Page 1

Dynamic power control

CDP- 0, CDP- G

INSTRUCTION MANUAL

(M98250001-03-15A)

Page 2

CDP

2 Instruction Manual

Page 3

CDP

Incorrect handling or installation of the unit may result in injury to personnel as well

Consult the instruction manual b efore using the unit

SAFETY PRECAUTIONS

Follow the warnings described in this manual with the symbols shown below.

DANGER

Warns of a risk, which could result in personal injury or material damage

.

ATTENTION

Indicates that special attention should be paid to a specific point.

If you must handle the unit for its installation, start-up or maint e nance, the following should be taken into consideration:

as damage to the unit. In particular, handling with voltage applied may result in electric shock, which may cause death or serious injury to personnel. Defective inst allation or maintenance may also lead to the risk of fire.

Carefully read the manual prior to connecting the unit. Follow all installation and

maintenance instructions throughout the unit's working life. Pay special attention to

the installation standards of the National Electrical Code.

In this manual, if the instructions marked with this symbol are not respected or carried out correctly, it can result in injury or damage to the unit and /or installations

CIRCUTOR, SA reserves the right to modify features or the product manual without prior notification.

DISCLAIMER

CIRCUTOR, SA

reserves the right to make modifications to the device or the

unit specifications set out in this instruction manual without prior notice.

CIRCUTOR, SA

, on its web site, supplies its customers with the latest versions

of the device specifications and the most updated manuals.

www.circutor.com

.

Instruction Manual 3

Page 4

CDP

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................... 3

DISCLAIMER ........................................................................................................................................ 3

CONTENTS .......................................................................................................................................... 4

LOG OF REVISIONS ........................................................................................................................... 6

1.- VERIFICATION UPON RECEIPT .................................................................................................. 7

2.- PRODUCT DESCRIPTION ............................................................................................................ 7

3.- INSTALLATION OF THE UNIT ...................................................................................................... 8

3.1.- PRELIMINARY RECOMMENDATIONS ......................................................................................8

3.2.- INSTALLATION...............................................................................................................................9

3.3.- LASER MARKING ..........................................................................................................................9

3.4.- UNIT TERMINALS .......................................................................................................................10

3.5.- CONNECTION DIAGRAMS .......................................................................................................11

3.5.1. AUXILIARY POWER SUPPLY ............................................................................................11

3.5.2. COMMUNICATIONS CONNECTION .................................................................................11

3.5.3. VOLTAGE MEASUREMENT AND CURRENT CONNECTION .....................................14

4.- OPERATION .................................................................................................................................. 15

4.1.- OPERATING PRINCIPLE ...........................................................................................................15

4.1.1. DESCRIPTION OF THE MEASUREMENT SYSTEM .....................................................15

4.1.2. OPERATION OF THE GRID INJECTION PROTECTION RELAY.................................15

4.1.3. MANAGEMENT OF NON-CRITICAL LOADS (CDP-G Model) ......................................19

4.2.- APPLICATIONS ............................................................................................................................21

4.2.1. BASIC SINGLE-PH A SE C ON NEC T I O N ...........................................................................21

4.2.1.1. Voltage connection ............................................................................................................21

4.2.1.2. Current connection ............................................................................................................22

4.2.2. SINGLE-PHASE CONNECTION WITH MONITORING ..................................................22

4.2.2.1. Voltage connection ............................................................................................................23

4.2.2.2. Current connection ............................................................................................................23

4.2.3. BASIC THREE-PHASE CONNECTION ............................................................................23

4.2.4. THREE-PHASE CONNECTION WITH MONITORING ...................................................24

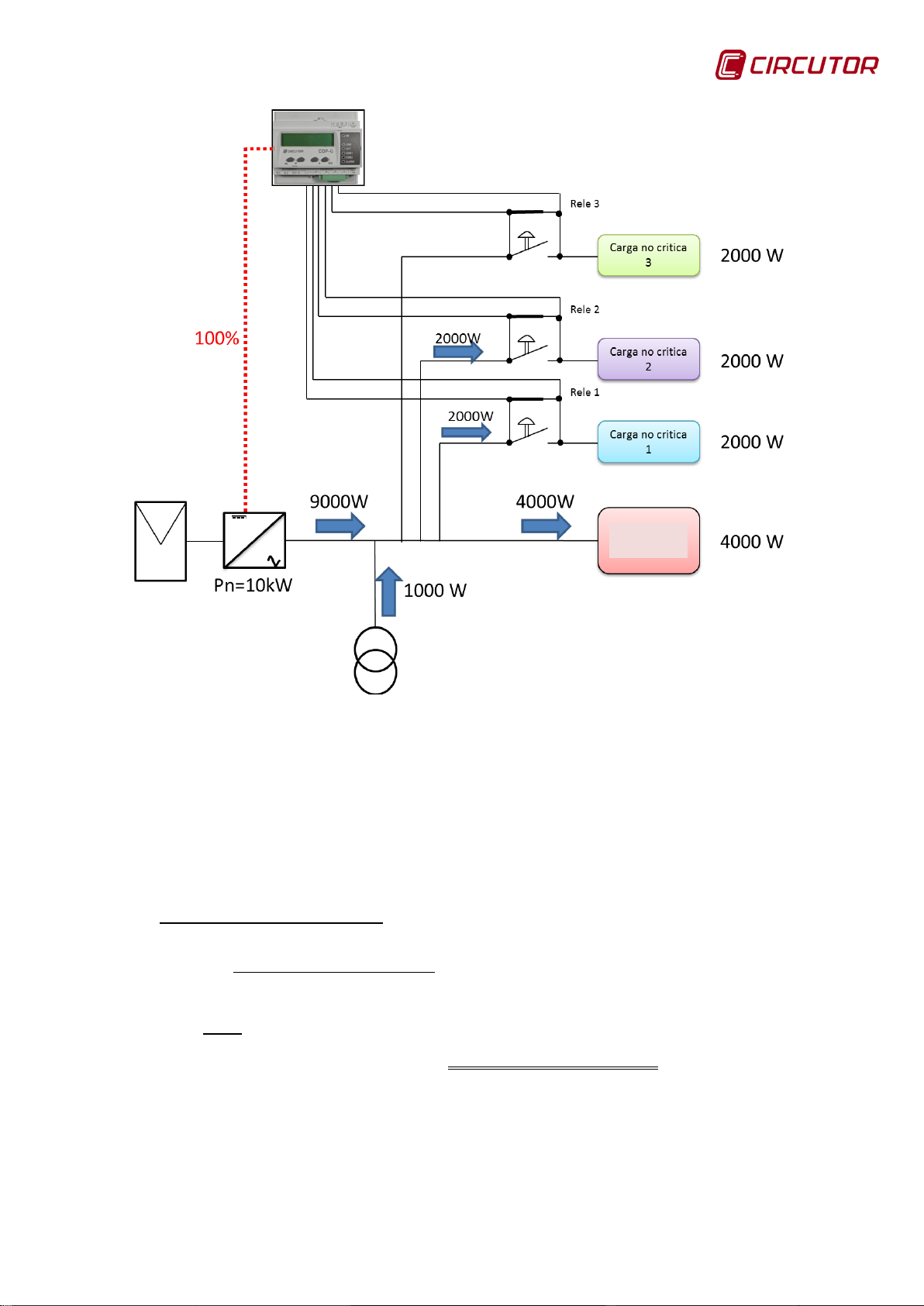

4.3.- OPERATING EXAMPLES FOR THE CDP-G MODEL ............................................................25

4.3.1. SINGLE-PHASE INSTALLATION WITH 1 LOAD TO BE CONNECTED .....................25

4.3.2. SINGLE-PHASE INSTALLATION WITH 3 LOADS TO BE CONNECTED ...................28

4.4.- KEY FUNCTIONS ........................................................................................................................34

4.5.- LED INDICATORS .......................................................................................................................35

4.6.- DISPLAY ........................................................................................................................................36

5.- DISPLAY AND CONFIGURATION .............................................................................................. 38

5.1. MEASURES MENU ......................................................................................................................38

5.2. NETWORK MENU ........................................................................................................................41

5.2.1. DHCP ASSIGNMENT ...........................................................................................................42

4 Instruction Manual

Page 5

CDP

5.2.2. DHCP OPTION: YES ............................................................................................................43

5.2.3. DHCP OPTION: NO ..............................................................................................................43

5.3. SYSTEM MENU ............................................................................................................................45

6.- COMMUNICATIONS..................................................................................................................... 46

6.1. CONFIGURATION WEB SITE .....................................................................................................46

6.1.1. CDP Setup..............................................................................................................................48

6.1.2. Power control & Data logger ................................................................................................50

6.1.2.1. Inverter ................................................................................................................................50

6.1.2.2. Control .................................................................................................................................51

6.1.2.3. Inverse current relay ..........................................................................................................54

6.1.2.4. Auxiliary load relays ...........................................................................................................54

6.1.2.5. Data logger .........................................................................................................................56

6.1.3. Analyzers setup .....................................................................................................................56

6.1.4. Network & Security Setup ....................................................................................................57

6.1.5. Save setup, Load default setup and Reset CDP ..............................................................58

6.2. DISPLAY WEB SITE .....................................................................................................................60

6.2.1. CDP AS A DATA LOGGER ..................................................................................................61

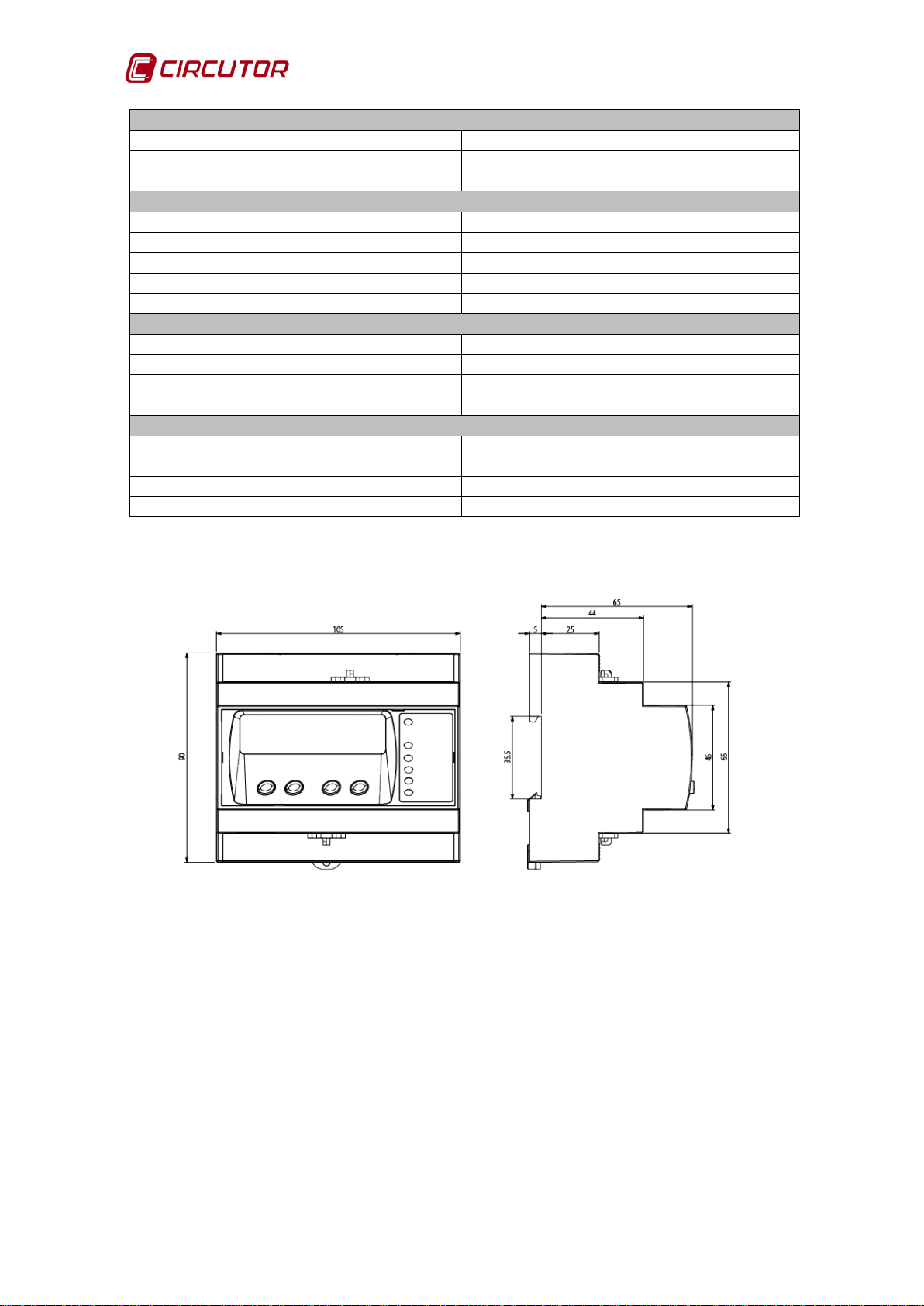

7.- TECHNICAL FEATURES ............................................................................................................. 67

8.- MAINTENANCE AND TECHNICAL SERVICE .......................................................................... 69

9.- GUARANTEE ................................................................................................................................ 69

10.- CE CERTIFICATE ....................................................................................................................... 70

APPENDIX A: M O DBUS MAP ......................................................................................................... 71

Instruction Manual 5

Page 6

CDP

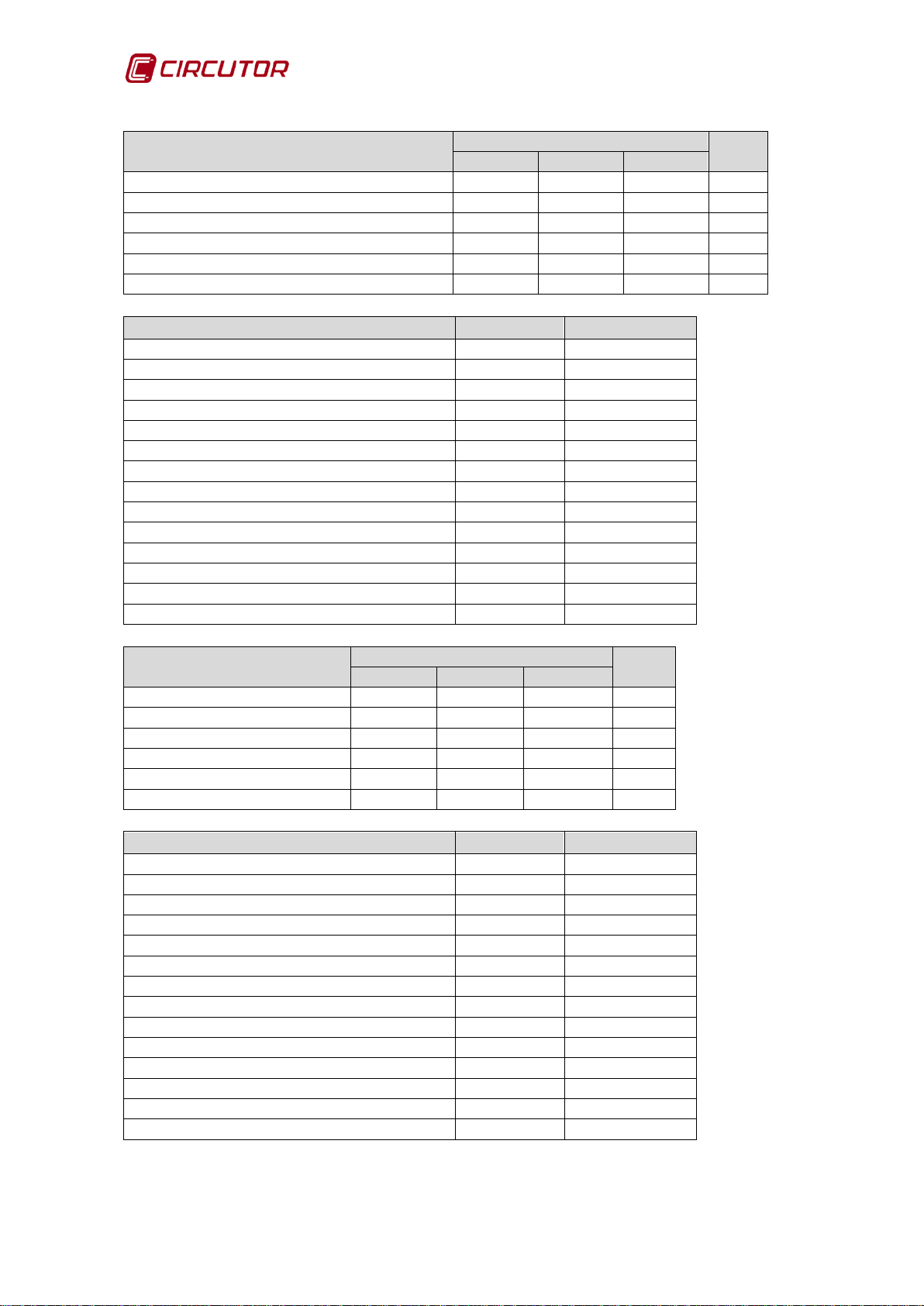

Date

Revision

Description

M98250001-03-13A

Original version

07/14

M98250001-03-14A

General revision

09/14

M98250001-03-14B

Introduction model CDP-G

Changes in the following sections:

6.1.2.3.- 6.1.2.5.- 6.1.5. – Appendix A

LOG OF REVISIONS

Table 1: Log of revisions.

01/15 M98250001-01-15A

3.5.2.- 4.1.2.- 4.6.- 5 – 5.2.- 5.3. -6.1.1.- 6.1.2.1.-

Note: The images of the units are solely for the purpose of illustration and may

differ from the original uni t.

6 Instruction Manual

Page 7

CDP

1.- VERIFICATION UPON RECEIPT

Check the following points when you receive the unit:

a) The unit meets the specifications described in your order.

b) The unit has not suffered any damage during transport.

c) Perform an external visual inspection of the unit prior to switching it on.

d) Check that it has been deliv ered w i th the foll owing:

- An installation guide.

If any problem is noticed upon reception, immediately contact the

transport company and/or CIRCUTOR's after-sales service.

2.- PRODUCT DESCRIPTION

CDP units are a family of dynamic power controllers that shift the operating point

of the solar field, enabling regulation of the inverter's generation level based on

user consumption.

The unit features:

-1 Ethernet communications channel for Online monitoring from any PC or

mobile device with a web browser.

- 20-character, 2-line display for viewing all the electric variables measured by

the unit.

- 6 indicator LEDs indicating the communications and alarm status in real time.

- 4 keys to browse the menu.

The CDP-G model can manage up to 3 non-critical loads.

Instruction Manual 7

Page 8

CDP

In order to use the unit safely, it is critical that individuals who handle it

Disconnect the unit from the power supply (unit and measuring system

3.- INSTALLATIO N OF THE UNIT

3.1.- PRELIMINARY RECOMMENDATIONS

follow the safety measures set out in the standards of the country

where it is being used, use the necessary personal pr ot ecti ve equipment, and pay attention to the various warnings indicated in this instruction manual.

The

The power supply plug must be disconnected and measuring systems switched

off before handling, altering the connections or replacing the unit. It is dangerous

to handle the unit while it is powered.

Also, it is critical to keep the cables in perfect condition in order to avoid accidents, personal injury and damage to installations.

The manufacturer of the unit is not responsible for any damage resulting from

failure by the user or installer to observe the warnings and/or recommendations

set out in this manual, nor for damage resul ting from the use of non-original

products or accessories or those made by other manufacturers.

If an anomaly or malfunction is detected in the unit, do not use the unit to take

any measurements.

Inspect the work area before taking any measurements. Do not take measurements in dangerous areas or where there is a risk of explosion.

unit must be installed by author i sed and qual ified staff.

CDP

power supply) before maintaining, repairing or handling the unit's connections.

