Page 1

Power Source

U

n

I

b

CS5480

VIN 1+

VIN1-

N3

U3

CDB5480U

I3

PPS400.3

Power R eferen ce

U3

N3

I3

PRS400.3

Energy P ulses

+3.3V DC Power Supply

+3.3V GND

USB

M

C

U

DO1

TX

RX

PC

CDB5480U GUI

CAMCAL

®

for

WINDOWS

RS232

RS232

Current

Sensor

METE R

SH2003

IIN1-

IIN1+

27n

27n

1K100

1K100

27n

27n

GND

IIN1-

IIN1+

J1

V+

V-

GND

27n

27n

LINE 1

GND

J4

422K 422K 422K422K

1K

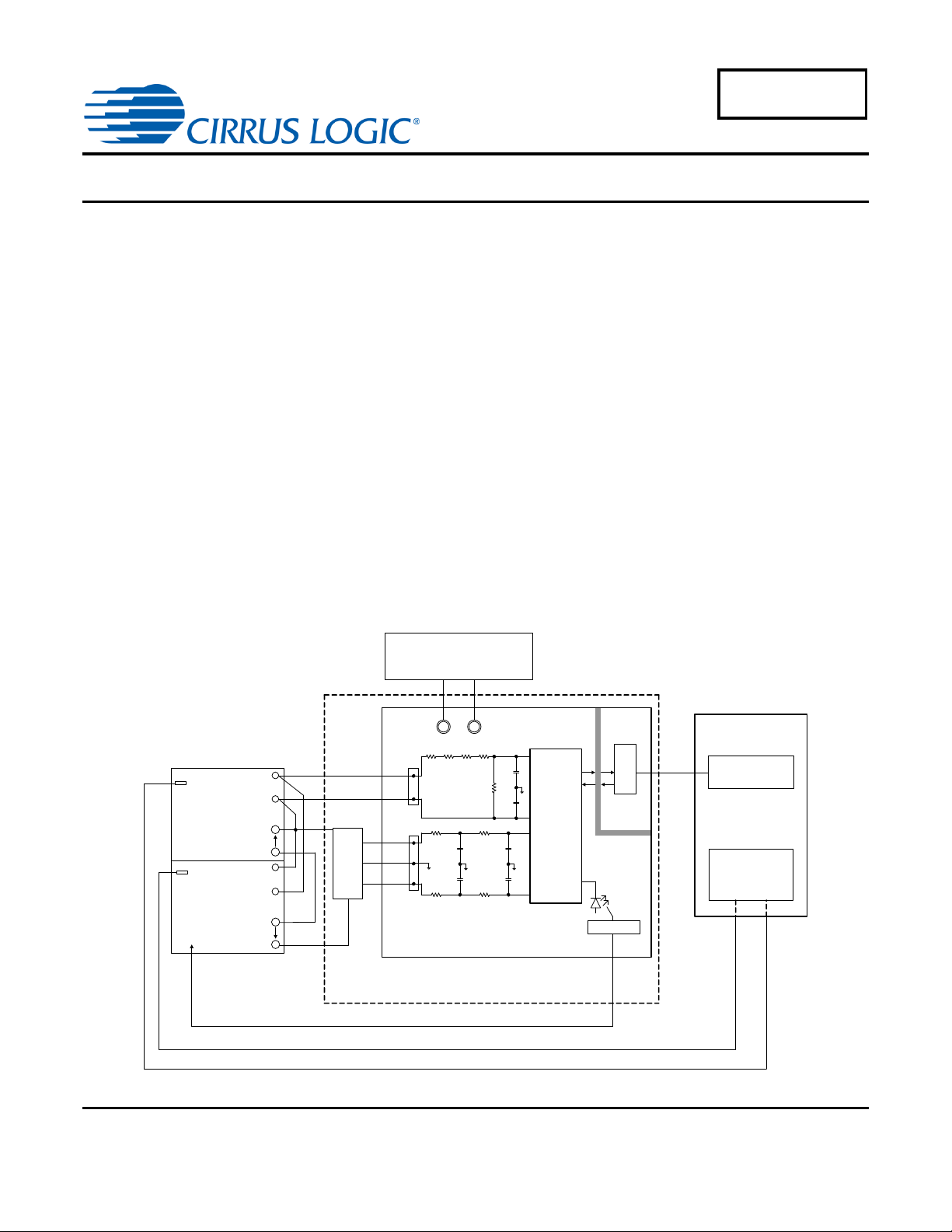

Figure 1. Test Setup Connection Diagram

AN362

Application Note

CS5480/84/90 Measurement Accuracy

vs. IEC Standards

1. Introduction

Cirrus Logic’s CS5480, CS5484, and CS5490 energy measurement ICs benefit from on-chip, high-performance, 24bit ADC converters in conjunction with its digital calibration and compensation algorithms. This application note presents accuracy results from testing the CS5480. The CS5484 and CS5490 uses the same core technology as the

CS5480. Testing results of the CS5484 and CS5490 show nearly identical results.

