Page 1

386—STEERING

CHRYSLER SERVICE MANUAL

MANUAL STEERING

DATA

MODELS

King Pin Diameter

King Pin Bushings (Manual Steering) Type

Upper

Lower

King Pin Bushings (Power Steering) Type

Upper

Lower

Dimensions of Lower Bushings

Inside Diameter

Outside Diameter

Length

Ream After Installation

AND

SPECIFICATIONS

C-67, C-68, C-69, C-70

Needle Type Bearing

Floating Bushing

Floating Bushing

1.195 to 1.205 in.

.7960 to .7975 in.

.7953 in.

Bushing

.787 to .789 in.

.823

to .825 in.

COAXIAL POWER STEERING

MODELS

Fluid Capacity of Hydraulic System

Fluid Capacity of Worm Housing

Type of Fluid

Maximum Pump Pressure

Maximum Fluid Flow at

Maximum Pump Rotor Clearances:

Between Rotor Lobes

Between Outer Rotor and Bushing

3,000

R.P.M

C-67, C-68, C-69, C-70

2qts.

lpt.

Automatic Transmission Fluid,

Type A

750 to 800 psi.

2 gal. (Minimum)

.008 in.

.006 in.

Page 2

CHRYSLER SERVICE MANUAL

COAXIAL POWER STEERING (Cont'd)

End Clearance (Between Rotors and

STEERING—387

Face of Body)

Flow Control Valve Spring

Free Length

Working Length

Force at Working Length

Pressure Relief Valve Spring

Free Length

Working Length

Force at Working Length,

Front End Alignment

Steering Gear Ratio

Piston Rod Snap Ring Gap

(Upper and Lower) ...

.001

to .002 in.

2.13 in.

1.20 in.

14 lbs. ± lVo lbs.

1.51 in.

1.18 in.

30 to 33 lbs.

16.2:1

2

%4 in.

Tool Number

C-143

C-328

C-611

C-3428

C-619

C-630

SPECIAL TOOLS

MANUAL STEERING GEAR

Tool Name

Puller-—Steering Arm

Bushing—King Pin Remover

Bushing—Eccentric Adjusting

Puller—Steering Wheel

Bushing—Eccentric Adjusting

Reamer—Pilot Bushing

Page 3

388—STEERING

CHRYSLER SERVICE MANUAL

COAXIAL POWER STEERING GEAR

Tool Number Tool Name

C-760 Pliers—Gear Snap Ring—Straight Type

C-3102 Gauge—Hydraulic Pump and Gear Checking

C-3106 Pliers—Gear Snap Ring—Right Angle

C-3107 Wrench—Adjustable Spanner

C-3108 Studs—(Pr.) Power Cylinder

C-

3109 Spacer—Aligning Unit In Chassis

C-3112 Puller—Steering Gear Tube Coupling Adapters for C-293 Puller (C-3145

Covers C-3112 Parts and C-293 Parts Required To Pull Coupling)

C-3113 Driver—Steering Gear Shaft Outer Bearing

C-3114 Driver—Steering Gear Shaft Inner Bearing

C-3116 Pilots—(Pr.)Reservoir Installing

C-3117 Plug—Oil Pump Return Hole (Tapered) (Small)

C-3128 Pliers—Pump Shaft Rear Bearing Ring

C-3129 Driver—Pump Oil Seal and Bearing

C-3130 Thimble—Protector—Pump Oil Seal

C-3136 Sleeve—Shaft Oil Seal Installing

C-3137 Remover—Shaft Oil Seal

C-3141 Driver—Valve Block Adjusting Pin Roller

C-3142 Driver—Steering Gear Shaft Inner Seal

C-3143 Driver—Steering Tube Oil Seal In Valve Body Cap

C-3189 Plug—Oil Pump Return Hole (Tapered) (Large)

C-485,

C-524 or

C-612 Puller—Steering Wheel

C-685 or C-3380 Wrench—Inch-Pound Torque

C-3005..

Wrench—Foot-Pound Torque

SP-2623 Puller Screw—For Use With C-143 Puller (Previously Released)

C-3185 Remover—Pump Shaft Bushings and Seal

C-3211 Hose—High Pressure P/S Test

C-3214 Puller—Main Bearing

Page 4

CHRYSLER SERVICE MANUAL

STEERING—389

COAXIAL POWER STEERING GEAR (Cont'd)

Tool Number Tool Name

C-3227 Wrench—Flange Holding

C-3228 Thimble—Shaft Oil Seal Protecting

C-3229 Pliers

C-3230 Driver—Shaft Oil Seal Installing

C-3233 Driver—Shaft Bushing Installing

C-3234 Adapter—For using C-3214 Puller

C-3250 Pliers—Hose Clamp

C-3251 Driver—Main Bearing Installing

C-3309 Gauge—Oil Pump, pressure checking

C-3317 Driver—Worm Housing Oil Seal

C-3318 Hose—Low Pressure P/S Test W/adapters

C-3319 Nut—Worm Shaft Holding

C-3320 Wrench—Worm Shaft Bearing Adjusting Nut

C-3321 Wrench—Worm Connector Holding

C-3322 Remover and Installer Worm Housing Bearing Cups

C-3323 Fixture—Gear Assembly Holding

C-3328 Spanner—Upper Piston Rod Nut

C-3329 Thimble—Valve Control Spacer Seal Installing

C-3331 Driver—Housing Head and Gear Housing Seal

C-3333 Driver—Remove and Install Gear Shaft Bearing

C-3344—SP-2604 Installer—Piston and Ring Assembly

C-3350 Remover and Installer—Gear Shaft Oil Seal

C-3437 Protector—Lower Piston Rod Seal

C-3392 Wedge—Coupling Removing—(Not Required If C-3112 Is Available)

C-3398 Remover and Installer—Gear Shift Rod Bushings

C-3399 Tool—Shifter Dial Bulb Removing and Installing

C-3401 Thimble—Gearshift Adjusting Screw "0" Ring Installing

C-3469 Flange—Upper Housing—Used For Pretesting for Hydraulic Leaks

Page 5

390—STEERING CHRYSLER SERVICE MANUAL

TIGHTENING REFERENCE

MANUAL STEERING

Foot-Pounds

Steering Gear to Frame Bolt 50

Steering Gear Arm (Pitman) Lock Bolt Nut. 80

Steering Knuckle Tie Rod Clamp Bolt 15

Steering Gear Mounting Bracket Bolts 50

Steering Wheel Nut 40

Steering Knuckle Tie Rod End Ball Nut 75

Intermediate Steering Arm Pin Nut 50

POWER STEERING GEAR ASSEMBLY

Foot-Pounds

Pump Body to Cover Bolts 30-35

Pump Reservoir to Pump Body Bolts 12-17

Pump Mounting Bolts 18-23

Pump Reservoir Mounting Stud 30-35

Steering Knuckle Arm Nuts (Brake Anchor Nuts) 55-75

Steering Gear Arm to Shaft Nut 100-125

Steering Arm to Transverse Link Nut 50-55

Steering Gear Assembly Mounting to Frame 65-70

Steering Wheel to Steering Shaft Nut 35-40

Jacket to Instrument Panel Screws 15-20

Tie Rod Clamp Bolts 10-15

Page 6

CHRYSLER SERVICE MANUAL-

STEERING—391

POWER STEERING GEAR ASSEMBLY (Cont'd)

Foot-Pounds

Tie Rod to Steering Knuckle Arm Nuts 45-75

Pump Coupling Attaching Screw 15-20

Pump Flow Control and Relief

Pump Coupling Flange Attaching Screw 10-12

Upper Piston Rod Nut 25-30

Ball Guide Clamp Screws 10-12

Worm Housing to Gear Housing Screws 25-30

Gear Shaft Adjusting Screw Lock Nut 35-40

Valve

Adapter (Retaining) 45-50

RESERVOIR

Thread Size Foot-Pounds

Reservoir Cover Bolt %6 x 24 8

Relief Valve Assembly Cap 1x8 8

Hose Connector Inlet % x 18 30

PUMP

Thread Size Foot-Pounds

Pump Assembly Bolt %6 x 18 20

Hose Connector Outlet % x 18 30

By-Pass Plug % x 16 50

Relief Valve Plug 1 x 14 50

Flow Divider Valve Plug 1% x 12 50

94 e Drain Tube Nut % x 24 *y2 to % Turn

or 6 to 10

* The number of turns specified is after initial finger tightening.

Page 7

392—STEERING

CHRYSLER SERVICE MANUAL

WASHER

LOCKWASHER

NUT

OIL

WASHER

WASHER

SEAL

GROMMET

LEVER

KNOB

JACKET

INSULATOR

GROMMET

SWITCH

BRACKET

OILSEM

BUSHINGS<^T%

CAGE

AND

TUBE

AND

CAGE

AND

OIL

SHIMS

COVER

SCREW

NUT

WORM

ROLLERS

SEAL

'^J^\\

ROLLERS

CUP

\ *

NUT

54x677

A

Fig.

