Page 1

Programmable

DC Electronic Load

6310 Series

Operation & Programming

Manual

Edition

May 2002

P/N A11 000078

Page 2

Legal Notices

The information in this document is subject to change without notice.

Chroma ATE INC. makes no warranty of any kind with regard to this manual, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose.

Chroma ATE INC. shall not be held liable for errors contained herein or direct, indirect,

special, incidental or consequential damages in connection with the furnishing, performance,

or use of this material.

CHROMA ATE INC. 43 Wu-Chuan Road, Wu-Ku Industrial Park, Wu-Ku, Taipei, Taiwan

Copyright Notices. Copyright 2002 Chroma ATE INC., all rights reserved. Reproduction,

adaptation, or translation of this document without prior written permission is prohibited,

except as allowed under the copyright laws.

ii

Page 3

Warranty

All Chroma instruments are warranted against defects in material and workmanship for a

period of one year after date of shipment. Chroma agrees to repair or replace any assembly

or component found to be defective, under normal use during this period. Chroma's

obligation under this warranty is limited solely to repairing any such instrument, which in

Chroma's sole opinion proves to be defective within the scope of the warranty when returned

to the factory or to an authorized service center. Transportation to the factory or service

center is to be prepaid by purchaser. Shipment should not be made without prior authorization

by Chroma.

This warranty does not apply to any products repaired or altered by persons not authorized by

Chroma, or not in accordance with instructions furnished by Chroma. If the instrument is

defective as a result of misuse, improper repair, or abnormal conditions or operations, repairs

will be billed at cost.

Chroma assumes no responsibility for its product being used in a hazardous or dangerous

manner either alone or in conjunction with other equipment. High voltage used in some

instruments may be dangerous if misused. Special disclaimers apply to these instruments.

Chroma assumes no liability for secondary charges or consequential damages and in any

event, Chroma's liability for breach of warranty under any contract or otherwise, shall not

exceed the purchase price of the specific instrument shipped and against which a claim is

made.

Any recommendations made by Chroma for use of its products are based upon tests believed

to be reliable, but Chroma makes no warranty of the results to be obtained. This warranty is

in lieu of all other warranties, expressed or implied, and no representative or person is

authorized to represent or assume for Chroma any liability in connection with the sale of our

products other than set forth herein.

CHROMA ATE INC.

43 Wu-Chuan Road, Wu-Ku Industrial Park,

Wu-Ku, Taipei Hsien, Taiwan

Tel: 886 -2-2298-3855

Fax: 886-2-2298-3596

http://www.chromaate.com

iii

Page 4

CE-Conformity Declaration

For the following equipment:

Product Name: DC Electronic Load

Model Name: 6314, 6312, 63101, 63102, 63103, 63105, 63106, 63107, 63108, 63112

Manufacturer’s Name: Chroma ATE Inc.

Manufacturer’s Address: 43 Wu-Chuan Road, Wu-Ku Industrial Park,

Wu-Ku, Taipei Hsien, Taiwan

is herewith confirmed to comply with the requirements set out in the Council

Directive on the Approximation of the Laws of the Member States Relating to

Electromagnetic Compatibility(89/336/EEC) and electrical equipment designed

for use within certain voltage limits(73/23/EEC;93/68/EEC)

For electromagnetic compatibility, the following standards were applied:

EMC: EN55011:1991 (Group I Class A)

EN60555-2:1987--EN 61000-3-2(1995)

EN60555-3:1987--EN 61000-3-3(1995)

EN50082-1:1992

IEC 1000-4-3(1995) - 3 V/m

1 kV Power Lines

For safety requirement, the following standard was applied:

Safety: EN61010-1(1993)+A2(1995)

Taiwan July 1999

Place Date Neng-Sung Lee/Vice President, Engineering

Warning:

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

IEC 1000-4-2(1995):1991 - 8 kV AD, 4 kV CD (Class B)

IEC 1000-4-4(1995) - 0.5 kV Signal Lines

iv

Page 5

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or specific

WARNINGS given elsewhere in this manual will violate safety standards of design,

manufacture, and intended use of the instrument. Chroma assumes no liability for the

customer’s failure to comply with these requirements.

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage and the correct fuse is

installed.

PROTECTIVE GROUNDING

Make sure to connect the protective grounding to prevent an electric shock before turning on

the power.

NECESSITY OF PROTECTIVE GROUNDING

Never cut off the internal or external protective grounding wire, or disconnect the wiring of

protective grounding terminal. Doing so will cause a potential shock hazard that may bring

injury to a person.

FUSES

Only fuses with the required rated current, voltage, and specified type(normal blow, time

delay, etc.)should be used. Do not use repaired fuses or short-circuited fuse holders. To

do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

DO NOT REMOVE THE COVER OF THE INSTRUMENT

Operating personnel must not remove the cover of the instrument. Component replacement

and internal adjustment can only be done by qualified service personnel.

v

Page 6

SAFETY SYMBOLS

DANGER - High voltage.

Explanation:To avoid injury, death of personnel, or damage to the

WARNING

CAUTION

instrument, the operator must refer to an explanation in the instruction

manual.

Protective grounding terminal:To protect against electrical shock in

case of a fault. This symbol indicates that the terminal must be

connected to ground before operation of equipment.

The WARNING sign denotes a hazard. It calls attention to a procedure,

practice, or the like, which, if not correctly performed or adhered to, could

result in personal injury. Do not proceed beyond a

the indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating

procedure, or the like, which, if not correctly performed or adhered to,

could result in damage to or destruction of part or all of the products. Do

not proceed beyond a

fully understood and met.

CAUTION sign until the indicated conditions are

WARNING sign until

vi

Page 7

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

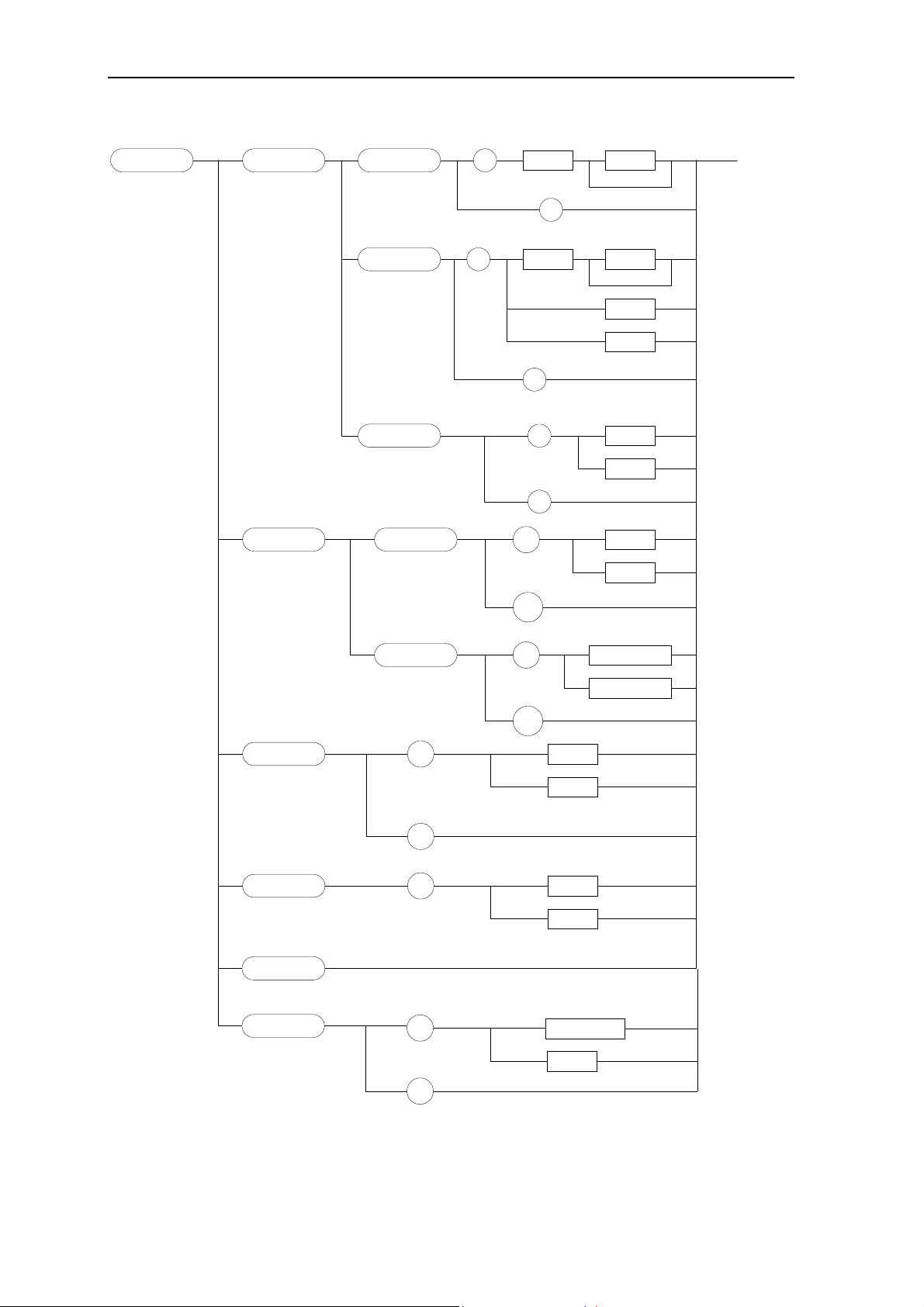

Table of Contents

PART 1: Operation

1. General Information ................................................................................................ 1-1

