Page 1

Application Note

USING THE CS5460A AUTO-BOOT MODE

AN225

1. Which EEPROMs Can Be Used?

Several industry-standard serial EEPROMs that

will successfully run auto-boot with the CS5460A

are listed below:

•Atmel

AT25010

AT25020

AT25040

• National Semiconductor

NM25C040M8

NM25020M8

•Xicor

X25040SI

These types of serial EEPROMs expect a specific

8-bit command word (00000011) in order to perform a memory download. The CS5460A has been

hardware programmed to transmit this 8-bit command word to the EEPROM at the beginning of the

auto-boot sequence.

1.1 Further Explanation of the Auto-Boot Sequence

The auto-boot sequence is terminated by writing a

‘1’ to the STOP bit in the CS5460A’s Control Register. This action is performed as the last command

in the EEPROM command sequence. At the completion of the write to the Control Register (provided STOP bit = “1”), SCLK stops, and CS

thereby reducing power consumed by the EEPROM. At completion of the Auto-Boot sequence,

the serial port will revert to functioning as a slavemode interface. Therefore, if desired, the

CS5460A registers can still be read by an external

device, such as a central office controller, connected to the meter assembly by a bus interface.

1.2 Sample Auto-Boot Sequence

The serial data for such a sample sequence is

shown below in single-byte hexidecimal notation:

rises,

40 00 00 61 ;In Configuration Register,

turn high-pass filters on, set

K=1.

44 7F C4 A9 ;Write value of 0x7FC4A9 to

Current Channel Gain Register.

46 7F B2 53 ;Write value of 0x7FB253 to

Voltage Channel DC Offset

Register.

4C 00 00 14 ;Set Pulse Rate Register to

0.625 Hz.

74 00 00 04 ;Unmask bit #2 (“LSD” bit in

the Mask Register).

E8 ;Start performing continuous

computation cycles.

78 00 01 40 ;Write STOP bit to Control

Register, to terminate autoboot initialization sequence,

andalsosettheEOUT

output to Mechanical Counter

Format.

When the CS5460A is commanded by the EEPROM to perform a certain operation, the operation will not be pre-maturely terminated by the

assertion of the Control Register’s STOP bit. In the

above example, the ‘Start Conversions’ command

(0xE8) is issued from the EEPROM, and therefore

the CS5460A will continue to perform continuous

A/D conversions even after the STOP bit is asserted.

1.3 How do I reset the CS5460A in Auto-Boot Mode during Brown-Out/Black-Out conditions?

The power line that is to be metered may enter a

black-out or brown-out condition at certain times,

due to problems at the power plant or other environmental conditions (ground fault, electrical

storms, etc.) In such conditions, it is important for

the meter assembly to accomplish a proper reset,

pulse

www.cirrus.com

CopyrightCirrus Logic, Inc. 2003

(All Rights Reserved)

FEB ‘03

AN225REV1

1

Page 2

AN225

so that it can continue normal metering operations

once the line power is restored. When the

CS5460A is controlled by a microcontroller, the microcontroller is typically programmed (by the user)

