Page 1

CS5525

CS5526

16-bit/20-bit, Multi-range ADC with 4-bit Latch

Features

z Delta-sigma A/D Converter

- Linearity Error: 0.0015%FS

- Noise-free Resolution: 18-bits

z Bipolar/Unipolar Input Ranges

- 25 mV, 55 mV, 100 mV, 1 V, 2.5 V and 5 V

z Chopper Stabilized Instrumentation Amplifier

z On-chip Charge Pump Drive Circuitry

z 4-bit Output Latch

z Simple three-wire serial interface

- SPI™ and Microwire™ Compatible

- Schmitt Trigger on Serial Clock (SCLK)

z Programmable Output Word Rates

- 3.76 Sps to 202 Sps (XIN = 32.768 kHz)

- 11.47 Sps to 616 Sps (XIN = 100 kHz)

z Output Settles in One Conversion Cycle

z Simultaneous 50/60 Hz Noise Rejection

z System and Self-calibration with

Read/Write Registers

z Single +5 V Analog Supply

+3.0 V or +5 V Digital Supply

z Low-power Mode Consumption: 4.9 mW

- 1.8 mW in 1 V, 2.5 V, and 5 V Input Ranges

General Description

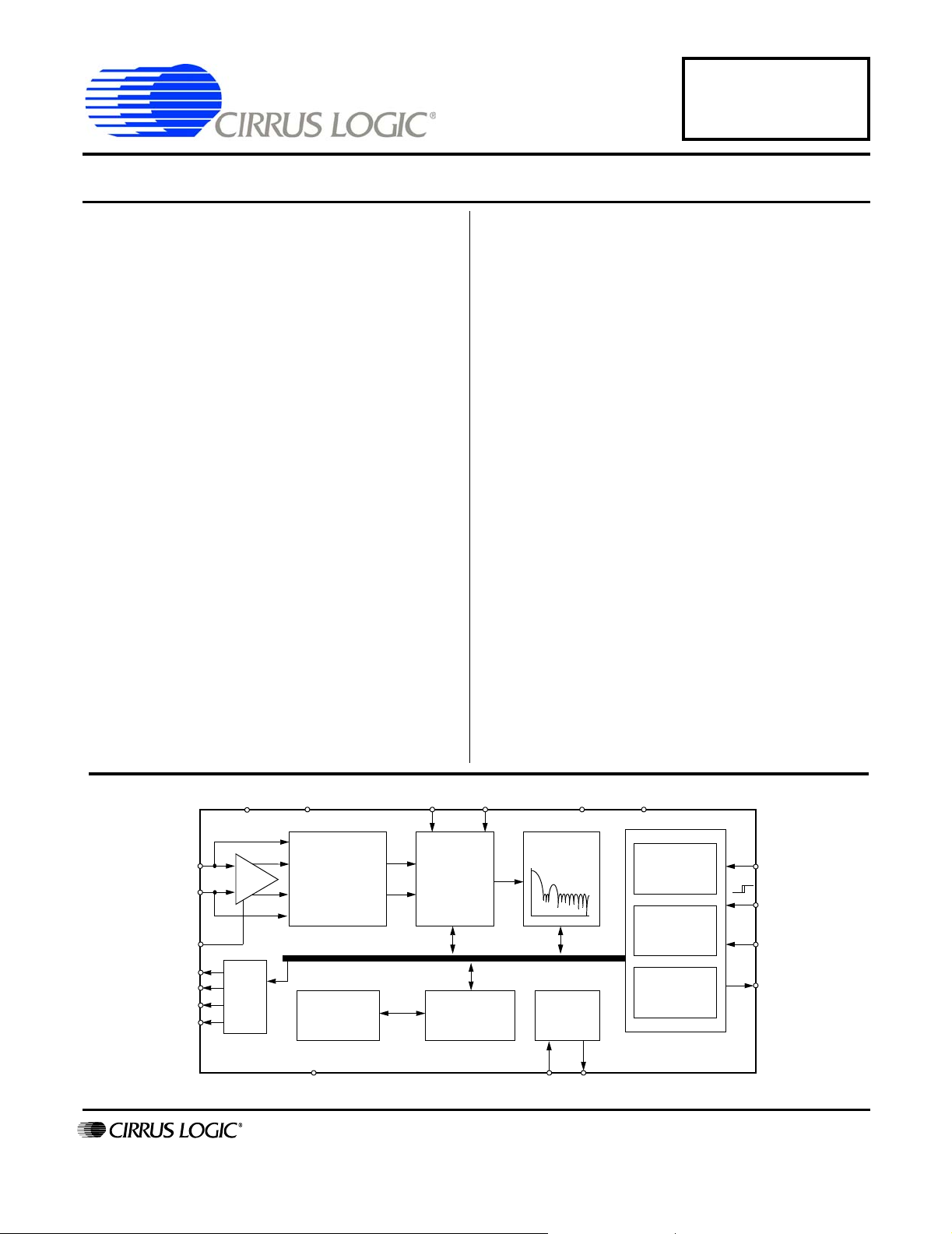

The 16-bit CS5525 and the 20-bit CS5526 are highly integrated ∆Σ A/D converters which include an

instrumentation amplifier, a PGA (programmable gain

amplifier), eight digital filters, and self and system calibration circuitry.

The converters are designed to provide their own negative supply which enables their on-chip instrumentation

amplifiers to measure bipolar ground-referenced signals

≤±100 mV. By directly supplying NBV with -2.5 V and

with VA+ at 5 V,

can be measured.

The digital filters provide programmable output update

rates between 3.76 Sps to 202 Sps (XIN = 32.768 kHz).

Output word rates can be increased by approximately 3X

by using XIN = 100 kHz. Each filter is designed to settle

to full accuracy for its output update rate in one conversion cycle. The filters with word rates of 15 Sps or less

(XIN = 32.768 kHz) reject both 50 and 60 Hz (

interference simultaneously.

Low power, single conversion settling time, programmable output rates, and the ability to handle negative input

signals make these single supply products ideal solutions for isolated and non-isolated applications.

ORDERING INFORMATION

See page 29.

±2.5 V signals (with respect to ground)

±3 Hz) line

AIN+

AIN-

NBV

A0

A1

A2

A3

http://www.cirrus.com

VA+ AGND VREF+ VREF- VD+DGND

+

X20

-

Latch

Programmable

Gain

Calibration

Memory

CPD

Differential

4th Order

Delta-Sigma

Modulator

Calibration µC

Copyright © Cirrus Logic, Inc. 2005

(All Rights Reserved)

Digital Filter

Clock

Gen.

