Page 1

Page 2

CONTENTS

General Specifications 1

Section I—Suspension 4

Section II—Axle—Rear 16

Section III—Brakes 17

Section IV—Accessory Belt Drives 23

Section V—Cooling System 26

Section VI—Electrical System 27

Section VII—Engine 41

Section VIII—Fuel and Exhaust System 70

Section IX—Frame 74

Section X—Steering 76

Section XI—Transmission 80

Section XII—Universal Joints and Propeller Shaft 83

Section XIII—Wheels and Tires 84

Section XIV—Body and Sheet Metal—Town and Country Models 85

Section XV—Lubrication 88

Section XVI—Radio and Heater 88

Section XVII—Heater—Air Conditioning 97

MyMopar.com

Page 3

CHRYSLER SERVICE MANUAL

SERVICING THE 1959 CHRYSLER AND IMPERIAL

GENERAL SPECIFICATIONS—1

This supplement contains advanced service information

on

perial Models. Only changes and improvements affecting

are included.

procedures will remain the same as those

If

the information desired cannot

be

found

for

corresponding models covered

Chrysler and Imperial Service Manual D-16350.

In order

Service Manual D-l 6350, the corresponding

The supersedence

The service tools referred

Company, 17640 Grand River, Detroit 27, Michigan,

Extra copies

Order from Chrysler Division, P.O.

to

use this supplement to best advantage with

or

of

these models is as follows:

Chrysler Models:

Windsor

Saratoga

New Yorker

Imperial Models

Custom,

and LeBaron

of

this Supplement

Crown,

to in

this manual are available through the Miller Manufacturing

are

available at $2.00 each, under part number D-l6798.

Box

1958

LC-1

LC-2

LC-3

1958

LY-1

1658, Detroit 31, Michigan.

the

superseding car models must be understood.

U.S.A.,

the new 1959 Chrysler^ and Im-

the

servicing

in

this supplement

of the new

the

models

servicing

in the 1958

previous Chrysler and Imperial

1959

MC-1

MC-2

MC-3

1959

MY-1

unless otherwise specified.

CHRYSLER DIVISION

Chrysler Corporation

DETROIT 31, MICHIGAN

Chrysler Corporation reserves

ments

in its

manufactured.

D-l 6798 12M-SD & TO-10-58

product without imposing

the

right

to

make changes

any

obligations upon itself

in

design

to

or to

make additions

install them

on its

products previously

to or

LITHO

improve-

IN

U.S.A.

MyMopar.com

Page 4

2—GENERAL SPECIFICATIONS

CHRYSLER SERVICE MANUAL

MC-l WINDSOR

MC-2 SARATOGA

MC-3 NEW YORKER

MY-1 fMPERiAL

1959 Chrysler and Imperial Models

59 x 143

MyMopar.com

Page 5

CHRYSLER SERVICE MANUAL

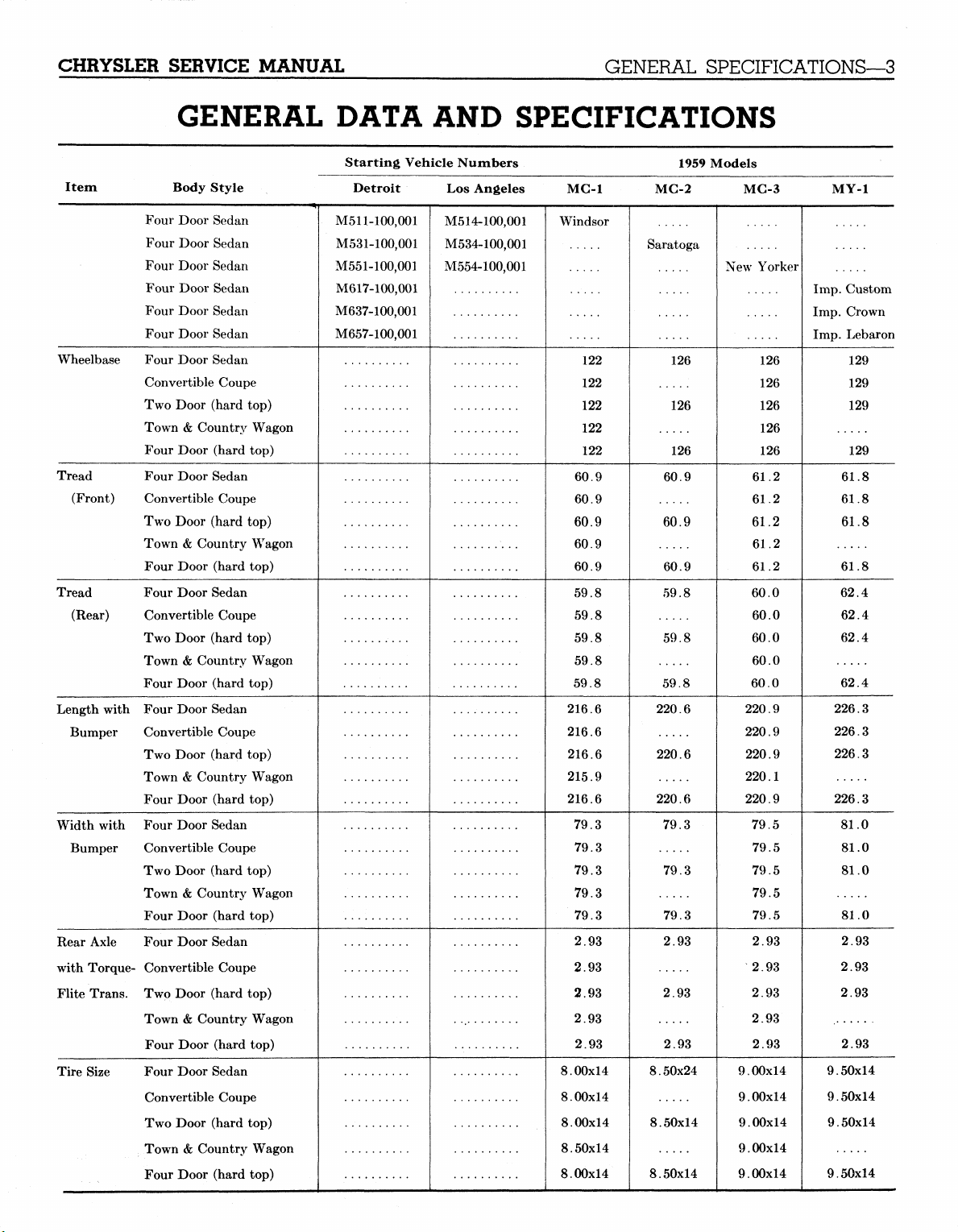

GENERAL DATA AND SPECIFICATIONS

GENERAL SPECIFICATIONS—3

Item Body Style

Four Door Sedan

Four Door Sedan

Four Door Sedan

Four Door Sedan

Four Door Sedan

Four Door Sedan

Wheelbase Four Door Sedan

Convertible Coupe

Two Door (hard top)

Town & Country Wagon

Four Door (hard top)

Tread Four Door Sedan

(Front) Convertible Coupe

Two Door (hard top)

Town & Country Wagon

Four Door (hard top)

Tread Four Door Sedan

(Rear) Convertible Coupe

Two Door (hard top)

Town & Country Wagon

Four Door (hard top)

Length with Four Door Sedan

Bumper Convertible Coupe

Two Door (hard top)

Town & Country Wagon

Four Door (hard top)

Width with Four Door Sedan

Bumper Convertible Coupe

Two Door (hard top)

Town & Country Wagon

Four Door (hard top)

Rear Axle Four Door Sedan

with Torque- Convertible Coupe

Flite Trans. Two Door (hard top)

Town & Country Wagon

Four Door (hard top)

Tire Size Four Door Sedan

Convertible Coupe

Two Door (hard top)

Town & Country Wagon

Four Door (hard top)

Starting Vehicle Numbers

Detroit

M511-100,001

M531-100,001

M551-100,001

M617-100,001

M637-100,001

M657-100,001

Los Angeles

M514-100,001

M534-100,001

M554-100,001

MC-1

Windsor

122

122

122

122

122

60.9

60.9

60.9

60.9

60.9

59.8

59.8

59.8

59.8

59.8

216.6

216.6

216.6

215.9

216.6

79.3

79.3

79.3

79.3

79.3

2.93

2.93

2.93

2.93

2.93

8.00x14

8.00x14

8.00x14

8.50x14

8.00x14

1959 Models

MC-2

Saratoga

126

126

126

60.9

60.9

60.9

59.8

59.8

59.8

220.6

220.6

220.6

79.3

79.3

79.3

2.93

2.93

2.93

8.50x24

8.50x14

8.50x14

MC-3

New Yorker

126

126

126

126

126

61.2

61.2

61.2

61.2

61.2

60.0

60.0

60.0

60.0

60.0

220.9

220.9

220.9

220.1

220.9

79.5

79.5

79.5

79.5

79.5

2.93

2.93

2.93

2.93

2.93

9.00x14

9.00x14

9.00x14

9.00x14

9.00x14

MyMopar.com

MY-1

Imp.

Imp.

Imp.

9.50x14

9.50x14

9.50x14

9.50x14

Custom

Crown

Lebaron

129

129

129

129

61.8

61.8

61.8

61.8

62.4

62.4

62.4

62.4

226.3

226.3

226.3

226.3

81.0

81.0

81.0

81.0

2.93

2.93

2.93

2.93

Page 6

4—SUSPENSION

CHRYSLER SERVICE MANUAL

Section I

SUSPENSION (FRONT SUSPENSION)

DATA AND SPECIFICATIONS

FRONT HEIGHT SPECIFICATIONS

MC-1,

MC-2, MC-3 and MY-1

Town and Country Models and Cars Equipped with Heavy Duty Springs

On Gars With True-Level Torsion Aire

MC-1,

MC-2,

MY-1

CASTER AND CAMBER WITH MANUAL STEERING

MC-3..

.iyg"+or

•

2Vs"+0T

Caster

~H° ± H°

Caster Camber

Type

Length

Width

Number of Leaves—Std. Susp

Rate—Std. Susp

Number of Leaves—True-Level. . .

Rate—True-Level

Steering Axis

Camber

0° ± M° (right)

+ H° ± H° (left)

Inclination

5° to 7°

At 0° Camber

(Vs"

WITH POWER STEERING

Steering Axis

Inclination

0°± M° (right)

Ji°.± M°(left)

5° to 7°

At 0° Camber

REAR SUSPENSION

REAR SPRINGS

MC-1

Sedans &

Coupes

Semi-Elliptic Semi-Elliptic Semi-Elliptic Semi-Elliptic Semi-Elliptic

57"

2.5"

5

95

# per in.

5

80 # per in.

Town &

Country

57"

2.5"

125

# per in.

95

# per in.

6

5

MC-2

Sedans &

Coupes

60"

2.5"

6

90

# per in.

6

75

# per in.

Sedans &

Coupes

60"

2.5"

7

90

# per in.

6

75

# per in.

MC-3

Town &

Country

60"

2.5"

135

# per in.

100

# per in.

7

7

Toe-In

y%

± w

Preferred)

Toe-In

± W

Preferred)

Semi-Elliptic

90

83

MY-1

Sedans &

Coupes

60"

2.5"

7

# per in.

6

# per in.

MyMopar.com

Page 7

CHRYSLER SERVICE

MANUAL

REAR SUSPENSION (Cont'd)

SUSPENSION—5

FRONT PIVOT

REAR

SHOCK ABSORBERS

TYPE

Silent Block Rubber'

Shackle with Rubber

Oriflow, Double Acting

Bushings

Bushing

Hydraulic

TRUE-LEVEL TORSION AIRE

CAR REAR HEIGHT (Axle Housing

Imperial Models Only

MC-1,

MC-2, MC-3 Models Only 4%

HEIGHT CONTROL VALVE

Make Midland-Ross

Type Bleed-Feed

AIR PRESSURE

High Pressure Tank 220

Low Pressure Volume Tank

COMPRESSOR

Make Tecumseh

Type Balanced Head

4% + or

to

Frame)

(1

pass, load)

(6 pass, load) 70

(9 pass, load)

20 psi

90 psi

+ or — y% inch

+ or

approximately

psi

approximately

approximately

—y% inch

—20

psi

TORQUE SPECIFICATIONS

AIR LINE

Elbow Mounting Screw 100

High Pressure Tank

Air Hose Assembly

Compressor Check Valve

Compressor

AIR SPRING

Retainer Bolt

COMPRESSOR

Adjusting Strap Bolts

Adjusting Strap

Bracket

Bracket

Cylinder Head Bolt 155

Front Bearing Housing Bolt

Oil Inlet Connector 130

Rear Cover Plate Bolt

Strap Bolt

Suction Muffler Retaining Screw

Support Bracket

Support

to Air

to

Support Bolt

to Air

Nut 35 ft. lbs.

to

Cylinder Head Bolt 70

to

Low Pressure Tank Height Control Valve Tube Nuts

to

High Pressure Tank Tube

to Air

Line Check Valve 130

Nut

10

30 ft. lbs.

to

T-Nut Bolt 15

30 ft. lbs.

Conditioning Compressor Bolt

17 in. lbs.

to

Water Pump Body

Hose Assembly Tube

f

17 in. lbs.

(or

Nut

125

Nut 90 in. lbs.

Nut 30 ft. lbs.

17 in. lbs.

Cylinder Block

or

Cylinder Head Bolt) 30

(4) 85 in. lbs.

Pounds Torque

in. lbs.

in. lbs.

in. lbs.

ft. lbs.

ft. lbs.

in. lbs.

in. lbs.

ft. lbs.

ft. lbs.

MyMopar.com

Page 8

6—SUSPENSION

CHRYSLER SERVICE MANUAL

TORQUE SPECIFICATIONS (Cont'd)

HEIGHT CONTROL VALVE

Axle Housing Link Bracket Bolt

Minimum Pressure Valve 130

Mounting Nuts 100

Nut 30 ft. lbs.

Pounds Torque

in. lbs.

in. lbs.

HIGH PRESSURE TANK

Drain

and

Charging Valve 140 in.

Mounting Bolts (%>) 10

Mounting Bolts

LOW PRESSURE VOLUME TANK

Mounting Bracket Screw 100

(%)

*

100

TOOL LIST

C-3128 Snap Ring Pliers

C-3293 300

C-3569 Detector Torch

C-3670

C-3677 Crankshaft Support Stand

C-3680 Front

C-3693 Adapter—used with Tool C-3293,

C-3694 Hold-Down Straps

PO-11 Pulley Puller

Air

lb.

Pressure Gauge

Spring Height Gauge

Oil

Seal Protector

(Pr.)

300 lb.

lbs.

ft. lbs.

in. lbs.

in. lbs.

pressure gauge

SUSPENSION (FRONT SUSPENSION)

The

new

upper control

plify

the

method

Tool C-3669

trol arm bushings.

OPERATION (FIG.

The upper control arms attach

welded

welded

openings

bolts have

matching removable cam

end.

is

required

to the

to its

frame. Each bracket has cam retainers

front and rear faces, around

for the

an

integral

arm and

of

adjusting caster

for

installation

1)

attaching bolts. Each

cam at the

is

installed

frame brackets

and

of

upper con-

to

brackets which

the

of the

head

of the

at the

Section

sim-

camber.

are

slotted

four

bolt.

A

threaded

I

Cams can be adjusted only

of

the

bolt. Turning

ball joint fore

camber). Turning both bolts

amount

ball joint

is 180°, therefore

direction

specifications

ADJUSTMENT

Apply MoPar solvent, Part

brushing dirt

in the

or aft to

in or out to

of

rotation

on

to

one

bolt will move

affect

same direction will move

affect camber. Full bolt travel

it

may

be

necessary

of the

both caster

expose bolt threads.

bolts

No.

by

turning the head

the

the

caster (more than

on one

and

side

an

the

to

reverse

in

order

camber.

1879318, after wire

In

addition

to

MyMopar.com

end

upper

equal

upper

the

attain

to

Page 9

CHRYSLER SERVICE MANUAL

SUSPENSION—7

RONT ADJUSTING JOLT

59x120 *&' .•- mmi

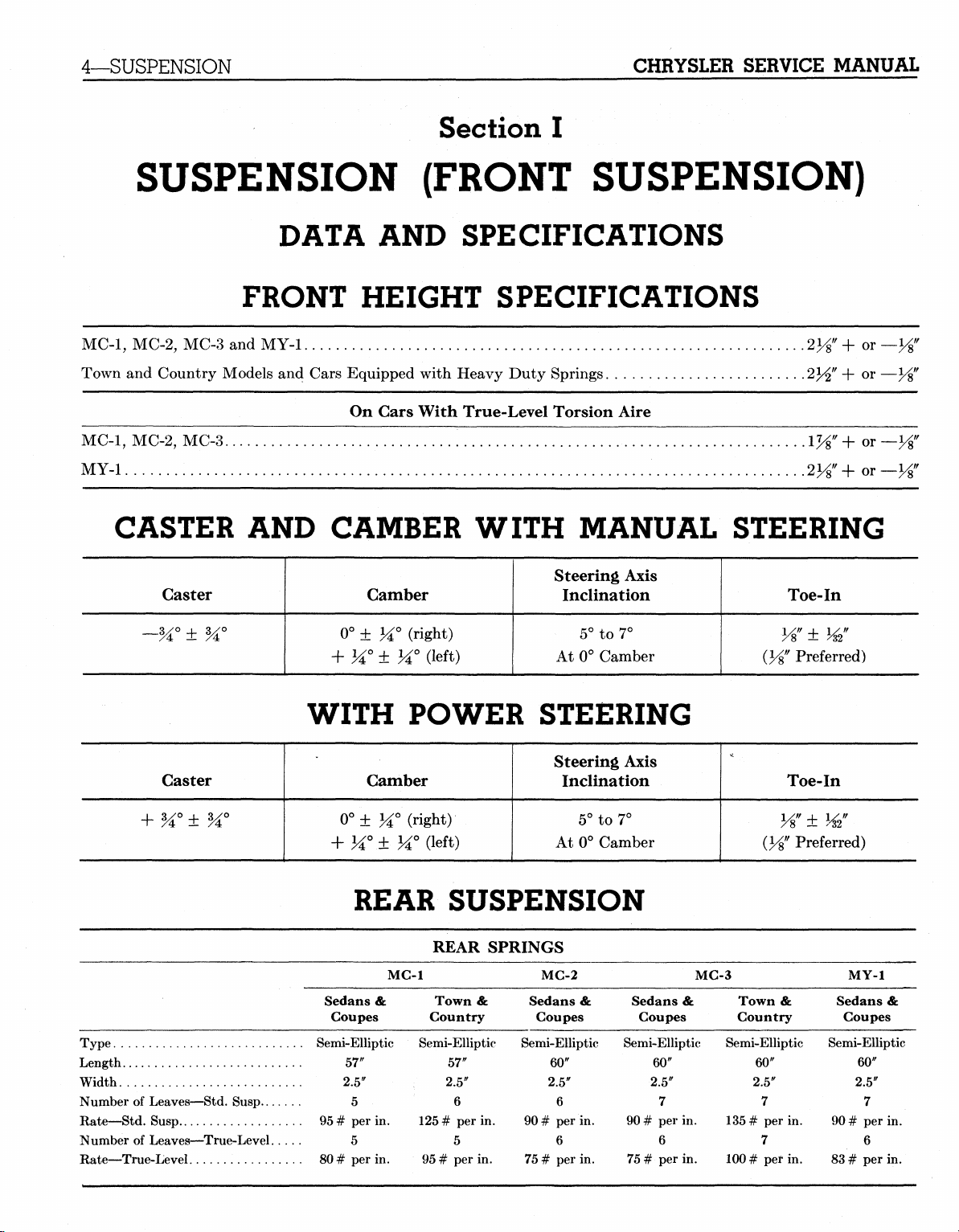

Fig.

