Page 1

Maximum demand control

MDC-4

INSTRUCTION MANUAL

(M013B01-03-15C)

Page 2

MDC-4

2

Instruction Manual

Page 3

MDC-4

SAFETY PRECAUTIONS

Follow the warnings described in this manual with the symbols shown below.

DANGER

Warns of a risk, which could result in personal injury or material damage.

ATTENTION

Indicates that special attention should be paid to a speci c point.

If you must handle the unit for its installation, start-up or maintenance, the following

should be taken into consideration:

Incorrect handling or installation of the unit may result in injury to personnel as well as damage

to the unit. In particular, handling with voltages applied may result in electric shock, which may

cause death or serious injury to personnel. Defective installation or maintenance may also

lead to the risk of re.

Read the manual carefully prior to connecting the unit. Follow all installation and maintenance

instructions throughout the unit’s working life. Pay special attention to the installation standards of the National Electrical Code.

Refer to the instruction manual before using the unit

In this manual, if the instructions marked with this symbol are not respected or carried out correctly, it can

result in injury or damage to the unit and /or installations.

CIRCUTOR, SA reserves the right to modify features or the product manual without prior noti cation.

DISCLAIMER

CIRCUTOR, SA reserves the right to make modi cations to the device or the unit speci ca-

tions set out in this instruction manual without prior notice.

CIRCUTOR, SA on its web site, supplies its customers with the latest versions of the device

speci cations and the most updated manuals.

www.circutor.com

Instruction Manual

3

Page 4

MDC-4

CONTENTS

SAFETY PRECAUTIONS ���������������������������������������������������������������������������������������������������������������������������������������3

DISCLAIMER ����������������������������������������������������������������������������������������������������������������������������������������������������������3

CONTENTS ������������������������������������������������������������������������������������������������������������������������������������������������������������� 4

REVISION LOG �������������������������������������������������������������������������������������������������������������������������������������������������������5

1�- VERIFICATION UPON RECEPTION ����������������������������������������������������������������������������������������������������������������� 6

2�- PRODUCT DESCRIPTION �������������������������������������������������������������������������������������������������������������������������������� 6

3�- UNIT INSTALLATION ���������������������������������������������������������������������������������������������������������������������������������������� 7

3�1�- PRIOR RECOMMENDATIONS�������������������������������������������������������������������������������������������������������������������7

3�2�- INSTALLATION ������������������������������������������������������������������������������������������������������������������������������������������8

3�3�- UNIT TERMINALS �������������������������������������������������������������������������������������������������������������������������������������� 9

3�4�- CONNECTION DIAGRAM ������������������������������������������������������������������������������������������������������������������������ 10

3�4�1�- Three-phase network measurement with a 4-wire connection� ��������������������������������������������������� 10

3�4�2�- Three-phase network measurement with a 3-wire connection� ��������������������������������������������������� 11

3�4�3�- Single-phase network measurement� ���������������������������������������������������������������������������������������������12

4�- OPERATION ���������������������������������������������������������������������������������������������������������������������������������������������������13

4�1�- OPERATING PRINCIPLE ������������������������������������������������������������������������������������������������������������������������� 13

4�2�- PARAMETERS �����������������������������������������������������������������������������������������������������������������������������������������14

4�3�- KEYS FUNCTIONS ����������������������������������������������������������������������������������������������������������������������������������15

4�4�- DISPLAY ���������������������������������������������������������������������������������������������������������������������������������������������������15

4�5�- LED INDICATORS ������������������������������������������������������������������������������������������������������������������������������������ 16

4�6�- DISPLAY IMPROVEMENTS ���������������������������������������������������������������������������������������������������������������������17

4�6�1�- Maximum demand screens� ������������������������������������������������������������������������������������������������������������17

4�6�2�- Measuring screens� ��������������������������������������������������������������������������������������������������������������������������18

4�7�- OUTPUT RELAYS ������������������������������������������������������������������������������������������������������������������������������������19

4�8�- PROGRAMMING �������������������������������������������������������������������������������������������������������������������������������������� 19

4�8�1� Current primary ���������������������������������������������������������������������������������������������������������������������������������19

4�8�2� Selecting the maximum demand variable ��������������������������������������������������������������������������������������� 20

4�8�3� Period of maximum demand integration �����������������������������������������������������������������������������������������20

4�8�4� Contracted power ������������������������������������������������������������������������������������������������������������������������������ 20

4�8�5� Deleting the maximum demand maximum value� ������������������������������������������������������������������������� 20

4�8�6� Deleting the energy value ����������������������������������������������������������������������������������������������������������������� 21

4�8�7� Deleting the output relay disconnection times� �����������������������������������������������������������������������������21

4�8�8� Level of output relay no� 1 ���������������������������������������������������������������������������������������������������������������� 21

4�8�9� Hysteresis of output relay no� 1 ������������������������������������������������������������������������������������������������������� 21

4�8�10� Delay in connecting output relay no� 1 �����������������������������������������������������������������������������������������22

4�8�11� Delay in disconnecting output relay no� 1 ������������������������������������������������������������������������������������22

4�8�12� Status of the contacts for output relay no� 1 �������������������������������������������������������������������������������� 22

4�9�- PROGRAMMING THE CURRENT DATE AND TIME ������������������������������������������������������������������������������23

4�9�1� Day ������������������������������������������������������������������������������������������������������������������������������������������������������ 23

4�9�2� Month ��������������������������������������������������������������������������������������������������������������������������������������������������23

4�9�3� Year ����������������������������������������������������������������������������������������������������������������������������������������������������� 24

4�9�4� Time ���������������������������������������������������������������������������������������������������������������������������������������������������� 24

4�9�5� Minutes ����������������������������������������������������������������������������������������������������������������������������������������������� 24

5�- TECHNICAL FEATURES ��������������������������������������������������������������������������������������������������������������������������������25

6�- MAINTENANCE AND TECHNICAL SERVICE ������������������������������������������������������������������������������������������������27

7�- GUARANTEE ���������������������������������������������������������������������������������������������������������������������������������������������������27

8�- CE CERTIFICATE �������������������������������������������������������������������������������������������������������������������������������������������� 28

