Page 1

AN130

Application Note

Interfacing the CS5521/22/23/24/28 to the PIC16C84

TABLE OF CONTENTS

1. INTRODUCTION ................................................... 1

2. ADC DIGITAL INTERFACE ................................... 1

3. SOFTWARE DESCRIPTION ................................. 2

3.1 Initialize ............................................................. 2

3.2 Write Channel Setup Registers ........................ 2

3.3 Self-Offset Calibration ....................................... 3

3.4 Read/Write Gain Register ................................. 3

3.5 Acquire Conversion .......................................... 4

4. MAXIMUM SCLK RATE ......................................... 4

5. SERIAL PERIPHERAL INTERFACE ..................... 4

6. DEVELOPMENT TOOL DESCRIPTION ................ 5

7. CONCLUSION ....................................................... 5

8. APPENDIX: PIC16C84 MICROCODE TO

INTERFACE TO THE CS5521/22/23/24/28 .......... 6

1. INTRODUCTION

This application note details the interface of Crys-

tal Semiconductor’s CS5521/22/23/24/28 Analogto-Digital Converter (ADC) to the Microchip

PIC16C84 microcontroller. This note takes the

reader through a simple example which demonstrates how to communi cate between t he microcontroller and the ADC. All algorithms discussed are

included in Section 8. “APPENDIX: PIC16C84

Microcode to Interface to the

CS5521/22/23/24/28” on page 6.

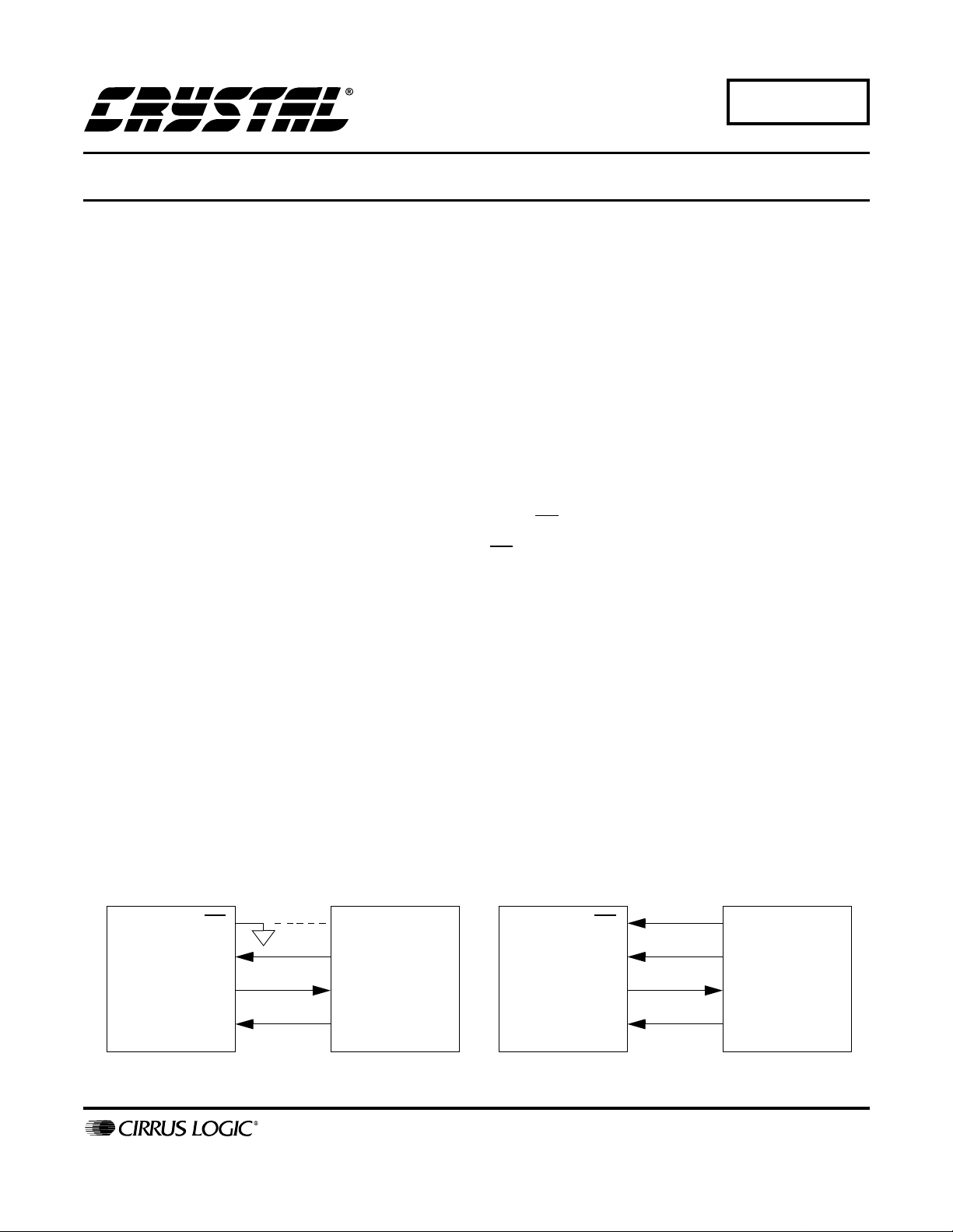

2. ADC DIGITAL INTERFACE

The CS5521/22/23/24/28 interfaces to the

PIC16C84 through either a three-wire or a fourwire interface. Figure 1 depicts the interface between the two devices. Though this software was

written to interface to Port A (RA) on the

PIC16C84 with a four-wire interface, the algorithms can be easily modified to work with the

three-wire format.

