CIAT V300 User Manual

NA 12.54 D

12 - 2016

Control manual

V300

CONTENTS PAGE

1 - SAFETY/HANDLING GUIDELINES 2

1.1 General information 2

1.2 Protection against electrocution 2

1.3 Use 2

1.4 Warnings and danger: 2

2 - V300 3

3 - OPERATION 4

4 - USER TERMINAL AND RADIO-FREQUENCY TERMINAL 5

5 - DETAILS OF THE DISPLAY TERMINAL SCREENS 6

6 - MEANING OF SYMBOLS 6

7 - INSTALLATION PARAMETERS 7

8 - DIAGNOSTICS 9

9 - WIRING SCHEMATIC DIAGRAM FOR INDIVIDUAL UNITS 10

10 - MEASURING THE TEMPERATURE 11

11 - CHARACTERISTICS OF THE SENSORS USED BY THE V300 12

12 - MEASURING THE WATER TEMPERATURE 12

13 - RADIO-FREQUENCY TERMINAL 13

14 - MASTER/SLAVE FUNCTION 14

15 - PI CONTROL 17

16 - UNIVERSAL INPUTS 17

17 - CONNECTING THE FRAME CONTACT 18

18 - CENTRALISED MANAGEMENT WITH V300 19

19 - ELECTRICAL CONNECTIONS - CABLE TYPES 20

20 - TERMINAL DIMENSIONS 21

21 - USING THE USER TERMINALS 22

EN

Original text: French Version

EN - 1 N 12.54 D

1 - SAFETY/HANDLING GUIDELINES

1.1 General information

Installation, start-up and maintenance operations for this equipment may be dangerous if certain factors particular to this

installation, such as the presence of electrical and live components and the installation location, are not taken into account.

Only trained, qualified installers and technicians, who have undergone specific training on the product in question, are authorised

to install and start up this equipment.

During any servicing operations, all the recommendations and instructions given in the maintenance brochures, on the labels or in

the instructions accompanying the equipment must be observed, along with any other applicable safety instructions.

- Observe all the regulations in the safety codes.

- Wear safety goggles and work gloves

- Handle heavy or bulky equipment with care when lifting, moving and setting down

1.2 Protection against electrocution

Only personnel qualified in accordance with the IEC (International Electrotechnical Commission) recommendations must be

allowed to access the electrical components. It is particularly recommended that all the electrical supplies to the unit are switched

off before any work is carried out. Cut the main power supply using the disconnect switch or circuit breaker.

Important: the V300 control system includes electronic components. These may cause or be subject to electromagnetic

disturbance if they are not installed and used in accordance with these instructions

Important: this equipment has been found to comply with the essential requirements of the directives in reference to the

following standards:

- Electromagnetic compatibility: 2014/30/EU

- Low voltage directives: 2014/35/EU

- Directive concerning the restriction of the use of hazardous substances in electrical and electronic equipment

(RoHS): 2011/65/EU

1.3 Use

This appliance is not designed to be used by persons (including children) with limited physical, sensory or mental

capabilities, or by persons with insufficient experience or knowledge, unless they are being supervised by a person

responsible for their safety or have received instructions on the use of the appliance from such a person.

Children must be supervised to ensure that they do not play on or with the appliance. Children must not be allowed to

carry out cleaning or maintenance work whilst unattended.

1.4 Warnings and danger:

Follow the precautions and instructions below to ensure your safety and that of your environment, and to prevent

damage to your equipment.

Warning : the equipment must be connected to an electrical system that conforms to

the standards in force in the country (NFC 15-100 in France). It must be equipped with

protection against overcurrent, overvoltage and earth faults.

Warning : for your own safety, it is essential to switch off and disconnect the equipment from

the mains before carrying out any work on it.

Warning : the safety of this product is only guaranteed if it is used as intended. Maintenance

may only be carried out by qualified personnel.

The PRODUCT must only be used indoors, at an altitude below 2000 metres.

NA 12.54 D EN - 2

General danger : If the instructions are not followed, there is a risk of equipment damage.

Electrical danger : If the instructions are not followed, there is a risk of electrocution and

injury.

Read the instructions in this manual.

Part of Class II equipment

Protective device Devices that protect against overloads, short circuits and earth faults must conform to standard NF C 15-100,

and must be part of the building in which the equipment is installed. The circuit breaker must be designed for a nominal current

in Amperes that corresponds to the CIAT equipment model purchased.

Waste disposal by users in private households within the European Union.

EN

This symbol, either on the product or its packaging, indicates that the product must not be disposed of in ordinary

household waste. Instead, it is your responsibility to ensure that you dispose of your waste by taking it to a

designated recycling point for electrical and electronic devices. Separating your waste for recycling during disposal

helps preserve natural resources, protect the environment and safeguard health. To find your nearest recycling

centre, contact your local council, waste disposal service or the store from which you purchased the product.

