Page 1

Chromalox

3901

Chromalox

®

Overtemperature Controller

Issue Date

Dec 1993

User’s Manual

0037-75121

U

L

®

FM

APPROVED

Page 2

i Chromalox 3901 User’s Manual

Table of Contents

Sections

Section Topic Page

1 Introduction to the 3901 Controller 1

2 Installation 3

3 Operation 9

4 Calibration 13

5 Specifications 15

6 Warranty and Return Information 17

Illustrations

Figure Topic Page

1.1 Overtemperature Control Application 1

1.2 Model Identification Table 2

2.1 Removing the Back Cover 4

2.2 Mounting Dimensions 4

2.3 Mounting Diagram 5

2.4 Wiring Connections 7

3.1 Front Panel Identification 10

3.2 Set Point Limit Potentiometer 12

4.1 Zero and Span Calibration Potentiometer 13

Page 3

Chromalox 3901 User’s Manual 1

The Chromalox 3901 Overtemperature Controller

gives you reliable and economical digital indicating,

overtemperature control in a compact 1/4 DIN

package. Figure 1.1 illustrates a typical overtemperature application.

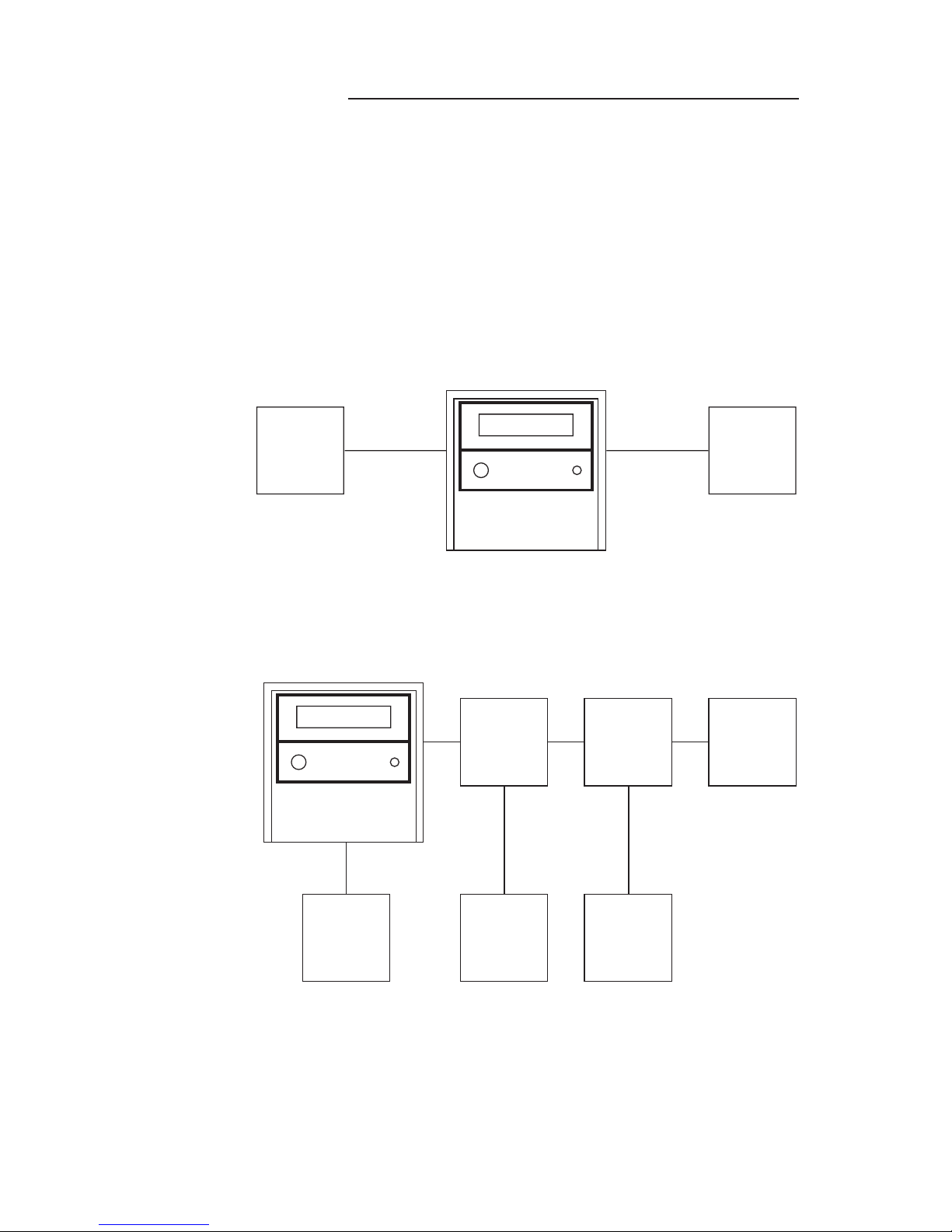

Figure1.1

Overtemperature Control Application

Chromalox

READ

TEMP

ALARM

HEAT

SOURCE

SHUTDOWN

CONTACTOR

3901

°

F

OVERTEMP FOR PROCESSOR HEATER SHEATH PROTECTOR

Chromalox

READ

TEMP

ALARM

3901

°F

FLOW

SWITCH

LEVEL

CONTROL

SHUTDOWN

CONTACTOR

AIR

FLOW

LEVEL

SENSOR

HEAT

SOURCE

OVERTEMP APPLIED WITH OTHER CUTOUT DEVICES

Section 1

Introduction to the

3901 Controller

Page 4

2 Chromalox 3901 User’s Manual

Before You

Install

Before proceeding with installation and operation of

your controller, it is important that you identify the

model you have purchased. This will determine how

you install and wire the controller, and how you may

apply it. Check the serial number tag on the inside

front door flap of the controller to confirm your

model number.

