Page 1

AN31

Application Note

A Collection of Brid ge Transducer Digitizer Cir cuits

by

Jerome Johnston

Introduction

Bridge transducers are common in

instrumentation. This application note illustrates

some bridge transducer digitizer circuits which

use the CS5504/5/6/ 7/8/9 A/D converters and the

CS5516/20 A/D co nverters.

The CS5504/5/6/7/8 converters can be operated

with a variety of power supply arrangements;

including operating from a single +5 V supply;

operating from +5 and -5 analog supplies with

+3.3 V or +5 V on the digital supply; or

operating with an analog supply from +5 to

+11 V and a digi tal supply of +5 V.

The CS5509 can oper ate with +5 V on its analog

and digital supplies; or with +5 V analog and

+3.3 V digita l.

The CS5516 and CS5520 are A/D converters

optimized for bridge transducer applications and

are designed to operate from +5 and -5 V

supplies. Several circuits which utilize these

ADCs will be presented.

The applicatio n note is divi ded into two sections:

1. DC-excited bridge circuits.

2. AC-excited bridge circuits with a discu ssion

of the benefits of AC excitation.

Bridge Tran sducers

Bridge transducers are manufactured with

various technologies. The strain-sensing

elements which make up the bridge may be

made of diffused silicon, bonded silicon bars,

deposited thin film, or bonded foil materials.

The choice of technology will determine the

performance of the transducer, including the

sensitivity, the linearity, and the thermal

stability. Si licon-based gages hav e good linearity

with sensitivities between 3 mV/V and

20 mV/V, but tend to exhibit more drift as

temperature changes. Metal foil or thin film

gages have good linearity with sensitivities

between 1 mV/V and 4 mV/V. Precision bridge

transducers include some type of temperature

compensation as part of the bridge .

Most bridge circuits are excited with a dc

voltage, 10 v olts bei ng very common . With 10 V

excitation, the full scale signa ls from the various

transducers, can be as low as 10 mV to as high

as several hundred millivolts. When digitizing

these signals to high resolution (for discussion in

this application note, high resolution means

greater than 10,000 counts), one count can

represent a very small voltag e. It can be diffi cult

to amplify and digitize these low level bridge

transducer signals. Measurement performance

can be hindered by such things as amplifier

Crystal Semiconductor Corporation

P.O. Box 17847, Austin, TX 78760

(512) 445-7222 FAX 445-7581

http://www.crysta l.com

Copyright Crystal Semiconductor Corporation 1996

(All Rights Reserved)

JAN ’95

AN31REV3

1

Page 2

Bridge Transducer Digitizer Circuits

offset drift, amplifier noise (both thermal and

1/f), amplifier finite open loop gain, and

parasitic thermocouples. Parasitic thermocouples

are introduced any time two dissimilar metals

are connected. For example, using tin-lead solder

to solder a wire to a copper PC trace can

introduce an unwanted thermocouple junction

which changes as much as 3 µV/°C when

subjected t o temperat ure gradient s.

This application note will introduce some A/D

converter circuits which illustrate a number of

application ideas to the design engineer who

uses bridge transducers. In the AC-excited

bridge section, a number of design ideas will b e

introduced which offer very good solutions to

some of the problems encountered in low level

bridge measurement.

+5

5.23k

350350

100 pF

-

5k

350 350

40.2k

1k

Optional

Zero

Trim

5k

3 mV/V

Transducer

+

LTC1051

0.1

3

2

6

5

1

0.47

0.47

7

4

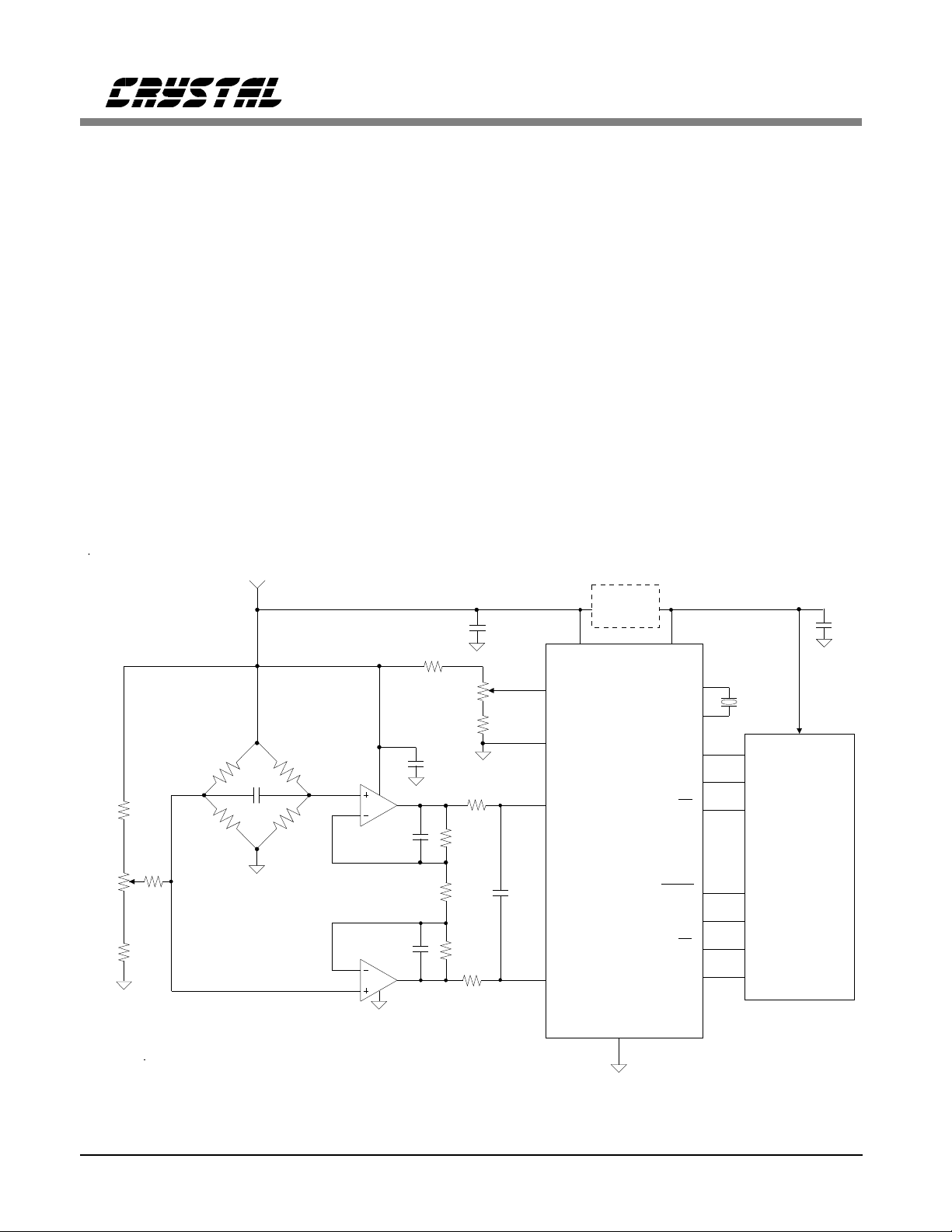

DC-EXCITED BRIDGE CIRCUITS

CS5507,8,9 Bridg e Transducer Operating

From a Single +5 V Supply, or with the

Analog Supply at +5 V and Digital Supply at

+3.3 V

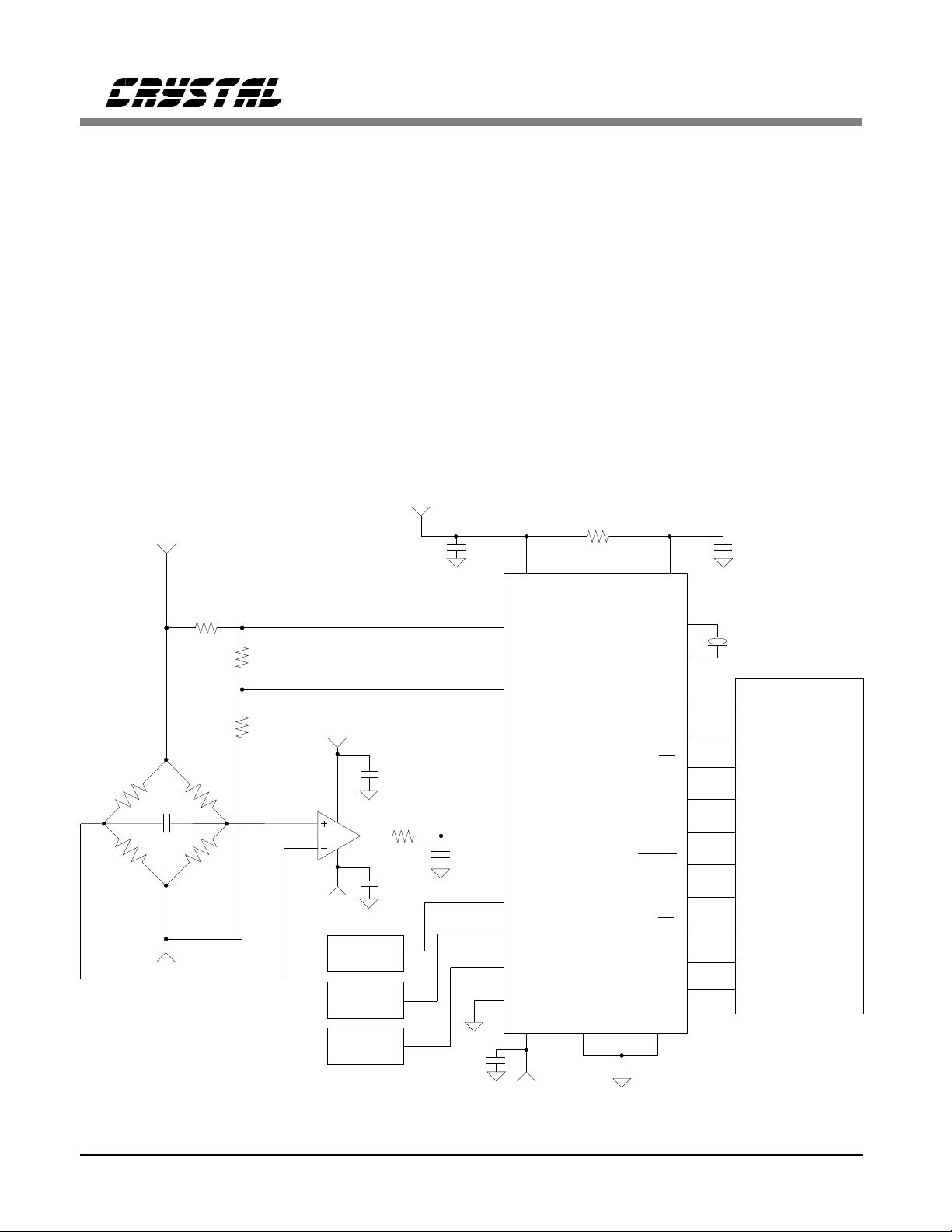

Figure 1 illustrates the low cost CS5509 16-bit

converter operating from +5 V. The A/D can

operate in either unipolar or bipolar mode and

yields 20 c onversions/second wh en running from

a low cost 32.76 8 kHz crystal. When operated at

32.768 kHz the digital filter in the converter

notches out 50 and 6 0 Hz line interfere nce.

