Page 1

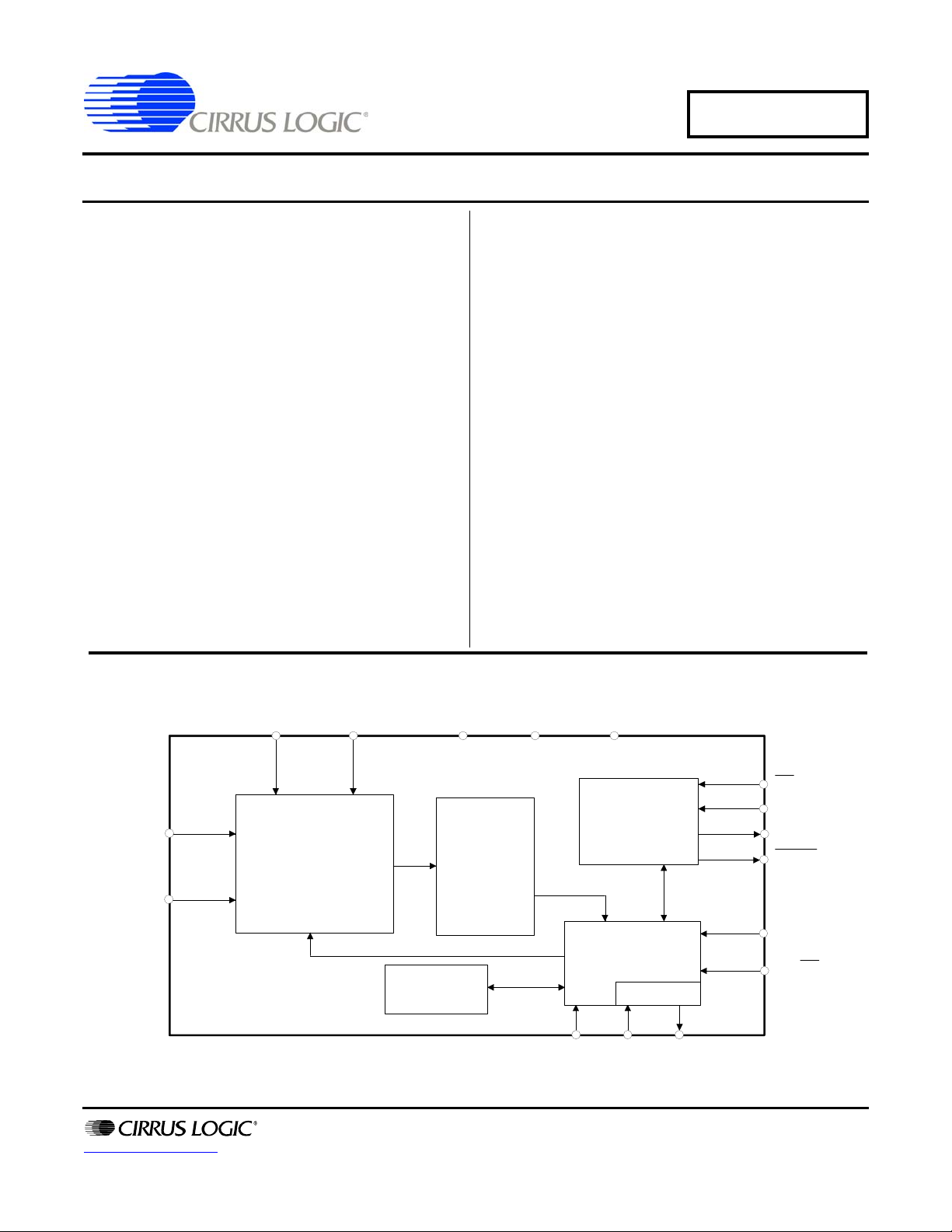

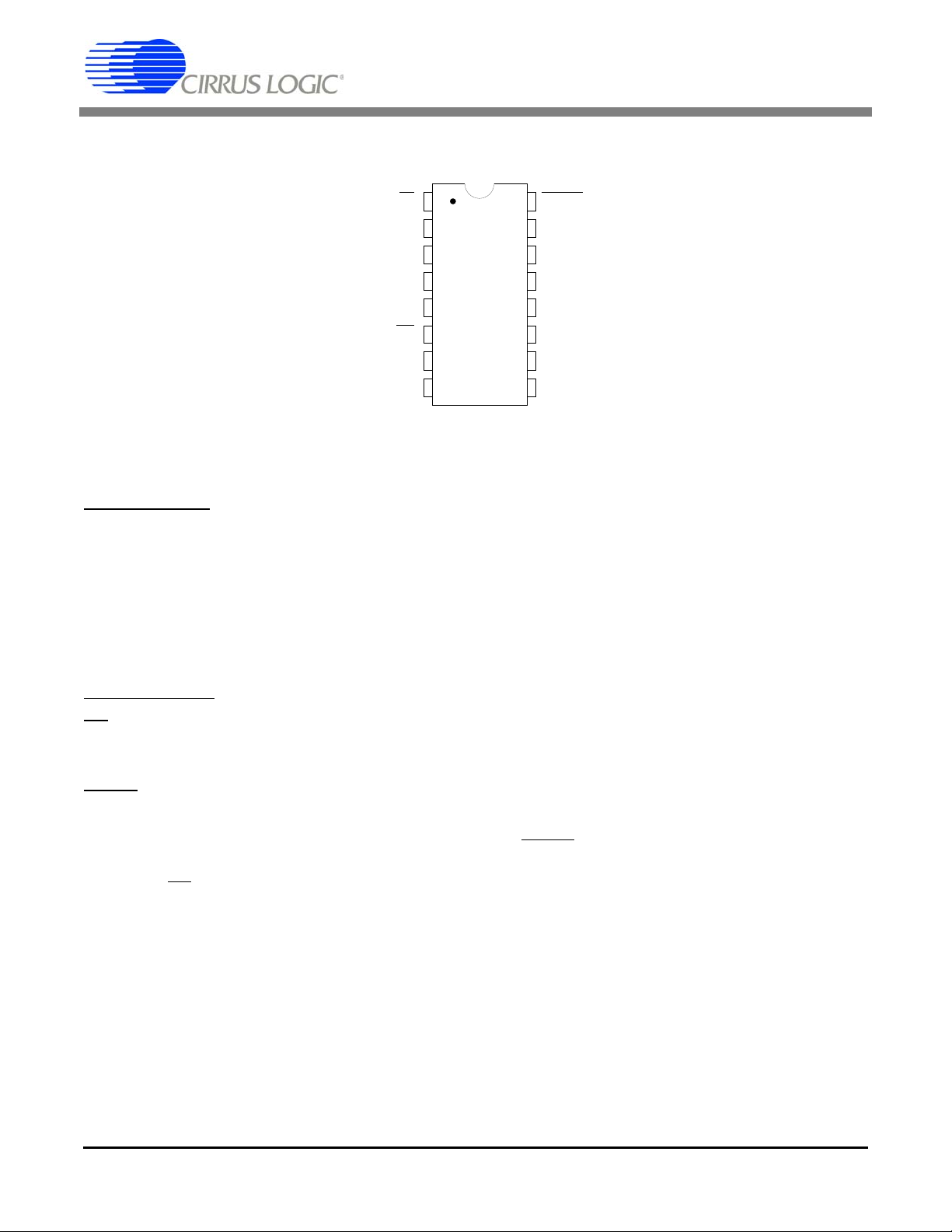

Single-supply, 16-bit A/D Converter

Differential

4th order

delta-sigma

modulator

VD+

13

VA+VREF+9VREF-

10

AIN-

8

AIN+

7

Calibration

SRAM

Serial

Interface

Logic

Digital

Filter

XIN4XOUT

5

CONV

2

Calibration µC

OSC

CAL

3

6

BP/UP

CS

1

DRDY

16

SDATA

15

SCLK

14

11

GND

12

CS5509

Features

Delta-sigma A/D Converter

- 16-bit, No Missing Codes

- Linearity Error: ±0.0015%FS

Differential Input

- Pin-selectable Unipolar/Bipolar Ranges

- Common Mode Rejection

105 dB @ dc

120 dB @ 50, 60 Hz

Either 5V or 3.3V Digital Interface

On-chip Self-calibration Circuitry

Output Update Rates up to 200/second

Ultra Low Power: 1.7 mW

I

Description

The CS5509 is a single-supply, 16-bit, serial-output

CMOS A/D converter. The CS5509 uses charge-balanced (delta-sigma) techniques to provide low-cost,

high-resolution measurements at output word rates up to

200 samples per second.

The on-chip digital filter offers superior line rejection at

50Hz and 60Hz when the device is operated from a

32.768 kHz clock (output word rate = 20 Sps).

The CS5509 has on-chip self-calibration circuitry which

can be initiated at any time or temperature to ensure

minimum offset and full-scale errors.

Low power, high resolution, and small package size

make the CS5509 an ideal solution for loop-powered

transmitters, panel meters, weigh scales, and battery

powered instruments.

