CS5521/22/23/24/28

16-Bit or 24-Bit, 2/4/8-Channel ADCs with PGIA

Features

l Low Input Current (100 pA), Chopper

Stabilized Instrumentation Amplifier

l Scalable Input Span (Bipolar/Unipolar)

- 2.5V VREF: 25 mV, 55 mV, 100 mV, 1 V, 2.5 V,

5V

- External: 10 V, 100 V

l Wide V

l Fourth Order Delta-Sigma A/D Converter

l Easy to Use Three-wire Serial Interface Port

- Programmable/Auto Channel Sequencer with

Conversion Data FIFO

- Accessible Calibration Registers per Channel

- Compatible with SPI

l System and Self-Calibration

l Eight Selectable Word Rates

- Up to 617 Hz (XIN = 200 kHz)

- Single Conversion Settling

- 50/60 Hz ±3 Hz Simultaneous Rejection

l Single +5 V Power Supply Operation

- Charge Pump Drive for Negative Supply

- +3 to +5 V Digital Supply Operation

l Low Power Consumption: 5.5 mW

Input Range (+1 to +5 V)

REF

TM

and Microwire

TM

General Description

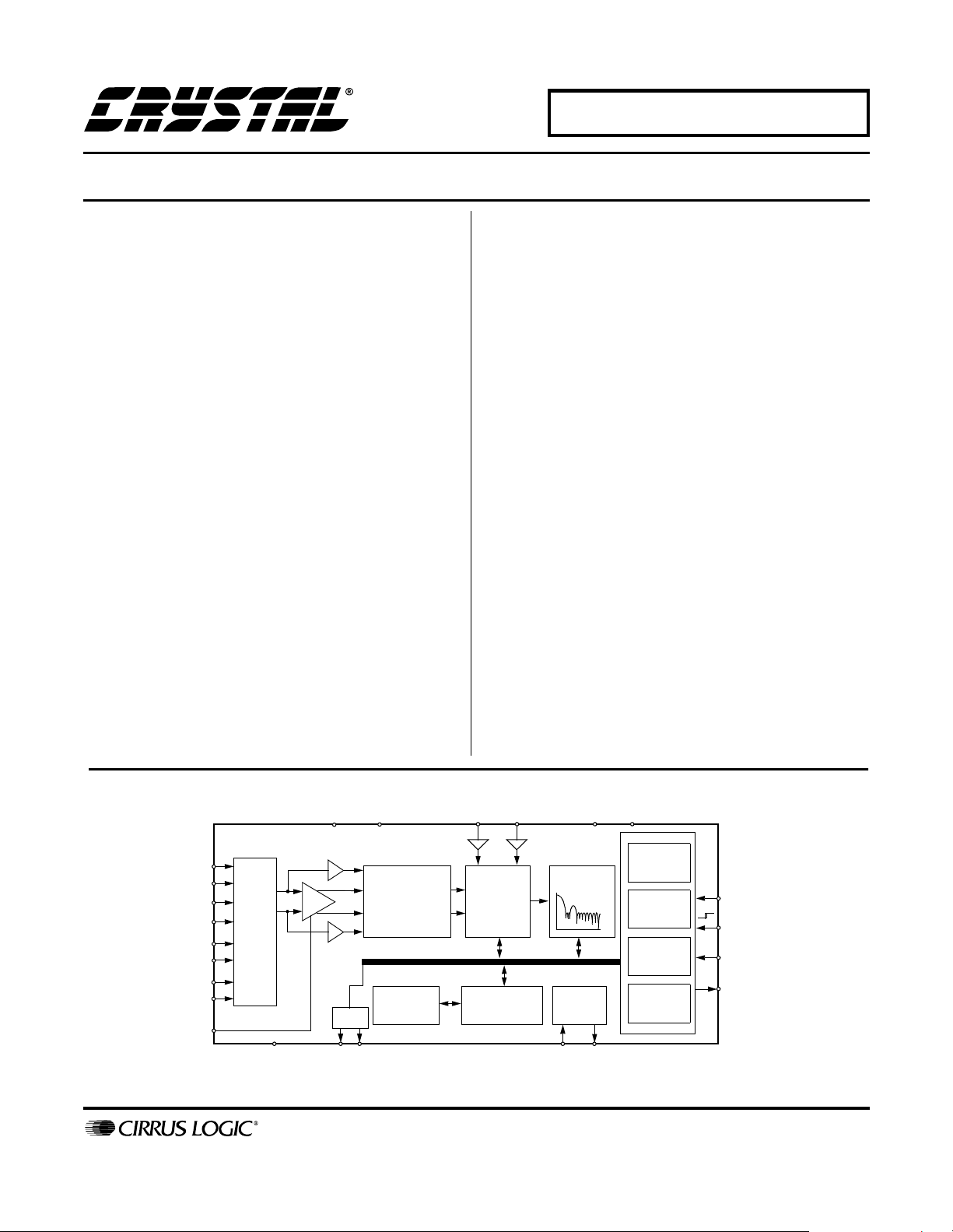

The CS5521/22/23/24/28 are highly in tegrated ∆Σ Analog-to-Digital Converters (ADCs) which use chargebalance techniques to ac hieve 16-bit (CS5521/23) and

24-bit (CS5522/24/28) performance. The ADCs

either two-channel (CS5521/22), four-channel

(CS5523/24), or eight-channel (CS5528) devices, and

include a low input current, chopper-stabilized instrumentation amplifie r. To pe rmit s elec table i nput s pans o f

25 mV, 55 mV, 100 mV, 1 V, 2.5 V, and 5 V, the ADCs

include a PGA (programmable gain amplifier). To accommodate ground-based thermocouple applications,

the devices include a Charge Pump Drive which provides a negative bias voltage to the on-chip amplifiers.

These devices also inc lude a fourth or der ∆Σ modulat or

followed by a digital filter

output word rates

. The digital filters are designed to settle

which provides eight selectable

to full accuracy wi thin one conversion cycle and whe n

operated at word rates b elo w 30 Hz, they reject both 50

and 60 Hz interference.

These single supply products are ideal solutions for

measuring isolated and non-isolated, low-level signals in

process control applications.

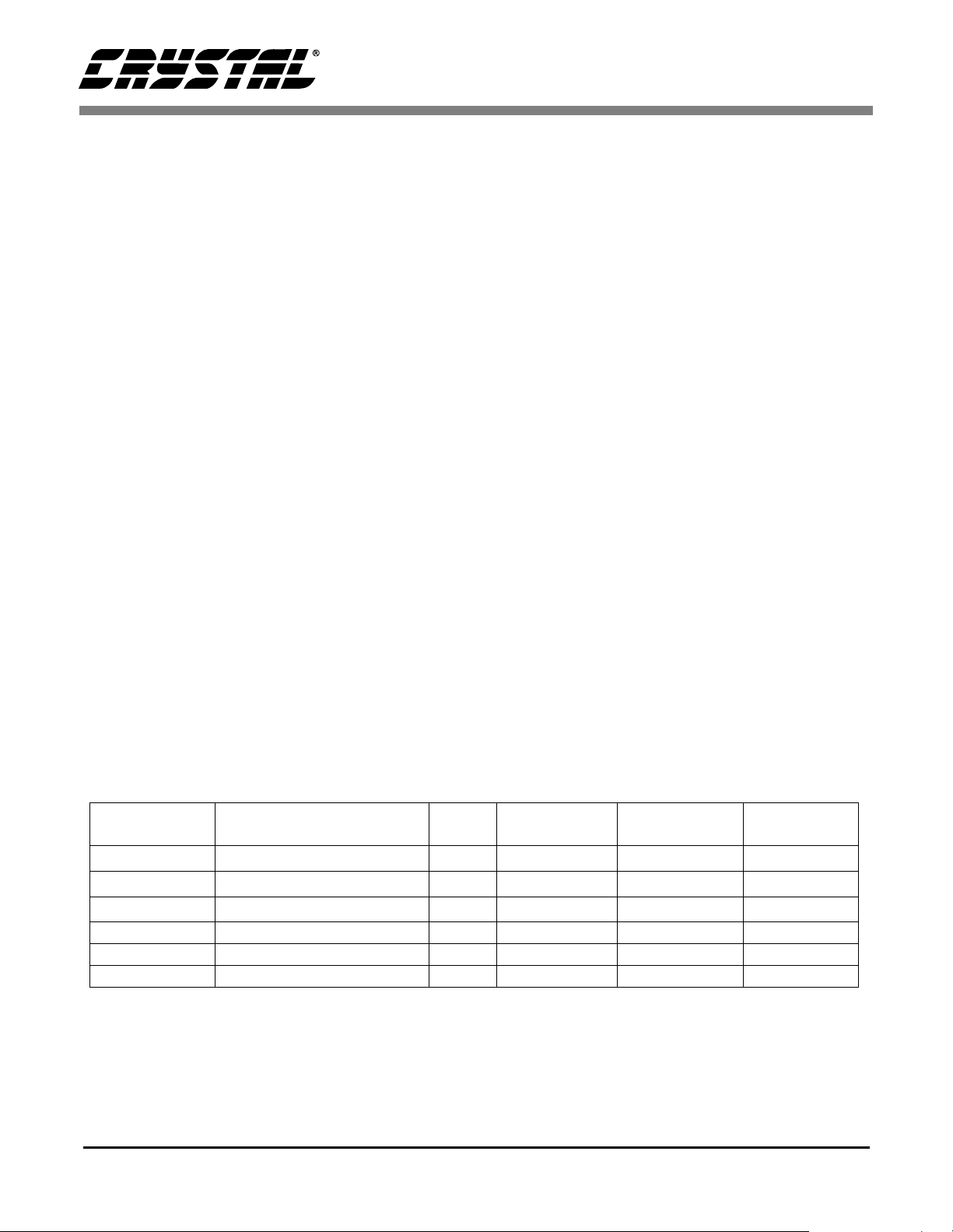

ORDERING INFORMATION

See page 51.

come as

AIN1+

AIN1-

AIN2+

AIN2-

AIN3+

AIN3-

AIN4+

AIN4-

NBV

MUX

CS5524

Shown

CPD

+

X20

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

VA+ AGND VREF+ VREF- VD+DGND

X1

X1

Latch

A0 A1

Programmable

Gain

Calibration

Memory

X1

Differential

4th Order

∆Σ

Modulator

Calibration µC

Copyright Cirrus Logic, Inc. 2000

Digital F ilte r

Clock

Gen.

XIN XOUT

(All Rights Reserved)

Data

FIFO

Calibration

Register

Control

Register

Output

Register

CS

SCLK

SDI

SDO

MAY ‘00

DS317F2

1

TABLE OF CONTENTS

1. CHARACTERISTICS AND SPECIFICATIONS .................................. ....... ...... ....... ...... ....... ..... 5

ANALOG CHARACTERISTICS................................................................................................ 5

TYPICAL RMS NOISE, CS5521/23..........................................................................................7

TYPICAL NOISE FREE RESOLUTION (BITS), CS5521/23 ....................................................7

TYPICAL RMS NOISE, CS5522/24/28.....................................................................................8

TYPICAL NOISE FREE RESOLUTION (BITS), CS5522/24/28 ...............................................8

5 V DIGITAL CHARACTERISTICS...........................................................................................9

3 V DIGITAL CHARACTERISTICS...........................................................................................9

DYNAMIC CHARACTERISTICS ............................................................................................10

RECOMMENDED OPERATING CONDITIONS.....................................................................10

ABSOLUTE MAXIMUM RATINGS .........................................................................................10

SWITCHING CHARACTERISTICS ................................. ...... ....... ...... ....... ...... .......................11

2. GENERAL DESCRIPTION .....................................................................................................13

2.1 Analog Input .....................................................................................................................13

2.1.1 Instrumentation Amplifier .........................................................................................14

2.1.2 Coarse/Fine Charge Buffers ............................................................................... 14

2.1.3 Analog Input Span Considerations ..........................................................................15

2.1.4 Measuring Voltages Higher than 5 V .................................................................. 15

2.1.5 Voltage Reference .............................................................................................. 16

2.2 Overview of ADC Register Structure and Operating Modes ............................................16

2.2.1 System Initialization ............................................................................................ 18

2.2.2 Serial Port Initialization Sequence ...................................................................... 18

2.2.3 Command Register Quick Reference ............................................................... 19

2.2.4 Command Register Descriptions ........................................................................ 20

2.2.5 Serial Port Interface ............................................................................................ 25

2.2.6 Reading/Writing the Offset, Gain, and Configuration Registers ..........................26

2.2.7 Reading/Writing the Channel-Setup Registers ................................................... 26

2.2.7.1 Latch Outputs ......................................................................................28

2.2.7.2 Channel Select Bits .............................................................................28

2.2.7.3 Output Word Rate Selection ............................................................... 28

2.2.7.4 Gain Bits .............................................................................................. 28

2.2.7.5 Unipolar/Bipolar Bit .............................................................................28

2.2.8 Configuration Register ........................................................................................ 28

2.2.8.1 Chop Frequency Select .......................................................................28

2.2.8.2 Conversion/Calibration Control Bits .................................................... 28

2.2.8.3 Power Consumption Control Bits ........................................................ 28

CS5521/22/23/24/28

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

SPI™ is a trademark of Motorola Inc., Microwire™ is a trademark of National Semiconductor Corp.

