Page 1

AN131

Application Note

Interfacing the CS5521/22/23/24/28 to the 68HC05

TABLE OF CONTENTS

1. INTRODUCTION ................................................... 1

2. ADC DIGITAL INTERFACE ................................... 1

3. SOFTWARE DESCRIPTION ................................. 2

3.1 Initialize ............................................................. 2

3.2 Write Channel Setup Registers ........................ 2

3.3 Self-Offset Calibration ....................................... 3

3.4 Read/Write Gain Register ................................. 3

3.5 Acquiring Conversions ...................................... 4

4. MAXIMUM SCLK RATE ......................................... 4

5. CONCLUSION ....................................................... 5

6. APPENDIX: 68HC05 MICROCODE TO INTERFACE

TO THE CS5521/22/23/24/28 ................................ 6

1. INTRODUCTION

This application note details the int erface of Ci rrus

Logic’s Crystal® CS5521/22/23/24/28 Analog-to-

Digital Converter (ADC) to a Motorola 68HC05

microcontroller. This note takes the reader through

a simple example describing how to communicate

with the ADC. All algorithms discussed are i ncluded in Section 6. “APPENDIX: 68HC05 Microcode

to Interface to the CS5521/22/23/24/28” on page 6.

2. ADC DIGITAL INTERFACE

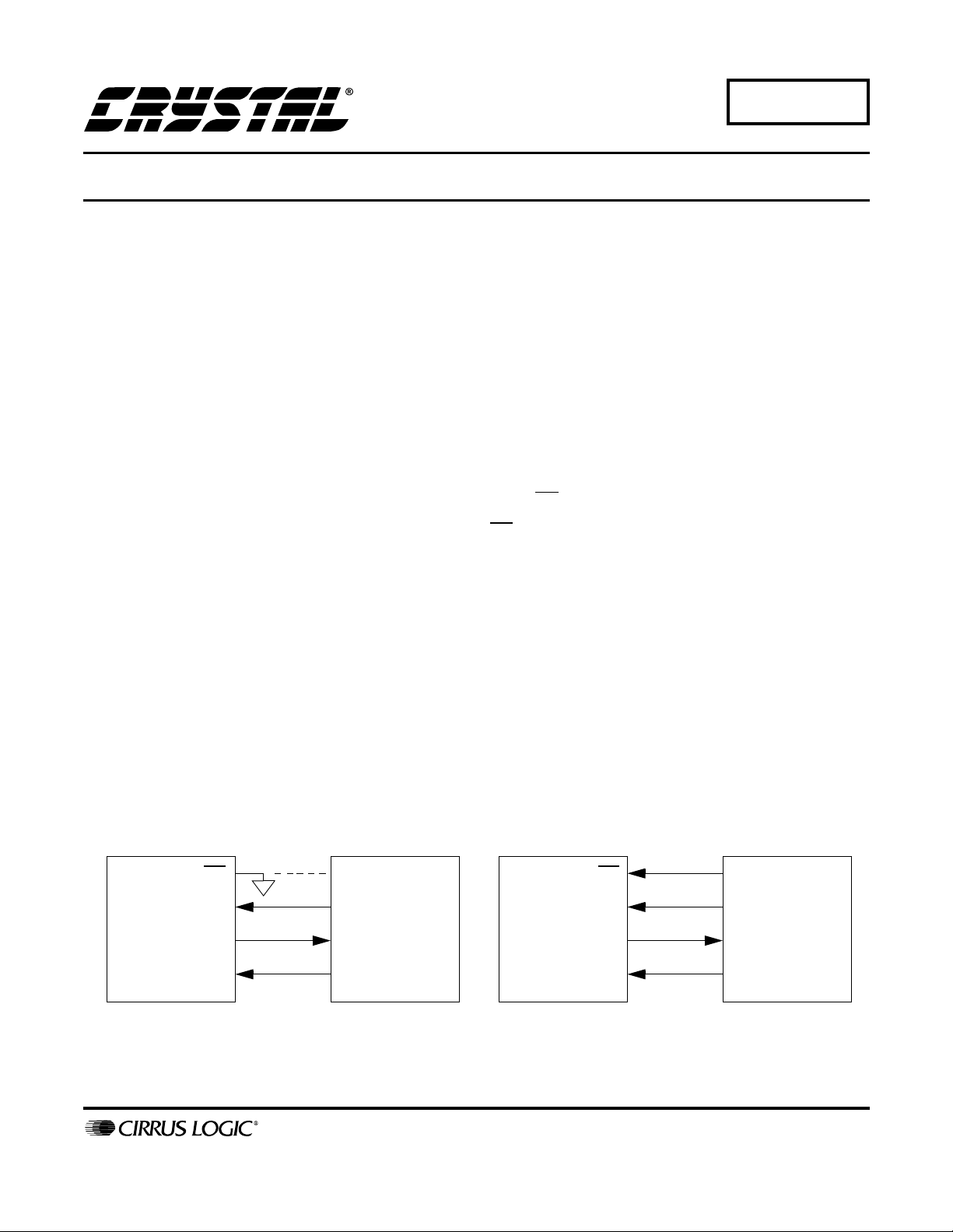

The CS5521/22/23/24/28 interfaces to the 68HC05

through either a three-wire or a four-wire interface.