1—Typical Steering Gear (Exploded View)

Page 8

CHRYSLER SERVICE MANUAL

STEERING—393

Section

STEERING

(SEE FIG.

1.

LINKAGE

The symmetrical idler arm type

shown

in

Figure 2,

is

used on

ter link relays the motion from the Pitman arm

to an idler arm at its opposite end. The idler arm

is mounted

on a

bracket attached

Two equal length tie rods connect from the center relay link to the steering knuckle arms. Both

tie rods

are

threaded

for

adjustment.

2.

STEERING GEAR (THREE-TOOTH ROLLER

AND WORM) (Mechanical)

A three-tooth roller

is

mounted

bearings on a steel cross-shaft inserted through

the steering gear shaft.

of

all

models. A cen-

to the

proper

on

steering,

as

frame.

toe

aligning

needle roller

X

1)

The worm

and

is

bearings. The worm bearing pre-load is adjusted

by means

and housing end cover. The steering gear shaft

rotates

steering gear housing.

on

the

the steering wheel

the steering gear shaft

Pitman arm, which

shaft and held

Backlash between the steering gear shaft roller tooth and

justing screw that is threaded through the shaft

and roller cover. The base end

screw

is

steering gear shaft. Correct backlash

is

integral with

supported

of

in

two bronze bushings pressed into

shaft

engaged

at

each

shims placed between

is

meshed with

is

turned,

is

splined

in

place with

the

worm

in a

the

steering tube

end by

tapered roller

the

The

three-tooth roller

the

worm. When

the

worm rotates

and

roller, moving

to the

a nut.

is

controlled

of

the adjusting

slot

in the end of the

housing

the

the

end

of the

by an ad-

can be

STEERING KNUCKLE

ARM-RIGHT

TIE

ROD

END-OUTER

TIE

ROD

ENDS-INNER

CENTER LINK

IDLER

ARM

STEERING GEAR

STEERING KNUCKLE

ARM-LEFT

STEERING GEAR

ARM

55x5

Fig.

2—Idler Arm Type Steering Linkage

Page 9

394—STEERING

CHRYSLER SERVICE MANUAL

obtained by turning the adjusting screw in or

out, as required.

The steering wheel and Pitman arm are

splined to the steering tube and steering gear

shaft, respectively. Both the steering wheel and

the Pitman arm have master serrations to in-

sure correct installation.

The high point is the point of least clearance

between the worm and roller and is at the midpoint of the worm and roller travel.

An oil seal is installed in the bore of the

steering gear housing at the outer end of the

shaft to prevent oil leakage and to keep foreign

material from entering the steering unit.

3.

REMOVAL OF STEERING WHEEL

ASSEMBLY

Disconnect battery and center the steering

wheel in the straight-ahead position. Press down

on the horn blowing ring ornament and turn

counter-clockwise. Lift out ornament retaining

spring and pad. Disconnect horn wire from terminal on travel plate and insulator assembly.

Remove bushing, travel plate, horn blowing contact ring spring, and triangular ground plate.

Curl and push horn wire into the steering gear

tube to make room for steering wheel puller

pilot. Remove the steering wheel nut. Attach

puller and remove steering wheel.

Drain lubricant from the steering gear housing. Mount the gear assembly in a suitable bench

vise,

holding the assembly by the housing to

chassis mounting flange, with the steering column in the horizontal position. Remove the shaft

cover attaching cap screws, cover, gasket and

steering gear shaft, and roller tooth assembly.

Loosen the column jacket clamp bolt, pry

open clamp and remove column jacket from

steering housing. Remove steering worm, lower

oil seal housing cover bolts, cover and shims.

Pull steering tube and worm assembly bearing

cups and bearing cages out of the lower end of

steering housing.

Clean the steering gear housing shaft, bearings and other parts thoroughly with a suitable

cleaning solvent. Inspect roller tooth shaft, shaft

serrations, bearings, bearing cups, oil seals,

worm and tube for wear, nicks and flat spots.

Replace with new parts as necessary.

Remove roller tooth assembly shaft cover

adjusting screw nut and locking plate. Check

adjusting screw threads in cover and on the

adjusting screw. Replace if necessary.

6. ASSEMBLY OF STEERING GEAR

(Unit Removed From Car)

4.

REMOVAL OF STEERING GEAR

ASSEMBLY

It is not necessary to remove the complete steering column and mast assembly from the car for

servicing the gear chuck and worm shaft. To

remove the gear chuck and worm shaft assembly proceed as follows. Disconnect the battery,

press down on the horn ring ornament while rotating it, and remove ornament. Remove steering column worm shaft nut. Pull steering wheel

with puller. Loosen jacket bracket bolts at instrument panel. Remove dust pad retaining

screws. Raise front of car and remove steering

gear (Pitman) arm from gear shaft. Loosen

jacket to gear chuck clamp bolt. Remove gear

chuck to frame attaching bolts and work gear

chuck and shaft assembly out of jacket. Remove

assembly from lower side of car.

5.

DISASSEMBLY OF STEERING GEAR

(Unit Removed From Car)

To disassemble the Manual Steering Gear As-

sembly, proceed as follows:

NOTE

When the steering gear assembly is disassembled,

it is always advisable to install new seals

and gaskets to insure against oil leaks.

If either of the worm thrust tapered roller

bearings have become damaged, it is advisable

to replace both bearings. After thoroughly

cleaning all parts, assemble the parts without

any lubrication. Lubrication should be done

after the adjustments have been completed. If

bushings or needle bearings have been removed,

press new bushings or needle bearings into

place. Use new oil seals.

Insert the worm and tube into the housing

with bearings and cups in the proper order, as

shown in Figure 2. Install the shims and lower

housing cover, making sure that bearings are

seated in cups before tightening

the cover screws evenly, turning the worm tube

at intervale to be sure no bind occurs. Final

screws.

Tighten

Page 10

CHRYSLER SERVICE MANUAL

STEERING—395

tightening of the screws should cause the end

play to just disappear with the torque required

to rotate the wheel from % to % of a pound,

when measured with the pull applied at rim of

wheel. If a bind in the rotation of the tube occurs

when the cover screws are fully tightened, it

will be necessary to add shim thickness until

bind just disappears. If end play is present after

final tightening, less shim thickness is required.

Shims are available in .003, .006, .011 and .025

inch. By using a micrometer to measure shims, #

the proper combination can be chosen.

Refer to Figure 2 and 3. Install the roller

shaft bearing in the housing. Before installing

the cover, turn.the adjusting screw all the way

out (counter-clockwise). When the roller shaft

assembly is completely installed, with the exception of the Pitman arm, adjust as follows:

Place the steering wheel on the tube and rotate the wheel in either direction to the end of

its travel. Then, rotate in the opposite direction

to the end of travel while counting the turns.

Rotate the wheel back 1/2 the full number of

turns.

This is the center of travel (mid-travel or

high point). Turn the adjusting screw in (clockwise) until all end play in the roller shaft disappears. Roll the wheel back and forth several

times.

There should be no bind. Rotate the wheel

to one of the ends of travel and apply a spring

scale or torque wrench. With the pull applied

at the rim of the wheel, the tension should measure from 1 to 2 pounds. Rotate the wheel back

to the center and on past the center position.

The greatest tension should be felt as the wheel

is rotated through the center position. Adjust

the bearing load by turning adjusting screw in

or out of the cover, as required. Install lock

plate, nut, and Pitman arm. Fill the gear housing with SAE 90 Fluid Gear Lubricant. Rotate

the wheel back and forth through its full travel

several times to be sure all parts are fully lu-

bricated and check for leaks.

7.

ADJUSTING WORM BEARINGS (In Car)

Rotate steering wheel to extreme right or left

and turn back % turn. Press a finger at joint

between bottom of steering wheel hub and shell.

Have another mechanic shake the front wheels

hard sideways, but not enough to turn steering

wheel. Any end play in worm bearings can be

felt at steering wheel hub. There should be no

end play at the

fused with clearance between the roller and

worm. If any excessive end play exists, remove

the steering gear arm, drain the housing, and

disconnect the horn wire at connector between

steering gear and horn.

Remove cap

cover at bottom of steering gear housing. Remove shims of sufficient thickness between this

cover and housing to eliminate the end play in

worm, but not enough to cause binding when

cover is bolted tightly in place. Turn steering

wheel from extreme right to left. If any

ness exists, too many shims have been removed,

or the steering gear assembly is misaligned on

car.

8. INSTALLATION AND ALIGNMENT OF

STEERING GEAR ASSEMBLY

a. Installation

Where gear chuck and worm shaft assembly has

been removed for service, install as follows.

Raise front of car, insert worm shaft into jacket

and move gear chuck assembly up into position.

