CiDRA GVF-100 User Manual

MODEL VF & GVF-100 FLOW and

ENTRAINED GAS MONITORING

SYSTEM

INSTALLATION & STARTUP

MANUAL

CiDRA Corporation 50 Barnes Park North Wallingford, CT 06492

Tel. 203-265-0035 Fax. 203-294-4211 www.cidra.com

Table of Contents

1 INTRODUCTION.................................................................................1-1

1.1 Sensor Head Description and Function..............................................1-1

1.2 Transmitter Description and Function ................................................1-1

2 INTELLECTUAL PROPERTY NOTICES.............................................2-1

3 EQUIPMENT SAFETY COMPLIANCE ...............................................3-1

3.1 Safety.................................................................................................3-1

3.2 North American Emissions.................................................................3-1

3.3 European Emissions and Immunity....................................................3-1

3.4 CE Marking.........................................................................................3-2

4 WARRANTY........................................................................................4-1

5 GENERAL SAFETY GUIDELINES......................................................5-1

5.1 Introduction.........................................................................................5-1

5.2 Safety Precautions.............................................................................5-1

5.3 Definitions of Symbols........................................................................5-1

5.3.1 General Warning or Caution.........................................................5-2

5.3.2 Grounding.....................................................................................5-2

5.3.3 On.................................................................................................5-2

5.3.4 Off.................................................................................................5-2

5.3.5 General Warnings ........................................................................5-3

5.3.6 General Cautions .........................................................................5-4

6 UNPACKING AND PARTS LIST.........................................................6-1

6.1 Unpacking ..........................................................................................6-1

6.2 Inventory of Parts...............................................................................6-1

6.3 Class I, Division 2 Labels...................................................................6-2

7 SENSOR INSTALLATION...................................................................7-1

7.1 Class I, Division 2, Groups A, B, C, and D Rated Equipment ............7-1

7.2 Tools Required For Installation .......................................................... 7-1

7.3 Sensor Installation Guidelines............................................................7-2

7.4 Process Piping Considerations ..........................................................7-2

7.4.1 Pipe Preparation...........................................................................7-2

7.4.2 Determine the Pipe Inner Diameter (ID).......................................7-3

7.5 Sensor Band Installation ....................................................................7-4

7.5.1 Sensor Band Short Test...............................................................7-8

7.6 Sensor Cover Installation...................................................................7-9

7.6.1 Fiberglass Cover Installation......................................................7-10

7.6.2 Stainless Steel Cover Installation...............................................7-13

7.6.3 Sensor Assembly Cable Connection..........................................7-17

7.6.4 Rain Boot Installation .................................................................7-18

7.6.5 Sensor Calibration Label............................................................7-18

7.7 Sensor to Transmitter Cable Connections .......................................7-20

7.7.1 Sensor End Cable Attachment...................................................7-20

7.8 Installations on Tubing .....................................................................7-21

8 TRANSMITTER INSTALLATION.........................................................8-1

8.1 Transmitter Power Requirements.......................................................8-1

8.2 Transmitter Environmental Conditions ...............................................8-1

8.3 Transmitter Mounting Instructions......................................................8-1

8.3.1 Bulkhead Mounting.......................................................................8-2

8.3.2 Pipe Mounting ..............................................................................8-2

8.4 Transmitter Cable Connections..........................................................8-3

Copyright © 2006 CiDRA Corporation Page i

20675-01 Rev 02

8.4.1 Transmitter Housing Cable Entry.................................................8-3

8.4.2 Transmitter Output, Sensor and Sensor Head Connections........8-4

8.4.3 Transmitter Electrical Power Cable Installation..........................8-10

8.4.4 Sensor Calibration Label............................................................8-12

9 TRANSMITTER FUNCTIONS.............................................................9-1

9.1 Transmitter Layout .............................................................................9-1

9.2 Transmitter Output Definitions............................................................9-2

9.3 Transmitter Input Definitions ..............................................................9-6

9.4 Keypad...............................................................................................9-7

9.5 Transmitter Display ............................................................................9-8

9.5.1 Operational Mode.........................................................................9-8

9.5.2 Menu Mode ................................................................................9-12

10 TRANSMITTER SETUP....................................................................10-1

10.1 Transmitter Menus ...........................................................................10-1

10.1.1 Basic Config Menu .....................................................................10-1

10.1.2 Output Config Menu ...................................................................10-3

10.1.3 Input Config..............................................................................10-13

10.1.4 Customize Menu ......................................................................10-13

10.1.5 Communications Menu.............................................................10-15

10.1.6 Diagnostics Menu.....................................................................10-15

10.1.7 Info Menu .................................................................................10-17

10.2 Resetting Processor.......................................................................10-18

10.3 Resetting to Factory Defaults.........................................................10-19

11 TRANSMITTER STARTUP & OPERATION......................................11-1

11.1 Initial Start-up...................................................................................11-1

11.1.1 Initial Setup.................................................................................11-1

12 TRANSMITTER USB PORT ..............................................................12-1

12.1 USB Port File Naming Convention...................................................12-3

12.2 Save Snapshot.................................................................................12-4

12.3 Load Configuration...........................................................................12-4

12.4 Advanced Functions.........................................................................12-5

13 SENSOR REMOVAL PROCEDURE.................................................13-1

Appendix A SONARtrac

Appendix B SONARtrac

Appendix C

INCENDIVE........................................................................................C-1

Appendix D

Appendix E

Appendix F

Appendix G

Appendix H

Appendix I

SYSTEM CONTROL DRAWING SONARtracTM, NON-

MATERIAL SAFETY DATA SHEETS......................................D-1

CONVERSION FACTORS ...................................................... E-1

PHYSICAL PROPERTIES OF WATER....................................F-1

END USER LICENSE AGREEMENT......................................G-1

SPARE PARTS LIST............................................................... H-1

DIRECTIVE 2002/96/EC ON WASTE ELECTRICAL AND

ELECTRONIC EQUIPMENT (WEEE)..................................................I-1

TM

VF & GVF-100 SPECIFICATIONS................... A-1

TM

EC DECLARATION OF CONFORMITY........... B-1

Copyright © 2006 CiDRA Corporation Page ii

20675-01 Rev 02

List of Figures

Figure 1 General Warning or Caution Symbol..........................................5-2

Figure 2 Grounding Symbol......................................................................5-2

Figure 3 On Symbol..................................................................................5-2

Figure 4 Off Symbol..................................................................................5-2

Figure 5 Class I Division 2 Label Information............................................6-2

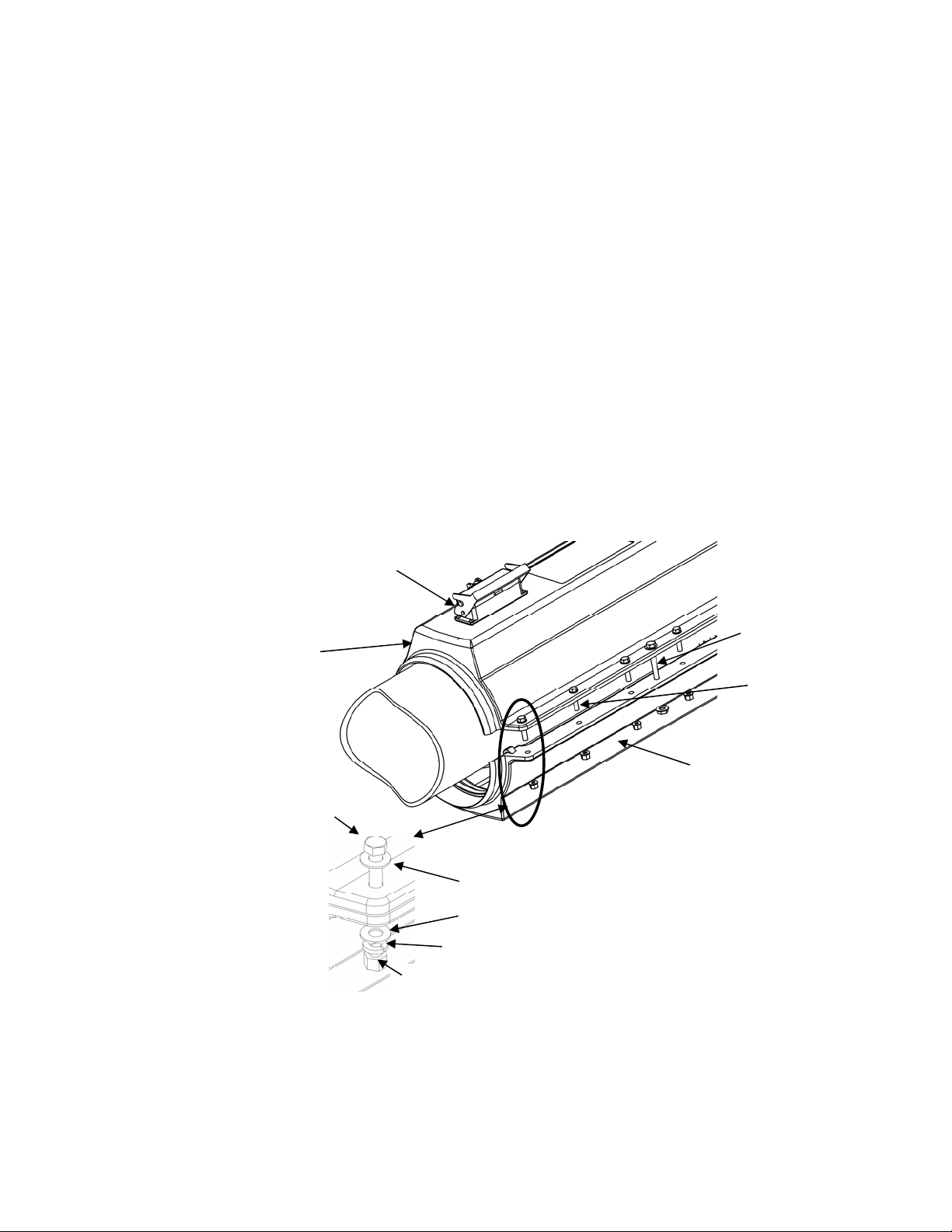

Figure 6 Sensor Band Screw and Alignment Pins....................................7-4