ORDERING INFORMATION

CS5509-ASZ -40 °C to +85 °C 16-pin SOIC Lead Free

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2009

(All Rights Reserved)

SEP ‘09

DS125F3

1

Page 2

CS5509

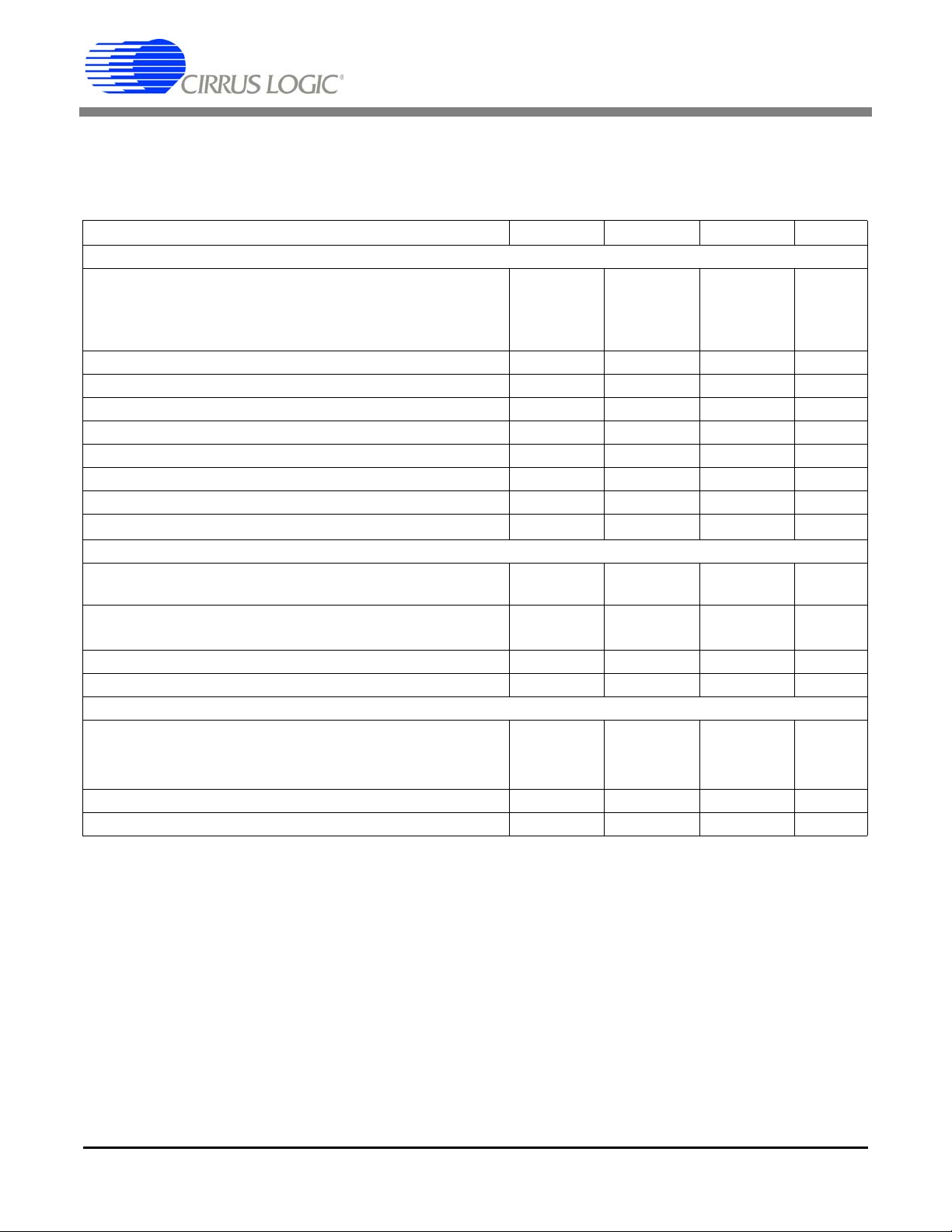

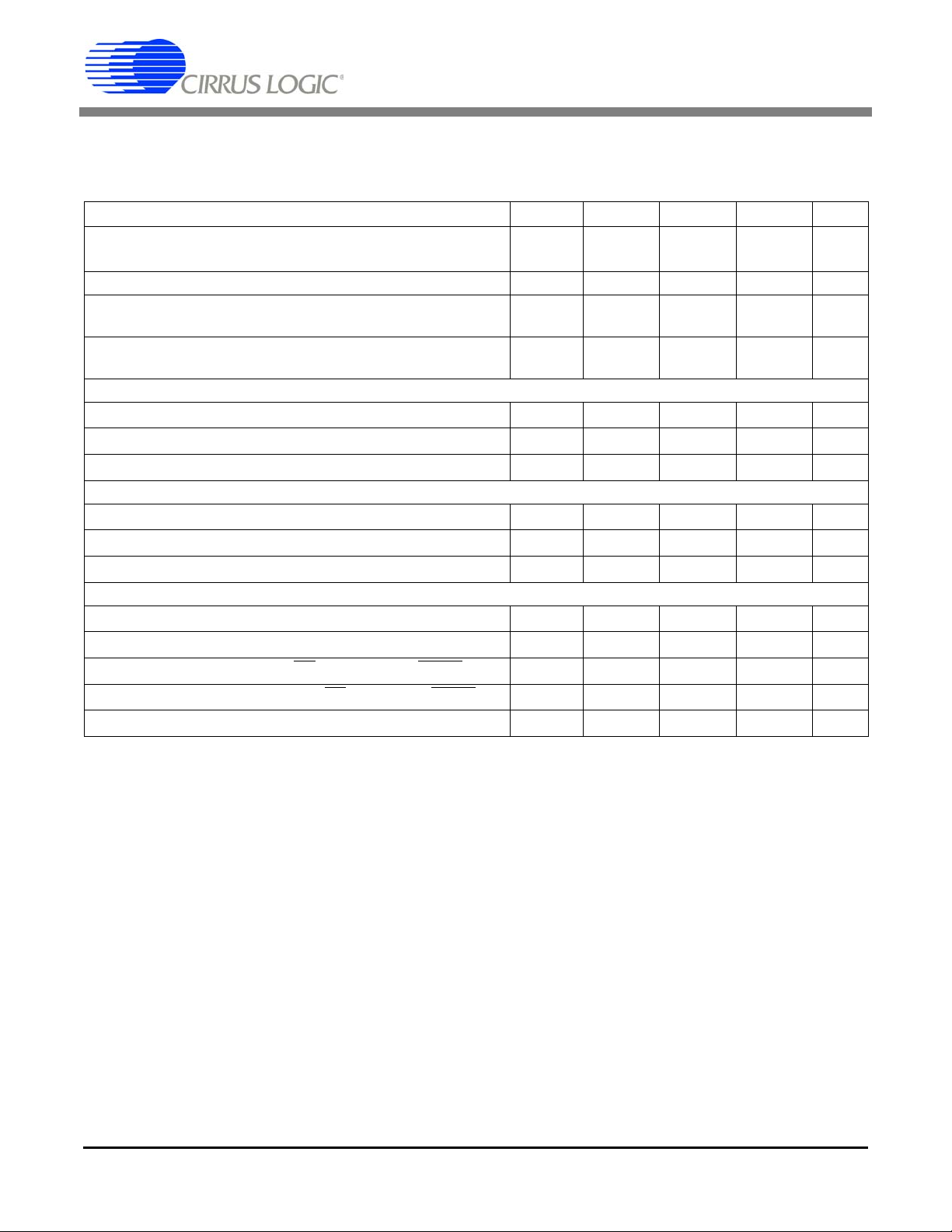

ANALOG CHARACTERISTICS (T

VREF- = 0V; f

= 32.768 kHz; Bipolar Mode; R

CLK

= 25 °C; VA+ = 5V ±5%; VD+ = 3.3V ±5%; VREF+ = 2.5V,

A

= 40 Ω with a 10 nF to GND at AIN; AIN- = 2.5V; unless oth-

source

erwise specified.) (Notes 1 and 2)

Parameter* Min Typ Max Unit

Accuracy

Linearity Error f

= 32.768 kHz

CLK

f

= 165 kHz

CLK

f

= 247.5 kHz

CLK

f

= 330 kHz

CLK

-

-

-

-

0.0015

0.0015

0.0015

0.005

0.003

0.003

0.003

0.0125

± %FS

± %FS

± %FS

± %FS

Differential Nonlinearity - ±0.25 ±0.5 LSB

Full-scale Error (Note 3) - ±0.25 ±2 LSB

Full-scale Drift (Note 4) - ±0.5 - LSB

Unipolar Offset (Note 3) - ±0.5 ±2 LSB

Unipolar Offset Drift (Note 4) - ±0.5 - LSB

Bipolar Offset (Note 3) - ±0.25 ±1 LSB

Bipolar Offset Drift (Note 4) - ±0.25 - LSB

Noise (Referred to Output) - 0.16 -

LSB

Analog Input

Analog Input Range Unipolar

Bipolar (Notes 5 and 6)

Common Mode Rejection dc

f

= 32.768 kHz 50, 60 Hz (Note 2)

CLK

-

-

-

120

0 to +2.5

±2.5

105

-

-

-

-

-

V

V

dB

dB

Input Capacitance - 15 - pF

DC Bias Current (Note 1) - 5 - nA

Power Supplies

DC Power Supply Currents I

Total

I

Analog

I

Digital

-

-

-

350

300

60

450

-

-

µA

µA

µA

Power Dissipation (Note 7) - 1.7 2.25 mW

Power Supply Rejection - 80 - dB

rms

Notes: 1. Both source resistance and shunt capacitance are critical in determining the CS5509's source

impedance requirements. Refer to the text section Analog Input Impedance Considerations.

2. Specifications guaranteed by design, characterization and/or test.

3. Applies after calibration at the temperature of interest.

4. Total drift over the specified temperature range since calibration at power-up at 25 °C.

5. The input is differential. Therefore, GND ≤ Signal + Common Mode Voltage ≤ VA+.

6. The CS5509 can accept input voltages up to the VA+ analog supply. In unipolar mode the CS5509 will

output all 1's if the dc input magnitude ((AIN+) - (AIN-)) exceeds ((VREF+) - (VREF-)) and will output all

0's if the input becomes more negative than 0 Volts. In bipolar mode the CS5509 will output all 1's if the

dc input magnitude ((AIN+) - (AIN-)) exceeds ((VREF+) - (VREF-)) and will output all 0's if the input

becomes more negative in magnitude than -((VREF+) - (VREF-)).