XIN XOUT

Calibration

Register

Control

Register

Output

Register

CS

SCLK

SDI

SDO

AUG ‘05

DS202F5

Page 2

CS5525 CS5526

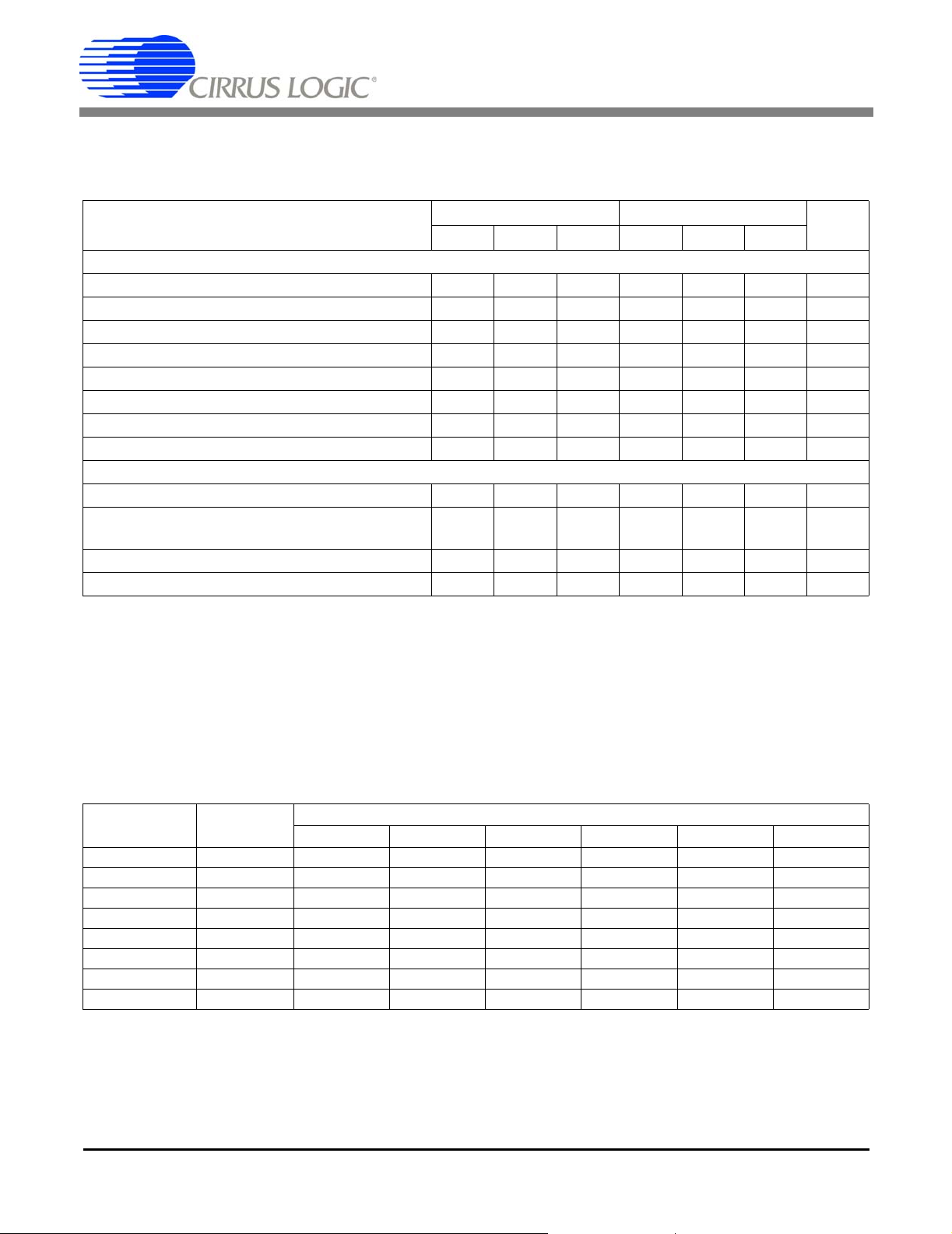

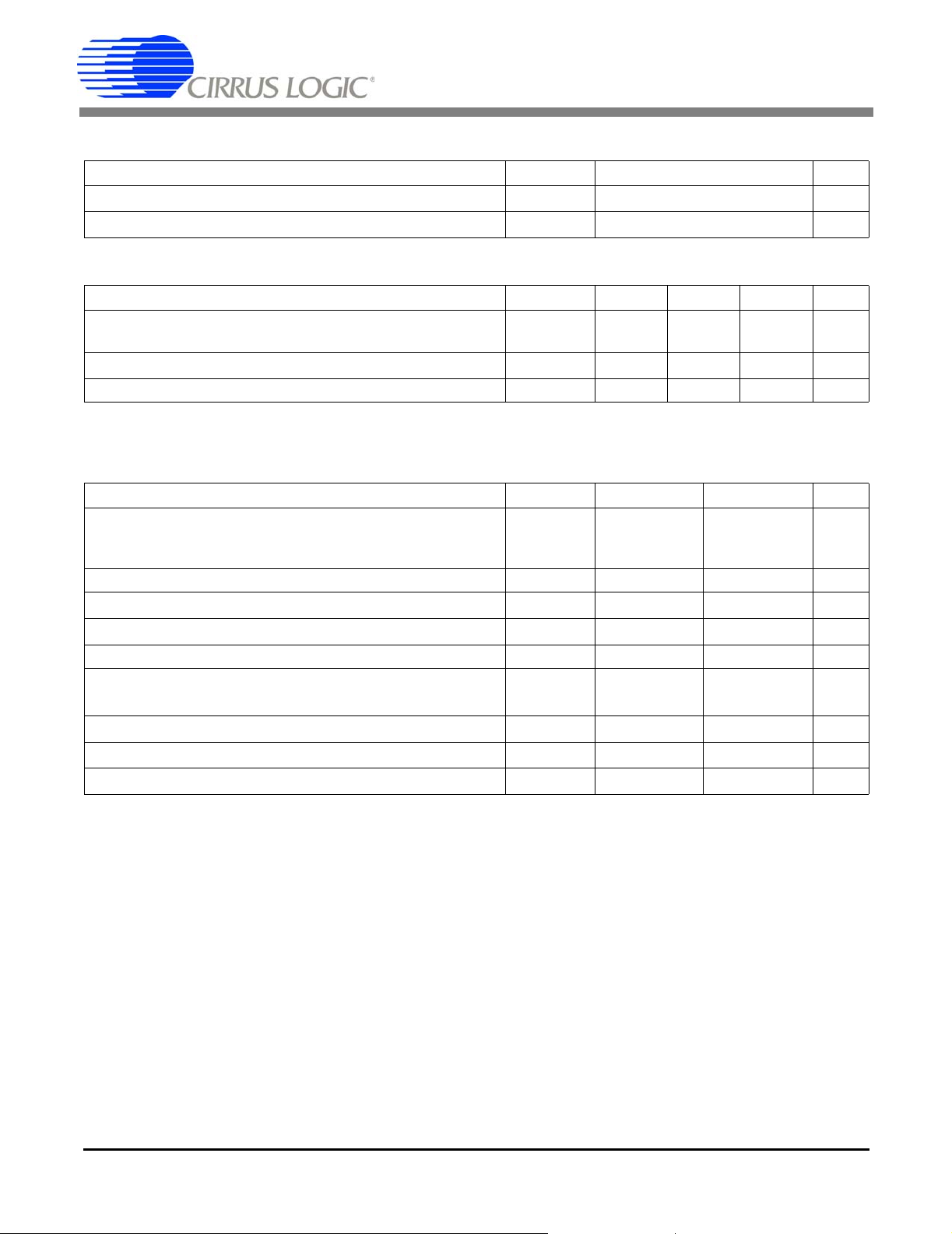

ANALOG CHARACTERISTICS (T

NBV = -2.1 V, FCLK = 32.768 kHz, OWR (Output Word Rate) = 15 Sps, Bipolar Mode, Input Range = ±100 mV;

See Notes 1 and 2.)

Parameter

Accuracy

Linearity Error - ±0.0015 ±0.003 - ±0.0007 ±0.0015 %FS

No Missing Codes 16 - - 20 - - Bits

Bipolar Offset (Note 3) - ±1±2 -±16 ±32 LSB

Unipolar Offset (Note 3) - ±2 ±4-±32 ±64 LSB

Offset Drift (Notes 3 and 4) - 20 - - 20 - nV/°C

Bipolar Gain Error - ±8 ±31 - ±8 ±31 ppm

Unipolar Gain Error - ±16 ±62 - ±16 ±62 ppm

Gain Drift (Note 4) - 1 3 - 1 3 ppm/°C

Voltage Reference Input

Range (VREF+) - (VREF-) 1 2.5 3.0 1 2.5 3.0 V

Common Mode Rejection dc

50, 60 Hz

Input Capacitance - 16 - - 16 - pF

CVF Current (Note 5) - 0.6 - - 0.6 - µA/V

= 25 °C; VA+, VD+ = 5 V ±5%; VREF+ = 2.5 V, VREF- = AGND,

A

CS5525 CS5526

Min Typ Max Min Typ Max Unit

-

-

110

130

-

-

-

-

110

130

-

-

dB

dB

Notes: 1. Applies after system calibration at any temperature within -40 °C ~ +85 °C.

2. Specifications guaranteed by design, characterization, and/or test.

3. Specification applies to the device only and does not include any effec ts by exte rn al pa ra sit ic

thermocouples. LSB = LSB

4. Drift over specified temperature range after calibration at power-up at 25 °C.

5. See the section of the data sheet which discusses input models on page 15.

for the CS5525, and LSB20 for the CS5526.

16

RMS NOISE (Notes 6 and 7)

Output Rate

(Sps)

3.76 3.27 90 nV 90 nV 130 nV 1.0 µV 2.0 µV 4.0 µV

7.51 6.55 110 nV 130 nV 190 nV 1.5 µV 3.0 µV 7 µV

15.0 12.7 170 nV 200 nV 250 nV 2.0 µV 5.0 µV 10 µV

30.1 25.4 250 nV 300 nV 500 nV 4.0 µV 10 µV 15 µV

60.0 50.4 500 nV 1.0 µV 1.5 µV 15 µV 45 µV 85 µV

123.2 (Note 8) 103.6 2.0 µV 4.0 µV 8.0 µV 72 µV 190 µV 350 µV

168.9 (Note 8) 141.3 10 µV 20.0 µV 30 µV 340 µV 900 µV 2.0 mV

202.3 (Note 8) 169.2 30 µV 55 µV 105 µV 1.1 mV 2.4 mV 5.3 mV

Notes: 6. Wideband noise aliased into the baseband. Referred to the input. Typical val ues shown for 25 °C.

7. For Peak-to-Peak Noise multiply by 6.6 for all ranges and output rates.

8. For input ranges <100 mV and output word rates >60 Sps, 32.768 kHz chopping frequency is used.

-3 dB Filter

Frequency

25 mV 55 mV 100 mV 1 V 2.5 V 5 V

Specifications are subject to change without notice.

Input Range, (Bipolar/Unipolar Mode)

2 DS202F5

Page 3

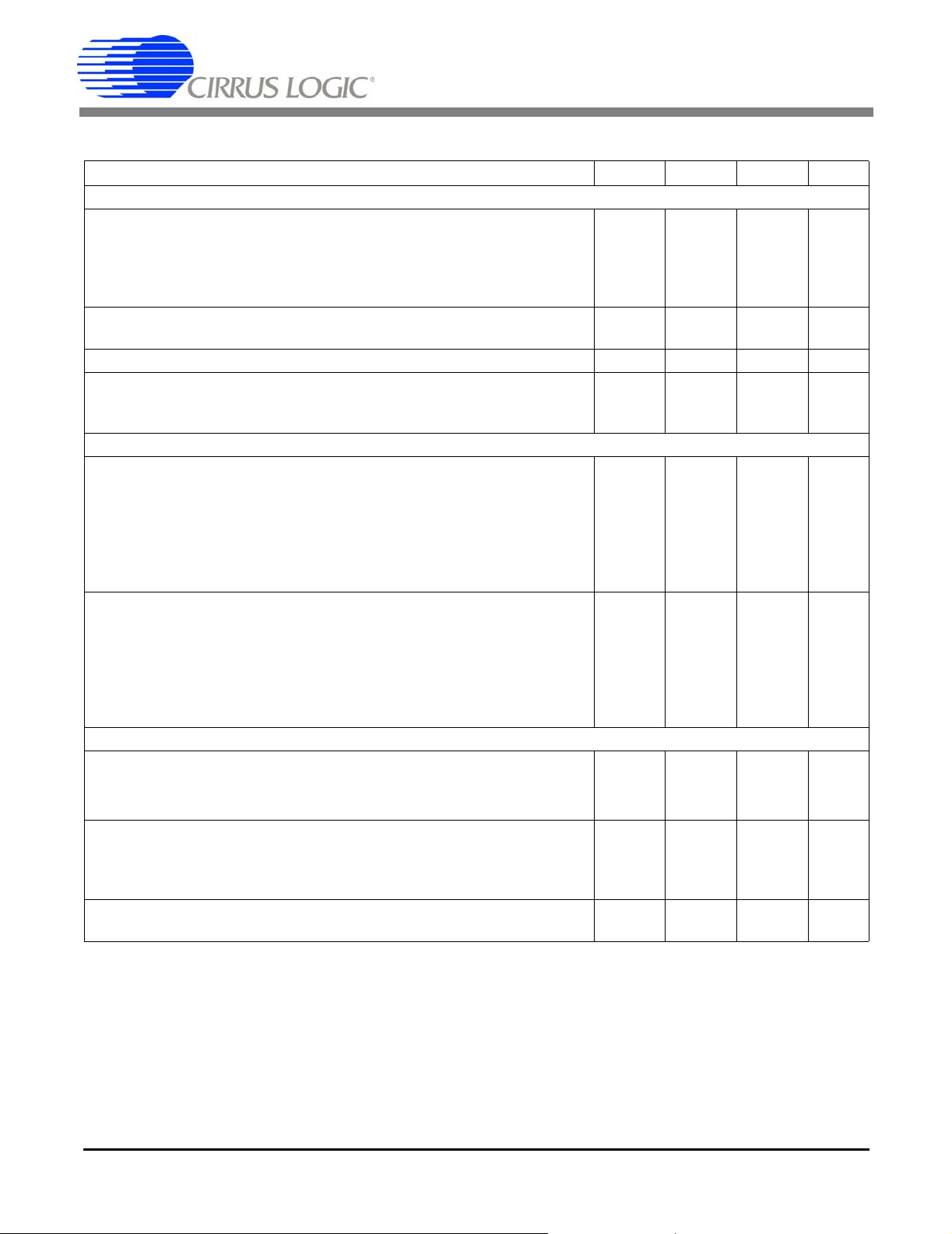

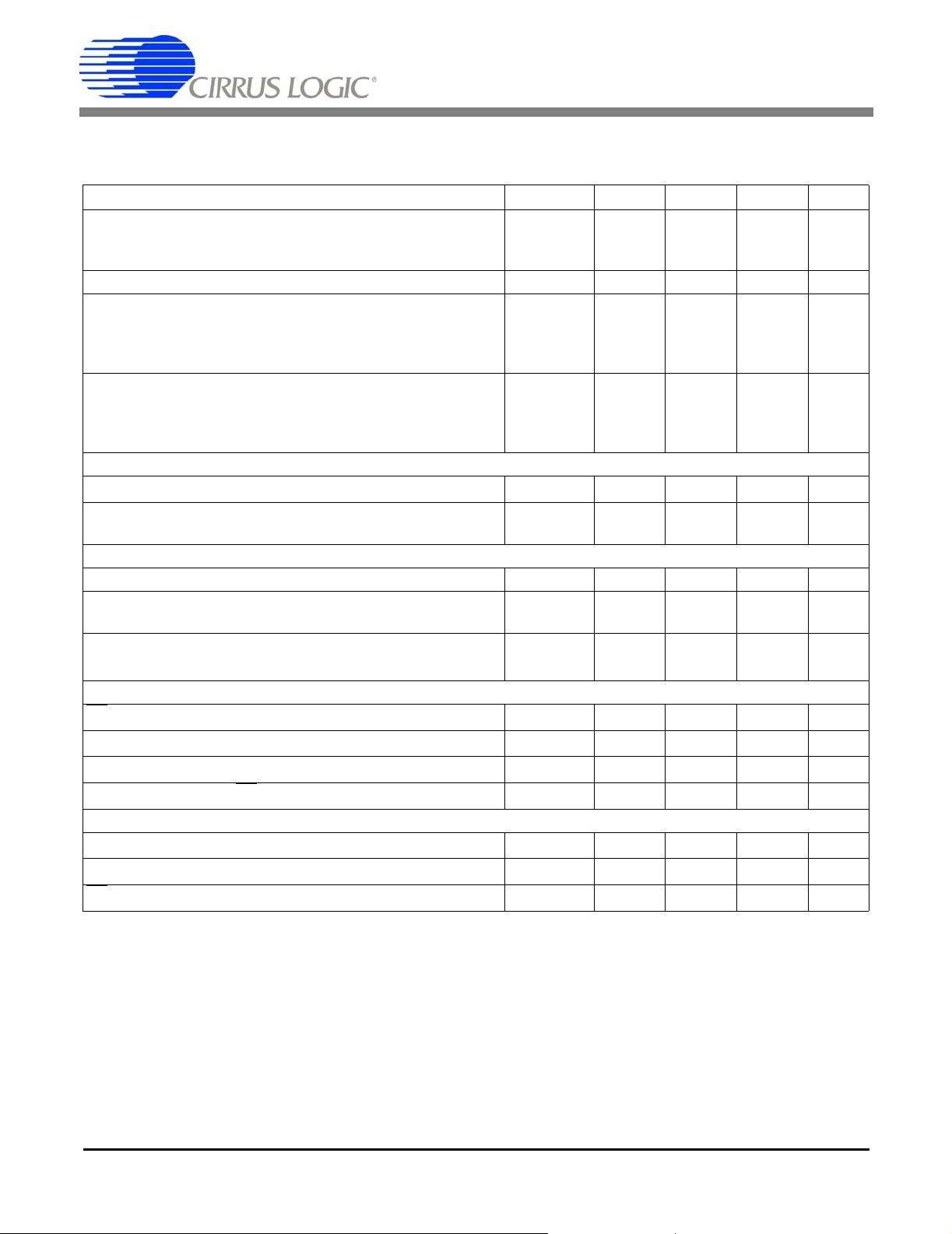

CS5525 CS5526

ANALOG CHARACTERISTICS (Continued)