The LTC1051 dual chopper amplifier is used as

the bridge amplifier. Bandwidth is limited to

about 3.8 Hz b y the 100k and 0.47 µF feedback

+3.3 V

500

10k

100k

931

100k

100

100

0.1

Optional

Gain

Trim

≈

3.25 V

0.1

VA+ VD+

9

VREF+

10

VREF-

7

AIN+

8

AIN-

Regulator

11 13

XIN

XOUT

CAL

CONV

CS

CS5509

16 bits

DRDY

SDATA

BP/UP

SCLK

+5V or +3.3V

4

5

3

2

1

16

15

6

14

VD+ can be

32.768kHz

Microcontroller

0.1

System

20 Conversions/sec.

GND

12

Figure 1. CS5507,8,9 Bridge Transducer Operating from a Single +5 V Supply, or with the Analog Supply at +5 V

and Digital Supply at +3.3 V.

2 AN31REV3

Page 3

Bridge Transducer Digitizer Circuits

elements of the amplifier stage. Note that an

instrumentation amplifier is not needed because

the A/D input is fully differential. The dual

amplifier functions as a differential in,

differential out amplifier. The circuit yields

about 9000 noise-free counts when measuring

unipolar s ignals. Averag ing 10 sample s increases

this to about 28,500 noise-free counts.

"Noise-free counts" means full scale signal

divided by six times the rms noise. Noise-free

counts is good figure of merit for comparing

A/D converters used in dc measurement

applications. There is more discussion on this

topic at the e nd of the app lication no te.

The circuit illustrated uses a 3 mV/V transducer

excited with +5 V for a full scale transducer

output of 15 mV. The transducer output is

amplified with a gain of about 216 to yield

3.25 V full scale. A dual stage amplifier, as

shown in Figure 2 may be preferred to minimiz e

errors due to limited loop gain. The A/D is

operated in bipolar mode to achieve more

µV/LSB. The reference voltage for the converter

is derived from th e +5 V excitation voltage. The

measurement remains ratiometric should the

+5 V excitatio n change.

Figure 1 includes potentiometers for offset and

gain adjustment , as do a numbe r of other circuits

in this application note. Many system designers

prefer to eliminate potentiometers and do all

offset and gain correction in software. To

+5

10k

1k

10k

x216

4.32k

20k

20k

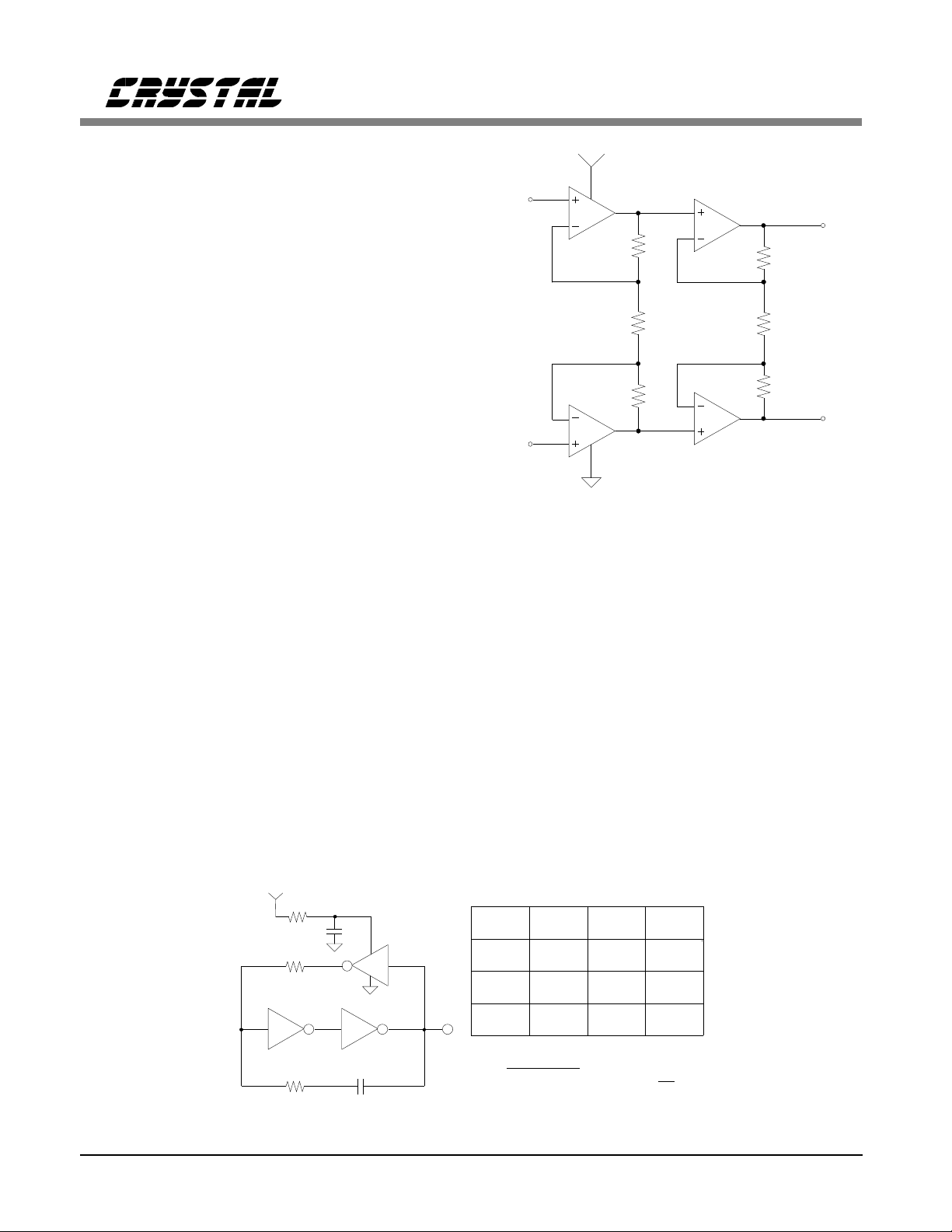

Figure 2. Dual Stage Amplifier

achieve this in some of the circuits may require

changes to gain stages or voltage references , but

potentiometers are shown for all the engineers

who are more comfortable with screwdrivers

than software.

The CS5509 in Figure 1 can run as fast as 200

conversions per second if operated with a

330kHz external clock. Figure 3 shows an RC

gate oscillator which can produce stable

frequencies, or a CMOS 555 timer can be used.

The gate oscillator ca n be operated from either a

+5 or +3.3 V supply and maintains fairly good

frequency sta bility ove r temperatur e.

+3.3 to +5

10

R

R

1

74HC04

2

0.1

f

162kHz

200kHz

output

330kHz

C

f ≈

2 (R + R ) C

R

1

10k

8.2k

5k

1.44

1 2

R

3.4k

2.7k

1.6k

2

R

2 1

330pF

330pF

330pF

≈

R

3

C

Figure 3. Temp erature -Stabl e Gate Oscill ator fo r +5 or +3 .3 Vol ts.

AN31REV3 3

Page 4

Bridge Transducer Digitizer Circuits

All of the converters (CS5504-09) can be

operated with a single +5 V supply. All of the

converters can also be operated with +5 V

analog supply and +3.3 V on the digital supply.

If this dual supply arrangement is used, the

digital supply should be derived from the analog

supply to ensure proper operation. Under all

conditions, including start-up, th e voltage on the

VA+ pin must be the more positive than any

other pin on the device to ensure proper

substrate bias ing of the c hip.