It may be necessary for an assistant to guide

the top of the worm shaft through the upper

jacket alignment bearing. Install gear chuck to

bracket attaching bolts and tighten forward

bolt to a snug fit. Lower car to floor. Center the

jacket in the instrument panel and tighten

bracket bolts. Install and tighten dust pad retaining screws. Install steering wheel horn ring

and ornament. Raise front of car. Tighten attaching bolts. Install steering (Pitman) arm

and tighten nut.

b.

Alignment (All Models)

A slight bind of the steering gear is sometimes

caused by shifting of body due to loosened bolts.

If this condition occurs, body bolts should first

be tightened. Then, the steering gear should be

loosened at frame, frame bracket and dash

bracket, and allowed to seek its natural position.

Position the center of steering column in cen-

ter of instrument cluster. If this cannot be ac-

complished by the shifting of the frame bracket,

as provided for by the oversize and elongated

mounting screw holes, it will be necessary to

add metal washer shims between the frame and

frame bracket. Tighten dash bracket and tighten steering gear to frame.

hub.

End play should not be con-

screws which hold grease retainer

stiff-

Page 11

396—STEERING

CHRYSLER SERVICE MANUAL

NOTE

Be sure the body to frame bolts are tight and

the spacers are in place. With the body bolts

tight, loosen the gear housing mounting bolts

to allow the steering gear to move in relation

to the frame. Tighten the mounting bolts to

50 foot-pounds torque. Loosen the steering col-

umn bolts that hold column to instrument panel

to determine if the column shifts its position in

relation to the support.

9. ADJUSTMENT OF ROLLER TOOTH AND

WORM (In Car)

End play of steering arm shaft and mesh of

roller tooth with steering worm may be adjusted

as follows:

Remove steering gear (Pitman) arm from

shaft and install another arm for making adjustments. Turn steering wheel to mid-position.

This is obtained by turning wheel to extreme

right or left, and then turning it to opposite extreme, counting number of turns required. Turn

steering wheel back 1/2 the number of turns required for turning it from one extreme to the

other. With steering wheel in mid-position,

attempt to move steering gear arm back and

forth to determine whether or not there is any

backlash. There should be no backlash. But if

backlash exists, the roller tooth and worm

should be adjusted.

Remove roller tooth shaft adjustment screw

lock nut. Slide off lock plate far enough to clear

lock boss on roller tooth shaft cover. Tighten

roller tooth shaft adjusting screw (Fig. 3)

enough to eliminate free play between roller

tooth shaft and worm; but, it must not bind.

Slide lock plate in position against roller tooth

shaft cover and lock it. Install and tighten

roller tooth shaft adjustment screw lock nut.

Check steering gear operation again for binding

and backlash. Correct any inaccuracies in adjustments. Install steering gear arm with tie

rods.

WORM BEARING ADJUSTING SHIMS

ADJUSTING SCREW

ADJUSTING SCREW

LOCK PLATE

-LOCK PLATE

Fig.

3—Steering Gear Adjustments

NUT

54x46

the idler assembly. Screw the new idler arm

into the bracket until the shoulder on the arm

contacts the face of the bracket. Turn arm out

of bracket one complete turn. It may be necessary to rotate the arm slightly to line up the

bracket for installing attaching bolts.

11.

REMOVAL AND INSTALLATION OF

STEERING KNUCKLE TIE RODS

Remove cotter pin and loosen nut on upper end

of the rod ball. With Tool C-3394, remove tie

rod from steering arm (Fig. 4). Tie rod balls

are not removable from tie rod ends. If replace-

ment of either is necessary, the complete tie rod

end and ball assembly should be replaced. Loosen

clamping bolt nut on the tie rod end. Unscrew

tie rod end assembly from tie rod.

When assembling tie rod ends to tube body,

be sure to thread the ends evenly on tube body

to the nominal length listed in Data and Specifications. This is necessary to obtain proper positioning of the steering wheel with respect to the

straight-ahead position of the front wheels.

Care must be taken to make certain the clamping bolts are beneath the tie rods to prevent

interference on turns.

10.

SERVICING IDLER ARM

Service of the idler arm is restricted to replacement and adjustment. When replacing the idler

arm, disconnect the relay rod (center link) from

the idler arm. Remove the bracket attaching

screws from the bracket and frame and remove

12.

ADJUSTMENT OF FRONT WHEEL

BEARINGS

After removing the hub cap and the grease cap,

remove the cotter pin in the bearing adjusting

nut at the outer end of the steering knuckle

Page 12

CHRYSLER SERVICE MANUAL

STEERING—397

STEERING KNUCKLE

Fig.

4—Removing Tie Rod From Steering Knuckle Arm

(Tool C-3394)

(wheel spindle). Turn bearing adjusting

(Fig.

5)

hand tight. Turn adjusting

one slot. Turn

cotter

pin

new cotter pin.

be

in

good condition and the cotter pin properly

the nut

hole centers over hole

The

bearing

ARM

nut

nut

back

back until slot nearest

and

nut

threads must

install

a

installed and spread. Always use new cotter pins.

13.

RECONDITIONING FRONT WHEEL HUB

AND DRUM ASSEMBLY

Raise front

end of car

until wheel

is off

floor.

Remove hub cap. Remove wheel hub bolts. Bolts

on left wheels have left-hand threads and those

on right wheels have right-hand threads.

move wheel

special Tool C-438,

driver

move threaded type

hub.

Remove cotter

wheel bearing adjusting

bearing and pull hub

not necessary

is

to

be removed from steering knuckle spindle.

Wheel and hub may

unit. Inspect

Before installing front wheel

hub

grease

and

tapping with a light hammer.

cup

or by

by

unscrewing

(snap type) with

prying with a screw

pin and

nut.

off

steering knuckle.

to

remove wheel from hub

be

removed

oil

seal

and

replace

unscrew front

Remove outer

as a

if

necessary.

hub and

ing assembly, remove lubricant from

and bearings and make sure parts

condition. Install inner

so there

ders.

is no

clearance between the hub shoul-

Pack bearings with Short Fiber Wheel

and

outer bearing cups

are in

Re-

Re-

cap

from

It is

if

hub

complete

bear-

the hub

good

Bearing Lubricant (Medium). When installing

the

oil

seals, make certain that

the

seal flange

bottoms on the bearing cup.

14.

REMOVAL AND INSTALLATION

OF

STEERING KNUCKLE KING PINS AND

BUSHINGS

NOTE

Should servicing

of

the steering knuckle be nec-

1—Bearing

2—Bearing thrust washer

3—Outer bearing cup

4—Hub

nut

Fig.

5—Front Wheel Bearings

5—Inner bearing cone and rollers

6-Hub dust seal

7—Hub cap

8—Grease cap

°—Bearing nut cotter pin

10—Outer bearing cone and rollers

11—Steering knuckle

12—Inner bearing cup

Page 13

398—STEERING CHRYSLER SERVICE MANUAL

Fig.

6—Removing Brake Support

Fig.

7—Removing King Pin Bushing or Bearing

essary, time can

ing knuckle

Remove steering knuckle and brake support

an

assembly.

If

it

is

done

support. Remove brake hose connections,

leave brake support

move unit as an assembly with steering knuckle

after king pin is

ings,

seals,

knuckle and support assembly.

be

saved by removing the steer-

arm

from

the

steering knuckle.

as

Make necessary

in

this manner, eliminate removing

repairs

on

a bench.

but

on

removed.

steering knuckle.

Always use new bush-

Re-

and pins ivhen servicing the steering

1—King

pin bushing

at top and oil hole

hole

in

steering knuckle. Stationary type bushings (Fig.

move

8)

the

upper needle bearing. Install reamer

or

in

should

bearing 2—Tool C-328

bearing lined

be

line-reamed. First

up

with

oil

re-

pilot bushing Tool C-631 and reamer Tool C-379.

When installing lower

bushing (Fig.

9),

to the top. Both types

and

upper floating type

place open end

of

lower bushings should

of oil

groove

Remove wheel and hub assembly. Block brake

pedal

so it

cannot

and bolts that fasten brake support

knuckle. Remove steering knuckle

steering knuckle. Remove brake hose

nections and lift

be

depressed. Remove nuts

to

arm

and

off

brake support (Fig. 6). Do

steering

from

con-

not allow brake support and shoe assembly to be

supported

by

flexible brake hose. Remove king

pin locking pin.

Drive a punch into upper steering knuckle

welch plug and

Drive king

welch plug. A soft brass drift should

when driving against top

steering knuckle upper needle bearing

ing

by

pulling

special

tool,

ing knuckle lower bushing.

stationary type, use special tool to remove

The upper needle bearing must

from

top of

pry it out of

pin

downward, forcing

it

toward center knuckle, using

as shown in Figure

steering knuckle.

out

be

of

king pin. Remove

or

7.

Remove steer-

If

bushing

is of

lower

used

bush-

the

it.

be

installed

steering knuckle, with trade mark

49x607

Fig.