Parameter Min Typ Max Unit

Analog Input

Common Mode + Signal on AIN+ or AIN- Bipolar/Unipolar Mode

NBV = -1.8 to -2.5 V Range = 25 mV, 55 mV, or 100 mV

Range = 1 V , 2.5 V, or 5 V

NBV = AGND Range = 25 mV, 55 mV, or 100 mV

Range = 1 V , 2.5 V, or 5 V

Common Mode Rejection dc

50, 60 Hz

-0.150

NBV

1.85

0.0

-

-

-

-

-

-

120

120

Input Capacitance - 10 - pF

CVF Current on AIN+ or AIN- (Note 5)

Range = 25 mV, 55 mV, or 100 mV

Range = 1 V , 2.5 V, or 5 V

-

-

100

1.2

System Calibration Specifications

Full-scale Calibration Range Bipolar/Unipolar Mode (Note 9)

25 mV

55 mV

100 mV

1 V

2.5 V

5 V

17.5

38.5

70

0.70

1.75

3.50

-

-

-

-

-

-

Offset Calibration Range Bipolar/Unipolar Mode

25 mV

55 mV

100 mV (Note 10)

1 V

2.5 V

5 V

-

-

-

-

-

-

-

-

-

-

-

-

Power Supplies

DC Power Supply Currents (Normal Mode) I

I

NBV

A+

I

D+

Power Consumption Normal Mode (Note 11)

Low Power Mode

Standby

Sleep

Power Supply Rejection dc Positive Supplies

dc NBV

-

-

-

-

-

-

-

-

-

1.65

15

475

9.4

4.9

1.2

500

95

110

0.950

VA+

2.65

VA+

-

-

300

-

32.5

71.5

105

dB

dB

pA

µA/V

mV

mV

mV

1.30

3.25

VA+

±12.5

±27.5

±50

mV

mV

mV

±0.5

±1.25

±2.50

2.2

30

700

12.7

8.5

-

-

-

-

mA

µA

µA

mW

mW

mW

µW

dB

dB

V

V

V

V

V

V

V

V

V

V

Notes: 9. The minimum Full-scale Calibration Range (FSCR) is limited by the maximum allowed gain register

value (with margin). The maximum FSCR is limited by the ∆Σ modulator’s 1’s density range.

10. The maximum full-scale signal can be limited by saturation of circuitry within the internal signal path.

11. All outputs unloaded. All input CMOS levels.

DS202F5 3

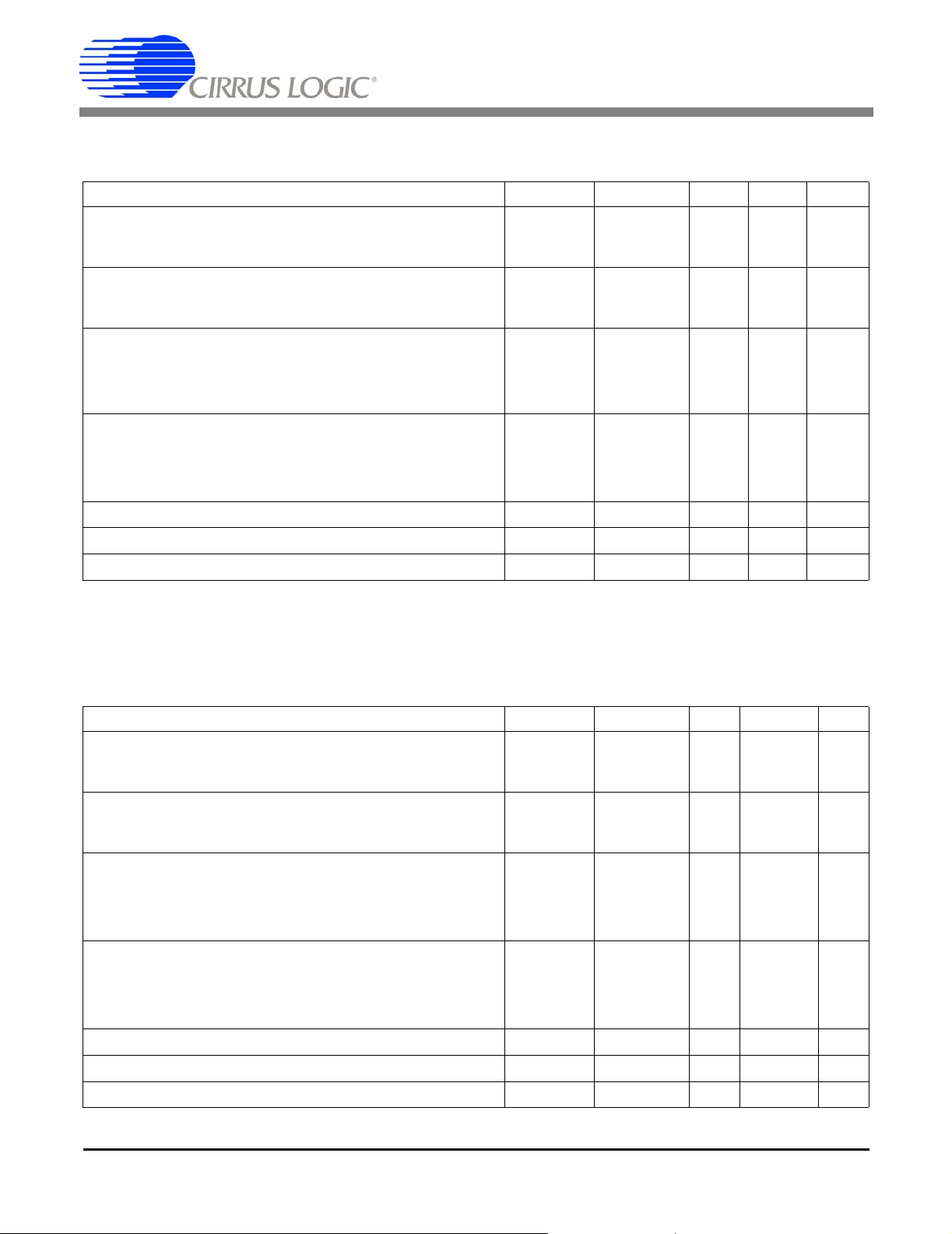

Page 4

CS5525 CS5526

5 V DIGITAL CHARACTERISTICS (T

= 25 °C; VA+, VD+ = 5 V ±5%; GND = 0;

A

See Notes 2 and 12.))

Parameter Symbol Min Typ Max Unit

High-level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

Low-level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

High-level Output Voltage

All Pins Except CPD and SDO (Note 13)

CPD, I

SDO, I

= -4.0 mA

out

= -5.0 mA

out

Low-level Output Voltage

All Pins Except CPD and SDO, I

CPD, I

SDO, I

= 1.6 mA

out

= 2 mA

out

= 5.0 mA

out

Input Leakage Current I

3-state Leakage Current I

Digital Output Pin Capacitance C

V

IH

0.6 VD+

3.5

(VD+) - 0.45

V

IL

-

0.0

-

V

OH

(VA+) - 1.0

(VD+) - 1.0

(VD+) - 1.0

V

OL

-

-

-

in

OZ

out

-±1±10µA

--±10µA

-9-pF

-

-

-

-

-

-

-

-

-

-

-

-

-

VD+

-

0.8

1.5

0.6

-

-

-

0.4

0.4

0.4

V

V

V

V

V

V

V

V

V

V

V

V

Notes: 12. All measurements performed under static conditions.

13. I

3.0 V DIGITAL CHARACTERISTICS (T

= -100 µA unless stated otherwise. (VOH = 2.4 V @ I

out

= 25 °C; VA+ = 5 V ±5%; VD+ = 3.0 V ±10%; GND = 0;

A

See Notes 2 and 12.))

Parameter Symbol Min Typ Max Unit

High-level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

Low-level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

High-level Output Voltage

All Pins Except CPD and SDO, I

CPD, I

SDO, I

= -400 µA

out

= -4.0 mA

out

= -5.0 mA

out

Low-level Output Voltage

All Pins Except CPD and SDO, I

CPD, I

SDO, I

= 400 µA

out

= 2 mA

out

= 5.0 mA

out

Input Leakage Current I

3-state Leakage Current I

Digital Output Pin Capacitance C

out

V

IH

V

IL

V

OH

V

OL

in

OZ

out

= -40 µA.)

0.6 VD+

0.54 VA+

(VD+) - 0.45

0.0

(VA+) - 0.3

(VD+) - 1.0

(VD+) - 1.0

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

VD+

-

0.16 VD+

1.5

0.6

-

-

-

0.3

0.4

0.4

V

V

V

V

V

V

V

V

V

V

V

V

-±1±10µA

--±10µA

-9-pF

4 DS202F5

Page 5

DYNAMIC CHARACTERISTICS

Parameter Symbol Ratio Unit

Modulator Sampling Frequency f

Filter Settling Time to 1/2 LSB (Full Scale Step) t

CS5525 CS5526

s

s

XIN/2 Hz

1/f

out

s

RECOMMENDED OPERATING CONDITIONS

(AGND, DGND = 0 V; See Note 14.))

Parameter Symbol Min Typ Max Unit

DC Power Supplies Positive Digital

Positive Analog

Analog Reference V oltage (VREF+) - (VREF-) VRef

VD+

VA+

diff

2.7

4.75

5.0

5.0

5.25

5.25

1.0 2.5 3.0 V

V

V

Negative Bias Voltage NBV -1.8 -2.1 -2.5 V

Notes: 14. All voltages with respect to ground.

ABSOLUTE MAXIMUM RATINGS (AGND, DGND = 0 V; See Note 14.)

Parameter Symbol Min Max Unit

DC Power Supplies (Note 15)

Positive Digital

Positive Analog

Negative Bias Voltage Negative Potential NBV +0.3 -3.0 V

Input Current, Any Pin Except Supplies (Note 16 and 17) I

Output Current I

Power Dissipation (Note 18) PDN - 500 mW

Analog Input Voltage VREF pins

AIN Pins

Digital Input Voltage V

Ambient Operating Temperature T

Storage Temperature T

VD+

VA+

IN

OUT

V

INR

V

INA

IND

A

stg

-0.3

-0.3

+6.0

+6.0

V

V

-±10mA

-±25mA

-0.3

NBV - 0.3

(VA+) + 0.3

(VA+) + 0.3

V

V

-0.3 (VD+) + 0.3 V

-40 85 °C

-65 150 °C

Notes: 15. No pin should go more negative than NBV - 0.3 V.

16. Applies to all pins including continuous overvoltage conditions at the analog input (AIN) pins.

17. Transient current of up to 100 mA will not cause SCR latch-up. Maximum input current for a power

supply pin is ±50 mA.