The ADC’s serial port consists of four control

lines: CS, SCLK, SDI, and SDO.

CS, Chip Select, is the control line which enables

access to the serial port.

SCLK, Serial Clock, is the bit-clock which controls

the shifting of data to or from the ADC’s serial

port.

SDI, Serial Data In, is the data signal used to transfer data from the PIC16C84 to the ADC.

SDO, Serial Data Out, is the data signal used to

transfer output data from the ADC to the

PIC16C84.

3-Wire Interface 4-Wire Interface

CS5521/22/23/24/28

CS

SDI

SDO

SCLK

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

PIC16C84

NC (RA0)

RA1

RA2

RA3

Figure 1. 3-Wire and 4-Wire Interfaces

CS5521/22/23/24/28

SDO

SCLK

Copyright Cirrus Logic, Inc. 1999

(All Rights Reserved)

CS

SDI

PIC16C84

RA0

RA1

RA2

RA3

NOV ‘99

AN130REV2

1

Page 2

AN130

3. SOFTWARE DESCRIPTION

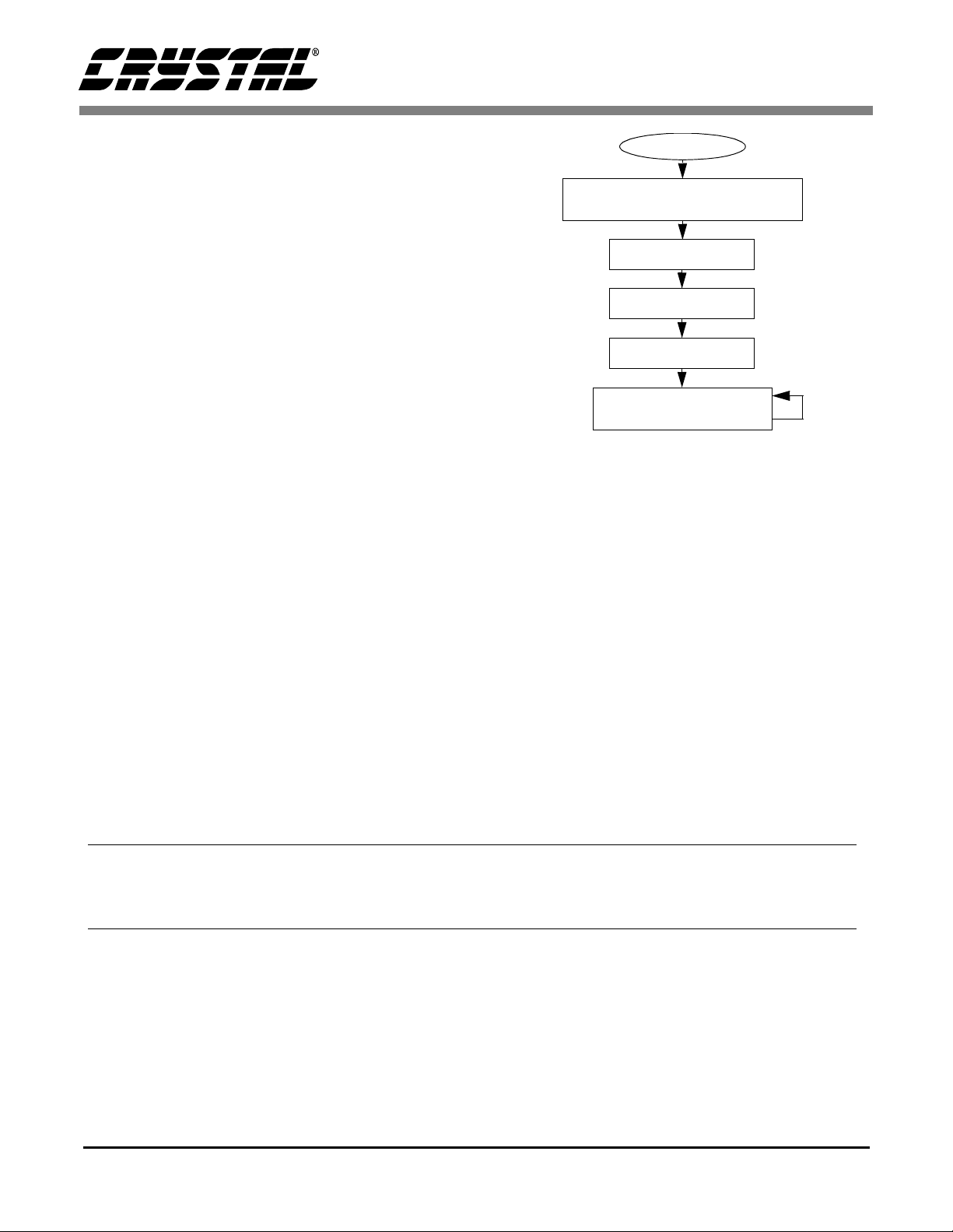

This note presents algorithms to initialize the

PIC16C84 and the CS5521/22/23/24/28, perform

calibrations, modify the CS5521/22/23/24/28’s internal registers, and acquire a conversion. Figure 2

depicts a block diagram of the main program structure. While reading this application note, please refer to Section 8. “APPENDIX: PIC16C84

Microcode to Interface to the

CS5521/22/23/24/28” on page 6 for the code listing.

3.1 Initialize

Initialize is a subroutine that configures Port A

(RA) on the PIC16C84 and places the serial port of

the CS5521/22/23/24/28 into the command state.