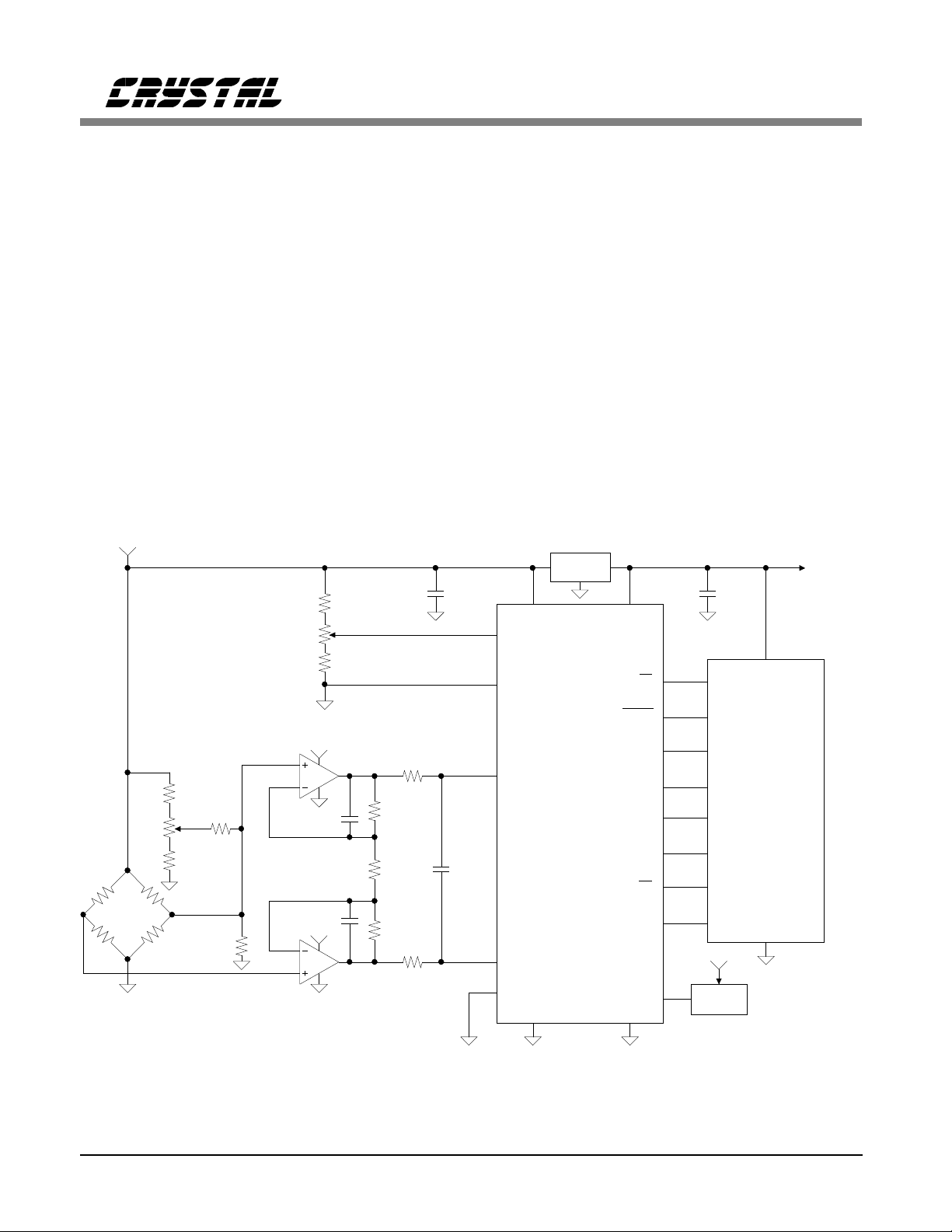

CS5507/8 with +10 V Analog Suppl y and

+5 V Digital Supply

It is common for many weigh scales to be

operated from batteries with a 12 V

+10

Optional

-

350 Ω Bridge

2mV/V

5k

3.57k

1k

Optional

Fine

Offset

Adjust

+

Resistor

200k

Coarse

200k

Offset

100 Conversions/sec

20k

1k

10k

x332

+10

LT1007

0.047

0.047

+10

LT1007

Gain

Trim

100

75k

453

75k

100

automotive-type battery being common. The

CS5504/5/6/7/8 devices can be operated with

higher supply voltage on the analog portion of

the chip than on the digital portion (Note: the

CS5509 is an e xception and is specified with an

analog supply of +5 V onl y). The analog supply

(VA+) must always be the most positive voltage

on the chip to ensure proper operation. Figure 4

illustrates the CS5507 operating from +10 V on

the analog an d +5 V on the digit al. The bridge is

excited wit h the +10 V and resistors are used to

divide this excitation supply to obtain a

ratiometric vol tage reference of abou t 3.33 V for

the converter. The circuit is designed to operate

with the A/D in bipolar mode to yield more

µV/count. Th e A/D is set-up for an inpu t span of

± 3.33 V. A 200k pull down resistor forces a

+5Volt

Regulator

0.33

≈

3.33 V

0.047

14

VA+ VD+

VREF+

11

VREF-

12

8

AIN+

CS5507

CS5508

16 or

20 bits

10

AIN-

13

VREFOUT

VA- DGND

15

+5

17

CS

DRDY

SCLK

SDATA

CONV

M/SLP

BP/UP

CAL

XIN

16

1

20

18

19

2

6

7

3

4

0.1

+5

System

Microcontroller

+5

162kHz

+5

Figure 4. CS5507/8 with +10V Analog Supply and +5 V Digital Supply.

4 AN31REV3

Page 5

Bridge Transducer Digitizer Circuits

negative offset into the amplifier and the zero

trim is used to finely ad just this offset . With zero

weight on the scale, the zero trim is adjusted to

yield -30,000 co unts if the CS5507 1 6-bit A/D is

used or to -500,000 counts if a 20-bit CS5508 is

used. With full scale we ight on the scale the gai n

trim is adjusted for +30,000 counts in the

CS5507 or +500,000 counts in the CS5508

(Note that the CS5507 and CS5508 are pin

compatible). This leaves some counts for both

zero underflow and for overrange . The amplifier

components set the bandwidth to 45 Hz. With

the 45 Hz bandwidth, the circuit exhibits about

50,000 noise-free counts. With an external 162

kHz clock, the converter can operate at 100

+5

+5

7.5k

5k

-

0.47

2 mV/V

350 350

-5

20 Conversions/sec

7.5k

350350

+

2mV/V

Transducer

x100

3

2

INA131

+5

7

6

4

-5

Bridge Amp

#2

#3

#4

0.1

2.4k

0.1

conversions per second. If 20 conversion words

from the CS5508 are averaged, the circuit will

yield more than 200,000 noise-free counts. A

limitation of this circuit is that the bipolar

amplifiers can exhibit significant offset drift as

the temperature changes. There are several

circuits in this application note which will show

how to overcome offset drift.

CS5505/6 Operating Fro m ± 5 V Supplies

The CS5504/5/6 /7/8 converte rs (not the CS550 9)

can be operated wit h ±5 V on the analog sectio n

of the converter, and with either + 5 V or +3.3 V

on the digita l section.

10

VD+

XIN

CS

A0

A1

0.1

20

5

32.768kHz

6

4

3

2

1

24

23

22

8

21

7

1916

System

Microcontroller

≈

0.1

0.1

2.5 V

10

0.1

14

15

12

13

11

9

17

VA+

VREF+

VREF-

CS5505

CS5506

AIN1+

AIN2+

AIN3+

AIN4+

AIN-

-5

20 bits

VREFOUTVA- DGND

18

XOUT

CAL

CONV

16 or

DRDY

SDATA

BP/UP

SCLK

M/SLP

Figure 5. CS5505/6 Operating from ± 5V Supplies.

AN31REV3 5

Page 6

Bridge Transducer Digitizer Circuits

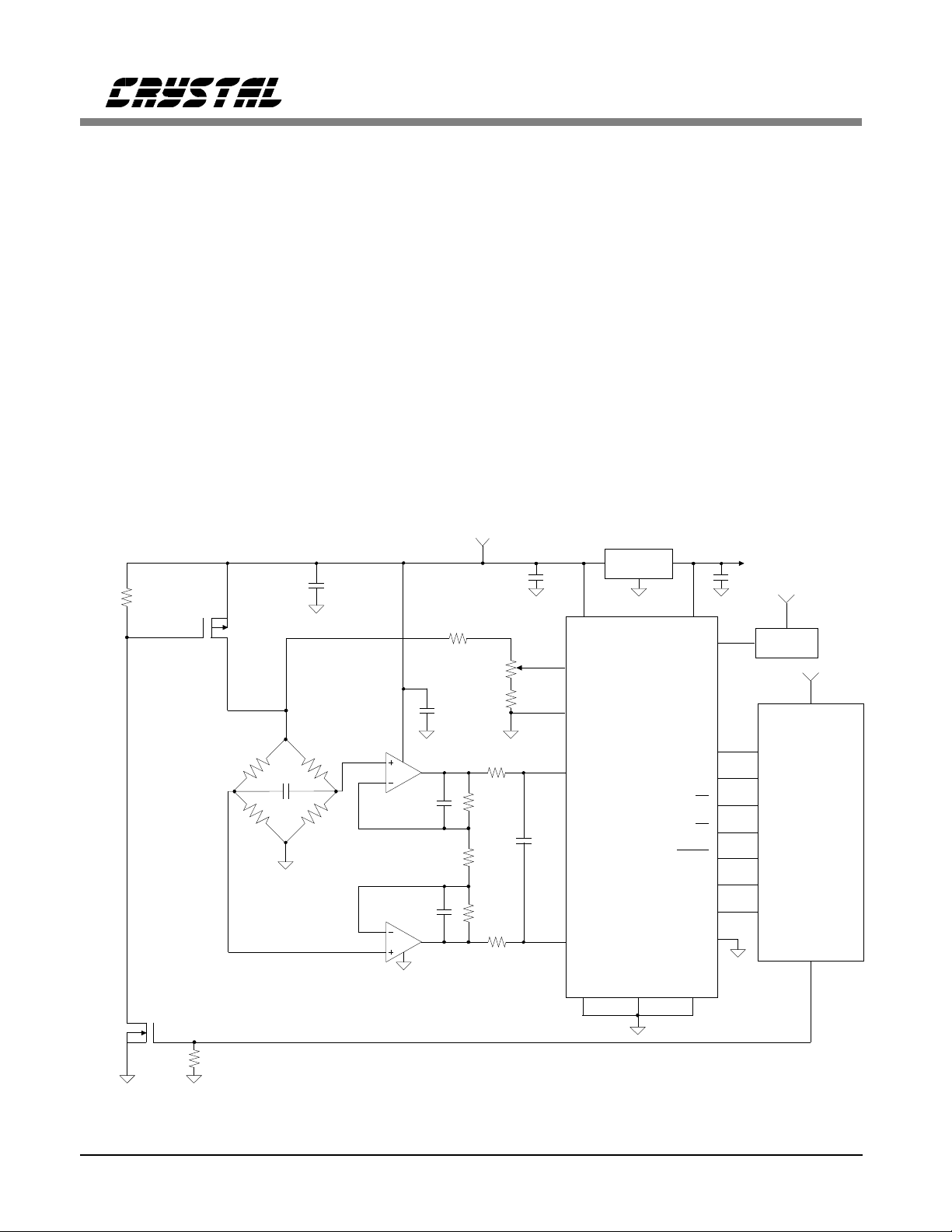

Figure 5 illustrates an ap plication which uses an

instrumentation a mplifier to ampli fy and convert

the differential bridge signal to a

ground-referenced signal for the converter. Full

scale for the converter is set by the divider

resistors which determine the voltage reference

input to the VR EF+/- pins of the converter. The

reference voltage in the figure is set to 2.5 V.

The bridge sensitivity is 2 mV/V so the full

+

100k

TP0610L

Q2

10

0.1

scale bridge output is 20 mV. This is amplified

by the 100 gain of the instrumentation amplifier

to obtain 2 .0 V into the conv erter. The converter

can be operated in either unipolar or bipolar

mode. Up to four load cells, each with its own

amplifier, can be input to the CS5506. The

measurement assumes the voltage reference will

remain ratiom etric acros s all four l oad cells .

CS5507 Switched -Bridge Lo w-power

Digitizer with +10 V Excitation

Some applications call for reduced operating

power. One method of significantly redu cing the

power consumption is to apply the supply

voltage to the bridge transducer only when a

+10

10k

500

14

VA+

VREF+

VREF-

+5V Regulator

17

VD+

XIN

0.1

Optional

Gain

11

Trim

3.33 V

≈

5k

12

+5

0.1

4

162 kHz

+5

OSC

+5

3

CAL

CONV

BP/UP

DRDY

SDATA

SCLK

M/SLP

CS

1613

2

1

7

20

19

18

6

System

Microcontroller

2N7000

Q1, Q2 Siliconix

Q1

100k

350350

100pF

-

350

350

2 mV/V

Transducer

3

8

+

2

0.015

LT1013

0.015

6

5

1 Conversion = 20 msec

226

18.7k

x166

18.7k

100

100

0.047

8

AIN+

CS5507

16 bits

10

AIN-

VREFOUTVA- DGND

15

1

7

4

Figure 6. CS5 507 S witched- Bridg e Low -power Dig itizer wit h +10 Volt Excita tion .

6 AN31REV3

Page 7

Bridge Transducer Digitizer Circuits

measurement is required. Figure 6 illustrates an

example circuit in which the power to the bridg e

transducer is switched on only when a

measurement is desired.

The circuit as shown is optimized for a +10 V

analog supply. The circuit can be modified

(optimized) to operate from any analog supply

from 11 V to 6.5 V (assuming the +5 V

regulator needs 1.5 V of input/output

differential) by changing the resistor values

which determine the voltage reference to the

converter and by changing the gain resistors in

the amplifier to compensate for the cha nge in the

bridge output signal. The circuit shown

illustrates a 2 mV/V transducer outputting

20 mV full-scale. A g ain of 166 ampl ifies this to

3.32 V into th e A/D. The full-scale of the A/D is

set at 3.33 V by dividing down the excitation

voltage.