18. Total power dissipation, including all inpu t currents and output currents.

WARNING: Operation at or beyo nd these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

DS202F5 5

Page 6

CS5525 CS5526

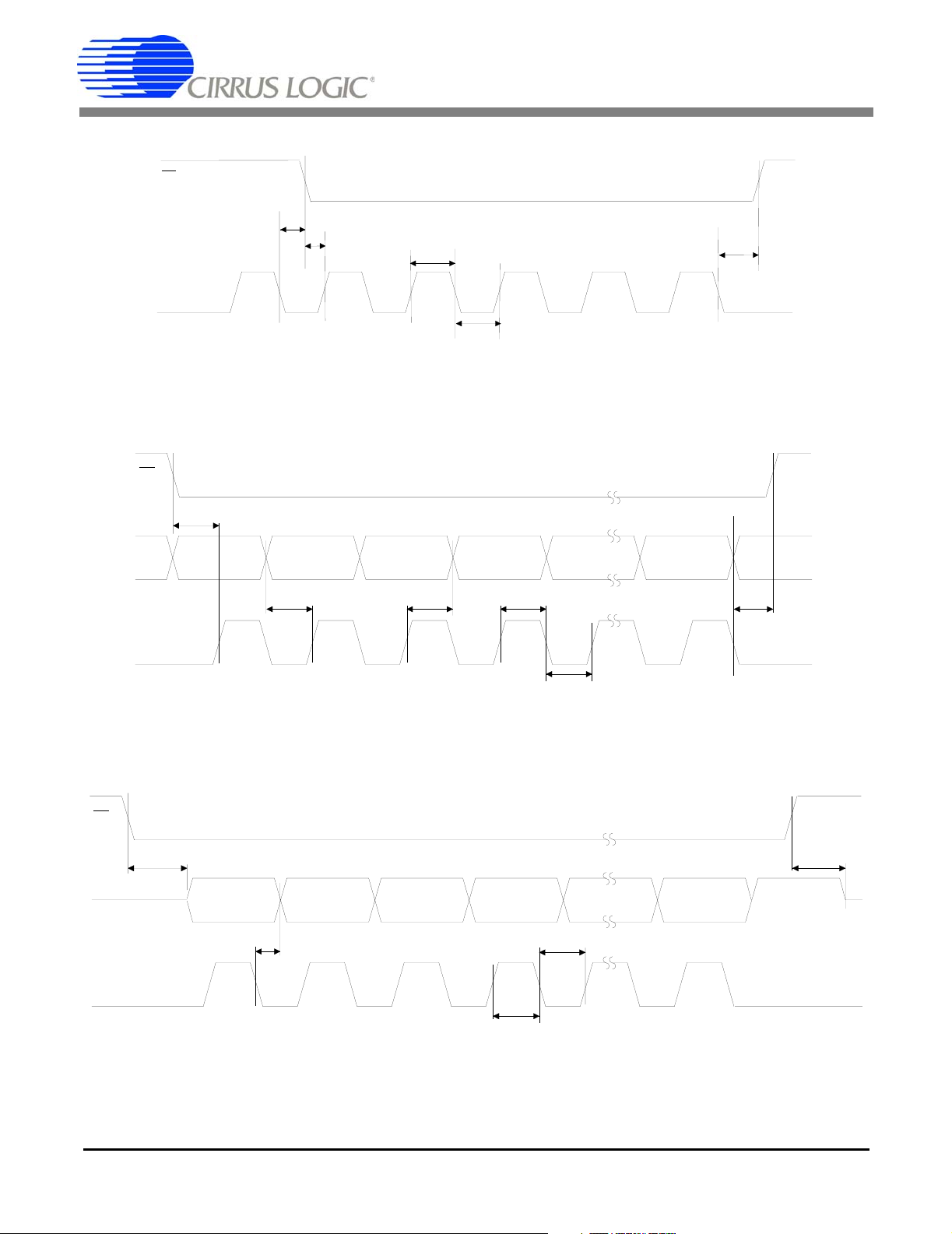

SWITCHING CHARACTERISTICS (T

Input Levels: Logic 0 = 0 V, Logic 1 = VD+; C

= 50 pF.))

L

= 25 °C; VA+ = 5 V ±5%; VD+ = 3.0 V ±10% or 5 V ±5%;

A

Parameter Symbol Min Typ Max Unit

Master Clock Frequency (Note 19)

Internal Clock

External Clock

XIN

30

30

32.768

32.768

36

100

kHz

Master Clock Duty Cycle 40 - 60 %

Rise Times (Note 20)

Any Digital Input Except SCLK

SCLK

Any Digital Output

Fall Times (Note 20)

Any Digital Input Except SCLK

SCLK

Any Digital Output

t

t

rise

fall

-

-

-

-

-

-

-

-

50

-

-

50

1.0

100

-

1.0

100

-

µs

µs

ns

µs

µs

ns

Start-up

Oscillator Start-up Time XTAL = 32.768 kHz (Note 21) t

Power-on Reset Period t

ost

por

-500-ms

- 1003 - XIN

cycles

Serial Port Timing

Serial Clock Frequency SCLK 0 - 2 MHz

SCLK Falling to CS

Falling for continuous running SCLK

t

0

100 - - ns

(Note 22)

Serial Clock Pulse Width High

Pulse Width Low

t

1

t

2

250

250

-

-

-

-

ns

ns

SDI Write Timing

CS

Enable to Valid Latch Clock t

Data Set-up Time prior to SCLK rising t

Data Hold Time After SCLK Rising t

SCLK Falling Prior to CS

Disable t

3

4

5

6

50 - - ns

50 - - ns

100 - - ns

100 - - ns

SDO Read Timing

to Data Valid t

CS

SCLK Falling to New Data Bit t

Rising to SDO Hi-Z t

CS

7

8

9

--150ns

--150ns

--150ns

Notes: 19. Device parameters are specified with a 32.768 kHz clock; however, clocks up to 100 kHz can be used

for increased throughput.

20. Specified using 10% and 90% points on wa veform of interest. Output loaded with 50 pF.

21. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an

external clock source.

22. Applicable when SCLK is continuously running.

6 DS202F5

Page 7

CS

CS

SCLK

CS5525 CS5526

t

0

t

t

t

3

1

t

2

Continuous Running SCLK Timing (Not to Scale)

t

3

6

CS

SDO

SCLK

SCLK

t

7

MSB

MSB

MSB-1 LSBSDI

t

4

t

5

t

1

t

2

t

6

SDI Write Timing (Not to Scale)

t

9

MSB-1 LSB

t

8

t

2

t

1

SDO Read Timing (Not to Scale)

DS202F5 7

Page 8

CS5525 CS5526

DETAILED DESCRIPTION

The CS5525 and CS5526 are 16-bit and 20-bit pin

compatible converters which include a chopperstabilized instrumentation amplifier input, and an

on-chip programmable gain amplifier. They are

both optimized for measuring low-level unipolar or

bipolar signals in process control and medical applications.

The CS5525/26 also include a fourth order deltasigma modulator, a calibration microcontroller,

eight digital filters, a 4-bit analog latch, and a serial

port. The digital filters provide any one of eight

different output update rates.

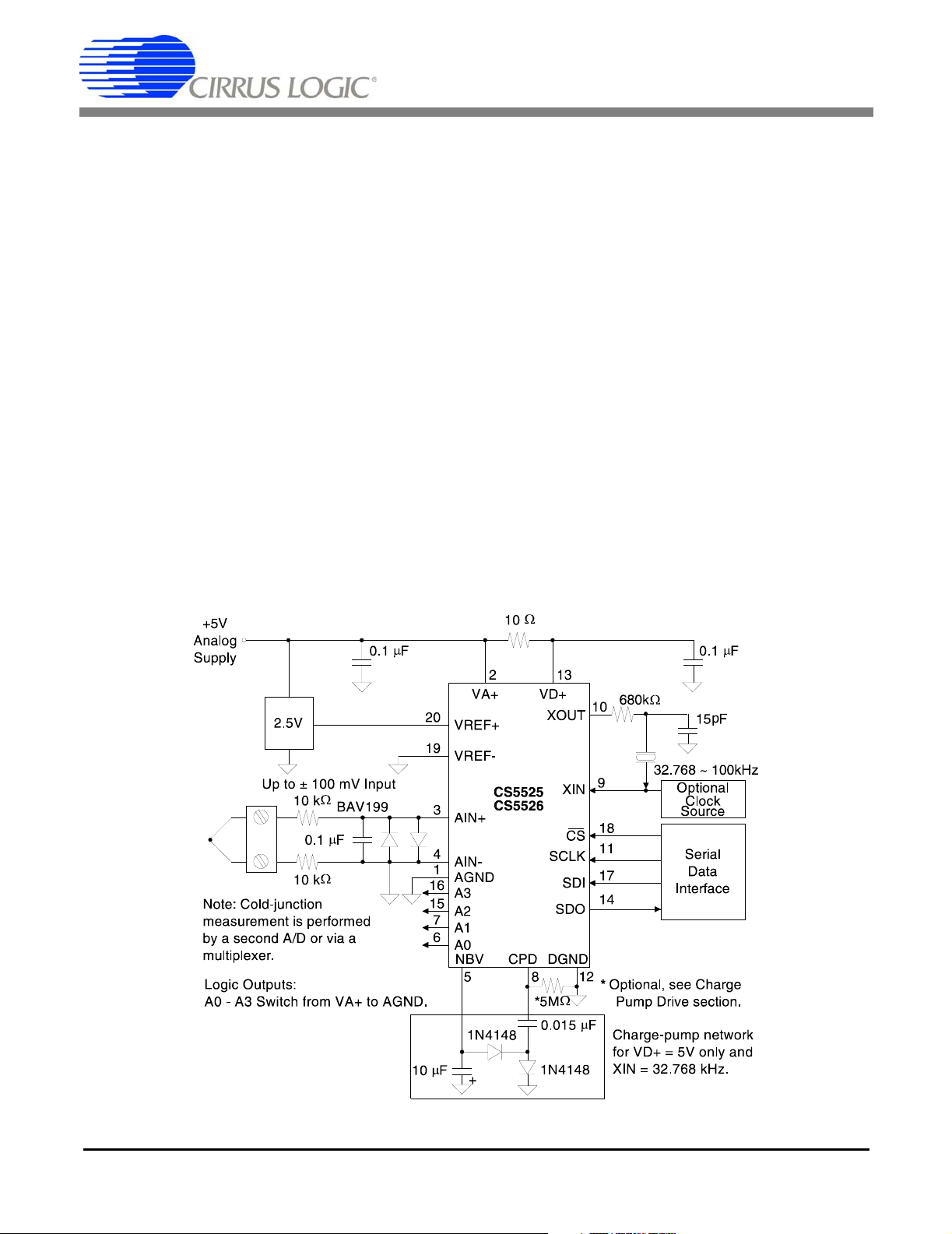

The CS5525/26 include a CPD (Charge Pump

Drive) output (shown in Figure 1). CPD provides a

negative bias voltage to the on-chip instrumentation amplifier when used with a combination of external diodes and capacitors. This enables the

CS5525/26 to measure negative voltages with re-

spect to ground, making the converters ideal for

thermocouple temperature measurements.

Theory of Operation

The CS5525/26 A/D converters are designed to operate from a single +5 V analog supply and provide

several different input ranges. See the Analog

Characteristics section on page 3 for details.