1 — Caster and Camber Adjusting Bolts

the regular checks of tire size, tread wear, air pressure,

car loading, looseness and wear before measuring car height, caster and camber, the car must be

kept at one level whenever measurements are made.

Do this operation the same way every time a measurement is to be made: bounce the car, front first,

then rear, several times by grasping the center of

the bumpers. Release the bumpers on the down

stroke each time after the same number of bounces.

CASTER AND CAMBER

Front suspension height must be correct before

measuring caster and camber.

After Solvent No. 1879318 has loosened any rust,

carefully loosen the upper control arm attaching

nuts while holding the bolts from turning. Once

caster and camber has been adjusted, a very small

turn of the bolts will affect the gauge readings.

Turning one bolt affects caster more than camber.

By bringing caster to approximate specifications,

then turning both bolts an equal amount in the same

direction to bring camber to the preferred specification, will usually bring caster to the preferred setting. Tighten nuts to 60-70 foot pounds torque using

Tools C-3675 and C-3696. However, due to length of

Tools C-3675 and C-3696 used with torque wrenches

Tool C-524 or Tool C-3005 a recalibration will be

necessary in order to obtain proper torque. Using

Tool C-3675, the torque reading on wrench must

show 45 foot-pounds torque, which is equivalent to

60-70 foot-pounds torque; and using wrench C-3696,

torque reading must be 55 foot-pounds torque, which

again is equivalent to 60-70 foot-pounds torque. Recheck gauge readings.

All Chrysler Models with True-Level Torsion Aire

must maintain the specified rear height of 4% inches

-f or — i/8 inch, the Imperial (MY-1), rear height if

4%

+ or — % inch while setting the front end, with

engine running (see True-Level Torsion Aire).

REAR SUSPENSION

REAR SPRINGS

The rear springs remain the same with the following exception: the springs have a rubber pad between the springs and the axle housing. The "U"

bolt nut torque is 70 + or — 15 foot-pounds.

SHOCK ABSORBERS

The 1959 model cars are equipped with Oriflow shock

absorbers of the same type as used on the 1958 mod-

TRUE-LEVEL TORSION AIRE

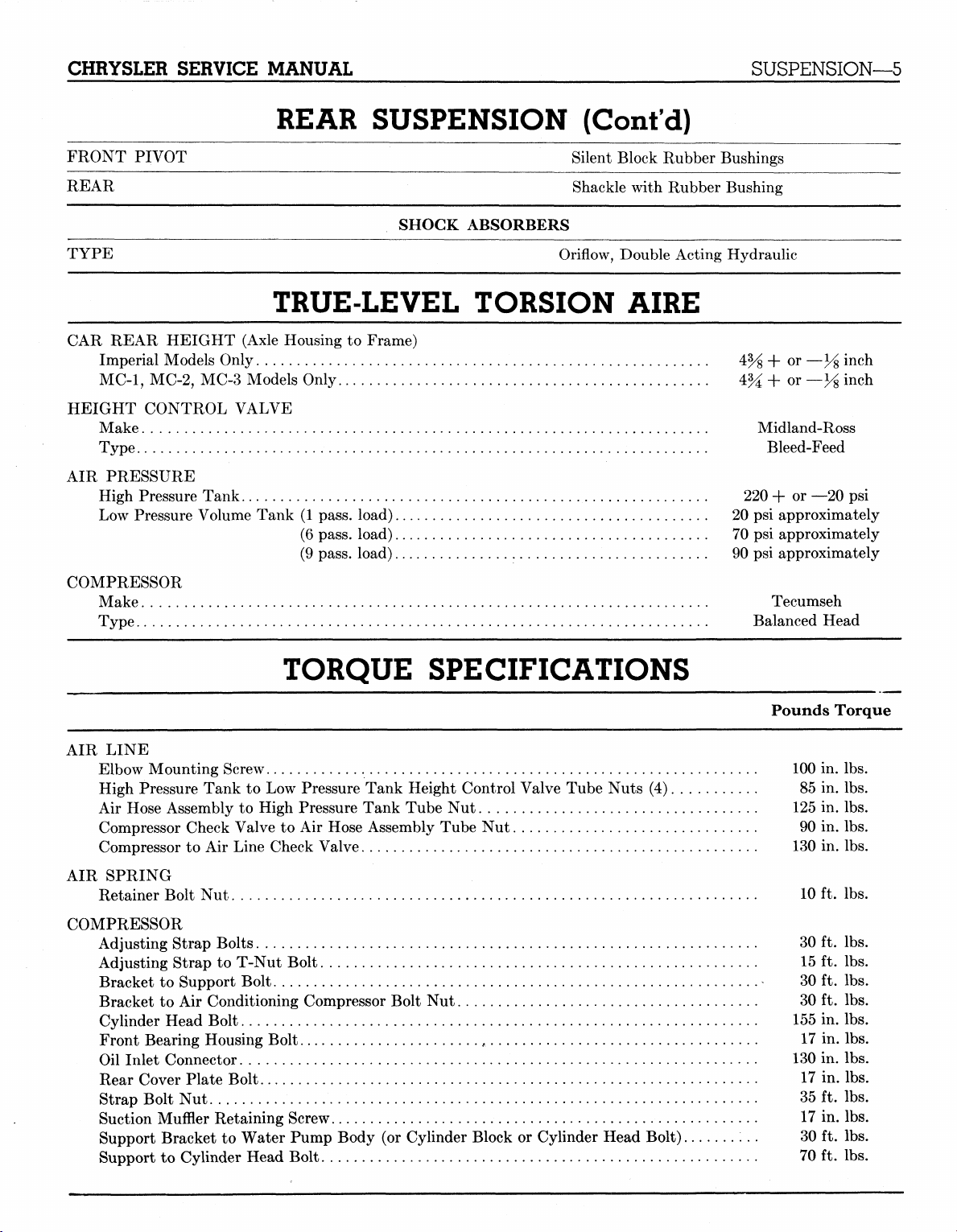

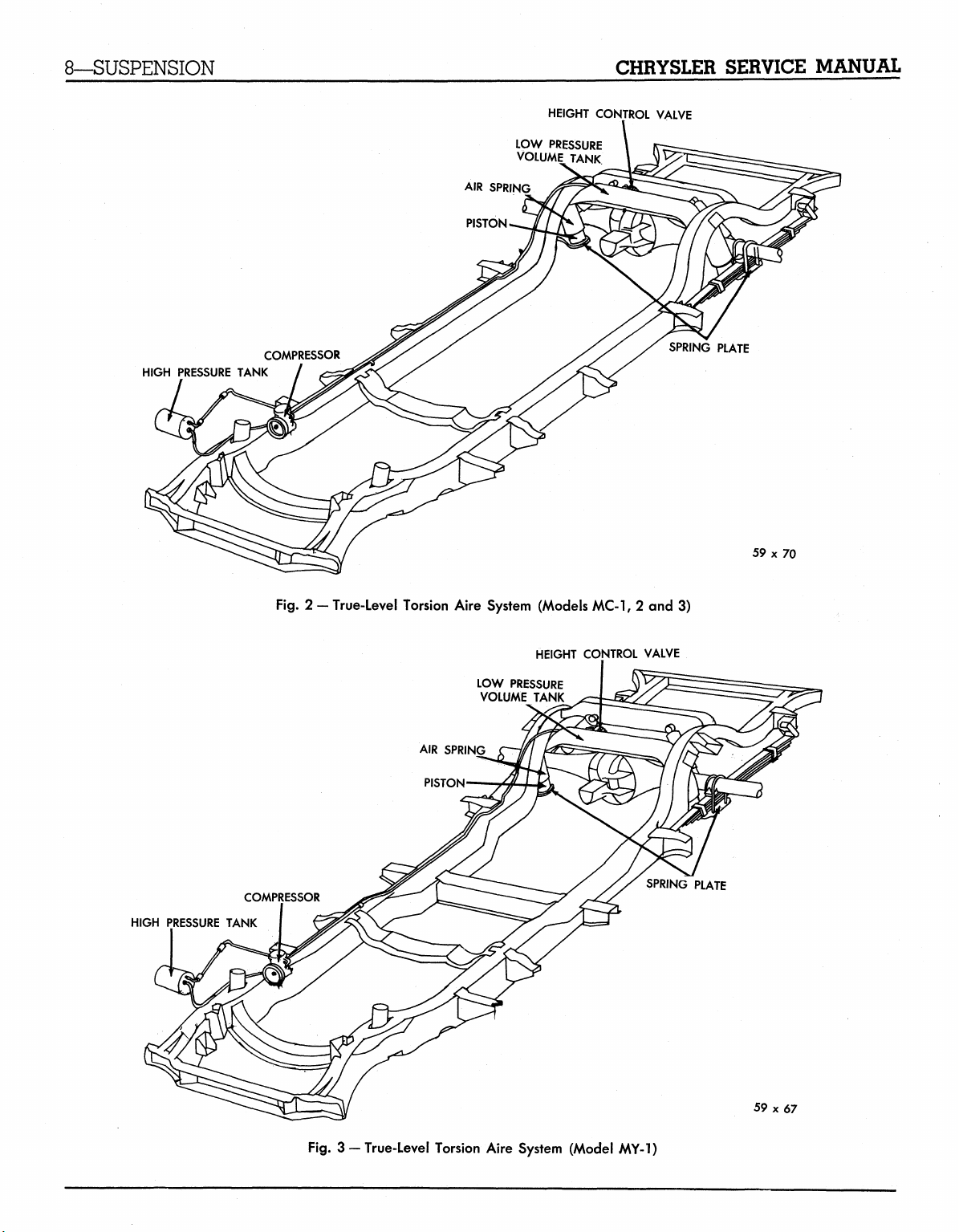

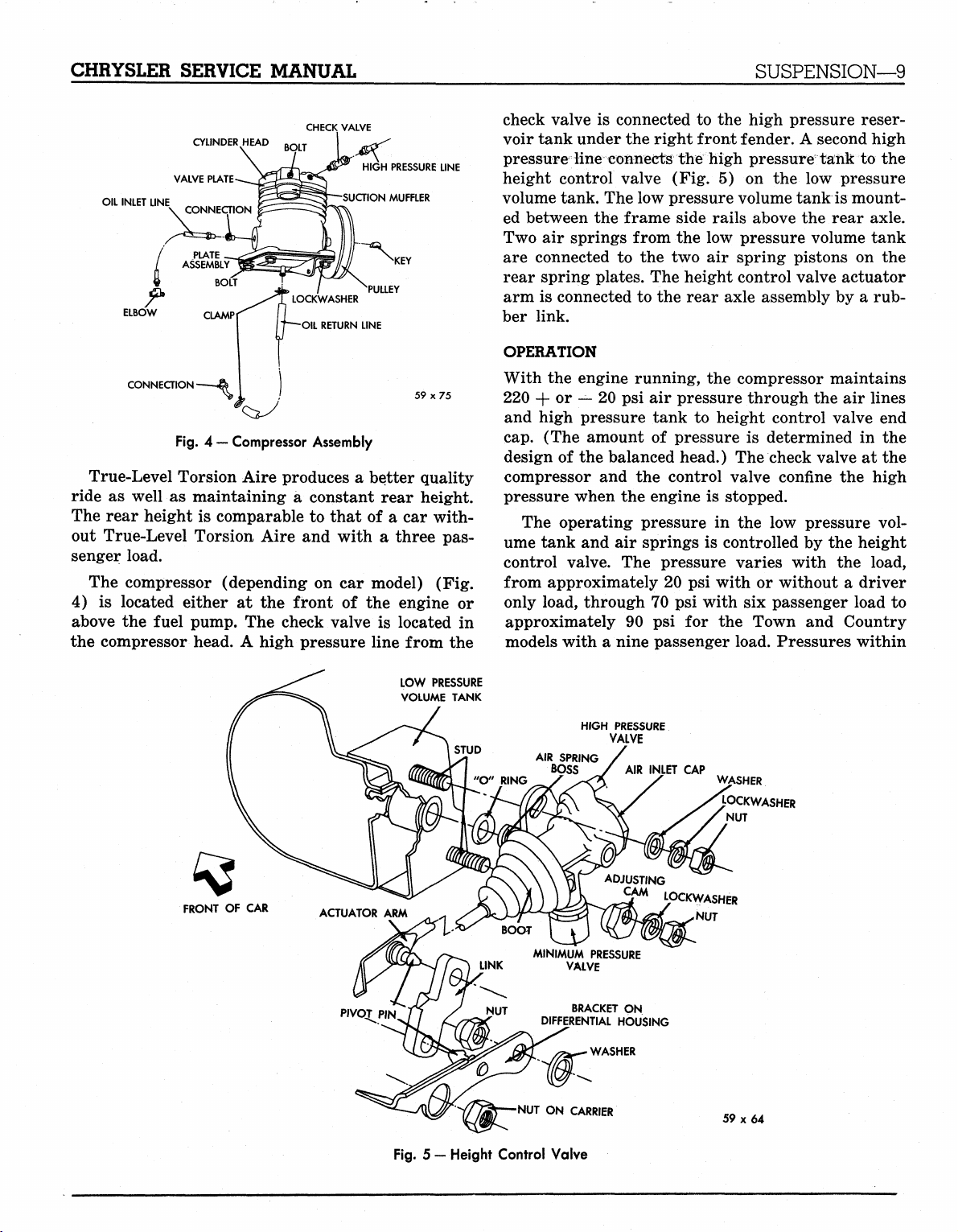

The True-Level Torsion Aire System (Figs 2 and 3)

available as optional equipment on the 1959 Chrysler

and Imperial cars consists of an engine driven bal-

anced head compressor, compressor drive belt, check

valve, high pressure air lines, high pressure reser-

voir tank, low pressure volume tank, height control

NOTE;

equal amount will change camber with little or no

change of caster. Turning both cams an equal

amount in opposite directions will change the caster

with little or no change of camber.

els.

ual,

Turning both cams in the same direction an

Refer to the 1958 Chrysler and Imperial Man-

D-16350, for information on the removal and

installation of the Oriflow shock absorbers.

CAUTION

When car is equipped with True-Level Torsion Aire,

do not use a frame contact type hoist when removing

shock absorbers, as the air springs will become unseated from the upper spring seat.

valve assembly, air springs and valve (actuating)

rubber linkage.

On cars equipped with True-Level Torsion, Aire

System, conventional steel semi-elliptic leaf springs

and shock absorbers are used, however, spring load

and rate have been reduced approximately ten per

cent.

MyMopar.com

Page 10

8—SUSPENSION

CHRYSLER SERVICE MANUAL

HEIGHT CONTROL VALVE

LOW PRESSURE

VOLUME TANK

AIR SPRING

PISTON.

HIGH PRESSURE TANK

COMPRESSOR

Fig.

2 - True-Level Torsion Aire System (Models MC-1, 2 and 3)

HEIGHT CONTROL VALVE

LOW PRESSURE

VOLUME TANK

SPRING PLATE

59 x 70

HIGH PRESSURE TANK

COMPRESSOR

Fig.

3 —True-Level Torsion Aire System (Model MY-1)

SPRING PLATE

59x67

MyMopar.com

Page 11

CHRYSLER SERVICE MANUAL

SUSPENSION—9

CHECK VALVE

PRESSURE LINE

SUCTION MUFFLER

59x75

OIL INLET LINE

CONNECTION

CYLINDER HEAD

VALVE PLATE

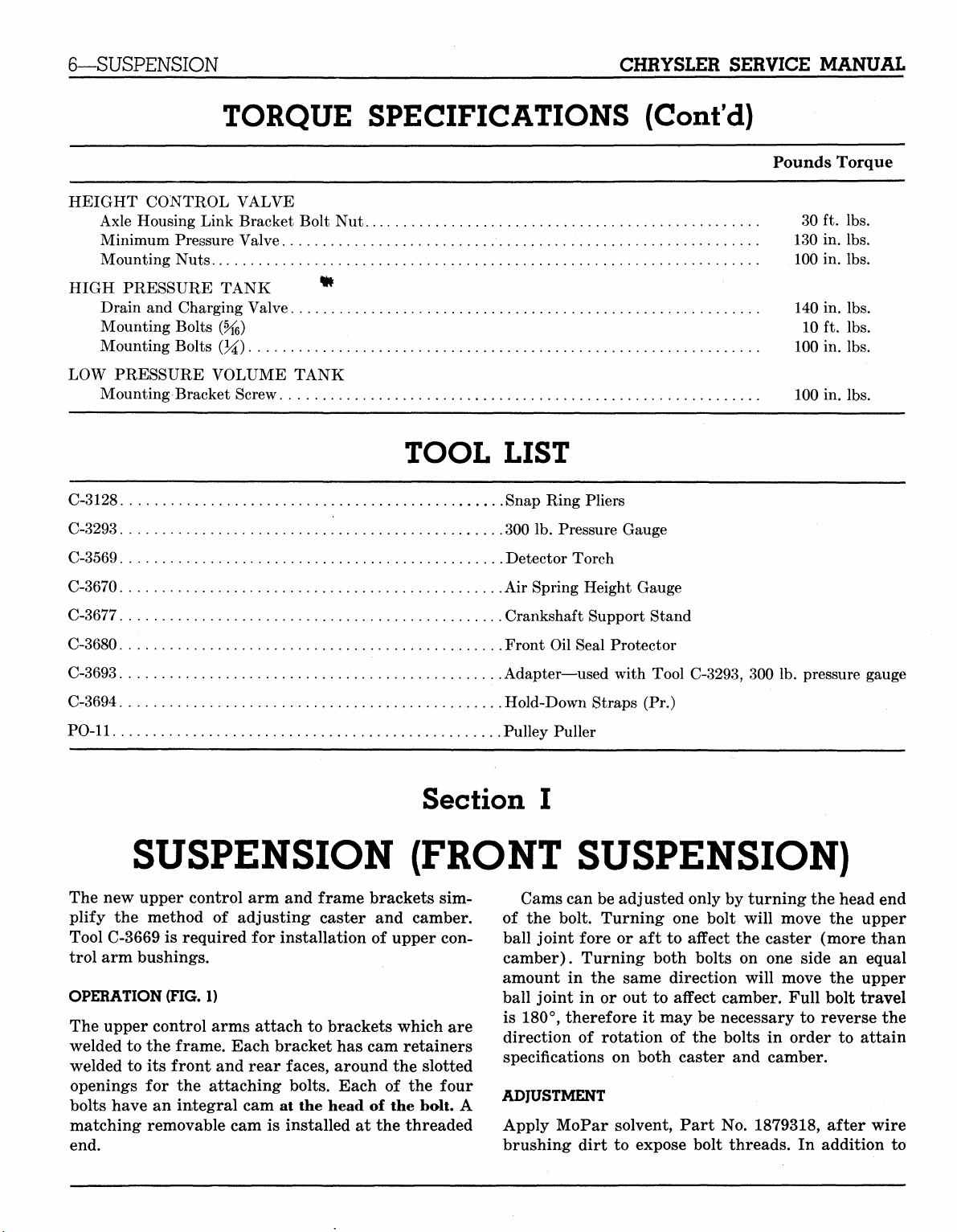

Fig.

