounding pad.

Step 6 Place the grounding lug against the grounding pad.

Step 7 Insert two screws through the holes in the grounding lug and the grounding pad.

Ensure that the grounding lug will not interfere with other switch hardware or

rack equipment.

Step 8 Install the locking washers and nuts; tighten them to secure the grounding lug to

the grounding pad.

Step 9 Prepare the other end of the grounding wire and connect it to an appropriate

grounding point in your site to ensure adequate earth ground for the switch.

Installing the Power Supplies

As your communication requirements change, you might want to upgrade your system and

add or replace a power supply.

You need the following tools to remove and install a power supply:

• A 1/4-inch flat-blade screwdriver to remove and install filler plates and to loosen or

tighten the captive installation screw on the power supply.

• Filler plates to install over empty power supply bays to protect the connectors

from contamination.

Installing the Chassis 3-15

Page 48

System Ground Connection

To install an AC-input or DC-input power supply, follow these steps:

Warning Voltage is present on the backplane when the system is operating. To

reduce risk of an electric shock, keep hands and fingers out of the power supply

bays and backplane areas.

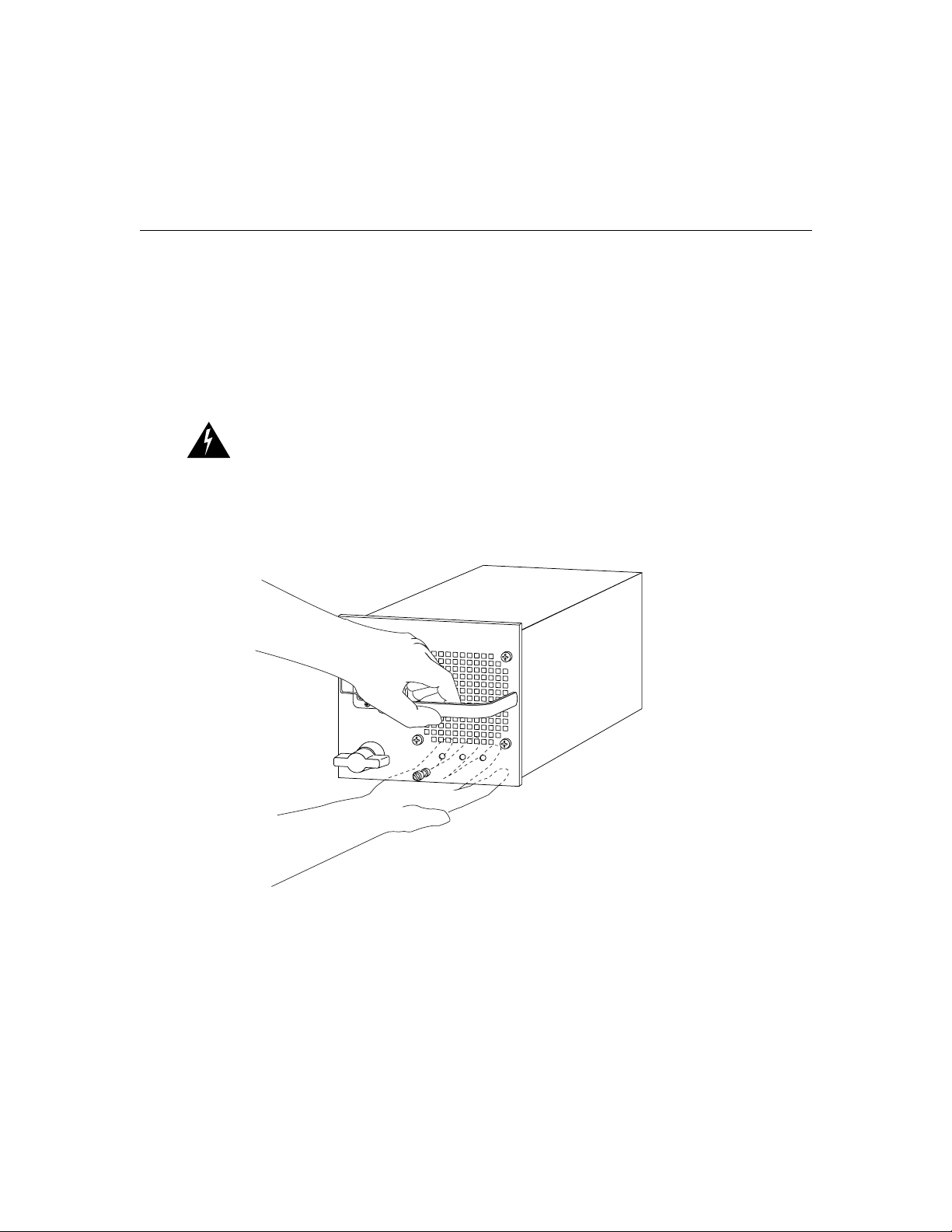

Step 1 Grasp the power supply handle with one hand. Place your other hand underneath

Step 2 Place the power supply into the power supply bay and push the power supply

Step 3 Tighten the captive installation screw by turning it clockwise.

For detailed power supply installation, removal, and maintenance information, see the

section “Removing and Installing Power Supplies” in the chapter

“Maintaining the Chassis.”

Figure 3-7 Handling a Power Supply

to support the bottom of the supply, as shown in Figure 3-7.

into the bay until the power supply faceplate is flush with the cover.

3-16

14305

Catalyst 8540 Chassis Installation Guide

Page 49

Confirming the Installation

If your system has problems starting up, use the information in this section to help isolate

the cause. Problems with the initial startup are usually caused by an interface processor or

power supply that has become dislodged from the backplane or chassis power connector.

Although overtemperature conditions rarely occur at initial startup, the environmental

monitoring functions are included because they also monitor DC line voltages. This

publication covers the system hardware installation only. At the initial system boot, you

