Page 1

5/4/09

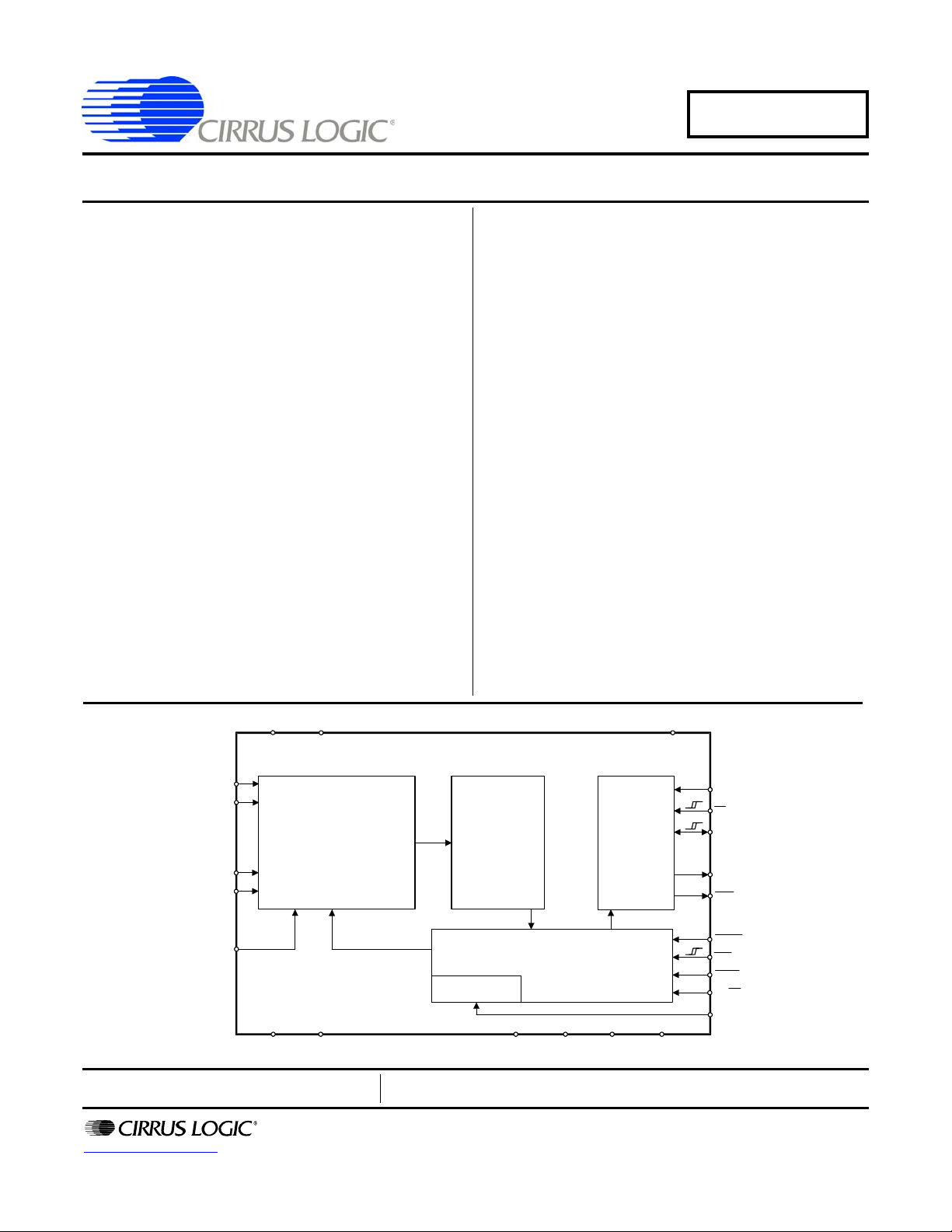

AIN+

AIN-

CS

SCLK

SMODE

VREF+

VREF-

RDY

OSC/CLOCK

GENERATOR

CONV

BP/UP

DIGITAL CONTROL

SERIAL

INTERFACE

ADC

DIGITAL

FILTER

LOGIC

VL

MCLK

SDO

RST

SLEEP

TST

DCR

V1-

V2-

BUFEN

V2+

V1+

CS5566

VLR

VLR2

CS5566

±2.5 V / 5 V, 5 kSps, 24-bit

Features & Description

Differential Analog Input

On-chip Buffers for High Input Impedance

Conversion Time = 200 μS

Settles in One Conversion

Linearity Error = 0.0005%

Signal-to-Noise = 110 dB

24 Bits, No Missing Codes

Simple three/four-wire serial interface

Power Supply Configurations:

- Analog: +5V/GND; IO: +1.8V to +3.3V

- Analog: ±2.5V; IO: +1.8V to +3.3V

Power Consumption: 20 mW @ 5 kSps

ΔΣ

ADC

General Description

The CS5566 is a single-channel, 24-bit analog-to-digital

converter capable of 5 kSps conversion rate. The input

accepts a fully differential analog input signal. On-chip

buffers provide high input impedance for both the AIN inputs and the VREF+ input. This significantly reduces the

drive requirements of signal sources and reduces errors

due to source impedances. The CS5566 is a delta-sigma

converter capable of switching multiple input channels at

a high rate with no loss in throughput. The ADC uses a

low-latency digital filter architecture. The filter is designed

for fast settling and settles to full accuracy in one conv ersion. The converter's 24-bit data output is in serial form,

with the serial port acting as either a master or a slave. The

converter is designed to support bipolar, ground-referenced signals when operated from ±2.5V analog supplies.

The converter can operate from an analog supply of 0-5V

or from ±2.5V. The digital interface supports standard logic operating from 1.8, 2.5, or 3.3 V.

Preliminary Product Information

http://www.cirrus.com

ORDERING INFORMATION:

See Ordering Information on page 30.

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

Copyright Cirrus Logic, Inc. 2009

(All Rights Reserved)

MAY ‘09

DS806PP2

Page 2

5/4/09

CS5566

TABLE OF CONTENTS

1. CHARACTERISTICS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ANALOG CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SWITCHING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

DIGITAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

DIGITAL FILTER CHARACTERISTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

GUARANTEED LOGIC LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

RECOMMENDED OPERATING CONDITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ABSOLUTE MAXIMUM RATINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2. OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3. THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.1 Converter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2 Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Voltage Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.5 Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6 Output Coding Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.7 Typical Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.8 AIN & VREF Sampling Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.9 Converter Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.10 Digital Filter Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.11 Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.11.1 SSC Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.11.2 SEC Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.12 Power Supplies & Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.13 Using the CS5566 in Multiplexing Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.14 Synchronizing Multiple Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4. PIN DESCRIPTIONS 26

5. PACKAGE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6. ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7. ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION . . . . . . . . . . . . . .30

8. REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2 DS806PP2

Page 3

5/4/09

CS5566

LIST OF FIGURES

Figure 1. Converter Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. SSC Mode - Read Timing, CS remaining low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. SSC Mode - Read Timing, CS falling after RDY falls . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. SEC Mode - Continuous SCLK Read Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. SEC Mode - Discontinuous SCLK Read Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Power Consumption vs. Conversion Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. Voltage Reference Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 8. CS5566 Configured Using ±2.5V Analog Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 9. CS5566 Configured Using a Single 5V Analog Supply . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10. CS5566 DNL Plot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 11. Spectral Performance, 0 dB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 12. Spectral Performance, -6 dB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 13. Spectral Performance, -12 dB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 14. Spectral Performance, -20 dB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 15. Spectral Performance, -80 dB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 16. Spectral Performance, -120 dB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 17. Spectral Performance, -130 dB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 19. Noise Histogram (4096 Samples) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 18. Spectral Plot of Noise with Shorted Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 20. Digital Filter Response (DC to 2.5 kHz). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LIST OF TABLES

Table 1. Output Coding, Two’s Complement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 2. Output Coding, Offset Binary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DS806PP2 3

Page 4

5/4/09

CS5566

1. CHARACTERISTICS AND SPECIFICATIONS

• Min / Max characteristics and specifications are guaranteed over the specified operating conditions.

• Typical characteristics and specifications are measured at nominal supply voltages and T

• VLR = 0 V. All voltages with respect to 0 V.

= 25°C.

