Page 1

8003

1/8 DIN

Temperature Controller

Issue Date

April 1994

❒ USER’S MANUAL

0037-75212

Page 2

Contents

Model Identification .................................................................................................................................... Page ii

Dimensions and Panel Cutout ............................................................................................................................1

Wiring ........................................................................................................................................................................... 2

Hardware Setup .......................................................................................................................................................3

Configuration Mode ............................................................................................................................................... 4

Operator Mode .........................................................................................................................................................9

Error Messages ..................................................................................................................................................... 12

Warranty and Return ........................................................................................................................................... 14

Chromalox 8003 User's Manual i

Page 3

Model Identification

Model

8003 1/8 DIN Temperature Controller

8003 - 11130Typical Model Number

ii Chromalox 8003 User's Manual

Code Output 1 - Heat or Cool

1 SPDT Relay, 3 Amps at 250 Vac (Resistive) or

SSR Drive, 14V @ 20mA, Jumper Selectable

Code Output 2 - Cool or Alarm

1 Relay, 2 Amps at 250 Vac (Resistive) or

SSR Drive, 14V @ 20mA, Jumper Selectable

Code Options

0 None

1 Alarm #2, 2 Amps at 250 Vac (Resistive load)

Code Power Supply

3 100/240 Vac

5 24 Vac/dc

Code

0 Add to complete model number

Page 4

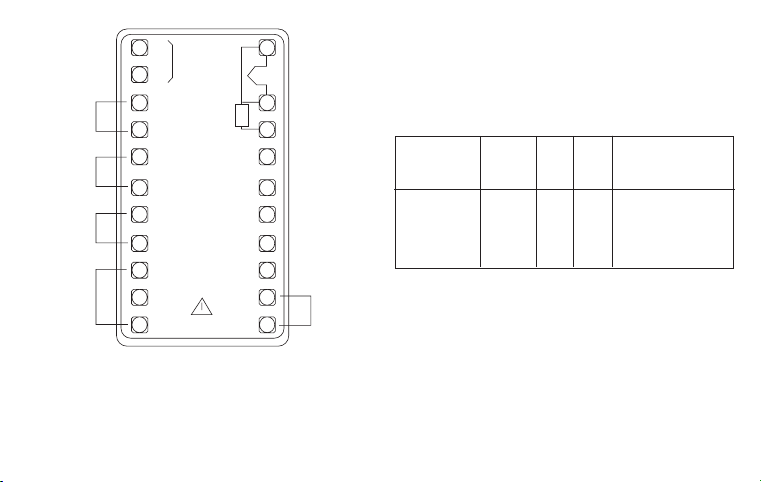

Dimensions in inches (mm in parenthesis)

3.62

(92)

1.77

(45)

5.1

(125)

0.5

(12.8)

(89)

Chromalox

PV

3.5

(96)

3.8

SP

MAIN AL1 AL2 SMRT

COOL HB

FUNC

SMRT

(48)

1.9

(60)

2.4

Chromalox 8003 User's Manual 1

Page 5

Wiring

OUT2

SSR

AL1/COOL

OUT2

RELAY

AL1/COOL

OUT1

SSR

OUT1

RELAY

12

Line

PWR

13

14

-

15

+

16

NO

C

17

18

-

19

+

20

C

NO

21

22

NC

1

TC+

TC

3

TC-

RTD

4

5

6

7

8

9

10

C

NO

OUT3

AL2

RELAY

11

Warnings:

• When a relay output is used to drive an inductive

load, it is suggested that you connect an external

snubber network (RC) across the terminals in

accordance with the following table (or use

Chromalox snubber P/N 0149-01305):

Load

Current (mA)

<40 mA

<150 mA

<0.5 A

C

(mF)

0.047

0.1

0.33

R

(Ω)

100

22

47

P.

(W)

1/2

2

2

Operating

Voltage

260 Vac

260 Vac

260 Vac

• Do not run sensor input wires together with power

cables.

• For thermocouple (TC) wiring, use matching

thermocouple extension wire (i.e. for J T/C, use type

“J” thermocouple extension wire).

• When using shielded sensor cable, ground the shield

at one end only.