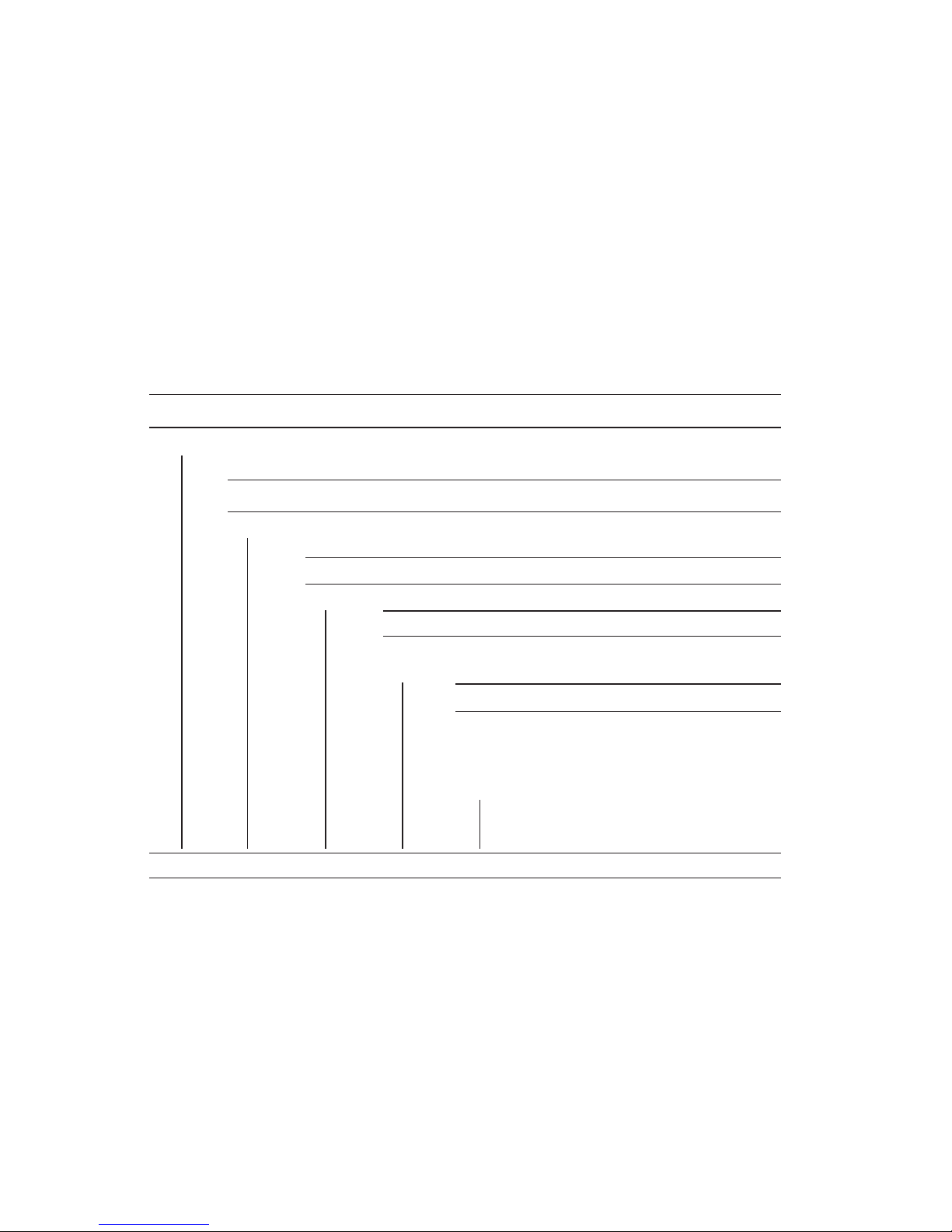

Figure 1.1

Model Identification Table

Model Overtemperature Controller

3901 Digital Indicating, UL Listed, FM Approved, Terminals for Remote Reset;

1/4 DIN Panel Cutout, 2.4 Inch Depth Behind Panel

Code Control Output

1 Relay, up to 230 Vac, 20 amp resistive load, SPST Latching,

Normally-Energized, Normally-Open Contact

Code Terminations

1 Barrier Strip with Screw Terminals

Code Instrument Power

1 120 Vac, +10%, -15%, 50/60 Hz

2 230 Vac, +10%, -15%, 50/60 Hz

Code Input Type/Indication Range

04 Type J Thermocouple, 0-999°F

08 Type J Thermocouple, 0-500°C

12 Type K Thermocouple, 0-1999°F

18 Type K Thermocouple, 0-1100°C

3901- 1 1 1 04 Typical Model Number

Page 5

Chromalox 3901 User’s Manual 3

Section 2

Installation

Inspection &

Unpacking

On receipt of your 3901 controller, immediately make

note of any visible damage to the shipment packaging

and record this damage on the shipping documents.

Unpack the controller and carefully inspect it for

obvious damage due to shipment. If any damage has

occurred, YOU must file a claim with the transporter,

as they will not accept a claim from the shipper.

Storage If the controller will not be immediately installed and

placed into operation, it should be stored in a cool, dry

environment in its original protective packaging until

time for installation and operation. Temperature

extremes and excessive moisture can damage the

instrument.

Installation

Steps

Installation of the 3901 controller requires 3 steps:

Step 1 - Accessing Internal Adjustments

Step 2 - Mounting

Step 3 - Wiring

Step 1

Accessing

Internal

Adjustments

The back cover of the 3901 can be easily removed to

access the following internal adjustment:

• Set Point Limit Potentiometer (page 11)

The page number referenced above describes this

internal adjustment. Although it is not necessary, it is

easier to make this adjustment prior to mounting

and wiring the controller. If you want to establish a

Set Point Limit for your controller, read the page

referenced above before mounting and wiring the

3901.

