CiDRA Passive Sonar Transmitters User Manual

Use of Modbus

with Passive Sonar

Transmitters

®

Protocol

Table of Contents

1 TRANSMITTER MODBUS CONFIGURATION OVERVIEW .............................................1-1

1.1 Introduction.................................................................................................................

1.1.1 Passive Sonar Transmitters That Support MODBUS

1.1.2 Modbus Variants Suppo

1.2 CONFI

1.2.1 Transmissio

1.2.2 Serial Communications Settings

1.2.3 MODBUS Options ..............................................................................................

1.3 Transmitter Menus .....................................................................................................

1.3.1 Serial Settings ....................................................................................................

1.3.2 Modbus Opt

2 Transmitter MODBUS Register Overview..........................................................................

2.1 Introduction.................................................................................................................

2.2 Making and Saving Cha

2.3 Passwords..................................................................................................................

2.4 Transmitter MODBUS Supported Function Code

2.5 Other Registers..........................................................................................................

2.6 Diagnostics.................................................................................................................

2.7 Other Functions..........................................................................................................

2.7.1 17 Read Slave ID ...............................................................................................

2.7.2 43/14 Read Device Identification........................................................................

3 M

ODBUS REGISTERS......................................................................................................3-1

3.1 Modbus Input Registers .............................................................................................

3.2 Modbus Holding Registe

GURATION SETTINGS..................................................................................1-3

n Modes ..........................................................................................1-3

ions.................................................................................................1-7

rted by Transmitter.......................................................1-1

.........................................................................1-4

nges .....................................................................................2-1

s.....................................................2-3

rs.........................................................................................3-5

.........................................1-1

1-1

1-5

1-6

1-6

2-1

2-1

2-1

2-4

2-4

2-4

2-4

2-4

3-1

List of Figures

Figure 1 RS-232 / RS-485 Configuration.............................................................................. 1-6

Figure 2 Baud Rate ..............................................................................................................

Figure 3 Data Bits.................................................................................................................

Figure 4 Parity......................................................................................................................

Figure 5 Stop Bits.................................................................................................................

Figure 6 Transmissio

Figure 7 Device Address......................................................................................................

Figure 8 ASCII Time

n Mode................................................................................................1-7

out........................................................................................................1-7

