Page 1

AN168

Application Note

ACOUSTIC PATH DESIGN FOR FULL-DUPLEX CELLULAR

HANDS-FREE CAR KITS

This application note describes a design procedure

coupled with some testing procedures to enable a

system designer to implement a low cost

full-duplex cellular hands-free system for cars

using the CS6422 Enhanced Echo Cancelling IC.

This application note focuses on the design of the

acoustic path, that is, the path between the acoustic

output (AO) and the acoustic input (APO) of the

CS6422. The acoustic path contains the speaker

driver, the speaker, the air path between the

speaker and the microphone, the microphone, and

the microphone preamp.

Additionally, a suggested set of CS6422

configuration parameters is presented as well as

some system-level tests that can be used to

optimize the parameters for a particular

environment.

1. DESIGN PROCESS AND CONSIDERATIONS

There are four parts to the hands-free design

process: mechanical design, electrical design, echo

canceler coefficient optimization, and testing. This

note will investigate all four.

1.1 Design Flow

The design flow for full-duplex systems is as

follows:

1) Design the mechanical and electrical systems

for low distortion, specifically less than

2% THD across frequency.

2) Install the equipment in the target test system,

usually a car.

3) Tweak the mic preamp gain to achieve -9 dB

acoustic coupling.

4) Load the starting point example CS6422 register configuration.

5) Perform parameter optimization tweaking

tests.

6) Test under actual driving conditions. If necessary, modify speaker/mic placement and test

again.

http://www.cirrus.com

Copyright © Cirrus Logic, Inc. 2006

(All Rights Reserved)

MAR ‘06

AN168REV2

Page 2

AN168

TABLE OF CONTENTS

1. DESIGN PROCESS AND CONSIDERATIONS ........................................................................1

1.1 Design Flow ........................................................ .... ... ... ... .................................................. 1

1.2 Mechanical Design ............................................................................................................. 4

1.2.1 Selecting the Acoustic Components .....................................................................4

1.2.1.1 Speaker Requirements ................................................. ... .....................4

1.2.1.2 Microphone Requirements ......................................................... ... ... .... . 4

1.2.1.3 Speaker Housing Requirements ......................... .... ... ... ... .... ... ... ... ... .... . 5

1.2.2 Placing the Speaker and Microphone ................................................................... 5

1.3 Electrical Design ........................................... ... ... .... ... ... ... .... .............................................. 5

1.3.1 Selecting the Speaker Driver ................................................................................ 5

1.3.2 Setting the Speaker Driver Gain ........................................................................... 6

1.3.3 Volume Control ...... ... .... ... ... ... ... .... ... ... ..................................................................7

1.3.4 Acoustic Coupling .. ... .... ... ... ... ... .... ... ... .......................................... ... .... ... ... ... ... .... . 8

1.3.5 Setting the Mic Preamp Gain ........................................ ... ... .... .............................. 8

1.3.6 Acoustic Sidetone .. .......................................... ... .... ... ... ... ... ................................ 11

1.4 Echo Canceler Parameter Optimization ...........................................................................11

1.4.1 Starting Example .................................... .... ... ... ............................................. ... ... 11

1.4.2 Tweaking the Parameters ...................................................................................12

1.4.3 Network Sidetone ............................. ... ... .... ... ... ... .... ... ... ... ................................... 13

1.4.4 Loop Gain .................. .... .......................................... ... ... ... ... ................................ 14

1.5 Tests ................................................ ... ... .... ... ... ... .......................................... .... ... ............ 14

1.5.1 Acoustic Coupling .. ... .... ... ... ... ... .... ... ... .......................................... ... .... ... ... ... ... ... 15

1.5.1.1 Loop Gain Method ...................... ................... ................... ................... 15

1.5.1.2 Frequency Response Method .............................................................17

1.5.2 Acoustic Distortion ..................................................... ......................................... 17

1.5.2.1 Frequency Sweep Test .......................................................................18

1.5.2.2 Buzz Test ......................... ... ... .... ... .......................................... ... ... ... ... 18

1.5.3 Acoustic ERLE ....................... ... .... ... ... .......................................... ... .... ... ... .........19

1.5.3.1 White Noise RMS Method .......................... ......................................... 19

1.5.3.2 Loop Gain Method ...................... ................... ................... ................... 20

1.5.4 Call Testing and Coefficient Optimization ........................................................... 23

1.5.4.1 Far-end single-talk counting ................................................................23

1.5.4.1.1 Subtest A, EC Convergence Test .............................................. 23

1.5.4.1.2 Subtest B, Half-Duplex to Full-Duplex transition time ................ 24

1.5.4.1.3 Subtest C, Transmit Suppression test .......................................24

1.5.4.2 Double-talk .......................................................... ................................ 24

1.5.4.3 Half-duplex alternate counting ................................................ ... ... ... ... 25

1.6 Layout Guidelines ................................................... ... ... ... .... ... ... ... ................................... 25

1.6.1 CS6422-specific guidelines ........................ ... ... ... .... ... ......................................... 25

1.6.2 Car-Kit guidelines ............................. ... ... .... .......................................... ... ... ... ... ... 26

1.6.2.1 +5VA/AGND Components ............. ... ... .... ......................................... ... 26

1.6.2.2 +5VD/DGND Components ............................... ... .... ............................ 26

1.6.2.3 +12VBATT/BATTGND Components ................................................... 27

1.7 Quick list of important points: .................................. ... ... ... .... ... ... ...................................... 27

1.7.1 Reset and configuration timing ............................................................................ 27

1.7.2 Distortion .................................................................... ... ...................................... 27

1.7.3 Speaker/mic placement ................. ... ... ... .... ... ... ............................................. ... ... 27

1.7.4 Acoustic coupling ................................... .... ... .......................................... ... ... ... ... 28

1.7.5 Training sequence ......................... ............. ......... ............. ............. ............. ......... 28

2. APPENDIX - EXAMPLE SPEAKER DRIVER CIRCUITS ...................................................... 29

2.1 Example 1: TDA1519A -- 15 Watts into 4 W ................................................................. ... 29

2.2 Example 2: TDA2003 -- 3 Watts into 4 W ........................................................................29

2.3 Example 3: TDA1905 -- 2.5 Watts into 4 W .....................................................................33

2.4 Example 4: LM1877-- 2 Watts into 4 W ...........................................................................34

2.5 Example 5: LM4861-- 1 Watt into 4 W .............................................................................34

2 AN168REV2

Page 3

AN168

n

t

o

f

y

s

.

e

s

A

A

e

LIST OF FIGURES

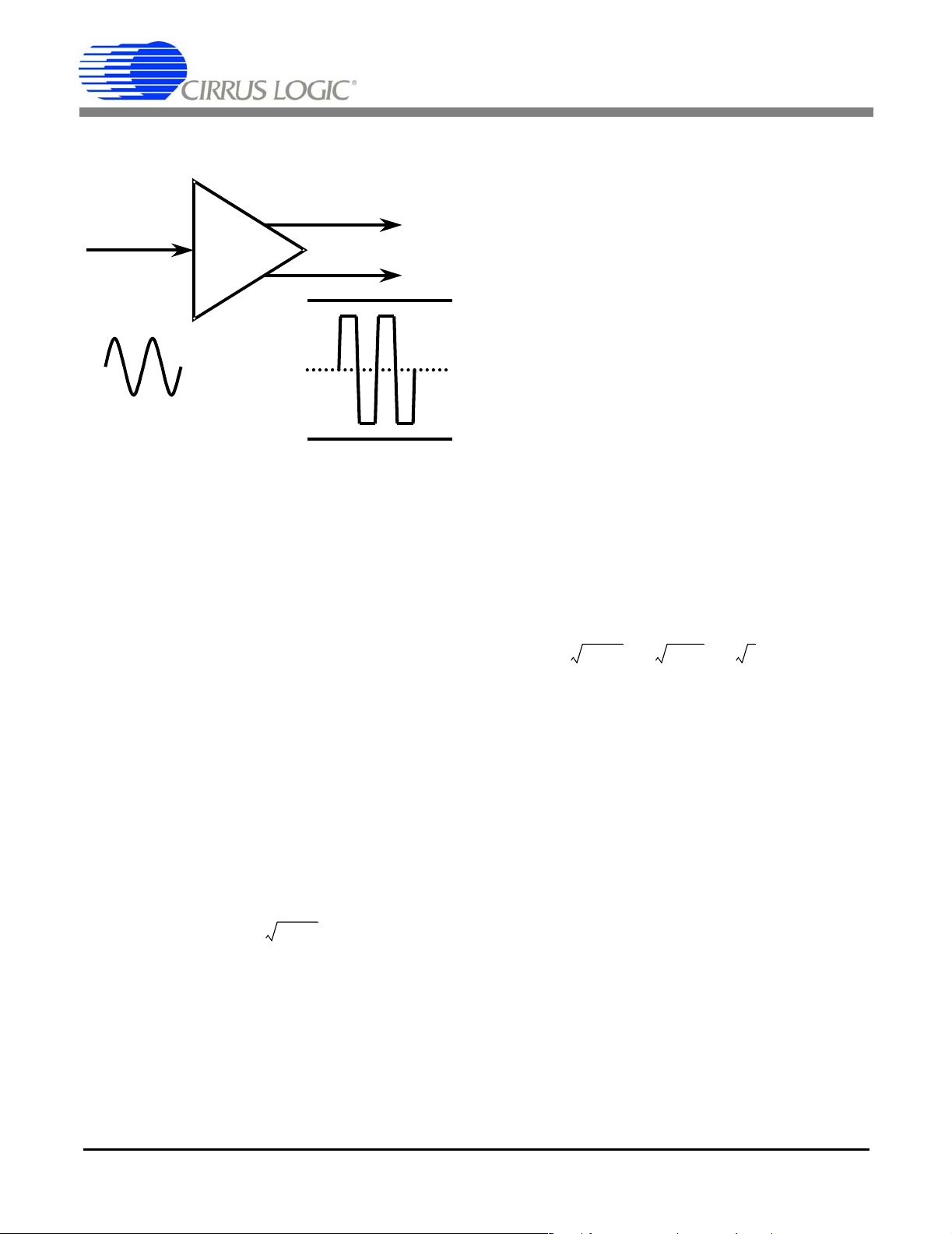

Figure 1. Speaker Distortion.................................................................................................................... 4