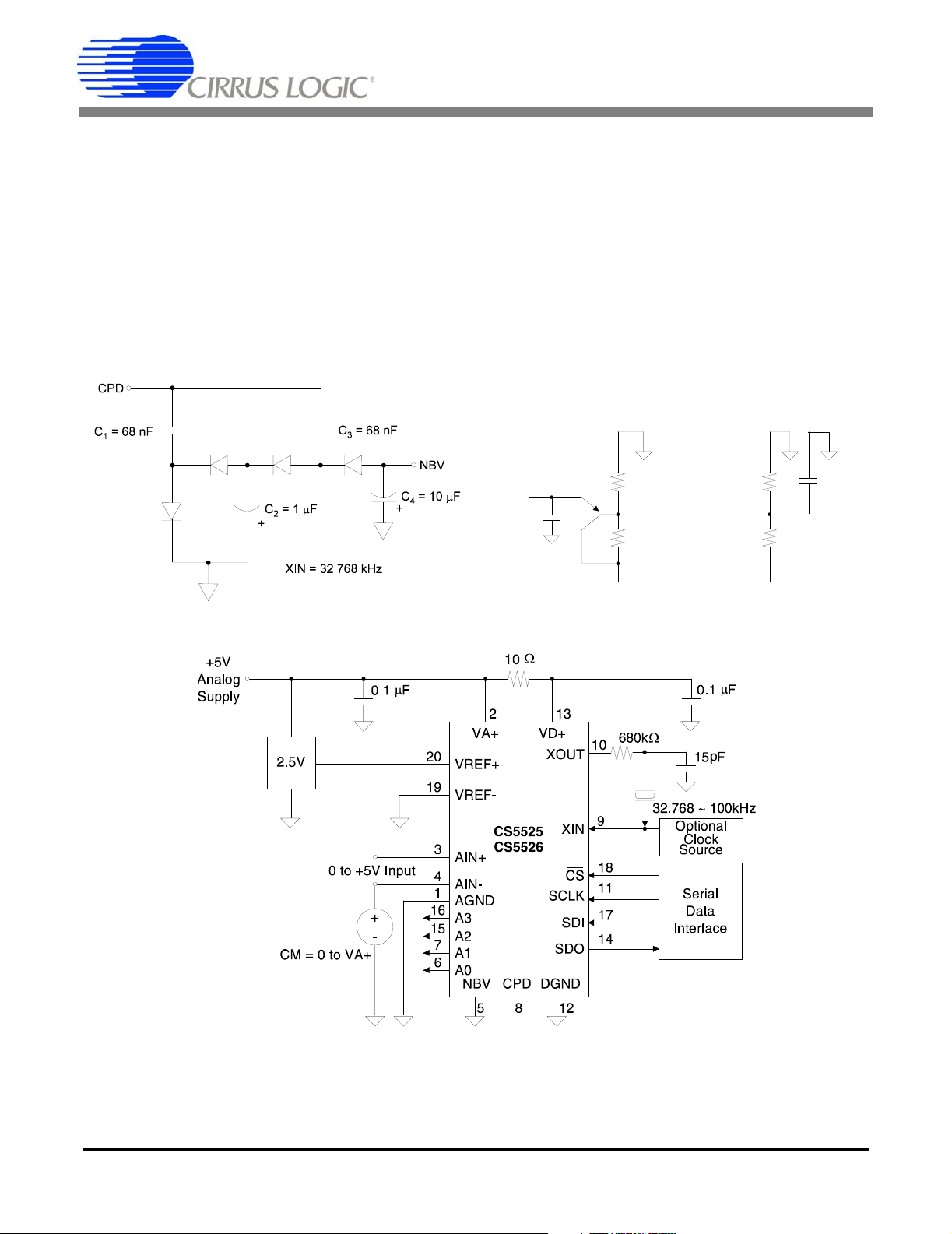

Figure 1 illustrates the CS5525/26 connected to

generate their own negative bias supply using the

on-chip CPD (Charge Pump Drive). This enables

the CS5525/26 to measure ground referenced signals with magnitudes down to NBV (Negative Bias

Voltage, approximately -2.1 V in this example).

Figure 2 illustrates a charge pump circuit when the

converters are powered from a +3.0 V digital supply. Alternatively, the negative bias supply can be

generated from a negative supply voltage or a resistive divider as illustrated in Figure 3.

Figure 1. CS5525/26 Configured to use on-chip charge pump to supply NBV.

8 DS202F5

Page 9

CS5525 CS5526

Figure 4 illustrates the CS5525/26 connected to

measure ground referenced unipolar signals of a

positive polarity using the 1 V, 2.5 V, and 5 V input

voltage ranges on the converter. For the 25 mV, 55

mV, and 100 mV ranges the signal must have a

common mode near +2.5 V (NBV = 0V).

The CS5525/26 are optimized for the measurement

of thermocouple outputs, but they are also well

suited for the measurement of ratiometric bridge

transducer outputs. Figure 5 illustrates the

CS5525/26 connected to measure the output of a

ratiometric differential bridge transducer while operating from a single +5 V supply.

2N5087

or similar

NBV

10µF

+

Figure 2. Charge Pump Drive Circuit for VD+ = 3 V. Figure 3. Alternate NBV Circuits.

-5V

34.8K

30.1K

2.0K

NBV

2.1K

-5V

+

10 µF

Figure 4. CS5525/26 Configured for ground-referenced Unipolar Signals.

DS202F5 9

Page 10

CS5525 CS5526

Figure 5. CS5525/26 Configured for Single Supply Bridge Measurement.

System Initialization

When power to the CS5525/26 is applied, they are

held in a reset condition until their 32.768 kHz oscillators have started and their start-up counter-timer elapses. Due to the high Q of a 32.768 kHz

crystal, the oscillators take 400-600 ms to start. The

converter’s counter-timer counts no more than

1024 oscillator clock cycles to make sure the oscillator is fully stable. During this time-out period the

serial port logic is reset and the RV (Reset Valid)

bit in the configuration register is set. A reset can be

initiated at any time by writing a logic 1 to the RS

(Reset System) bit in the configuration register.

This automatically sets the RV bit until the RS bit

is written to logic 0, and the configuration register

is read. After a reset, the on-chip registers are initialized to the following states and the converters

are ready to perform conversions.

Command Operation

The CS5525/26 include a microcontroller with five

registers used to control the converter. Each register is 24-bits in length except the 8-bit command

register (command, configuration, offset, gain, and

conversion data). After a system initialization or reset, the serial port is initialized to the command

mode and the converter stays in this mode until a

valid 8-bit command is received (the first 8-bits

into the serial port). Table 1 lists all the valid commands. Once a valid 8-bit command (a read or a

write command word) is received and interpreted

by the command register, the serial port enters the

data mode. In data mode the next 24 serial clock

pulses shift data either into or out of the serial port

(72 serial clock pulses are needed if set-up register

is selected). See Table 2 for configuring the

CS5525/26.

configuration register: 000040(H)

offset register: 000000(H)

gain register: 800000(H)

10 DS202F5

Page 11

CS5525 CS5526

Reading/Writing On-Chip Registers

The CS5525/26’s offset, gain, and configuration

registers are read/writable while the conversion

data register is read only.

CC, and PS/R bits must be logic 0 and the CB (MSB)

bit must be a logic 1. The register to be written is selected with the RSB2-RSB0 bits of the command

word. Figure 6 illustrates the serial sequence necessary to write to, or read from the serial port.

To perform a read from a specific register, the R/W

bit of the command word must be a logic 1. The SC,

CC, and PS/R bits must be logic 0 and the CB

(MSB) bit must be a logic 1. The register to be written is selected with the RSB2-RSB0 bits of the

command word.

If the Set-up Registers are chosen with the RSB2RSB0 bits, the registers are read or written in the

following sequence: Offset, Gain and Configuration. This is accomplished by following one 8-bit

command word with three 24-bit data words for a

total of 72 data bits.

To perform a write to a specific register, the R/W

bit of the command word must be a logic 0. The SC,

Command Register

D7(MSB)D6D5D4D3D2D1D0

CB SC CC R/W

RSB2 RSB1 RSB0 PS/R

BIT NAME VALUE FUNCTION

D7 Command Bit, CB 0

D6 Single Conversion, SC 0

D5 Continuous Conversions,

CC

D4 Read/Write

D3-D1 Register Select Bit,

RSB2-RSB0

D0 Power Save/Run

, R/W 0

000

001

010

011

100

101

110

111

, PS/R 0

Table 1. Command Set

1

1

0

1

1

1

Null command (no operation). All command bits, including

CB must be 0.

Logic 1 for executable commands.

Single Conversion not active.

Perform a conversion.

Continuous Conversions not active.

Perform conversions continuously.

Write to selected register.

Read from selected register.

Offset Register

Gain Register

Configuration Register

Conversion Data Register (read only)

Set-up Registers (Offset, Gain, Configuration)

Reserved

Reserved

Reserved

Run

Power Save

DS202F5 11

Page 12

CS5525 CS5526

Confi

guration Register

D23(MSB) D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12

A3 A2 A1 A0 NU CFS NU LPM WR2 WR1 WR0 U/B

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

G2 G1 G0 PD RS RV PF PSS DF CC2 CC1 CC0

BIT NAME VALUE FUNCTION

D23-D20 Latch Outputs, A3-A0 0000 R* Latch Output Pins A3-A0 mimic the D23-D20 Register bits.

D19 Not Used, NU 0 R Must always be logic 0.

D18 Chop Frequency Select,

CFS

D17 Not Used, NU 0 R Must always be logic 0.

D16 Low Power Mode, LPM 0

D15-D13 Word Rate, WR2-0

Note: For

XIN = 32.768kHz

D12 Unipolar/Bipolar

D11-D9 Gain Bits, G2-G0 000

D8 Pump Disable, PD 0

D7 Reset System, RS 0

D6 Reset Valid , RV 0

D5 Port Flag, PF 0

D4 Power Save Select, PSS 0

D3 Done Flag, DF 0

D2-D0 Calibration Control Bits,

CC2-CC0

, U/B 0

0

1

1

000

001

010

011

100

101

110

111

1

001

010

011

100

101

110/111

1

1

1R

1

1

1

000

001

010

011

100

101

110

111

R 256 Hz Amplifier chop frequency

32768 Hz Amplifier chop frequency

R Normal Mode

Reduced Power mode

R 15.0 Sps (2182 XIN cycles)

30.1 Sps (1090 XIN cycles)

60.0 Sps (546 XIN cycles)

123.2 Sps (266 XIN cycles)

168.9 Sps (194 XIN cycles)

202.3 Sps (162 XIN cycles)

3.76 Sps (8722 XIN cycles)

7.51 Sps (4362 XIN cycles)

R Bipolar Measurement mode

Unipolar Measurement mode

R 100 mV (assumes VREF = 2.5V)

55 mV

25 mV

1V

5.0 V

2.5 V

Not Used.

R Charge Pump Enabled

For PD = 1, the CPD pin goes to a Hi-Z output state.

R Normal Operation

Activate a Reset cycle. To return to Normal Operation write bit to zero.

No reset has occurred or bit has been cleared (read only).

Valid Reset has occurred. (Cleared when read.)

R Port Flag mode inactive

Port Flag mode active

R Standby Mode (Oscillator active, allows quick power-up)

Sleep Mode (Oscillator inactive)

R Done Flag bit is cleared (read only).

Calibration or Conversion cycle completed (read only).

R Normal Operation (no calibration)

Offset -- Self-Calibration

Gain -- Self-Calibration

Offset Self-Calibration followed by Gain Self-Calibration

Not used.

Offset -- System Calibration

Gain -- System Calibration

Not Used.

* R indicates the bit value after the part is reset

Table 2. Configuration Register

12 DS202F5

Page 13

CS5525 CS5526

CS

SCLK

SDI

CS

SCLK

SDI

SDO

Command Time

8 SCLKs

Command Time

8 SCLKs

MSB

Write Cycle

MSB

Read Cycle

LSB

Data Time 24 SCLKs

(or 72 S C LKs for Set-up R e gisters)

LSB

Data Tim e 24 S C LK s

(or 72 S C LKs for Set-up Registers)

SCLK

SDI

t *

Command Time

8 SCLKs

SDO

* td = XIN/OWR clock cycles for each conversion except the

first conversion which will take XIN/OWR + 7 clock cycles

d

SDO Continuous Conversion Read (PF bit = 1)

8 SCLKs Clear SDO Flag

MSB

Data Time

24 SCLKs

XIN/OWR

Clock Cycles

LSB

Figure 6. Command and Data Word Timing.

DS202F5 13

Page 14

CS5525 CS5526

Analog Input

Figure 7 illustrates a block diagram of the analog input signal path inside the CS5525/26. The front end

consists of a chopper-stabilized instrumentation amplifier with 20X gain and a programmable gain section. The instrumentation amplifier is powered from

VA+ and from the NBV (Negative Bias Voltage) pin

allowing the CS5525/26 to be operated in either of

two analog input configurations. The NBV pin can

be biased to a negative voltage between -1.8 V and

-2.5 V, or tied to AGND. The choice of the operating

mode for the NBV voltage depends upon the input

signal and its common mode voltage.

For the 25 mV, 55 mV, and 100 mV input ranges, the

input signals to AIN+ and AIN- are amplified by the

20X instrumentation amplifier. For ground referenced signals with magnitudes less then 100 mV, the

NBV pin should be biased with -1.8 V to -2.5 V. If

NBV is tied between -1.8 V and -2.5 V, the (Common Mode + Signal) input on AIN+ and AIN- must

stay between -0.150 V and 0.950 V to ensure proper operation. Alternatively, NBV can be tied to

AGND where the input (Common Mode + Signal)

on AIN+ and AIN- must stay between 1.85 V and

2.65 V to ensure that the amplifier operates properly.

For the 1 V, 2.5 V, and 5 V input ranges, the instrumentation amplifier is bypassed and the input signals are directly connected to the Programmable

Gain block. With NBV tied between -1.8 V and

-2.5 V, the (Common Mode + Signal) input on

AIN+ and AIN- must stay between NBV and VA+.