Prelimina ry p rodu ct info r mati on descr ibe s pr od ucts wh ich are i n pr od ucti on , but fo r wh ich ful l cha r acte riz at ion d ata is not yet available. Advance

product information describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best effor ts

to ensure that the information contained in this document is accurate and reliable. However, the information is subject to change without notice

and is provided “AS IS” without warranty of any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of th is

information, nor for infringements of patents or other rights of third parties. This document is the property of Cirrus Logic, Inc. and implies no

license unde r patents, copy ri ghts, tradema r k s , or t r ade secrets. No part of this pu blication may be copied, re pr oduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or otherwise). Furthermore, no part of this publication

may be used as a basis for manufacture or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of

Cirrus Logic, Inc. or other vendors and suppliers appearing in this document may be trademarks or service marks of their respective owners

which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

2 DS317F2

CS5521/22/23/24/28

2.2.8.4 Charge Pump Disable ......................................................................... 29

2.2.8.5 Reset System Control Bits .................................................................. 29

2.2.8.6 Data Conversion Error Flags .............................................................. 29

2.3 Calibration ....................................................................................................................... 31

2.3.1 Self Calibration .................................................................................................... 31

2.3.2 System Calibration .............................................................................................. 32

2.3.3 Calibration Tips ................................................................................................... 34

2.3.4 Limitations in Calibration Range ......................................................................... 34

2.4 Performing Conversions and Reading the Data Conversion FIFO .................................. 34

2.4.1 Conversion Protocol .................. ...... ....... ...... ....................................... ...... ....... ... 35

2.4.1.1 Single, One-Setup Conversion ........................................................... 35

2.4.1.2 Repeated One-Setup Conversions without Wait ................................ 35

2.4.1.3 Repeated One-Setup Conversions with Wait ..................................... 36

2.4.1.4 Single, Multiple-Setup Conversions .................................................... 36

2.4.1.5 Repeated Multiple-Setup Conversions without Wait ........................... 37

2.4.1.6 Repeated Multiple-Setup Conversions with Wait ................................ 37

2.4.2 Calibration Protocol ............................................................................................. 38

2.4.3 Example of Using the CSRs to Perform Conversions and Calibrations .............. 38

2.5 Conversion Output Coding .............................................................................................. 40

2.5.1 Conversion Data FIFO Descriptions ...... ...... ...... ....... ....................................... ... 41

2.6 Digital Filter ..................................................................................................................... 42

2.7 Clock Generator .............................................................................................................. 42

2.8 Power Supply Arrangements ........................................................................................... 43

2.8.1 Charge Pump Drive Circuits ............................................................................... 45

2.9 Digital Gain Scaling ........................................................................................................ 45

2.10 Getting Started .............................................................................................................. 46

2.11 PCB Layout ................................................................................................................... 47

3. PIN DESCRIPTIONS ....................... ...... ....................................... ...... ....... ...... ....... ...... ...... . ... 48

3.1 Clock Generator .............................................................................................................. 49

3.2 Control Pins and Serial Data I/O ..................................................................................... 49

3.3 Measurement and Reference Inputs ............................................................................... 49

3.4 Power Supply Connections ............................................................................................. 50

4. SPECIFICATION DEFINITIONS ............................................................................................. 51

5. ORDERING GUIDE ............................................................... ....... ...... ....... ...... ....................... 51

6. PACKAGE DIMENSION DRAWINGS ................................................................................... 52

DS317F2 3

LIST OF FIGURES

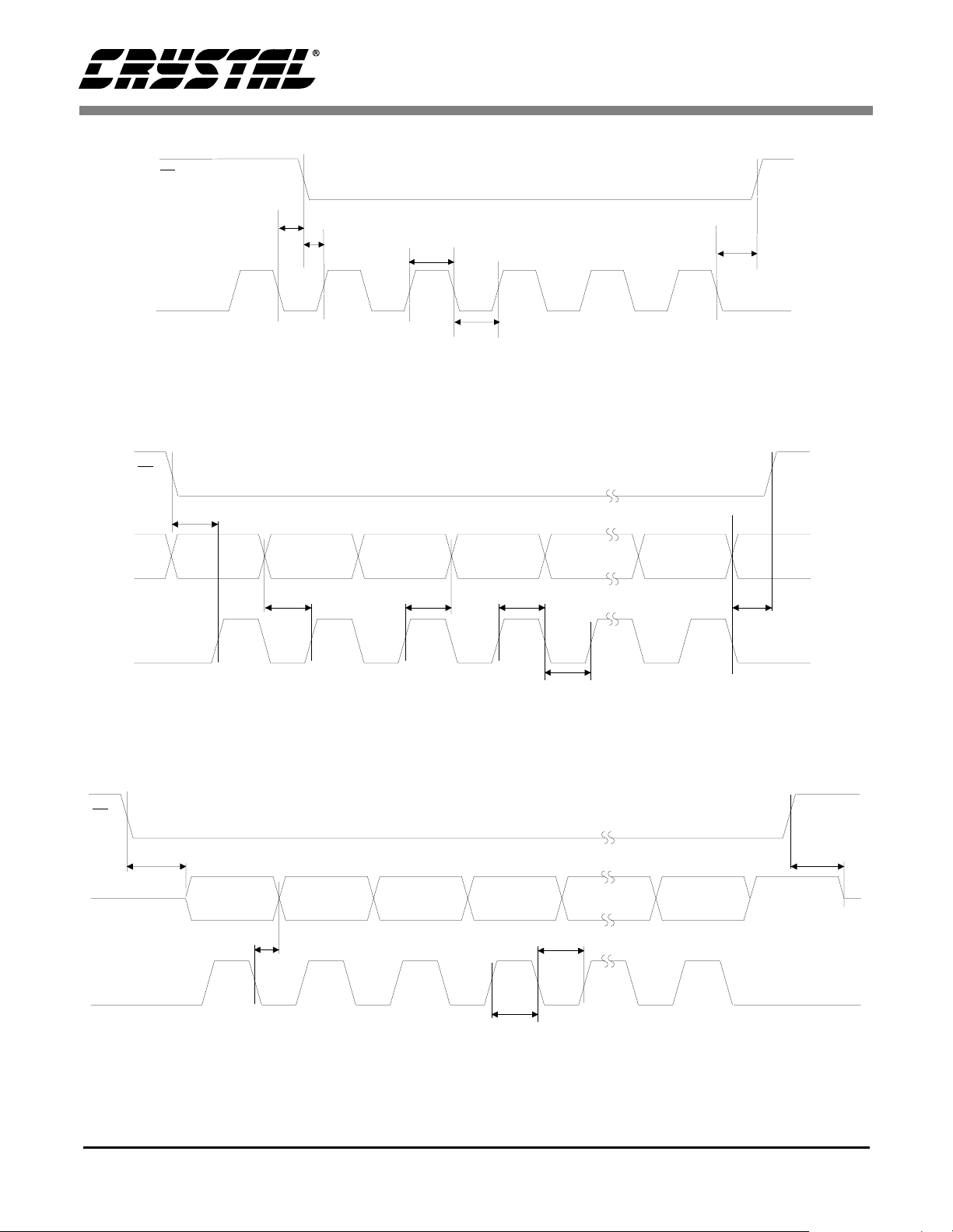

Figure 1. Continuous Running SCLK Timing (Not to Scale) .........................................................12

Figure 2. SDI Write Timing (Not to Scale).....................................................................................12

Figure 3. SDO Read Timing (Not to Scale)...................................................................................12

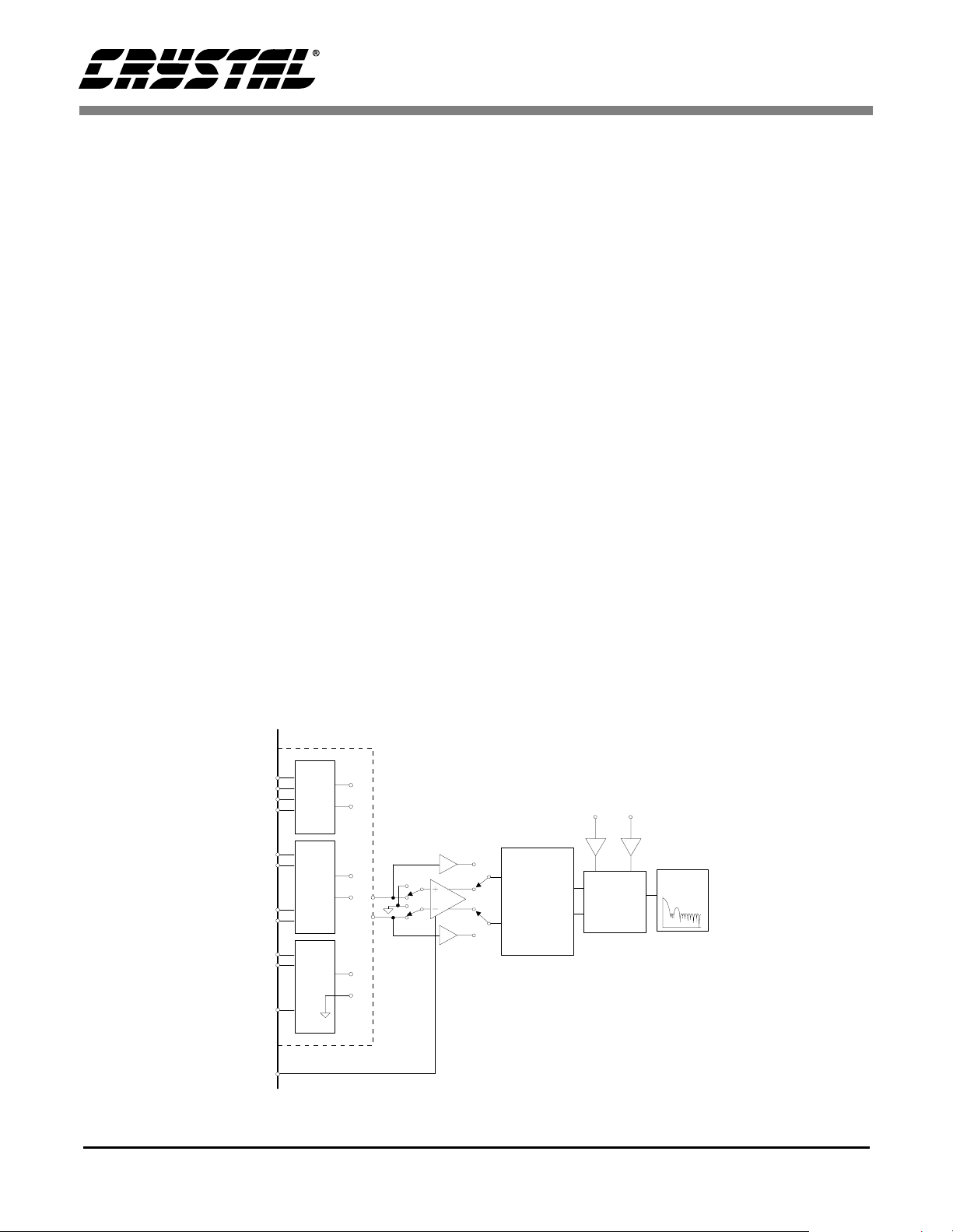

Figure 4. Multiplexer Configurations..............................................................................................13

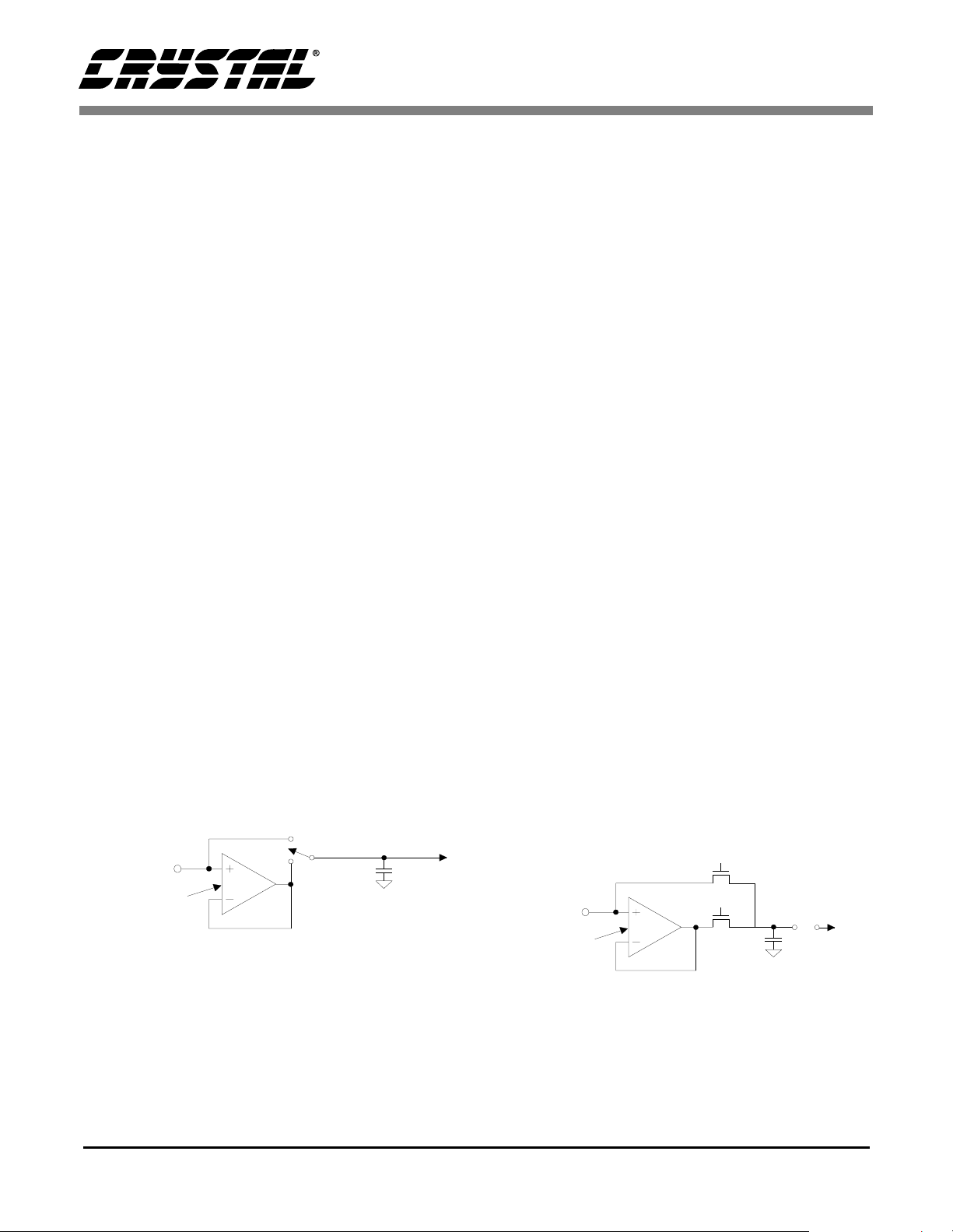

Figure 5. Input Models for AIN+ and AIN- pins, £(100 mV Input Ranges...................................... 14

Figure 6. Input Models for AIN+ and AIN- pins, >100 mV input ranges ........................................14

Figure 7. Input Ranges Greater than 5 V ......................................................................................16

Figure 8. Input Model for VREF+ and VREF- Pins........................................................................16

Figure 9. CS5523/24 Register Diagram ........................................................................................17

Figure 10. Command and Data Word Timing................................................................................ 25

Figure 11. Self Calibration of Offset (Low Ranges)....................................................................... 32

Figure 12. Self Calibration of Offset (High Ranges)......................................................................32

Figure 13. Self Calibration of Gain (All Ranges) ...........................................................................32

Figure 14. System Calibration of Offset (Low Ranges).................................................................32

Figure 15. System Calibration of Offset (High Ranges)................................................................33

Figure 16. System Calibration of Gain (Low Ranges)...................................................................33

Figure 17. System Calibration of Gain (High Ranges)..................................................................33

Figure 18. Filter Response (Normalized to Output Word Rate = 1) ..............................................42

Figure 19. Typical Linearity Error for CS5521/23..........................................................................42

Figure 20. Typical Linearity Error for CS5522/24/28.....................................................................42

Figure 21. CS5522 Configured to use on-chip charge pump to supply NBV ................................ 43

Figure 22. CS5522 Configured for ground-referenced Unipolar Signals.......................................44

Figure 23. CS5522 Configured for Single Supply Bridge Measurement.......................................44

Figure 24. Charge Pump Drive Circuit for VD+ = 3 V.................................................................... 45

Figure 25. Alternate NBV Circuits .................................................................................................45

CS5521/22/23/24/28

LIST OF TABLES

Table 1. Relationship between Full Scale Input, Gain Factors, and Internal Analog

Signal Limitations .............................................................................................................15

Table 2. Command Register Quick Reference..............................................................................19

Table 3. Channel-Setup Registers................................................................................................27

Table 4. Configuration Register.....................................................................................................30

Table 5. Offset and Gain Registers...............................................................................................31

Table 6. Output Coding for 16-bit CS5521/23 and 24-bit CS5522/24/28......................................40