In the power arrangement shown, the CS5507

A/D uses about 4 mW. The con verter is clocked

from an external gate oscillator clock (162 kHz)

to yield a conversion time of 10 msec. When

power is applied to the bridge, a delay must

occur to allow the signal to settle before a valid

conversion can be pe rformed. Settling time to 16

bits after power is applied to the bridge takes

about 3.3 msec. The microcontroller can use an

internal ti mer to time about 4 msec. to allow for

the delay or the microcontroller can perform a

dummy conversion in the converter to allow for

settling time. When the dummy conversion is

finished (10 msec. later) the conversion data is

discarded and a second conversion is then

performed to make a valid measurement. After

the second conversion is complete (

DRDY falls

the second time) power to the bridge is

deactivated and the conversion word is clocked

out of the conv erter’s serial port.

Power consumed by the transducer dominates

the power dissipated in the circuit. Average

power consumption in the bridge c an be reduced

by a factor o f at leas t fifty (<6 mW) if the b ridge

is powered for only 20 msec. for a reading each

second. If even lower off power is desired, the

supply to the LT1013 ca n also be swit ched along

with the bridge excitation.

CS5509 Switched -Bridge Lo w-power

Digitizer with +5 V Excitation

The circuit in Figure 7 is similar to t he previous

one, but op erates from a sing le +5 V. The ci rcuit

shows a load cell with 3 mV/V sensitivity. A

2 mV/V transduce r can be use d if additional gain

is added; or the voltage reference into the

converter can be lowered to 1.67 V with some

minor increase in noise. Average power

consumption in the load cel l is only 1.5 mW for

one reading per se cond.

CS5516/CS5520 Using DC B ridge Excitation

The CS5516 (16-bit) and CS5520 (20-bit) A/D

converters are designed for bridge measurement

applications. They include an instrumentation

amplifier with X25 gain, a PGA (programmable

gain amplifier) with gains of 1, 2, 4, and 8, and

a four bit DAC which can trim out offset up to

± 200% of the full scale signal magnitude. The

input span can be adjusted by changing either

the magnitude of the voltage at the VREF pins

of the converter or by changing t he PGA gain.

In the circuit shown in Figure 8, the bridge is

excited with ± 5 v olts. Resis tors R1, R2 , and R3

divide the excitation voltage to give a 2.5 V

reference signal into the VREF pins. The input

span at the AIN pins of the converter is

determined by dividing the voltage at the VREF

pins by the PGA gain and the X25

instrumentation amplifier gain. For example,

with 2.5 V into the VREF pins, and the PGA set

to a gain o f 8, the input span at the AIN pins is

2.5/(8 X 25) = 12.5 mV in unipolar mode or

± 12.5 mV in bipolar mode. Th e converter offers

several calibration features to remove offset and

to calibrate the gain slope. The input span of

AN31REV3 7

Page 8

Bridge Transducer Digitizer Circuits

+5

+5

+5

+5

0.1

13

11

0.1

10k

VD+

VA+

OSC

162 kHz

3

4

XIN

VREF+

9

Gain

Optional

500

VREF-

10

Trim

10k

0.1

2

CAL

CONV

AIN+

7

100

1

8

System

Microcontroller

1

6

16

15

14

CS

18.7k

0.015

DRDY

BP/UP

CS5509

16 bits

0.047

X 166

226

SCLK

SDATA

12

GND

AIN-

8

18.7k

0.015

100

7

4

100k

3

2

10

+

+

350350

100 pF

LT1013

350

3 mV/V

6

5

1 Conversion = 20 msec

Figure 7. CS5 509 S witched- Bridg e Low -power Dig itizer wit h +5 V olt E xcit atio n.

-

Q2

TP0610L

100k

350

Q1, Q2 Siliconix

Q1

2N7000

8 AN31REV3

Page 9

POST

Bridge Transducer Digitizer Circuits

(See Text)

PROCESSOR

SID

SOD

SCLK

DRDY

CS

RST

Serial

Interface

.

.

_

2

FIR

Channel

Modulator

2-Channel

IN2 OUT2

Delta-Sigma

DGND

0.1

10

VA- VD-

0.1

-5

Filter

VD+

1

MDRV-

IN1 OUT1

10

CS5516

SMODE

CS5520

16 or 20 bits

Σ

XOUT

4-bit D/A

4.096 MHz

XIN

Calibration

Converter

Gain

Block

1,2,4,8

VA+ MDRV+

+5

0.1 0.1

50 Conversions/sec before averaging

Sync

BX2

Bridge

BX1

1X

+

_

VREF-

VREF+

470pF

470pF

5k

7.5k

R1

R3

+5

301

7.5k

R2

+

-

4.7 nF

25X

_

+

AGND1 AGND2

AIN-

AIN+

4.7 nF

301

-5

Figure 8. CS5516/CS5520 Using dc Bridge Excitation.

AN31REV3 9

Page 10

Bridge Transducer Digitizer Circuits

12.5 mV (considered the nominal value for this

particular selection of PGA gain and VREF

voltage) can be gain calibrated for input signals

from 20 % less than or 20 % greater than the

nominal 12.5 mV value. In othe r words, the gain

can be calibr ated with an in put as low as 10 mV

or as high as 15 mV when the nominal value is

set for 12.5 mV. The nominal input can be

changed by changing the PGA gain or by

changing the divider resistors for the excitation

voltage. The converter can accep t a VREF input

voltage of any value between 2.0 to 3.8 V.

The CS5516 and CS5520 can be operated on

any clock frequ ency from 1.0 MHz to 5.0 MHz.

the digital filter will give greater than 90 dB of

attenuation to 50 and 60 Hz line interference if

the input clock is 4.096 mHz or less. With a

4.096 MHz clock into the converter it will

output conversion words at a 50 Hz rate. For

optimal fil tering it is desirable to av erage output

words from the converter. If ten output words

are averaged, the noise bandwidth is reduced to

about 2.5 Hz.

The CS5516 and CS5520 support eit her dc or ac

bridge excitatio n.

performance when used in a high resolution

bridge digitizer. Another limitation of a chopp er

amplifier is that it corrects only its own offset

errors and does not correct offsets or parasitic

thermocouples external to itself, including those

created when its own package leads connect to

the circuit ca rd traces.

There are several other approaches to chopping

the signal which can be used to enhance

performance. Circuits will illustrate a number of

these approaches. Some chop the signal after it

is output from the bridge. Others actuall y switch

the polarity to the bridge itself. Either method

can be used to remove amplifier offsets and

parasitic thermocouple effects. Switching the

bridge has the advantage that it enables any

nonratiometric offset of the bridge to be

removed. But caution is advised; some silicon

gages can be damag ed if the excitation supply is

reversed. Check with the gage manufacturer to

determine if a silicon gage bridge can be used

with AC excitat ion.

Switching the bridge may not be practical in

applications which have very long cables due to

the large cabl e capacita nce.

AC-EXCITED OR CHOPPED SIGNAL

BRIDGE CIRCUITS

When measuring low level signals,

measurement performance can be enhanced if

the signal is "chopped". Chopper amplifiers are

commonly used to minimize amplifier offset

drift. The disadvantage of chopper amplifiers is

that they are generally manufactured using

CMOS technology and have higher thermal

noise than bipola r amplifiers. Chopper amplifiers

have low offset drift and the 1/f noise of the

amplifier tends to be averaged out due to

chopping. St ill, CMOS integrated circuit chopper

amplifiers tend to have noise performance

somewhere between 45 nV/√Hz to

250 nV/ √H z. This noise limi ts the measurement

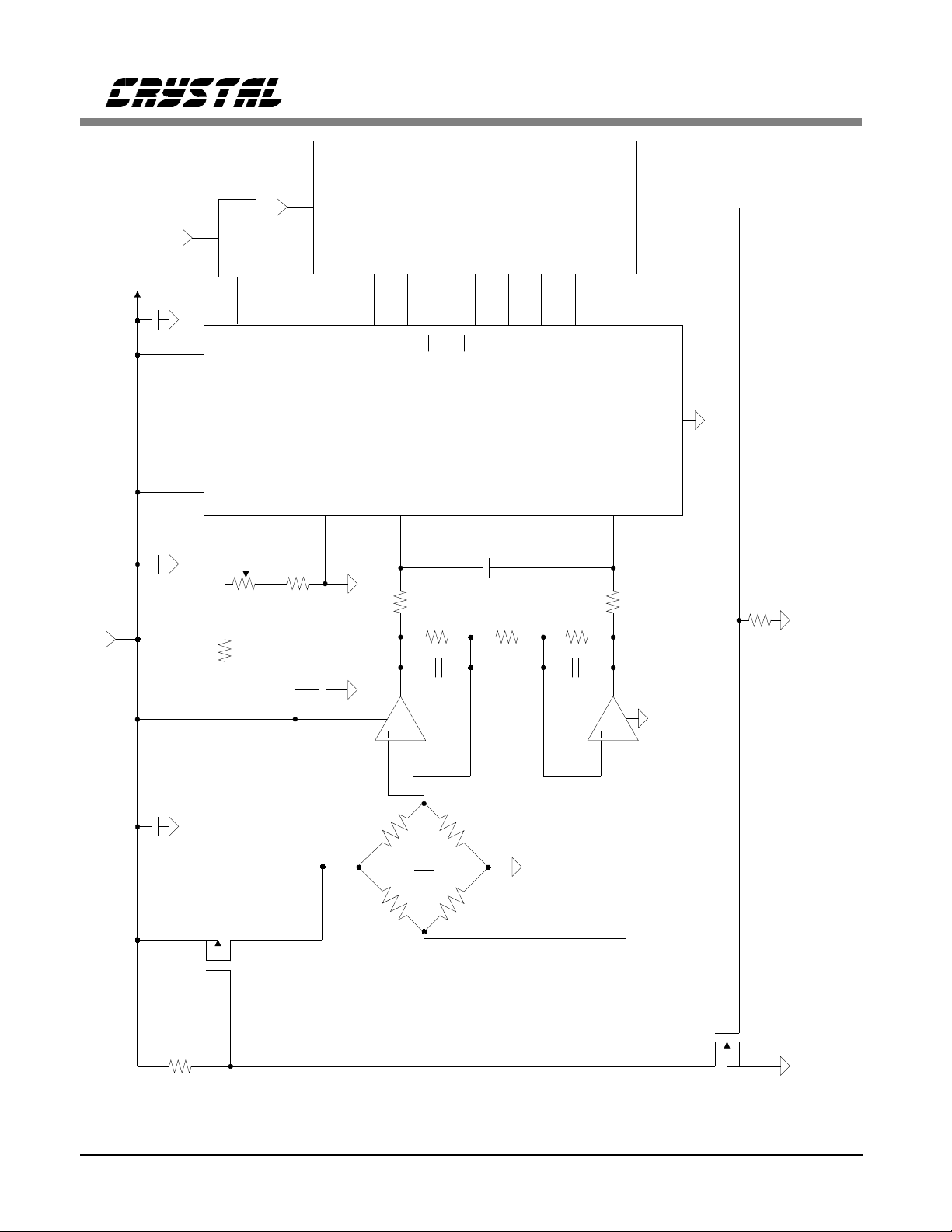

Bridge with Digital Offset Correction and

Kelvin Reference Sensing.