Figure 2. Speaker Driver Distortion......................................................................................................... 6

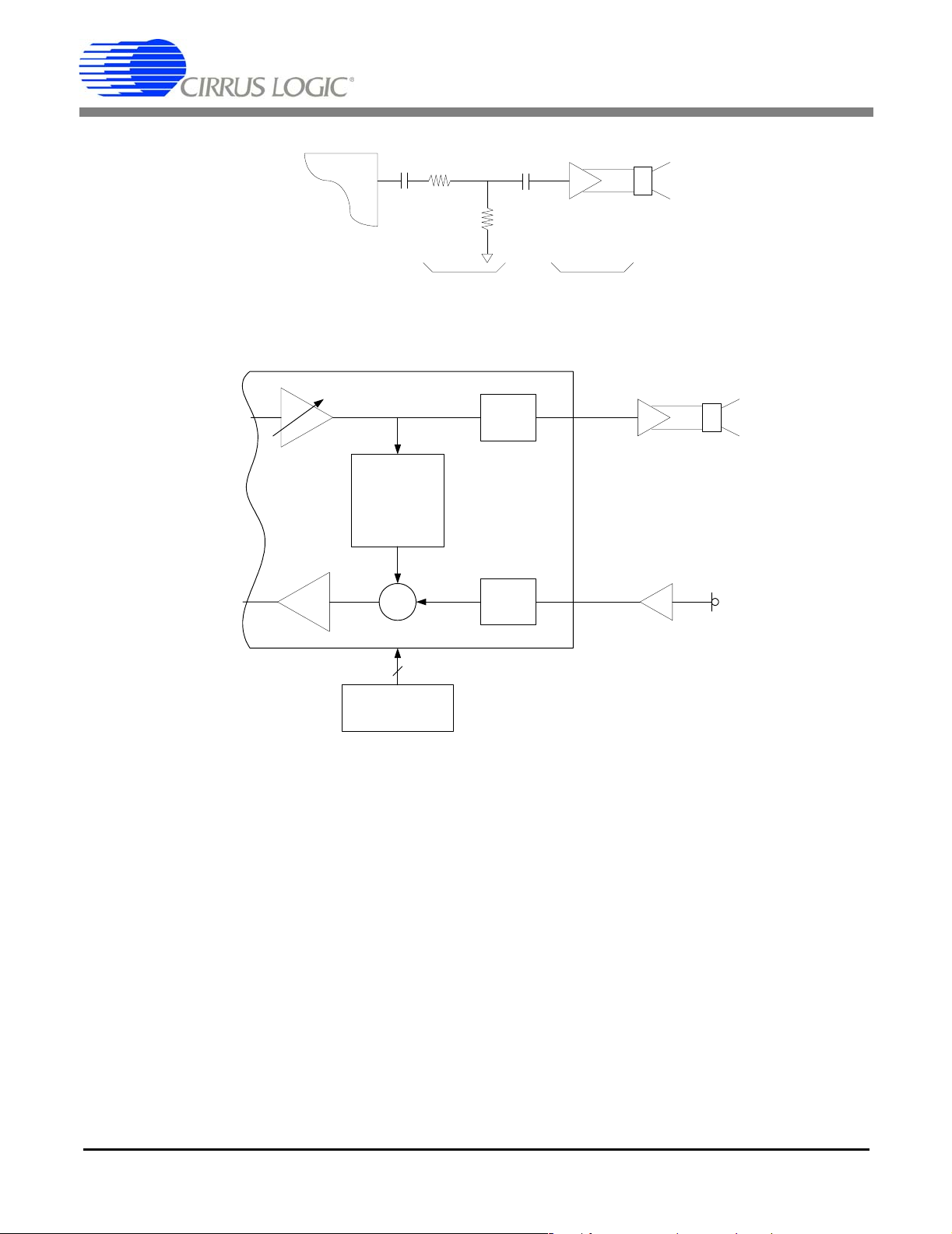

Figure 3. Generic Speaker Driver Configuration.....................................................................................7

Figure 4. Using RVol to Implement Volume Control................................................................................7

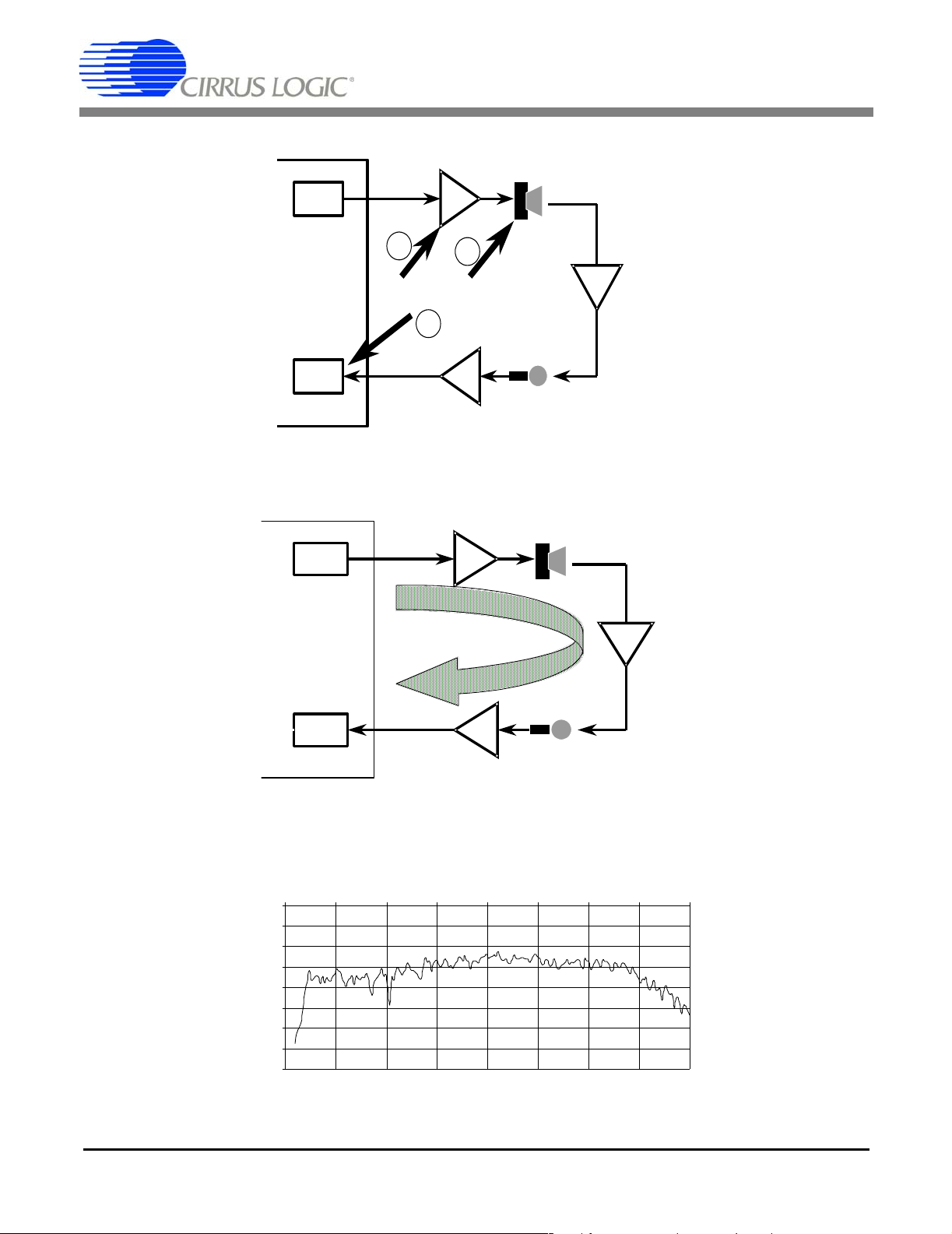

Figure 5. Three Common Sources of Acoustic Path Distortion............................................................... 9

Figure 6. Acoustic Coupling Design Target.............................................................................................9

Figure 7. Example Acoustic Coupling Frequency Response..................................................................9

Figure 8. Setting the Acoustic Coupling................................................................................................10

Figure 9. Loop Gain with Network Sidetone..........................................................................................13

Figure 10. Loop Gain Diagram.............................................................................................................. 15

Figure 11. Acoustic Coupling Measurement Method ............................................................................ 16

Figure 12. Example Acoustic Coupling Frequency Response.............................................................. 17

Figure 13. Relative THD+N................................................................................................................... 18

Figure 14. Coupling-Weighted THD+N..................................................................................................19