A

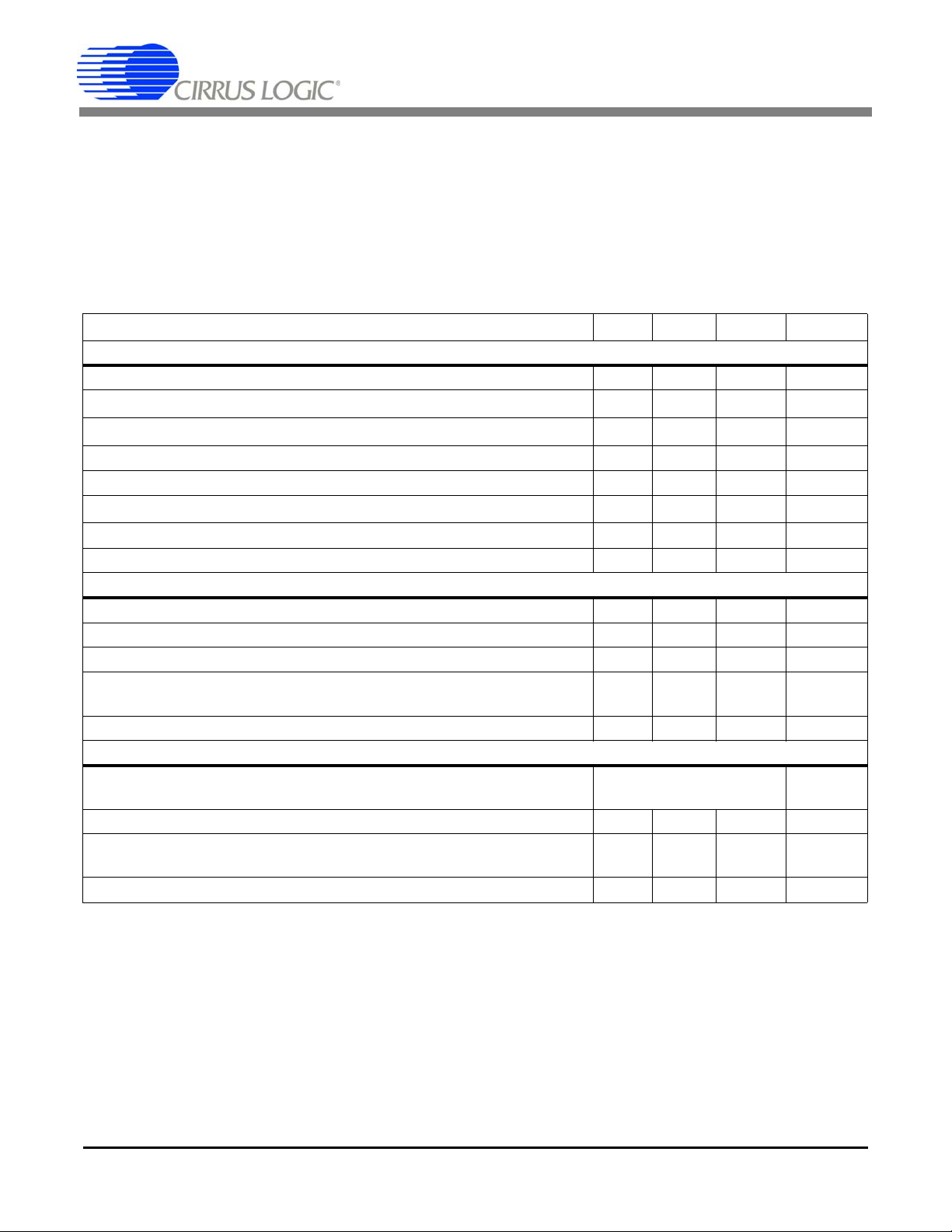

ANALOG CHARACTERISTICS T

±5%; VL -VLR = 3.3 V, ±5%; VREF = (VREF+) - (VREF-) = 4.096V; MCLK = 8 MHz; SMODE = VL. BUFEN = V1+

unless otherwise stated. Connected per Figure 8. Bipolar mode unless otherwise stated.

Parameter Min Typ Max Unit

Accuracy

Linearity Error - 0.0005 - ±%FS

Differential Linearity Error (Note 1) - ±0.1 - LSB

Positive Full-scale Error - 1.0 - %FS

Negative Full-scale Error - 1.0 - %FS

Full-scale Drift (Note 2) - 1 - PPM / °C

Bipolar Offset (Note 2) - ±500 - LSB

Bipolar Offset Drift (Note 2) - 1 - LSB / °C

Noise - 9.5 - μVrms

Dynamic Performance

Peak Harmonic or Spurious Noise 200 Hz, -0.5 dB Input - -115 - dB

Total Harmonic Distortion 200 Hz, -0.5 dB Input - -110 -100 dB

Signal-to-Noise 108 110 - dB

S/(N + D) Ratio -0.5 dB Input, 200 Hz

-3 dB Input Bandwidth (Note 3) - 21 - kHz

Analog Input

Analog Input Range (Differential) Unipolar

Input Capacitance - 10 - pF

CVF Current (Note 4) AIN Buffer On (BUFEN = V+)

Common Mode Rejection Ratio (DC to 2 kHz) -100 -110 - dB

= -40 to +85 °C; V1+ = V2+ = +2.5 V, ±5%; V1- = V2- = -2.5 V,

A

-60 dB Input, 200 Hz--

Bipolar

AIN Buffer Off (BUFEN = V-)--

109

50

0 to +VREF

±VREF

600

130

-

-

-

-

24

24

dB

dB

V

V

nA

μA

1. No missing codes is guaranteed at 24 bits resolution over the specified temperature range.

2. One LSB is equivalent to (2 x VREF) ÷ 2

3. Scales with MCLK.

4. Measured using an input signal of 1 V DC.

4 DS806PP2

24

or (2 x 4.096) ÷ 16, 777,216 = 488 n V.

Page 5

5/4/09

CS5566

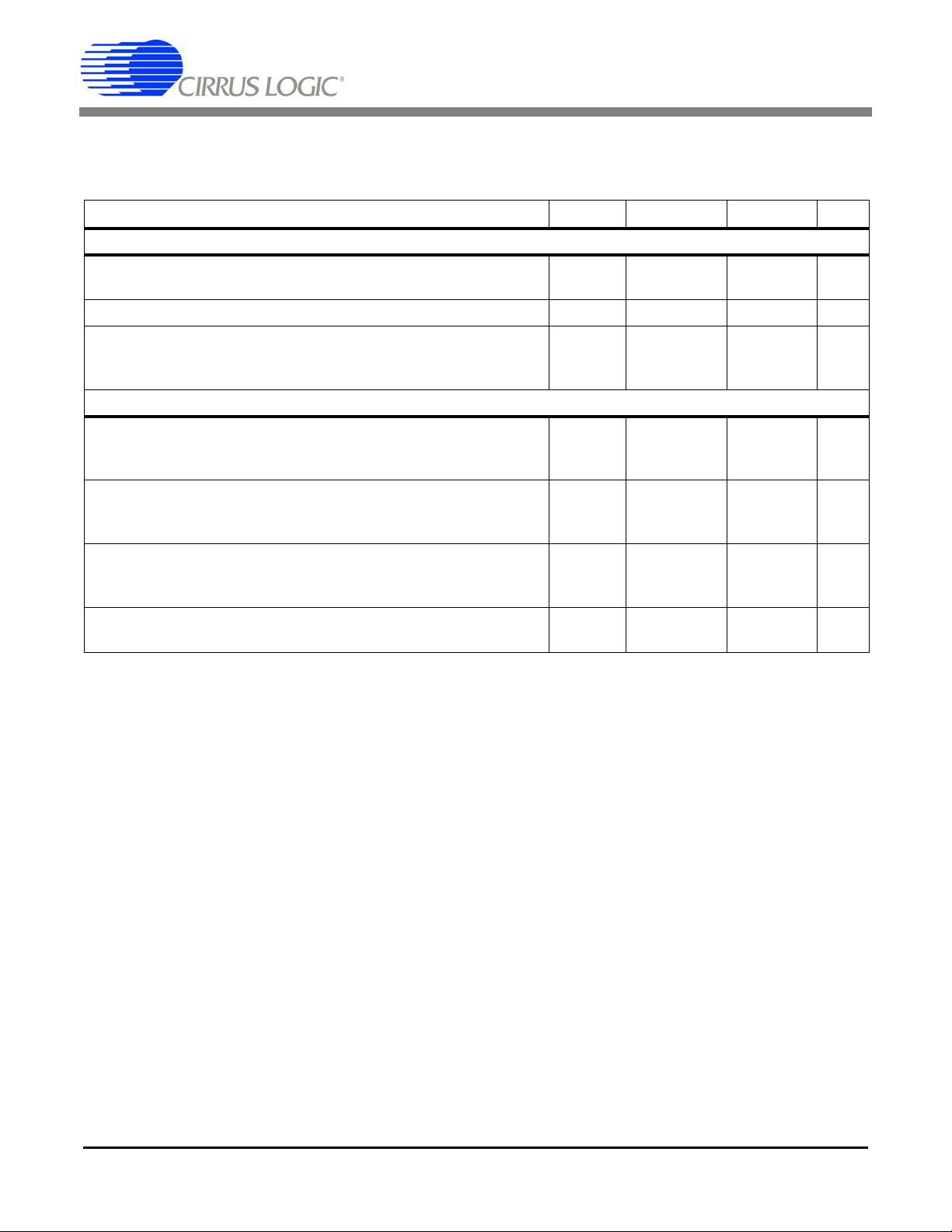

ANALOG CHARACTERISTICS (CONTINUED) T

= -40 to +85 °C; V1+ = V2+ = +2.5 V, ±5%; V1- =

A

V2- = -2.5 V, ±5%; VL -VLR = 3.3 V, ±5%; VREF = (VREF+) - (VREF-) = 4.096V; MCLK = 8 MHz; SMODE = VL.;

BUFEN = V1+ unless otherwise stated. Connected per Figure 8.

Parameter Min Typ Max Unit

Voltage Reference Input

Voltage Reference Input Range

(VREF+) – (VREF-) (Note 5) 2.4 4.096

4.2

V

Input Capacitance - 10 - pF

CVF Current VREF+ Buffer On (BUFEN = V+)

VREF+ Buffer Off (BUFEN = V-)

VREF-

-

-

-

3

1

1

-

-

-

μA

mA

mA

Power Supplies

Average DC Power Supply Currents (Note 6) I

Peak DC Power Supply Currents (Note 6) I

V1

I

V2

I

VL

V1

I

V2

I

VL

Average Power Consumption Normal Operation Buffers On

(Note 6) Buffers Off

Sleep (SLEEP = 0)

Power Supply Rejection (Note 7) V1+ , V2+ Supplies

V1-, V2- Supplies

75

75

-

-

-

-

-

-

-

-

-

20

15

6

85

85

-

-

-

-

-

-

5

0.6

0.4

9

1.2

280

-

-

-

-

-

mA

mA

mA

mA

mA

μA

mW

mW

mW

dB

dB

5. For optimum performance, VREF+ should always be less than (V+) - 0.2 volts to prevent saturation of the VREF+ input buffer.