Alternatively, NBV can be tied to AGND where

the input (Common Mode + Signal) on AIN+ and

AIN- pins can span the entire range between

AGND and VA+.

The CS5525/26 can accommodate full scale ranges

other than 25 mV, 55 mV, 100 mV, 1 V, 2.5 V and

5 V by performing a system calibration within the

limits specified. See the Calibration section for

more details. Another way to change the full scale

range is to increase or to decrease the voltage reference to other than 2.5 V. See the Voltage Refer-

ence section for more details.

Three factors set the operating limits for the input

span. They include: instrumentation amplifier saturation, modulator 1’s density, and a lower reference

voltage. When the 25 mV, 55 mV or 100 mV range

is selected, the input signal (including the common

mode voltage and the amplifier offset voltage)

must not cause the 20X amplifier to saturate in either its input stage or output stage. To prevent saturation the absolute voltages on AIN+ and AINmust stay within the limits specified (refer to the

‘Analog Input’ table on page 3). Additionally, the

differential output voltage of the amplifier must not

exceed 2.8 V. The equation

ABS(VIN + VOS) x 20 = 2.8 V

defines the differential output limit, where

VIN = (AIN+) - (AIN-)

is the differential input voltage and VOS is the absolute maximum offset voltage for the instrumentation amplifier (VOS will not exceed 40 mV). If the

VREF+

AIN+

AIN-

NBV

14 DS202F5

X20

Figure 7. Block Diagram of Analog Signal Path

Programmable

Gain

Differential 4th

order delta-

sigm a modulator

VREF-

Dig ital F ilter

Page 15

CS5525 CS5526

Input Range

± 25 mV

± 55 mV

± 100 mV

± 1.0 V - 2.5V 2.5 ± 1.0 V ± 1.5 V

± 2.5 V - 2.5V 1.0 ± 2.5 V ± 5.0 V

± 5.0 V - 2.5V 0.5 ± 5.0 V 0V, VA+

Note: 1. The converter's actual input range, the delta-sigma's nominal full scale input, and the delta-sigma's

(1)

maximum full scale input all scale directly with the value of the voltage reference. The values in the

table assume a 2.5 V VREF voltage.

Table 3. Relationship between Full Scale Input, Gain Factors, and Internal Analo g Signal Limitations

differential output voltage from the amplifier exceeds 2.8 V, the amplifier may saturate, which will

cause a measurement error.

The input voltage into the modulator must not

cause the modulator to exceed a low of 20 percent

or a high of 80 percent 1's density. The nominal full

scale input span of the modulator (from 30 percent

Max. Differential Output

20X Amplifier

(2)

2.8 V

(2)

2.8 V

(2)

2.8 V

VREF Gain Factor

2.5V 5 ± 0.5 V ± 0.75 V

2.5V 2.272727... ± 1.1 V ± 1.65 V

2.5V 1.25 ± 2.0 V ± 3.0 V

Note: Residual noise appears in the converter’s baseband for

output word rates greater than 60 Sps if CFS is logic 0. By setting CFS to logic 1, the amplifier’s chop frequency chops at

32768 Hz eliminating the residual noise, but increa sing the

current. Note that C=48pF is for input current modeling only.

For physical input capacitance see ‘Input Capacitance’ specification under ‘Analog Characteristics’ on page 3.

25mV, 55mV, and 100mV Ranges

∆-Σ Nominal

Differential Input

(1)

(1)

∆-Σ

Max. Input

to 70 percent 1’s density) is determined by the

VREF voltage divided by the Gain Factor. See Table 3 to determine if the CS5525/26 are being used

properly. For example, in the 55 mV range to determine the nominal input voltage to the modulator,

divide VREF (2.5 V) by the Gain Factor (2.2727).

When a smaller voltage reference is used, the re-

AIN

V ≤ 25mV

os

i = fV C

osn

CF S = 0 , f = 256 H z

CF S = 1 , f = 32.76 8 k H z

C = 48pF

sulting code widths are smaller causing the converter output codes to exhibit more changing codes

for a fixed amount of noise. Table 3 is based upon

a VREF = 2.5 V. For other values of VREF, the values in Table 3 must be scaled accordingly.

Figure’s 8 and 9 illustrate the input models for the

AIN and VREF pins. The dynamic input current for

AIN+

Figure 8. Input models for AIN+ and AIN- pins

1V, 2.5 V, and 5V Ranges

AIN-

i = [(V ) - (V )] fC

n

AIN+ AIN-

f = 32.768 kHz

C = 32pF

each of the pins can be determined from the models

shown and is dependent upon the setting of the CFS

(Chop Frequency Select) bit. The effective input

VREF+

VREF-

C = 16pF

impedance for the AIN+ and AIN- pins remains

i = [(V REF +) - (VR EF -)] fC

constant for the three low level measurement ranges (25 mV, 55 mV, and 100 mV). The input current

is lowest with the CFS bit cleared to logic 0.

Figure 9. Input model for VREF+ and VREF- pins.

n

f = 32.768 kHz

DS202F5 15

Page 16

CS5525 CS5526

Charge Pump Drive

The CPD (Charge Pump Drive) pin of the converters can be used with external components (shown

in Figure 1) to develop an appropriate negative bias

voltage for the NBV pin. When CPD is used to generate the NBV, the NBV voltage is regulated with

an internal regulator loop referenced to VA+.

Therefore, any change on VA+ results in a proportional change on NBV. With VA+ = 5 V, NBV’s

regulation is set proportional to VA+ at approximately -2.1 V.

Figure 3 illustrates a means of supplying NBV voltage from a -5 V supply. For ground based signals

with the instrumentation amplifier engaged (when

in the 25mV, 55mV, or 100mV ranges), the voltage

on the NBV pin should at no time be less negative

than -1.8 V or more negative than -2.5 V. To prevent excessive voltage stress to the chip the NBV

voltage should not be more negative than -3.0 V.

The components in Figure 1 are the preferred components for the CPD filter. However, smaller capacitors can be used with acceptable results. The

10

µF ensures very low ripple on NBV. Intrinsic

safety requirements prohibit the use of electrolytic

capacitors. In this case, two 0.47 µF ceramic capacitors in parallel can be used.

The CPD pin itself is a tri-state output and enters

tri-state whenever the converters are placed into the

Sleep Mode, Standby Mode, or when the charge

pump is disabled (when the Pump Disable bit, bit

D8 in the configuration register, is set). Once in tristate, the digital current can increase if this CPD

output floats near 1/2 digital supply. To ensure the

CPD pin stays near ground and to minimize the

digital current, add a 5MΩ resistor between it and

DGND (see Figure 1). If the resistor is left out, the

digital supply current may increase from 2 µA to 10

µA.

Voltage Reference

The CS5525/26 are specified for operation with a

2.5 V reference voltage between the VREF+ and

VREF- pins of the devices. For a single-ended reference voltage, such as the LT1019-2.5, the reference’s output is connected to the VREF+ pin of the

CS5525/26. The ground reference for the LT1019-

2.5 is connected to the VREF- pin.

The differential voltage between the VREF+ and

VREF- can be any voltage from 1.0 V up to 3.0 V,

however, the VREF- pin can not go below analog

ground.

Calibration

The CS5525/26 offer five different calibration

functions including self calibration and system calibration. However, after the CS5525/26 are reset,

they can perform measurements without being calibrated. In this case, the converters will utilize the

initialized values of the on-chip registers (Gain =

1.0, Offset = 0.0) to calculate output words for the

±100 mV range. Any initial offset and gain errors

in the internal circuitry of the chips will remain.

The gain and offset registers, which are used for

both self and system calibration, are used to set the

zero and full-scale points of the converter’s transfer

i 0=

∑

-24

pro-

-23

). The

N

i–

function. One LSB in the offset register is 2

portion of the input span (bipolar span is 2 times the

unipolar span). The MSB in the offset register determines if the offset to be trimmed is positive or

negative (0 positive, 1 negative). The converters

can typically trim ±50 percent of the input span.

The gain register spans from 0 to (2 - 2

decimal equivalent meaning of the gain register is

Db020b121–b222–… bN2

++++ bi2

==

N–

where the binary numbers have a value of either

zero or one (b

corresponds to the MSB). Refer to

0

Table 4 for details.

16 DS202F5

Page 17

CS5525 CS5526

Offset Register

MSB LSB

-2

-3

-4

-5

Register

Reset (R) 000000 000000

Sign

2

2

2

2

-6

2

-19

2

≈

-20

2

-21

2

-22

2

-23

2

-24

2

One LSB represents 2

-24

proportion of the input span (bipolar span is 2 times unipolar span)

Offset and data word bits align by MSB (bit MSB-4 of offset register changes bit MSB-4 of data)

Gain Register

MSB LSB

0

-1

-2

-3

-4

Register

Reset (R) 100000 000000

The gain register span is from 0 to (2-2

2

2

2

2

2

-23

). After Reset the MSB = 1, all other bits are 0.

-5

2

Table 3.

Table 4. Offset and Gain Registers

The offset and gain calibration steps each take one

conversion cycle to complete. At the end of the calibration step, the calibration control bits will be set

back to logic 0, and the DF (Done Flag) bit will be

set to a logic 1. For the combination self-calibration (CC2-CC0= 011; offset followed by gain), the

calibration will take two conversion cycles to complete and will set the DF bit after the gain calibration is completed. The DF bit will be cleared any

time the data register, the offset register, the gain

register, or the setup register is read. Reading the

configuration register alone will not clear the DF

bit.

-18

2

-19

2

-20

2

-21

2

-22

2

2

≈

of the modulator are connected together and then

routed to the VREF- pin as shown in Figure 11.

For self-calibration of gain, the differential inputs

of the modulator are connected to VREF+ and

S1

OPEN

AIN+

AIN-

S2

CLOSED

+

X20

-

-23

+

-

Self Calibration

Figure 10. Self Calibration of Offset (Low Ranges).

The CS5525/26 offer both self offset and self gain

calibrations. For the self-calibration of offset in the

25 mV, 55 mV, and 100 mv ranges, the converter

internally ties the inputs of the instrumentation amplifier together and routes them to the AIN- pin as

shown in Figure 10. For proper self-calibration of

offset to occur in the 25 mV, 55 mV, and 100 mV

AIN+

AIN-

VREF-

+

X20

-

ranges, the AIN- pin must be at the proper common-mode-voltage (i.e. AIN- = 0V, NBV must be

between -1.8 V to -2.5 V). For self-calibration of

offset in the 1.0 V, 2.5 V, and 5 V ranges, the inputs

DS202F5 17

Figure 11. Self Calibration of Offset (High Ranges).

S1

OPEN

S2

OPEN

S4

CLOSED

S3

CLOSED

+

-

Page 18

Reference

+

-

AIN+

AIN-

VREF+

VREF-

CS5525 CS5526

OPEN

+

X20

OPEN

CLOSED

CLOSED

+

-

External

Connections

+

0V

-

+

CM

-

AIN+

AIN-

+

X20

-

+

-

Figure 12. Self Calibration of Gain (All Ranges).

VREF- as shown in Figure 12. For any input range

other than the 2.5 V range, the modulator gain error

can not be completely calibrated out. This is due to

the lack of an accurate full scale voltage internal to

the chips. The 2.5 V range is an exception because

the external reference voltage is 2.5 V nominal and

is used as the full scale voltage. In addition, when

self-calibration of gain is performed in the 25 mV,

55 mV, and 100 mV input ranges, the instrumentation amplifier’s gain is not calibrated. These two

factors can leave the converters with a gain error of

up to ±20% after self-calibration of gain. Therefore, a system gain is required to get better accuracy, except for the 2.5 V range.

System Calibration

For the system calibration functions, the user must

supply the converters calibration signals which represent ground and full scale. When a system offset

calibration is performed, a ground reference signal

must be applied to the converter. See Figures 13

and 14. As shown in Figures 15 and 16, the user

must input a signal representing the positive full

scale point to perform a system gain calibration. In

either case, the calibration signals must be within

the specified calibration limits for each specific

calibration step (refer to the System Calibration

Specifications).

Figure 13. System Calibration of Offset (Low Ranges).

External

Connections

0V

CM

AIN+

+

-

AIN-

+

-

+

X20

-

+

-

Figure 14. System Calibration of Offset (High Ranges).