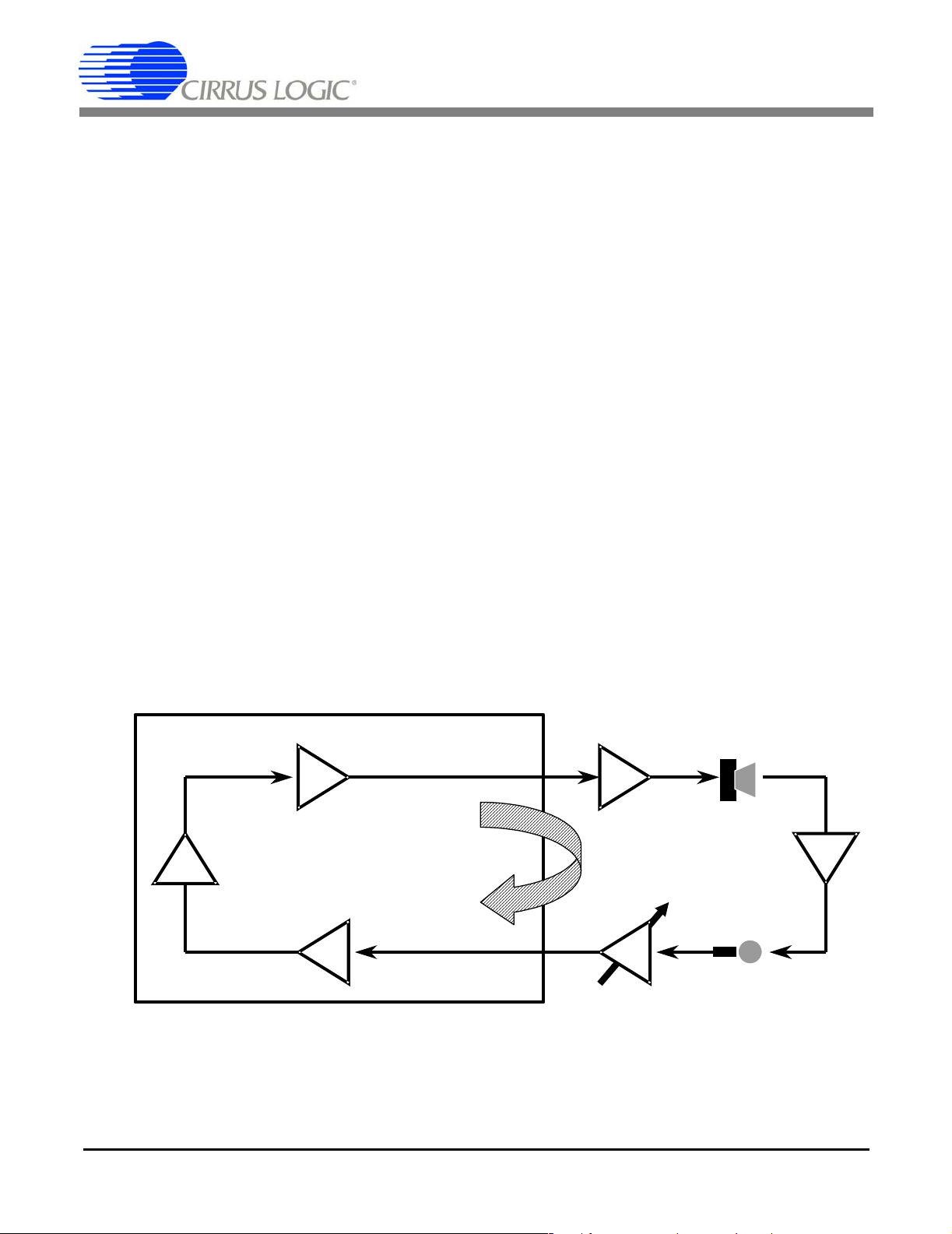

Figure 15. Acoustic ERLE Measurement -- Train the AEC................................................................... 21

Figure 16. Acoustic ERLE Measurement -- Freeze AEC...................................................................... 22

Figure 17. Acoustic ERLE Measurement -- Clear AEC......................................................................... 22

Figure 18. Suggested CS6422 Layout..................................................................................................25

Figure 19. Speaker Driver Implementation............................................................................................ 26

Figure 20. CS6422 Reset and Configuration Timing............................................................................. 27

Figure 21. Example 4 kHz, 3-Pole Butterworth Low-Pass Filter ........................................................... 30

Figure 22. TDA 1519A Schematic.........................................................................................................31

Figure 23. TDA 2003 Schematic...........................................................................................................32

Figure 24. TDA 1905 Schematic...........................................................................................................33

Figure 25. LM 1877 Schematic ............................................................................................................. 35

Figure 26. LM 4861 Schematic ............................................................................................................. 36

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find the one nearest to you go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliabl e. However, the informatio

is subject to change without notice and is provided "AS IS" without warranty of any kind (express or implied). Customers are advised to obtain the lates

version of relevant information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject t

the terms and conditions of sale supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation o

liability. No responsibility is assumed by Cirrus for the use of this information, including use of this information as the basis for manufacture or sale of an

items, or for infringement of patents or other rights of third parties. This document is the property of Cirrus and by furnishing this information, Cirru

grants no license, express or implied under any patents, mask work rights, copyrights, trademarks, trade secrets or other intellectual property rights

Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information onl y for us

within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent does not extend to other copying such a

copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED

OR WARRANTED FOR USE IN AIRCRAFT SYSTEMS, MILITARY APPLICATIONS, PRODUCTS SURGICALLY IMPLANTED INTO THE BODY,

UTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS

PRODUCTS IN SUCH APPLICATIONS IS UN DE RS TOO D TO BE FULLY AT THE CUS TOMER ’ S RISK AND CIRRU S DI S CLA IMS AND MA KES NO

WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

PARTICULAR PURPOSE, WITH REGA RD TO A NY CI R RUS PRODUCT TH A T IS US E D IN SUCH A MAN NER. IF THE CUSTOM ER OR

CUSTOMER’S CUSTOMER USES OR PERMITS THE USE OF CIRRUS P R O DUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY

SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEE S, DI S TRIB UTORS AND OTHER AGENTS FROM ANY

ND ALL LIABILITY, INCLUDI NG ATTORNEY S ’ FEES AND COS TS, THAT MA Y RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in this document may b

trademarks or service marks of their respective owners.

AN168REV2 3

Page 4

AN168

1.2 Mechanical Design

The performance of full-duplex hands-free designs

is strongly influenced by the mechanical hardware,

far more so than comparable half-duplex systems.

Upgrading a half-duplex design by adding a

full-duplex echo controller without changing the

half-duplex mechanical hardware typically results

in a system whose performance is unacceptable.

This section describes the critical parameters of the

mechanical design that ensure quality full-duplex

operation.

The mechanical design consists of speaker and

microphone component selection, speaker housing

and mounting, and speaker and microphone

placement in the car..

1.2.1 Selecting the Acoustic Components

1.2.1.1 Speaker Requirements

The quality of the speaker in a full-duplex system

is critical to system performance because echo

cancelers are sensitive to signal distortion. Because

the echo canceler uses a linear filter to model the

acoustic path, the acoustic path to be modeled must

be linear in order for the echo canceler to work

well. The total worst-case distortion in the acoustic

path, which includes the speaker driver, the

speaker, the microphone, and the microphone

preamp, should be less than 2% THD across

frequency.

The speakers in automotive hands-free systems are

typically driven with a maximum RMS power

between 0.5 and 5 Watts. In order to maintain

2% THD or less, it is necessary to install a speaker

whose RATED power is at least twice as large as

the maximum power to be driven. For example, if

we wish to drive 2 Watts into the speaker, then the

speaker's RATED power should be 4 Watts or

greater. The RATED power of a speaker is the

power at which the distortion performance is

specified. The typical distortion specification for a

speaker operating at its RATED power is either 5%

or 10% THD, depending on how the manufacturer

specifies distortion.

Speakers are also specified with a MAX power

rating. The MAX power is the power level above

which the speaker can be damaged. The RATED

power, if it is given, is typically about half as large

as the MAX power. Thus if the RATED power is

not given, a good rule is to assume that the RATED

power is about half of the MAX power.

NOTE: The above RATED power/MAX power

generalization does not hold for new generation

ultra-thin Mylar speakers. The poor distortion

performance of these thin speakers makes them

unsuitable for full-duplex car designs. Thick

speakers exhibit a more linear behavior than thin

speakers of equal diameter and are preferred in

full-duplex designs.

1.2.1.2 Microphone Requirements

Less care is needed in microphone selection than in

Speaker

Figure 1. Speaker Distortion

4 AN168REV2

speaker selection. Almost any standard

inexpensive electret microphone will work because

microphones are inherently fairly linear devices.

Microphones that cancel background noise due to

their mechanical construction are preferred over

those that do not. Microphones that are

omnidirectional are preferred over those that are

directional.

Page 5

AN168

1.2.1.3 Speaker Housing Requirements

The quality of the speaker housing affects the

performance of the system because the speaker can

induce vibrations in its housing if it is not properly

mounted. These vibrations tend to create “buzzing”

artifacts which are not linear and result in poor

echo canceler performance.

Speakers that are supplied after-market in a

housing and speakers that are part of the car's radio

system generally do not present problems. It is the

speakers that are glued or otherwise rigidly affixed

to their plastics that create nonlinear buzzing

artifacts.

Speakers should be soft-mounted to their housings

by using soft pliable acoustic foam. Care should be

taken to minimize any physical means by which the

speaker can induce vibrations in the plastics.

The Test section contains a test procedure for

testing and eliminating buzzing artifacts.

1.2.2 Placing the Speaker and Microphone

The placement of the speaker and the microphone

affects the gain selection portion of the electrical

design of the system which will be covered shortly.

The microphone should be placed as close as

feasible to the talker's mouth. This maximizes the

signal-to-noise ratio (SNR) of the talker's speech.

In a car, the optimal place for the microphone is

near the rear view mirror, usually attached to the

driver’s visor.

There are two considerations for the speaker

placement. The more important of the two is that

the speaker be placed such that there is a minimum

of movement in the air space between the speaker

and the microphone. This will minimize the

number of updates and corrections that the adaptive

filter makes during the call, resulting in the

transmission of very little residual echo to the

far-end listener. The second consideration is that

the speaker should be placed as far from the

microphone as possible. This minimizes the

acoustic coupling between the speaker and mic and

allows the mic preamp gain and speaker driver gain

to be maximized.

The optimum placement for the speaker in a car is

the top of the dashboard. Whereas this does not

minimize the distance between the speaker and the

mic, it does limit the changes in the acoustic path,

allowing the adaptive filter to update less often,

resulting in less residual echo transmission. Other

placement options, below the dash, driver's side

door, and passenger's side door, favorably decrease

the acoustic coupling, but result in the driver or the

passengers being positioned directly in the path

between the speaker and the microphone.