Figure 7 Sensor Band Screw Tightening Sequence.................................7-5

Figure 8 Sensor Band Screw Assembly....................................................7-6

Figure 9 Sensor Band Spacer Tool........................................................... 7-6

Figure 10 Sensor Band Spacing Tool Installed on Sensor Screw ..............7-7

Figure 11 Installed Sensor Band.................................................................7-8

Figure 12 Upper Sensor Cover Assembly Outside View ............................7-9

Figure 13 Upper Sensor Cover Assembly Inside View...............................7-9

Figure 14 Orientation (Clocking) of Sensor Cover....................................7-10

Figure 15 Sensor Cover Bolt Installation...................................................7-11

Figure 16 Sensor Cover Bolt Tightening Sequence..................................7-12

Figure 17 Stainless Steel Cover Assembly...............................................7-13

Figure 18 Applying GelTek to Gasket Edge..............................................7-14

Figure 19 Boot Gasket Band Kit................................................................7-14

Figure 20 Boot Gasket Band Installation...................................................7-14

Figure 21 Splice Protector Plate Installation.............................................7-15

Figure 22 BAND-IT

Figure 23 Final Alignment and Securing of Gasket Band.........................7-16

Figure 24 Band Termination......................................................................7-16

Figure 25 Boot Gasket Fender Assembly.................................................7-17

Figure 26 Sensor Assembly Cable Installation .........................................7-17

Figure 27 Sensor Calibration Label...........................................................7-19

Figure 28 Elastomeric Strip Installation on Tubes.....................................7-21

Figure 29 Bulkhead Mount Hole Pattern.....................................................8-2

Figure 30 Pole Mount Kit.............................................................................8-2

Figure 31 Power and Signal Interconnects.................................................8-3

Figure 32 Transmitter Housing Cable Gland Holes ....................................8-3

Figure 33 Terminal Board Layout................................................................8-4

Figure 34 Transmitter Output Terminals.....................................................8-5

Figure 35 Transmitter Sensor Terminals.....................................................8-6

Figure 36 Sensor Head to Transmitter Cable Connection Terminals .........8-7

Figure 37 Armored Cable Stiffener Plate Installation..................................8-8

Figure 38 Removal of Cable Armor.............................................................8-9

Figure 39 Armored Cable Connector Installed............................................8-9

Figure 40 Armored Cable Installation........................................................8-10

Figure 41 Transmitter Power Connection .................................................8-11

Figure 42 Sensor Calibration Label...........................................................8-12

Figure 43 Transmitter Layout......................................................................9-1

Figure 44 Transmitter Output Terminals.....................................................9-2

Figure 45 Pulse Switch Closure..................................................................9-3

Figure 46 Alarm Switch Closure..................................................................9-3

Figure 47 Internally (Transmitter) Powered 4–20mA Loop.........................9-4

Figure 48 Externally Powered 4–20mA Loop..............................................9-5

Figure 49 Transmitter Sensor Terminals.....................................................9-6

®

Model C001 Tool Use..............................................7-15

Copyright © 2006 CiDRA Corporation Page iii

20675-01 Rev 02

Figure 50 Transmitter Front Panel Keyboard..............................................9-7

Figure 51 VF & GVF Startup Screen...........................................................9-8

Figure 52 Operating Transmitter Display....................................................9-9

Figure 53 Initialization Mode.....................................................................9-12

Figure 54 GVF Measurement Screen.......................................................9-12

Figure 55 Typical Menu Screen................................................................9-14

Figure 56 Editing Parameter By Digits......................................................9-14

Figure 57 Editing Whole Parameter..........................................................9-15

Figure 58 Low End Output Configuration Example Screen ......................10-4

Figure 59 High End Output Configuration Example Screen......................10-4

Figure 60 4-20mA Output Set to 0 – 30 fps ..............................................10-5

Figure 61 4-20mA Trim Message box.......................................................10-6

Figure 62 Speed Of Sound and Gas Volume Fraction Pulse Output........10-8

Figure 63 Total Flow Pulse Output............................................................10-8

Figure 64 Test Passes Display Example ................................................10-15

Figure 65 Test Failed..............................................................................10-15

Figure 66 Error Codes Listed in Event Log.............................................10-18

Figure 67 Sensor Max/Min Display.........................................................10-18

Figure 68 System Start Display.................................................................11-1

Figure 69 Sensor Cable Connector Removal ...........................................13-1

List of Tables

Table 1 SONARtracTM VF & GVF-100 Parts List......................................6-1

Table 2 Installation Tools For SONARtrac

TM

VF & GVF-100 Monitoring

System........................................................................................7-1

Table 3 Recommended Distances From Flow Disturbances....................7-2

Table 4 Gauge Block and Screw Size......................................................7-5

Table 5 List of Transmitter Signal Outputs...............................................8-5

Table 6 Sensor to Transmitter Cable Terminal Connections....................8-8

Table 7 Keypad Functions in Operational and Menu Modes....................9-7

Table 8 Line 1 and Line 2 Values.............................................................9-9

Table 9 Status Line Code.........................................................................9-9

Table 10 Status Line Messages...............................................................9-10

Table 11 Quality Message Definitions .....................................................9-10

Table 12 Mode Message Definitions........................................................9-11

Table 13 SONARtrac

TM

VF & GVF-100 Menu Diagram Software Release

03.03.XX...................................................................................9-13

Table 14 Transmitter Menu Tree Software Release 03.03.XX................9-16

Table 15 Maximum Pulse Per Second Based On Pulse Width ...............10-7

Table 16 Alarm Triggers ........................................................................10-10

Table 17 Transmitter Setup .....................................................................11-7

Table 18 USB Port Menu.........................................................................12-2

Table 19 USB Port File Naming Convention............................................12-3

Table 20 USB Port File Name Examples.................................................12-3

Copyright © 2006 CiDRA Corporation Page iv

20675-01 Rev 02

1 INTRODUCTION

The CIDRA Corporation SONARtracTM Model VF & GVF-100

(Volumetric Flow and Gas Volume Fraction) System is a clamp-on

process monitoring system used to measure the volumetric flow rate

and the amount of entrained air / gas (also referred to as gas volume

fraction or GVF) contained in a fluid within process pipes on a realtime basis. The SONARtracTM VF & GVF-100 utilizes patented array

processing techniques to listen to and interpret the flow turbulence

generated by fluid flow and the acoustic field generated by machinery,

piping and flow present in process flow. The clamp-on design

eliminates the need for cutting pipe or interrupting process flow during

installation.

The SONARtracTM VF & GVF-100 consists of a common transmitter

and sensor heads sized for different pipe diameters.

SONARtracTM flow and entrained gas meters certified for use in

hazardous areas are rated for use in Class I, Division 2, Groups A, B,

C, and D environments (per US and Canadian standards).

This manual covers the basic installation and setup of the

SONARtracTM Model VF & GVF-100 Monitoring System. In all cases,

local safety and operating practices take precedence over the

information contained within this document.

For additional information, contact your local sales agent or CiDRA

Corporation Customer Support by telephone at 1-877-243-7277

(1-877-CIDRA77) or by E-Mail at customersupport@cidra.com

1.1 Sensor Head Description and Function

The SONARtracTM sensor head contains no moving parts. The sensor

head includes a sensor band and a fiberglass or stainless steel cover

assembly to protect the sensor band. The sensor band is wrapped

around and clamped onto the process pipe. A multi-conductor cable

electrically connects the sensors to an electronic module mounted in

the cover assembly. Signals from the electronic module exit through a

NEMA 4X rated connector mounted to the outer surface of the cover

assembly.