8—Bearing and Stationary Type Bushing

Installed

1—Bearing identification mark 3—Lubricant holes

2—Bushing identification line

or

notch A—3/32 inch

B-l/16inch

Page 14

CHRYSLER SERVICE MANUAL

STEERING—399

STAKE IN PLACE

AS SHOWN

STAKE SECURELY

4 PLACES AS

SHOWN BOTH

ENDS

Fig.

9—Bearing and Floating Type Bushing Installed

1—Bearing identification mark

2—Lubricant holes

3—Floating type bushing

A-3/16inch

be installed with oil hole in bearing lined up

with oil hole in steering knuckle. On cars

equipped with Power Steering, the king pin

bushings should be installed with the open end

of the oil groove leading towards the "O" seal

rings.

After installing the steering knuckle, make

sure it is free in the support. Binding at this

point may cause sensitive steering and car wander. There should be .006 to .008 inch clearance

between the steering knuckle and the knuckle

support. This clearance can be adjusted by the

49x701

Fig.

10—Welch Plug and King Pin Lock Pin Installed

use of shims between the steering knuckle and

the thrust bearings.

When installing a welch plug, it is necessary

to stake it after it is properly in place, as shown

in Figure 10.

Before installing hub and drum assembly,

perform Major Brake Adjustment, described

in Section III, Brakes, as applied to cars

equipped with Manual Steering. After installing hub, drum and wheel assembly, check king

pin inclination, caster, camber, and toe-in or

toe-out, as outlined in Front Wheel Alignment

in this Section. Adjust brakes.

COAXIAL POWER STEERING

15.

DESCRIPTION (Fig. 11)

The Coaxial Power Steering Unit incorporates two basic gear mechanisms, a worm and

worm connector and a rack and sector gear.

The worm and worm connector act in a man-

ner similar to a bolt and nut assembly, rotation

of the worm causes linear (axial) motion of the

worm connector. Fastened to the worm connector, in succession, are an upper piston rod, a

piston, and a lower piston rod, all concentric to

the steering column axis. (This arrangement

provides a means for adding power assistance

to the system.)

Page 15

400—STEERING

CHRYSLER SERVICE MANUAL

Page 16

CHRYSLER SERVICE MANUAL

STEERING—401

FLOW CONTROL VALVE (CLOSED)

PRESSURE RELIEF

VALVE

HIGH PRESSURE - LOW FLOW

FLOW CONTROL VALVE (OPEN)

PRESSURE RELIEF

VALVE (CLOSED)

A rack, machined

lower piston

rod,

in

the lower portion

of

the

meshes with a sector gear.

This combination produces rotation of the steering gear arm and thereby actuates the steering

linkage.

The hydraulic system of the Coaxial gear con-

sists

of a

double-acting piston, a valve (which

fits inside the piston), and a hydraulic reaction

chamber (which gives

the road). Axial positioning

high pressure oil

double-acting piston.

to

one side

the

At

driver

the

the

of

the valve directs

or

the other

same time, valve

"feel"

of

of

the

movement opens an oil return line which carries

oil from

the oil reservoir. The direction

depends upon

the

low pressure side

the

direction

of

the

piston

of

oil

flow

of

steering wheel

to

(which

rotation) is such that hydraulic force is added to

the driver's effort and

rack and sector gear

Other components

is

transmitted through the

to the

of

steering gear

the

hydraulic system

arm.

are, a generator-driven oil pump with pressure

relief valve

with

the oil

limits the oil

(IV2 gallons

horsepower required

and

flow control valve,

reservoir.

flow

per

The

to a

predetermined maximu^n

minute)

to

drive the

and a filter

flow control valve

and

thus holds

oil

pump

tHe

to

minimum.

a

LOW PRESSURE - HIGH FLOW

•FLOW CONTROL VALVE (OPEN)

PRESSURE RELIEF

VALVE (OPEN)

HIGH PRESSURE - HIGH FLOW

Fig.

12—Pump Pressure

and

Flow

53x632

a. Power Steering

Assembly

The

oil

pump

mounted

at

cartridge-type filter element

reservoir. Oil from

flows through

body, through

the reservoir chamber. From

Oil

and

the

rear

end

the

an

internal passage

the

full-flow

Pump, Reservoir

and

reservoir assembly

of

the

generator.

is

located

in the

steering gear assembly

oil

the

in the

filter,

reservoir,

pump

and

is

A

into

oil

enters the oil pump intake (Fig. 12). The position

of

the oil pump

tain level fluid

is

adjustable

in

reservoir when drive belt

to

help main-

is

adjusted.

A small diaphragm vent valve

in

the

reservoir cover is forced open to provide a passage to

the atmosphere,

if

excessive pressure occurs

in

the reservoir.

With cold

through

pressure would build-up

the

oil,

filter

insufficient

to

the

reservoir,

in

oil

the

line from

would pass

and the oil

the

steering gear assembly. Therefore, a spring-

Page 17

402—STEERING

OUT

(LOW

PRESSURE

CHRYSLER SERVICE MANUAL

OIL)

SPOOL VALVE

IN NEUTRAL POSITION,

AND VALVE BODY OFFER LITTLE FLOW RESTRICTION

PRESSURE

HOLDS PISTON STATIONARY.

PISTON

Fig.

THE

OPENINGS BETWEEN

IS LOW.

13—Oil Flow—Neutral Valve Position

EQUAL PRESSURE

(N

(LOW

THE

ON

BOTH PISTON FACES

PRESSURE

53x859

VALVE

SO OIL

OIL)

OUT (LOW PRESSURE

t

SPOOL VALVE

WHEN

"A"

AND "BM. OIL

LIC FORCE

PRESSURE CYLINDER,

FORCED

PISTON

OIL)

THE

VALVE

ON

PISTON.

OUT

RETURN PASSAGES.

IS

PULLED

PRESSURE INCREASES GREATLY, CREATING A HYDRAU-

AND OIL IN THE LOW

UP, IT

AS

PISTON MOVES,

OFFERS FLOW RESTRICTION

OIL

ENTERS

PRESSURE CYLINDER

THE

IN (HIGH PRESSURE

AT

HIGH

IS

OIL)

53x860

Fig.

14—Oil Flow—Right Turn—Valve Pulled

Up

Page 18

CHRYSLER SERVICE MANUAL

STEERING—403

loaded relief valve is provided at the top of the

filter element. When oil pressure in the filter

builds up to about 5 to 7 psi., this valve opens

and permits oil to pass directly into the reservoir chamber.

The rotary oil pump is driven from the rear

end of the generator armature shaft through a

flexible coupling. The single rotor in the pump

draws oil from the reservoir, and discharges it

through the built-in combination flow control

valve and pressure relief valve to the valve in

the power unit assembly.

In the power steering pump, the flow control

valve and pressure relief valve are combined in

a single assembly, as shown in Figure 12. The

spring-loaded pressure relief valve is concentric

with and fits inside the spring-loaded flow control valve. When the pressure relief valve is

closed, it seats against a snap ring in the flow

control valve. An orifice in the pressure relief

valve provides the oil pressure drop that controls the operation of the flow control valve.

When the oil flow from the pump tends to rise

above l1/^ gallons per minute, the difference in

pressure across the orifice overcomes the spring

load, and the flow control valve moves to uncover a passage to the intake side of the pump.

By preventing excessive oil flow, the flow control valve limits the pressure drop through the

hydraulic system and thus limits the horsepower required to drive the pump. Oil flow of

the pump when the engine is idling is about 1%

gallons per minute.

Oil pressure in the hydraulic system builds up

to that required to overcome the resistance to

turning of the road wheels. In other words,

straight-ahead highway steering requires a relatively low oil pressure, while a higher oil pressure is required when turning a corner. A rapid

build-up of oil pressure tends to occur when the

road wheels are turned against a curb or when

the steering wheel is turned all the way in one

direction so that the piston reaches the end of

the stroke. To prevent excessive oil pressure,

the pressure relief valve in the pump limits the

oil pressure from 750 to 800 psi.

b.

How the Coaxial Power Steering Operates

The heart of the Coaxial Power Steering Unit

has two parts; the valve and the valve body

(actually a part of the hydraulic piston, as

shown in Figure 13). Together, these two pieces

control the operation of the entire power system.

When the driver turns the steering wheel,

the valve moves with respect to the hydraulic

piston, and power asistance instantly responds.

The relative movement between the valve and

piston is very slight (it seldom excee Is .0025

inch) and must not be confused with the gen-

eral movement of the whole step'ing system

as the front wheels turn. The driver controls the

power steering unit by governing the relative

movement between the valve and hydra ilic piston.

Control movements are based o. feel of

the road that comes through the steering wheel

from a hydraulic reaction chamber inside the

power unit. Relative movement of the valve and

piston affects hydraulic action as follows:

As the valve moves relative to the piston, it

regulates oil pressure and directs oil flow

through the hydraulic circuit. Consider the case

where the steering wheel is not turned and the

valve is in neutral position, as shown in Figure

13.

In this position, the valve leaves openings

between it and the valve body so oil flows

through the unit quite easily with very little

flow restriction. Therefore, the oil pump has

only a slight resistance to overcome, and the oil

entering the power steering unit is under low

pressure.