Please contact the after-sales service if you suspect that there is an

operational fault in the unit .

8 Instruction Manual

Page 9

CDP

Terminals, opening covers or removing elements can expose parts that

are hazardous to the touch while the unit is powered. Do not use the

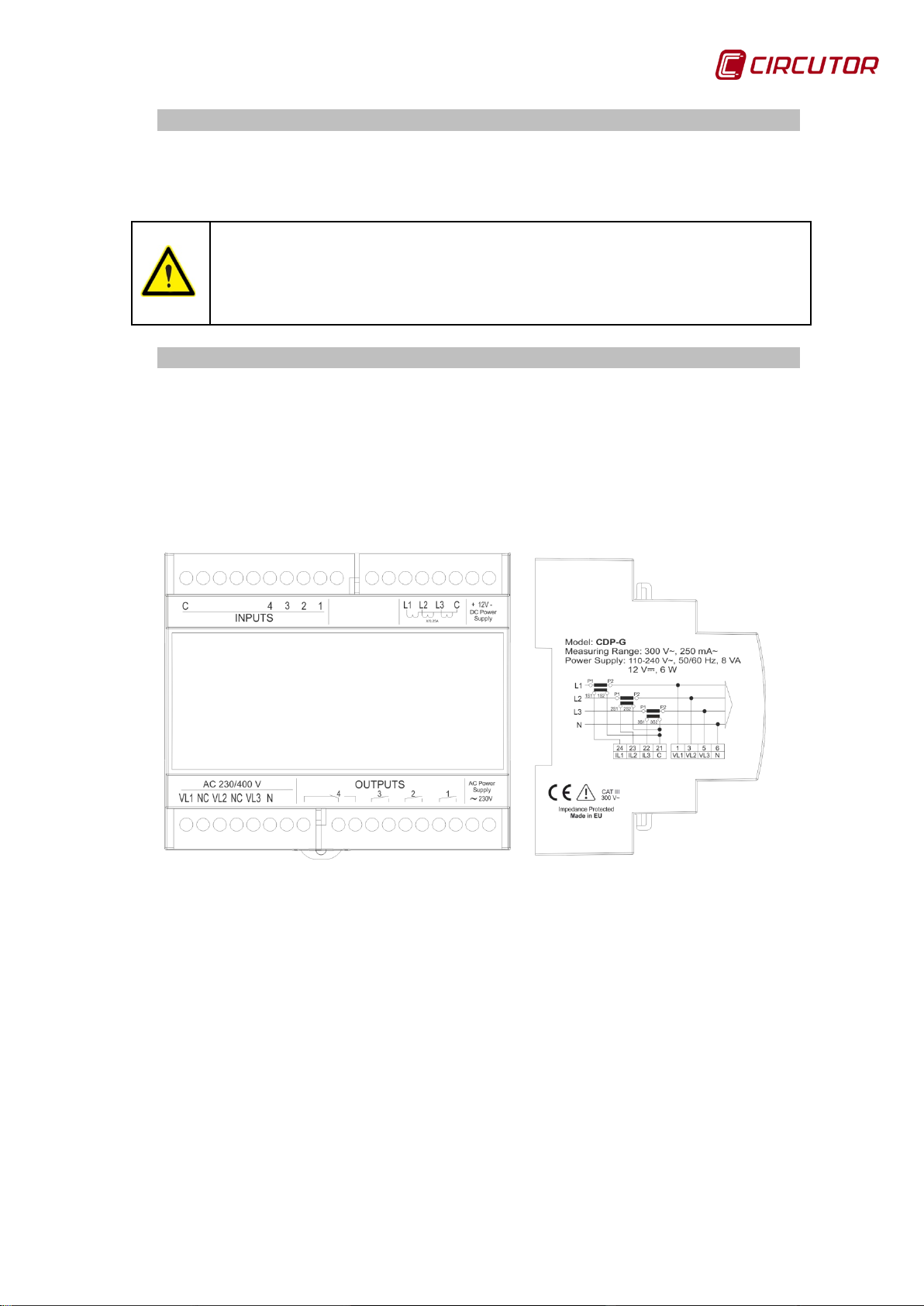

3.2.- INSTALLATION

Install the unit on a DIN 46277 rail (EN 50022). All connections are located

inside the electric panel.

unit until it is fully installed.

3.3.- LASER MARKING

The front view of the CDP shows that the numerical identification of the terminals

and symbols associated with their features have been marked with a laser.

The side view shows the electrical features of the unit and a diagram of its

single-phase connection, illustrating the user, grid and inverter power

measurement connection.

Figure 1: Description of the laser marking.

Instruction Manual 9

Page 10

CDP

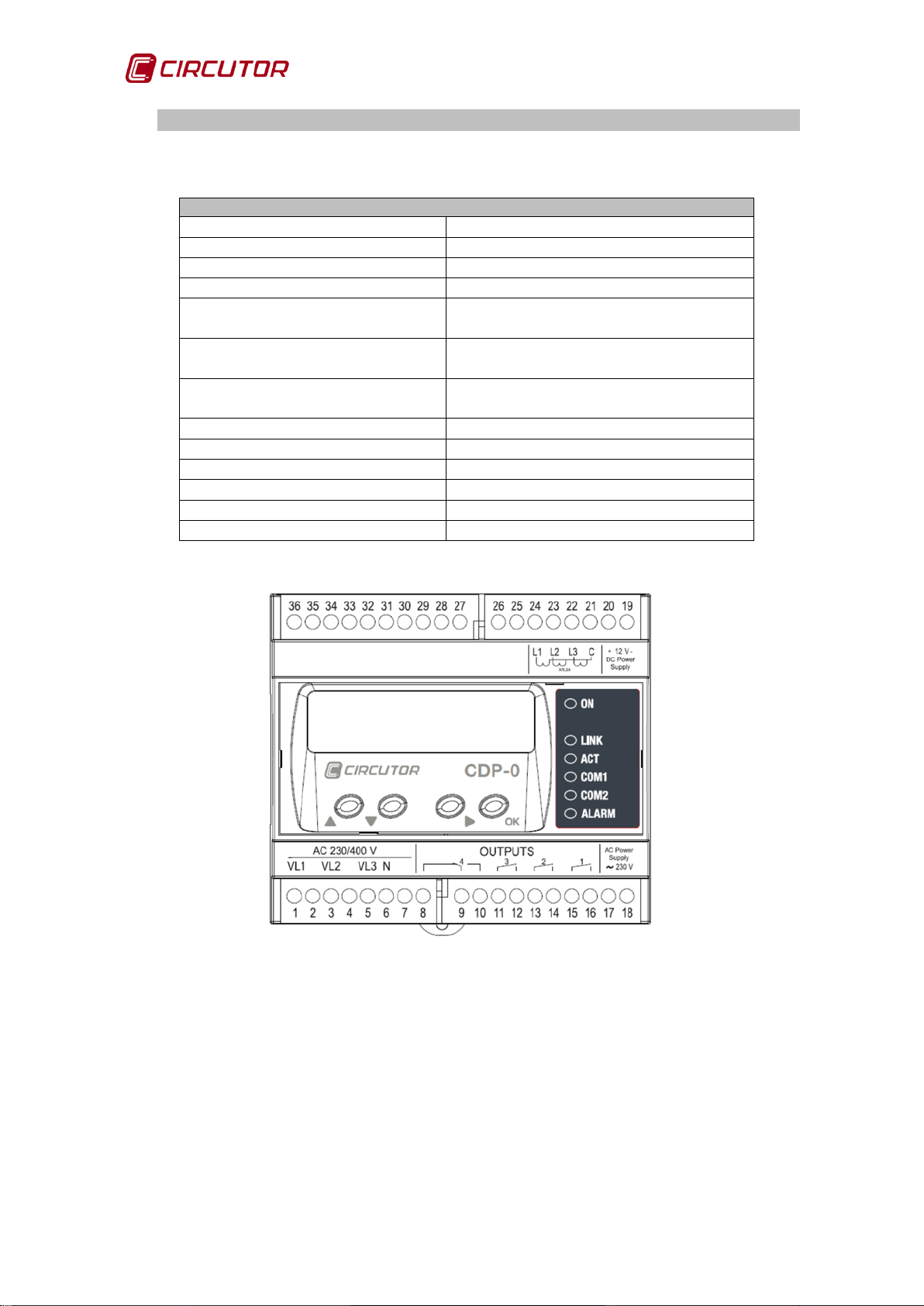

Unit terminals

1: Voltage measurement VL1

17: Auxiliary power supply

3: Voltage measurement VL2

18: Auxiliary power supply

5: Voltage measurement VL3

19: DC Auxiliary power supply (-)

6: Voltage measurement neutral

20: DC Auxiliary power supply (+)

8: Inverse current relay 4 /

Auxiliary relay 4 (NC)

9: Inverse current relay 4 /

Auxiliary relay 4 (COM)

10: Inverse current relay 4 /

Auxiliary relay 4 (NO)

11: Auxiliary relay 3

24: L1 current measurement

12: Auxiliary relay 3

28: Digital input 1

13: Auxiliary relay 2

29: Digital input 2

14: Auxiliary relay 2

30: Digital input 3

15: Auxiliary relay 1

31: Digital input 4

16: Auxiliary relay 1

36: Digital inputs common

3.4.- UNIT TERMINALS

Table 2: List of CDP terminals.

21: Current measurement common

22: L3 current measurement

23: L2 current measurement

Figure 2: CDP terminals

10 Instruction Manual

Page 11

CDP

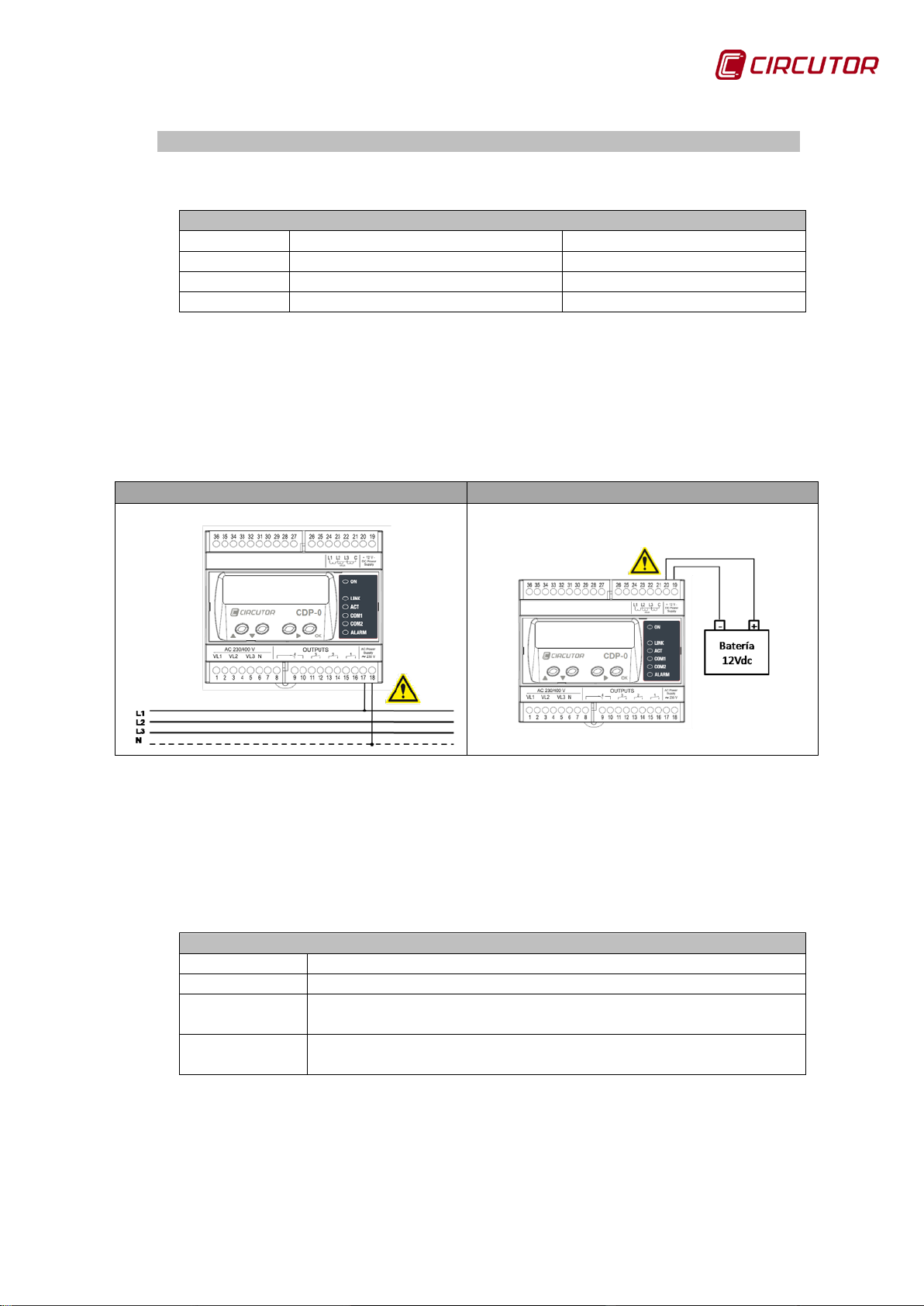

Equivalence between the single-phase and three-phase connection

Connection

Single-phase connection

Three-phase connection

VL1 – IL1

User consumption

Phase 1 consumption

VL2 – IL2

Consumption from the grid

Phase 2 consumption

VL3 – IL3

Power injected by the inverter

Phase 3 consumption

AC power supply

DC power supply

Description of the communications channels

Channel

Description of the channel

R1

Ethernet communications channel

Channel for communicating with the inverter:

RS422/RS485/RS232

Channel for communicating with the external measuring parts:

RS485

3.5.- CONNECTION DIAGRAMS

Table 3: Equivalences between the single-phase and three-phase connection.

3.5.1. AUXILIARY POWER SUPPLY

The unit has terminals for supplying it either AC voltage (17-18) or DC voltage

(19-20):

Figure 3: AC and DC power supply connection.

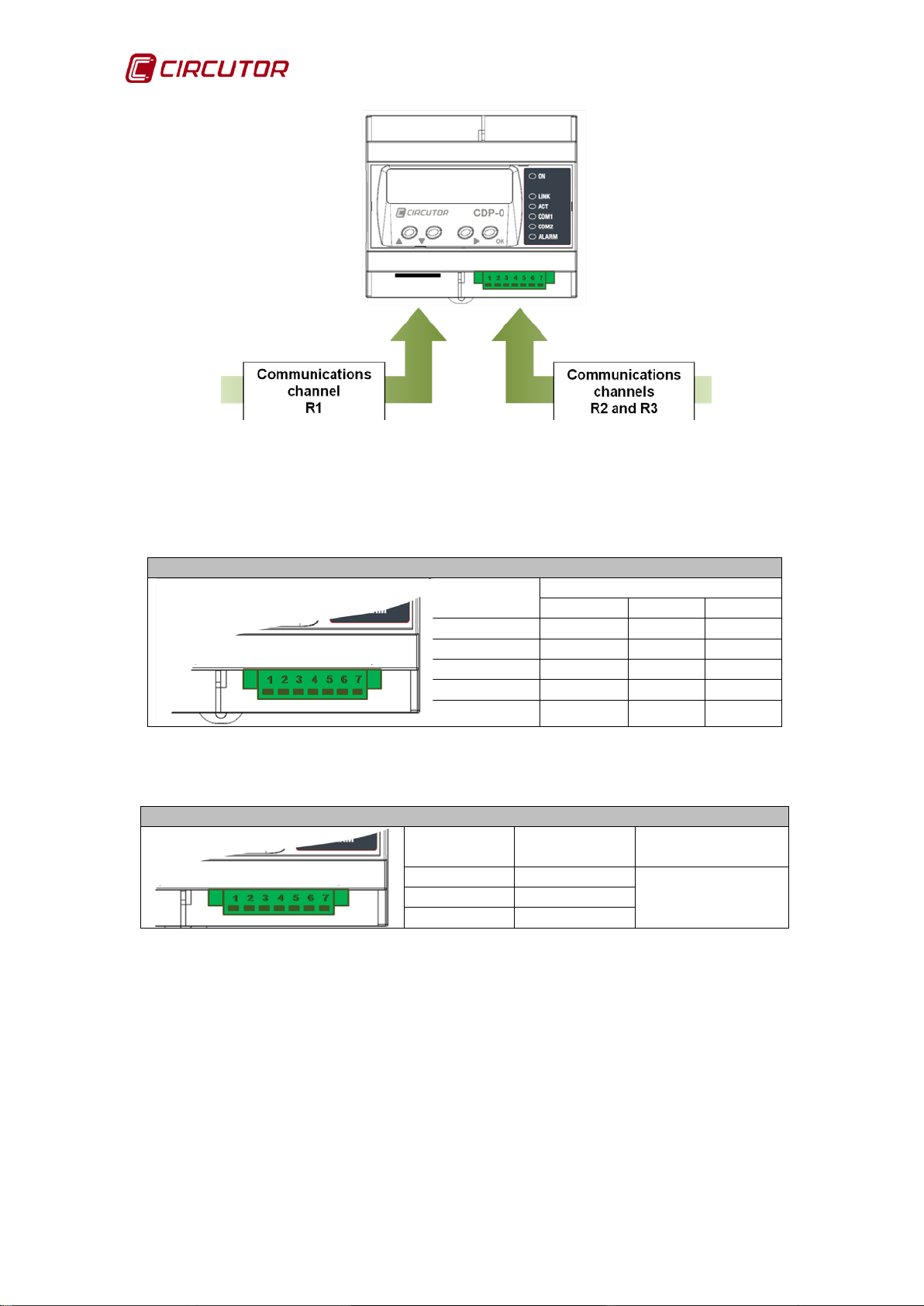

3.5.2. COMMUNICATIONS CONNECTION The CDP has three communications channels referred to as R1, R2 and R3.

Table 4: Des cription of the communications channels.

R2

R3

Instruction Manual 11

Page 12

CDP

Description of the R2 communications channel connector

Description of terminal

RS-422

RS-485

RS-232

1

TxD +

A+

CTS

2

RxD –

NC

(1)

RTS

3

TxD -

B-

RX

4

RxD +

NC

(1)

TX

GND

GND

GND

Description of the R3 communications channel connector

Description

of terminal

Communication

s channel

5

GND

6

B- 7 A+

Figure 4: Communications channels.

The removable connector terminals are described as follows:

Table 5: Description of the R2 channel terminals.

Terminals

5

(1)

NC: Not connected.

Table 6: Des cription of the R3 channel terminals.

Terminals

RS-485

The R2 channel is used for communications with the inverter and the R3 to

create a network with the auxiliary units that help measure the power in threephase installations.

Note: For the proper working of RS-485 communications, always connect the

GND terminal.