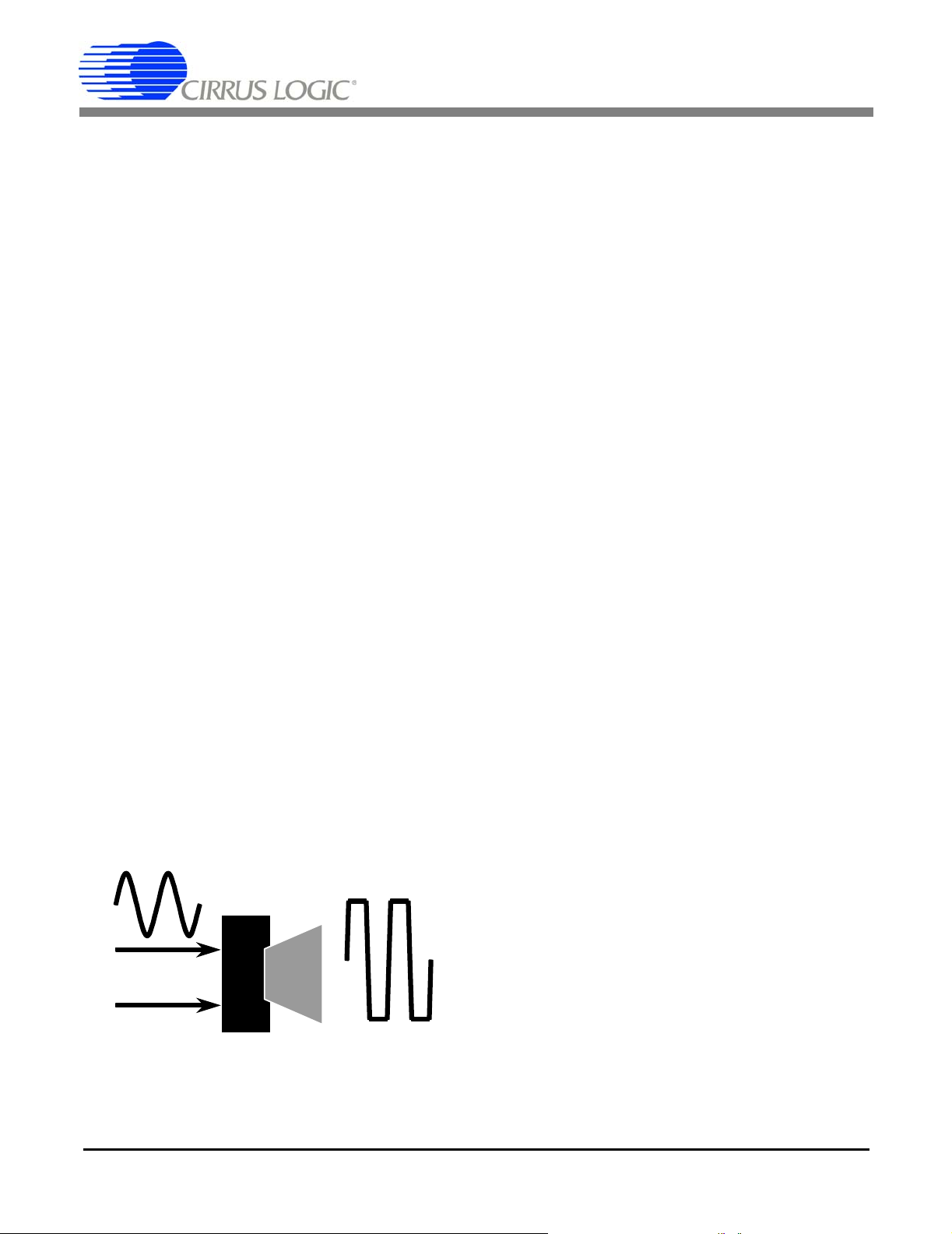

1.3 Electrical Design

The electrical design process consists of the

component selection of the speaker driver, the gain

selections of the speaker driver and the mic

preamp, and the implementation of an acoustic

sidetone. The primary design consideration of the

electrical design process is to limit the distortion in

the acoustic path to less than 2% THD.

1.3.1 Selecting the Speaker Driver

Many system designers overestimate the quality of

their speaker drivers. For example, a speaker driver

that claims to be “5 Watts” on the cover of its data

sheet is not suitable to drive 5 Watts of power into

the speaker of a full-duplex echo cancelling

system. The reasons are two-fold:

1) The “5 Watts” number is usually a Typical

number, not a Maximum or a Minimum specification

2) “5 Watts” is specified with a THD of 10%, not

the 2% number that we are designing to.

AN168REV2 5

Page 6

AN168

Speaker Driver

Vout

Rx Out

VCC

GND

Figure 2. Speaker Driver Distortion

The Appendix lists five example speaker driver

circuits that are suitable for full-duplex hands-free

systems.

1.3.2 Setting the Speaker Driver Gain

V

Gain

-------- -

=

Vin

where Vin = full-scale voltage at the AO pin of the

CS6422, which is 1 Vrms, or 0 dBV.

Additionally, the gain can be expressed in dB using

the following relationship:

Gain dB() 20 Gain()log×=

The following example shows how to derive the

gain required to drive 2 Watts of RMS power into

a 4 Ω speaker. Keep in mind that the RATED

power for this speaker should be 4 Watts or greater,

and the MAX power should be 8 Watts or greater.

2

V

PIV×

==

----- -

R

The speaker’s RATED power and the power driven

into the speaker are RMS powers. The RMS power

is given by the product of the RMS current and the

RMS voltage, or the square of the RMS voltage

over the speaker resistance.

The maximum speaker driver gain is determined by

the square root of the product of the RMS power

and the speaker driver resistance:

2

V

PVI×

==

----- -

R

VPR×=

where P = RMS power delivered to speaker, V =

RMS voltage across speaker terminals, I = RMS

current through speaker, and R = resistance of

speaker in Ohms.

VPR× 24× 8 2.828====

Gain

V

-------- -

Vin

2.828

------------1

2.828== =

Gain dB() 20 2.828()log× 9dB==

Many speaker drivers suitable for hands-free

full-duplex design have fixed gains of 20 dB or

more, or are not stable for gains less than 20 dB.

Adding 20 dB of gain to the full-scale output of the

CS6422 (=1 Vrms, =0 dBV, =2.8 Vpp) results in a

huge signal at the speaker terminals (=10 Vrms,

=20dBV, =28Vpp). Because of this, the speaker

driver gain is implemented in two stages, an

attenuator stage followed by a gain stage. The

attenuator can be implemented using a simple

resistor voltage divider network as shown in

Figure 3.

6 AN168REV2

Page 7

AN168

CS6422

A0

R

+

1

R

2

Attenuation Gain

+20 dB

+

Figure 3. Generic Speaker Driver Configuration

CS6422

RVol

TVol

Acoustic

Echo

Canceler

-

Σ

+

D/A

A/D

Speaker

Driver

Mic

Preamp

3

Microcontroller

Figure 4. Using RVol to Implement Volume Control

1.3.3 Volume Control

In most half-duplex systems, volume control is

implemented by changing the gain of the speaker

driver. In a full-duplex system, this is undesirable

because gain changes in the acoustic path require

the echo canceler to readapt, resulting in elevated

levels of residual echo during the training process

or a temporary drop to half-duplex operation.

In CS6422 systems, it is best to implement volume

changes by using the RVol control. The RVol

control provides up to +30 dB of AGC'ed gain to

the receive path, and because the output of the

RVol control is fed both to the echo canceler and to

the DAC driving the speaker, changes in RVol do

not cause changes in the acoustic path, which keeps

the echo canceler from having to readapt. This

portion of the signal flow diagram is shown in

Figure 4.

In general, the RVol control should be set to a value

between +6 dB and +30 dB. In systems which have

a network sidetone (a coupling path between NO

and NI supplied by the phone), the maximum RVol

value may need to be limited due to loop gain

concerns. See the sections entitled Network

Sidetone and Loop Gain for more information.

AN168REV2 7

Page 8

AN168

1.3.4 Acoustic Coupling

Figure 5 shows the three most common places for

distortion to be introduced into the acoustic path.

These are the speaker driver, the speaker, and

clipping at the A/D converter after the mic preamp.

With careful choice of the speaker and speaker

driver gain, we can eliminate the first two by using

the techniques previously discussed. The third

distortion source, clipping at the A/D converter, is

controlled by limiting the amount of acoustic

coupling.

The acoustic coupling is defined as the gain (or

loss) between the AO pin and the APO pin on the

CS6422, with TGain set to 0 dB. If TGain is set to

a non-zero value, then the TGain value is added to

the AO/APO gain number to compute the amount

of acoustic coupling.

The acoustic coupling is determined by 5 factors:

the speaker driver gain, the speaker efficiency, the

air coupling between the speaker and the

microphone, the microphone sensitivity, and the

mic preamp gain. Assuming the speaker and mic

have been chosen, the remaining design variables

are the speaker driver gain, the mic preamp gain,

and the speaker and mic position.

Usually, the speaker driver gain is chosen based on

the linearity requirements previously described.

The speaker and mic placement are determined by

ergonomic factors and the desired acoustic path

stability described above. The remaining variable

is the mic preamp gain, which is typically set such

that the worst-case acoustic coupling is between

-9 dB and -15 dB, the first number being the

preferred design target, as shown in Figure 6.

The acoustic path response is highly frequency

dependent. The contributions of the speaker driver

and the mic preamp to the frequency response are

essentially negligible since both of these amplifiers

typically have a stable and well-behaved frequency

response. The dominant factors in the frequency

response of the acoustic path are the speaker's

inherent frequency response, the microphone's

inherent frequency response, and the frequency

response of the path between the speaker and the

mic which is strongly affected by the speaker's

housing. The flatter the frequency response, the

better the echo cancellation.

Figure 7 shows an example acoustic path frequency

response for a speaker and microphone separated

by approximately one meter.

The signal at APO will visibly clip for signals

greater than +5 dBV (5 Vpp). Keep in mind that the

acoustic A/D converter clips at 0 dBV (2.8 Vpp)

when TGain is set to 0 dB.

1.3.5 Setting the Mic Preamp Gain

As stated above, the design goal is to have the

worst-case value for the acoustic coupling, the

highest value across the frequency band of interest,

less than or equal to -9 dB. Strictly speaking, it

need only be less than 0 dB to avoid clipping at the

acoustic A/D converter. The additional 9 dB

provides margin for component tolerance variation

(dominated by speaker variation), component

installation (dominated by speaker/mic placement),

and acoustic path variation (dominated by the

position of the driver, passengers, and objects in the

car). The mic preamp gain is adjusted to achieve

the desired level of acoustic coupling.