Page 6

4 Chromalox 3901 User’s Manual

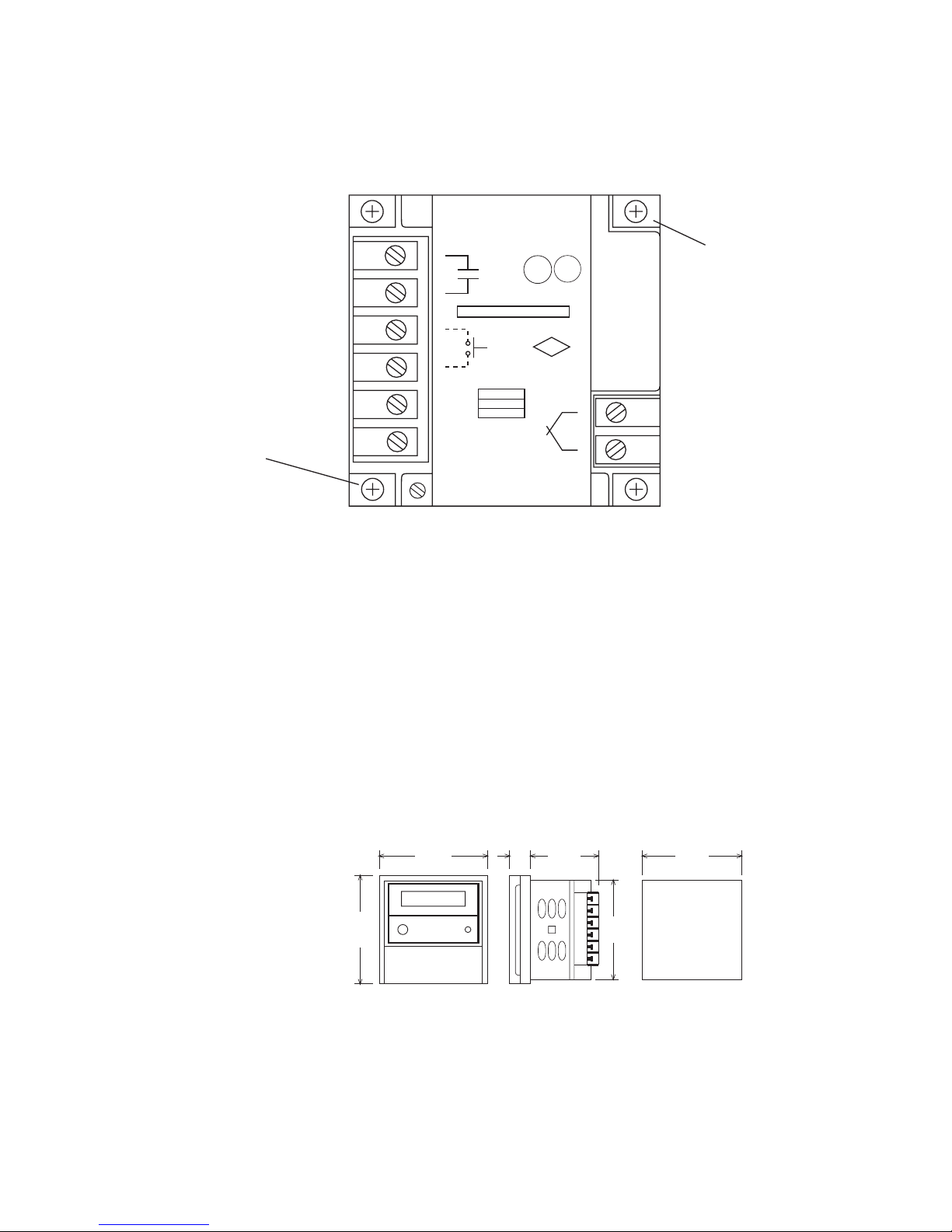

To remove the back cover, loosen the two back cover

screws shown in Figure 2.1 and lift the cover off of

the controller chassis.

Loosen screw

Loosen screw

After completing the internal adjustment(s), replace

the cover and re-secure the two screws.

Step 2

Mounting

The controller should be mounted in a location free

from excessive dust, oil accumulations and moisture.

It may be mounted in any position at ambient

temperatures of 30°F to 130°F (0°C to 55°C).

Figure 2.2 gives the mounting dimensions for the

controller.

Chromalox

READ

TEMP

ALARM

3.8

(96)

3.8

(96)

2.4

(61)

.8

(19)

3.6

(92)

3.5

(89)

PANEL CUTOUT

Measurements are shown in inches.

Millimeters are shown in parenthesis.

Figure 2.2

Mounting

Dimensions

Figure 2.1

Removing the

Back Cover

WARNING

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, PANEL MOUNT IN A CONTROLLED

ENVIRONMENT ENCLOSURE RELATIVELY FREE

OF CONTAMINANTS.

HAC

LAC/N

120 V AC

230 VAC

5 VA

1

2

3

4

5

6

CASE GND

7

8

+

REMOTE

RESET

INTERNAL

ALARM

RELAY

U

L

®

LISTED

35MO

20A RES 55 C 120/230 VAC

RELAY RATING

FM

APPROVED

TC INPUT

NOTE: USE COPPER CONDUCTORS ONLY

Page 7

Chromalox 3901 User’s Manual 5

1. Cut a square mounting hole (3.6” x 3.6”) in the

panel or mounting surface and place the controller

through the cutout.

2. Two mounting brackets are provided to secure the

controller in the cutout. Loosen the screws on the two

brackets. Place the mounting tabs into the mounting

holes located on the sides of the controller.

3. From the rear of the controller, tighten the screws

until the brackets are tight against the panel, securing

the controller in the panel cutout.

4. For other mounting configurations, the mounting

bracket tabs may be placed in the controller casing

vent slots.