The CS5480 has world-leading accuracy over an extensive, dynamic range. This application note cites measurements of active energy, reactive energy, and I

types of current sensor: Rogowski coil, current transformer (CT), and shunt. A comparison between the CS5480

measurements and the IEC 62053 standards is presented. This comparison shows that the CS5480 meets IEC

62053-22 class 0,2S standards for active energy and IEC 62053-23 class 2 standards for reactive energy. Comparison with the ANSI C12.20 standard is not included in this application note because the ANSI standard is less stringent than the IEC 62053 standard, so it is implied that the CS5480 meets it.

load performance acquired from the CS5480 using three different

RMS

2. Test Setup

The following diagram illustrates the connections between the PPS400.3 power source, PRS400.3 power reference,

current sensor, CDB5480U board (+3.3V DC power supply), and a host PC.

Cirrus Logic, Inc.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2012

(All Rights Reserved)

MAR’12

AN362REV1

Page 2

AN362

The Cirrus Logic CDB5480U demonstration board and current sensor form a single-phase, two-wire energy meter.

The CDB5480U software is installed on a host PC and used to configure, calibrate, and control the meter using the

USB port. The software collects the measurement results from the CS5480 registers once per second. CAMCAL

for WINDOWS software controls the MTE Meter Test Equipment AG PPS400.3 power source and PRS400.3 power

reference using two COM ports. CAMCAL performs the active and reactive accuracy test procedure automatically.

The active or reactive energy pulses provided by the CS5480 drive the on-board LED using energy pulse output

DO1. The energy pulses are sensed by photoelectric scanning head SH2003 and directed back into PRS400.3. The

accuracy of the active and reactive energy is then measured by PRS400.3 and sent to the CAMCAL software. The

meter constant is 2000 impulses/ kWh, or 2000 impulses/ kVarh.

I

accuracy is manually calculated and based on a 10-second average using the I

RMS

register is read once per second using the CDB5480U software.

2.1Calibrations and Meter Types

Prior to the accuracy test, the following calibrations and compensations were performed:

• Gain calibration

• AC offset calibration

• Phase compensation

• Active and reactive power offset correction

Using the CDB5480U board with different current sensors forms different types of meters. To test the accuracy of

the CS5480, the following meters were formed:

register values. The I

RMS

RMS

®

• Rogowski coil meter, where U

• Current transformer (CT) meter, where U

• Shunt meter, where U

= 240V and I

n

= 240V and I

n

b(max)

= 2 (80A) at 50Hz

b(max)

= 240V and I

n

b(max)

= 2.5 (100A) at 50Hz

= 2.5 (100A) at 50Hz

All accuracy tests were conducted at room temperature. Influences from ambient temperature and self-heating are

not included.

Refer to Application Note 366, entitled CS5480/ 84 / 90 Power Meter Calibration, for more information about calibra-

tions and compensations.

Refer to the CDB5480U data sheet, entitled CDB5480U Engineering Board and GUI Software, for more information

about the CDB5480U board.

Refer to the CS5480 data sheet, entitled Three Channel Energy Measurement IC, for more information about the

CS5480.