6. Specification is for MCLK = 8MHz and 5 kSps conversion rate. MCLK frequency and conversion rate affect power consumption.

See Section 3.2 Power Consumption for more details.

7. Tested with 100 mVP-P on any supply up to 2 kHz. V1+ and V2+ supplies at the same voltage potential, V1- and V2- supplies at

the same voltage potential.

DS806PP2 5

Page 6

5/4/09

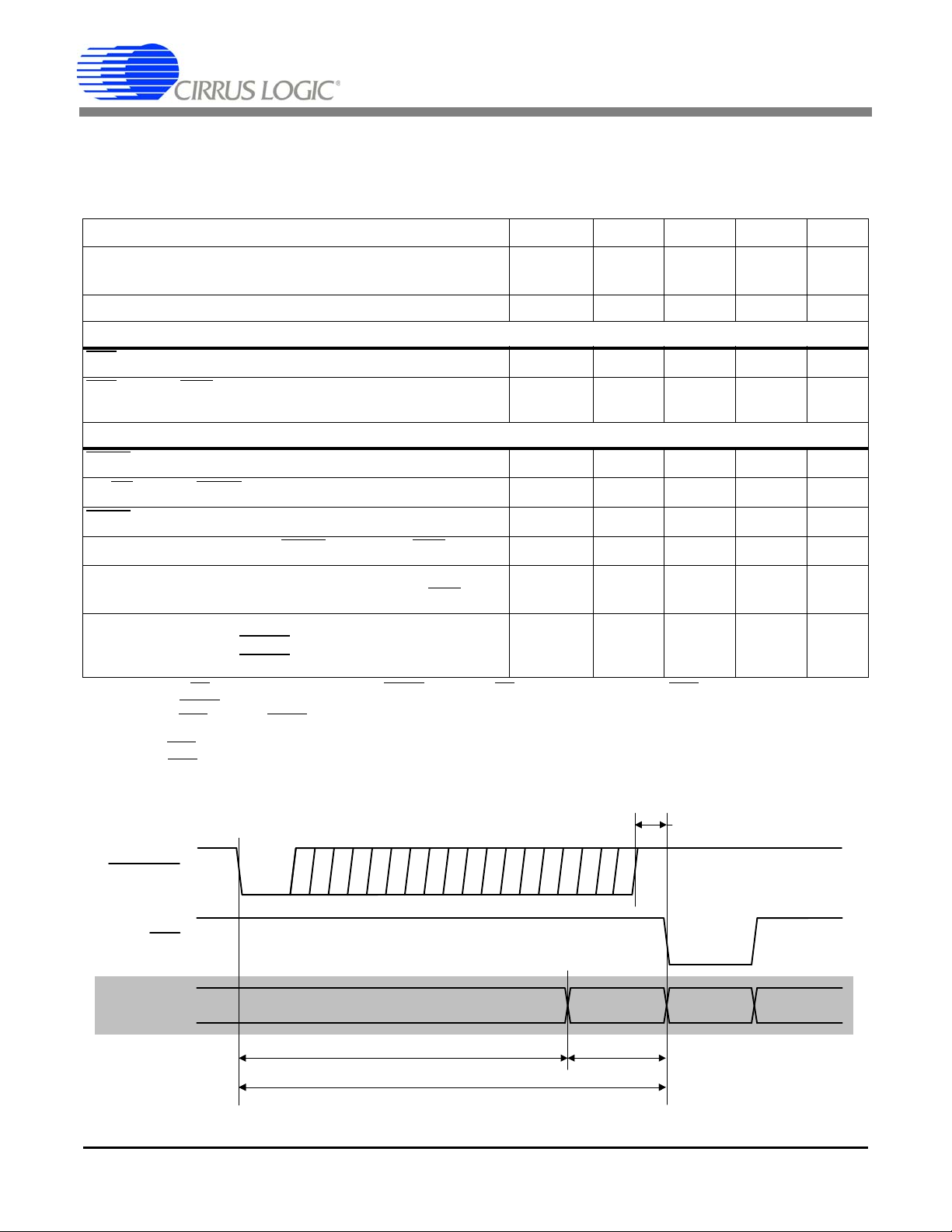

1182 - 1186 MCLKs

Converter

Status

CONVERT

RDY

IDLEIDLE CONVERT

SDO

ACTIVE

t

bus

354 + 64 MCLKs

1600 - 1604 MCLKs

SWITCHING CHARACTERISTICS

TA= -40 to +85 °C; V1+ = V2+ = +2.5 V, ±5%; V1- = V2- = -2.5 V, ±5%;

VL - VLR = 3.3 V, ±5%, 2.5 V, ±5%, or 1.8 V, ±5%

Input levels: Logic 0 = 0V Low; Logic 1 = VD+ = High; CL = 15 pF.

Parameter Symbol Min Typ Max Unit

CS5566

Master Clock Frequency Internal Oscillator

External Clock

XIN

f

clk

6

0.5

7

8

8

8.1

MHz

MHz

Master Clock Duty Cycle 40 - 60 %

Reset

RST

Low Time t

rising to RDY falling Internal Oscillator

RST

External Clock

t

wup

res

1--µs

-

-

240

3084

-

-

µs

MCLKs

Conversion

CONV

Pulse Width t

setup to CONV falling (Note 8) t

BP/UP

low to start of conversion t

CONV

Perform Single Conversion (CONV

high before RDY falling) t

cpw

scn

scn

bus

4--MCLKs

0--ns

- 1182 1186 MCLKs

20 - - MCLKs

Conversion Time (Note 9)

Start of Conversion to RDY

falling t

buh

- - 1604 MCLKs

Sleep Mode

SLEEP

SLEEP

8. BP/UP can be changed coincident CONV falling. BP/UP must remain stable until RDY falls.

9. If CONV

If RDY is tied to CONV, conversions will occur every 1602 MCLKs.

If CONV is operated asynchronously to MCLK, a conversion may take up to 1604 MCLKs.

RDY falls at the end of conversion.

10. RDY

is held low continuously, conversions occur every 1600 MCLK cycles.

will fall when the device is fully operational when coming out of sleep mode.

low to low-power state

high to device active (Note 10)

t

t

con

con

-

-

50

3083

-

-

µs

MCLKs

Figure 1. Converter Status (Not to scale)

6 DS806PP2

Page 7

5/4/09

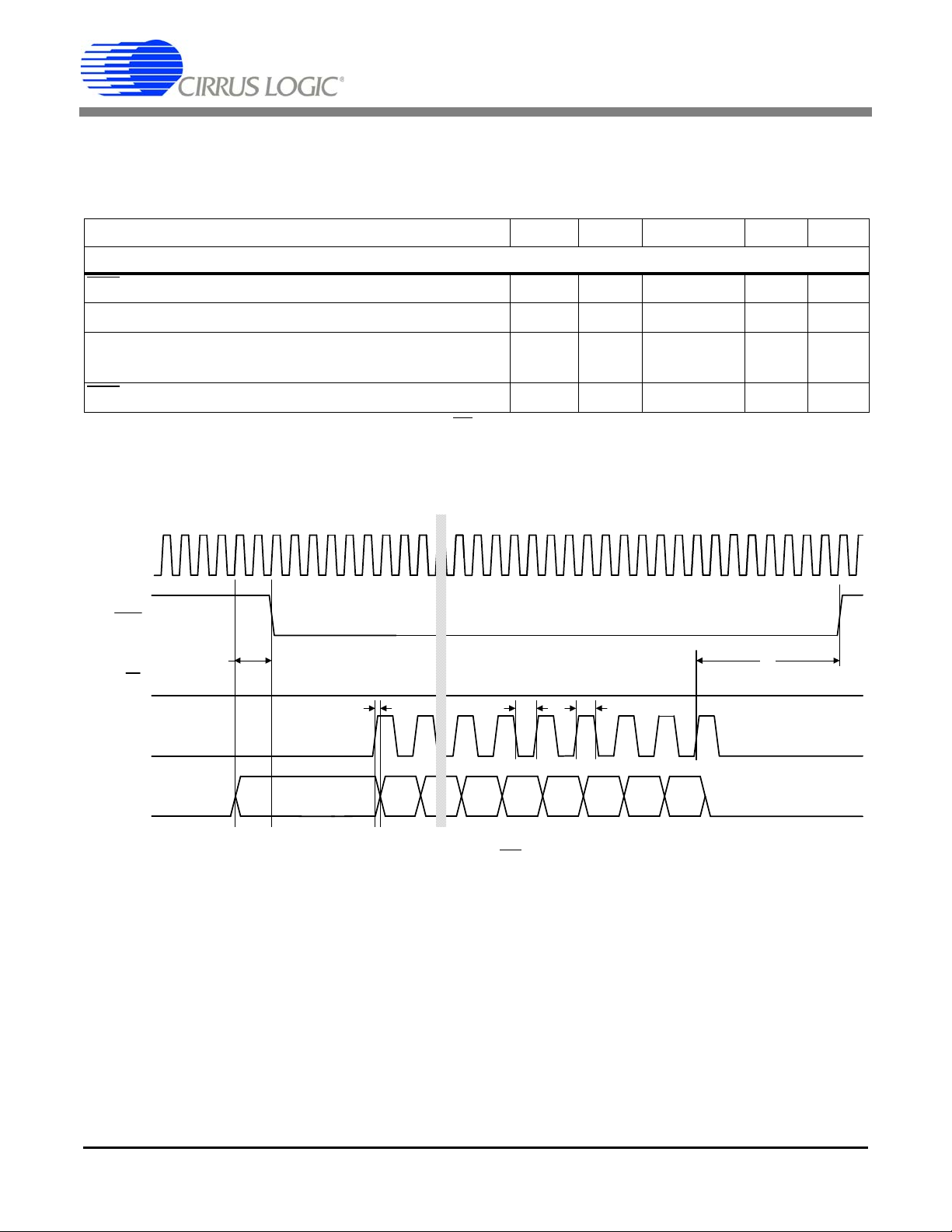

MCLK

RDY

SCLK(o)

SDO

MSB MSB–1

LSB

LSB+1

CS

t

1

t

2

t

3

t

4

t

5

Figure 2. SSC Mode - Read Timing, CS remaining low (Not to Scale)

SWITCHING CHARACTERISTICS (CONTINUED)

TA=-40to+85°C;V1+=V2+=+2.5V, ±5%; V1- = V2- = -2.5 V, ±5%;

VL - VLR = 3.3 V, ±5%, 2.5 V, ±5%, or 1.8 V, ±5%

Input levels: Logic 0 = 0V Low; Logic 1 = VD+ = High; CL = 15 pF.