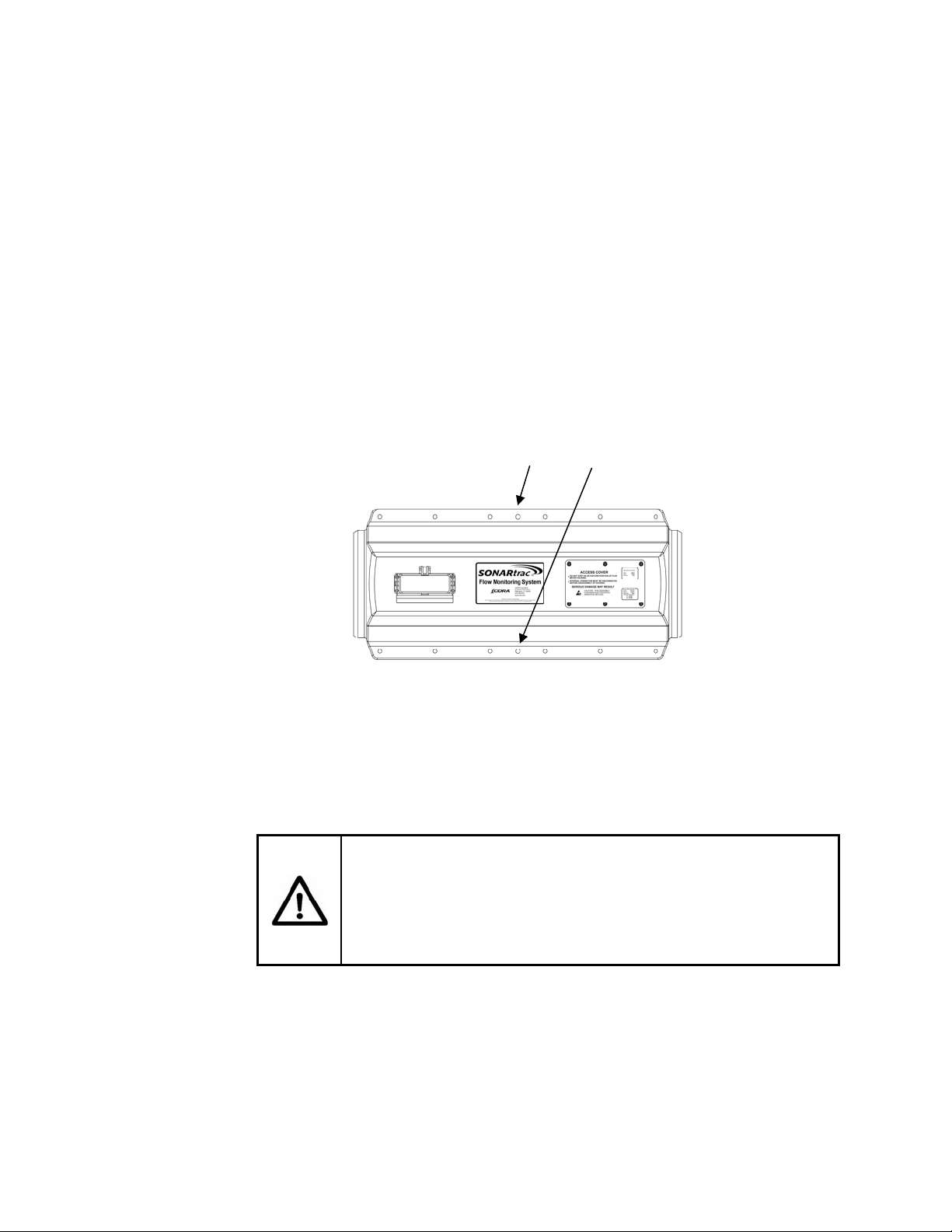

1.2 Transmitter Description and Function

The SONARtracTM transmitter receives electrical signals from the

sensor head. The signals are processed using SONARtrac

processing firmware that displays the calculated results on an integral

LCD screen. Results can also be transmitted using the 4–20mA

analog output, pulse output, alarm output or the RS-485/232 digital

TM

array

Copyright © 2006 CiDRA Corporation Page 1-1

20675-01 Rev 02

output. The electronic assembly is housed in a rugged NEMA 4X

enclosure.

Copyright © 2006 CiDRA Corporation Page 1-2

20675-01 Rev 02

2 INTELLECTUAL PROPERTY NOTICES

CiDRA Corporation’s Process Monitoring Products may be covered by

one or more of the following granted U.S. Patent(s): 6,354,147,

6,587,798, 6,609,069, 6,435,030, 6,691,584, 6,732,575, 6,782,150,

6,862,920, 6,889,562, 6,732,150. Other patents are pending; see

www.cidra.com for the latest listing of patents.

This manual is covered by U.S. and international copyright laws. No

part of this manual may be reproduced, modified or transmitted in

whole or in part in any form or by any means, electronic or

mechanical, including photocopy, recording, or any information

storage and retrieval system, without permission in writing from

CiDRA Corporation.

Third party end-user license agreements (“EULA”) are provided in

Appendix G of this document.

Copyright © 2006 by CiDRA Corporation, all rights reserved.

SONARtrac, SONARstick and logo are trademarks of CiDRA

Corporation.

Copyright © 2006 CiDRA Corporation Page 2-1

20675-01 Rev 02

3 EQUIPMENT SAFETY COMPLIANCE

3.1 Safety

This equipment is listed with TÜV Rheinland of North America, Inc., a

nationally recognized testing laboratory, and certified for ordinary

location use per the following US, Canadian, and European standards:

UL 61010A-1, CSA C22.2 No. 1010, and EN 61010-1:2001.

If so marked, this equipment is certified by Underwriters Laboratories

for use in areas that - under fault conditions - include explosive gas

atmospheres as defined by Class I, Division 2, Groups A, B, C, and D

per compliance with these US and Canadian standards: UL 1604, UL

508, CSA C22.2 No. 213, and CSA C22.2 No. 142.

3.2 North American Emissions

This equipment is compliant with Class A limits for radiated and

conducted radio noise emissions, as defined in Subpart A of Part 15 of

the FCC rules, as well as the requirements defined in ICES-003 for

Canada.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-

003 du Canada.

3.3 European Emissions and Immunity

This equipment is compliant with the requirements set forth in EN

61326-1:1997, Electrical Equipment for Measurement, Control and

Laboratory Use - EMC requirements as well as EN 55011:1998

Industrial, Scientific, and Medical (ISM) Radio Frequency Equipment Radio Disturbance Characteristics - Limits and Methods of

Measurement.

For the purpose of Electromagnetic Compatibility (EMC) requirements,

this product is categorized as Group 1, Class A ISM equipment. This

categorization applies to Industrial, Scientific or Medical equipment

that intentionally generates or uses conductively coupled (but not

intentionally radiated) radio-frequency energy that is necessary for the

internal functioning of the equipment. The level of EMC compliance is

consistent with industrial use but not for domestic purposes.

CAUTION

Class A equipment is intended for use in an industrial

environment. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments, due to

conducted as well as radiated disturbances.

Copyright © 2006 CiDRA Corporation Page 3-1

20675-01 Rev 02

3.4 CE Marking

This equipment is CE marked for ordinary location use and complies

with the following European Directives:

73/23/EEC Low-Voltage Directive

89/336/EEC EMC Directive

Further details are listed in the EC Declaration of Conformity (P/N

20634-01), a copy of which can be found in Appendix B of this

Document as well as on our website at http://www.cidra.com.

Copyright © 2006 CiDRA Corporation Page 3-2

20675-01 Rev 02

4 WARRANTY

The terms and conditions, including warranty, of the purchase of

CiDRA’s Process Monitoring Products is outlined in the document

entitled “CiDRA’s Terms and Conditions of Sale”.

Copyright © 2006 CiDRA Corporation Page 4-1

20675-01 Rev 02

5 GENERAL SAFETY GUIDELINES

CiDRA Corporation recommends the installer fully read this manual

prior to installing and operating the SONARtrac

Note: Items that pertain to systems rated for Class I, Division 2,

Groups A, B, C, and D operation are highlighted in italic print.

5.1 Introduction

This manual is intended to be a general installation guide for the

CiDRA SONARtracTM VF & GVF-100 System. It is not intended to

cover the installation details for every process due to the wide variety

of applications and processes on which the system can be used. In all

cases, local safety and operating practices should take precedence

over instructions contained within this manual.

5.2 Safety Precautions

The following style of Warnings and Cautions are used throughout the

manual to draw attention to information regarding personnel safety

and equipment care. They are not intended to replace local or plant

safety procedures.

WARNING

TM

system.

Situation has the potential to cause bodily harm or death.

Situation has the potential to cause damage to property or

equipment.

5.3 Definitions of Symbols

The following terms and symbols are used in this document and on

the SONARtracTM system where safety related issues occur.

CAUTION

Copyright © 2006 CiDRA Corporation Page 5-1

20675-01 Rev 02

5.3.1 General Warning or Caution

Figure 1 General Warning or Caution Symbol

The Exclamation Symbol in Figure 1 appears in Warning and Caution

tables throughout this document. This symbol designates an area

where personal injury or damage to the equipment is possible.

5.3.2 Grounding

Figure 2 Grounding Symbol

The Grounding Symbol in Figure 2 appears on labels affixed to the

SONARtracTM system. This symbol identifies a terminal intended for

connection to an external (ground) conductor for protection against

electric shock in case of a fault, or the terminal of a protective earth

(ground) electrode.

5.3.3 On

The On Symbol in Figure 3 represents the Power ON condition of the

power switch on the SONARtrac

• Class I, Division 2 rated systems do not have this switch.