Figure 2.3

Mounting

Diagram

Mounting Hole

Mounting Tab

Loosen Screw

Page 8

6 Chromalox 3901 User’s Manual

Important

Wiring

Information

To insure that the 3901 controller performs

optimally, it is imperative that you read this section

and become familiar with “Good Wiring Practices”

critical to eliminating electrical noise. Failure to

follow good wiring practices can result in poor

temperature measurement and ineffective high limit

control.

Snubbers Snubbers should be used to protect the controller

from electrical noise generated by inductive loads

such as motors, solenoids, coils and relays operating

near the 3901 controller. The recommended snubber

is a .1uf capacitor (600 Vdc rating) in series with a

100 ohm resistor and is available from Chromalox

(PCN 314448). The wiring diagram in this manual

illustrates the snubber connection.

Good

Wiring

Practice

Read and follow these Good Wiring Practices when

connecting this and any other controller:

1. Do not run sensor leadwires and power leads

together in the same conduit or wire tray.

2. When planning the system wiring, be sure to

consider the importance of separating wiring into

functionally similar bundles—i.e. power leads,

sensor leads, output signal lines, etc. If the power

leads and sensor leads must cross, they should cross

at a 90° angle to each other (perpendicular).

3. Locate all sources of noise in your system—

motors, contacts, solenoids, etc. Then design your

system such that wiring is separated as far as

possible from these noise sources.

4. Shielded, twisted wire should be used for the

control circuit signals if they are run in parallel with

other control circuit signal wires, or if they are run

distances greater than 2-3 feet.

5. To protect against noise, use shielded cables for all

low power signal lines.

6. Additional information on good wiring practices is

available from IEEE, 345 East 47th St., NY, NY

10017. Request IEEE Standard No. 5128-1982.

Page 9

Chromalox 3901 User’s Manual 7

Step 3

Wiring

Make all electrical wiring connections on the back of

the controller before power is applied to the unit.

All wiring must comply with local codes, regulations

and ordinances. This instrument is intended for panel

mounting and the terminals must be enclosed with a

panel. Use National Electric Code (NEC) Class 1

wiring for all terminals except the sensor terminals.

Figure 2.4

Wiring

Connections

Instrument Power Connections

Check the serial number tag located inside the door

flap to confirm the model number of your controller.

The model number identifies the instrument power of

your controller.

Instrument Power 3901 - **1** 120 Vac

3901 - **2** 230 Vac

Make the instrument power connections for your

controller type (120 Vac or 230 Vac) as shown in

Figure 2.4.

WARNING

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, PANEL MOUNT IN A CONTROLLED

ENVIRONMENT ENCLOSURE RELATIVELY FREE

OF CONTAMINANTS.

HAC

LAC/N

120 V AC

230 VAC

5 VA

1

2

3

4

5

6

CASE GND

7

8

+

REMOTE

RESET

INTERNAL

ALARM

RELAY

U

L

®

LISTED

35MO

20A RES 55 C 120/230 VAC

RELAY RATING

FM

APPROVED

TC INPUT

NOTE: USE COPPER CONDUCTORS ONLY

REMOTE

RESET

AC COMMON OR

230 VAC

LOAD

SNUBBER

120 or 230 VAC

AC NEUTRAL

120 or 230 VAC

+

Page 10

8 Chromalox 3901 User’s Manual

Sensor Input Connections

The thermocouple input is connected at terminals 7

(+) and 8 (-) as indicated by the wiring decal on the

back of the controller. The table below shows typical

color coding for the thermocouples used with this

controller:

T/C Type

J

K

Material Plus(+) Minus (-)

Iron/Constantan White Red

Chromel/Alumel Yellow Red

If shielded thermocouple wire is used, the shield

must be grounded at one end only, preferably at the

case ground (CASE GND) of the controller.

If thermocouple extension wire is required, it must

be the same type of extension wire as the

thermocouple (for example, if the thermocouple is

Type J, the extension wire must be Type J).

Alarm Output Connection

The alarm relay output connections are made at

terminals 1 and 2. Make the wiring connections as

shown in Figure 2.4, using the recommended

snubber circuit as discussed on page 6.

Remote Alarm Reset Connection

Terminals 3 and 4 are provided for connection of a

remote, normally-open reset switch. Make the reset

switch connection as shown in Figure 2.4.

Page 11

Chromalox 3901 User’s Manual 9

Section 3

Operation

Before applying power to the controller and

proceeding with Operation, verify that all wiring is

correct.