4 DS317F2

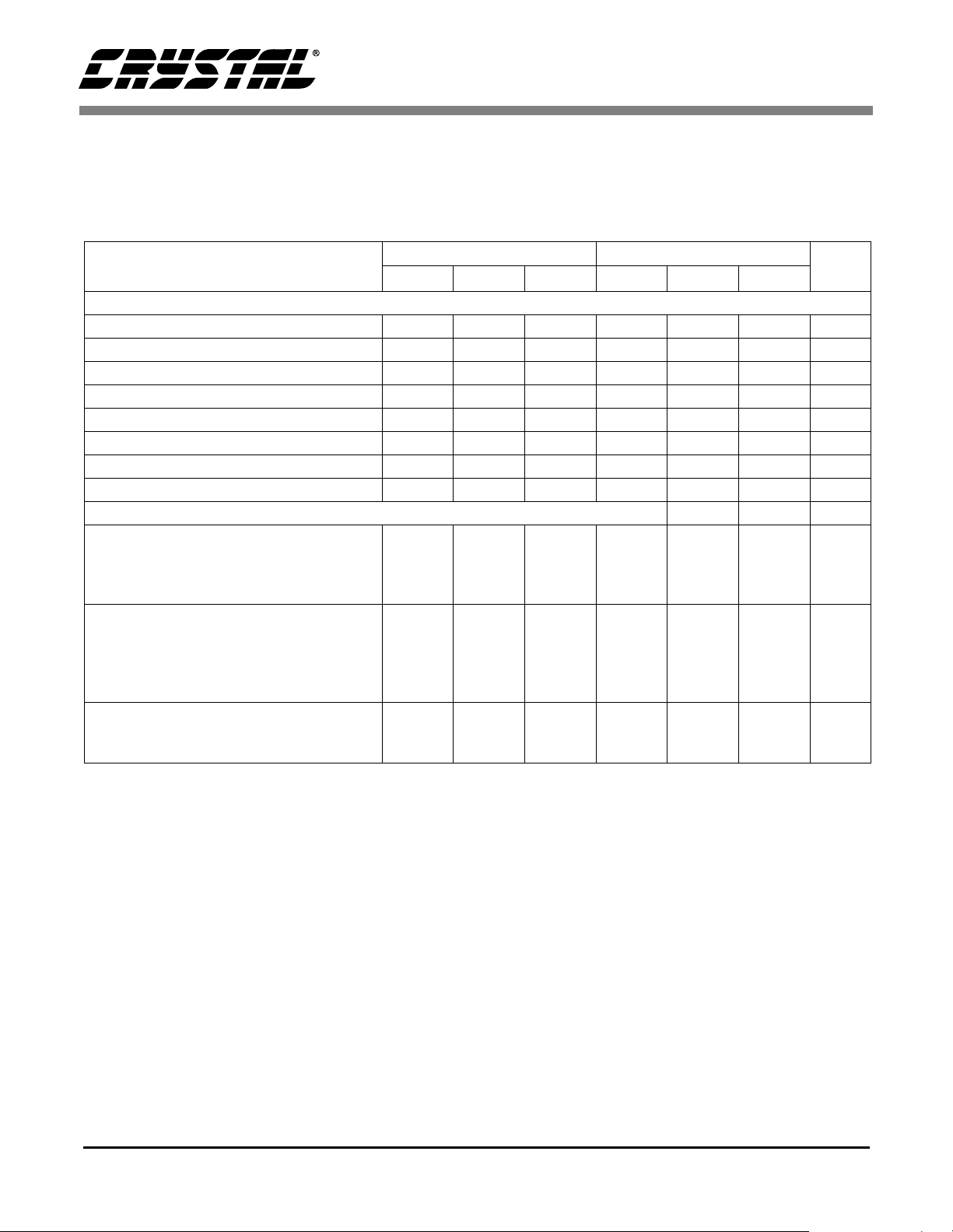

1. CHARACTERISTICS AND SPECIFICATIONS

CS5521/22/23/24/28

ANALOG CHARACTERISTICS (T

= 25° C; VA+, VD+ = 5 V ±5%; VREF+ = 2.5 V, VREF- = AGND,

A

NBV = -2.1 V, XIN = 32.768 kHz, CFS1-CFS0 = ‘00’, OWR (Output Word Rate) = 15 Hz, Bipolar Mode, Input

Range = ±100 mV; See Notes 1 and 2.)

CS5521/23 CS5522/24/28

Parameter

UnitMin Typ Max Min Typ Max

Accuracy

Resolution --16--24Bits

Linearity Error - ±0.0015 ±0.003 - ±0.0007 ±0.0015 %FS

Bipolar Offset (Note 3) - ±1±2 -±16 ±32 LSB

Unipolar Offset (Note 3) - ±2 ±4-±32 ±64 LSB

N

N

Offset Drift (Notes 3 and 4) - 20 - - 20 - nV/°C

Bipolar Gain Error - ±8 ±31 - ±8 ±31 ppm

Unipolar Gain Error - ±16 ±62 - ±16 ±62 ppm

Gain Drift (Note 4) - 1 3 - 1 3 ppm/°C

Power Supplies

Power Supply Currents (Normal Mode)

(Note 5)I

I

I

A+

D+

NBV

-

-

-

0.9

90

260

1.2

135

375

-

-

-

1.5

90

525

1.9

135

700

mA

µA

µA

Power Consumption (Note 6)

Normal Mode

Low Power Mode

Standby

Sleep

-

N/A

-

-

5.5

N/A

1.2

500

7.5

N/A

-

-

-

-

-

-

9

5.5

1.2

500

12

7.5

-

-

mW

mW

mW

µW

Power Supply R eje ction

Positive Supplies

dc NBV

-

-

120

110

-

-

-

-

120

110

-

-

dB

dB

Notes: 1. Applies after system calibration at any temperature within -40° C ~ +85° C.

2. Specifications guaranteed by design, characterization, and/or test.

3. Specification applies to the device only and does not include any effects by external parasitic

thermocouples. LSB

: N is 16 for the CS5521/23 and N is 24 for the CS5522/24/28

N

4. Drift over specified temperature range after calibration at power-up at 25° C.

5. Measured with Charge Pump Drive off.

6. All outputs unloaded. All input CMOS levels and the CS5521/23 do not have a low power mode.

DS317F2 5

CS5521/22/23/24/28

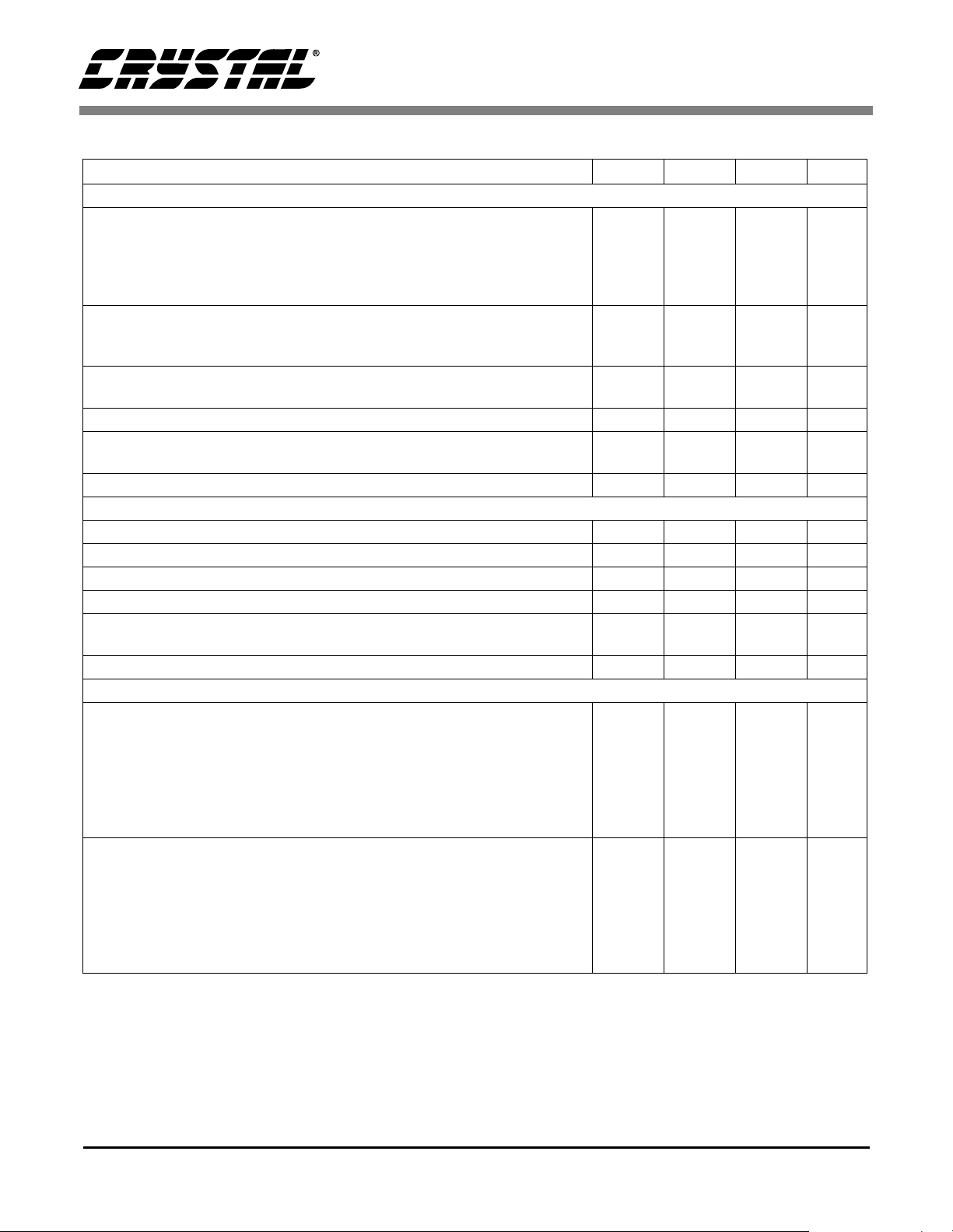

ANALOG CHARACTERISTICS (Continued)

Parameter Min Typ Max Unit

Analog Input

Common Mode + Signal on AIN+ or AIN- Bipolar/Unipolar Mode

NBV = -1.8 to -2.5 V Range = 25 mV, 55 mV, or 100 mV

Range = 1 V , 2.5 V, or 5 V

NBV = AGND Range = 25 mV, 55 mV, or 100 mV (Note 7)

Range = 1 V , 2.5 V, or 5 V

CVF Current on AIN+ or AIN- (Note 8)

Range = 25 mV, 55 mV, or 100 mV

Range = 1 V , 2.5 V, or 5 V

Input Current Drift (Note 8)

Range = 25 mV, 55 mV, or 100 mV - 1 - pA/°C

Input Leakage for Multiplexer when Off - 10 - pA

Common Mode Rejection dc

50, 60 Hz

Input Capacitance - 10 - pF

Voltage Reference Input

Range (VREF+) - (VREF-) 1 2.5 VA+ V

VREF+

VREF- NBV CVF Current (Note 8) - 5.0 - nA

Common Mode Rejection dc

50, 60 Hz

Input Capacitance - 16 - pF

System Calibration Specifications

Full Scale Calibration Range (VREF = 2.5V) Bipolar/Unipolar Mode

25 mV

55 mV

100 mV

1 V

2.5 V

5 V

Offset Calibration Range Bipolar/Unipolar Mode

25 mV

55 mV

100 mV (Note 9)

1 V

2.5 V

5 V

-0.150

NBV

1.85

0.0

-

-

-

-

(VREF-)+1

-

-

10

25

40

0.40

1.0

2.0

-

-

-

-

-

-

-

-

-

-

100

10

120

120

-VA+V

110

130

-

-

-

-

-

-

-

-

-

-

-

-

0.950

VA+

2.65

VA+

300

-

-

-

(VREF+)-1

-

-

32.5

71.5

105

1.30

3.25

VA+

±12.5

±27.5

±50

±0.5

±1.25

±2.50

pA

nA

dB

dB

dB

dB

mV

mV

mV

mV

mV

mV

V

V

V

V

V

V

V

V

V

V

V

Notes: 7. For the CS5528, the 25 mV, 55 mV and 100 mV ranges cannot be used unless NBV is powered at -1.8

to -2.5 V

8. See the section of the data sheet which discusses input models. Chop clock is 256 Hz (XIN/128) for

PGIA (programmable gain instrumentation amplifier). XIN = 32.768 kHz.

9. The maximum full scale signal can be limited by saturation of circuitry within the internal signal path.

6 DS317F2

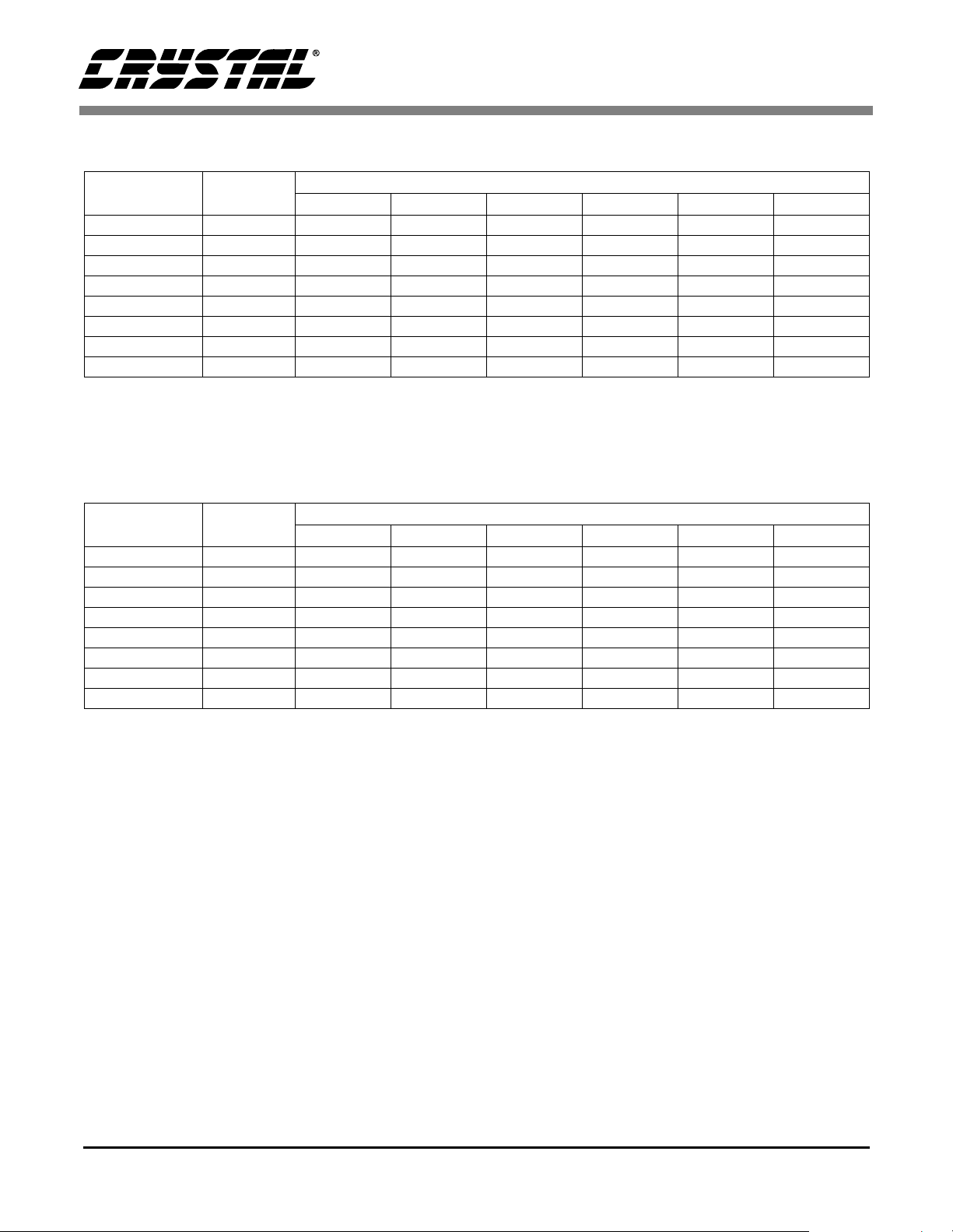

TYPICAL RMS NOISE, CS5521/23 (Notes 10 and 11)

CS5521/22/23/24/28

Output Rate

(Hz)

1.88 1.64 90 nV 148 nV 220 nV 1.8 µV 3.9 µV 7.8 µV

3.76 3.27 122 nV 182 nV 310 nV 2.6 µV 5.7 µV 11.3 µV

7.51 6.55 180 nV 267 nV 435 nV 3.7 µV 8.5 µV 18.1 µV

15.0 12.7 280 nV 440 nV 810 nV 5.7 µV 14 µV 28 µV

30.0 25.4 580 nV 1.1 µV 2.1 µV 18.2 µV 48 µV 96 µV

61.6 (Note 12) 50.4 2.6 µV 4.9 µV 8.5 µV 92 µV 238 µV 390 µV

84.5 (Note 12) 70.7 11 µV 27 µV 43 µV 458 µV 1.1 mV 2.4 mV

101.1 (Note 12) 84.6 41 µV 72 µV 130 µV 1.2 mV 3.4 mV 6.7 mV

Notes: 10. Wideband noise aliased into the baseband. Referred to the input. Typical values shown for 25° C.