should verify the following:

• The power supplies are installed properly and are supplying power to the system.

• The system fan assembly is operating.

• The system software boots successfully.

• The route processor, switch modules, and line modules are properly installed in their

slots and each is initialized without problems.

When all of these conditions are met, the hardware installation is complete and you can

begin software configuration of the Catalyst 8540 route processor. Refer to the following

publications for detailed software configuration information:

• Catalyst 8540 Campus Switch Router Software Feature and Configuration Guide

Confirming the Installation

• Catalyst 8540 MSR Software Configuration Guide

If you are unable to easily solve the problem, contact a customer service representative for

assistance and further instructions. To help your service provider assist you, gather the

following information before you call:

• The date you received the chassis

• The chassis serial number (located on a label on the front of the chassis)

• The type of software and release number

• A brief description of the problem

• A brief explanation of the steps already taken to isolate and resolve the problem

• The maintenance agreement or warranty information

Installing the Chassis 3-17

Page 50

System Ground Connection

3-18

Catalyst 8540 Chassis Installation Guide

Page 51

CHAPTER

4

Maintaining the Chassis

This chapter describes how to add and replace internal system components such as system

fan assemblies and power supplies for the chassis.

Your chassis is configured as specified in your order and is ready for installation and startup

when it leaves the factory. As your communication requirements change, you can upgrade

your system, add components, or change the initial configuration. Software and component

upgrades require specific documents and other frequently updated information; therefore,

only basic replacement guidelines are included in this publication.

There are two kinds of replaceable system components: those that support hot swapping

and those that require the system power to be shut down before they are replaced.

Redundant power supplies, line modules, and the fan assembly are hot swappable.

This chapter contains the following sections:

• Removing and Installing Power Supplies

• Replacing the Chassis Fan Assembly

Warning Ultimate disposal of this product should be handled according to all

national laws and regulations.

