Chromalox ADHT-005, ADH-010, ADHT-010, ADH-015, ADHT-015 Installation Operation and RENEWAL PARTS IDENTIFICATION

...Page 1

Chromalox

Type ADH and ADHT

Air Duct Heaters

© 2008 Chromalox, Inc.

No. Mtg.

Approx. Approx. Holes

Net. Wt. Net. Wt. No. 9/32” No.

Dimensions (In.)

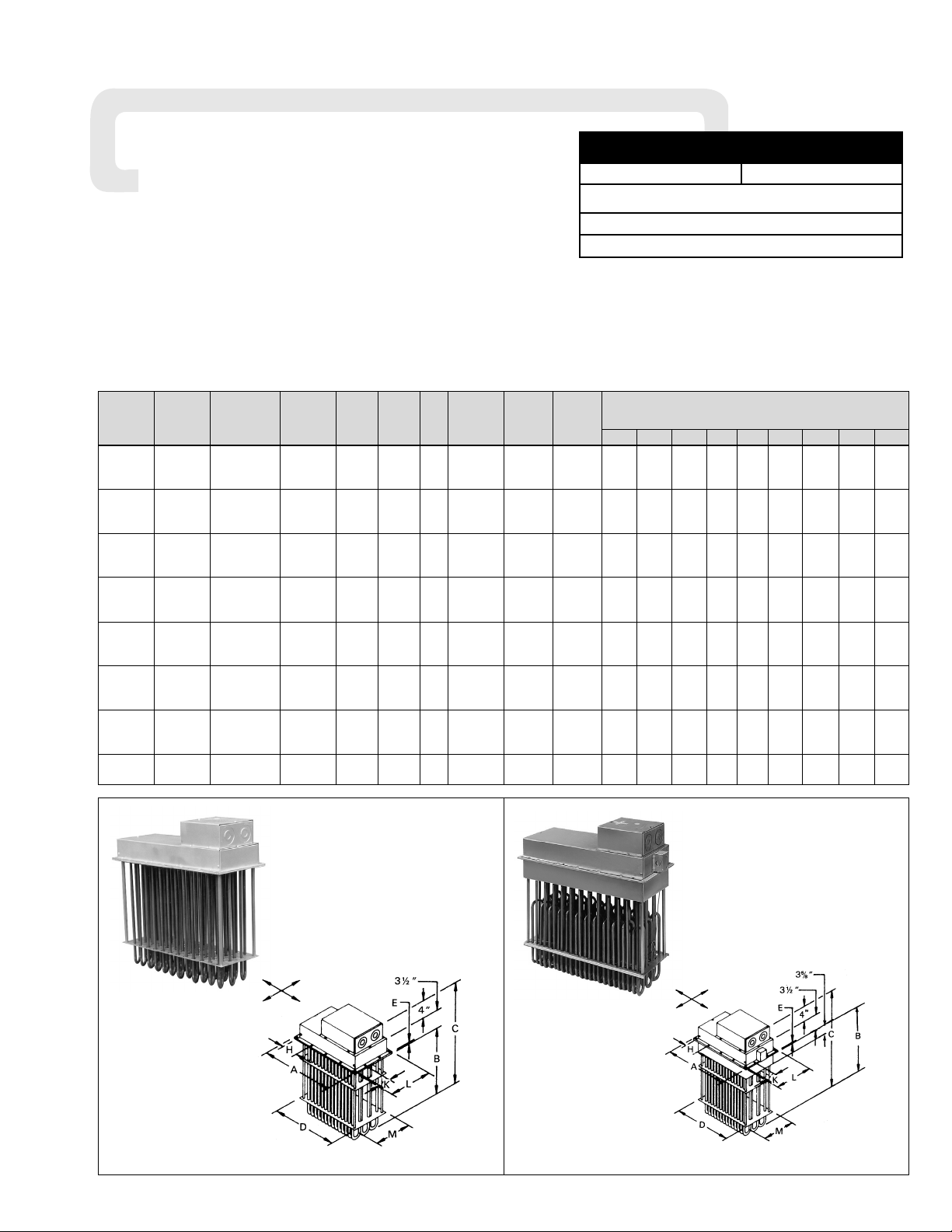

Model (Lbs.) Model (Lbs.) Volts Phase kW Elements Dia. Circuits A B C D E H K L M