2 AN362REV1

Page 3

AN362

CS5480

IIN 1-

IIN 1+

27nF

27nF

1K Ω100Ω

1KΩ100Ω

27nF

27nF

V+

V-

GND

GND

IIN1-

IIN1+

J1

Rogow s ki Coi l

PA 3202 NL

Current

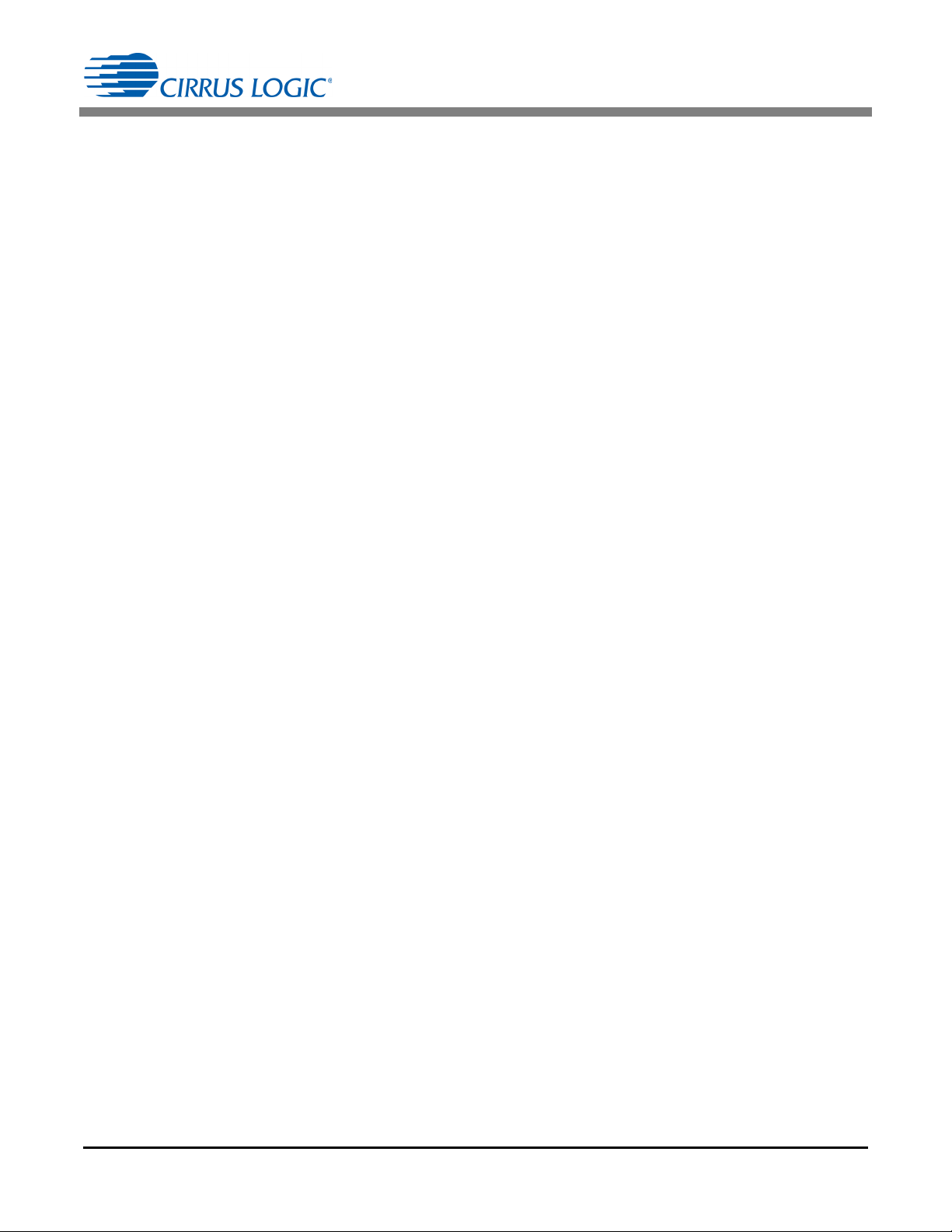

3. Accuracy Test with Rogowski Coil, Un = 240V and I

b(max)

= 2(80A) at 50Hz

Pulse PA3202NL is used as the current sensor. The secondary output voltage of PA3203NL is 416μV/A at

50Hz. When the meter is applied with the maximum load current, I

put is approximately 33 mV

, which is below the CS5480 maximum I-channel input range when setting the

RMS

= 80A, the Rogowski coil secondary out-

max

PGA for current channel 1 (I1) to 50x.

High-pass filter (HPF) is enabled on the voltage channel: V1FLT[1:0] = ‘01’

Integrator is enabled on the current channel: I1FLT[1:0] = ‘11’

