Chromalox TTUH-10A, TTUH-15A, TTUH-20A, TTUH-25A, TTUH-30A Installation, Operation and MAINTENANCE

...Page 1

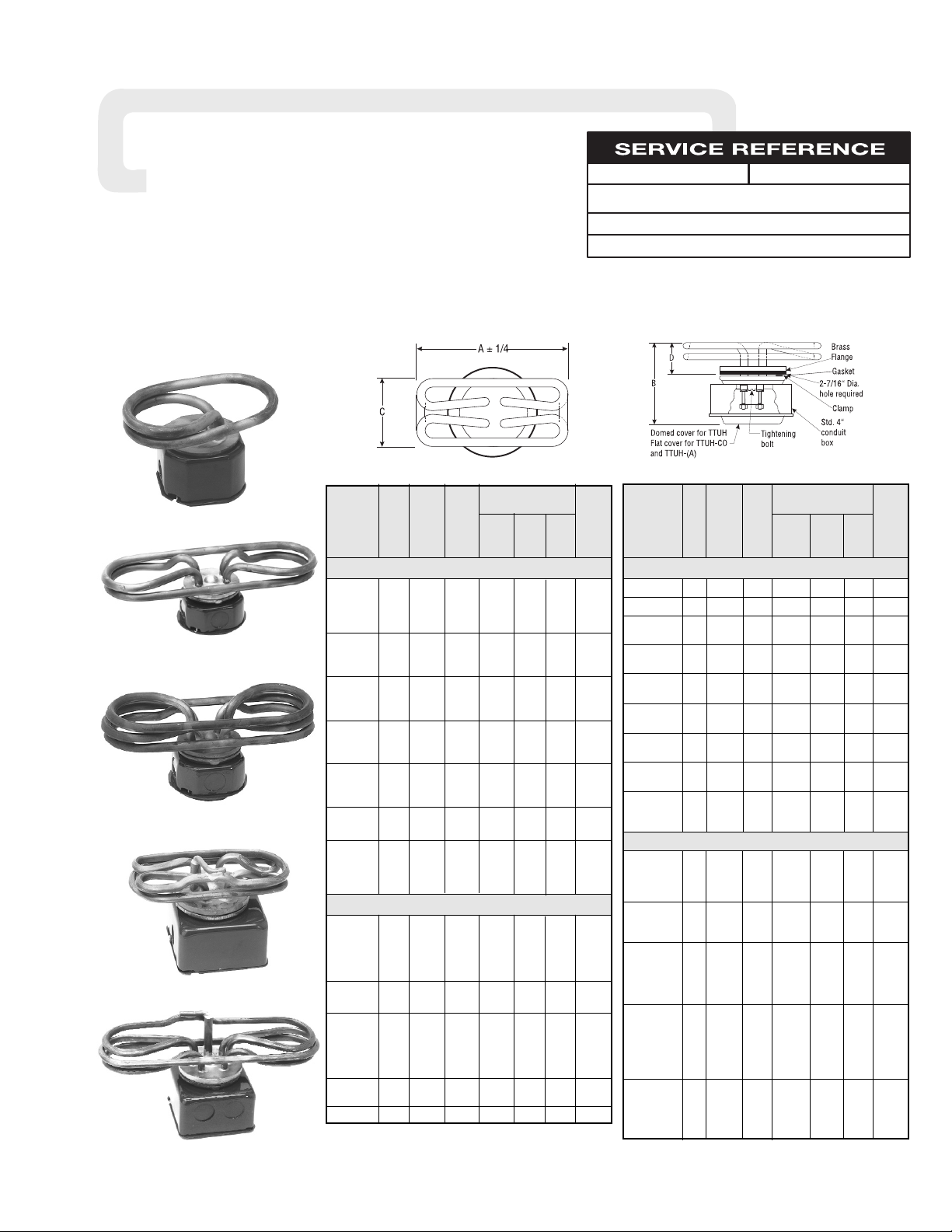

Dimensions (In.)