ADH-005 8 ADHT-005 10 480 3 5 3 10 1 5-5/8 20-3/8 28-1/8 4 1/4 2-1/2 3-1/2 11-1/8 9-1/2

ADH-010 15 ADHT-010 20 480 3 10 6 10 1 7-5/8 20-3/8 28-1/8 6 1/4 3-1/2 3-1/2 11-1/8 9-1/2

ADH-015 25 ADHT-015 30 480 3 15 9 12 1 9-5/8 20-3/8 28-1/8 8 1/4 3 3-1/2 11-1/8 9-1/2

ADH-020 35 ADHT-020 40 480 3 20 12 14 1 11-5/8 20-3/8 28-1/8 10 1/4 2-3/4 3-1/2 11-1/8 9-1/2

ADH-025 40 ADHT-025 50 480 3 25 15 14 1 13-5/8 20-3/8 28-1/8 12 1/4 3-1/4 3-1/2 11-1/8 9-1/2

ADH-030 55 ADHT-030 65 480 3 30 18 14 1 15-5/8 20-3/8 28-1/4 14 3/8 3-3/4 3-1/2 11-1/8 9-1/2

ADH-035 65 ADHT-035 80 480 3 35 21 14 1 17-5/8 20-3/8 28-1/4 16 3/8 4-1/4 3-1/2 11-1/8 9-1/2

ADH-040 70 ADHT-040 90 480 3 40 24 14 2 19-5/8 20-3/8 28-1/4 18 3/8 4-3/4 3-1/2 11-1/8 9-1/2

ADH-045 80 ADHT-045 100 480 3 45 27 14 2 21-5/8 20-3/8 28-1/4 20 3/8 5-1/4 3-1/2 11-1/8 9-1/2

ADH-050 90 ADHT-050 110 480 3 50 30 14 2 23-5/8 20-3/8 28-1/4 22 3/8 5-3/4 3-1/2 11-1/8 9-1/2

ADH-060 105 ADHT-060 130 480 3 60 36 18 2 27-5/8 20-3/8 28-1/4 26 3/8 4-1/2 3-1/2 11-1/8 9-1/2

ADH-080 140 ADHT-080 175 480 3 80 48 22 4 35-5/8 20-3/8 28-1/4 34 3/8 4-3/8 3-1/2 11-1/8 9-1/2

ADH-090 160 ADHT-090 200 480 3 90 54 22 5 39-5/8 20-3/8 28-1/4 38 3/8 4-7/8 3-1/2 11-1/8 9-1/2

ADH-100 175 ADHT-100 220 480 3 100 60 22 5 43-5/8 20-3/8 28-1/4 42 3/8 5-3/8 3-1/2 11-1/8 9-1/2

— — ADHT-120 205 480 3 120 36 18 4 27-5/8 35 42-7/8 26 3/8 4-1/2 3-1/2 11-1/8 9-1/2

ADH-144 165 — — 480 3 144 48 22 4 35-5/8 35 42-7/8 34 3/8 4-3/8 3-1/2 11-1/8 9-1/2

— — ADHT-160 270 480 3 160 48 22 8 35-5/8 35 42-7/8 34 3/8 4-3/8 3-1/2 11-1/8 9-1/2

ADH-162 185 — — 480 3 162 54 22 6 39-5/8 35 42-7/8 38 3/8 4-7/8 3-1/2 11-1/8 9-1/2

— — ADHT-180 305 480 3 180 54 22 6 39-5/8 35 42-7/8 38 3/8 4-7/8 3-1/2 11-1/8 9-1/2

ADH-216F 240 — — 480 3 216 72 22 6 27-5/8 35 42-7/8 26 3/8 4-1/2 3-7/8 20 18-3/8

— — ADHT-240F 400 480 3 240 72 22 8 27-5/8 35 42-7/8 26 3/8 4-1/2 3-7/8 20 18-3/8

ADH-270F 300 — — 480 3 270 90 22 8 33-5/8 35 42-7/8 32 3/8 5-1/2 3-7/8 20 18-3/8

— — ADHT-300F 500 480 3 300 90 22 10 33-5/8 35 42-7/8 32 3/8 5-1/2 3-7/8 20 18-3/8

Specifications — Table A

Figure 1 — Dimensions Figure 2 — Dimensions

Type ADH Type ADHT

Airflow

Direction

Airflow

Direction

®

Installation Operation

and

DIVISION 4 SECTION ADH

SALES

REFERENCE

(Supersedes PF438-2)

PF438-3

161-057949-001

SERVICE REFERENCE

RENEWAL PARTS IDENTIFICATION

MARCH, 1999

DATE

Page 2

WARNING: Hazard of Electric Shock. Disconnect all

power before installing heater.