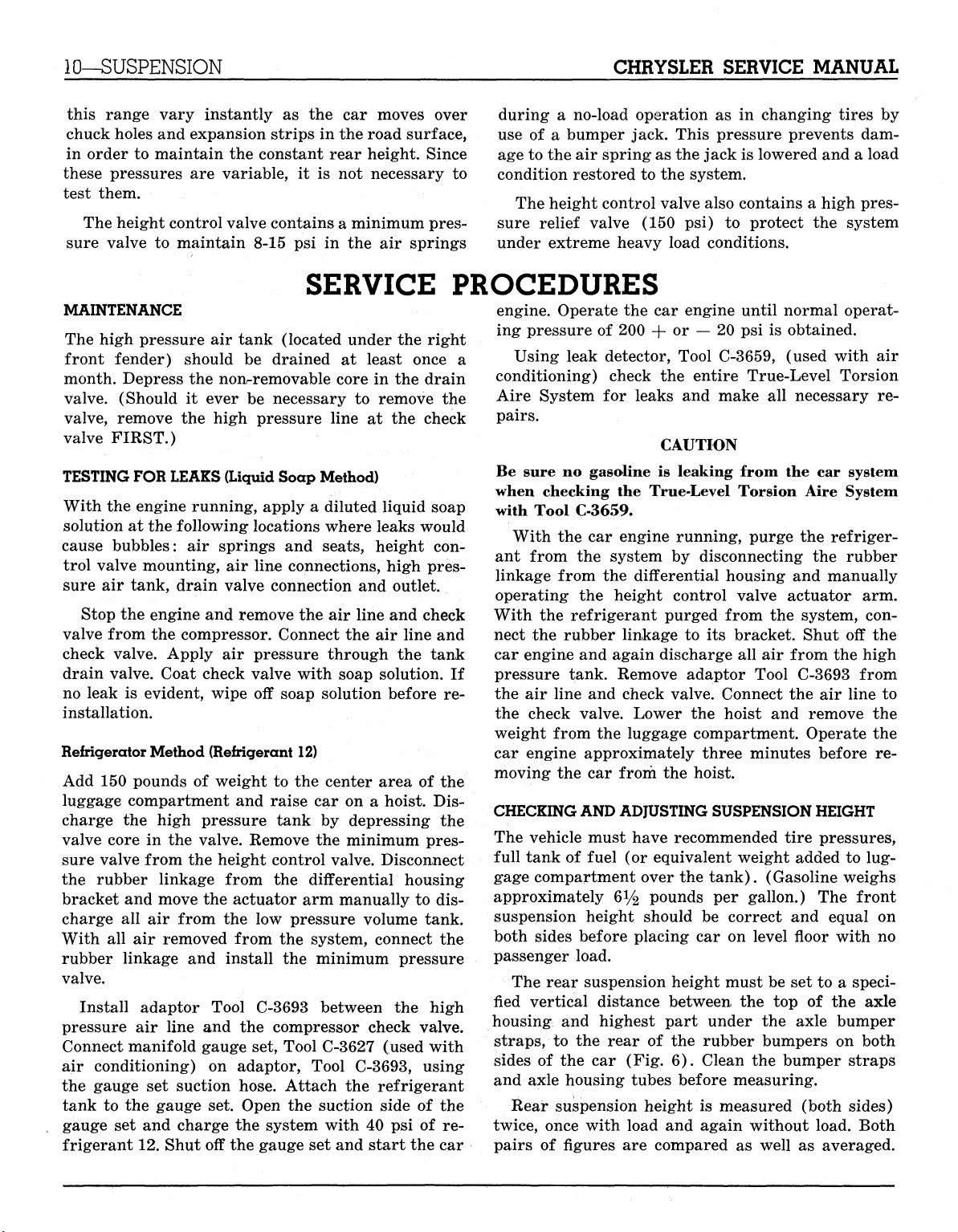

4 — Compressor Assembly

True-Level Torsion Aire produces a better quality

ride as well as maintaining a constant rear height.

The rear height is comparable to that of a car without True-Level Torsion Aire and with a three passenger load.

The compressor (depending on car model) (Fig.

4) is located either at the front of the engine or

above the fuel pump. The check valve is located in

the compressor head. A high pressure line from the

check valve is connected to the high pressure reservoir tank under the right front fender. A second high

pressure line connects the high pressure" tank to the

height control valve (Fig. 5) on the low pressure

volume tank. The low pressure volume tank is mounted between the frame side rails above the rear axle.

Two air springs from the low pressure volume tank

are connected to the two air spring pistons on the

rear spring plates. The height control valve actuator

arm is connected to the rear axle assembly by a rubber link.

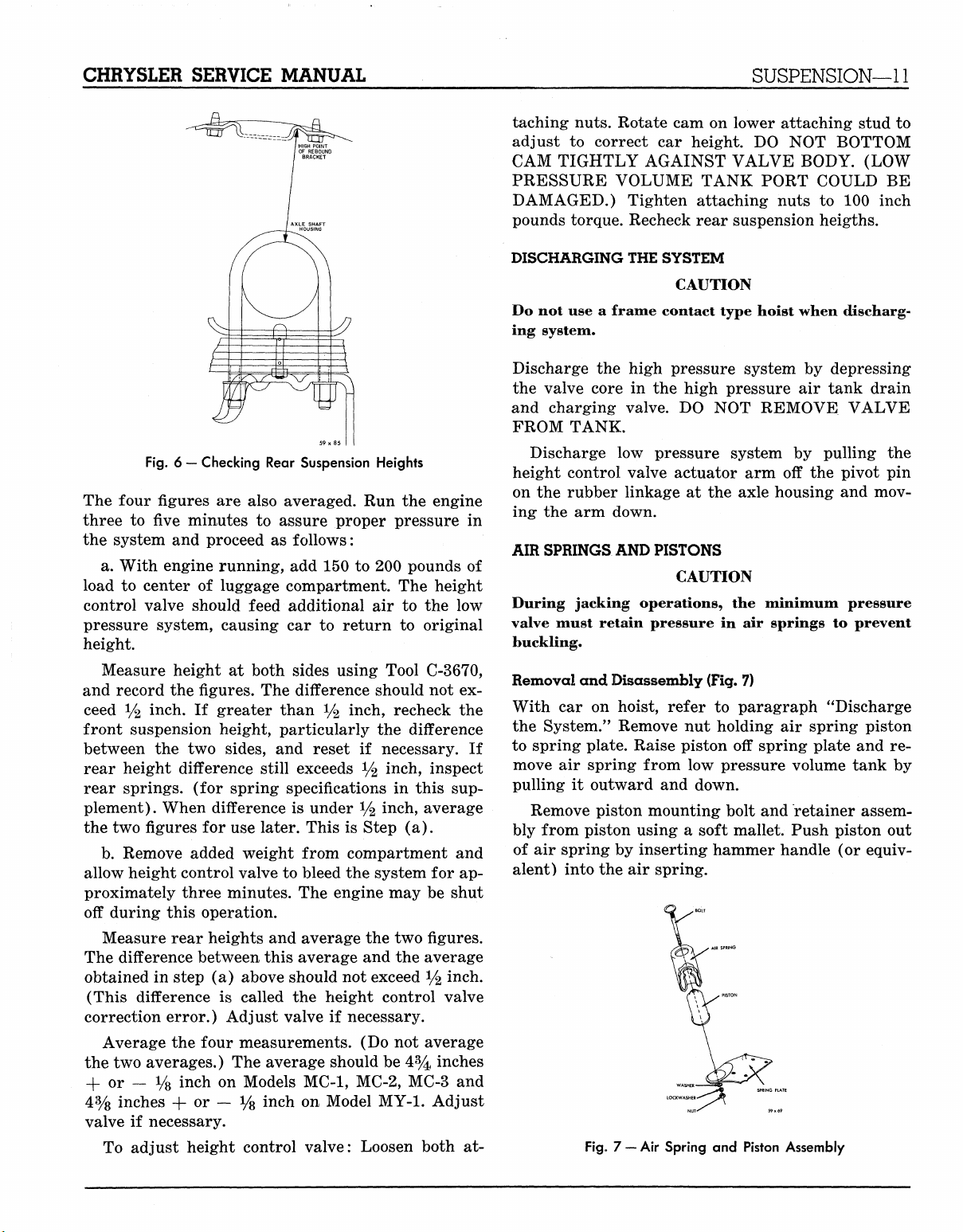

OPERATION

With the engine running, the compressor maintains

220 + or — 20 psi air pressure through the air lines

and high pressure tank to height control valve end

cap.

(The amount of pressure is determined in the

design of the balanced head.) The check valve at the

compressor and the control valve confine the high

pressure when the engine is stopped.

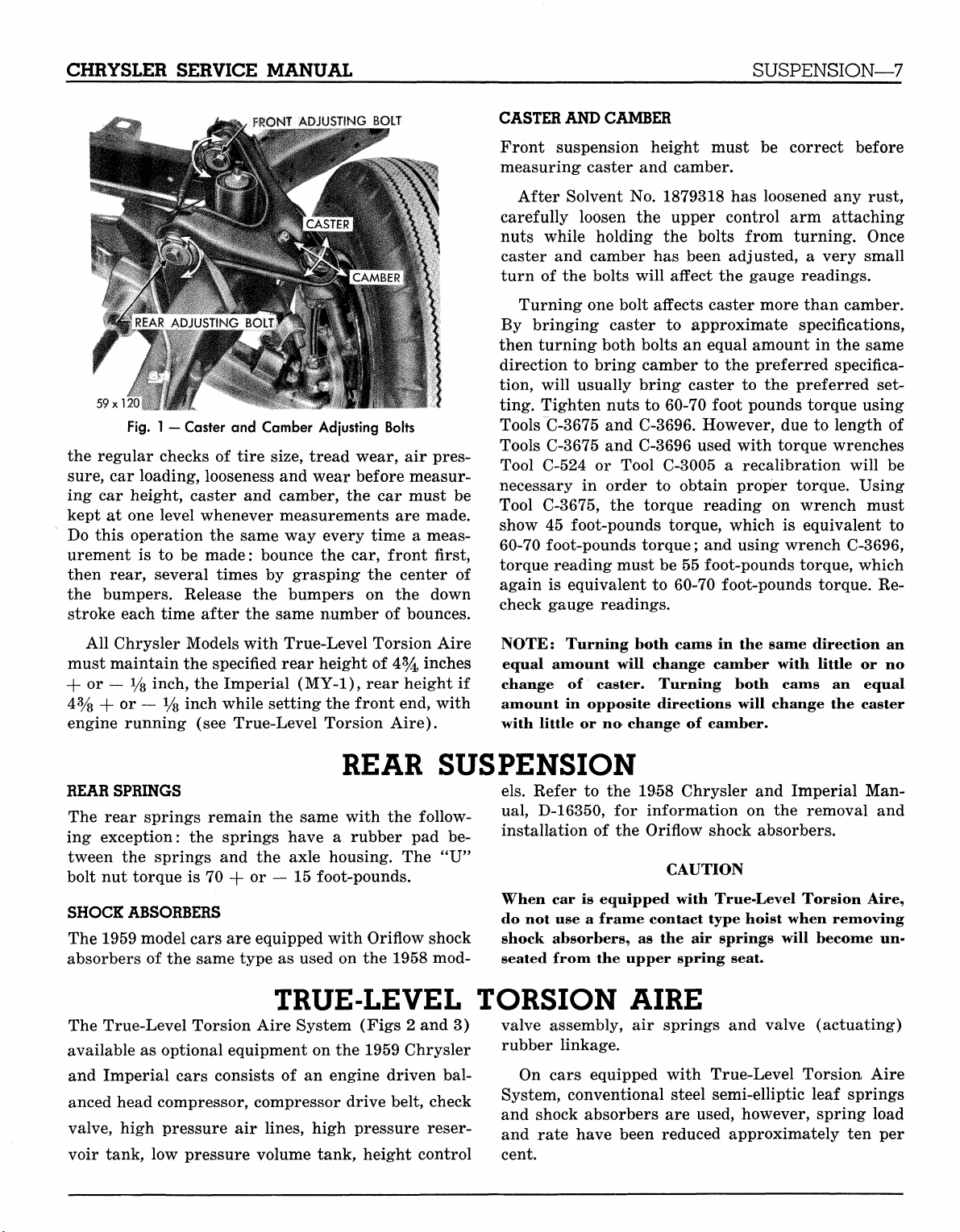

The operating pressure in the low pressure volume tank and air springs is controlled by the height

control valve. The pressure varies with the load,

from approximately 20 psi with or without a driver

only load, through 70 psi with six passenger load to

approximately 90 psi for the Town and Country

models with a nine passenger load. Pressures within

FRONT OF CAR

LOW PRESSURE

VOLUME TANK

HIGH PRESSURE

BRACKET ON

DIFFERENTIAL HOUSING

•NUT ON CARRIER

VALVE

ADJUSTING

CAM

LOCKWASHER

CAP

NUT

WASHER

LOCKWASHER

NUT

59x64

Fig.

5 —Height Control Valve

MyMopar.com

Page 12

10—SUSPENSION

CHRYSLER SERVICE MANUAL

this range vary instantly as the car moves over

chuck holes and expansion strips in the road surface,

in order to maintain the constant rear height. Since

these pressures are variable, it is not necessary to

test them.

The height control valve contains a minimum pres-

sure valve to maintain 8-15 psi in the air springs

SERVICE PROCEDURES

MAINTENANCE

The high pressure air tank (located under the right

front fender) should be drained at least once a

month. Depress the non-removable core in the drain

valve. (Should it ever be necessary to remove the

valve, remove the high pressure line at the check

valve FIRST.)

TESTING FOR LEAKS (Liquid Soap Method)

With the engine running, apply a diluted liquid soap

solution at the following locations where leaks would

cause bubbles: air springs and seats, height con-

trol valve mounting, air line connections, high pressure air tank, drain valve connection and outlet.

Stop the engine and remove the air line and check

valve from the compressor. Connect the air line and

check valve. Apply air pressure through the tank

drain valve. Coat check valve with soap solution. If

no leak is evident, wipe off soap solution before reinstallation.

Refrigerator Method (Refrigerant 12)

Add 150 pounds of weight to the center area of the

luggage compartment and raise car on a hoist. Discharge the high pressure tank by depressing the

valve core in the valve. Remove the minimum pressure valve from the height control valve. Disconnect

the rubber linkage from the differential housing

bracket and move the actuator arm manually to discharge all air from the low pressure volume tank.

With all air removed from the system, connect the

rubber linkage and install the minimum pressure

valve.

Install adaptor Tool C-3693 between the high

pressure air line and the compressor check valve.

Connect manifold gauge set, Tool C-3627 (used with

air conditioning) on adaptor, Tool C-3693, using

the gauge set suction hose. Attach the refrigerant

tank to the gauge set. Open the suction side of the

gauge set and charge the system with 40 psi of refrigerant 12. Shut off the gauge set and start the car

during a no-load operation as in changing tires by

use of a bumper jack. This pressure prevents damage to the air spring as the jack is lowered and a load

condition restored to the system.

The height control valve also contains a high pressure relief valve (150 psi) to protect the system

under extreme heavy load conditions.

engine. Operate the car engine until normal operat-

ing pressure of 200 + or — 20 psi is obtained.

Using leak detector, Tool C-3659, (used with air

conditioning) check the entire True-Level Torsion

Aire System for leaks and make all necessary repairs.

CAUTION

Be sure no gasoline is leaking from the car system

when checking the True-Level Torsion Aire System

with Tool C-3659.

With the car engine running, purge the refrigerant from the system by disconnecting the rubber

linkage from the differential housing and manually

operating the height control valve actuator arm.

With the refrigerant purged from the system, connect the rubber linkage to its bracket. Shut off the

car engine and again discharge all air from the high

pressure tank. Remove adaptor Tool C-3693 from

the air line and check valve. Connect the air line to

the check valve. Lower the hoist and remove the

weight from the luggage compartment. Operate the

car engine approximately three minutes before removing the car from the hoist.

CHECKING

The vehicle must have recommended tire pressures,

full tank of fuel (or equivalent weight added to luggage compartment over the tank). (Gasoline weighs

approximately 6% pounds per gallon.) The front

suspension height should be correct and equal on

both sides before placing car on level floor with no

passenger load.

The rear suspension height must be set to a speci-

fied vertical distance between, the top of the axle

housing and highest part under the axle bumper

straps,

sides of the car (Fig. 6). Clean the bumper straps

and axle housing tubes before measuring.

Rear suspension height is measured (both sides)

twice, once with load and again without load. Both

pairs of figures are compared as well as averaged.

AND

ADJUSTING SUSPENSION HEIGHT

to the rear of the rubber bumpers on both

MyMopar.com

Page 13

CHRYSLER SERVICE MANUAL

SUSPENSION—11

taching nuts. Rotate cam on lower attaching stud to

adjust to correct car height. DO NOT BOTTOM

CAM TIGHTLY AGAINST VALVE BODY. (LOW

PRESSURE VOLUME TANK PORT COULD BE

DAMAGED.) Tighten attaching nuts to 100 inch

pounds torque. Recheck rear suspension heigths.

Fig. 6 — Checking Rear Suspension Heights

The four figures are also averaged. Run the engine

three to fiwe minutes to assure proper pressure in

the system and proceed as follows:

a. With engine running, add 150 to 200 pounds of

load to center of luggage compartment. The height

control valve should feed additional air to the low

pressure system, causing car to return to original

height.

Measure height at both sides using Tool C-3670,

and record the figures. The difference should not ex-

ceed */2 inch. If greater than % inch, recheck the

front suspension height, particularly the difference

between the two sides, and reset if necessary. If

rear height difference still exceeds */2 inch, inspect

rear springs, (for spring specifications in this supplement). When difference is under

y%

inch, average

the two figures for use later. This is Step (a).

b.

Remove added weight from compartment and

allow height control valve to bleed the system for approximately three minutes. The engine may be shut

off during this operation.

Measure rear heights and average the two figures.

The difference between this average and the average

obtained in step (a) above should not exceed % inch.

(This difference is called the height control valve

correction error.) Adjust valve if necessary.

Average the four measurements. (Do not average

the two averages.) The average should be 4% inches

+ or — y8 inch on Models MC-1, MC-2, MC-3 and

4%

inches -(-or — Vs inch on Model MY-1. Adjust

valve if necessary.

To adjust height control valve: Loosen both at-

DISCHARGING

THE

SYSTEM

CAUTION

Do not use a frame contact type hoist when discharging system.

Discharge the high pressure system by depressing

the valve core in the high pressure air tank drain

and charging valve. DO NOT REMOVE VALVE

FROM TANK.

Discharge low pressure system by pulling the

height control valve actuator arm off the pivot pin

on the rubber linkage at the axle housing and moving the arm down.

AIR SPRINGS

AND

PISTONS

CAUTION

During jacking operations, the minimum pressure

valve must retain pressure in air springs to prevent

buckling.

Removal and Disassembly

(Fig.

7)

With car on hoist, refer to paragraph "Discharge

the System." Remove nut holding air spring piston

to spring plate. Raise piston off spring plate and re-

move air spring from low pressure volume tank by

pulling it outward and down.

Remove piston mounting bolt and retainer assembly from piston using a soft mallet. Push piston out

of air spring by inserting hammer handle (or equivalent) into the air spring.