2 - V300

CIAT's V300 control is designed for use with system-powered comfort units (AHUs, cassettes, etc.) in 2-tube, 2-tube/2-wire and

4-tube applications using recirculated air

It can be used to follow a time schedule (connected to the V300 zone timer as an option) and operate using a master/slave

function. It controls 230 V thermo valve actuators.

The V300 system comprises a controller integrated in the comfort unit and a user terminal for adjusting the setpoints and

operating modes.

The terminal is available in a wall-mounted wired version (to be connected to the controller by the installer), a flush-mounted

version (assembled and connected in the factory), and a radio-frequency version (terminal + receiver supplied in kit form)

Main functions:

- PI action

- Controlling a 3-speed or HEE fan, automatically or manually.

- Automatic heating/cooling switching with changeover sensor (2-tube application).

- 2 potential-free inputs for window switch, alarm or timer.

- 4 operating modes: Comfort/Economy/Frost protection/Off

Eubac certification

• The V300 controller is Eubac-certified under licence No.215472

• The corresponding CA values are as follows:

Applications: → 2-tube: Heating: 0,1 Cooling: 0,1

→ 2-tube/2-wire: Heating: 0,2 Cooling: 0,1

→ 4-tube: Heating: 0,1 Cooling: 0,1

• Labelling: AA

Note:

- These values are obtained with the CIAT NTC 10k Ω return air temperature sensor at 25°C

- These values can be viewed on the Eubac certification website: http://www.eubaccert.eu