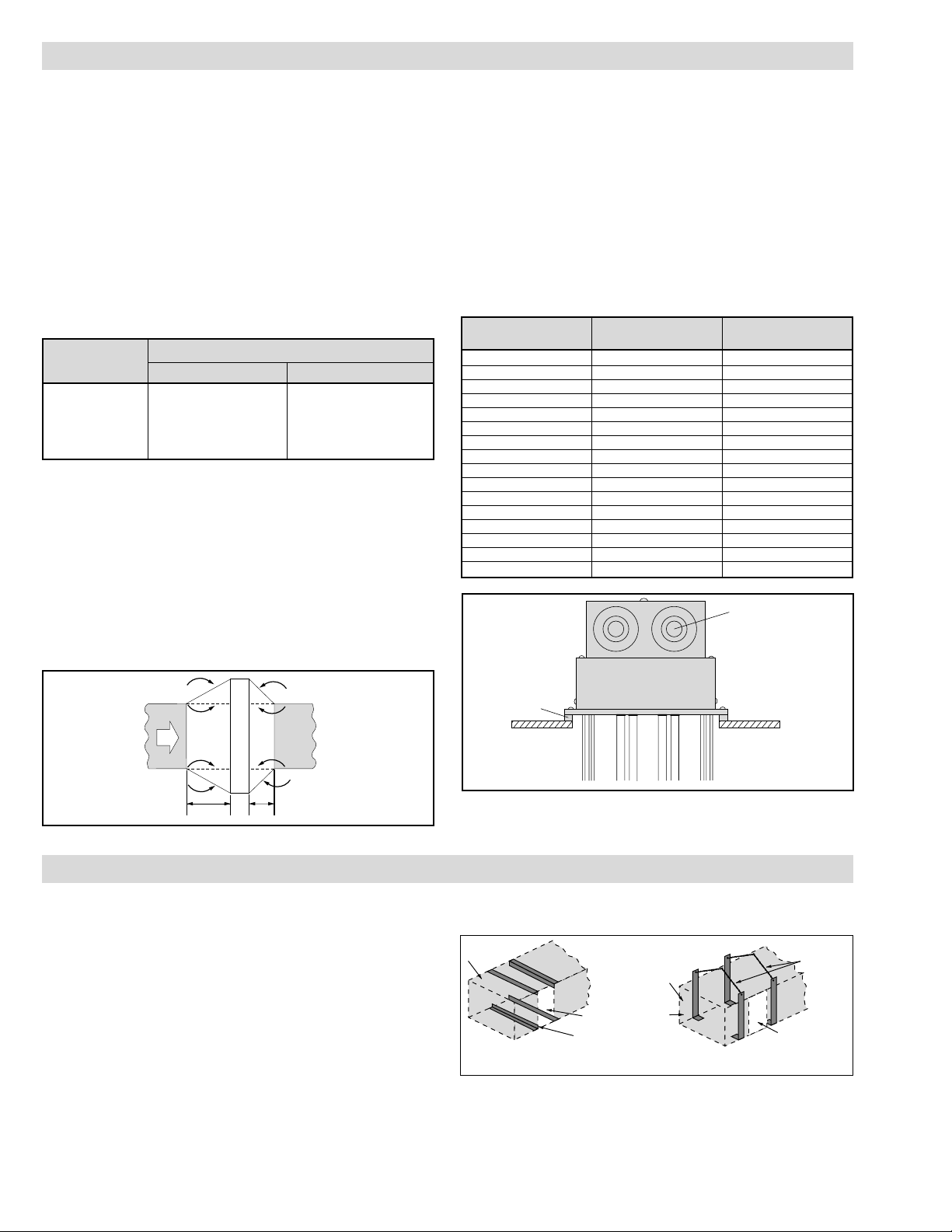

1. Locate and position heater in duct in accordance with both

process requirements and recommendations given.

2. Refer to Figures 1 and 2, layout “D” and “M” dimensions on

duct mounting face established in step 1.

3. With tools suitable for sheet metal work, cut layout opening in

duct.

4. In general, heaters less than 35 pounds in weight may be mounted

directly in opening without additional duct reinforcement if duct

installation and condition permits. To fasten heater to duct wall use

#14 pan or round head self-tapping screws. The flange mounting

gasket supplied with the heater is recommended for insertion

between heater flange and duct to minimize air leakage.

5. For heater weights greater than 35 pounds (see Specifications

Table A, page 1) due consideration should be given to; (a)

mechanically strengthening duct work with, for example, angle

irons or chains (see Figure 5), and (b) heat insulating duct line

in immediate area of heater location to prevent excessive heat

loss. Consult your local sheet metal contractor.

6. In high ambient temperature operations, least corrosive action

and least oxidation to the terminals will occur if the heaters are

mounted with the terminals in the coolest possible ambient,

usually on the bottom or side of the duct.

A. Minimum duct size is “A” or “L” dimension +3/8” and “B”

dimension +1-5/8”.

WARNING: This heater is not intended for use in hazardous atmospheres where flammable vapors, gases,

liquids or other combustible atmospheres are present

as defined in the National Electrical Code. Failure to

comply can result in explosion or fire.

1. Heater construction characteristics —

A. Alloy sheathed tubular elements, .475” diameter

B. Steel flange

C. Stainless steel support construction

D. High temperature alloy terminals and connections

E. Replaceable individual heating elements

F. Wiring terminals located outside the heated zone

2. Maximum Temperatures — Types ADH and ADHT process

air heaters can generally be used at the following maximum

temperatures shown, provided the minimum air velocity is

maintained uniformly through the heater.

CAUTION: Do not energize heater in air with a

velocity less than 1 Ft. Per Second.

3. The heater may be bolted to the duct with the terminal housing

and flange at the top, at either side or at the bottom.

4. Several heaters may be mounted in tandem so long as proper

controls are used to limit the maximum temperature attained.

5. Installation with duct transitions in some air distribution systems, the duct heater may be considerably larger than the ductwork and the duct area must be increased by a sheet metal transition. The slope of the transformation piece on the upstream

side of the equipment is limited to 30° as indicated in Figure 3.

On the leaving side, the slope should not be more than 45°.

6. Use moisture proof terminal cover in atmospheres bearing corrosive fumes or excessive moisture.

7. Use explosion resistant heaters in explosive atmospheres and

reduce current rating to elements.

8. Gas tight design — Achieved by the use of threaded fittings

with fiber washers to attach heating elements to flange — pre

vents leakage of ducted air into terminal housing.

9. Overtemperature protection — Thermocouple fastened to the element sheath surface and wired to a terminal block can be provided for accurate overheat protection (standard on ADHT models).

10. Flange mounting gasket — Packed separately with each duct

heater to minimize air leakage between the flange and air duct.

Refer to Table B and Figure 3.

