Page 1

AN152

Application Note

USING THE CS5521/23, CS5522/24/28, AND CS552 5/26

CHARGE PUMP DRIVE FOR EXTERNAL LOADS

By Bill Durbin and Jerome Johnston

INTRODUCTION

The CS5521/23, CS5522/24/28, and CS5525/26

series of A/D converters include on-chip circuitry

to drive and regulate a diode charge pump. The

purpose of this application note is to explain the

charge pump circuitry and how it can be used in a

system design.

CS552X Overview

The CS5521/23, CS5522/24/28, and CS5525/26

series of A/D converters include a chopper-stabilized instrumentation am plifier for measureme nt of

low level dc signals (±100 mV or less). This amplifier is designed to produce very low input sampling

1.The CS5529 is not included in this Application

Note because it does not contain a charge pump.

Ve

+

-

T/C

10 K

10 K

0.1 uF

current (I

input current minimizes the errors that can occur in

1

< 300 pA over -40 to +85 C). A low

CVF

thermocouple measurements when high impedance

circuitry is used for input protection as shown in

Figure 1.

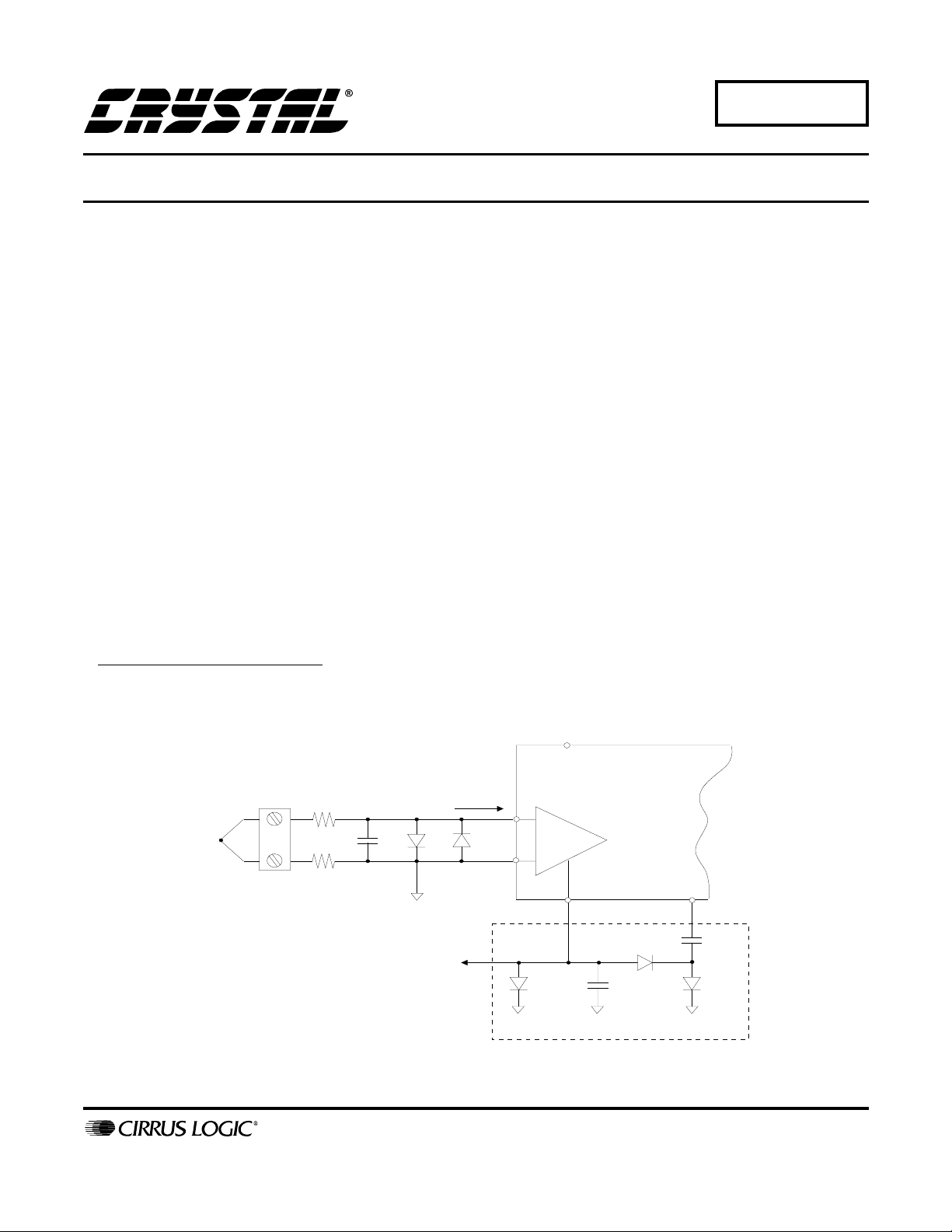

The charge pump circuitry, illustrated in Figure 1,

is used to generate a negative supply (approximately -2.1 V) to power the on-chip instrumentation

amplifier. This enables the amplifier to measure

low level input signals that are negative relative to

ground while maintaining low input current. Within certain constraints, which are described in this

document, the charge pump can be used to power

some additional circuitry outside the converter,

such as an amplifier or a multiplexer.

VA+

CS5521/23,

CS5522/24/28,

I

+

-

& CS5525/26

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

NBV

External Load

BAT85

+

Charge Pump Circuit

Figure 1. Input Amplifier inside CS552x ADCs.

Copyright Cirrus Logic, Inc. 1999

(All Rights Reserved)

CPD

1N4148

1N4148

AUG ‘99

AN152REV1

1

Page 2

Frequency = f

+5 V

Q

AN152

1

C

1

D

2

-V

Q

Figure 2. Charge Pump Components

V

D

C

1

-

+

D

I

1

(a) (b)