7. All outputs unloaded. All inputs CMOS levels.

* Refer to the Specification Definitions immediately following the Pin Description Section.

2 DS125F3

Page 3

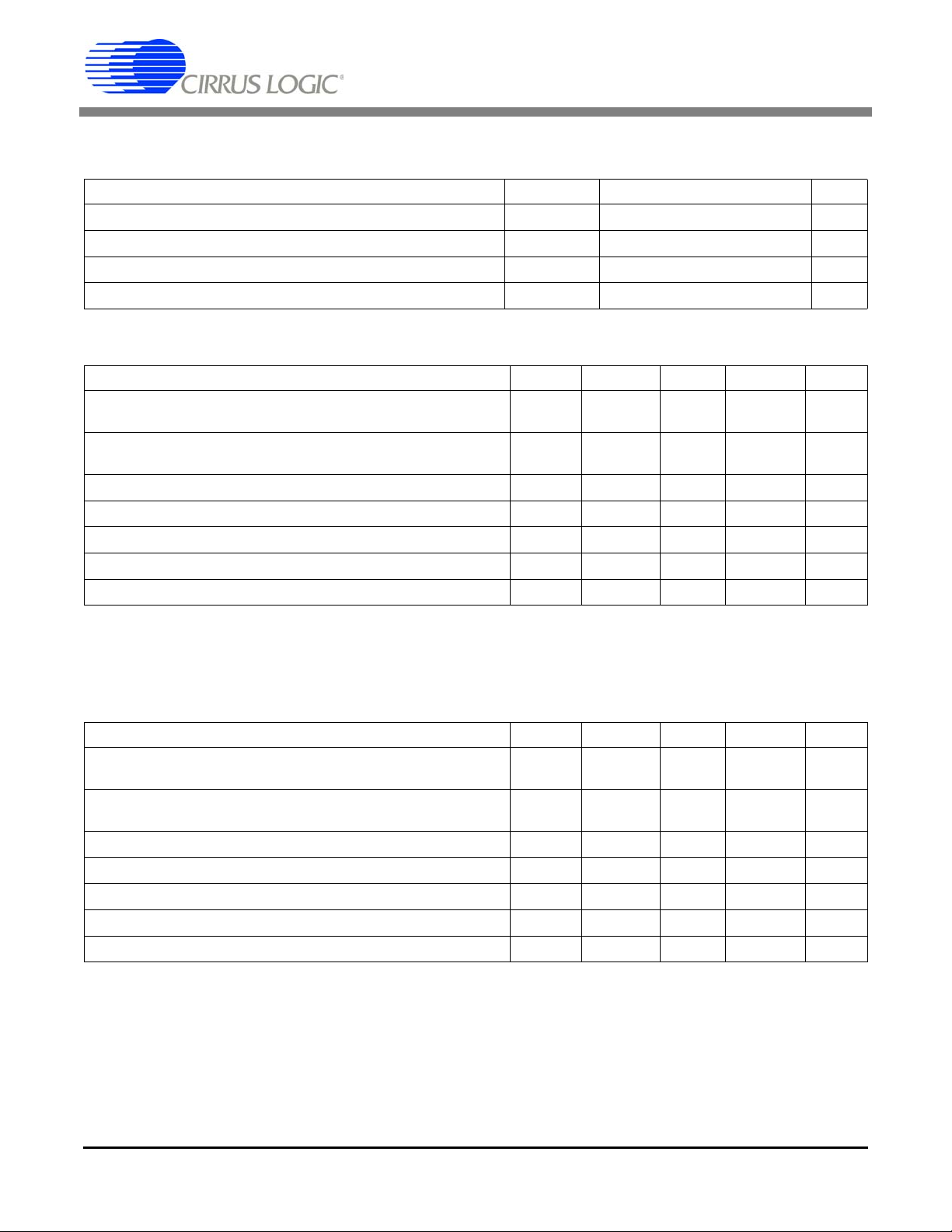

DYNAMIC CHARACTERISTICS

Parameter Symbol Ratio Unit

Modulator Sampling Frequency

Output Update Rate (CONV = 1)

Filter Corner Frequency

Settling Time to 1/2 LSB (FS Step)

f

out

f

-3dB

CS5509

f

f

clk

f

clk

/2

clk

/1622

/1928

1/f

out

Hz

Hz

Hz

s

f

s

t

s

5V DIGITAL CHARACTERISTICS (T

= 25 °C; VA+, VD+ = 5V ±5%; GND = 0) (Notes 2 and 8)

A

Parameter Symbol Min Typ Max Unit

High-level Input Voltage XIN

All Pins Except XIN

V

IH

Low-level Input Voltage XIN

All Pins Except XIN

High-level Output Voltage (Note 9)

Low-level Output Voiltage I

= 1.6 mA V

out

Input Leakage Current

3-State Leakage Current

Digital Output Pin Capacitance

V

IL

V

OH

OL

I

in

I

OZ

C

out

Notes: 8. All measurements are performed under static conditions.

9. I

3.3V DIGITAL CHARACTERISTICS (T

= -100 µA. This guarantees the ability to drive one TTL load. (VOH = 2.4 V at I

out

= 25 °C; VA+ = 5V ±5%; VD+ = 3.3V ±5%; GND = 0)

A

(Notes 2 and 8)

Parameter Symbol Min Typ Max Unit

High-level Input Voltage XIN

All Pins Except XIN

V

IH

Low-level Input Voltage XIN

All Pins Except XIN

High-level Output Voltage (Note 9)

Low-level Output Voltage I

= 1.6 mA V

out

Input Leakage Current

3-state Leakage Current

Digital Output Pin Capacitance

V

IL

V

OH

OL

I

in

I

OZ

C

out

3.5

2.0

-

-

-

-

-

-

-

-

1.5

0.8

V

V

V

V

(VD+) -1.0 - - V

--0.4V

-±1±10µA

--±10µA

-9-pF

= -40 µA).

out

0.7 VD+

0.6 VD+

-

-

-

-

-

-

-

-

0.3 VD+

0.16 VD+

V

V

V

V

(VD+) -0.3 - - V

--0.3V

-±1±10µA

--±10µA

-9-pF

Specifications are subject to change without notice

DS125F3 3

Page 4

CS5509

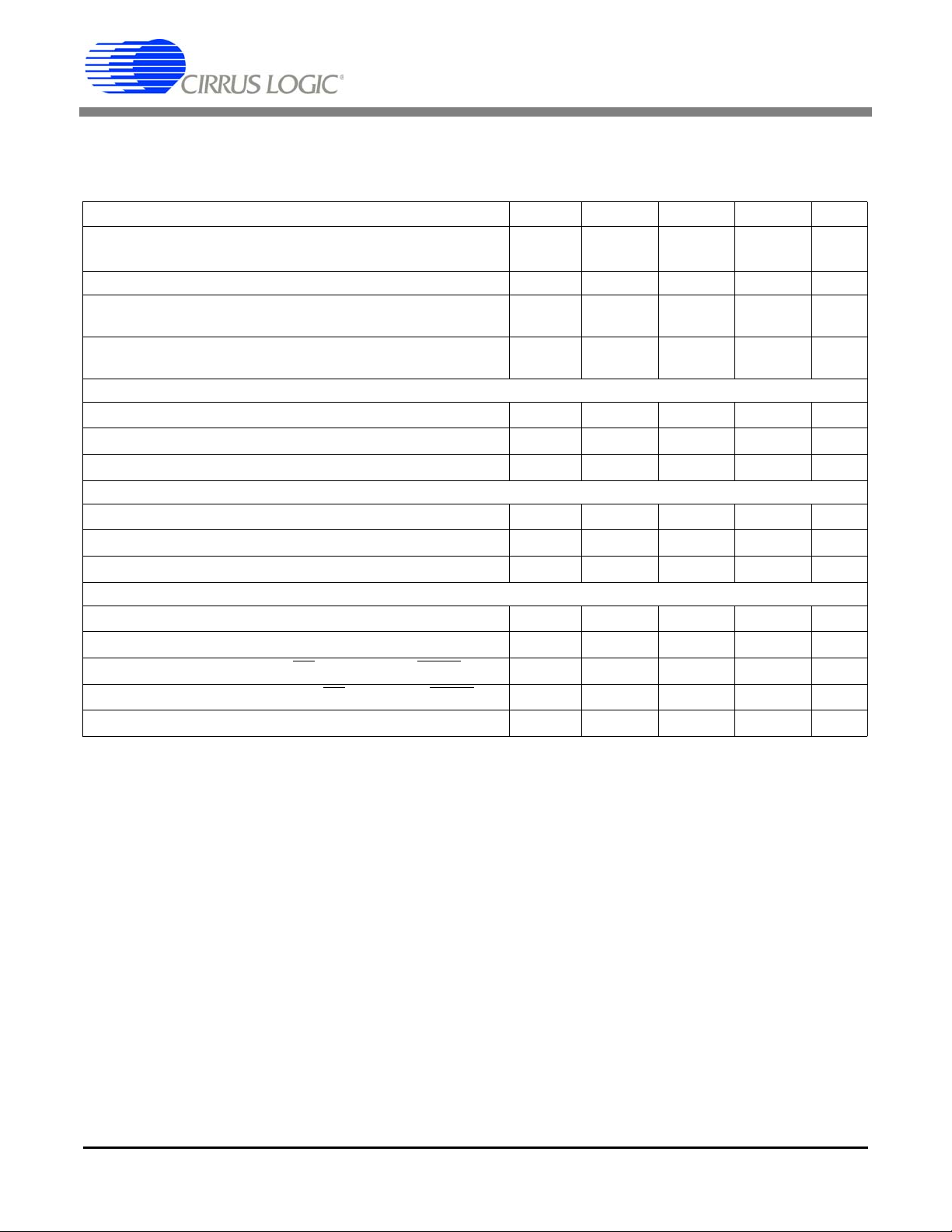

5V SWITCHING CHARACTERISTICS (T

Input Levels: Logic 0 = 0V, Logic 1 = VD+; C

= 50 pF) (Note 2)