11. To estimate Peak-to-Peak Noise, multiply RMS noise by 6.6 for all ranges and output rates.

12. For input ranges <100 mV and output rates ≥60 Hz, 16.384 kHz chopping frequency is used.

-3 dB Filter

Frequency

25 mV 55 mV 100 mV 1 V 2.5 V 5 V

Input Range, (Bipolar/Unipolar Mode)

TYPICAL NOISE FREE RESOLUTION (BITS), CS5521/23 (Note 13)

Output Rate

(Hz)

1.88 1.64 16 16 16 16 16 16

3.76 3.27 16 16 16 16 16 16

7.51 6.55 15 16 16 16 16 16

15.0 12.7 15 15 15 16 16 16

30.0 25.4 14 14 14 14 14 14

61.6 (Note 12) 50.4 12 12 12 12 12 12

84.5 (Note 12) 70.7 9 9 9 9 9 9

101.1 (Note 12) 84.6 8 8 8 8 8 8

-3 dB Filter

Frequency

25 mV 55 mV 100 mV 1 V 2.5 V 5 V

Input Range, (Bipolar Mode)

Notes: 13. For bipolar mode, the number of bits of Noise Free Resolution is LOG((2XInput Range)/(6.6xRMS

Noise))/LOG(2) rounded to the nearest bit. For unipolar mode, the number of bits of Noise Free

Resolution is LOG((Input Range)/(6.6xRMS Noise))/LOG(2) rounded to the nearest bit. Also, the

CS5521/23’s output conversions are 16 bits. Noise free Resolution numbers are based upon

VREF = 2.5 V and XIN = 32.768 kHz. The values will be affected directly by changes in VREF, but the

effects due to changes in the XIN frequency will be minor.

DS317F2 7

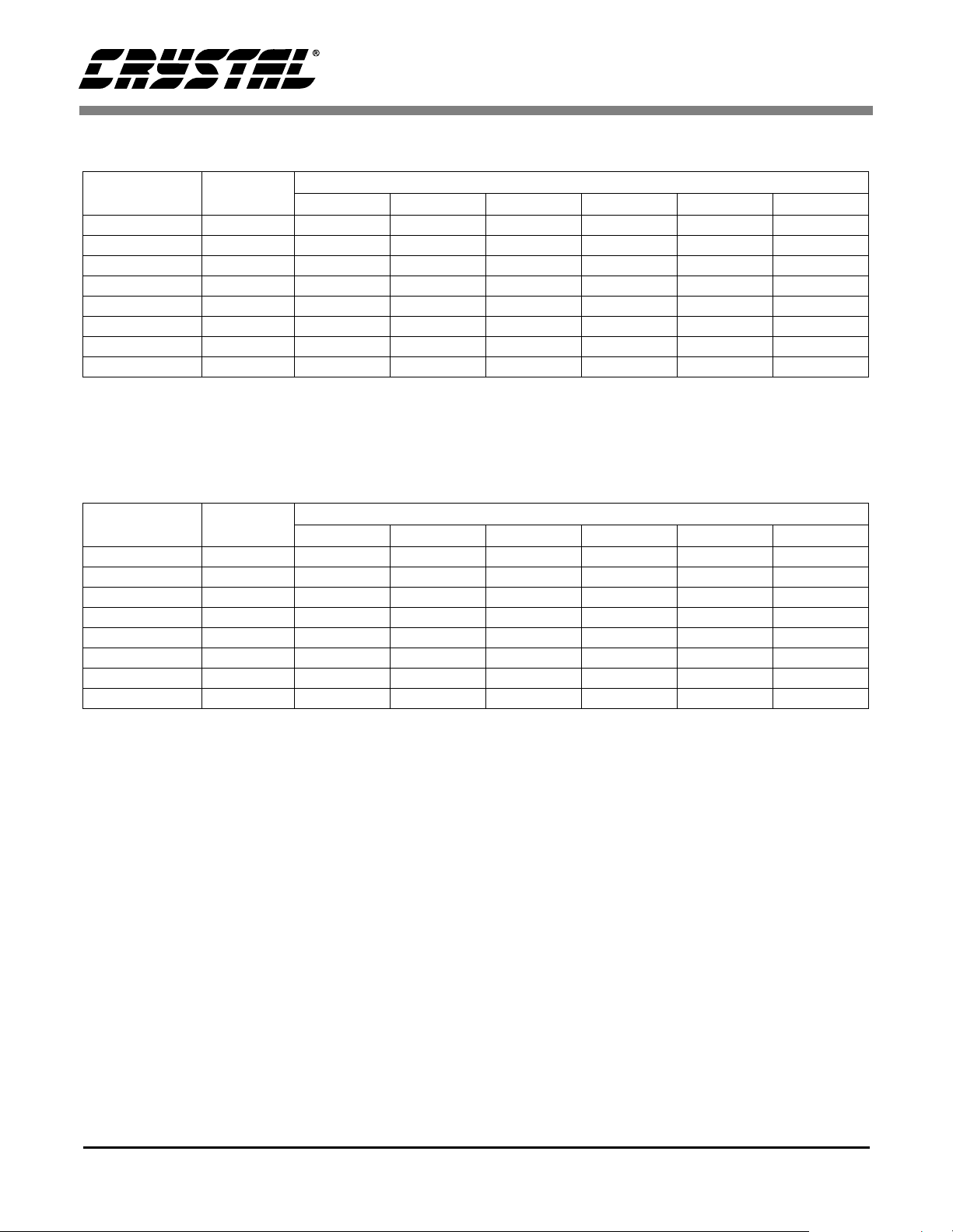

TYPICAL RMS NOISE, CS5522/24/28 (Notes 14 and 15)

CS5521/22/23/24/28

Output Rate

(Hz)

1.88 1.64 90 nV 95 nV 140 nV 1.5 µV 3 µV 6 µV

3.76 3.27 110 nV 130 nV 190 nV 2 µV 4 µV 8 µV

7.51 6.55 170 nV 200 nV 275 nV 2.5 µV 6 µV 11.5 µV

15.0 12.7 250 nV 330 nV 580 nV 4.5 µV 10 µV 20 µV

30.0 25.4 500 nV 1 µV 1.5 µV 16 µV 45 µV 85 µV

61.6 (Note 16) 50.4 2 µV 4 µV 8 µV 72 µV 195 µV 350 µV

84.5 (Note 16) 70.7 10 µV 20 µV 35 µV 340 µV 900 µV 2 mV

101.1 (Note 16) 84.6 30 µV 60 µV 105 µV 1.1 mV 3 mV 5.3 mV

Notes: 14. Wideband noise aliased into the baseband. Referred to the input. Typical values shown for 25° C.

15. To estimate Peak-to-Peak Noise, multiply RMS noise by 6.6 for all ranges and output rates.

16. For input ranges <100 mV and output rates ≥60 Hz, 16.384 kHz chopping frequency is used.

-3 dB Filter

Frequency

25 mV 55 mV 100 mV 1 V 2.5 V 5 V

Input Range, (Bipolar/Unipolar Mode)

TYPICAL NOISE FREE RESOLUTION (BITS), CS5522/24/28 (Note 17)

Output Rate

(Hz)

1.88 1.64 16 17 18 18 18 18

3.76 3.27 16 17 17 17 18 18

7.51 6.55 15 16 17 17 17 17

15.0 12.7 15 16 16 16 16 16

30.0 25.4 14 14 14 14 14 14

61.6 (Note 16) 50.4 12 12 12 12 12 12

84.5 (Note 16) 70.7 10 10 10 10 10 10

101.1 (Note 16) 84.6 8 8 8 8 8 8

-3 dB Filter

Frequency

25 mV 55 mV 100 mV 1 V 2.5 V 5 V

Input Range, (Bipolar Mode)

Notes: 17. For bipolar mode, the number of bits of Noise Free Resolution is LOG((2XInput Range)/(6.6xRMS

Noise))/LOG(2) rounded to the nearest bit. For unipolar mode, the number of bits of Noise Free

Resolution is LOG((Input Range)/(6.6xRMS Noise))/LOG(2) rounded to the nearest bit. Also, the

CS5522/24/28’s output conversions are 24 bits. Noise free Resolution numbers are based upon

VREF = 2.5 V and XIN = 32.768 kHz. The values will be affected directly by changes in VREF, but the

effects due to changes in the XIN frequency will be minor.