Extends

Overall Into

Length Tank

Model Volts kW W/In

2

ABCD‡

TTUH — 1 Phase — 3” min. liquid depth

TTUH-10A 120 1 42 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-15A 120 1.5 57 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-15A 208 1.5 57 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-15A 240 1.5 57 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-20A 120 2 57 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-20A 208 2 57 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-20A 240 2 57 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-25A 120 2.5 58 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-25A 208 2.5 58 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-25A 240 2.5 58 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-30A 120 3 55 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-30A 208 3 55 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-30A 240 3 55 6-3/4 4-9/16 4-1/4 2-5/16

TTUH-40A 120 4 53 9-1/2 4-9/16 4 1-3/8

TTUH-40A 208 4 53 9-1/2 4-9/16 4 1-3/8

TTUH-40A 240 4 53 9-1/2 4-9/16 4 1-3/8

TTUH-50 208 5† 39 12-3/4 4-9/16 4 1-11/16

TTUH-50 240 5† 39 12-3/4 4-9/16 4 1-11/16

TTUH-60 208 6† 42 14-1/2 4-9/16 4 1-11/16

TTUH-60 240 6† 42 14-1/2 4-9/16 4 1-11/16

TTUH-70 208 7† 49 14-1/2 4-9/16 4 1-11/16

TTUH-70 240 7† 49 14-1/2 4-9/16 4 1-11/16

TTUH — 3 Phase — 3” min. liquid depth

TTUH-303 208 3† 55 8-3/4 4-5/8 3-1/8 1-15/16

TTUH-303 240 3† 55 8-3/4 4-5/8 3-1/8 1-15/16

TTUH-403 208 4† 74 8-3/4 4-5/8 3-1/8 1-15/16

TTUH-403 240 4† 74 8-3/4 4-5/8 3-1/8 1-15/16

TTUH-408 480 4† 74 8-3/4 4-5/8 3-1/8 1-15/16

TTUH-503 208 5† 73 11 4-5/8 3-1/8 1-15/16

TTUH-503 240 5† 73 11 4-5/8 3-1/8 1-15/16

TTUH-603 208 6† 67 11-1/16 5 4-1/16 2-3/8

TTUH-603 240 6† 67 11-1/16 5 4-1/16 2-3/8

TTUH-603 480 6† 67 11-1/16 5 4-1/16 2-3/8

TTUH-703 208 7† 78 11-1/16 5 4-1/16 2-3/8

TTUH-703 240 7† 78 11-1/16 5 4-1/16 2-3/8

TTUH-803 208 8† 69 11-1/8 5 4-1/16 2-3/8

TTUH-803 240 8† 69 11-1/8 5 4-1/16 2-3/8

TTUH-1203 240 12† 98 17-3/4 5 4-1/16 2-3/8

(Supersedes PD400-14)

PD400-15

TTUH

161-048415-001

OCTOBER, 2000

4

RENEWAL PARTS IDENTIFICATION

Installation, Operation

and

DATE

SALES

REFERENCE

DIVISION SECTION

Chromalox

®

Type TTUH and TTUH-CO URN Heaters

Dimensions (In.)