In this section you will learn how to make the

following selections and adjustments:

Set Point

Alarm Reset

Remote Alarm Reset

Set Point Limit

Initial

Power-Up

When power is applied to the 3901, it will begin

operating using the factory-set alarm set point shown

in the digital display. The process temperature

measured by the thermocouple can be selected for

display by pushing the “READ TEMP” pushbutton.

The ALARM LED will be illuminated only if the

process temperature is at or above the set point

temperature, or if the thermocouple is open.

The 3901’s front panel displays and indications, and

the RESET pushbutton and Set Point adjustment knob

located behind the front door flap are shown in Figure

3.1. Familiarize yourself with the front panel before

proceeding in this section.

Page 12

10 Chromalox 3901 User’s Manual

Figure 3.1

Front Panel

Identification

READ

TEMP

ALARM

°F

RESET

SET POINT

8 5 4

Hold Pushbutton to

Display Process

Temperature

Release Pushbutton

to Display Set Point

Overrange and Open

Sensor Indicator

Pushbutton to

Reset Latching

Overtemperature

Alarm

Set Point

Adjustment Knob

LED Indicates

Alarm Condition

Digital Display for

Alarm Set Point and

Process Temperature

Alarm

Set Point

Adjust Set Point—To adjust the alarm set point,

locate the SET POINT adjustment behind the front

door flap. Insert a screwdriver in the hole in the

knob, and turn the SET POINT knob until the

desired set point appears in the digital display.

Alarm

Reset

To reset the latching alarm relay, press the RESET

switch located behind the front door flap. If you

attempt to reset the alarm before the process

temperature has reached a normal state (below set

point), the RESET pushbutton will be ineffective.

Page 13

Chromalox 3901 User’s Manual 11

Remote

Alarm Reset

The Remote Alarm Reset works exactly like the Alarm

Reset function described above, except that the relay

is reset by pushing a remote momentary switch that

has been connected to terminals 3 and 4 (see page 7

for wiring).

Set Point

Limit

Adjust Set Point Limit—The 3901 has a set point

limit feature that allows you to preset an upper limit

for the set point adjustment. The set point limit can be

used to prevent an operator from selecting a set point

which could damage the process, product or

equipment.

The set point Limit is set at 100% of sensor span when

shipped from the factory (i.e. 1000°F for Type J

thermocouples and 2000°F for Type K thermocouples).

An internal potentiometer allows you to adjust the set

point limit from a range of 100% to 20% of sensor

span. To adjust the set point limit, remove the back

cover of the 3901 as described on page 4. Locate the

set point limit potentiometer shown in Figure 3.2.

USE EXTREME CAUTION: The set point limit can

be set with the instrument power to the controller

either off or on. If the power is left on, the limit must

be adjusted only by a qualified electronic technician at

a test bench, using an insulated screwdriver.

CAUTION:

LINE VOLTAGE WILL BE EXPOSED!

☛

Page 14

12 Chromalox 3901 User’s Manual

Chromalox

Screwdriver

Set Point Limit

Figure 3.2

Set Point Limit

Potentiometer

Controller Bottom View

To adjust the set point limit:

1. Turn the SET PT knob on the front faceplate to its

full clockwise position (FULL ON).

2. Turn the set point limit potentiometer until the

digital display reads the desired set point limit. In the

full (clockwise) position, the set point limit is 100%,

or more, of span.

3. After reaching the desired set point limit setting,

be sure to readjust the process set point to the

application’s setting using the SET PT knob.

To verify the set point limit setting, attempt to adjust

the set point past the set point limit.

Page 15

Chromalox 3901 User’s Manual 13

Section 4

Calibration

☛

The 3901 controller has been calibrated and tested at

the factory prior to shipment. Calibration on receipt is

not necessary.

Equipment

Required

A precision thermocouple simulator and a small

instrument screwdriver are necessary to calibrate the

controller.

Locating

Calibration

Adjustments

Remove the back cover from the controller as

described on page 4. Figure 4.1 identifies the zero and

span calibration potentiometers.

Zero Potentiometer

Span Potentiometer

➛

Calibration

Procedure

1. Connect the sensor simulator to terminals 7 and 8,

making sure to connect the (+) to 7 and (-) to 8.

2. Set the sensor simulator to a minimum value (200°F

for J T/C, 350°F for K T/C). While pressing the

“READ TEMP” pushbutton, adjust the zero

potentiometer until the digital display equals the

sensor input value (200°F or 350°F).