8 DS317F2

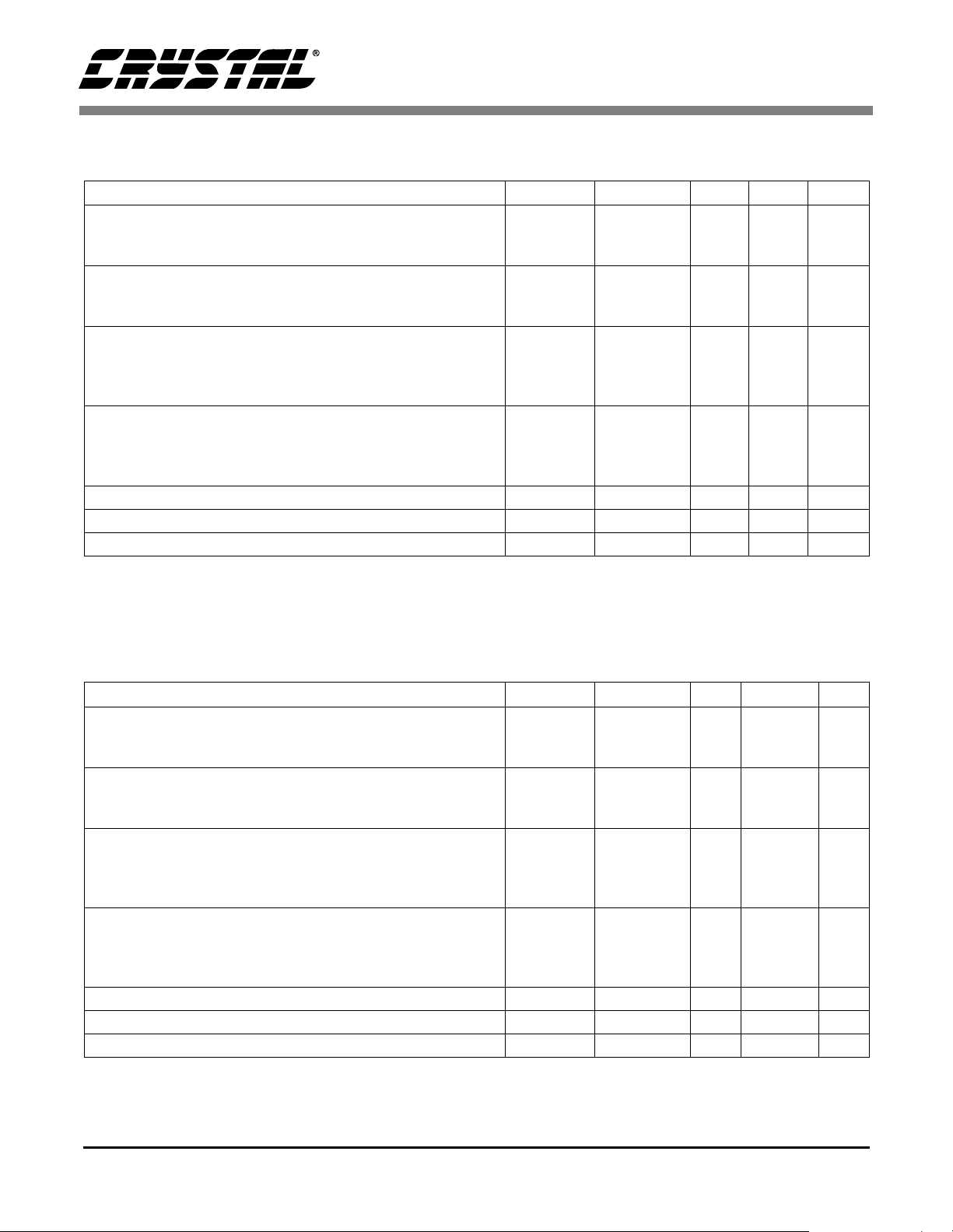

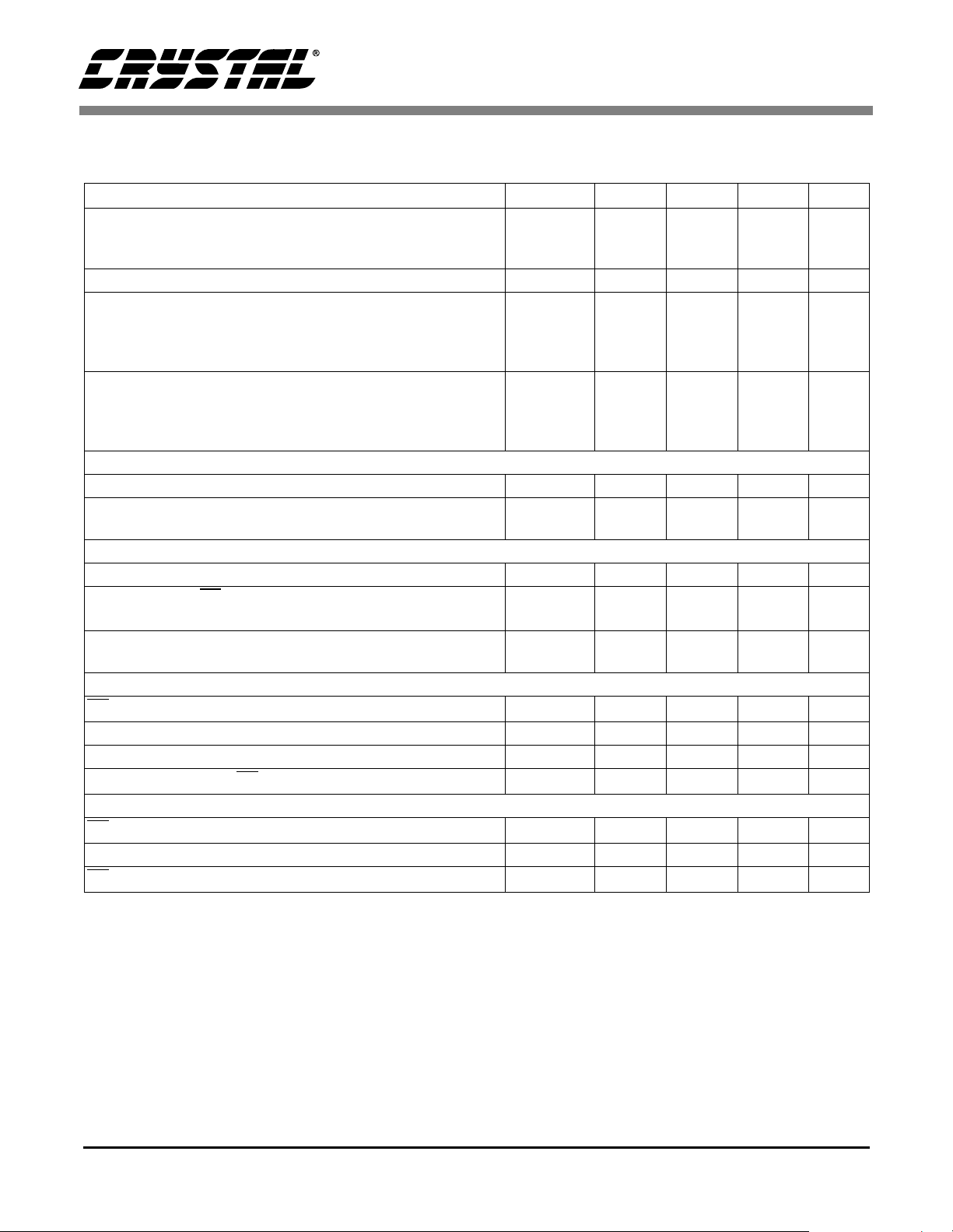

CS5521/22/23/24/28

5 V DIGITAL CHARACTERISTICS (T

= 25° C; VA+, VD+ = 5 V ±5%; GND = 0;

A

See Notes 2 and 18.))

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage All Pi ns Except XIN and SCL K

XIN

SCLK

Low-Level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

High-Level Output Voltage

All Pins Except CPD and SDO (Note 19)

CPD, I

SDO, I

= -4.0 mA

out

= -5.0 mA

out

Low-Level Output Voltage

All Pins Except CPD and SDO, I

CPD, I

SDO, I

= 1.6 mA

out

= 2 mA

out

= 5.0 mA

out

Input Leakage Current I

3-State Leakage Current I

Digital Output Pin Capacitance C

Notes: 18. All measurements performed under static conditions.

19. I

= -100 µA unless stated otherwise. (VOH = 2.4 V @ I

out

V

IH

V

IL

V

OH

V

OL

in

OZ

out

(VD+) - 0.45

= -40 µA.)

out

0.6 VD+

(VD+)-0.5

-

-

-

(VA+) - 1.0

(VD+) - 1.0

(VD+) - 1.0

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0.8

1.5

0.6

-

-

-

0.4

0.4

0.4

V

V

V

V

V

V

V

V

V

V

V

V

-±1±10µA

--±10µA

-9-pF

3 V DIGITAL CHARACTERISTICS (T

= 25° C; VA+ = 5 V ±5%; VD+ = 3.0 V ±10%; GND = 0;

A

See Notes 2 and 18.)

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage All Pi ns Except XIN and SCL K

XIN

SCLK

Low-Level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

High-Level Output Voltage

All Pins Exc ept CPD and SDO, I

CPD, I

SDO, I

= -400 µA

out

= -4.0 mA

out

= -5.0 mA

out

Low-Level Output Voltage

All Pins Except CPD and SDO, I

CPD, I

SDO, I

= 400 µA

out

= 2 mA

out

= 5.0 mA

out

Input Leakage Current I

3-State Leakage Current I

Digital Output Pin Capacitance C

V

IH

V

IL

V

OH

V

OL

in

OZ

out

0.6 VD+

(VD+)-0.5

(VD+) - 0.45

-

-

-

(VA+) - 0.3

(VD+) - 1.0

(VD+) - 1.0

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0.16 VD+

0.3

0.6

-

-

-

0.3

0.4

0.4

-±1±10µA

--±10µA

-9-pF

V

V

V

V

V

V

V

V

V

V

V

V

DS317F2 9

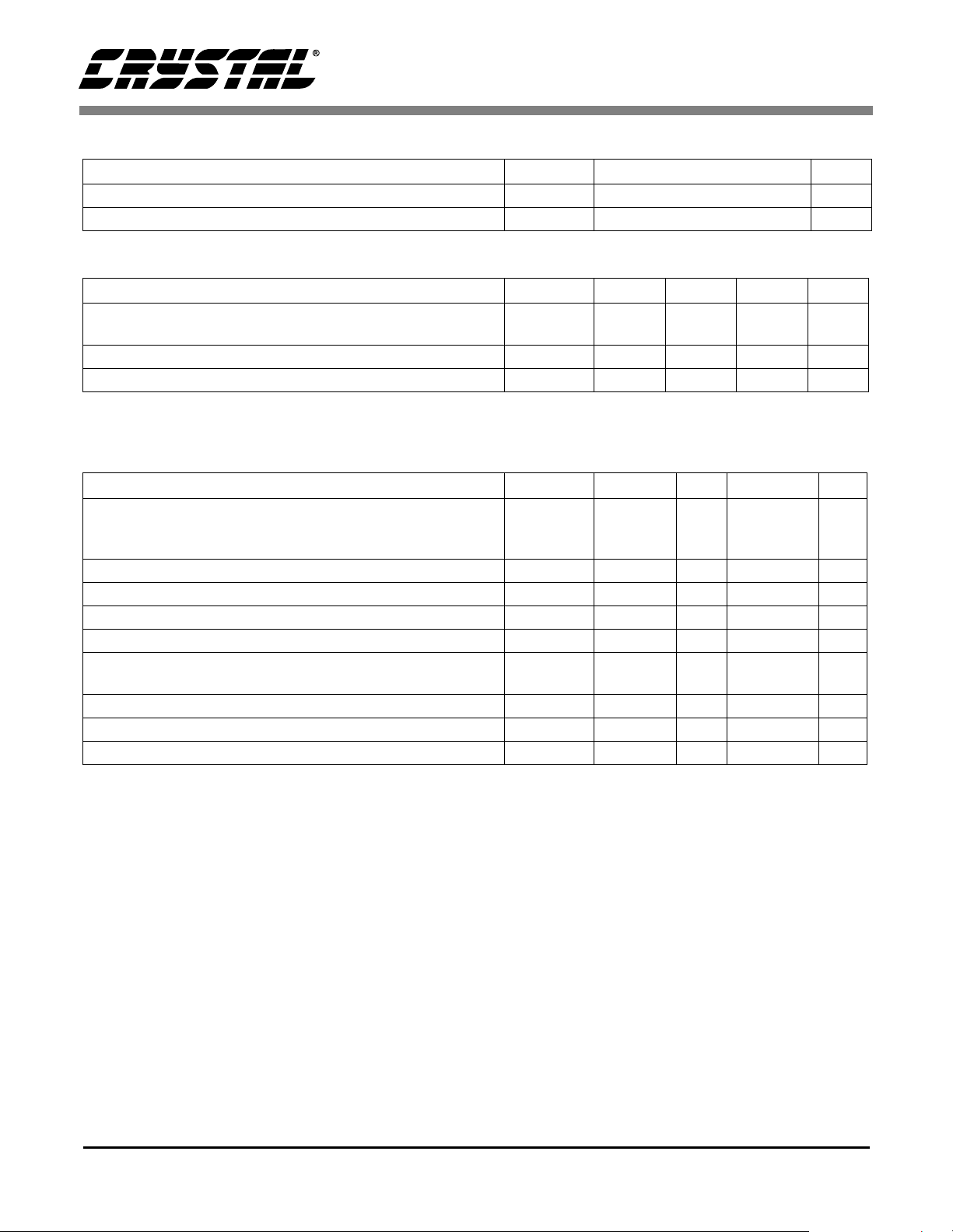

DYNAMIC CHARACTERISTICS

Parameter Symbol Ratio Unit

Modulator Sampling Frequency f

Filter Settling Time to 1/2 LSB (Full Scale Step) t

CS5521/22/23/24/28

s

s

XIN/4 Hz

1/f

out

s

RECOMMENDED OPERATING CONDITIONS

(AGND, DGND = 0 V; See Note 20.)

Parameter Symbol Min Typ Max Unit

DC Power Supplies Positive Digital

Positive Analog

Analog Reference Voltage (VREF+) - (VREF-) VRef

VD+

VA+

diff

2.7

4.75

5.0

5.0

5.25

5.25

1.0 2.5 VA+ V

V

V

Negative Bias Voltage NBV -1.8 -2.1 -2.5 V

Notes: 20. All voltages with respect to ground.

ABSOLUTE MAXIMUM RATINGS (AGND, DGND = 0 V; See Note 20.)

Parameter Symbol Min Typ Max Unit

DC Power Supplies (Note 21)

Positive Digital

Positive Analog

Negative Bias Voltage Negative Potential NBV +0.3 -2.1 -3.0 V

Input Current, Any Pin Except Supplies (Note 22 and 23) I

Output Current I

Power Dissipation (Note 24) PDN - - 500 mW

Analog Input Voltage VREF pins

AIN Pins

Digital Input Voltage V

Ambient Operating Temperature T

Storage Temperature T

VD+

VA+

IN

OUT

V

INR

V

INA

IND

A

stg

-0.3

-0.3

-

-

+6.0

+6.0

V

V

--±10mA

--±25mA

NBV -0.3

NBV -0.3

--(VA+) + 0.3

(VA+) + 0.3VV

-0.3 - (VD+) + 0.3 V

-40 - 85 °C

-65 - 150 °C

Notes: 21. No pin should go more negative than NBV - 0.3 V.

22. Applies to all pins including continuous overvoltage conditions at the analog input (AIN) pins.

23. Transient current of up to 100 mA will not cause S CR latch-up. Maximum in put current for a power

supply pin is ±50 mA.

24. Total power dissipation, including all input currents and output currents.

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

10 DS317F2

CS5521/22/23/24/28

SWITCHING CHARACTERISTICS (T

Levels: Logic 0 = 0 V, Logic 1 = VD+; C

= 50 pF.))

L

= 25° C; VA+ = 5 V ±5%; VD+ = 3.0 V ±10% or 5 V ±5%;

A

Parameter Symbol Min Typ Max Unit

Master Clock Frequency (Note 25)

External Clock or Internal Oscillator (CS5522/24/28)

(CS5521/23)

XIN

30

30

32.768

32.768

200

130

kHz

kHz

Master Clock Duty Cycle 40 - 60 %

Rise Times (Note 26)

Any Digital Input Except SCLK

SCLK

Any Digital Output

Fall Times (Note 26)

Any Digital Input Except SCLK

SCLK

Any Digital Output

t

rise

t

fall

-

-

-

-

-

-

50

50

-

-

-

-

1.0

100

-

1.0

100

-

µs

µs

ns

µs

µs

ns

Start-up

Oscillator Start-up Time XTAL = 32.768 kHz (Note 27) t

Power-on Reset Period t

ost

por

-500-ms

- 2006 - XIN

cycles

Serial Port Timing

Serial Clock Frequency SCLK 0 - 2 MHz

SCLK Falling to CS

Falling for continuous running SCLK

t

0

100 - - ns

(Note 28)

Serial Clock Pulse Width High

Pulse Width Low

t

1

t

2

250

250

-

-

-

-

ns

ns

SDI Write Timing

CS Enable to Valid Latch Clock t

Data Set-up Time prior to SCLK rising t

Data Hold Time After SCLK Rising t

SCLK Falling Prior to CS

Disable t

3

4

5

6

50 - - ns

50 - - ns

100 - - ns

100 - - ns

SDO Read Timing

CS to Data Valid t

SCLK Falling to New Data Bit t

Rising to SDO Hi-Z t

CS

7

8

9

--150ns

--150ns

--150ns

Notes: 25. Device parameters are specified with a 32.768 kHz clock; however, clocks up to 200 kHz

(CS5522/24/28) or 130 kHz (CS5521/23) can be used for increased throughput.

26. Specified using 10% and 90% points on waveform of interest. Output loaded with 50 pF.

27. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an

external clock source.

28. Applicable when SCLK is continuously running.

Specifications are subject to change without notice.

DS317F2 11

CS

CS

SCLK

CS5521/22/23/24/28

t

0

t

t

t

3

1

t

2

Figure 1. Continuous Running SCLK Timing (Not to Scale)

t

3

6

CS

SDO

SCLK

SCLK

t

7

MSB

MSB

MSB-1 LSBSDI

t

4

t

5

t

1

t

2

t

6

Figure 2. SDI Write Timing (Not to Scale)

t

9

MSB-1 LSB

t

8

t

2

t

1

Figure 3. SDO Read Timing (Not to Scale)

12 DS317F2

CS5521/22/23/24/28

2. GENERAL DESCRIPTION

The CS5521/22/23/24/28 are highly integrated ∆Σ

Analog-to-Digital Converters (ADCs) which use

charge-balance techniques to achieve 16-bit

(CS5521/23) and 24-bit (CS5522/24/28) performance. The ADCs come as either two-channel

(CS5521/22), four-channel (CS5523/24), or eightchannel (CS5528) devices, and include a low input

current, chopper-stabilized instrumentation amplifier. To permit selectable input spans of 25 mV,

55 mV, 100 mV, 1 V, 2.5 V, and 5 V, the ADCs include a PGA (programmable gain amplifier). To

accommodate ground-based thermocouple applications, the devices include a CPD (Charge Pump

Drive) which provides a negative bias voltage to

the on-chip amplifiers.

These devices also include a fourth order DS modulator followed by a digital filter

eight selectable output word rates of

3.76 Hz, 7.51 Hz, 15 Hz, 30 Hz, 61.6 Hz, 84.5 Hz,

and 101.1 Hz

(XIN = 32.768 kHz).

capable of producing output update rates up to

617 Hz when a 200 kHz clock is used

(CS5522/24/28) or up to 401 Hz using a 130 kHz

which provides

1.88 Hz,

The devices are

clock (CS5521/23). Further note that the digital filters are designed to settle to full accuracy within

one conversion cycle and simultaneously reject

both 50 Hz and 60 Hz interference when operated

at word rates below 30 Hz (assuming a XIN clock

frequency of 32.768 kHz).