4

Instruction Manual

Page 5

MDC-4

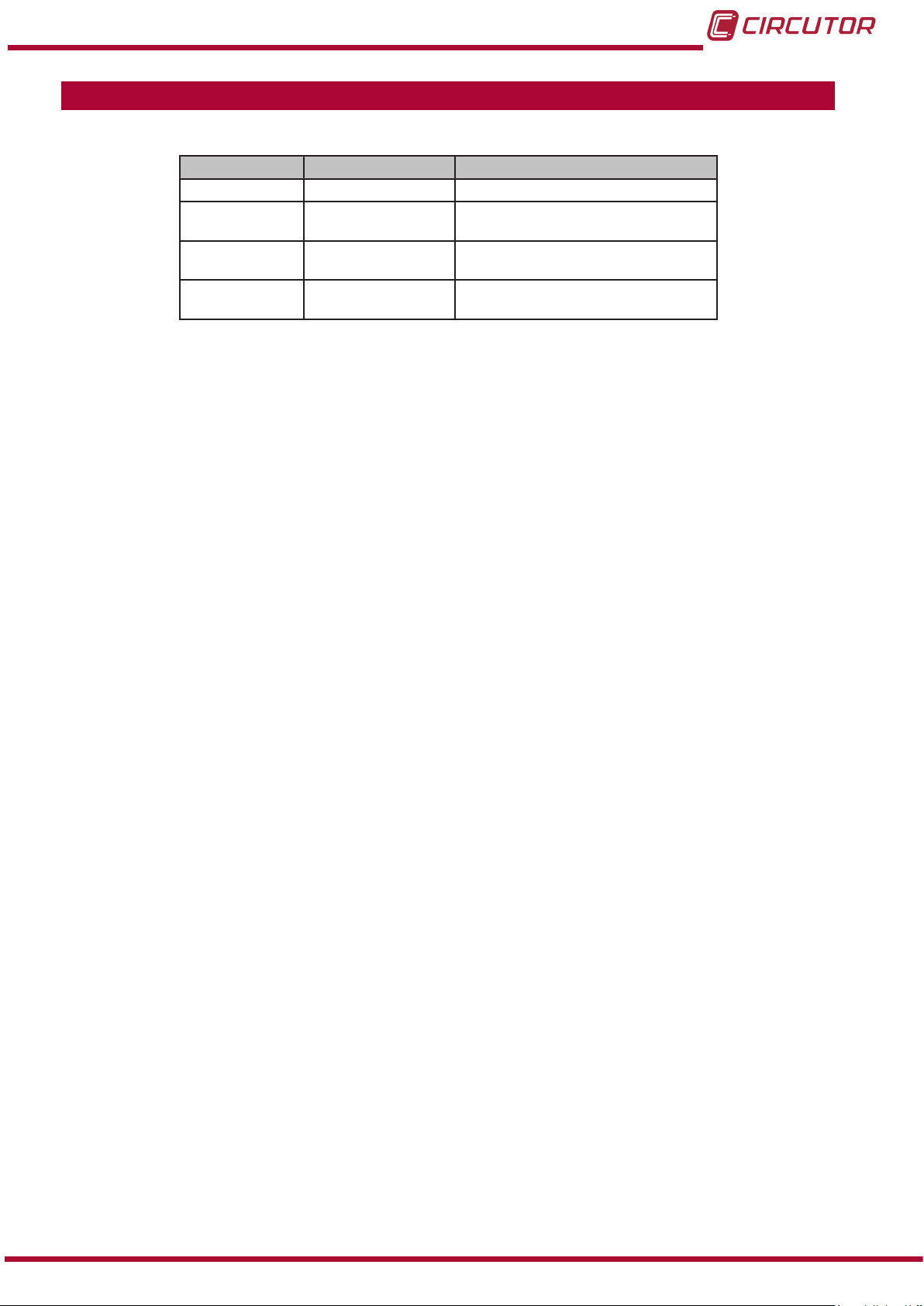

REVISION LOG

Table 1: Revision log�

Date Revision Description

09/14 M013B01-03-14A Initial Version

03/15 M013B01-03-15A

04/15 M013B01-03-15B

06/15 M013B01-03-15C

Changes in the following sections:

3.4. - 4.1. - 4.8.7.

Changes in the following sections:

4.2.- 4.6.1.- 4.6.2 - 4.8

Changes in the following sections:

4.8 - 5

Note: Unit images are for illustrative purposes only and may differ from the actual unit.

Instruction Manual

5

Page 6

MDC-4

1�- VERIFICATION UPON RECEPTION

Check the following points upon receiving the unit:

a) The unit meets the specications described in your order.

b) The unit has not suffered any damage during transport.

c) Perform an external visual inspection of the unit prior to switching it on.

d) Check that it has been delivered with the following:

- An installation guide.

If any problem is noticed upon reception, immediately contact the transport

company and/or CIRCUTOR's after-sales service.

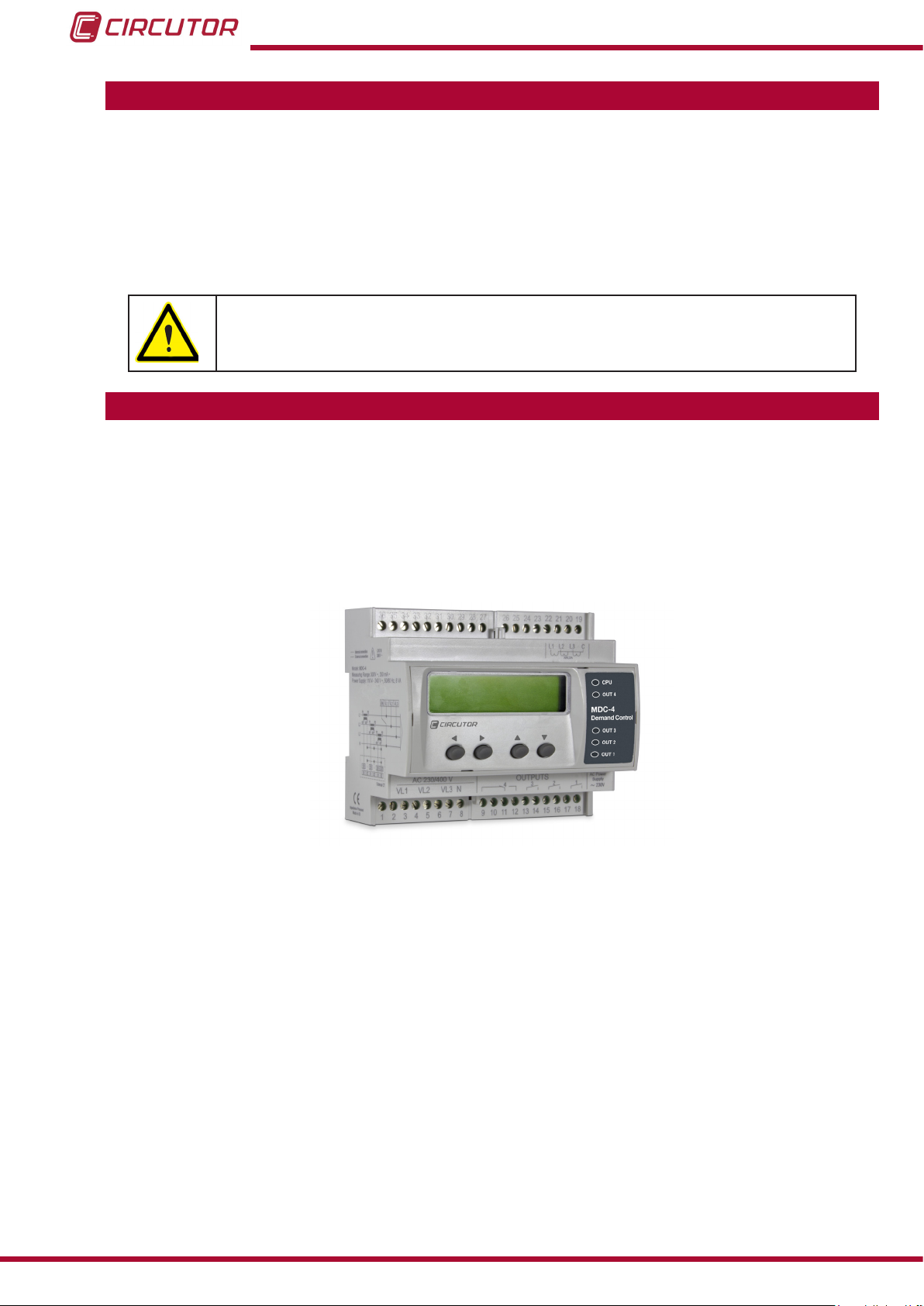

2�- PRODUCT DESCRIPTION

The MDC-4 unit controls maximum power demand, both in single and three-phase installations

with and without neutral. The unit is equipped with a power analyzer that measures electrical

parameters at the connection point. The measurement is taken in RMS, via four AC voltage

inputs and four current inputs.

