Page 1

Cisco ASA 5505 Adaptive Security

Appliance Hardware Installation Guide

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Customer Order Number: OL-18362-01

Text Part Number: OL-18362-01

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following inform ation is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required

to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency energy. If it is not

installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment has been tested and found to

comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These specifications are designed to provide reasonable

protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class A or Class B digital

devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference to radio or television

communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco equipment or one of its

peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio are on circuits

controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Cisco and the Cisco Logo are trademarks of Cisco Systems, Inc. and/or its affiliates in the U.S. and other countries. A listing of Cisco's trademarks can be found at

www.cisco.com/go/trademarks. Third party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1005R)

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

©2007 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

About This Guide v

Document Objectives v

Audience v

Document Organization v

Document Conventions vi

Installation Warnings vi

Where to Find Safety and Warning Information x

Obtaining Documentation and Submitting a Service Request 1-x

CHAPTER

CHAPTER

CHAPTER

1 Overview 1-1

Product Overview 1-1

Memory Requirements 1-3

Memory Requirements for the Software Version 8.3 and Later 1-3

2 Preparing for Installation 2-1

Installation Overview 2-1

Safety Recommendations 2-1

Maintaining Safety with Electricity 2-2

Preventing Electrostatic Discharge Damage 2-3

General Site Requirements 2-3

Site Environment 2-3

Preventive Site Configuration 2-3

Power Supply Considerations 2-4

Configuring Equipment Racks 2-4

3 Installing the Cisco ASA 5505 3-1

Installing the Chassis 3-1

OL-18362-01

Connecting the Interface Cables 3-1

Powering on the Cisco ASA 5505 3-3

Installing a Cable Lock 3-4

Rack or Wall Mounting the Cisco ASA 5505 3-4

Mounting the Chassis 3-5

Wall-Mounting the Chassis 3-5

Cisco ASA 5505 Hardware Installation Guide

iii

Page 4

Contents

Rack-Mounting the Chassis 3-7

Installing and Wall-Mounting the Cisco ASA 5505 FIPS Enclosure 3-11

CHAPTER

APPENDIX

4 Maintenance and Upgrade Procedures 4-1

Removing and Replacing the Chassis Cover 4-1

Working in an ESD Environment 4-1

Removing the Chassis Cover 4-2

Replacing the Chassis Cover 4-3

Replacing the Lithium Battery 4-3

Installing and Replacing the SSC 4-4

Installing an SSC 4-5

Replacing an SSC 4-6

Upgrading Memory 4-6

Removing the DIMM 4-7

Installing the DIMM 4-8

Verifying the Memory Upgrade 4-9

1 Cable Pinouts 1-1

10/100/1000BaseT Connectors 1-1

Console Port (RJ-45) 1-2

RJ-45 to DB-9 1-4

I

NDEX

MGMT 10/100/1000 Ethernet Port 1-4

Gigabit and Fibre Channel Ports 1-5

iv

Cisco ASA 5505 Hardware Installation Guide

OL-18362-01

Page 5

About This Guide

This preface includes the following sections:

• Document Objectives, page v

• Audience, page v

• Document Organization, page v

• Document Conventions, page vi

• Installation Warnings, page vi

• Obtaining Documentation and Submitting a Service Request, page x

Document Objectives

This guide describes how to perform installation and maintenance procedures on the Cisco ASA 5505

Adaptive Security Appliance.

Audience

This guide is for network administrators who perform any of the following tasks:

• Managing network security

• Installing and configuring firewalls

• Managing default and static routes, and TCP and UDP services

Document Organization

This guide includes the following chapters and appendices:

• Chapter 1, “Overview,” describes the product overview, LEDs and memory requirements.

• Chapter 2, “Preparing for Installation,” describes the installation overview, safety

recommendations, and general site requirements.

• Chapter 3, “Installing the Cisco ASA 5505,” describes how to connect the interface cables, and rack

or wall mount the chassis .

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

v

Page 6

• Chapter 4, “Maintenance and Upgrade Procedures,” describes the adaptive security appliance

maintenance and upgrade procedures.

• Appendix 1, “Cable Pinouts,” describes the cable pinouts.

Document Conventions

Command descriptions use these conventions:

• Braces ({ }) indicate a required choice.

• Square brackets ([ ]) indicate optional elements.

• Vertical bars (|) separate alternative, mutually exclusive elements.

• Boldface indicates commands and keywords that are entered literally as shown.

• Italics indicate arguments for which you supply values.

Examples use these conventions:

• Examples depict screen displays and the command line in screen font.

• Information you need to enter in examples is shown in boldface screen font.

About This Guide

• Variables for which you must supply a value are shown in

Graphical user interface examples uses these conventions:

• Boldface indicates buttons and menu items.

• Selecting a menu item (or pane) is indicated by the following convention:

Choose Start > Settings > Control Panel.

Note Means reader take note. Notes contain helpful suggestions or references to material not covered in the

manual.

Installation Warnings

Be sure to read the Regulatory Compliance and Safety Information for the Cisco ASA 5500 Series document

that accompanied this device before installing the chassis. This document contains important safety

information. This section includes the following warnings:

• Power Supply Disconnection Warning, page vii

• Jewelry Removal Warning, page vii

• Wrist Strap Warning, page vii

• Work During Lightning Activity Warning, page vii

italic screen

font.

vi

• Installation Instructions Warning, page vii

• Chassis Warning for Rack-Mounting and Servicing, page viii

• Short-Circuit Protection Warning, page viii

• SELV Circuit Warning, page viii

• Ground Conductor Warning, page viii

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 7

About This Guide

• Blank Faceplates and Cover Panels Warning, page viii

• Product Disposal Warning, page viii

• Short-Circuit Protection Warning, page ix

• Compliance with Local and National Electrical Codes Warning, page ix

• DC Power Connection Warning, page ix

• AC Power Disconnection Warning, page ix

• TN Power Warning, page ix

• 48 VDC Power System, page ix

• Multiple Power Cord, page ix

• Circuit Breaker (15A) Warning, page ix

• Grounded Equipment Warning, page x

• Safety Cover Requirement, page x

• Faceplates and Cover Panel Requirement, page x

Power Supply Disconnection Warning

Warning

Before working on a chassis or working near power supplies, unplug the power cord on AC units;

disconnect the power at the circuit breaker on DC units.

Jewelry Removal Warning

Warning

Before working on equipment that is connected to power lines, remove jewelry (including rings,

necklaces, and watches). Metal objects will heat up when connected to power and ground and can

cause serious burns or weld the metal object to the terminals.

Wrist Strap Warning

Warning

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly

touch the backplane with your hand or any metal tool, or you could shock yourself.

Work During Lightning Activity Warning

Warning

Do not work on the system or connect or disconnect cables during periods of lightning activity.

Statement 1001

Statement 12

Statement 43

Statement 94

Installation Instructions Warning

Warning

OL-18362-01

Read the installation instructions before connecting the system to the power source.

Statement 1004

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

vii

Page 8

Chassis Warning for Rack-Mounting and Servicing

About This Guide

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special

precautions to ensure that the system remains stable. The following guidelines are provided to

ensure your safety:

rack.When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

heaviest component at the bottom of the rack.If the rack is provided with stabilizing devices, install the

stabilizers before mounting or servicing the unit in the rack.

Short-Circuit Protection Warning

Warning

This product requires short-circuit (overcurrent) protection, to be provided as part of the building

installation. Install only in accordance with national and local wiring regulations.

SELV Circuit Warning

Warning

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-network

voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV circuits. Some

LAN and WAN ports both use RJ-45 connectors. Use caution when connecting cables.

Ground Conductor Warning

This unit should be mounted at the bottom of the rack if it is the only unit in the

Statement 1006

Statement 1045

Statement 1021

Warning

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection

authority or an electrician if you are uncertain that suitable grounding is available.