To ease communication between the ADCs and a

micro-controller, the converters include an easy to

use three-wire serial interfa ce which is SPI™ and

Microwire™ compatible.

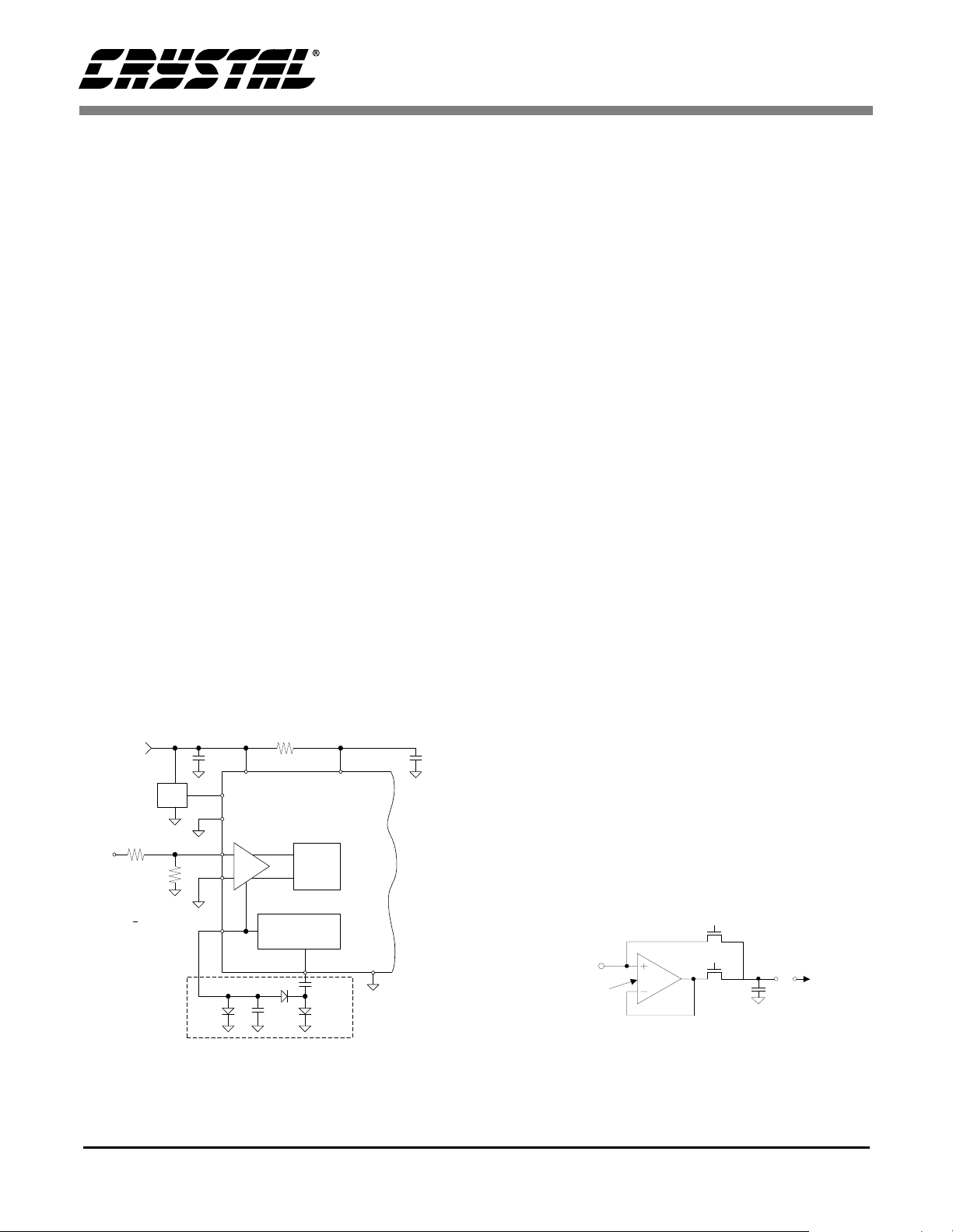

2.1 Analog Input

Figure 4 illustrates a block diagram of the analog input signal path inside the CS5521/22/23/24/28. The

front end consists of a multiplexer (break before

make configuration), a chopper-stabilized instrumentation amplifier with fixed gain of 20X,

coarse/fine charge buffers, and a programmable gain

section. For the 25 mV, 55 mV, and 100 mV input

ranges, the input signals are amplified by the 20X instrume ntatio n amp lifier . For the 1 V, 2.5 V, and 5 V

input ranges, the instrumentation amplifier is bypassed and the input signals are connected to the

Programmable Gain block via coarse/fine charge

buffers.

NBV

CS5522

IN+

M

U

IN-

X

CS5524

IN+

M

*

U

*

X

*

CS5528

M

*

U

*

X

*

IN-

IN+

IN-

IN+

IN-

X20

Programmable

Gain

NBV also supplies the negative

supply voltage for th e coarse/fine

change buffers

VREF+

Differen tial

4th order

delta-

modulator

VREF-

sigma

Digital

Filter

AIN2+

AIN2-

AIN1+

AIN1-

AIN4+

AIN4-

AIN1+

AIN1-

AIN8+

AIN7+

AIN1+

Figure 4. Multiplexer Configurations

DS317F2 13

CS5521/22/23/24/28

Figure 5. Input Models for AIN+ and AIN- pins,

≤(100 mV Input Ranges

2.1.1 Instrumentation Amplifier

The instrumentation amplifier is chopper stabilized

and is activated any time conversions are performed

with the low level input ranges, ≤100 mV. The amplifier is powered from VA+ and from the NBV

(Negative Bias Voltage) pin allowing the

CS5521/22/23/24/28 to be operated in either of two

analog input configurations. The NBV pin can be biased to a negative voltage between -1.8 V and -

2.5 V, or tied to AGND (for the CS5528, NBV has

to be between -1.8 V and -2.5 V for the ranges below

100 mV when the amplifier is engaged). The common-mode plus signal range of the instrumentation

amplifier is 1.85 V to 2.65 V with NBV grounded.

The common-mode plus signal range of the instrumentation amplifier is -0.150 V to 0.950 V with

NBV between -1.8 V to -2.5 V. Whether NBV is

tied between -1.8 V and -2.5 V or tied to AG ND,

the (Common Mode + Signal) input on AIN+ and

AIN- must stay between NBV and VA+.

Figure 5 illustrates an analog input model for the

ADCs when the instrumentation amplifier is engaged. The CVF (sampling) input current for each

of the analog input pins depends on the CFS1 and

CFS0 (Chop Frequency Select) bits in the configuration register (see Configuration Register for details). Note that the CVF current is lowest with the

CFS bits in their default states (cleared to logic 0s).

Further note that the CVF current into the instru-

mentation amplifier is less than 300 pA over -40°C

to +85°C. Note that Figure 5 is for input current

modeling only. For physical input capacitance see

‘Input Capacitance’ specification under ANALOG

CHARACTERISTICS. Also refer to Applications

Note AN30 “Switched-Capacitor A/D Converter

Input Structures” for more details on input models

and input sampling currents.

Note: Resi dual noise app ears in the converter ’s baseband for

output word rates greater than 61.6 Hz if the CFS bits

are logic 0 (chop clock = 256 Hz). For word rates of

30 Hz and lower, 256 Hz chopping is recommended,

and for 61.6 Hz, 84.5 Hz and 101.1 Hz filters, 4096 Hz

chopping is recommended.

2.1.2 Coarse/Fine Charge Buffers

The unity gain buffers are activated any time conversions are performed with the high level inputs ranges, 1 V, 2.5 V, and 5 V. The u nity gain bu ffer s ar e

designed to accommodate rail to rail input signals.

The common-mode plus signal range for the unity

gain buffer amplifier is NBV to VA+.

Typical CVF (sampling) current for the unity gain

buffer amplifiers is about 10 nA

(XIN = 32.768 kHz, see Figure 6).

25 mV,55 mV,and 100 mV Ranges

AIN

V≤25 mV

os

i=fVC

osn

CFS1/CFS0 = 00, f = 256 Hz

CFS1/CFS0 = 01, f = 4096 Hz

CFS1/CFS0 = 10, f = 16.384 kHz

CFS1/CFS0 = 11, f = 1024 Hz

14 DS317F2

C=48pF

1 V, 2.5 V and 5 V Ranges

φ

Fine

1

φ

Coarse

AIN

V≤25 mV

os

i=fVC

osn

f = 3 2.768 kHz

Figure 6. Input Models for AIN+ and AIN- pins,

>100 mV input ranges

1

C = 20 pF

CS5521/22/23/24/28

2.1.3 Analog Input Span Considerations

The CS5521/22/23/24/28 is designed to measure

full scale ranges of 25 mV, 55 mV, 100 mV, 1 V,

2.5 V and 5 V. Other full scale values can be accommodated by performing a system calibration

within the limits specified. See the Calibration section for more details. Another way to change the

full scale range is to increase or to decrease the

voltage reference to a voltage other than 2.5 . See

the Voltage Reference section for more details.

Three factors set the operating limits for the input

span. They include: instrumentation amplifie r satu-

ration, modulator 1’s density, and a lower reference

voltage. When the 25 mV, 55 mV or 100 mV range

is selected, the input signal (including the common

mode voltage and the amplifier offset voltage)

must not cause the 20X amplifier to saturate in either its input stage or output stage. To prevent saturation the absolute voltages on AIN+ and AINmust stay within the limits specified (refer to the

Analog Input section). Additionally, the differential output voltage of the amplifier must not exceed

2.8 V. The equation

is the differential input voltage and VOS is the absolute maximum offset voltage for the instrumentation amplifier (VOS will not exceed 40 mV). If the

differential output voltage from the amplifier exceeds 2.8 V, the amplifier may saturate, which will

cause a measurement error.

The input voltage into the modulator must not

cause the modulator to exceed a low of 20 perc ent

or a high of 80 percent 1's density. The nominal full

scale input span of the modulator (from 30 percent

to 70 percent 1’s density) is determined by the

VREF voltage divided by the Gain Factor. See

Table 1 to determine if the CS5521/22/23/24/28

are being used properly. For example, in the

55 mV range, to determine the nominal input voltage to the modulator, divide VREF (2.5 V) by the

Gain Factor (2.2727).

When a smaller voltage reference is used, the resulting code widths are smaller causing the converter output codes to exhibit more changing codes

for a fixed amount of noise. Table 1 is based upon

a VREF = 2.5 V. For other values of VREF, the

values in Table 1 must be scaled accordingly.

ABS(VIN + VOS) x 20 = 2.8 V

defines the differential output limit, where

VIN = (AIN+) - (AIN-)

Input Range

± 25 mV

± 55 mV

± 100 mV

± 1.0 V - 2.5V 2.5 ± 1.0 V ± 1.5 V

± 2.5 V - 2.5V 1.0 ± 2.5 V ± 5.0 V

± 5.0 V - 2.5V 0.5 ± 5.0 V 0V, VA+

Note: 1. The converter’s actual input range, the delta-sigma’s nominal full scale input, and the delta-sigma’s

(1)

maximum full scale input all scale directly with the value of the voltage reference. The values in the

table assume a 2.5

2. The 2.8 V limit at the output of the 20X amplifier is the differential output voltage.

Max. Differential Output

20X Amplifier

(2)

2.8 V

(2)

2.8 V

(2)

2.8 V

Table 1. Relationship between Full Scale Input, Gain Factors, and Internal Analog

VREF Gain Factor

Signal Limitations

V VREF voltage.

2.1.4 Measuring Voltages Higher than 5 V

Some systems require the measurement of voltages

greater than 5 V. The input current of the instru-

∆-Σ Nominal

Differential Input

2.5V 5 ± 0.5 V ± 0.75 V

2.5V 2.272727... ± 1.1 V ± 1.65 V

2.5V 1.25 ± 2.0 V ± 3.0 V

(1)

(1)

∆-Σ

Max. Input

DS317F2 15

CS5521/22/23/24/28

Voltage

Divider

PGIA set for

+

100 mV

±10V

Charge Pu mp

Regulator

∆Σ

ADC

PGIA

+5 V

2.5 V

VA+

VREF+

VREF-

VD+

+

-

NBV

V

≈

-2.1 V

+

10

µ

F

0.033

µ

F

CPD

0.1 µF

10

Ω

0.1 µF

1N4148

1N4148BAT85

Charge Pump

Circuitry

DGND

chop clock = 256 Hz

10 K

Ω

1 M

Ω

Figure 7. Input Ranges Greater than 5 V

mentation amplifier, typically 100 pA, is low

enough to permit large external resistors to divide

down a large external signal without significant

loading. Figure 7 illustrates an example circuit. Refer to Applications Note 158 for more details on

high voltage (>5 V) measurement.

2.1.5 Voltage Reference

The CS5521/22/23/24/28 are specified for operation with a 2.5 V reference voltage between the

VREF+ and VREF- pins of the device. For a singleended reference voltage, such as the LT1019-2.5,

the reference voltage is input into the VREF+ pin

of the converter and the VREF- pin is grounded.

The differential voltage between the VREF+ and

VREF- can be any voltage from 1.0 V up to VA+,

however, the VREF+ cannot go above VA+ and the

VREF- pin can not go below NBV.

Figure 8 illustrates the input models for the VREF

pins. The dynamic input current for each of the pins

can be determined from the models shown.