1-6

1-6

1-6

1-6

1-7

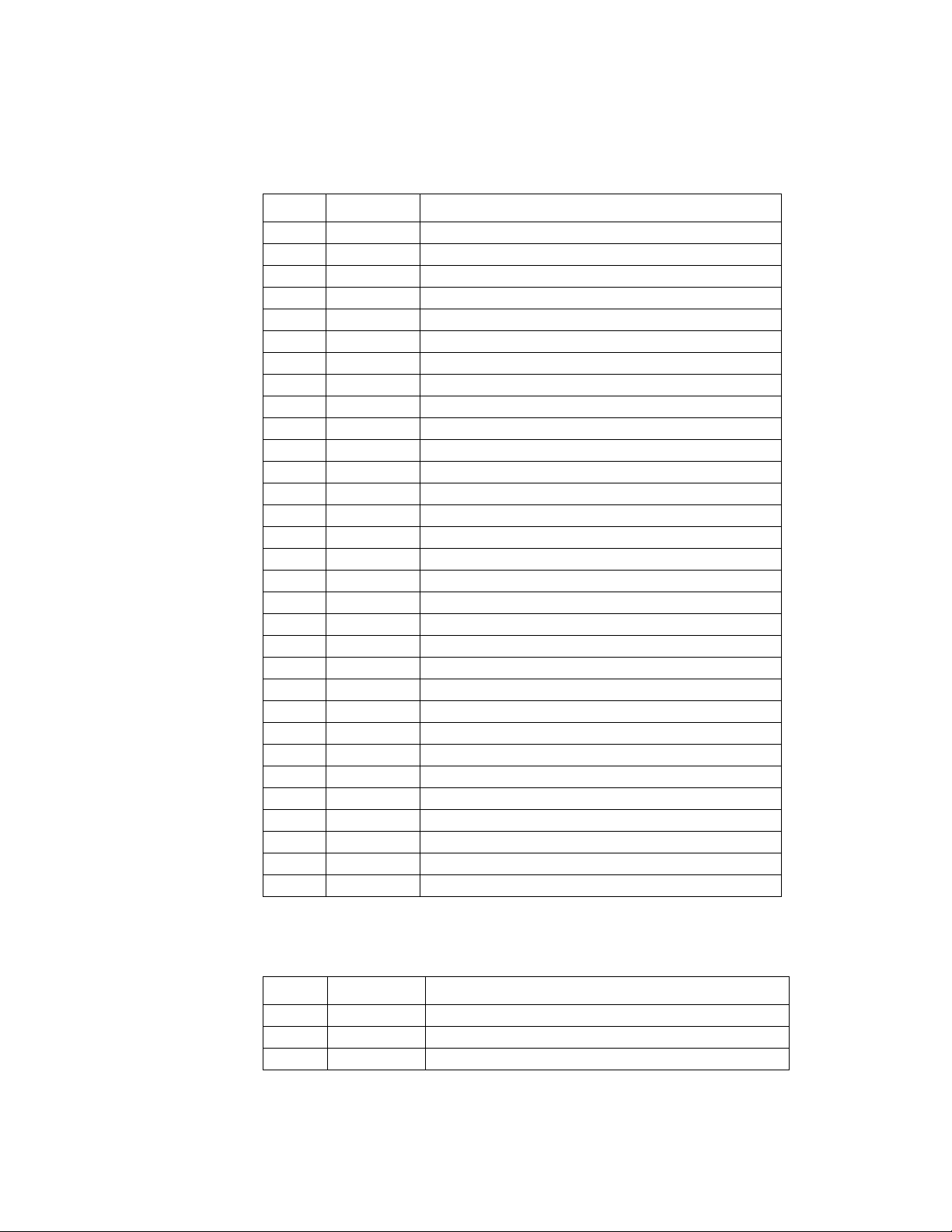

List of Tables

Table 1 Supported Modbus Function Codes .......................................................................2-3

Table 2 Non-Supported Modbus Function Codes...............................................................

Table 3 Diagnostic Register Bits.........................................................................................

Table 4 Modbus Input Registers .........................................................................................

Table 5 Modbus Holding Registers.....................................................................................

2-3

2-4

3-1

3-5

20959-01 Rev 02 Page i

20959-01 Rev 02 Page ii

1 TRANSMITTER MODBUS CONFIGURATION

OVERVIEW

1.1 Introduction

Modbus is an application layer messaging protocol that provides

client/server communication between devices connected on different

types of buses or networks.

Modbus has been industry’s serial de facto standard since 1979 and

enables millions of automation devices to communicate. Support for

the simple and elegant structure of Modbus continues to grow.

Modbus is a request/reply protocol and offers services specified by

function codes. Modbus function codes are elements of Modbus

request/reply messages.

This document describes the Modbus configuration options available

in the Passive sonar transmitter.

1.1.1 Passive Sonar Transmitters That Support MODBUS

The following transmitter model numbers will support Modbus

protocol:

• TB8-XX-XX-1X-XX where x can be any alpha-numeric

character. The ‘1’ indicates the transmitter firmware supports

Modbus communications.

1.1.2 Modbus Variants Supported by Transmitter

The passive sonar transmitter supports the following Modbus variants:

Media

• Asynchronous serial transmission over RS-232 or RS-485

Transmission Modes

• RTU

• ASCII

Serial Settings

• 7 / 8 Data Bits

• EVEN / ODD / NO Parity

• 1 / 2 Stop Bits

• 2400 / 9600 / 19200 / 38400 / 57600 / 115200 Baud

Other Modbus Options

• Device Address (001 – 247)

• ASCII Timeout (1 – 99 Seconds)

20959-01 Rev 02 Page 1-1

Transmission modes, serial settings and other options are available

from the transmitter front panel menu.

A configuration setting is available to swap 32 bit values (for example,

floating point numbers) for compatibility with Modbus masters that

may require it.