RA’s data direction is configured as depicted in

Figure 1 by writing to the TRISA register (for more

information on configuring ports, see the

PIC16C84 Data Sheet). The controller then enters

a number of delay states to allow the appropriate

time for the ADC’s oscillator to start up and stabilize (oscillator start-up time for a 32.768 KHz crystal is typically about 500ms). Finally, the ADCs

serial port is reset by sending fifteen bytes of logic

1’s followed by a single byte with its LSB at logic

0 to SDI (the serial port is initialized after any power-on reset, and this software re-initializa tion is for

demonstration purposes) Once the proper sequence

of bits has been received, the serial port on the

START

INITIALIZE

MICROCONTROLLER & ADC

WRITE CSRs

SELF-OFFSET CAL.

MODIFY GAIN

ACQUIRE CONVERSION

Figure 2. CS5521/22/23/24/28 Software Flowchart

ADC is in the command state, where it waits for a

valid command.

3.2 Write Channel Setup Registers

The subroutine write_csrs is an example of how to

write to the CS5521/22/23/24/28’s Channel Setup

Registers (CSRs). For this example, two CSRs

(four Setups) are written. The number of CSRs to

be accessed is determined by the Depth Pointer bits

(DP3-DP0) in the configuration register. The

Depth Pointer bits are set to “0011” to access the

two CSRs. The value “0011” is calculated by taking the number of Setups to be accessed and subtracting 1. Because each CSR holds two Setups,

this number must always be an odd value, that is,

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus. com/corporat e/contact s/

SPI is a trademark of Motorola.

MICROWIRE is a trademark of National Semiconductor.

MPLAB and MPASM are trademarks of Microchip.

Cirrus Logic, Inc. has made best efforts to ensure that the information contained in this document is accurate and reliable. However, the in-

formation is subject to change without notice and is provided “AS IS” without warranty of any kind (express or implied). No re sponsibility is

assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other rights of third parties. This document

is the property of Cirrus Logic, Inc. and implies no license under patents, copyrights, trademarks, or trade secrets. No part of this publication

may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic,

or otherwise). Furthermore, no part of this publication may be used as a basis for manufacture or sale of any items without the prior written

consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing in this document may be

trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks

and service marks can be found at http://www.cirrus.com.

2 AN130REV2

Page 3

AN130

DP0 must always be logic 1 when reading and writing the CSRs. To modify the Depth Pointer bits, the

configuration register is read to prevent corruption

of other bits. After the read_register routine is run

with the command 0x0B (HEX), the DP3-DP0 bits

are masked to “0011”. Then, the updated information is written back into the ADC with the command 0x03 (HEX) using the write_register routine.

After the depth pointer bits are set correctly, the

CSR information is written to the ADC. The command 0x05 (HEX) is sent to the ADC to begin the

write sequence (to read the CSRs, the command

would be 0x0D). At this point, the ADC is expecting to receive information for two 24-bit CSRs, or

48 bits, based on the Depth Pointer bits. The first

CSR is written with a value of 0x000000 (HEX).

This sets Setup 1 and Setup 2 both to convert bipolar, 100mV signals on physical channel 1 (PC1) at

an output word rate (OWR) of 15 Hz, and latch pins

A1-A0 equal to “00”. The second CSR is written

with the value 0x4C0105 (HEX). This sets Setup 3

to convert a bipolar, 100mV signal on PC2 at a

101.1 Hz OWR, with latch pins A1-A0 at “01”.

This also sets Setup 4 to convert a unipolar, 25mV

input signal at 15 Hz on PC3, with out put latch pins

A1-A0 set to “00”.

3.4 Read/Write Gain Register

The routine modify_gain provides an example of

how to modify the ADC’s internal gain registers.

To modify the gain register the command byte and

data byte variables are written with the appropriate

information. Modify_gain then calls the subroutine

write_register, which uses these variables to set the

contents of Physical Channel 1 (PC1)’s gain register to 0x800000 (HEX). The write_register routine

calls the send_byte algorithm four times, once to

send the command byte, and three more times to

send the three data bytes. Send_byte is a subroutine

used to ‘bit-bang’ a byte of information from the

PIC16C84 to the CS5521/22/23/24/28. A byte is

transferred one bit at a time, MSB (most significant

bit) first, by placing a bit of information on RA1

(SDI) and then pulsing RA3 (SCLK). The byte is

transferred by repeating this process eight times.

Figure 3 depicts the timing diagram for the writecycle in the CS5521/22/23/24/28’s serial port. It is

important to note here that this section of the code

demonstrates how to write to the gain register of

PC1. It does not perform a gain calibration. To

write to the other internal registers of the ADC, follow the procedures outlined in the

CS5521/22/23/24/28 data sheet.

3.3 Self-Offset Calibration

Calibrate is a subroutine that performs a self-offset

calibration using Setup 1. Calibrate does this by

sending the command 0x81 (HEX) to the ADC.

This tells the ADC to perform a self-offset calibration using Setup 1 (see the CS5521/22/23/24/28

Data Sheet for information on performing offset or

gain calibrations using other Setups). Once the

command has been sent, the controller polls RA2

(SDO) until it falls, indicating that the calibrat ion is

complete. Note that although calibrations are done

on a specific Setup, the offset or gain register that

is modified belongs to the physical channel referenced by that Setup.

AN130REV2 3

To read the value in the gain register of PC1, the

command byte is loaded with the value 0x0A

(HEX), and the read_register routine is called. It

duplicates the read-cycle timing diagram depicted

in Figure 4. Read_register asserts CS (RA0). The n

it calls send_byte once to transfer the command-

byte to the CS5521/22/23/24/28. This places the

converter into the data state where it waits until

data is read from its serial port. Read_register then

calls receive_byte three times and transfers three

bytes of information from the CS5521/22/23/24/28

to the PIC16C84. Similar to send_byte,

receive_byte acquires a byte one bit at a time, MSB

first. When the transfer is complete, the variables

high_byte, mid_byte, and low_byte contain the value present in PC1’s 24-bit gain register.