Parameter Symbol Min Typ Max Unit

Serial Port Timing in SSC Mode (SMODE = VL)

RDY falling to MSB stable t

Data hold time after SCLK rising t

Serial Clock (Out) Pulse Width (low)

(Note 11, 12) Pulse Width (high)

rising after last SCLK rising t

RDY

11. SDO and SCLK will be high impedance when CS is high. In some systems it may require a pull-down resistor.

12. SCLK = MCLK/2.

1

2

t

3

t

4

5

CS5566

--2-MCLKs

-10-ns

100

100

-8-MCLKs

-

-

-

-

ns

ns

DS806PP2 7

Page 8

5/4/09

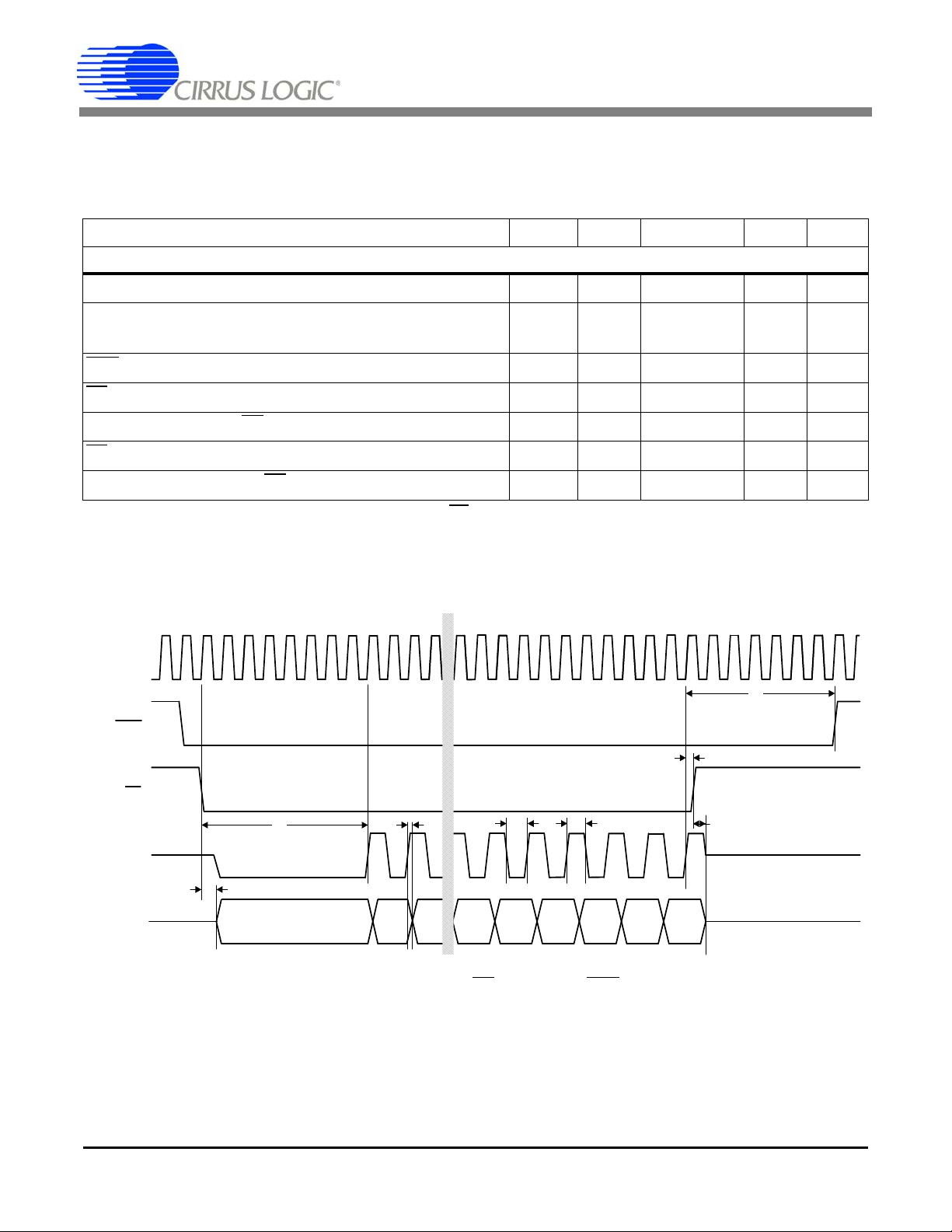

MCLK

RDY

SCLK(o)

SDO

CS

t

12

t

8

t

13

t

9

t

7

t

11

MSB MSB–1

LSB

LSB+1

t

14

t

10

Figure 3. SSC Mode - Read Timing, CS falling after RDY falls (Not to Scale)

SWITCHING CHARACTERISTICS (CONTINUED)

TA=-40to+85°C;V1+=V2+=+2.5V, ±5%; V1- = V2- = -2.5 V, ±5%;

VL - VLR = 3.3 V, ±5%, 2.5 V, ±5%, or 1.8 V, ±5%

Input levels: Logic 0 = 0V Low; Logic 1 = VD+ = High; CL = 15 pF.

Parameter Symbol Min Typ Max Unit

Serial Port Timing in SSC Mode (SMODE = VL)

Data hold time after SCLK rising t

Serial Clock (Out) Pulse Width (low)

(Note 13, 14) Pulse Width (high)

rising after last SCLK rising t

RDY

falling to MSB stable t

CS

First SCLK rising after CS falling t

hold time (low) after SCLK rising t

CS

SCLK, SDO tri-state after CS

13. SDO and SCLK will be high impedance when CS is high. In some systems SCLK and SDO may require pull-down

resistors.

14. SCLK = MCLK/2.

rising t

t

t

10

11

12

13

14

7

8

9

CS5566

-10-ns

100

100

-8-MCLKs

-10-ns

-8-MCLKs

10 - - ns

-5-ns

-

-

-

-

ns

ns

8 DS806PP2

Page 9

5/4/09

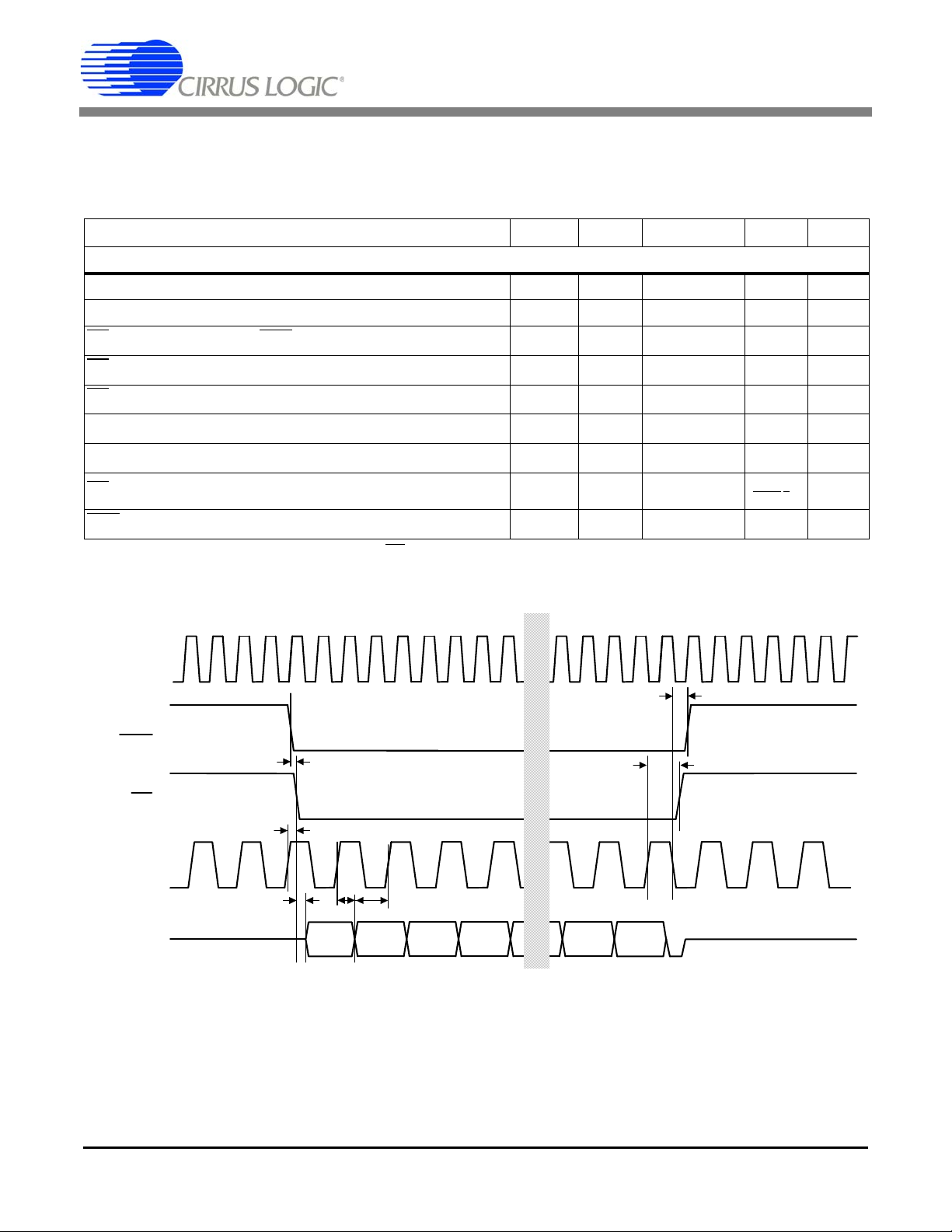

1

SCLK

10

MCLK

SCLK(i)