1.1 Introduction ........................................................................................................ 1-1

1.2 Description ......................................................................................................... 1-1

1.3 Overview of Key Features.................................................................................. 1-2

1.4 Specifications ..................................................................................................... 1-2

2. Installation ................................................................................................................ 2-1

2.1 Introduction ........................................................................................................ 2-1

2.2 Inspection ........................................................................................................... 2-1

2.3 Installing the Modules........................................................................................ 2-1

2.3.1 Channel Number ........................................................................................ 2-2

2.4 Installing the Mainframe .................................................................................... 2-3

2.4.1 Changing Line Voltage .............................................................................. 2-3

2.4.2 Turn-On Self-Test ...................................................................................... 2-4

2.5 Application Connection ..................................................................................... 2-5

2.5.1 Load Connections....................................................................................... 2-5

2.5.2 Remote Sensing Connections..................................................................... 2-6

2.5.3 Parallel Connections................................................................................... 2-6

2.6 Remote Control Connection............................................................................... 2-7

3. Operation Overview................................................................................................. 3-1

3.1 Introduction ........................................................................................................ 3-1

3.2 Front Panel Description...................................................................................... 3-1

3.3 Rear Panel Description....................................................................................... 3-2

3.4 Local/Remote Control........................................................................................ 3-3

3.5 Modes of Operation............................................................................................ 3-3

3.5.1 Constant Current Mode .............................................................................. 3-4

3.5.2 Constant Resistance Mode ......................................................................... 3-7

3.5.3 Constant Voltage Mode.............................................................................. 3-8

3.6 Load Synchronization ........................................................................................ 3-8

3.7 Measurements..................................................................................................... 3-9

3.8 Slew Rate & Minimum Transient Time............................................................. 3-9

3.9 Start/Stop Sink Current ...................................................................................... 3-9

3.10 Short On/Off..................................................................................................... 3-10

3.11 Load On/Off ..................................................................................................... 3-11

3.12 Protection Features........................................................................................... 3-11

3.13 Save/Recall Setting .......................................................................................... 3-12

3.14 Program ............................................................................................................ 3-12

4. Local Operation........................................................................................................ 4-1

4.1 Introduction ........................................................................................................ 4-1

4.2 Local Operation of Load Mainframe ................................................................. 4-1

4.2.1 Selecting the Channel................................................................................. 4-3

4.2.2 Setting the Operation Mode ....................................................................... 4-3

4.2.3 Setting the Program.................................................................................... 4-7

4.2.4 Running the Program ................................................................................. 4-9

4.2.5 Setting the Specification .......................................................................... 4-10

vii

Page 8

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

4.2.6 Setting the Configuration ......................................................................... 4-10

4.2.7 Recalling Files.......................................................................................... 4-15

4.2.8 Saving File/Default/Program.................................................................... 4-15

4.2.9 Going To Local ........................................................................................ 4-15

4.2.10 Lock Operation......................................................................................... 4-16

4.2.11 Setting System and RS-232C Connection................................................ 4-16

4.2.12 Connecting the GO/NG Output Port ........................................................ 4-16

4.2.13 Setting the GPIB Address ........................................................................ 4-17

4.3 Local Operation of Load Module..................................................................... 4-17

4.3.1 Local Operation of Single Channel/Module (Panel A)............................ 4-18

4.3.2 Local Operation of Double Channels/Module (Panel B)......................... 4-20

4.3.3 Online Change Level................................................................................ 4-22

PART 2: Programming

5. General Information for Programming ................................................................. 5-1

5.1 Introduction ........................................................................................................ 5-1

5.2 DIP Switches on the GPIB Card ........................................................................ 5-1

5.2.1 GPIB Address............................................................................................. 5-1

5.2.2 Other DIP Switches.................................................................................... 5-2

5.3 GPIB Capability of the Electronic Load ............................................................ 5-2

5.4 RS232C in Remote Control................................................................................ 5-3

6. Introduction to Programming................................................................................. 6-1

6.1 Basic Definition.................................................................................................. 6-1

6.2 Numerical Data Formats .................................................................................... 6-1

6.3 Character Data Formats...................................................................................... 6-2

6.4 Separators and Terminators................................................................................ 6-3

7. Language Dictionary................................................................................................ 7-1

7.1 Common Commands.......................................................................................... 7-1

7.2 Specific Commands............................................................................................ 7-5

7.2.1 ABORT Subsystem .................................................................................... 7-5

7.2.2 CHANNEL Subsystem .............................................................................. 7-6

7.2.3 CONFIGURE Subsystem........................................................................... 7-8

7.2.4 CURRENT Subsystem ............................................................................. 7-12

7.2.5 FETCH Subsystem................................................................................... 7-15

7.2.6 LOAD Subsystem .................................................................................... 7-16

7.2.7 MEASURE Subsystem ............................................................................ 7-19

7.2.8 MODE Subsystem.................................................................................... 7-21

7.2.9 PROGRAM Subsystem............................................................................ 7-22

7.2.10 RESISTANCE Subsystem ....................................................................... 7-27

7.2.11 RUN Subsystem ....................................................................................... 7-28

7.2.12 SHOW Subsystem.................................................................................... 7-28

7.2.13 SPECIFICATION Subsystem .................................................................. 7-29

7.2.14 STATUS Subsystem ................................................................................ 7-32

7.2.15 VOLTAGE Subsystem............................................................................. 7-36

8. Status Reporting....................................................................................................... 8-1

8.1 Introduction ........................................................................................................ 8-1

8.2 Register Information in Common ...................................................................... 8-1

viii

Page 9

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

8.3 Channel Status.................................................................................................... 8-3

8.4 Channel Summary.............................................................................................. 8-3

8.5 Questionable Status............................................................................................ 8-4

8.6 Output Queue ..................................................................................................... 8-4

8.7 Standard Event Status ........................................................................................ 8-4

8.8 Status Byte register ............................................................................................ 8-5

8.9 Service Request Enable register......................................................................... 8-6

9. An Example of Use ................................................................................................... 9-1

ix

Page 10

Page 11

PART 1

Operation

Page 12

Page 13

General Information

1. General Information

1.1 Introduction

This manual contains specifications, installation, operation, and programming instructions of

6314, 6312 electronic load mainframes as well as 63102, 63103, 63105 ... electronic load

modules. Here “Load” means the electronic load modules of Chroma 6310 series while

“Mainframe” the 6314, 6312 electronic load mainframes.

1.2 Description

The functions of 6314 and 6312 mainframes are the same. The former has four slots for

Load modules while the latter two slots. The functions of 63102, 63103, 63105, etc. are all

the same. The differences are in input voltage, load current, and power ratings. An

individual module may have one or two channels. Each channel has its own channel number,

load & measurement connectors, and operates independently in constant current (CC) mode,

constant resistance (CR) mode, or constant voltage (CV) mode.