20959-01 Rev 02 Page 1-2

1.2 CONFIGURATION SETTINGS

1.2.1 Transmission Modes

• RTU (Default)

• ASCII

1.2.1.1 RTU

In RTU (Remote Terminal Unit) mode, each 8–bit byte in a message

contains two 4–bit hexadecimal characters. The main advantage of

this mode is that its greater character density allows higher data

throughput than ASCII mode for the same baud rate. Each message

must be transmitted in a continuous stream of characters.

The default parity mode in the transmitter is EVEN parity.

1.2.1.2 ASCII

In ASCII (American Standard Code for Information Interchange)

mode, each 8–bit byte in a message is sent as two ASCII characters.

This mode is used when the physical communication link or the

capabilities of the device do not allow conformance with RTU mode

requirements.

Note: This mode is less efficient than RTU since each byte needs two

characters.

Example:

The byte 0X5B is encoded as two characters: 0x35 and 0x42

(0x35 ="5" and 0x42 ="B" in ASCII).

Even parity and no parity also are supported. The default parity mode

in the transmitter is EVEN parity.

20959-01 Rev 02 Page 1-3

1.2.2 Serial Communications Settings

1.2.2.1 Configuration

• RS-232

• RS-485 (Default)

1.2.2.2 Data Bits

• 7 bits

• 8 bits (Default)

The Data Bits setting should match the Transmission Mode as

follows. The ability to set the Data Bits independent of

Transmission Mode is to allow for maximum flexibility.

• RTU 8 Data Bits

• ASCII 7 Data Bits

1.2.2.3 Parity

• EVEN (Default)

• ODD

• NONE

1.2.2.4 Stop Bits

• 1 (Default)

• 2

1.2.2.5 Baud Rate

• 2400

• 9600 (Default)

• 19200

• 38400

• 57600

• 115200

Note: The Modbus specification requires the use of 2 Stop Bits when

No Parity is selected.

20959-01 Rev 02 Page 1-4

1.2.3 MODBUS Options

1.2.3.1 Device Address

Device Address is the address that a Modbus master will use to

communicate with the transmitter.

• Range: 1 – 247 (Default = 1)

1.2.3.2 ASCII Timeout

ASCII Timeout is the amount of time in seconds the transmitter will

wait before processing an ASCII Transmission Mode Modbus

message before a CR/LF termination. This may be increased to allow

for manual entry of an ASCII message on a terminal.

• Range: 1 – 99 Seconds (Default = 4)

20959-01 Rev 02 Page 1-5

1.3 Transmitter Menus

1.3.1 Serial Settings

Only the internal RS-232/RS-485 serial port on the transmitter

supports Modbus.

Figure 1 RS-232 / RS-485 Configuration

Figure 2 Baud Rate

Figure 3 Data Bits

Figure 4 Parity

Figure 5 Stop Bits

20959-01 Rev 02 Page 1-6

1.3.2 Modbus Options

Figure 6 Transmission Mode

Figure 7 Device Address

Figure 8 ASCII Timeout

20959-01 Rev 02 Page 1-7

2 TRANSMITTER MODBUS REGISTER OVERVIEW

2.1 Introduction

The chapter will describe the MODBUS registers available in the

transmitter, and how to read and write them.

Registers are arranged in groups by format (i.e. float, char) to facilitate

reading and writing in blocks, and function (User, Algorithm, Filter

etc.).

Multiple register values (for example, Floating Point values) by default

are arranged to conform to IEEE specifications for Floating Point

numbers. There is an option available through the meter configuration

to swap the two registers for compatibility.

2.2 Making and Saving Changes

In order to change Holding Registers, first write a value of 0x55AA to

Holding Register 4 (the ‘Run Mode’ Register to ‘Write Enabled’).

Changes to any Holding Register(s) can then be made.

In order to validate changes and commit them to FLASH, write a value

of 0xEDF1 (‘Commit Changes’) to the Run Mode register (address 4).

An error will be returned after a Commit if any of the Holding Register

changes are invalid (outside bounds, etc.).