There are two methods that can be used to set the

acoustic coupling: the frequency response method

and the loop gain method. The frequency response

method is good because it provides frequency

response information that can be used to increase

the quality of the system (flat frequency response is

desired). The loop gain method is quick, easy, and

requires no additional test hardware beyond the

ability to configure the CS6422's registers.

In the frequency response method, the acoustic

path frequency response, the gain between the AO

and the APO pins on the CS6422, is measured by

automated test equipment and plotted. The

8 AN168REV2

Page 9

AN168

Speaker Driver

Speaker

AO

DAC

1

2

Air

CS6422

Coupling

3

APO

ADC

Mic Preamp

Microphone

Figure 5. Three Common Sources of Acoustic Path Distortion

Speaker Driver

AO

DAC

Speaker

CS6422

ADC

Acoustic Path = -9dB

APO

Mic Preamp

Microphone

Figure 6. Acoustic Coupling Design Target

Acoustic Coupling (dB)

0 500 1000 1500 2000 2500 3000 3500 4000

0

-10

-20

-30

-40

-50

-60

-70

-80

Frequency (Hz)

Air

Coupling

Figure 7. Example Acoustic Coupling Frequency Response

AN168REV2 9

Page 10

AN168

maximum value of this curve is then noted, and

gain is added or subtracted at the mic preamp in

order to set this maximum value to -9 dBV (with

TGain set to 0 dB). This procedure is further

described in the Tests section of this note.

The loop gain method uses howling to determine

the optimum mic preamp gain. In short, the phone

network is disconnected from the CS6422, and

TVol, RVol and NSdt are used to create a +9 dB

path between APO and AO inside the CS6422. The

system will howl, go into regenerative feedback, at

the point that the total loop gain reaches a factor of

'1', or 0 dB. This happens whenever the gain

between AO and APO outside the CS6422 reaches

-9 dB. The frequency of the howl is the frequency

of the maximum loop gain, which is dominated by

the speaker, microphone, and the air path between

the two. Figure 8 illustrates.

The loop gain procedure is as follows:

1) Configure the CS6422 with its default configuration, with the exception of the following:

a) Mic = ‘1’ or ‘0’, depending on whether the

internal mic preamp is used or not

b) TSD = RSD = HDD = ‘1’, transmit and re-

ceive suppressors and half-duplex mode are

disabled

c) ACC = NCC = 'cleared', echo cancelers are

forced to a cleared state to prevent updates

d) AECD = NECD = ‘1’, echo cancelers are

disabled

e) TVol = +12 dB

f) NSdt = -12 dB

g) RVol = +9 dB

2) Adjust the mic preamp gain (or the speaker

driver gain) until the system is just on the verge

of howling. At this point the gain between AO

and APO will be the desired -9 dB.

Disconnect

Network

CS6422

-12dB

NSdt - Network

Sidetone

+9dB

RVol - Receive

Volume

TVol - Transmit

Volume

12dB

Figure 8. Setting the Acoustic Coupling

Goal is -

9dB

A

O

APO

0dB

Speaker

Driver

Adjust

?dB

Mic

Preamp

Air Coupling

-?dB

10 AN168REV2

Page 11

AN168

The register settings to accomplish the above are as

follows:

reg 0: 47a0 (or c7a0 if internal mic preamp is

used)

reg 1: 26a2

reg 2: 0004 (default)

reg 3: 0006 (default)

reg 4: 0008 (default)

reg 5: 033a

Note: If the mic preamp gain is not easily

adjustable in the test circuit, coarse amounts of gain

can be added by using the TGain control, which can

be set to 0 dB, +6 dB, +9.5 dB, or +12 dB.

1.3.6 Acoustic Sidetone

When the coupling path between the speaker and

the microphone is relatively consistent, linear, and

has a high signal-to-noise ratio (SNR), the CS6422

provides good echo cancellation and makes good

training decisions. In the car environment, the SNR

of the acoustic path can be degraded significantly

by road and engine noise and the separation

between the speaker and the mic. In these systems,

it is often useful to introduce a strong, linear,

predictable coupling path electrically by using an

acoustic sidetone.

The acoustic sidetone provides 3 main benefits:

1) The presence of a strong path decreases convergence time, meaning it decreases the time the

CS6422 spends in half-duplex.

2) The linear path enhances stability in systems in

which the strongest real (air) path is distorted.

Note that even though the echo canceller will

not cancel the nonlinear elements of the acoustic echo, it will make better decisions regarding

when to engage the supplementary suppression

algorithms to mask such echo. This results in

improved performance during far-end single-talk.

3) The consistent path provides an echo path that

is independent of the acoustic environment,

making the system less sensitive to path changes and noise. This enhances full-duplex performance by reducing the tendency of the CS6422

to drop to half-duplex when the driver moves.

The amount of sidetone required depends on

several factors. Typically, a good number is

between -24 dB and -12 dB. To be useful, the

electrical coupling should be about as strong as the

strongest typical air coupling, but not much

stronger. A good starting point for systems whose

peak acoustic coupling is -9 dB is -18 dB of

acoustic sidetone. The acoustic sidetone can be

implemented in CS6422 systems by using the ASdt

control, which is configurable to none, -24 dB,

-18 dB, or -12 dB.

1.4 Echo Canceler Parameter

Optimization

One of the benefits of the CS6422 is its high degree

of configurability. Whereas the number of

parameters may seem daunting at first, there are

only a few that need to be tweaked to optimize

performance. The rest can be set once and left

alone.

1.4.1 Starting Example

The following is an example register configuration

that is useful as a starting point for cellular car

hands-free systems.

Note: Actual performance testing should be

performed in a car, not a lab. This is because the car

and the lab present different acoustic environments

to the echo canceler, and the goal is to optimize the

parameters for the target environment, which

requires testing in that target environment.

The following parameter set assumes that there is

no coupling on the network interface to the phone.

If there is a network coupling path, see the Network

Sidetone and Loop Gain sections below.

AN168REV2 11

Page 12

AN168

Configure the CS6422 from reset with the

following:

1) Mic set to '1' or '0', depending on whether the

internal mic preamp is used or not

2) GB = 0.75 dB/ms

3) RVol = +18 dB (this is the default setting; RVol

should be set between +6 dB and +30 dB)

4) Taps = 55.5 ms

5) TVol = 0 dB (this is the default setting; close to

0 dB is better; TVol should be between 0 dB

and +12 dB)

6) NseRmp = 12 dB/s

7) HDly = 150 ms

8) IdlTx = enabled

9) TSAtt = 24 dB

10)PCSen = low

11)TSThd = 12 dB

12)TSBias = 18 dB (default setting)

13)AErle = 18 dB

14)AFNse = -42 dB

15)TGain = 0 dB (can be 0 dB, +6 dB, +9.5 dB, or

+12 dB, depending on mic preamp requirements)

16)NECD = ‘1’ (should be '0' if a network sidetone

is present)

17)ASdt = -18 dB

The register configuration which implements the

above is:

1.4.2 Tweaking the Parameters

1) TGain can be set to 0 dB, +6 dB, +9.5 dB, or

+12 dB, to add gain to the mic preamp if needed based on acoustic coupling tests.

2) RVol can be adjusted down or up based on desired signal level. The value should be kept between +6 dB and +30 dB.

3) TVol can be adjusted to a value between 0 dB

and +12 dB to add gain to the transmit path,

particularly if the mic preamp gain was reduced

to satisfy acoustic coupling requirements.

4) TSThd controls the ERLE level at which the

transmit suppressor engages during far-end single-talk (when the far-end is talking while the

near-end listener is silent). This parameter is

tested using the Far-End Single-Talk Counting

Test described in the Tests section.

5) TSBias controls the ERLE level at which the

transmit suppressor disengages during double-talk. Lower values make it easier to disengage the transmit suppressor, preventing the

undesirable attenuation of near-end speech.

This parameter is tested using the Double-talk

test described in the Tests section.

6) AErle and AFNse control the behavior of the

transition between half-duplex and full-duplex.

Specifically, they influence the time it takes for

the CS6422 to transition between half-duplex

and full-duplex. Lower values of AErle tend to

decrease the transition time. This parameter is

tested using the Full-duplex Transition test described in the Tests section.

reg 0: 1400 (9400 if internal mic preamp is

used)

reg 1: 0a22

reg 2: 0a14

reg 3: a046

reg 4: 5008

reg 5: 018a

12 AN168REV2

7) TSAtt controls the amount of attenuation added

to the transmit path when the transmit suppressor engages. This parameter is tested using the

Far-End Single Talk Test described in the Tests

section.

8) IdlTx causes the half-duplex engine to switch to

transmit during an idle period. This parameter

only has an effect during half-duplex operation.

Page 13

AN168

This parameter can be tested using the

Half-Duplex Alternate Counting Test as described in the Tests section.

9) RSD controls the enable/disable of the receive

suppression engine. The receive suppressor is a

noise squelch that provides 24 dB of attenuation to the receive path when the far-end talker

is silent. The receive suppressor operates in

half-duplex and full-duplex modes. When the

far-end talker is silent, the signal sent to the

speaker drops to almost nothing, that is, background noise is not transmitted. If this is undesirable, the receive suppressor can be disabled

by setting RSD to '1', allowing the noise to pass

to the speaker unattenuated.

1.4.3 Network Sidetone

Some cellular phones provide a coupling path

between the network transmit and network receive

paths which is used when a full-duplex earpiece

and mic are used. This sidetone path provides an

echo between the mic and the earpiece to let the

user know that the phone is active, similar to the

sidetone supplied by the Central Office in a

standard analog phone handset.

The presence of a network sidetone, here defined as

a coupling path between the NO pin and the NI pin

on the CS6422, increases the complexity of the

system considerably because it forms a closed loop

with the receive path, the acoustic path, and the

transmit path. When a system has a closed loop,

care must be taken to ensure that the loop gain of

the system remains below a factor of '1', or 0 dB, or

howling, regenerative feedback, will result. Figure

9 illustrates.