Maintaining the Chassis 4-1

Page 52

Removing and Installing Power Supplies

Removing and Installing Power Supplies

As your communication requirements change, you might want to upgrade your system and

add or replace a power supply. This section contains the following power supply

information:

• Power Supply LEDs

• Overvoltage and Overtemperature Protection

• Removing and Installing AC-Input Power Supplies

• Removing and Installing DC-Input Power Supplies

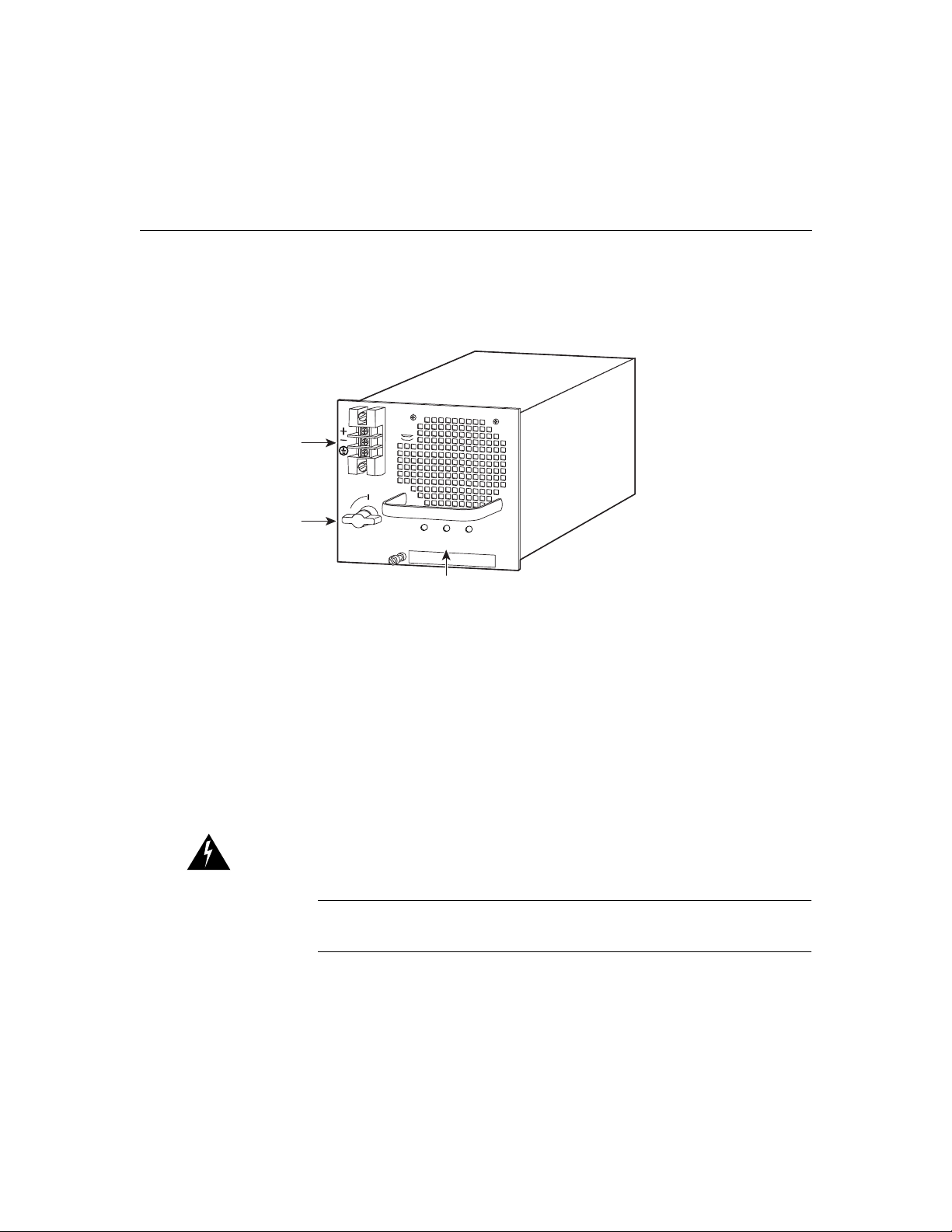

Power Supply LEDs

The three LEDs (see Figure 4-1) on the power supply indicate the status of the power

supply. The Input OK LED indicates that the power supply is on and receiving source

power. The Fan OK signal indicates that the fan assembly is operating properly. The Output

Fail LED is lit only when output voltage is outside of proper range,+3.3, +5, +12, and

+42 VDC.