L

= 25 °C; VA+, VD+ = 5V ±5%;

A

Parameter Symbol Min Typ Max Unit

Master Clock Frequency Internal Oscillator

External Clock

XIN

f

clk

30.0

30

32.768

-

53.0

330

kHz

kHz

Master Clock Duty Cycle 40 - 60 %

Rise Times Any Digital Input (Note 10)

Any Digital Output

Fall Time Any Digital Input (Note 10)

Any Digital Output

t

rise

t

fall

-

-

-

-

50

20

-

1.0

-

-

1.0

-

Start-Up

Power-On Reset Period (Note 11)

Oscillator Start-up Time XTAL = 32.768 kHz (Note 12)

Wake-up Period (Note 13)

t

t

t

res

osu

wup

-10-ms

-500-ms

-

1800/f

clk

-s

Calibration

CONV Pulse Width (CAL = 1) (Note 14)

CONV and CAL High to Start of Calibration

Start of Calibration to End of Calibration

t

t

ccw

t

scl

cal

100 - - ns

+200

clk

2/f

clk

-s

--

-

3246/f

Conversion

CONV Pulse Width

CONV High to Start of Conversion

Set Up Time BP/UP

Hold Time BP/UP

stable prior to DRDY falling

stable after DRDY falls

Start of Conversion to End of Conversion (Note 15)

t

cpw

t

scn

t

bus

t

buh

t

con

100 - - ns

+200

--

82/f

clk

2/f

clk

--s

0--ns

-

1624/f

clk

-s

µs

ns

µs

ns

ns

ns

Notes: 10. Specified using 10% and 90% points on waveform of interest.

11. An internal power-on-reset is activated whenever power is applied to the device.

12. Oscillator start-up time varies with the crystal parameters. This specification does not apply when using

an external clock source.

13. The wake-up period begins once the oscillator starts; or when using an external f

, after the power-on

clk

reset time elapses.

14. Calibration can also be initiated by pulsing CAL high while CONV=1.

15. Conversion time will be 1622/f

if CONV remains high continuously.

clk

4 DS125F3

Page 5

CS5509

3.3V SWITCHING CHARACTERISTICS (T

Levels: Logic 0 = 0V, Logic 1 = VD+; C

= 50 pF) (Note 2)

L

= 25 °C; VA+ = 5V ±5%; VD+ = 3.3V ±5%; Input

A

Parameter Symbol Min Typ Max Unit

Master Clock Frequency Internal Oscillator

External Clock

XIN

f

clk

30.0

30

32.768

-

53.0

330

kHz

kHz

Master Clock Duty Cycle 40 - 60 %

Rise Times Any Digital Input (Note 10)

Any Digital Output

Fall Time Any Digital Input (Note 10)

Any Digital Output

t

t

rise

fall

-

-

-

-

50

20

-

1.0

-

-

1.0

-

Start-Up

Power-On Reset Period (Note 11)

Oscillator Start-up Time XTAL = 32.768 kHz (Note 12)

Wake-up Period (Note 13)

t

res

t

osu

t

wup

-10-ms

-500-ms

-

1800/f

clk

-s

Calibration

CONV Pulse Width (CAL = 1) (Note 14)

CONV and CAL High to Start of Calibration

Start of Calibration to End of Calibration

t

t

t

ccw

scl

cal

100 - - ns

+200

clk

2/f

clk

-s

--

-

3246/f

Conversion

CONV Pulse Width

CONV High to Start of Conversion

Set Up Time BP/UP

Hold Time BP/UP

stable prior to DRDY falling

stable after DRDY falls

Start of Conversion to End of Conversion (Note 15)

t

cpw

t

scn

t

bus

t

buh

t

con

100 - - ns

+200

--

82/f

clk

2/f

clk

--s

0--ns

-

1624/f

clk

-s

µs

ns

µs

ns

ns

ns

DS125F3 5

Page 6

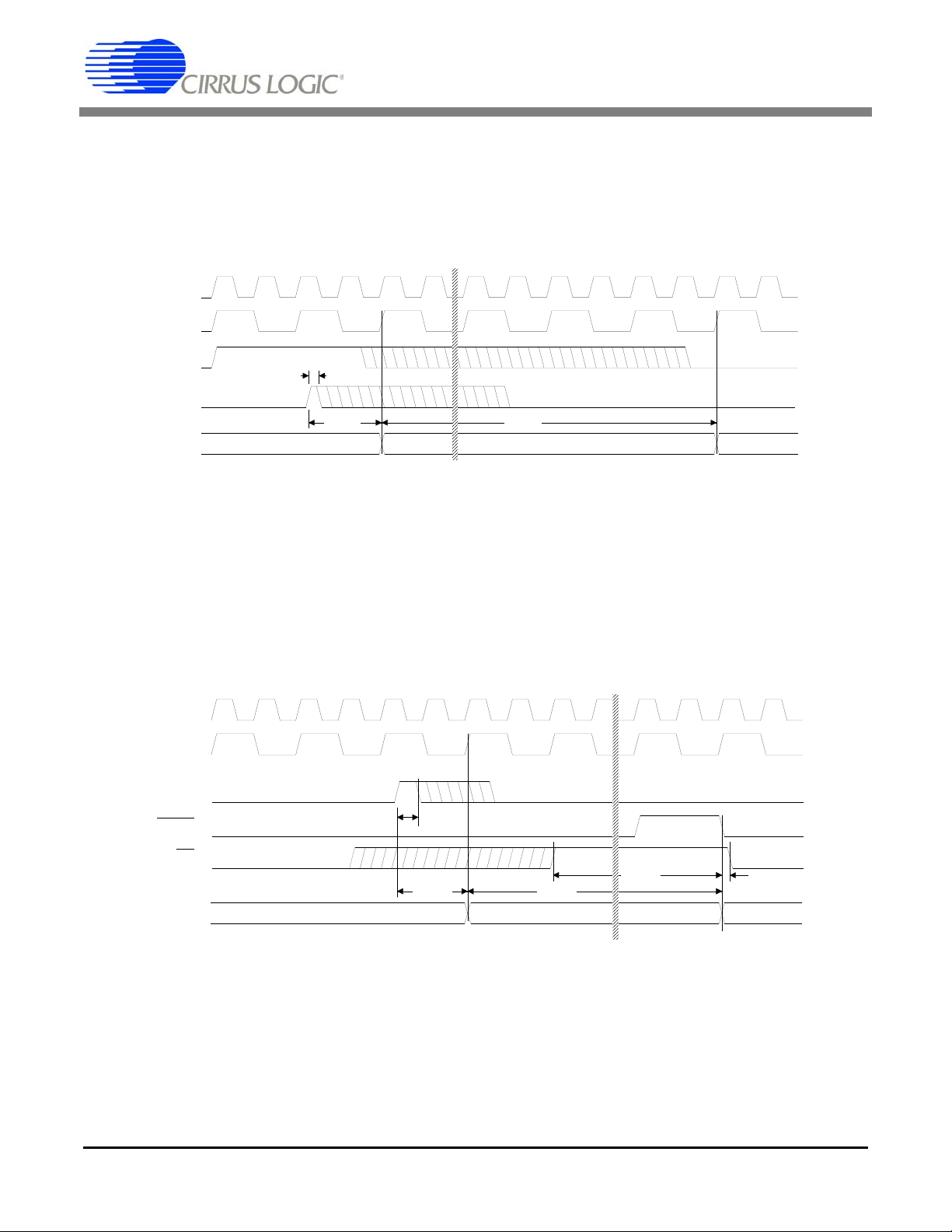

CS5509

t

ccw

XIN

Calibration StandbyStandby

t

scl

t

cal

XIN/2

STATE

CAL

CONV

Figure 1. Calibration Timing (Not to Scale)

XIN

XIN/2

t

buh

Conversion StandbyStandby

CONV

STATE

t

scn

t

con

DRDY

BP/UP

t

bus

t

cpw

Figure 2. Conversion Timing (Not to Scale)