Fig, 7 —

Air

Spring

and

Piston Assembly

MyMopar.com

Page 14

12—SUSPENSION

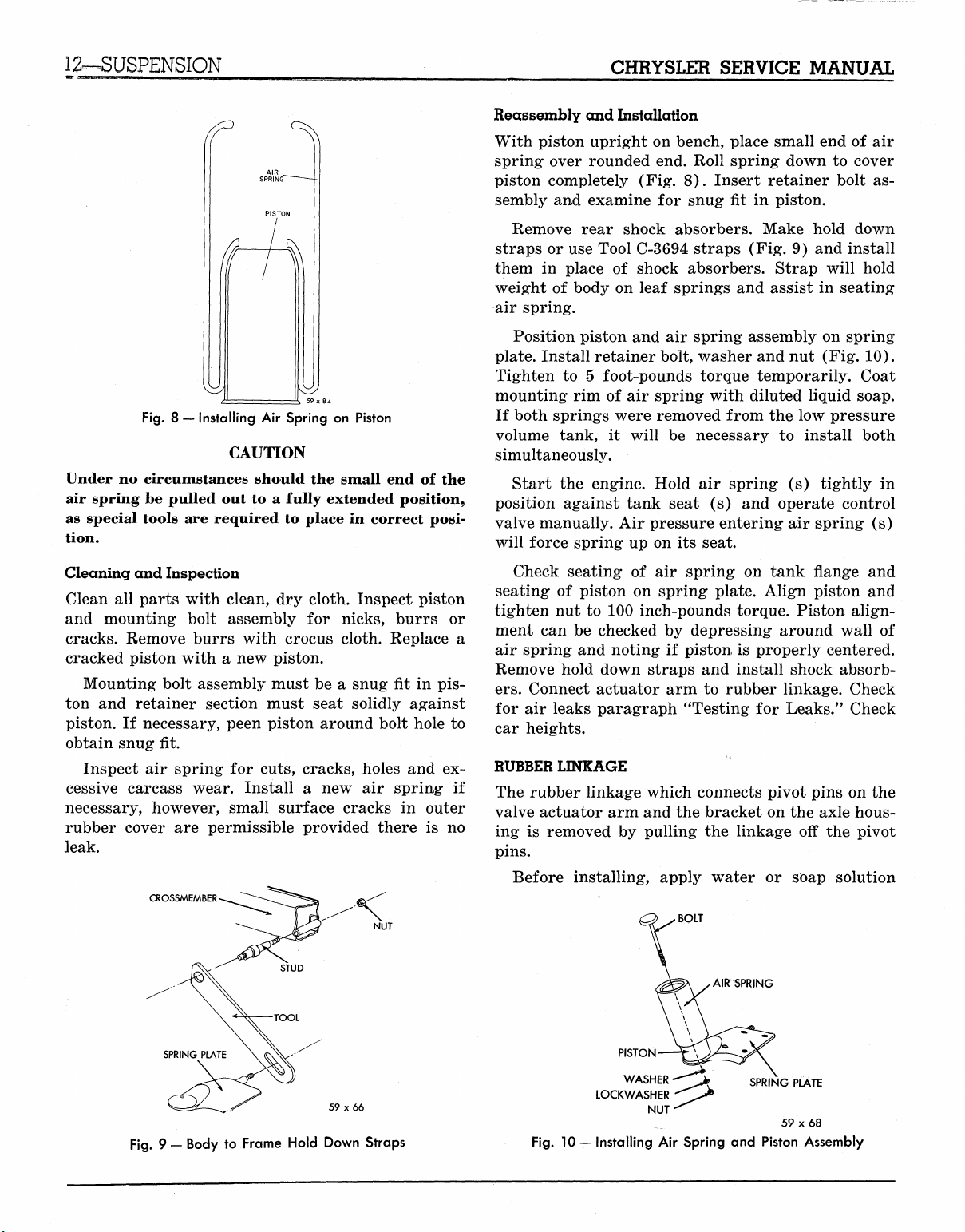

Fig.

8 — Installing Air Spring on Piston

CAUTION

Under no circumstances should the small end of the

air spring be pulled out to a fully extended position,

as special tools are required to place in correct position.

CHRYSLER SERVICE MANUAL

Reassembly and Installation

With piston upright on bench, place small end of air

spring over rounded end. Roll spring down to cover

piston completely (Fig. 8). Insert retainer bolt assembly and examine for snug fit in piston.

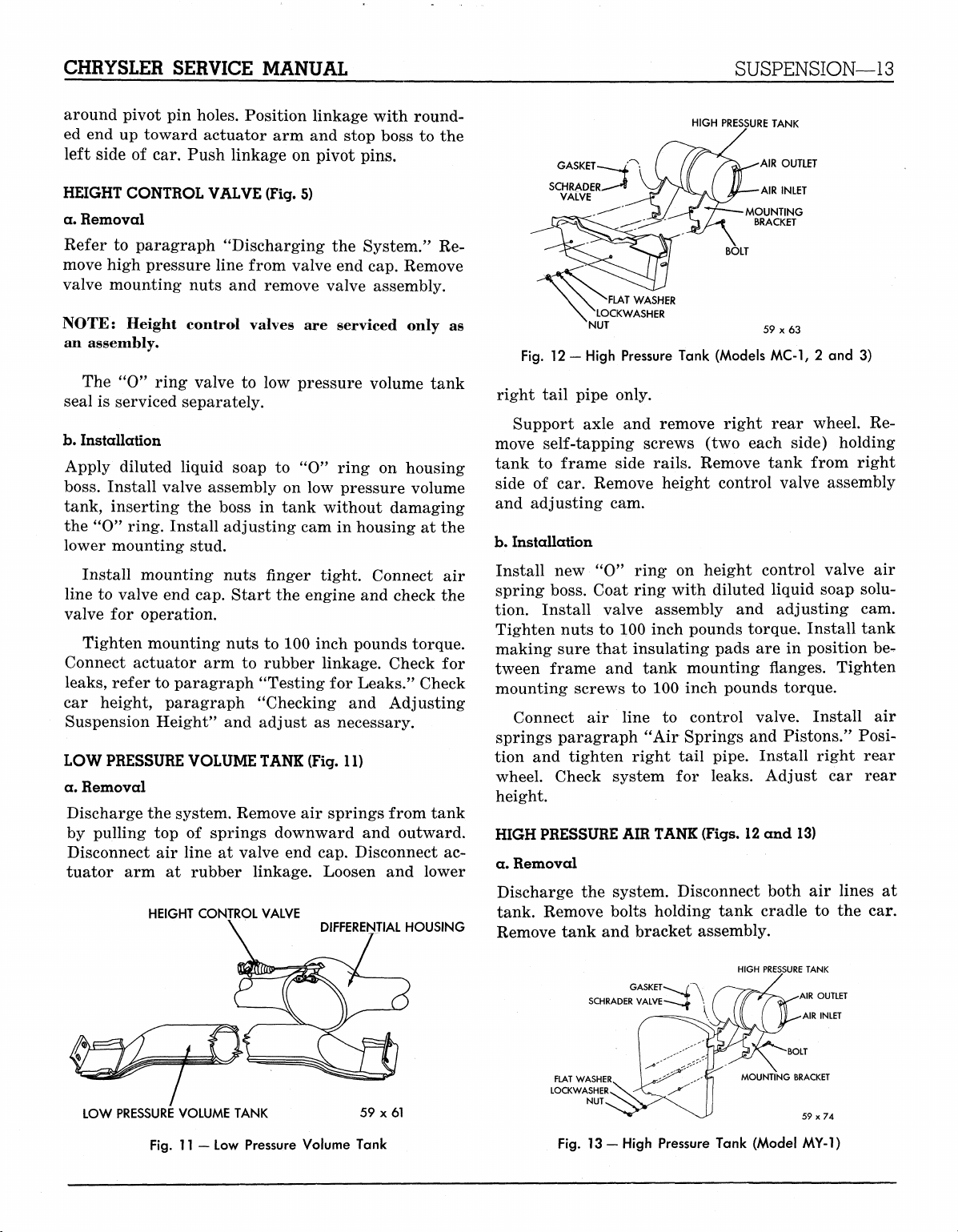

Remove rear shock absorbers. Make hold down

straps or use Tool C-3694 straps (Fig. 9) and install

them in place of shock absorbers. Strap will hold

weight of body on leaf springs and assist in seating

air spring.

Position piston and air spring assembly on spring

plate. Install retainer bolt, washer and nut (Fig. 10).

Tighten to 5 foot-pounds torque temporarily. Coat

mounting rim of air spring with diluted liquid soap.

If both springs were removed from the low pressure

volume tank, it will be necessary to install both

simultaneously.

Start the engine. Hold air spring (s) tightly in

position against tank seat (s) and operate control

valve manually. Air pressure entering air spring (s)

will force spring up on its seat.

Cleaning and Inspection

Clean all parts with clean, dry cloth. Inspect piston

and mounting bolt assembly for nicks, burrs or

cracks. Remove burrs with crocus cloth. Replace a

cracked piston with a new piston.

Mounting bolt assembly must be a snug fit in pis-

ton and retainer section must seat solidly against

piston. If necessary, peen piston around bolt hole to

obtain snug fit.

Inspect air spring for cuts, cracks, holes and ex-

cessive carcass wear. Install a new air spring if

necessary, however, small surface cracks in outer

rubber cover are permissible provided there is no

leak.

CROSSMEMBER

NUT

Check seating of air spring on tank flange and

seating of piston on spring plate. Align piston and

tighten nut to 100 inch-pounds torque. Piston alignment can be checked by depressing around wall of

air spring and noting if piston is properly centered.

Remove hold down straps and install shock absorbers.

Connect actuator arm to rubber linkage. Check

for air leaks paragraph "Testing for Leaks." Check

car heights.

RUBBER LINKAGE

The rubber linkage which connects pivot pins on the

valve actuator arm and the bracket on the axle hous-

ing is removed by pulling the linkage off the pivot

pins.

Before installing, apply water or soap solution

BOLT

AIRSPRING

59 x 66

Fig.

9 — Body to Frame Hold Down Straps

PISTON

WASHER

LOCKWASHER

Fig.

10 — Installing Air Spring and Piston Assembly

NUT

MyMopar.com

Page 15

CHRYSLER SERVICE MANUAL

SUSPENSION—13

around pivot

ed

end up

left side

HEIGHT CONTROL VALVE (Fig.

a. Removal

Refer

to

move high pressure line from valve

valve mounting nuts

NOTE:

pin

holes. Position linkage with round-

toward actuator

of car.

Push linkage

arm and

on

paragraph "Discharging

and

remove valve assembly.

Height control valves

stop boss

pivot pins.

5)

the

System."

end

are

serviced only

cap. Remove

an assembly.

The

"0"

ring valve

seal

is

serviced separately.

b.

Installation

Apply diluted liquid soap

boss.

Install valve assembly

tank, inserting

the

the "O" ring. Install adjusting

to low

boss

pressure volume tank

to "0"

on low

in

tank without damaging

ring

on

pressure volume

cam in

housing

lower mounting stud.

Install mounting nuts finger tight. Connect

line

to

valve

end

cap. Start

valve

for

operation.

Tighten mounting nuts

Connect actuator

leaks,

refer

arm to

to

paragraph "Testing

car height, paragraph "Checking

Suspension Height"

LOW PRESSURE VOLUME TANK (Fig.

a. Removal

Discharge

by pulling

Disconnect

tuator

the

top of

air

arm at

HEIGHT CONTROL VALVE

and

system. Remove

springs downward

line

at

rubber linkage. Loosen

the

engine

to 100

and

inch pounds torque.

rubber linkage. Check

for

Leaks." Check

and

adjust

as

necessary.

11)

air

springs from tank

and

valve

end cap.

Disconnect

DIFFERENTIAL HOUSING

Adjusting

and

to the

Re-

as

housing

at the

air

check

the

for

outward.

ac-

lower

HIGH PRESSURE TANK

AIR OUTLET

59x63

2 and 3)

Fig.

GASKET

SCHRADER

VALVE

'FLAT WASHER

\ NLOCKWASHER

NUT

12 -

High Pressure Tank (Models MC-1,

right tail pipe only.

Support axle

move self-tapping screws

tank

to

frame side rails. Remove tank from right

side

of car.

and adjusting

b.

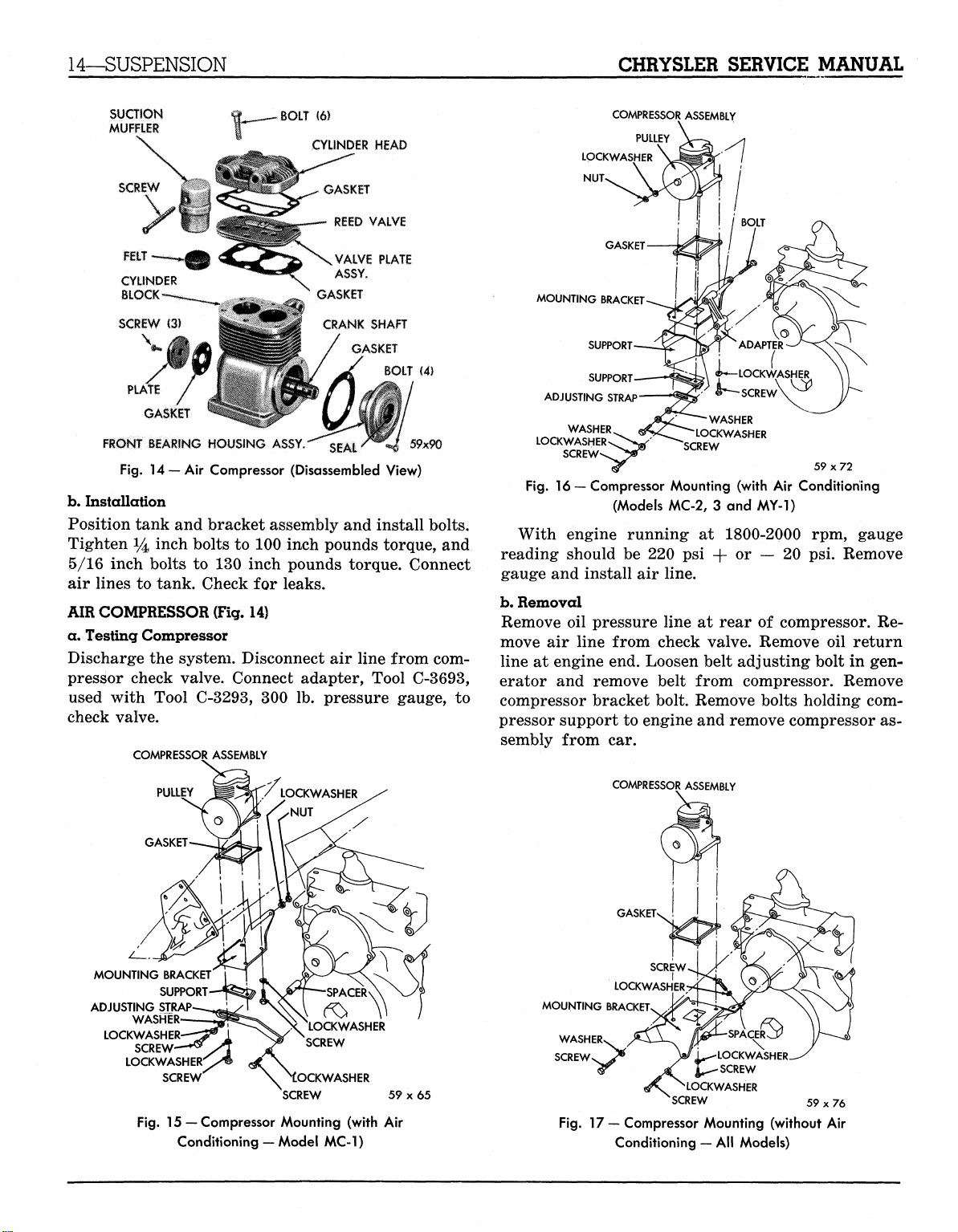

Installation

Install

new "0"

and

remove right rear wheel.

(two

each side) holding

Re-

Remove height control valve assembly

cam.

ring

on

height control valve

air

spring boss. Coat ring with diluted liquid soap solu-

tion. Install valve assembly

Tighten nuts

to 100

inch pounds torque. Install tank

making sure that insulating pads

tween frame

mounting screws

Connect

springs paragraph

tion

and

wheel. Check system

and

tank mounting flanges. Tighten

to 100

air

line

to

"Air

tighten right tail pipe. Install right rear

for

and

adjusting

are in

cam.

position

inch pounds torque.

control valve. Install

Springs

and

Pistons." Posi-

leaks. Adjust

car

be-

air

rear

height.

HIGH PRESSURE AIR TANK (Figs. 12

a. Removal

Discharge

the

system. Disconnect both

tank. Remove bolts holding tank cradle

Remove tank

and

bracket assembly.

and 13)

air

to the car.

lines

at

LOW PRESSURE VOLUME TANK

Fig.

11 — Low

Pressure Volume Tank

59 x 61

GASKET

SCHRADER VALVE

FLAT WASHER

LOCKWASHER

NUT

Fig.

13 - High Pressure Tank (Model

HIGH PRESSURE TANK

AIR OUTLET

AIR INLET

BOLT

MOUNTING BRACKET

59x74

MY-1)

MyMopar.com

Page 16

14—SUSPENSION

CHRYSLER SERVICE MANUAL

SUCTION

MUFFLER

FELT

CYLINDER

BLOCK

SCREW

C3)

\

FRONT SEARING HOUSING

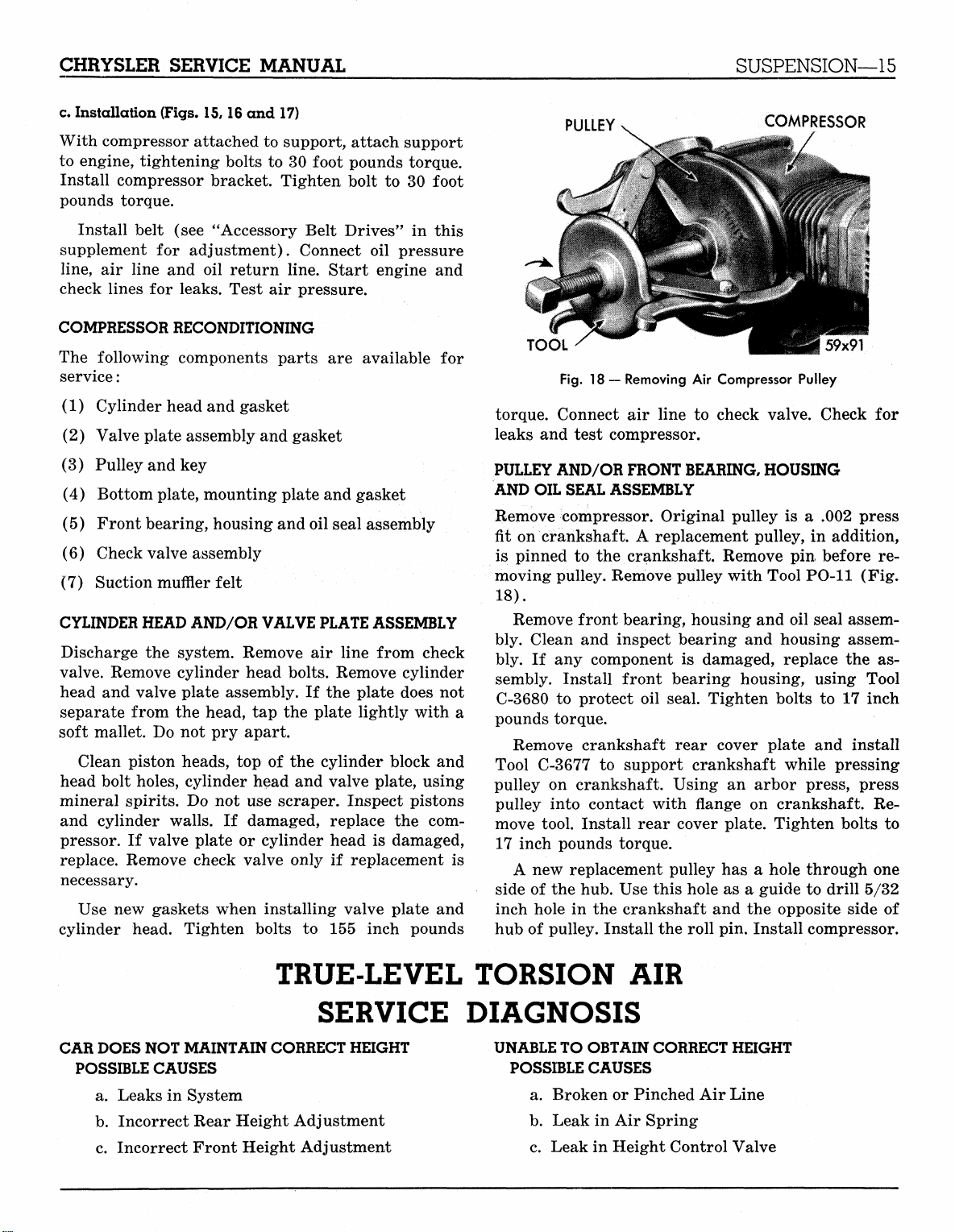

Fig.

14

—Air Compressor (Disassembled View)

b.

Installation

Position tank and bracket assembly and install bolts.