Blank Faceplates and Cover Panels Warning

Warning

Blank faceplates and cover panels serve three important functions: they prevent exposure to

hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI)

that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not

operate the system unless all cards, faceplates, front covers, and rear covers are in place.

1029

Product Disposal Warning

Warning

Ultimate disposal of this product should be handled according to all national laws and regulations.

Statement 1040

Statement 1024

Statement

viii

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 9

About This Guide

Short-Circuit Protection Warning

Warning

This product requires short-circuit (overcurrent) protection, to be provided as part of the building

installation. Install only in accordance with national and local wiring regulations.

Compliance with Local and National Electrical Codes Warning

Warning

Installation of the equipment must comply with local and national electrical codes.

DC Power Connection Warning

Warning

After wiring the DC power supply, remove the tape from the circuit breaker switch handle and

reinstate power by moving the handle of the circuit breaker to the ON position.

AC Power Disconnection Warning

Warning

Before working on a chassis or working near power supplies, unplug the power cord on AC units.

Statement 246

TN Power Warning

Statement 1045

Statement 1074

Statement 8

Warning

The device is designed to work with TN power systems.

48 VDC Power System

Warning

The customer 48 volt power system must provide reinforced insulation between the primary AC power

and the 48 VDC output.

Multiple Power Cord

Warning

This unit has more than one power cord. To reduce the risk of electric shock when servicing a unit,

disconnect the power cord of the power strip that the unit is plugged into.

Circuit Breaker (15A) Warning

Warning

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that

a fuse or circuit breaker no larger than 120 VAC, 15A U.S. (240 VAC, 10A international) is used on the

phase conductors (all current-carrying conductors).

Statement 19

Statement 128

Statement 137

Statement 13

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

ix

Page 10

Obtaining Documentation and Submitting a Service Request

Grounded Equipment Warning

About This Guide

Warning

This equipment is intended to be grounded. Ensure that the host is connected to earth ground during

normal use.

Statement 39

Safety Cover Requirement

Warning

The safety cover is an integral part of the product. Do not operate the unit without the safety cover

installed. Operating the unit without the cover in place will invalidate the safety approvals and pose

a risk of fire and electrical hazards.

Statement 117

Faceplates and Cover Panel Requirement

Warning

Blank faceplates and cover panels serve three important functions: they prevent exposure to

hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI)

that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not

operate the system unless all cards, faceplates, front covers, and rear covers are in place.

142

Where to Find Safety and Warning Information

For safety and warning information, see the Regulatory Compliance and Safety Information for the

Cisco ASA 5500 Series document that accompanied the product. This document describes the

international agency compliance and safety information for the Cisco ASA 5505 Adaptive Security

Appliance. It also includes translations of the safety warnings.

Statement

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional

information, see the monthly What’s New in Cisco Product Documentation, which also lists all new and

revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What’s New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed

and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free

service and Cisco currently supports RSS Version 2.0.

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

x

OL-18362-01

Page 11

CHA PTER

1

Overview

Read through the entire guide before beginning any of the procedures in this book.

Warning

Caution Read the safety warnings in the Regulatory Compliance and Safety Information for the Cisco ASA 5500

Only trained and qualified personnel should install, replace, or service this equipment.

Series and follow proper safety procedures when performing these steps.

This chapter describes the product and the memory requirements and includes the following topics:

• Product Overview, page 1-1

• Memory Requirements, page 1-3

Statement 49

Product Overview

The Cisco ASA 5505 Adaptive Security Appliance delivers unprecedented levels of defense against

threats to the network with deeper web inspection and flow-specific analysis, improved secure

connectivity via end-point security posture validation, and voice and video over VPN support. It also

provides enhanced support for intelligent information networks through improved network integration,

resiliency, and scalability.

The adaptive security appliance software combines firewall, VPN concentrator, and intrusion prevention

software functionality into one software image. Previously, these functions were available in three

separate devices, each with its own software and hardware. Combining the functionality into just one

software image provides significant improvements in the available features.

Additionally, the adaptive security appliance software supports Adaptive Security Device Manager

(ASDM). ASDM is a browser-based, Java applet used to configure and monitor the software on the

adaptive security appliances. ASDM is loaded from the adaptive adaptive security appliance, then used

to configure, monitor, and manage the device.

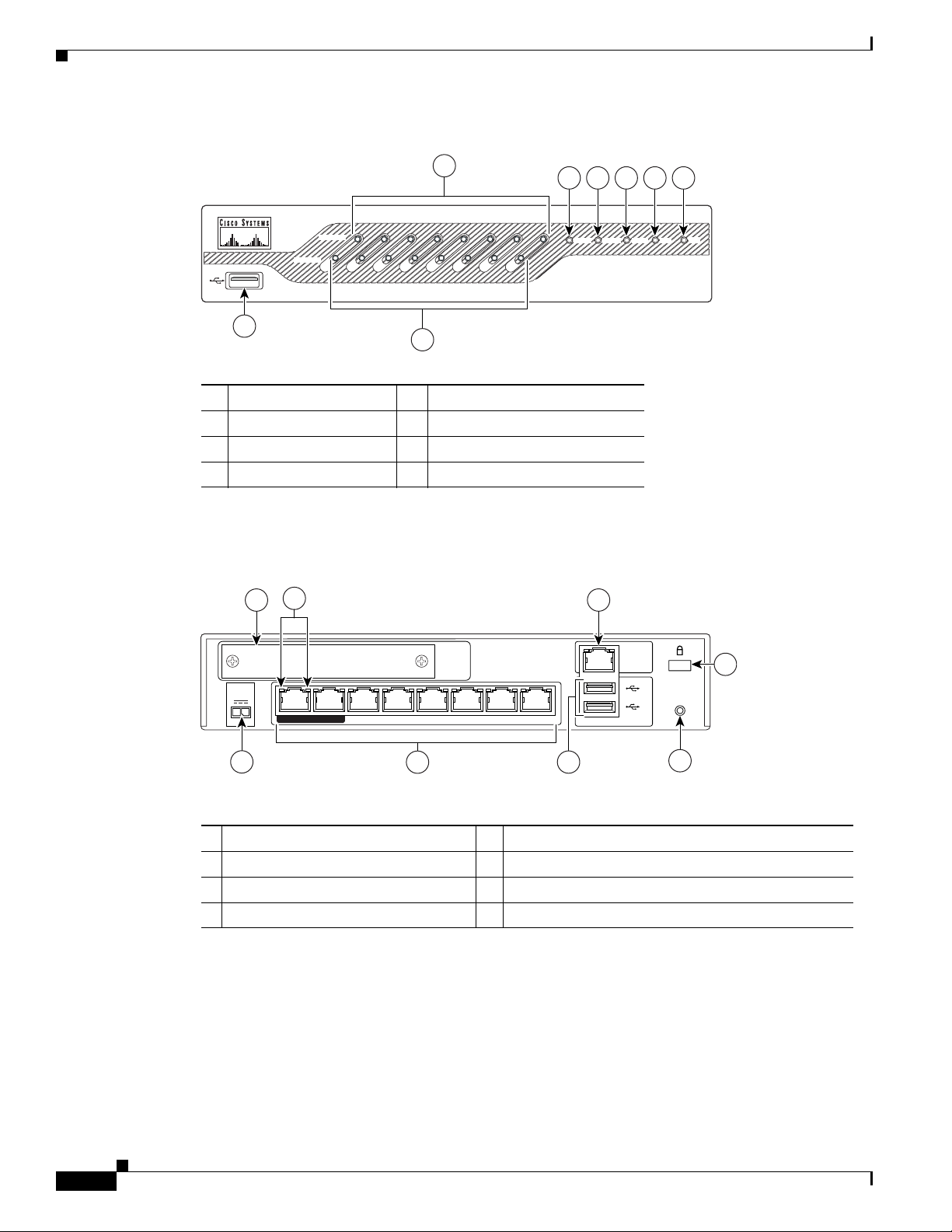

This section describes the front and rear panels. Figure 1-1 shows the front panel LEDs.