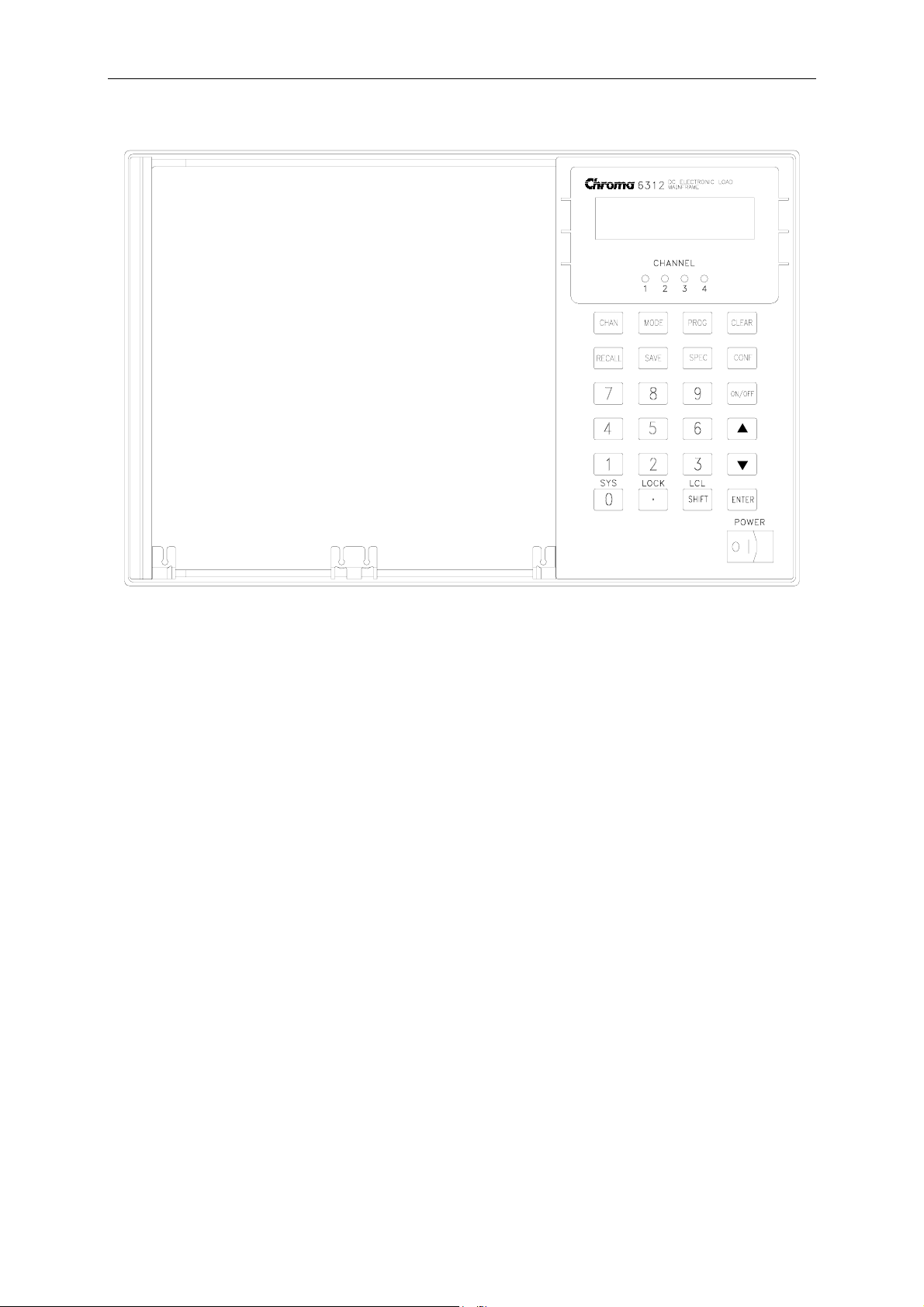

Figure 1-1 The Front Panel of the Electronic Load

On the front panel of the electronic load as shown in Figure 1-1 there are two groups of

keypads. One is the Mainframe keypad. The other is the Load keypad. In this manual,

Mainframe keypad is described as

MODE while Load keypad as SHORT.

1-1

Page 14

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

1.3 Overview of Key Features

A. Configuration

• Flexible configuration using plug-in electronic load modules to mainframes.

• Local operation on front panel keypad.

• Remote control via GPIB or RS-232C interface.

• Photocoupler isolation to offer true floating Load.

• Automatic fan speed control to reduce noise.

• Up to 8 channels for one Mainframe.

B. Load

• Constant current (CC), constant resistance (CR) and constant voltage (CV)

operation modes.

• Programmable slew rate, load levels, load periods and conduct voltage (Von).

• Programmable dynamic loading with speed up to 20KHz.

• Minimum input resistance allows load to sink high current even with low input

voltage (1 V).

• Selective voltage and current ranges.

• Remote sensing capability.

• 100 sets of memories to save/recall user-definable setups.

• 10 sets of programs to link files for automatic test.

• 15-bit A/D converter with precision measurement.

• Short circuit simulation.

• Automatic GO/NG inspection to confirm UUT within spec.

• Independent GO/NG signals for each channel.

1.4 Specifications

Mainframe : 6314/6312

AC input : 115/230 switchable or 100/200 switchable Vac line

Fuse : 5A, 250V/2A, 250V

Amplitude : ±10%

Frequency : 47 to 63 Hz

Maximum VA : 180VA/100VA

Trigger output : Vlo = 0.8V maximum at Ilo = 1 mA

Vhi = 3.2V minimum at Ihi = −40µA

Weight : 24Kg/15Kg

Dimension :

Width : 440mm/275mm

Height : 177.4 mm (excluding feet)

186mm (including feet)

Depth : 560mm (including Load module)

∗ The specifications of Load are listed below.

LNotice

1-2

Page 15

General Information

1. All specifications are tested under 20°C ∼ 30°C except otherwise stated.

2. The range of operation temperature is 0°C ∼ 40°C.

3. The specifications of DC current accuracy are tested after the input is applied for 30

seconds.

4. The power of the load module of 6310 series is supplied from 6314/6312 mainframe.

5. The typical temperature coefficient is 100ppm.

6. The specifications of CR mode accuracy: v means 1/ohm.

1-3

Page 16

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

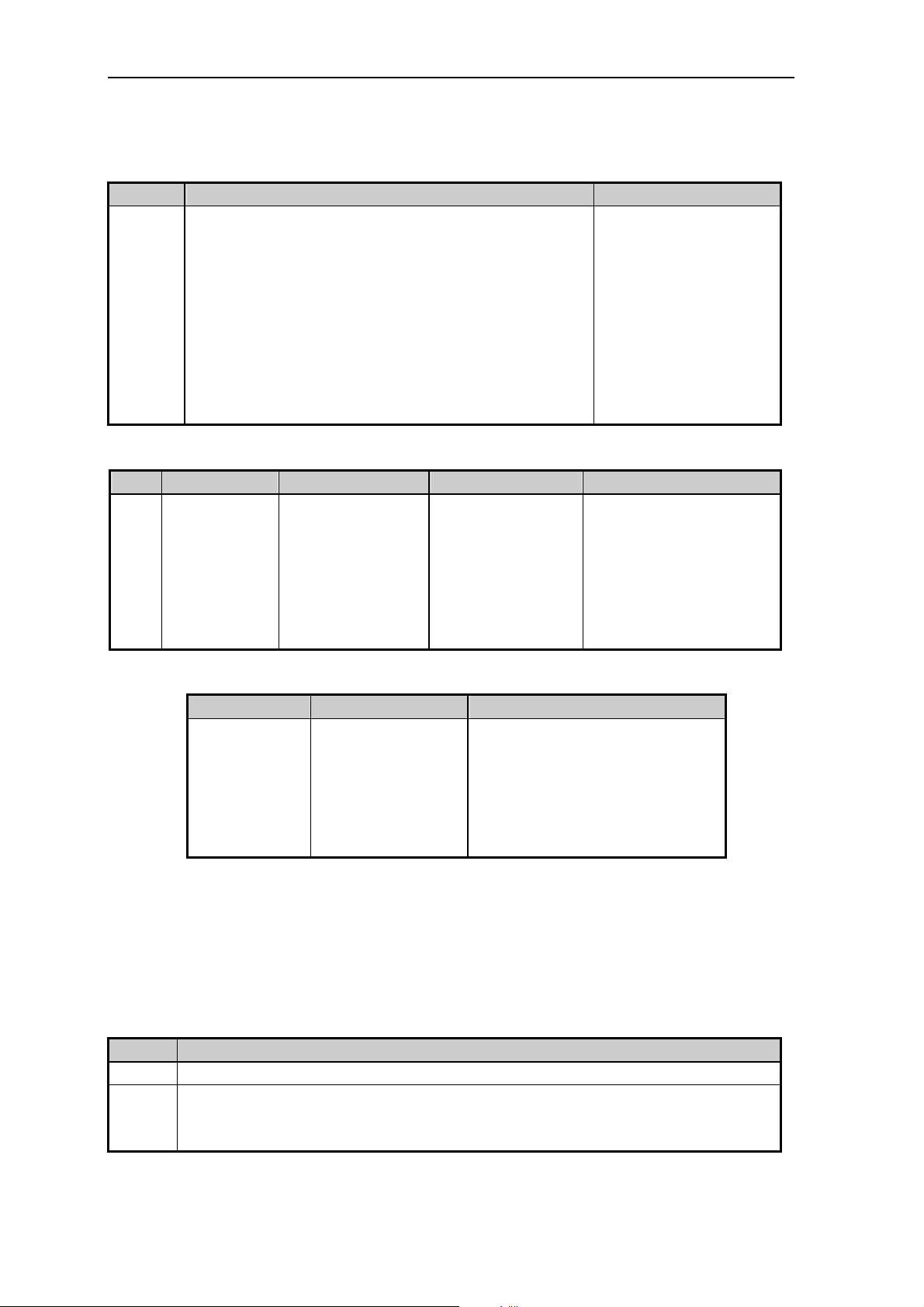

MODEL 63101 63105

POWER

CURRENT

VOLTAGE

MIN. OPERATING VOLTAGE

(DC)

CONSTANT CURRENT MODE

Range

Resolution 1mA 10mA 0.25mA 2.5mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.2%F.S. 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CONSTANT RESISTANCE

MODE

Range

Resolution 12 bits 12 bits

Accuracy

CONSTANT VOLTAGE MODE

Range

Resolution 20mV 125mV

Accuracy

20W 200W 30W 300W

0∼4A 0∼40A 0∼1A 0∼10A

1∼80V 2.5∼500V

1.0V at 4A 1.0V at 40A 2.5V at 1A 2.5V at 10A

0∼4A 0∼40A 0∼1A 0∼10A

0.0375Ω∼150Ω (200W/16V)

1.875Ω∼7.5KΩ (200W/80V)

150Ω : 0.1v+0.2%

7.5KΩ : 0.01v+0.1%

1∼80V 2.5∼500V

0.05%±0.1%F.S. 0.05%±0.1%F.S.