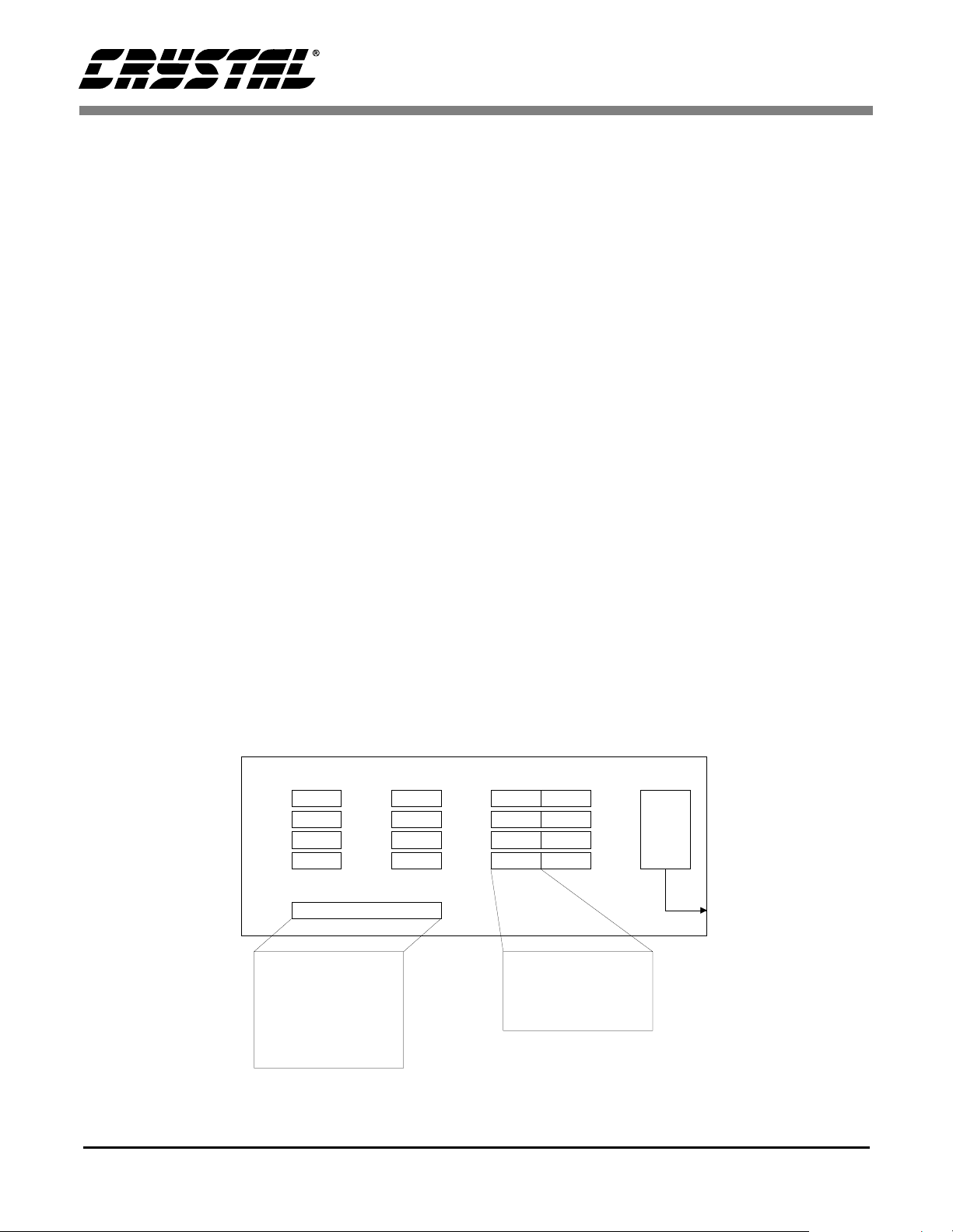

2.2 Overview of ADC Register Structure and Operating Modes

The CS5521/22/23/24/28 ADCs have an on-chip

controller, which includes a number of user-accessible registers. The registers are used to hold offset

and gain calibration results, configure the chip’s

operating modes, hold conversion instructions, and

to store conversion data words. Figure 9 depicts a

block diagram of the on-chip controller’s internal

registers for the CS5523/24.

Each of the converters has 24-bit registers to function as offset and gain calibration registers for each

channel. The converters with two channels have

two offset and two gain calibration registers, the

converters with four channels have four offset and

four gain calibration registers, and the eight channel converter has eight offset and eight gain calibration registers. These registers hold calibration

results. The contents of these registers can be read

or written by the user. This allows calibration data

to be off-loaded into an external EEPROM. The

user can also manipulate the contents of these registers to modify the offset or the gain slope of the

converter.

16 DS317F2

The converters include a 24-bit configuration register of which 17 of the bits are used for setting options such as the conversion mode, operating power

options, setting the chop clock rate of the instrumentation amplifier, and providing a number of

flags which indicate converter operation.

φ

Fine

1

φ

Coarse

VREF

V ≤ 25mV

os

i = fV C

osn

f = 32.768 kHz

Figure 8. Input Model for VREF+ and VREF- Pins

2

C = 10pF

CS5521/22/23/24/28

A group of registers, called Channel Set-up Registers, are also included in the converters. These registers are used to hold pre-loaded conversion

instructions. Each channel set-up register is 24 bits

long and holds two 12-bit conversion instructions

(Setups). Upon power up, these registers can be initialized by the users’ microcontroller with conversion instructions. The user can then use bits in the

configuration register to choose a conversion

mode.

Several conversion modes are possible. Using the

single conversion mode, an 8-bit command word

can be written into the serial port. The command in-

cludes pointer bits which ‘point’ to a 12-bit command in one of the Channel Setup Registers which

is to be executed. The 12-bit commands can be setup to perform a conversion on any of the input

channels of the converter. More than one of the 12bit Setups can be used for the same analog input

channel. This allows the user to convert on the

same signal with either a different conversion

speed, a different gain range, or any of the other options available in the Setup Register. The user can

set up the registers to perform different conversion

conditions on each of the input channels.

The ADCs also include multiple channel conversion capability. User bits in the configuration register of the ADCs can be configured to sequence

through the 12-bit command Setups, performing a

conversion according to the content of each 12-bit

Setup. This channel scanning capability can be

configured to run continuously, or to scan through

a specified number of Setup Registers and stop until commanded to continue. In the multiple channel

scanning modes, the conversion data words are

loaded into an on-chip data FIFO. The converter issues a flag on the SDO pin when a scan cycle is

completed so the user can read the FIFO. More details are given in the following pages.

Instructions are provided to initialize the converter,

perform offset and gain calibrations, and how to

configure the converter for the various conversion

modes. Each of the bits of the configuration register and of the Channel Setup Registers is described.

A list of examples follows the description section.

Table 2 can be used to decode all valid commands

(the first 8-bits into the serial port).

4 (24) 4 (24) 4 (12 x 2) 8 x 24

AIN1

AIN2

AIN3

AIN4

Off 1

Off 2

Off 3

Off 4

1 x 24

Configuration

Chop Frequency

Multiple Co nversio ns

Depth Pointer

Loop

Read Convert

Powerdown Modes

Flags

Etc.

Gain 1

Gain 2

Gain 3

Gain 4

Setup 1

Setup 3

Setup 5

Setup 7

Setup 2

Setup 4

Setup 6

Setup 8

Latch Outputs

Channel Select

Output Word Rate

PGA Selection

Unipolar/Bipolar

DATA

FIFO

SDO

Figure 9. CS5523/24 Register Diagram

DS317F2 17

CS5521/22/23/24/28

configuration registe r: 000040(H)

offset registers: 000000(H)

gain registers: 400000(H)

channel setup register s: 000000(H)

2.2.1 System Initialization

When power to the CS5521/22/23/24/28 is applied,

the chips are held in a reset condition until the

32.768 kHz oscillator has started and a countertimer elapses. Due to the high Q of the 32.768 kHz

crystal, the oscillator takes 400-600 ms to start. The

counter-timer counts 2006 oscillator clock cycles

to make sure the oscillator is fully stable. During

this time-out period the serial port logic is re set and

the RV (Reset Valid) bit in the configuration register is set to indicate that a valid reset occurred. After a reset, the on-chip registers are initialized to the

following states and the converter is placed in the

command mode where it waits for a valid command.

Note: A system reset can be initiated at any time by w riting

a logic 1 to the RS (Reset System) bit in the configuration register. After a reset, the RV b it is set until the

configuration register is read. The user must then

write a logic 0 to the RS bit to take the part out of the

reset mode. Any other bits written to the configuration

register at this time will be lost. The configuration register must be written again once RS = 0 to set any other

bits.

2.2.2 Serial Port Initialization Sequence

The serial port is initialized to the command mode

whenever a power-on reset is performed inside the

converter, or when the user transmits the port initialization sequence. The port initialization sequence involves clocking 15 bytes of all 1’s,

followed by one byte with the following bit con-

tents ‘11111110’. This sequence places the chip in

the command mode where it wait s for a va lid co mmand to be written.

18 DS317F2

CS5521/22/23/24/28

2.2.3 Command Register Quick Reference

D7(MSB)D6D5D4D3D2D1D0

CB CS2 CS1 CS0 R/W RSB2 RSB1 RSB0

BIT NAME VALUE FUNCTION

D7 Command Bit, CB 0

D6-D4 Channel Select Bits,

CSB2-CSB0

D3 Read/Write

D2-D0 Register Select Bit,

RSB2-RSB0

, R/W 0

000

111

000

001

010

011

101

110

111

1

.

.

1

Must be logic 0 for these commands.

See table below.

CS2-CS0 provide the address of one of the eight physical

channels. These bits are used to acce ss the c al ibra t io n reg is ters associated with respective channels.

Note: These bits are ignored when reading the data register.

Write to selected register.

Read from selected register.

Reserved

Offset Register

Gain Register

Configuration Register

Channel Set-up Registers

- register is 48-bits long for CS5521/22

- register is 96-bits long for CS5523/24

- register is 192-bits long for CS5528

Reserved

Reserved

D7(MSB)D6D5D4D3D2D1D0

CB CSRP3 CSRP2 CSRP1 CSRP0 CC2 CC1 CC0

BIT NAME VALUE FUNCTION

D7 Command Bit, CB 0

D6-D3 Channel Pointer Bits,

CSRP3-CSRP0

D2-D0 Conversion/Calibration

Bits, CC2-CC0

0000

1111

000

001

010

011

100

101

110

111

1

.

.

.

See table above.

Must be logic 1 for these commands.

These bits are used as pointers to the Setups.

Note: The MC bit, must be l ogic 0 for thes e bit s to t ake e ffe ct .

When MC = 1, these bits are ignored. The LP, MC, and RC

bits in the configuration register a re ignored during calib ration.

Normal Conversion

Self-Offset Calibration

Self-Gain Calibration

Reserved

Reserved

System-Offset Cali brati on

System-Gain Calibration

Reserved

Table 2. Command Register Quick Reference

DS317F2 19

CS5521/22/23/24/28

2.2.4 Command Register Descriptions

READ/WRITE INDIVIDUAL OFFSET CALIBRATION REGISTER

D7(MSB)D6D5D4D3D2D1D0

0 CS2 CS1 CS0 R/W

001

Function

:

These commands are used to access each offset register separately. CS1 - CS0 decode the

registers accessed.

R/W

(Read/Write)

0 Write to selected register.

1 Read from selected register.

CS[2:0] (Channel Select Bits)

000 Offset Register 1(All devices)

001 Offset Register 2 (All devices)

010 Offset Register 3 (CS5523/24/28 only)

011 Offset Register 4 (CS5523/24/28 only)

100 Offset Register 5 (CS5528 only)

101 Offset Register 6 (CS5528 only)

110 Offset Register 7 (CS5528 only)

111 Offset Register 8 (CS5528 only)

READ/WRITE INDIVIDUAL GAIN REGISTER

D7(MSB)D6D5D4D3D2D1D0

0 CS2 CS1 CS0 R/W 010

Function

:

These commands are used to access each gain register separately. CS1 - CS0 decode the registers accessed.

R/W

(Read/Write)

0 Write to selected register.

1 Read from selected register.

CS[2:0] (Channel Select Bits)

000 Gain Regis ter 1(All devi ces )

001 Gain Register 2 (All devices)

010 Gain Register 3 (CS5523/24/28 only)

011 Gain Register 4 (CS5523/24/28 only)

100 Gain Register 5 (CS5528 only)

101 Gain Register 6 (CS5528 only)

110 Gain Register 7 (CS5528 only)

111 Gain Register 8 (CS5528 only)

20 DS317F2

CS5521/22/23/24/28

READ/WRITE

D7(MSB)D6D5D4D3D2D1D0

0000R/W011

CONFIGURATION REGISTER

Function: These commands are used to read from or write to the configuration register.

R/W

(Read/Write)

0 Write to selected register.

1 Read from selected register.

READ/WRITE CHANNEL-SETUP REGISTER(S)

D7(MSB)D6D5D4D3D2D1D0

0000R/W

Function

:

These commands are used to access the channel-setup registers (CSRs). The number of

101

CSRs accessed is determined by the device being used and the number of CSRs that are being

accessed (i.e. the depth bits in the configuration register determine the number of levels accessed). This register is 48-bits long (4 Setups) for the CS5521/22, 96-bits long (8 Setups) for

the CS5523/24, and 192-bits (16 Setups) long for the CS5528.

(Read/Write)

R/W

0 Write to selected register.

1 Read from selected register.

DS317F2 21

CS5521/22/23/24/28

PERFORM CONVERSION

D7(MSB)D6D5D4D3D2D1D0

1 CSRP3 CSRP2 CSRP1 CSRP0 0 0 0

Function: These commands instruct the ADC to perform conversions on the physical input channel point-

ed to by the pointer bits (CSRP2 - CSRP0) in the channel-setup registers. The particular type

of conversion performed is determined by the states of the conversion control bits (the multiple

conversion bit, the loop bit, read convert bit, and the depth pointer bits) in the configuration register.

CSRP [3:0] (Channel Setup Register Pointer Bits)

0000 Setup 1 (All devices)

0001 Setup 2 (All devices)

0010 Setup 3 (All devices)

0011 Setup 4 (All devices)

0100 Setup 5 (CS5523/24/28)

0101 Setup 6 (CS5523/24/28)

0110 Setup 7 (CS5523/24/28)

0111 Setup 8 (CS5523/24/28)

1000 Setup 9 (CS5528 only)

1001 Setup 10 (CS5528 only)

1010 Setup 11 (CS5528 only)

1011 Setup 12 (CS5528 only)

1100 Setup 13 (CS5528 only)

1101 Setup 14 (CS5528 only)

1110 Setup 15 (CS5528 only)

1111 Setup 16 (CS5528 only)

22 DS317F2

CS5521/22/23/24/28

PERFORM CALIBRATION

D7(MSB)D6D5D4D3D2D1D0

1 CSRP3 CSRP2 CSRP1 CSRP0 CC2 CC1 CC0

Function: These commands instruct the ADC to perform a calibration on the physical input channel refer-

enced which is chosen by the command byte pointer bits (CSRP3 - CRSP0).

CSRP [3:0] (Channel Setup Register Pointer Bits)

0000 Setup 1 (All devices)

0001 Setup 2 (All devices)

0010 Setup 3 (All devices)

0011 Setup 4 (All devices)

0100 Setup 5 (CS5523/24/28 only)

0101 Setup 6 (CS5523/24/28 only)

0110 Setup 7 (CS5523/24/28 only)

0111 Setup 8 (CS5523/24/28 only)

1000 Setup 9 (CS5528 only)

1001 Setup 10 (CS5528 only)

1010 Setup 11 (CS5528 only)

1011 Setup 12 (CS5528 only)

1100 Setup 13 (CS5528 only)

1101 Setup 14 (CS5528 only)

1110 Setup 15 (CS5528 only)

1111 Setup 16 (CS5528 only)

CC [2:0] (Calibration Control Bits)

000 Reserved

001 Self-Offset Cali bration

010 Self-Gain Calibration

011 Reserved

100 Reserved

101 System-Offset Calibration

110 Syste m- Ga in Ca li bration

111 Reserved

DS317F2 23

CS5521/22/23/24/28

SYNC1

D7(MSB)D6D5D4D3D2D1D0

11111111

Function: Part of the serial port re-initialization sequence.

SYNC0

D7(MSB)D6D5D4D3D2D1D0

11111110

Function: End of the serial port re-initialization sequence.

NULL

D7(MSB)D6D5D4D3D2D1D0

00000000

Function: This command is used to clear a port flag and keep the converter in the continuous conversion

mode.

24 DS317F2

CS5521/22/23/24/28

2.2.5 Serial Port Interface

The CS5521/22/23/24/28’s serial interface consists

of four control lines: CS, SCLK, SDI, SDO.

Figure 10 illustrates the serial sequence necessary

to write to, or read from the serial port’s registers.