Figure 1 depicts the interface between the two devices. Though this software was written to interface to the three-wire SPITM on the 68HC05, the

algorithms can be easily modified to work in the

four-wire format.

The ADC’s serial port consists of four control

lines: CS, SCLK, SDI, and SDO.

CS, Chip Select, is the control line which enables

access to the serial port.

SCLK, Serial Clock, is the bit-clock which controls

the shifting of data to or from the ADC’s serial

port.

SDI, Serial Data In, is the data signal used to transfer data from the 68HC05 to the ADC.

SDO, Serial Data Out, is the data signal used to

transfer output data from the ADC to the 68HC05.

3-Wire Interface 4-Wire Interface

CS5521/22/23/24/28 68HC05

CS

SDI

SDO

SCLK

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

No Connect

MOSI (PD3)

MISO (PD2)

SCK (PD4)

Figure 1. 3-Wire and 4-Wire Interfaces

CS5521/22/23/24/28

CS

SDI

SDO

SCLK

Copyright Cirrus Logic, Inc. 1999

(All Rights Reserved)

68HC05

PA0

MOSI (PD3)

MISO (PD2)

SCK (PD4)

NOV ‘99

AN131REV2

1

Page 2

AN131

3. SOFTWARE DESCRIPTION

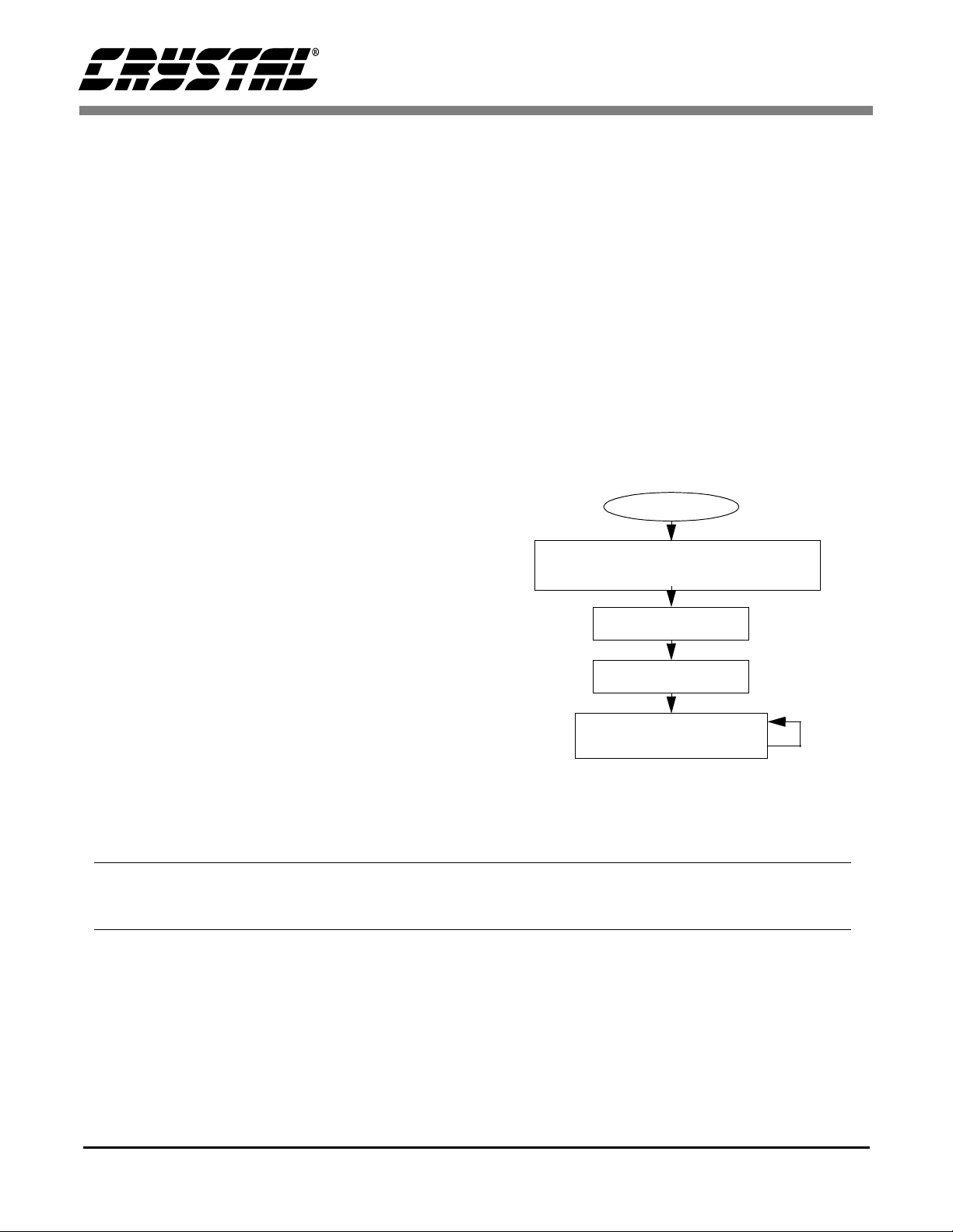

This note presents algorithms to initialize the

68HC05 and the CS5521/22/23/24/28, modify the

CS5521/22/23/24/28’s internal registers, perform

calibrations, and acquire conversions. Figure 2 depicts a block diagram of the program structure.