SDO

CS

RDY

LSBMSB

t

19

t

18

t

20

t

17

t

16

t

15

t

21

Figure 4. SEC Mode - Continuous SCLK Read Timing (Not to Scale)

SWITCHING CHARACTERISTICS (CONTINUED)

TA=-40to+85°C;V1+=V2+=+2.5V, ±5%; V1- = V2- = -2.5 V, ±5%;

VL - VLR = 3.3 V, ±5%, 2.5 V, ±5%, or 1.8 V, ±5%

Input levels: Logic 0 = 0V Low; Logic 1 = VD+ = High; CL = 15 pF.

Parameter Symbol Min Typ Max Unit

Serial Port Timing in SEC Mode (SMODE = VLR)

SCLK(in) Pulse Width (High)

SCLK(in) Pulse Width (Low)

-

-

CS5566

30 - - ns

30 - - ns

hold time (high) after RDY falling t

CS

hold time (high) after SCLK rising t

CS

low to SDO out of Hi-Z (Note 15) t

CS

Data hold time after SCLK rising t

Data setup time before SCLK rising t

CS

hold time (low) after SCLK rising

RDY

rising after SCLK falling t

15. SDO will be high impedance when CS is high. In some systems SDO may require a pull-down resistor.

15

16

17

18

19

t

20

21

10 - - ns

10 - - ns

-10-ns

-10-ns

10 - - ns

10 - ns

-10-ns

DS806PP2 9

Page 10

5/4/09

MCLK

SCLK(i)

SDO

CS

RDY

LSBMSB

t

19

t

18

t

20

t

17

t

15

t

21

Figure 5. SEC Mode - Discontinuous SCLK Read Timing (Not to Scale)

CS5566

DIGITAL CHARACTERISTICS

= TMIN to TMAX; VL = 3.3V, ±5% or VL = 2.5V, ±5% or 1.8V, ±5%; VLR = 0V

T

A

Parameter Symbol Min Typ Max Unit

Input Leakage Current I

Digital Input Pin Capacitance C

Digital Output Pin Capacitance C

in

in

out

--2µA

-3-pF

-3-pF

DIGITAL FILTER CHARACTERISTICS

= TMIN to TMAX; VL = 3.3V, ±5% or VL = 2.5V, ±5% or 1.8V, ±5%; VLR = 0V

T

A

Parameter Symbol Min Typ Max Unit

Group Delay (Note 16) - - 160 - MCLKs

16. See Figure 4 to understand conversion timing. The 160 MCLK group delay occurs during the 354 MCLK high-power period of a

conversion cycle. See Section 3.2 Power Consumption for more detail.

10 DS806PP2

Page 11

5/4/09

GUARANTEED LOGIC LEVELS

TA=-40to+85°C;V1+=V2+=+2.5V, ±5%; V1- = V2- = -2.5 V, ±5%;

VL - VLR = 3.3 V, ±5%, 2.5 V, ±5%, or 1.8 V, ±5%

Input levels: Logic 0 = 0V Low; Logic 1 = VD+ = High; CL = 15 pF.

Guaranteed Limits

Parameter Sym VL Min Typ Max Unit Conditions

Logic Inputs

3.3 1.9

Minimum High-level Input Voltage:

Maximum Low-level Input Voltage:

Logic Outputs

Minimum High-level Output Voltage:

Maximum Low-level Output Voltage:

V

IH

1.8 1.2

3.3 1.1

V

IL

1.8 0.6

3.3 2.9

V

OH

V

OL

2.5 2.1

1.8 1.65

3.3 0.36

2.5 0.36

1.8 0.44

CS5566

V2.5 1.6

V2.5 0.95

V

V

IOH=-2mA

IOH=-2mA

DS806PP2 11

Page 12

5/4/09

RECOMMENDED OPERATING CONDITIONS

(VLR = 0V, see Note 17)

Parameter Symbol Min Typ Max Unit

Single Analog Supply

DC Power Supplies: (Note 17)

V1+

V2+

V1V2-

Dual Analog Supplies

DC Power Supplies: (Note 17)

V1+

V2+

V1V2-

V1+

V2-

V1+

V2-

V1+

V2-

V1+

V2-

4.75

4.75

-

-

+2.375

+2.375

-2.375

-2.375

5.0

5.0

0

0

+2.5

+2.5

-2.5

-2.5

CS5566

5.25

5.25

-

-

+2.625

+2.625

-2.625

-2.625

V

V

V

V

V

V

V

V

Analog Reference Voltage (Note 18)

[VREF+] – [VREF-]

17. The logic supply can be any value VL – VLR = +1.71 to +3.465 volts as long as VLR ≥ V2- and VL ≤ 3.465 V.

18. The differential voltage reference magnitude is constrained by the V1+ or V1- supply magnitude.

ABSOLUTE MAXIMUM RATINGS

(VLR = 0V)

Parameter Symbol Min Typ Max Unit

DC Power Supplies:

[V1+] – [V1-] (Note 19)

VL + [ |V1-| ] (Note 20)

Input Current, Any Pin Except Supplies (Note 21) I

Analog Input Voltage (AIN and VREF pins) V

Digital Input Voltage V

Storage Temperature T

Notes:

19. V1+ = V2+; V1- = V2-

20. V1- = V2-

21. Transient currents of up to 100 mA will not cause SCR latch-up.

WARNING:

VREF 2.4 4.096 4.2 V

-

-

IN

INA

IND

stg

0

0

--±10mA

(V1-) – 0.3 - (V1+) + 0.3 V

VLR – 0.3 - VL + 0.3 V

-65 - 150 °C

-

-

5.5

6.1

V

V

Recommended Operating Conditions indicate limits to which the device is functionally operational. Absolute Maximum Ratings indicate limits beyond which permanent damage to the de vice may occur. The Absolute Maximum Ratings are stress ratings only and the device should not be operated at these limits.

Operation at conditions beyond the Recommended Operating Conditions may affect device reliability, and

functional operation beyond Recommended Operating Conditions is not implied. Performance specifications are intended for the conditions specified for each table in the Characteristics and Specifications section.

12 DS806PP2

Page 13

5/4/09

CS5566

2. OVERVIEW

The CS5566 is a 24-bit analog-to-digital converter capable of 5 kSps conversion rate. The device is capable of switching multiple input channels at a high rate with no loss in throughput. The ADC uses a

low-latency digital filter architecture. The filter is designed for fast settling and settles to full accuracy in

one conversion.

The converter is a serial output device. The serial port can be configu red to function as either a master or

a slave.

The converter can operate from an analog supply of 5V or from ±2.5V. The digital interface supports standard logic operating from 1.8, 2.5, or 3.3 V.

The CS5566 converts at 5 kSps when operating from a 8 MHz input clock.

3. THEORY OF OPERATION

The CS5566 converter provides high-performance measurement of DC or AC signals. The converter can

be used to perform single conversions or continuous conversions upon command. Each conversion is independent of previous conversions and can settle to full specified accuracy, even with a full-scale input

voltage step. This is due to the converter architecture which uses a combination of a high-speed delta-sigma modulator and a low-latency filter architecture.

Once power is established to the converter, a reset must be performed. A reset initializes the internal converter logic.

If CONV

is equivalent to 5 kSps if MCLK = 8.0 MHz. If CONV

1602 MCLKs. If CONV

falling to RDY falling.

Multiple converters can operate synchronously if they are driven by the same MCLK source and CONV

to each converter falls on the same MCLK falling edge. Alternately, CONV can be h eld low and all devices

are reset with RST

The output coding of the conversion word is a function of the BP/UP

The active-low SLEEP

verter will take 3083 MCLK cycles before conversions can be performed. RST

(high) when SLEEP

is held low then the converter will convert continuou sly with RDY falling every 1600 MCLKs. This

is tied to RDY, a conversion will occur every

is operated asynchronously to MCLK, it may take up to 1604 MCLKs from CONV

rising on the same falling edge of MCLK.

pin.

signal causes the device to enter a low-power state. When exiting sleep, the con-

should remain inactive

is asserted (low).

DS806PP2 13

Page 14

5/4/09

3.1 Converter Operation

The converter should be reset after the power supplies and voltage reference are stable.

CS5566

The CS5566 converts at 5 kSps when synchronously operated (CONV

clock. Conversion is initiated by taking CONV

CONV

when a conversion actually begins. This may extend the throughput to 1604 MCLKs

When the conversion is completed, the output word is placed into the serial port and RDY

convert continuously, CONV

conversion is performed in 1600 MCLK cycles. Alternately RDY

will occur every 1602 MCLK cycles.

To perform only one conversion, CONV

falls.

Once a conversion is completed and RDY

emptied from the serial port or if the conversion data is not read and CS

MCLK cycles before the end of conversion. RDY

is put into the port register.