1.25Ω∼5KΩ (300W/125V)

50Ω∼200KΩ (300W/500V)

5KΩ : 20mv+0.2%

200KΩ : 5mv+0.1%

DYNAMIC MODE

DYNAMIC MODE

T1 & T2

Accuracy

Slew Rate

Resolution

Current

Resolution 1mA 10mA 0.25mA 2.5mA

Current Accuracy 0.4% F.S. 0.4% F.S.

0.64∼160mA/µS 6.4∼1600mA/µS 0.16∼40mA/µS 1.6∼400mA/µS

0.64mA/µS 6.4mA/µS 0.16mA/µS 1.6mA/µS

C.C. MODE C.C. MODE

0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

1µS /1mS+100ppm 1µS /1mS+100ppm

0∼4A 0∼40A 0∼1A 0∼10A

0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

MEASUREMENT SECTION

VOLTAGE READ BACK

Range

Resolution 0.5mV 2.5mV 4mV 16mV

Accuracy 0.05%+0.05% F.S. 0.05%+0.05% F.S.

CURRENT READ BACK

Range

Resolution 0.125mA 1.25mA 4mA 16mA

Accuracy 0.1%+0.1% F.S. 0.1%+0.1% F.S.

0∼16V 0∼80V 0∼125V 0∼500V

0∼4A 0∼40A 0∼1A 0∼10A

PROTECTIVE SECTION

Over Power Protection

Over Current Protection

Over Temperature Protection

Over Voltage Protection

≒20.8W

≒4.08A

≒85°C

≒81.6V

≒208W

≒40.8A

≒31.2W

≒1.02A

≒85°C

≒510V

≒312W

≒10.2A

GENERAL

SHORT CIRCUIT

Current (CC)

Voltage (CV) 0V 0V 0V 0V

Resistance (CR)

INPUT RESISTANCE (LOAD

OFF)

SIZE

WEIGHT (Approx.)

EMC & SAFETY

≒4.4/4A

≒1.875Ω

100KΩ (Typical) 100KΩ (Typical)

81(W)× 172(H)×495(D) 81(W)× 172(H)×495(D)

≒44/40A

≒0.0375Ω

4.2Kg 4.2Kg

CE CE

≒1.1/1A

≒50Ω

≒11/10A

≒1.25Ω

1-4

Page 17

General Information

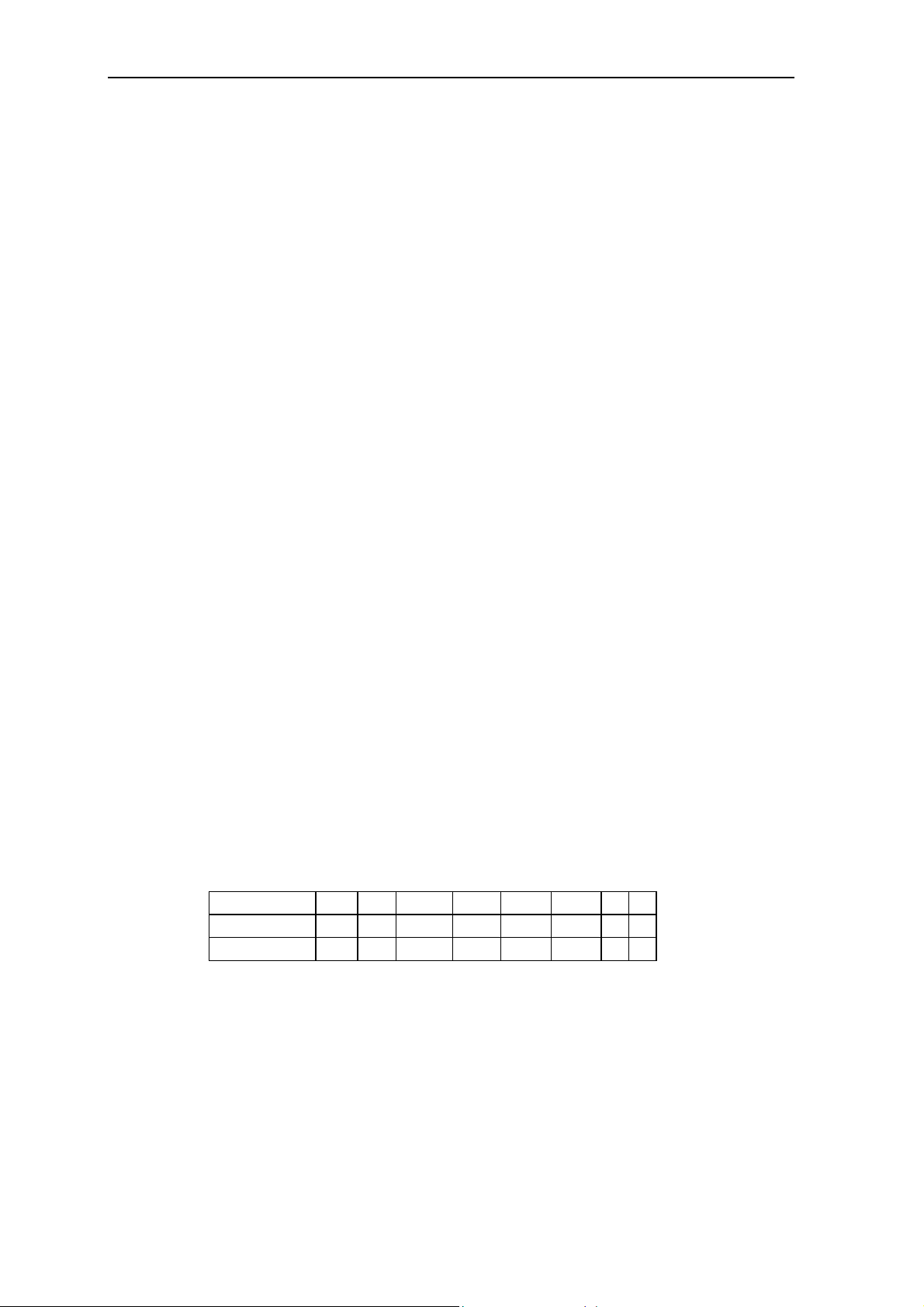

MODEL 63102(100W*2) 63103

POWER

CURRENT

VOLTAGE

MIN. OPERATING VOLTAGE

(DC)

CONSTANT CURRENT MODE

Range

Resolution 0.5mA 5mA 1.5mA 15mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.2%F.S. 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CONSTANT RESISTANCE

MODE

Range

Resolution 12 bits 12 bits

Accuracy

CONSTANT VOLTAGE MODE

Range

Resolution 20mv 20mv

Accuracy

20W 100W 30W 300W

0∼2A 0∼20A 0∼6A 0∼60A

1∼80V 1∼80V

1.0V at 2A 1.0V at 20A 1.0V at 6A 1.0V at 60A

0∼2A 0∼20A 0∼6A 0∼60A

0.075Ω∼300Ω (100W/16V)

3.75Ω∼15KΩ (100W/80V)

300Ω : 0.1v+0.2%

15KΩ : 0.01v+0.1%

1∼80V 2.5∼500V

0.05%±0.1%F.S. 0.05%±0.1%F.S.

0.025Ω∼100Ω (300W/16V)

1.25Ω∼5KΩ (300W/80V)

100Ω : 0.1v+0.2%

5KΩ : 0.01v+0.1%

DYNAMIC MODE

DYNAMIC MODE

T1 & T2

Accuracy

Slew Rate

Resolution

Current

Resolution 0.5mA 5mA 1.5mA 15mA

Current Accuracy 0.4% F.S. 0.4% F.S.

0.32∼80mA/µS 3.2∼800mA/µS 0.001∼0.25A/µS 0.01∼2.5A/µS

0.32mA/µS 3.2mA/µS 0.001A/µS 0.01A/µS

C.C. MODE C.C. MODE

0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

1µS /1mS+100ppm 1µS /1mS+100ppm

0∼2A 0∼20A 0∼6A 0∼60A

0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

MEASUREMENT SECTION

VOLTAGE READ BACK

Range

Resolution 0.5mV 2.5mV 0.5mV 2.5mV

Accuracy 0.05%+0.05% F.S. 0.05%+0.05% F.S.

CURRENT READ BACK

Range

Resolution 0.0625mA 0.625mA 0.1875mA 1.875mA

Accuracy 0.1%+0.1% F.S. 0.1%+0.1% F.S.