12 Instruction Manual

Page 13

CDP

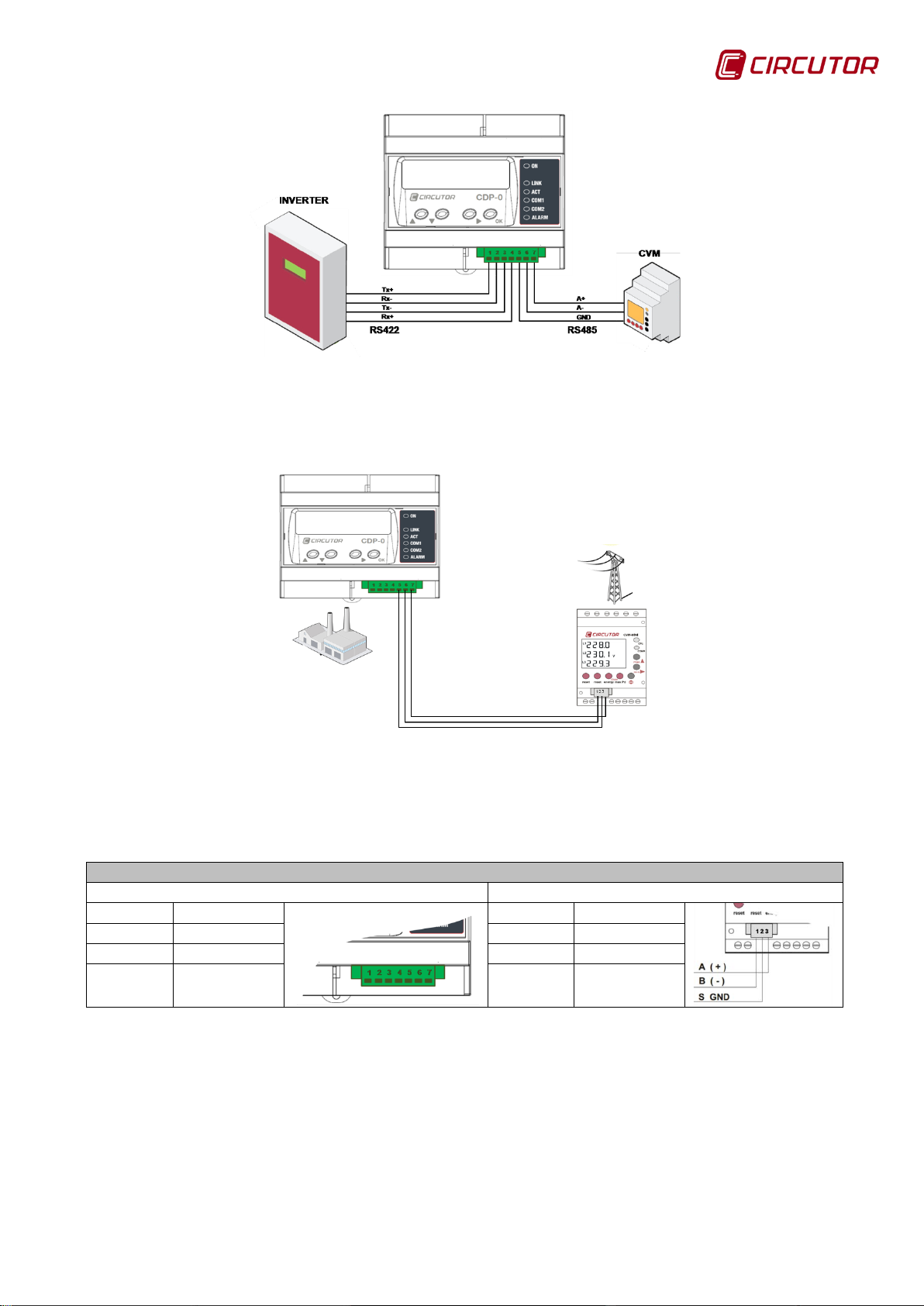

Correspondence between the CDP and CVM Mini connection

CDP

CVM MINI

Terminal

Description

Terminal

Description

5

GND

2

GND

6

B- 1 B-

Figure 5: Communications with the inverter and the CVM Mini.

Connection diagram fo r CDP communications with the external CVM Mini:

Figure 6: CDP connection with the external CVM Mini.

Table 7: Connection of communications between the CDP and the CVM Mini.

7 A+ 3 A+

To ensure that the CDP can communicate with the external CVM Mini, this must

be configured as per Table 8:

Instruction Manual 13

Page 14

CDP

Configuration of the external CVM Mini.

Parameter

Value

Peripheral number

Configurable

Bauds

Configurable

Bits

8

Parity

NO

Stop bits

1 Stop bit

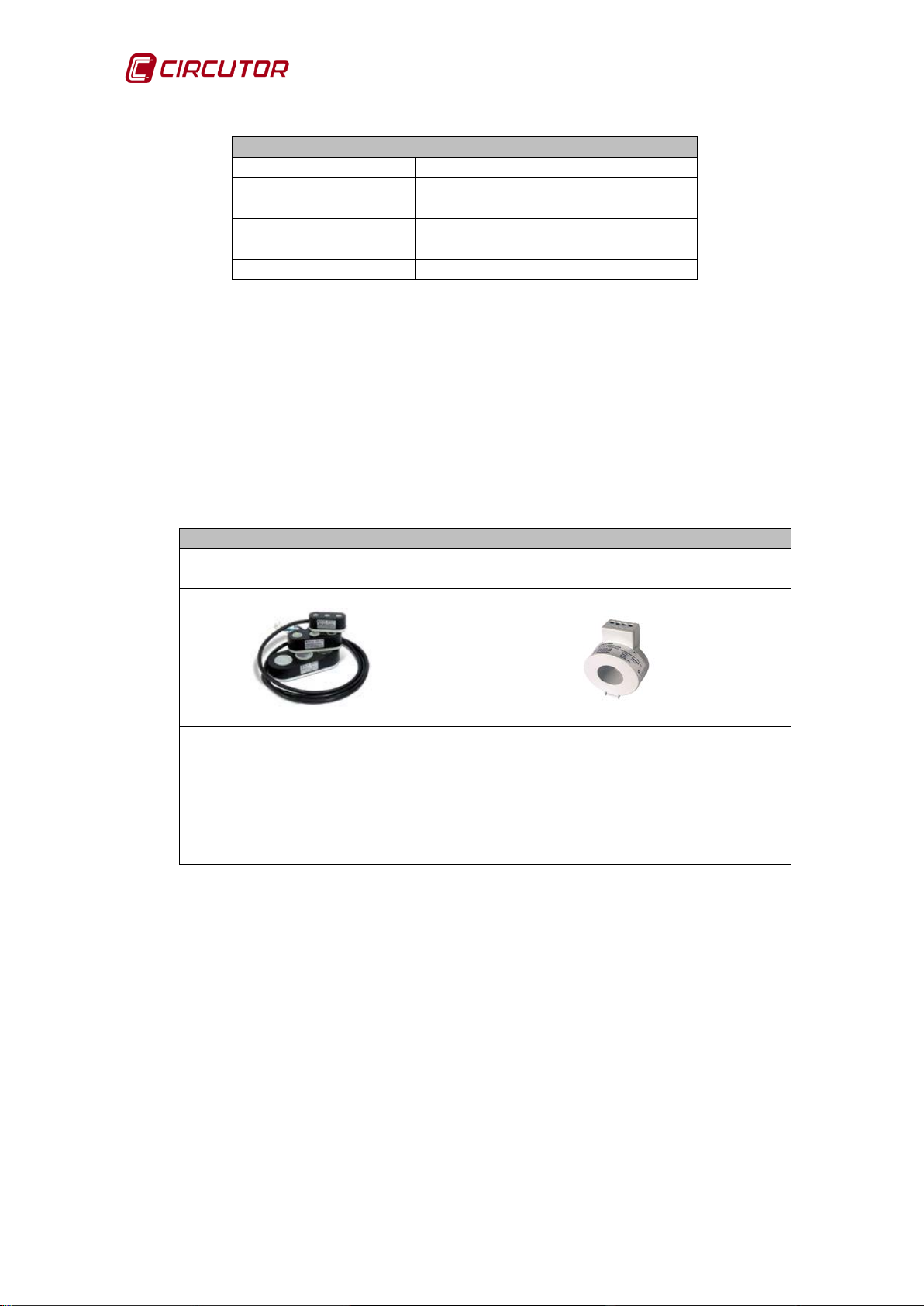

Transformer models

MC3 – three-phase

transformer

Models:

chosen ratio in the measuring unit.

Table 8: Configuration of the external CVM Mini.

It is recommended that a category 5e FTP cable or higher is used and a twisted

pair must be used for each earth leakage signal pair.

3.5.3. VOLTAGE MEASUREMENT AND CURRENT CONNECTION

The CDP measures current using the MC1 or MC3 transformers with a

secondary current of 250 mA

Table 9: Current measurement transformer models.

MC1- 1 transformer per phase

Models 63, 125 and 250 A.

150/200/250A, 250/400/500A,

50/100/150A, 500/1000/1500A,

1000/1500/2000 A

Each transformer has 3 ratio ranges,

changing a connection cable and the

14 Instruction Manual

Page 15

CDP

4.- OPERATION

4.1.- OPERATING PRINCIPLE

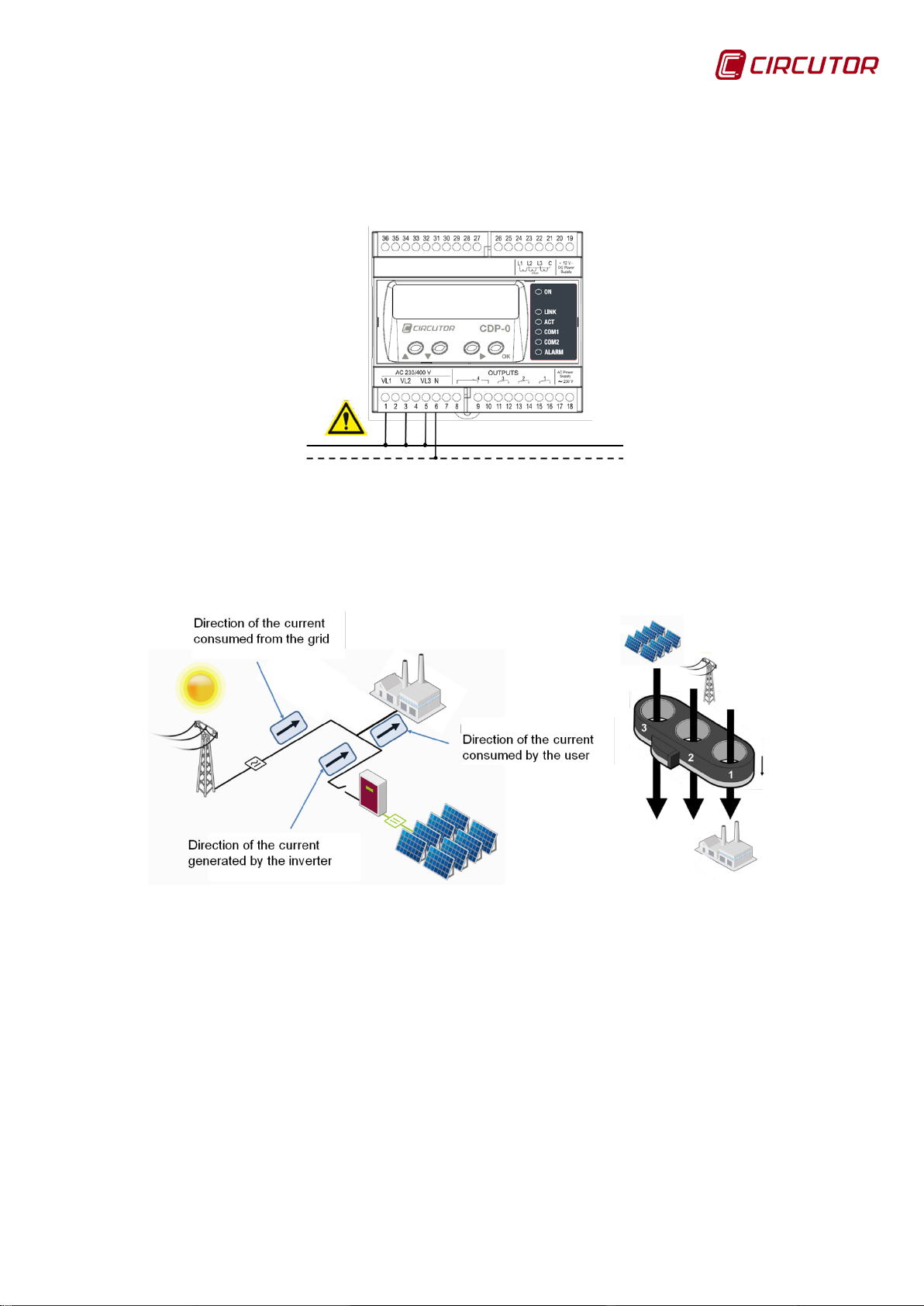

One of the main features of the CDP is that it can measure all the energy flows

of the installation:

Energy consumed by the user.

Energy generated by the inverter.

Energy consumed or injected into the grid.

The inverter power must be configured in the unit and, through a

communications channel, the CDP can adapt generation to energy consumption

with the aim of achieving zero grid injection

The CDP generates a database with all the power and energy information for

every measuring point, including the inverter's regulation percentage.

The following functions have also been implemented in the CDP:

• Grid injection alarm control.

• Management of non-critical loads, CDP-G model.

4.1.1. DESCRIPTION OF THE MEASUREMENT SYSTEM

The CDP measures the user's voltage and current and uses these values to

calculate the consumed power. If the power generated by the inverter differs

from that consumed, the unit changes the inverter's working setpoint to adjust it

to the real-time needs o f the inst al lat ion.

4.1.2. OPERATION OF THE GRID INJ ECTION PROTECTION RELAY

If measuring the power consumed from the grid, both in single-phase and threephase installations, the CDP can control a redundant grid current injection

protection relay. Relay number 4 is used for this function, by default the relay

status is NC (terminals 9-10).

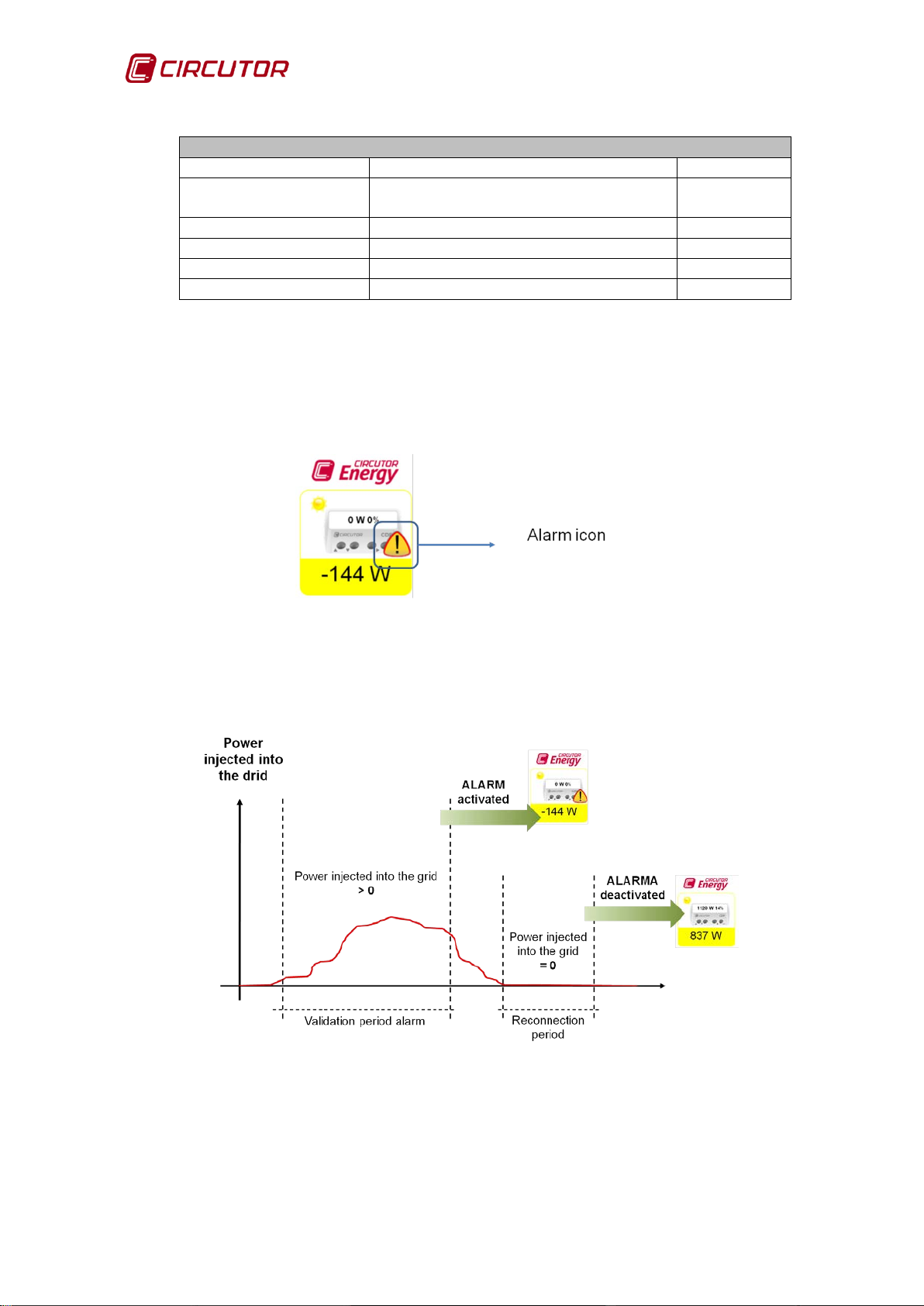

Table 10 describes the parameters that can be configured in the CDP in relation

to the control tasks of this function:

Instruction Manual 15

Page 16

CDP

Configuration parameters for the grid injection protection relay

Name

Description

Units

Enable inverse

current relay

Activation of the inverse current

protection

Stop time

Grid injection validation time

Seconds

Reconnection time

Reclosing time

Seconds

Max. Disconnections

Maximum number of reconnections

-

Disconnect. Timeout

Maximum reconnection time

Seconds

Table 10: Configuration parameters for the grid injection protection relay.

-

If power is injected into the grid during the period defined by the Stop time

parameter, relay number 4 (NO (terminals 9- 10)) is desactivated (If Stop time is

programmed with the value 0 this function remains deactivated). In addition, an

orange alarm icon appears on the web site, as shown in Figure 7:

Figure 7: Hardware control alarm activated.

When the current injected into the grid disappears, after the Reconnection

time, the alarm status is deactivated.

Figure 8: Inverse current relay reconnection time.