While reading this application note, please refer to

Section 6. “APPENDIX: 68HC05 Microcode to Interface to the CS5521/22/23/24/28” on page 6 for

the code listing.

3.1 Initialize

Initialize is a subroutine that configures the SPI on

the 68HC05 and places the CS5521/22/23/24/28

into the command state. The SPI is configured as

depicted in Figure 1 by selecting the 68HC05 as the

master. To function properly with the

CS5521/22/23/24/28, the SPI must be set up to use

a clock which idles low, and begins clocking data

with a rising edge in the center of the first bit (for

more information on configuring the SPI refer to

Motorola’s 68HC05 Application Guide). After

configuring the SPI, the controller enters a delay

state to allow time for the CS5521/22/23/24/28’s

power-on-reset and oscillator to start-up (oscillator

start-up time for a 32.768 KHz crystal is typically

500 ms). The last step is to reinitialize the serial

port on the ADC (reinitializing the seri al port is unnecessary here, and the code is for demonstration

purposes only). This is implemented by sending the

converter fifteen bytes of logic 1’s followed by one

final byte, with its LSB at logic 0. This sequence

places the serial port of the ADC into the command

state, where it waits for a valid command.

3.2 Write Channel Setup Registers

The subroutine write_csrs is an example of how to

write to the CS5521/22/23/24/28’s Channel Setup

Registers (CSRs). For this example, two CSRs

(four Setups) are written. The number of CSRs to

be accessed is determined by the Depth Pointer bits

(DP3-DP0) in the configuration register. The

Depth Pointer bits are set to “0011” to access the

two CSRs. The value “0011” is calculated by tak-

START

INITIALIZE MICROCONTROLLER

AND CS55 21/22/23/24/28

SELF-OFFSET CAL.

MODIFY GAIN

ACQUIRE CONVERSION

Figure 2. CS5521/22/23/24/28 Software Flowchart

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

SPI™ is a trademark of Motorola.

Microwire™ is a trademark of National Semiconductor.

Preliminary product inf o rmation describes products whi ch are in production, but for which full characteriza t i on da t a i s not yet available. Advance produ ct i nfor-

mation describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document i s accurat e and reli able. However , t he infor mation is subje ct to chang e without noti ce and is provi de d “AS IS” without warranty of

any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other rights

of third parties. This document is the pro perty of Cirrus Logi c, Inc. and i mplie s no licen se under patents, copyrights, tr ademarks, or trade secre ts. No part of

this publication may be copied, reproduced , stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or

otherwise) without the pr i or writ ten consent of Cirrus Logic, Inc. Ite ms f rom any Ci rrus L ogi c websi t e or disk may be printed for use by the user. However, no

part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical,

photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a basis for manufacture

or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing

in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

2 AN131REV2

Page 3

AN131

ing the number of Setups to be accessed and subtracting 1. Because each CSR holds two Setups,

this number must always be an odd value, that is,

DP0 must always be logic 1 when reading and writing the CSRs. To modify the Depth Pointer bits, the

configuration register is read to prevent corruption

of other bits. After the read_register routine is run

with the command 0x0B (HEX), the DP3-DP0 bits

are masked to “0011”. Then, the updated information is written back into the ADC with the command 0x03 (HEX) using the write_register routine.

After the depth pointer bits are set correctly, the

CSR information is written to the ADC. The command 0x05 (HEX) is sent to the ADC to begin the

write sequence (to read the CSRs, the command

would be 0x0D). At this point, the ADC is expecting to receive information for two 24-bit CSRs, or

48 bits, based on the Depth Pointer bits. The first

CSR is written with a value of 0x000000 (HEX).

This sets Setup 1 and Setup 2 both to convert bipolar, 100mV signals on physical channel 1 (PC1) at

an output word rate (OWR) of 15 Hz, and latch pins

A1-A0 equal to “00”. The second CSR is written

with the value 0x4C0105 (HEX). This sets Setup 3

to convert a bipolar, 100mV signal on PC2 at a

101.1 Hz OWR, with latch pins A1-A0 at “01”.

This also sets Setup 4 to convert a unipolar, 25mV

input signal at 15 Hz on PC3, with out put latch pins

A1-A0 set to “00”.

3.3 Self-Offset Calibration

Calibrate is a subroutine that performs a self-offset

calibration using Setup 1. Calibrate does this by

sending the command 0x81 (HEX) to the ADC

through the SPI. This tells the ADC to perform a

self-offset calibration using Setup 1 (see the

CS5522/24/28 and CS5521/23 Data Sheets for information on performing offset or gain calibrations

using other Setups). Once the command has been

sent, the controller polls MISO (SDO) until it falls,

indicating that the calibration is complete. Note

that although calibrations are done using a specific

Setup, the offset or gain register that is modified

belongs to the physical channel referenced by that

Setup.