EN - 3 N 12.54 D

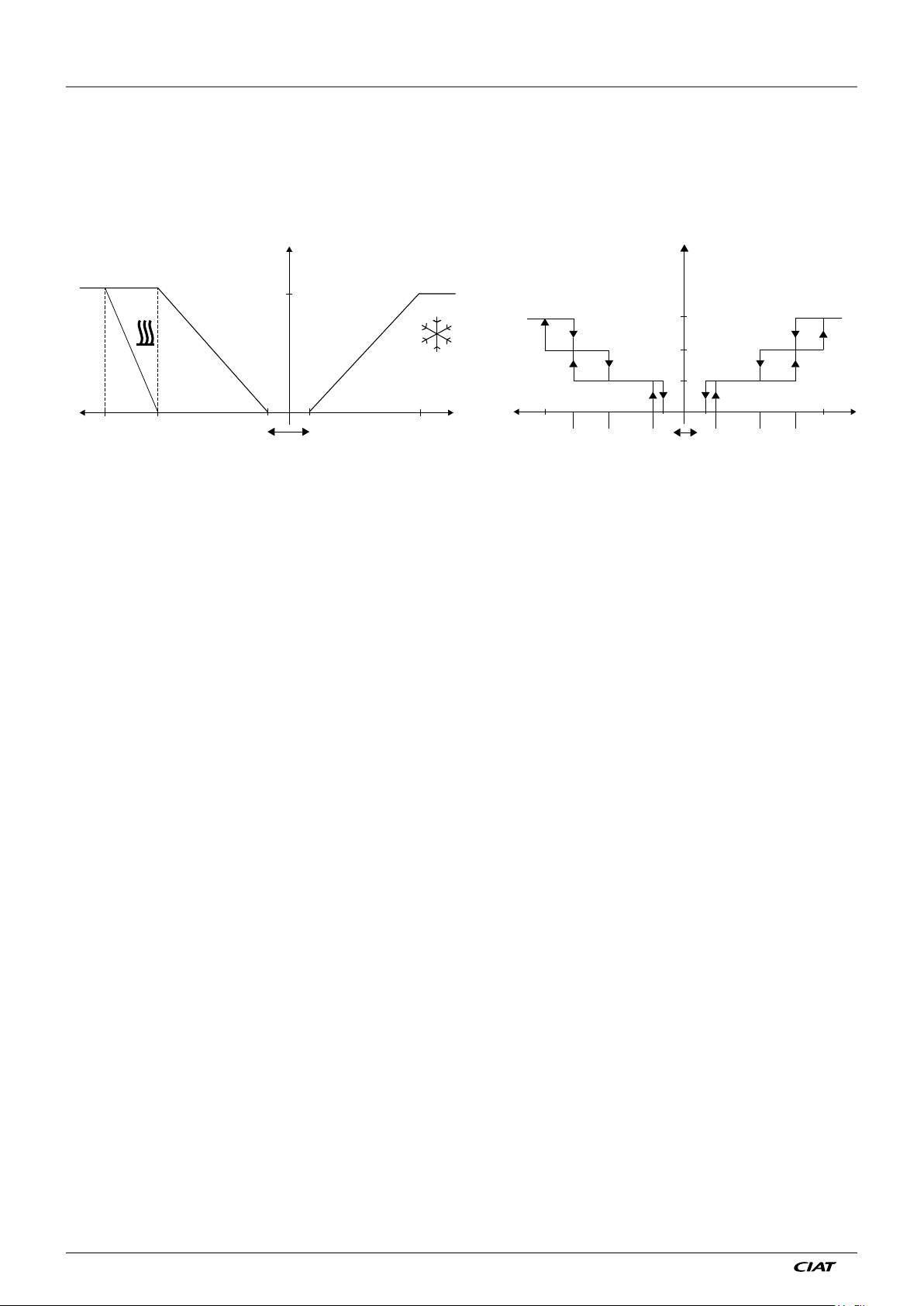

3 - OPERATION

The control is Proportional and Integral. It controls the valve(s), the electric heater and the ventilation speeds (3 speeds + Auto

position) simultaneously.

Valve opening + electric heater *

Ventilation speed in deadband cutout (3 speeds)

Calculated by the PI algorithm

100 %

3

2

1

0

Proportional band

100 %

120 %

Electricity *

valve

Proportional band

HT CT HT CT

100 %100 %

100 %

80 % 80 %50 % 50 %10 % 10 %

* Case 2T2F

Deadband adjustable by 2 K min. Deadband adjustable by 2 K min.

When exiting the heating or cooling mode, the fan continues to operate for 2 minutes, thereby ensuring post-ventilation of the unit.

The potential electric heater power is modulated by a time-proportional signal using a 4-minute time base.

All calculations take place in the controller. The control terminal is used to adjust the temperature setpoint, switch between

automatic and manual ventilation, switch the unit on or to standby and, if applicable, to measure the room temperature.

The connection between the terminal and the controller is a 4-wire connection (2 shielded twisted pairs) with the shielding

connected to the comfort unit earth. (see pp.10 & 16)

Regulation on the air:

The regulation V300 also allows a functioning on the air (without gate(crack))

- In this case, the use of pumps of condensats on devices equipped with this mode of regulation stays of the responsibility of the

customer and/or the installer in case of dysfunction of this pump (risk of overflowing of the tub(ferry,high school diploma) of the

condensats of in the permanent irrigation of the cold battery(drum kit)).

- For vertical units equippedwith this control principle, the effect of the continuous radiation from the exchanger coil on the sensor

vill not enable the control system to function correcty. It is the customer's responsibility to find a suitablelocation for optimum

positioning of the sensor and satisfactory operation of the units.

NA 12.54 D EN - 4

4 - USER TERMINAL AND RADIO-FREQUENCY TERMINAL

Wall terminal with

digital display

Radio + receiver wall-mounted terminal

1) Display:

This continuously displays the temperature detected by the sensor, the current operating mode, the chosen ventilation speed, and

any alarm present.

Flush-mounted terminal with digital display

EN

The desired temperature can be modified by pressing the

The temperature measured by the sensor is displayed again 8 seconds after the

It also displays error messages, reports windows opened or emergency switch-off activation, thereby enabling an initial diagnostic.

2) Temperature adjustment keys

and diagnostic values. +/- 4°K default setting (adjustable by parameter)

3) Standby key

chosen configuration).

4) Ventilation key

details below)

Note:

Different key combinations can be used to access:

- parameters

- diagnostics

- keypad lock

This enables you to change the operating mode (comfort, economy, frost protection or off according to the

. It is used to select the ventilation speed (Auto, 1, 2, 3) if the controller is in comfort mode (see display

or . These enable you to adjust the temperature setpoint and also access the set-up