0∼16V 0∼80V 0∼16V 0∼80V

0∼2A 0∼20A 0∼6A 0∼60A

PROTECTIVE SECTION

Over Power Protection

Over Current Protection

Over Temperature Protection

Over Voltage Protection

≒20.8W

≒2.04A

≒85°C

≒81.6V

≒104W

≒20.4A

≒31.2W

≒6.12A

≒85°C

≒81.6V

≒312W

≒61.2A

GENERAL

SHORT CIRCUIT

Current (CC)

Voltage (CV) 0V 0V 0V 0V

Resistance (CR)

INPUT RESISTANCE (LOAD

OFF)

SIZE

WEIGHT (Approx.)

EMC & SAFETY

≒2.2/2A

≒3.75Ω

100KΩ (Typical) 100KΩ (Typical)

81(W)× 172(H)×495(D) 81(W)× 172(H)×495(D)

≒22/20A

≒0.075Ω

4.2Kg 4.2Kg

CE CE

≒6.6/6A

≒1.25Ω

≒66/60A

≒0.025Ω

1-5

Page 18

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

MODEL 63107(30W,250W) 63106

POWER

CURRENT

VOLTAGE

MIN. OPERATING

VOLTAGE (DC)

CC MODE Range

Resolution 1.25mA 1mA 10mA 3mA 30mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.1%F.S. 0.1%+0.2%F.S. 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CR MODE Range

Resolution 12 bits 12 bits 12 bits

Accuracy

CV MODE Range

Resolution 20mV 20mV

Accuracy

30W 30W 250W 60W 600W

0∼5A 0∼4A 0∼40A 0∼12A 0∼120A

1∼80V 1∼80V

1.0V at 5A 1.0V at 4A 1.0V at 40A 1.0V at 12A 1.0V at 120A

0∼5A 0∼4A 0∼40A 0∼12A 0∼120A

0.3Ω∼1.2KΩ (30W/16v)

15Ω∼60KΩ (30W/80v)

12KΩ : 0.1v+0.2%

60KΩ : 0.01v+0.1%

0.05%±0.1%F.S. 0.05%±0.1%F.S.

0.375Ω∼150Ω (250W/16v)

1.875Ω∼7.5KΩ (250W/80v)

150Ω : 0.1v+0.2%

7.5KΩ : 0.01v+0.1%

1∼80V 1∼80V

12.5mΩ∼50Ω (600W/16v)

0.625Ω∼2.5KΩ (600W/80v)

50Ω : 0.1v+0.5%

2.5KΩ : 0.01v+0.2%

DYNAMIC MODE

DYNAMIC MODE

T1 & T2

Accuracy

Slew Rate

Resolution

Current

Resolution 1.25mA 1mA 10mA 3mA 30mA

Current Accuracy 0.4% F.S. 0.4% F.S.

0.8∼200mA/µS 0.64∼160mA/µS6.4∼1600mA/µS 0.002∼0.5A/µS 0.02∼5A/µS

0.8mA/µS 0.64mA/µS 6.4mA/µS 0.002A/µS 0.02A/µS

0∼5A 0∼4A 0∼40A 0∼12A 0∼120A

C.C. MODE C.C. MODE

0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

1µS /1mS+100ppm 1µS /1mS+100ppm

0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

MEASUREMENT SECTION

VOLTAGE READ

BACK

Range

Resolution 0.5mV 2.5mV 0.5mV 2.5mV 0.5mV 2.5mV

Accuracy 0.05%+0.05% F.S. 0.05%+0.05% F.S.

CURRENT READ

BACK

Range

Resolution 0.15625mA 0.125mA 1.25mA 0.375mA 3.75mA

Accuracy 0.1%+0.1% F.S. 0.1%+0.1% F.S.

0∼16V 0∼80V 0∼16V 0∼80V 0∼16V 0∼80V

0∼5A 0∼4A 0∼40A 0∼12A 0∼120A

PROTECTIVE SECTION

Over Power Protection

Over Current Protection

Over Temperature

Protection

Over Voltage Protection

≒31.2W

≒5.1A

≒31.2W

≒4.08A

≒85°C

≒81.6V

≒260W

≒40.8A

≒62.4W

≒12.24A

≒85°C

≒81.6V

≒624W

≒122.4A

GENERAL

SHORT CIRCUIT

Current (CC)

Voltage (CV) 0V 0V 0V 0V 0V

Resistance (CR)

INPUT

RESISTANCE

(LOAD OFF)

SIZE

WEIGHT (Approx.)

EMC & SAFETY

≒5.5/5A

≒15Ω ≒0.3Ω ≒1.875Ω

≒4.4/4A

100KΩ (Typical) 100KΩ (Typical)

81(W)× 172(H)×495(D) 162(W)× 172(H)×495(D)

4.2Kg 8.4Kg

CE CE

≒44/40A

≒0.0375Ω

≒13.2/12A ≒132/120A

≒0.625Ω

≒0.0125Ω

1-6

Page 19

General Information

MODEL 63108 63112

POWER

CURRENT

VOLTAGE

MIN. OPERATING VOLTAGE

(DC)

CONSTANT CURRENT MODE

Range

Resolution 0.5mA 5mA 6mA 60mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.2%F.S. 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CONSTANT RESISTANCE

MODE

Range

Resolution 12 bits 12 bits

Accuracy

CONSTANT VOLTAGE MODE

Range

Resolution 125mV 20mV

Accuracy

60W 600W 120W 1200W

0∼2A 0∼20A 0∼24A 0∼240A

2.5∼500V 1∼80V

2.5V at 2A 2.5V at 20A 1.0V at 24A 1.0V at 240A

0∼2A 0∼20A 0∼24A 0∼240A

0.625Ω∼2.5KΩ (600W/125V)

25Ω∼100KΩ (600W/500V)

2.5KΩ : 50mv+0.2%

100KΩ : 5mv+0.1%

2.5∼500V 1∼80V

0.05%±0.1%F.S. 0.05%±0.1%F.S.

6.25mΩ∼25Ω (1200W/16V)

0.3125Ω∼1.25KΩ (1200W/80V)

25Ω : 0.1v+0.8%

1.25KΩ : 0.01v+0.2%

DYNAMIC MODE

DYNAMIC MODE

T1 & T2

Accuracy

Slew Rate

Resolution

Current

Resolution 0.5mA 5mA 6mA 60mA

Current Accuracy 0.4% F.S. 0.4% F.S.

0.32∼80mA/µS 3.2∼800mA/µS 0.004∼1A/µS 0.04∼10A/µS

0.32mA/µS 3.2mA/µS 0.004A/µS 0.04A/µS

C.C. MODE C.C. MODE

0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

1µS /1mS+100ppm 1µS /1mS+100ppm

0∼2A 0∼20A 0∼24A 0∼240A

0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

MEASUREMENT SECTION

VOLTAGE READ BACK

Range

Resolution 4mV 16mV 0.5mV 2.5mV

Accuracy 0.05%+0.05% F.S. 0.05%+0.05% F.S.

CURRENT READ BACK

Range

Resolution 0.0625mA 0.625mA 0.75mA 7.5mA

Accuracy 0.1%+0.1% F.S. 0.15%+0.15% F.S.

0∼125V 0∼500V 0∼16V 0∼80V

0∼2A 0∼20A 0∼24A 0∼240A

PROTECTIVE SECTION

Over Power Protection

Over Current Protection

Over Temperature Protection

Over Voltage Protection

≒62.4W

≒2.04A

≒85°C

≒510V

≒624W

≒20.4A

≒124.8W

≒24.48A

≒85°C

≒81.6V

≒1248W

≒244.8A

GENERAL

SHORT CIRCUIT

Current (CC)

Voltage (CV) 0V 0V 0V 0V

Resistance (CR)

INPUT RESISTANCE (LOAD

OFF)

SIZE

WEIGHT (Approx.)

EMC & SAFETY

≒2.2/2A

≒25Ω

100KΩ (Typical) 100KΩ (Typical)

162(W)× 172(H)×495(D) 324(W)× 172(H)×495(D)

≒22/20A

≒0.625Ω

8.4Kg 16.8Kg

CE CE

≒26.4/24A

≒0.3125Ω

≒264/240A

≒0.00625Ω

1-7

Page 20

Page 21

Installation

2. Installation

2.1 Introduction

This chapter discusses how to install the Load to Mainframe and make connections to the

Loads. It discusses a turn-on check procedure and application considerations as well.

2.2 Inspection

As soon as the instrument is unpacked inspect any damage that might have occurred in

shipping. Keep all packing materials in case that the Load or the Mainframe has to be

returned. If any damage is found, please file a claim with the carrier immediately. Do not

return the instrument to Chroma without prior approval.

In addition to this manual, be sure that the following items have also been received with your

Mainframe and Load.

Mainframe: Power Cord, Manual

Load Module: Measurement and Load Cables

2.3 Installing the Modules

a CAUTION

Load module can be damaged by electronic discharge (static electricity). Use standard

anti-static work practices when you handle and install modules. Avoid touching the

connector and the circuit board.

The Chroma 6314 Mainframe has room for four single-width Loads (63102, 63103), or two

double-width Loads (63106). Loads can be combined in the Mainframe in any order. The

Chroma 6312 mainframe has room only for two single-width Loads or one double-width

Load. The procedures of the module installation in both Mainframes are the same. Only

the screwdriver is required in installing Load to Mainframe.