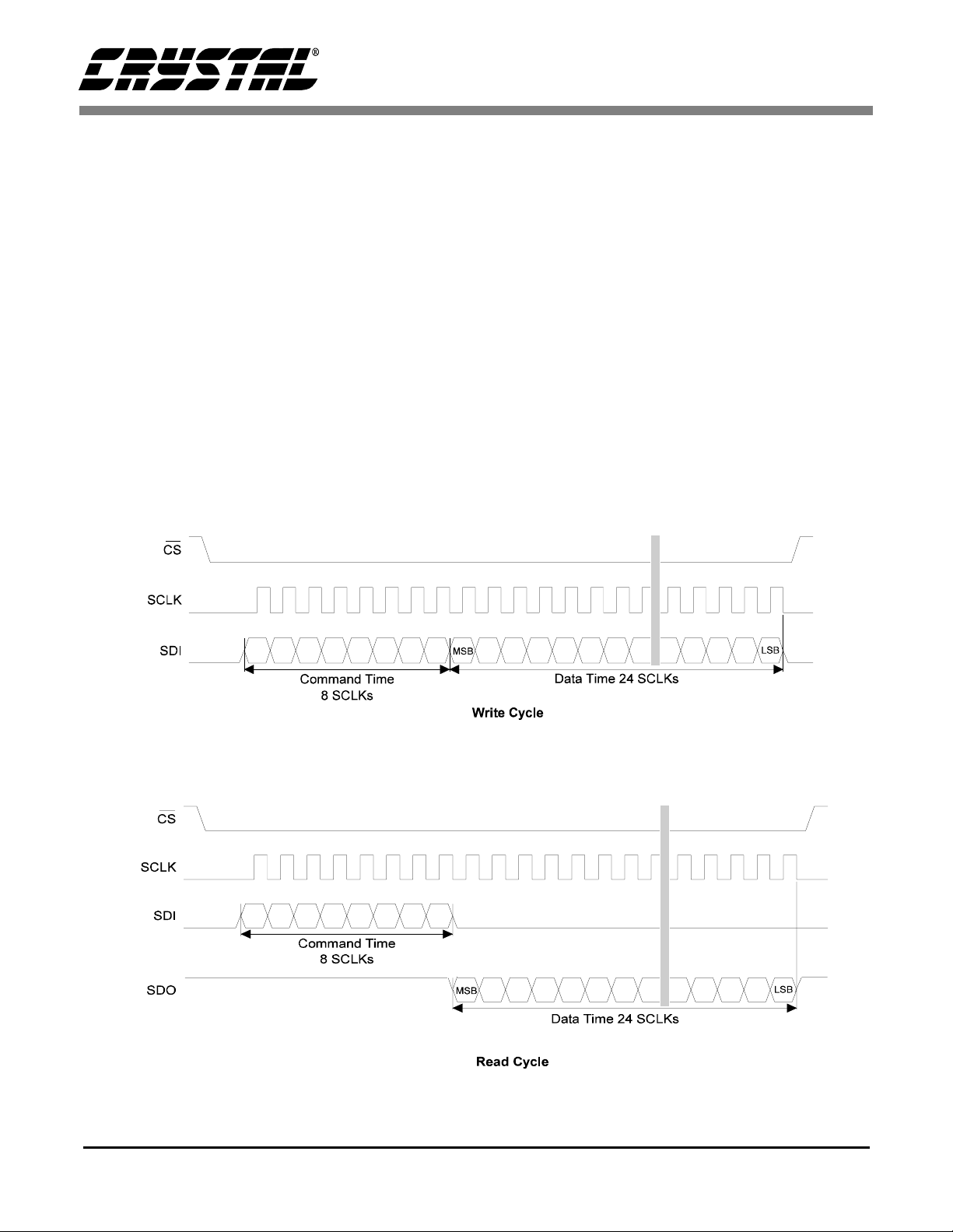

3.4 Read/Write Gain Register

The routine rwgain provides an example of how to

modify the ADC’s internal gain registers. To modify the gain register the command byte and data

byte variables are written with the appropriate information. rwgain then calls the subroutine

write_register, which uses these variables to set the

contents of Physical Channel 1 (PC1)’s gain register to 0x800000 (HEX). The write_register routine

calls the send_spi algorithm four times, once to

send the command byte, and three more times to

send the three data bytes. Send_spi is a subroutine

which transfers data to the CS5521/22/23/24/28

MSB-first through the SPI. Figure 3 depicts the

timing diagram for the write-cycle in the

CS5521/22/23/24/28’s serial port. It is important to

note here that this section of the code demonstrates

how to write to the gain register of PC1. It does not

perform a gain calibration. To write to the other internal registers of the ADC, follow the procedures

outlined in the CS5522/24/28 and CS5521/23 data

sheets.

To read the value in the gain register of PC1, the

command byte is loaded with the value 0x0A

(HEX), and the read_register routine is called. It

duplicates the read-cycle timing diagram depicted

in Figure 4. Read_register calls send_spi once to

transfer the command-byte to the

CS5521/22/23/24/28. This places the converter

into the data state where it waits until data is read

from its serial port. Read_register then calls

receive_spi three times and transfers three bytes of

information from the CS5521/22/23/24/28 to the

68HC05. Similar to send_spi, receive_spi acquires

a byte one bit at a time, MSB-first from the SPI.