2 Chromalox 8003 User's Manual

Page 6

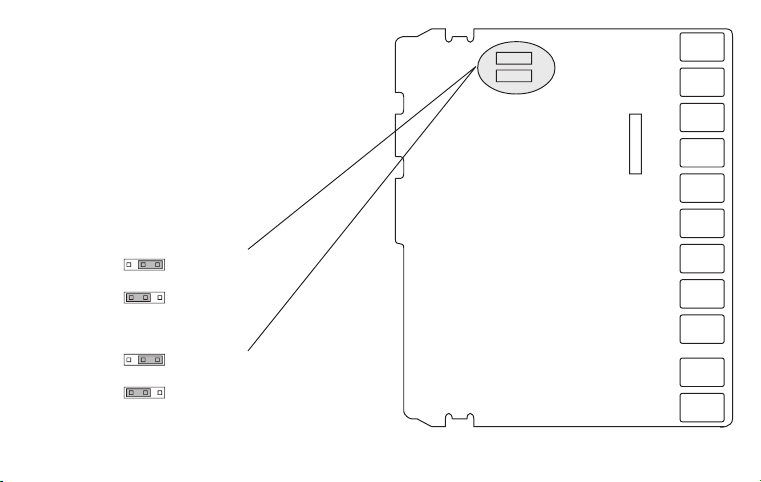

Hardware Setup

To select the output type(s) and the alarm contact settings:

1. Remove the instrument from its case.

2. Move the jumpers to the desired position as shown in

the diagram.

3. Set J304 and J305 as shown in the following figure.

3 2 1

J305

(MAIN output)

1-2 = SSR

2-3 = Relay

J305

J304

1

1

PZ22

PZ21

PZ20

PZ19

PZ18

PZ17

PZ16

PZ15

3 2 1

J304

(AL1, Cool.)

1-2 = SSR

2-3 = Relay

PZ14

PZ13

PZ12

Chromalox 8003 User's Manual 3

Page 7

General Operation

PZ1

There are two setup modes for the 8003:

• Configuration Mode

• Operator Mode

In general, the Configuration Mode is the initial setup of

the controller when first installed. Input type and alarm

setup are examples of Configuration Mode settings. The

Operator Mode includes settings that might be adjusted

frequently with daily control operations such as setpoints

and PID parameters.

PZ3

PZ4

PZ6

PZ7

Notes for Configuration Mode:

FUNC = Stores the new value of a selected parameter

and increments to the next parameter.

SMRT = Scrolls parameters back (in reverse order)

without storing the new parameter value.

▲ = Increases the value of the selected parameter.

▼ = Decreases the value of the selected parameter.

Configuration Procedure

1. Remove the instrument from its case.

2. Set the internal switch V2 (see the following

figure) in open position.

3. Reinsert the instrument in its case.

4. Switch on the instrument. “CNF” should be displayed

in the upper display.

Note: If "CAL" indication is immediately displayed,

press the ▲ pushbutton to return to the

configuration mode (CNF).

5. Push the FUNC pushbutton.

The lower display shows the parameter code while

PZ10

PZ11

the upper display shows the actual parameter value.

4 Chromalox 8003 User's Manual

V2

Page 8

P1 = Input Type and Standard Range

Range

0 = TC type L 0 / +800 °C

1 = TC type J 0 / +800 °C

2 = TC type K 0 / +999 °C

3 = TC type N 0 / +999 °C

4 = RTD type Pt 100 -199 / +500 °C

5 = RTD type Pt 100 -19.9 / +99.9 °C

8 = TC type L 0 / +999 °F

9 = TC type J 0 / +999 °F

10 = TC type K 0 / +999 °F

11 = TC type N 0 / +999 °F

12 = RTD type Pt 100 -199 / +999 °F

P2 = Initial Scale Value

Not present when P1 = 5

The initial and full scale values are used by the PID

algorithm to calculate the input span.

P3 = Full Scale Value

Not present when P1 = 5

The initial and full scale values are used by the PID

algorithm to calculate the input span.

Note: the minimum input span (P3 - P2) is 300°C or

600°F for TC input and 100°C or 200°F for RTD input.

Chromalox 8003 User's Manual 5

P4 = Output Configuration

H = Heating HC = Heating / cooling

P5 = Heating Output Type

rEL = Relay

SSr = SSR

The output type selected here must match hardware

jumper setup (see page 2).

P6 = Cooling Element

Available only when P4 = HC

AIr = Air

OIL = Oil

H2O = Water

P7 = Alarm 1 Type

Available only when P4 = H

0 = None

1 = Process alarm (absolute)

2 = Band alarm (+ and - deviation)

3 = Deviation alarm

P8 = Alarm 1 Operation

Available only when P7 is different from 0

H = High Alarm L = Low Alarm

(outside if band alarm) (inside if band alarm)

Page 9

P9 = Alarm 1 Inhibit

Available only when P7 is different from 0.