It is strongly recommended that the network

sidetone on the cellular phone be disabled if

possible. Most cellular phones that provide only an

analog hands-free interface have a means of

disabling the sidetone. Cellular phones that provide

both analog and digital hands-free interfaces

NI

NO

CS6422

RVol

Closed Loop

TVol

AO

Speaker

Driver

Air

Coupling

APO

Mic

Preamp

Cell Phone

Network

Sidetone

AN168REV2 13

NI

Gain

NO Gain

Figure 9. Loop Gain with Network Sidetone

Page 14

AN168

typically employ the sidetone only on the analog

interface, leaving the digital interface

sidetone-free.

If it is not possible to disable the sidetone or work

around it by using a different interface, then the

presence of the sidetone must be considered in the

design of the system. To minimize the loop gain as

well as to prevent the local mic signal from being

echoed out the speaker, it is necessary to enable the

Network Echo Canceler and to allocate Taps to it.

These are the two parameter changes necessary

from the recommendations given above.

Specifically, NECD should be set to '0', and Taps

should be set to either 47.5 ms/16 ms or

39.5 ms/24 ms. Either setting will work;

47.5 ms/16 ms is slightly more desirable since the

network path delay inside the phone is easily

handled by 16 ms of taps, allowing more taps to be

used for modeling the acoustic path.

1.4.4 Loop Gain

The presence of a network sidetone places

constraints on the total loop gain allowed in the

system. The network interface gains are

determined by matching the full scale level of the

phone to the full-scale level of the CS6422. The

speaker driver, acoustic coupling, and mic preamp

gains are determined as described earlier in this

note. The remaining gains are TVol and RVol

inside the CS6422.

Note: TGain is treated as part of the mic preamp

gain, and RGain is treated as part of the network

receive gain.

When the echo cancelers are enabled, they provide

additional loss in the loop that is equal to the ERLE

(Echo Return Loss Enhancement) of each echo

canceler. Because the network path is strong and

stable, the ERLE of the network echo canceler can

be relied upon to reduce the system loop gain.

Because the acoustic path is highly variable, the

ERLE of the acoustic echo canceler should NOT be

relied on to reduce the system loop gain.

The network echo canceler can provide, worst case,

15 dB of additional loss in the loop, provided that

the network path is linear and lossy, that is, the

signal level at NO is reflected back at NI at a lower

amplitude than it originated.

Here's an illustrative loop gain example. Assuming

that the worst-case acoustic coupling is -9 dB and

the network sidetone amplitude, here defined as the

gain between the NO and NI pins on the CS6422, is

-6 dB, and the network ERLE is 15 dB, then

RVol TVol+9615++ 30dB==

maximum. This +30 dB number can be distributed

arbitrarily between RVol and TVol. The placement

of the gain does not affect the stability of the

system. Usually, the gain is distributed to provide a

balance between the transmit path volume and the

receive path volume.

1.5 Tests

In this section, we present some tests which are

useful to identify and solve system-level problems.

These tests should be performed in the listed order.

The first set of tests, Acoustic Coupling, Acoustic

Distortion, and Acoustic ERLE, should be

performed in a lab and in a car. These tests verify

the electrical and the mechanical design of the

system.

The last set of tests, which are actual call test

scenarios, are used to fine-tune the CS6422 register

settings.

NOTE: These tests should be performed in a car.

The latter tests can be performed in a lab, however,

it is likely that the set of optimum coefficients

derived in lab testing will not be optimal for car

use.

14 AN168REV2

Page 15

AN168

1.5.1 Acoustic Coupling

The term ‘Acoustic Coupling’ refers to the gain

between the AO and the APO pins on the CS6422.

It includes the speaker driver gain, the efficiency of

the speaker, the loss in the air path between the

speaker and the microphone, the sensitivity of the

microphone, and the gain of the microphone

preamp.

Here we present two methods of measuring the

acoustic coupling, the loop gain method and the

frequency response measurement method. The

loop gain method is quick, easy, and requires no

additional test equipment to perform, yet provides

only one worst-case coupling number. The

frequency response method is more thorough and

yields more information, but requires automated

test equipment.

1.5.1.1 Loop Gain Method

When a system contains a closed loop whose gain

is greater than 1, howling, or regenerative

feedback, results. See Figure 10.

This howling phenomenon can be used to make a

quick and accurate measurement of the acoustic

coupling between a speaker and a microphone.

In essence, we create a known gain between APO

and AO inside the CS6422 using the TVol, NSdt,

and RVol controls, and increase this gain until

howling results. At the point that howling occurs,

the loop gain of the system is 0dB, or a factor of ‘1’.

In this particular example, we set TVol to +12dB,

NSdt to -12dB, and increase RVol until howling

occurs. The speaker driver gain and mic preamp

gain are known, and the remaining unknown, the

air coupling between the speaker and the mic, is

determined. See Figure 11.

‘a’ dB ‘b’ dB

Loop Gain is the gain of a ‘closed’ loop.

‘f’ dB

When Loop Gain is very slightly greater than 0dB (a factor of ‘1’), howling begins

AN168REV2 15

A closed loop has a path that returns to its starting point.

‘d’ dB‘e’ dB

Loop Gain (dB) = a + b + c + d + e + f

Figure 10. Loop Gain Diagram

‘c’ dB

Page 16

CS6422

Adjust

+?dB

AN168

AO

0dB

RVol - Receive

Volume

Disconnect

Network

Adjust RVol until howling begins; AC = 0 - RVo l - Mic -Spkr

-12dB

NSdt - Network

Sidetone

TVol - Transmit

Volume

Figure 11. Acoustic Coupling Measurement Method

The loop gain measurement procedure is as

follows:

1) Configure the CS6422 with its default configuration, with the exception of the following:

a) Mic = ‘1’ or ‘0’, depending on whether the

internal mic preamp is used or not

b) TSD = RSD = HDD = ‘1’, transmit and re-

ceive suppressors and half-duplex mode are

disabled

c) ACC = NCC = 'cleared', echo cancelers are

forced to a cleared state to prevent updates

d) AECD = NECD = ‘1’, echo cancelers are

disabled

Speaker

Driver

Air Coupling

APO

30dB12dB

Mic

Preamp

-?dB

The register settings to accomplish the above are as

follows:

reg 0: 4xa0 (or cxa0 if internal mic preamp is

used); “x” is the value of RVol

reg 1: 26a2

reg 2: 0004 (default)

reg 3: 0006 (default)

reg 4: 0008 (default)

reg 5: 033a

RVol contains a 4-bit value that results in a gain

given by the following equation:

e) TVol = +12 dB

Gain dB() 30dB RVol 3dB×()–=

f) NSdt = -12 dB

g) RVol = 0 dB

2) Adjust RVol until the system is just on the

verge of howling. At this point the loop gain is

0 dB, and the loss between AO and APO (outside the CS6422) is equal to the RVol value.

16 AN168REV2

For example, if the RVol value required to make

the system howl is ‘5’, then the loss between AO

and APO is (30 - 5 * 3 = 15 dB)

Physical law ensures that the system will howl at

the frequency of maximum coupling. Furthermore,

Page 17

AN168

the frequency of the howl itself is the frequency at

which the loop gain, whose frequency response is

dominated by the acoustic coupling, is maximum.

1.5.1.2 Frequency Response Method

Measuring the frequency response of the acoustic

path in the target environment is strongly

recommended. In general, the flatter the frequency

response, the better the performance of the echo

canceler.

In this method, an automated piece of test

equipment that contains a variable-frequency sine

wave generator coupled with an RMS

measurement device, such as an Audio Precision

System One or System Two, or a Rohde and

Schwarz UPL or UPD is used. Automated

equipment is recommended over a manual sine

wave generator due to the number of frequency

points required (100 or more) and the difficulty of

measuring the mic signal due to constructive and

destructive interference.

The measurement device’s generator can be

connected to the input of the speaker driver or to

the NI pin of the CS6422 through a DC-blocking

capacitor. If connected to the NI pin, RGain and

RVol should each be set to 0 dB, RSD and HDD

should be set to ‘1’, and NCC should be set to

‘cleared’. If connected to the speaker driver input,

the connection between the AO pin and the speaker

driver should be broken.

The sine wave generator should be configured to

output a 1 Vrms (0 dBV) sine wave that sweeps

between 100 Hz and 4 kHz, log distribution is

preferred over linear, and samples at least 100

points, preferably 200 or more for this range.

The return signal can be monitored either at the

APO pin or the NO pin of the CS6422. If monitored

at the NO pin, TSD should be set to ‘1’, and ACC

should be set to ‘cleared’. In either case, the Mic bit

should be set to ‘1’ if the internal mic preamp is

used, or ‘0’ if the internal mic preamp is not being

used.

An example acoustic coupling plot is shown in

Figure 12.

1.5.2 Acoustic Distortion

Earlier in this note, we described a process by

which we could limit the distortion in the acoustic

path by designing the electrical system carefully. It

is still necessary to test the distortion to verify that

the distortion level is below 2% THD.

Acoustic Coupling (dB)

0 500 1000 1500 2000 2500 3000 3500 4000

0

-10

-20

-30

-40

-50

-60

-70

-80

Frequency (Hz)

Figure 12. Example Acoustic Coupling Frequency Response

AN168REV2 17

Page 18

AN168

There are two tests which should be performed, a

Frequency Sweep distortion test and a Buzz test.

1.5.2.1 Frequency Sweep Test

In this test, a piece of automated test equipment

sweeps a sinewave between 100 Hz and 4 kHz,

similar to the Frequency Response Method of

testing acoustic coupling. In this test, the input to

the analyzer is analyzed for relative THD+N by

filtering with a high-Q notch filter at the

fundamental frequency of the input. Additionally, a

C-message filter or a high-order (5 poles or more)

4 kHz low-pass filter should be applied to keep

out-of-band noise from corrupting the

measurement.

The resulting curve shows relative THD+N vs.

Frequency. An example is shown in Figure 13.

This curve, although useful, is not complete

because it lacks information about the coupling

strength at each frequency. A relative THD+N

reading can be degraded by an increase in the

distortion component or a decrease in SNR (which

can be caused by a decrease in signal level or an

increase in noise level). The residual echo level is

dependent only on the amount of distortion. An

SNR degradation due to a decrease in signal level

means that there is no echo at those frequencies to

cancel.