When the transfer is complete, the variables

high_byte, mid_byte, and low_byte contain the value present in PC1’s 24-bit gain register.

AN131REV2 3

Page 4

AN131

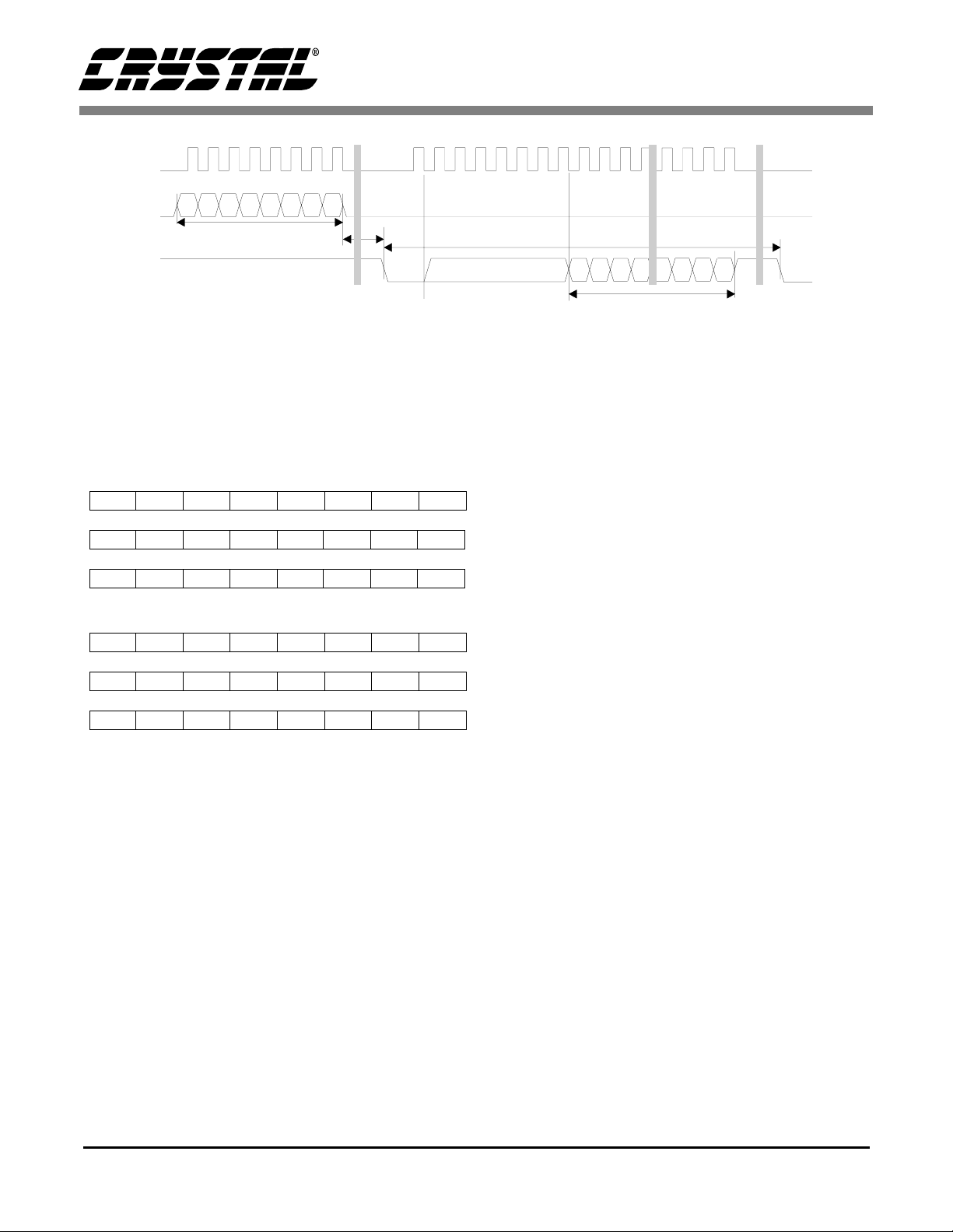

3.5 Acquiring Conversions

To acquire a conversion the subroutine convert is

called. For single conversions on one physical

channel, the MC (multiple conversion) and the LP

(loop) bits in the configuration register must be logic 0. To prevent corruption of the configuration

register, convert instructs the 68HC05 to read and

save the contents. This information is stored in the

variables HIGHBYTE, MIDBYTE and LOWBYTE. Then the MC, LP, and RC (read conver t)

bits are masked to logic 0, and the new information

is written back to the ADC’s co nfiguration regis ter.

A conversion is initiated using Setup 1 by sending

the command 0x80 to the converter. At this time,

the controller polls MOSI (SDO) until it falls to a

logic 0 level (see Figure 5). After SDO falls, con-

vert calls send_spi to send one byte of all 0’s to the

converter to clear the SDO flag. The 68HC05 then

reads the conversion data word by calling

receive_spi three times. Figure 6 depicts how the

16 and 24-bit data words are stored in the memory

locations HIGHBYTE, MIDBYTE, and LOWBYTE.

