Page 1

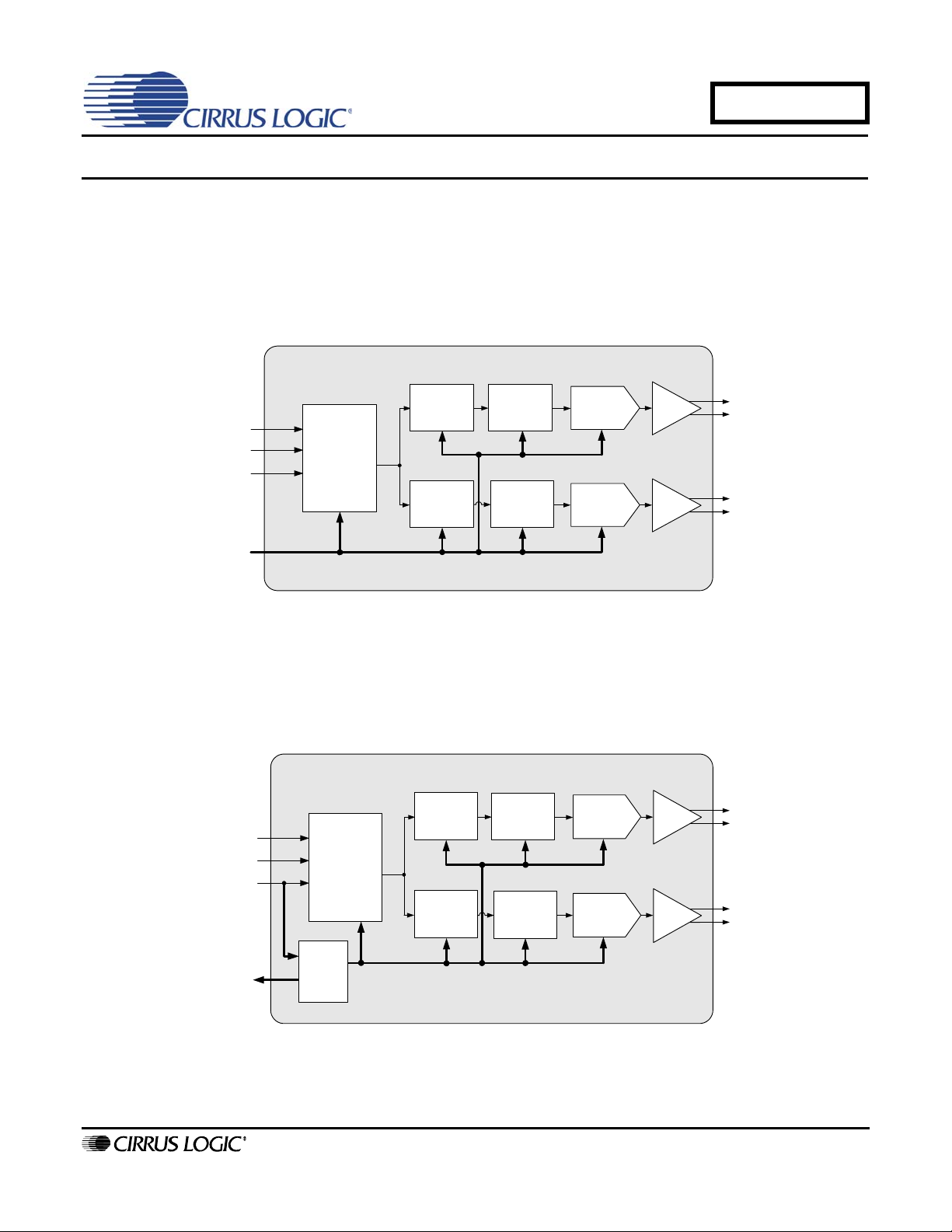

PCM

Serial

Interface

Serial Data Input

Right

Channel

Output

Left

Channel

Output

Left-Right Clock

Master Clock

Interpolation

Filter with

Volume

Control

Interpolation

Filter with

Volume

Control

Multibit ΔΣ

Modulator

Multibit ΔΣ

Modulator

Amp

+

Filter

Amp

+

Filter

DAC

DAC

Serial Clock

Figure 1. Typical DAC Architecture with Master Clock Input

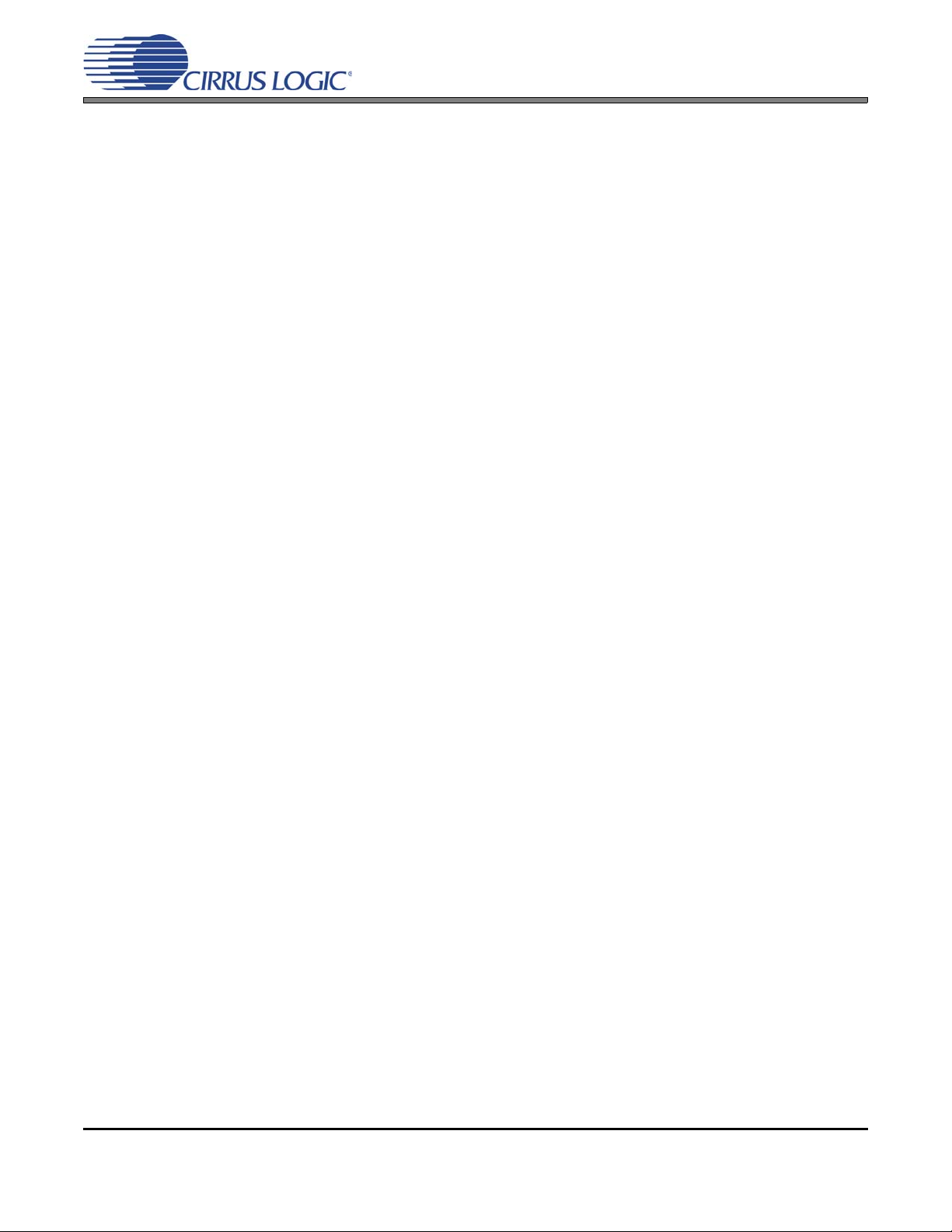

PCM

Serial

Interface

Serial Data Input

Right

Channel

Output

Left

Channel

Output

Left-Right Clock

Recovered MCLK

Phase

Locked

Loop

Interpolation

Filter with

Volume

Control

Interpolation

Filter with

Volume

Control

Multibit ΔΣ

Modulator

Multibit ΔΣ

Modulator

Amp

+

Filter

Amp

+

Filter

DAC

DAC

Serial Clock

Internal MCLK

Figure 2. CS4350 PLL DAC Architecture

AN306

Simplifying System Design Using the CS4350 PLL DAC

1. INTRODUCTION

Typical Digital to Analog Converters (DACs) require a high- speed Master Clock to clock their digital filter s and modulators, as well as some portions of their discrete time analog circuitry. This Master Clock (or system clock) is typically required to be synchronous to the left-right (frame or word) clock (LRCK) in order to maintain sample alignment

in the digital filters, state machines, modulator and discrete time analog sections. Figure 1 below shows an example

of a typical DAC clocked by an external Master Clock. The clock is applied to the MCLK pin and then distributed to

any internal logic that requires it.