Extends

Overall Into

Length Tank

Model Volts kW W/In

2

ABCD‡

TTUH-CO — 1 Phase with cutout — 3-1/4” min. liquid depth

TTUH-CO-10 120 1 42 7-7/16 4-8/16 3-1/16 1-3/8

TTUH-CO-15 120 1.5 62 7-7/16 4-13/16 3-1/16 2-3/8

TTUH-CO-15 208 1.5† 62 7-7/16 4-13/16 3-1/16 2-3/8

TTUH-CO-15 240 1.5† 62 7-7/16 4-13/16 3-1/16 2-3/8

TTUH-CO-20 208 2 60 9-7/16 4-13/16 3-1/16 2-1/8

TTUH-CO-20 240 2 60 9-7/16 4-13/16 3-1/16 2-1/8

TTUH-CO-25 208 2.5 40 6-3/4 4-13/16 3-1/16 2-1/8

TTUH-CO-25 240 2.5 40 6-3/4 4-13/16 3-1/16 2-1/8

TTUH-CO-30 208 3 55 6-3/4 4-13/16 3-1/16 2-1/8

TTUH-CO-30 240 3 55 6-3/4 4-13/16 3-1/16 2-1/8

TTUH-CO-40 208 4† 64 9-1/2 4-13/16 3-1/16 2-1/8

TTUH-CO-40 240 4† 64 9-1/2 4-13/16 3-1/16 2-1/8

TTUH-CO-50 208 5† 70 12-3/4 5-3/8 4 2-11/16

TTUH-CO-50 240 5† 70 12-3/4 5-3/8 4 2-11/16

TTUH-CO-60 208 6† 73 14-1/2 5-3/8 4 2-11/16

TTUH-CO-60 240 6† 73 14-1/2 5-3/8 4 2-11/16

TTUH-CO-70 240 7† 85 14-1/2 5-3/8 4 2-11/16

TTUH-CO — 3 Phase with cutout — 3-1/2” min. liquid depth

TTUH-CO-303 208 3 55 8-3/4 5-13/16 3-1/8 2-23/32

TTUH-CO-303 240 3 55 8-3/4 5-13/16 3-1/8 2-23/32

TTUH-CO-403 208 4 74 8-3/4 5-13/16 3-1/8 2-23/32

TTUH-CO-403 240 4 74 8-3/4 5-13/16 3-1/8 2-23/32

TTUH-CO-503 208 5 73 11 5-13/32 3-1/8 2-23/32

TTUH-CO-503 240 5 73 11 5-13/32 3-1/8 2-23/32

TTUH-CO-503 480 5 73 11 5-13/32 3-1/8 2-23/32

TTUH-CO-603 208 6 72 11-1/16 5-3/4 4-1/16 3

TTUH-CO-603 240 6 72 11-1/16 5-3/4 4-1/16 3

TTUH-CO-703 208 7 78 11-1/16 5-3/4 4-1/16 3

TTUH-CO-703 240 7 78 11-1/16 5-3/4 4-1/16 3

TTUH-CO-703 480 7 78 11-1/16 5-3/4 4-1/16 3

TTUH-CO-803 208 8 69 14-1/2 5-3/4 4-1/16 3

TTUH-CO-803 240 8 69 14-1/2 5-3/4 4-1/16 3

TTUH-CO-803 480 8 69 14-1/2 5-3/4 4-1/16 3

TTUH-CO-903 208 9 78 14-1/2 5-3/4 4-1/16 3

TTUH-CO-903 240 9 78 14-1/2 5-3/4 4-1/16 3

TTUH-CO-903 480 9 78 14-1/2 5-3/4 4-1/16 3

TTUH-CO-1003 208 10 82 17-11/16 5-3/4 4-1/16 3

TTUH-CO-1003 240 10 82 17-11/16 5-3/4 4-1/16 3

TTUH-CO-1003 480 10 82 17-11/16 5-3/4 4-1/16 3

TTUH-CO-1203 240 12 98 17-11/16 5-3/4 4-1/16 3

TTUH-CO-1203 480 12 98 17-11/16 5-3/4 4-1/16 3

Specifications — TTUH Specifications — TTUH-CO

‡ Minimum liquid level should be maintained at 1/2” above D dimension.

† Brazed terminal construction; cannot be wired for 3 heats.

‡ Minimum liquid level should be maintained at 1/2” above D dimension.

† Brazed terminal construction; cannot be wired for 3 heats.

TTUH-20A

TTUH-50

TTUH-CO-30

TTUH-CO-503

© 2010 Chromalox, Inc.

TTUH-703WSS

Page 2

2

FIRE/EXPLOSION HAZARD. This heater is not

intended for use in hazardous atmospheres where

flammable vapors, gases, liquids or other combustible atmospheres are present as defined in the

National Electrical Code. Failure to comply can

result in personal injury or property damage.

Chromalox TTUH and TTUH-CO food equipment heaters are

ideal for coffee urns, steam tables, kettles, humidifiers and other

commercial uses.

Heater Construction Characteristics

A. An opening of 2-7/16” in diameter in the bottom of the tank is

required to insert the heater.