See Section 3.11 Serial Port for information about reading conversion data.

Conversion performance can be affected by several factors. These include the cho ice of clock source for

the chip, the timing of CONV

The converter can be operated from an internal oscillator. This clock source has greater jitter than an ex-

ternal crystal-based clock. Jitter may not be an issue when measuring DC signals, or very-low-frequency

AC signals, but can become an issue for higher frequency AC signals. For maximum performance when

digitizing AC signals, a low-jitter MCLK should be used.

is asynchronous to MCLK there may be an uncertainty of 0-4 MCLK cycles after CONV falls to

should be held low. In continuous conversion mode with CONV held low, a

should return high at least 20 master clock cycles before RDY

, and the choice of the serial port mode.

low. A conversion lasts 1600 master clock cycles, but if

can be tied to CONV and a conversion

falls, RDY will return high when all the bits of the data word are

will fall at the end of the next conversion when new data

= VLR) from a 8.0 MHz master

goes low. To

is held low, RDY will go high two

To maximize performance, the CONV

form multiple conversions, or CONV

If the converter is operated at maximum throughput, the SSC serial port mode is less likely to cause interference to measurements as the SCLK output is synchronized to the MCLK. Alternately, any interference due to serial port clocking can also be minimized if data is read in the SEC serial port mode when a

conversion is not in progress.

14 DS806PP2

pin should be held low in the continuous conversion state to per-

should occur synchronous to MCLK, falling when MCLK falls.

Page 15

5/4/09

7.5

10

12.5

15

17.5

20

0 500 1k 1.5 2k2.5k3k3.5k4k4.5k5k

Word Rate (Sps)

Power Consumption (mW)

MCLK = 8MHz

MCLK = 4MHz

CS5566

3.2 Power Consumption

The power consumption of the CS5566 converter is a function of the conversion rate. Figure 6 illustrates

the typical power consumption of the converter when operating from either MCLK = 8 MHz or

MCLK = 4 MHz. The rate at which conversions are performed directly affects the power consumption.

When the converter is powered but not converting, it is in an idle state where its power consumption is

about 11 mW. When the CONV

of conversion for 1182 to 1186 MCLK cycles, depending upon how CONV

conversion sequence is shown in Figure 1 on page 6. After the 1182 - 1186 MCLK delay from when

CONV

lower-power state for 64 MCLK cycles, after which the RDY

conversion. Since the peak operating current for the converter occurs during the 354 MCLK, higher-power state, it is recommended that a large capacitor be used on the supply to the converter (as shown in

Figures 9 and 10). This capacitor filters the peak current demand from the power supply. The average

power consumption for the converter will depend upon the frequency of MCLK and the rate at which conversions are performed as illustrated in Figure 1 on page 6.

goes low, the converter enters a higher-power state for 354 MCLK cycles and then returns to a

signal goes low to start a conversion, the converter delays the actual start

is controlled. The timing for the

signal falls to indicate the completion of a

Figure 6. Power Consumption vs. Conversion Rate

DS806PP2 15

Page 16

5/4/09

2k

10μF

5.5 to 15 V

VIN

VOUT

GND

4. 096 V

Refer to V1- and VREF1 pins.

CS5566

3.3 Clock

The CS5566 can be operated from its internal oscillator or from an external master clock. The state of

MCLK determines which clock source will be used. If MCLK is tied low, the internal oscillator will start and

be used as the clock source for the converter. If an external CMOS-compatible clock is input into MCLK

the converter will power down the internal oscillator and use the external clock. If the MCLK pin is held

high, the internal oscillator will be held in the stopped state. The MCLK input can be held high to delete

clock cycles to aid in operating multiple converters in different phase relationships.

The internal oscillator can be used if the signals to be measured are essentially DC. The internal oscillator

exhibits jitter at about 500 picoseconds rms. If the CS5566 is used to digitize AC signals, an external

low-jitter clock source should be used.

If the internal oscillator is used as the clock for the CS5566, the maximum conversion rate will be dictated

by the oscillator frequency.

If driven from an external MCLK source, the fast rise and fall times of the MCLK signal can result in clock

coupling from the internal bond wire of the IC to the analog input. Adding a 50 ohm resistor on the external

MCLK source significantly reduces this effect.

3.4 Voltage Reference

The voltage reference for the CS5566 can range from 2.4 volts to 4.2 volts. A 4.096 volt reference is required to achieve the specified performance. Figure 8 and Figure 9 illustrate the connection of the voltage

reference with either a single +5 V analog supply or with ±2.5 V.

For optimum performance, the voltage reference device should be one that provides a capacitor connection to provide a means of noise filtering, or the output should include some type of bandwidth-limiting filter. Some 4.096 volt reference devices need only 5 volts total supply for operation and can be connected

as shown in Figure 8 or Figure 9. The reference should have a local bypass capacitor and an appropriate

output capacitor.

Some older 4.096 voltage reference designs require more headroom and must operate from an input voltage of 5.5 to 6.5 volts. If this type of voltage reference is used ensure that when power is applied to the

system, the voltage reference rise time is slower than the rise time of the V1 + and V1- power sup ply voltage to the converter. An example circuit to slow the output startup time of the reference is illustrated in

Figure 7.

16 DS806PP2

Figure 7. Voltage Reference Circuit

Page 17

5/4/09

NOTE: VREF = (VREF+) - (VREF-)

Table 1. Output Coding, Two’s Complement

Bipolar Input Voltage

Two’s

Complement

>(VREF-1.5 LSB) 7F FF FF

VREF-1.5 LSB

7F FF FF

7F FF FE

-0.5 LSB

00 00 00

FF FF FF

-VREF+0.5 LSB

80 00 01

80 00 00

<(-VREF+0.5 LSB) 80 00 00

NOTE: VREF = (VREF+) - (VREF-)

Table 2. Output Coding, Offset Binary

Unipolar Input Voltage

Offset

Binary

>(VREF-1.5 LSB) FF FF FF

VREF-1.5 LSB

FF FF FF

FF FF FE

(VREF/2)-0.5 LSB

80 00 00

7F FF FF

+0.5 LSB

00 00 01

00 00 00

<(+0.5 LSB) 00 00 00

CS5566

3.5 Analog Input

The analog input of the converter is fully differential with a peak-t o-peak input of 4.096 volts on each input.

Therefore, the differential, peak-to-peak input is 8.192 volts. This is illustrated in Figure 8 and Figure 9.

These diagrams also illustrate a differential buffer amplifier configuration for driving the CS5566.

The capacitors at the outputs of the amplifiers provide a charge reservoir for the dynamic current from t he

A/D inputs while the resistors isolate the dynamic current from the amplifier. The amplifiers can be powered from higher supplies than those used by the A/D but precautions should be taken to ensure that t he

opamp output voltage remains within the power supply limits of the A/D, especially under start-up conditions.

3.6 Output Coding Format

The reference voltage directly defines the input voltage range in both the unipolar and bipolar configurations. In the unipolar configuration (BP/UP

the final code transition occurs 1.5 LSBs below VREF. In the bipolar configuration (BP/UP

code transition occurs 0.5 LSB above -VREF and the last transition occurs 1.5 LSBs below +VREF. See

Table 1 for the output coding of the converter.

low), the first code transition occurs 0.5 LSB above zero, and

high), the first

DS806PP2 17

Page 18

5/4/09

VREF-

VREF+

+4.096

Voltage

Reference

(NOTE 1)

+2.5 V

SMODE

CS

5

SCLK

5

SDO

RDY

CONV

MCLK

SLEEP

RST

BP/UP

1. See Section 3.3 Voltage Reference for information on required

voltage reference performance criteria.

2.Locate capacitors so as to minimize loop length.

3. The ±2.5 V supplies should also be bypassed to ground at the converter.

4. VLR and the power supply ground for the ±2.5 V should be

connected to the same ground plane under the chip.

5. SCLK and SDO may require pull-down resistors in some applications.

6. An RC input filter can be used to band limit the input to reduce noise.

Select R to be equal to the parallel combination of the feedback of the

feedback resistors 4.99k || 4.99k = 2.5k00

NOTES

-2.5 V

BUFEN

(V-) Buffers Off

(V+) Buffers On

10 µF0.1 µF

V1+

V2+

V1-

V2-

VL

VLR

DCR

+2.5 V

+3.3 V to +1.8 V

0.1 µF

0.1 µF

X7R

0.1 µF

10

-2.5 V

CS5566

TST

10

0.1 µF

AIN-

AIN+

49.9

47pF

4.99k

4700pF

C0G

49.9

47pF

4.99k

4700pF

C0G

4.99k

4.99k

-2.048 V

+2.048 V

0 V

+2.048 V

-2.048 V

0 V

R

1

R

1

C

1

C

1

50

VLR2

47 µF

CS5566

3.7 Typical Connection Diagrams

The following figure depicts the CS5566 powered from bipolar analog supplies, +2.5 V and - 2.5 V.

Figure 8. CS5566 Configured Using ±2.5V Analog Supplies

18 DS806PP2

Page 19

5/4/09

AIN-

AIN+

SMODE

CS

4

SCLK

4

SDO

RDY

CONV

BP/UP

MCLK

SLEEP

RST

TST

VREF-

VREF+

+4.096

Voltage

Reference

(NOTE 1)

+5 V

BUFEN

1. See Section 3.3 Voltage Reference for information on

required voltage reference perfor mance criteria.

2. Locate capacitors so as to minimize loop length.

3. V1-, V2-, and VLR should be connected to the same

ground plane under the chip.

4. SCLK and SDO may require pull-down resistors in

some applications.