Procedures:

1. Disconnect the power cord with the Mainframe power off.

2. Remove any packing materials from the Mainframe.

3. Start installing the modules in the slot (see Figure 2-1).

4. Plug the load module into the slot of the Mainframe along the rail.

5. Lock the module in place by use of the screwdriver (see Figure 2-1).

6. Install each additional module in the slot next to the previous one likewise if applicable.

2-1

Page 22

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

Figure 2-1 Installing Modules in the Electronic Load

" WARNING

If the Mainframe is not installed with all modules, the empty module position must be

installed with the panel cover (Chroma part No: L00 000190) for safety and airflow.

2.3.1 Channel Number

The channel number of a specific Load is determined by the location of that module in

relation to the farthest left side of Mainframe. Because some Load (63102) has two

channels in one module, channel 1 and 2 are always on the farthest left slot of the Mainframe,

and channel 7 and 8 on the farthest right. The channel number is fixed for Mainframe even

Load module is empty. Figure 2-2 shows the channel assignments for a Chroma 6314

Mainframe containing two Loads of 63103 single channel/module, and two Loads of 63102

double channel/module. Channel number is automatically assigned to each channel: 1, 3, 5,

6, 7, 8. At this moment channel 2 and 4 are empty. 6312 Mainframe has only four

channels (1, 2, 3, 4).

2-2

Page 23

Installation

Figure 2-2 Channel Number Example

2.4 Installing the Mainframe

The electronic Load can operate well within temperature range of 0 to 40 degree C.

However, you must install the electronic Load in a location that has enough space at the top,

four sides, and the rear of the unit for adequate air flowing through and escaping from the

back. You must leave at least 3 cm (1 inch) space above the unit for adequate air circulation.

Note that the feet of the unit have enough vertical space for air circulation when it is stacked.

The feet of the Mainframe can be removed for rack mounting.

If you install equipment on top of your electronic Load in the cabinet, you must use a filter

panel above the unit to ensure adequate air circulation. A 1U (EIA standard) panel is

sufficient.

2.4.1 Changing Line Voltage

The electronic Load can operate with a 115/230 Vac input as indicated on the rear LINE label.

The 100/200 line voltage input model is used only in Japan. If the factory set switch on this

label does not correspond to your nominal line voltage, turn the Mainframe power off, and

disconnect the power cord. Set switch to the correct line voltage as shown in Figure 2-3.

L Notice

Line fuses do not need to be changed when the line voltage is changed. The line fuses will

protect the electronic Load in any indicated voltage setting.

2-3

Page 24

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

Figure 2-3 Line Voltage Switch

2.4.2 Turn-On Self-Test

Before turning on the Load check the following things.

1. The unit has been factory set to the correct line voltage. Refer to line voltage on the

rear panel.

2. The power cord is connected to the AC input socket.

" WARNING

The power provides a chassis ground through a third connector. Be sure that your outlet is

of three-conductor type with the correct pin connected to earth ground.

Turn on the Load by the power switch on the front panel of the Mainframe and observe the

display. Immediately after turning on, the electronic Load executes a self-test which checks

the GPIB interface board and the input circuitry of the installed modules. All of the LED

segments on the front panel are momentarily activated. The Mainframe displays

and then displays

LOAD MODULE

CHANNEL SCANing

The LCD displays the GPIB address in power-on condition. The GPIB address switch is on

the rear panel if the GPIB card is installed. If the GPIB card is not installed, the LCD will

show LOAD MODULE CHANNEL SCANing. Mainframe checks the existing channels when

the display is CHANNEL SCANing. The LED segment on the front panel are momentarily

activated. If the Mainframe fails any portion of the self-test, the LED will blink, and the

LCD has no display. When self-test completes, the Mainframe will display the active

channel, which is installed.

The Load module also executes a self-test that checks firmware and communication with

Mainframe. All of the LEDs on the front panel are momentarily activated, and the

7-segment LED displays model number as well as firmware version. If any error is found in

self-test, the display will stick here. Check the Load and Mainframe connection when an

error occurs. When the self-test completes, the 7-segment will display measurement V & I.

GPIB ADDRESS = 1

2-4

Page 25

The double channel/module goes to L channel.

Installation

Figure 2-4 Module Panel Self-test Display

In case of failure return the Mainframe or Load module to Chroma sales or service office for

repair.

63103 < --- Model Number

1.02 < --- F/W version

2.5 Application Connection

2.5.1 Load Connections

WARNING

"

To satisfy safety requirements, load wires must be heavy enough not to overheat while

carrying the short-circuit output current of the device connected to the electronic Load.

Before connecting load wires to Load module, remove the terminal cover from the Load.

Install it after load wires are connected. Input connections are made to the + and − terminal

block on the front of each Load module. The major considerations in making input

connections are the wire size, length and polarity. The minimum wire size required to

prevent overheating may not be enough to maintain good regulation. The wires should be

large enough to limit the voltage drop to no more than 0.5V per lead. The wires should be as

short as possible, and bundled or tied together to minimize inductance and noise picked up

from them. Connect the wire from the PLUS (+) terminal on the module to the HIGH

potential output terminal of the power supply (UUT). Connect the wire from the MINUS (−)

terminal on the module to the LOW potential output terminal of the power supply (UUT).

Figure 2-5 illustrates the typical setup for the Load module to the UUT.

" WARNING

To prevent accidental contact with hazardous voltage, cover of terminal must be installed

correctly. Each terminal can carry 40 Amps at most. If the input current of Load is over 40

Amps, you must use multiple terminals of connections.

2-5

Page 26

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

Figure 2-5 Load & Remote Sensing Connection

2.5.2 Remote Sensing Connections

There are two sensing points for the electronic Load module. One is measurement at Load,

terminal, and another is measurement at Vsense. The Load module will automatically

switch to Vsense when Vsense terminals are connected to UUT, otherwise it will measure at

Load terminals. Remote sensing compensates for voltage drop in applications that require

long lead lengths. It is useful when a module is operating in CV or CR mode, or when it

needs precise measurement. Figure 2-5 also illustrates a typical setup for remote sensing

operation.

LNotice

The potential of Vsense red connector must be higher than that of Vsense black connector.

2.5.3 Parallel Connections

Figure 2-6 illustrates how modules can be paralleled for increased power dissipation.

Modules can be directly paralleled in CC, CR modes of static operation, but cannot be

paralleled in CV mode. Each module will dissipate the power it has been programmed.

For example, if two modules are connected in parallel, one is programmed 10A, and another

15A, the total current drawn from the source is 25A.

2-6

Page 27

Installation

Figure 2-6 Parallel Connection

2.6 Remote Control Connection

The remote operation of Load can be done through GPIB or RS-232C. These connectors on

the rear panel connect the Load to the controller or computer. The GPIB interface of the

electronic load is optional. The 6310 series Remote Controller can control load through

RS-232C port. Connect Remote Controller to the electronic Load before powering on. If

you have not done thus, Load will shut down, or fuse for remote controller in Mainframe will

be broken.

2-7

Page 28

Page 29

Operation Overview

3. Operation Overview

3.1 Introduction

The Chroma 6314 and 6312 multiple electronic load mainframes are used for design,

manufacturing, testing and quality assurance. The Mainframe contains four (two) slots for

load modules. Load modules occupy either one or two slots. It depends on the power

rating of the module. The Mainframe can dissipate up to 1200 watts when it is full loaded.

It contains a processor, GPIB and RS-232C connectors, front panel keypad and display, and

PASS/FAIL signals. Built-in remote control function allows you to control, read back

current, voltage and status. The SYNC function of the Mainframe synchronizes each

module when module current/voltage level changes. Save/Recall feature allows you to save

up to 100 files, 10 programs, and one default setting. All of them can be saved in

Mainframe EEPROM for future use.

The Mainframe contains three (two) cooling fans, and the module one cooling fan. The fan

speed can automatically increase or decrease when the module power rises or falls. This

feature reduces overall noise level because the fans do not always run at the maximum speed.

Each module can operate independently in constant current (CC), constant resistance (CR),

and constant voltage (CV) modes. An individual module may have one or two channels.

Each of them has its own channel number, contains its own input connectors, and can be

turned on/off or short-circuited independently. If your application requires a greater power

or current capacity than one module can provide, you have to connect load modules in

parallel in CC or CR mode.

Each load module can be independently controlled either remotely via GPIB/RS-232C or

locally via the front panel. Once a channel is selected or addressed, all subsequent

commands go to that channel till another channel is selected or addressed. Operation of all

models in the Mainframe is similar in spite of power ratings. The module has a keypad to

control itself too.

3.2 Front Panel Description

The front panel of Mainframe includes a 16 × 2 character LCD display, 8 (4) channel

indicators, and keypads. All parameters of Load are set through Mainframe. The LCD

display also shows which function is being performed when you use the keypads. Three of

the keys perform two functions. The alternative function is labeled in blue above the key.