OFF = inhibit disabled

ON = inhibit enabled

Note: The Alarm Inhibit disables the alarm action after a

setpoint change. At startup, it automatically enables the

alarm when the process temperature reaches the present

condition.

P10 = Alarm 2 Type

P13 = Type of OFFSET Applied to the Measured Value

P13 = 0 = constant OFFSET (P14) all over the range

P13 different from 0 = P13 shows the application point

of the offset value set by P14 parameter.

P14 = OFFSET Value

When P13 = 0, P14 is programmable, in engineering

units, from -20 % to +20 % of the input range.

When P13 is different from 0, P14 is programmable from

-20 % to + 20 % of P13 value.

0 = Not provided 2 = Band alarm

1= Process alarm 3 = Deviation alarm

P11 = Alarm 2 Operative Mode

Available only when P10 is different from 0.

H = High Alarm L = Low Alarm

P12 = Alarm 2 Inhibit

Available only when P10 is different from 0

OFF = Inhibit disabled

ON = Inhibit enabled

Note: The Alarm Inhibit disables the alarm action after a

setpoint change. At startup, it automatically enables the

-20% to +20%

Readout

P14

P13 = 0

Real curve

Adjusted

curve

Input

Readout

P14

Real curve

Adjusted curve

Input

P13

alarm when the process temperature reaches the present

condition.

6 Chromalox 8003 User's Manual

Page 10

P15 = Threshold of the “Soft Start” Function

Enter the threshold value, in °F or °C, for the automatic

start of the "Soft Start" function (output power limit).

The range of this setting is determined by the range of the

sensor selected in P1 (i.e., if type J T/C °F is selected in

P1, range is 0-999).

If the unit powers-up below the threshold value, the "Soft

Start" function is enabled and limits the power output to

"OLH" for "toL" minutes. “OLH” and “toL are setup in

the Operator Mode.

P16 = Not used

P17 = Not used

P18 = User Defined Security Code

0 = Security lock disabled (all Operator Mode parameters

may be adjusted)

1 = Security lock enabled (only setpoints may be adjusted)

From 2 to 499 = SP parameter may be modified and

other Operator Mode parameters may

be accessed.

From 500 to 999 = SP, A1 and A2 parameters may be

modified and other Operator Mode

parameters may be accessed.

Chromalox 8003 User's Manual 7

• When configuration is completed, the instrument

shows " -.-.-. " on both displays.

End of Configuration

• Push the FUNC pushbutton. The instrument will

return to the beginning of the configuration procedure.

For Advanced Configuration

• Push the ▲ or ▼ pushbutton and set the “217” code on

the upper display.

• Push FUNC. The following advanced configuration

parameters, P19-P29 will be displayed.

P19 = Main Output Action

Available only when P4 = H

r = Reverse (heating)

d = Direct (cooling)

Note: when P4 = HC, this parameter is forced to "r"

P21 = Alarm 1 Relay Action

This parameter is available only if P7 is different from 0

and P4 = H.

r = Reverse (relay de-energized in alarm condition)

d = Direct (relay energized in alarm condition)

Page 11

P22 = Alarm 2 Relay Action

This parameter is available only if P10 is different from 0

and P16 is different from OFF.

r = Reverse (relay de-energized in alarm condition)

d = Direct (relay energized in alarm condition)

P23 = Automatic Adjustment of "Relative Cooling Gain"

OFF = the SMART function does not adjust the

"relative cooling gain" parameter

ON = the SMART function adjusts the "relative

cooling gain" parameter

P24 = Output Maximum Rate of Change

This parameter allows you to set the output maximum

rate of change. P24 is programmable from 1 to 10% per

second change of the control output. If blank display, no

rate is applied and output changes in steps.

P25 = Protected Parameter Viewing

This parameter is available only if P18 is different from 0.

OFF = all protected parameters are not displayed

ON = the parameter values are displayed

8 Chromalox 8003 User's Manual

P26 = SMART enabled/disabled

0 = SMART function is disabled

1 = SMART function enabling/disabling is NOT

protected by the security code

2 = SMART function enabling/disabling is protected

by the security code

P27 = Proportional Band Maximum Limit is Adjustable

SMART function—This parameter may be programmed

from P28 or P29 value to 99.9.

P28 = Proportional Band Minimum Limit is Adjustable

SMART function in heating control only—This

parameter may be programmed from 1.0% to P27 value.

P29 = Proportional Band Minimum Value is Adjustable

SMART function in heating/cooling only—This

parameter may be programmed from 1.5% to P27 value.

Page 12

SMART Function

SMART automatically determines the best PID control

parameters for your application.