GENERAL

Max. Outlet Air Temp. (˚F)

Air Velocity

(Ft./Sec.) ADH ADHT

4 800 1050

9 800 1100

16 800 1150

25 800 1200

36 800 1200

Flange Gasket Used On

Part No. Flange Size ADH and ADHT

168-055429-001 11-1/8 x 5-5/8 5 kW

168-055429-002 11-1/8 x 7-5/8 10 kW

168-055429-003 11-1/8 x 9-5/8 15 kW

168-055429-004 11-1/8 x 11-5/8 20 kW

168-055429-005 11-1/8 x 13-5/8 25 kW

168-055429-006 11-1/8 x 15-5/8 30 kW

168-055429-007 11-1/8 x 17-5/8 35 kW

168-055429-008 11-1/8 x 19-5/8 40 kW

168-055429-009 11-1/8 x 21-5/8 45 kW

168-055429-010 11-1/8 x 23-5/8 50 kW

168-055429-011 11-1/8 x 27-5/8 60, 120 kW

168-055429-013 11-1/8 x 35-5/8 80, 144, 160 kW

168-055429-014 11-1/8 x 39-5/8 90, 162, 180 kW

168-055429-015 11-1/8 x 43-5/8 100 kW

168-055429-017 20 x 27-5/8 216, 240 kW

168-055429-018 20 x 33-5/8 270, 300 kW

Specifications — Table B

Figure 3

Figure 4

INSTALLATION

Figure 5

2

30"

45˚

Max

2-1/2" x 1-1/4" x 3/4"

Knockouts

Flange

Mounting

Gasket

Air

Flow

4 Ft. Min.

Duct Heater

45˚

30˚

Max

4 Ft. Min.

Duct Wall

uct

Duct

Heater

Opening

Angle Iron

Metal

Strapping

Chains

Heater Opening

Page 3

7. DANGER: Hazard of Fire. Since these heaters are

capable of developing high temperatures, extreme

care should be taken to:

A. Avoid installing heaters in an atmosphere containing com-

bustible gases and vapors.

B. Avoid contact between heater and combustible material.

C. Keep combustible materials far enough away to be free of

the effects of high temperatures.

INSTALLATION

Temperature Control Instructions

1. A Chromalox thermal cutout or thermostat is recommended for

overheat protection and control of heater and process. Consult

local Chromalox representative.

2. In general, place thermostat sensing element close to the heating elements, near top of duct, at right angles to the direction of

air flow, and on the downstream side of the heater. Thermostat,

provided with a manual reset button, is separately mounted.

3. For heater protection, the indicated maximum temperature of

the control unit should be 50°F less than the actual maximum

air temperature that will be permitted, to allow for overshoot.

4. Single circuit heater elements may be wired into two circuits to

allow for partial heating and control. It is important to have

thermal control wired into all electric power circuits, so that all

elements may be protected from overheat.