Inside the unit, the oil reaches the valve

through holes drilled in the piston. At the valve

the flow divides, and oil travels toward both

ends of the valve. It flows through succeeding

openings between the valve and adjacent valve

body until it reaches the main return passage

drilled through the lower piston rod. It then

returns to the reservoir and filter. In the neutral

position, oil pressure on both sides of the power

piston is the same. Consequently, the piston

remains stationary.

The entire hydraulic oil system for power

steering has a capacity of 2 quarts of SAE

10 W engine, or type "A" oil. The worm housing capacity is one pint which is separate from

the pressure system.

When the driver turns the steering wheel, the

valve moves either up or down, depending on

which direction he turns. Suppose that he moves

the valve up slightly, relative to the piston. By

moving the valve this small amount, the driver

Page 19

404—STEERING

CHRYSLER SERVICE MANUAL

puts the power system into operation, as shown

in Figure 14.

The instant the valve is moved, two important things happen: (1) the inlet oil pressure

increases because of restricted openings ber

tween the valve and valve body, and (2) the

increased pressure is directed to one side of the

power piston. The restrictions causing the pressure rise are marked "A and B" in Figure 14.

These narrow spaces "dam up" the oil that is

being forced through the system by the oil

pump. Because the pump is a positive-displacement type, the oil must keep moving. As the oil

"piles-up" behind the restrictions, its pressure

increases tremendously, squeezing oil through

the narrow spaces at a very fast rate. Often

the restrictions may close completely, giving

operating pressure at the fastest possible rate.

The maximum pressure build-up is limited to

800 psi by a pressure relief valve in the pump

assembly.

The high oil pressure is directed to the lower

end of the cylinder (for this case through the

passages indicated in Figure 14). However, the

opposite end of the cylinder is open to the

return line. Therefore, a difference in pressure

exists in each end of the cylinder and the piston

moves. Oil trapped in the lower pressure cylin-

der is forced through the return passages as

the piston moves up.

By careful design, all of these elements have

been combined into two compact units which

are connected by a pair of flexible hoses. The

power unit contains the power piston, spool

valve, and hydraulic reaction chamber. Tne

supply unit incorporates the reservoir and the

oil pump with its valves.

If the driver stops turning the steering wheel

and holds it in a fixed position, the front wheels

immediately stop turning. This is how it happens:

with the steering wheel held, the valve

remains in its pulled up position because the

valve is mechanically connected to the steering

wheel. The piston, on the other hand, is moving

up under the action of the pressure in the lower

end of the cylinder, and continues to move up

for the briefest instant until the relative motion

between piston and valve has returned them to

the neutral position. In neutral position, there

is

very little

flow

restriction, as explained before,

UPPER PISTON ROD

VALVE

OPERATING

ROD

CONNECTOR NUT

VALVE CONTROL

SPACER SEAL

-SEAL RETAINERS

ADJUSTING DISC RETAINER

VALVE ADJUSTING DISC

ADJUSTING

TANG

WORM

CONNECTOR

PISTON ROD NUT AND LOCK CUP

53x861

Fig.

15—Hydraulic Reaction Assembly

Page 20

CHRYSLER SERVICE MANUAL STEERING—405

OIL IS SUPPLIED FROM MAIN LINE AT OPERATING PRESSURE. DRIVER'S STEERING FORCE PASSES

FROM WORM CONNECTOR TO REACTION RING TO THE OIL-FILLED SEAL WHICH RESISTS BEING

SQUEEZED BECAUSE OF THE PRESSURE WITHIN IT. THIS RESISTANCE GIVES DRIVER THE "FEEL"

OF STEERING BECAUSE OPERATING PRESSURE IS PROPORTIONAL TO TURNING LOAD.

UPPER PISTON

ROD

WORM SEAL

CONNECTOR RETAINERS

OIL FROM

MAIN LINE

VALVE

SPOOL

•-VALVE

OPERATING ROD

Fig.

16—Hydraulic Reaction Chamber

so oil pressure drops to its lowest point. Power

assistance ceases and the front wheels remain

where the steering wheel indicates. The entire

action is instantaneous because the relative

movement between valve and piston is so slight.

What causes the relative movement between

these parts and how does the driver get his

"feel" of the road?

The first important fact to remember is that

the valve is mechanically connected to the steering wheel, as shown in Figure 15. The valve

solidly connects to the worm connector through

the valve-operating rod. The worm connector is

attached to the steering wheel through a worm

shaft, as shown in Figure 11. Hence, the slightest steering wheel movement is transferred

through the worm connector to the valve.

Another important fact, is that the upper pis-

ton rod is hydraulically attached to the worm

connector through two seal retainers and a rubber reaction seal whenever the power system is

operating (Fig. 16). The connection is called hy-

draulic because the rubber seal, one of the con-

necting links between the worm connector and

piston rod, is filled with oil. Oil from the main

oil line is supplied to the seal through a hole

VALVE CONTROL

SPACER SEAL

OPERATING CLEARANCES

53x862

drilled in the piston and another drilled down

the long axis of the upper piston rod. The oil in

the reaction seal is, therefore, at full operating

pressure.

Suppose the steering wheel is turned in such

a direction so that the worm connector (and

valve) tries to move up (right turn). In trying

to move up, the worm connector pushes on the

lower seal retainers and squeezes the oil-filled

seal. Because the valve has been in neutral

position until this instant, the pressure inside

the reaction seal is low and the seal compresses,

allowing the worm connector — and valve — to

move without moving the piston rod. In other

words, there is relative motion between the

valve and piston which is fastened to the piston

rod.

Therefore, oil pressure rises in the system

because of the restrictions between the valve

and valve body, and the piston begins to move

the steering parts that connect to the front

wheels. At the same time, the higher oil pressure is felt inside the oil-filled reaction seal.

The greater pressure inside the reaction seal

attempts to force the seal and the worm connector back to their original (neutral) positions.

Therefore, the driver feels a resistance to turning the steering wheel (a resistance proportional

Page 21

OIL

RING

"O"

RING

SNAP RING

OIL SEAL

ROD,

LEVER

BODY

PLUNGER

SPRING

"O"

RETAINER

RING

"O"

RING

PISTON AND ROD

RETAINER

RING

RING

"O"

"O"

RING'

SNAP RING-

RING<

HEAD-

SCREW

HOUSING

"O"

RING

COVER \

SNAP RING

ADAPTER SCREW

WASHER

GASKET

.. RETAINER

^f I

ADAPTER

DISC

CUP

WORM

\ BEARING

CUP INNER

--*. GUIDE

V

^ CLAMP

SCREW

SPACER

Fig.

17—Coaxial Power Steering (Exploded View)

BALL PACKAGE

XUP OUTER

'PLUG

PLUG

HOUSING

BEARING

CUP OUTER

WASHER

C P INNER

WASHER

OIL SEAL

WASHER

55x84

Page 22

CHRYSLER SERVICE MANUAL

STEERING—407

to the steering resistance at the road). This

permits a desirable "feel" of the road with a

minimum of driving effort.

It should be remembered that the process just

described is instantaneous as far as the driver is

concerned; it has been broken into steps simply

for explanation.

The driver controls the front wheels surely

and accurately with his steering wheel. If he

stops turning, piston movement will return the

system to neutral, as already explained. If he

keeps turning, he maintains the relative movement between valves and piston, and the power

system keeps operating. During operation, the

driver always "feels" the road through the

steering wheel.

The driver is helped by power assistance, if

road disturbances try to turn the front wheels

off course. When a driver holds the steering

wheel fixed, he actually is commanding the

power system to hold the front wheels fixed,

regardless of the forces that try to turn them.

The power system complies by acting "in

reverse" whenever road obstructions jar the

wheels. For example, suppose the front wheel

strikes a rut or chuck hole. The wheel begins

to deflect from its course. The first slightest

amount of off-course deflection is transmitted

through the steering linkage to the hydraulic

piston. The piston moves a fraction. However,

because the driver is holding the steering wheel,

the valve cannot move. There is relative motion

between the valve and piston (this time caused

by piston motion rather than the valve motion).

Therefore, oil pressure builds up in the one end

of the cylinder, creating a hydraulic force that

pushes the piston back toward the neutral position in direct opposition to the disturbing

obstruction. Hence, the front wheels

The driver maintains control on bad roads with

a minimum of steering effort.

If oil pressure is somehow interrupted (such

as the fan belt breaking), the small operating

clearances in the hydraulic reaction chamber

close up as the driver turns the wheel one

way or the other, giving solid metal connections (Fig. 16). Therefore, the system steers

mechanically; that

travel through the worm connector, through one

seal retainer, through the piston rod and piston,

and through the rack and sector gear to the

linkage that connects to the front

condition is allowed to continue, steering wheel

play will greatly increase and oil will be pumped

out of the system through the reservoir vent.

is,

steering wheel movements

do

not turn.

wheels.