6 DS125F3

Page 7

CS5509

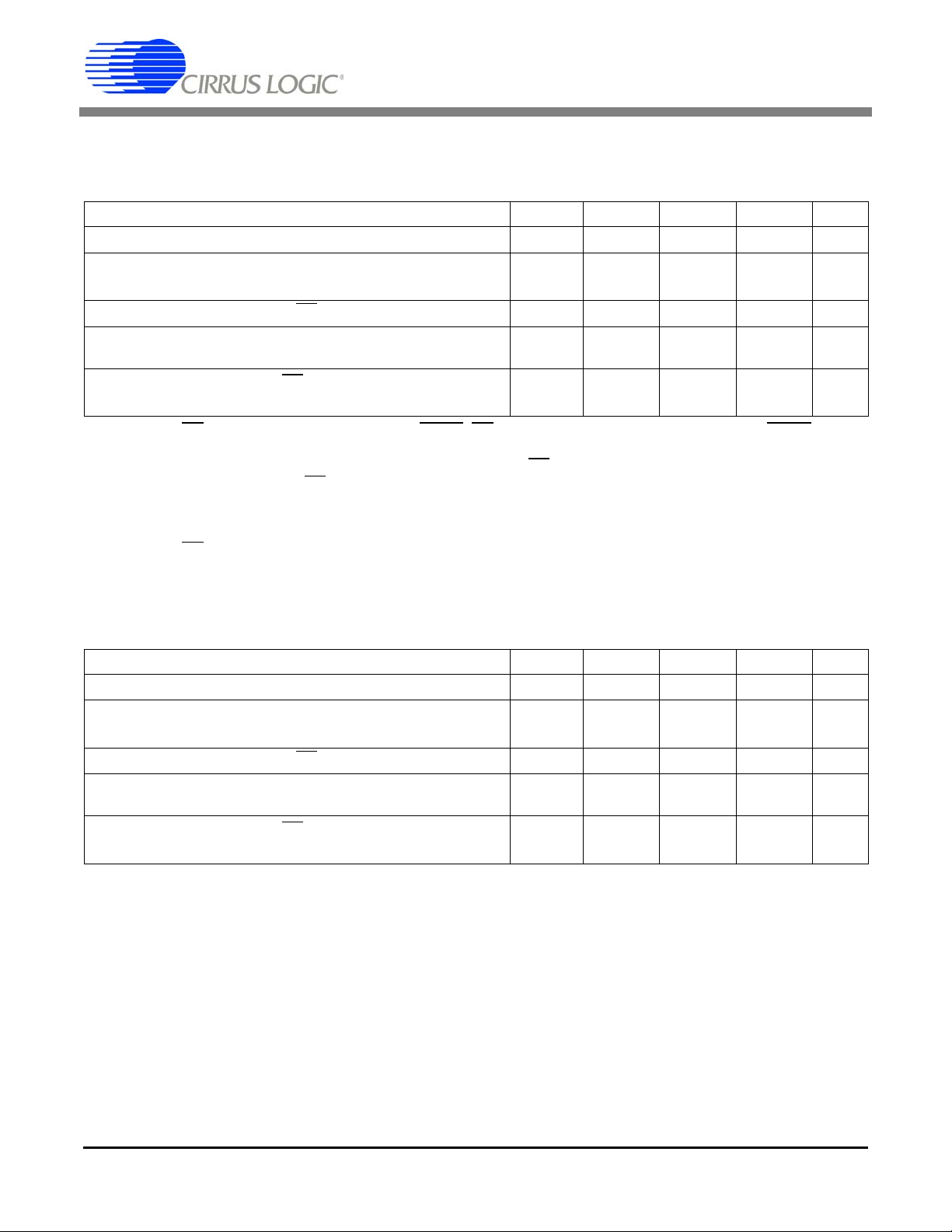

5V SWITCHING CHARACTERISTICS (T

0V, Logic 1 = VD+; C

= 50 pF) (Note 2)

L

= 25 °C; VA+, VD+ = 5V ±5%; Input Levels: Logic 0 =

A

Parameter Symbol Min Typ Max Unit

Serial Clock

Serial Clock Pulse Width High

Pulse Width Low

Access Time CS

Low to data valid (Note 16)

f

t

t

sclk

ph

t

pl

csd

0-2.5MHz

200

200

-

-

-

-

ns

ns

-60200ns

Maximum Delay Time (Note 17)

t

t

t

dd

fd1

fd2

-150310ns

-

-

60

160

150

300

ns

ns

SCLK falling to new SDATA bit

Output Float Delay CS

High to output Hi-Z (Note 18)

SCLK falling to Hi-Z

Notes: 16. If CS is activated asynchronously to DRDY, CS will not be recognized if it occurs when DRDY is high

for 2 clock cycles. The propagation delay time may be as great a s 2 f

proper clocking of SDATA when using asynchronous CS

2 f

+ 200 ns after CS goes low.

clk

, SCLK(i) should not be taken high sooner than

cycles plus 200 ns. To guarantee

clk

17. SDATA transitions on the falling edge of SCLK. Note that a rising SCLK must occur to enable the serial

port shifting mechanism before falling edges can be recognized.

18. If CS

is returned high before all data bits are output, the SDATA output will complete the current data

bit and then go to high impedance.

3.3V SWITCHING CHARACTERISTICS (T

Levels: Logic 0 = 0V, Logic 1 = VD+; C

= 50 pF) (Note 2)

L

= 25 °C; VA+ = 5V ±5%; VD+ = 3.3V ±5%; Input

A

Parameter Symbol Min Typ Max Unit

Serial Clock

Serial Clock Pulse Width High

Pulse Width Low

Access Time CS

Low to data valid (Note 16)

Maximum Delay Time (Note 17)

SCLK falling to new SDATA bit

Output Float Delay CS

High to output Hi-Z (Note 18)

SCLK falling to Hi-Z

f

t

t

t

t

t

sclk

ph

t

pl

csd

dd

fd1

fd2

0 - 1.25 MHz

200

200

-

-

-

-

ns

ns

-100200ns

-400600ns

-

-

70

320

150

500

ns

ns

DS125F3 7

Page 8

CS5509

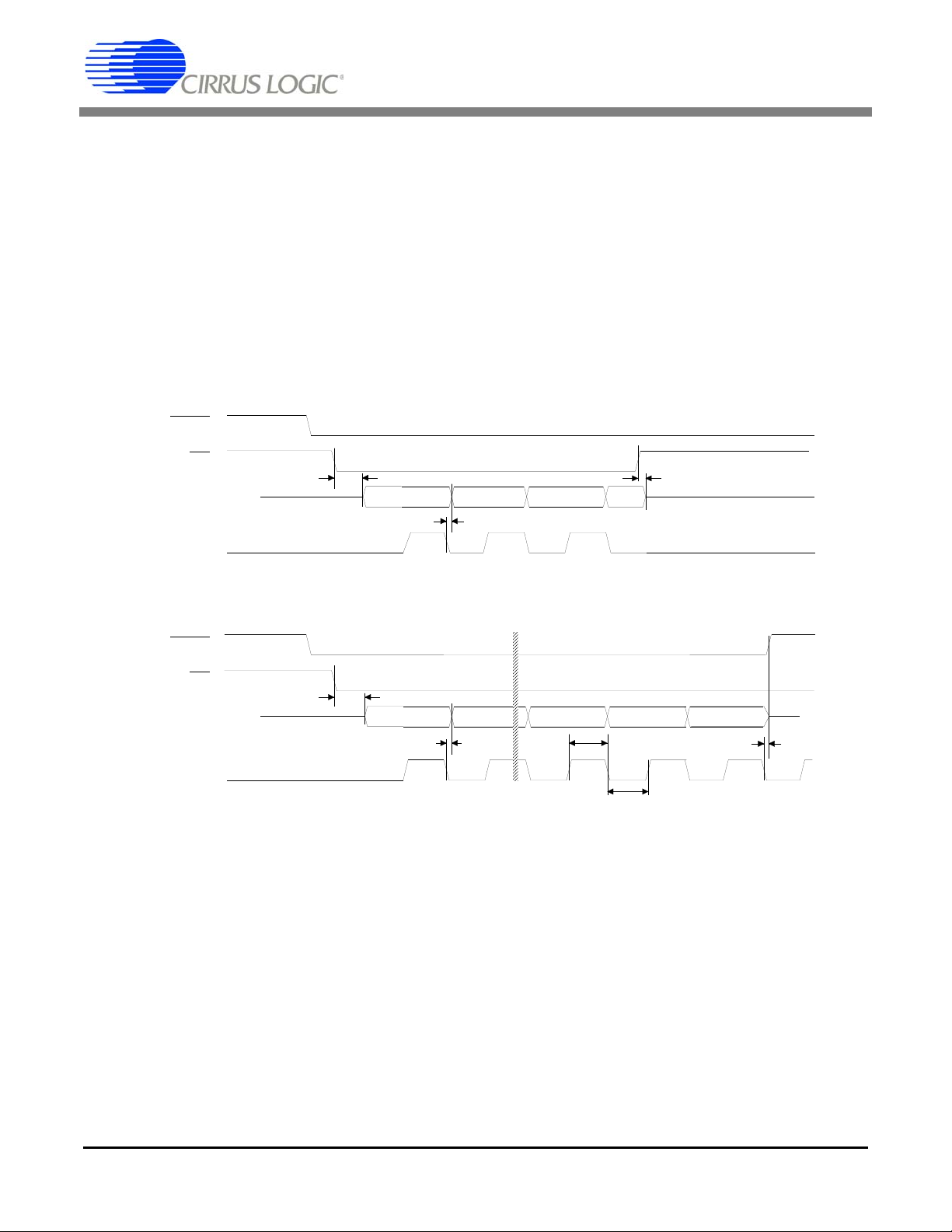

SCLK(i)

MSB-1MSB MSB-2SDATA(o) Hi-Z

MSB-1MSB LSB+2 LSB+1 LSB

SCLK(i)

SDATA(o) Hi-Z

t

fd1

t

csd

t

dd

t

ph

t

pl

t

dd

t

csd

CS

CS

DRDY

DRDY

t

fd2

Figure 3. Timing Relationships (Not to Scale)

8 DS125F3

Page 9

CS5509

RECOMMENDED OPERATING CONDITIONS (DGND = 0V) (Note 19)

Parameter Symbol Min Typ Max Unit

DC Power Supplies Positive Digital

Positive Analog

Analog Reference Voltage (Note 20)

Analog Input Voltage (Note 6)

Unipolar

Bipolar

Notes: 19. All voltages with respect to ground.