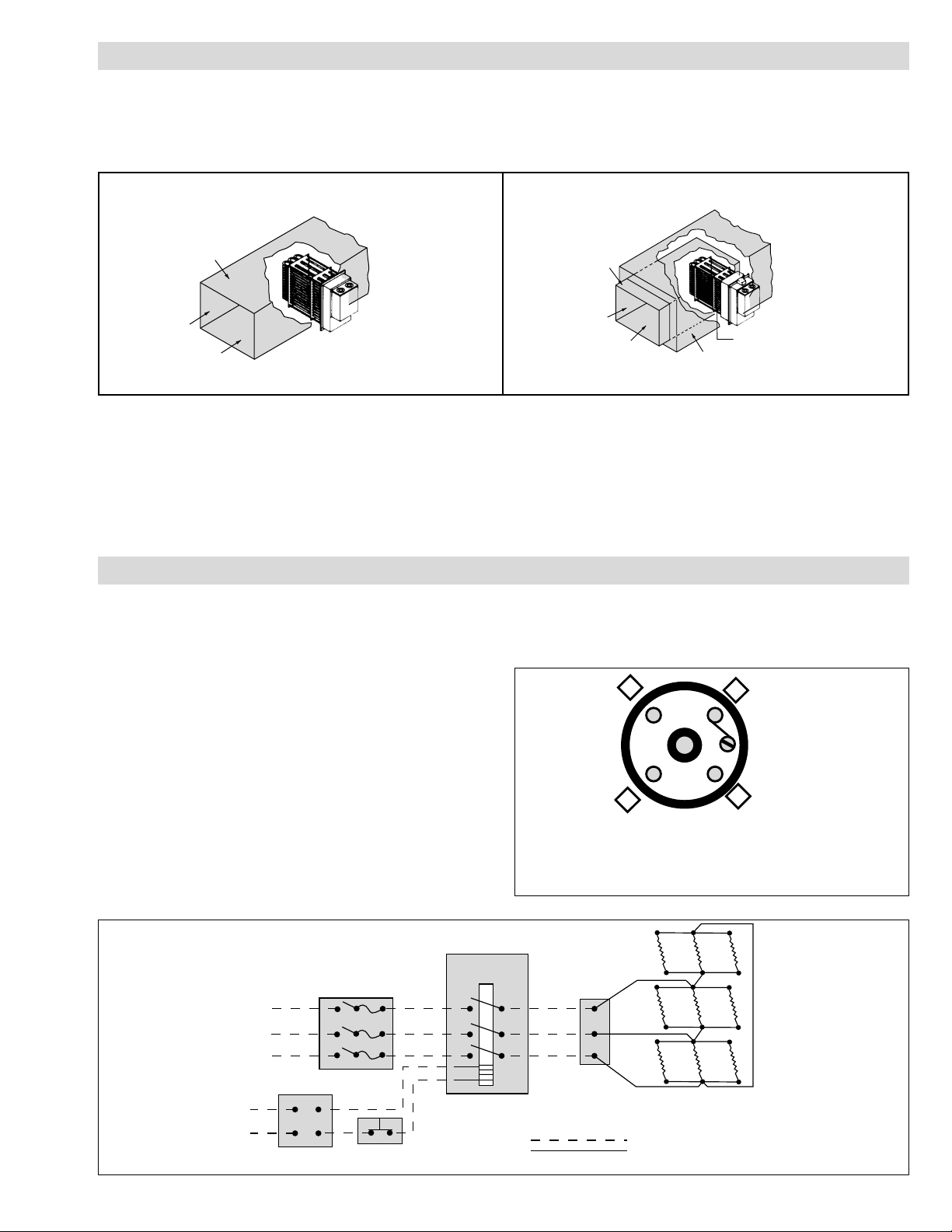

Figure 6 Figure 7

WARNING: Hazard of Electric Shock. Any installation involving electric heaters must be effectively

grounded in accordance with the National

Electrical Code to eliminate shock hazard.

1. All wiring should be done in accordance with National Electrical

Code and with local codes by a qualified person.

2. Connect air heaters to same line voltage, phase, and frequency

as on heater nameplate.

3. Teflon insulated nickel plated copper wire or bus bar is recommended for power connections to heater terminals and for

wiring runs in heated zones. When ambient temperature in

heated zone exceeds that for which insulated wire is recommended use bare nickel-plated copper with porcelain beads,

tubing or bus bar. Consult local Chromalox representative.

4. Users should install adequate back-up controls and safety

devices with their electric heating equipment. Selection of controls, thermostat, SCR units, contactors and etc. depends on the

degree of accuracy required, reliability, electrical rating of

heater and economic considerations.

5. Below is an example of a standard ADH-015, 480V 3 Ø 15 kW,

wired with recommended back-up controls. (Figure 8)

6. Individual terminal blocks with threaded stud type terminals

are provided for each circuit to permit quick positive attachment of circuit wiring conductors (one terminal block per circuit). (Figure 9)

WIRING

Figure 8

Figure 9

ADH-015, 15 kW 480V 3ø, 1 Circuit

(9) - 480V, 1667 Watt Elements

3

Duct

Air

Air

Insulation

(3" max.)

Standoff Collar

ADH Low temperature duct heaters — can be fastened directly to the sheet metal duct

work with bolts or sheet metal screws.

ADHT High temperature duct heaters — are generally mounted on field fabricated stand

off supports from the ductwork to position the heater such that the 3” insulation housing

is in the same plane as the duct insulation.

Duct

Air

Air

Fused

Switch

L1

L2

L3

Magnetic

Contactor

Terminal

L1

✸

L2

Terminal block

(303-027852-001)

X Circuit label indicated here.

Block

L1

L2

L3

G

L3

Control

Voltage

120 or 240V

Control Switch

Thermostat

ADH-015

Customer Supplied Wiring

Factory Supplied Wiring

Page 4

ADH-005, ADHT-005 ADH-010, ADHT-010 ADH-015, ADHT-015

ADH-020, ADHT-020 ADH-025, ADHT-025

ADH-030, ADHT-030 ADH-035, ADHT-035

WARNING: Users should install adequate controls

and safety devices with their electric heating equipment. Where the consequences of failure may be

severe, back-up controls are essential.

Although the safety of the installation is the responsibility of the user, Chromalox will be glad to make

equipment recommendations.

1. Do not operate heater at voltages in excess of that stamped on

the heater since excess voltage will shorten heater life.

OPERATION

WARNING: Hazard of Severe Shock. Disconnect all

power to heater before servicing or replacing heaters.

1. Periodically clean terminals and terminal covers of dust and

corrosion to maintain good electrical connections and to permit

rapid heat dissipation. Use airblast, and be careful to avoid

damage to mica insulation.

2. Check for loose terminal connections.

MAINTENANCE

ADH-005, ADHT-005, ADH-010, ADHT-010,

ADH-015, ADHT-015, ADH-020, ADHT-020,

ADH-025, ADHT-025, ADH-030, ADHT-030,

ADH-035, ADHT-035 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ADH-040, ADHT-040, ADH-045, ADHT-045,

ADH-050, ADHT-050, ADH-060, ADHT-060,

ADH-080, ADHT-080, ADH-090, ADHT-090,

ADH-100, ADHT-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ADHT-120, ADH-144, ADHT-160, ADH-162,