Tighten 14 i

5/16 inch bolts

ncn

bolts to 100 inch pounds torque, and

to

130 inch pounds torque. Connect

air lines to tank. Check

AIR COMPRESSOR (Fig.

for

14)

BOLT

ASSY.

leaks.

(6)

CYLINDER HEAD

^^

GASKET

REED VALVE

VALVE PLATE

ASSY.

GASKET

CRANK SHAFT

GASKET

SEAL'**

BOLT

59x90

(4)

a. Testing Compressor

Discharge the system. Disconnect

air

line from com-

pressor check valve. Connect adapter, Tool C-3693,

used with Tool C-3293,

300 lb.

pressure gauge,

to

check valve.

COMPRESSOR ASSEMBLY

COMPRESSOR ASSEMBLY

PULLEY

LOCKWASHER

NUT>

BOLT

MOUNTING BRACKET

SUPPORT

SUPPORT

ADJUSTING STRAP

WASHER

LOCKWASHER

Fig.

16 — Compressor Mounting (with Air Conditioning

(Models MC-2, 3 and MY-1)

With engine running

reading should

gauge and install

b.

Removal

Remove

move

line

erator

oil

air

at

engine end. Loosen belt adjusting bolt in gen-

and

be 220 psi

air

line.

pressure line

line from check valve. Remove

remove belt from compressor. Remove

i^LOCKWASHER

«^- SCREW

WASHER

LOCKWASHER

SCREW

at

1800-2000

or

+

at

rear

o

ADAPTER

—

20 psi.

of

compressor.

59x72

rpm,

Remove

oil

gauge

Re-

return

compressor bracket bolt. Remove bolts holding com-

pressor support to engine and remove compressor as-

sembly from

car.

PU

MOUNTING BRACKET

ADJUSTING STRAP

LOCKWASHER

SUPPORT

WASHER

SCREW

LOCKWASHERO^

SCREW

Fig.

15— Compressor Mounting (with Air

Conditioning — Model MC-1)

I I

LOCKWASHER

SCREW

OCKWASHER

SCREW

59x65

COMPRESSOR ASSEMBLY

GASKET

MOUNTING BRACKET

WASHER

SCREWS ^ Vi^

Fig.

17 —

Compressor Mounting (without

Conditioning

LOCKWASHER

JSCREW

*

LOCKWASHER

'SCREW

59x76

— All

Models)

-

Air

MyMopar.com

Page 17

CHRYSLER SERVICE MANUAL

SUSPENSION—15

c. Installation

(Figs.

15,16 and 17)

With compressor attached to support, attach support

to engine, tightening- bolts to 30 foot pounds torque.

Install compressor bracket. Tighten bolt to 30 foot

pounds torque.

Install belt (see "Accessory Belt Drives" in this

supplement for adjustment). Connect oil pressure

line,

air line and oil return line. Start engine and

check lines for leaks. Test air pressure.

COMPRESSOR RECONDITIONING

The following components parts are available for

service:

(1) Cylinder head and gasket

(2) Valve plate assembly and gasket

(3) Pulley and key

(4) Bottom plate, mounting plate and gasket

(5) Front bearing, housing and oil seal assembly

(6) Check valve assembly

(7) Suction muffler felt

CYLINDER HEAD AND/OR VALVE PLATE ASSEMBLY

Discharge the system. Remove air line from check

valve. Remove cylinder head bolts. Remove cylinder

head and valve plate assembly. If the plate does not

separate from the head, tap the plate lightly with a

soft mallet. Do not pry apart.

Clean piston heads, top of the cylinder block and

head bolt holes, cylinder head and valve plate, using

mineral spirits. Do not use scraper. Inspect pistons

and cylinder walls. If damaged, replace the compressor. If valve plate or cylinder head is damaged,

replace. Remove check valve only if replacement is

necessary.

Use new gaskets when installing valve plate and

cylinder head. Tighten bolts to 155 inch pounds

COMPRESSOR

59x91

TOOL

PULLEY

Fig.

18 — Removing Air Compressor Pulley

torque. Connect air line to check valve. Check for

leaks and test compressor.

PULLEY AND/OR FRONT BEARING, HOUSING

AND OIL SEAL ASSEMBLY

Remove compressor. Original pulley is a .002 press

fit on crankshaft. A replacement pulley, in addition,

is pinned to the crankshaft. Remove pin before re-

moving pulley. Remove pulley with Tool PO-11 (Fig.

18).

Remove front bearing, housing and oil seal assem-

bly. Clean and inspect bearing and housing assembly. If any component is damaged, replace the assembly. Install front bearing housing, using Tool

C-3680 to protect oil seal. Tighten bolts to 17 inch

pounds torque.

Remove crankshaft rear cover plate and install

Tool C-3677 to support crankshaft while pressing

pulley on crankshaft. Using an arbor press, press

pulley into contact with flange on crankshaft. Remove tool. Install rear cover plate. Tighten bolts to

17 inch pounds torque.

A new replacement pulley has a hole through one

side of the hub. Use this hole as a guide to drill 5/32

inch hole in the crankshaft and the opposite side of

hub of pulley. Install the roll pin. Install compressor.

TRUE-LEVEL TORSION AIR

CAR

DOES

NOT

MAINTAIN CORRECT

POSSIBLE

a. Leaks in System

b.

c. Incorrect Front Height Adjustment

CAUSES

Incorrect Rear Height Adjustment

SERVICE DIAGNOSIS

HEIGHT

UNABLE TO OBTAIN

POSSIBLE

a. Broken or Pinched Air Line

b.

c. Leak in Height Control Valve

CAUSES

Leak in Air Spring

CORRECT

HEIGHT

MyMopar.com

Page 18

16—AXLE—REAR

CHRYSLER SERVICE MANUAL

d. Fast Leak in Low Pressure Volume Tank

e. Height Control Valve Out of Adjustment

f. Rubber Linkage Loose or Broken at Differen-

tial

g. Broken Height Control Actuator Arm

LOW AIR PRESSURE

POSSIBLE CAUSES

a. Leak in Air Line

b.

Compressor Belt Broken or Out of Adjust-

ment

c. Slipping Drive Belt

d. Plugged Check Valve

REAR AXLE

DATA AND SPECIFICATIONS

e. Leaking Cylinder Head Gasket

f. Leaking Valve Plate Gasket

g. Cracked Cylinder Head

h. Worn Reed Valves

i. Excessive Cylinder Wall Wear

j.

EXCESSIVE AIR PRESSURE

POSSIBLE CAUSES

a. Carbon Build Up on Cylinder Head

b.

c. Excessive Oil on Top of Piston

Section II

Excessive Piston Ring Wear

Carbon Build Up on Pistons

MODELS MC-1, MC-2, MC-3, MY-1

TYPE Semi-Floating

GEAR TYPE -.. Hypoid

RINIG GEAR DIAMETER... 8.75 inch

PINON BEARING 2

TYPE .....: Tapered Roller

ADJUSTMENT Shim Pack

DIFFERENTIAL BEARINGS 2

TYPE Tapered Roller

ADJUSTMENT Threaded Adjuster

DRIVE GEAR AND PINION. Matched Sets

DRIVE GEAR RUNOUT .005 inch Maximum

DRIVE GEAR AND PINION BACKLASH. .006 to .008 inch

DIFFERENTIAL SIDE GEAR CLEARANCE .001 to .012 inch

MODELS MC-1, MC-2, MC-3, MY-1

Including Town

AXLE RATIO

Standard Ratio .. 2.93 to 1

Ratio with Air Conditioning 2.93 to 1

No.

of Drive Gear Teeth 41

No.

of Drive Pinion Teeth 14

8B

Country Models

WHEEL BEARINGS

Type. Tapered Roller

Adjustment Select Shims

Axle End Play .013 to .018 inch

MyMopar.com

Page 19

CHRYSLER SERVICE MANUAL

BRAKES—17

REAR AXLE

There is no basic design change in the rear axle and

sure grip differential except the larger diameter

pinion shaft is now used on all models for 1959. The

Service Procedures will remain the same on the Rear

Section

Axle and Sure Grip Differential as specified in the

1958 Chrysler and Imperial Service Manual, D-

16350.

III

BRAKES

DATA

MODELS

TYPE Total Contact (Floating Shoe) Hydraulic

DRUM DIAMETER

LINING

MC-1

... ,

Type Moulded Asbestos

Attachment Cyclebond

Width 2Y2 in.

Thickness

l

AND

SPECIFICATIONS

MC-2, MC-3,

11

in.

12

%i

MY-1

in.

in-

BRAKE SHOE RETURN SPRING TENSION USING

FISH SCALE HOOKED

BRAKE PEDAL FREE PLAY

WHEEL CYLINDER BORE

Front—Upper

Rear

1K mMASTER CYLINDER BORE V/% in.

PISTON CLEARANCE .003

and

AT TOE OF

% in. to J^ in.

Lower 1%

SHOE 35

to

45 lbs. required

between shoe

(in models with Power Brakes)

in. to

to

break contact

and

push

in.

.0065

in.

HAND BRAKE

MODELS MC-1, MC-2, MC-3,

TYPE Internal Expanding

LOCATION Propeller Shaft

DRUM DIAMETER.

LINING TYPE

Length 13.06 inch

Width

2 in.

Thickness

Clearance .015

%

7

,

Moulded

at

Rear

inch

and

Compressed Asbestos

m

in. to

MY-1

of

Transmission

-

.020

in.

MyMopar.com

rod

Page 20

18—BRAKES

CHRYSLER SERVICE MANUAL

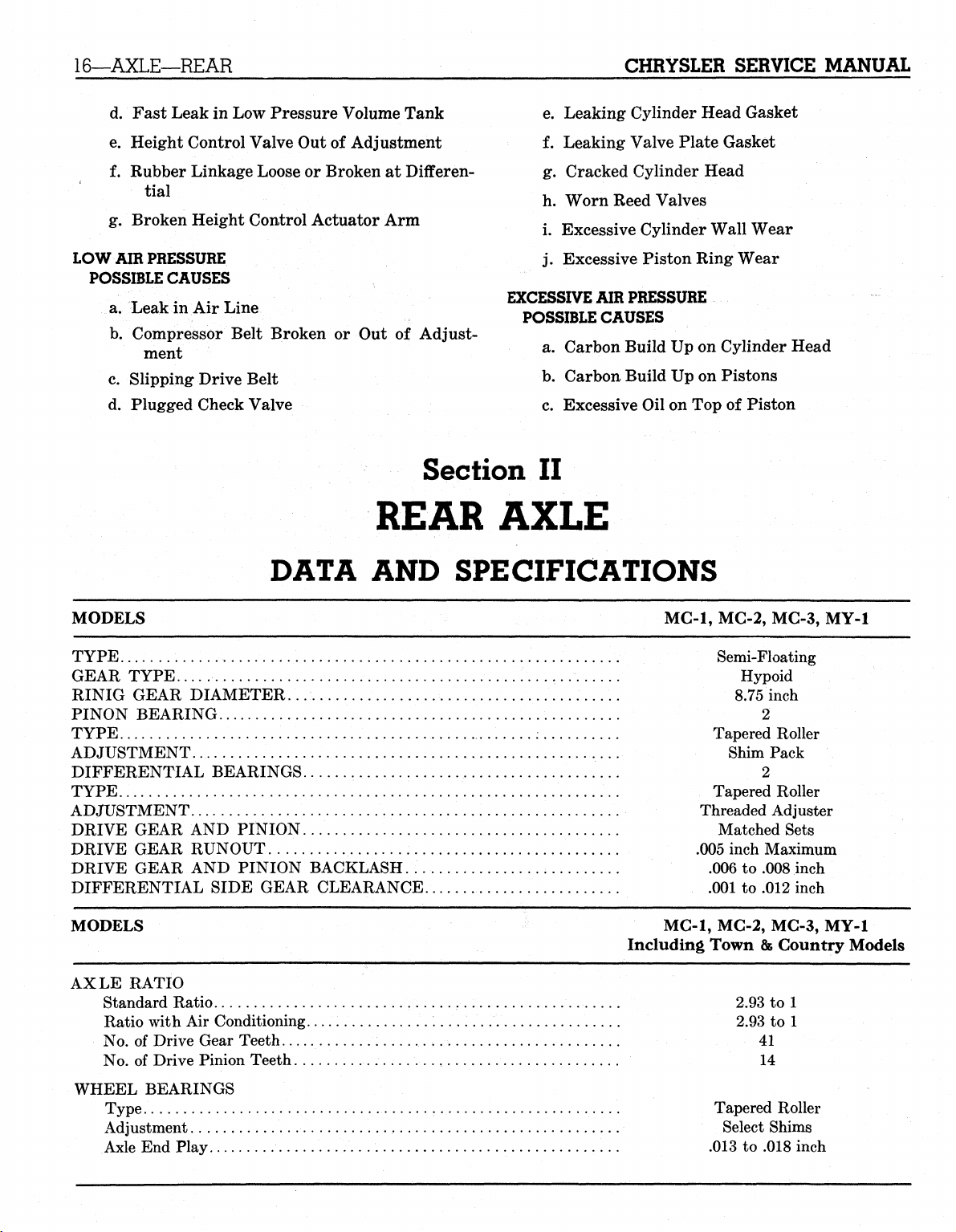

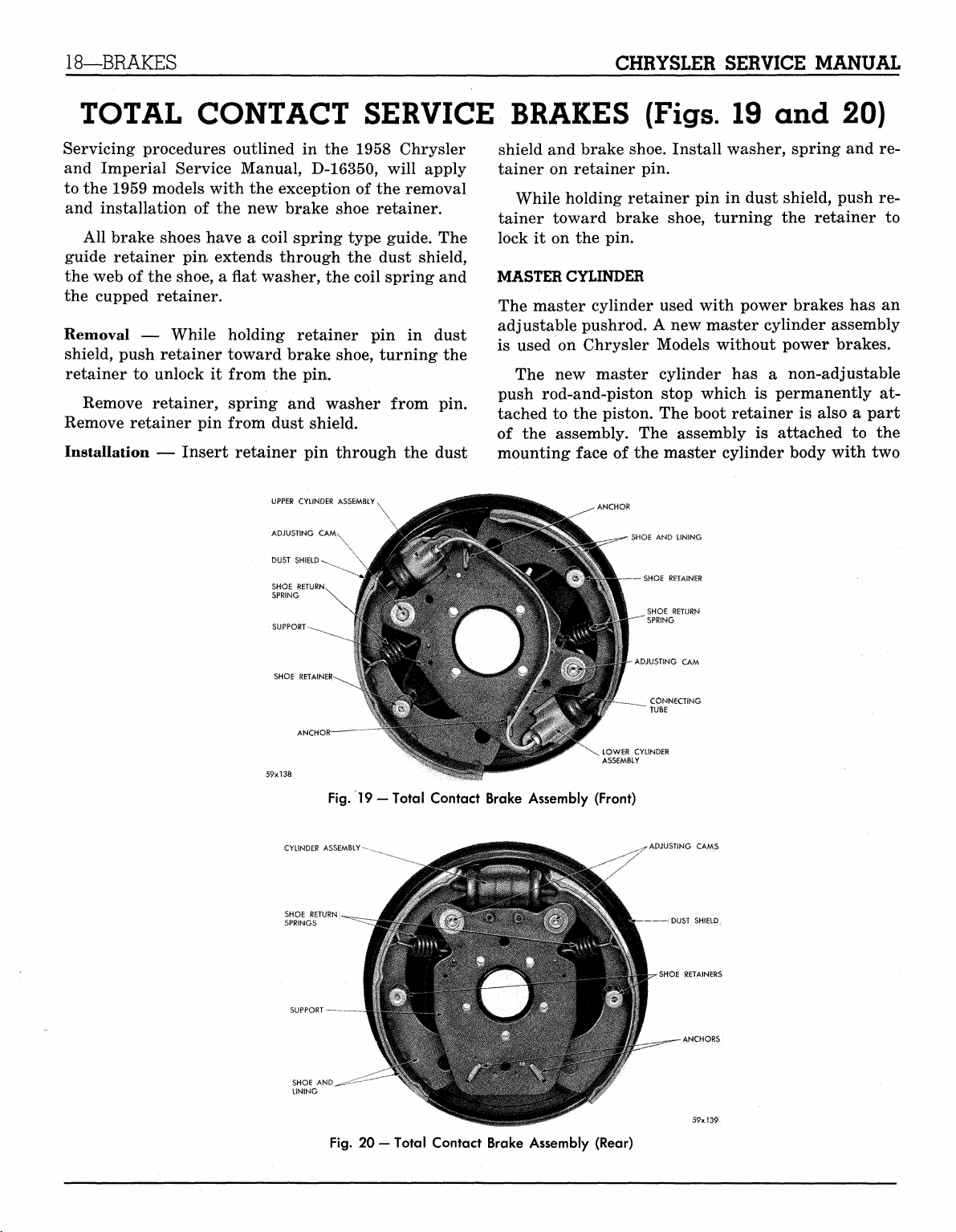

TOTAL CONTACT SERVICE BRAKES

Servicing procedures outlined in the 1958 Chrysler

and Imperial Service Manual, D-16350, will apply

to the 1959 models with the exception of the removal

and installation of the new brake shoe retainer.

All brake shoes have a coil spring type guide. The

guide retainer pin extends through the dust shield,

the web of the shoe, a flat washer, the coil spring and

the cupped retainer.

Removal — While holding retainer pin in dust

shield, push retainer toward brake shoe, turning the

retainer to unlock it from the pin.

Remove retainer, spring and washer from pin.

Remove retainer pin from dust shield.

Installation — Insert retainer pin through the dust

UPPER CYLINDER

ADJUSTING

CAM

DUST SHIELD-v.

SHOE RETURN

SPRING

SUPPORT-^

shield and brake shoe. Install washer, spring and retainer on retainer pin.

While holding retainer pin in dust shield, push retainer toward brake shoe, turning the retainer to

lock it on the pin.

MASTER CYLINDER

The master cylinder used with power brakes has an

adjustable pushrod. A new master cylinder assembly

is used on Chrysler Models without power brakes.

The new master cylinder has a non-adjustable

push rod-and-piston stop which is permanently attached to the piston. The boot retainer is also a part

of the assembly. The assembly is attached to the

mounting face of the master cylinder body with two

(Figs.

.- SHOE

AND

UNING

— SHOE RETAINER

SHOE RETURN

:

SPRING

19 and 20)

SHOE RETAINE

CYLINDER ASSEMBLY

SHOE

RE'

SPRINGS

SUPPORT

SHOE AND

LINING

Fig.

19

—Total Contact Brake Assembly (Front)

^**z~~-

-ADJUSTING

CONNECTING

TUBE

LOWfi? CYLINDER

ADJUSTING CAMS

CAM

DUST SHIELD

SHOE RETAINERS

ANCHORS

Fig.

20 — Total Contact Brake Assembly (Rear)

MyMopar.com

Page 21

CHRYSLER SERVICE MANUAL

BRAKES—19

screws. No attempt should be made to disassemble

this push rod and piston.

The combined action of the piston return spring

and the pressure in the master cylinder is sufficient

to hold the brake pedal in the "off" position, without

a pedal return spring and pedal stop. The brake

pedal should never be pulled back beyond the limit

controlled by the piston stop. A minimum pull of 50

pounds could pull the piston off the push rod.