If this

MAINTENANCE AND ADJUSTMENT

POWER STEERING

16.

REMOVAL OF COAXIAL POWER

STEERING UNIT FROM CAR

Remove horn ring ornament from steering

wheel. Disconnect horn wire and remove horn

ring. Remove steering wheel with puller and

remove turn signal lever and plate. Loosen the

steering column to instrument panel bracket.

Loosen steering column jacket clamp screws

and raise front of car. Disengage drag link

from Pitman arm and pull Pitman arm with

Tool C-3402. Loosen three gear housing to

frame attaching

ing plate and rubber dust pad. Disconnect pres-

sure and return hoses and drain gear assembly

by slowly rotating steering wheel until all oil is

expelled from unit. Fasten disconnected ends

hoses above oil level in reservoir to prevent

further loss of oil and cap the ends to prevent

bolts.

Remove floor mat retain-

of

any foreign matter from entering. Remove gear

housing to frame attaching bolts and alignment

wedge. Remove gear assembly from lower side

of car.

17.

a. Precautions to Follow During Disassembly

Cleanliness throughout the entire disassembly

and assembly operations is absolutely essential.

The unit should be thoroughly cleaned in a suitable solvent when removed from vehicle. When

disassembling, each part should be placed in

the solvent, washed, and dried by compressed

air. Careful handling of parts must be exercised to avoid nicks and burrs. Crocus cloth may

be used to remove small nicks or burrs, provided it is used carefully. When used on valve

OF

DISASSEMBLING THE COAXIAL POWER

STEERING UNIT (Fig. 17)

and Assembly

COAXIAL

Page 23

408—STEERING

CHRYSLER SERVICE MANUAL

spool, use extreme care not to round off the

sharp edge portion. The sharp edge portion is

vitally important to this type of valve since

it helps to prevent dirt and foreign matter from

getting between the valve and bore, thus reduc

ing the possibilities of sticking.

Remove and discard all "0" seal rings, and

seals.

Use new ones lubricated with Lubriplate

when reassembling. To disassemble the Power

Steering Unit for repair or overhaul, refer to

Figure 17, and proceed as follows:

b.

Removal of Worm Housing from Gear

Housing

Drain lower portion of steering gear through

pressure and return connections by turning

steering tube coupling from one extreme of

travel to the other. Using a %e inch Allen

wrench, remove worm housing filler plug and

drain the worm (upper) housing. Attach holding

fixture to unit and place in a vise. Use concave

type washers when mounting steering housing

on tool. Remove tube coupling screw, lockwasher and washer from center of coupling. Remove

coupling from worm shaft, as shown in Figure

18.

Remove the worm housing oil seal with a

screwdriver from the housing. Use extreme

care to avoid damaging housing when removing

seal. Unlock bearing adjusting nut by bending

tang of lockwasher. (Only one tang locks nut

in position.) Place tools over worm shaft, as

shown in Figure 19. Holding the worm stationary, remove worm bearing adjusting nut, lockwasher and thrust washer. The worm bearing

adjusting nut is tapered on the bearing side.

Remove the worm outer bearing race and bearing roller from worm. Remove the three worm

to gear housing screws and concave washers

and remove worm housing. It may be necessary

to tap housing lightly due to interference fit

with "0" ring seal between housing head and

housing. The concave side of the washers fit

against housing. Use care to avoid dropping the

inner bearing during this operation. Remove

lower bearing roller from housing. Inspect bearing roller and the upper and lower bearing cups

in housing. Do not remove bearing cups unless

inspection reveals it is necessary. To remove

upper and lower bearing cups, use Tool C-3322,

as shown in Figure 20.

c. Removal of Worm Connector

Remove housing head "0" ring. Unlock worm

connector nut lock and slide lock back sufficient-

ly to loosen worm connector nut. With Tool C3321 attach to worm connector, remove connector nut, as shown in Figure 21. It may be

necessary to rotate steering gear shaft (by

installing Pitman arm), to raise worm connector

in order to permit installation of Tool C-3326.

Slide worm connector assembly from valve con-

trol spacer.

d. Disassembly of Worm Connector Assembly

Disassembly of the worm connector and worm

shaft assembly is not recommended unless damaged or worn.

CAUTION

Caution should be exercised not to bottom the

worm shaft in the outward direction upon disassembly or assembly. Bottoming the worm

shaft may damage the ball guides and cause a

tight and rough operating worm.

COUPLING

Fig.

18—Removing Tube Coupling (Tool C-3392)

53x801

HOLD

WORM SHAFT

STATIONARY

54x626

Fig.

19—Removing or Installing Bearing

Adjusting Nut

Page 24

CHRYSLER SERVICE MANUAL

STEERING—409

J--

I H

I l

I 1

_; REMOVING INNER BEARING CUP INSTALLING INNER BEARING CUP

Fig.

20—Removing or Installing Upper and Lower Bearing Cups (Tool C-3322)

REMOVING OUTER BEARING CUP

INSTALLING OUTER BEARING CUP

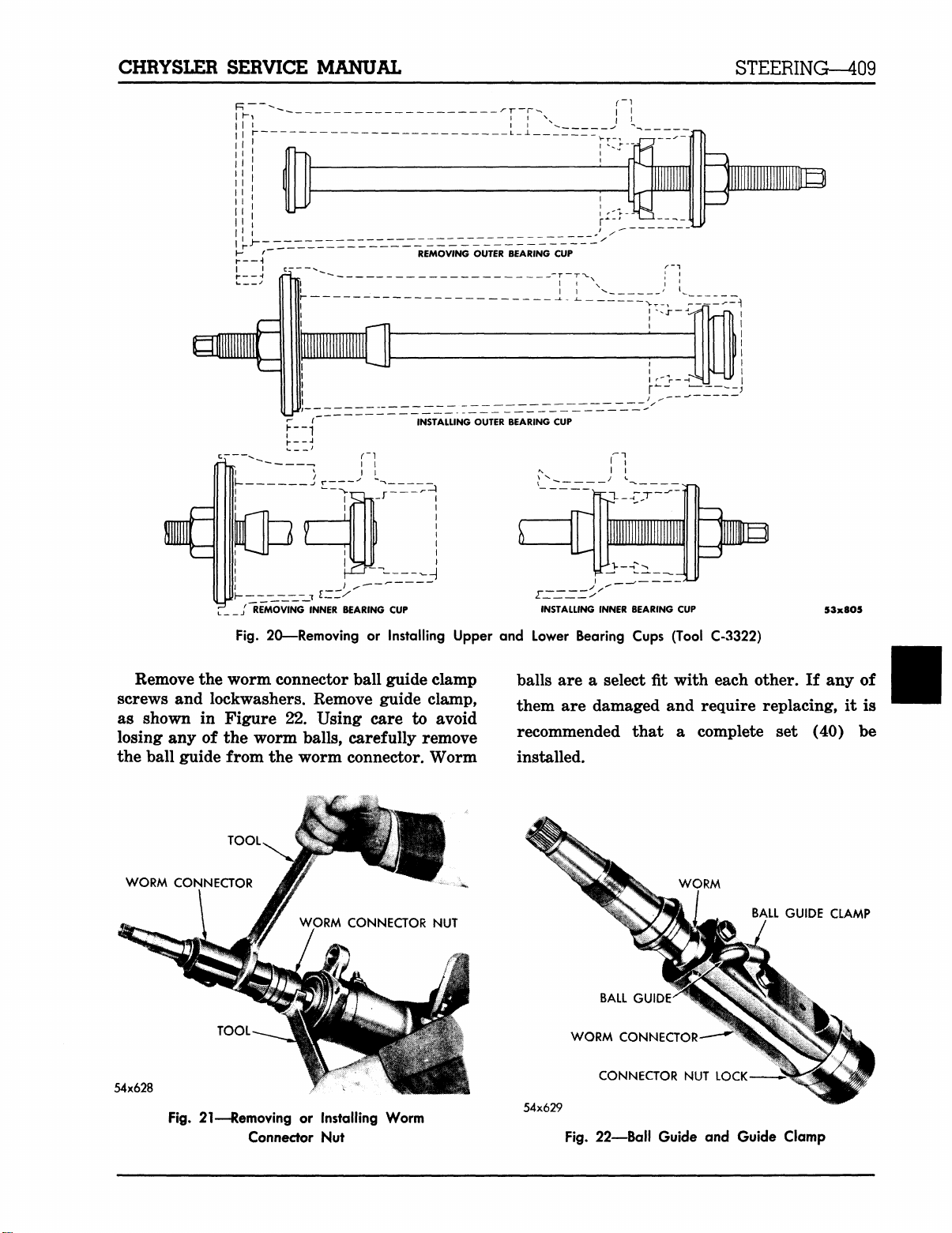

Remove the worm connector ball guide clamp

screws and lockwashers. Remove guide clamp,

as shown in Figure 22. Using care to avoid

losing any of the worm balls, carefully remove

the ball guide from the worm connector. Worm

-L--TT-

53x805

balls are a select fit with each other. If any of

them are damaged and require replacing, it is

recommended that a complete set (40) be

installed.