to handle these power-fail-reset situations. In the

case of auto-boot, the CS5460A may be expected

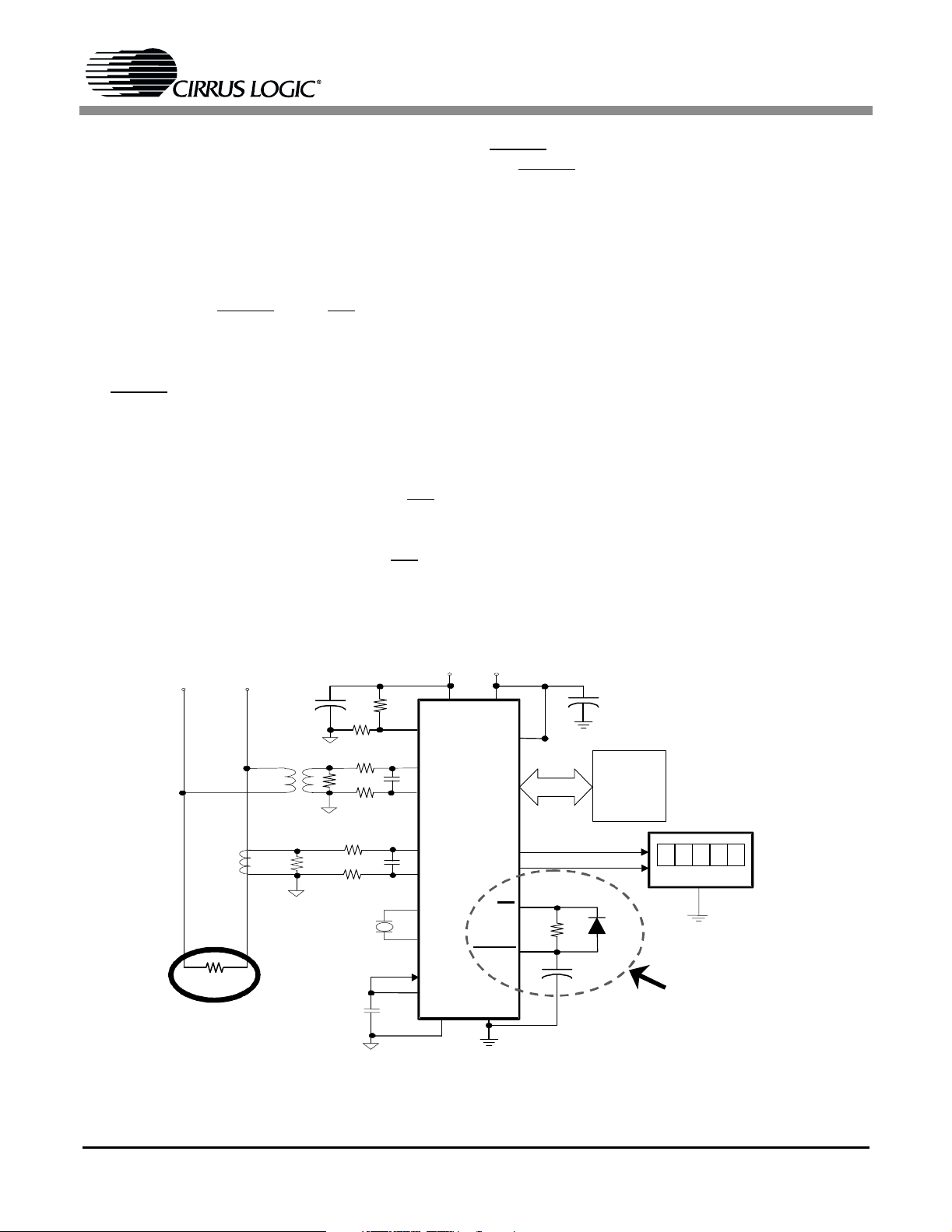

to reset itself (by re-executing the Auto-Boot sequence) whenever the line-power is restored. Figure 1 shows a reasonably reliable way to configure

the CS5460A’s RESET

and INT pins of the

CS5460A to restart the Auto-Boot sequence after

a brown-out or black-out condition. This configuration employs a diode, a resistor, and a capacitor on

the RESET

pininanattempttoallowtheCS5460A

to reboot after a sudden loss of power, followed by

a reinstatement of power.

Note that in the above auto-boot example code set

(see Section 1.2) the LSD bit is un-masked, in order to cause a high-to-low transition on the INT

pin

whenever the PFMON low-supply threshold is

reached on the PFMON pin. If a power supply loss

condition is sensed on PFMON, then the INT

pin is

asserted to low (because LSD is un-masked),

which allows the BAT85 diode to quickly drain the

charge on C

. But whenever the +5V power is

BOOT

restored, the resistor-capacitor network will force

RESET

the RESET

to recharge slowly. The slow rise-time on

pin can help to allow the oscillator circuitry and the CS5460A’s internal reference circuitry enough time to stabilize before the device

attempts to re-execute with the Auto-Boot sequence. This will allow the CS5460A to resume its

normal metering operations after power is restored. (User must provide suitable resistor divider

configuration on the PFMON pin, see Figure 1.)

Use of this configuration does not guarantee that

the CS5460A will reset properly, when exposed to

any sudden disturbance in power.

In addition to the configuration described above,

the designer should include sizeable commonmode capacitors to the VA+/VD+ pins (see

Figure 1). Such capacitance on the analog/digital

power supply pins will increase the amount of time

over which the CS5460A will remain operational

after power is lost, which therefore increases the

chances that the CS5460A will successfully re-execute a proper reboot upon restoration of power.

Suggested values are >47 µF (per pin) or >100 µF

(total).

N

LOAD

Figure 1. CS5460A Auto-Boot Configuration: Automatic Restart After Power Failure

L

T2

47 uF

AGND

T1

AGND

AG

+

ND

4.096 MHz

CRYSTAL

AGND

+5V

VA+ VD+

PFMON

VIN+

VIN-

CS5460A

IIN+

IIN-

XIN

XOUT

REFIN

REFOUT

VA- DGND

+5V

Mode

EOUT

EDIR

INT

RESET

DGND

10k

30uF

SPI

+

+

C

47 uF

BOOT

DGND

E2PROM

BAT85

00000

TOTALIZER

DGND

This resistor-capacitor- diode

configuration helps to ensure a

smooth power-down, as well as

a proper power-up/reset during

and after a power black-out or

brown-out event.

2

Page 3

AN225

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find one nearest you go to www.cirrus.com

IMPORTANT NOTICE

“Preliminary” product information describes products that are in production, but for which f ull char acterization data is not yet available. “Advance” product information describes products that are in devel opment and subject to development changes. Cirrus Logic, Inc. and its subsi diaries (“Cirrus”) believe that the information contained in this document is accurate and reli able. However, the information is subject to change without notice and is provided “AS IS” without warranty

of any kind (express or implied). Customers are advised to obtain the latest version of relevant information to verify, before placing orders, that information being

relied on is current and complete. All products are sold subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaini ng to warranty, patent infringement, and limitation of liability. No r esponsibi lity is assumed by Cirrus for the use of thi s information, i ncluding use of this

informati on as the basis for manufacture or sale of any items, or for infri ngement of patents or other rights of thi rd parties. This document is the property of Cirrus

and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights, copyrights, trademarks, trade secrets or

other intellectual property rights. Cirrus owns the copyri ghts associated with the information contained herein and gi ves consent for copies to be made of the

informati on only for use within your organization with respect to Cirrus int egrated circuits or other parts of Cirrus. This consent does not extend to other copying

such as copying for general distribution, advertising or promotional pur poses, or for creating any work for resale.

An export permit needs to be obtained from the competent authorities of the Japanese Government if any of the products or technologi es describe d in thismaterial and controlled under the “Foreign Exchange and Forei gn Trade Law” is to be exported or taken out of Japan. An export l icense and/or quota needs to be

obtained from the competent authorities of the Chinese Government if any of the products or technologies described in this material is subject to the PRC Foreign

Trade Law and is to be exported or taken out of the PRC.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE

PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS

IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK.

Cirrus Logic, Cirrus, and the Cirrus Logic l ogo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in this document may be trademarks or service marks of their respecti ve owners. Microwire is a trademark of National Semiconductor Corporation.

3

Page 4

Loading...

Loading...