To enable the SMART function, push the SMRT

pushbutton. The SMRT LED will light or flash according

Operator Mode

1. Remove the instrument from its case

2. Set the internal switch V2 in closed position

3. Re-insert the instrument

4. Switch on the instrument

to the algorithm automatically selected.

When the SMART function is enabled, it is possible to

PZ1

display, but not to modify, the control parameters (PB,

TI, TD and rC).

When the traditional PID control is desired, push the

SMRT pushbutton again. The instrument maintains the

PZ3

PZ4

last set of SMART PID control parameters and enables

parameter modification.

Notes: 1. When ON/OFF control is programmed (PB = 0),

the SMART function is disabled.

PZ6

PZ7

2. The SMART enabling/disabling is protected by

security code.

PZ10

PZ11

V2

Chromalox 8003 User's Manual 9

Page 13

The upper display will show the measured value while the

lower display will show the programmed setpoint value

(we define this status as “normal display mode”).

Pushbutton functionality during operating mode :

FUNC = Stores the new value of a selected parameter

and increments to the next parameter.

SMRT = Scrolls parameters back (in reverse order)

without storing the new parameter value.

▲ = Increases the value of the selected parameter.

▼ = Decreases the value of the selected parameter.

Note: A 10 second timeout is operative during parameter

modification.

If, during operator parameter modification, no

pushbuttons are pressed for more than 10 seconds, the

instrument goes automatically to the “normal display

mode” and it stores only the new settings that were

followed by pressing FUNC pushbutton.

10 Chromalox 8003 User's Manual

Output Power Off

To turn OFF the output signal, push and hold the ▲

pushbutton, then push FUNC. Pressing both pushbuttons

for more than 3 seconds will cause the instrument to

display "OFF" instead of the setpoint value.

In the output power off condition, the parameters can

always be reviewed and modified.

To return to normal control, press and hold the ▲

pushbutton and then push the FUNC pushbutton.

Press and hold both pushbuttons for more than 3 seconds.

The instrument then goes to the NORMAL DISPLAY

MODE.

Page 14

8003 Operator Parameters

Push the FUNC pushbutton. The lower display shows the cue,

the upper display shows the value of the selected parameter.

Cue Description

SP Control Setpoint, range from "rL" to "rH".

nnn Software key for parameter protection set in

Conf mode P18.

A1 Alarm 1 Setpoint, range from Conf mode P2 to P3.

A2 Alarm 2 Setpoint, range from Conf mode P2 to P3.

H1 Alarm 1 hysteresis (deadband) 0.1 to 10.0% of

alarm span.

H2 Alarm 2 hysteresis (deadband) 0.1 to 10.0% of

alarm span.

Pb Proportional Band, range from 1.0 to 99.9% of

span for heating output, 1.5 to 99.9% of span

for heating/cooling output. If Pb = 0, ON/OFF

control is enabled and ti, td, C, C2, rC, OLP,

OLH and IOL are not displayed.

HS Hysteresis (deadband) for ON/OFF control

(active if Pb = 0), range 0.1 to 10.0% of span.

ti Integral time (automatic reset), range 1 minute

and 20 seconds to 20 minutes and 00 seconds,

or if blank integral is disabled.

Chromalox 8003 User's Manual 11

td Derivative (rate), range 1 second to 9 minutes

and 59 seconds. If 0, derivative is disabled.

C Heating cycle time, range 1 to 200 seconds (30

seconds or greater recommended for relay outputs).

C2 Cycle Time for Output 2 (heat/cool control

selected), range 1 to 200 seconds (30 seconds

or greater recommended for relay outputs).

rC Relative cooling gain (for heat/cool) control

range 0.20 to 1.00.

OLP Overlap/Deadzone (for heat/cool) Positive value

is amount of overlap; negative value separation

between heat and cool Pbs, range -20 to 50% of Pb.

rL SP minimum value (low limit)

rH SP maximum value (high limit)

rP Ramp on setpoint changes, range 1 to 100

degrees/minute or blank (step change).

OLH Output power max. value, range 0 to 100%

heating, -100 to 100% heat/cool, limits power

continuously (tOL = blank) or on startup per

tOL settings.

tOL Time interval for OLH power output limit, range

1 to 100 minutes or if blank infinite. The timer

starts if the actual temperature is less than P15

(threshold value).

Page 15

Error Messages

Overrange or Underrange Indications

The instrument shows the OVERRANGE conditions

with the following indication on the upper display:

The instrument shows the UNDERRANGE conditions

with the following indication on the upper display:

12 Chromalox 8003 User's Manual

Burn-out conditions are shown as well as overrange

condition.