ADHT-180, ADH-216F, ADHT-240F, ADH-270F,

ADH-300F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

WIRING DIAGRAMS

1 Circuit, 3 Elements per Heater 1 Circuit, 6 Elements per Heater 1 Circuit, 9 Elements per Heater

AL1

AL2

AL3

AL1

AL3

AL2

AL1

AL2

AL3

1 Circuit, 12 Elements per Heater 1 Circuit, 15 Elements per Heater

AL1

AL2

AL3

AL1

AL2

AL3

1 Circuit, 18 Elements per Heater 1 Circuit, 21 Elements per Heater

AL1

AL2

AL3

AL1

AL2

AL3

Circuit ACircuit ACircuit A

Circuit A

Circuit A

Circuit A

Circuit A

4

Page 5

WIRING DIAGRAMS

ADH-040, ADHT-040 ADH-045, ADHT-045

2 Circuits per Heater, Circuit A, B, 12 Elements per Circuit,

24 Elements per Heater

AL1, BL1

AL2, BL2

AL3, BL3

Typical Circuit

AL1

AL2

AL3

BL1

BL2

BL3

2 Circuits per Heater, Circuit A, 15 Elements,

Circuit B, 12 Elements, 27 Elements per Heater

Circuit A Circuit B

ADH-050, ADHT-050

2 Circuits per Heater, Circuit A, B 18 Elements, Circuit C, 12 Elements, 30 Elements per Heater

AL1, BL1

AL2, BL2

AL3, BL3

CL1

CL2

CL3

Circuit A, B

Circuit C

Typical Circuit

ADH-060, ADHT-060 ADH-080, ADHT-080

2 Circuits per Heater, Circuit A, B,

18 Elements per Circuit, 36 Elements per Heater

AL1, BL1

AL2, BL2

AL3, BL3

ADH-090, ADHT-090 ADH-100, ADHT-100

4 Circuits per Heater, Circuit A, B, C, D,

12 Elements per Circuit, 48 Elements per Heater

AL1, BL1, CL1, DL1

AL2, BL2, CL2, DL2

AL3, BL3, CL3, DL3

Circuit A, B, C, D

5

Typical Circuit

EL2

AL1, BL1, CL1, DL1

EL1

EL3

AL2, BL2, CL2, DL2

AL3, BL3, CL3, DL3

Circuit E

5 Circuits per Heater, Circuit A, B, C, D, 12 Elements per Circuit,

Circuit E, 6 Elements, 54 Elements per Heater

5 Circuits per Heater, Circuit A, B, C, D, E,

12 Elements per Circuit, 60 Elements per Heater

AL1, BL1, CL1, DL1, EL1

AL2, BL2, CL2, DL2, EL2

AL3, BL3, CL3, DL3, EL3

Typical Circuit

Page 6

AL1, BL1, CL1, DL1

AL2, BL2, CL2, DL2

AL3, BL3, CL3, DL3

4 Circuits per Heater, Circuit A, B, C, D,

12 Elements per Circuit, 48 Elements per Heater

WIRING DIAGRAMS

ADHT-120 ADH-144

ADH-160 ADH-162, ADHT-180

ADH-216F ADHT-240F ADH-270F ADH-300F

4 Circuits per Heater, Circuit A, B, C, D,

9 Elements per Circuit, 36 Elements per Heater

AL1, BL1, CL1, DL1

AL2, BL2, CL2, DL2

AL3, BL3, CL3, DL3

6

Typical Circuit Typical Circuit

8 Circuits, Circuit A, B, C, D, E, F, G, H,

6 Elements per Circuit, 48 Elements per Heater

AL1, BL1, CL1, DL1, EL1, FL1, GL1, HL1

AL2, BL2, CL2, DL2, EL2, FL2, GL2, HL2

AL3, BL3, CL3, DL3, EL3, FL3, GL3, HL3

Typical Circuit

6 Circuits, Circuit A, B, C, D, E, F,

9 Elements per Circuit, 54 Elements per Heater

Typical Circuit

AL1, BL1, CL1, DL1, EL1, FL1

AL2, BL2, CL2, DL2, EL2, FL2

AL3, BL3, CL3, DL3, EL3, FL3

Typical Circuit

Typical Circuit

8 Circuits,

Circuit A, B, C, D, E, F, G, H,

9 Elements per Circuit, 72

Elements per Heater

6 Circuits,

Circuit A, B, C, D, E, F,

12 Elements per Circuit, 72

Elements per Heater

AL1, BL1, CL1,

DL1, EL1, FL1

AL2, BL2, CL2,

DL2, EL2, FL2

AL3, BL3, CL3,

DL3, EL3, FL3

AL1, BL1,

CL1, DL1,

EL1, FL1,

GL1, HL1

AL3, BL3,

CL3, DL3,

EL3, FL3,

GL3, HL3

L2, BL2,

L2, DL2,

L2, HL2

AL1, BL1,

CL1, DL1,

EL1, FL1,

GL1, HL1,

IL1, JL1

AL3, BL3,

CL3, DL3,

EL3, FL3,

GL3, HL3,

IL3, JL3

AL2, BL2,

CL2, DL2,

EL2, FL2,

GL2, HL2,

IL2, JL2

AL1, BL1,

CL1, DL1,

EL1, FL1, GL1

HL1

HL2

HL3

AL2, BL2,

CL2, DL2,

EL2, FL2, GL2

AL3, BL3,

CL3, DL3,

EL3, FL3, GL3

10 Circuits,

Circuit A, B, C, D, E, F, G, H, I, J,

9 Elements per Circuit,

90 Elements per Heater

8 Circuits,

Circuits A, B, C, D, E, F, G,

12 Elements per Circuit, Circuit H,

6 Elements, 90 Elements per Heater

Typical CircuitCircuit A - G Circuit H

Page 7

RENEWAL PARTS IDENTIFICATION — TYPE ADH

7

Other Parts Common to all Heaters

❶❷❸ * ❹❺ ❻

Individual

Replacement Flange

Element Element Support Rod Terminal Block

Model

Element

Retaining Clip Spacer Plate Spacers Assembly

ADH-005 393-055440-007 (3) 121-055367-001 272-511327-001 (6) 271-055370-001 242-055376-001 (4) 303-027852-001

ADH-010 393-055440-006 (6) 121-055367-002 272-511327-001 (12) 271-055370-002 242-055376-001 (4) 303-027852-001