The current is measured indirectly with efcient transformers of the MC1 and MC3 series.

The unit features:

- 4 output relays, to disconnect and connect the loads.

- 4 keys, to browse through the different screens.

- 5 indicator LEDs, to show the status of the loads and the CPU.

- 1 Display, for viewing all the parameters.

6

Instruction Manual

Page 7

MDC-4

3�- UNIT INSTALLATION

3.1.- PRIOR RECOMMENDATIONS

In order to use the unit safely, it is critical that individuals who handle it follow

the safety measures set out in the standards of the country where it is being

used, use the necessary personal protective equipment, and pay attention to

the various warnings indicated in this instruction manual.

The MDC-4 unit must be installed by authorised and qualied staff.

The power supply plug must be disconnected and measuring systems switched off before handling, altering the connections or replacing the unit. It is dangerous to handle the unit while it is

powered.

Also, it is critical to keep the cables in perfect condition in order to avoid accidents, personal

injury and damage to installations.

The manufacturer of the unit is not responsible for any damage resulting from failure by the

user or installer to observe the warnings and/or recommendations set out in this manual, nor for

damage resulting from the use of non-original products or accessories or those made by other

manufacturers.

If an anomaly or malfunction is detected in the unit, do not use it to take any measurements.

Inspect the work area before taking any measurements. Do not take measurements in dangerous areas or where there is a risk of explosion.

Disconnect the unit from the power supply (unit and measuring system power

supply) before maintaining, repairing or handling the unit's connections.

Please contact the after-sales service if you suspect that there is an operational

fault in the unit.

Instruction Manual

7

Page 8

MDC-4

3.2.- INSTALLATION

The unit is installed on a DIN rail.

The unit must be mounted inside an electric panel.

The unit must be connected to a power circuit that is protected with gL fuses (IEC 269) or M

fuses, with a rating of 1 to 2 A. It must be tted with a circuit breaker or equivalent device for

disconnecting the unit from the power supply mains.

The power and voltage measuring circuit must be connected with cables that have a minimum

cross-section of 1mm2.

Terminals, opening covers or removing elements can expose parts that are

hazardous to the touch while the unit is powered. Do not use the unit until it is

fully installed.