Page 4

AN130

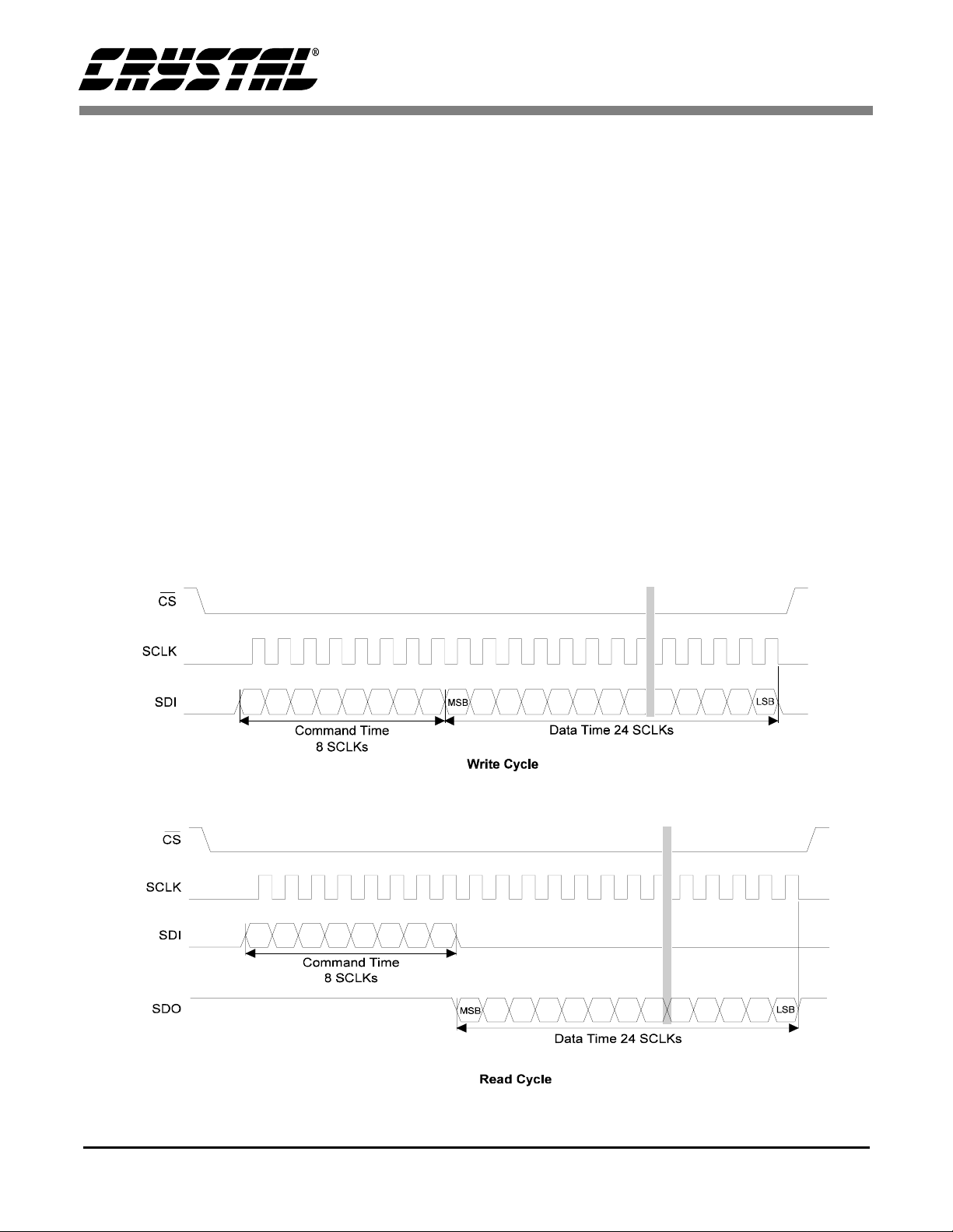

3.5 Acquire Conversion

To acquire a conversion the subroutine convert is

called. For single conversions on one physical

channel, the MC (multiple conversion) and the LP

(loop) bits in the configuration register must be logic 0. To prevent corruption of the configuration

register, convert instructs the PIC16C84 to read

and save the contents. This information is stored in

the variables HIGHBYTE, MIDBYTE and LOWBYTE. Then the MC, LP, and RC (read conver t)

bits are masked to logic 0, and the new information

is written back to the ADC’s co nfiguration regis ter.

A conversion is initiated on Setup 1 by sending the

command 0x80 to the converter. At this time, the

controller polls RA2 (SDO) until it falls to a logic

0 level (see Figure 5). After SDO falls, convert applies a logic 0 to RA1 (SDI) and pulses RA3

(SCLK) eight times to initiate the data transfer

from the ADC. The PIC16C84 then reads the conversion data word by calling receive_byte three

times. Figure 6 depicts how the 16 or 24-bit data

word is stored in the memory locations HIGHBYTE, MIDBYTE, and LOWBYTE.

4. MAXIMUM SCLK RATE

An instruction cycle in the PIC16C84 consists of

four oscillator periods, or 400ns if the microcontroller’s oscillator frequency is 10 MHz. Since the

CS5521/22/23/24/28’s maximum SCLK rate is

2MHz, additional no operation (NOP) delays may

be necessary to reduce the tra nsfer rate if the microcontroller system requires higher rate oscillators.