One method of gett ing the lower noise of bi polar

amplifiers and achiev e good offset stabili ty is to

use digital offs et correction. Figure 9 il lustrates a

circuit in which the input of the amplifier stage

is periodically shorted and the offset measured

with the A/D. The digital code is then used to

correct readings from the converter when the

signal is being measured. The schematic shows

only the circuitry for one channel (the CS5504

has two input channels). Only one half of the

DG303 is used per channel. LT1007 op amps are

used for their low noise; but a dual LT1013 or

quad LT1014 could be used if higher noise is

acceptable. The LT1013 and LT1 014 are capable

of measuring signals with an input range which

10 AN31REV3

Page 11

+5

Bridge Transducer Digitizer Circuits

OSC

330 kHz

0.1

5

17

5 Volt

Regulator

14

0.47

+10

7

3

LT1006

XIN

VA+ VD+

VREF+

12

3.6V

≈

6

4

35.7k

2

35.7k

4

VREF-

13

0.1

+10

3

7

CAL

AIN1+

8

100

7

49.9k

6

4

2

18

BP/UP

SCLK

20 bits

CS5504

0.005

604

0.005

0.005

(2) LT1007

19

System

Microcontroller

20

SDATA

AIN1-

10

49.9k

6

7

+10

2

3

2

DRDY

100

4

3

CS

CONV

AIN2-

AIN2+

9

11

Channe l 2

Circuitry for

DGND

VA-

A0

16

1

15

200 Conversions/sec before

averaging and offset removal

100k

S3

IN1

8

V-

0.1

D3

100k

D1

Figure 9. B ridge with Digi tal Of fset C orrect ion and Kelvi n Refe rence S ensing .

14

+10

S1

+-

350

100pF

350

1/2

DG303

350350

2mV/V

Transduc er

7

GND

+10 V

SIG1+

SIG1-

SIG2+

SIG2-

T

R

AN31REV3 11

Page 12

Bridge Transducer Digitizer Circuits

includes the negative supply rail. One

application for this may be for measuring a

temperature compensating resistor in series with

the bridge (see in set in Figure 9).

The converter in Figure 9 is set up in bipolar

mode (use bipolar mode even if you want

unipolar measurements as the bipolar setup

provides less noise per code and allows for

negative tempco drift of t he zero referenc e point)

and runs at 20 0 conversions a sec ond. To correct

offset and measurements on both channels, the

following measurement sequence was used:

Select the DG303 to short the inputs to both

channel one and channel two. Use A0 on the

converter to select channel one. Perform one

conversion and discard the data to allow for

settling. Perform a second conversion and keep

the offset code for channel one. Change A0 to

opposite state and measure the offset code for

channel two. Switch the DG303 on both

channels to measure the input signal and set A0

to measure channel one. Perform one dummy

conversion and di scard the data. Then perform a

second conversion and keep the reading.

Correct this re ading with the o ffset reading take n

for the same ch annel. Then change A0 and read

channel two and correct it for offset. Each

channel takes four conversions per result, so for

two channels, outputs are available at 25 per

second. A running average of 12 corrected

words is recommended to improve noise

performance. With 12 words averaged, the

performance is greater than 150,000 noise-free

counts with two updates per second for each

channel.

If the circuit in Figure 9 is used at higher

temperatures, one DG303 should be used for

each amplifier stage with a switch (always on)

included in the negative lead of the bridge

circuit. With t his configuration, the errors due to

leakage currents and the on resistance of the

switches will be more balan ced on both the plus

and minus leads o f the bridge.

The voltage reference input to th e A/D converter

is buffered to reduce loa ding by the Kelvin sense

leads. If the voltage reference Kelvin sensing

lines are long, 50 and 60 Hz line interference

may be picked up. The v oltage reference input to

the CS5504/5/6/7/8/9 should be filtered to

prevent line interference if the devices are

operated at a clock frequency other than

32.768 kHz.

Bridge with Signal Chopping Us ing CS5504

The load cell is ofte n the dominant cost factor in

many weighing systems. A lower cost load cell

can be achieved by leaving out the temperature

compensation gages and reducing testing during

manufacturing. As long as the load cell

temperature drift is repeatable, the entire system

can be compensated with software in a

microcontroller. In this type of system, a

temperature sensor is usually embedded inside

the load cell. The entire system is then

characterized over temperature. A

microcontroller reads the load cell and its

temperature and uses a look-up table to correct

the load cell output for drift over temperature.

Figure 10 illus trates an exa mple.

The circuit uses the CS5504 two channel fully

differential A/D configured to convert at 200

samples per second. The analog portion of the

A/D and the bridge are operated from +10 volts.

The voltage reference for the A/D is developed

from the bridge excitation. Channel two of the

converter measures the output of a thermistor

mounted in th e load cell housing . The thermistor

is excited with t he same volt age as the brid ge.

The output o f the bridge is amplified by a buffer

amplifier composed of two LT1007s. The

CS5504 is operated in bipolar mode with

± 524,000 counts. A DG303 analog switch is

used to revers e the polarity of t he signal into th e

amplifier upon command from the

microcontroller. A conv ert (CONV) command is

12 AN31REV3

Page 13

+5

Bridge Transducer Digitizer Circuits

+10

OSC

330 kHz

0.1

5

17

5 Volt

Regulator

14

0.47

17.8k

XIN

VA+ VD+

VREF+

VREF-

12

3.6V

≈

10k

13

4

AIN2+

9

Thermistor mounted

7

CAL

inside load cell

BP/UP

11

18

SCLK

20 bits

CS5504

AIN1+

AIN2-

8

100

7

+10

3

49.9k

6

4

2

19

System

Microcontroller

3

CS

CONV

AIN1-

10

49.9k

100

6

7

4

2

3

16

DGND

1

A0VA-

15

50 Conversions/sec before

≈

averaging and chopped signal

DRDY

0.005

2

+10

20

SDATA

0.005

604

0.005

LT1007

T

R

V+

4

D1

S1

5

12

D4

S4

13

20k

14

+10

3

D3

S3

2

11

D2

S2

10

6

IN1

9

IN2

DG303

8

V-

7

GND

Figure 10. Bridge with Signal Chopping Using CS5504.

+

350

100pF

350

-

350350

2mV/V

Transducer

AN31REV3 13

Page 14

Bridge Transducer Digitizer Circuits

issued to the converter only after the DG303

switch has been switched to one position long

enough for the buffer amplifier to have settled

on the signal. With the DG303 in one position,

the output of the amplifier will result in a

positive voltage into the converter; when

switched to the other position the output of the

amplifier will be negative into the converter.

The negative reading is then subt racted from the

positive reading and then divided by

two[(+answer - (-answer)]/2. The result will be a

reading of the l oad cell signal with the offset of

the amplifier removed. For example, let us

assume the circuitry has +332 counts of offset

and the signal from the bridge (the bridge itself

has no offset fo r illustration purposes) shoul d be

4700 counts. The reading from the converter

with a positive inpu t signal will be 5032 counts;

the reading with the signal reversed will be

-4368 counts. [5032 - (-4368)]/2 = 470 0 counts,

which is the ans wer with the offset av eraged out.

Note that dividing by two is really unnecessary

as the number (9400) is representative of the

signal magnitude. The converter can sample at

200 samples per second; performing a

conversion ev ery 5 msec. The converte r has two

channels but needs not to measure the

temperature channel very often. The

measurement sequence for channel one is

follows: Switch the DG303 to condition one

(switches 1 and 2 are on, switches 3 and 4 are

off); perform a conversion but throw the data

away as this convers ion time is used to allow th e

amplifier to settle (the circuit shown takes less

than 4 msec. to settle). Then perform a second

conversion and kee p the data. Switch the DG303

to conditi on two (switches 3 and 4 are on, 1 an d

2 are off); perform a conversion but throw away

the data to allow for settling. Then perform a

second conversion, subtract the negative answer

from the previous positive one (from switch

condition one) and divide the answer by two (if

you need the actual answer). Since it will take

four conversion cycles to obtain one averaged

answer, the c onverter will be able to update at a

50 Hz rate (assu ming the tempera ture channel is

not being read). The effects of noise in the

output data can be reduced if words are

averaged. An average of 20 of the fin al readings

will result in a noise reduction of 4.4 times.

Converting in this fashion will result in a

converter with greater than 150,000 noise-free

counts, and an update rate of about two and a

half times per second. Chopping the signal

lowers the input drift in the amplifier to about

125 nV peak-to-peak under slowly varying

temperature cond itions.

Switched Bridge with CS5504 Us ing +10 V

Analog Supply

The previous circuit achieved offset stability by

chopping the bridge output. In the circuit in

Figure 11 the po larity of the excitation vo ltage to

the bridge is periodically reversed. Channel one

of the CS5504 is used to measure the amplified

signal from the bridge. The second channel of

the converter is used to measure the magnitude

of the bridge ex citation. The bridge exc itation is

measured because the driver exhibits some

change in drive output over temperature. The

measurement sequence is as follows. For

notation let the bridge excitation be in position

one when the top of the bridge is +10 V (the

actual voltage will be about 9.5 to 9.8 V

depending upon the driver source impedance).

When switched to this position, the

microcontroller pau ses for a short delay (1 msec

or so) before performing a conversion on

channel two to ensure that the ci rcuit has settled.

Once the conversion is performed on channel

two, the data is saved. Then the A0 line to the

converter is switched t o select channel one. The

amplifier has settled during the time the

conversion was performed on channel two. A

conversion is performed on channel one and the

data is saved. Then the bridge excitation is

flipped to p osition two ( the top of the bridg e is

grounded). After a 1 msec delay a conversion is

performed on channel two; the negative answer

is subtracted from the previously collected

positive answer from channel two. Then A0 on

14 AN31REV3

Page 15

Bridge Transducer Digitizer Circuits

+10V

OSC

330 kHz

0.1

5

17

5 Volt

Regulator

14

0.47

17.8k

XIN

VA+ VD+

VREF+

12

3.6V

≈

10k

4

VREF-

AIN2+

9

13

0.01

CAL

3.33V

≈

Trim

Gain

7

11

18

BP/UP

SCLK

20 bits

CS5504

AIN2-

AIN1+

8

100

49.9k

0.01

6

4

7

+10

3

2

19

SDATA

0.005

System

0.005

604

LT1007

20

Microcontroller

2

DRDY

0.005

3

CS

CONV

116

A0

AIN1-

10

49.9k

6

7

+10

2

3

VA- DGND

15

100

before averaging

40 Conversions/sec

4

1k

2k

200

1k

2k

+10

+

350

350

100pF

-

350350

2mV/V

Transducer

2

6

7

10

+

0.1

4

3

5

MIC4428orMIC4425

Figure 11. Switched Bridge with CS5504 Using +10 Volt Analog Supply

AN31REV3 15

Page 16

Bridge Transducer Digitizer Circuits

the converter is flipped and a conversion is

performed on channel one of the converter. The

negative answer for channel one is then

subtracted from the previous positive reading

from channel o ne.