8

Instruction Manual

Page 9

MDC-4

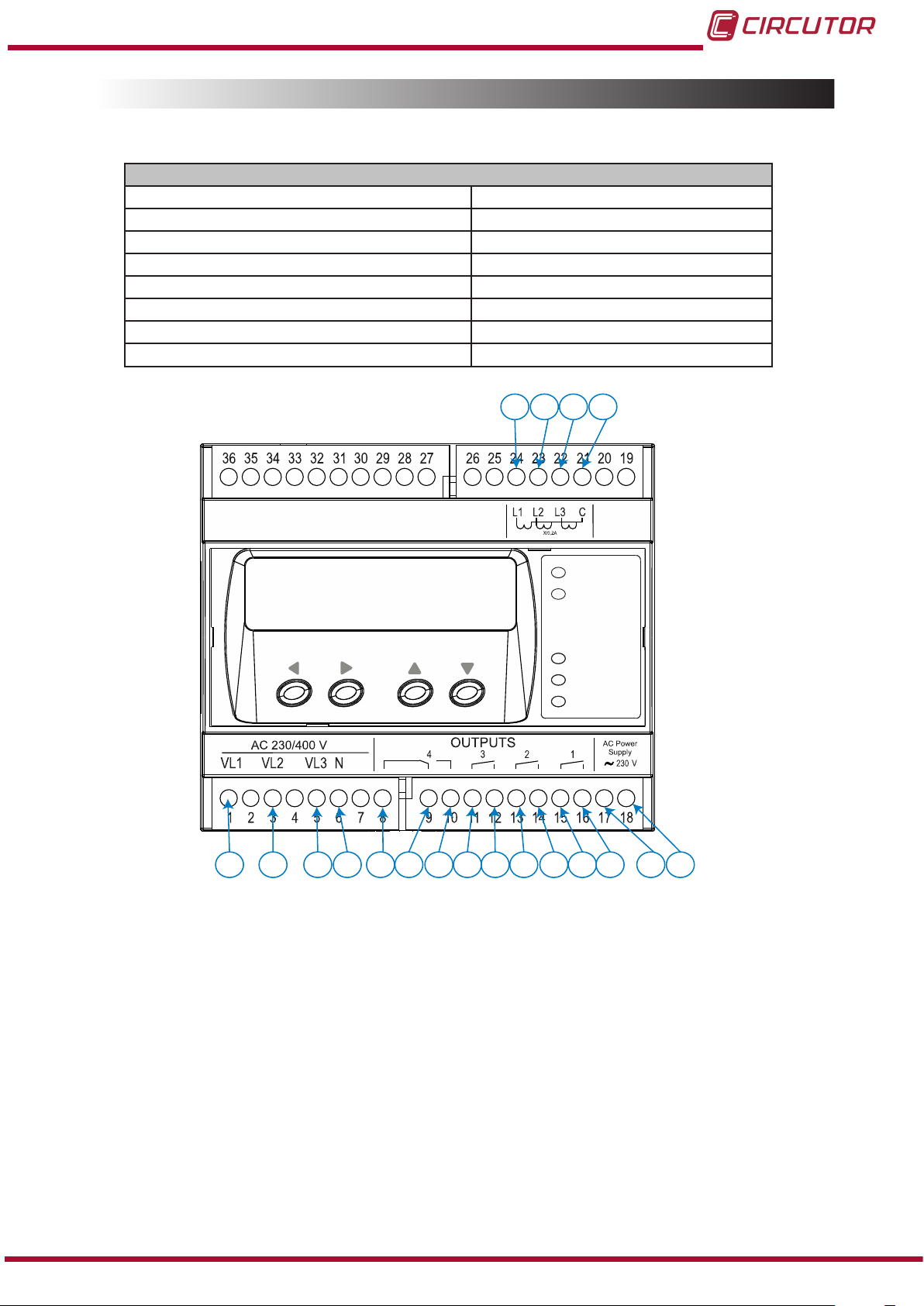

3.3.- UNIT TERMINALS

1: VL1, Voltage input L1 13, 14: Relay output 2

3: VL2, Voltage input L2 15, 16: Relay output 1

5: VL3, Voltage input L3 17: Auxiliary Power Supply

6: N, Voltage input neutral 18: Auxiliary Power Supply

8: Relay output 4, NC 21: COM, Common current inputs

9: Relay output 4, C 22: S1, Current input L3

10: Relay output 4, NO 23: S1, Current input L2

11, 12: Relay output 3 24: S1, Current input L1

Table 2:List of MDC-4 terminals

Unit terminals

24 2123 22

1

3 5 6 9

8

Figure 1:MDC-4 terminals�

10 11

12

13 14

CPU

OUT 4

MDC-4

OUT 3

OUT 2

OUT 1

15 16

17

18

Instruction Manual

9

Page 10

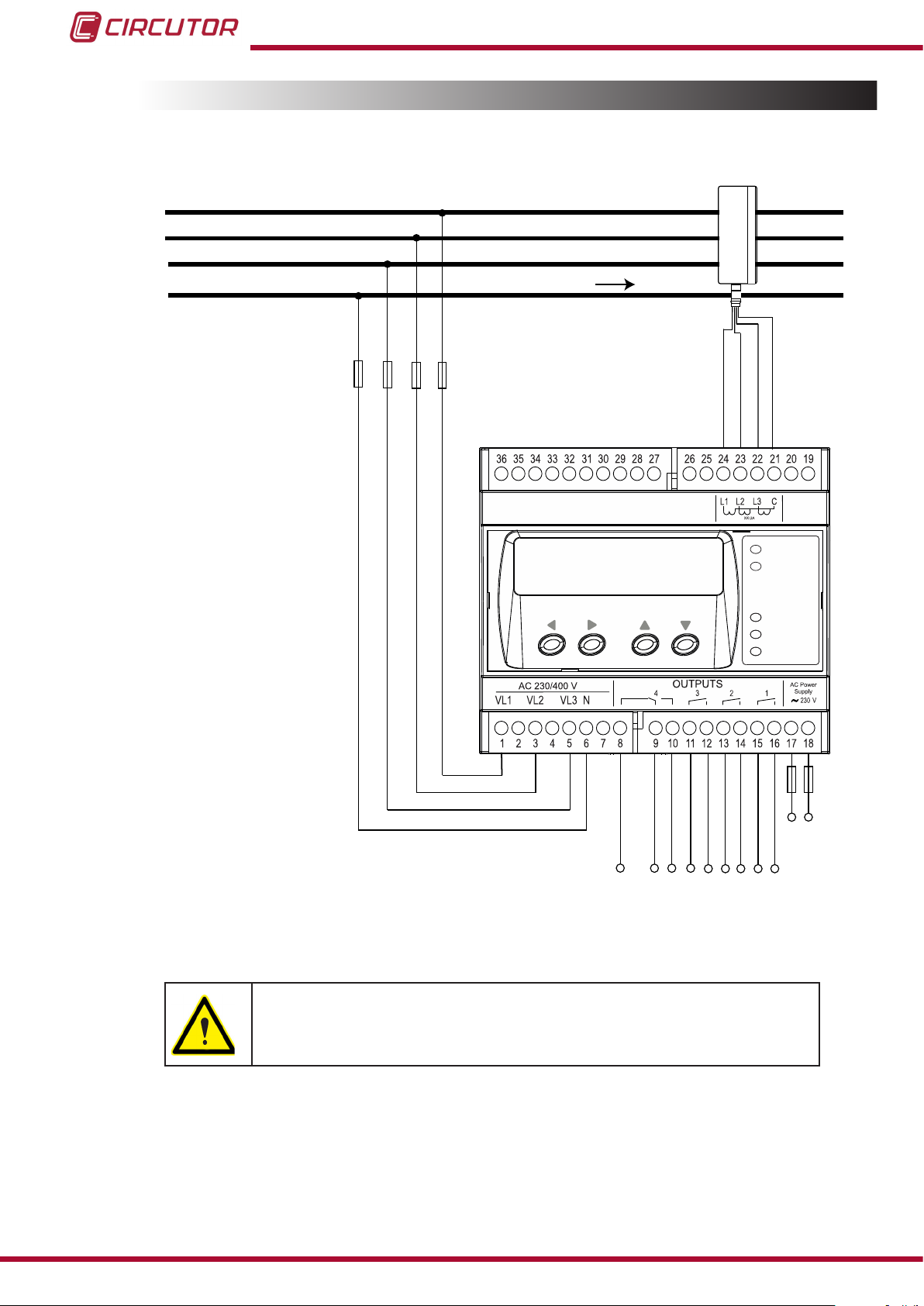

3.4.- CONNECTION DIAGRAM

MDC-4

CPU

OUT 4

OUT 3

OUT 2

OUT 1

Power

Supply

V

L1

L1

L2

L3

3P1

2P1 1P1

3P2

2P2 1P2

N

V

L2

V

L3

N

LOAD

Brown / Green

Grey / Pink

Green / White

Red / Blue

OUT 1OUT 2OUT 3OUT 4

3�4�1�- Three-phase network measurement with a 4-wire connection�

MDC-4

Figure 2: Three-phase network measurement with a 4-wire connection�

The MC3 transformer secondary value is set to 0.250 A.

10

Instruction Manual

Page 11

MDC-4

CPU

OUT 4

OUT 3

OUT 2

OUT 1

Power

Supply

V

L1

L1

L2

L3

3P1

2P1 1P1

3P2

2P2 1P2

V

L2

V

L3

LOAD

Brown /Green

Grey / Pink

Green /White

Red /cBlue

OUT 1OUT 2OUT 3OUT 4

MDC-4

3�4�2�- Three-phase network measurement with a 3-wire connection�

Figure 3: Three-phase network measurement with a 3-wire connection�

The MC3 transformer secondary value is set to 0.250 A.