or keys

or key was pressed

EN - 5 N 12.54 D

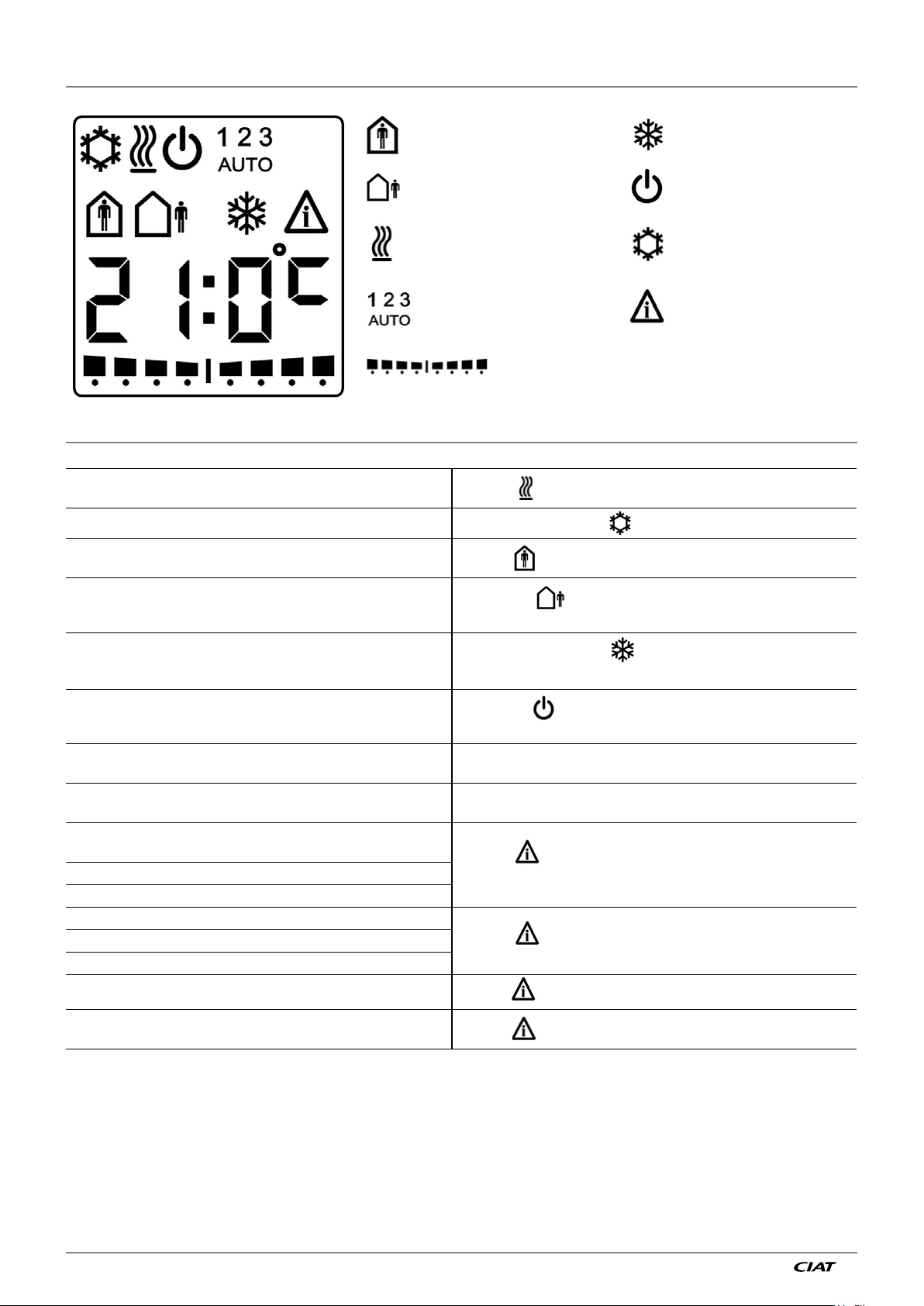

5 - DETAILS OF THE DISPLAY TERMINAL SCREENS

: Comfort mode

: Economy mode

: Heating in progress : Cooling in progress

: Manual ventilation speeds

: Automatic position

: Setpoint shift bar chart

6 - MEANING OF SYMBOLS

Heating

Refrigeration Air conditioning symbol fixed

Comfort

Heating

Symbol

symbol fixed

: Frost protection mode

: Off mode

: Alarm and fault

Economy set using the zone timer or sleep button on the

terminal (depending on configuration).

Frost protection by window contact

Frost protection set using the zone timer or sleep button on

the terminal (depending on configuration).

Off set using the zone timer or sleep button on the

(depending on configuration

Setpoint adjustment

Ventilation

Indoor environment sensor fault if indoor environment sensor

assigned priority

Return sensor fault if return sensor assigned priority

Simultaneous fault on indoor environment and return sensors

Condensate drain pump alarm

Fan motor assembly unit alarm (if HEE)

General alarm

Master unit but communication lost with slave(s)

Master or Individual unit but communication lost with the

Zone timer

).

terminal

Eco symbol

No ventilation indication

Frost protection symbol

No ventilation indication

Off symbol

No ventilation indication

Setpoint adjustment depends on the configuration (± 4°K by

default)

1, 2 or 3: LS, MS or HS manual selected

AUTO: ventilation controlled automatically by the controller

Symbol

Symbol

Symbol (see d07 = 1.0.0)

Symbol (see d08 = 2)

(see d07 = 0.0.1)

(see d07 = 0.1.0)

NA 12.54 D EN - 6

Loading...

Loading...