4. MAXIMUM SCLK RATE

A machine cycle in the 68HC05 consists of 2 oscillator periods or 500 ns if the microcontroller’s oscillator frequency is 4 MHz. Since the

CS5521/22/23/24/28’s maximum SCLK rate is

2 MHz, additional no operation (NOP) delays may

be necessary to reduce the tra nsfer rate if the microcontroller system requires higher rate oscillators.

Figure 3. Write-Cycle Timing

Figure 4. Read-Cycle Timing

4 AN131REV2

Page 5

SCLK

SDI

*

t

ommand Time

C

8SCLKs

DO

S

td = XIN/OWR clock cycles for each conversion except the

*

first conversion which will take XIN/OWR + 7 clock cycles

d

Data SDO Continuous Conversion Read

Figure 5. Conversion/Acquisition Cycle Timing

SCLKs Clear SDO Flag

8

5. CONCLUSION

AN131

IN/OWR

X

Clock Cycles

SB

M

ata Time

D

24 SCLKs

SB

L

MSB High-Byte

D23 D22 D21 D20 D19 D18 D17 D16

Mid-Byte

D15 D14 D13 D12 D11 D10 D9 D8

Low-Byte

D7 D6 D5 D4 D3 D2 D1 D0

A) 24-Bit Conversion Data Word (CS5522/24/28)

MSB High-Byte

D15 D14 D13 D12 D11 D10 D9 D8

Mid-Byte

D7 D6 D5 D4 D3 D2 D1 D0

Low-Byte

1110CI1CI0ODOF

B) 16-Bit Conversion Data Word (CS5521/23)

0- always zero, 1- always one,

CI1, CI0 - Channel Indicator Bits

OD - Oscillation Detect, OF - Overflow

Figure 6. Bit Representation/Storage in 68HC05

This application note presents an example of how

to interface the CS5521/22/23/24/28 to the

68HC05. It is divided into two main sections: hardware and software. The hardware interface illustrates both three-wire and a four-wire interface.

The three-wire interface is SPI and Microwire™

compatible. The software section illustrate s how to

initialize the converter and microcontroller, write

to the CSRs, write and read the ADC’s interna l registers, perform calibrations, and acquire conversions. The software is modularized and provides

important subroutines such as write_register,

read_register, write_csrs and convert, which were

all written in 68HC05 assembly language.

The software described in the note is included in

Section 6. “APPENDIX: 68HC05 Microcode to Interface to the CS5521/22/23/24/28” on page 6.

AN131REV2 5

Page 6

AN131

6. APPENDIX: 68HC05 MICROCODE TO INTERFACE TO THE CS5521/22/23/24/28

;*****************************************************************************

;* File: 55226805.ASM

;* Date: September 23, 1998

;* Revision:0

;* Processor:68HC05

;*

;* Program entry point at routine ’main’. Entry point address is $100

;*

;* This program is an example on how to interface a 68HC05 Microcontro ller

;* to a CS5521/22/23/24/28 ADC. The program interfaces via the SPI port (Port D)

;* on the microcontroller, which controls the serial communications,

;* calibration, and conversion cycles.

;*****************************************************************************

;*** Memory Map Equates ***

PORTA EQU $00 ;General Purpose I/O Port

DDRA EQU $04 ;Data Direction Control for Port A

PORTD EQU $03 ;Port D Direct Pin Access (Input)

SPCR EQU $0A ;Serial Peripheral Control Register

SPSR EQU $0B ;Serial Periph e ral S tatus Register

SPDR EQU $0C ;Serial Peripheral Data I/O Register

SPIF EQU 7 ;Serial Peripheral Data Transfer Flag

;*** RAM Values ***

ORG $50

HIGHBYTE RMB 1 ;Upper 8 bits of Conversion Register

MIDBYTE RMB 1 ;Middle 8 bits of Conversion Register

LOWBYTE RMB 1 ;Lower 8 bits of Conversion Register

COMMAND RMB 1 ;Command Byte storage location

;*****************************************************************************

;* Program Code

;************* *** *** ********************************* *** *** *******************

ORG $100

;************* *** *** ********************************* *** *** *******************

;* Routine - main

;* Input - none

;* Output - none

;* This is the entry point and the main loop of the program.

;*****************************************************************************

6 AN131REV2

Page 7

MAIN EQU * ;Start from reset vector

;*** Initialize and Calibrate the system ***

JSR initialize ;Initialize the System

JSR write_csrs ;Modify the Chann e l Setup Registers

JSR calibrate ;Calib rate ADC Offset

JSR rwgain ;Write and read gain register

;*** Continuously perform single conversions ***

mloop: JSR convert ;Obtain a conversion from the ADC

JMP mloop ;Keep Looping

;*** End MAIN ***

;*****************************************************************************

;* Subroutines

;************* ********************************** ***************** *************

AN131

;************* ********************************** ***************** *************

;* Routine - initialize

;* Input - none

;* Output - none

;* This subroutine initializes Port D as a SPI port to interface to the

;* CS5521/22/23/24 / 28 ADC .

;* A time delay for the ADC oscillator start-up period is provided, as well

;* as a delay for the ADC’s power-on reset.

;* Typically, a 32.768 KHz crystal has a start-up time of about 500ms. After

;* this delay, an additional 1003 XIN cycles are delayed for the ADC reset.