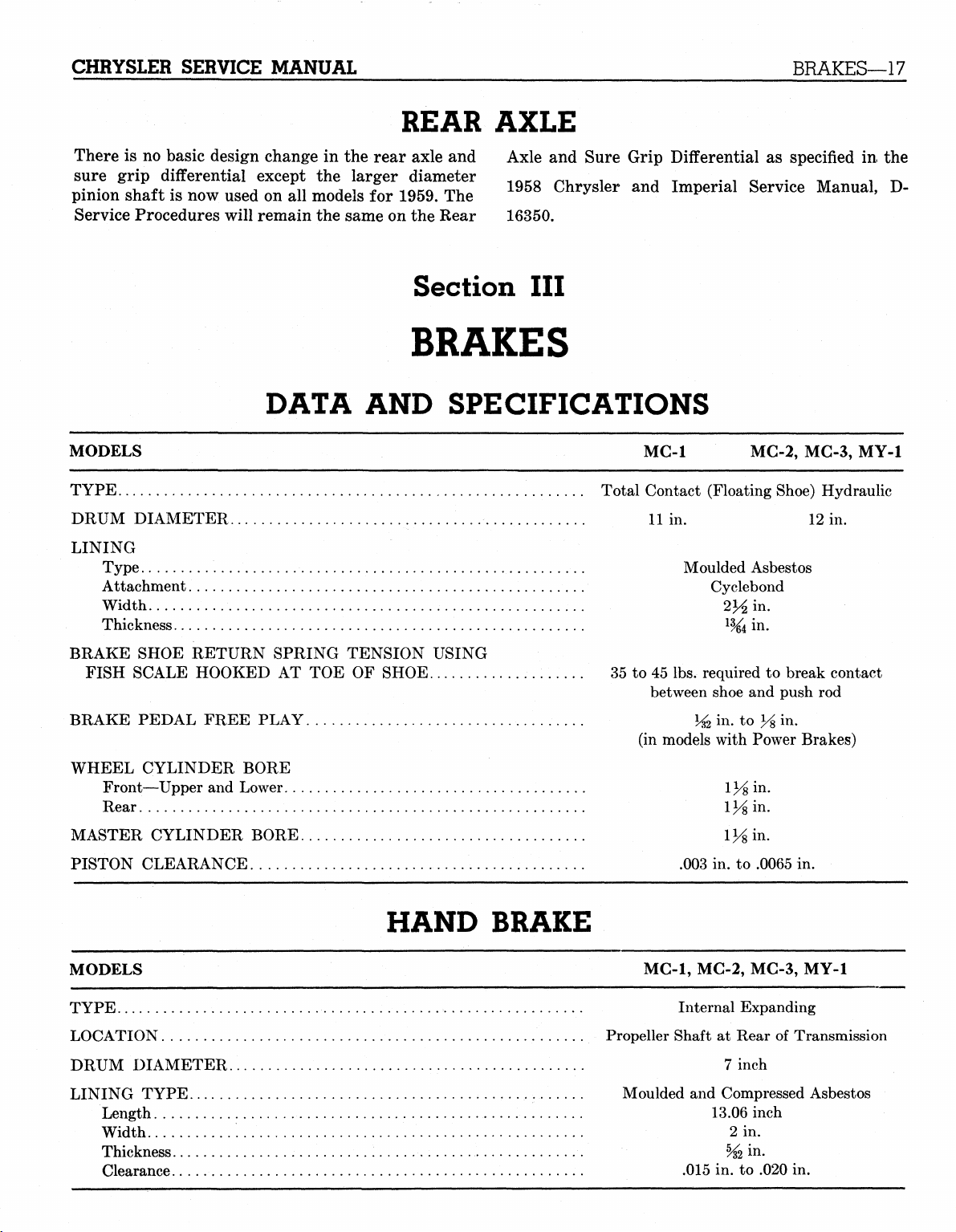

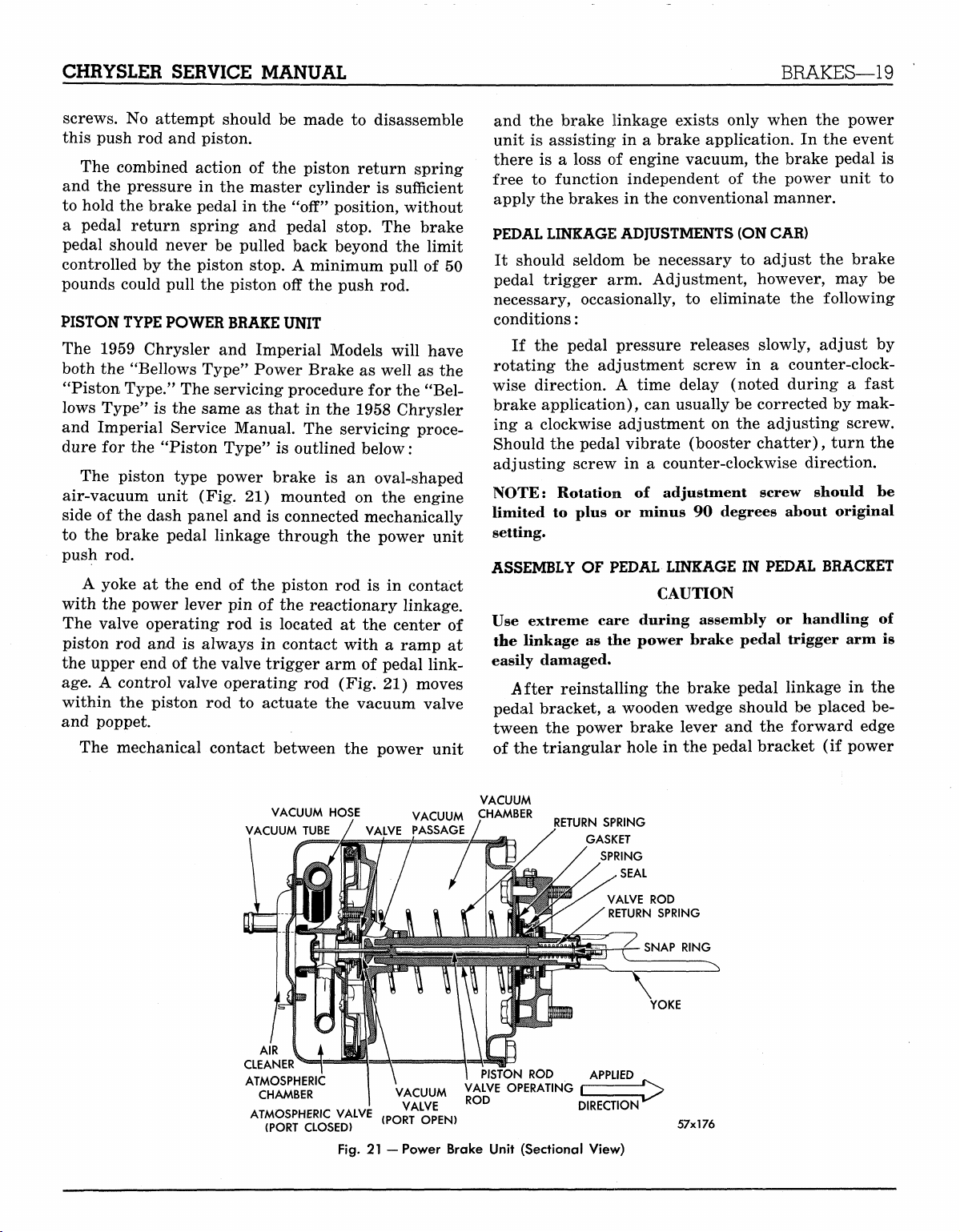

PISTON TYPE POWER BRAKE UNIT

The 1959 Chrysler and Imperial Models will have

both the "Bellows Type" Power Brake as well as the

"Piston, Type." The servicing procedure for the "Bellows Type" is the same as that in the 1958 Chrysler

and Imperial Service Manual. The servicing procedure for the "Piston Type" is outlined below:

The piston type power brake is an oval-shaped

air-vacuum unit (Fig. 21) mounted on the engine

side of the dash panel and is connected mechanically

to the brake pedal linkage through the power unit

push rod.

A yoke at the end of the piston rod is in contact

with the power lever pin of the reactionary linkage.

The valve operating rod is located at the center of

piston rod and is always in contact with a ramp at

the upper end of the valve trigger arm of pedal linkage.

A control valve operating rod (Fig. 21) moves

within the piston rod to actuate the vacuum valve

and poppet.

The mechanical contact between the power unit

and the brake linkage exists only when the power

unit is assisting in a brake application. In the event

there is a loss of engine vacuum, the brake pedal is

free to function independent of the power unit to

apply the brakes in the conventional manner.

PEDAL LINKAGE ADJUSTMENTS (ON CAR)

It should seldom be necessary to adjust the brake

pedal trigger arm. Adjustment, however, may be

necessary, occasionally, to eliminate the following

conditions:

If the pedal pressure releases slowly, adjust by

rotating the adjustment screw in a counter-clockwise direction. A time delay (noted during a fast

brake application), can usually be corrected by mak-

ing a clockwise adjustment on the adjusting screw.

Should the pedal vibrate (booster chatter), turn the

adjusting screw in a counter-clockwise direction.

NOTE: Rotation of adjustment screw should be

limited to plus or minus 90 degrees about original

setting.

ASSEMBLY OF PEDAL LINKAGE IN PEDAL BRACKET

CAUTION

Use extreme care during assembly or handling of

the linkage as the power brake pedal trigger arm is

easily damaged.

After reinstalling the brake pedal linkage in the

pedal bracket, a wooden wedge should be placed between the power brake lever and the forward edge

of the triangular hole in the pedal bracket (if power

VACUUM HOSE VACUUM CHAMBER

VACUUM TUBE / VALVE PASSAGE

AIR

CLEANER

ATMOSPHERIC

CHAMBER

ATMOSPHERIC VALVE

(PORT CLOSED)

Fig.

VACUUM

VALVE

(PORT OPEN)

21

—Power Brake Unit (Sectional View)

/

VALVE OPERATING

ROD

VACUUM

RETURN SPRING

GASKET

SPRING

SEAL

VALVE

RETURN SPRING

£

DIRECTION

ROD

57x176

MyMopar.com

Page 22

20—BRAKES

CHRYSLER SERVICE MANUAL

ARBOR f-<

(TOOL) ^

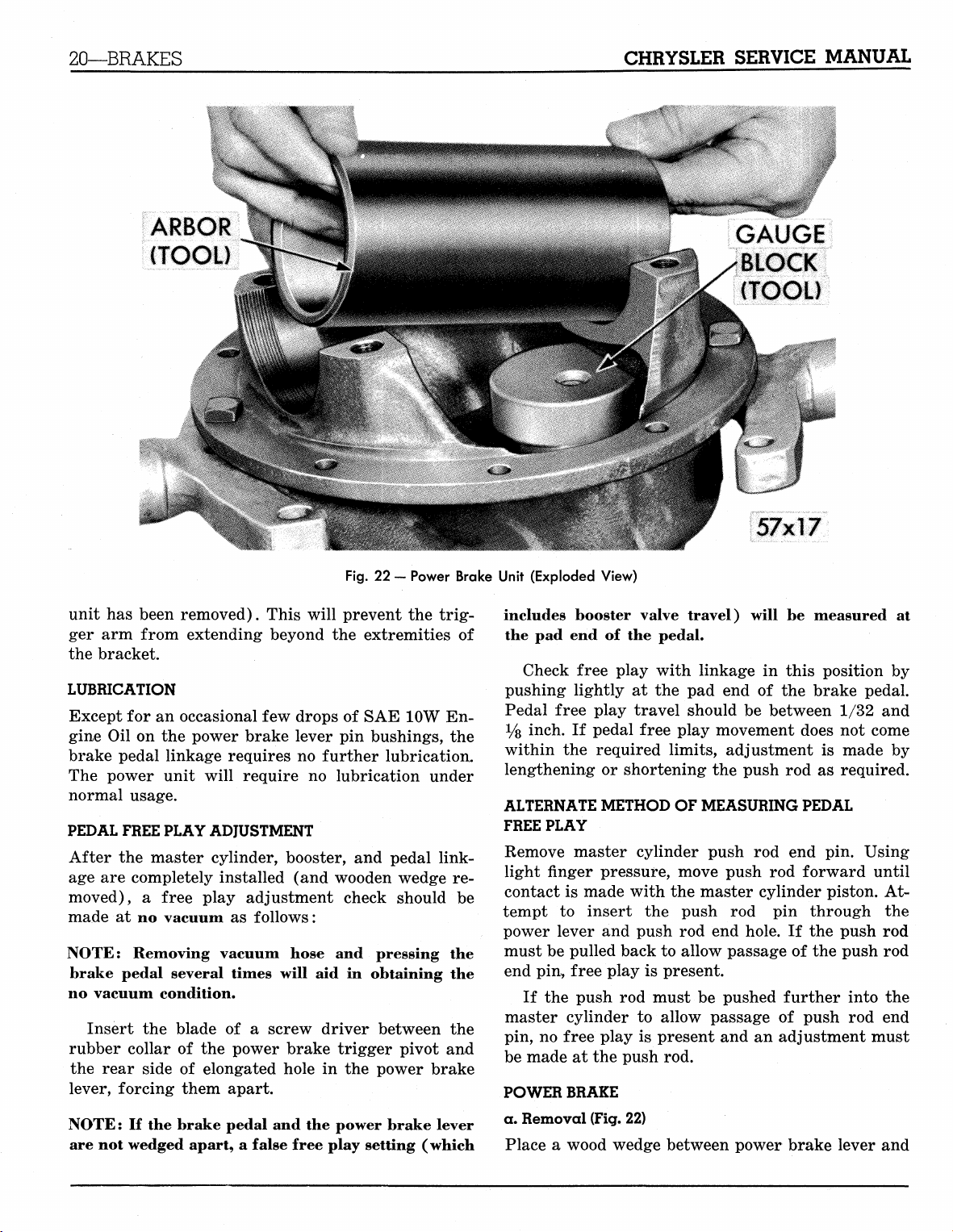

Fig.

22 - Power Brake Unit (Exploded View)

unit has been removed). This will prevent the trigger arm from extending beyond the extremities of

the bracket.

LUBRICATION

Except for an occasional few drops of SAE 10W Engine Oil on the power brake lever pin bushings, the

brake pedal linkage requires no further lubrication.

The power unit will require no lubrication under

normal usage.

PEDAL FREE PLAY ADJUSTMENT

After the master cylinder, booster, and pedal linkage are completely installed (and wooden wedge removed), a free play adjustment check should be

made at no vacuum as follows:

NOTE: Removing vacuum hose and pressing the

brake pedal several times will aid in obtaining the

no vacuum condition.

Insert the blade of a screw driver between the

rubber collar of the power brake trigger pivot and

the rear side of elongated hole in the power brake

lever, forcing them apart.

NOTE: If the brake pedal and the power brake lever

are not wedged apart, a false free play setting (which

GAUGE

BLOCK

(TOOL)

57x17

includes booster valve travel) will be measured at

the pad end of the pedal.

Check free play with linkage in this position by

pushing lightly at the pad end of the brake pedal.

Pedal free play travel should be between 1/32 and

Vs inch. If pedal free play movement does not come

within the required limits, adjustment is made by

lengthening or shortening the push rod as required.

ALTERNATE METHOD OF MEASURING PEDAL

FREE PLAY

Remove master cylinder push rod end pin. Using

light finger pressure, move push rod forward until

contact is made with the master cylinder piston. Attempt to insert the push rod pin through the

power lever and push rod end hole. If the push rod

must be pulled back to allow passage of the push rod

end pin, free play is present.

If the push rod must be pushed further into the

master cylinder to allow passage of push rod end

pin, no free play is present and an adjustment must

be made at the push rod.

POWER BRAKE

a. Removal (Fig. 22)

Place a wood wedge between power brake lever and

MyMopar.com

Page 23

CHRYSLER SERVICE MANUAL

BRAKES—21

forward edge

prevent trigger

ities

of

NOTE:

hole

If

in

of

triangular hole

arm

bracket.

pedal linkage

dash panel

from extending beyond extrem-

the

trigger

Disconnect vacuum hose

attaching bolts

at

dash panel

power unit assembly.

NOTE: Use care

cross

pin.

b.

Disassembly

Scribe across flange

guide

to

correct assembly (Fig.

NOTE:

Do not

to

prevent loss

of

clamp yoke

tion.

Remove

ing

the

the

cylinder shell

vacuum hose from

CAUTION

The vacuum tube must

(Fig.

4).

diaphragm

Make certain

is in the

the

annular groove

plate assembly.

Install valve

rod

poppet

NOTE: Before installing

the following test.

Depress

to blow through

through

the

valve

the

the

hose indicates

rod and at the

vacuum hose. Failure

properly seated.

VACUUM CYLINDER

AIR CLEANER

COVER

AIR CLEANER

HAIR

NUT (4)

in

pedal bracket,

is

allowed

to

extend through

arm may be

at

power unit. Remove

and

carefully remove

cylinder

of the

and end

pedal linkage

23).

in

vise during any opera-

and

gasket, disconnect-

the air

be in the

bead

cleaner cover.

lowest quadrant

at

outer diameter

of the

and

applying diaphragm.

the

vacuum cylinder, make

same time,

the

poppet assembly

END PLATE

MATING MARKS

damaged.

plate

as a

tube

and

try

to

blow

GASKET

to

of

is

END PLATE SPRING ROD

RETAINER PLATE

POPPET DIAPHRAGM

APPLYING

DIAPHRAGM

VALVE

ROD

APPLYING

SCREW

Fig.

Install

PIN

TUBE

AND

PLATE

ASSEMBLY

(4)

24

— Disassembly

a new

SPRING VALVE

VACUUM HOSE 57x201

of

Tube

and

vacuum cylinder gasket

vacuum hose. Align vacuum cylinder

scribe marks

and

assembly.

END

SPRING

RETAINER

WASHER

PISTON

ROD

Plate Assembly

and

and end

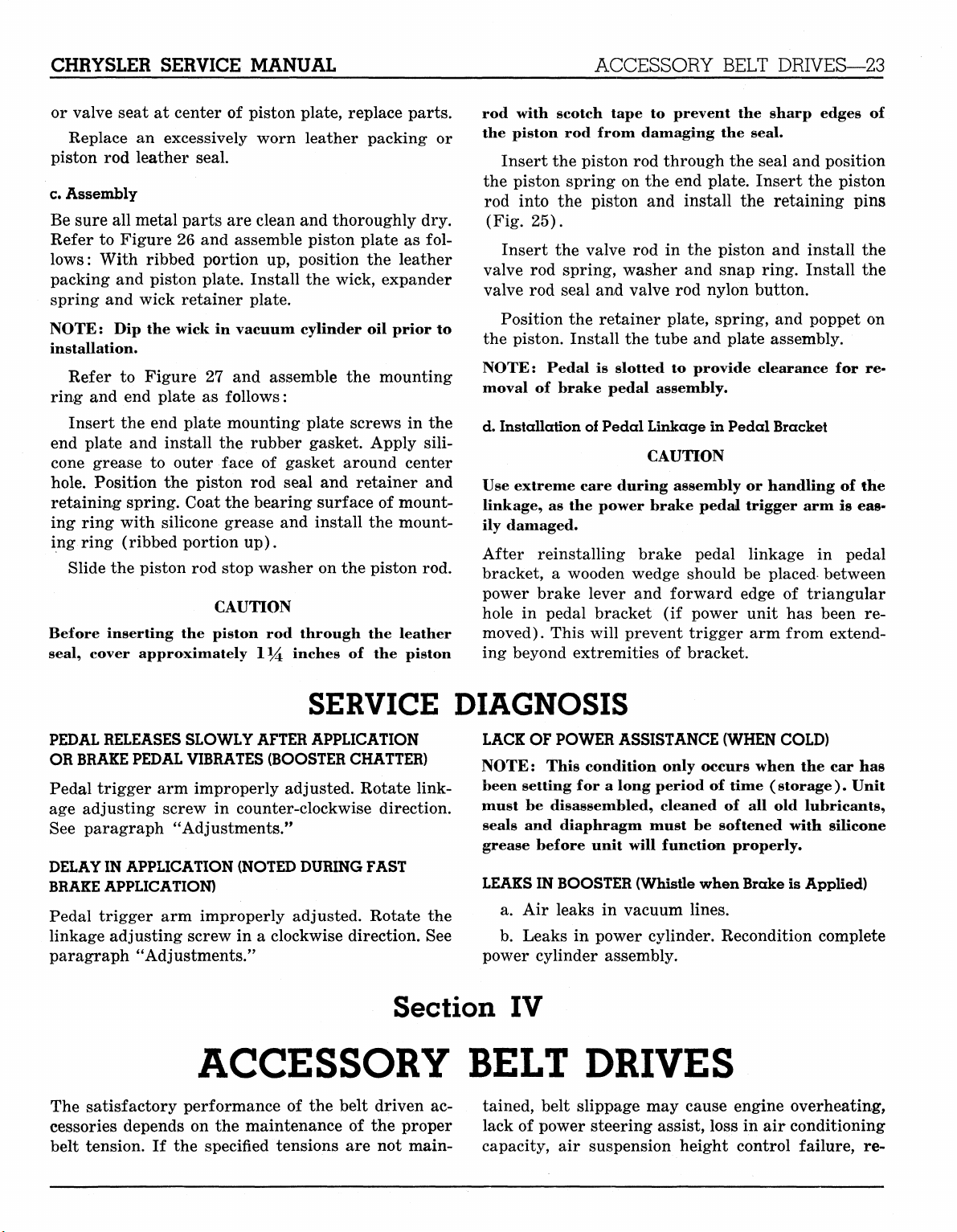

c. Installation

Position

so that

(Fig.