ADH-015 393-055440-007 (9) 121-055367-003 272-511327-001 (18) 271-055370-003 242-055376-001 (4) 303-027852-001

ADH-020 393-055440-006 (12) 121-055367-004 272-511327-001 (24) 271-055370-004 242-055376-001 (4) 303-027852-001

ADH-025 393-055440-007 (15) 121-055367-005 272-511327-001 (30) 271-055370-005 242-055376-001 (4) 303-027852-001

ADH-030 393-055440-006 (18) 121-055367-006 272-511327-001 (36) 271-055370-006 242-055376-001 (4) 303-027852-001

ADH-035 393-055440-007 (21) 121-055367-007 272-511327-001 (42) 271-055370-007 242-055376-001 (4) 303-027852-001

ADH-040 393-055440-006 (24) 121-055367-008 272-511327-001 (48) 271-055370-008 242-055376-001 (4) 303-027852-001 (2)

ADH-045 393-055440-007 (27) 121-055367-009 272-511327-001 (54) 271-055370-009 242-055376-001 (4) 303-027852-001 (2)

ADH-050 393-055440-006 (30) 121-055367-010 272-511327-001 (60) 271-055370-010 242-055376-001 (4) 303-027852-001 (2)

ADH-060 393-055440-006 (36) 121-055367-011 272-511327-001 (72) 271-055370-011 242-055376-001 (4) 303-027852-001 (2)

ADH-080 393-055440-006 (48) 121-055367-013 272-511327-001 (96) 271-055370-013 242-055376-001 (5) 303-027852-001 (4)

ADH-090 393-055440-006 (54) 121-055367-014 272-511327-001 (108) 271-055370-014 242-055376-001 (6) 303-027852-001 (5)

ADH-100 393-055440-006 (60) 121-055367-015 272-511327-001 (120) 271-055370-015 242-055376-001 (6) 303-027852-001 (5)

ADH-144 393-055440-009 (48) 121-055367-013 272-511327-001 (96) 271-055370-013 (2) 242-055376-001 (10) 303-027852-001 (4)

ADH-162 393-055440-009 (54) 121-055367-014 272-511327-001 (108) 271-055370-014 (2) 242-055376-001 (12) 303-027852-001 (6)

ADH-216F 393-055440-171 (72) 121-055367-032

271-055370-056 (2) 242-055376-001 (12) 303-027852-001 (6)

ADH-270F 393-055440-171 (90) 121-055367-033

271-055370-057 (2) 242-055376-001 (12) 303-027852-001 (8)

NOTE: Number in parentheses ( ) indicates the quantity of that part required.

* Older heaters may have retaining channels instead of clips. Contact Factory for

part number and quantity.

❷

❶

❹

❺

❸

❻

Lower

Terminal Box

Upper

Terminal Box

Knockouts for

Line Connections

ADH Replacement Element Rating

Part No. Volts Watts

393-055440-171 480 3000

393-055440-006 240 1667

393-055440-007 480 1667

393-055440-009 480 3000

(except ADH-216F

and ADH-270F)

Page 8

RENEWAL PARTS IDENTIFICATION — TYPE ADHT

Other Parts Common to all Heaters

❶❷❸❹ * ❺❻❼❽

Individual

Replacement Thermocouples Flange

Element Element Support Rod Terminal Block Thermocouple

Model

Element

Retaining Clip Spacer Plate Spacers Assembly Terminal Block

ADHT-005 393-055441-007 (3) 309-122380-003 121-055367-001 272-511327-001 (6) 271-055370-016 242-055376-002 (4) 303-027852-001 303-122014-002

ADHT-010 393-055441-006 (6) 309-122380-003 121-055367-002 272-511327-001 (12) 271-055370-017 242-055376-002 (4) 303-027852-001 303-122014-002

ADHT-015 393-055441-007 (9) 309-122380-003 121-055367-003 272-511327-001 (18) 271-055370-018 242-055376-002 (4) 303-027852-001 303-122014-002

ADHT-020 393-055441-006 (12) 309-122380-003 121-055367-004 272-511327-001 (24) 271-055370-019 242-055376-002 (4) 303-027852-001 303-122014-002

ADHT-025 393-055441-007 (15) 309-122380-003 121-055367-005 272-511327-001 (30) 271-055370-020 242-055376-002 (4) 303-027852-001 303-122014-002

ADHT-030 393-055441-006 (18) 309-122380-003 121-055367-006 272-511327-001 (36) 271-055370-021 242-055376-002 (4) 303-027852-001 303-122014-002

ADHT-035 393-055441-007 (21) 309-122380-003 121-055367-007 272-511327-001 (42) 271-055370-022 242-055376-002 (4) 303-027852-001 303-122014-002

ADHT-040 393-055441-006 (24) 309-122380-003 121-055367-008 272-511327-001 (48) 271-055370-023 242-055376-002 (4) 303-027852-001 (2) 303-122014-002

ADHT-045 393-055441-007 (27) 309-122380-003 121-055367-009 272-511327-001 (54) 271-055370-024 242-055376-002 (4) 303-027852-001 (2) 303-122014-002

ADHT-050 393-055441-006 (30) 309-122380-003 121-055367-010 272-511327-001 (60) 271-055370-025 242-055376-002 (4) 303-027852-001 (2) 303-122014-002

ADHT-060 393-055441-006 (36) 309-122380-003 121-055367-011 272-511327-001 (72) 271-055370-026 242-055376-002 (4) 303-027852-001 (2) 303-122014-002