Instruction Manual

11

Page 12

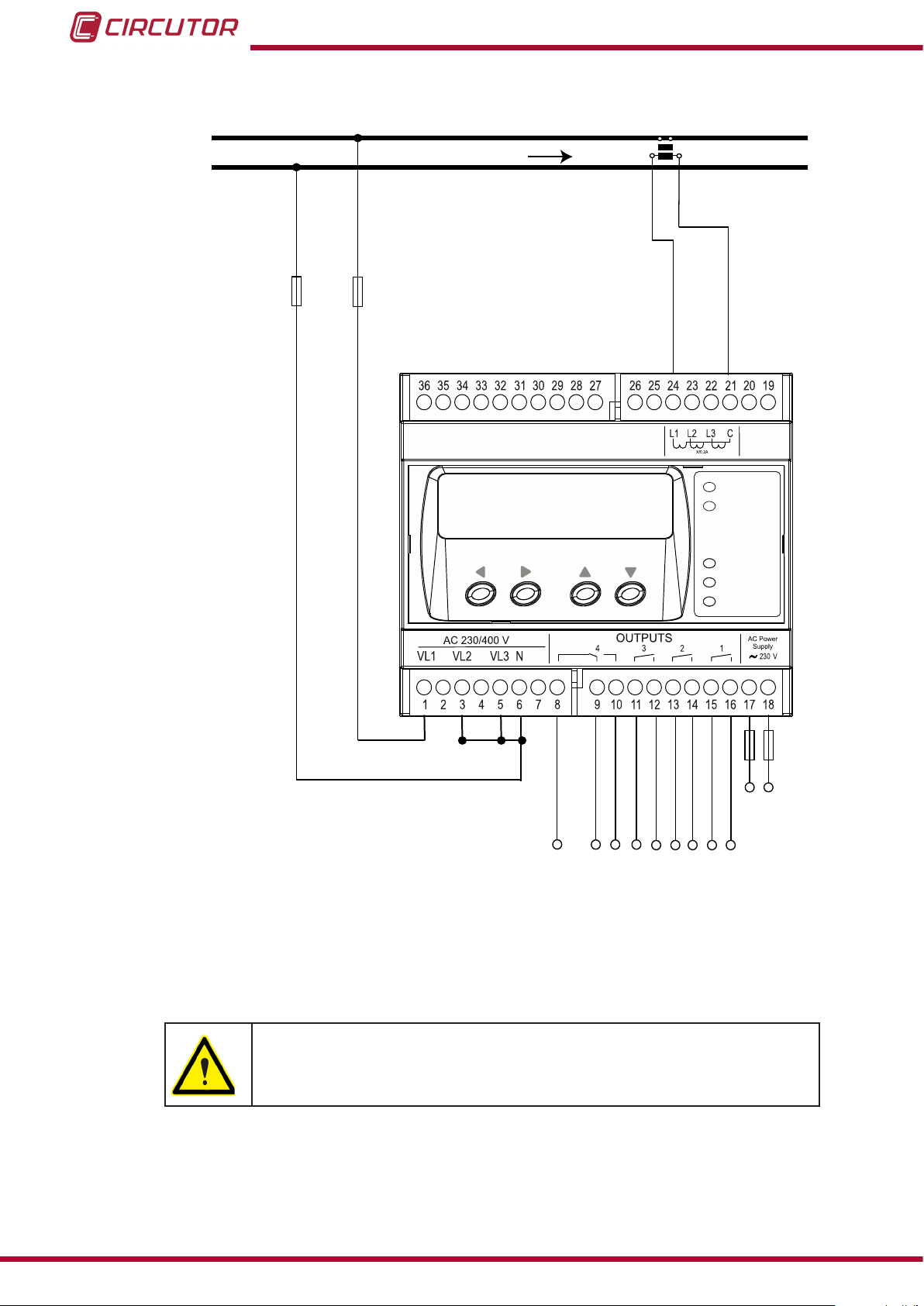

3�4�3�- Single-phase network measurement�

MDC-4

CPU

OUT 4

OUT 3

OUT 2

OUT 1

Power

Supply

V

L1

L1

N

S1

S2

P1 P2

N

LOAD

OUT 1OUT 2OUT 3OUT 4

MDC-4

Figure 4: Single-phase network measurement�

12

The MC1 transformer secondary value is set to 0.250 A.

Instruction Manual

Page 13

MDC-4

4�- OPERATION

4.1.- OPERATING PRINCIPLE

The MDC-4 has been designed to control the maximum demand of an installation.

The unit is equipped with a power analyzer that measures electrical parameters at the connection point.

The unit calculates the maximum demand by scrolling window, do not need a sync pulse.

Depending on the unit's conguration and bearing in mind the calculated maximum demand,

the unit connects and disconnects the installation's electrical loads (which should not be priority

loads) in order to avoid exceeding the congured maximum power. Load connection or disconnection depends on the instantaneous level of maximum demand. This system proceeds to

disconnect the loads in accordance with the % maximum demand value measured.

The load control by level ensures that the user does not exceed the contracted power, which

generally implies having to pay high penalties. At the same time, it enables adjusting the contract to the real power each installation needs and managing the punctual disconnection of

some non-priority loads, which also results in important power savings in the electricity bill.

The unit is equipped with relay outputs for the management of up to 4 electrical loads or load

groups.

Example: Let's take an installation such as that shown in Figure 5, in which the level of each

of the output relays has been programmed as follows:

OUT1: 70% of the contracted power.

OUT2: 80% of the contracted power.

OUT3: 90% of the contracted power.

OUT4: 95% of the contracted power.

Instruction Manual

Figure 5: MDC-4 installation�

13

Page 14

The graph in Figure 6 shows the unit's response:

MDC-4

Figure 6: Graph with the response of the MDC-4

4.2.- PARAMETERS

The unit displays the electrical parameters shown in Table 3.

Table 3: MDC-4 measuring parameters�

Measuring parameter Units

Phase-neutral voltage V

Phase-phase voltage V

Current A

Active power W

Reactive power var

Apparent power VA

Cos φ φ

Active Energy kW·h

Current Date and Time -

Maximum demand parameters Units

Contracted power W / VA / mA

Instantaneous maximum demand W / VA / mA

Status of the output relays Maximum demand maximum value W / VA/ mA

The % of time that each output relay has been disconnected

Phases

L1-L2-L3

%

Total

III

14

Instruction Manual

Page 15

MDC-4

4.3.- KEYS FUNCTIONS

The MDC-4 has 4 keys that allow you to browse the various screens and program the unit.

Key functions on the measuring screens (Table 4):

Table 4: Key functions on measuring screens�

Key Short keystroke

Previous Measuring screen

Next Measuring screen

Long keystroke

(2 s)

Previous Maximum demand screen

Next Maximum demand screen

Key functions in the programming menus (Table 5):

Table 5: Function of keys�

Key Keystroke

Moves an editable digit

Go to programming screen

Increases the digits (0-9) or rotates between the different options.

Viewing the maximum demand maximum value.

Opens the programming menu

Opens the menu for programming the

current Date and Time.

4.4.- DISPLAY

The unit has a display of two lines each containing 20 characters, on which all the measuring

parameters are viewed, in addition to specic information for the control of the unit's relay outputs and the operation time of each of the loads.

Instruction Manual

15

Page 16

4.5.- LED INDICATORS

The MDC-4 unit features:

- A CPU LED, which indicates that the unit is working correctly when it ashes for 1 sec-

ond.

- Four LEDs (OUT 1, OUT 2, OUT 3, OUT 4), which indicate whether the load is connected or disconnected. If the LED is on, this indicates that the load is disconnected.

MDC-4

CPU

Figure 7: LED indicators�

OUT 4

OUT 3

OUT 2

OUT 1

16

Instruction Manual

Page 17

MDC-4

4.6.- DISPLAY IMPROVEMENTS

The unit has two types of screens for viewing:

Maximum demand screens. Measuring screens.