The graph that we need is a relative THD+N curve

that is weighted with the acoustic coupling

information. This curve can be constructed by

normalizing the acoustic coupling curve by shifting

it vertically such that the maximum value is set at

0 dB then adding this normalized curve to the

relative THD+N curve. An example is shown in

Figure 14. Keep in mind that the goal is to have this

weighted distortion curve below 2% THD, or

-34 dB at all points.

These curves were constructed by saving the data

in text format to a file, then importing the

information into a spreadsheet for normalization

and addition.

1.5.2.2 Buzz Test

The distortion measurement method above is

designed to detect harmonic distortion resulting

from clipping at the speaker driver, the speaker, or

the mic preamp. This method is not good at

measuring non-harmonic distortion that results

when the speaker induces mechanical vibrations in

its housing. We refer to these induced vibrations as

‘buzzing’.

Relative THD+N (dB)

0 500 1000 1500 2000 2500 3000 3500 4000

0

-10

-20

-30

-40

-50

-60

Frequency (Hz)

Figure 13. Relative THD+N

18 AN168REV2

Page 19

Coupling-Weighted THD (%)

1.2

1

0.8

0.6

0.4

0.2

0

0 500 1000 1500 2000 2500 3000 3500 4000

Frequency (Hz)

Figure 14. Coupling-Weighted THD+N

AN168

Similar to harmonic distortion, these ‘buzzing’

artifacts cause elevated levels of residual echo

because they result from a non-linear phenomenon

that the echo canceler cannot model.

The test for buzzing is similar to the frequency

sweep distortion test. A full-scale sine-wave is

injected into the speaker-driver input (or the NI

input on the CS6422), and swept slowly between

100 Hz and 4 kHz. This sweep can be performed

manually. As the frequency is swept, listen for the

induced buzzing vibrations. Try placing your hand

on the speaker housing to test for mechanical

vibrations as well. When a buzz is detected, try to

isolate the mechanical cause of the induced

vibration and fix it. Typical solutions involve

inserting spongy foam gaskets between connecting

pieces of plastic or inserting spongy foam between

the speaker’s mounting rim and the housing.

1.5.3 Acoustic ERLE

In order to tell if the system is properly designed, it

is useful to measure the ERLE (Echo Return Loss

Enhancement) that the echo canceler is able to

provide. We present two methods to test ERLE, the

White Noise RMS method and the Loop Gain

method.

The White Noise RMS method measures the

difference in the spectral power level of the signal

with the echo canceler present in the acoustic path

and removed. The Loop Gain method measures the

worst-case ERLE that the echo canceler is able to

achieve by measuring the difference in loop gain

with the echo canceler present in the loop versus

absent.

Both tests are useful. The White Noise RMS

method requires a white noise source and a

band-limited RMS voltage measurement

instrument. The Loop Gain method requires no

additional hardware beyond the ability to configure

the CS6422.

1.5.3.1 White Noise RMS Method

In this test, the CS6422 in configured such that the

transmit and receive suppressors and half-duplex

are disabled. A 2.8 Vpp white noise signal is

injected at NI, and the band-limited (preferably

C-message) RMS voltage is measured at NO with

the echo canceler enabled (ACC = ‘normal’) and

disabled (ACC = ‘cleared).

The test procedure is as follows:

1) Set up the speaker and microphone and adjust

the acoustic coupling to -9 dB by the methods

AN168REV2 19

Page 20

AN168

discussed earlier in this note.

2) Configure the CS6422 from reset with the exception of the following:

a) Mic set to '1' or '0', depending on whether

the internal mic preamp is used or not

b) HDD = ‘1’

c) GB = 0.75 dB/ms

d) TSD = ‘1’

e) ACC = ‘Cleared’

f) Taps = 55.5 ms

g) RSD = ‘1’

h) NseRmp = 12 dB/s

i) PCSen = ‘low’

j) AErle = 18 dB

k) AFNse = -42 dB

l) NECD = ‘1’

m) ASdt = -18 dB

The register configuration which implements the

above is:

reg 0: 5480 (d480 if internal mic preamp is

used)

reg 1: 0a82

reg 2: 0804

reg 3: 2006

reg 4: 5008

reg 5: 018a

3) Inject 2.8 Vpp white noise into NI (capacitively

coupled), and measure the RMS signal level at

NO. The measured signal should be band-limited with either a C-message filter or at least a

5-pole low-pass filter with a corner frequency

of 4 kHz in order to remove out-of-band noise.

4) Record the band-limited RMS voltage level at

NO.

5) Turn OFF the white noise source.

6) Set ACC to ‘Normal’.

7) Turn ON the white noise source.

8) Record the band-limited RMS voltage level at

NO after 5 seconds or more of white noise.

The ERLE is the difference in dB voltage levels of

(8) and (4):

ERLE 20 meas 8()()log× 20 meas 4()()log×–=

The signal at NO can be monitored through

headphones to actually hear the echo canceler train

to the acoustic path.

If the above tests are to be repeated, it is important

to set ACC = ‘cleared’ and to turn off the white

noise source between each test, otherwise results

may be inconsistent.

Typical values obtained using the above technique

range between -9 dB and -30 dB. In general, the

closer together the speaker and mic are and,

consequently, the lower the speaker driver gain, the

better the performance.

1.5.3.2 Loop Gain Method

The loop gain method allows the worst-case ERLE

to be determined without the use of a white noise

source or an RMS voltage meter. In this method,

the adaptive filter is trained on the acoustic path

using speech or white noise, its coefficients are

then frozen, and a closed loop is formed between

TVol, NSdt, RVol, and the acoustic path, which

includes the echo canceler. As in the acoustic

coupling loop gain test, the receive volume is

incremented until howling occurs, and this number

is recorded.

The echo canceler coefficients are then cleared,

effectively removing the EC from the path, and the

receive volume is adjusted again until the point at

which howling occurs. This new value is recorded.

20 AN168REV2

Page 21

AN168

The difference between the two RVol values is the

worst-case ERLE of the echo canceler. Here is the

detailed procedure:

1) Set up the speaker and microphone and mic

preamp gain for -9 dB of acoustic coupling.

2) Configure the CS6422 from reset with the exception of the following:

a) Mic set to '1' or '0', depending on whether

the internal mic preamp is used or not

b) HDD = ‘1’

c) GB = 0.75 dB/ms

d) TSD = ‘1’

e) ACC = ‘Cleared’

f) Taps = 55.5 ms

g) RSD = ‘1’

h) NseRmp = 12 dB/s

i) PCSen = ‘low’

j) AErle = 18 dB

k) AFNse = -42 dB

l) NECD = ‘1’

m) ASdt = -18 dB

The register configuration which implements the

above is:

reg 0: 5480 (d480 if internal mic preamp is

used)

reg 1: 0a82

reg 2: 0804

reg 3: 2006

reg 4: 5008

reg 5: 018a

3) Set ACC to ‘Normal’.

4) Inject speech or 2.8 Vpp white noise into NI for

5 to 10 seconds. This trains the AEC to the

acoustic path. See Figure 15.

5) Set ACC to ‘Freeze’. Try to minimize the

movement in the acoustic path from here on, as

path changes will adversely affect the ERLE re-

CS6422

NI

TVol - Transmit

+0dB

Volume

RVol - Receive

Volume

AEC

‘normal’

-

Mute

+

Mute TVol and train the AEC using speech...

Figure 15. Acoustic ERLE Measurement -- Train the AEC

AN168REV2 21

AO

0dB

Speaker

Driver

-?dB

Air Coupling

APO

30dB

Mic

Preamp

Page 22

AN168

sults.

6) Disconnect the signal source from NI (or simply turn it off).

7) Close the loop by setting NSdt to ‘-12dB’,

RVol to ‘0 dB’, and TVol to ‘+12 dB’.

8) Increase (or decrease) RVol until the system

CS6422

Adjust

+0dB

RVol - Receive

Volume

NSdt - Network

-12dB

Increase RVol until howling begins…record RVol value

Sidetone

TVol - Transmit

Volume

12dB

AEC

‘freeze’

just starts howling. Record this value. See Figure 16.

9) Set ACC to ‘cleared’.

10)Decrease RVol until the system just stops

howling. Record this value. See Figure 17.

11)The worst-case ERLE is the difference between

AO

0dB

Speaker

Driver

Air Coupling

-?dB

-

APO

30dB

+

Mic

Preamp

Figure 16. Acoustic ERLE Measurement -- Freeze AEC

CS6422

Adjust

AO

+0dB

RVol - Receive

Volume

AEC

‘cleared’

-

-12dB

NSdt - Network

Sidetone

TVol - Transmit

Volume

12dB

+

Clear AEC and decrease RVol until howling stops…the difference in RVol is AERLE

0dB

Speaker

Driver

APO

30dB

Mic

Preamp

Figure 17. Acoustic ERLE Measurement -- Clear AEC

Air Coupling

-?dB

22 AN168REV2

Page 23

AN168

the two RVol values in dB.

1.5.4 Call Testing and Coefficient Optimization

The following tests are useful for optimizing the

CS6422 register settings. These tests should be

performed in a car, not a lab. They can be

performed in a lab, but the resulting coefficients

and settings will not be optimal for actual car use.

First, a note on safety. One of the compelling forces

driving the use of hands-free kits in cars is added

safety. Many governments have realized the

dangers inherent when people drive and talk on the

phone at the same time and have mandated the use

of hands-free accessories when cell phones are

used in cars. The studies do not mention the

dangers involved in driving while fine-tuning

hands-free system parameters.

Please, be careful.

on changes in path. In this test, the CS6422 is

loaded with the starting register configuration set

listed earlier in this note, which is repeated here for

convenience:

Configure the CS6422 from reset with the

following:

1) Mic set to '1' or '0', depending on whether the

internal mic preamp is used or not

2) GB = 0.75 dB/ms

3) RVol = +18 dB (this is the default setting; RVol

should be set between +6 dB and +30 dB)

4) Taps = 55.5 ms

5) TVol = 0 dB (this is the default setting; close to

0 dB is better; TVol should be between 0 dB

and +12 dB)

6) NseRmp = 12 dB/s

7) HDly = 150 ms

Optimal car testing requires a minimum of three

people: a driver, a passenger, and a far-end talker.