As an alternative, PLL DACs are designed to derive their internal synchronous Master Clock from some other external source. This source could be any clock, but in practice it is commonly a video clock (27 MHz) or one of the

slower SCLK or LRCK signals which are mandatory for typical PCM audio interfaces (See AN282 “The 2-Channel

Serial Audio Interface: A Tutorial”). In practice, the CS4350 PLL DAC generates its Master Clock from the input leftright clock. Figure 2 shows the CS4350 PLL DAC architecture; from the input LRCK signal, the internal PLL derives

the Master Clock signal that is used to drive the internal system timing.

The internal Master Clock generation of a PLL DAC yields inherent benefits that simplify the design of audio systems. The CS4350’s unique implementation of the feature ta kes the concept a ste p further to provide an even grea ter degree of design simplicity, flexibility, and performance.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2009

(All Rights Reserved)

AUG '09

AN306REV1

Page 2

AN306

2. SIMPLIFIED SYSTEM DESIGN

In the design and layout of an audio mixed signal system, the conditioning and routing of the clocks are one of the

most important considerations. Because a converter’s Master Clock signal provides the sample clock that is used

as the time base for its modulator and switched ana log filters, it is typically the most sensitive to jitter and clock coupling. Eliminating the need for an external Master Clock signal provides for easier signal routing, reduced potential

for electromagnetic interference (EMI), and improved jitter immunity.

2.1 Eased Signal Routing

The Master Clock is typically generated in the digital section of a mixed signal system. This high-speed clock

then needs to be routed across the board to the an alog or mixed signal section in order to p rovide the master

clock for the converters. Since the CS4350 PLL DAC does not require a Master Clock input signal, it does

not need to be routed across the system board to re ach the conver ter. This eases the routing necessary for

the remaining clocks.

2.2 Reduced Potential for EMI

The Master Clock is typically the fastest clock used by a mixed signal audio converter. Routing any highspeed clock takes careful consideration in order to keep EMI to a minimum. The CS4350 PLL DAC provides

an easy way to ease EMI concerns by removing the dependency on the Master Clock, thus reducing the

number of high-speed clocks necessary to implement an audio subsystem.

2.3 Improved Jitter Immunity

As system designs become increasingly complex, the system clocking sources also become increasingly

complex. In many designs, the system clock is derived from a PLL within a large SOC (System on a Chip),

and is often used as the Master Clock source for the audio converters. The clocks generated from such

SOCs often exhibit high amounts of jitter, primarily as a result of the many asynchronous operations within

the SOC coupling into the clock signal. This high amount of jitter often limits the distortion (THD+N) performance and dynamic range of the mixed signal systems that use the SOC generated system clock.

Because the CS4350 PLL DAC generates its Master Clock internally, the jitter on an SOC or other system

clock source is of no consequence. When locking to LRCK, the CS4350’s PL L can reject any high-frequency

jitter that may be present on the slower LRCK.

3. LOCKING TO LRCK

The CS4350’s PLL locks to the incoming LRCK signal, and locking to LRCK provides some noteworthy advantages

over locking to another clock in the system. Specifically, locking to a system or video clock requires routing a highspeed clock to the converter and does not provide the EMI and routing advantages of locking to LRCK. Locking to

LRCK also provides for improved jitter rejection due to the lower native frequency of the left-right clock; this allows

a lower high-pass corner to be achieved in the PLL’s loop filter. When locking to LRCK, no other clocks are needed

beyond those already required in the serial PCM interface (SCLK, LRCK, and SDATA).

4. NO EXTERNAL LOOP FILTER COMPONENTS

A typical PLL consists of a phase comparator, ch arge pump, loop filte r and a VCO. The loo p filter creates an ana log

filter for the internal VCO control signal. Many PLLs require the loop filter components (typica lly two capacitors and

a resistor) to be external to the device because of internal size constraints. The CS4350 PLL uses a PLL configuration that requires no external PLL loop filter components. This allows the converter’s PLL to be self-sufficient and

also reduces the implementation cost in terms of external component price and total integration area.

2 AN306REV1

Page 3

AN306

PCM

Serial

Interface

Serial Data Input 1

Phase Locked

Loop

Left-Right Clock

Local Recovered MCLK

Serial Clock

PCM

Serial

Interface

Serial Data Input 2

PCM

Serial

Interface

Serial Data Output

CS4350

PLL DAC

DAC

ADC

SDIN1

SCLK

RMCK

LRCK

SDIN2

SCLK

LRCK

MCLK

SDOUT

SCLK

LRCK

MCLK

Long Board Traces

DSP/SOC

Figure 3. Localized MCLK using CS4350 RMCK Output

5. LOCALIZED MASTER CLOCK RECOVERY AND DISTRIBUTION

The Recovered Master Clock (RMCK) output is a unique feature of the CS4350. The RMCK output allows the

CS4350’s high-speed recovere d clock Master Clock signal to be used as the Master Clock for other more typical

audio converters that do not have built-in PLLs. Thi s feature is useful for localizing the high-speed clock to a portion

of the circuit board separate from the rest of the system, or when the integrity of a long Master Clock run could affect

the converter performance.