16 Instruction Manual

Page 17

CDP

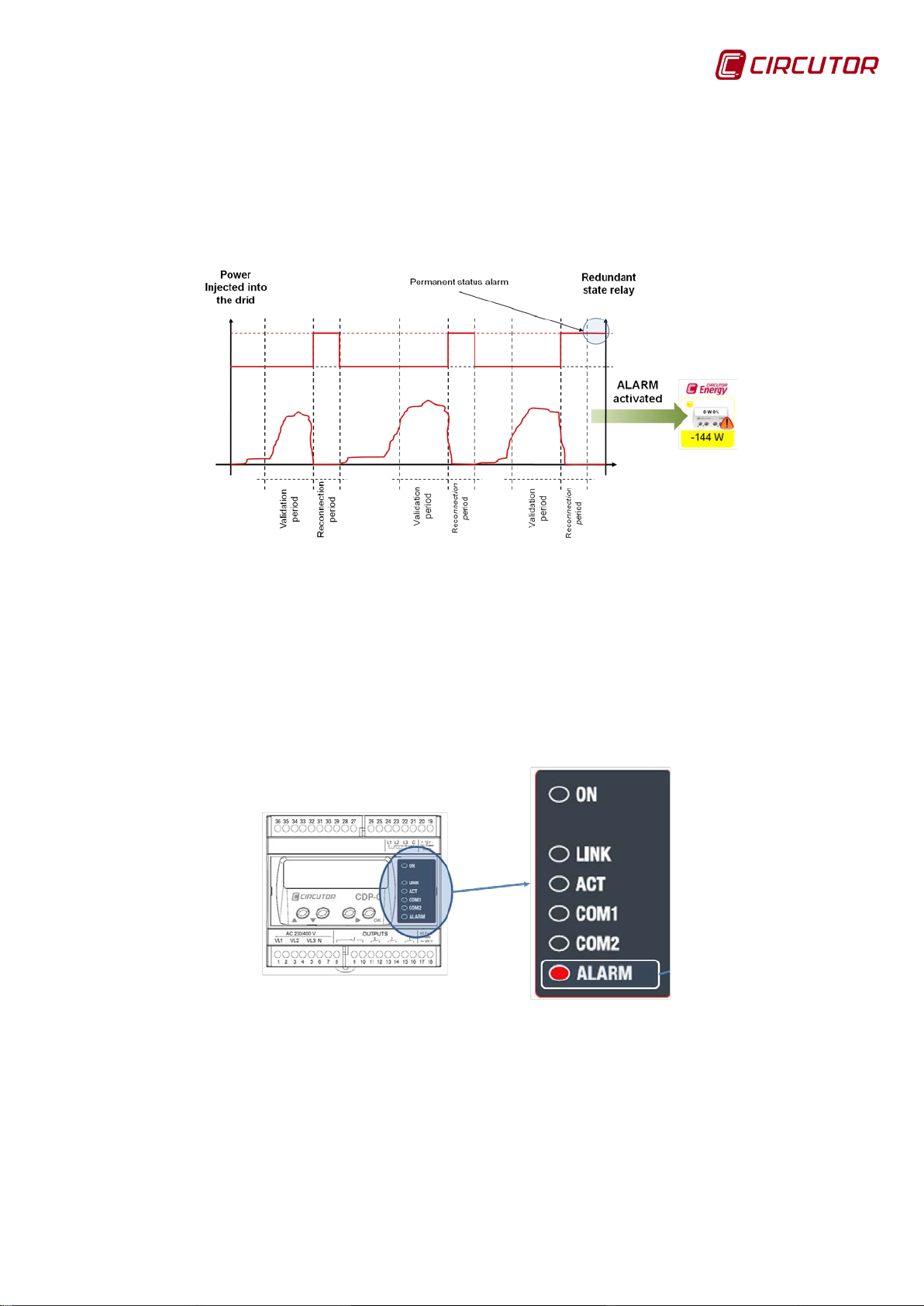

If the maximum number of reconnection attempts defined in the Max

Disconnections parameter is reached within the time defined in the maximum

reconnection period, Disconnect. Timeout parameter, the unit definitively

activates the alarm.

Figure 9: alarm reconnection sequence.

The following indications appear in the CDP when the reconnection sequence

has been completed:

• Alarm LED: The alarm LED is activated in the CDP indicating that power

is being injected into the grid and that the reconnection sequence is

complete.

Figure 10: Inverse current relay alarm.

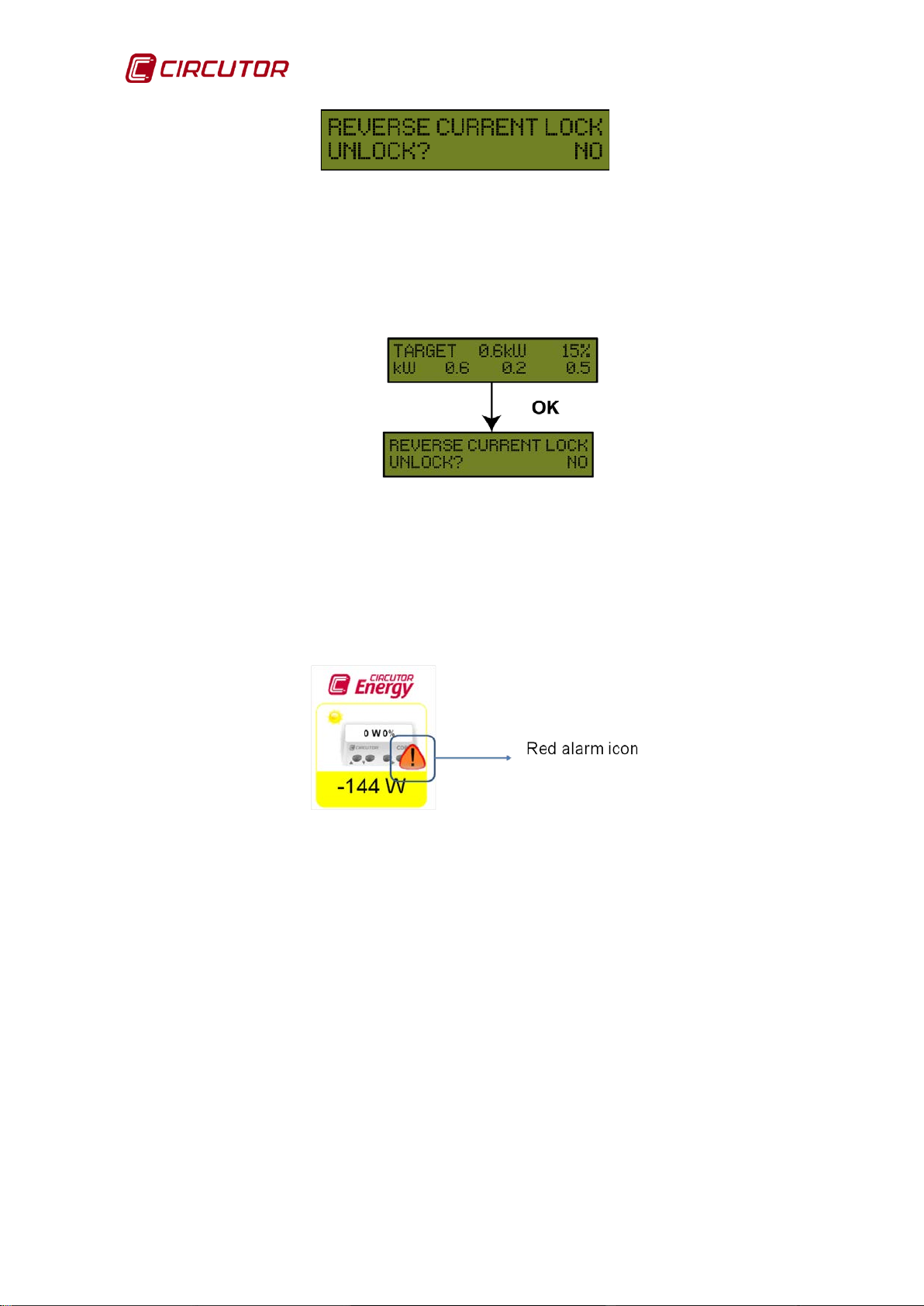

• Unit screen: A screen appears on the CDP indicating that the unit has

activated the inverse current protection relay, and there is an option to

unlock it. The option NO appears on the home screen; this can be

changed with the UP and DOWN keys to YES. Press the OK key to

validate the selected option.

Instruction Manual 17

Page 18

CDP

Figure 11: Inverse current alarm screen.

If NO is selected, the alarm remains permanently activated. If the OK key

is pressed on the main screen, the option to deactivate the inverse current

alarm is displayed.

Figure 12: Inverse current alarm display.

If the inverse current alarm is activated, although the unit turns off and on

again, this condition is memorised and the alarm notification will appear

on the screen indicating that it is possible to unlock it.

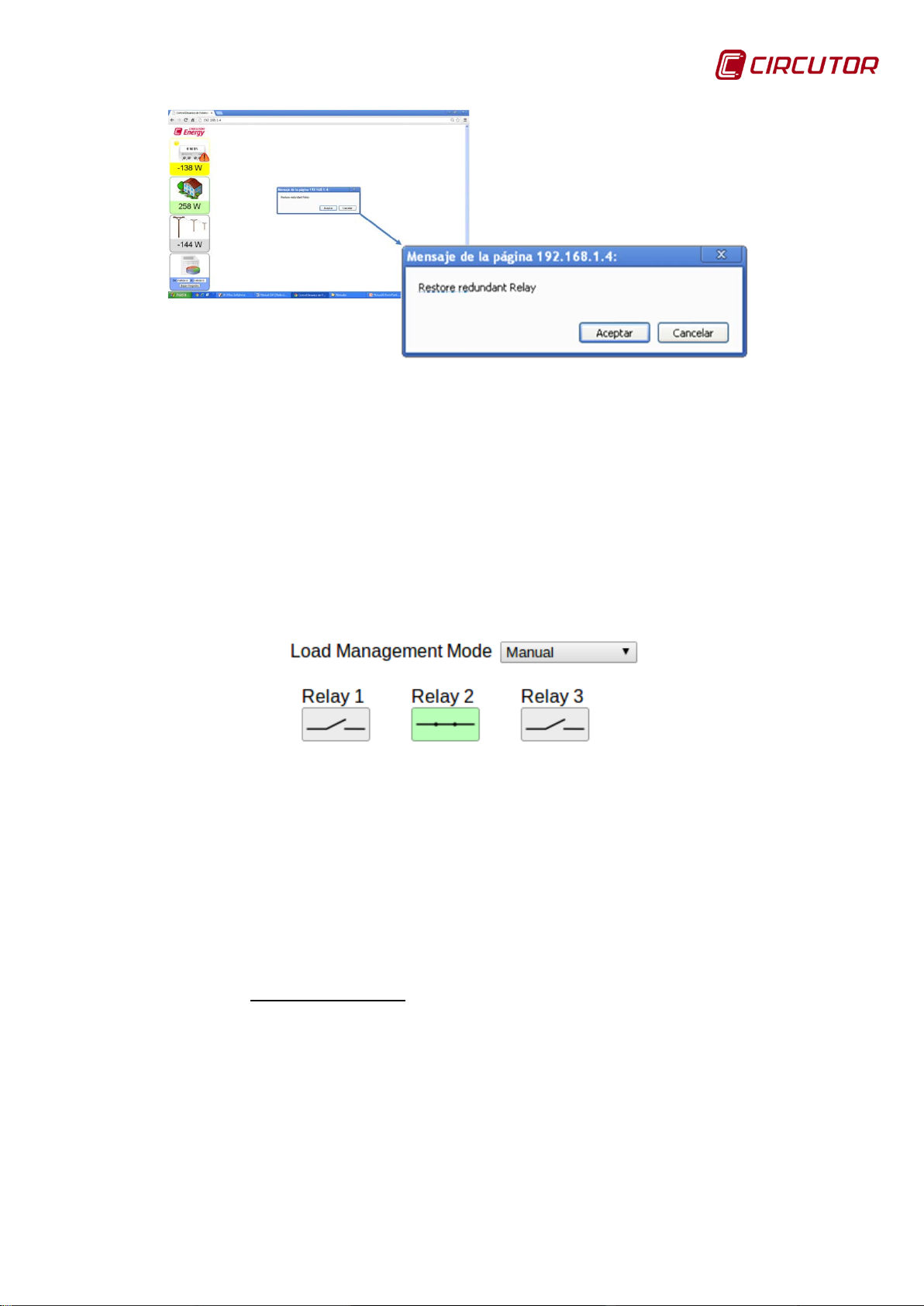

Web site: The icon is red indicating that the alarm has been activated.

Figure 13: Inverse current relay alarm activated.

If you press above the alarm icon a message will appear asking if you want

to deactivate the grid injection alarm. You can accept or cancel this option as

shown in Figure 14.

18 Instruction Manual

Page 19

CDP

Figure 14: Deactivating the alarm on the web site.

4.1.3. MANAGEMENT OF NON-CRITICAL LOADS (CDP-G Model)

This functionality allows you to add non-critical loads depending on if more

power can be obtained from the inverter. This management can be manual or

dynamic and is carried out through the use of the system's auxiliary relays

(Terminals 11 to 16 of Table 2).

Manual management is performed from the configuration web site, from which

you can view and modify the status of the relays (Figure 15).

Figure 15: Manual management of no n-critical loads from the web site.

When managing dynamic control, the loads are connected based on having

met two conditions:

1.-

Setpoint value ≤ Maximum modulation value.

100 .

Equation 1: Condition 1 for load connection.

Where the Maximum modulation value is the ratio between the power

consumed by the user and the maximum power that can be obtained by the

configured inverters. In other words, the maximum modulation value (%) is:

Instruction Manual 19

Page 20

CDP

Equation 2: Maximum modulation value.

100

2.-

If Injection Margin = 0%

The Grid power < ( 2 x 0.03 x Consumed power)

Equation 3: Condition 2 for load connection (Injection Margin = 0%).

If Injection Margin ≠ 0%

The Grid power < ( 2 x Injection Margin x Consumed power)

Equation 4: Condition 2 for load connection (Injection Margin ≠ 0%).

As soon as conditions 1 and 2 are met, a new load will be added to the system

via the unit's auxiliary relays.

The loads will be disconnected, based on the maximum grid contribution. This

parameter is the ratio between the power supplied to the grid and the sum of the

powers of the loads managed by the system.

Grid

· 100

GC

Equation 5: Maximum grid contribution.

As soon as the value is greater than or equal to the value programmed by the

user, the last relay to be activated will be deactivated.

To ensure correct system stability, a minimum reclosing time (programmable by

the user) must pass between the activation and deactivation of two loads or a

single load.

The order in which loads are activated is another parameter that can be set by

the user. The order may be set as: connection by priority or rotating connection.

Connection by priority: In this case the user sets the order in which

loads are to be activated.

Rotating conne ction: Each connection cycle begins with a different load.

In other words, the first connection cycle begins by connecting load 1,

then 2 and finally 3. The following connection cycle will begin with the load

from relay 2, then 3 and finally 1, and so on and so forth.

The disconnection order for both modes is based on a LIFO system in which the

last load connected to the system will be the first load to be disconnected.

20 Instruction Manual

Page 21

CDP

4.2.- APPLICATIONS

The CDP is the ideal unit for managing photovoltaic installations for selfconsumption with and without grid injection.

Four types of configurations can be distinguished depending on the type of grid

connection:

Basic single-phase connection, in which the CDP only measures the

power consumed by the user.

Single-phase connection with monitoring, the CDP measures the

power consumed by the user, the power generated by the inverter and the

power consumed from the gri d.

Basic three-phase connection, in which the CDP only measures the

power consumed by the user.

Three-phase connection with monitoring, the CDP measures the

power consumed by the user, the power consumed from the grid and

calculates the power generated by the inverter.

The different configurations are described below.

4.2.1. BASIC SINGLE-PHASE CONNECTION

The CDP has a voltage measuring channel (VL1) and a current measuring

channel (IL1) and measures the single-phase power consumed by the user

using a current transformer (an MC1 or channel of an MC3). In this case, since it

does not measure the grid power, it cannot have the grid injection protection

relay function.

Figure 16: Connection diagram for the single-phase measurement system.

4.2.1.1. Voltage connection

For the basic single-phase connection, terminals VL1 and N must be connected

to the single-phase grid (it is recommended that VL2 and VL3 are connected to

N to avoid false measurement s due to noi s e) .

Instruction Manual 21

Page 22

CDP

Figure 17: Voltage connection diagram.

4.2.1.2. Current connection

Only one MC3 channel must be used to measure the current, in this case

number 1. The cable direction is that indicated in Figure 18.

Figure 18: Current connection diagram.

4.2.2. SINGLE-PHASE CONNECTION WITH MONITORING

The CDP has three voltage measuring channels (VL1, VL2 and VL3) and three

current measuring channels (IL1, IL2 and IL3) and uses an MC3 current

transformer to measure the power consumed by the user (VL1, IL1), the power

consumed from the grid (VL2, IL2) and the power generated by the inverter

(VL3, IL3).

Figure 19: Connection diagram for the single-phase measurement system with

monitoring.

22 Instruction Manual

Page 23

CDP

4.2.2.1. Voltage connection

For the single-phase connection with monitoring, the terminals VL1, VL2 and

VL3 must be connected and bridged and connected to the single-phase grid

phase and terminal N to the neutral.

Figure 20: Voltage connection diagram,

4.2.2.2. Current connection

The three channels of the MC3 must be used to measure the current. The cable

direction is that indicated in Figure 21.

Figure 21: Current connection diagram.

4.2.3. BASIC THREE-PHASE CONNECTION

The CDP has three voltage measuring channels (VL1, VL2 and VL3) and three

current measurement channels (IL1, IL2 and IL3), and will measure the threephase power consumed by the user using an MC3 current transformer. In this

case, since it does not measure the grid power, it cannot use the grid injection

protection relay funct ion.

Instruction Manual 23

Page 24

CDP

Figure 22: Connection diagram for the basic three-phase system.

Since this is a three-phase installation connection, each of the measuring

channels VL1, VL2 and VL3 are connected to their corresponding phase of the

three-phase grid.

4.2.4. THREE-PHASE CONNECTION WITH MONITORING

Figure 23 shows a three-phase installation in which the CDP directly measures

the user's consumption, in this case a small-scale industry, by connecting an

MC3 current measurement transformer. The power control uses its RS485

channel to communicate with a CVM type three-phase measuring unit. This unit

is responsible for measuring the power consumed by the grid.

Figure 23: Connection diagram for the three-phase system with monitoring.

Since this is a three-phase installation connection, each of the measuring

channels VL1, VL2 and VL3 are connected to their corresponding phase of the

three-phase grid.

24 Instruction Manual

Page 25

CDP

Loads

4.3.- OPERATING EXAMPLES FOR THE CDP-G MODEL

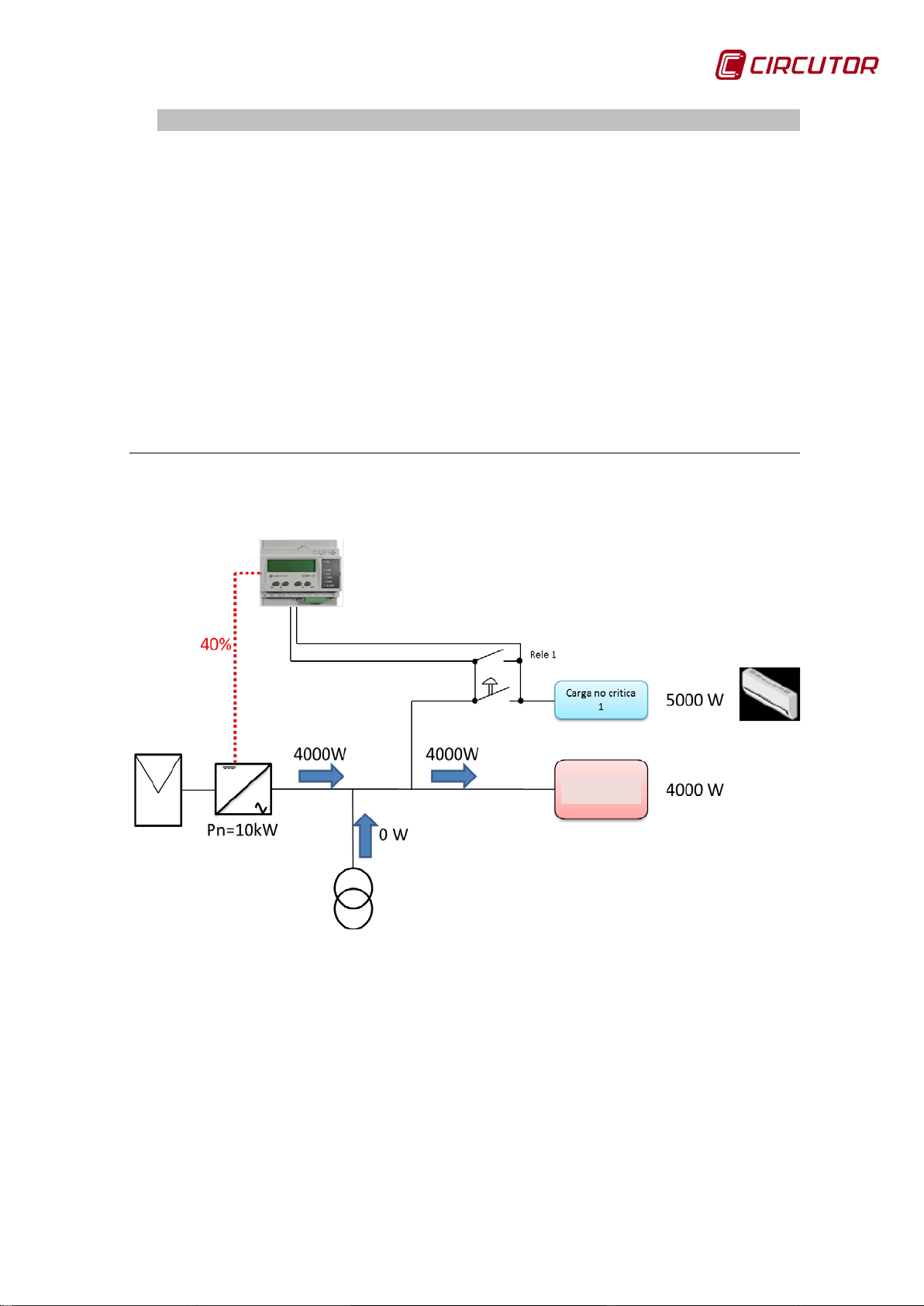

4.3.1. SINGLE-PHASE INSTALLATION WITH 1 LOAD TO BE CONNECTED

We start with a single-phase installation in which we want to use the excess

photovoltaic production to supply 1 non-critical load, such as a heat pump.