Figure 3. Charge Pump Cycle Sequence

Charge Pump Basics

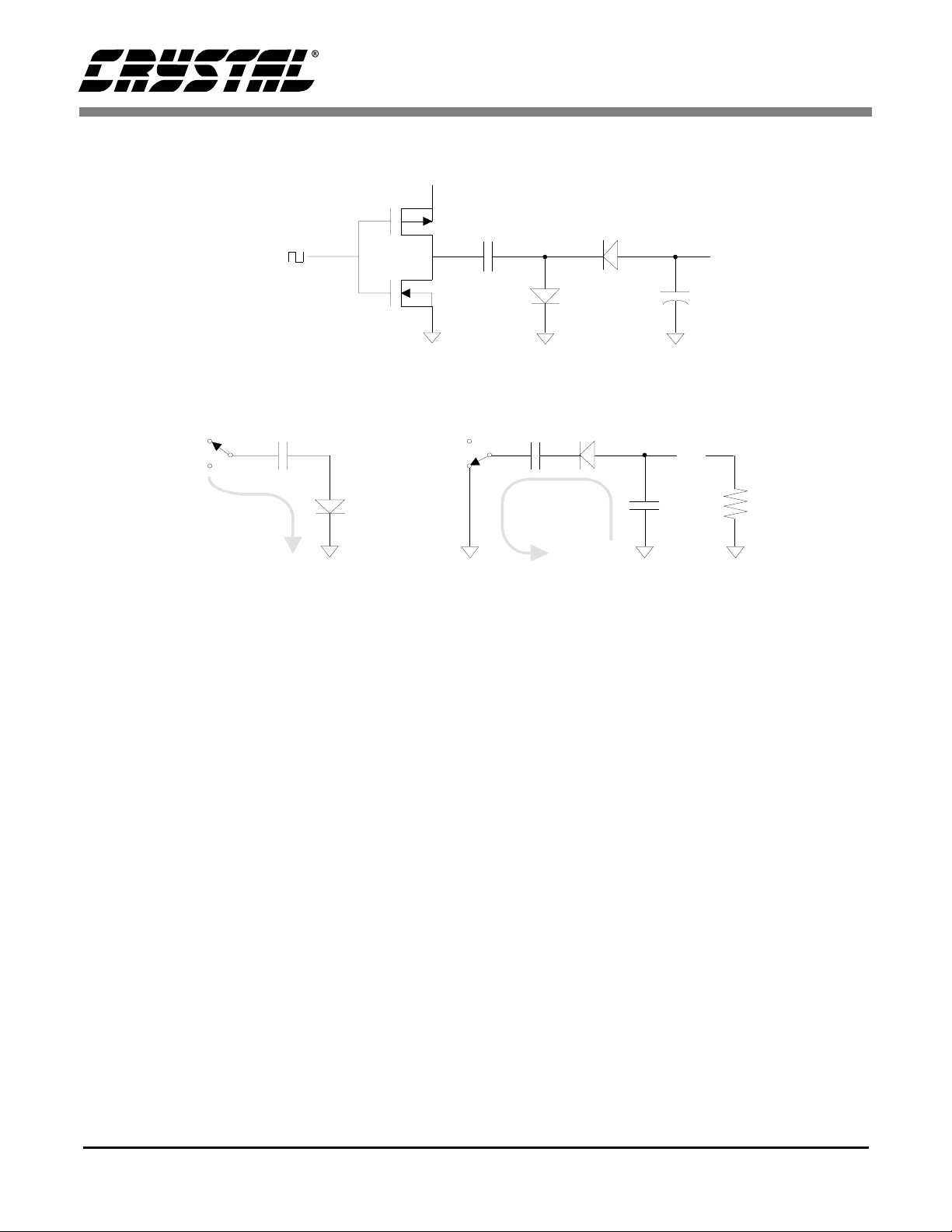

Figure 2 illustrates a basic diode charge pump.

Transistors Q1 and Q2 represent the output transistors of a CMOS inverter. When the input to the inverter causes transistor Q1 to be turned on (Q2 is

off) C1 is charged through diode D1 to a voltage of

approximately 5 V minus the forward voltage of

the diode. When the output of inverter switches to

Q1 off, Q2 on, the positively charged lead of C1

will be connected to ground. Since the voltage

across a capacitor cannot change instantaneously,

the lead of C1 which is connected to diode D2 will

go negative, turning on diode D2. The charge on

C1 will then flow onto C2 and produce a negative

output voltage. Capacitor C2 acts as a reservoir for

charge and is much larger than the charge pump capacitor C1. After many charge pump cycles, capacitor C2 will be charged to a voltage that is about

two diode drops below 5 V.

Figure 3 illustrates each of the two charge pump se-

2

D

1

C

2

+

C

+

D

1

-

2

V

0

I

C

2

+

R

L

quences. Capacitor C2 acts as a reservoir for

charge and is much larger than the charge pump capacitor C1.

The CS552X’s Charge Pump

Figure 4 illustrates a simplified version of t he basic

charge pump regulation loop that is inside the A/D

converters listed in this application note. The

charge pump drive pin (CPD) is driven from a

clock (CPCLK) derived from the XIN frequency.

In the CS5525 and CS5526 the XIN frequency is

used directly. The CS5521/22/23/24/28 devices

use a clock that is XIN/2. A regulator loop compares the magnitude of the voltage generated on the

charge reservoir capacitor to a proportion of the

VA+ supply magnitude. The loop is designed to

regulate the voltage at NBV to be -[VA+/2.38] V.