The resultan t readings from each channel can be

averaged to reduce the effe cts of noise. T hen the

readings from the two channels are ratioed. The

channel two data represents the value of the

excitation on the bridge. Channel one data

represents t he output signal from th e bridge as a

proportion of t he bridge voltage. By ratioin g the

data (AIN1/AIN2) any drift in the bridge

2k

1k

Optional

-

350

0.1

100pF

2mV/V

Transducer

MIC4428

500

350

+

350350

7

10

+

5

-5

2k

+5

6

2N3906

2

4

3

-5

Gain

Trim

1k

+5

3

7

6

4

2

-5

0.005

LT1007

0.005

+5

2

7

4

-5

2k

10k

6

40 Conversions/sec

before averaging

3

10k

10k

excitation voltage (such as those caused by

changes in the driver output impedance) is

compensated.

The circuit can read both channels and calculate

a final answer for the bridge signal in less than

25 msec.; which means an output word can be

calculated at a rate of 40 times p er second. If 20

output words are averaged the circuit will yield

better than 100,000 noise-free counts with the

offset drift of the digitizer bei ng less than 50 nV

over time.

+5

0.01

0.01

3.83k

49.9k

604

49.9k

100

100

10k

≈

3.6V

≈

3.33V

0.005

0.1

12

VREF+

VREF-

13

AIN2+

9

11

AIN2-

8

AIN1+

10

AIN1-

15

-5

10

14

VA+ VD+

BP/UP

CS5504

SCLK

20 bits

SDATA

DRDY

CONV

A0VA- DGND

116

0.1

17

CAL

XIN

CS

0.1

5

330 kHz

4

7

18

19

20

2

3

System

Microcontroller

+5

OSC

Figure 12. Switched Bridge with CS5504 Using ± 5 Volt Analog Supplies.

16 AN31REV3

Page 17

Bridge Transducer Digitizer Circuits

68HC705

SOD

SMODE

SID

SCLK

DRDY

CS

RST

Serial

Interface

DGND

VD-

10

VA-

-5

VD+

MDRV-

0.1 0.1

1

10

CS5516

16 or

CS5520

.

.

_

2

FIR

Filter

Channel

OUT2

20 bits

2-Channel

IN2

Delta-Sigma

OUT1

Modulator

IN1

Σ

XOUT

4-bit D/A

4.096 MHz

XIN

Calibration

Sync

Bridge

BX2

BX1

10k

100k

10k

1X

_

+

VREF-

VREF+

470pF

470pF

Converter

Gain

Block

1,2,4,8

25X

_

+

AIN-

AIN+

4.7 nF

VA+ MDRV+

+5

AGND1 AGND2

4.7 nF

50 Conversions/sec before averaging

0.1 0.1

Figure 13. CDB5516/20 Evaluation Board Circuit.

7.5k

R1

5.0k

R3

TP0610

2

+5

6

7

MICREL

MIC4428

100.1

+

4

-5

3

5

7.5k

R2

301

+

-

301

AN31REV3 17

Page 18

Bridge Transducer Digitizer Circuits

Switched Bridge with CS5504 Us ing ± 5 V

Analog Supplies

This circui t in Figure 12 is basical ly identical to

the previous circuit, but is configured to run

from ± 5 V on the analog s upplies .

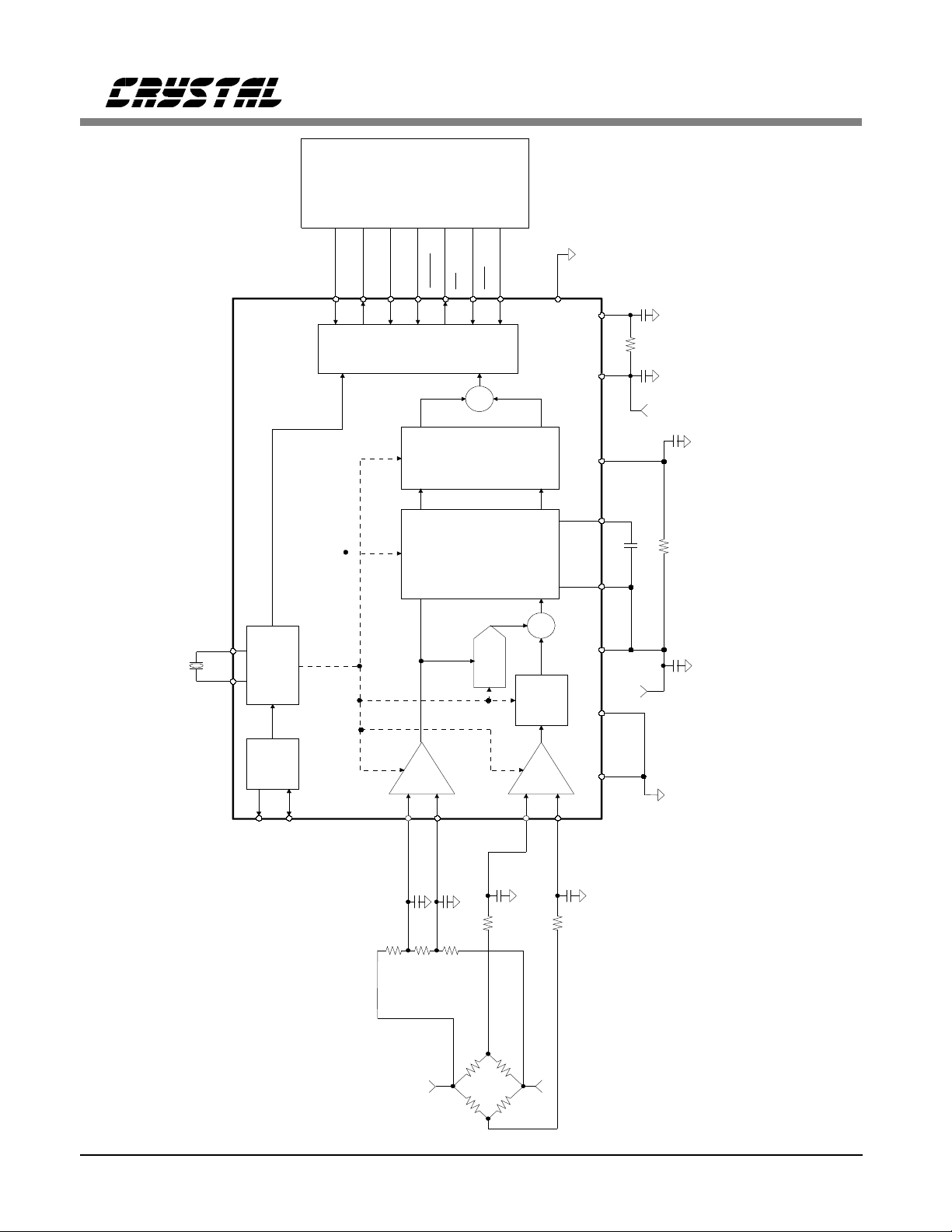

CDB5516/20 Eva luation Board Circui t

The CDB5516 and CDB5520 evaluation boards

use the circ uit in Figure 13. T he CS5516 (1 6-bit)

and CS5520 (20-bit) converters are optimized

for bridge measurement applications. The

evaluation board comes with software which

runs on a PC-compatible computer. The

evaluation board includes a microcontroller

which communi cates with t he PC via the RS-232

serial port. The software allows the user to read

and write all of the registers inside the

CS5516/20 converter, perform conversions, save

conversion data to a file, and perform some

noise statistic s on the ca ptured data .

The CS5516 and CS5520 support both

dc-excited bridges and ac-excited bridges.

Figure 14 illustrates the benefit of AC excitation.

In one of the plots in Figure 14, the CS5520

converter was set up for a bipolar input span of

± 12.5 mV and dc bridge excitation.

Conversions were performed with a zero input

signal from the brid ge and data was col lected for

a one hour time interval. One LSB of the

CS5520 was equiv alent to ab out 25 nV. The data

collected indicates that over the one hour period

the average value of the data drifted as much as

1.25 µV, or abou t 50 counts. The d rift is due to

parasitic thermocouples in the components or

wiring of the board. The evaluation board was

open to the air. The data illustrates that the

cycling of the air conditioner induced thermal

gradients across the circuitry, changing the

voltage effects of the parasitic thermocouples in

the circuitry. The second plot in Figure 14

illustrates the stability of the data when the

converter is set up for the same operating

conditions, but with ac bridge excitation. The

plot illustrates the normal thermal noise of the

circuit but the average value remains sta ble over

time.

The CS5516 (16-bit) and CS5520 (20-bit) A/D

converters include an instrumentation amplifier

with X25 gain, a PGA (programmable gain

amplifier) with g ains of 1, 2, 4, and 8, an d a four

bit DAC which can trim out offset up to ± 200%

of the full scale signal magnitude. The input

span can be adjusted by changing either the

magnitude of the voltage at the VREF pins of

the converter o r by changin g the PGA ga in.

In the circuit shown in Figure 13, the bridge is

excited with a 1 kHz square wave from the

MIC4428 (or the Micrel MIC4425) driver. The

driver outputs about ± 5 V. The 1 kHz drive

signal is output from the BX2 pin of the

CS5520. Control bits in a configuration register

inside the ch ip have been set to selec t internal ac

excitation with a frequency of 1 kHz (XIN =

4.096 MHz). The converter is designed to

perform synchronous detection on the AIN and

VREF input signals when operated in the ac

excitation mode. This means that the converter

measures the signal which is of the same

frequency and phase as the excitation clock

coming from the BX 2 pin.