• Load 1: 5000 W heat pump

The goal is to activate these loads during times in which there is a production

excess, thus reducing energy costs.

This is the baseline data:

Phase P. Inverter Consumption Setpoint Current production

L1 10000 W 4000 W 40% 4000 W (40% of the nominal)

Figure 24: Single-phase installation with 1 load to connect.

The CDP-G programming is shown in Table 11 :

Instruction Manual 25

Page 26

CDP

VARIABLE

VALUE

Inverter power

10000 W

Number of inverters

1

Phase control

Single-phase

Injection margin

0 %

Load management Mode

Dynamic

Max. modulation value

90 %

Max. grid contribution

20 %

Reconnecting time

5 minutes

Relay 1

Relay 2

Relay 3

Power

5000 W

Power

Power

Min.

time

Min.

time

Min.

time

Table 11: CDP-G programming (Single-phase installation with 1 load to connect).

connection

90 minutes

connection

connection

• Max. modulation value = 90%. This means that as long as the ratio be-

tween Pconsumed/Available PV Power is below 90%, the CDP-G will try to

connect the associated loads.

• Max. grid contribution = 20% This means that as long as the load can op-

erate with less than 20% of the power in the distribution lines, the CDP-G will

keep the loads connected. If the load needs more than 20% of the grid power, the CDP-G will disconnect the load once the Min. disconnection time has

passed.

In this situation, the CDP-G checks its working conditions:

• Condition 1:

100 .

(

100 = 40%) 40% ≤ 90% this condition is met

• Condition 2:

-If Injection Margin = 0% It checks whether:

Pgrid < 2 x (0.03) x Pconsumed

-If Injection Margin ≠ 0% It checks whether:

Pgrid < 2 x Injection Margin x Pconsumed

0 < 2 x 0.03 x 4000 this condition is met

If the 2 conditions are met, the relay closes and connects

the load. (Figure 25)

26 Instruction Manual

Page 27

CDP

Loads

Figure 25: Single-phase installation with 1 load to connect (Load Connected).

In this situation the CDP-G maintains the system without adding or removing any

loads for a time equalling the longer of the configured “Reconnection time” and

“Min. disconnection time” variables, in order to achieve system stability (in this

case 90 minutes).

To check if this load must be disconnected, the CDP-G waits for the amount of

time programmed in the “Min. connection time” variable and then checks if the

following condition is met:

• Disconnection condition:

< .

(

= 60%) 60% ≤ 20%

this condition is NOT met the CDP-G open the relay.

Instruction Manual 27

Page 28

CDP

Loads

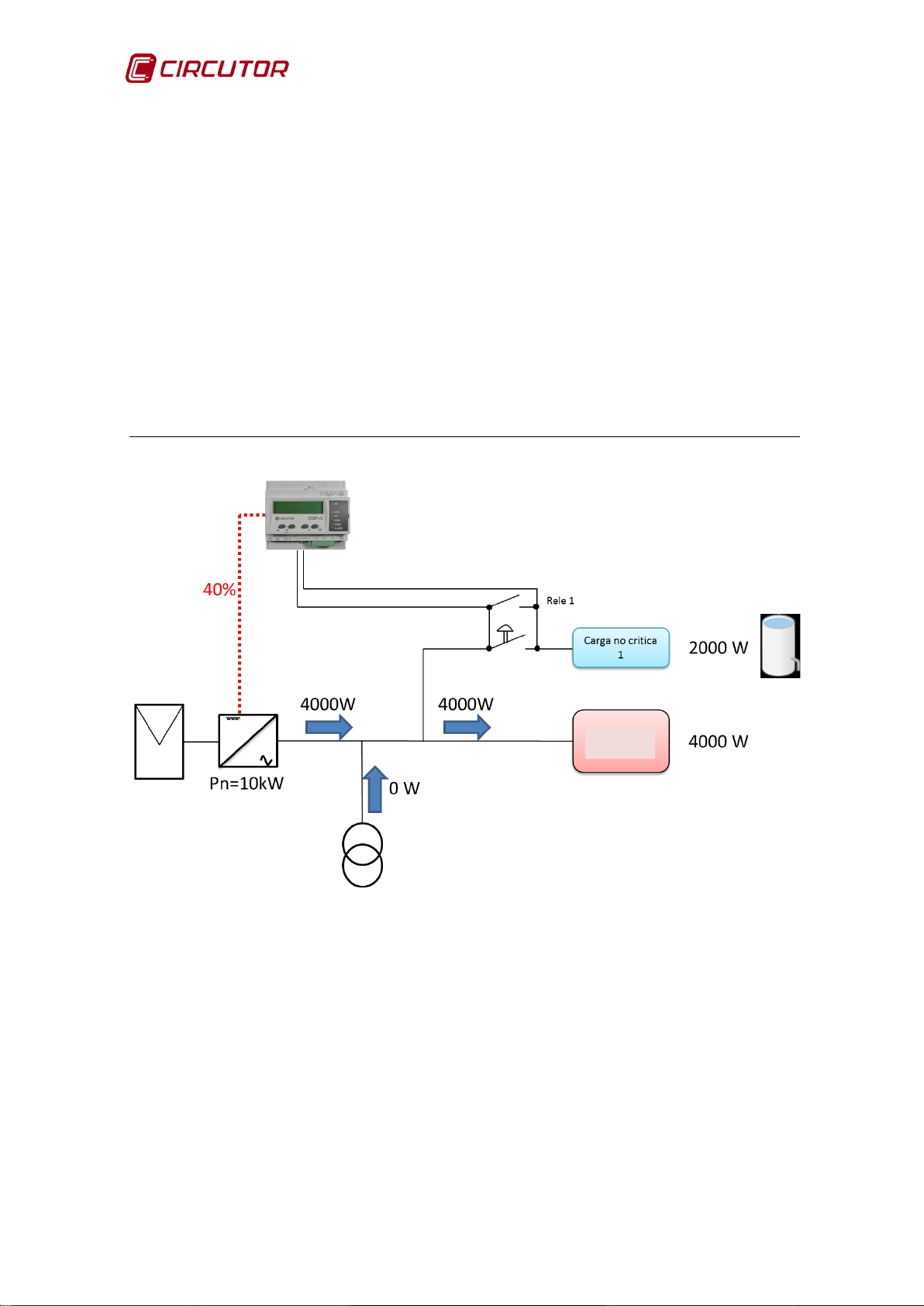

4.3.2. SINGLE-PHASE INSTALLATION WITH 3 LOADS TO BE CONNECTED

We start with a single-phase installation in which we want to use the excess

photovoltaic production to supply 3 non-critical loads:

• Load 1: 2000 W water pump

• Load 2: 2000 W heat pump

• Load 3: 1000 W washing machine

The goal is to activate these loads during times in which there is a production

excess, thus reducing energy costs.

This is the baseline data:

PhaseP. Inverter Consumption Setpoint Current production

L1 10000 W 4000 W 40% 4000 W (40% of the nominal)

Figure 26: Single-phase installation with 3 loads to be connected.

The CDP-G programming is shown in Table 12 :

28 Instruction Manual

Page 29

CDP

VARIABLE

VALUE

Inverter power

10000 W

Number of inverters

1

Phase control

Single-phase

Injection margin

0 %

Load management Mode

Dynamic

Max. modulation value

90 %

Max. grid contribution

50 %

Reconnecting time

5 minutes

Relay 1

Relay 2

Relay 3

Power

2000 W

Power

2000 W

Power

1000 W

Min.

time

2 minutes

Min.

time

2 minutes

Min.

time

90 minutes

Table 12: CDP-G programming (Single-phase installation with 3 loads to connect).

connection

connection

connection

• Max. modulation value = 90%. This means that as long as the ratio be-

tween Pconsumed/Available PV Power is below 90%, the CDP-G will try to

connect the associated loads.

• Max. grid contribution = 50%. This means that as long as the load can op-

erate with less than 50% of the power in the distribution lines, the CDP-G will

keep the loads connected. If it needs more than 50% of the grid power, it will

disconnect the loads connected to the relays.

In this situation, the CDP-G checks its working conditions to connect the first

load:

• Condition 1:

100 .

(

100 = 40%) 40% ≤ 90% this condition is met

• Condition 2:

-If Injection Margin = 0% It checks whether:

Pgrid < 2 x (0.03) x Pconsumed

-If Injection Margin ≠ 0% It checks whether:

Pgrid < 2 x Injection Margin x Pconsumed

0 < 2 x 0.03 x 4000 this condition is met

If the 2 conditions are met, the relay closes and connects

the load. (Figure 27)

Instruction Manual 29

Page 30

CDP

Loads

Figure 27: Single-phase installation with 3 loads to connect (Load 1 Connected).

In this situation the CDP-G maintains the system without adding or removing any

loads for a time equalling the longer of the configured “Reconnection time” and

“Min. disconnection time” variables, in order to achieve system stability (in this

case 5 minutes).

To check if this load must be disconnected, the CDP-G waits for the amount of

time programmed in the “Min. connection time” variable and then checks if the

following condition is met:

• Disconnection condition:

< .

Then, the CDP-G will check whether it can connect the next load. To do so, it

must verify whether the 2 connection conditions are met:

• Condition 1:

(

= 0%) 0% ≤ 50%

this condition is met relay 1 stays connected

(

100 = 60%) 60% ≤ 90% this condition is met

100 .

30 Instruction Manual

Page 31

CDP

Loads

• Condition 2:

-If Injection Margin = 0% It checks whether:

Pgrid < 2 x (0.03) x Pconsumed

-If Injection Margin ≠ 0% It checks whether:

Pgrid < 2 x Injection Margin x Pconsumed

0 < 2 x 0.03 x 6000 this condition is met

If the 2 conditions are met, the relay closes and connects the load.

So, the CDP-G will connect the second load, as shown in Figure 28:

Figure 28: Single-phase installation with 3 loads to connect (Load 1 and 2 Connected).

In this situation the CDP-G maintains the system without adding or removing any

loads for the amount of time configured in the “Reconnection time” variable, in

order to achieve system stability (in this case 5 minutes).

To check if this load must be disconnected, the CDP-G waits for the amount of

time programmed in the “Min. connection time” variable and then checks if the

following condition is met:

Instruction Manual 31

Page 32

CDP

• Disconnection condition:

< .

(

= 0%) 0% ≤ 50%

this condition is met relay 2 stays connected

At this point, the CDP-G will check whether it can connect the third load. To do

so, it must verify whether the connection condition is met:

• Condition 1:

(

100 = 80%) 80% ≤ 90% this condition is met

• Condition 2:

-If Injection Margin = 0% It checks whether:

Pgrid < 2 x (0.03) x Pconsumed

-If Injection Margin ≠ 0% It checks whether:

Pgrid < 2 x Injection Margin x Pconsumed

0 < 2 x 0.03 x 8000 this condition is met

If the 2 conditions are met, the relay closes and connects load number 3.

100 .

(Figure 29)

32 Instruction Manual

Page 33

CDP

Loads

Figure 29: Single-phase installation with 3 loads to connect (Load 1, 2 and 3 Connected).

As shown in Figure 29, we can see that although the inverter is 10 kW the

existing radiation only allows it to produce 9 kW, so to get 10 kW of consumption

it will have to take 1 kW from the grid.

In this situation the CDP-G maintains the system without adding or removing any

loads for the amount of time configured in the “Reconnection time” variable, in

order to achieve system stability (in this case 5 minutes).

• Disconnection condition:

< .

this condition is met relay 3 stays connected

(

= 10%) 10% ≤ 50%

Instruction Manual 33

Page 34

CDP

Reference

name

4.4.- KEY FUNCTIONS

The CDP has four keys so that the user can browse through the different

screens on the unit.

Figure 30: Description of the keys.

Table 13: Description of the key operations.

Format Description FUNCTIONALITY IMPROVEMENTS

Scroll up

Scroll down

Scroll right

OK validation key

Allows you to go back through the

display of the unit's screens

Allows you to go forward through the

display of the unit's screens

Allows you to go forward in the list of

options on the menus.

Allows you to validate the parameter

entries.

DOWN

RIGHT

The reference name will be that used in the document to define the functions of

each key.

The keys must be held down for 1 second.

UP

OK

34 Instruction Manual

Page 35

CDP

Function

Description

Flashing mode indicates that the unit is ON (flashes at a rate of 1 second).

LINK

Connection to the active Ethernet network (fixed value).

ACT

Communication frames are being sent (flashing)

Indicates the communications status of the R2 channel to which the inverters

inverters it has connected and responding.

Indicates the communications status of the R3 channel through which the

CDP communicates with the auxiliary CVM Mini units (flashing).

ALARM

Indicates the grid injection alarm status. (fixed value)

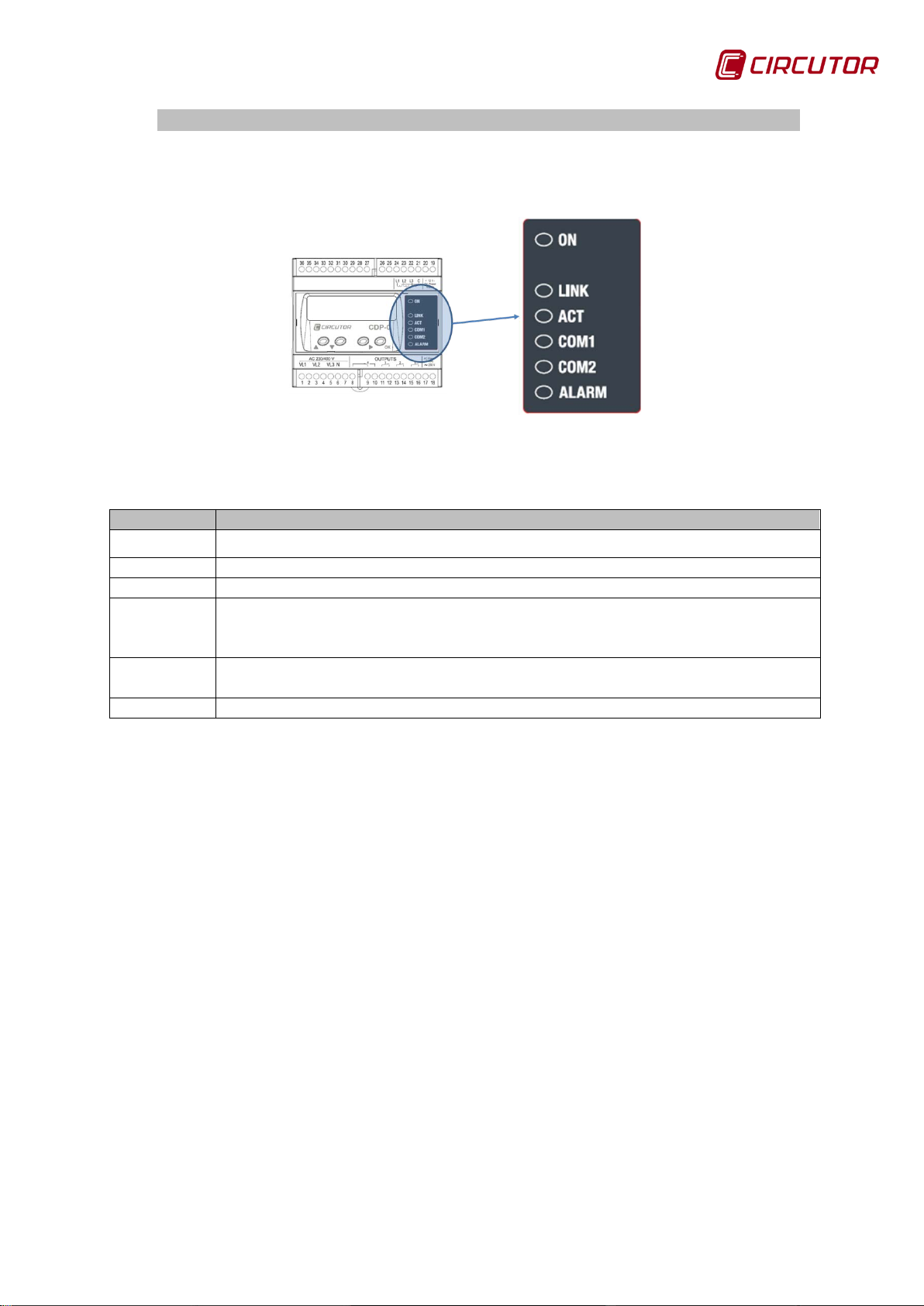

4.5.- LED INDICA TORS

The CDP has six LEDs so that it is easy for the user to identify the operating

status of the unit.

Figure 31: CDP LED indicators.

Table 14: Description of the LED operation.

ON

COM1

COM2

are connected. In 1 second, the unit flashes as many times as the number of

Instruction Manual 35

Page 36

CDP

4.6.- DISPLAY

The CDP includes a 20-character, two-line display which is used as a user

interface.

If the unit is configured to work in single-phase mode, the default screen is

shown in Figure 32.

The regulation percentage and corresponding power are indicated on the line

above; in the example shown in the figure below, the nominal power of the

inverter is 4.0 kW and the CDP is sending an order to inject 15%, corresponding

to 0.6 kW.

Figure 32: Description of the first line of the standby screen.

If the connection has been performed correctly, the three power values should

appear with a positive sign. If any of the values appear with a negative sign, this

means that the cable of the phase in question has been connected the other way

round and should there fore be tur ne d.

The power consumption for each of the three measuring channels is indicated

on the line below.

Figure 33: Description of the second line of the standby screen.

If the unit is configured to work in three-phase mode, the default screen is

shown in Figure 34.

The same information as the single-phase configuration is shown on the first

line.

The total three-phase power is shown on the second line.

36 Instruction Manual

Page 37

CDP

Figure 34: Home screen for the three-phase configuration.

When you pre ss the RIGHT key the menu is displayed with the following options

(Figure 35):

• Measures: Displays the electrical parameters measured by the unit.

• Network: Configuration of the unit's network.

• System: Displays the unit version and the date and time of configur ation.

Figure 35: Management of the main menus.

Press the UP or DOWN key to browse the options.

Press the RIGHT key to enter any of the two options.

Press the OK key to exit this menu.

Instruction Manual 37

Page 38

CDP

5.- DISPLAY AND CONFIGURATION

5.1. MEASURES MENU

The following screen sequence appears when you select the “Measures” option:

1- If the unit is configured in single-phase, the voltage and current for each

of the phases are displayed on this screen, the resolution is set with one decimal

place:

Figure 36: First screen of the measures menu in single-phase mode.

If the unit is configured in the three-phase, mode, the average of the

voltage and current for each of the three phases is displayed in the first

column, the resolution is set with one decimal place:

Figure 37: First screen of the measures menu in three-phase mode.

2- If the unit is configured in single-phase mode, the inductive reactive

power and voltage and three-phase capacitive power are displayed in the first

column, the resolution is set with one decimal place:

Figure 38: Second screen of the measures menu in single-phase mode.