5. SERIAL PERIPHERAL INTERFACE

When using a built-in Serial Peripheral Interface

(SPI) port, the designer must pay special attention

to how the port is configured. Most SPI ports allow

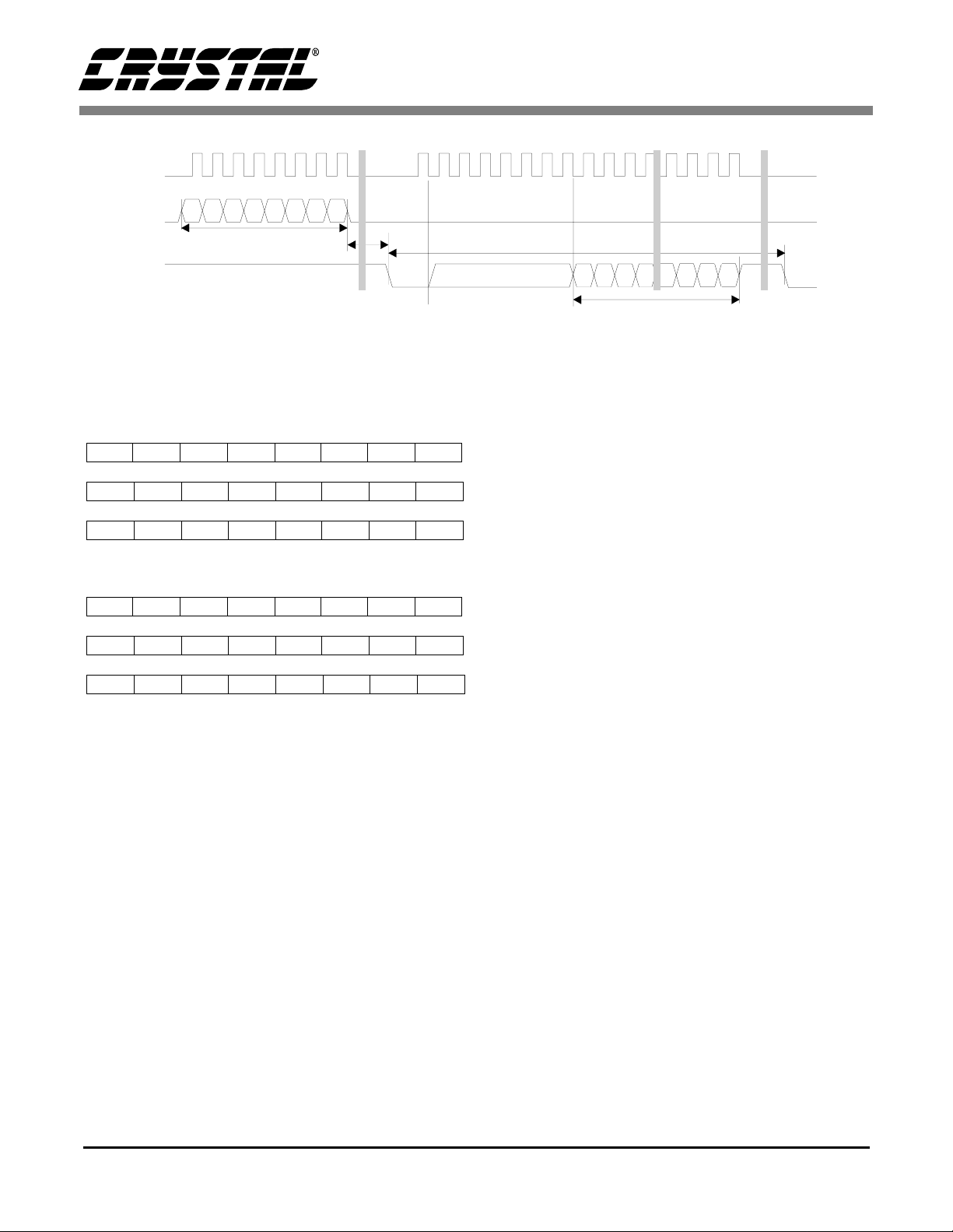

Figure 3. Write-Cycle Timing

Figure 4. R ead-Cycle Timing

4 AN130REV2

Page 5

SCLK

SDI

*

t

ommand Time

C

8SCLKs

DO

S

td = XIN/OWR clock cycles for each conversion except the

*

first conversion which will take XIN/OWR + 7 clock cycles

d

Data SDO Continuous Conversion Read

Figure 5. Conversion/Acquisition Cycle Timing

SCLKs Clear SDO Flag

8

AN130

IN/OWR

X

Clock Cycles

SB

M

ata Time

D

24 SCLKs

SB

L

MSB High-Byte

D23 D22 D21 D20 D19 D18 D17 D16

Mid-Byte

D15 D14 D13 D12 D11 D10 D9 D8

Low-ByteLSB

D7 D6 D5 D4 D3 D2 D1 D0

A) 24-Bit Conversion Data Word (CS5522/24/28)

MSB High-Byte

D15 D14 D13 D12 D11 D10 D9 D8

Mid-Byte

D7 D6 D5 D4 D3 D2 D1 D0

Low-Byte

1110CI1CI0ODOF

B) 16-bit Conversion Data Word (CS5521/23)

0 - always zero, 1 - always 1

CI1, CI0 - Channel Indicator Bits

OD - Oscillation Detect, OF - Overflow

Figure 6. Bit Representation/Storage in the PIC16C84

for a selectable clock polarity. However, many do

not have the capability to select the clock’s phase.