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

1-1

Page 12

Product Overview

Chapter 1 Overview

Figure 1-1 Front Panel LEDs and Ports

3

4 7 8

5 6

LINK/ACT

100 MBPS

0

0 1 2 3 4 5 6 7

Power Status Active VPN SSC

Cisco ASA 5505 Series

Adaptive Security Appliance

1

2

1 USB 2.0 interface 5 Status

2 100 Mbps 6 Active

3 LINK/ACT LEDs 7 VPN

4 Power 8 SSC

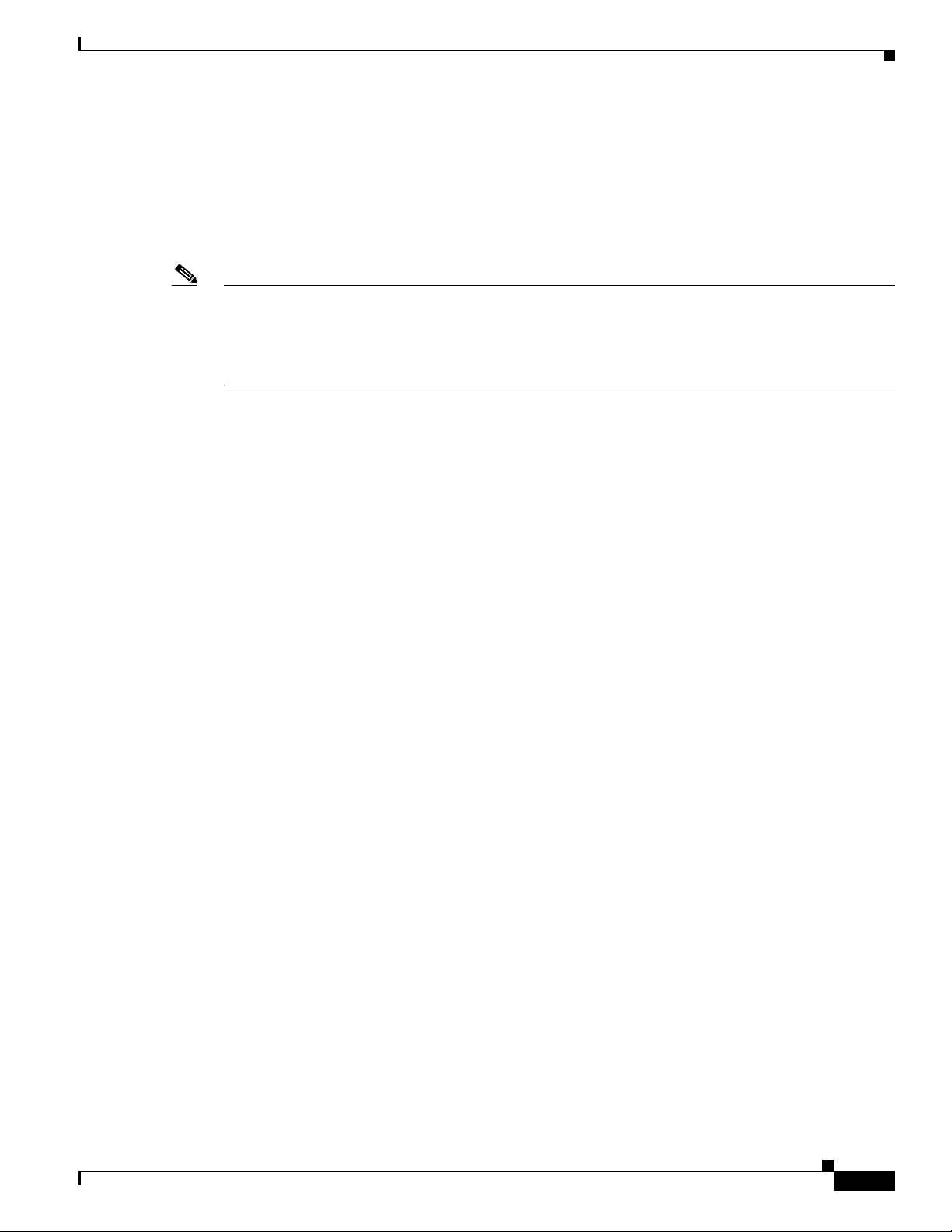

Figure 1-2 shows the rear panel LEDs and Ports.

Figure 1-2 Rear Panel LEDs and Ports (AC Power Supply Model Shown)

3

2

5

153644

POWER

48

VDC

1

7

POWER over ETHERNET 6

Security

Services

Card Slot

543210

4

6

Console

1

2

8

RESET

153645

7

1 Power 48VDC 5 Console port

2 SSC slot 6 USB 2.0 interface

3 Network interface LEDs 7 Reset button

4 Network interfaces

1. Ports 6 and 7 are 15-Watt output PoE ports, used for devices, such as IP phones, which can be powered by the network

interface. They can also be used as regular Ethernet switch ports, just like the ports numbered 0 through 5.

1

8 Lock slot

1-2

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 13

Chapter 1 Overview

Memory Requirements

The default DRAM memory is 256MB and the default internal flash memory is 128MB for the

Cisco ASA 5505.

In a failover configuration, the two units must have the same hardware configuration They must be the

same model, have the same number and types of interfaces, and the same amount of RAM.

Note The two units do not have to have the same size Flash memory. If using units with different Flash

memory sizes in your failover configuration, make sure the unit with the smaller Flash memory has

enough space to accommodate the software image files and the configuration files. If it does not,

configuration synchronization from the unit with the larger Flash memory to the unit with the smaller

Flash memory will fail.

For more information, see the Cisco Security Appliance Command Line Configuration Guide.

Memory Requirements for the Software Version 8.3 and Later

Memory Requirements

For information on memory requirements for the adaptive security appliance for software Version 8.3 or

later, go to:

http://www.cisco.com/en/US/prod/collateral/vpndevc/ps6032/ps6094/ps6120/product_bulletin_c25-58

6414.html

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

1-3

Page 14

Memory Requirements

Chapter 1 Overview

1-4

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 15

Preparing for Installation

The information in this guide applies to the Cisco ASA 5505 In this guide, references to “adaptive

security appliance” or security appliance apply to the Cisco ASA 5505 chassis unless specifically noted

otherwise.

This chapter describes the steps to follow before installing new hardware or performing hardware

upgrades, and includes the following sections:

• Installation Overview, page 2-1

• Safety Recommendations, page 2-1

• General Site Requirements, page 2-3

Installation Overview

To prepare for the installation of the chassis, perform the following steps:

CHA PTER

2

Step 1 Review the safety precautions outlined in the Regulatory Compliance and Safety Information for the

Cisco ASA 5500 Series document.

Step 2 Read the release notes for the respective software version.

Step 3 Unpack the chassis. An accessory kit ships with the chassis and includes the following items:

documentation, a product CD, a power cord (AC models only), two RJ-45 Ethernet cables, one RJ-45 to

DB-9 console cable, a rack-mounting kit, and four self-adhesive feet (for desktop mounting).

Step 4 Place the chassis on a stable work surface.

Safety Recommendations

Use the following guidelines and the information in the following sections to help ensure your safety and

protect the adaptive security appliance. The list of guidelines may not address all potentially hazardous

situations in your working environment, so be alert and exercise good judgement at all times.

Note If you need to remove the chassis cover to install a hardware component, such as additional memory or

an interface card, doing so does not affect your Cisco warranty. Upgrading the adaptive security

appliance does not require any special tools and does not create any radio frequency leaks.

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

2-1

Page 16

Safety Recommendations

The safety guidelines are as follows:

• Keep the chassis area clear and dust-free before, during and after installation.

• Keep tools away from walk areas where you and others could fall over them.

• Do not wear loose clothing or jewelry, such as earrings, bracelets, or chains, that could get caught

in the chassis.

• Wear safety glasses if you are working under any conditions that might be hazardous to your eyes.

• Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

This section includes the following topics:

• Maintaining Safety with Electricity, page 2-2

• Preventing Electrostatic Discharge Damage, page 2-3

Maintaining Safety with Electricity

Chapter 2 Preparing for Installation

Warning

Before working on a chassis or working near power supplies, unplug the power cord on AC units;

disconnect the power at the circuit breaker on DC units.

Statement 12

Follow these guidelines when working on equipment powered by electricity:

• Before beginning procedures that require access to the interior of the chassis, locate the emergency

power-off switch for the room in which you are working. Then, if an electrical accident occurs, you

can act quickly to turn off the power.

• Do not work alone if potentially hazardous conditions exist anywhere in your work space.

• Never assume that power is disconnected from a circuit; always check the circuit.

• Look carefully for possible hazards in your work area, such as moist floors, ungrounded power

extension cables, frayed power cords, and missing safety grounds.

• If an electrical accident occurs, proceed as follows:

–

Use caution; do not become a victim yourself.

–

Disconnect power from the system.

–

If possible, send another person to get medical aid. Otherwise, assess the condition of the victim

and then call for help.

–

Determine if the person needs rescue breathing or external cardiac compressions; then take

appropriate action.

• Use the adaptive security appliance chassis within its marked electrical ratings and product usage

instructions.

• Install the adaptive security appliance in compliance with local and national electrical codes as listed

in the Regulatory Compliance and Safety Information for the Cisco ASA 5500 Series document.

2-2

• The adaptive security appliance models equipped with AC-input power supplies are shipped with a

3-wire electrical cord with a grounding-type plug that fits only a grounding-type power outlet. Do

not circumvent this safety feature. Equipment grounding should comply with local and national

electrical codes.

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 17

Chapter 2 Preparing for Installation

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD damage occurs

when electronic components are improperly handled and can result in complete or intermittent failures.

• Always follow ESD-prevention procedures when removing and replacing components. Ensure that

the chassis is electrically connected to earth ground. Wear an ESD-preventive wrist strap, ensuring

that it makes good skin contact. Connect the grounding clip to an unpainted surface of the chassis

frame to safely ground ESD voltages. To properly guard against ESD damage and shocks, the wrist

strap and cord must operate effectively. If no wrist strap is available, ground yourself by touching

the metal part of the chassis.

• For safety, periodically check the resistance value of the antistatic strap, which should be between

1 and 10 megohms (Mohms).

General Site Requirements

The topics in this section describe the requirements your site must meet for safe installation and

operation of your system. Ensure that your site is properly prepared before beginning installation.

General Site Requirements

This section includes the following topics:

• Site Environment, page 2-3

• Preventive Site Configuration, page 2-3

• Power Supply Considerations, page 2-4

• Configuring Equipment Racks, page 2-4

Site Environment

Place the chassis on a desktop or mount it on a rack. The location of the chassis and the layout of the

equipment rack or wiring room are extremely important for proper system operation. Equipment placed

too close together, inadequate ventilation, and inaccessible panels can cause system malfunctions and

shutdowns, and can make the chassis maintenance difficult.

For information on physical specifications, see table 7 at the following url:

http://www.cisco.com/en/US/prod/collateral/vpndevc/ps6032/ps6094/ps6120/product_data_sheet0900a

ecd802930c5.html.

When planning the site layout and equipment locations, keep in mind the precautions described in the

next section “Preventive Site Configuration, page 2-3,” to help avoid equipment failures and reduce the

possibility of environmentally caused shutdowns. If you are currently experiencing shutdowns or

unusually high error rates with your existing equipment, these precautions may help you isolate the

cause of failures and prevent future problems.

Preventive Site Configuration

The following precautions will help plan an acceptable operating environment for the chassis and avoid

environmentally caused equipment failures:

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

2-3

Page 18

General Site Requirements

• Electrical equipment generates heat. Ambient air temperature might not be adequate to cool

equipment to acceptable operating temperatures without adequate circulation. Ensure that the room

in which you operate your system has adequate air circulation.

• Always follow the ESD-prevention procedures described previously to avoid damage to equipment.

Damage from static discharge can cause immediate or intermittent equipment failure.

• Ensure that the chassis top panel is secure. The chassis is designed to allow cooling air to flow

effectively within it. An open chassis allows air leaks, which may interrupt and redirect the flow of

cooling air from the internal components.

Power Supply Considerations

For information on power supply considerations including environmental operating ranges and power

requirements, see table 7 at the following url:

http://www.cisco.com/en/US/prod/collateral/vpndevc/ps6032/ps6094/ps6120/product_data_sheet0900a

ecd802930c5.html

Observe the following considerations:

Chapter 2 Preparing for Installation

• Check the power at the site before installing the chassis to ensure that the power is “clean” (free of

spikes and noise). Install a power conditioner if necessary, to ensure proper voltages and power

levels in the source voltage.

• Install proper grounding for the site to avoid damage from lightning and power surges.

• In a chassis equipped with an AC-input power supply, use the following guidelines:

–

The chassis does not have a user-selectable operating range. Refer to the label on the chassis for

the correct AC-input power requirement.

–

Several styles of AC-input power supply cords are available; make sure you have the correct

style for your site.

–

Install an uninterruptible power source for your site, if possible.

–

Install proper site grounding facilities to guard against damage from lightning or power surges.

Configuring Equipment Racks

For information on physical specifications, see table 7 at the following url:

http://www.cisco.com/en/US/prod/collateral/vpndevc/ps6032/ps6094/ps6120/product_data_sheet0900a

ecd802930c5.html.

2-4

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 19

Installing the Cisco ASA 5505

Installing the Chassis

This section contains the following topics:

• Connecting the Interface Cables, page 3-1

• Powering on the Cisco ASA 5505, page 3-3

• Installing a Cable Lock, page 3-4

• Rack or Wall Mounting the Cisco ASA 5505, page 3-4

Connecting the Interface Cables

This section describes how to connect the cables to the Ethernet and Console ports.

CHA PTER

3

Warning

Caution Read the safety warnings in the Regulatory Compliance and Safety Information for the Cisco ASA 5505

Step 1 Place the chassis on a flat, stable surface.

Step 2 Before connecting a computer or terminal to the ports, check to determine the baud rate of the serial port. The

Step 3 Connect the cables to the ports.

Only trained and qualified personnel should install, replace, or service this equipment. Statement 49

Adaptive Security Appliance and follow proper safety procedures when performing these steps.

To connect cables to the ports perform the following steps:

baud rate must match the default baud rate (9600 baud) of the Console port of the adaptive security

appliance. Set up the terminal as follows: 9600 baud (default), 8 data bits, no parity, 1 stop bits, and Flow

Control (FC) = Hardware.

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

3-1

Page 20

Connecting the Interface Cables

a. Ethernet ports

Step 1 Connect Port 0, the outside Ethernet port, to the public network, that is, the Internet:

Note By default, switch port 0/0 is the outside port. If needed you can change the inside and outside

Step 2 Connect your network devices with an Ethernet cable to one of the inside ports (numbered 1 through 7).

If you are connecting any PoE devices, connect them to one of the switch ports that support PoE (ports

numbered 6 and 7).

Step 3 Check the LINK LED to verify that the network devices have basic connectivity to the Cisco ASA 5505

on one of the inside ports (numbered 0 through 7). When connectivity is established, the LINK LED on

the front panel of the Cisco ASA 5505 lights up solid green.

Figure 3-1 Connecting Cables to Network Interfaces

Chapter 3 Installing the Cisco ASA 5505

ports assignments later.

Step 4

power

48

VDC

7 POWER over ETHERNET 6

Security

Services

Card Slot

543210

Console

1

2

RESET

153646

1

2

1 RJ-45 Ethernet ports 2 RJ-45 connector

Connect the power cord to the adaptive security appliance and plug the other end to the power source.