4-2

Figure 4-1 Power Supply

Power

Metal prongs

Cable

retention

clip

Power

switch

connection

Captive screw

Catalyst 8540 Chassis Installation Guide

INPUT

16787

FAN

OUTPUT

O

K

OK

FAIL

Page 53

Overvoltage and Overtemperature Protection

Overvoltage and Overtemperature Protection

The power supply monitors its own temperature and internal voltages. If the power supply

detects an overvoltage or overtemperature condition, it shuts down to avoid damage to the

power supply or other system components.

Note If the power supply shuts down, turn the power switch off (0), wait several minutes

for the supply to cool, and then turn the power switch on ( | ). If the power supply shuts

down again, remove and replace it.

Removing and Installing AC-Input Power Supplies

The redundant 1300W power supplies (AC-input) support hot swapping. When two power

supplies are installed, you can remove or install one supply without affecting system

operation. When power is removed from one supply, the redundant power feature causes

the second supply to ramp up to full power and maintain uninterrupted system operation.

In systems with dual power supplies, connect each power supply to separate input lines so

that, in case of a line failure, the second source is available and can maintain uninterrupted

power to the system.

A 20A modular power cord should connect each AC-input power supply to a separate site

power source.

Note Each AC-input power supply weighs 22 pounds.

Caution Use both hands to remove and install power supplies.

Maintaining the Chassis 4-3

Page 54

Removing and Installing Power Supplies

Tools Required

You need the following tools to remove and install a power supply:

• A 1/4-inch flat-blade screwdriver to remove and install filler plates and to loosen or

tighten the captive installation screw on the power supply.

• Filler plates to install over empty power supply bays to protect the connectors

from contamination.

Removing AC-Input Power Supplies

To remove an AC-input power supply, follow these steps:

Step 1 Turn off the power switch on the power supply you are removing.

(See Figure 4-2.)

Caution Failure to turn off the AC-input power supply could result in equipment

damage.

Figure 4-2 AC-Input Power Supply Switch, AC Connection, and Captive Screws

Power

Metal prongs

connection

4-4

Cable

retention

clip

Power

switch

Captive screw

Catalyst 8540 Chassis Installation Guide

INPUT

OK

16787

FAN

OUTPUT

OK

FAIL

Page 55

Removing and Installing AC-Input Power Supplies

Step 2 Disconnect the AC power cord from the power source.

Step 3 Remove the input power cord from the power inlet.

Warning Before working on a system that has an on/off switch, turn off the

power and unplug the power cord.

Step 4 Loosen the captive installation screw on the power supply with a screwdriver.

(See Figure 4-2.)

Step 5 Grasp the power supply handle with one hand. Slowly pull the power supply out

of the chassis toward you. (See Figure 4-3.)

Warning Voltage is present on the backplane when the system is operating. To

reduce risk of an electric shock, keep hands and fingers out of the power supply

bays and backplane areas.

Figure 4-3 Power Supply Removal and Installation

16788

Maintaining the Chassis 4-5

Page 56

Removing and Installing Power Supplies

Step 6 While holding the power supply handle with one hand, place your other hand

underneath to support the bottom of the supply, as shown in Figure 4-4.

Step 7 Pull the power supply out of the bay and put it aside.

Step 8 If the power supply bay is to remain empty, install a filler plate over the opening

and secure it with the mounting screws.

Warning Blank faceplates and cover panels serve three important functions: they

prevent exposure to hazardous voltages and currents inside the chassis; they

contain electromagnetic interference (EMI) that might disrupt other equipment;

and they direct the flow of cooling air through the chassis. Do not operate the

system unless all cards, faceplates, front covers, and rear covers are in place.