When using a microcontroller with both features,

the clock polarity should be set to idle low, and the

clock phase should be set to begin clocking in the

middle of the data bits. For an SPI port without the

variable clock phase feature to function properly

with the CS5521/22/23/24/28, the clock polarity

needs to be set to idle high, and the ADC’s serial

port must be re-initialized anytime new information is transmitted bet ween t he mic rocontroller and

the converter.

6. DEVELOPMENT TOOL DESCRIPTION

The code in this application note was developed

with MPLABTM, a development package from Microchip, Inc. It was written in Microchip assembly

and compiled with the MPASMTM assembler.

7. CONCLUSION

This application note presents an example of how

to interface the CS5521/22/23/24/28 to the

PIC16C84. It is divided into two main sections:

hardware and software. The hardware section illustrates both a three-wire and a four- wire interface.

The three-wire interface is SPI™ and MICROW-

IRE™ compatible. The software, developed using

tools from Microchip, Inc., illustrates how to initialize the converter and microcontroller, write to

the CSRs, write and read the ADC’s internal registers, perform calibrations, and acquire conversions.

The software is modularized and provides important subroutines such as write_register,

read_register, write_csrs and convert, which were

all written in PIC assembly language.

The software described in the note is included in

Section 8. “APPENDIX: PIC16C84 Microcode to

Interface to the CS5521/22/23/24/28” on page 6.

AN130REV2 5

Page 6

AN130

8. APPENDIX: PIC16C84 MICROCODE TO INTERFACE TO THE CS5521/22/23/24/28

;*****************************************************************************

;* File: 55221684.ASM

;* Date: November 1, 1999

;* Revision: 1

;* Processo r :PI C16C84

;* Program entry point at routine "main". Entry point address is 0x05.

;*****************************************************************************

;* This program is designed to provide examples of how to interface the

;* CS5521/22/23/24/28 ADCs to a PIC16C84 Microcontroller. The software handles all

;* of the serial communications between the controller and the ADC to perform

;* system calibration and acquire 24 and 16-bit conversion words.

;*****************************************************************************

;*** Memory Map Equates ***

STATUS equ 0x03 ; STATUS register

PORTA equ 0x05 ; I/O Port A address

TRISA equ 0x85 ; Port A Data Direction Co ntrol Latch

CARRY equ 0x00 ; Carry Bit in STATUS

RP0 equ 0x05 ; Register Bank Select Bit in STATUS

CS equ 0x00 ; Port A bit 0 - Chip Select

SDI equ 0x01 ; Port A bit 1 - Serial Data In

SDO equ 0x02 ; Port A bit 2 - Serial Data Out

SCLK equ 0x03 ; Port A bit 3 - Serial Clock

HIGHBYTE equ 0X0C ; Upper 8 Bits of Conversion Registe r

MIDBYTE equ 0x0D ; Middle 8 Bits of Conversion Register

LOWBYTE equ 0x0E ; Lowest 8 bits of Conversion Register

COMMAND equ 0x0F ; Command Byte RAM location

TEMP equ 0x10 ; Temporary Data storage RAM location

COUNT equ 0x11 ; Software Counter RAM location

SERI_DATA equ 0x12 ; Serial Data RAM location

;*****************************************************************************

;* Program Code

;************* *** *** ********************************* *** *** *******************

processor 16C84 ; Set Processor Type

org 0x00 ; Reset Vector Location

goto main ; Start at "main" routine

;*****************************************************************************

6 AN130REV2

Page 7

;* Routine - main

;* Input - none

;* Output - none

;* This is the entry point to the program, as well as the central loop.

;*****************************************************************************

org 0x05 ; program memory beginning location

main

;*** Initialize and Calibrate System ***

CALL initialize ; Initialize the System

CALL write_csrs ; Modify the Channel Setup Registers

CALL calibrate ; Calibrate ADC Offset

CALL modify_gain ; Write and Read gain register

;*** Loop to perform continuous single conversions ***

mloop: CALL convert ; Obtain conversions from ADC

goto mloop ; Keep looping

AN130

;*** End main ***

;*****************************************************************************

;* Subroutines

;************* ********************************** ***************** *************

;************* ********************************** ***************** *************

;* Routine - initialize

;* Input - none

;* Output - none

;* This subroutine initializes Port A to interface to the CS5521/22/23/24/28 ADC.

;* A time delay is provided to allow for the ADC oscillator to power up.

;* Typically, a 32.768 KHz crystal has a start-up time of about 500ms.

;* Additionally, 1003 XIN cycles are delayed for the ADC’s power-on reset

;* after the crystal has stabilized. The total delay is 660ms upon system

;* power-up, assuming that the microcontroller has no start-up delay.

;*****************************************************************************

initialize CLRF PORTA ; Clear Port A Output data latches

BSF STATUS, RP0 ; Select Register Bank 1 - control

MOVLW 0x04 ; Directional Values for Port A:

MOVWF TRISA ; RA2 = input, RA0-1 & 3-4 = output

BCF STATUS, RP0 ; Select Register Bank 0 - normal

MOVLW 0x32 ; Load W for delay count

CALL delay ; Delay 1003 XIN cycles

AN130REV2 7

Page 8

MOVLW 0xFF ; Load W for new delay count

CALL delay ; Delay for Oscillator start-up 158ms

CALL delay ; Delay for Oscillator start-up 158ms

CALL delay ; Delay for Oscillator start-up 158ms

CALL delay ; Delay for Oscillator start-up 158ms

;*** ADC Serial Port Initialization ***

MOVLW 0x0F ; Load W with a value of 15

MOVWF TEMP ; Loop count variable = TEMP

BCF PORTA, CS ; Clear CS to enable ADC

loop: MOVLW 0xFF ; Load W with all 1’s

CALL send_byte ; send all 1’s to ADC

DECFSZ TEMP, 1 ; loop through to send 15 bytes of all 1’s

goto loop

MOVLW 0xFE ; Load W with last byte - ’11111110’