20. The CS5509 can be operated with a reference voltage as low as 100 mV; but with a corresponding

reduction in noise-free resolution. The common mode voltage of the voltage r eference may be any value

as long as +VREF and -VREF remain inside the supply values of VA+ and GND.

ABSOLUTE MAXIMUM RATINGS*

Parameter Symbol Min Typ Max Unit

DC Power Supplies Ground (Note 21)

Positive Digital (Note 22)

Positive Analog

Input Current, Any Pin Except Supplies (Notes 23 and 24)

Output Current

Power Dissipation (Total) (Note 25) - - 500 mW

Analog Input Voltage AIN and VREF pins

Digital Input Voltage

Ambient Operating Temperature

Storage Temperature

VD+

VA+

(VREF+) -

(VREF-) 1.0 2.5 3.6 V

VAIN

VAIN

-((VREF+) - (VREF-))--

3.15

4.75

0

GND

VD+

VA+

I

V

V

T

I

in

out

INA

IND

T

stg

5.0

5.0

(VREF+) - (VREF-)

(VREF+) - (VREF-)

-0.3

-0.3

-0.3

--±10mA

--±25mA

-0.3 - (VA+)+0.3 V

-0.3 - (VD+)+0.3 V

A

-40 - 85 °C

-65 - 150 °C

-

-

-

5.5

5.5

(VD+)-0.3

6.0

6.0

V

V

V

V

V

V

V

Notes: 21. No pin should go more positive than (VA+) + 0.3 V.

22. VD+ must always be less than (VA+) + 0.3 V, and can never exceed +6.0 V.

23. Applies to all pins including continuous overvoltage conditions at the analog input (AIN) pin.

24. Transient currents of up to 100 mA will not cause SCR latch-up. Maximum input current for a power

supply pin is ± 50 mA.

25. Total power dissipation, including all input currents and output currents.

*WARNING:Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

DS125F3 9

Page 10

CS5509

GENERAL DESCRIPTION

The CS5509 is a low power, 16-bit, monolithic

CMOS A/D converter designed specifically for

measurement of dc signals. The CS5509 includes a

delta-sigma charge-balance converter, a voltage

reference, a calibration microcontroller with

SRAM, a digital filter and a serial interface.

The CS5509 is optimized to operate from a 32.768

kHz crystal but can be driven by an external clock

whose frequency is between 30kHz and 330kHz.

When the digital filter is operated with a 32.768

kHz clock, the filter has zeros precisely at 50 and

60 Hz line frequencies and multiples thereof.

The CS5509 uses a "start convert" command to

start a convolution cycle on the digital filter. Once

the filter cycle is completed, the output port is updated.When operated with a 32.768kHz clock the

ADC converts and updates its output port at 20

samples/sec.The output port operates in a synchronous externally-clocked interface format.

THEORY OF OPERATION

Basic Converter Operation

The CS5509 A/D converter has three operating

states. These are stand-by, calibration, and conversion. When power is first applied, an internal power-on reset delay of about 10 ms resets all of the

logic in the device. The oscillator must then begin

oscillating before the device can be considered

functional. After the power-on reset is applied, the

device enters the wake-up period for 1800 clock

cycles after clock is present. This allows the deltasigma modulator and other circuitry (which are operating with very low currents) to reach a stable

bias condition prior to entering into either the calibration or conversion states. During the 1800 cycle

wake-up period, the device can accept an input

command. Execution of this command will not occur until the complete wake-up period elapses. If

no command is given, the device enters the standby

state.

Calibration

After the initial application of power, the CS5509

must enter the calibration state prior to performing

accurate conversions. During calibration, the chip

executes a two-step process. The device first performs an offset calibration and then follows this

with a gain calibration. The two calibration steps

determine the zero reference point and the full scale

reference point of the converter's transfer function.

From these points it calibrates the zero point and a

gain slope to be used to properly scale the output

digital codes when doing conversions.

The calibration state is entered whenever the CAL

and CONV pins are high at the same time. The state

of the CAL and CONV pins at power-on are recognized as commands, but will not be executed until

the end of the 1800 clock cycle wake-up period.

If CAL and CONV become active (high) during the

1800 clock cycle wake-up time, the converter will

wait until the wake-up period elapses before executing the calibration. If the wake-up time has

elapsed, the converter will be in the standby mode

waiting for instruction and will enter the calibration

cycle immediately if CAL and CONV become active. The calibration lasts for 3246 clock cycles.

Calibration coefficients are then retained in the

SRAM (static RAM) for use during conversion.

The state of BP/UP is ignored during calibration

but should remain stable throughout the calibration

period to minimize noise.

When conversions are performed in unipolar mode

or in bipolar mode, the converter uses the same calibration factors to compute the digital output code.

The only difference is that in bipolar mode the onchip microcontroller offsets the computed output

word by a code value of 8000H. This means that the

bipolar measurement range is not calibrated from

full scale positive to full scale negative. Instead it is

calibrated from the bipolar zero scale point to full

scale positive. The slope factor is then extended below bipolar zero to accommodate the negative in-

10 DS125F3

Page 11

CS5509

put signals. The converter can be used to convert

both unipolar and bipolar signals by changing the

BP/UP pin. Recalibration is not required when

switching between unipolar and bipolar modes.

At the end of the calibration cycle, the on-chip microcontroller checks the logic state of the CONV

signal. If the CONV input is low the device will enter the standby mode where it waits for further instruction. If the CONV signal is high at the end of

the calibration cycle, the converter will enter the

conversion state and perform a conversion on the

input channel. The CAL signal can be returned low

any time after calibration is initiated. CONV can

also be returned low, but it should never be taken

low and then taken back high until the calibration

period has ended and the converter is in the standby

state. If CONV is taken low and then high again

with CAL high while the converter is calibrating,

the device will interrupt the current calibration cycle and start a new one. If CAL is taken low and

CONV is taken low and then high during calibration, the calibration cycle will continue as the conversion command is disregarded. The state of

BP/UP is not important during calibrations.

If an "end of calibration" signal is desired, pulse the

CAL signal high while leaving the CONV signal

high continuously. Once the calibration is completed, a conversion will be performed. At the end of

the conversion, DRDY will fall to indicate the first

valid conversion after the calibration has been

completed.

The BP/UP pin is not a latched input. The BP/UP

pin controls how the output word from the digital

filter is processed. In bipolar mode the output word

computed by the digital filter is offset by 8000H

(see Understanding Converter Calibration). BP/UP

can be changed after a conversion is started as long

as it is stable for 82 clock cycles of the conversion

period prior to DRDY falling. If one wishes to intermix measurement of bipolar and unipolar signals

on various input signals, it is best to switch the

BP/UP pin immediately after DRDY falls and

leave BP/UP

The digital filter in the CS5509 has a Finite Impulse Response and is designed to settle to full accuracy in one conversion time.

If CONV is left high, the CS5509 will perform continuous conversions. The conversion time will be

1622 clock cycles. If conversion is initiated from

the standby state, there may be up to two XIN clock

cycles of uncertainty as to when conversion actually begins. This is because the internal logic operates at one half the external clock rate and the exact

phase of the internal clock may be 180° out of

phase relative to the XIN clock. When a new conversion is initiated from the standby state, it will

take up to two XIN clock cycles to begin. Actual

conversion will use 1624 clock cycles before

DRDY

been updated. See the Serial Interface Logic section of the data sheet for information on reading

data from the serial port.

stable until DRDY falls again.

goes low to indicate that the serial port has

Conversion

The conversion state can be entered at the end of

the calibration cycle, or whenever the converter is

idle in the standby mode. If CONV is taken high to

initiate a calibration cycle ( CAL also high), and remains high until the calibration cycle is completed

(CAL is taken low after CONV transitions high),

the converter will begin a conversion upon completion of the calibration period.

DS125F3 11

In the event the A/D conversion command (CONV

going positive) is issued during the conversion

state, the current conversion will be terminated and

a new conversion will be initiated.

Voltage Reference

The CS5509 uses a differential voltage reference

input. The positive input is VREF+ and the negative input is VREF-. The voltage between VREF+

and VREF- can range from 1 volt minimum to 3.6

volts maximum. The gain slope will track changes

Page 12

CS5509

FFFF

FFFE

--------------- -

8000

7FFF

-------------- -

0001

0000

------------ -

in the reference without recalibration, accommodating ratiometric applications.

Analog Input Range

The analog input range is set by the magnitude of

the voltage between the VREF+ and VREF- pins.

In unipolar mode the input range will equal the

magnitude of the voltage reference. In bipolar

mode the input voltage range will equate to plus

and minus the magnitude of the voltage reference.

While the voltage reference can be as great as 3.6

volts, its common mode voltage can be any value as

long as the reference inputs VREF+ and VREFstay within the supply voltages VA+ and GND.

The differential input voltage can also have any

common mode value as long as the maximum signal magnitude stays within the supply voltages.

The A/D converter is intended to measure dc or low

frequency inputs. It is designed to yield accurate

conversions even with noise exceeding the input

voltage range as long as the spectral components of

this noise will be filtered out by the digital filter.

For example, with a 3.0 volt reference in unipolar

mode, the converter will accurately convert an input dc signal up to 3.0volts with up to 15% overrange for 60Hz noise. A 3.0volt dc signal could

have a 60Hz component which is 0.5volts above

the maximum input of 3.0 (3.5 volts peak; 3.0 volts

dc plus 0.5 volts peak noise) and still accurately

convert the input signal (XIN = 32.768 kHz). This

assumes that the signal plus noise amplitude stays

within the supply voltages.

The CS5509 converters output data in binary format when converting unipolar signals and in offset

binary format when converting bipolar signals. Table 1 outlines the output coding for both unipolar

and bipolar measurement modes.