Figure 2. Connection between Rogowski Coil and CS5480

AN362REV1 3

Page 4

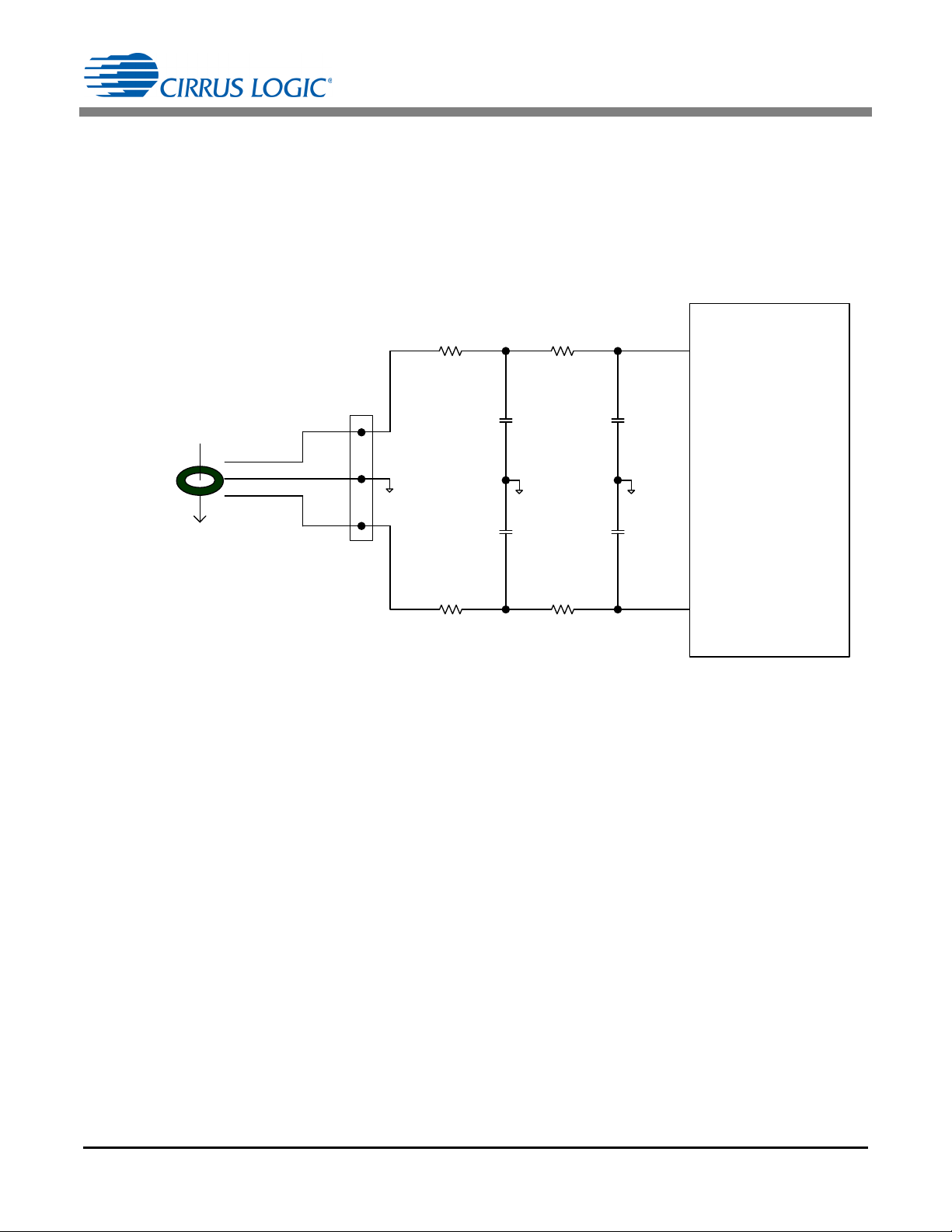

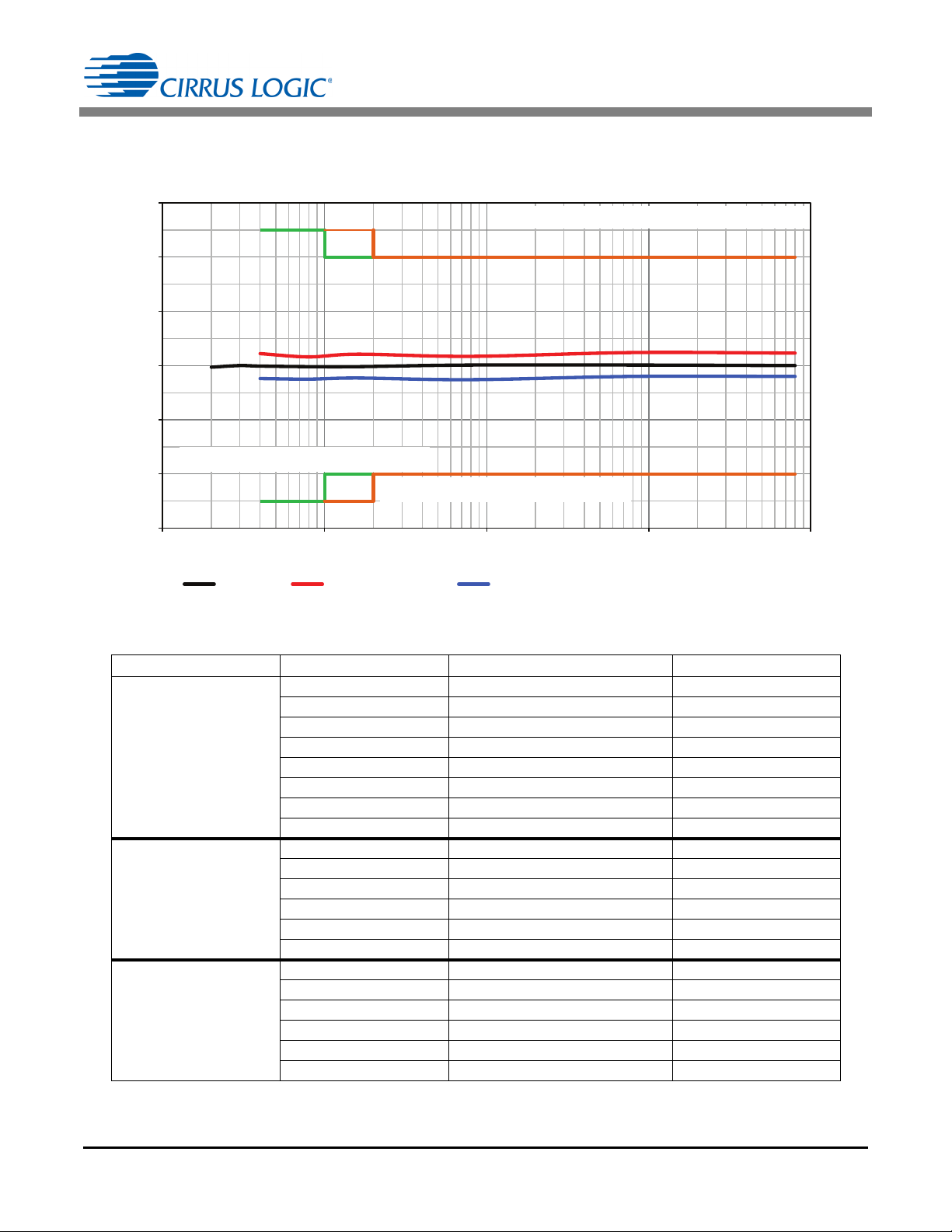

3.1Accuracy Results for Active Energy Load Performance

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.01 0.1 1 10 100

Percent Error (%)

Load Current (A)

PF = 1 Lagging PF = 0.5 Leading PF = 0.5

Note: CS5480, where Un = 240 V, I

b(max)