For information on powering on the chassis, see the “Powering on the Cisco ASA 5505” section on

page 3-3

3-2

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 21

Chapter 3 Installing the Cisco ASA 5505

b. Console port

You can access the command line for administration using the console port on theCisco ASA 5505. To

connect to the console port and run a serial terminal emulator on a PC or workstation, perform the

following steps:

Step 1 Plug one end of the PC terminal adapter into a standard 9-pin PC serial port on your PC.

Step 2 Plug one end of the blue console cable into the PC terminal adapter.

Step 3 Plug the other end of the blue console cable into the Console port.

Step 4 Configure the PC terminal emulation software or terminal for 9600 baud, 8 data bits, no parity, and 1

stop bit.

Figure 3-2 Connecting to the Console Cable

Powering on the Cisco ASA 5505

Security

Services

Card Slot

power

48

VDC

7

POWER over ETHERNET

6

54 3210

1 RJ-45 Console port 2 RJ-45 to DB-9 console cable

Powering on the Cisco ASA 5505

To power on the Cisco ASA 5505, perform the following steps:

Step 1 Connect the power supply with the power cable.

Step 2 Connect the small, rectangular connector of the power supply cable to the power connector on the rear.

Console

1

RESET

2

1

2

153643

OL-18362-01

Step 3 Connect the AC power connector of the power supply input cable to an electrical outlet.

Note The Cisco ASA 5505 does not have a power switch. Completing Step 3 powers on the device.

Step 4 Check the power LED; if it is solid green, then the device is powered on.

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

3-3

Page 22

Installing a Cable Lock

Note The light will be solid green, only for 100Mbps devices.

Installing a Cable Lock

The Cisco ASA 5505 includes a slot that accepts standard desktop cable locks to provide physical

security. The cable lock is not included.

To install a cable lock, perform the following steps:

Step 1 Follow the directions from the manufacturer for attaching the other end of the cable for securing the

Cisco ASA 5505.

Step 2 Attach the cable lock to the lock slot on the back panel of the Cisco ASA 5505.

Chapter 3 Installing the Cisco ASA 5505

Rack or Wall Mounting the Cisco ASA 5505

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special

precautions to ensure that the system remains stable. The following guidelines are provided to ensure

your safety:

mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest component

at the bottom of the rack. If the rack is provided with stabilizing devices, install the stabilizers before mounting

or servicing the unit in the rack.

The following information can help plan equipment rack installation:

• Allow clearance around the rack for maintenance.

• If the rack contains stabilizing devices, install the stabilizers prior to mounting or servicing the unit

in the rack.

• When mounting a device in an enclosed rack, ensure adequate ventilation. Do not overcrowd an

enclosed rack. Make sure that the rack is not congested, because each unit generates heat.

• When mounting a device in an open rack, make sure that the rack frame does not block the intake

or exhaust ports.

• If the rack contains only one unit, mount the unit at the bottom of the rack.

• If the rack is partially filled, load the rack from the bottom to the top, with the heaviest component

at the bottom of the rack.

This unit should be mounted at the bottom of the rack if it is the only unit in the rack. When

Statement 1006

3-4

This section contains the following topics:

• Mounting the Chassis, page 3-5

• Installing and Wall-Mounting the Cisco ASA 5505 FIPS Enclosure, page 3-11

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 23

Chapter 3 Installing the Cisco ASA 5505

Mounting the Chassis

You can wall-mount or rack-mount the adaptive security appliance. The part number for ordering a

wall-mount kit for the adaptive security appliance is ASA-5505-WALL-MNT= , the part number for

ordering a rack-mount kit for the adaptive security appliance is ASA5505-RACK-MNT= . This section

includes the following topics:

• Wall-Mounting the Chassis, page 3-5

• Rack-Mounting the Chassis, page 3-7

Wall-Mounting the Chassis

To wall-mount the chassis, perform the following steps:

Step 1 Choose a wall where you would like to mount the adaptive security appliance.

Step 2 Using the wall-mounting bracket as a template, use a pencil to mark the location for the four plastic anchors,

used to secure the adaptive security appliance to the wall. Make sure all the pencil marks are located in the

center as shown in Figure 3-10.

Rack or Wall Mounting the Cisco ASA 5505

Figure 3-3 Wall-Mounting Bracket

1

1

2

3

2

2

3

2

1

Screws

(4)

Anchors

(4)

Sheet metal screws

(3)

191805

1 M3 x 12 screws 3 Plastic anchors for vertical mounting (optional)

2 Plastic anchors

OL-18362-01

Step 3 Drill a hole on the wall at each mark you made for the location for the plastic anchors.

Step 4 Press the four plastic anchors into the holes.

Step 5 Screw the four screws provided in the accessory kit into the anchors, but not all the way. Allow them to

protrude about 1/8-inch (0.317 cm).

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

3-5

Page 24

Rack or Wall Mounting the Cisco ASA 5505

Step 6 Remove the three screws from the bottom of the adaptive security appliance as shown in Figure 3-13.

Discard these screws as you will not need them.

Step 7 Place the wall-mount bracket on the adaptive security appliance. Use the three screws provided in the

accessory kit to screw the wall-mount bracket to the adaptive security appliance as shown in Figure 3-13.

Figure 3-4 Removing and Replacing the Screws

Chapter 3 Installing the Cisco ASA 5505

Step 8

191806

Pick up the adaptive security appliance with the wall-mount bracket facing the wall, align the screws in the

anchors with the holes in the brackets.

3-6

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 25

Chapter 3 Installing the Cisco ASA 5505

Step 9 Allowing the screws in the anchors to go through the holes in the brackets, mount and slide down the

adaptive security appliance.

Figure 3-5 Mounting the Cisco ASA 5505 Chassis

Rack or Wall Mounting the Cisco ASA 5505

1

1 Screws

Step 10

Connect the interface cables.

For information on installing the cables

Rack-Mounting the Chassis

To rack-mount the adaptive security appliance chassis, perform the following steps:

Step 1 Remove the three screws from the bottom of the adaptive security appliance as shown in Figure 3-13.

Discard these screws as you will not need them.

Step 2 Place the wall-mount bracket on the adaptive security appliance. Use the three screws provided in the

accessory kit to screw the wall-mount bracket to the adaptive security appliance as shown in Figure 3-13.

190683

, see the “Connecting the Interface Cables” section.

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

3-7

Page 26

Rack or Wall Mounting the Cisco ASA 5505

Step 3 Place the wall-mount bracket with the adaptive security appliance attached to it on the rack mount tray

as shown in Figure 3-6.

Figure 3-6 Placing the Device on the Rack Mount Tray

LINK/ACT

100 MBPS

0

0

1

2

3

4

1

Power Status

7

Active VPN SSC

Cisco ASA 5505

Adaptive Security Appliance

Series

LINK/ACT

100 MBPS

0

0

1

2

3

4

Power Status

7

Active

Cisco ASA 5505

Adaptive Security Appliance

Series

5

6

5

6

2

2

1

VPN SSC

Chapter 3 Installing the Cisco ASA 5505

3

4

5

4

191807

Step 4

1 Wall-mount bracket 2 Cisco ASA 5505 chassis 5 Ve l cr o

3 Cable manager 4 Power supply

Place the power supply adapter on the rack-mount tray and use the velcro provided to hold it in place as

shown in Figure 3-6.

3-8

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 27

Chapter 3 Installing the Cisco ASA 5505

Step 5 Screw in the security bracket to the front of the rack mount as shown in Figure 3-7, to hold it in place.

Rack or Wall Mounting the Cisco ASA 5505

Figure 3-7 Attaching the Security Bracket

LINK/ACT

100 MBPS

0

0

1

2

3

4

5

6

7

Cisco ASA 5505

sco ASA 5505

Power Status

Active VPN SSC

Series

Adaptive Security Appliance

atus

Adaptive Security Appliance

1

Active

Series

0

VPN

SSC

2

LINK/ACT

100 MBPS

0

1

2

3

Power

4

Status

6

7

Cisco ASA 5505

Adaptive Security Appliance

Active

VPN

SSC

Series

191809

5

0

1 Security bracket 2 Screw

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

3-9

Page 28

Rack or Wall Mounting the Cisco ASA 5505

Step 6 Attach the rack-mount tray to the rack using the supplied screws, as shown in Figure 3-8.