Figure 4-4 Handling an AC-Input Power Supply

4-6

16748

Catalyst 8540 Chassis Installation Guide

Page 57

Installing the AC-Input Power Supply

To install an AC-input power supply, follow these steps:

Step 1 Grasp the power supply handle with one hand. Place your other hand underneath

to support the bottom of the supply, as shown in Figure 4-4.

Step 2 Place the power supply into the power supply bay and push the power supply

into the bay until the power supply faceplate is flush with the cover.

Warning Voltage is present on the backplane when the system is operating. To

reduce risk of an electric shock, keep hands and fingers out of the power supply

bays and backplane areas.

Step 3 Tighten the captive installation screw by turning it clockwise.

Connecting the AC-Input Power Supply

Connect an AC-input power supply as follows:

Step 1 Plug a power cord into the power inlet of one AC-input power supply.

(See Figure 4-5.)

Removing and Installing AC-Input Power Supplies

Step 2 Connect the other end of the AC-input power supply cord to an input line.

Warning The plug-socket combination must be accessible at all times because it

serves as the main disconnecting device.

To complete the installation, see the section “Power Cord Connections.”

Connecting Redundant AC-Input Power Supply

Connect the redundant AC-input power supply to a separate input line as follows:

Step 1 Plug in the power cord on the redundant AC power supply. (See Figure 4-5.)

Step 2 Connect the redundant power supply cord to an input line other than the initial

power supply line.

Maintaining the Chassis 4-7

Page 58

Removing and Installing Power Supplies

Figure 4-5 Power Cord Connections

4-8

IN

PU

T

FA

N

O

UTP

UT

IN

PU

T

FA

N

OK

O

U

TP

U

T

O

K

FAIL

O

K

O

K

FA

IL

Power

supply 0

Power

cord

connection

connection

Catalyst 8540 Chassis Installation Guide

Power

cord

IN

PU

O

K

Power

supply 1

T

FA

N

O

U

TP

U

T

O

K

FAIL

16789

Page 59

Removing and Installing DC-Input Power Supplies

Powering Up the AC-Input Power Supply

Perform these steps to power up the AC-input power supply and confirm the installation:

Step 1 Turn the power switch of the AC-input power supply on ( | ).

Step 2 Verify that the LEDs (See Figure 4-1.) on the front panel of the power supply are

in the following state within 5 seconds of operation:

• Input OK: ON

• Fan OK: ON

• Output Fail: OFF

Removing and Installing DC-Input Power Supplies

The redundant DC power supplies support hot swapping. When two power supplies are

installed, you can install, remove, or replace one supply without affecting system operation.

When power is removed from one supply, the redundant power feature causes the second

supply to ramp up to full power and maintain uninterrupted system operation. In systems

with dual power supplies, connect each power supply to separate DC-input lines; in the

event of a line failure, the second source is still available.

The DC-input power supply is required by many telcos because these installations are

powered by -48 or -60 VDC batteries. From an operational perspective, the DC-input

power supply has the same characteristics as the AC-input version.

Figure 4-6 shows the location of the DC-input power supplies in a redundant configuration.

In a nonredundant configuration, the power supply goes in the slot labeled Power Supply 0.

Maintaining the Chassis 4-9

Page 60

Removing and Installing Power Supplies

Figure 4-6 DC-Input Power Supply Location

o

INP

UT

OK

FAIL

O

K

Power supply 0

o

Power supply 1

Removing the DC-Input Power Supply

To remove a DC-input power supply, follow these steps:

Step 1 Verify that the power is off to the DC circuit furnishing power to the power

supply you are removing.

Warning Before connecting or disconnecting ground or power wires to the

chassis, ensure that power is removed from the DC circuit. To ensure that all

power is OFF, locate the circuit breaker on the panel board that services the DC

circuit, switch the circuit breaker to the OFF position, and tape the switch handle

of the circuit breaker in the OFF position.

INP

UT

OK

FAIL

OK

16609

4-10

Catalyst 8540 Chassis Installation Guide

Page 61

Removing and Installing DC-Input Power Supplies