NOTE:

that

nylon bushings

stall

nuts securely,

and hose clips, operate engine

play. Refer adjustment

the

power brake unit

its

axis inclines down toward front

28)

As

yoke passes through dash panel,

it

engages pedal linkage correctly

on

power brake lever cross

and

connect master cylinder.

Replace four

hex

nuts

and

and

release pedal. Install vacuum hose

on

"pedal free play."

on

dash panel

by

sliding over

lockwashers, tighten

and

check pedal free

d. Lubrication

The power unit will require

normal use.

or repair,

If the

all

unit

oil seals

is

and

no

lubrication under

disassembled

for

"0" rings must be suitably

coated with silicone grease before assembly.

RETAINING PINS

STOP WASHER

VALVE

ROD

SEAL

connect

plate

of car

of car.

be

sure

pin. In-

overhaul

SCREWS

LOCKWASHER

(3)

Fig.

23 — Removal of Air Cleaner and

Vacuum Cylinder)

BOLT

57 x 200

AND

(4)

PISTON

ROD

END PLATE

57x202

Fig.

25 — Removal of Vacuum Piston, Spring and Piston Rod

MyMopar.com

Page 24

22—BRAKES

CHRYSLER SERVICE MANUAL

LEATHER PACKING

EXPANDER SPRING

RETAINER PLATE

COTTON WICK

EXPANDER SPRING

SCREW

(6) W 57x203

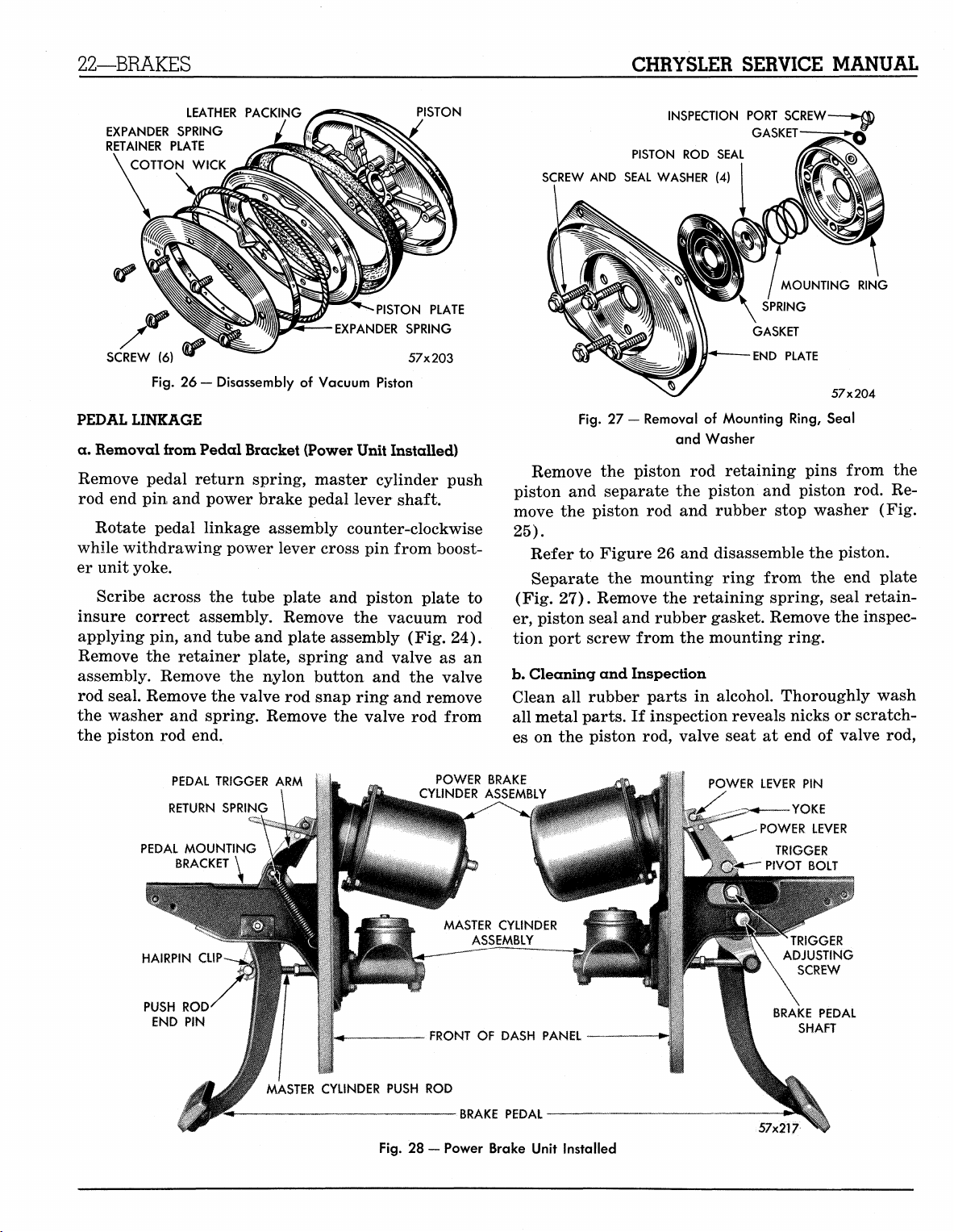

Fig.

26

— Disassembly

of

Vacuum Piston

PISTON

PISTON PLATE

PEDAL LINKAGE

a. Removal from Pedal Bracket (Power Unit Installed)

Remove pedal return spring, master cylinder push

rod end pin and power brake pedal lever shaft.

Rotate pedal linkage assembly counter-clockwise

while withdrawing power lever cross pin from booster unit yoke.

Scribe across the tube plate and piston plate to

insure correct assembly. Remove the vacuum rod

applying pin, and tube and plate assembly (Fig. 24).

Remove the retainer plate, spring and valve as an

assembly. Remove the nylon button and the valve

rod seal. Remove the valve rod snap ring and remove

the washer and spring. Remove the valve rod from

the piston rod end.

INSPECTION PORT SCREW

GASKET

PISTON

ROD

SEAL

SCREW

AND

SEAL WASHER

Fig.

27 —

Removal

(4)

GASKET

END PLATE

of

Mounting Ring, Seal

and Washer

MOUNTING RING

SPRING

57x204

Remove the piston rod retaining pins from the

piston and separate the piston and piston rod. Remove the piston rod and rubber stop washer (Fig.

25).

Refer to Figure 26 and disassemble the piston.

Separate the mounting ring from the end plate

(Fig. 27). Remove the retaining spring, seal retainer, piston seal and rubber gasket. Remove the inspection port screw from the mounting ring.

b.

Cleaning and Inspection

Clean all rubber parts in alcohol. Thoroughly wash

all metal parts. If inspection reveals nicks or scratches on the piston rod, valve seat at end of valve rod,

PEDAL TRIGGER

RETURN SPRING

PEDAL MOUNTING

BRACKET

PUSH

ROD

END

PIN

!

^ . MASTER CYLINDER PUSH

ARM

\

POWER BRAKE

CYLINDER ASSEMBLY

MASTER CYLINDER

FRONT

ROD

Fig.

28 —

Power Brake Unit Installed

ASSEMBLY

OF

DASH PANEL

W

:

POWER LEVER

•——YOKE

POWER LEVER

TRIGGER

*~^" PIVOT BOLT

ADJUSTING

BRAKE PEDAL

MyMopar.com

PIN

TRIGGER

SCREW

SHAFT

Page 25

CHRYSLER SERVICE MANUAL

ACCESSORY BELT DRIVES—23

or valve seat at center of piston plate, replace parts.

Replace an excessively worn leather packing or

piston rod leather seal.

c.

Assembly

Be sure all metal parts are clean and thoroughly dry.

Refer to Figure 26 and assemble piston plate as follows:

With ribbed portion up, position the leather

packing and piston plate. Install the wick, expander

spring and wick retainer plate.

NOTE: Dip the wick in vacuum cylinder oil prior to

installation.

Refer to Figure 27 and assemble the mounting

ring and end plate as follows:

Insert the end plate mounting plate screws in the

end plate and install the rubber gasket. Apply sili-

cone grease to outer face of gasket around center

hole.

Position the piston rod seal and retainer and

retaining spring. Coat the bearing surface of mounting1 ring with silicone grease and install the mounting ring (ribbed portion up).

Slide the piston rod stop washer on the piston rod.

CAUTION

Before inserting the piston rod through the leather

seal, cover approximately 1*4 inches of the piston

rod with scotch tape to prevent the sharp edges of

the piston rod from damaging the seal.

Insert the piston rod through the seal and position

the piston spring on the end plate. Insert the piston

rod into the piston and install the retaining pins

(Fig. 25).

Insert the valve rod in the piston and install the

valve rod spring, washer and snap ring. Install the

valve rod seal and valve rod nylon button.

Position the retainer plate, spring, and poppet on

the piston. Install the tube and plate assembly.

NOTE: Pedal is slotted to provide clearance for re-

moval of brake pedal assembly.

d. Installation of Pedal Linkage in Pedal Bracket

CAUTION

Use extreme care during assembly or handling of the

linkage, as the power brake pedal trigger arm is easily damaged.

After reinstalling brake pedal linkage in pedal

bracket, a wooden wedge should be placed between

power brake lever and forward edge of triangular

hole in pedal bracket (if power unit has been removed). This will prevent trigger arm from extending beyond extremities of bracket.

SERVICE DIAGNOSIS

PEDAL RELEASES SLOWLY AFTER APPLICATION

OR BRAKE PEDAL VIBRATES (BOOSTER CHATTER)

Pedal trigger arm improperly adjusted. Rotate linkage adjusting screw in counter-clockwise direction.

See paragraph "Adjustments."

DELAY IN

BRAKE APPLICATION)

Pedal trigger arm improperly adjusted. Rotate the

linkage adjusting screw in a clockwise direction. See

paragraph ''Adjustments."

APPLICATION (NOTED DURING FAST

Section

ACCESSORY BELT DRIVES

The satisfactory performance of the belt driven accessories depends on the maintenance of the proper

belt tension. If the specified tensions are not main-

LACK OF POWER ASSISTANCE (WHEN COLD)

NOTE: This condition only occurs when the car has

been setting for a long period of time ( storage

must be disassembled, cleaned of all old lubricants,

seals and diaphragm must be softened with silicone

grease before unit will function properly.

LEAKS IN

a. Air leaks in vacuum lines.

b.

power cylinder assembly.

BOOSTER (Whistle when Brake is Applied)

Leaks in power cylinder. Recondition complete

).

Unit

IV

tained, belt slippage may cause engine overheating,

lack of power steering assist, loss in air conditioning

capacity, air suspension height control failure, re-

MyMopar.com

Page 26

CHRYSLER SERVICE MANUAL

ACCESSORY BELT DRIVES—23

or valve seat at center of piston plate, replace parts.

Replace an excessively worn leather packing or

piston rod leather seal.

c.

Assembly

Be sure all metal parts are clean and thoroughly dry.

Refer to Figure 26 and assemble piston plate as follows:

With ribbed portion up, position the leather

packing and piston plate. Install the wick, expander

spring and wick retainer plate.

NOTE: Dip the wick in vacuum cylinder oil prior to

installation.

Refer to Figure 27 and assemble the mounting

ring and end plate as follows:

Insert the end plate mounting plate screws in the

end plate and install the rubber gasket. Apply sili-

cone grease to outer face of gasket around center

hole.

Position the piston rod seal and retainer and

retaining spring. Coat the bearing surface of mounting1 ring with silicone grease and install the mounting ring (ribbed portion up).

Slide the piston rod stop washer on the piston rod.

CAUTION

Before inserting the piston rod through the leather

seal, cover approximately 1*4 inches of the piston

rod with scotch tape to prevent the sharp edges of

the piston rod from damaging the seal.

Insert the piston rod through the seal and position

the piston spring on the end plate. Insert the piston

rod into the piston and install the retaining pins

(Fig. 25).

Insert the valve rod in the piston and install the

valve rod spring, washer and snap ring. Install the

valve rod seal and valve rod nylon button.

Position the retainer plate, spring, and poppet on

the piston. Install the tube and plate assembly.

NOTE: Pedal is slotted to provide clearance for removal of brake pedal assembly.

d. Installation of Pedal Linkage in Pedal Bracket

CAUTION

Use extreme care during assembly or handling of the

linkage, as the power brake pedal trigger arm is eas-

ily damaged.

After reinstalling brake pedal linkage in pedal

bracket, a wooden wedge should be placed between

power brake lever and forward edge of triangular

hole in pedal bracket (if power unit has been removed). This will prevent trigger arm from extending beyond extremities of bracket.

SERVICE DIAGNOSIS

PEDAL RELEASES SLOWLY AFTER APPLICATION

OR BRAKE PEDAL VIBRATES (BOOSTER CHATTER)

Pedal trigger arm improperly adjusted. Rotate linkage adjusting screw in counter-clockwise direction.

See paragraph "Adjustments."

DELAY IN

BRAKE APPLICATION)

Pedal trigger arm improperly adjusted. Rotate the

linkage adjusting screw in a clockwise direction. See

paragraph ''Adjustments."

APPLICATION (NOTED DURING FAST

Section

ACCESSORY BELT DRIVES

The satisfactory performance of the belt driven accessories depends on the maintenance of the proper

belt tension. If the specified tensions are not main-

LACK OF POWER ASSISTANCE (WHEN COLD)

NOTE: This condition only occurs when the car has

been setting for a long period of time ( storage

must be disassembled, cleaned of all old lubricants,

seals and diaphragm must be softened with silicone

grease before unit will function properly.

LEAKS IN

a. Air leaks in vacuum lines.

b.

power cylinder assembly.

BOOSTER (Whistle when Brake is Applied)

Leaks in power cylinder. Recondition complete

).

Unit

IV

tained, belt slippage may cause engine overheating,

lack of power steering assist, loss in air conditioning

capacity, air suspension height control failure, re-

MyMopar.com

Page 27

24—ACCESSORY BELT DRIVES

CHRYSLER SERVICE MANUAL

duced generator charging rates, and greatly reduced

belt life. To avoid any such adverse effects, the following service procedure should be followed:

1.

Adjust all belts "in use"* to the specified belt

tension at new car preparation.

2.

Readjust all belts at the 2,000 mile inspection

and service.

3.

Check all belts by the deflection method at serv-

icing and readjust if needed,

4.

The new belt tension specifications should be

used on all new belt installations and the above procedure followed thereafter.

There are two methods by which belt tensions can

be properly established:

Torque Method — All generator and power steering

pump belts can be tightened to the specified tension

(see Tension Specifications that follow), by use of a

torque wrench. The generator belts are tensioned by

using a special tool C-3379, and torque wrench. The

power steering belts are tightened by inserting the

torque wrench in the square hole provided in the

bracket. Other belts can also be tightened by this

method if the adjusting bracket has a square hole.

To tighten belts by the torque method, loosen all

mounting bolts and apply the specified torque to the

accessory or idler. Tighten all mounting bolts while

the torque is applied to the accessory. If it is not possible to use the torque wrench because of clearance,

use an extension.

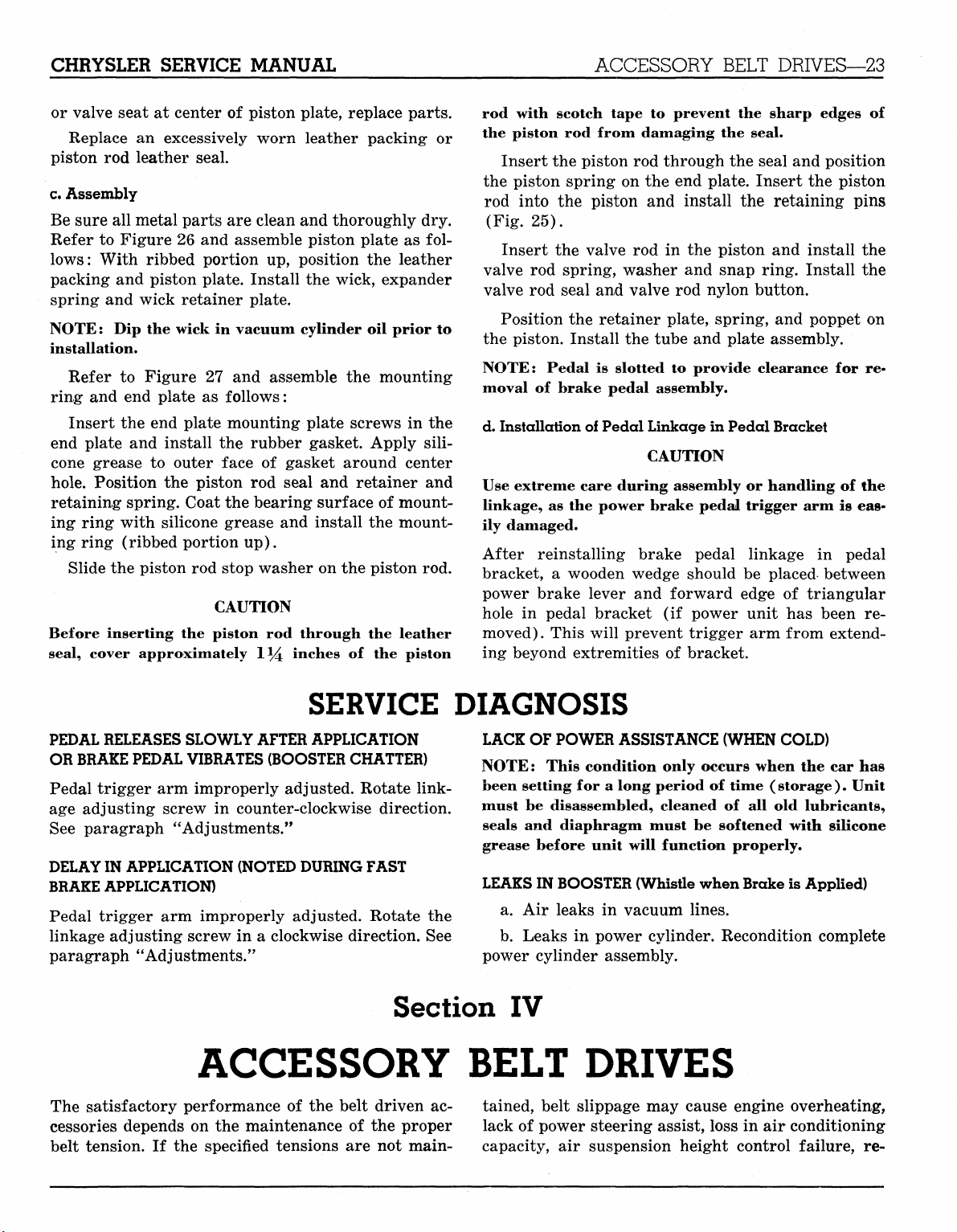

Belt Deflection Method — All belts can also be adjusted by measuring the deflection of the belt at the

mid-point between two pulleys under a five-pound

push or pull. A small spring scale can be used to establish the

five-pound

load. See Figure 29 for correct

location at which to measure deflection.