ADHT-080 393-055441-006 (48) 309-122380-003 121-055367-013 272-511327-001 (96) 271-055370-028 242-055376-002 (5) 303-027852-001 (4) 303-122014-002

ADHT-090 393-055441-006 (54) 309-122380-003 121-055367-014 272-511327-001 (108) 271-055370-029 242-055376-002 (6) 303-027852-001 (5) 303-122014-002

ADHT-100 393-055441-006 (60) 309-122380-003 121-055367-015 272-511327-001 (120) 271-055370-030 242-055376-002 (6) 303-027852-001 (5) 303-122014-002

ADHT-120 393-055441-009 (36) 309-122380-003 121-055367-011 272-511327-001 (72) 271-055370-026 (2) 242-055376-002 (8) 303-027852-001 (4) 303-122014-002

ADHT-160 393-055441-009 (48) 309-122380-003 121-055367-013 272-511327-001 (96) 271-055370-028 (2) 242-055376-002 (10) 303-027852-001 (8) 303-122014-002

ADHT-180 393-055441-009 (54) 309-122380-003 121-055367-014 272-511327-001 (108) 271-055370-029 (2) 242-055376-002 (12) 303-027852-001 (6) 303-122014-002

ADHT-240F

393-055441-159

(72)

309-122380-003

121-055367-032

271-055370-833 (2) 242-055376-002 (12) 303-02

7852

-001 (8)

303-122014-002

ADHT-300F

393-055441-159 (90)

309-122380-003

121-055367-033

271-055370-834 (2) 242-055376-002 (12) 303-027852-001 (10)

303-122014-002

NOTE: Number in Parentheses ( ) indicates the quantity of that part required.

* Older heaters may have retaining channels instead of clips. Contact Factory for part

number and quantity.

ADHT Replacement Element Rating

Part No. Volts Watts

393-055441-159 480 3333

393-055441-006 240 1667

393-055441-007 480 1667

393-055441-009 480 3333

❷

❶

❹

❺

❸

❻

❼

❽

Upper

Terminal Box

Lower

Terminal Box

Knockouts for

Line Connections

Thermocouple

Terminal Box

(except ADHT-240F

and ADHT-300F)

Max. Temp 800˚F

99 - 052

TA - Q9 - EF.

Litho in U.S.A.

Chromalox warrants only that the Products and parts manufactured by Chromalox, when shipped, and the work performed by

Chromalox when performed, will meet all applicable specification and other specific product and work requirements (including

those of performance), if any, and will be free from defects in material and workmanship under normal conditions of use. All

claims for defective or nonconforming (both hereinafter called defective) Products, parts or work under this warranty must be

made in writing immediately upon discovery, and in any event, within one (1) year from delivery, provided, however all claims for

defective Products and parts must be made in writing no later than eighteen (18) months after shipment by Chromalox. Defective

and nonconforming items must be held for Chromalox's inspections and returned to the original f.o.b. point upon request. THE

FOREGOING IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES WHATSOEVER, EXPRESS, IMPLIED AND STATUTORY,

INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

Notwithstanding the provisions of this WARRANTY AND LIMITATION Clause, it is specifically understood that Products and

parts not manufactured and work not performed by Chromalox are warranted only to the extent and in the manner that the same

are warranted to Chromalox by Chromalox's vendors, and then only to the extent that Chromalox is reasonably able to enforce

such warranty, it being understood Chromalox shall have no obligation to initiate litigation unless Buyer undertakes to pay all cost

and expenses therefor, including but not limited to attorney's fees, and indemnifies Chromalox against any liability to Chromalox's

vendors arising out of such litigation.

Upon Buyer's submission of a claim as provided above and its substantiation, Chromalox shall at its option either (i) repair or

replace its Products, parts or work at the original f.o.b. point of delivery or (ii) refund an equitable portion of the purchase price.

THE FOREGOING IS CHROMALOX'S ONLY OBLIGATION AND BUYER'S EXCLUSIVE REMEDY FOR BREACH OF WARRANTY,

AND IS BUYER'S EXCLUSIVE REMEDY AGAINST CHROMALOX FOR ALL CLAIMS ARISING HEREUNDER OR RELATING HERETO WHETHER SUCH CLAIMS ARE BASED ON BREACH OF CONTRACT, TORT (INCLUDING NEGLIGENCE AND STRICT LIABILITY) OR OTHER THEORIES, BUYER'S FAILURE TO SUBMIT A CLAIM AS PROVIDED ABOVE SHALL SPECIFICALLY WAIVE ALL

CLAIMS FOR DAMAGES OR OTHER RELIEF, INCLUDING BUT NOT LIMITED TO CLAIMS BASED ON LATENT DEFECTS. IN NO

EVENT SHALL BUYER BE ENTITLED TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND BUYER SHALL HOLD CHROMALOX

HARMLESS THEREFROM. ANY ACTION BY BUYER ARISING HEREUNDER OR RELATING HERETO, WHETHER BASED ON

BREACH OF CONTRACT, TORT (INCLUDING NEGLIGENCE AND STRICT LIABILITY) OR OTHER THEORIES, MUST BE COMMENCED WITHIN ONE (1) YEAR AFTER THE DATE OF SHIPMENT OR IT SHALL BE BARRED.

W2008M

WARRANTY AND LIMITATION OF REMEDY AND LIABILITY

Insulation

Housing

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

Loading...

Loading...