(continued on next page)

Figure 4.1

Zero and Span

Calibration

Potentiometers

Page 16

14 Chromalox 3901 User’s Manual

Calibration

Procedure

(continued)

3. Set the sensor simulator to a maximum (900°F for

J T/C, 1600°F for K T/C). While pressing the

“READ TEMP” pushbutton, adjust the span

potentiometer until the digital display equals the

sensor input value (900°F or 1600°F).

4. Repeat steps 2 and 3 as many times as necessary

until both displays equal their respective sensor input

values.

5. Calibration complete.

Page 17

Chromalox 3901 User’s Manual 15

Section 5

Specifications

Alarm Output

Repeatability +/- 1°F or 1°C

Reset

Differential

5°F or 3°C, nominal

Alarm Relay Normally-open, normally-energized, SPST, latching

relay (contacts open on alarm & when no power is

applied to controller - failsafe)

Rating at 120 or 240 Vac (resistive load):

20 amps, 150,000 operations

15 amps, 200,000 operations

5 amps, 800,000 operations

Mechanical life, 10 million operations

Input

Specifications

Type J

Thermocouple

0 to 999°F, 0 to 500°C

Type K

Thermocouple

0 to 1999°F, 0 to 1100°C

Input Loop

Resistance

Up to 150 ohms

Cold Junction

Compensation

Automatic, typically less than 0.1°F per 1°F over

ambient 50 to 120°F

Indications

Open Sensor

Indications

Red LED lamp for J thermocouple input, “1”

illuminates for K thermocouple input Upscale burnout,

alarm indication, contacts open

Accuracy of

Indication

+/- 0.5% of span over mid-80% of scale

Resolution 1°F or 1°C

Repeatability 1°F or 1°C

Alarm Output Red “ALARM” LED

Page 18

16 Chromalox 3901 User’s Manual

General

Instrument

Power

120 or 230 Vac, +10%, -15%, 50/60 Hz, 10 VA

nominal power consumption

Operating

Environment

30 to 130°F with relative humidity less than 95%

non-condensing

Dimensions Requires 3.6” x 3.6” (92 mm x 92mm) panel cutout

Depth behind panel of 2.4” (61 mm)

Projection at front of panel 0.8” (20 mm)

Mounting Two screw-in mounting brackets to secure controller

in panel

Influence of

Line Voltage

Variation

Maximum change of +/- 1°F for +/- 10% nominal

line voltage change

Noise Rejection

Common

Mode

Less than 2°F with 230 Vac, 60 Hz applied from

sensor input to instrument case

Series Mode Less than 2°F with 100 mV, peak to peak series

mode noise

Page 19

Chromalox 3901 User’s Manual 17

Section 6

Warranty and Return

The warranty complies with the Federal Law

applicable to products manufactured after December

31, 1976. This warranty gives you specific legal rights.

You may also have other rights which vary from state

to state.

Warranty Chromalox Instruments and Controls’ products are

warranted against defects in workmanship and

materials. No other express warranty, written or oral,

applies with the exception of a written statement from

an officer of Chromalox Instruments and Controls,

Wiegand Industrial Division, Emerson Electric Co.

Warranty

Period

This warranty extends for twelve months from the date

of shipment from the factory or an authorized

distributor.

Limitations Products must be installed and maintained in

accordance with Chromalox instructions. Users are

responsible for the suitability of the products to their

application. There is no warranty against damage

resulting from corrosion, misapplication, improper

specification or other operating conditions beyond our

control. Claims against carriers for damage in transit

must be filed by the buyer.

Returns Items returned to Chromalox Instruments and Controls

must be accompanied by a Return Authorization

Number. This number may be obtained from

Chromalox Instruments and Controls, Customer

Service Department, Telephone Number (615) 793-

3900. It should appear on the exterior of the shipping

carton and on the shipping documents. Defective items

will be repaired or replaced at our option, at no charge.

Return the defective part or product, freight prepaid,

to:

Chromalox Instruments and Controls

1382 Heil-Quaker Blvd.

LaVergne, TN 37086-3536

Page 20

Chromalox

®

INSTRUMENTS AND CONTROLS

1382 HEIL QUAKER BOULEVARD

LAVERGNE, TN 37086-3536

PHONE (615) 793-3900

FAX (615) 793-3563

WIEGAND INDUSTRIAL DIVISION

EMERSON ELECTRIC CO.

®

Loading...

Loading...