WORM CONNECTOR

54x628

Fig.

21—Removing or Installing Worm

TOOL

TOOL

Connector Nut

WORM CONNECTOR NUT

54x629

WORM

BALL GUIDE CLAMP

BALL GUIDE-

WORM CONNECTOR-

CONNECTOR NUT LOCK-

Fig.

22—Ball Guide and Guide Clamp

Page 25

410—STEERING CHRYSLER SERVICE MANUAL

PISTON AND ROD ASSEMBLY

GEAR HOUSING

54x630

Fig.

23—Removing Gear Shaft Oil Seal

(Tool C-3350)

Turn worm connector assembly over and

carefully thread the remaining worm balls out

of the worm connector by turning the worm in

and out. Count the worm balls which were

removed. There should be a total of 40 balls.

Remove worm from connector. Slide connector

nut lock from connector. Inspect guide rails on

connector for nicks and burrs.

e. Removal of Piston and Rods from Gear

Housing

To remove the steering gear shaft oil seal,

remove lock ring, and proceed as follows. Slide

threaded portion of tool over steering shaft, and

screw tightly into seal. To do this, install tool

GEAR SHAFT

THRUST WASHER

54x633

Fig.

25—Removing Piston and Rod Assembly

nut on steering gear shaft and force the

threaded portion of tool into seal. Install the

two half collars to lock the tool together, and

install the half collar retaining ring. Turn nut

and pull seal out of housing, as shown in Figure

23.

Remove the tool.

Remove the lock nut from shaft adjusting

screw. Remove the three screws from cover.

Remove the steering gear shaft cover from

housing by turning adjusting screw in.

Remove steering gear shaft assembly from

gear housing by using a fiber hammer and tapping lightly. Align gear on gearshaft to clear

opening in lower housing before attempting

removal. Removal of adjusting screw is not

necessary unless screw is damaged.

Using Tool C-3229, remove adjusting screw

retainer snap ring. Remove adjusting screw,

thrust washer, and washer from steering gear

shaft, as shown in Figure 24. Remove adjusting

^ „ "O" RING

WASHER-

ADJUSTING SCREW-

LOCK RIN<

Fig.

24—Gear Shaft Adjusting Screw Assembly

54x631

VALVE ROD ADJUSTING DISC

VALVE ROD ADJUSTING DISC RETAINER

Fig.

26—Removing Valve Rod Adjusting Disc

53x811

Page 26

CHRYSLER SERVICE MANUAL STEERING—411

UPPER PISTON ROD

UPPER PISTON

ROD NUT

53x812

Fig.

27—Removing Upper Piston Rod Nut

(Tool C-3328)

screw "O" ring. Inspect bearing surface on

shaft for being pitted or scored. Inspect condition of teeth on shaft. Place a suitable container under the assembly to catch trapped oil

and slide piston assembly and rods from gear

housing, as shown in Figure 25.

CAUTION

Use extreme care in handling to avoid dam-

aging the sealing surfaces on housing

head.

f. Disassembly of Piston and Rods

Remove valve rod adjusting disc from valve

VALVE CONTROL SPACER

WORM CONNECTOR NUT

HOUSING HEAD

HOUSING HEAD"

Fig.

29—Removing or Installing Housing Head

rod,

as shown in Figure 26. To remove a tight

53x815

fitting adjusting disc, wrap tape around the

edge (this will prevent damaging disc), and

grip it with multi-grip pliers. Tool C-3445 may

be used to easily turn the valve rod from the disc.

Slide valve rod adjusting disc retainer from

upper piston rod, as shown in Figure 26. Remove

upper piston rod nut lock cap. Remove upper

piston rod nut, as shown in Figure 27.

If the piston and upper piston rod turn when

removing the upper piston rod nut, wrap several layers of masking tape around center piston,

and clamp in a vise with protective jaws.

The piston nut can then be removed. Support

upper piston rod on a block of wood to help

prevent damaging the housing head when remov-

ing nut. Slide valve control spacer assembly

from upper piston rod, as shown in Figure 28.

Remove spacer seal retainers from spacer and

slide seal assembly from valve control spacer.

Remove worm connector nut from upper piston rod. Slide housing head off upper piston rod,

as shown in Figure 29. Remove housing head

"0"

ring. Using a suitable drift, remove upper

piston rod seal (lip type) from housing head.

CONTROL SPACER RETAINER

VALVE ROD'

Fig.

28—Removing Valve Control Spacer Seal and

Seal Assembly

53x813

PISTON RING (STEEL)

Fig.

30—Removing Piston Rings

UPPER PISTON ROD SNAP RING

53x816

Page 27

412—STEERING

PISTON ASSEMBLY

CHRYSLER SERVICE MANUAL

VALVE ASSEMBLY

Fig.

31—Removing Valve Assembly from Piston

53x819

Remove the two backup (steel) and "D" type

(neoprene) piston rings from piston, as shown

in Figure 30. Part of the 1955 production does

not use steel rings. A new and wider type rubber

ring is used instead.

Using snap ring pliers, remove lower piston

rod snap ring and slide lower piston rod from

piston.

Using care not to bend the valve piston rod,

slide valve assembly from piston assembly, as

shown in Figure 31. Using a lA inch punch,

drive piston pin into upper piston rod, as shown

in Figure 32. Using snap ring pliers, remove

upper piston rod snap ring. Note the position

and construction of snap ring.

Remove upper piston rod from piston, as

shown in Figure 33. Using a wire hook, remove

piston pin and "0" ring from piston rod, as

PISTON PIN HOLES

53x821

Fig.

33—Removing Upper Piston Rod

shown in Figure 34. Make sure the oil passage

is open. Inspect the sealing surface on piston

rod for being scored. Remove the two small

valve rod "O" rings from the bore of the upper

piston rod (one in each end). Remove the large

upper piston rod "O" ring.

Remove lower piston rod "0" ring. Inspect

rack teeth and sealing surfaces on lower piston

rod.

g. Removal of Relief Valve Assembly

Thread a V4 inch 28NF bolt into threads provided in plug (Fig. 35). Clamp bolt head in a

vise and, by pulling on lower piston rod, plug

can be removed. Should end plug be seized in

rod, a fiber

hammer may be used to tap on retaining flange of lower piston rod. Inspect piston

for nicks and burrs. Make sure all oil passages

are open and free from dirt.

53*MO

Fig.

32—Removing Upper Piston Rod Pin

UPPER PISTON ROD

PISTON PIN ASSEMBLY

WIRE HOOK

Fig.

34—Removing Piston Pin from Upper

Piston Rod

53x822

Page 28

CHRYSLER SERVICE MANUAL

STEERING—413

RELIEF VALVE PLUG

LOWER PISTON

Fig.

35—Removing Lower Piston Rod Relief

ROD

54x636

Valve Plug

h. Disassembly of Steering Gear Housing

Inspect steering gear shaft needle bearing in

gear housing for broken or rough needles. Do

not remove bearing unless inspection reveals it

is necessary to do so. If it is necessary to remove needle bearings, use puller Tool C-3333 to

pull steering gear housing shaft needle bearings

from inside gear housing as shown in Figure 36.

Using snap ring pliers, remove gear housing

cover snap ring (tapered) at bottom of housing.

TOOL

55x173

Fig.

37—Removing Lower Piston Rod Seal

(Tool.

C-3331)

Remove housing cover and remove "0" ring

from housing. Use extreme care when removing

the lower plug to prevent cocking. A cocked plug

is apt to result in a broken gear housing.

Remove lower piston rod seal (lip type) from

housing, as shown in Figure 37. The lower rod is

supported by a half bushing. The bushing is a

friction fit over a dowel pin. If it is necessary to

replace the support bushing it may be pried from

the dowel pin with a screwdriver.

18.

ASSEMBLY OF COAXIAL POWER

STEERING GEAR

a. Assembly of Steering Gear Housing

Fig.

36—Removing Steering Gear Housing Shaft

Needle Bearing (Tool

C-3333)

Place a new piston rod seal over driver so the

lip will be facing up or to the inside of the cylin-

DRfVER

PISTON

ROD

SEAL

ALIGNING PILOT

54x639

Fig.

38—Installing Lower Piston Rod Seal

(Tool C-3395)

Page 29

414—STEERING

CHRYSLER SERVICE MANUAL

PISTON

BUSHING

Fig.

39—Support Bushing Installed

der when installed. Insert seal aligning pilot

tool

in

end

of

driver and drive lower piston rod

seal into position

in

gear housing,

as

shown

of

in

Figure 38.

Using driver

needle bearing assemblies

bearings bottom

Always drive

Tool

in the

on

letter side

C-3333,

in

bores

install housing shaft

gear housing until

(if

removed).

of

bearing. Other-

wise, damage to bearing may result. Install pis-

ton rod support bushing in housing, making sure

bushing is properly seated over dowel, as shown

in Figure 39

b.