= 2 (80 A) at 50 Hz

IEC 62053-22 Class 0,2S Spec, Lagging PF = 0.5 or Leading PF = 0.8

IEC 62053-22 Class 0,2S Spec, PF = 1

AN362

Figure 3. Active Energy Load Performance vs. IEC 62053-22 Class 0,2S Standard

Power Factor Load Current (A) Current Dynamic Range (x:1) Error

80 1 0.04%

8 10 0.04%

0.8 100 0.04%

PF = 1

0.16 500 0.04%

0.08 1000 0.07%

0.04 2000 0.05%

0.03 3333 0.06%

0.02 4000 0.02%

80 1 0.05%

8 10 0.05%

Lagging PF = 0.5

0.8 100 0.04%

0.16 500 0.06%

0.08 1000 0.05%

0.04 2000 0.06%

80 1 0.04%

Leading PF = 0.5

8 10 0.04%

0.8 100 0.05%

0.16 500 0.04%

0.08 1000 0.05%

0.04 2000 0.07%

Table 1. Active Energy Load Performance

4 AN362REV1

Page 5

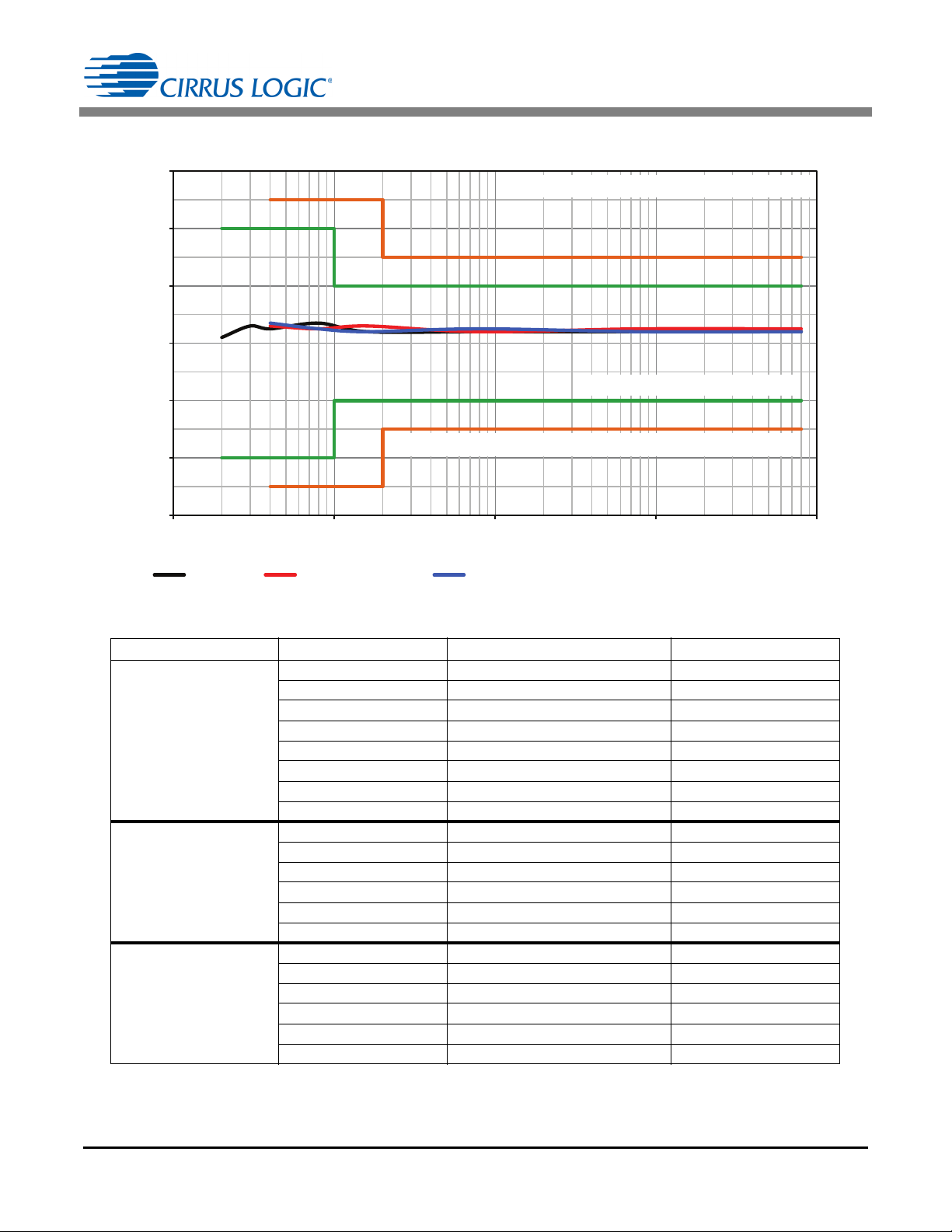

3.2Accuracy Results for Reactive Energy Load Performance

-3

-2

-1

0

1

2

3

0.01 0.1 1 10 100

Percent Error (%)

Load Current (A)

sin ࢥ = 1 Lagging sin ࢥ = 0.5 Leading sin ࢥ = 0.5

Note: CS5480, where Un = 240 V, I

b(max)

= 2 (80 A) at 50 Hz

IEC 62053-23 Class 2 Spec, sinࢥ = 0.5

IEC 62053-23 Class 2 Spec, sinࢥ = 1

AN362

Figure 4. Reactive Energy Load Performance vs IEC 62053-23 Class 2 Standard

Power Factor Load Current (A) Current Dynamic Range (x:1) Error

80 1 0.00%

8 10 0.01%

0.8 100 0.01%

sin = 1

0.16 500 -0.02%

0.08 1000 -0.02%

0.04 2000 -0.01%

0.03 3333 0.00%

Lagging sin = 0.5

0.02 4000 -0.03%

80 1 0.23%

8 10 0.24%

0.8 100 0.17%

0.16 500 0.21%

0.08 1000 0.16%

0.04 2000 0.22%

80 1 -0.20%

Leading sin = 0.5

8 10 -0.20%

0.8 100 -0.26%

0.16 500 -0.23%

0.08 1000 -0.25%

0.04 2000 -0.24%

Table 2. Reactive Energy Load Performance

AN362REV1 5

Page 6

AN362

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.1 1 10 100

Percent Error (%)

Load Current (A)

Note: CS5480, where Un = 240 V, I

b(max)

= 2 (80 A) at 50 Hz

3.3Accuracy Results for I

Load Current (A)

80 1 0.60011034 0.02%

8 10 0.06009873 0.02%

0.8 100 0.006001252 0.02%

0.16 500 0.001200491 0.04%

0.08 1000 0.000600857 0.14%

Load Current Performance

RMS

Figure 5. I

Current Dynamic

Range (x:1)

Table 3. I

Load Current Performance

RMS

I

(10-Second Average)

Load Current Performance

RMS

Register Value

RMS

I

RMS

Error

6 AN362REV1

Page 7

AN362

CS5480

IIN 1-

IIN 1+

1KΩ

1K Ω

V+

V-

IIN1-

IIN1+

J1

CT

TZ76V

Current

4Ω

1KΩ

1KΩ

27nF

27nF

4. Accuracy Test with Current Transformer CT, Un = 240V and I

b(max)

= 2.5(100A) at 50Hz

Taehwatrans TZ76V is used as the current sensor. The CT has the turn's ratio of 2500:1. Use 4Ω as the load

resistor. When the meter is applied with the maximum load current, I

is (100/2500) × 4 = 0.16 V

, which is below the maximum I-channel input range when setting the PGA for

RMS

= 100A, the secondary output voltage

max

current channel 1 (I1) to 10x.