External

Connections

+

X20

-

Full Scale

CM

AIN+

+

-

AIN-

+

-

Figure 15. System Calibration of Gain (Low Ranges)

External

Connections

+

X20

-

Full Scale

CM

AIN+

+

-

AIN-

+

-

+

-

+

-

Figure 16. System Calibration of Gain (High Ranges).

18 DS202F5

Page 19

CS5525 CS5526

Assuming a system can provide two known voltages, equations can allow the user to manually compute the calibration register’s values based on two

uncalibrated conversions. The offset and gain calibration registers are used to adjust a typical conversion as follows:

Rc = (Ru + Co>>4) * Cg / 2

23

.

Calibration can be performed using the following

equations:

Co = (Rc0/G - Ru0) << 4

Cg = 2

23

* G

where G = (Rc1 - Rc0)/(Ru1-Ru0).

Note: Uncalibrated conversions imply that the gain and offset

registers are at default {gain register = 0x800000 (Hex) and

offset register = 0x000000 (Hex)}.

The variables are defined below.

V0 = First calibration voltage

V1 = Second calibration voltage (greater than V0)

Ru = Result of any uncalibrated conversion

Ru0 = Result of uncalibrated conversion V0

(20-bit integer or 2’s complement)

Ru1 = Result of uncalibrated conversion of V1

(20-bit integer or 2’s complement)

Rc = Result of any conversion

Rc0 = Desired calibration result of converting V0

(20-bit integer or 2’s complement)

Rc1 = Desired calibration result of converting V1

(20-bit integer or 2’s complement)

Co = Offset calibration register value (24-bit 2’s

complement)

Cg = Gain calibration register value

(24-bit integer)

>> = The shift right operator (e.g. x >>2 is x shift-

ed right 2 bits)

<< = The shift left operator (e.g. x<<2 is x

shifted left 2 bits)

Note: The shift operators are used here to align the decimal

points of words of various lengths. Data to the right of the

decimal point may be used in the calculations shown. For the

CS5525 all conversion results (Ru, Rc...) are 16 bits instead

of 20 bits. To get the equations to work correctly pad the 16

bit results with four zeros (on the right).

Calibration Tips

Calibration steps are performed at the output word

rate selected by the WR2-WR0 bits of the configuration register. Since higher word rates result in

conversion words with more peak-to-peak noise,

calibration should be performed at lower output

word rates. Also, to minimize digital noise near

the devices, the user should wait for each calibration step to be completed before reading or writing

to the serial port.

For maximum accuracy, calibrations should be performed for offset and gain for each gain setting (selected by changing the G2-G0 bits of the

configuration register). And if factory calibration is

performed using the system calibration capabilities

of the CS5525/26, the offset and gain register contents can be read by the system microcontroller and

recorded in EEPROM. These same calibration

words can then be uploaded into the offset and gain

registers of the converters when power is first applied to the system, or when the gain range is

changed.

Two final tips include two ways to determine when

calibration is complete: 1) wait for SDO to fall. It

falls to logic 0 if the PF (Port Flag) bit of the configuration register is set to logic 1; or 2) poll the DF

(Done Flag) bit in the configuration register which

is set at completion of calibration. Whichever

method is used, the calibration control bits (CC2CC0) will return to logic 0 upon completion of any

calibration.

Limitations in Calibration Range

System calibration can be limited by signal headroom in the analog signal path inside the chip as

discussed under the Analog Input section of this

data sheet. System calibration can also be limited

by the intrinsic gain errors of the instrumentation

amplifier and the modulator. For gain calibrations

DS202F5 19

Page 20

CS5525 CS5526

the input signal can be reduced to the point in

which the gain register reaches its upper limit of 2.0

(decimal) [FFFFFF Hex] (this is most likely to occur with an input signal approximately 1/2 the

nominal range). Alternatively, the input signal can

be increased to a point in which the modulator

reaches its one’s density upper limit of 80% (this is

most likely to occur with an input signal approximately 1.5 times the nominal range). Also, for full

scale inputs larger than the nominal full scale value

of the range selected, there is some voltage at

which the various internal circuits may saturate due

to limited amplifier headroom (this is most likely to

occur on the 100 mV range setting when NBV = -

1.8 V).

Analog Output Latch Pins

The A3-A0 pins of the converters mimic the D23D20 bits of the configuration register. A3-A0 can

be used to control multiplexers and other logic

functions outside the converter. The outputs can

sink or source at least 1 mA, but it is recommended

to limit drive currents to less than 20 µA to reduce

self-heating of the chip. These outputs are powered

from VA+, hence, their output voltage for a logic 1

will be limited to the VA+ voltage.

Serial Port Interface

The CS5525/26 serial interface consist of four pins,

SCLK, SDO, SDI, and CS. The CS pin must be

held low (logic 0) before SCLK transitions can be

recognized by the port logic. The SDO output will

be held at high impedance any time CS is a logic 1.

If the CS

three wire interface.

The SCLK input is designed with a Schmitt-trigger

input to allow an optoisolator with slower rise and

fall times to directly drive the pin.

The SDO output is capable of sinking or sourcing

up to 5 mA to directly drive an optoisolator LED.

SDO will have less than a 400 mV loss in the drive

voltage when sinking or sourcing 5 mA.

pin is tied low, the port can function as a

Serial Port Initialization

The serial port is initialized to the command mode

whenever a power-on reset is performed inside the

converter, when the port initialization sequence is

completed, or whenever a command byte, data

word sequence is completed. The port initialization

sequence involves clocking 15 (or more) bytes of

all 1's, followed by one byte with the following bit

contents (11111110). This sequence places the

chips in the command mode where it waits for a

valid command.

Performing Conversions (With PF bit = 0)

Setting the SC (Single Conversion) bit of the command word to a logic 1 with the CB bit = 1, all other

command bits = 0, the CS5525/CS5526 will perform one conversion. At the completion of the conversion the DF (Done Flag) bit of the configuration

register will be set to a logic 1. The user can read

the configuration register to determine if the DF bit

is set. If DF has been set, a command can be issued

to read the conversion data register to obtain the

conversion data word. The DF bit of the configuration register will be cleared to logic 0 when the

data register, the gain register, the offset register, or

the set-up registers are read. Reading only the configuration register will not clear the DF flag bit.

If an SC command is issued to the converters while

they are performing a conversion, the filter will restart a convolution cycle to perform a new conversion.

Performing Conversions (With PF bit = 1)

Setting the PF bit of the configuration register to a

logic 1 enables the SDO output pin to behave as a

flag signal whenever conversions are completed.

This eliminates the need for the user to read the DF

flag bit of the configuration register to determine if

the conversion data word is available.

If the SC (Single Conversion) command is issued

(SC = 1, CB= 1, all other command bits = 0) the

SDO pin will go low at the completion of a conver-

20 DS202F5

Page 21

CS5525 CS5526

sion. The user would then issue 8 SCLKs (with

SDI = logic 0) to clear the SDO flag. Upon the falling edge of the 8th SCLK, the SDO pin will present

the first bit (MSB) of the conversion word. 24

SCLKs (high, then low) are required to read the

conversion word from the port. The user must not

give an explicit command to read the conversion

data register when the PF bit is set to logic 1. The

data conversion word must be read before a new

command can be entered (if the SC command is

used with PF = 1).

If the CC (Continuous Conversion) command is issued (CC = 1, CB =1, all other command bits = 0)

the SDO pin will go low at the completion of a conversion. The user would then issue 8 SCLKs (with

SDI = logic 0) to clear the SDO flag. Upon the falling edge of the 8th SCLK, the SDO pin will present

the first bit (MSB) of the conversion word. 24

SCLKs (high, then low) are required to read the

conversion word from the port. The user must not

give an explicit command to read the conversion

data register when the PF bit is set to logic 1. When

operating in the continuous conversion mode, the

user need not read every conversion. If the user

does nothing after SDO falls, SDO will rise one

XIN clock cycle before the next conversion word is

available and then fall again to signal that another

conversion word is available. If the user begins to

clear the SDO flag and read the conversion data,

this action must be finished before the conversion

cycle which is occurring in the background is complete if the user wants to be able to read the new

conversion data.

To exit the continuous conversion mode, issue any

valid command to the SDI input when the SDO flag

falls. If a CC command is issued to the converter

while it is performing a conversion, the filter will

restart a convolution cycle to perform a new conversion.

Output Word Rate Selection

The WR2-WR0 bits of the configuration register

set the output conversion word rate of the converters as shown in Table 2. The word rates indicated

in the table assume a master clock of 32.768 kHz.

Upon reset the converters are set to operate with an

output word rate of 15.0 Sps.

Clock Generator

The CS5525/26 include a gate which can be connected with an external crystal to provide the master

clock for the chips. They are designed to operate using a low-cost 32.768 kHz “tuning fork” type crystal. The 32.768 kHz crystal should be connected as

shown in Figure 18. Lead lengths should be minimized to reduce stray capacitance.

The converters will operate with an external

(CMOS compatible) clock with frequencies up to

three times the typical crystal frequency of 32.768

kHz. Figure 17 details the converter’s performance

at increased clock rates.

Figure 17. High Speed Clock Performance

The 32.768 kHz crystal is normally specified as a

time-keeping crystal with tight specifications for

both initial frequency and for drift over temperature.

To maintain excellent frequency stability, these

crystals are specified only over limited operating

temperature ranges (i.e. -10 °C to +60 °C). However,

applications with the CS5525/26 don’t generally require such tight tolerances. When 32.768 kHz tuning

fork crystals are used, it is recommended that protection components, an external resistor and capacitor

as shown in Figure 18, be used.

DS202F5 21

Page 22

Figure 18. Tuning Fork Crystal Connection Diagram

Digital Filter

Attenuation (dB)

-100

-110

-120

-130

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

0

123456

CS5525 CS5526

for OWR = 15.0 Hz

f1 = 47.5 Hz

f2 = 65.5 Hz

fS/2 = XIN/4

f2

f1

7

8 9 10 11 12 13 14 15

Sps

The CS5525/26 have eight different linear phase

digital filters which set the output word rates

(OWRs) as stated in Table 2. These rates assume

that XIN is 32.768 kHz. Each of the filters has a

magnitude response similar to that shown in Figure

19. The filters are optimized to settle to full accuracy every conversion and yield better than 80 dB rejection for both 50 and 60 Hz with output word

rates at or below 15.0 Sps.

The converter’s digital filters scale with XIN. For

example with an output word rate of 15 Hz, the filter’s corner frequency is typically 12.7 Hz. If XIN

is increased to 64.536 kHz the OWR doubles and

the filter’s corner frequency moves to 25.4 Hz.

Output Coding

The CS5525/26 output data in binary format when

operating in unipolar mode and in two's complement when operating in bipolar mode.

The output conversion word is 24 bits, or three

bytes long, as shown in Table 5. The MSB is output

Figure 19. Filter Response

(Normalized to Output Word Rate = 1)

first followed by the rest of the data bits in descending order. For the CS5525 the last byte is composed

of bits D7-D4, which are always logic 1; D3-D2,

which are always logic 0; and bits D1-D0 which are

the two flag bits. For the CS5526 the last byte includes data bits D7-D4, D3-D2 which are always

logic 0 and the two flag bits.

The OF (Overrange Flag) bit is set to a logic 1 any

time the input signal is: 1) more positive than positive full scale, 2) more negative than zero (unipolar

mode), 3) more negative than negative full scale

(bipolar mode). It is cleared back to logic 0 whenever a conversion word occurs which is not overranged.

The OD (Oscillation Detect) bit is set to a logic 1 any

time that an oscillatory condition is detected in the

modulator. This does not occur under normal operating

conditions, but may occur whenever the input to the

converters is extremely overranged. If the OD bit is set,

Output Conversion Data CS5525 (16 bits + flags)

D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

MSB1413121110987654321LSB111100ODOF

Output Conversion Data CS5526 (20 bits + flags)

D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

MSB1817161514131211109 8 7 654321LSB00ODOF

Table 5. Data Conversion Word

22 DS202F5

Page 23

CS5525 CS5526

CS5525 16-Bit Output Coding CS5526 20-Bit Output Coding

Unipolar Input

Voltage

>(VFS-1.5 LSB) FFFF >(VFS-1.5 LSB) 7FFF >(VFS-1.5 LSB) FFFFF >(VFS-1.5 LSB) 7FFFF

VFS-1.5 LSB

VFS/2-0.5 LSB

+0.5 LSB

<(+0.5 LSB) 0000 <(-VFS+0.5 LSB) 8000 <(+0.5 LSB) 00000 <(-VFS+0.5 LSB) 80000

Note: VFS in the table equals the voltage between ground and full scale for any of the unipolar gain ranges, or the

voltage between ± full scale for any of the bipolar gain ranges. See text about error flags under overrange

conditions.

the conversion data bits can be completely erroneous.