If the unit is configured in three-phase mode, the inductive reactive

power and three-phase capacitive power are shown in the first column,

the resolution is set with one decimal place:

Figure 39: Second screen of the measures menu in three-phase mode.

Note: A negative sign indicates that the direction of the current is inversed.

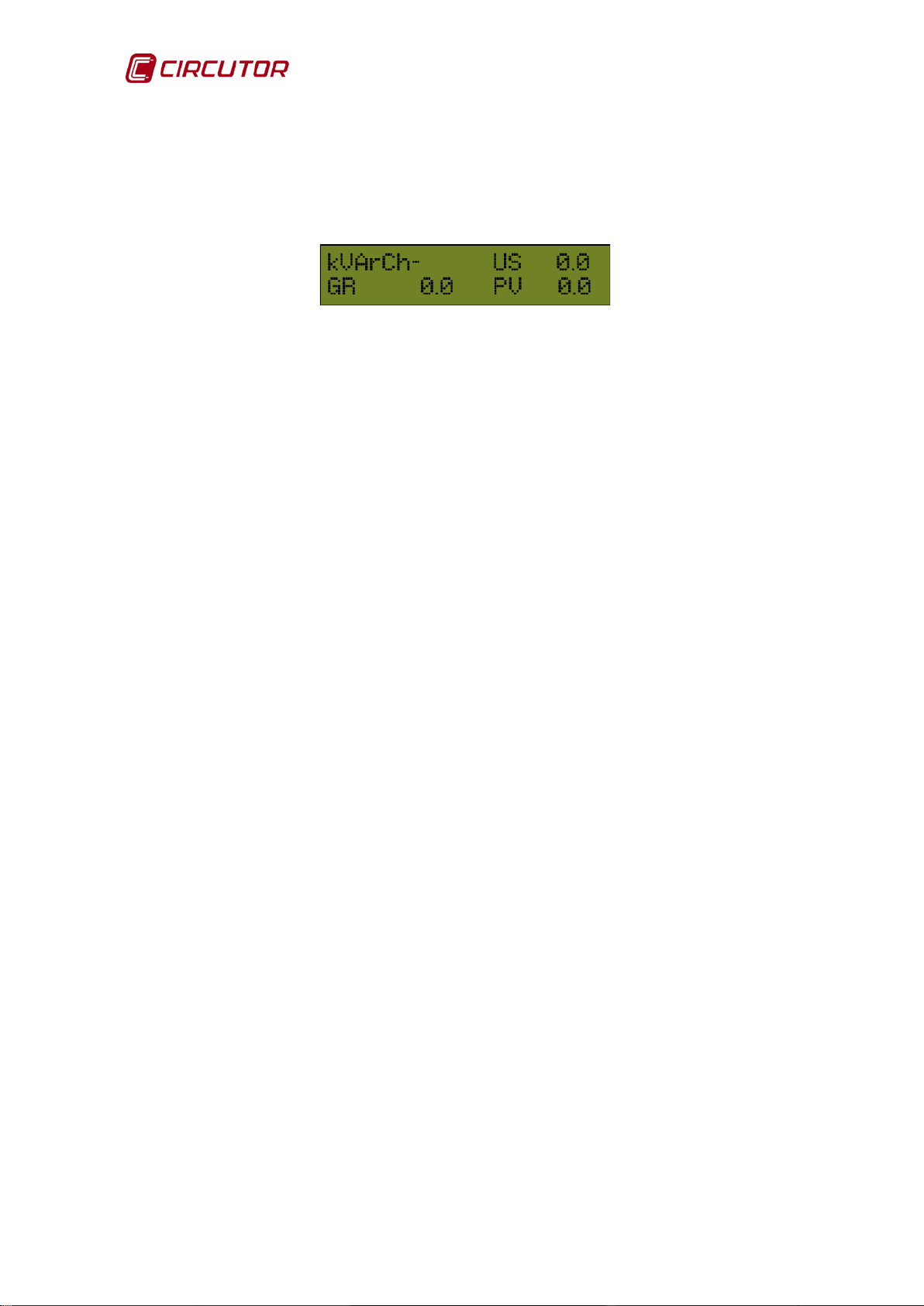

3- Consumed active energy:

US corresponds to the user's energy, GR is the energy from the grid and

PV is that from the inverter.

The units are kWh and the resolution is set with one decimal place:

38 Instruction Manual

Page 39

CDP

Figure 40: Third screen on the measures menu.

4- Inductive reactive energy consumed.

US corresponds to the user's energy, GR is the energy from the grid and

PV is that from the inverter.

The units are kVArh and the resolution is set with one deci mal pl ace :

Figure 41: Fourth screen on the measures menu.

5- Capacitive reactive energy consumed.

US corresponds to the user's energy, GR is the energy from the grid and

PV is that from the inverter.

The units are kVA r h and the resolution is set with one decimal place:

Figure 42: Fifth screen on the measures menu.

6- Active energy generated by each of the three phases.

US corresponds to the user's energy, GR is the energy from the grid and

PV is that from the inverter.

The units are kWh and the resolution is set with one decimal place:

Figure 43: Sixth screen on the measures menu.

7- Inductive reactive energy generated.

US corresponds to the user's energy, GR is the energy from the grid and

PV is that from the inverter.

The units are kVArh and the resolution is set with one decimal place:

Figure 44: Seventh screen on the measures menu.

Instruction Manual 39

Page 40

CDP

8- Capacitive reactive energy generated.

US corresponds to the user's energy, GR is the energy from the grid and

PV is that from the inverter.

The units are kVArh and the resolution is set with one decimal place:

Figure 45: Eighth screen on the measures menu.

From the first screen using the UP and DOWN keys the following sequence

continues until the sequence of the rotating menu is complete and you return to

the first screen.

Press the OK key to exit this menu and return to the previous menu.

Figure 46 shows the screen sequence included in the Measures me nu, for the

single-phase and three-phase configuration.

40 Instruction Manual

Page 41

CDP

Figure 46: Measurement display menu

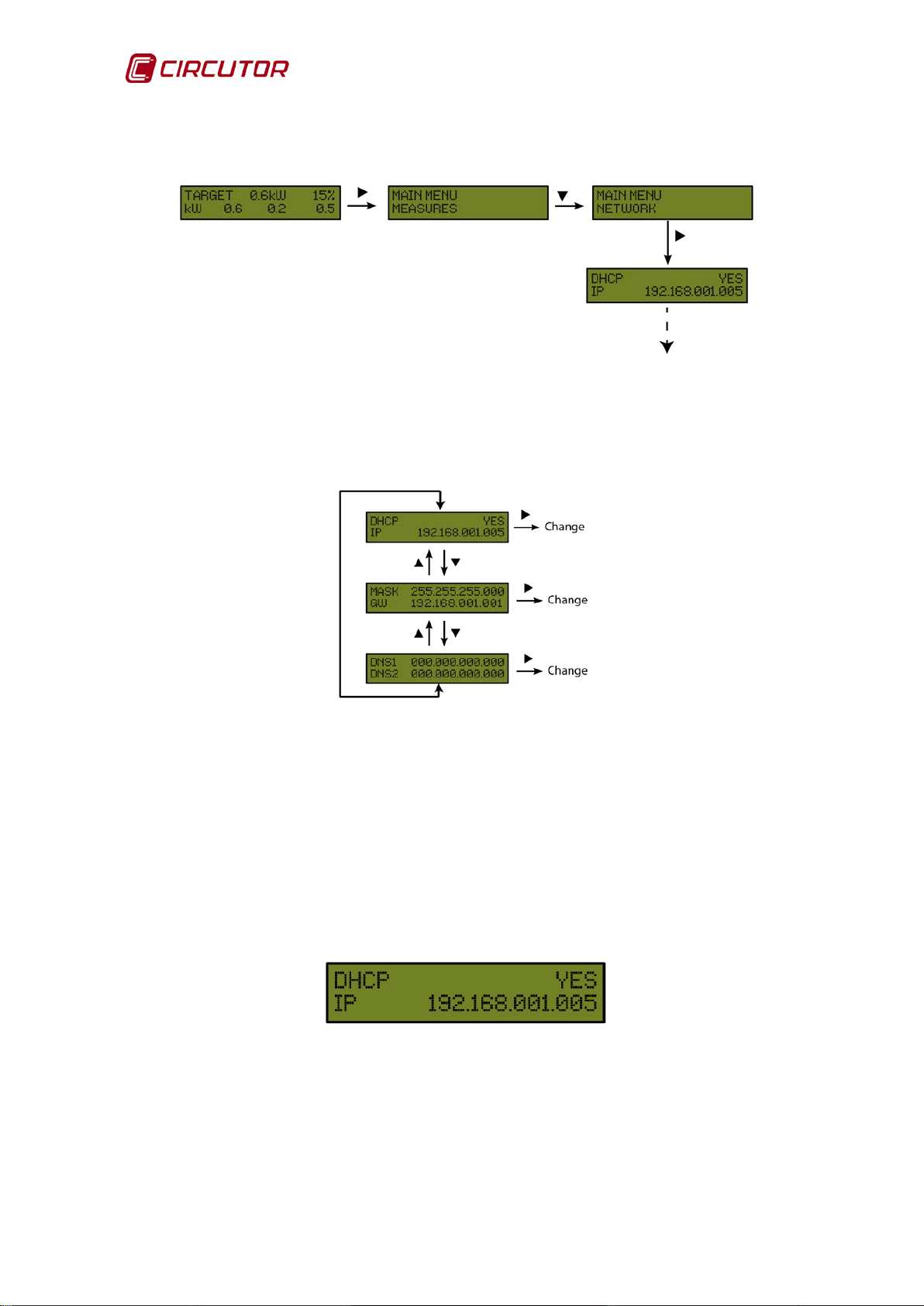

5.2. NETWORK MENU

The CDP unit has self-detecting Ethernet 10/100BaseTX connectivity which

means that, in order to integrate the device into a Local Area Network, it must be

provided with a previous IP addressing configuration.

The user can access the configuration parameters via the display and the

function keys on the front panel of the unit, or through the internal configuration

web site, which is accessible via a conventional Internet browser. (See section

6.1.SETUP WEB SITE)

Instruction Manual 41

Page 42

CDP

The following sequence must be completed to access the Ethernet channel's

setup menu, Figure 47:

Figure 47: Communications setup sequence.

Figure 48 shows the group of screens included in the setup of the Ethernet

communications channel communications.

Figure 48: Communications pa rameters to be configured on the CDP.

5.2.1. DHCP ASSIGNMENT

After entering the setup menu, the unit displays DHCP (Dynamic Host

Configuration Protocol), and by default shows the YES option. To modify the

option shown on the screen, press the RIGHT key and DHCP will b e displayed

intermittently, if you press the UP or DOWN key the NO option will be displayed.

Do this twice and the unit cyclically displays both options until one of them is

validated with the OK key.

Figure 49: First communications setup screen on the CDP.

42 Instruction Manual

Page 43

CDP

5.2.2. DHCP OPTION: YES

The unit will then display the parameters assigned by the DHCP server. The unit

will display the following fields which cannot be edited.

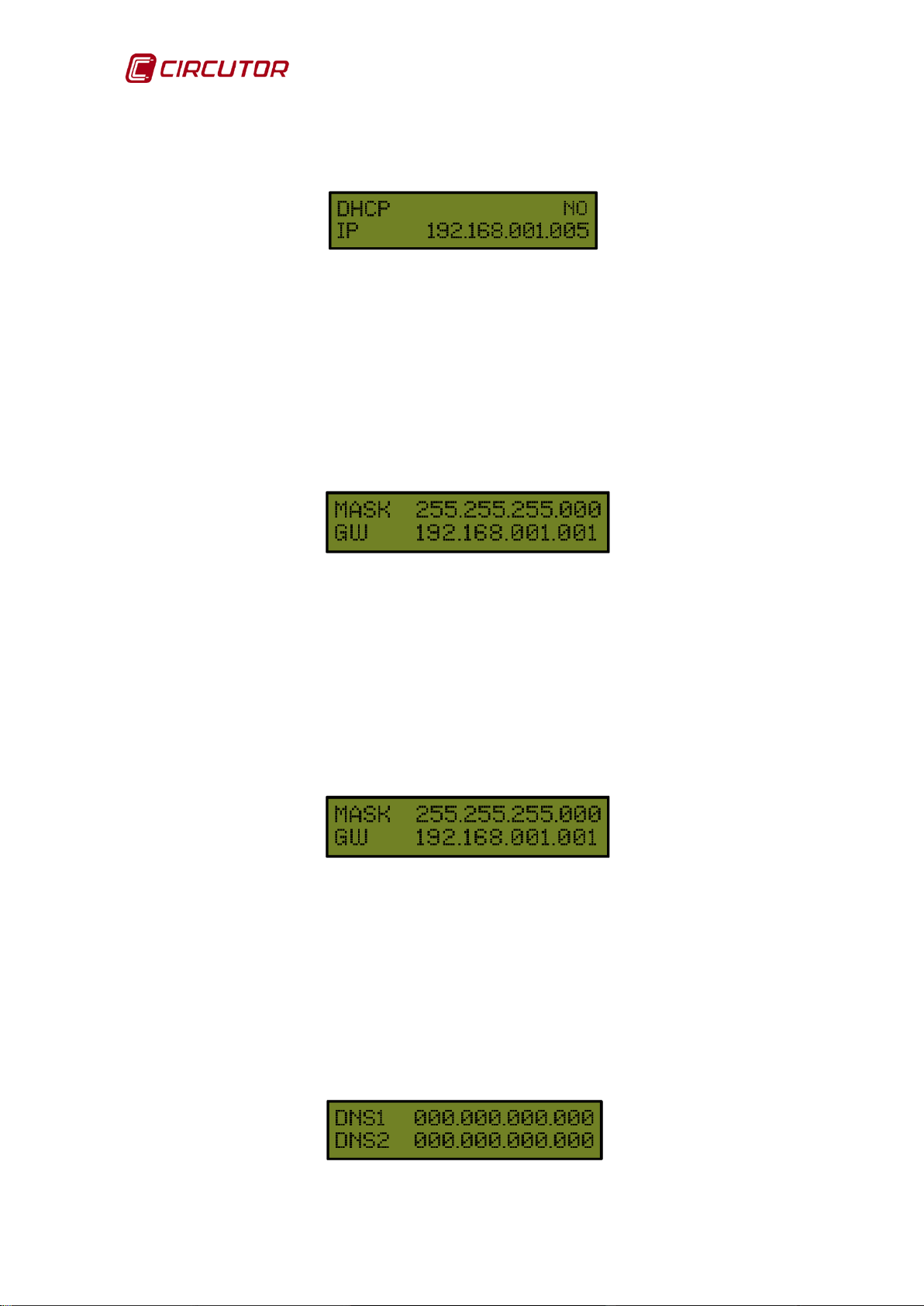

• IP Configuration

The second line shows the IP address than has been dynamically assigned.

Figure 50: First setup screen if DHCP is YES.

• NetMask and Gateway

The netmask is shown on the first line and the Gateway on the second.

Figure 51: Second setup screen if DHCP is YES.

• Primary DNP and Secondary DNS

The preferred DNS server is shown on the first line and the alternative on the

second.

Figure 52: Third setup screen if DHCP is YES.

5.2.3. DHCP OPTION: NO

If the DHCP server is not activated, validate the NO option using the UP and

DOWN keys, moving to the next screen.

Figure 53: First setup screen if DHCP is NO.

Instruction Manual 43

Page 44

CDP

• IP

The user configures an IP address for the CDP unit using the setup optio n.

Figure 54: First setup screen if DHCP is NO.

• NetMask

To configure the NetMask, press the Scroll RIGHT key, activating the edit cursor

on the first digit. Press the UP and DOWN keys to establish the parameters of a

000.000.000.000 type numeric data entry. After establishing the parameters,

press the RIGHT key repeatedly until the edit cursor disappears and validate the

data with the OK key, moving to the next line.

Figure 55: Second setup screen if DHCP is NO.

• Gateway

To configure the Gateway, press the Scroll RIGHT key, activating the edit cursor

on the first digit. Press the UP and DOWN keys to establish the parameters of a

000.000.000.000 type numeric data entry. After establishing the parameters,

press the RIGHT key repeatedly until the edit cursor disappears and validate the

data with the OK key, moving to the next screen.

Figure 56: Second setup screen if DHCP is NO.

• Primary DNS

To conf igu re t he Pr imary DNS pre ss t he RIGHT key, activating the edit cursor on

the first digit. Press the UP and DOWN keys to establish the parameters of a

000.000.000.000 type numeric data entry. After establishing the parameters,

press the RIGHT key repeatedly until the edit cursor disappears and validate the

data with the OK key, moving to the next line.

Figure 57: Third setup screen if DHCP is NO.

44 Instruction Manual

Page 45

CDP

• Secondary DNS

To configure the Secondary DNS server, carry out the same procedure as with

the Primary DNS.

Figure 58: Third setup screen if DHCP is NO.

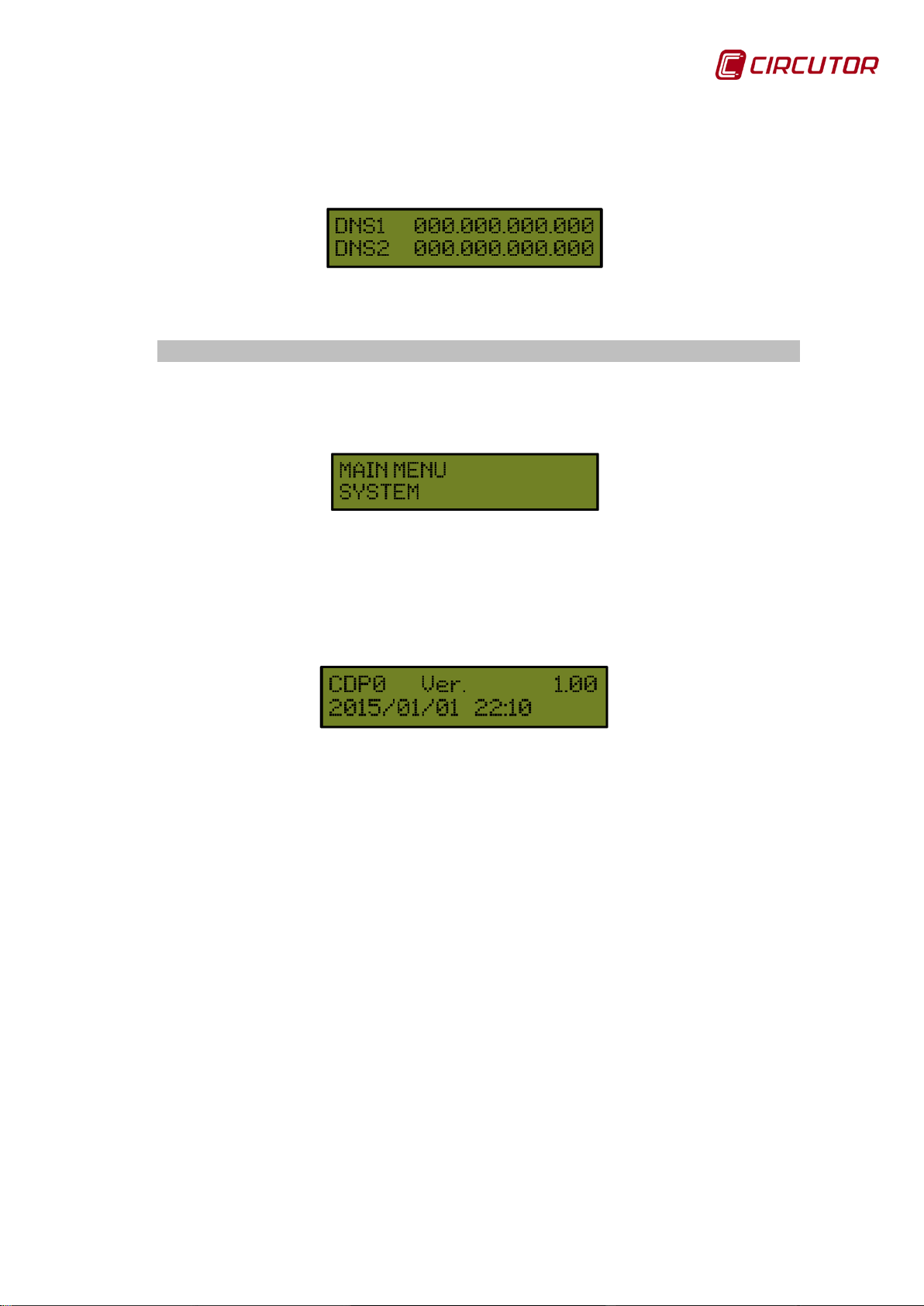

5.3. SYSTEM MENU

The SYSTEM option appears on the CDP's main menu and displays the

firmware version of the unit, allowing you to adjust the time.