Assembly

Insert relief valve spring followed

(if

previously removed).

of

Piston and Rods

by

plunger

into valve body and insert assembly (milled end

first) into lower piston rod. Press end plug into

lower piston

rod

sufficiently

to

seat against

the

relief valve body.

N

VALVE AND VALVE

Fig.

41—Installing Valve Assembly

ROD

53x831

NOTE

A suitable adaptor will be required to press end

plug into place. Otherwise, damage

result.

If

plug

is not

pressed

in far

properly seat against the valve

duce a rattling

draulic pressure

pressed

ports

in too

in the

the plunger

resulting

in

or

clattering sound when

is

applied.

tightly,

valve body

and

lack

it

will cause

to

collapse,

creating high back pressure,

of

steering assistance

to rod

body,

If the

will

enough

it

to

will pro-

hy-

plug

is

the

relief

restricting

and a

hissing noise.

Remove

Lubricate

Lubriplate

piston

rings

all

burrs from around

the two

and

rod, as

are

seated properly. Lubricate

valve

install one

shown

in

rod "0"

in

Figure

the

rings with

each end

40.

end plug.

of

upper

Make sure

the two

large "O" rings with Lubriplate and install one

on each upper

they seat properly

lower piston rod (with rack) into end

assembly opposite

pliers,

install snap ring.

and

lower piston rod. Make sure

in the

pin

ring grooves. Install

hole. Using snap ring

of

piston

;<O>< RING

Fig.

40—Installing Valve

53x830

Rod "O"

Ring

53x832

PISTON

PIN

UPPER PISTON

Fig.

42—Installing Upper Piston

HOLES

VALVE

PISTON

ROD

ROD

Rod

Page 30

CHRYSLER SERVICE MANUAL

PISTON PIN

O" RING SEAL

53x833

Fig.

43—Installing Piston Pin

NOTE

When installing the snap ring, it must be installed with the tapered side away from the piston

so

that the taper is visible after installation.

The gap between the ends of the installed snap

ring should be measured to be sure the ring is

seated.

inch.

The minimum permissible gap is 2%

Be sure the snap ring

does

not restrict any

part of the ports in the end of the piston rod.

Lubricate valve assembly with Lubriplate

STEERING—415

SEAL RETAINER ASSEMBLY

Fig.

45—Installing Valve Control Spacer

(Tool C-3393)

and slide into position in assembly, as shown in

Figure 41. Using care not to damage the "0"

rings,

slide upper piston rod over the valve rod,

aligning the piston pin hole in the piston assembly with the hole in the upper piston rod, as

shown in Figure 42. Lubricate a new piston pin

"0"

ring with Lubriplate and install on piston

pin, as shown in Figure 43. With the piston pin

holes aligned in both the piston and upper piston rod, position piston pin (tapered end first)

in position. Use a % inch punch and hammer,

tap lightly until piston pin is flush or slightly

below bottom of piston ring groove (Figure 43).

If piston pin is too high in groove, piston ring

will not properly seal. This will cause unequal

pressure when valve is centered in piston.

4

Using snap ring pliers, install the upper pis-

ton rod snap ring. Use the same precautions

and specifications as previously used in positioning the lower piston rod snap ring. Select snap

ring of sufficient thickness to prevent turning of

snap ring after it is installed. If it is too loose,

the piston will move with relation to the piston

55x175

TOOL

Fig.

44—Installing Upper Piston Rod Seal

(Tool C-3395)

53x834

Fig.

46—Locking Upper Piston Rod Nut Lock Cap

53x837

Page 31

416—STEERING

SfEEL RINGS-

TYPE NEOPRENE RINGS

53x839

Fig.

47—Installing Piston Rings

rod and prevent consistent adjustment of control valve. Place a new upper piston rod seal on

jdriver (lip of seal facing" tool). Insert seal in

end of driver and drive upper piston rod seal

(lip of seal out) into position in housing head,

as shown in Figure 44. Lubricate seal with Lu-

briplate.

CHRYSLER SERVICE MANUAL

GEAR SHAFT ADJUSTING SCREW

TOOL

Fig.

49—Installing Gear Shaft Adjusting Screw

"O"

Ring (Tool C-3401)

install in center of valve control spacer. Should

it be necessary to replace the valve control

spacer or upper piston rod for any reason, al-

ways select a spacer to match. The length of the

valve control spacer selected must be identical

to the distance between the seat of the valve

control spacer seal retainer and seated upper

piston rod nut. Place tool over threaded end of

upper piston rod.

Install housing head assembly (sealing lip

first) onto upper piston rod. Use same precautions to protect sealing surfaces on housing

head as used when disassembling. Slide con-

nector nut onto the upper piston rod with open

threaded end away from piston. Lubricate the

valve control spacer seal with Lubriplate and

TOOl

TOOi

Fig.

48—Installing Piston and Rod Assembly

Lubricate the valve control spacer retainers

with Lubriplate and place into position (small

diameter first) so they nest in valve control

spacer. Slide spacer, seal and retainer assembly

over tool and into position on piston rod, as

shown in Figure 45, and remove tool.

Install upper piston rod nut and, using Tool

C-3328, tighten from 25 to 30 foot-pounds

torque. Lock in place using piston rod nut lock

by tapping outer diameter of lock into nut recess,

as shown in Figure 46.

Slide valve rod adjusting disc retainer (largest diameter first) over end of upper piston rod.

Thread valve rod disc (extended lock thread

section outward) onto valve rod until approximately three threads show for aid in later adjustment. When installing disc on rod, consider-

able resistance should be noticed. If not, crimp

end of disc slightly to cause the threads of the

disc to bind on rod. The maximum torque required to turn disc on rod should not exceed 20

inch-pounds, maximum. Place lock sleeve on

worm connector (tang of sleeve) toward

threaded end.

Page 32

CHRYSLER SERVICE MANUAL

55x176

Fig.

50—Positioning Rack

Lubricate the two "D" type (neoprene) piston rings with Lubriplate and install on piston.

To aid in installation of rings, first slide rings

over ring lands and to center of piston, with lips

facing away from each other. Slide rings into

position in ring lands, as shown in Figure 47.

Install back-up (steel) rings, one on each end

of the piston. Part of production does not use

steel rings. Wider rubber rings are used instead.

c. Installation oi Piston and Rod Assembly in

Gear Housing

Lubricate lower piston rod, teeth of rack and

tool with Lubriplate, and position tool in teeth

of rack. Lubricate large "0" rings with Lubriplate and install on the side of housing head that

faces piston assembly.

For

Timing

STEERING—417

54x647

Fig.

51—Installing Gear Shaft

(Tool

C-3350)

d. Installing Gear Shaft

Install thrust button on gear shaft adjusting

screw and position tool over thread of screw.

Lubricate gear shaft adjusting screw "O" ring

with Lubriplate and slide over tool and into

position on adjusting screw, as shown in Figure

49.

Remove tool and insert adjusting screw

thrust button into gear end of steering gear

shaft. Insert adjusting screw assembly into

gear shaft and lock in position by installing internal snap ring. Use pliers, Tool C-3229, and

make sure snap ring is properly seated. Screw

the shaft adjusting screw with gear attached

into the gear shaft cover assembly as far as

possible. Position center groove (third from

Oil

Seal

Place ring compressing tool on gear housing.

Position piston and rod assembly so the teeth

on rack are 180 degrees from bushing support

and install into gear housing, as shown in Figure 48. Use extreme care when performing this

operation so as not to damage gear housing oil

seal or piston rings. Do not use a screwdriver

to compress piston rings. To further aid in installation, piston and cylinder may be lubricated

with Lubriplate. If the rack is not positioned

properly when it is installed, it may be corrected by rotating the lower piston rod with a

screwdriver through opening in end of gear

housing. Remove ring compressing tool and

other tool from teeth of rack through opening

in gear housing.

Fig.

52—Removing Sleeve (Part

with Friction Tape

of

Tool

54x648

C-3350)

Page 33

418—STEERING

CHRYSLER SERVICE MANUAL

either end) of the rack over center line of the

gear shaft cover opening in gear housing. Position the middle tooth of the gear shaft with the

third tooth groove from (either) end of rack.

Insert gear shaft assembly with cover attached

into gear housing, and tap lightly into position,

as shown in Figure 50. It is of the utmost im-

portance that the center tooth of the gear shaft

lines up with the center slot in the lower piston

rod rack. Failure to observe this precaution will

result in a broken gear housing. Install gasket

and cover and tighten the cover screws evenly.

e. Seal

Before attempting to install a new gear shaft

seal, thoroughly clean the sealing surfaces on

the gear shaft and counterbore of steering gear

shaft oil seal with Lubriplate and place (lip of

seal down) on a piece of clean paper. Carefully

install tapered end of sleeve (part of Tool

C-3350) in seal and slide seal back approxi-

mately 14 *

ncn

on sleeve. Install this assembly