;* The ADC’s serial port is also reset at this time

;*****************************************************************************

initialize LDA #%01010000 ;Load ACCA with values for SPCR

STA SPCR ;Setup SPI Port

LDA #$40 ;Load ACCA with delay count value

JSR delay ;Delay 1003 XIN for power-on reset

LDA #220 ;Load ACCA with delay count value

JSR delay ;Delay for oscillator start-up 170ms

JSR delay ;Delay for oscillator start-up 170ms

JSR delay ;Delay for oscillator start-up 170ms

;*** Initialize ADC serial port ***

LDX #$0F ;Value of 15 for first 15 Bytes

LDA #$FF ;Load ACCA with all 1’s

sloop: JSR send_sp i ;Send info to ADC

DECX ;Decrement Counter

AN131REV2 7

Page 8

BNE sloop ;Repeat loop if counter isn’t zero

LDA #%11111110 ;Load ACCA with last byte

JSR send_spi ;Send final byte to ADC

RTS ;Exit routine

;*****************************************************************************

;* Routine - write_csrs

;* Input - none

;* Output - none

;* This subroutine is used to write to the Channel Setup Reg isters. It first

;* changes the depth pointer bits in the configuration register to reflect

;* the number of CSRs to be written, and then writes information to th e

;* appropriate number of CSRs.

;*****************************************************************************

write_csrs LDA #$0B ;Command to read config. register

STA COMMAND ;Prepare command byte

JSR read_register;Read the configuration register

;*** Mask DP3-DP0 to access two CSRS (four Setups) ***

LDA MIDBYTE ;Get Middle Byte in ACCA

AND #$3F ;Mask DP3-DP2 low

ORA #$30 ;Mask DP1-DP0 high

STA MIDBYTE ;Put info back in to Middle Byte location

LDA #$03 ;Command to write back to config Register

STA COMMAND ;Prepare Command Byte

JSR write_register;Write Configuratio n Register

AN131

;*** Write to CSRs - note, the ADC expects information for the number of

; CSRs indicated in the Depth Bits (DP3-DP0 in the configuration

; register) so all of the CSRs must be written at this time.

LDA #$05 ;Command to write CSRs

JSR send_spi ;send command to ADC

;*** Setup CSR #1 - Setups 1 and 2

; Sets both Setups to a default value of ’000’

; (A1-A0 = 00, Physical Channel = 1, OWR = 15Hz,

; Input V-range = 100mV, Bipolar Measurement Mode)

LDA #$00 ;Load ACCA with zeros

JSR send_spi ;One byte of zero...

JSR send_spi ;Two bytes of zero...

JSR send_spi ;Three bytes of zero.

;*** Setup CSR #2 - Setups 3 and 4

; Sets Setup 3 to ’4C0’ and Setup 4 to ’105’

; Setup 3 Settings - (A1-A0 = 01, Physical Channel = 2, OWR = 101.1Hz,

; input V-range = 100mV, Bipolar)

8 AN131REV2

Page 9

; Setup 4 Settings - (A1-A0 = 00, Physical Channel = 3, OWR = 15Hz,

; input V-range = 25mV, Unipolar)

LDA #$4C ;Load ACCA with first byte of CSR #2

JSR send_spi ;Send byte number one

LDA #$01 ;Load ACCA with second byte of CSR #2

JSR send_spi ;Send byte number two

LDA #$05 ;Load ACCA with third byte of CSR #2

JSR send_spi ;Send byte number three

RTS ;Exit subroutine

;*****************************************************************************

;* Routine - calibrate

;* Input - none

;* Output - none

;* This subroutine instructs the CS5521/22/23/24/28 to perform a self-calibration on

;* Setup 1.

;************* ***************** ***********************************************

AN131

calibrate LDA #$81 ;Command for Self-Offset Cal, Set up 1

JSR send_spi ;Send Self-Cal command to ADC

poll_sdo1 BRSET 2,PORTD, poll_sdo1 ;Wait for SDO to fall

RTS ;Exit Routine

;*****************************************************************************

;* Routine - rwgain

;* Input - none

;* Output - cont ents of gain registe r on PC1 in HIGH, MID and LOW bytes

;* This subroutine first writes, and then reads back the value of the gain

;* register on Physical Channel 1

;*****************************************************************************

;*** Write to Gain Register of Physical Channel 1 ***

rwgain LDA #$02 ;Command to Write Gain Register of PC 1

STA COMMAND ;Prepeare COMMAND byte

LDA #$80 ;Value for High Byte

STA HIGHBYTE ;Prepare HIGHBYTE

CLR MIDBYTE ;Prepare MIDBYTE

CLR LOWBYTE ;Prepare LOWBYTE

JSR write_register;Write to Gain Register

;*** Read From Gain Register of Physical Channel 1 ***

LDA #$0A ;Command to Read Gain Register of PC 1

STA COMMAND ;Prepare COMMAND byte

JSR read_register;Read from Gain Register

RTS ;Return

AN131REV2 9

Page 10

AN131

;*****************************************************************************

;* Routine - convert

;* Input - none

;* Output - conversion results in memory locations HIGHBYTE, MIDBYTE and

;* LOWBYTE. This algorithm performs single conversions on

;* Setup 1. See the CS5521/22/23/24 /28 data sheet for multiple

;* conversions or conversions on other channels.