5.3.4 Off

Figure 3 On Symbol

TM

system, if so equipped.

Figure 4 Off Symbol

The Off Symbol in Figure 4 represents the Power Off condition of the

TM

power switch on the SONARtrac

system, if so equipped.

• Class I, Division 2 rated systems do not have this switch.

Copyright © 2006 CiDRA Corporation Page 5-2

20675-01 Rev 02

5.3.5 General Warnings

Observe these general warnings when operating or servicing this

equipment:

• Prior to operation of this equipment, personnel should read the

instruction manual thoroughly.

• For systems installed in Class I, Division 2 areas, Power Entry and

Inputs/Outputs must be installed in accordance with Article

501.10(B)(1) of the National Electrical Code ANSI/NFPA 70:2005.

• For systems installed in Class I, Division 2 areas, Sensor Head

Cable must be installed in accordance with Article 501.10(B)(3) of

the National Electrical Code ANSI/NFPA 70:2005.

• Only equipment rated for Class I, Division 2, Groups A, B, C, and

D should be installed in those areas. Verify the system rating on

the equipment labels (refer to Section 6.3 of this manual).

• Use a damp cloth to wipe sensor band cover and transmitter when

installed in Class I, Division 2 areas to dissipate potential static

charge buildup.

WARNING

Using a dry cloth to clean the transmitter enclosure can cause

static discharge, which could result in an explosion in an

explosive atmosphere. Always use a damp cloth to clean the

transmitter enclosure.

• If the sensor band was shipped with a sensor band shorting plug

installed on the sensor band to preamplifier cable connector,

ensure the sensor band shorting plug is installed on the sensor

band cable prior to installing sensor band. Sensors bands with an

‘R” in the Part Number suffix (e.g. Part #: 20686-26-R) do not

require a shorting plug.

• As for any electrical equipment in Class I, Division 2 installations

wherein explosive atmospheres might be present, it is especially

important to de-power and remove the SONARtracTM meter from

service if its appearance or operating behavior indicates that it is

damaged or malfunctioning and/or that its safety features have

been otherwise compromised.

• Trained personnel must carry out service on this equipment.

• Follow all warnings on the unit and in the operating instructions.

• This equipment is grounded through the grounding conductor of

the power cord.

Copyright © 2006 CiDRA Corporation Page 5-3

20675-01 Rev 02

• Ensure all power cords, sensor to transmitter cable and signal

cables are properly routed to eliminate damage to them. Cable

conduit may be desirable to minimize potential damage.

• Prior to servicing, lockout all electrical power sources.

• Care should be taken when using the operator keypad to avoid

touching any electrical connection or contact points.

• Do not wear rings or wristwatches when servicing this equipment.

• Use only the specified fuse(s) with the correct type number,

voltage and current ratings as referenced in the appropriate

locations in the service instructions or on the equipment.

5.3.6 General Cautions

Observe these cautions when operating or servicing this equipment:

• Read the instructions for proper input voltage range selection.

• There are no user serviceable parts inside the SONARtrac

sensor band. Modification or disassembly may void the system

warranty.

TM

• Disconnect power to transmitter prior to replacing fuse(s).

• Use only CiDRA specified replacement parts.

• Follow static sensitive device precautions when servicing.

• This product should only be powered as described in the manual.

• Do not run power and signal wires in a common conduit.

Copyright © 2006 CiDRA Corporation Page 5-4

20675-01 Rev 02

6 UNPACKING AND PARTS LIST

6.1 Unpacking

The SONARtracTM VF & GVF-100 will typically be packaged in three

shipping containers. One box will contain the sensor band and sensor

cover assemblies, and installation hardware; the second box will

contain the transmitter assembly and installation hardware; and the

third box will contain the sensor to transmitter cable assembly.

Note: Cidra Corp. recommends the original packing materials be

saved in the event that the system is removed or relocated.

CAUTION

Use care in unpacking and transporting system. Improper

handling may result in damage to system components.

Whenever possible use the original packing materials to transport the

system to the installation site to minimize the likelihood of damage.

WARNING

Static discharge may occur when handling sensor band and

packing material. Remove from packing materials when entering

hazardous areas. Always keep the sensor band shorting plug

installed until sensor band is installed on the process pipe.

6.2 Inventory of Parts

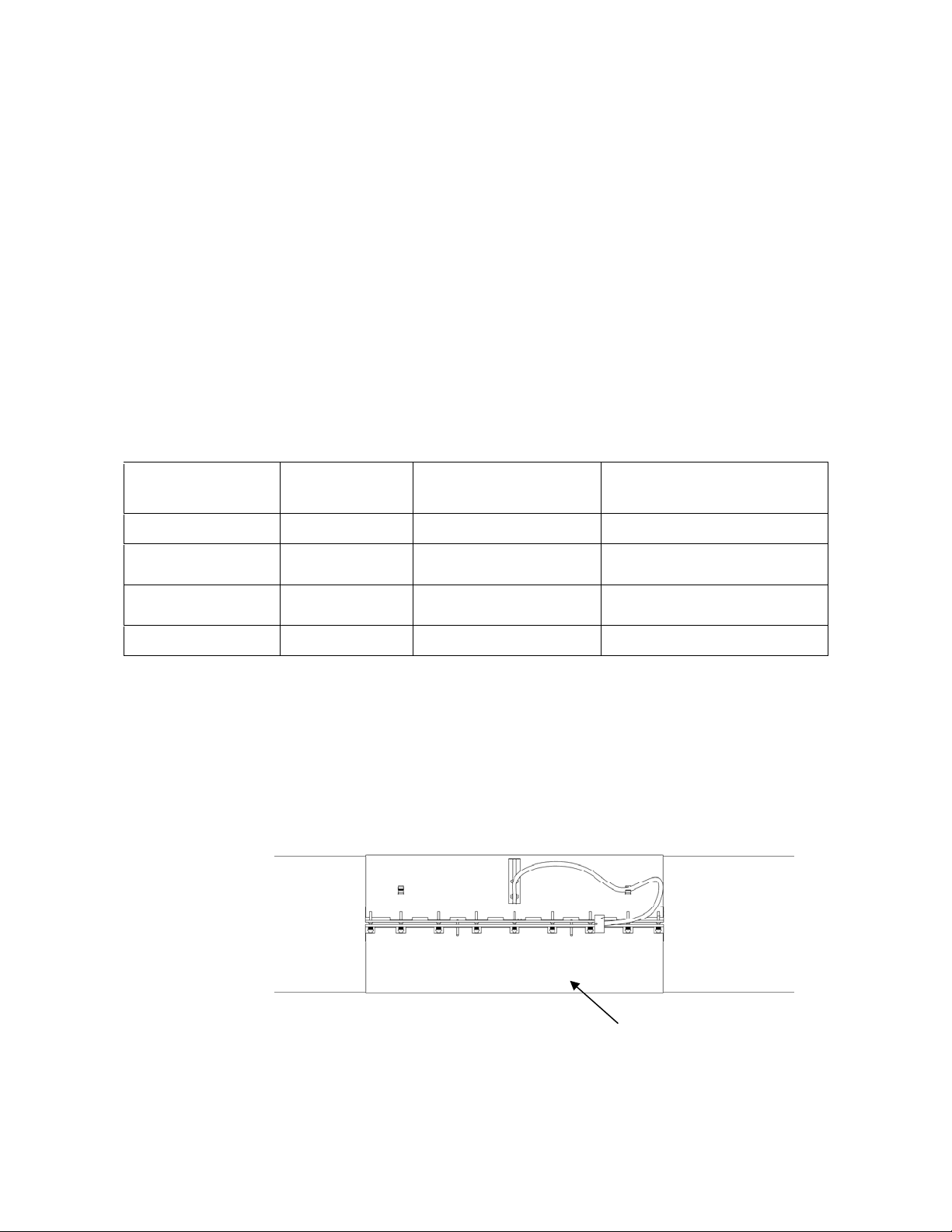

Table 1 lists the parts contained in the shipping containers.