For TC input it is possible to specify optional underrange

indication when ordering the controller. Contact the

factory for information.

Note: When an overrange condition is detected, the

instrument forces the control output to the minimum

possible value.

When an underrange condition is detected, the

instrument forces the control output to the maximum

possible value.

Page 16

Error Messages

The instrument has a self-diagnostic algorithm. When an

error is detected, the instrument shows “Err” indication

on the lower display while the upper display shows the

code of the detected error.

Error List

100 Write EEPROM error.

150 CPU error.

200 Write on protected memory.

201-2xx Configuration parameter error. The two least

significant digit’s show the number of the

wrong parameter (ex. 209 Err shows an Error

on P9 parameter)

301 RTD input calibration error

305 TC input calibration error

307 RJ input calibration error

310 CT input calibration error

Chromalox 8003 User's Manual 13

400 Control parameters error

500 Auto-zero error

502 RJ error

510 General error during calibration

procedure

Note: 1. When a configuration parameter error is

parameter only.

2. If an error 400 is detected, simultaneously push

the ▲ and ▼ pushbuttons for loading the

default parameters, then repeat control

parameter setting.

3. For all the other errors, contact your supplier.

Page 17

Warranty And Limitation Of Remedy

And Reliability

Chromalox warrants only that the Products and parts

manufactured by Chromalox, when shipped, and the work

performed by Chromalox when performed, will meet all

applicable specification and other specific product and

work requirements (including those of performance), if

any, and will be free from defects in material and

workmanship under normal conditions of use. All claims

for defective or nonconforming (both hereinafter called

defective) Products, parts or work under this warranty

must be made in writing immediately upon discovery, and

in any event, within three (3) years from delivery,

provided, however all claims for defective Products and

parts must be made in writing no later than eighteen (18)

months after shipment by Chromalox. Defective and

nonconforming items must be held by Chromalox’s

inspections and returned to the original f.o.b. point upon

request. THE FOREGOING IS EXPRESSLY IN LIEU OF

ALL OTHER WARRANTIES WHATSOEVER,

EXPRESS, IMPLIED AND STATUTORY,

INCLUDING, WITHOUT LIMITATION, THE

IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

14 Chromalox 8003 User's Manual

Notwithstanding the provisions of this WARRANTY

AND LIMITATIONS Clause, it is specifically understood

that Products and parts not manufactured and work not

performed by Chromalox are warranted only to the extent

and in the manner that the same are warranted to

Chromalox by Chromalox’s vendors, and then only to the

extent that Chromalox is reasonably able to enforce such

a warranty, it being understood Chromalox shall have no

obligation to initiate litigation unless buyer undertakes to

pay all cost and expenses therefore including but not

limited to attorney’s fees, and indemnifies Chromalox

against any liability to Chromalox’s vendors arising out of

such litigation.

Upon buyer’s submission of a claim as provided above and

in its substantiation, Chromalox shall at its option either

(i) repair or replace its Products, parts or work at the

original f.o.b. point of delivery or (ii) refund an equitable

portion of the purchase price.

The foregoing is Chromalox’s only obligation and buyer’s

exclusive remedy for breach of warranty, and is buyer’s

exclusive remedy against Chromalox for all claims arising

hereunder or relating hereto whether such claims are

based on breach of contract, tort (including negligence

and strict liability) or other theories, buyer’s failure to

Page 18

submit a claim as provided above shall specifically waive

all claims for damages or other relief, including but not

limited to claims based on latent defects. In no event

shall buyer be entitled to incidental or consequential

damages and buyer should hold Chromalox harmless

therefrom. Any action by buyer arising hereunder or

relating hereto, whether based on breach of contract, tort

(including negligence and strict liability) or other

theories, must be commenced within three (3) years after

the date of shipment or it shall be barred.

Chromalox 8003 User's Manual 15

Returns

Items returned to Chromalox Instruments and Controls

must be accompanied by a Return Authorization Number.

This number may be obtained from Chromalox

Instruments and Controls, Customer Service Department,

Telephone Number (615) 793-3900. It should appear on

the exterior of the shipping carton and on the shipping

documents. Defective items will be repaired or replaced at

our option, at no charge.

Return the defective part or product, freight prepaid, to:

Chromalox Instruments and Controls

1382 Heil-Quaker Blvd.

LaVergne, TN 37086-3536

Page 19

Chromalox

INSTRUMENTS AND CONTROLS

1382 HEIL QUAKER BOULEVARD

LAVERGNE, TN 37086-3536

PHONE (615) 793-3900

FAX (615) 793-3563

®

Loading...

Loading...