High-pass filter (HPF) is enabled on the voltage channel: V1FLT[1:0] = ‘01’

High-pass filter (HPF) is enabled on the current channel: I1FLT[1:0] = ‘01’

Figure 6. Connection between Current Transformer CT and CS5480

AN362REV1 7

Page 8

4.1Accuracy Results for Active Energy Load Performance

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.01 0.1 1 10 100

Percent Error (%)

Load Current (A)

PF = 1 Lagging PF = 0.5 Leading PF = 0.5

IEC 62053-22 Class 0,2S Spec, PF = 1

IEC 62053-22 Class 0,2S Spec, Lagging PF = 0.5 or Leading PF = 0.8

Note: CS5480, where Un = 240 V, I

b(max)

= 2.5 (100 A) at 50 Hz

AN362

Figure 7. Active Energy Load Performance vs IEC 62053-22 Class 0,2S Standard

Power Factor Load Current (A) Current Dynamic Range (x:1) Error

100 1 0.04%

10 10 0.03%

1 100 0.04%

PF = 1

0.2 500 0.03%

0.1 1000 0.04%

0.05 2000 0.01%

0.03 3333 0.03%

0.025 4000 0.09%

100 1 -0.02%

10 10 0.07%

Lagging PF = 0.5

1 100 0.11%

0.2 500 0.11%

0.1 1000 0.09%

0.05 2000 0.05%

100 1 0.08%

10 10 0.00%

Leading PF = 0.5

1 100 -0.04%

0.2 500 -0.08%

0.1 1000 -0.14%

0.05 2000 -0.14%

Table 4. Active Energy Load Performance

8 AN362REV1

Page 9

4.2Accuracy Results for Reactive Energy Load Performance

-3

-2

-1

0

1

2

3

0.01 0.1 1 10 100

Percent Error (%)

Load Current (A)

sin ࢥ = 1 Lagging sin ࢥ = 0.5 Leading sin ࢥ = 0.5

Note: CS5480, where Un = 240 V, max = 2.5 (100 A) at 50 Hz

IEC 62053-23 Class 2 Spec, sinࢥ = 0.5

IEC 62053-23 Class 2 Spec, sinࢥ = 1

AN362

Figure 8. Reactive Energy Load Performance vs IEC 62053-23 Class 2 Standard

Power Factor Load Current (A) Current Dynamic Range (x:1) Error

100 1 -0.05%

10 10 -0.03%

1 100 -0.01%

sin = 1

0.2 500 -0.03%

0.1 1000 -0.02%

0.05 2000 -0.06%

0.03 3333 -0.06%

0.025 4000 -0.07%

100 1 0.28%

10 10 0.16%

Lagging sin = 0.5

1 100 0.11%

0.2 500 0.09%

0.1 1000 0.06%

0.05 2000 -0.08%

100 1 -0.29%

10 10 -0.21%

Leading sin = 0.5

1 100 -0.15%

0.2 500 -0.16%

0.1 1000 -0.16%

0.05 2000 -0.32%

Table 5. Reactive Energy Load Performance

AN362REV1 9

Page 10

AN362

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.01 0.1 1 10 100

Percent Error (%)

Load Current (A)

Note: CS5480, where Un = 240 V, I

b(max)

= 2.5 (100 A) at 50 Hz

4.3Accuracy Results for I

Load Current (A)

100 1 0.59990938 -0.02%

10 10 0.059996352 -0.01%

1 100 0.00600099 0.02%

0.2 500 0.001200253 0.02%

0.1 1000 0.000600082 0.01%

0.05 2000 0.000300026 0.01%

0.03 3333 0.00018006 0.03%

Load Current Performance

RMS

Figure 9. I

Current Dynamic

Range (x:1)

Table 6. I

Load Current Performance

RMS

I

(10-Second Average)

Load Current Performance

RMS

Register Value

RMS

I

RMS

Error

10 AN362REV1

Page 11

AN362

CS5480

IIN 1-

IIN 1+

1K Ω

1KΩ

27nF

27nF

V+

V-

IIN1-

IIN1+

J1

Shunt

100μΩ

Current

5. Accuracy Test with Shunt, Un = 240V and I

b(max)

= 2.5(100A) at 50Hz

A 100μΩ shunt is used as the current sensor. When the meter is applied with the maximum load current,

I

= 100A, the voltage output from the shunt is 10mV

max

, which is below the maximum I-channel input range

RMS

when setting the PGA for current channel 1 (I1) to 50 x.