Description

SONARtracTM VF & GVF-100 Gas Volume Fraction Process Monitoring

System

Sensor Head Cable

Installation Hardware

Sealant, Joint and Thread, PTFE Paste, 3.5 oz Tube – included with

fiberglass sensor cover assemblies

Gauge, Spring Gap (used for sensor installation) - included with sensor

band assembly

Model VF & GVF-100 Flow and Entrained Air Process Monitoring

System Installation & Startup Manual

Kit, Parts, Pole Mounting (Option)

Sensor Rain Guard Kit for vertical installations (Option)

Table 1 SONARtracTM VF & GVF-100 Parts List

Copyright © 2006 CiDRA Corporation Page 6-1

20675-01 Rev 02

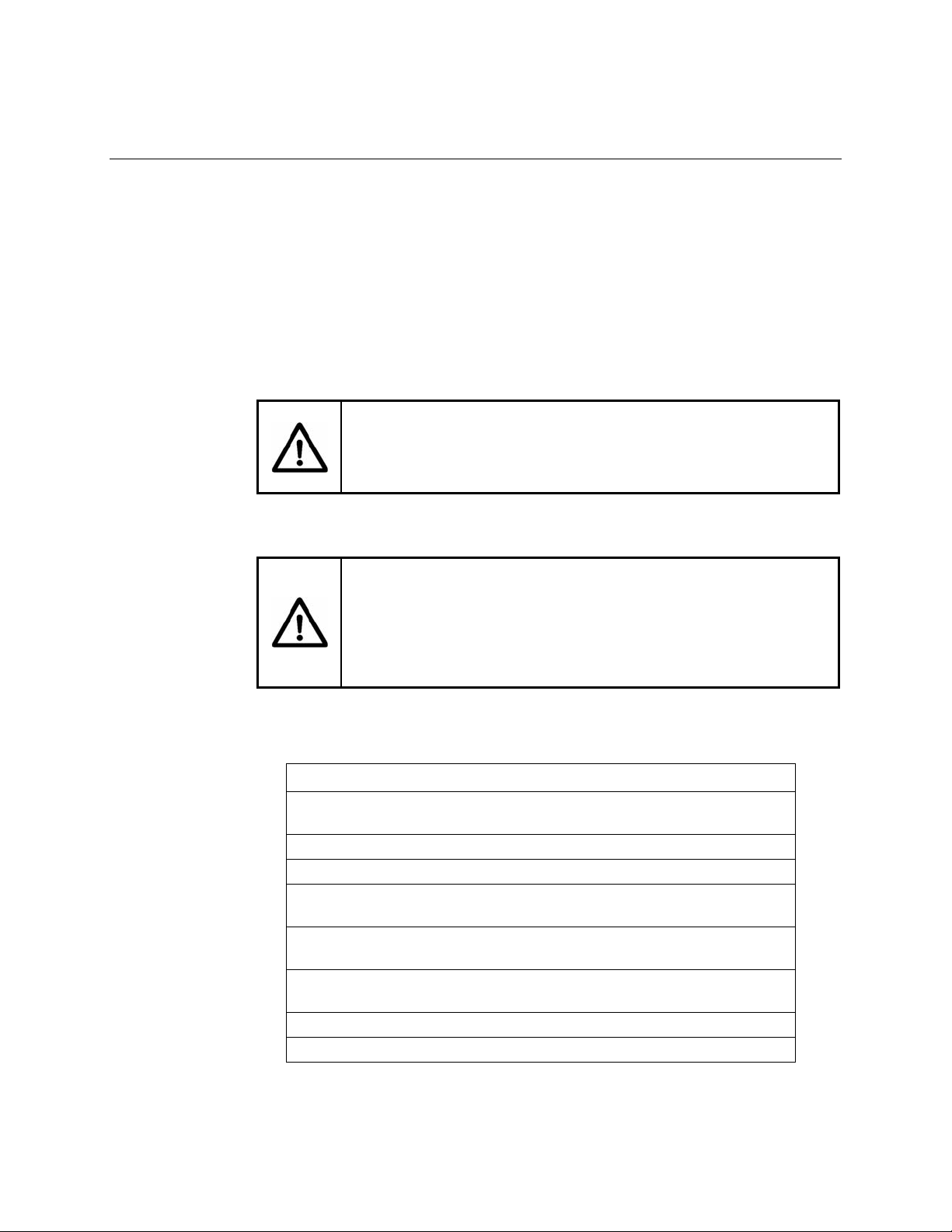

6.3 Class I, Division 2 Labels

Transmitters and sensor covers rated for use in Class I, Division 2

areas are labeled with the following information (or a subset of it) so

they can be identified for use in those areas.

Telemetering Equipment For Use in Hazardous Locations

Class I, Division 2, Groups A, B, C, and D Hazardous Locations

Providing Nonincendive Field Circuits When Connected Per DWG #

20332-01

Figure 5 Class I Division 2 Label Information

WARNING

Use of non- Class I, Division 2 rated equipment in Class I,

Division 2 areas may result in a fire or explosion.

Copyright © 2006 CiDRA Corporation Page 6-2

20675-01 Rev 02

7 SENSOR INSTALLATION

7.1 Class I, Division 2, Groups A, B, C, and D Rated Equipment

• Equipment so marked is suitable for use in Class I, Division 2,

Groups A, B, C, and D or non-hazardous locations only.

• WARNING – EXPLOSION HAZARD – Do not disconnect

equipment unless power has been removed or the area is known

to be non-hazardous.

• WARNING – EXPLOSION HAZARD –Substitution of components

may impair suitability for Class I, Division 2.

• WARNING – EXPLOSION HAZARD –Do not replace fuses unless

power has been switched off or the area is known to be nonhazardous.

• WARNING – EXPLOSION HAZARD –Ensure a sensor band

shorting plug is installed on the sensor band cable connector

during installation and removal from process pipe.

7.2 Tools Required For Installation

The following tools are required for system installation. Additional

tools may be required based on particular installation needs.

Required Tools Recommended Tools

Cable cutter Wire number markers

Wrenches, 1/2 “x 9/16”, combination,

open-end, 2 ea

Wire strippers for 20 gauge wire Open end or combination wrench set

Allen wrench or hex driver, 7/64-inch for

No. 6 socket head cap screw, or 5/32inch for No. 10 socket head cap screw

Spacer tool, sensor fastener (provided

with sensor band)

Screw drivers, Blade, 3/16” and 1/4”,

Phillips medium blade

14” Adjustable wrench (armored cable) Socket wrench set

Sandpaper, cleaning rags, etc as

required for pipe cleaning

BAND-IT® Tool Model C001 (or

equivalent) for use with stainless steel

covers. Refer to

for distributor information.

Table 2 Installation Tools For SONARtrac

www.band-it-idex.com

Portable electric screw driver with 7/64

or 5/32-inch hex driver bit

Spring clamps to hold cover halves in

place temporarily

Cable jacketing removal tool

Hacksaw and or armor cutter (armored

cable cutting)

Volt-ohm meter

Electricians tape

System

TM

VF & GVF-100 Monitoring

Copyright © 2006 CiDRA Corporation Page 7-1

20675-01 Rev 02

7.3 Sensor Installation Guidelines

The following are general installation guidelines and recommendations

for installing a

SONARtrac

TM

sensor.

• Where necessary, get a Hot Work Permit prior to installation of

system.

• Select locations with well-developed flow profiles.

• Avoid installation locations directly after piping configurations that

cause flow jetting.

• Install flow sensor upstream of control valves, “T”s, orifice plates,

and any other severe source of flow disturbance.

• Locate the sensor upstream of pipe taps such as those used for

temperature and pressure sensors.

• Good piping practices are required near flanges. This includes

good alignment of pipes, and properly sized and installed gaskets

that do not disturb the flow profile.

• Contact your local distributor or CiDRA Technical Support if you

have questions.

Table 3 lists the recommended installation distances from flow

disturbances. These recommendations apply to flow measurement

installations.

Feature

Upstream

pipe

diameters

90 Degree Elbow 15 5

Double Elbow in plane 25 5

Double Elbow out of plane 40 5

Diffuser (expansion) 30 5

Reducer 15 5

Control Valve 40 10

Flange 2 2

Table 3 Recommended Distances From Flow Disturbances

7.4 Process Piping Considerations

The SONARtracTM sensor head assembly mounts on the process

pipe. There is no need for breaking any process connections or for

shutting down the process. The sensor head must be installed in a

location that ensures a full pipe during operation.

7.4.1 Pipe Preparation

Downstream

pipe

diameters

Remove pipe insulation if it is present.

Copyright © 2006 CiDRA Corporation Page 7-2

20675-01 Rev 02

WARNING

Asbestos containing insulation materials may be present.

Asbestos fibers have been known to cause health problems. If

unsure of the contents of pipe insulation materials contact the

plant representative for that area.

WARNING

Process Heating Tapes may be present. This may present an

electrical shock hazard. Follow plant Lock-out / Tag-out

requirements.

WARNING

Process pipes may be hot. A burn hazard may exist. Use care

when working with hot pipes.

Clean pipe surface using a scraper, sand paper strips, a water (or

solvent for greasy pipes) rinse and final wipe with a clean rag. The

pipe surface under the sensor band assembly should be clean and

free of rust and rust spots, grit, grease, protruding weld spots and

weld splatter. A good guideline is to clean the pipe as if it were going

to be painted.

Avoid dents as they can create flow disturbances within the pipe.

Select a location that ensures full contact between the sensor and the

pipe.

Painted surfaces are normally satisfactory provided they are smooth

and free of chips over 0.25-inch (6.4 mm) diameter. Ensure a smooth

painted finish by sanding the area where the sensor will be mounted.

Finally, wipe the pipe using a damp cloth rag or paper towel.

7.4.2 Determine the Pipe Inner Diameter (ID)

Record the nominal pipe size based on the pipe size and pipe

schedule, as this will be input into the transmitter.

Alternatively, measure and calculate the pipe ID. Accurately measure

the pipe outside diameter (OD). Use an ultrasonic thickness

measurement gauge to determine the wall thickness (t

of 4 locations equally spaced around the pipe and average the

measurements. Calculate the pipe inner diameter (ID = OD – (2t

(There are several vendors of ultrasonic thickness gauges.)