NOTES

0.1 µF

(V-) Buffers Off

(V+) Buffers On

0.1 µF10 µF

V1+

V2+

V1-

V2-

VL

VLR

DCR

+5 V

+3.3 V to 1.8 V

0.1 µF

0.1 µF

X7R

0.1 µF

10

CS5566

49.9

47pF

4.99k

4700pF

C0G

49.9

47pF

4.99k

4700pF

C0G

+0.452 V

4.548 V

2.5 V

+4.548 V

+0.452 V

2.5 V

2.048 V

4.096 V

50

VLR2

47 µF

The following figure depicts the CS5566 device powered from a single 5V analog supply.

CS5566

Figure 9. CS5566 Configured Using a Single 5V Analog Supply

DS806PP2 19

Page 20

5/4/09

(Zoom View)

CS5566

3.8 AIN & VREF Sampling Structures

The CS5566 uses on-chip buffers on the AIN+, AIN-, and the VREF+ inputs. Buffers provide much higher

input impedance and therefore reduce the amount of drive current required from an external source. This

helps minimize errors.

The Buffer Enable (BUFEN) pin determines if the on-chip buffers are used or not. If the BUFEN pin is connected to the V1+ supply, the buffers will be enabled. If the BUFEN pin is connected to the V1- pin, the

buffers are off. The converter will consume about 5 mW less power when the buffers are off, but the input

impedances of AIN+, AIN- and VREF+ will be significantly less than with the buffers enabled.

3.9 Converter Performance

The CS5566 achieves excellent differential nonlinearity (DNL). Figure 10 illustrates the code widths on

the typical scale of ±1 LSB and on a zoomed scale of ±0.2 LSB.

Figure 10. CS5566 DNL Plot

20 DS806PP2

Page 21

5/4/09

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

0 500 1k 1.5k 2k 2.5k

Frequency (Hz)

277 Hz, 0 dB

32k Samples @ 5 kSps

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

0 500 1k 1.5k 2k 2.5k

Frequency (Hz)

277 Hz, -6 dB

32k Samples @ 5 kSps

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

0 500 1k 1.5k 2k 2.5k

Frequency (Hz)

277 Hz, -12 dB

32k Samples @ 5 kSps

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

0 500 1k 1.5k 2k 2.5k

Frequency (Hz)

277 Hz, -20 dB

32k Samples @ 5 kSps

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

0 500 1k 1.5k 2k 2.5k

Frequency (Hz)

277 Hz, -80 dB

32k Samples @ 5 kSps

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

0 500 1k 1.5k 2k 2.5k

Frequency (Hz)

277 Hz, -120 dB

32k Samples @ 5 kSps

Figure 11. Spectral Performance, 0 dB Figure 12. Spectral Performance, -6 dB

Figure 13. Spectral Performance, -12 dB Figure 14. Spectral Performance, -20 dB

Figure 15. Spectral Performance, -80 dB Figure 16. Spectral Performance, -120 dB

CS5566

Figure 11 through Figure 16 illustrate the performance of the converter with various input signal magni-

tudes.

DS806PP2 21

Page 22

5/4/09

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

0 500 1k 1.5k 2k 2.5k

Frequency (Hz)

277 Hz, -130 dB

32k Samples @ 5 kSps

0

10

20

30

40

50

60

70

80

90

100

4096 Samples

Mean = 96.32

Std. Dev. = 21.3

Max - Min = 150

Output Codes

Number of Occurances

-180

-160

-140

-120

-100

-80

-60

0.1 1 10 100 1k

2.5k

Frequency (Hz)

Shorted Input

2M Samples @ 5 kSps

16 Averages

Figure 17. Spectral Performance, -130 dB

Figure 19. Noise Histogram (4096 Samples)

Figure 18. Spectral Plot of Noise with Shorted Input

CS5566

Figure 16 illustrates the device with a small signal 1/1,000,000 of full scale. The signal input for Figure 16

is about 8.2 microvolts peak to peak, or about 17 codes peak to peak. Figure 17 illustrates the converter

with a signal at about 2.6 microvolts peak to peak, or about 5 codes peak to peak. The CS5566 achieves

superb performance with this small signal.

Figure 18 illustrates the noise floor of the converter from 0.1 Hz to 2.5 kHz. The plot is entirely free of spu-

rious frequency content due to digital activity inside the chip.

Figure 19 illustrates a noise histogram of the converter constructed from 4096 samples.

22 DS806PP2

Page 23

5/4/09

Frequency (Hz)

-0.001646 dB

-0.00663 dB

-0.0149 dB

-0.0262 dB

-0.0414 dB

fs = 5 kSps

CS5566

3.10 Digital Filter Characteristics

The digital filter is designed for fast settling, therefore it exhibits very little in-band attenuation. The filter

attenuation is -0.0414 dB at 2.5 kHz when sampling at 5 kSps.

Figure 20. Digital Filter Response (DC to 2.5 kHz)

DS806PP2 23

Page 24

5/4/09

CS5566

3.11 Serial Port

The serial port on the CS5566 can operate in two different modes: synchronous self clock (SSC) mode &

synchronous external clock (SEC) mode. The serial port must be placed into the SEC mode if the offset

and gain registers of the converter are to be read or written. The converter must be idle when reading or

writing to the on-chip registers.

3.11.1 SSC Mode

If the SMODE pin is high (SMODE = VL), the serial port operates in the SSC (Synchronous Self Clock)

mode. In the SSC mode the port shifts out conversion data words with SCLK as an output. SCLK is generated inside the converter from MCLK. Data is output from the SDO (Serial Data Output) pin. If CS

high, the SDO and SCLK pins will stay in a high-impedance state. If CS

version data word will be output from SDO MSB first. Data is output on the rising edge of SCLK and should

be latched into the external logic on the subsequent rising edge of SCLK. When all bits of the conversion

word are output from the port the RDY

3.11.2 SEC Mode

If the SMODE pin is low (SMODE = VLR), the serial port operates in the SEC (Synchronous External

Clock mode). In this mode, the user usually monitors RDY

the conversion data word is placed into the output data register in the serial port. CS

to enable data output. Note that CS

output operate in the high impedance state. When CS

word is then shifted out of the SDO pin by driving the SCLK pin from system logic external to the convert er.

Data bits are advanced on rising edges of SCLK and latched by the subsequent rising edge of SCLK.

signal will return to high.

. When RDY falls at the end of a conversion,

can be held low continuously if it is not necessary to have the SDO

is taken low (after RDY falls) the conversion data

is low when RDY falls, the con-

is then activated low

is

is held low continuously, the RDY signal will fall at the end of a conversion and th e conversio n data

If CS

will be placed into the serial port. If the user starts a read, th e user will maintain control over th e serial port

until the port is empty. However, if SCLK is not toggled, the converter will overwrite the conversion data

at the completion of the next conversion. If CS

prior to the end of the next conversion and then fall to signal that new data has been written into the serial

port.

is held low and no read is performed, RDY will rise just

24 DS806PP2

Page 25

5/4/09

CS5566

3.12 Power Supplies & Grounding

The CS5566 can be configured to operate with its analog supply operating from 5V, or with its analog supplies operating from ±2.5V. The digital interface supports digital logic operating from either 1.8V, 2.5V, or

3.3V.

Figure 8 on page 18 illustrates the device configured to operate from ±2.5V analog. Figure 9 on page 19

illustrates the device configured to operate from 5V analog. Note that the schematic indicates a 47 μF capacitor between V1+ and V1-. This capacitor is necessary to reduce the peak current required from the

power supply during conversion. See Power Consumption on page 16 for a more detailed discussion.

To maximize converter performance, the analog ground and the logic ground for th e converter shou ld be

connected at the converter. In the dual analog supply configuration, the analog ground for the ±2.5V supplies should be connected to the VLR pin at the converter with the converter placed entirely over the analog ground plane.

In the single analog supply configuration (+5V), the ground for the +5V supply should be directly tied to

the VLR pin of the converter with the converter placed entirely over the analog ground plane. Refer to

Figure 9 on page 19.

3.13 Using the CS5566 in Multiplexing Applications

The actual conversion process inside the CS5566 begins 1182 MCLK cycles after the CONV signal is taken low. This would be over 147 microseconds when MCLK = 8 MHz. If the input channel of an external

multiplexer is changed coincident with CONV

adequate time for settling. If there is an operational amplifier between the multiplexer and the converter,

one should be certain that the amplifier can settle within the 1182 MCLK d elay period. If not, the multiplexer will need to be switched some time prior to CONV

going low, the 1182 MCLK delay should be more than an

going low.

3.14 Synchronizing Multiple Converters

Many measurement systems have multiple converters that need to operate synchronously. The converters should all be driven from the same master clock. In this configuration, the converters will convert synchronously if the same CONV

of MCLK. If CONV

if RST

is released on a falling edge of MCLK.

is held low continuously, reset (RST) can be used to synchronize multiple converters

signal is used to drive all the converters, and CONV falls on a falling edge

DS806PP2 25

Page 26

4. PIN DESCRIPTIONS

SLEEP 12Sleep Mode Select

BP/UP 11Bipolar/Unipolar Select

VREF- 10Voltage Reference Input

VREF+ 9Voltage Reference Input

BUFEN 8Buffer Enable

V1+ 7Positive Power 1

V1- 6Negative Power 1

AIN- 5Differential Analog Input

AIN+ 4Differential Analog Input

3

2

CS 1Chip Select

RST13Reset

VLR214Logic Interface Return

CONV15Convert

DCR16Digital Core Regulator

V2+

17

Positive Voltage 2

V2-

18

Negative Voltage 2

MCLK19Master Clock

VLR20Logic Interface Return

VL

21

Logic Interface Power

SDO22Serial Data Output

SCLK23Serial Clock Input/Output

RDY24Ready

TSTFactory Test

SMODESerial Mode Select

CS – Chip Select, Pin 1

The Chip Select pin allows an external device to access the serial port. If SMODE = VL (SSC

Mode) and CS

high-impedance output state.