Figure 59: Date and time setup me n u .

The firmware version of the unit is displayed on the first line.

The second line shows the date and time, if you press the RIGHT key the digits

will be displayed intermittently. Using the UP and DOWN, keys you can modify

any date and year value and the changes can be saved by pressing the OK key.

Figure 60: Date and time setup me n u .

Note: If the CDP is used as a data logger, check that the date and time are

correct.

Instruction Manual 45

Page 46

CDP

Default

value

Inverter power

W

1

Number of inverters

-

1

Work mode configuration

-

Single-phase

Activate compensation

-

0

No injection threshold

%

3

Permitted power to be injected

%

0

Activate the management of non-critical loa ds

-

disabled

Maximum modulation value

%

50

Relay connection order

-

Priority

Maximum grid contribution value

%

25

Minimum reconnection time

Minutes

5

Power to be consumed by eac h of the l oads connected

to the relays

Minimum time that the load must stay connected

Minutes

15

Activate reverse current relay

-

1

Grid injection validation time

Seconds

0

Reconnection time

Seconds

0

Maximum number of reconnections

-

0

Reconnection period

Seconds

0

Time between datalogger logs

Minutes

15

Activate external unit to measure the user's current

-

0

Transformation ratio for the current of L1 (Channel for

measuring the user's current in single-phase mode)

Peripheral number address

(External unit activated)

Transformation ratio for th e current of L2 (Channel for

measuring the grid's current in single-phase mode)

Peripheral number address

-

1

Activate external unit to measure the inverter's current

-

0

Transformation ratio for th e current of L3 (Channel for

measuring the inverter's current in single-phase mode)

Peripheral number address (External unit activated)

-

2

Communication speed with the grid ana lyzers.

Bauds

19200

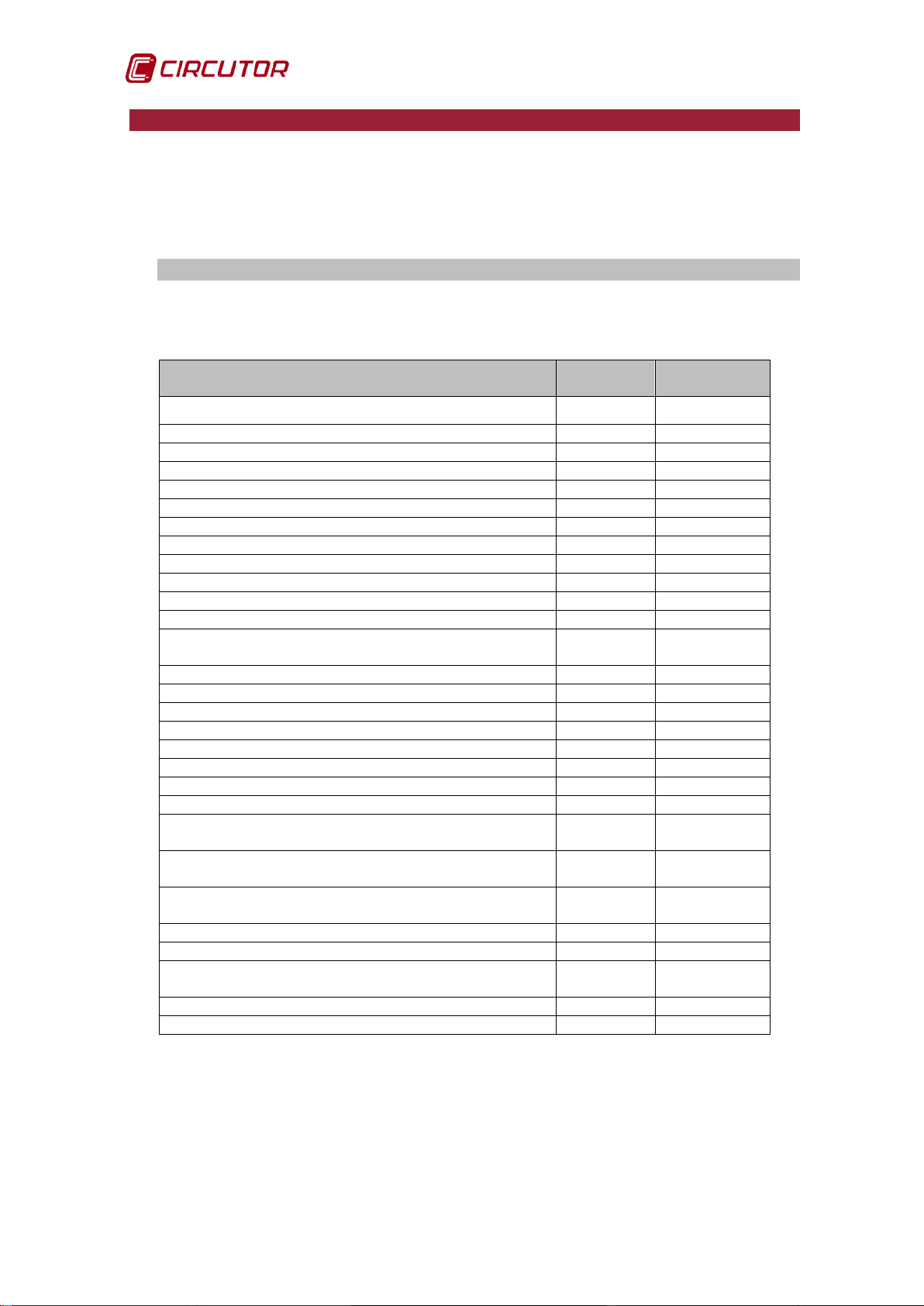

6.- COMMUNICATIONS

The unit has two web sites:

Configuration web site.

Display web site.

6.1. CONFIGURATION WEB SITE

The CDP can be used to configure the parameters of the Table 15, via Web.

Table 15: Configuration parameters.

Description Units

Inverter type - Fronius

W -

A/250 mA 1

- -

A/250 mA 1

A/250 mA 1

46 Instruction Manual

Page 47

CDP

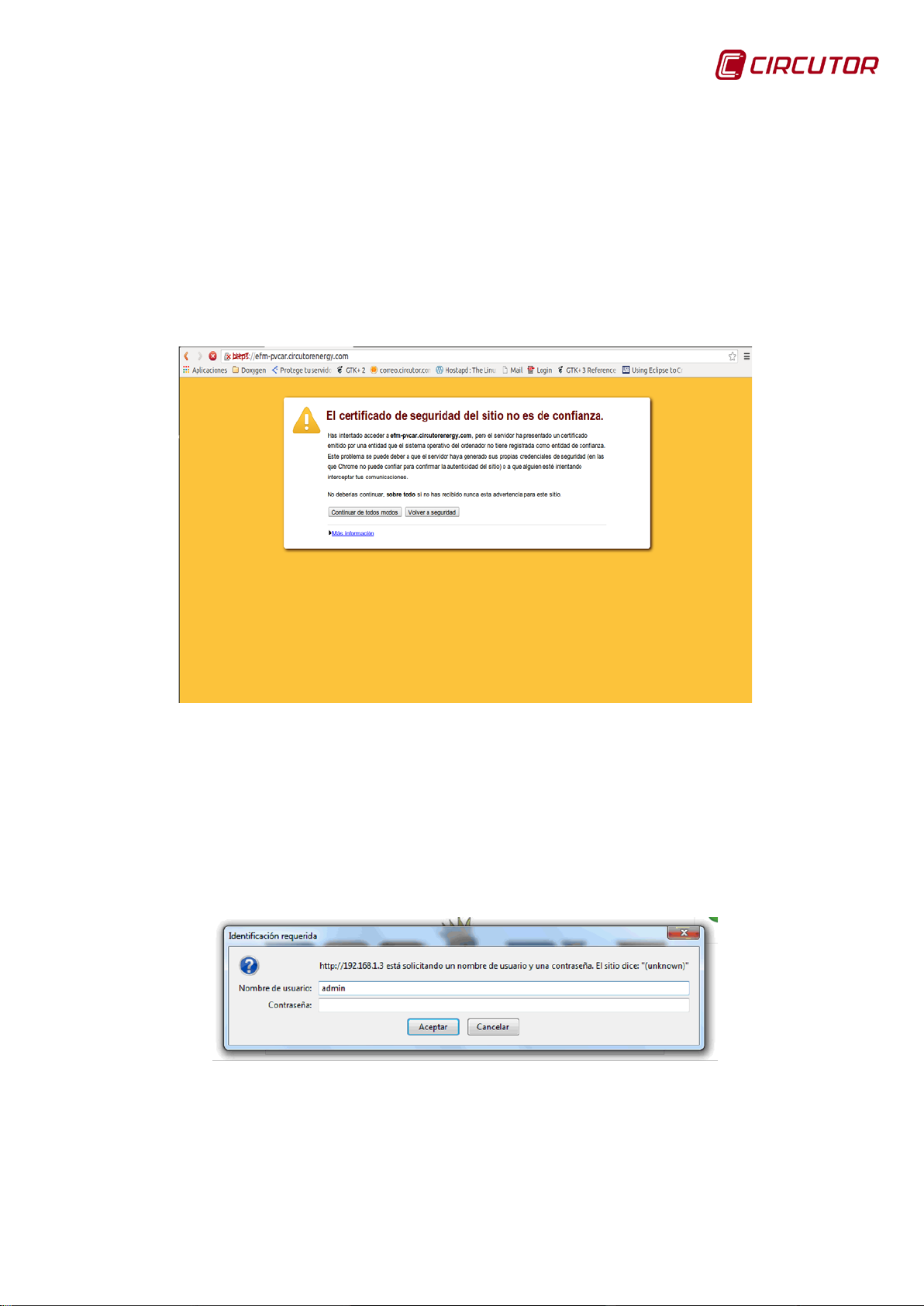

You can enter the unit web site from any browser using the IP address.

https://xxx.xxx.xxx.xxx/setup/index.html

Where xxx.xxx.xxx.xxx is the IP address assigned by the user.

Note: Use Google Chrome.

Note: When you access the CDP web site for the first time, you will have to

accept the security certificate so that you can use secure connections.

Figure 61: Acceptance alert for the SSL secure connection certificate.

Access via password

If a password has been parameterised, the unit requests these access

parameters when trying to access via the web site in the following pop-up screen

(username: admin):

Figure 62: Screen for enterin g u sername and password

Instruction Manual 47

Page 48

CDP

6.1.1. CDP Setup

The unit information is displayed in the upper part of the web site, Figure 63.

Figure 63: Setup web site: unit information.

• Firmware upgrade

It is possible to upgrade the firmware of the unit with the Upgrade button. The

upgrade file must be downloaded from the Circutor web site

( www.circutor.es).

When press ing the Upgrade button, the s creen in Figure 64 appears, where

you will need to find the upgrade file that you have downloaded onto the

computer and press the Upgr ade button.

Figure 64: Firmware upgrade screen.

During the upgrade process, you will see the screen in Figure 65.

Figure 65: Screen during the upgrade process.

.

48 Instruction Manual

Page 49

CDP

Note: If the CDP is upgraded with the wrong firmware version for the product,

a version error message will appear on the display as shown in Figure 66.

Figura 66: Version error screen.

• Date

The date on which the web site is updated is displayed in this parameter.

It is also possible to change the date and time of the unit, entering the

required value and pressing the Update button.

• Config File

When pres sing the Download button, the configuration file is downloaded in

.txt format.

• Data Logger

It is possible to reset the historical data stored in the data logger by pressing

the Reset button.

Instruction Manual 49

Page 50

CDP

6.1.2. Power control & Data logger

In this part, Figure 67, five groups of parameters are displayed:

Those related to the model and number of inverters: Inverter.

Those related to inverter control: Control.

Those related to the operation of the reverse current control relay:

Reverse current relay.

Those related to managing non-critical loads: Auxiliary load relays.

That related to the data log generated: Data logger.

Figure 67: Setup web site: Power control & Data logger.

6.1.2.1. Inverter

In this section you can select:

• Inverter type: Inverter model to be used in the installation. All inverters

connected to the CDP must be of the same type.

If you select the option Generic 4 inputs, the parameter Mode appears on the

screen with two possible options (Figure 68):

Discrete: this option allows 4 regulation stages: 0%, 30%, 60% and 100%.

50 Instruction Manual

Page 51

CDP

When the Binary option is activated, relay number 4 stops functioning

as a protection against reverse current and starts functioning like the

rest of the relays.

Binary: this option allows 16 regulation stages between 0% and 100% of the

inverter's nominal power. The relay combinations are done using binary logic.

Figure 68: Setup web site: detail of the inverter section.

If the SMA option is selected, the Inverter X S/N, Figure 69 parameter will

appear on the screen, where you will need to enter the serial numbers of

each of the inverters.

It is important to enter the serial number of each inverter in the phase in

which it was installed, so that the device can detect it.

Figure 69: Setup web site: detail of th e Inverter section (SMA).

• Inverter power: Total power to be controlled by the CDP. (in the event of two

2000 W inverters, enter 4000 W).

The power limit is 1 MW.

• Number of inverters: number of inverters to control.

6.1.2.2. Control

Inverter control param eter s :

• Phase: the architecture of the inverter grid connection must be selected. The

available options are:

Single phase: single-phase installation with single-phase inverters.

Three phase: three-phase installation with three-phase inverters.

Three single phases: three-phase installation with three single-phase

inverters .

Instruction Manual 51

Page 52

CDP

If we select the Three phase option the parameter Three phases mode will

appear on the screen, allowing us to select the control mode. The options

are:

Min. power phase, control by minimum power: when this option is selected

the CDP sends a production setpoint based on the phase of the minimum

consumption.

Max. power phase, control by maximum power: the CDP sends a production

setpoint based on the phase of the maximum consumption.

Selected phase, control by set phase: this option allows the user to set a

phase such that the CDP will always send the production setpoint to the

inverter based on that phase's consumption. When this option is selected a

dropdown menu appears on the screen allowing you to select the phase

(Figure 70)

Average power, control by average power: this option takes an average of the

consumption of the three phases and sends a production setpoint to the

inverter with the value of the average power.

Figure 70: Setup web site: detail of the inverter section.

• Allow compensation (from 2 inverters): This function allows you to manage

several inverters independently to obtain the maximum generation fr om each

of them.

Example: For example, an installation with two 5 kW inverters connected to

2 strings of independent panels on a gabled roof in the east-west direction

and consumption of 4 k W.

If in the morning, inverter 1 can generate 5 kW but inverter 2 can only generate 1 kW, because the panels are not receiving sufficient radiation, rather

than requesting 2 kW from each inverter, the CDP will request the maximum

power from the inverter that generates the least (1 kW) and the remainder

will be requested from the inverter which generates more (3 kW), to try to

reach the required consumption.

To do this, it will gradually increase the regulation percentage of both inverters at the same time until both generate a total power equivalent to that required by the load.

Note: In three-phase systems, the connection of a CVM Mini is mandatory to

measure the power consumed/delivered to the mains.

52 Instruction Manual

Page 53

CDP

Digital input

Default value

1

0

2

30

3

60

4

100

• Enable remote control: on activating this option, the options injection mar-

gin and allowed injection are deactivated.

This option facilitates the remote control of the setpoint value, through the

unit's digital inputs.

The value of the digital input selected is a percentage that it added to the

fixed setpoint value.

By default, the value of the digital inputs are:

Table 16: Default values of the digital inputs.

Example: For a consumption of 600 W and a 4kW inverter

Under these conditions the CDP will calculate a setpoi nt of 15%.

No input activated: the CDP maintains the calculated setpoint.

Input 1 activated: the CDP maintains the calculated setpoint.

Input 2 activated: the CDP adds 30% to the calculated setpoint (the new set-

point will be 45%).

Input 3 activated: the CDP adds 60% to the calculated setpoint (the new set-

point will be 75%).

Input 4 activated: the CDP sends the 100% setpoint to the inverter. (100%

will be the maximum setpoint).

If several digital inputs are activated, the CDP will always take the highest as

a reference.

• Injection margin: Minimum contribution from the grid as a percentage of the

consumed power. Default value: 3%.

Example: if consumption is 3 kW, and the injection margin is 10%, the CDP

will try to take 300 W from the grid and will therefore send the inverter a setpoint so that it will provide 2700 W.

• Allowed injection: Percentage of injection in excess of the consumed

power.

This value can be positive or negative with respect to the photovoltaic power.

The negative values are used for hybrid networks, renewable and nonrenewable networks (UPS, generator set, grid, etc.), where it is important that

the non-renewable network is not permanently connecting and disconnecting.

A negative Allowed injection forces the non-renewable energy source to

constantly supply a residual percentage of the consumption.

Example: For example, an installation with one 5 kW inverter and a 100 kW

generator set.

Consumption is 4 kW and one of the loads needs to be permanently supplied.

Instruction Manual 53

Page 54

CDP

In this case, the variable Inverter power will be programmed to 5000 W and

the variable Allowed injection to a value of -1%. Therefore, the generator

set will always be connected, supplying 50 W.

6.1.2.3. Inverse current relay

Parameters for the inverse current control relay (see 4.1.2. OPERATION OF THE

GRID INJECTION PROTECTION RELAY):

• Enable inverse current relay: activates the inverse current relay protection.

If the unit measures a negative power value in the grid, it desactivates the

inverse current relay (relay no. 4, NO terminals 9-10) to disconnect the

inverter.

This relay acts as redundant protection against a possible grid injection.

The relay has 3 terminals and can be NO or NC, depending on how it is

connected.

In three-phase mode it is essential to install a CVM Mini to measure the grid.

• Stop time: time during which the grid injection condition must remain active

before activating the inverse current relay (seconds).

• Reconnection time: time the unit waits before deactivating relay no. 4

(seconds) when it stops measuring the inverse current.

• Max. Disconnections: number of disconnections the CDP can perform via

the inverse current before it is definitively locked.

• Disconnect. Timeout: once the maximum number of reconnections has

been reached, this is the time taken for the unit to secure the inverse current

relay. This value must be equal to or higher than:

Disconnect. Timeout > = ( Stop time+ Reconnection time) x (Max.Disconnections).

6.1.2.4. Auxiliary load relays

(see 4.1.3. MANAGEMENT OF NON-CRITICAL LOADS (CDP-G Model))

• Load Management Mode: allows you to select if you want to manage non-

critical loads:

Disabled : It does not manage non-critical loads.

Manual: It manages non-critical loads manual ly.

Dynamic : It manages non-critical loads dynamically.

If you select the Manual option, the 3 relays appear on the screen (Figure 71):

54 Instruction Manual

Page 55

CDP

Figure 71: Setup web site: Auxiliary load relays (Manual).

You can manually activate each relay by pressing the corresponding button for

each one.

If you select dynamic management of the loads (Figure 72), you have to program

the following parameters:

Figure 72: Setup web site: Auxiliary load relays (Dynamic).