It is selected by pressing the blue

3-1 shows the front panel of Mainframe 6312.

SHIFT key and the function key simultaneously. Figure

3-1

Page 30

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

Figure 3-1 The Front Panel of Mainframe 6312

3.3 Rear Panel Description

The rear panel of Mainframe includes an RS-232C connector, a GO/NG output port, an AC

LINE socket, a fuse holder, an optional GPIB connector, and three cooling fans. Figure 3-2

shows the rear panel of Mainframe 6314.

3-2

Page 31

Operation Overview

Figure 3-2 The Rear Panel of Mainframe 6314

3.4 Local/Remote Control

Local (front panel) control is in effect immediately after power is applied. The front panel

keypad and display allow manual control of individual module when Load is used in bench

test applications. Remote control goes into effect as soon as the Mainframe receives a

command via GPIB or RS-232C. With remote control in effect, only the computer can

control the Load. The front panel keypad has no effect except the

return the Load to local control from remote control by pressing LCL key. The SHIFT key

acts as LCL when Load is in remote state.

Most of the functions that perform remotely can perform locally too at the front panel of

Mainframe. The keypads on the module can perform simple functions like short, load on/off,

static /dynamic, and load A/B or display selection R/L.

Details of local operation are given in Chapter 4 Local Operation. Fundamentals of remote

programming are described in the second part of this manual, Chroma 6310 Programming

Manual.

LCL key. You can

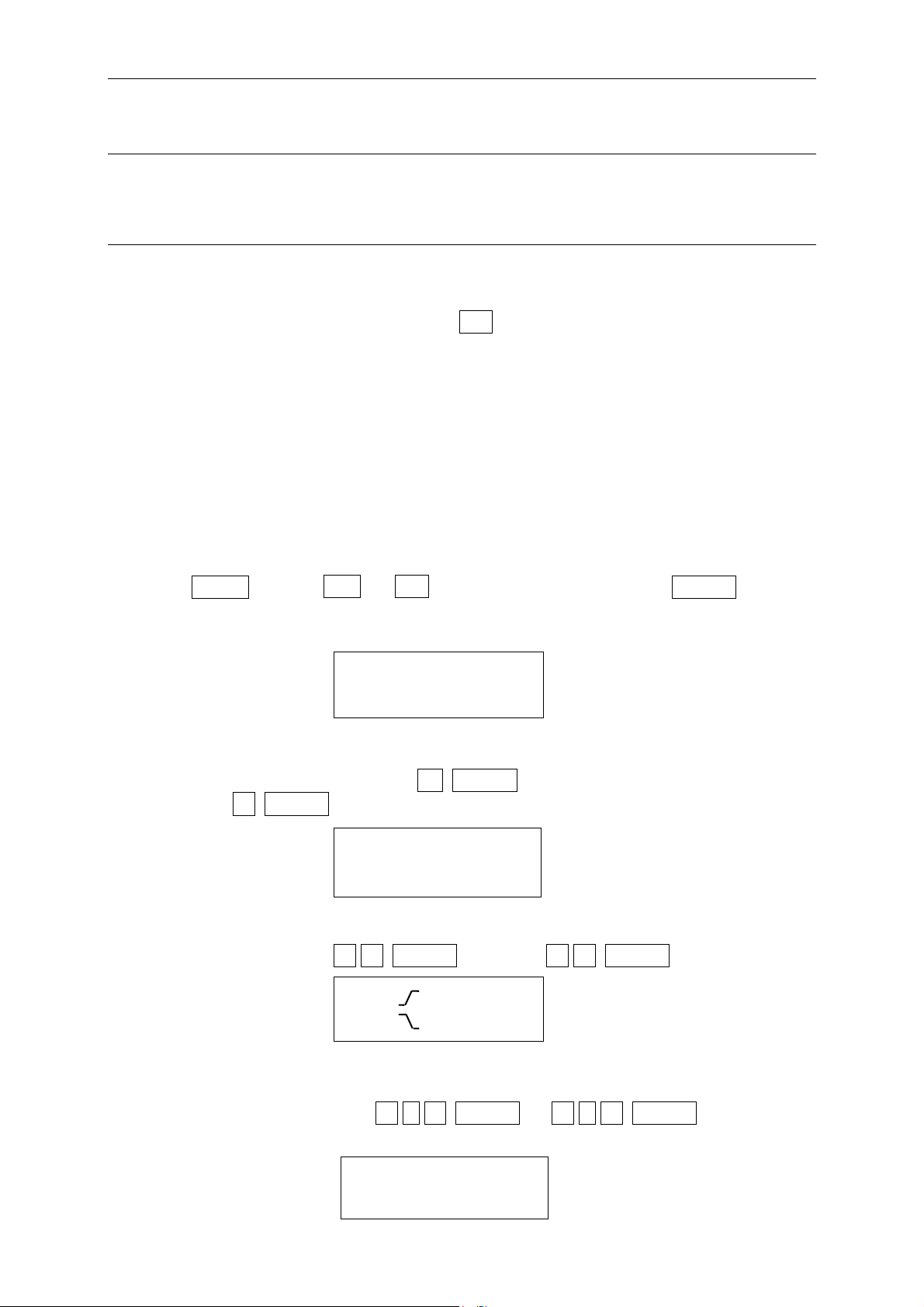

3.5 Modes of Operation

There are three modes of operation: Constant Current (CC), Constant Resistance (CR), and

Constant Voltage (CV).

When you press

change of modes the module’s input is momentarily disabled before a new mode is enabled.

ENTER key to program to a mode, a module will change to a new mode. In

3-3

Page 32

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

This ensures that there will be minimum overshoots in change of modes. The parameters in

current, resistance or voltage mode can be programmed simply as the mode is presently

selected.

All data set in CC/CR/CV mode will be rescaled to fit the resolution of current/voltage levels

or slew rate. In local mode any value can be set to a module from the keypad. There are

no upper and lower limits that would cause an error. Mainframe automatically selects data,

which are rescaled from the programmed value, truncates and checks high, low boundary

before fitting memory. When programmed data are over the boundary, Mainframe will set

maximum or minimum level for the Load module. In remote mode programmed value

cannot be over boundary. An error will occur when data are over the maximum or minimum

value.

3.5.1 Constant Current Mode

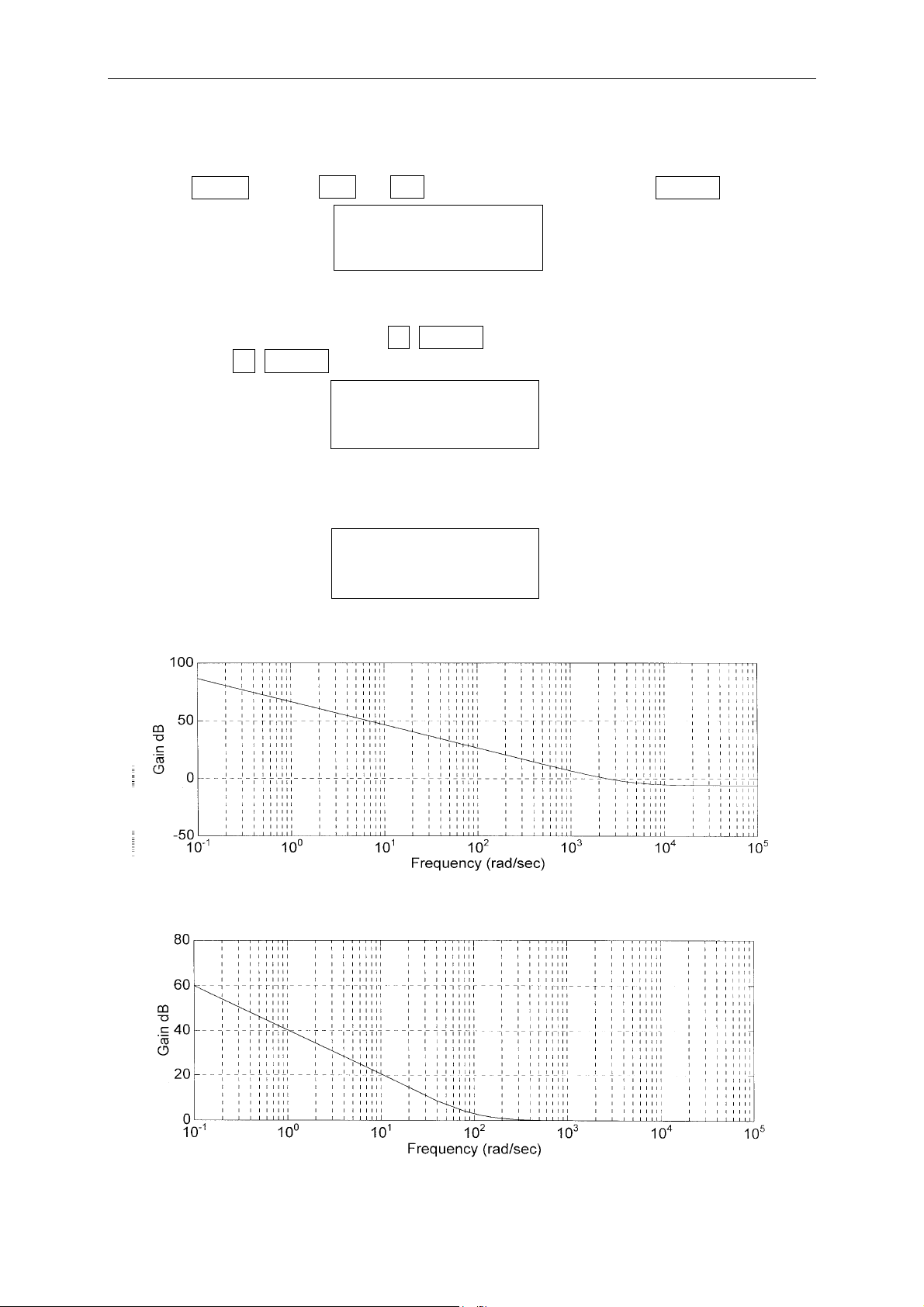

Figure 3-3 Constant Current Mode

In CC mode, the Load will sink a current in accordance with the programmed value

regardless of input voltage. The CC mode can be set with front panel key

MODE. When

MODE SELECT is displayed, it means to select static low range CCL or static high range CCH.