CALL send_byte ; send final initialize byte to ADC

BSF PORTA, CS ; Set CS to disable ADC

RETURN ; Exit to "main"

AN130

;*****************************************************************************

;* Routine - calibrate

;* Input - none

;* Output - none

;* This subroutine tells the ADC to perform self-offset calibration on Setup 1

;*****************************************************************************

calibrate MOVLW 0x81 ; Command for Self-Offset Calibration

BCF PORTA, CS ; Enable ADC

CALL send_byte ; Send Calibration Command to ADC

poll_sdo1: BTFSC PORTA, SDO ; Wait until SDO falls to indicate

goto poll_sdo1 ; calibration completion.

BSF PORTA, CS ; Disable ADC

RETURN ; Exit to "main"

;*****************************************************************************

;* Routine - modify_gain

8 AN130REV2

Page 9

;* Input - none

;* Output - none

;* This subroutine writes to and reads from the gain register on ph ysical

;* channel 1.

;************* ****************************************************************

modify_gain MOVLW 0x02 ; Command to write Gain register

MOVWF COMMAND ; Set command byte

MOVLW 0x80 ; High byte information

MOVWF HIGHBYTE ; Set high byte

CLRF MIDBYTE ; Set middle byte

CLRF LOWBYTE ; Set low byte

CALL write_register ; Write 0x800000 to Gain Register

MOVLW 0x0A ; Command to read Gain Regi ster

MOVWF COMMAND ; Set Command byte

CALL read_register ; Read data from the Gain Register

RETURN ; Exit

AN130

;*****************************************************************************

;* Routine - write_csrs

;* Input - none

;* Output - none

;* This subroutine is used to modify the information in the Channel Setup

;* Registers. It first changes the depth pointer bits in the ADCs config.

;* register to reflect the number of CSRs to be written, and then writes to

;* the appropriate CSRs

;************* ****************************************************************

write_csrs MOVLW 0x0B ; Co m mand to read Config. Register

MOVWF COMMAND ; set command byte

CALL read_register ; read the config. register

;*** Mask DP3-DP0 to access two CSRs (four Setups) ***

MOVLW 0x3F ; mask DP3-DP2 low

ANDWF MIDBYTE, 1 ; change DP3 and DP2

MOVLW 0x30 ; mask DP1-DP0 high

IORWF MIDBYTE, 1 ; change DP1 and DP0

MOVLW 0x03 ; Command to write config. register

MOVWF COMMAND ; set command byte

CALL write_register ; Change Depth Pointer Bits

;*** Write to CSRs - note, the ADC expects information for the

; number CSRs indicated in the Depth Bits (DP3-0 in the

; configuration register) so all of the CSRs are

; written at this time ***

AN130REV2 9

Page 10

MOVLW 0x05 ; Command to write CSR s

BCF PORTA, CS ; select the ADC

CALL send_byte ; send command byte to ADC

;*** Setup CSR #1 - Setups 1 and 2

; setting both to default value of ’000’

; (A1-A0 = 00, Physical Channel = 1, OWR = 15Hz,

; input V-range = 100mV, Bipolar Measurement mode) ***

MOVLW 0x00 ; all zeros

CALL send_byte ; send first byte

CALL send_byte ; send second byte

CALL send_byte ; send third byte

;*** Setup CSR #2 - Setups 3 and 4

; setting Setup 3 to ’4C0’ and Setup 4 to ’105 ’

; Setup 3 Settings - (A1-A0 = 01, Physical Channel = 2,

; OWR = 101.1 Hz, input V-range = 100mV, Bipolar)

; Setup 4 Settings - (A1-A0 = 00, Physical Channel = 3,

; OWR = 15 Hz, input V-range = 25mV, Unipolar)

AN130

MOVLW 0x4C ; first byte of info

CALL send_byte ; send first byte

MOVLW 0x01 ; second byte of info

CALL send_byte ; send second byte

MOVLW 0x05 ; third byte of info

CALL send_byte ; send last byte

BSF PORTA, CS ; de-select the ADC

RETURN ; exit

;*****************************************************************************

10 AN130REV2

Page 11

;* Routine - convert

;* Input - none

;* Output - 24-bit Conversion Results in memory locations HIGHBYTE, MIDBYTE

;* and LOWBYTE.

;* The Algorithm itself will only perform a single

;* conversion using Setup 1. For mu ltiple continuous

;* conversions, or for conversions using other setups, the routine

;* must be modified. (see the CS5521/22/23/24/28 data sheet for more info)

;*****************************************************************************

convert MOVLW 0x0B ; Command to read Configuration Reg.

MOVWF COMMAND ; Set Command Byte

CALL read_register ; Read Config. Register Information

MOVLW 0xF8 ; Load mask info into W

ANDWF HIGHB YTE, 1; Mask MC, LP, and RC to 0

MOVLW 0x03 ; Command to write Configuration Reg.

MOVWF COMMAND ; Set Command Byte

CALL write_register ; Write C onf ig. Register with new info

; *** Receive Conversion Data ***

AN130

BCF PORTA, CS ; Enable ADC

MOVLW 0X80 ; Command for conversion using Setup 1

CALL send_byte ; send command byte

poll_sdo2: BTFSC PORTA, SDO; Wa it until SDO falls to indicate

goto poll_sdo2 ; conversion completion

MOVLW 0X00 ; Command to start data output

CALL send_byte ; send command

CALL receive_byte ; Receive data...