• Max. modulation value: In this section you enter the maximum modulation

value and can add dynamic loads to the system below.

• Connection Order: Select how you are going to connect the relays: By pri-

ority or rotating

• 1st/2nd/3rd Priority: If you have selected priority connection, you will then

select the priority for each of the relays.

• Max. grid contribution: In this section you enter the value for maximum grid

contribution, which is the minimum value for deactivating loads.

• Reconnecting time: Minimum time to allow system stabilisation between:

- the activation of two loads.

- the deactivation of two loads.

- the deactivation of the last load and the activation of a new one.

Instruction Manual 55

Page 56

CDP

• Relay 1, Relay 2, Relay 3: Configuration of the relays.

- Power : Power to be consumed by the load. If it is zero, the load is

considered to be deactivated.

- Min. connection time: Minimum time that a load must stay connected

before it can be deactivated, if required.

6.1.2.5. Data logger

(see 6.2.1. CDP AS A DATA LOGGER)

• Time between logs: time to record logs in the Data Logger: 1, 5, 10, 15

or 60 minutes.

6.1.3. Analy zers setup

It is also possible to configure the communications between the CDP and the

CVM Mini or CVM Net power analyzers (Figure 73) on the web site.

Figure 73: Setup web site: Analyzers setup.

6.1.3.1. Load analyzer

• Enable external analyzer: facilitates the use of an external analyzer rather

than the CDP as a measuring unit.

• Primary current: primary value of the load analyzer of the current

transformer.

• Device number: Peripheral number of the external analyzer.

(Only activated when the “Enable external analyzer” option is activated).

6.1.3.2. Grid analy zer

• Primary current: primary value of the grid analyzer of the current

transformer.

• Device number: peripheral number of the CVM power analyzer installed to

measure the consumption of the grid.

56 Instruction Manual

Page 57

CDP

6.1.3.3. PV analy zer

(1)

• Enable external analyzer: facilitates the use of an external analyzer rather

than the CDP as a measuring unit to produce photovoltaic energy.

(Only in three-phase installations).

• Primary current: primary value of the PV analyzer of the current

transformer.

• Device number: Peripheral number of the external analyzer.

(Only activated when the “Enable external analyzer” option is activated).

(1)

The CDP automatically calculates the values of the photovoltaic production

using the consumption measurements (Load analyzer) and the grid (Grid

analyzer).

Therefore, enabling this option is only of interest in installations which already

have a CVM power analyzer installed, which is not communicating with any

system (software or automaton) and the user wants the CDP to read the values

measured by this analyzer.

6.1.3.4. Communications

This section can be used to configure the transmission speed of the RS-485 bus

(Baudrate).

6.1.4. Network & Security Setup (see 5.2.1. DHCP ASSIGNMENT)

6.1.4.1. Network

To assign the fixed IP address, enter the MAC address shown on the side label

attached to the unit, the format of which is 00:26:45:XX:XX:XX.

Enter the IP address that must be configured in the Address f ield; do the same

with the Netmask a nd the Gateway if necessary.

6.1.4.2. Security

This section allows you to enter or change a password to access the setup

menu. When this password is activated, the web browser will allow access to

monitoring, but the access password will be requested when a user wants to

enter the setup:

Instruction Manual 57

Page 58

CDP

Figure 74: Setup web site: Network & Security Setup.

6.1.5. Save setup, Load default setup and Reset CDP

There are 3 buttons at the bottom of the web sit e, Figure 75.

Figure 75: Setup web site: Save setup, Load default setup, Reset CDP.

58 Instruction Manual

Page 59

CDP

When all the changes have been made, select the SAVE SETUP option at the

bottom of the web site and the configuration will be saved in the CDP.

When selecting this button, the unit loads the default values.

When selecting this button, the CDP is reset.

Instruction Manual 59

Page 60

CDP

6.2. DISPLAY WEB SITE

The unit has a web site that can display the energy generated, the energy

consumed and the energy injected into the grid. Moreover, in the upper section,

the regulation percentage and the corresponding power with respect to the

inverter nominal power are displayed.

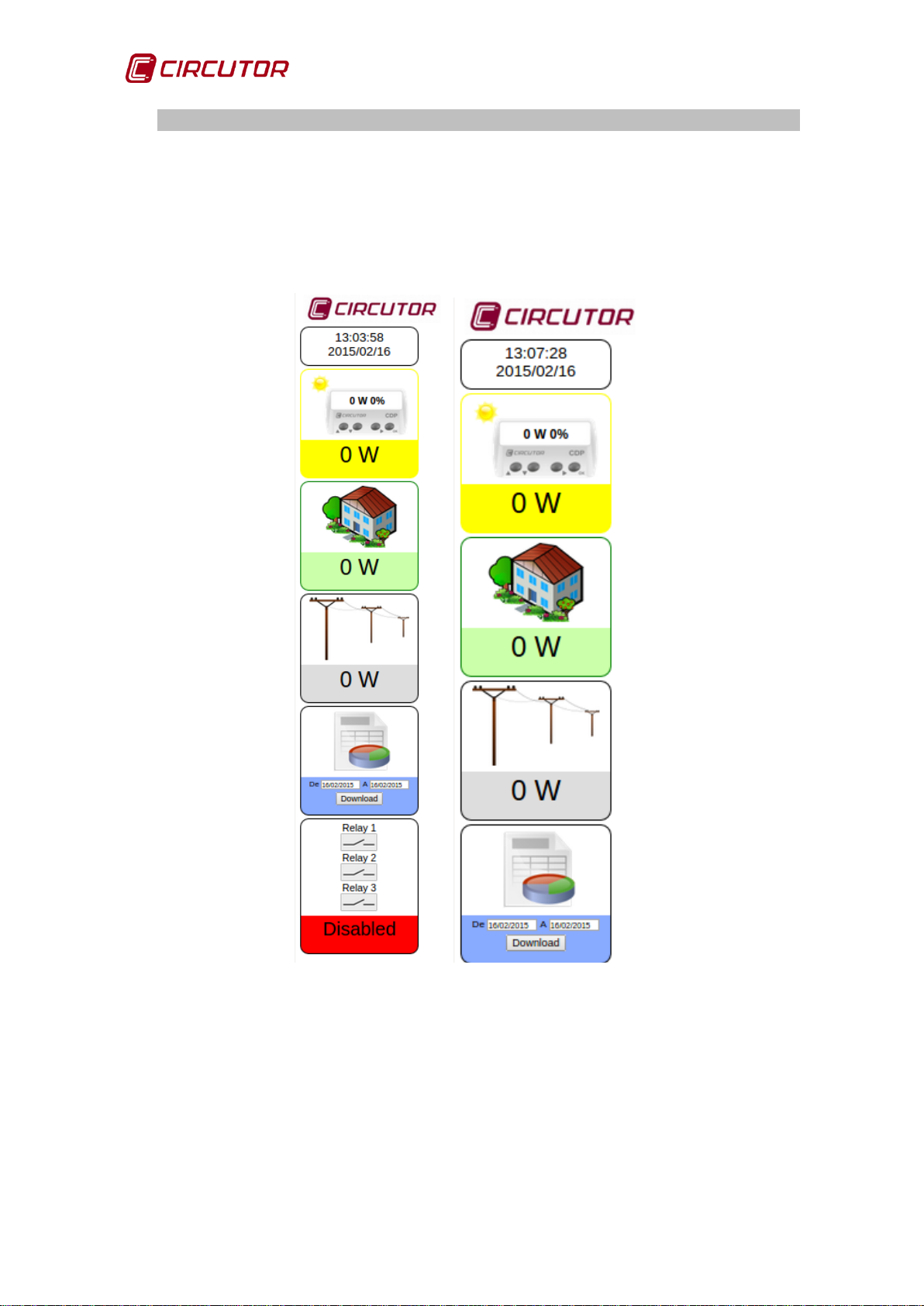

CDP-G CDP-0

Figure 76: Information that appears on the CDP web site.

60 Instruction Manual

Page 61

CDP

6.2.1. CDP AS A DATA LOGGER

This function allows you to install only the CDP in a first phase, without the

inverters and solar panels, so that you can regularly analyse the power

consumed and the energy accumulated, in order to analyse the performance of

the installation and thus design the future self-consumption installation.

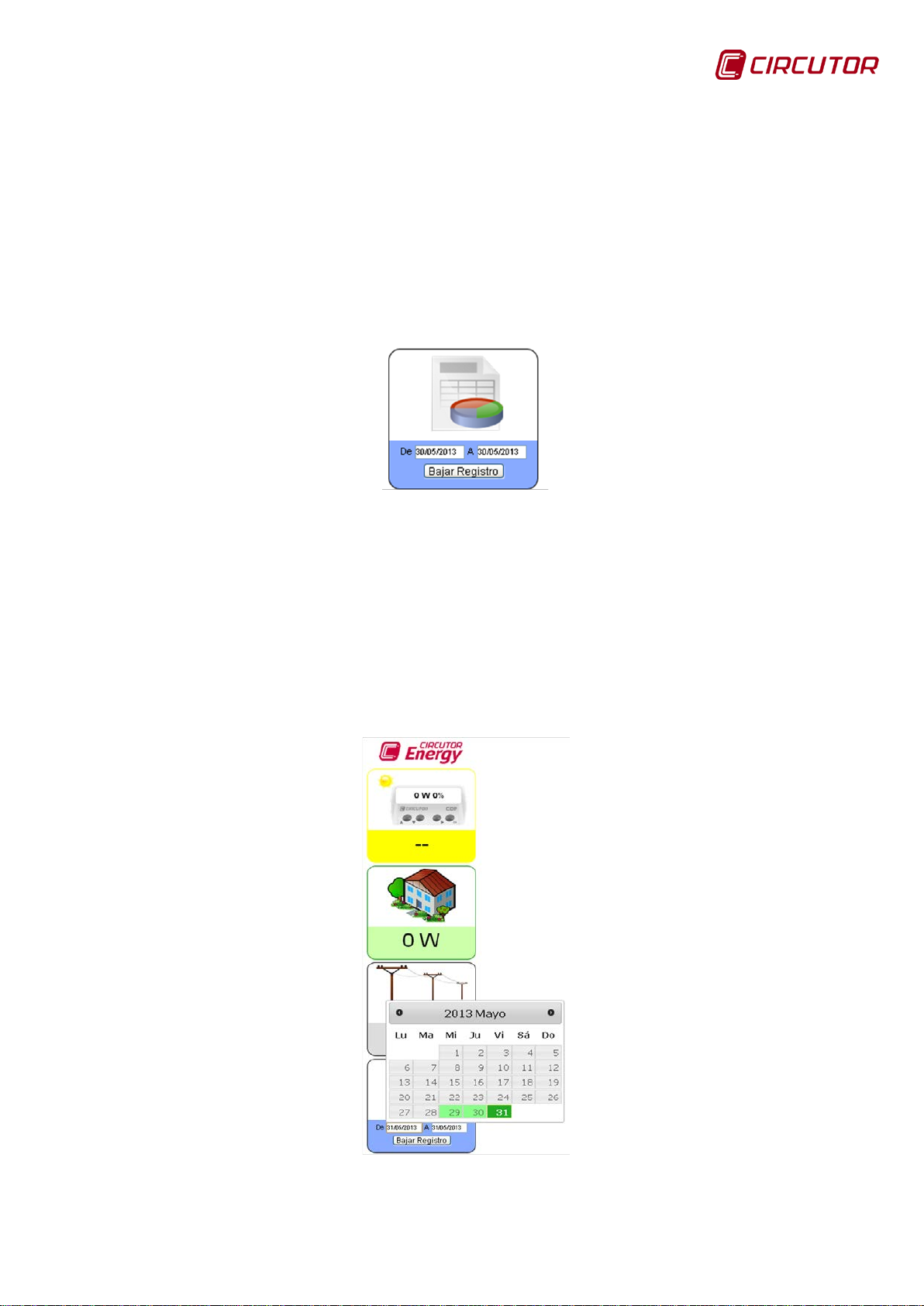

The data is downloaded by accessing the CDP web site. To download the data,

the user must select the days between which they want to download the file with

the data log.

Figure 77: Selecting the download period.

From, Start date for the download period. The download will start at

00:00.

To, End date for the download period. The download will end at 23:59.

On selecting the start or end date a calendar appears which allows you to select

the download period, Figure 78.

The days marked in green are days with a corresponding log.

Figure 78: Introducing the download start and end date.

Instruction Manual 61

Page 62

CDP

Once the start and end date are selected, press the “Download log” key and a

file with the name cdp.csv will be downloaded to the path configured in the web

browser.

The file is downloaded in CSV format and can be opened in Microsoft Excel.

CSV files ( comma-separated values) are a simple file format to represent data

in the form of a table, in which the columns are separated by commas (or a

semicolon in countries which use the comma as the decimal separator: Spain,

France, Italy, etc.) and rows are separated by line feeds.

The file size is 100 MBytes allowing users to save approximately 5200 days in

total. The memory is of the rotating type; when it is full the oldest value is

replaced with the newest one. The size of each log is approximately 200 bytes.

If the time is changed and delayed, the existing log is opened as well as the new

one.

The downloaded file is given the name cdp.csv. If another file is downloaded to

a directory which already contains a file, a new file is generated with the name

cdp (1).csv. The number in brackets increases with the number of successive

downloads in the same directory.

Figure 79: Example of download directory for CDP files.

The files are saved in the download directory selected in the browser.

Figure 80 shows the steps to be performed to configure the download in the

GOOGLE CHROME browser:

1. Select the browser customise icon.

2. Once the setup menu is open, select the "Settings" option.

3. In the setup menu, under the "show advanced settings" option, you can

select the folder in which you would like downloaded files to be saved.

62 Instruction Manual

Page 63

CDP

Figure 80: Selecting the download directory.

Figure 81: Selecting the download directory in Google Chrome.

The CDP can act as a Data Logger and record the electrical parameters that it

measures every 1, 5, 10 or 15 minutes.

If the CDP is configured to work in three-phase mode and the information from

the external CVM Minis is not available, “nan” appears in the corresponding

column.

Instruction Manual 63

Page 64

CDP

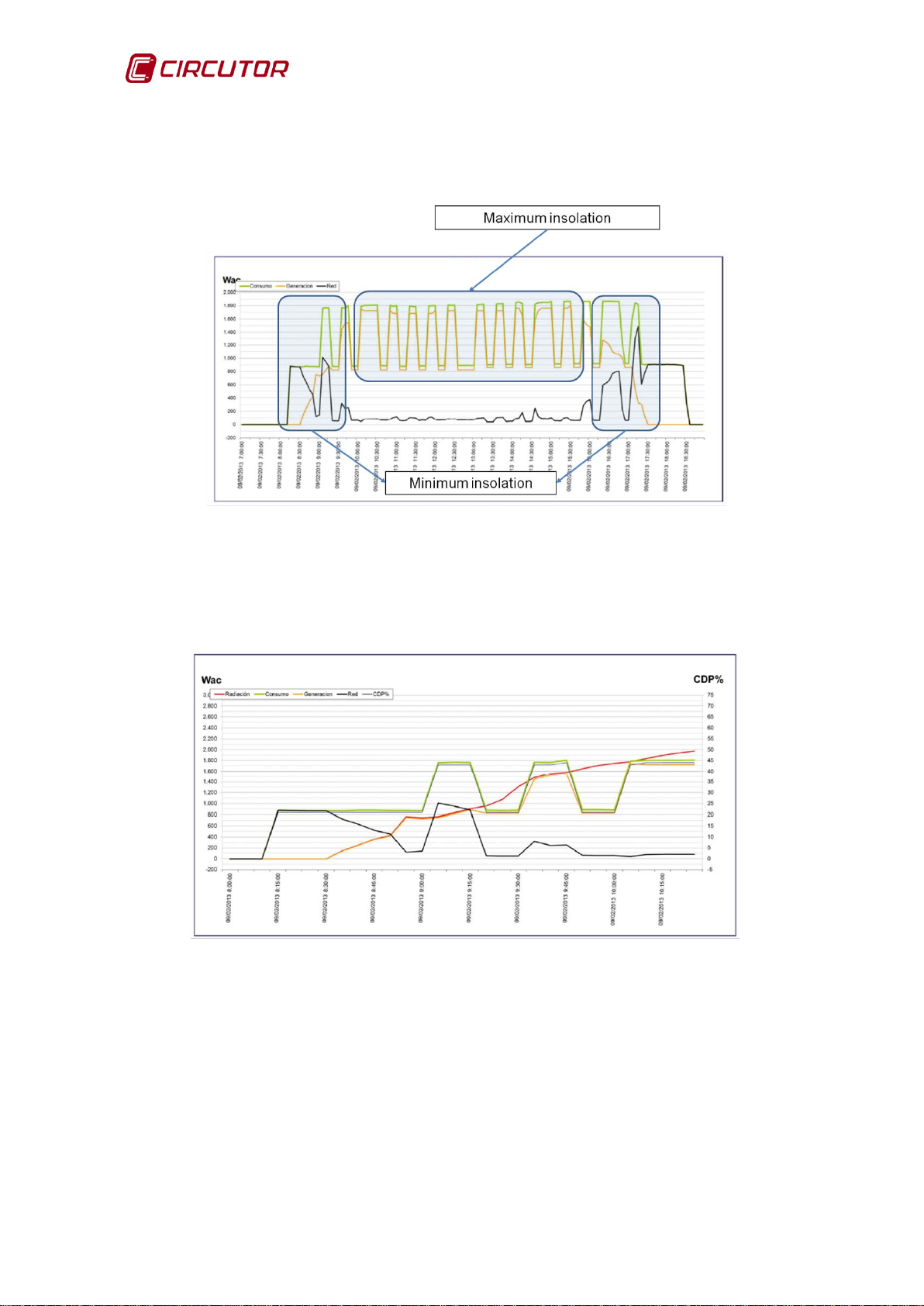

Figure 82 shows that during periods in which insolation is minimum, the user's

consumption is taken from the grid, however, it is the inverter that supplies

energy during periods with maximum insolation.

Figure 82: Graph showing the operation of the CDP based on insolation.

Figure 83 shows the above in more detail: as insolation increases (the red

curve), grid consumption (black line) decreases and the energy generated by the

inverter increases.

Figure 83: Detail of the CDP operation.

When the CDP is configured to work in three-phase mode and there is a

problem with the external CVM Minis or these have not been connected, dashes

appear in the corresponding power indication on the web site.

64 Instruction Manual

Page 65

CDP

Column

Name

(2)

Units

Resolution

Description

DD/MM/YY

HH:MM

Photovoltaic power

produced in L1

Photovoltaic power

produced in L2

Photovoltaic power

produced in L3

Power consumed by

phase 1 load

Power consumed by

phase 2 load

Power consumed by

phase 3 load

GRID

W L1

GRID

W L2

GRID

W L3

Figure 84: In the three-phase configuration there is no communication with the external

CVM Min i

The following table shows the fields recorded in the CDP file.

Table 17: Description of the columns in the CDP file.

1 Date and time

2

3

4

5

6

PV W L1

PV W L2

PV W L3

LOAD W L1

LOAD W L2

W 0.1 W

W 0.1 W

W 0.1 W

W 0.1 W

W 0.1 W

Minute Log date

7

8

9

10

Instruction Manual 65

LOAD W L3

CONSUMPTION

CONSUMPTION

CONSUMPTION

W 0.1 W

W 0.1 W

W 0.1 W

W 0.1 W

Power consumed by

the phase 1 grid.

Power consumed by

the phase 2 grid.

Power consumed by

the phase 3 grid.

Page 66

CDP

Column

Name

(2)

Units

Resolution

Description

GRID INJECTION

W L1

Power injected into

the phase 1 grid.

GRID INJECTION

W L2

Power injected into

the phase 2 grid.

Power injected into

the phase 3 grid.