Converter Performance

The CS5509 A/D converter has excellent linearity

performance. Calibration minimizes the errors in

Unipolar Input

Voltage

> (VREF - 1.5 LSB)

VREF - 1.5 LSB VREF - 1.5 LSB

VREF/2 - 0.5 LSB -0.5 LSB

+0.5 LSB -VREF + 0.5 LSB

< (+0.5 LSB)

Note: T able excludes commo n mode voltage on the

signal and reference inputs.

Table 1. Output Coding

Output

Codes

FFFF

0000

Bipolar Input

Voltage

> (VREF - 1.5 LSB)

< (-VREF + 0.5 LSB)

offset and gain. The CS5509 device has no missing

code performance to 16-bits. Figure4 illustrates the

DNL of the CS5509. The converter achieves Common Mode Rejection (CMR) at dc of 105dB typical, and CMR at 50 and 60Hz of 120dB typical.

The CS5509 can experience some drift as temperature changes. The CS5509 uses chopper-stabilized

techniques to minimize drift. Measurement errors

due to offset or gain drift can be eliminated at any

time by recalibrating the converter.

Analog Input Impedance Considerations

The analog input of the CS5509 can be modeled as

illustrated in Figure 5. Capacitors (15 pF each) are

used to dynamically sample each of the inputs

(AIN+ and AIN-). Every half XIN cycle the switch

alternately connects the capacitor to the output of

the buffer and then directly to the AIN pin. Whenever the sample capacitor is switched from the output of the buffer to the AIN pin, a small packet of

charge (a dynamic demand of current) is required

from the input source to settle the voltage of the

sample capacitor to its final value. The voltage on

the output of the buffer may differ up to 100 mV

from the actual input voltage due to the offset voltage of the buffer. Timing allows one half of a XIN

clock cycle for the voltage on the sample capacitor

to settle to its final value.

12 DS125F3

Page 13

CS5509

Figure 4. CS5509 Differential Nonlinearity Plot

+

15 pF

V

os

≤

100 mV

+

V

os

≤

100 mV

Internal

Bias

Voltage

15 pF

AIN+

AIN-

-

-

Figure 5. Analog Input Model

Rs

max

1–

2XIN 15pF C

EXT

+()

V

e

V

e

15pF 100mV()

15pF C

EXT

+

-------------------------------------+

---------------------------------------------------

ln

-------------------------------------------------------------------------------------------------------------------------=

The VREF+ and VREF- inputs have nearly the

same structure as the AIN+ and AIN- inputs.

Therefore, the discussion on analog input impedance applies to the voltage reference inputs as well.

Digital Filter Characteristics

The digital filter in the CS5509 is the combination

of a comb filter and a low pass filter. The comb filter has zeros in its transfer function which are optimally placed to reject line interference frequencies

(50 and 60 Hz and their multiples) when the

CS5509 is clocked at 32.768 kHz. Figures 6, 7 and

An equation for the maximum acceptable source

resistance is derived.

This equation assumes that the offset voltage of the

buffer is 100 mV, which is the worst case. The value of Ve is the maximum error voltage which is acceptable. C

is the combination of any external

EXT

or stray capacitance.

For a maximum error voltage (Ve) of 10 µV in the

CS5509 (1/4LSB at 16-bits), the above equation indicates that when operating from a 32.768 kHz

XIN, source resistances up to 110 kΩ are acceptable in the absence of external capacitance

(C

DS125F3 13

=0).

EXT

8 illustrate the magnitude and phase characteristics

of the filter. Figure 6 illustrates the filter attenuation from dc to 260 Hz. At exactly 50, 60, 100, and

120 Hz the filter provides over 120 dB of rejection.

Table 2 indicates the filter attenuation for each of

the potential line interference frequencies when the

converter is operating with a 32.768 kHz clock.

The converter yields excellent attenuation of these

interference frequencies even if the fundamental

line frequency should vary ± 1% from its specified

frequency. The -3 dB corner frequency of the filter

when operating from a 32.768 kHz clock is 17 Hz.

Figure 8 illustrates that the phase characteristics of

the filter are precisely linear phase.

If the CS5509 is operated at a clock rate other than

32.768kHz, the filter characteristics, including the

comb filter zeros, will scale with the operating

clock frequency. Therefore, optimum rejection of

Page 14

CS5509

0

0

40

402.8380805.66

120

1208.5

160

1611.3

200

2014.2

240

2416.9

Frequency (Hz)

-160

-140

-120

-100

-80

-60

-40

-20

0

Atte nua tion (d B)

XIN = 32.768 kHz

X1

X2

X1 = 32.768kHz

X2 = 330.00kHz

Figure 6. Filter Magnitude Plot to 260 Hz

0 5

10 15 20 25 30 35 40 45 50

Frequency (Hz)

-140

-120

-100

-80

-60

-40

-20

0

Attenuation (dB)

Flatness

dB

-0.010

-0.041

-0.093

-0.166

-0.259

-0.510

-0.667

-0.846

-1.047

-3.093

1

2

3

4

5

6

7

8

9

10

17

XIN = 32.768 kHz

Frequency

-0.374

Figure 7. Filter Magnitude Plot to 50 Hz

05

10 15 20 25 30 35 40 45 50

Frequency (Hz)

-180

-135

-90

-45

0

45

90

135

180

Phase (Degrees)

XIN = 32.768 kHz

Figure 8. Filter Phase Plot to 50 Hz

line frequency interference will occur with the

CS5509 running at 32.768kHz.

14 DS125F3

Frequency

(Hz)

50

Notch

Depth

(dB)

125.6

Frequency

(Hz)

Minimum

Attenuation

50 ±1% 55.5

(dB)

60 126.7 60 ±1% 58.4

100 145.7 100 ±1% 62.2

120 136.0 120 ±1% 68.4

150

180

200

240

T able 2. Filter Notch Attenuation (XIN = 32.768 kHz)

118.4

132.9

102.5

108.4

150 ±1% 74.9

180 ±1% 87.9

200 ±1% 94.0

240 ±1% 104.4

Anti-Alias Considerations for Spectral Measurement Applications

Input frequencies greater than one half the output

word rate (CONV = 1) may be aliased by the converter. To prevent this, input signals should be limited in frequency to no greater than one half the

output word rate of the converter (when CONV

=1). Frequencies close to the modulator sample rate

(XIN/2) and multiples thereof may also be aliased.

If the signal source includes spectral components

above one half the output word rate (when CONV

= 1) these components should be removed by

means of low-pass filtering prior to the A/D input

Page 15

CS5509

to prevent aliasing. Spectral components greater

than one half the output word rate on the VREF inputs (VREF+ and VREF-) may also be aliased. Filtering of the reference voltage to remove these

spectral components from the reference voltage is

desirable.

Crystal Oscillator

The CS5509 is designed to be operated using a

32.768kHz "tuning fork" type crystal. One end of

the crystal should be connected to the XIN input.

The other end should be attached to XOUT. Short

lead lengths should be used to minimize stray capacitance.

Over the industrial temperature range (-40 to

+85 °C) the on-chip gate oscillator will oscillate

with other crystals in the range of 30kHz to 53 kHz.

The chip will operate with external clock frequencies from 30kHz to 330kHz over the industrial temperature range. The 32.768 kHz crystal is normally

specified as a time-keeping crystal with tight specifications for both initial frequency and for drift

over temperature. To maintain excellent frequency

stability, these crystals are specified only over limited operating temperature ranges (i.e. -10 °C to

+60 °C) by the manufacturers. Applications of

these crystals with the CS5509 does not require

tight initial tolerance or low tempco drift. Therefore, a lower cost crystal with looser initial tolerance and tempco will generally be adequate for use

with the CS5509. Also check with the manufacturer about wide temperature range application of

their standard crystals. Generally, even those crystals specified for limited temperature range will operate over much larger ranges if frequency stability

over temperature is not a requirement. The frequency stability can be as bad as ±3000 ppm over the

operating temperature range and still be typically

better than the line frequency (50 Hz or 60Hz) stability over cycle-to-cycle during the course of a

day.

Serial Interface Logic

The digital filter in the CS5509 takes 1624 clock

cycles to compute an output word once a conversion begins. At the end of the conversion cycle, the

filter will attempt to update the serial port. Two

clock cycles prior to the update DRDY will go

high. When DRDY goes high just prior to a port update it checks to see if the port is either empty or

unselected (CS = 1). If the port is empty or unselected, the digital filter will update the port with a

new output word. When new data is put into the

port DRDY will go low.

Reading Serial Data

SDATA is the output pin for the serial data. When

CS goes low after new data becomes available

(DRDY goes low), the SDATA pin comes out of

Hi-Z with the MSB data bit present. SCLK is the

input pin for the serial clock. If the MSB data bit is

on the SDATA pin, the first rising edge of SCLK

enables the shifting mechanism. This allows the

falling edges of SCLK to shift subsequent data bits

out of the port. Note that if the MSB data bit is output and the SCLK signal is high, the first falling

edge of SCLK will be ignored because the shifting

mechanism has not become activated. After the

first rising edge of SCLK, each subsequent falling

edge will shift out the serial data. Once the LSB is

present, the falling edge of SCLK will cause the

SDATA output to go to Hi-Z and DRDY

high. The serial port register will be updated with a

new data word upon the completion of another conversion if the serial port has been emptied, or if the

CS is inactive (high).