2.3 Passwords

Password functions are available, but by default are disabled. A user

would write their password to the Password Input Holding Register

(Register 0) to set the access level for the session. Sessions timeout

after a configurable number of seconds of no valid reads or writes.

Passwords consist of single register integer values that range from 1

thru 65535 (0xFFFF hex).

All passwords are set to 0, disabling the password feature by default.

Passwords affect Read/Write access to Holding Registers. Input

Registers are always readable.

The three levels of access are:

• Administrator Ability to set any passwords, as well as read or

write Holding Registers

• Level 1 Ability to Read or Write any Holding Registers, as well

as setting Level 1 or Level 2 passwords

• Level 2 Ability to Read Holding Registers, as well as setting

the Level 2 password.

20959-01 Rev 02 Page 2-1

To use all three levels of access, set the Administrator password first,

log in as Administrator, then set Level 1, and then Level 2.

If any password is set to something other than 0, and others are set to

0, then only the non-zero password will function. If a Level 2

password is first set, you will not be able to log in as an Administrator,

but only read holding registers. In some instances this may be a

desirable mode.

20959-01 Rev 02 Page 2-2

2.4 Transmitter MODBUS Supported Function Codes

The transmitter supports these MODBUS Function Codes:

Code Sub Code Function

01 Read Coils

02 Read Discrete Inputs

03 Read holding Registers

04 Read Input Registers

05 Write Single Coil

06 Write Single Registers

07 Read Exception Status (Serial only)

08 Diagnostics (Serial only)

08 00 Return Query Data

08 01 Restart Communications Option

08 02 Return Diagnostic Register

08 03 Change ASCII Input Delimiter

08 04 Force Listen Only Mode

08 10 Clear Counters and Diagnostic Register

08 11 Return Bus Message Count

08 12 Return Bus Communications Error Count

08 13 Return Bus Exception Error Count

08 14 Return Slave Message Count

08 15 Return Slave No Response Count

08 16 Return Slave NAK Count

08 17 Return Slave Busy Count

08 18 Return Bus Character Overrun Count

08 20 Clear Overrun Counter and Flag

11 Get Communications Event Counter (Serial only)

12 Get Communications Event Log (Serial only)

15 Write Multiple Coils

16 Write Multiple Registers

17 Report Slave ID (Serial only)

22 Mask Write register

23 Read/Write Multiple registers

43 14 Read Device Identification

Table 1 Supported Modbus Function Codes

The transmitter does NOT support these MODBUS Function Codes:

Code Sub Code Function

20 Read File Record

21 Write File Record

24 Read FIFO Queue

Table 2 Non-Supported Modbus Function Codes

20959-01 Rev 02 Page 2-3

2.5 Other Registers

Coils and Discreet inputs are not used in the transmitter. All

configurations are performed with Holding Registers, and

measurements read from Input Registers.

2.6 Diagnostics

08/02 Read Diagnostic Register

• Diagnostic Register Bits

Bit

Number

0 STATUS_BIT_DEFAULTS

1 STATUS_BIT_DSP_DEAD

2 STATUS_BIT_DSP_NO_RESP

3 STATUS_PREAMP_FAILURE

4 SOS_SINGULAR_MATRIX_ERR

5 VF_SINGULAR_MATRIX_ERR

6 VFCENTROID_DIV0_ERROR

7 SOSCENTROID_DIV0_ERROR

8 NO_VALID_FREQ_POINTS

9 SENSOR_OVERLOAD_ERROR

10 VF_DATA_OVERANGE

11 SOS_DATA_OVERANGE

12 unused

13 unused

14 unused

15 unused

Description

Table 3 Diagnostic Register Bits

2.7 Other Functions

2.7.1 17 Read Slave ID

Slave ID returned by this command is based on the software revision

of the transmitter as follows:

Software version V4.01.02 returns a Slave ID of 40102.

2.7.2 43/14 Read Device Identification

This function code returns three string objects as follows:

CiDRA Corp.

TB8-XX-XX-XX-XX

V4.01.02

20959-01 Rev 02 Page 2-4

Loading...

Loading...