Chapter 3 Installing the Cisco ASA 5505

Figure 3-8 Attaching the Rack Mount Tray to the Rack

LINK/A

CT

100 MBPS

0

0

1

2

Power

3

Status

4

Active

5

VPN

6

7

Cisco ASA 5505

Adaptive Security Appliance

SSC

Ser

ies

100 MBPS

0

CISCO

ASA

5530

Adaptive Security Appliance

SE

LINK/A

CT

0

1

2

3

RIES

Pow

er

Status

4

Act

ive

5

VPN

6

7

Cisco ASA 5505

Adaptive Security Appliance

SSC

Series

191808

To remove the chassis from the rack, remove the screws that attach the chassis to the rack, and then

remove the chassis.

3-10

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 29

Chapter 3 Installing the Cisco ASA 5505

Rack or Wall Mounting the Cisco ASA 5505

Installing and Wall-Mounting the Cisco ASA 5505 FIPS Enclosure

Figure 3-9 shows the FIPS enclosure for the Cisco ASA 5505.

Figure 3-9 FIPS Enclosure

272363

To install and wall-mount the Cisco ASA 5505 FIPS enclosure, perform the following steps:

Step 1 Choose a wall where you would like to mount the Cisco ASA 5505.

Step 2 Using the FIPS enclosure as a template, use a pencil to mark the location for the four plastic anchors, used

to secure the adaptive security appliance to the wall. Make sure all the pencil marks are located in the center

as shown in Figure 3-10.

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

3-11

Page 30

Rack or Wall Mounting the Cisco ASA 5505

Figure 3-10 Bottom View of the FIPS Enclosure

1

Chapter 3 Installing the Cisco ASA 5505

1

2

3

2

2

3

2

272365

1

1 M3 x 12 screws 3 Plastic anchors for vertical mounting (optional)

2 Plastic anchors

Step 3

Step 4 Press the four plastic anchors into the holes.

Step 5 Screw the four screws provided in the accessory kit into the anchors, but not all the way. Allow them to

Drill a hole on the wall at each mark you made for the location for the plastic anchors.

protrude about 1/8-inch (0.317 cm).

You must apply three tamper evident labels. Tamper evident labels are inclued in the FIPS kit,

Cisco-FIPS-KIT=. Clean the chassis of any grease, dirt, or oil before applying the tamper evident labels.

Alcohol-based cleaning pads are recommended for this purpose.

3-12

Step 6 Apply the first tamper evident label as shown in Figure 3-11.

Figure 3-11 Cisco ASA 5505 Tamper Evident Label Placement

1

Security

Services

Card Slot

POWER

48

VDC

7

POWER over ETHERNET 6

543210

1 Ta m per lab e l

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

Console

1

2

RESET

250576

OL-18362-01

Page 31

Chapter 3 Installing the Cisco ASA 5505

Step 7 Remove the three screws from the bottom of the Cisco ASA 5505 as shown in Figure 3-12.

Figure 3-12 Removing the Screws

Rack or Wall Mounting the Cisco ASA 5505

250575

Step 8 Slide the ASA 5540 into the FIPS enclosure as shown in Figure 3-13.

Figure 3-13 Sliding the Cisco ASA 5505 Chassis into the FIPS Enclosure

CO ASA 5505

CIS

Securi

Adaptive

Step 9

Turn the FIPS enclosure with the chassis securely inside and use the three screws you removed in Step 6

to screw the FIPS enclosure to the Cisco ASA 5505.

Appliance

ty

IES

SER

272362

OL-18362-01

Step 10 Apply the second tamper evident label over the screw as shown in Figure 3-14.

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

3-13

Page 32

Rack or Wall Mounting the Cisco ASA 5505

Figure 3-14 Tamper Evident Label Applied Over the Screw

Chapter 3 Installing the Cisco ASA 5505

250578

1

Step 11

1 Ta m per lab e l

The third tamper evident label should be placed so that the one half of the tamper evident label covers

the enclosure and the other half covers the Cisco ASA 5505 chassis as shown in Figure 3-15.

Figure 3-15 Tamper Evident Label Applied Over the Chassis and the FIPS Enclosure

1

0

LINK/AC

T

100

MB

PS

0

1

2

3

4

5

6

7

Pow

er

Cis

co ASA 5505

Status

Adap

tiv

Act

ive

VPN

Series

e Security Appliance

SSC

250577

3-14

1 Ta m per lab e l

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 33

Chapter 3 Installing the Cisco ASA 5505

Step 12 Pick up the Cisco ASA 5505 with the FIPS enclosure facing the wall, align the screws in the anchors with

the holes in the enclosure.

Step 13 Allowing the screws in the anchors to go through the holes in the enclosure, mount and slide down the

Cisco ASA 5505 as shown in Figure 3-16.

Figure 3-16 Mounting the Cisco ASA 5505 Chassis

Rack or Wall Mounting the Cisco ASA 5505

Step 14

272361

1 Screws

Connect the interface cables.

For information on installing the cables

1

272361

, see the “Connecting the Interface Cables” section.

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

3-15

Page 34

Rack or Wall Mounting the Cisco ASA 5505

Chapter 3 Installing the Cisco ASA 5505

3-16

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 35

CHA PTER

Maintenance and Upgrade Procedures

This chapter describes how to install the chassis on the wall or rack, remove and replace the chassis

cover, the power supply, and the CompactFlash. This chapter includes the following sections:

• Removing and Replacing the Chassis Cover, page 4-1

• Replacing the Lithium Battery, page 4-3

• Installing and Replacing the SSC, page 4-4

• Upgrading Memory, page 4-6

Removing and Replacing the Chassis Cover

This section describes how to remove and replace the chassis cover. This section includes the following

topics:

• Working in an ESD Environment, page 4-1

4

• Removing the Chassis Cover, page 4-2

• Replacing the Chassis Cover, page 4-3

Working in an ESD Environment

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD damage occurs

when electronic components are improperly handled and can result in complete or intermittent failures.

Always follow ESD-prevention procedures when you remove and replace components. Ensure that the

chassis is electrically connected to earth ground. Wear an ESD-preventive wrist strap, ensuring that it

makes good skin contact. Connect the grounding clip to an unpainted surface of the chassis frame to

safely ground unwanted ESD voltages. To guard against ESD damage and shocks, the wrist strap and

cord must operate properly. If no wrist strap is available, ground yourself by touching the metal part of

the chassis.s

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

4-1

Page 36

Removing and Replacing the Chassis Cover

Removing the Chassis Cover

To remove the chassis cover, perform the following steps:

Note Removing the chassis cover does not affect Cisco warranty. Upgrading the adaptive security appliance

does not require any special tools and does not create any radio frequency leaks.

Step 1 Read the Regulatory Compliance and Safety Information for the Cisco ASA 5500 Series document.

Step 2 Power off the adaptive security appliance.

Chapter 4 Maintenance and Upgrade Procedures

Warning

Before working on a system that has an On/Off switch, turn OFF the power and unplug the power cord.

Statement 1

Step 3 Turn the chassis upside down so that the top of the chassis is resting on a flat surface, and the front of

the chassis is facing toward you.

Step 4 Remove the three screws located on the bottom of the chassis as shown in Figure 4-1.

Figure 4-1 Removing the Screws

250575

4-2

Step 5

Return the chassis to the upright position. Note that the chassis is comprised of two sections: top and

bottom.

Step 6 Hold both sides of the top section, at the base of the appliance in the rear and pull outward while gently

lifting upward.

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 37

Chapter 4 Maintenance and Upgrade Procedures

Replacing the Chassis Cover

Caution Do not operate the adaptive security appliance without the chassis cover installed. The chassis cover

protects the internal components, prevents electrical shorts, and provides proper air-flow for cooling the

electronic components.