CS

can be operated asynchronously to the DRDY

signal. The DRDY signal need not be monitored as

long as the CS signal is taken low for at least two

XIN clock cycles plus 200ns prior to SCLK being

toggled. This ensures that CS has gained control

over the serial port.

to return

DS125F3 15

Page 16

CS5509

Power Supplies and Grounding

The analog and digital supply pins to the CS5509

are brought out on separate pins to minimize noise

coupling between the analog and digital sections of

the chip. In the digital section of the chip the supply

current flows into the VD+ pin and out of the GND

pin. As a CMOS device, the CS5509 requires that

the supply voltage on the VA+ pin always be more

positive than the voltage on any other pin of the device. If this requirement is not met, the device can

latch-up or be damaged. In all circumstances the

VA+ voltage must remain more positive than the

VD+ or GND pins; VD+ must remain more positive than the GND pin.

Figure 9a illustrates the System Connection Diagram for the CS5509. Note that all supply pins are

bypassed with 0.1 µF capacitors and that the VD+

digital supply is derived from the VA+ supply. Figure 9b illustrates the CS5509 operating from a +5V

analog supply and +3.3V digital supply.

When using separate supplies for VA+ and VD+,

VA+ must be established first. VD+ should never

become more positive than VA+ under any operating condition. Remember to investigate transient

power-up conditions, when one power supply may

have a faster rise time.

16 DS125F3

Page 17

CS5509

CS5509

+5V

Analog

Supply

VD+VA+

VREF+

VREF-

GND

0.1 µF 0.1 µF

8

7

9

10

11

12

13

+

-

Analog

Signal

AIN+

AIN-

SCLK

SDATA

14

15

XIN

XOUT

16

DRDY

CAL

3

1

CS

CONV

2

6

BP/UP

4

5

32.768 kHz

10

Ω

Voltage

Reference

Optional

Clock

Source

Serial

Data

Interface

Control

Logic

Figure 9a. System Connection Diagram Using a Single Supply

DS125F3 17

Page 18

CS5509

CS5509

+5V

Analog

Supply

VD+VA+

VREF+

VREF-

GND

0.1 µF 0.1 µF

8

7

9

10

11

12

13

+

-

Analog

Signal

AIN+

AIN-

SCLK

SDATA

14

15

XIN

XOUT

16

DRDY

CAL

3

1

CS

CONV

2

6

BP/UP

4

5

32.768 kHz

Voltage

Reference

Optional

Clock

Source

Serial

Data

Interface

Control

Logic

+3.3V to +5V

Digital

Supply

Note: VD+ must never be more positive than VA+

Figure 9b. System Connection Diagram Using Split Supplies

18 DS125F3

Page 19

PIN DESCRIPTIONS*

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DRDY

SDATA

SCLK

VD+

GND

VA+

VREFVREF+AIN-

AIN+

BP/UP

XOUT

XIN

CAL

CONV

CS

DIFFERENTIAL ANALOG INPUT

DIFFERENTIAL ANALOG INPUT

BIPOLAR / UNIPOLAR

CRYSTAL OUT

CRYSTAL IN

CALIBRATE

CONVERT

CHIP SELECT DATA READY

SERIAL DATA OUTPUT

SERIAL CLOCK INPUT

POSITIVE DIGITAL POWER

GROUND

POSITIVE ANALOG POWER

VOLTAGE REFERENCE INPUT

VOLTAGE REFERENCE INPUT

* Pinout applies to both PDIP and SOIC

Clock Generator

CS5509

XIN; XOUT - Crystal In; Crystal Out, Pins 4, 5.

A gate inside the chip is connected to these pins and can be used with a crystal to provide the

master clock for the device. Alternatively, an external (CMOS compatible) clock can be

supplied into the XIN pin to provide the master clock for the device. Loss of clock will put the

device into a lower powered state (approximately 70% power reduction).

Serial Output I/O

CS - Chip Select, Pin 1.

This input allows an external device to access the serial port.

DRDY - Data Ready, Pin 16.

Data Ready goes low at the end of a digital filter convolution cycle to indicate that a new

output word has been placed into the serial port. DRDY

shifted out of the serial port or two master clock cycles before new data becomes available if

the CS pin is inactive (high).

SDATA - Serial Data Output, Pin 15.

SDATA is the output pin of the serial output port. Data from this pin will be output at a rate

determined by SCLK. Data is output MSB first and advances to the next data bit on the falling

edges of SCLK. SDATA will be in a high impedance state when not transmitting data.

SCLK - Serial Clock Input, Pin 14.

DS125F3 19

A clock signal on this pin determines the output rate of the data from the SDATA pin. This pin

must not be allowed to float.

will return high after all data bits are

Page 20

Control Input Pins

CAL - Calibrate, Pin 3.

When taken high the same time that the CONV pin is taken high the converter will perform a

self-calibration which includes calibration of the offset and gain scale factors in the converter.

CONV - Convert, Pin 2.

The CONV pin initiates a calibration cycle if it is taken from low to high while the CAL pin is

high, or it initiates a conversion if it is taken from low to high with the CAL pin low. If CONV

is held high (CAL low) the converter will do continuous conversions.

BP/UP - Bipolar/Unipolar, Pin 6.

CS5509

The BP/UP

convert bipolar input signals; when low it will convert unipolar input signals.

Measurement and Reference Inputs

AIN+, AIN- - Differential Analog Inputs, Pins 7, 8.

Analog differential inputs to the delta-sigma modulator.

VREF+, VREF- - Differential Voltage Reference Inputs, Pins 9, 10.

A differential voltage reference on these pins operates as the voltage reference for the

converter. The voltage between these pins can be any voltage between 1.0 and 3.6 volts.

Power Supply Connections

VA+ - Positive Analog Power, Pin 11.

Positive analog supply voltage. Nominally +5 volts.

VD+ - Positive Digital Power, Pin 13.

Positive digital supply voltage. Nominally +5 volts or +3.3 volts.

pin selects the conversion mode of the converter. When high the converter will

GND - Ground, Pin 12.

Ground.

20 DS125F3

Page 21

SPECIFICATION DEFINITIONS

Linearity Error

The deviation of a code from a straight line which connects the two endpoints of the A/D

Converter transfer function. One endpoint is located 1/2 LSB below the first code transition and

the other endpoint is located 1/2 LSB beyond the code transition to all ones. Units in percent of

full-scale.

Differential Nonlinearity

The deviation of a code's width from the ideal width. Units in LSBs.

Full Scale Error

The deviation of the last code transition from the ideal [{(VREF+) - (VREF-)} - LSB]. Units

are in LSBs.

Unipolar Offset

The deviation of the first code transition from the ideal ( LSB above the voltage on the AINpin.) when in unipolar mode (BP/UP low). Units are in LSBs.

CS5509

Bipolar Offset

The deviation of the mid-scale transition (011...111 to 100...000) from the ideal ( LSB below

the voltage on the AIN- pin.) when in bipolar mode (BP/UP high). Units are in LSBs

DS125F3 21

Page 22

PACKAGE DIMENSIONS

SOIC

MILLIMETERS

INCHES

MIN MAX

MAX

MIN

0.095

0.105

2.41

2.67

0.008

0.015

0.203

0.381

0.398

0.420

10.11

10.67

0.0200.013

0.51

0.33

0.016

0.035

0.41

0.89

8°0°

0°

8°

MILLIMETERS

INCHES

MIN

MAX MAX

MIN

pins

0.410

0.390

9.91

10.41

16

0.510

0.490

12.45

12.95

20

0.610

0.590

14.99

15.50

24

0.710

0.690

17.53

18.03

28

0.0120.0050.127 0.300

1.14

0.040

DIM

E

E

b

L

D

e

A

A

c

0.292 0.298

7.42

7.57

D

E

E

1

e

A

A

b

1

A

2

c

L

µ

1

µ

1

1.40

0.055

A

2

see table above

NOM

2.54

0.280

10.41

0.46

-

-

NOM

10.16

12.70

15.24

17.78

-

7.49

1.27

2.29

2.542.41

NOM

0.100

0.011

0.410

0.018

-

-

NOM

0.400

0.500

0.600

0.700

-

0.295

0.050

0.1000.090 0.095

CS5509

22 DS125F3

Page 23

ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION

Model Peak Relfow Temp MSL Rating* Maximum Floor Life

CS5509-ASZ (lead free) 260 °C 3 7 Days

* MSL (Moisture Sensitivity Level) as specified by IPC/JEDEC J-STD-020.

CS5509

DS125F3 23

Page 24

REVISION HISTORY

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find the one nearest to you go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries (“Cirrus”) believe that the informati on contained in this document is accurate and reliable. However, the information is subject

to change without noti ce and is provide d “AS IS” wi thout wa rranty o f any ki nd (expre ss or impl ied). Cu stomers ar e advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledg ment, including those pe rtaining to warranty, ind emnification, an d limitation of liabili ty. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this inform atio n, Cirrus gr ants no license , express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual p roperty rights. Cirrus owns the cop yrights associated with the informatio n contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCT OR PRODUCT S MAY I NVOL VE POTE NTI A L RISK S OF DEATH, PE RS ONAL IN JURY , OR SE VERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE

IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RI SK AND

CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER OR

CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO

FULLY INDEMNIFY CIRRUS, I TS OFFICERS, DIRECTORS, EMPLOYEES, DIST RIBUT ORS AN D OTHE R AGENTS FRO M ANY A ND ALL LI ABILITY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE US ES .

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are tradem arks of Cirr us Log ic, Inc. All other brand an d prod uct nam es in this do cum ent m ay be tradem ar ks

or service marks of their respective owners.

Revision Date Changes

F1 Aug ‘97 First “final” release.

F2 Aug ‘05 Added lead-free device ordering info. Added legal notice. Added MSL data.

F3 Jul ‘09 Removed PDIP and leaded (Pb) devices from ordering information.

CS5509

24 DS125F3

Loading...

Loading...