The driver’s responsibility is solely to drive the car

and to avoid accidents. The passenger and the

far-end talker perform the call testing and

parameter optimization.

Once the test hardware is installed in the car, set the

Acoustic Coupling to a value of -9 dB using the

techniques discussed earlier in this note. Then

begin testing.

1.5.4.1 Far-end single-talk counting

The first test is the Far-End Single-Talk Counting

test. In this test, the far-end talker speaks, usually

incremental counting, and the near-end talker

remains silent.

This test has several sub-tests which are used to

configure specific parameters.

1.5.4.1.1 Subtest A, EC Convergence Test

The EC Convergence Test allows the far-end

listener to hear the echo canceler train, and retrain

8) IdlTx = enabled

9) TSAtt = 24 dB

10)PCSen = low

11)TSThd = 12 dB

12)TSBias = 18 dB (default setting)

13)AErle = 18 dB

14)AFNse = -42 dB

15)TGain = 0 dB (can be 0 dB, +6 dB, +9.5 dB, or

+12 dB, depending on mic preamp requirements)

16)NECD = ‘1’ (should be '0' if a network sidetone

is present)

17)ASdt = -18 dB

The register configuration which implements the

above is:

reg 0: 1400 (9400 if internal mic preamp is

used)

reg 1: 0a22

AN168REV2 23

Page 24

AN168

reg 2: 0a14

reg 3: a046

reg 4: 5008

reg 5: 018a

For the EC Convergence Test, we also disable

Half-Duplex mode and the Transmit Suppressor by

setting HDD = TSD = ‘1’.

Start the test by setting ACC to ‘cleared’ and then

back to ‘normal’. This resets the adaptive filter to a

cleared state.

Initiate the call and have the far-end talker begin

counting while listening for his or her echo. The

level of the echo should lessen with each count

until it reaches a point at which it will attenuate no

further. The test is simply to find out if the echo

level drops on successive counts or not. If it doesn’t

attenuate, then there’s a problem in the system,

usually caused by too much distortion in the path.

The test can be repeated by setting ACC to

‘cleared’ and then back to ‘normal’.

1.5.4.1.2 Subtest B, Half-Duplex to Full-Duplex transition time

Subtest B measures the time it takes for the CS6422

to train sufficiently to move from Half-Duplex

mode to Full-Duplex mode.

The CS6422 is loaded with the standard

recommended coefficient set. At the start of the

test, ACC is set to ‘cleared’ then back to ‘normal’.

This resets the adaptive filter to its cleared state and

prepares it to train to the acoustic path.

After ACC has been set to ‘normal’, the far-end

talker begins counting and listening for echo. The

number at which echo first appears indicates the

transition time to full-duplex.

If it is difficult to determine when the echo appears,

the transmit suppressor can be disengaged for this

test by setting TSD to ‘1’. This removes the

supplementary echo suppression.

1.5.4.1.3 Subtest C, Transmit Suppression test

This test verifies that the TSThd parameter is set

correctly, which controls the engagement of the

Transmit Suppressor. If TSThd is set too high, the

suppressor will not engage reliably, and the far-end

listener will hear residual echo during single-talk.

In this test, the CS6422 is loaded with the standard

coefficient set, with TSMde set to ‘1’, Noise Guard

disabled. The far-end talker counts until the device

transitions to full-duplex. Once in full-duplex, the

transmit suppressor is disengaged by setting TSD

to ‘1’. The far-end talker resumes counting. If there

is no noticeable reduction in the echo level, then the

transmit suppressor is not engaging, and the TSThd

value should be reduced.

1.5.4.2 Double-talk

In the Double-talk test, both the far-end talker and

the near-end talker speak simultaneously. In the

Double-talk test, the CS6422 is loaded with the

recommended set of coefficients. The AEC trains

when the far-end talker speaks while the near-end

talker remains silent. Once the far-end talker hears

the system move to full-duplex, Double-talk testing

can begin.

During the testing, we recommend that one end of

the link count numbers while the other end names

letters of the alphabet, days of the week, months of

the year, or any other syllabic progression that is

easy to generate and easy to detect dropped words.

The goals are to detect how “stable” the system is

in full-duplex by seeing how long the double-talk

can persist without the system dropping to

half-duplex and to test the operation of the transmit

suppressor.

The transmit suppressor should disengage when the

near-end talker speaks. If it doesn’t disengage

properly, then the near-end talker’s speech will be

severely attenuated while the far-end is speaking.

If this happens, adjust the TSBias control to a lower

value (15 dB) and test again.

24 AN168REV2

Page 25

AN168

1.5.4.3 Half-duplex alternate counting

The Half-duplex alternate counting test tests the

half-duplex behavior of the system. This test is

useful even if half-duplex mode is disabled,

because the half-duplex engine controls in part the

training of the adaptive filters.

In the Half-duplex alternate counting test, the

CS6422 is loaded with the recommended

configuration set, with the exception that ACC is

set to ‘cleared’, which prevents the echo canceler

from training and keeps the system in half-duplex.

HDD must be set to ‘0’ for this test.

In this test, the talkers alternate counting in

sequence. For example, the far-end says, “one”,

followed by the near-end saying, “two”, followed

by the far-end saying “three”, etc.

Each side listens for the expected count, and looks

for dropped counts. If the near-end environment is

noisy, it make take a few seconds for the

half-duplexor to begin switching properly.

Parameters that can be adjusted for this test are

HDly, THDet, RHDet, and RSThd. HDly controls

the delay between the system switching from

transmit mode to receive mode. RHDet and THDet

control the SNR level at which speech is detected.

Generally, RHDet and THDet should be equal;

however, if one end of the link is consistently cut

off, they may need to be imbalanced in order to

improve performance.

If there is a network sidetone, it is important that

the Network Echo Canceler be enabled during

half-duplex testing, otherwise the transmit path

may be cut off by its own network echo, causing

halted speech.

1.6 Layout Guidelines

This section contains guidelines regarding PCB

layout in CS6422 systems and car kits in particular.

1.6.1 CS6422-specific guidelines

1) All ground pins on the CS6422 should be referenced to AGND (analog ground plane).

Signals should NOT be routed under the CS6422,

with the exception of the crystal oscillator signals

and the MB signal as shown in Fig. 18.

+5V

Analog

Supply

AVDD

AGND

CS6422

DVDD

DGND

Figure 18. Suggested CS6422 Layout

AN168REV2 25

MB

From

Ferrite

Bead

Page 26

AN168

2) Decoupling and loading capacitors should be

placed as close as possible to the pins they decouple (AVDD, AGND, DVDD, DGND, MB,

CLKI, CLKO), with the smaller-valued capacitor closest to the pin.

3) The traces between the MB pin and the decoupling capacitors connected to it should be short,

shielded with ground plane, and located far

from potentially interfering signals.

1.6.2 Car-Kit guidelines

Cellular car kits typically have three power

networks: +12VBATT/BATTGND,

+5VD/DGND, and +5VA/AGND.

Components powered from a particular power

network should have ground connections to the

ground associated with that power network. For

example, the CS6422 should be powered from

+5VA and its ground pins, including power supply

decoupling capacitor grounds and signal grounds,

should tie to AGND.

The one exception to this is that the attenuator

resistor in the resistor divider between AO and the

speaker driver should be tied to the ground of the

speaker driver, typically BATTGND if the speaker

driver is powered from the +12V battery source.

This prevents the speaker driver from amplifying

noise caused by potential differences between

AGND and BATT GND.

Following are listed the power networks and

components associated with each network.

1.6.2.1 +5VA/AGND Components

1) CS6422, AVDD, DVDD, AGND, DGND, decoupling capacitors, crystal loading capacitors,

signal R’s and C’s with the exception of the attenuator resistor in the voltage divider between

AO and the speaker driver input.

2) Op-amps and analog circuitry between the cell

phone and the CS6422’s NO and NI pins.

1.6.2.2 +5VD/DGND Components

1) Microcontroller

2) Additional +5V control logic circuitry

Note: If the CS6422 and the microcontroller are

powered from the same +5V regulator, +5VA

should be derived from the regulator output

(+5VD) through a ferrite bead.

+5 VA

+

R

+

AO

CS6422

AGND

Gain (dB) = 20 log ( )

Figure 19. Speaker Driver Implementation

26 AN168REV2

1

R

2

BATT

GND

10 µF10 µF

R

2

R1 + R

+

BATT

GND

2

+12 V

-

+

BATT

GND

Gain = +40 dB

+

BATT GND

BATT

GND

4

Ω

Speaker

Page 27

AN168

1.6.2.3 +12VBATT/BATTGND Components

1) Cell-phone battery charger circuitry

2) Speaker driver (if powered from +12V source)

Most cellular phones provide two grounds at the

hands-free connector, DGND and AGND. DGND

ties to the phone battery, and should be connected

to BATTGND on the hands-free kit. The cell

phone’s analog interface pins are referenced to the

AGND signal, and this AGND should tie to AGND

on the hands-free kit.

The DGND plane on the hands-free kit should be

connected to AGND plane in exactly one place.

1.7 Quick list of important points:

The following is a list of things to verify in the

system.

1.7.1 Reset and configuration timing

It is vital that the CS6422 receive a cold reset after

power-on.

1) The RST low time should be at least 1 µs.

2) The time between RST rising and DRDY falling should be at least 110 ms. This is commonly overlooked.

3) Furthermore, when writing multiple control

words to the CS6422, the words themselves

cannot be written at a rate faster than one every

125 µs, since this is the rate at which they are

polled by the DSP. That is, the time from

DRDY falling to DRDY falling must be at least

125 µs.

In implementation, it is easiest to ensure this timing

by limiting the STROBE frequency. Setting the

STROBE period to 10µs, for example, makes the

total time for a register write 200µs (16 data bits +

4 extra STROBE pulses = 20 cycles; 20 cycles *

10µs = 200µs).

1.7.2 Distortion

The total distortion present in any signal path that