The OD flag bit will be cleared to logic 0 when the

modula t o r b e c o mes stable. Table 6 illustrates the output coding for the CS5525/26.

Power Consumption

The CS5525/26 accommodate four power consumption modes: normal, low power, standby, and sleep.

The normal mode, the default mode, is entered after a

power-on-reset and typically consumes 9.4 mW. The

low power mode is an alternate mode that reduces the

Offset

Binary

FFFF

-----

FFFE

8000

-----

7FFF

0001

-----

0000

Bipolar Input

Voltage

VFS-1.5 LSB

-0.5 LSB

-VFS+0.5 LSB

Two's

Complement

7FFF

-----

7FFE

0000

-----

FFFF

8001

-----

8000

Table 6. 5525/26 Output Coding

Unipolar Input

Voltage

VFS-1.5 LSB

VFS/2-0.5 LSB

+0.5 LSB

1.2mW. The standby mode leaves the oscillator and

the on-chip bias generator running. This allows the

converters to quickly return to the normal or low

power mode once the PS/R

If D4 in the configuration register and CB and PS/R

in the command word are set to logic 1, the sleep

mode is entered reducing the consumed power to less

than 500 µW. Since the sleep mode disables the oscillator, approximately a 500ms oscillator start-up delay

period is required before returning to the normal or

low power mode.

Offset

Binary

FFFFF

-----

FFFFE

80000

-----

7FFFF

00001

-----

00000

Bipolar Input

Voltage

VFS-1.5 LSB

-0.5 LSB

-VFS+0.5 LSB

Two's

Complement

7FFFF

-----

7FFFE

00000

-----

FFFFF

80001

-----

80000

bit is set back to a logic 1.

consumed power to 4.9 mW. It is entered by setting

bit D16 (the low power mode bit) in the configuration

register to logic 1. Since the converter’s noise performance improves with increased power consumption,

slightly degraded noise or linearity performance

should be expected in the low power mode. The final

two modes are referred to as the power save modes.

They power down most of the analog portion of the

chips and stop filter convolutions. The power save

modes are entered whenever the PS/R

bit and the CB

bit of the command word are set to logic 1. The particular power save mode entered depends on state of

bit D4 (the Power Save Select bit) in the configura-

PCB Layout

The CS5525/26 should be placed entirely over an analog ground plane with both the AGND and DGND

pins of the device connected to the analog plane.

Place the analog-digital plane split immediately adjacent to the digital portion of the chip.

The XIN pin represents a very high impedance when

used with a crystal, so care should be taken in routing

the trace from the crystal to the XIN pin to keep it as

short as possible. Stray capacitance between the CPD

pin and the XIN pin should be minimizedby keeping

the CPD pin trace away from XIN.

tion register. If D4 is logic 0, the converters enters the

standby mode reducing the power consumption to

DS202F5 23

Page 24

PIN DESCRIPTIONS

CS5525 CS5526

ANALOG GROUND AGND VREF+VOLTAGE REFERENCE INPUT

POSITIVE ANALOG POWER VA+ VREF- VOLTAGE REFERENCE INPUT

DIFFERENTIAL ANALOG INPUT AIN+ CS

DIFFERENTIAL ANALOG INPUT AIN- SDI SERIAL DATA INPUT

NEGATIVE BIAS VOLTAGE NBV A3 LOGIC OUTPUT

LOGIC OUTPUT A0 A2 LOGIC OUTPUT

LOGIC OUTPUT A1 SDO SERIAL DATA OUTPUT

CHARGE PUMP DRIVE CPD VD+ POSITIVE DIGITAL POWER

CRYSTAL IN XIN DGND DIGITAL GROUND

CRYSTAL OUT XOUT SCLK SERIAL CLOCK INPUT

1

2

3

4

5

6

7

8

9

10 11

20

19

18

17

16

15

14

13

12

CHIP SELECT

Clock Generator

XIN; XOUT - Crystal In; Crystal Out, Pins 9, 10.

A gate inside the chip is connected to these pins and can be used with a crystal to provide the

master clock for the device. Alternatively, an external (CMOS compatible) clock can be

supplied into the XIN pin to provide the master clock for the device.

Control Pins and Serial Data I/O

CS - Chip Select, Pin 18.

When active low, the port will recognize SCLK. When high the SDO pin will output a high

impedance state. CS should be changed when SCLK = 0.

SDI - Serial Data Input, Pin 17.

SDI is the input pin of the serial input port. Data will be input at a rate determined by SCLK.

SDO - Serial Data Output, Pin 14.

SDO is the serial data output. It will output a high impedance state if CS

SCLK - Serial Clock Input, Pin 11.

A clock signal on this pin determines the input/output rate of the data for the SDI/SDO pins

respectively. This input is a Schmitt trigger to allow for slow rise time signals. The SCLK pin

will recognize clocks only when CS

is low.

A0, A1, A2, A3 - Logic Outputs, Pin 6, 7, 15, 16.

The logic states of A0-A3 mimic the states of the D20-D23 bits of the configuration register.

Logic Output 0 = AGND, and Logic Output 1 = VA+.

= 1.

24 DS202F5

Page 25

Measurement and Reference Inputs

AIN+, AIN- - Differential Analog Input, Pins 3, 4.

Differential input pins into the device.

VREF+, VREF- - Voltage Reference Input, Pins 20, 19.

Fully differential inputs which establish the voltage reference for the on-chip modulator.

NBV - Negative Bias Voltage, Pin 5.

Input pin to supply the negative supply voltage for the 20X gain instrumentation amplifier.

May be tied to AGND if AIN+ and AIN- inputs are centered around +2.5 V; or it may be tied

to a negative supply voltage (-2.1 V typical) to allow the amplifier to handle low level signals

more negative than ground.

CPD - Charge Pump Drive, Pin 8.

Square wave output used to provide energy for the charge pump.

Power Supply Connections

CS5525 CS5526

VA+ - Positive Analog Power, Pin 2.

Positive analog supply voltage. Nominally +5 V.

VD+ - Positive Digital Power, Pin 13.

Positive digital supply voltage. Nominally +3.0 V or +5 V.

AGND - Analog Ground, Pin 1.

Analog Ground.

DGND - Digital Ground, Pin 12.

Digital Ground.

DS202F5 25

Page 26

SPECIFICATION DEFINITIONS

Linearity Error

The deviation of a code from a straight line which connects the two endpoints of the A/D

Converter transfer function. One endpoint is located 1/2 LSB below the first code transition

and the other endpoint is located 1/2 LSB beyond the code transition to all ones. Units in

percent of full-scale.

Differential Nonlinearity

The deviation of a code's width from the ideal width. Units in LSBs.

Full Scale Error

The deviation of the last code transition from the ideal [{(VREF+) - (VREF-)} - 3/2 LSB].

Units are in LSBs.

Unipolar Offset

The deviation of the first code transition from the ideal (1/2 LSB above the voltage on the

AIN- pin.). When in unipolar mode (U/B

CS5525 CS5526

bit = 1). Units are in LSBs.

Bipolar Offset

The deviation of the mid-scale transition(111...111 to 000...000) from the ideal (1/2 LSB below

the voltage on the AIN- pin). When in bipolar mode (U/B

bit = 0). Units are in LSBs.

26 DS202F5

Page 27

20 PIN PLASTIC (PDIP) PACKAGE DRAWING

D

1

TOP VIEW

DIM MIN MAX MIN MAX

A 0.155 0.180 3.94 4.57

A1 0.020 0.040 0.51 1.02

b 0.015 0.022 0.38 0.56

b1 0.050 0.065 1.27 1.65

c 0.008 0.015 0.20 0.38

D 0.960 1.040 24.38 26.42

E 0.240 0.260 6.10 6.60

e 0.095 0.105 2.41 2.67

eA 0.300 0.325 7.62 8.25

L 0.125 0.150 3.18 3.81

∝

E

A1

A

L

SEATING

PLANE

b1

e

BOTTOM VIEW

b

INCHES MILLIMETERS

0° 15° 0° 15°

CS5525 CS5526

∝

eA

SIDE VIEW

c

Notes: 1. Positional tolerance of leads shall be within 0.25 mm (0.010 in.) at maximum material condition, in

relation to seating plane and each other.

2. Dimension eA to center of leads when formed parallel.

3. Dimension E does not include mold flash.

DS202F5 27

Page 28

CS5525 CS5526

20 PIN SSOP PACKAGE DRAWING

N

1

23

TOP VIEW

D

E

e

2

b

SIDE VIEW

A2

A1

A

SEATING

PLANE

L

INCHES MILLIMETERS

1

E1

END VIEW

NOTE

DIM MIN MAX MIN MAX

A -- 0.084 -- 2.13

A1 0.002 0.010 0.05 0.25

A2 0.064 0.074 1.62 1.88

b 0.009 0.015 0.22 0.38 2,3

D 0.272 0.295 6.90 7.50 1

E 0.291 0.323 7.40 8.20

E1 0.197 0.220 5.00 5.60 1

e 0.024 0.027 0.61 0.69

L 0.025 0.040 0.63 1.03

∝

0° 8° 0° 8°

Notes: 1. “D” and “E1” are reference datums and do not included mold flash or protrusions, but do include mold

mismatch and are measured at the parting li ne, mold flash or protrusions shall not exceed 0.20 mm per

side.

2. Dimension “b” does not include dambar protrusion/intrusion. Allowable dambar protrusion shall be

0.13 mm total in excess of “b” dimension at maximum material condition. Dambar intrusion shall not

reduce dimension “b” by more than 0.07 mm at least material condition.

3. These dimensions apply to the fl at section of the lead between 0.10 and 0.25 mm from lead tips.

28 DS202F5

Page 29

ORDERING INFORMATION

CS5525 CS5526

Model Package

CS5525-AS

20-pin SSOP

CS5525-ASZ (Lead Free)

CS5526-BP 20-pin Plastic Dip (0.300”)

CS5526-BS

20-pin SSOP

CS5526-BSZ (Lead Free)

Linearity Error (Max)

±0.003%

±0.0015%

ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION

Model Number Peak Reflow Temp MSL Rating* Max Fl oor Life

CS5525-AS

CS5525-ASZ (Lead Free)

CS5526-BP

CS5526-BS

CS5526-BSZ (Lead Free)

* MSL (Moisture Sensitivity Level) as specified by IPC/JEDEC J-STD-020.

240 °C 2 365 Days

260 °C 3 7 Days

260 °C 1 No Limit

240 °C 2 365 Days

260 °C 3 7 Days

Temperature

-40 to +85 °C

DS202F5 29

Page 30

REVISION HISTORY

Revision Date Changes

F4 JUN 2005 Added Lead-free device ordering information.

F5 AUG 2005 Revised Lead-free device ordering information. Added MSL data.

CS5525 CS5526

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find the one nearest to you go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and it s subs i dia ri e s (“Ci r ru s”) be li eve tha t t he in for mat i o n cont ai n ed in t hi s document i s acc ur at e and re l i abl e . Ho wev er , th e in fo rmation is subject

to change without noti ce and is provi ded “AS I S” with out warran ty of any kind ( express or implied ). Cust omers are a dvised to obtain the latest version of relevant

information to verify, before placing orders, tha t inform atio n bei ng relied on is curr ent and com plete. Al l prod ucts are sold s ubject to the ter ms and co nditio ns of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Ci rrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for ge neral distribution, advertising or promotional purposes, or for creating any work for re sa l e.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE

IN AIRCRAFT SYSTEMS, MILITARY APPLICATIONS, PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UND ERSTOOD

TO BE FULLY AT THE CUSTOMER'S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO AN Y CI RR US PRODUCT THAT IS USED

IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER

AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH

THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in this document may be trademarks

or service marks of their respective owners.

SPI is a trademark of Motorola, Inc.

Microwire is a trademark of National Semiconductor Corporation.

30 DS202F5

Loading...

Loading...