Note: The accuracy of the pipe inner diameter measurement is critical

for high accuracy flow rate measurements as there is a direct

correlation between this measurement and the reported flow rate.

) at a minimum

w

)).

w

Copyright © 2006 CiDRA Corporation Page 7-3

20675-01 Rev 02

7.5 Sensor Band Installation

It will be helpful to have a second person available to assist with

holding the sensor assembly in position during installation.

Note: Prior to installing the sensor band, remove and save the plastic

bag from the sensor band that contains two sensor calibration factor

labels. These will be used as described later in this manual for input

to the transmitter.

Ensure there is no dirt or other foreign material on the sensor

assembly. Remove dirt or foreign matter using a clean cloth

dampened with water.

If the sensor band was shipped with a sensor band shorting plug

installed on the sensor band to preamplifier cable connector, ensure

the sensor band-shorting plug is installed on the sensor band cable

prior to installing sensor band. Sensors bands with an ‘R” in the Part

Number suffix (e.g. Part #: 20686-26-R) do not require a shorting plug.

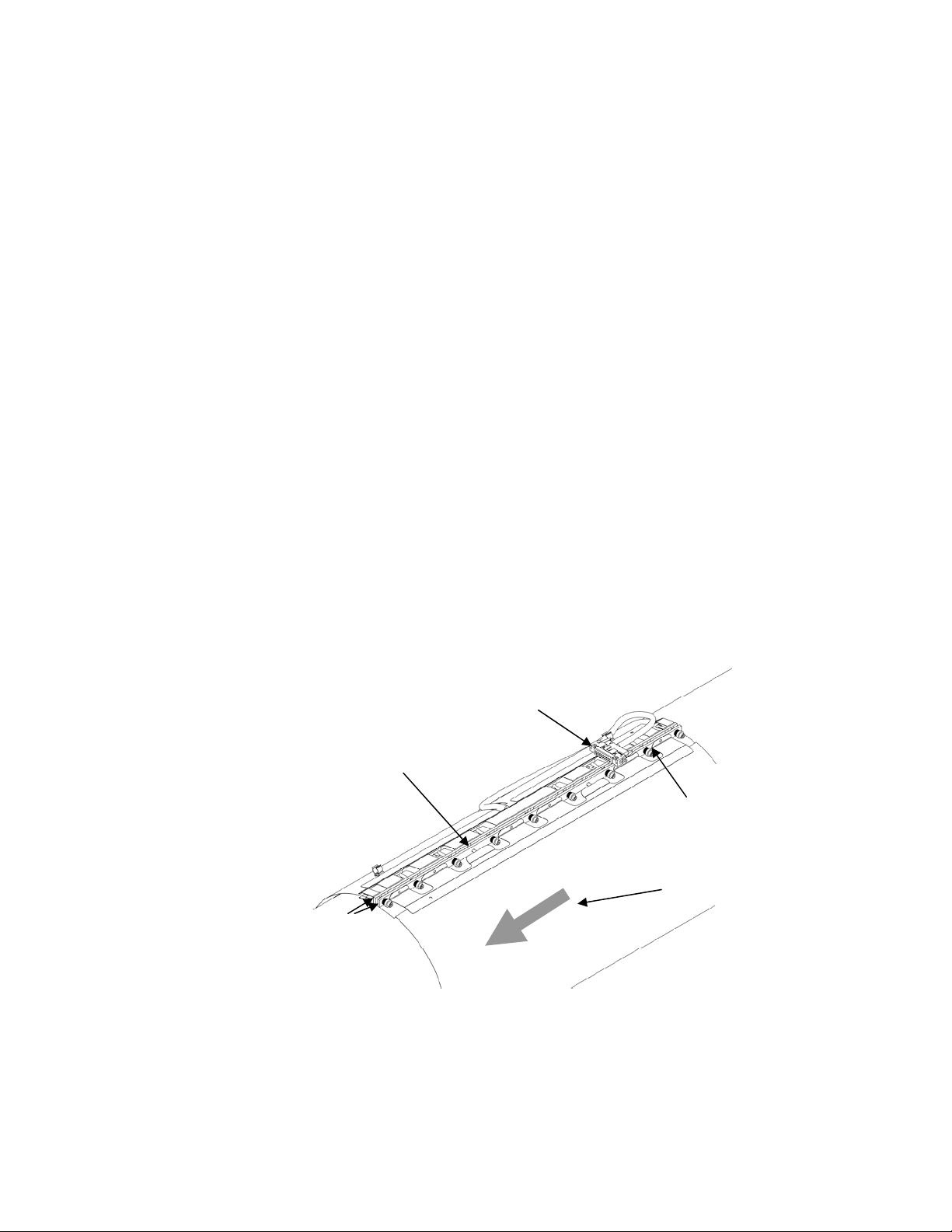

Position the

SONARtrac

polyimide film (amber colored) against the pipe surface. If possible,

orient the flow direction arrow on the sensor assembly with the

direction of flow within the pipe.

installation constraints, e.g. access to sensor fasteners, install

opposite to flow direction.

TM

sensor band assembly on the pipe with the

Note: If this is not possible due to

Alignment pins

(typical 2 places)

Attachment rails

Figure 6 Sensor Band Screw and Alignment Pins

Sensor band shorting plug

Sensor attachment screw

assembly (typical 9 places)

Flow direction arrow

Copyright © 2006 CiDRA Corporation Page 7-4

20675-01 Rev 02

Wrap the sensor band around the pipe and slide the alignment pins on

the attachment rail through their mating holes on the opposite

attachment rail. If the process pipe has a welded seam, align the gap

between the sensor attachment rails along the pipe weld seam. Final

positioning can be made after the sensor screws have been started.

Note: When installing the sensor band keep in mind the requirement

for transmitter connector socket assembly orientation as described in

Section 7.6. If necessary, due to cover installation constraints, wrap

the sensor band over the weld seam.

Carefully start threading the screws into their screw holes (avoid cross

threading) by using the hex driver until each screw is engaged about 2

turns. Once all screws are engaged make final positioning of the

sensor assembly with respect to pipe weld seam or desired orientation

on the pipe. The following table provides guidance for selecting the

proper hex tool and spacer gauge.

Sensor Band P/N

20380- ALL SIZES 20143-01 7/64 1/8 x 3/8

20409- ALL SIZES 20143-02 7/64 1/8 x 3/8

20690- ALL SIZES 20143-04 5/32 1/4 x 1/2

20686- ALL SIZES 20143-04 5/32 1/4 x 1/2

Spacer Gauge

P/N

Socket Head Screw

Hex Size (inch)

Table 4 Gauge Block and Screw Size

Band Attachment Rail

Size (Ref)

Start with the center most screw and tighten screws, alternating from

side to side, 3 - 4 turns at a time. Refer to the following figure for the

screw tightening sequence.

Note: Repeat the tightening sequence

only until the Belleville disc springs on the screws begin to compress.

The sensor screw stack up assembly is illustrated in Figure 8.