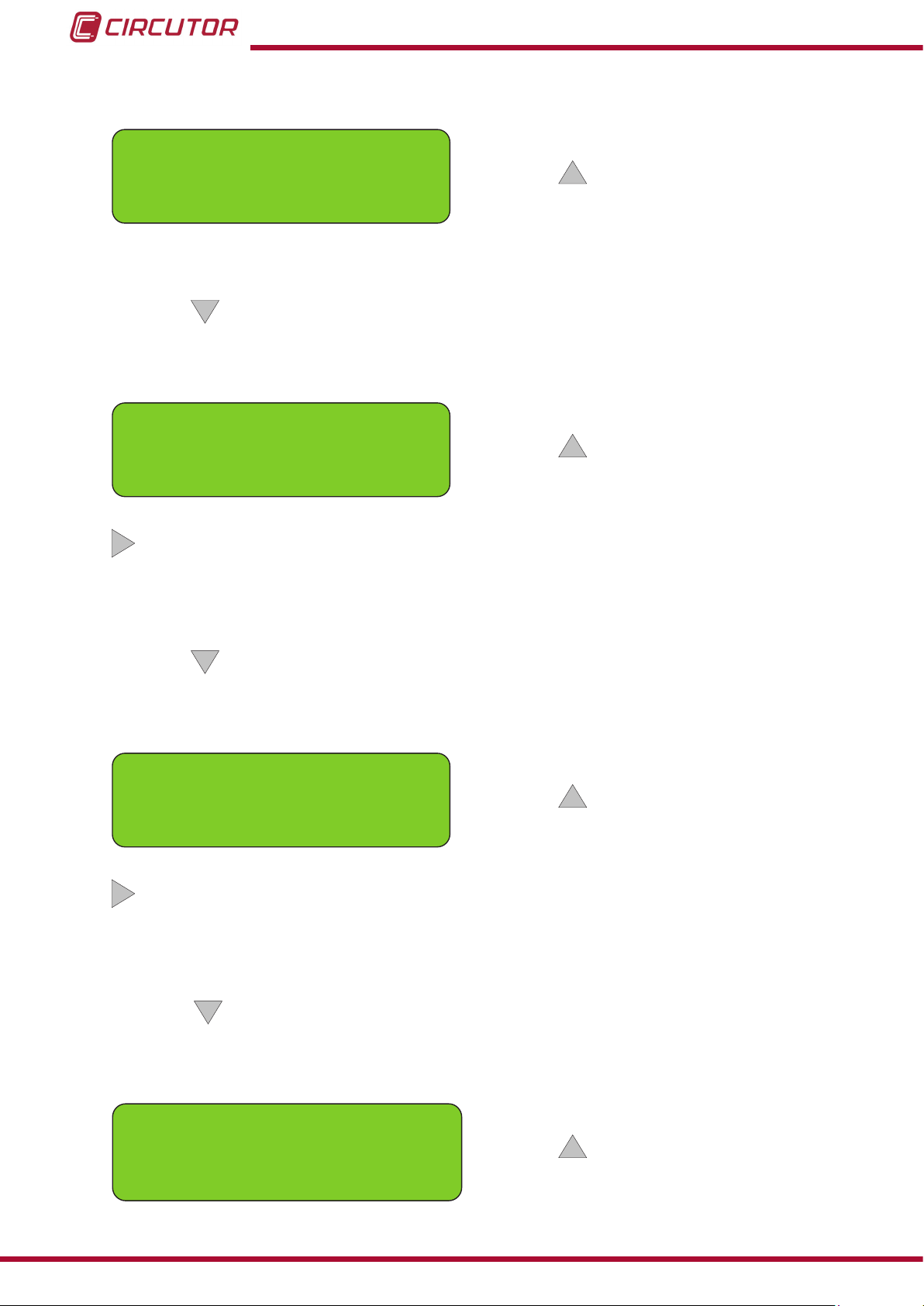

4�6�1�- Maximum demand screens�

Use keys and to browse the various screens.

The measuring screens are viewed by pressing the or keys.

Table 6: Maximum demand screens�

Screen Parameters (units)

Pc: Power contracted by the user (W or VA or mA).

Pd: Instantaneous calculated maximum demand

:60000 :56687

: : : :

(W or VA or mA).

o1 ...o4: Status of the output relays:

0 : Load connected

1 : Load disconnected

Holding down the key (2 seconds).

d max:

// ::

% % % %

Pd max: Maximum demand maximum value

Date and time when maximum value occurred.

It returns to the contracted power screen after 10

seconds.

The % of time that each output relay has been disconnected since it was connected to the unit or since

the last reset.

The % of time that each output relay has been disconnected and the maximum demand maximum value that can be reset in the programming menu.

Instruction Manual

17

Page 18

4�6�2�- Measuring screens�

Use keys and to browse the various screens.

The maximum demand screens are viewed by pressing the or keys.

Table 7: Measuring screens�

Screen Parameters (units)

MDC-4

vL12 vL23 vL31

519.3 519.8 519.6

vL1 vL2 vL3

299.9 300.0 300.0

a1 A2 a3

62.82 62.99 63.05

W1 W2 W3

18868 18893 18912

va1 va2 va3

-25 -81 -207

VL12: Phase-Phase Voltage L1-L2 (V).

VL23: Phase-Phase Voltage L2-L3 (V).

VL31: Phase-Phase Voltage L3-L1 (V).

VL1: Phase-Neutral Voltage L1 (V).

VL2: Phase-Neutral Voltage L2 (V).

VL3: Phase-Neutral Voltage L3 (V).

A1: Current L1 (A).

A2: Current L2 (A).

A3: Current L3 (A).

W1: Active power L1 (W).

W2: Active power L2 (W).

W3: Active power L3 (W).

VAr1: Reactive power L1 (Var).

VAr2: Reactive power L2 (Var).

VAr3: Reactive power L3 (Var).

COs1 COS2 COS3

-0.99 -0.99 -0.99

COs III VAIII

-0.99 -5

W III KW

56624 00000122.637

VA Iii AIII

0 0.00

DATE TIME

28/04/2014 14:08:54

COS 1: Cos φ L1

COS 2: Cos φ L2

COS 3: Cos φ L3

COS III: Cos φ III

VArIII: Reactive power III (Var).

W III: Active power III (W).

kWh: Active energy III (kWh).

VA III: Apparent power III (VA).

AIII: Current III (A).

Current date and time.

18

The active energy III value can be reset in the programming menu.

Instruction Manual

Page 19

MDC-4

4.7.- OUTPUT RELAYS

The unit has four relays (terminals 8, 9, 10, 11, 12, 13, 14, 15 and 16 in Figure 1) for connecting

and disconnecting the installation's loads, to ensure that the programmed maximum power is

not exceeded.

4.8.- PROGRAMMING

From the programming menu you can:

Program the current primary.

Program the maximum demand period.

Program the contracted power.

Delete the value for energy, the load disconnection times and the maximum demand

maximum value.

Congure the output relays.

The MDC-4 does not record the programming changes until all parameters have been programmed. If the unit is RESET before programming all parameters or no key is pressed for 60

seconds, the conguration will not be stored in the memory and relays return to its resting state

for a short time.

To enter the programming menu, hold the and keys for two seconds; the main programming screen will be displayed.

SETUP

Press the key to enter the rst programming screen.

4�8�1� Current primary

In this step the current primary value is pro-

Set P. A

063

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

grammed.