Note that if the VA+ supply voltage to the chip is

above +5 V, the voltage that results out of the

charge pump on NBV will be proportionally more

negative. When the voltage on the NBV pin reach-

2 AN152REV1

Page 3

AN152

VA+ = 5 V

+

-

-1x

Load Current

Extra

Load

RD C

NBV

L3

D , D = 1N4148

2

1

D = BAT 85

3

Figure 4. ADC Charge Pump Regulation Loop

es the proper magnitude, cycles of the charge pump

clock are deleted. The regulation loop maintains

the pulse rate out of the CPD pin at an average frequency that yields the proper output voltage. The

CPD driver output is supplied from the VD+ supply

as shown in Figure 4. This can be +5 V or +3 V.

The diode charge pump shown in Figure 4 is for a

+5 V supply. Diode D3, a Schottky, ensures that the

NBV pin will not go more than a diode drop above

ground. This ensures proper start-up of the regulator loop. Figure 5 illustrates the diode connections

needed if VD+ is 3 V.

Figure 6 illustrates a plot of the average freque ncy

VD+ = 5 V

CPCLK

D

DGND

1

CPD

C

1

+

-

Partial of ADC

D

2

2

+

output from CPD when the external load on the

output of the charge pump is changed. The charge

pump clock (CPCLK) is derived from XIN/2,

therefore the maximum frequency which can be

output from CPD is equal to XIN/2.

The load current in each of the plots exclude the

current used by the on-chip instrumentation amplifier (approximately 450 µA for the CS5525/26; 375

µA for the CS5521/23; and 700 µA for the

CS5522/24/28).

The plot illustrates the average CPD frequency for

two different sizes of charge pump capacitors with

the VA+ supply adjusted to 4.5, 5.0 and 5.5 V. The

Figure 5. Charge Pump Drive Diode Circuit For VD+ = 3V

AN152REV1 3

Page 4

1600

1400

1200

AN152

1000

(µA)

800

Load Cu rrent (uA)

600

400

200

0

0.00 2.00 4.00 6.00 8.00 10.00 12.00 14.00 16.00 18.00

Figure 6. Load Current vs. Frequency for the CS5521/23 and CS5522/24/28; VA+ = VD+

plot shows that if the charge pump output has no

external load, its average output frequency (VA+ =

5 V, C =0.033 uF) is approximately 8 kHz which is

about ½ the maximum possible output frequency.

The charge pump runs at this average frequency to

support the load of the on-chip instrumentation amplifier.

Figure 7 illustrates load current vs. CPD frequency

for the CS5525/26 devices. The charge pump clock

(CPCLK) is derived from XIN (set to 32.768 kHz),

therefore the maximum frequency which can be

output from CPD is equal to XIN.

The plots show data similar to tha t in figure 6. Because the charge pump frequency in the CS5525/26

devices is twice as fast as that used in the

CS5521/22/23/24/28 devices, the charge pump capacitor is ½ the size (for the same X IN clock frequency).

V

5

.

5

6

0

.

0

Frequency (KHz)

@

F

u

8

u

8

6

0

.

0

V

0

.

5

@

F

u

8

6

0

.

0

V

5

.

4

@

F

u

3

3

0

.

0

3

0

.

0

0

.

0

V

5

.

5

@

F

F

u

3

3

3

V

0

.

5

@

5

.

4

@

F

u

Figure 8 illustrates the CS5521/22/23/24/28 with

the charge pump capacitor increased to 0.15 µF.

This charge pump capacitor is about 4.5 times larger than the nominal capacitor. Under this condition

the charge pump could readily supply 2 mA to an

external load. While the pl ot indicates that 3 mA

can be supplied, it is not recommended that the external load exceed 2 mA. This allows for some

margin in the design. The actual maximum output

load capability is affected by the tolerances of

VA+, VD+, and the tolerance limits of the charge

pump capacitor.