3 4 5 6 7 8 9

1 2

Sensor band assembly

Figure 7 Sensor Band Screw Tightening Sequence

Copyright © 2006 CiDRA Corporation Page 7-5

20675-01 Rev 02

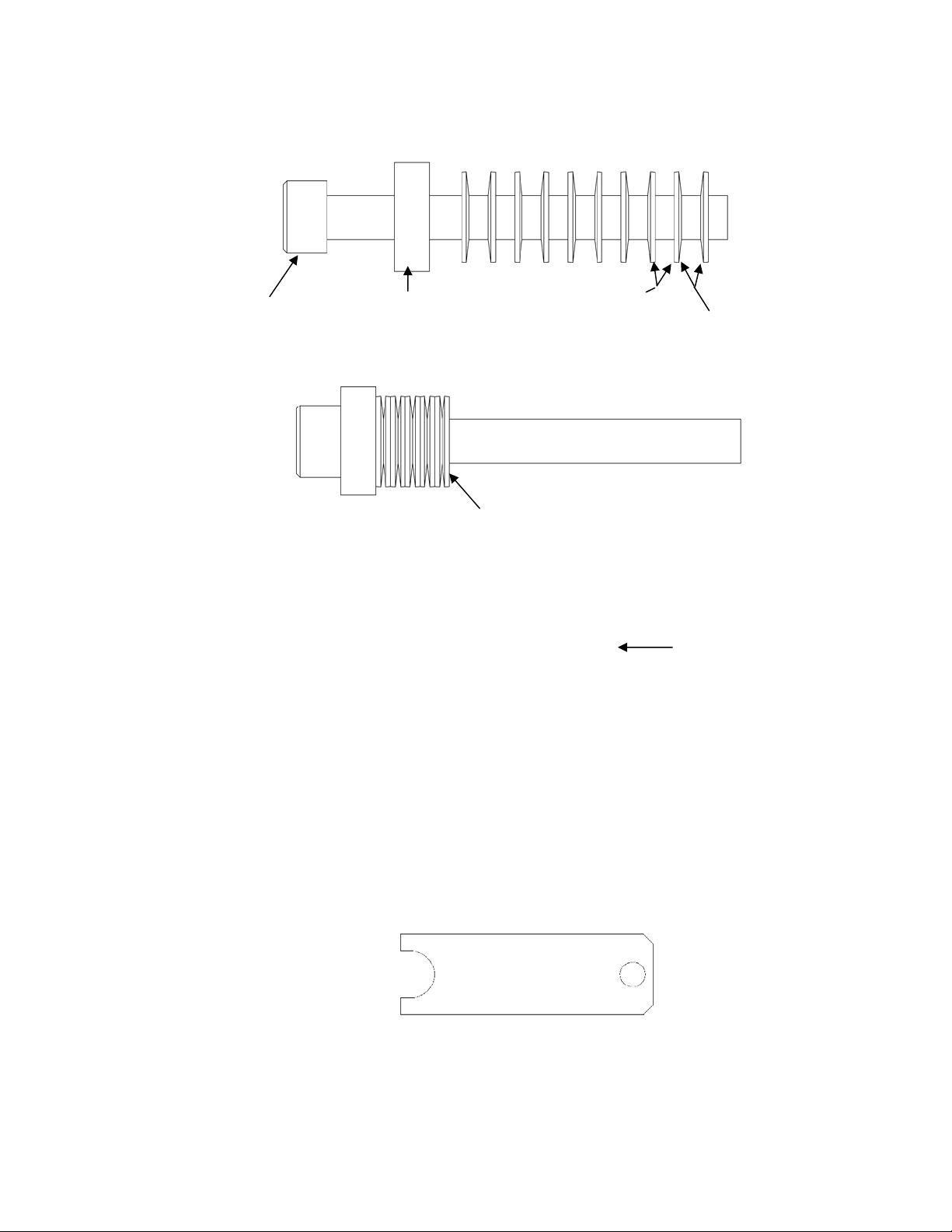

)

Sensor screw

Sensor screw spacer

(may be integral to

screw head

Sensor Belleville washers

concave side

Note: 10 Belleville Washers on 2-16” bands

Sensor Belleville washers

convex side

Belleville washers and spacer

compressed against screw head

Note: Sensor bands 18” and

) ( ) ( ) ( ) ( ) ( ) ( ) (

larger have 14 Belleville washers

per screw arranged as shown

Figure 8 Sensor Band Screw Assembly

Further tightening of the sensor band screws is made while using the

sensor band spacer tool (shown below) furnished with the sensor

band. The spacer tool is used to set the compression on the Belleville

washers referred to above. Refer to Table 4 for the appropriate

spacer tool based on sensor band part number.

Figure 9 Sensor Band Spacer Tool

Copyright © 2006 CiDRA Corporation Page 7-6

20675-01 Rev 02

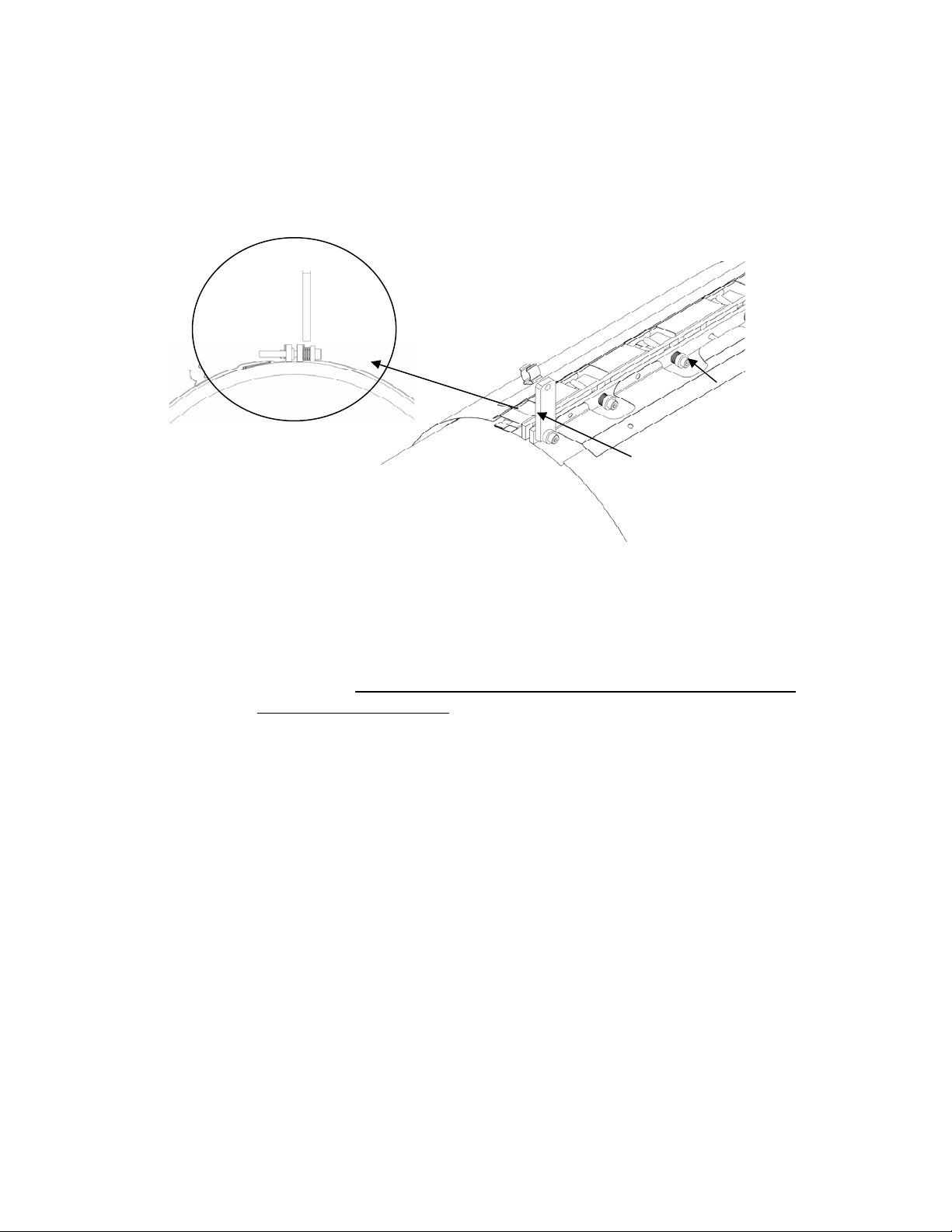

Using the sensor band screw tightening sequence shown in Figure 9,

insert the sensor band spacer tool over the Belleville washers on the

middle sensor screw assembly and tighten it such that it is snug but

the spacer tool can still be removed. The following figure illustrates

use of the sensor band screw spacer tool.

Side view

Sensor screw with

Belleville washers

compressed (typ)

Sensor screw spacing tool

installed on sensor screw

Figure 10 Sensor Band Spacing Tool Installed on Sensor Screw

Note: Ensure the spacer tool is perpendicular to the attachment rail to

ensure proper tightness. Remove the tool, move to the next sensor

screw, and repeat the tightening on each of the sensor screws.

Important: Tighten each screw once only. Do not retighten each

screw using the gauge.

Final sensor band screw tightening is as follows:

A. For sensor bands sized for 6” and smaller pipe:

1. Tighten screws #1-7 an additional one-half turn in the numbered

sequence given in Figure 7. Do not tighten screw #8 & 9 (screws

on either end of the sensor band).

B. For sensor bands sized for 8” and larger pipe:

1. Starting at screw #1 in Figure 7, tighten each screw an additional

one-half turn in the given numbered sequence.

2. Once all nine screws have been tightened, tighten each screw an

additional one-half turn in the given numbered sequence.

3. Once all nine screws have been tightened a second time, tighten

screws #1-7 an additional one-half turn in the given numbered

sequence.

Attach the sensor cable in the retaining clip on the top of the sensor

band. The connector on this cable will attach to the sensor cover

Copyright © 2006 CiDRA Corporation Page 7-7

20675-01 Rev 02

connector as described later in the manual. If necessary, use a piece

of tape to temporarily retain the connector on the band so it will be

positioned directly below the sensor cable access panel. The final

sensor band assembly is illustrated below.

Sensor screws

tightened

Sensor cable installed

in cable retaining clip

Sensor cable connector with

shorting plug installed

Alignment pins

Figure 11 Installed Sensor Band

CAUTION

Over-tightening of fasteners may damage threads on the sensor.

Under tightening may affect flow meter performance. Always

use the sensor fastener spacer tool to ensure proper fit of the

sensor assembly.

7.5.1 Sensor Band Short Test

Shorting of the sensor band to the process pipe may cause signal

interference or electrical faults in the system in some instances. The

sensor band must be electrically isolated from the process pipe.

Use an ohm meter and verify the sensor band is isolated from the

pipe. Measure the resistance between the sensor rails and the pipe to

ensure there is no continuity between the sensor band and the

process pipe. If the band is shorted identify where the short is located

and eliminate the short. For example, if a sensor screw is shorting to

a pipe weld bead, reposition the sensor band, or lightly file the weld

bead to eliminate the interference.