Press the

currently ashing.

button to increase the digit that is

Maximum value: 250 A.

Minimum value: 1 A.

Press the key to access the next programming step.

Instruction Manual

19

Page 20

)

MDC-4

4�8�2� Selecting the maximum demand variable

In this step the variable for calculation the maxi-

SET PD V

P (W)

W: Active power.

VA: Apparent power.

mA: Current III

Press the key to access the next programming step.

4�8�3� Period of maximum demand integration

Set PD

015

When the desired value is shown on the screen, move onto the next digit by pressing the key

mum demand is programmed.

Press the

sible options:

In this step the maximum demand integration

period is programmed.

Press the

currently ashing.

button to select between the pos-

button to increase the digit that is

to modify the remaining values.

Maximum value: 60 minutes.

Minimum value: 1 minute.

Press the key to access the next programming step.

4�8�4� Contracted power

In this step the contracted power for the installa-

Set (W/v/m

_05000

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

Maximum value: 500,000 (W /VA / mA)

Minimum value: 0 (W /VA / mA)

tion is programmed.

Press the

currently ashing.

button to increase the digit that is

20

Press key to access the next programming step.

4�8�5� Deleting the maximum demand maximum value�

In this step you select whether or not to delete

Clea PD mAX

NO

the maximum demand maximum value.

Press the

possible options: No or Yes.

button to select between the two

Instruction Manual

Page 21

out % Time

MDC-4

Press key to access the next programming step.

4�8�6� Deleting the energy value

In this step you select whether or not to delete

Clea Energy

NO

Press key to access the next programming step.

4�8�7� Deleting the output relay disconnection times�

Clea

the energy value.

Press the

possible options: No or Yes.

In this step you select whether or not to delete

the % of time that each output relay has been

disconnected.

button to select between the two

NO

Press key to access the next programming step.

4�8�8� Level of output relay no� 1

out1 Level (%)

Press the button to select between the two

possible options: No or Yes.

In this step you program the value (%) of contracted power from which the output relay is

disconnected.

75

Example: If OUT1 is programmed to 75%, when the maximum demand value reaches 75%

of the contracted power in the installation, output relay no.1 will be disconnected, thus disconnecting all the corresponding loads.

Press the key to increase the digit that is currently ashing.

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

Maximum value: 99%.

Minimum value: 0 %.

Default: OUT1 : 75% , OUT2 : 80%, OUT3 : 90%, OUT4 : 95%

Press key to access the next programming step.

4�8�9� Hysteresis of output relay no� 1

The hysteresis value, i.e., difference between the

out1 Hyst (%)

05

relay connection and disconnection point, in %,

is programmed in this step.

Press the

currently ashing.

button to increase the digit that is

Instruction Manual

21

Page 22

)

MDC-4

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

Maximum value: 99 %.

Minimum value: 0 %.

Press key to access the next programming step.

4�8�10� Delay in connecting output relay no� 1

In this step the delay in connecting the output

out1 Delay ON (s)

05

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

relay is programmed.

Press the

currently ashing.

button to increase the digit that is

Maximum value: 99 seconds.

Minimum value: 0 seconds.

Press key to access the next programming step.

4�8�11� Delay in disconnecting output relay no� 1

In this step the delay in disconnecting the output

out1 Delay OFF (s

05

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

Maximum value: 99 seconds.

Minimum value: 0 seconds.

Press key to access the next programming step.

relay is programmed.

Press the

currently ashing.

button to increase the digit that is

22

4�8�12� Status of the contacts for output relay no� 1

In this step the status of the output relay contact

out1 Contact

N.C.

N.C. normally closed.

N.O. normally open.

Press key to access the next programming step.

is selected.

Press the button to select between the two

possible options:

Instruction Manual

Page 23

MDC-4

In the next steps, the level, hysteresis and connection and disconnection delays are programmed, as well as the status of the contactors for output relays 2, 3 and 4.

The programming is identical to that of sections 4�8�8, 4�8�9, 4�8�10, 4�8�11 and 4�8�12�

4.9.- PROGRAMMING THE CURRENT DATE AND TIME

The MDC-4 does not record the programming changes until all parameters have been programmed. If the unit is RESET before programming all parameters or no key is pressed for 60

seconds, the conguration will not be stored in the memory.

To enter the programming menu for the current date and time, hold the and key for 2

seconds; the main programming screen will be displayed.

SETUP DATE

Press the key to enter the rst programming step.

4�9�1� Day

In this step the day of the month is programmed.

SET DAY

_8

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

Press key to access the next programming step.

4�9�2� Month

SET MONTH

04

When the desired value is shown on the screen, move onto the next digit by pressing the key

Press the

currently ashing.

In this step the current month is programmed.

Press the

currently ashing.

button to increase the digit that is

button to increase the digit that is

to modify the remaining values.

Press key to access the next programming step.

Instruction Manual

23

Page 24

4�9�3� Year

MDC-4

SET YEA

2014

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

Press key to access the next programming step.

4�9�4� Time

SET Hours

_4

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

In this step the current year is programmed.

Press the

currently ashing.

In this step the current hour is programmed.

Press the

currently ashing.

button to increase the digit that is

button to increase the digit that is

Press key to access the next programming step.

4�9�5� Minutes

SET minutes

15

When the desired value is shown on the screen, move onto the next digit by pressing the key

to modify the remaining values.

Press key to access the next programming step.

NB: The unit does not automatically change from summer time to winter time.

In this step the minutes are programmed.

Press the

currently ashing.

button to increase the digit that is

24

Instruction Manual

Page 25

MDC-4

5�- TECHNICAL FEATURES

AC power supply

Rated voltage 110 ...240 V ~

Frequency 50 / 60Hz

Consumption 4...6 VA

Installation category CAT III 300 V

Voltage measurement circuit

Rated voltage (Un) 300 V P-N, 520 V P-P

Voltage measurement margin 5 ... 120% Un

Frequency measurement margin 45 ... 65Hz

Input impedance 400kΩ

Minimum measurement voltage (Vstart) 15 V

Installation category CAT III 300 V

Current measurement circuit

Nominal current (In) ... / 0.250 A

Current measurement margin 5 ... 100% In

Minimum measurement current (Istart) 10 mA

Installation category CAT III 300 V

Measurement accuracy

Accuracy in voltage measurement 0.5%

Accuracy in current measurement 0.5%

Accuracy in power measurement 1%

Relay outputs

Quantity 4

Maximum voltage, open contacts 250 ~

Maximum current 6 A

Maximum switching power 750 W

Electrical working life (250 VAC / 5A) 60x103 cycles

Mechanical working life 10x106 cycles

User interface

Display Alphanumeric LCD screen,

2 lines each containing 20 characters

Keys 4 keys

LED 5 LEDs

Environmental features

Operating temperature 0ºC ... +50ºC

Storage temperature -10ºC ... +60ºC

Relative humidity (non-condensing) 5 ... 95%

Maximum altitude 2,000 m

Protection degree

IP20

Mechanical features

Dimensions Figure 8

Weight 250 gr

Enclosure UL94-V0 self-extinguishing plastic

Instruction Manual

25

Page 26

105

MDC-4

65

44

5 25

90

Figure 8: Dimensions of the MDC-4�

35.5

45

Standards

UNE-EN 61010-1:2011 Safety requirements for electrical equipment for measurement, con-

trol and laboratory use -- Part 1: General requirements

UNE-EN 61000-4-2:2010 Electromagnetic compatibility (EMC) -- Part 4-2: Testing and measu-

rement techniques - Electrostatic discharge immunity test

UNE-EN 61000-4-3: 2007 Electromagnetic compatibility (EMC) -- Part 4-3: Testing and measu-

rement techniques - Radiated, radio-frequency, electromagnetic eld

immunity test

UNE-EN 61000-4-4: 2013

UNE-EN 61000-4-5: 2007

Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test

Electromagnetic compatibility (EMC) -- Part 4-5: Testing and measurement techniques - Surge immunity test