CS, Chip Select, is the control line which enables

access to the serial port. If the CS pin is tied low,

the port can function as a three wire interface.

SDI, Serial Data In, is the data signal used to transfer data to the converters.

SDO, Serial Data Out, is the data signal used to

transfer output data from the converters. The SDO

CS

SCLK

SDI

Command Time

8SCLKs

CS

output will be held at high impedance any time CS

is at logic 1.

SCLK, Serial Clock, is the serial bit-clock which

controls the shifting of data to or from the ADC’s

serial port. The CS pin must be held low (logic 0)

before SCLK transitions can be recognized by the

port logic. To accommodate optoisolators SCLK is

designed with a Schmitt-trigger input to allow an

optoisolator with slower rise and fall times to directly drive the pin. Additionally, SDO is capable

of sinking or sourcing up to 5 mA to directly drive

an optoisolator LED. SDO will have less than a

400 mV loss in the drive voltage when sinking or

sourcing 5 mA.

MSB

Data T ime 24 SCLKs

Write Cycle

LSB

SCLK

SDI

Command Time

8SCLKs

SDO

SCLK

SDI

t *

Command Time

8 SCLKs

SDO

* td = XIN /OWR clock cycles for each co nversion except the

first conversion which will take XIN/OWR + 7 clock cycles

d

Figure 10. Command and Data Word Timing

MSB

Data Time 24 SC LKs

Read Cycle

8 SCLKs Clear SDO Flag

MSB

LSB

XIN/OWR

Clock Cycles

LSB

Data Time

24 SCLKs

DS317F2 25

CS5521/22/23/24/28

2.2.6 Reading/Writing the Offset, Gain, and Configuration Registers

The CS5521/22/23/24/28’s offset, gain, and c o nfiguration registers are accessed individual ly and can

be read from or written to. To write to an offset, a

gain, or the configuration register, the user must

transmit the appropriate writ e command which accesses the particular register and then follow that

command by 24 bits of data (r efer to Figure 10 for

details). For example, to write 0x800000 (hexadecimal) to physical channel one’s gain register, the user

would transmit the command byte 0x02 (hexadecimal) and then follow that command byte with the

data 0x800000 (hexadecimal). Similarly, to read

physical channel one’s gain register , the user must

first transmit the command byte 0x0A (hexadecimal) and then read the 24 bits of data. Once an of fset, a gain, or the configuration register is written to

or read from, the serial p

mode.

2.2.7 R

i

sters

The CS5521/22 have two 24-bit channel-setup registers (CSRs). The CS5523/24 have four CSRs, and

the CS5528 has eight CSRs (refer to Table 3 for

more detail on the CSRs). These r egisters are accessed in conjunction with the depth pointer bits in

the configuration register. Each CSR contains two

12-bit Setups which are programmed by the user to

contain data conversion or calibration information

such as:

1) state of the output latch pins

2) output word rate

3) gain range

4) polarity

5) the address of a physical input channel to be

eading/Writing the Channel-Setup Reg-

converted.

ort returns to the command

Once programmed they are used to determine th e

mode (e.g. unipolar, 15 Hz, 100 mV range etc.) the

ADC will operate in when future conversions or

calibrations are performed.

To access the CSRs, the user must first initialize the

depth pointer bits in the configuration register as

these bits determine the number of CSRs to read

from or write to. For example, to write CSR1

(Setup1 and Setup2), the user would first program

the configuration register’s depth pointer bits with

‘0001’ binary. This notifies the ADC’s serial port

that only the first CSR is to be accessed. Then, the

user would transmit the write command, 0x05

(hexadecimal) and follow that command with 24bits of data. Similarly, to read CSR 1, the use r must

transmit the command byte 0x0D (hexadecimal)

and then read the 24 bits of data. To write more

than one CSR, for instance CSR1 and CSR2

(Setup1, Setup2, Setup3 and Setup4), the user would

first set the depth pointer bits in the configuration

register to ‘0011’ binary. The user would then transmit the write CSR command 0x05 (hexadecimal)

and follow that with the information for Setup1,

Setup2, Setup 3, and Setup 4 which is 48-bits of information. Note that while reading/writing CSRs,

two Setups are accessed in pairs as a single 24-bit

CSR register. Even if one of the Setups isn’t used, it

must be written to or read. Further note that the

CSRs are accessed as a closed array, the user can not

access CSR2 without accessing CSR1. This requirement means that the depth bits i n the configuration register can only be set to one of the following

states when the CSRs are being read from or written

to: 0001, 0011, 0101, 0111, 1001, 1011, 1101, 1111.

Examples detailing the power of the CSRs are provided in the

the Data Conversion FIFO

are written to or read from, the seri al port ret urns to

the command

Performing Conversions and Reading

section. Once the CSRs

mode.

26 DS317F2

CS5521/22/23/24/28

CSR (Channel-Setup Register) CSR CSR

#1 LC (Log. Channel) 1

Bits <47:36>

#2 LC 3

Bits <23:12>

CS5521/22 CS5523/24 CS5528

D23(MSB) D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12

A1 A0 CS2 CS1 CS0 WR2 WR1 WR0 G2 G1 G0 U/B

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

A1 A0 CS2 CS1 CS0 WR2 WR1 WR0 G2 G1 G0 U/B

BIT NAME VALUE FUNCTION

D23-D22/

D11-D10

D21-D19/

D9-D7

D18-D16/

D6-D4

D15-D13/

D3-D1

D12/D0 Unipolar/Bipolar, U/B

Latch Outputs, A1-A0 00 *R Latch Output Pins A1-A0 mimic D23/D11-D22/D10 register bits.

Channel Select, CS2CS0

Word Rate, WR2-WR0 000

Gain Bits, G2-G0 000

LC 2

Bits <35:24>

LC 4

Bits <11:0>

000

001

010

011

100

101

110

111

001

010

011

100

101

110

111

001

010

01 1

100

101

110

111

0

1

#1 LC 1

Bits <95:84>

#4 LC 7

Bits <23:12>

R Select physical channel 1 (All devices)

Select physical channel 2(All devices)

Select physical channel 3 (CS5523/24/28 only)

Select physical channel 4 (CS5523/24/28 only)

Select physical channel 5 (CS552 8 only )

Select physical channel 6 (CS552 8 only )

Select physical channel 7 (CS552 8 only )

Select physical channel 8 (CS552 8 only )

R 15.0 Hz (2180 XIN cycles).

30.0 Hz (1092 XIN cycles).

61.6 Hz (532 XIN cycles).

84.5 Hz (388 XIN cycles).

101.1 Hz (324 XIN cycles).

1.88 Hz (17444 XIN cycles).

3.76 Hz (8724 XIN cycles).

7.51 Hz (4364 XIN cycles).

R 100 mV (assumes VREF Differen tia l = 2.5 V)

55 mV

25 mV

1.0 V

5.0 V

2.5 V

Not used.

Not used.

R Bipolar measurement mode.

Unipolar measurement mode.

LC 2

Bits <83:72>

LC 8

Bits <11:0>

#1 LC 1

Bits <191:180>

#8 LC 15

Bits <23:12>

LC 2

Bits <179:168>

LC 16

Bits <11:0>

* R indicates the bit value after the part is reset

Table 3. Channel-Setup Registers

DS317F2 27

CS5521/22/23/24/28

2.2.7.1 Latch Outputs

The A1-A0 pins mimic the latch output, D23/D11D22/D10, bits of the channel-setup registers. A1-A0

can be used to control external multiplexers and other logic functions outside the converter. The outputs

can sink or source at least 1 mA, but it is recommended to limit drive currents to less than 20µA to

reduce self-heating of the chip. T

powered from VA+, hence, their output voltage for

a logic 1 will be limited to the VA+ supply voltag e.

hese outputs are

2.2.7.2 Channel Select Bits

The channel select, CS1-CS0, bits are used to determine which physical input channel will be used

when a conversion is performed with a particular

Setup.

2.2.7.3 Output Word Rate Selection

The word rate, WR2-WR0, bits of the channel-setup registers set the output conversion word rate of

the converter when a conversion is performed with

a particular Setup. The word rates indicated in

Table 3 assume a master clock of 32.768 kHz, and

scale linearly when using other master clock frequencies. Upon reset the converter is set to operate

with an output word rate of 15.0 Hz.

2.2.7.4 Gain Bits

The gain bits, G2-G0, of the channel-setup registers set the full scale differential input range for the

ADC when a conversion is performed with a particular Setup. The input ranges in the table assume a

2.5 V reference voltage, and scale linearly when

using other reference voltages.

2.2.8 Configuration Register

The configuration register is 24-bits long. The following subsections detail the bits in the configuration register. Table 4 summarizes the configuration

register.

2.2.8.1 Chop Frequency Select

The chop frequency select (CFS1-CFS0) bits are

used to set the rate at which the instrumentation

amplifier’s chop switches modulate the input signal. The 256 Hz rate is desirable as it provides the

lowest input CVF (sampling) current, <300 pA

over -40 to 85 C. The higher rates can be used to

eliminate modulation/aliasing effects as the frequency of the input signal increases.

2.2.8.2 Conversion/Calibration Control Bits

The conversion/calibration control bits in the configuration register are used to control the particular

type of conversion required for the users applications. In short, the depth pointer (DP3-DP0) bits

determine the number of Setups that will be referenced when conversions are performed. The multiple conversion (MC) bit instructs the converter to

perform conversions on the number of Setups in the

channel-setup registers which are referenced by the

depth pointer bits. The converter begins with

Setup1 and moves sequentially through the Setups

in this mode. The Loop (LP) bit instructs the converter to continuously perform conversions until a

stop command is sent to the converter. The read

convert (RC) bit instructs the converter to wait until

the conversion data is read before performing the

next conversion or set of conversions.

2.2.7.5 Unipolar/Bipolar Bit

The unipolar/bipolar bit is used to determine the

type of conversion, unipolar/bipolar, that will be

performed with a particular Setup.

28 DS317F2

2.2.8.3 Power Consumption Control Bits

The CS5522/24/28 accommodate four power consumption modes: normal, low power, standby, and

sleep. The CS5521/23 accommodate three power

consumption modes: normal, standby, and sleep.

The normal (default) mode is entered after a poweron-reset. In normal mode, the CS5522/24/28 typi-

CS5521/22/23/24/28

cally consume 9.0 mW. The CS5521/23 typically

consume 5.5 mW. The low power mode is an alternate mode in the CS5522/24/28 that reduces the

consumed power to 5.5 mW. It is entered by setting

bit D8 (the low power mode bit) in the configuration register to logic 1. Slightly degraded noise or

linearity performance should be expected in the

low power mode. Note that the XIN clock should

not exceed 130 kHz in low power mode. The final

two modes accommodated in all devices are referred to as the power save modes. They power

down most of the analog portion of the chip and

stop filter convolutions. The power save modes are

entered whenever the PS/R bit of the configuration

register is set to logic 1. The particular power save

mode entered depends on state of bit D11 (PSS, t he

Power Save Select bit) in the configuration register.

If PSS is logic 0, the converters enters the standby

mode reducing the power consumption to 1.2 mW.

The standby mode leaves the oscillator and the onchip bias generator running. This allows the converter to quickly return to the normal or low power

mode once the PS/R bit is set back to a logic 1. If

PSS and PS/R in the configuration register are set

to logic 1, the sleep mode is entered reducing the

consumed power to around 500 µW. Since the

sleep mode disables the oscillator, ap proximat ely a

500ms oscillator start-up delay period is required

before returning to the normal or low power mode.

2.2.8.4 Charge Pump Disable

The pump disable (PD) bit permits the user to turn

off the charge pump drive thus enabling the user to

reduce the radiation of digital interference from the

CPD pin when the charge pump is not being used.

2.2.8.5 Reset System Control Bits

The reset system (RS) bit permits the user to perform a system reset. A system reset can be initiated

at any time by writing a logic 1 to the RS bit in the

configuration register. After a system reset cycle is

complete, the reset valid (RV) bit is set indicating

that the internal logic was properly reset. The RV

remains set until the configuration register is read.

Note that the user must write a logic 0 to the RS bit

to take the part out of the reset mode. No other bits

in the configuration register can be written at this

time. A subsequent write to the configuration register is necessary to write to any other bits in this

register. Once reset, the on-chip regi sters are initialized to the following states.

configuration registe r: 000040(H)

offset registers: 000000(H)

gain registers: 400000(H)

channel setup register s: 000000(H)

2.2.8.6 Data Conversion Error Flags

The oscillation detect (OD) and over flow (OF) bits

in the configuration register are flag bits used to indicate that the ADC performed a conversion on an

input signal that was not within the conversion

range of the ADC. For convenience, the OD and

OF bits are also in the data conversion word of the

CS5521/23.

The OF bit is set to logic 1 when the input signal is:

1) more positive than full scale

2) more negative than zero in unipolar mode, or

3) more negative than negative full scale in bipolar mode.

The OF flag is cleared to logic 0 when a conversion

occurs which is not out of range.

The OD bit is set to logic 1 any time that an oscillatory condition is detected in the modulator. This

does not occur under normal operating conditions,

but may occur when the input is extremely overranged. The OD flag will be cleared to logic 0 when

the modulator becomes stable.

DS317F2 29

CS5521/22/23/24/28

D23(MSB) D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12

NU NU CFS1 CFS0 NU MC LP RC DP3 DP2 DP1 DP0

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

PSS PD PS/R LPMRSRV ODOFNUNUNUNU

BIT NAME VALUE FUNCTION

D23-D22 Not Used, NU 00 R* Must always be logic 0.

D21-D20 Chop Frequency Select,

CFS1-CFS0

D19 Not Used, NU 0 R Must always be logic 0.

D18 Multiple Conversion, MC 0

D17 Loop, LP 0

D16 Read Convert, RC 0

D15-D12 Depth Pointer, DP3-DP0 0000

D11 Power Save Select, PSS 0

D10 Pump Disable, PD 0

D9 Power Save/Run

D8 Low Power Mode, LPM 0

D7 Reset System, RS 0

D6 Reset Valid, RV 0

D5 Oscillation Detect, OD 0

D4 Overrange Flag, OF 0

D3-D0 Not Used, NU 0000 R Must always be logic 0.

, PS/R 0

00

01

10

11

1111

R 256 Hz Amplifier chop frequency. (XIN = 32.768 kHz)

R Perform single-Setup conversions. MC bit is ignored during calibrations.

1

R The conversions on the single Setup (MC = 0) or multiple Setups (MC =

1

R Don’t wait for use r to fi ni sh reading data before starting new convers io ns.

1

R When writing or reading the CSRs, these bits (DP3-DP0) determine the

.

.

R Standby Mode (Oscillator active, allows quick power-up).

1

R Charge Pump Enabled.

1

RRun.

1

R Normal Mode (LPM bit is only for the CS5522/24/28)

1

R Normal Opera tion.

1

1R

R Bit is clear when an oscillation condition has not occurred (read only).

1

R Bit is clear when an overr ange condition has not occurred (read only).

1

4,096 Hz Amplifier chop frequency.

16,384 Hz Amplifier chop frequency.

1,024 Hz Amplifier chop frequency.

Perform multiple-Setup conversions on Setups in the channel-setup register by issuing only one command with MSB = 1.