Resistors R1, R2, and R3 divide the excitation

voltage to give a 2.5 V reference signal into the

VREF pins. The input span at the AIN pins of

the converter is determined by dividing the

voltage at the VREF pins by the PGA gain and

the X25 instrumentation amplifier gain. For

example, with 2.5 V into the VREF p ins, and the

PGA set to a gain of 8, the input span at the

AIN pins is 2.5/(8 X 25) = 12.5 mV in unipolar

mode or ± 12.5 mV in bipolar mode. The

converter offers several calibration features to

remove offset and to adapt the gain. The

nominal input span of 12.5 mV can be gain

calibrated for input signals within ± 20% of

18 AN31REV3

Page 19

Bridge Transducer Digitizer Circuits

Nanovo lts

1250

1000

750

500

250

0

-250

-500

-750

-1000

-1250

0.00

DC Excitation

Time Domain Data

1 LSB = 25 nV 1 LSB = 25 nV

0.50

time (hours)

1.00

Figure 14. DC Versus AC Excitatio n.

nominal. In other words, the gain can be

calibrated for an input as low as 10 mV or as

high as 15 mV whe n the nominal val ue is set for

12.5 mV. The nominal input can be changed by

changing the PGA gain or by changing the

divider resistors for the excitation voltage. The

converter can accept a VREF input voltage of

any value between 2.0 to 3.8 V. The CS5516

and CS5520 can be operated on any clock

frequency from 1.0 MHz to 5.0 MHz. The

digital filter will give greater than 90 dB of

attenuation to 50 and 60 Hz line interference if

the input clock is 4.096 mHz or less. With a

4.096 MHz clock into the converter it will

output conversion words at a 50 Hz rate. For

optimal fil tering it is desirable to av erage output

words from the converter. If ten output words

are averaged, the noise bandwidth is reduced to

about 2.5 Hz.

CS5516 with External 25 Hz AC E xcitation

Nanovolts

1250

1000

750

500

250

0

-250

-500

-750

-1000

-1250

0.00 0.50 1.00

AC Excitation

Time Domain Data

time ( h ours)

oscillator frequency on the chip and is output

from the BX1 and BX2 pins. In the external

excitation mode (selected by setting a bit in the

configuration register of the converter), a square

wave whose frequency is a sub-multiple of the

XIN frequency to the converter (see the

CS5516/20 data sheet for details) is input into

the BX1 pin of th e converter .

When using the CS5516 or CS5520 in the ac

excitation mod e, the AIN and VREF signals into

the converter are sampled 64 XIN clock cycles

after the excitation signal is switched. When the

square wave excitation changes polarity, the

circuitry, including the bridge, the load cell

cable, and any filtering components must settle

to at least 5 per cent acc uracy within t he 64 XIN

clock cycles after the switching edge. This can

be a limiting factor in using square wave ac

excitation, especially with long cables which

have a large capac itance.

The CS5516 and CS5520 support two ac bridge

excitation modes; internal and external. In the

internal excitation mode, the excitation clock is

derived internal to the converter from the

AN31REV3 19

The excitation frequency can be lowered to

XIN/(10 X 2

14

) if output words from the

converter are averaged over several conversion

cycles. Fo r example, with a 4.096 MHz c lock, a

Page 20

Bridge Transducer Digitizer Circuits

decade divider (74HC4017) can be followed by

a binary 2

14

divider (74HC4020) to yield a

25 Hz excitation frequency. The converter will

output convers ion words at a 50 Hz rate, or two

output words for each one cycle of the bridge

excitation. The 25 Hz excitation reduces the

switching frequency of the bridge so the circuit

spends more time measuring and less time

settling. This will improve measurement

performance, but multi ple output words (an even

number of them) must be averaged to ensure

+5

MICREL

MIC4428

-

6

7

5

3

-5

+

TP0610

2

4

+

100.1

7.5k

R1

5k

R3

7.5k

R2

301

301

100k

10k

10k

4.7 nF

25Hz

See Text

for another

control option.

470pF

470pF

4.7 nF

equal samples for both polarities of the

excitation clock. Figure 15 illustrates this

circuit. Note that the details on connecting the

clock divider chips have not been shown to

simplify the s chematic.

CS5516/CS5520 with AC-Exci tation

Controlled b y a Microcon troller

If the load cell cables are very long, the

capacitance may be so large that the circuit

cannot settle and yield an accurate result with

the 25 Hz circuit. Another option exist. Rather

than use the counters in Figu re 15 to control the

BX1 signal an d the drive polarity, o ne can use a

microcontroller output line. With the converter

set up in the external excitation mode, the

microcontroller can control the polarity of the

14

÷

2

74HC4020

BX1

BX2

10

÷

74HC4017

Bridge

Sync

4.096 MHz

XINXOUT

Calibration

CS5516

CS5520

16 or 20 bits

VREF+

VREF-

AIN+

AIN-

+

_

+

_

1X

25X

Gain

Block

1,2,4,8

25 Conversions/sec averaging required

AGND1 AGND2

Figure 15. CS5516 with External 25 Hz AC Excitation.

20 AN31REV3

Page 21

Bridge Transducer Digitizer Circuits

excitation. In external excitation mode, the BX1

pin of the converter is an input and is used to

determine the polarity of the excitation. The

phase of the signal at BX1 contro ls the phase of

the internal detection circuitry. Each time the

polarity of the excitation is changed, the

converter needs six conversion word periods for

the internal digital filter to accurately settle on

the input signal. To yield a proper result, the

sixth conversion word for each of the excitation

phases will need to be averaged together. For

optimum throughput, the excitation polarity

should be changed when the

DRDY signal falls.

The on-chip calibration features may not be

usable directly when operating in this manner,

but the user microcontroller can manipulate the

gain and offset registers in the converter to

optimize the the offset and gain adjustments for

optimum operation. If the bridge polarity is

reversed every six conversion words, an output

result can be computed every twelve filter

cycles. This will yield an effective conversion

update rate of about four updates per second

(XIN = 4.096 MHz).

CS5516 or CS5520 and a 1 m V/V

AC-Excited Load Cell

Metal film or metal foil strain gages are

generally configured to yield a sensitivity of

2 mV/V or 3 mV/V from a load cell. A load cell

may be used at 1/2 or 1/3 its rated capacity to

allow it to have greater overload capacity. A

designer may trade sensitivity for overload

capability. For example, using a 2 mV/V load

cell at 1/2 capacity yields a 1 mV/V sensitivity,

but with greater ruggedness. The lower

sensitivity results in less output signal for a

given excitation. The usable portion of the

output signal may be further reduced bec ause the

load cell may be part of a s ystem where the pan

weight consumes a good portion of the signal

span of the load cel l output. For ex ample, a scal e

designed to weigh 10 Kg (22 lbs.) may have a

pan weight which weighs 5 Kg. (11 lbs.) and

therefore the pan weight consumes half of the

signal span out of the load cell. The application

may require protection against high impact, such

as when the it ems being weighed are dropped o n

the scale. A 2 mV/V load cell may be derated

which results in lower output sensitivity

(1 mV/V or so) to allow gre ater impact capacity

for the lo ad cell.

Figure 16 illustrates such an application. The

signal to measured from the bridge is only 5 mV

over the measurement range (the pan weight

consumes 5 mV of the load cell span). The

offset calibration capability of the

CS5516/CS5520 converter can readily remove

the offset due to th e pan weight. If the converter

was configured to measure the 5 mV signal

without the addi tional buffer amplifier, the 5 mV

signal would only use part of the converter’s

span. For example, if the VREF voltage is

reduced to 2.0 V and the PGA gain inside the

converter is set to 8, the input span expected by

the converter would be 2.0/(25 X 8) = 10 mV.

To calibrate the converter with only a 5 mV

signal would force the gain register to a value

outside the recommended range (1.2 to 0.8).

This situation can be overcome by using an

external buffer amplifier made up of two OP-27

op amps. Th e VREF voltage for the c onverter is

set to 3.33 V by using three equal resistors for

R1, R2, and R3. The PGA gain is set to 1 which

makes the input sensitivity at the AIN pins of

the converter to be 3.33 /(25 X 1) = 1 33 mV. The

buffer amplifies the usable portion of the load

cell output signal (5 mV) by a gain of 26 to

yield an input to the converter of 130 mV.

Stability of the gain resistors is important but

tight initial tolerance is not needed as the gain

calibration feature of the CS5516/CS5520 can

accommodate up to ± 20% gain scaling. AC

excitation re moves the offs et of the OP-2 7s.

The circui t is operated with th e load cell excite d

with a 1 kHz bridge drive frequency. When

operating in b ipolar mode, the CS5516 con verter

will yield about 27,000 noise-free counts over

AN31REV3 21

Page 22

Bridge Transducer Digitizer Circuits

POST

(See Text)

PROCESSOR

SMODE

SOD

SID

SCLK

DRDY

CS

RST

Serial

Interface

DGND

VD-

10

VA-

0.1 0.1

-5

VD+

MDRV-

0.1

1

10

CS5516

CS5520

.

.

_

2

FIR

Filter

Channel

OUT2

2-Channel

16 or 20 bits

IN2

Delta-Sigma

OUT1

Modulator

IN1

Σ

XOUT

4-bit D/A

4.096 MHz

XIN

Calibration

Sync

Bridge

BX1

BX2

10k

2k

10k

10k

1X

+

_

VREF-

VREF+

470pF

470pF

Converter

Gain

Block

1,2,4,8

25X

_

+

AIN-

AIN+

4.7 nF

VA+ MDRV+

+5

AGND1 AGND2

4.7 nF

50 Conversions/sec before averaging

0.1

Figure 16. CS5516 or CS5520 and a 1 mV/V AC-Excited Load Cell.

2.5k

R1

2.5k

R3

2N3906

2

+5

6

7

MICREL

MIC4428

100.1

+

4

-5

3

5

2.5k

R2

301

2.5k

200

R5

R4

+5

-5

OP-27

+

1.0 mV/V

-

10kg

(22lb)

301

2.5k

R6

+5

-5

22 AN31REV3

Page 23

Bridge Transducer Digitizer Circuits

the 5 mV span at a fifty samples per second

update rate. The CS5520 should be used if

higher resolution is desired at the 50 Hz update

rate. Averaging 25 samples will yield an output

with an effective 135,000 noise-free counts at

two updates per second; this on a 5 mV signal

span. The AIN ratiometric calibration register

inside the converter can be used to add or

subtract offset from the signal and give some

counts for zero weight underflow (if used in

unipolar mode) or some counts for full scale

overrange (if bipolar mode is used). Averaging

as many as fifty output words may be desirable

in some appl ications where mechan ical vibration

is a problem.

CS5520 and an AC-Excited 1. 9 mV/V Weigh

Platform

Figure 17 il lustrates another very high resolution

digitizer. A GSE model 4444 "floating beam"

platform is use d as the weigh bridge. The model

4444 has a full scale capa city of 100 p ounds and

a sensitivity of 1.9 mV/V. The full-scale output

signal from the bridg e is (1.9 mV/V) X 9.5 volts

excitation or about 18 mV. The 18 mV output

signal is amplified by two LT1115 amplifiers

configured as a high input impedance buffer

amplifier with a fixed gain of 8. When the 18

mV signal is amplified by 8 it yields an input

signal to the converter slightly above the

nominal value determined by the voltage

reference. T he calibr ation featur es of the C S5520

enable it to accommodate input spans which are

as much as 20 % above or 20 % below the

nominal value set by the reference voltage.

Vishay resistors (R4-R6) are used in the buffer

amplifier to maintain a stable gain over

temperature. The LT1115 was chosen for it s low

noise while sustaining a loop gain greater than

one million. With a X8 closed loop gain, an

open loop gain of 138 dB must be maintained.