High-pass filter (HPF) is enabled on the voltage channel: V1FLT[1:0] = ‘01’

High-pass filter (HPF) is enabled on the current channel: I1FLT[1:0] = ‘01’

Figure 10. Connection between Shunt and CS5480

AN362REV1 11

Page 12

5.1Accuracy Results for Active Energy Load Performance

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.01 0.1 1 10 100

Percent Error (%)

Load Current (A)

PF = 1 Lagging PF = 0.5 Leading PF = 0.5

IEC 62053-22 Class 0,2S Spec, PF = 1

IEC 62053-22 Class 0,2S Spec, Lagging PF = 0.5 or Leading PF = 0.8

Note: CS5480, where Un = 240 V, I

b(max)

= 2.5 (100 A) at 50 Hz

AN362

Figure 11. Active Energy Load Performance vs IEC 62053-22 Class 0,2S Standard

Power Factor Load Current (A) Current Dynamic Range (x:1) Error

100 1 0.02%

10 10 0.01%

1 100 0.02%

PF = 1

0.2 500 0.00%

0.1 1000 0.06%

0.05 2000 0.06%

0.03 3333 0.05%

0.025 4000 0.03%

100 1 -0.02%

10 10 0.02%

Lagging PF = 0.5

1 100 0.02%

0.2 500 -0.03%

0.1 1000 -0.02%

0.05 2000 0.04%

100 1 -0.01%

Leading PF = 0.5

10 10 0.01%

1 100 -0.04%

0.2 500 -0.09%

0.1 1000 -0.03%

0.05 2000 0.04%

Table 7. Active Energy Load Performance

12 AN362REV1

Page 13

AN362

-3

-2

-1

0

1

2

3

0.01 0.1 1 10 100

Percent Error (%)

Load Current (A)

sin ࢥ = 1 Lagging sin ࢥ = 0.5 Leading sin ࢥ = 0.5

Note: CS5480, where Un = 240 V, I

b(max)

= 2.5 (100 A) at 50 Hz

IEC 62053-23 Class 2 Spec, sinࢥ = 1

IEC 62053-23 Class 2 Spec, sinࢥ = 0.5

Figure 12. Reactive Energy Load Performance vs IEC 62053-23 Class 2 Standard

Power Factor Load Current (A) Current Dynamic Range (x:1) Error

100 1 -0.01%

10 10 -0.01%

1 100 -0.02%

sin = 1

0.2 500 -0.05%

0.1 1000 0.02%

0.05 2000 0.06%

0.03 3333 0.06%

0.025 4000 0.03%

100 1 0.20%

10 10 0.17%

Lagging sin = 0.5

1 100 0.19%

0.2 500 0.09%

0.1 1000 0.11%

0.05 2000 0.05%

100 1 -0.22%

10 10 -0.20%

Leading sin = 0.5

1 100 -0.23%

0.2 500 -0.26%

0.1 1000 -0.27%

0.05 2000 -0.35%

Table 8. Reactive Energy Load Performance

AN362REV1 13

Page 14

AN362

-0.30

-0.20

-0.10

0.00

0.10

0.20

0.30

0.1 1 10 100

Percent Error (%)

Load Current (A)

Note: CS5480, where Un = 240 V, I

b(max)

= 2.5 (100 A) at 50 Hz

5.2Accuracy Results for I

Load Current (A)

100 1 0.599839375 -0.03%

10 10 0.059990012 -0.02%

1 100 0.00599035 -0.02%

0.2 500 0.001199412 -0.05%

0.1 1000 0.000599265 -0.12%

Load Current Performance

RMS

Figure 13. I

Current Dynamic

Range (x:1)

Table 9. I

Load Current Performance

RMS

I

(10-Second Average)

Load Current Performance

RMS

Register Value

RMS

I

RMS

Error

6. Summary

The CS5480 supports three current sensors: Rogowski coil, current transformer, and shunt. It achieves 0.1% accuracy over 4000:1 dynamic range at PF = 1 for active energy and sin

energy load performance exceeds IEC 62053-22 class 0,2S specifications and IEC 62053-23 class 2 specifications,

respectively. The CS5480 is the best-in-class analog front-end device for high-accuracy electricity meters with extensive load range: I

14 AN362REV1

/ Ib ≥ 40.

max

ϕ = 1 for reactive energy. The active and reactive

Page 15

7. Revision History

Revision Date Changes

REV1 MAR 2012 Initial Release.

AN362

AN362REV1 15

Page 16

AN362

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find one nearest you go to http://www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without notice and is provided "AS IS" without warranty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE

IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK AND

CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER OR

CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO

FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, the Cirrus Logic logo designs, EXL Core, and the EXL Core logo design are trademarks of Cirrus Logic, Inc. All other brand and

product names in this document may be trademarks or service marks of their respective owners.

CAMCAL is a trademark or registered trademark of Energie-Messtechnik GmbH Meter Test Equipment AG.

16 AN362REV1

Loading...

Loading...