Electromagnetic compatibility (EMC) -- Part 4-11: Testing and mea-

UNE-EN 61000-4-11:2005

surement techniques - Voltage dips, short interruptions and voltage

variations immunity tests

UNE-EN 61000-6-4:2007/A1:2011 Electromagnetic compatibility (EMC) -- Part 6-4: Generic standards -

Emission standard for industrial environments

65

26

Instruction Manual

Page 27

MDC-4

6�- MAINTENANCE AND TECHNICAL SERVICE

In the case of any query in relation to unit operation or malfunction, please contact the

CIRCUTOR, SA Technical Support Service.

Technical Assistance Service

Vial Sant Jordi, s/n, 08232 - Viladecavalls (Barcelona)

Tel: 902 449 459 ( España) / +34 937 452 919 (outside of Spain)

email: sat@circutor.es

7�- GUARANTEE

CIRCUTOR guarantees its products against any manufacturing defect for two years after the

delivery of the units.

CIRCUTOR will repair or replace any defective factory product returned during the guarantee

period.

• No returns will be accepted and no unit will be repaired or replaced if it is not accompanied by a report indicating the defect detected or the reason for the return.

•The guarantee will be void if the units has been improperly used or the storage, installation and maintenance instructions listed in this manual have not been

followed. “Improper usage” is de ned as any operating or storage condition contrary to the national electrical code or that surpasses the limits indicated in the

technical and environmental features of this manual.

• CIRCUTOR accepts no liability due to the possible damage to the unit or other

parts of the installation, nor will it cover any possible sanctions derived from a possible failure, improper installation or “improper usage” of the unit. Consequently,

this guarantee does not apply to failures occurring in the following cases:

- Overvoltages and/or electrical disturbances in the supply;

- Water, if the product does not have the appropriate IP classi cation;

- Poor ventilation and/or excessive temperatures;

- Improper installation and/or lack of maintenance;

- Buyer repairs or modi cations without the manufacturer’s authorisation.

Instruction Manual

27

Page 28

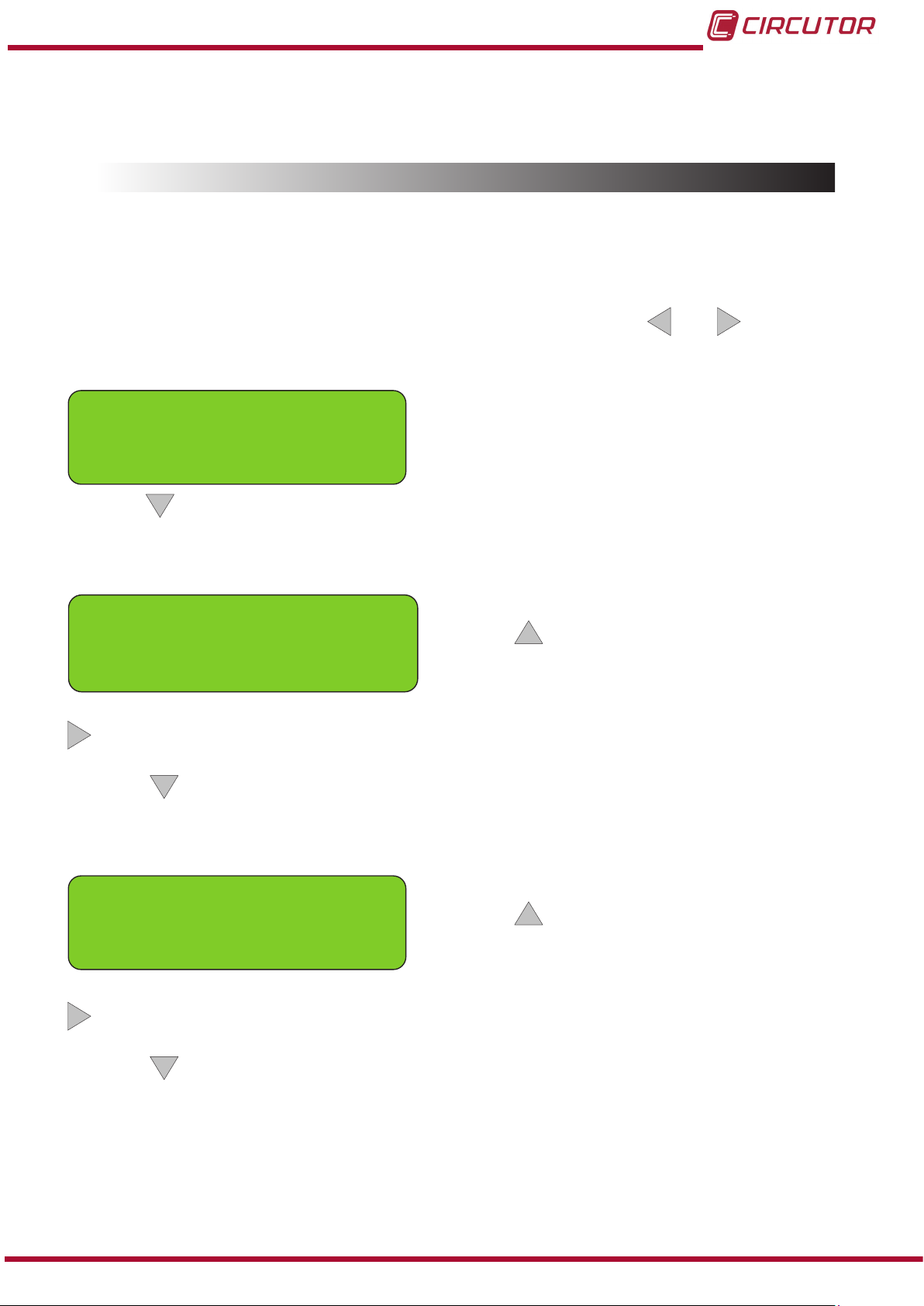

8�- CE CERTIFICATE

MDC-4

28

Instruction Manual

Page 29

MDC-4

Instruction Manual

29

Page 30

CIRCUTOR, SA

Vial Sant Jordi, s/n

08232 -Viladecavalls (Barcelona)

Tel.: (+34) 93 745 29 00 - Fax: (+34) 93 745 29 14

www.circutor.es central@circutor.es

Loading...

Loading...