5/4/09

CS5566

is held high, the SDO output and the SCLK output will be held in a

TST – Factory Test, Pin 2

Factory test only. Connect to VLR.

SMODE – Serial Mode Select, Pin 3

The serial interface mode pin (SMODE) dictates whether the serial port behaves as a master or

slave interface. If SMODE is tied high (to VL), the port will operate in the Synchronous

Self-Clocking (SSC) mode. In SSC mode, the port acts as a master in which the converter outputs both the SDO and SCLK signals. If SMODE is tied low (to VLR), the port will operate in the

Synchronous External Clocking (SEC) mode. In SEC mode, the port acts as a slave in which

the external logic or microcontroller generate s the SCLK used to output the conversion data

word from the SDO pin.

AIN+, AIN- – Differential Analog Input, Pin 4, 5

AIN+ and AIN- are differential inputs for the converter.

V1- – Negative Power 1, Pin 6

The V1- and V2- pins provide a negative supply voltage to the core circuitry of the chip. These

two pins should be decoupled as shown in the application block diagrams. V1- and V2- should

be supplied from the same source voltage. For single-supply operation, these two voltages are

nominally 0 V (Ground). For dual-supply operation, they are nominally -2.5 V.

V1+ – Positive Power 1, Pin 7

The V1+ and V2+ pins provide a positive supply voltage to the core circuitry of the chip. These

two pins should be decoupled as shown in the application block diagrams. V1+ a nd V2+ should

be supplied from the same source voltage. For single supply-operation, these two voltages are

nominally +5 V. For dual-supply operation, they are nominally +2.5 V.

BUFEN – Buffer Enable, Pin 8

Buffers on input pins AIN+ and AIN- are enabled if BUFEN is connected to V1+ and disabled if

connected to V1-.

VREF+, VREF- – Voltage Reference Input, Pin 9, 10

26 DS806PP2

A differential voltage reference input on these pins functions as the vo ltage reference for the

converter. The voltage between these pins can range between 2.4 volts and 4.2 volts, with

4.096 volts being the nominal reference voltage value.

Page 27

BP/UP – Bipolar/Unipolar Select, Pin 11

The BP/UP

select BP (bipolar), the input span of the converter is -4.096 volt s to +4.096 volts fully dif ferential

(assuming the voltage reference is 4.096 volts) and output data is coded in two's complement

format. When set low to select UP

the output data is coded in binary format.

pin determines the span and the output coding of the converter. When set high to

5/4/09

CS5566

(unipolar), the input span is 0 to +4.096 fully differential and

SLEEP

CONV

– Sleep Mode Select, Pin 12

When taken low , the SLEEP

will stop the internal oscillator and power down all internal analog circuitry.

– Reset, Pin 13

RST

Reset is necessary after power is initially applied to the converter. When the RST

low, the logic in the converter will be reset. When RST

the analog circuitry are started. RDY

– Convert, Pin 15

The CONV

progress. When the conversion cycle is completed, the conversion word is output to the serial

port register and the RDY

falls, another conversion cycle will be started.

DCR – Digital Core Regulator , Pin 16

DCR is the output of the on-chip regulator for the digital logic core. DCR should be bypassed

with a capacitor to V2-. The DCR pin is not designed to power any external load.

V2+ – Positive Power 2, Pin 17

The V1+ and V2+ pins provide a positive supply voltage to the circuitry of the chip. These two

pins should be decoupled as shown in the application block diagrams. V1+ and V2+ should be

supplied from the same source voltage. For single-supply operation, these two voltages are

nominally +5 V. For dual-supply operation, they are nominally +2.5 V.

V2- – Negative Power 2, Pin 18

The V1- and V2- pins provide a negative supply voltage to the circuitry of the chip. These two

pins should be decoupled as shown in the application block diagrams. V1- and V2- should be

supplied from the same source voltage. For single-supply operation, these two voltages are

nominally 0 V (Ground). For dual-supply operation, they are nominally -2.5 V.

pin initiates a conversion cycle if taken low, unless a previous conversion is in

pin will cause the converter to enter into a low-power state. SLEEP

input is taken

is released to go high, certain portions of

falls when reset is complete.

signal goes low . If CONV is held low and remains low when RDY

MCLK – Master Clock, Pin 19

The master clock pin (MCLK) is a multi-function pin. If tied low (MCLK = VLR), the on-chip oscillator will be enabled. If tied high (MCLK = VL), all clocks to the internal circuitry of the converter

will stop. When MCLK is held high the internal oscillator will also be stopped. MCLK can also

function as the input for an external CMOS-compatible clock that conforms to supply voltages

on the VL and VLR pins.

VLR2, VLR, VL – Logic Interface Power/Return, Pins 14, 20, 21

VL and VLR are the supply voltages for the digital logic interface. VL and VLR can be configured with a wide range of common mode vol tage. The following interface pins function from the

VL/VLR supply: SMODE, CS

SDO – Serial Data Output, Pin 22

SDO is the output pin for the serial output port. Data from this pin will be output at a rate determined by SCLK and in a format determined by the BP/UP

advances to the next data bit on the rising edges of SCLK. SDO will be in a high impedance

state when CS

DS806PP2 27

is high.

, SCLK, SDO, RDY, SLEEP, CONV, RST, BP/UP, and MCLK.

pin. Data is output MSB first and

Page 28

5/4/09

SCLK – Serial Clock Input/Output, Pin 23

The SMODE pin determines whether the SCLK signal is an input or an output signal. SCLK

determines the rate at which data is clocked out of the SDO pin. If the converter is in SSC

mode, the SCLK frequency will be determined by the master clock frequency of the converter

(either MCLK or the internal oscillator). In SEC mode, the user determines the SCLK frequency.

CS5566

If SMODE = VL (SSC Mode), SCLK will be in a high-impedance state when CS

– Ready, Pin 24

RDY

If CONV

the conversion is completed. At the end of any conversion RDY

sion word has been placed into the serial port. RDY

out of the serial port or two master clock cycles before new data becomes available if the CS

is inactive (high); or two master clock cycles before new data becomes available if the user

holds CS

is high.

is low the converter will immediately start a conversion and RDY will remain high until

falls to indicate that a conver-

will return high after all data bits are shifted

pin

low but has not started reading the data from the converter when in SEC mode.

28 DS806PP2

Page 29

5/4/09

24L SSOP PACKAGE DRAWING

E

N

1

23

e

b

2

A1

A2

A

D

SEATING

PLANE

E1

1

L

SIDE VIEW

END VIEW

TOP VIEW

∝

5. PACKAGE DIMENSIONS

INCHES MILLIMETERS NOTE

DIM MIN NOM MAX MIN NOM MAX

A -- -- 0.084 -- -- 2.13

A1 0.002 0.006 0.010 0.05 0.13 0.25

A2 0.064 0.068 0.074 1.62 1.73 1.88

b 0.009 -- 0.015 0.22 -- 0.38 2,3

D 0.311 0.323 0.335 7.90 8.20 8.50 1

E 0.291 0.307 0.323 7.40 7.80 8.20

E1 0.197 0.209 0.220 5.00 5.30 5.60 1

e 0.022 0.026 0.030 0.55 0.65 0.75

L 0.025 0.03 0.041 0.63 0.75 1.03

∝

0° 4° 8° 0° 4° 8°

CS5566

JEDEC #: MO-150

Controlling Dimension is Millimeters.

Notes: 1.“D” and “E1” are reference datums and do not included mold flash or protrusions, but do include mold mismatch and are measured

at the parting line, mold flash or protrusions shall not exceed 0.20 mm per side.

2.Dimension “b” does not include dambar protrusion/intrusion. Allowable dambar protrusion shall be 0.13 mm total in excess of “b”

dimension at maximum material condition. Dambar intrusion shall not reduce dimension “b” by more than 0.07 mm at least

material condition.

3.These dimensions apply to the flat section of the lead between 0.10 and 0.25 mm from lead tips.

DS806PP2 29

Page 30

5/4/09

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find the one nearest to you go to www.cirrus.com

IMPORTANT NOTICE

"Preliminary" product information descr ibes products that are in production, but for which full characterization da ta is no t yet available.

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without noti ce and is p rovided "AS I S" withou t warrant y of any k ind (expres s or implie d). Customer s are advi sed to ob tain the latest version of relevant

information to verify, before placing ord er s, th at in formation being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assum ed by C irrus

for the use of this information, includ ing use of th is in form atio n a s the basis for ma nufactur e or sale of any item s, o r for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MA Y INVOLVE PO TENTIA L RISKS OF DE ATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARR ANTED FOR USE

IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AU TOMOTIVE SAFETY OR SEC URITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING T HE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER OR C USTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY

INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM ANY AND ALL LIABI LITY, INCLUDI NG ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in this document may be trademarks

or service marks of their respective owners.

CS5566

6. ORDERING INFORMATION

Model Linearity Temperature Conversion Time Throughput Package

CS5566-ISZ 0.0005% -40 to +85 °C 200 μs 5 kSps 24-pin SSOP

7. ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION

Model Number Peak Reflow Temp MSL Rating* Max Floor Life

CS5566-ISZ

260 °C 3 7 Days

* MSL (Moisture Sensitivity Level) as specified by IPC/JEDEC J-STD-020.

8. REVISION HISTORY

Revision Date Changes

PP1 MAR 2008 Preliminary release.

PP2 MAY 2009 Corrected cross reference on page 22.

30 DS806PP2

Loading...

Loading...