Figure 3 shows the CS4350 receiving only the necessary PCM clocks from a distant source while generating a re-

covered Master Clock to be used locally to the CS4350. This allows the RMCK signal recovered and provided by

the CS4350 to be used in a small area, thereby easing the system design and the routing of clocks.

Some audio converters require specific MCLK to LRCK ratios that vary according to the sample rate. The CS4350’s

RMCK output can provide this ratio variance independently from its internal Master Clock signal. This allows flexibility in the local audio converters that are using the CS4350’s RMCK output by providing a wider range of

MCLK/LRCK ratios for use.

For converters that have an automatic speed mode detection feature, no register writes are necessary to change

from 44.1 kHz to 96 kHz sample rates as the CS4350’s RMCK can be set to automatically adjust the MCLK to LRCK

ratio accordingly. See Section 4.2.1 of the CS4350 data sheet for more details on this feature.

AN306REV1 3

Page 4

AN306

Figure 4. Typical 128x DAC Out-of-Band Noise Figure 5. CS4350 Out-of-Band Noise

-150

+0

-140

-130

-120

-110

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

d

B

V

20k 120k40k 60k 80k 100k

Hz

6. OUT-OF-BAND PERFORMANCE

Converters that rely on an external Master Clock signal are often only able to operate with an internal over-sampling

rate of 128 times the sample rate (128 x Fs). This can limit the performance of the modulator by requiring the mo dulator noise shaping to begin rising at a lower frequency tha n would be possible if a higher modulator rate were a vailable.

Because the CS4350’s circuitry has access to the internal high-frequency output of the PLL, it is able to achieve a

4x higher modulator rate than typical audio converters. This allows for much lower out-of-band noise than is typically

achievable in a 128x over-sampling DAC. See Figure 4 and Figure 5 .

As a result, the CS4350 is able to achieve lower noise within much wider frequency band than many similar typical

DACs that require an external Master Clock signal. This can provide significant benefits for application s that are sensitive to noise outside of the typical 20 kHz audio band. Achieving similar out-of-band performance using a typical

128x over-sampling DAC would require high-order off-chip analo g filtering.

+0

-10

-20

-30

-40

-50

-60

d

-70

B

-80

V

-90

-100

-110

-120

-130

-140

-150

20k 120k40k 60k 80k 100k

Hz

7. CS4350 ANALOG ARCHITECTURE

The CS4350 implements a current-based DAC with on chip current-to -voltage (I-to- V) conversio n and a con tinuous

time summing amplifier. It offers both differential and single-ended analog output options with an analog supply of

3.3 V or 5 V. For design flexibility, the full-scale output reference level is set by an internal fixed reference to allow

operation with a 2 Vrms differential, or 1 Vrms single-ended output, regardless of changes to the VA supply.

8. CONCLUSIONS

The CS4350 PLL DAC offers a number of advantag es rela tive to con vention al d igital- to -a nalog co nver ters, e ach o f

which can be instrumental in simplifying the design of audio systems. From flexible output options, to localized Master Clock recovery and distribution, to low out-of-band noise performance, to system clock jitter independence, to

the easing of PCB layout and EMI concerns, the CS4350 can be called upon to solve many real-world problems of

audio system designers.

For more information about the CS4350 PLL DAC, please refer to the CS4350 datasheet available at www.cir-

rus.com.

4 AN306REV1

Page 5

REVISION HISTORY

Revision Changes

REV1 Initial Release

AN306

AN306REV1 5

Page 6

AN306

Contacting Cirrus Logic Support

For all product questions and inquiries, contact a Cirrus Logic Sales Representative.

To find the one nearest you, go to www.cirrus.com

.

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries (“Ci rrus”) believe that t he information contained in this document is accurate and reliable. However, the information is subject

to change without noti ce and is p rovided “AS IS” wit hout warran ty of any k ind (expr ess or i mplied). Customers are advis ed to ob tain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other inte llectual property rig hts. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARR ANTED FOR USE

IN AIRCRAFT SYSTEMS, MILITARY APPLICATIONS, PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD

TO BE FULLY AT THE CUSTOMER’S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTO RY OR IMPL IED, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED

IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER’S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER

AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS’ FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH

THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo design s ar e tra de m a rks of Ci rru s Lo gi c, Inc. All o ther bra nd and product names in this document may be trademarks

or service marks of their respective owners.

6 AN306REV1

Loading...

Loading...