The operationa l amplifier must maintain its high

open loop gain with reduced supply voltages (±5

V) and with enviro nmental temperature changes.

A loop gain greater t han one million e nsures that

gain stabilit y will be dictated by the gain-set ting

resistors and not by limited loop gain. Offset

voltage, offset drift, bias current, and bias

current drift are unimportant when ac excitation

is used as these errors are modulated out-o f-band

and filtered out by the digital filter inside the

CS5520. Thermal noise at the excitation

frequency remains as the limitation to achieving

high dynamic range. Although the LT1115 is a

very low noise amplifier, the noise in the

digitizer circuit is actually dominated by noise

referred to the buffer amplifier’s input from the

A/D. (Note that a lower cost amplifier such as

the LT1007 can be used with only a minor

increase (5 %) in peak-to -peak noise) . The effects

of the thermal no ise can be redu ced by averagin g

output conversion words. With the digitizer

using the LT1115s for optimum performance,

you can capture output conversion words from

the digitiz er and examin e the noise co ntent in th e

50 Hz conversion words. You should capture at

least 1000 co nversion words from the CS55 20 to

have a large enough sample to minimize

statistical uncertainty. The input to the digitizer

should be held at a stable value while the

conversion words are captured. Once the

samples are ca ptured, a frequency di stribution of

the samples is computed and plotted.

Spreadsheets such as Lotus or Quattro can be

used to compute and plot the frequency

distribution of the data. Figure 18 illustrates the

histogram of 1000 50 Hz output samples from

the digitizer of Figure 17. The histogram

illustrates that the 50 Hz output words from the

converter have a peak-to-peak noise amplitude

which is less than 6 LSBs (least significant bits)

99% of the time. The noise in the output codes

has a Gaussian characteristic and therefore

averaging can be used to reduce its value.

Averaging samples which include Gaussian

noise will reduce the noise amplitude in

proportion to the square root of the number of

samples which are averaged together. The post

processor computes an average of 50 CS5520

output words to yield a post-filte red output word

AN31REV3 23

Page 24

Bridge Transducer Digitizer Circuits

POST

(See Text )

PROCESSOR

SMODE

SOD

SID

SCLK

DRDY

CS

RST

Serial

Inte rface

.

.

_

2

FIR

Channel

DGND

VD-

10

VA-

0.1 0.1

-5

Filter

VD+

OUT2

20 bits

CS5520

2-Chann el

IN2

Delta-Sigma

OUT1

Modulator

IN1

1

MDRV-

10

Σ

XOUT

4-bit D/A

Converter

Gain

Block

1,2,4,8

25X

_

+

AIN-

AIN+

4.7 nF

*

301

350*100*350

R4

-5

R5

+5

LT1115orLT1007

R2

+5

+

1.9 mV/V

-

MICREL

100k

Calibration

Sync

Bridge

BX2

BX1

10k

10k

TP0610

2

6

7

MIC4428

10 0.1

+

4

-5

3

5

1X

_

+

VREF-

VREF+

5k*6k*5k

R1

R3

4.096 MH z

XIN

+5

VA+ MDRV+

+5

AGND1 AGND2

4.7 nF

*

301

R6

-5

* VISHAY S102K Series Resistors

50 Con versions/s ec b efore ave rag ing

0.1 0.1

Figure 17. CS5520 and an AC-Excited 1.9 mV/V Weigh Platform.

Platform

GSE 4444

Floating Beam

24 AN31REV3

Page 25

Bridge Transducer Digitizer Circuits

OCCURANCES

400

300

200

100

379

1000 Conversions

1 = 1.07 LSB

Average = 0.035 LSB

Output word

rate = 50/second

249

227

68

4

59

0

-4 -3 -2 -1 0 1 2 3 4

OUTPUT CODE (1 LSB = 34.3 nV)

Figure 18. Noise Histogram of 1000 Conversions.

13

1

NOISE (LSBs)

2.0

1 LSB = 34.3 nV

1.0

0.0

-1.0

-2.0

0.0 0.5 1.0

TIME (hour)

Figure 19. Digitizer Stability Over One Hour.

AN31REV3 25

Page 26

Bridge Transducer Digitizer Circuits

rate of 1/second. Averaging 50 words reduces

the noise by √50 , or by a factor of 7.07. Since

the standard deviation, or rms va lue of the noise

illustrated in Figure 18 is 1.07 LSB, the rms

output noise in the post-filtered samples will be

1.07/7.07 = 0.151 LSB rms. You can use the

rule of thumb that peak to peak noise is

approximately 6 to 6.6 times greater than the

rms value to predict the peak-to-peak noise in

the post-processed output words. This results in

a peak- to-peak noise in the post-filtered output

words of less than ±1 LSB for greater than

99.9% of th e post-fil tered ou tput words.

To illustrate the dc stability and noise of the

post-filtered output words over time, the 1 Hz

post-filtered output words were collected for a

period of one hour. Note that for this test the

input to the bridge amplifier was removed from

the load ce ll and tied to ground t hrough two 350

ohm resistors. This eliminates the load cell’s

sensitivity to vibration when studying the

digitizer input n oise characte ristics.

this configuration the digitizer can accurately

digitize an overra nge signal, even up to 195% of

full scal e.

The GSE 4444 platform has mechanical stops

which activate at approximately 120% of

capacity, so the synchronous detection weigher

will yield a noise-free 19-bit measurement, with

a 20% overrange capacity. If the digitizer was

used with a tension-compression load cell such

as the BLH E lectronics model LPT , the digitizer

would yield better than ±500,000 noise-free

counts.

Digitizer Noise And Averag ing

As illustrated in the previous example circuit, it

is good practice to ev aluate the performan ce of a

prototype digitizer. While many measures of

performance should be investigated (linearity,

stability over temperature, etc.), one of the

primary factors which limits measurement

resolution is noise in the digitizer circuit itself.

Figure 19 illustrates the peak-to-peak noise of

the digitizer over a one hour period. The plot

indicates that the drift and noise are less than

±1 LSB for more than 99.9% of the output

samples over the hour long period. This is

superb performance and illustrates the b enefit of

synchronous detection. Figure 18 and Figure 19

indicate that the 50 Hz output data from the

converter can averaged to yield a 1 Hz update

rate which is sta ble to 1 cou nt in ±524,000 when

the converter is set up for bipolar mode. The

CS5520 includ es a DAC and a ratiometric offset

register which can be used to offset the sp an in a

negative direction by 500,000 counts. This

allows the weig h scale to have 24, 000 counts of

underrange to accommodate any zero drift or

creep in the loa d cell. The measur ement span for

the 18 mV load cell output would be over

524,287 coun ts, but abo ve this would be another

500,000 counts which would allow the digitizer

to accurately measure overranged weights. In

Investigating the noise performance of the

digitizer should begin in the design phase.

Analysis should yield an estimate of the amount

of noise in the circuit. This discussion will not

focus on the a nalysis but will instead be limited

to evaluatin g the noise in the digiti zer circuit.

One simple method of evaluating digitizer noise

is to "ground" the input and collect enough

samples to evaluate the noise statistically.

"Grounding" the input involves connecting the

signal + and signal - leads of the digitizer input

amplifier to a quiet node which has a voltage

equivalent to the common mode output of the

bridge to be measured. In a system with l oad cell

excitation of +5 V and -5 V the inputs can be

tied to ground. If the load cell is excited with a

single supply ( for example, +5 V or +10 V), a

quiet source with a common mode voltage

compatible with the input of the amplifi er should

be generated. For ex ample, if the circuit runs on

26 AN31REV3

Page 27

Bridge Transducer Digitizer Circuits

a single +5 V supp ly, use two 100 ohm resistors

connected in series between +5 V and ground.

Then conne ct the input of the digiti zer circuit to

the 2.5 V node of the resistor pair . While a load

cell simulator may be used in many

circumstances, this can be a source of some

problems. Some simulators exhibit 1/f noise

which can adversely affect the data output from

a high resolution digitizer. And some simulators

may not work well with the circuits which use

ac-excitation. This is because some simulators

use switches which rectify the ac excitation

signal; th erefore the actual sign al to be measur ed

is corrupted. This can re sult in greater noise than

expected as well as a dc off set error.

The biggest difficulty in evaluating the noise

performance of a circuit is that some means of

getting the data out of the digitizer and into a

computer must be designed into the circuit. For

the CS5504/5/6/7/8/9 devices this can be

accomplished by making the SCLK, SDATA

and

DRDY signals available on a header. The

CDBCAPTURE system from Crystal has a

standard 10 pin (two rows of 5 pins) stake

header which can interface to the

CS5504/5/6/7 /8/9 products and capture dat a from

these converters. Alternatively, a designer may

include some other type of interface in his

system to port dat a to a PC-compatibl e computer

via the serial or p arallel port.

Once an interface is available, it is a matter

collecting enough conversion words to perform

meaningful statistical analysis on the data. The

CDBCAPTURE system enables the user to

capture data from the CS5504/5/6/7/8/9 and to

produce noise histograms. The CS5516 and

CS5520 are not supported with the

CDBCAPTURE system, but the CDB5516 or

CDB5520 evaluation boards can be configured

to collect data from these chips. Once data has

been collected into a file on a computer,

spreadsheets such as Quattro, Lotus, or Excel

can be used to analyze the data using a

frequency distribution function and statistical

functions. The data should also be plotted as

shown in Figure 18 to give the user an ind ication

that the data actually follows a Gaussian

(Normal) distribu tion. Thermal noise will have a

"bell-shaped" histogram. If the data words

represent thermal noise, one standard deviation

is equivalent to the rms nois e; while 99.9% of all

the data should fall within ± 3.3 standard

dev ia t io n s o f the mean. T herefore the peak-to-peak

noise is approximately 6.6 times the rms noise.

When performing statistical analysis on a

digitizer’s output, at least 500 to 1000 conversion

words should be included to lower statistical

uncertainty to an acceptable level.

Once the rms nois e is known (by calculatin g the

standard devia tion of the da ta set), avera ging can

be used to improve system resolution if it has

been confirmed that the noi se follows a Gau ssian

distribution. Data may not follow a Gaussian

distribution because it includes interference due

to dc-dc conve rters or to clock cou pling which is

picked-up by the sensitive analog circuitry. In

this case averaging output words may be

deceptive. Averaging will reduce the

peak-to-peak noise but the mean can be

adversely affected by the interference which is

included with the signal.

One additional noise test is to measure noise

over the entire input span of the converter. If

noise increases with higher signal amplitudes, it

suggests the voltage reference input to the

converter i s excessiv ely noi sy.

Conclusion

The circuits in this application note were

designed, constructed, and tested with the intent

of illustrating a wide variety of bridge digitizer

solutions. The circuits demonstrate various

power supply arrang ements and various levels of

measurement resolution; all with the intent of

helping designers understand the flexibility of

the A/D converters wh ich have been u sed.

AN31REV3 27

Page 28

• Notes •

Bridge Transducer Digitizer Circuits

28 AN31REV3

Loading...

Loading...