B. High watt density.

C. 4” conduit box is mounted to the tank by a tightening bolt.

The system designer is responsible for the safety

of this equipment and should install adequate

back-up controls and safety devices with their

electric heating equipment. Where the consequences of failure could result in personal injury or

property damage, back-up controls are essential.

GENERAL

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70.

FIRE HAZARD. Since heaters are capable of developing high temperatures, extreme care should be

taken to:

A. Avoid mounting heaters in an atmosphere con-

taining combustible gases and vapors.

B. Avoid contact between heaters and combustible

materials.

C. Keep combustible materials far enough away to

be free of the effects of high temperature.

D. Keep heater immersed at all times.

INSTALLATION

Page 3

3

Note: Mount heater in horizontal position.

1. Cut a hole 2-7/16” in diameter in bottom of tank unless already

done.

2. Insert heater with gasket. (Use sealer if tank wall is corroded.)

3. Mount the combination terminal enclosure and clamp over the ele-

ment flange. (On 3 phase, first remove center jumper strap.)

4. Use bolt to draw mounting flange tight to tank bottom. (Reconnect

jumper strap on 3 phase.)

5. For connecting heaters, see wiring diagrams.

6. 120V elements can be connected in series for high voltage opera-

tion.

Figure 2

1. Remove cover.

2. Loosen set screw with 5/64” balldriver L-wrench. (Alan wrench).

3. Remove thermal cutout by pulling directly out.

4. Remove enclosure flange assembly by removing 5/16” socket

head cap screw in center.

5. Insert element and gasket in tank opening (use sealer if tank wall

is corroded).

6. Replace enclosure flange assembly and the 5/16” socket head

cap screw.

7. Push cutout into place. Be sure the thermal cutout is properly

located and seated on the conductor rod. (See Figures 3A & 4A).

8. Secure cutout to the conductor rod with the set screw. (See Figure

3A).

9. Make sure fully insulated 1/4” female spade connectors are used

when connecting to the thermal cutout.

10. On all single phase units less than 3kW – attach power leads to T1

& T2 (see Figure 4A) and connect cutout lead to one terminal on

the cutout.

Note: Single phase heaters 3kW and above and all three phase

models require the use of a suitable magnetic contactor. (Supplied

by customer).

11. On all TTUH-CO Three Phase Delta Units – Twist 1L3 & 2L3 leads

together to create L3, then, attach power leads to L1, L2 & L3.

Connect coutout to relay or contactor coil. (See Figures 5A & 9)

12. Replace cover with the “push to reset” hole directly over the

cutout.

13. Refer to the main portion of the instruction, operation and maintenance instructions for all other information.

14. The thermal cutout on the TTUH-CO provides run dry burn-out

protection only. Partial immersion of the elements while energized

can shorten element life. The cutout is a safety device only &

should not be used continuously as a low-liquid-level control.

15. Should the thermal cutout trip during operation, disconnect all

power to the heater before resetting.

16. Apply the manual reset locator label 170-122103-111, in view, to help

locate the manual reset button. See procedure 223-304407-007.

TTUH TTUH-CO

Heating

Element

Gasket

Center

Bolt

Pigtail Leads TTUH-A

Series (See Fig. 12)

Spacer

Tank Wall

Washer

Nut

Terminal

Box

Cover

Cover

Screws

Terminal

Box

Enclosure

ø 3/16 Hole

Set Screw for TTUH-CO

Using Alternate Cutout

P/N 248-049593-026

Mounting Clamp for

TTUH-CO Using

Alternate Cutout

P/N 056-019044-003

5/64" Balldriver

L-Wrench (Alan Wrench)

"Customer Supplied"

INSTALLATION

Cutout Lead

Fully Insulated

Female Spade

Connector

T1

T2

Make sure the

cutout is seated

all the way down

on the connector

rod

Alternate Thermal

Cutout for TTUH-CO

P/N 300-012172-006

Customer Supplied

Connector

L3

1L3

2L3

L1

L2

Cutout

240 Volts

(Max.)

Manual Reset Button

(Disconnect all power

before resetting)

Connect in Series

with Relay or

Contactor Coil

Figure 3

Figure4

Figure 5

Page 4

4

ELECTRIC SHOCK HAZARD. Any installation involving electric heaters must be performed by a qualified person and must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

1. Be sure line voltage matches heater voltage (on nameplate).

2. Electric wiring to heater must be installed in accordance with

the National Electrical Code and with local codes by a qualified person.