Figures 9 and 10 illustrate the CS5521/22/23/24/28

running with a VD+ supply of 3 V. Figure 9 indicates the variation in load current capa bility when

VA+ varies from 4.5 to 5.5 V (VD+ =3.0 V). Figure 10 illustrates the variation in load capability

when VA+ is a constant 5.0 V, but VD+ is varied

V

4 AN152REV1

Page 5

(µA)

Load Current (uA)

1400

1200

1000

800

600

400

200

AN152

V

5

.

5

@

F

u

3

3

0

.

0

3

3

0

.

0

V

0

.

5

@

F

u

u

3

3

0

.

0

V

5

.

4

@

F

u

5

1

0

.

0

0

V

5

.

5

@

F

u

5

1

0

.

1

0

.

0

V

0

.

5

@

F

u

5

V

5

.

4

@

F

(µA)

Load Current

0

0.0 5.0 10.0 15.0 20.0 25.0 30.0 35.0

Frequency (KHz)

Figure 7. Load Current vs. Frequency for the CS5525/26; VA+ = VD+

3500

3000

2500

2000

1500

1000

500

0

0.00 2.00 4.00 6.00 8.00 10.00 12.00 14.00 16.00 18.00

Frequency

Figure 8. Load Current vs. Frequency; VA+ = VD+ = 5 V, Capacitor Size = 0.15 uF; CS5521/22/23/24/28

AN152REV1 5

Page 6

1000

900

800

700

(µA)

600

500

Load Current

400

300

200

100

0

0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0

+

A

V

Frequency

V

5

.

4

=

V

0

.

5

=

+

A

V

V

5

.

5

=

+

A

V

Figure 9. Load Current vs. Frequency for VD+ = 3.0 V, Capacitor Sizes = 0.47 uF

CS5521/22/23/24/28

AN152

1200

1000

800

V

3

.

3

(µA)

600

Load Current (uA )

400

200

0

0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0

=

+

D

V

V

Frequency (KHz)

V

0

.

3

=

+

D

7

.

2

=

+

D

V

Figure 10. Load Current vs. Frequency for VA+ = 5.0 V, Capacitor Sizes = 0.47 uF

CS5521/22/23/24/28

6 AN152REV1

Page 7

AN152

from +3.3 down to 2.7 V. The external load capability of the charge pump is limited when VD+ gets

to 2.7 V.

quency is changed to some other frequency, the

charge pump capacitor should be scaled inversely.

For example, if XIN is scaled from 32.768 kHz to

100 kHz, the charge pump capacitor should re-

Running the CS552X at Frequencies other than 32.768 kHz

The XIN frequency into the converters is used to

derive the charge pump clock frequency. The XIN

duced to about 1/3 of the value used at 32.768 kHz.

See the appendix for more exact equations which

can help determine the value of the charge pump

capacitor.

frequency is nominally 32.768 kHz. If this fre-

APPENDIX

Equation for charge pump as depicted in figure 4.

I = vfc

Current = Voltage x Frequency x Capacitor

I

+ I

NBV

I

= Current via NBV pin. Nominally 450µA for CS5525/26; 375 µA for CS5521/23; and 700 µA for

NBV

CS5522/24/28.

= [(VD+) - (2 x VD) - (2.1 V)] [η CPCLK] [CC]

EXT

I

= Current via External Load

EXT

VD+ = VD+ supply Voltage; typically 5 V.

VD = Forward Diode Voltage; typically 0.65 V.

-2.1 V = Regulated value of NBV (could use VA+/2.38 if VA+ is other than 5.0 V).

CPCLK = Charge Pump Clock. Nominally 32.768 kHz for CS5525 and CS5526; 16.384 kHz for

CS5521/22/23/24/28.

η = Duty cycle of CPCLK (average CPCLK frequency / maximum CPCLK frequency) to regulate NBV,

typically 0.3 to 0.7.

Choose CC to give the proper I

NBV

+ I

with the lowest VD+ and η set to some value between 0.3 and

EXT

0.7.

Note: I

should never exceed 2 mA.

EXT

AN152REV1 7

Page 8

Loading...

Loading...