To replace the chassis cover on the adaptive security appliance, perform the following steps:

Step 1 Place the chassis on a secure surface with the front panel facing you.

Step 2 Hold the chassis cover so that the rear of the chassis cover are aligned with the chassis bottom.

Step 3 Lower the front of the cover onto the chassis, making sure that the side tabs of the cover fit under the

side panels of the chassis.

Step 4 Slide the chassis cover toward the front, making sure that the cover tabs fit under the back panel, and the

back panel tabs fit under the chassis cover.

Step 5 Secure the chassis cover with the screw you set aside earlier.

Step 6 Reconnect the network interface cables.

Replacing the Lithium Battery

Step 7 Reconnect the power cord to the power outlet to power on the adaptive security appliance.

Replacing the Lithium Battery

This section describes how to remove and replace the lithium battery in the adaptive security appliance.

The lithium battery is a field-replaceable unit (FRU).

Warning

Step 1 Remove the chassis cover as described in the “Removing the Chassis Cover” section on page 4-2.

Step 2 Slide the metal clip back and pull the battery out.

Danger of explosion exists if the lithium battery is incorrectly replaced. Replace only with the same

or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer's instructions.

Statement 33

To remove and replace the battery in the adaptive security appliance, perform the following steps:

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

4-3

Page 38

Installing and Replacing the SSC

Figure 4-2 Cisco ASA 5505 Lithium Battery Location

Security

Services

Card Slot

2

1 Battery 2 Metal clip

Chapter 4 Maintenance and Upgrade Procedures

2

1

191733

1

0

Console

1

2

RESET

Step 3

Place the used battery aside.

Step 4 Replace the battery with a compactible Lithium CR-2032 battery (which is available at your local electronics

or drug store), by sliding the metal clip back and sliding the battery into place.

Step 5 Replace the chassis cover as described in the “Replacing the Chassis Cover” section on page 4-3.

Installing and Replacing the SSC

This section describes how to install and replace the Security Services Card (SSC) . This section includes

the following topics:

• Installing an SSC, page 4-5

• Replacing an SSC, page 4-6

Figure 4-3 lists the SSC LEDs.

Figure 4-3 SSC LEDs

1

4-4

Cisco ASA SSC-05

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

STAT US

251164

OL-18362-01

Page 39

Chapter 4 Maintenance and Upgrade Procedures

Table 4-1 describes the SSC LEDs.

Table 4-1 SSC LEDs

LED Color State Description

1 STATUS Green Flashing

Installing an SSC

To install a new SSC for the first time, perform the following steps:

Step 1 Power off the adaptive security appliance.

Step 2 Locate the grounding strap from the accessory kit and fasten it to your wrist so that it contacts your bare

skin. Attach the other end to the chassis.

Step 3 Remove the two screws (as shown in Figure 4-4) at the left rear end of the chassis, and remove the slot

cover.

Solid

Installing and Replacing the SSC

The system is booting.

The system has passed power-up diagnostics.

Step 4

Figure 4-4 Removing the Screws from the Slot Cover

POWER

48

VDC

7

POWER over ETHERNET

6

54 3210

Security

Services

Card Slot

Console

1

2

Insert the SSC into the slot opening as shown in Figure 4-5.

Figure 4-5 Inserting the SSC into the Slot

POWER

48

VDC

7

POWER over ETHERNET

C

i

sc

o

A

S

A

S

S

C

-05

S

T

A

T

U

S

6

RESET

Security

Services

Card Slot

543210

Console

1

2

251165

RESET

251166

OL-18362-01

Step 5 Attach the screws to secure the SSC to the chassis.

Step 6 Power on the adaptive security appliance.

Step 7 Check the LEDs. If the SSC is installed properly the STATUS LED flashes green.

Step 8 Connect one end of the RJ-45 cable to the port and the other end of the cable to your network devices.

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

4-5

Page 40

Upgrading Memory

Replacing an SSC

To replace an existing SSC, perform the following steps:

Step 1 Enter the hw-mod mod 1 shut command in privileged EXEC mode. Verify if the module is down by

checking the LEDs.

Step 2 Locate the grounding strap from the accessory kit and fasten it to your wrist so that it contacts your bare

skin. Attach the other end to the chassis.

Step 3 Remove the two screws (as shown in Figure 4-4) at the left rear end of the chassis.

Step 4 Remove the SSC. Set it aside.

Step 5 Replace the existing card by inserting the new SSC through the slot opening as shown in Figure 4-5.

Step 6 Attach the screws to secure the SSC to the chassis.

Step 7 Enter the hw-mod mod 1 reset command in privileged EXEC mode to reset the SSC.

Step 8 Check the LEDs. If the SSC is installed properly, the STATUS LED flashes green.

Step 9 Connect one end of the RJ-45 cable to the port and the other end of the cable to your network devices.

Chapter 4 Maintenance and Upgrade Procedures

Upgrading Memory

The memory upgrade kit, ASA5505-MEM-512=, allows you to upgrade the Cisco ASA 5505 to 512 MB

of memory. To determine how much memory your adaptive security appliance has, use the show version

command:

hostname# show version

Cisco Adaptive Security Appliance Software Version 8.0(0)

Device Manager Version 6.0(0)

Compiled on Mon 16-April-07 03:29 by root

System image file is "disk0:/cdisk.bin"

Config file at boot was "disk0:/main_backup.cfg"

hostname up 2 days 10 hours

failover cluster up 2 days 11 hours

Hardware: ASA5505, 256 MB RAM, CPU Pentium 4 Celeron 2000 MHz

BIOS Flash M50FW016 @ 0xffe00000, 2048KB

Table 2 lists the memory for the Cisco ASA 5505.

Table 2 Memory Upgrade

Model Current Memory Upgrade to

Cisco ASA 5505 256 MB 512 MB

4-6

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 41

Chapter 4 Maintenance and Upgrade Procedures

This section describes how to remove and install the memory module on the adaptive security appliance.

This section includes the following topics:

• Removing the DIMM, page 4-7

• Installing the DIMM, page 4-8

Removing the DIMM

To remove the memory module, perform the following steps:

Step 1 Determine the location of the memory sockets, see Figure 6.

Figure 6 System Memory Location in the Cisco ASA 5505

Upgrading Memory

1

2

3

281045

1 DIMM

2 CompactFlash

3 Battery

Step 2 Locate the wrist grounding strap and connect one end to the adaptive security appliance, and securely

attach the other to your wrist so it contacts your bare skin. See,

“Working in an ESD Environment” for

more information.

Note Handle the edges of the DIMM only; avoid touching the memory modules, pins, or traces (the

metal fingers along the connector edge of the DIMM), along the connector edge.

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

4-7

Page 42

Upgrading Memory

Step 3 Pull the latches away from the DIMM at both ends. See Figure 8.

Step 4 When both ends of the DIMM are released from the socket, grasp the ends of the DIMM with your thumb

Chapter 4 Maintenance and Upgrade Procedures

To prevent ESD damage, handle DIMMs as shown in Figure 7.

Figure 7 Handling a DIMM

33115

and forefinger and pull the DIMM completely out of the socket.

Figure 8 Releasing the DIMM Latches

Step 5 Place the DIMM in an antistatic container to protect it from ESD damage.

Installing the DIMM

To install the memory module, perform the following steps:

Step 1 Make sure that both latches on the DIMM connector are open.

Step 2 Remove a new DIMM from the antistatic container.

2

1

1

203845

4-8

The DIMM is designed in such a way that the connector will fit only one way.

Step 3 Hold the DIMM component side up, with the connector edge away from you. Line up the notch in the

connector traces with the notch in the socket on the board.

Step 4 Carefully insert the connector edge into the socket and firmly press the DIMM into the socket until both

latches rotate to the close position against the DIMM. See Figure 9.

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 43

Chapter 4 Maintenance and Upgrade Procedures

Figure 9 Inserting the DIMM

2 2

Caution When inserting DIMMs, use firm but not excessive pressure. You can cause damage to the socket.