This method should be used only when it is not

possible to use the torque method, as it is a less accurate method. To tension the belts by the deflection

method, loosen all mounting bolts and use a bar to

apply tension to the belts being careful not to damage the accessory. A Johnson bar can be used if the

accessory has a square hole. Tighten the mounting

bolts and check the deflection, (see Belt Tension

specifications). It may be necessary to repeat this

procedure several times to establish the correct tension.

* Any belt that has operated for a minimum of a

half-hour is considered to be "in use."

1.

CS-Crankshaft

2.

WP-Water Pump

3. G—Generator

4. PS—Power Steering

MC-2,

MC-3, MY-1 MC-1

Fig.

29 — Belt Deflection Location

59xll8

5.

I—Idler

6. AC-Air Conditioning

7. SC—Suspension Compressor

MyMopar.com

Page 28

CHRYSLER SERVICE MANUAL

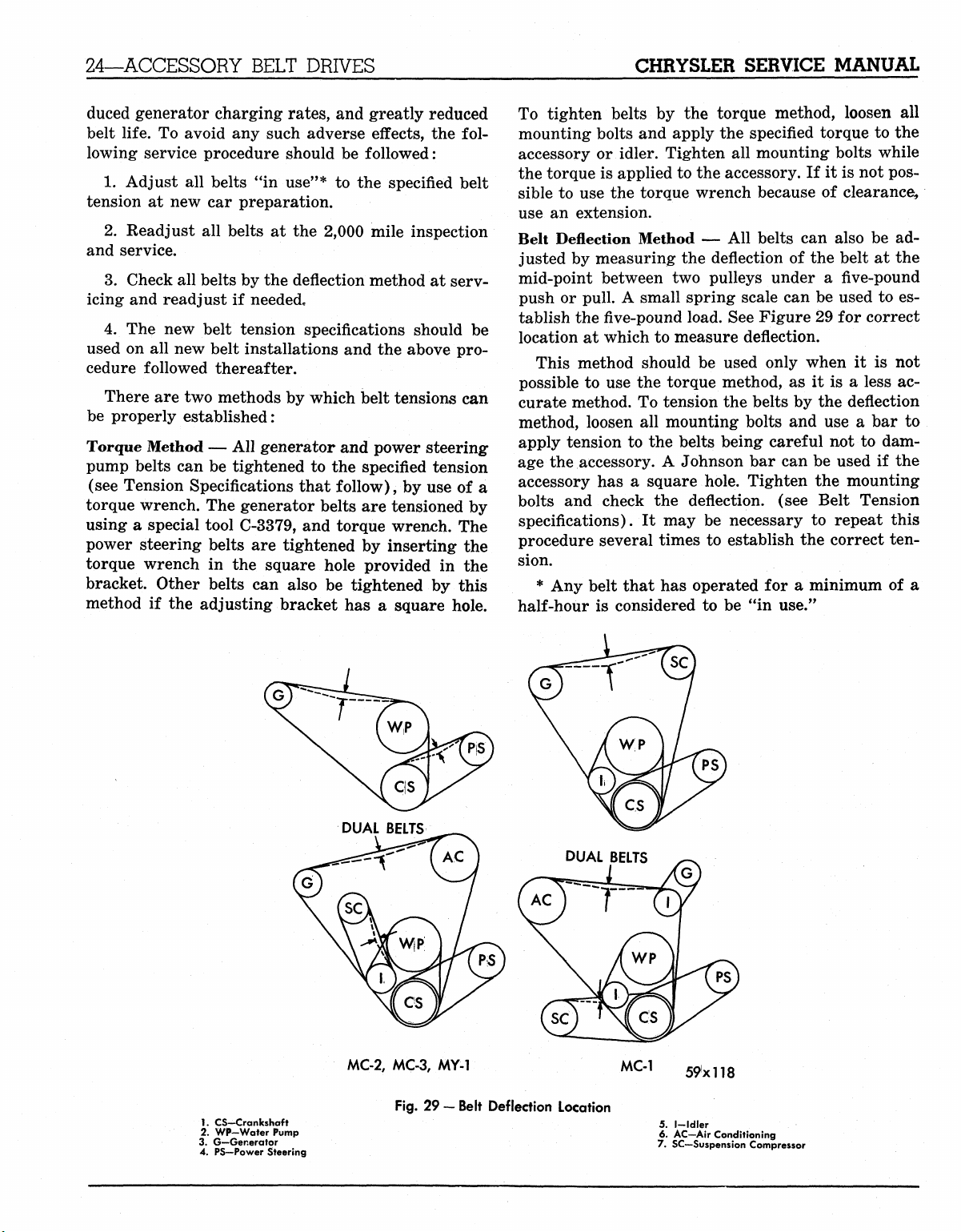

BELT TENSION SPECIFICATIONS

Torque (Ft. Lbs.) to be Applied to Components

ACCESSORY BELT DRIVES—25

TORQUE METHOD

ACCESSORY

POWER STEERING BRACKET

GENERATOR—WITHOUT AIR CONDITIONING

MC-1 WITH AIR CONDITIONING

MC-2,

MC-3, MY-1 WITH AIR CONDITIONING

WITH SUSPENSION COMPRESSOR

FAN IDLER BRACKET

AIR CONDITIONING IDLER BRACKET (MC-1)

BELT DEFLECTION METHOD

Deflection (inches) to be Applied at Mid-Point of Belt Segment Under a 5 pound Load—See Figure 29

ACCESSORY

POWER STEERING

FAN BELT—IDLER

GENERATOR—WITHOUT AIR CONDITIONING

WITH SUSPENSION COMPRESSOR

MC-1 WITH AIR CONDITIONING

MC-2,

MC-3, MY-1—WITH AIR CONDITIONING

SUSPENSION COMPRESSOR BELT MC-1 WITH

AIR CONDITIONING

SUSPENSION COMPRESSOR BELT MC-2, MC-3, MY-1 WITH

AIR CONDITIONING

BELT IN USE

55

20

10

35

30

35

50

NEW BELT

90

30

15

65

40

50

85

BELT IN USE NEW BELT

%,

Vs

VA

%>

Vs

Vs

Vs

Hi

Vs

%

Vs

M

Vs

Hi

SERVICE DIAGNOSIS

Insufficient Accessory Output Due to Belt Slippage

Check belt tension and belt condition. If belt is excessively glazed or worn, install new belts and adjust

as specified.

Belt Squeal when Accelerating Engine

a. Belts too loose—retighten.

b.

Belts glazed—install new belts.

Belt Squeak at Idle

a. Misaligned pulleys—align accessories

brackets or use spacers as required).

b.

Non-uniform groove or eccentric pulley—re-

place pulley.

(file

c. Non-uniform belt—replace belt.

d. Dirt and paint imbedded in belt—replace belt.

e. Belt too loose—retighten.

f. Belts glazed—install new belts and tighten to

specified tension.

Belt Rolled Over in Groove

Broken cord in belt—replace belt.

Belt Jumps Off

a. Belt too loose—retighten.

b.

Misaligned pulleys—align accessories.

MyMopar.com

Page 29

26—COOLING SYSTEM

CHRYSLER SERVICE MANUAL

Section V

COOLING SYSTEM

DATA AND SPECIFICATIONS

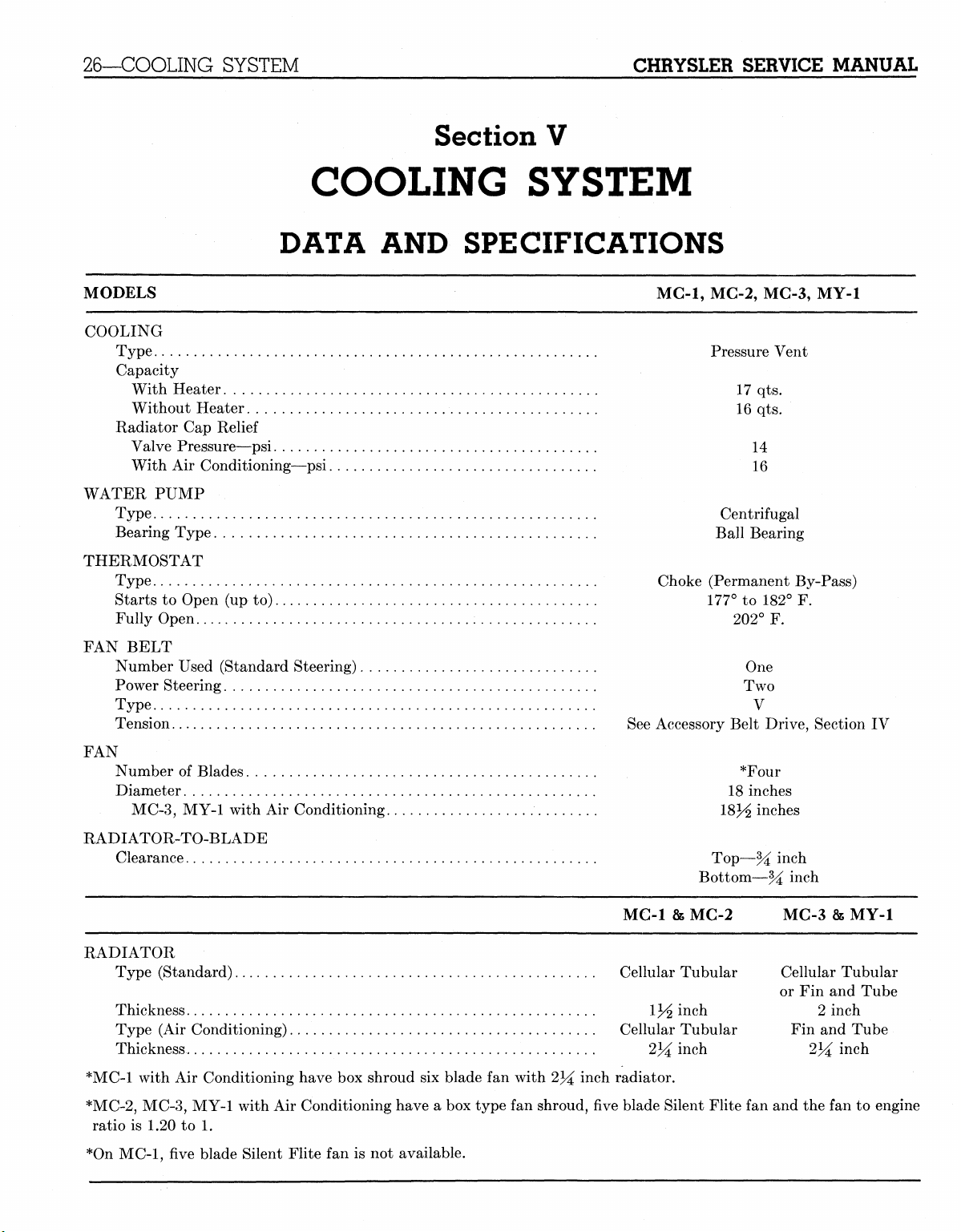

MODELS MC-1, MC-2, MC-3, MY-1

COOLING

Type Pressure Vent

Capacity

With Heater 17 qts.

Without Heater 16 qts.

Radiator Cap Relief

Valve Pressure—psi 14

With Air Conditioning—psi 16

WATER PUMP

Type Centrifugal

Bearing Type Ball Bearing

THERMOSTAT

Type Choke (Permanent By-Pass)

Starts to Open (up to) 177° to 182° F.

Fully Open 202° F.

FAN BELT

Number Used (Standard Steering) One

Power Steering Two

Type V

Tension See Accessory Belt Drive, Section IV

FAN

Number of Blades , *Four

Diameter 18 inches

MC-3,

MY-1 with Air Conditioning 18J^ inches

RADIATOR-TO-BLADE

Clearance Top—% inch

Bottom—% inch

MC-1 & MG-2 MC-3 & MY-1

RADIATOR

Type (Standard) Cellular Tubular Cellular Tubular

or Fin and Tube

Thickness 1J/2 inch 2 inch

Type (Air Conditioning) Cellular Tubular Fin and Tube

Thickness 2^ inch 2lA inch

*MC-1 with Air Conditioning have box shroud six blade fan with 234 inch radiator.

*MC-2,

*On MC-1, five blade Silent Flite fan is not available.

MC-3, MY-1 with Air Conditioning have a box type fan shroud, five blade Silent Flite fan and the fan to engine

ratio is 1.20 to 1.

MyMopar.com

Page 30

CHRYSLER SERVICE MANUAL

ELECTRICAL SYSTEM—27

COOLING SYSTEM

The cooling system servicing is the same for 1959

with the exception of the following: The capacity of

the radiator cooling system is 17 quarts with a heater and 16 quarts without a heater.

The radiator oil cooler located in the bottom of the

pan in the radiator tank has a new service proce-

dure.

Testing for Leaks

Remove the two oil cooler lines at the radiator. Con-

nect a pressure gauge to one cooler outlet. Connect

a source of air pressure with a shut-off valve (closed

Section VI

ELECTRICAL SYSTEM

DATA AND SPECIFICATIONS

BATTERY

position) to the other outlet. Do not use pipe sealers

since the sealer may get into transmission oil circuit.

Open valve slightly and admit air pressure not to

exceed 50 psi gauge reading, then close valve. If the

cooler and all fittings are leak

ing will remain constant.

When a leak is detected, remove radiator from car.

Remove radiator lower tank (soft solder). Test the

cooler with 50 psi air pressure in water to locate leak.

Repair the leak using silver solder. If necessary, have

a competent radiator repair shop repair the leak or

install a new cooler.

MG-1,

proof,

MG-2, MG-3, MY-1

the gauge read-

Voltage

Capacity

Terminal Ground

78 Plate 70 Amp Hour

12

Negative

STARTER

MC-1,

MC-2, MC-3, MY-1

Car Model Usage MDT-6002-1770712

Starter Model „ MDT-6002

Voltage 12

No.

of Fields 4

No.

of Poles 4

Brushes 4

Spring Tension 32 to 48 Ounces

Drive Solenoid Shift Overrunning Clutch

End Play .005" Minimum

Free Running Test

Voltage 11

Amperage Draw 80 Amps Minimum

Minimum Speed rpm 3800 Minimum

Stall Torque Test

Torque Foot-Pounds 8.5

Voltage 4

Amperage Draw 350

Pinion to Housing .070" to .120"

Clearance Between Pinion Stop

(with Armature End Play removed)

MyMopar.com

Page 31

CHRYSLER SERVICE MANUAL

ELECTRICAL SYSTEM—27

COOLING SYSTEM

The cooling system servicing is the same for 1959

with the exception of the following: The capacity of

the radiator cooling system is 17 quarts with a heater and 16 quarts without a heater.

The radiator oil cooler located in the bottom of the

pan in the radiator tank has a new service proce-

dure.

Testing for Leaks

Remove the two oil cooler lines at the radiator. Con-

nect a pressure gauge to one cooler outlet. Connect

a source of air pressure with a shut-off valve (closed

Section VI

ELECTRICAL SYSTEM

DATA AND SPECIFICATIONS

BATTERY

position) to the other outlet. Do not use pipe sealers

since the sealer may get into transmission oil circuit.

Open valve slightly and admit air pressure not to

exceed 50 psi gauge reading, then close valve. If the

cooler and all fittings are leak

ing will remain constant.

When a leak is detected, remove radiator from car.

Remove radiator lower tank (soft solder). Test the

cooler with 50 psi air pressure in water to locate leak.

Repair the leak using silver solder. If necessary, have

a competent radiator repair shop repair the leak or

install a new cooler.

MG-1,

proof,

MG-2, MG-3, MY-1

the gauge read-

Voltage

Capacity

Terminal Ground

78 Plate 70 Amp Hour

12

Negative

STARTER

MC-1,

MC-2, MC-3, MY-1

Car Model Usage MDT-6002-1770712

Starter Model „ MDT-6002

Voltage 12

No.

of Fields 4

No.

of Poles 4

Brushes 4

Spring Tension 32 to 48 Ounces

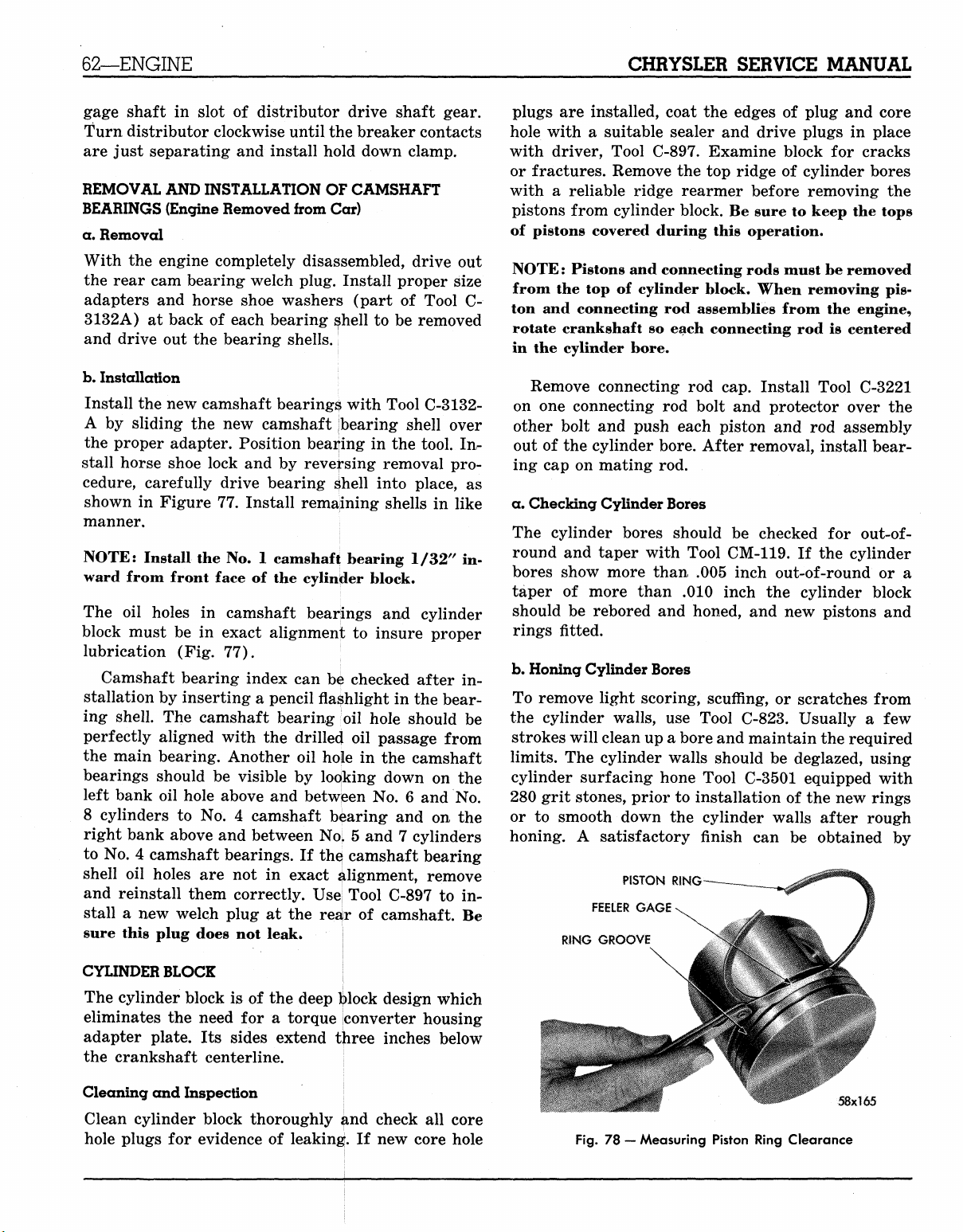

Drive Solenoid Shift Overrunning Clutch