;* This subroutine performs a Single conversion using Setup 1

;*****************************************************************************

convert LDA #$0B ;Command to read Configuration Register

STA COMMAND ;Prepare COMMAND byte

JSR read_register;Read Config. Register

LDA HIGHBYTE ;Get High Byte in ACCA

AND #$F8 ;Mask MC, LP and RC bits to 0

STA HIGHBYTE ;Put info back into High Byte location

LDA #$03 ;Command to write back to config Register

STA COMMAND ;Prepare Command Byte

JSR write_register;Write Configuratio n Register

;*** Receive Conversion Data ***

LDA #$80 ;Command to convert on Setup 1

JSR send_spi ;Send Command to ADC

poll_sdo2: BRSET 2,PORTD,poll_sdo2 ;Wait for SDO to fall

LDA #$00 ;Load A with all 0’s

JSR send_spi ;Send all 0’s to ADC

JSR receive_spi ;Get high conversion byte

STA HIGHBYTE ;Move info to High Byte location

JSR receive_spi ;Get middle conversion byte

STA MIDBYTE ;Move info to Middle Byte location

JSR receive_spi ;Get low conversion byte

STA LOWBYTE ;Move info to Low Byte location

RTS ;Return

;*****************************************************************************

;* Routine - write_register

;* Input - COMMAND, HIGHBYTE, MIDBYTE, LOWBYTE

;* Output - none

;* This subroutine is used to write information to the int ernal registers of

;* the CS5521/22/23/24/28

;************* *** *** ** *** ********************************** *** *** *** ** ********

write_register LDA COMMAND ;Load ACCA with COMMAND

JSR send_spi ;Transfer command byte

LDA HIGHBYTE ;Load ACCA with HIGHBYTE

JSR send_spi ;Transfer high byte

LDA MIDBYTE ;Load ACCA with MIDBYTE

JSR send_spi ;Transfer middle byte

LDA LOWBYTE ;Load ACCA with LOWBYTE

10 AN131REV2

Page 11

JSR send_spi ;Transfer low byte

RTS ;Return

;*****************************************************************************

;* Routine - read_register

;* Input - COMMAND

;* Output - HIGHBYTE, MIDBYTE, LOWBYTE

;* This subroutine is used to read from the internal registers of the

;* CS5521/22/23/24 / 28

;************* *** *** ********************************* *** *** *******************

read_register LDA COMMAND ;Load ACCA with COMMAND

JSR send_spi ;Send command byte

JSR receive_spi ;Receive a byte

STA HIGHBYTE ;Store value in HIGHBYTE

JSR receive_spi ;Receive a byte

STA MIDBYTE ;Store value in MIDBYTE

JSR receive_spi ;Receive a byte

STA LOWBYTE ;Store value in LOWBYTE

RTS ;Return

AN131

;*****************************************************************************

;* Routine - send_spi

;* Input - Byte to be send is placed in ACCA

;* Output - none

;* This subroutine sends a byte to the ADC using the SPI po rt.

;*****************************************************************************

send_spi STA SPDR ;Move ACCA to the SPI Data Register

wait0: BRCLR SPIF,SPSR,wait0 ;Loop until byte has been transmitted

RTS ;Return

;*****************************************************************************

;* Routine - receive_spi

;* Input - none

;* Output - Received byte is placed in ACCA

;* This subroutine receives a byte from the ADC using the SPI port

;*****************************************************************************

receive_spi CLRA ;Load ACCA Register with all Zeros

STA SPDR ;Transfer 8 0’s to clock next byte

wait1: BRCLR SPIF,SPSR,wait1 ;Reset SPIF bit

LDA SPDR ;Get received information

RTS ;Return

;*****************************************************************************

AN131REV2 11

Page 12

;* Routine - delay

;* Input - count in ACCA

;* Output - none

;* This routine delays by using the count specified in ACCA. The 68HC05

;* Development Board uses a 4.0MHz clock (E = 2.0MHz), thus each cycle is

;* 500ns. This delay is equivalent to (500ns)*(1545)(count value)

;* A count of 720 provides a 556ms delay.

;*****************************************************************************

delay NOP

outlp: CLRX ;X used as inner loop count

innlp: DECX ;256 loops on inner

NOP ;2 cycles

NOP ;2 cycles

BNE innlp ;10 cycles*256*500ns=1.28ms

DECA ;countdown accumulator

BNE outlp ;2569 cycles*500ns*ACC A

RTS ;Return

;************* *** *************************************************** ** ********

;* Interrupt Vectors

;************* *** ********************************** ** ***************** *** *****

AN131

NOT_USEDRTI ;Return from interrupt

ORG $1FF4 ;Int Vector location

FDB NOT_USED ;SPI interrupt

FDB NOT_USED ;SPI interrupt

FDB NOT_USED ;SPI interrupt

FDB NOT_USED ;SPI interrupt

FDB NOT_USED ;SPI interrupt

FDB MAIN ;Reset interrupt - power on reset

12 AN131REV2

Page 13

• Notes •

Page 14

Loading...

Loading...