When you finish installing new memory, replace the chassis cover.

Upgrading Memory

1

242881

Verifying the Memory Upgrade

You can verify that the memory upgrade has been completed successfully by entering the show version

command:

hostname# show version

Cisco Adaptive Security Appliance Software Version 8.0(0)

Device Manager Version 6.0(0)

Compiled on Mon 16-April-07 03:29 by root

System image file is "disk0:/cdisk.bin"

Config file at boot was "disk0:/main_backup.cfg"

hostname up 2 days 10 hours

failover cluster up 2 days 11 hours

Hardware: ASA5505, 512 MB RAM, CPU Pentium 4 Celeron 2000 MHz

BIOS Flash M50FW016 @ 0xffe00000, 2048KB

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

4-9

Page 44

Upgrading Memory

Chapter 4 Maintenance and Upgrade Procedures

4-10

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 45

Cable Pinouts

This appendix describes pinout information for 10/100/1000BaseT ports, console and the RJ-45 to DB-9

ports, and the Management 10/100/1000 Ethernet port, and includes the following sections:

• 10/100/1000BaseT Connectors, page 1-1

• Console Port (RJ-45), page 1-2

• RJ-45 to DB-9, page 1-4

• MGMT 10/100/1000 Ethernet Port, page 1-4

• Gigabit and Fibre Channel Ports, page 1-5

10/100/1000BaseT Connectors

The adaptive security appliance supports 10/100/1000BaseT ports. You must use at least a Category 5

cable for 100/1000baseT operations, but a Category 3 cable can be used for 10BaseT operations.

APPENDIX

1

The 10/100/1000BaseT ports use standard RJ-45 connectors and supports MDI and MDI-X connectors.

Ethernet ports normally use MDI connectors and Ethernet ports on a hub normally use an MDI-X connector.

Use an Ethernet straight-through cable to connect an MDI to an MDI-X port. Use a cross-over cable to

connect an MDI to an MDI port, or an MDI-X to an MDI-X port.

Figure 1-1 shows the 10BaseT and the 100BaseTX connector (RJ-45).

Figure 1-1 10/100 Port Pinouts

231 45678Pin Label

1

2

3

4

5

6

7

8

RD+

RD-

TD+

NC

NC

TD-

NC

NC

H5318

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

1-1

Page 46

Console Port (RJ-45)

Appendix 1 Cable Pinouts

Figure 1-2 shows the 10BaseT, 100BaseTX, and 1000BASE-T connector (RJ-45).

Figure 1-2 10/100/1000 Port Pinouts

231 45678Pin Label

1

2

3

4

5

6

7

8

TP0+

TP0-

TP1+

TP2+

TP2-

TP1-

TP3+

TP3-

Console Port (RJ-45)

Cisco products use the following types of RJ-45 cables:

• Straight-through

• Crossover

Note Cisco does not provide these cables; they are widely available from other sources.

Figure 1-3 shows the RJ 45 cable.

Figure 1-3 RJ-45 Cable

60915

1-2

8 7 6 5 4 3 2 1

RJ-45 connector

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

H2936

OL-18362-01

Page 47

Appendix 1 Cable Pinouts

Console Port (RJ-45)

To identify the RJ-45 cable type, hold the two ends of the cable next to each other so that you can see

the colored wires inside the ends, as shown in Figure 1-4.

Figure 1-4 RJ-45 Cable Identification

H5663

Examine the sequence of colored wires to determine the type of RJ-45 cable, as follows:

• Straight-through—The colored wires are in the same sequence at both ends of the cable.

• Crossover—The first (far left) colored wire at one end of the cable is the third colored wire at the

other end of the cable.

Table 1-1 lists the rolled (console) cable pinouts for RJ-45.

Table 1-1 RJ-45 Rolled (Console) Cable Pinouts

Signal Pin Pin Pin

- 18-

- 27-

- 36-

- 45-

- 54-

- 63-

- 72-

- 81-

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

1-3

Page 48

RJ-45 to DB-9

RJ-45 to DB-9

Table 1-2 lists the cable pinouts for RJ-45 to DB-9 or DB-25.

Table 1-2 Cable Pinouts for RJ-45 to DB-9 or DB-25

Signal RJ-45 Pin DB-9 Pin

RTS 8 8

DTR 7 6

TxD 6 2

GND 5 5

GND 4 5

RxD 3 3

DSR 2 4

CTS 1 7

Appendix 1 Cable Pinouts

MGMT 10/100/1000 Ethernet Port

The MGMT 10/100/1000 Ethernet port is an Ethernet port with an RJ-45 connector. You can use a

modular, RJ-45, straight-through UTP cable to connect the management port to an external hub, switch,

or router.

Table 1-3 lists the cable pinouts for 10/100/1000BASE-T Management Port Cable Pinouts (MDI).

Table 1-3 10/100/1000BASE-T Management Port Cable Pinouts (MDI)

Signal Pin

TD+ 1

TD- 2

RD+ 3

RD- 6

Not used 4

Not used 5

Not used 7

Not used 8

1-4

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 49

Appendix 1 Cable Pinouts

Gigabit and Fibre Channel Ports

Table 1-4 lists the types of SFP modules and connectors used in the adaptive security appliance.

Table 1-4 Types of SFP Modules and Connectors

Port Compliance Connector Fiber Type

Gigabit Ethernet 1000BASE-SX SW MMF

1000BASE-LX LW SMF

Table 1-5 lists the SFP port cabling specifications for the SFP modules and connectors used in the

adaptive security appliance.

Table 1-5 SFP Port Cabling Specifications

Gigabit and Fibre Channel Ports

Cisco Product

Number

GLC-SX-MM= 850 62.5

GLC-LH-SM= 1300 9.0 1.0625 10 km

Wavelength

(nanometer)

Core Size

(micron) Baud Rate Cable Distance

50.0

1.0625

1.0625

300 m

500 m

OL-18362-01

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

1-5

Page 50

Gigabit and Fibre Channel Ports

Appendix 1 Cable Pinouts

1-6

Cisco ASA 5505 Adaptive Security Appliance Hardware Installation Guide

OL-18362-01

Page 51

INDEX

B

battery 4-3

remove 4-3

replace 4-4

C

chassis

rack-mount 3-7

rack mount tray 3-8

security bracket 3-9

wall-mount 3-5

chassis covers

removing 4-2

replace 4-3

Cisco warranty 2-1

D

FIPS enclosure 3-11

install 3-11

tamper labels 3-12

wall-mount 3-11

I

installing cables 3-1

console port 3-3

ethernet ports 3-2

L

LED

front panel LEDs 1-1

LINK LED 3-2

power LED 3-3

rear panel LEDs 1-2

SSC LEDs 4-5

desktop cable lock 3-4

install 3-4

E

electrostatic discharge

see ESD

ESD

preventing 2-3, 4-1

F

failover 1-3

OL-18362-01

M

memory 4-6

DIMM 4-7

DRAM memory 1-3

flash memory 1-3

P

PoE 1-2, 3-2

power supplies

considerations 2-4

Cisco ASA 5505 Hardware Installation Guide

IN-1

Page 52

Index

R

RJ-45 connector

pinouts 1-4

S

Security Services Card (SSC) 4-4

install 4-5

replace 4-6

site environment 2-3

W

Warning

AC Power 1-ix

Blank Faceplates 1-viii

Chassis 1-viii

Circuit Breaker 1-ix

Cover Panels 1-viii

Ground Conductor 1-viii

Grounded Equipment 1-x

Instructions 1-vii

Jewelry 1-vii

Lightning 1-vii

power Supply 1-vii

Product Disposal 1-viii

Rack-Mounting 1-viii

SELV 1-viii

Short-Circuit 1-viii, 1-ix

TN Power 1-ix

Wrist Strap 1-vii

IN-2

Cisco ASA 5505 Hardware Installation Guide

OL-18362-01

Loading...

Loading...