Copyright © 2006 CiDRA Corporation Page 7-8

20675-01 Rev 02

t

r

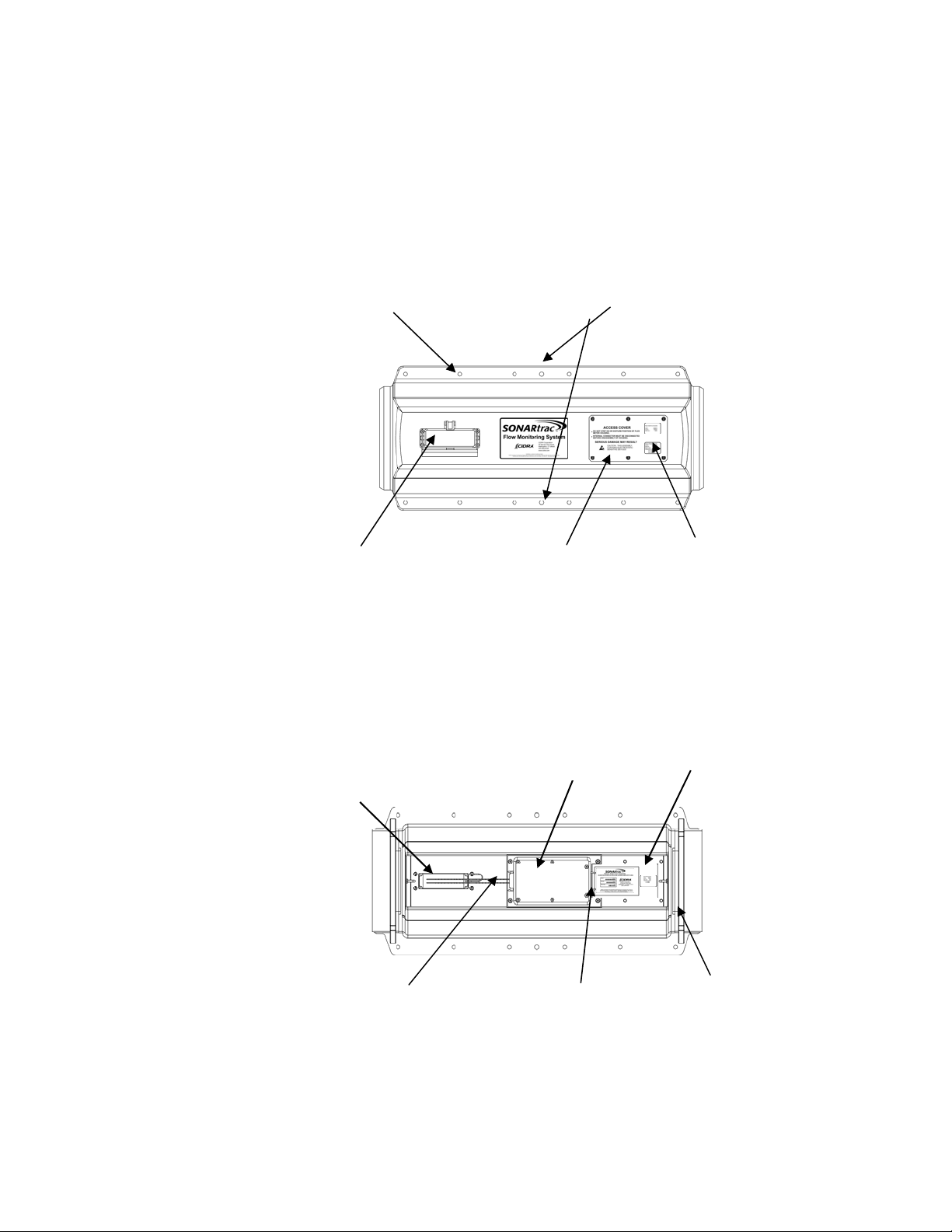

7.6 Sensor Cover Installation

The upper sensor cover assembly outside and inside are illustrated in

the following figures. Cover sizes up to 16 inch are typically made of

fiberglass. Cover sizes 18 inch and above are made from stainless

steel. The layout of both styles is essentially the same. The

differences in installation will be called out in the following sections.

Sensor cover bolt holes (12 places)

Transmitter cable

connector socke

Sensor cable access panel

Figure 12 Upper Sensor Co ver Assembly Outside View

Transmitter cable

connector socket base

Sensor cover alignment bolt holes (2 places)

Pre-amplifier

electronics board and

Pre-amplifier

cove

Sensor band

information label

Sensor cable access panel

Pre-amplifier outlet cable

connector assembly

Sensor band cable socket

Upper cover gasket

Figure 13 Upper Sensor Co ver Assembly Inside View

Copyright © 2006 CiDRA Corporation Page 7-9

20675-01 Rev 02

It is helpful to have a second person available to help when installing

the cover assembly. When the sensor head is installed on a

horizontal pipe, the sensor cover should be installed such that the

transmitter cable connector socket is located within the 105° arcs

shown in the following figure. Do not install the cover with the

transmitter cable connector socket installed downward. (An electrical

pre-amplifier board is mounted on the inside of the cover.) The ability

to route the sensor band to sensor cover cable may dictate cover

orientation. The cable gland on the sensor head to transmitter cable

connector, when installed, should face away from the cover.

Transmitter cable

connector socket

Lower cover assembly

Figure 14 Orientation of Sensor Cover

If the sensor head is installed on a vertical pipe, the cable connector

should be located so it is facing downward.

7.6.1 Fiberglass Cover Installation

Remove the sensor cable access panel from the sensor upper cover

assembly.

Apply a coating of the P/N 52307-01 PTFE Pipe Sealant (acts as a

lubricant during installation and sealant once cured) to the cover

gaskets.

Note: This sealant is not used with stainless steel covers.

Upper cover

assembly

Install the sensor upper cover assembly over the sensor assembly.

Install the lower sensor cover. Hold the halves in place with spring

clamps.

cable.

Note: Ensure the sensor cover does not pinch the sensor

Note: Ensure the sensor cable connector is accessible through

the sensor cable access panel. (Reposition cover or cable connector

if necessary.)

Care must be taken during installation of the sensor band and sensor

band cover to ensure the sensor band cable does not become

pinched between the cover halves. The problem may show up as a

sensor failure during sensor tests and operation of the meter.

This potential problem is most likely to occur in small size meters (<6inch) due to the length and stiffness of the sensor band cable.

Copyright © 2006 CiDRA Corporation Page 7-10

20675-01 Rev 02

y

The following steps will help minimize this problem:

1. Visually look between the cover halves to ensure the cable is not

being pinched.

2. Once the cover halves are bolted in place and during installation of

the sensor band cable connector into the pre-amplifier through the

access cover, verify the sensor band cable is free and not pinched

between the cover halves.

3. If the cable is not free and appears to be pinched, remove the

sensor band cable from the pre-amplifier, unbolt the cover, free the

cable from between the cover halves and then re-install. Note this

on the installation report for future reference.

Refer to the following figure. Align the center alignment holes on the

sensor cover. Install a 3” long 3/8” diameter alignment bolt, with

washer under the bolt head, in center holes on both sides of the cover.

Install a washer and nut on the alignment bolts. Install a 5/16”-18 x

1.5” tin plated 316 SST bolt with washer into each of the 12 cover bolt

holes in the upper cover.

Transmitter cable connector

socket

Upper cover

assembly

Bolt

Nut

Cover bolt

Assembl

Washer

Washer

Lock washer

Alignment

bolts

(2 places)

Lower cover

assembly

Cover bolt

assemblies

(12 places)

Figure 15 Sensor Cover Bolt Installation

Copyright © 2006 CiDRA Corporation Page 7-11

20675-01 Rev 02

6

8

7

3

5

9

Tighten the alignment bolts 2 – 3 turns alternating between both sides

of the cover until the cover bolts protrude through the lower cover

assembly.

Note: Use of the alignment bolts may not be necessary if

the cover bolts and nuts can be made up.

Place a washer, lock washer and nut on the end of the sensor cover

bolt once it is through both halves of the cover and begin drawing the

cover halves together using the cover bolts. It is no longer necessary

to use the alignment bolts to draw the cover halves together.

Continue tightening the sensor cover bolts 1 - 2 turns in the tightening

sequence shown in Figure16. The gasket on the cover will compress

and the cover assembly halves will pull together. Tighten the cover

bolts until the two halves of the cover are drawn together so that there

are no gaps along the axis of the cover.

Note: There may be some

small gaps between the cover halves in between the bolts; this is

normal.

Alignment bolts

11

1

10

2

4

12

Figure 16 Sensor Cover Bolt Tightening Sequence

Note: The gaskets on the cover assembly will compress and conform

to the pipe surface during installation. Upon removal the gasket will

relax a little and will provide proper sealing if re-installed at the same

location from where it was removed.

CAUTION

The sensor cover gasket on fiberglass covers should be

replaced, if the assembly is moved to another pipe, to minimize

the potential for water leakage into the cover. Refer to rework

instructions (RI-0001) for information.

Following installation of the cover fasteners remove the alignment

bolts.

Copyright © 2006 CiDRA Corporation Page 7-12

20675-01 Rev 02

Loading...

Loading...