MOVWF HIGHBYTE ; High Byte 1st..

CALL receive_byte

MOVWF MIDBYTE ; then the Middle Byte..

CALL receive_byte

MOVWF LOWBYTE ; and finally the Low Byte.

BSF PORTA, CS ; Disable ADC

RETURN ; Exit to "main"

;*****************************************************************************

AN130REV2 11

Page 12

;* Routine - write_register

;* Input - COMMAND, HIGHBYTE, MIDBYTE, LOWBYTE

;* Output - none

;* This subroutine writes to the internal registers of the CS55/212 2/ 23/24/28

;*****************************************************************************

write_register BCF PORTA, CS ; Enable ADC

MOVF COMMAND, 0; Load W with Command byte

CALL send_byte ; Send command info

MOVF HIGHBYTE, 0; Load W with high byte

CALL send_byte ; Send high byte first..

MOVF MIDBYTE, 0 ; Load W with middle byte

CALL send_byte ; Then the middle byte..

MOVF LOWBYTE, 0 ; Load W with low byte

CALL send_byte ; .. and then the low byte last.

BSF PORTA, CS ; Disable ADC

RETURN ; Exit Subroutine

;*****************************************************************************

;* Routine - read_register

;* Input - COMMAND

;* Output - HIGHBYTE, MIDBYTE, LOWBYTE

;* This subroutine reads from the internal regis ters of the CS5521/22/23/24/28

;*****************************************************************************

AN130

read_register BCF PORTA, CS ; Enable ADC

MOVF COMMAND, 0; Load W with Command Byte

CALL send_byte ; Send Command info

CALL receive_byte ; receive High byte first..

MOVWF HIGHBYTE ; Move W to HIGHBYTE

CALL receive_byte ; and then the middle byte..

MOVWF MIDBYTE ; Move W to MIDBYTE

CALL receive_byte ; and finally the Low byte.

MOVWF LOWBYTE ; Move W to LOWBYTE

BSF PORTA, CS ; Disable ADC

RETURN ; Exit Subroutine

;*****************************************************************************

12 AN130REV2

Page 13

;* Routine - send_byte

;* Input - Byte stored in W register

;* Output - none

;* This subroutine sends a byte, one bit at a time, MSB first, to the ADC

;*****************************************************************************

send_byte MOVWF SERI_DATA ; Move W to SERI_DATA

MOVLW 0x08 ; Set COUNT to 8

MOVWF COUNT ; to trasnsmit each bit individually

bitloop1: RLF SERI_DATA, 1 ; Rotate SERI_DATA to send MSB first

BTFSC STATUS, CARRY ; If bit is low, skip next instruction

BSF PORTA, SDI ; If high, set SDI

BTFSS STATUS, CARRY ; If bit is high, skip next instr.

BCF PORTA, SDI ; If low, clear SDI

BSF PORTA, SCLK ; Toggle SCLK High

BCF PORTA, SCLK ; Toggle SCLK Low

DECFSZ COUNT, 1 ; Go to next bit unless done

goto bitloop1

BCF PORTA, SDI ; Return SDI to low state

RETURN ; Exit Subroutine

AN130

;*****************************************************************************

;* Routine - receive_byte

;* Input - none

;* Output - Byte stored in W register

;* This subroutine receives a byte, one bit at a time, MSB first, from the ADC

;*****************************************************************************

receive_byte MOVLW 0x08 ; Set COUNT to 8

MOVWF COUNT ; to receive each bit individually

bitloop2: BTFSC PORTA, SDO ; If Bit is low, skip next instruction

BSF STATUS, CARRY ; Otherwise, set carry bit

BTFSS POR TA, SDO ; If Bit is high, skip next instruction

BCF STATUS, CARRY ; Otherwise, clear carry bit

RLF SERI_DATA, 1 ; Rotate Carry into SERI_DATA, MSB first

BSF PORTA, SCLK ; Toggle SCLK High

BCF PORTA, SCLK ; Toggle SCLK Low

DECFSZ COUNT, 1 ; Go to next bit unless finished

goto bitloop2

MOVF SERI_DATA, 0 ; Put received byte into W

RETURN ; Exit Subroutine

;*****************************************************************************

AN130REV2 13

Page 14

;* Routine - delay

;* Input - Count in W register

;* Output - none

;* This subroutine delays by using a count value stored in register W. This

;* example was tested using a 10MHz clock (E = 2.5 MHz), thus each

;* cycle is 400ns. This delay is approximately equivalent to:

;* (400ns)*(1536)*(count value in W) - A count of 720 provides a 445ms delay

;*****************************************************************************

delay MOVWF COUNT ; Move delay value to COUNT

outlp: CLRF TEMP ; TEMP used for inner loop counter

innlp: NOP ; 1 cycle - 400ns

NOP ; 2 cycles - 800ns

NOP ; 3 cycles - 1.2 us

NOP ; 4 cycles - 1.6 us

DECFSZ TEMP, 1 ; Decrement TEMP and loop 256 times

goto innlp

DECFSZ COUNT, 1 ; Decrement COUNT and loop

goto outlp

RETURN ; Exit delay

AN130

;*****************************************************************************

;* Interrupt Vectors

;************* *** ********************************** ** *************************

NOT_USEDRETFIE

ORG 0x04 ; originate interrupt vector here

goto NOT_USED ; no interrupts enabled

end ; end program listing

14 AN130REV2

Page 15

• Notes •

Page 16

Loading...

Loading...