CAUTION: Use copper conductors only.

3. When element wattages are not equal, heaters must not be connected in series.

4. Make necessary wiring connections as shown on wiring diagram (Figures 6 thru 11).

WIRING

WIRING DIAGRAMS

Figure 6 — TTUH 1 Phase

Figure 7 — TTUH 3 Phase Delta Figure 8 — TTUH-CO 1 Phase Figure 9 — TTUH-CO 3 Phase Delta

Figure 10 — TTUH 3 Phase Wye Figure 11 — TTUH-CO 3 Phase Wye

Note: Contactors shown in Figure 7, 8, 9, 10 and 11 are supplied by customer.

208, 240 & 480V

Note: All 3 phase heaters require the

use of a contactor.

L2

L3

T3

T2

T1

L1

C1

C2

120, 208 & 240V

Note: Single phase heaters 3 kW and

above require the use of a contactor.

C1

C2

L1

L2

T2

T1

208, 240 & 480V

Note: All 3 phase heaters require the

use of a contactor.

T1

T2

T3

L2

L3

L1

C1

C2

L2

L1

1 Heat-Parallel —

120, 208 & 240V

#10 Studs & Cup Washers Or

Cup Washers

L2

L1

Common

120, 208 & 240V — 3 Heat

#10 Studs & Cup Washers Or

Cup Washers

Jump Strap

120V Element

240V Series Connected

T1

T2

T3

L2

L3

L1

C1

C2

208, 240 & 480V

Note: All 3 phase heaters require the

use of a contactor.

T1

T2

T3

L2

L3

L1

C1

C2

208, 240 & 480V

Note: All 3 phase heaters require the

use of a contactor.

1

4

3

2

1

4

3

2

1

4

3

2

L2

L1

Medium

L2

L1

Low

L2

L1

Green

Ground

120, 208 & 240V - 3 Heat

Figure 12 — TTUH - (A) 1 Phase

High

Page 5

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater or resetting

the manual reset button. Failure to do so could

result in personal injury or property damage.

Heater must be installed by a qualified person in

accordance with the National Electrical Code.

NFPA 70.

IMPORTANT: It is the responsibility of the purchaser of the heater to make the ultimate choice of

sheath material based upon his knowledge of the

chemical composition of the corrosive solution,

character of the materials entering the solution,

and controls which he maintains on the process.

1. Heaters should be checked periodically for coatings and corrosion and cleaned if necessary.

2. Tank should be checked regularly for sediment around the

heater. Sediment can act as an insulator and shorten heater life.

3. Check for loose terminal connections.

4. If corrosion is indicated in the terminal enclosure, check termi-

nal box gasket and replace if necessary, and check conduit layout to correct conditions that allow corrosion to enter the terminal housing.

5. Clean terminal ends of all contamination.

OPERATION

1. Do not operate at voltages in excess of that stamped on the

heater since excess voltage will shorten heater life.

IMPORTANT: Mount heater in the tank so the liquid

level will always be above the effective heated portion of the heater. Provide expansion tank if necessary.

Note: The Thermal cutout on the TTUH-CO provides run dry

burn-out protection only. Partial immersion of the elements while

energized can shorten element life. The cutout is a safety device

only and should not be used continuously as a low-liquid-level

control.

6

Page 6

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

00 - 000

TA - X0 - EF

Litho in U.S.A.

RENEWAL PARTS IDENTIFICATION

THERMAL CUTOUT

For TTUH-CO only

GASKET

For all heaters

P/N 132-010737-001

MOUNTING CLAMP

For TTUH

(1 and 3 Phase)

P/N 056-016147-001

For TTUH-CO

P/N 056-019044-003

MOUNTING BOLT

For all heaters

5/16 x 1” Lg. Hex

Socket head cap screw

P/N 345-041953-001

Set Screw P/N 248-049593-026

PCN 427725

Note: New cutout will not work

with old style TTUH-CO models.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...