Current Ranges (Low, High)

Current can be programmed in either of the two ranges, low range and high range. The low

range provides better resolution at low current setting. If any value is over the maximum of

low range, you must select the high range. Press

MODE key first, then use ▲ or ▼

key to select the current range.

MODE SELECT

CCL Select Static Constant Current low range

MODE SELECT

3-4

Page 33

Operation Overview

CCH Select Static Constant Current high range

MODE SELECT

CCDL Select Dynamic Constant Current low range

MODE SELECT

CCDH Select Dynamic Constant Current high range

Select range by pressing

ENTER key.

The change of modes will affect the module, so will the change of range. Both cause the

input to go through an off state. If the CC mode of Load module is active, the new setting

will immediately change the input at a rate determined by the slew rate setting.

STATic/DYNAmic Functions

In CC mode two operation functions (STATic, DYNAmic) can be selected. STATic

function checks the stability of output voltage from a power supply. In some modules

(single channel/module) there are two current levels (A or B) for static function. Both states

A and B use the same range. You can select A (CCL1 or CCH1) or B (CCL2 or CCH2)

through the

A/B key on the module’s keypad or Mainframe keypad when level1 (A) or level2

(B) changes. Slew rate determines the rate at which Load level changes from one load level

state to another. Figure 3-3 shows current level of load module after pressing of

A/B key.

CCL1:4A, CCL2:2A, CCL : 0.2A/µS, CCL : 0.08A/µS

Current

rise slew rate

fall slew rate

4A

2A

State A

State B

Time

10uS

Figure 3-4 Load Level after Pressing A/B Key

Dynamic load operation enables you to program two load levels (CCDL1, CCDL2), load

duration (CCDLT1, CCDLT2), and slew rate (CCDL , CCDL ). During operation the

loading level is switched between those two load levels according to your specific setting.

The dynamic load is commonly used in the test of UUT’s performance under transient loading

condition. Figure 3-4 shows current waveform of dynamic function.

CCDL1:4A, CCDL2:2A, CCDL :1A/µS, CCDL : 1A/µS, CCDLT1:10mS,

CCDLT2:10mS

25uS

press key "A/B"

3-5

Page 34

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

Current

4A

2A

Load1

load2

Time

10mS 10mS

T1

T2

Figure 3-5 Dynamic Current Waveform

The STATic/DYNAmic functions can be also selected through

Load module.

Slew Rate (Rise, Fall A/µS or mA/µS)

Slew rate determines the rate at which the current input of a module changes to a newly

programmed value. There are two slew rate values. One is for rise rate, and another for

fall rate.

Voltage Ranges (Low, High)

There are two voltage ranges for voltage measurement and Von voltage setting. The low

range provides better resolution at low voltage measurements. If any value is over the

maximum of low range, you must select the high range. The voltage range selection of CC

mode is in configuration setting.

10mS 10mS

T1

T2

STATIC/DYNAMIC key on the

3-6

Page 35

Operation Overview

3.5.2 Constant Resistance Mode

Figure 3-6 Constant Resistance Mode

In CR mode, the Load will sink a current linearly proportional to the input voltage in

accordance with the programmed resistance. There is a double pole RC filter of input

voltage, so high frequency parts will be removed. The time constant of low pass filter is

about 47 µS. The load sink current of CR mode is proportioned to the input voltage through

a double pole RC filter. To prevent the load current change caused by the input voltage

variation, the power source impedance should be as low as possible, and remote sensing cable

must be used to sense load input voltage when high sink current (low setting resistance) is

programmed.

Voltage Ranges (Low, High)

Resistance can be programmed in either of the two ranges, low range and high range. The

low range is used for input voltage in low voltage range while the high range for input voltage

over low voltage range. The current range of CR mode is high range.

MODE SELECT

CRL Select Constant Resistance low voltage range

MODE SELECT

CRH Select Constant Resistance high voltage range

Select range by pressing

If input voltage is over the maximum of low range, you must select the high range. Press

MODE key first, and then use ▲ or ▼ key to select voltage range. In some

modules (single channel/module) there are two resistance levels (A or B) for CR function.

Both states A/B use the same range. You can select A (CRL1 or CRH1) or B (CRL2 or

CRH2) through

A/B key on the module’s keypad. Slew rate determines the rate at which

ENTER key.

3-7

Page 36

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

load level changes from one load level state to another.

Slew Rate (Rise, Fall A/µS)

Slew rate in constant resistance mode is programmed in Amps/second.

3.5.3 Constant Voltage Mode

Figure 3-7 Constant Voltage Mode

In CV mode the Load will sink current to control the voltage source in programmed value.

In some modules (single channel/module) there are two voltage levels (A or B) for CV

function. You can select A (CV1) or B (CV2) through

There are two response speed of CV modes: fast and slow. The fast/slow respond speed

means the slew rate of current change.

Voltage & Current Range (High)

The voltage and current range of CR mode is high range.

A/B key on the module’s keypad.

3.6 Load Synchronization

The Chroma 6314/6312 multiple electronic load mainframes contain eight and four load

channels respectively. The channel on/off or change of load timing is important. You can

set module change synchronously through SYNC RUN in configuration setting. If a channel

is set at SYNC RUN ON, it means that channel on/off or change of load level is synchronized

with other Load modules. In other cases channel on/off can be controlled only by the

module’s

LOAD key.

3-8

Page 37

Operation Overview

3.7 Measurements

Each module measures current and voltage of the UUT. The sampling rate is about 12 mS.

Voltage and current measurements are performed with a 15-bit resolution of full-scale ratings.

3.8 Slew Rate & Minimum Transient Time

Slew rate is defined as the change in current over time. A programmable slew rate allows a

controlled transition from one load setting to another to minimize induced voltage drops on

inductive power wiring, or control induced transients on a test device. If the transient from

one setting to another is large, the actual transient time can be calculated by dividing the

current transition by the slew rate. The actual transition time is defined as the time required

for the change of input from 10% to 90% or from 90% to 10% of the programmed excursion.

If the transition from one setting to another is small, the small signal bandwidth of Load will

limit the minimum transition time for all programmable slew rates. Because of the limit, the

actual transition time is longer than the expected time based on the slew rate. Therefore,

both minimum transition time and slew rate must be considered in the determination of actual

transition time. The minimum transition time is from 24 µS to 6 mS, which depends on slew

rate setting.

3.9 Start/Stop Sink Current

In the simulation of transient characteristics of load to UUT, the critical problems are when

and how the Load starts sinking current to UUT. You may set the conducting voltage Von

to solve the problems. The Load will start or stop sinking current when the output voltage of

UUT reaches the Von voltage. You can start sinking current when setting is load ON, and

the input voltage of the module is over Von voltage, but stop sinking when load OFF, or the

input voltage below Von voltage. For start and stop sinking current refer to Figure 3-7 and

3-8 separately.

There are two operation modes for Von control. One is latch, and another non-latch. Latch

means that when voltage is over Von voltage, Load will start sinking current continuously in

spite that input voltage drop is below Von voltage. Non-latch means that when input voltage

is below Von voltage, Load will stop sinking current. The Von voltage and operation mode

of Von is set in configuration.

3-9

Page 38

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

Figure 3-8 Start Sinking Current (Von Non-Latch)

Figure 3-9 Stop Sinking Current (Von Non-Latch)

3.10 Short On/Off

Load module can simulate a short circuit at its input by setting the load on with full-scale

current. The short circuit can be on/off at the front panel or via remote control. There are

two operations for

controlled by key. They are selected in configuration. The SHORT key will be enabled

only when Load is ON.

3-10

SHORT key on the front panel. One is toggled on/off, and another

Page 39

Operation Overview

Toggled on/off means pressing SHORT once to enable short circuit, and again to disable.

Control by Key means pressing SHORT and holding it to enable short circuit, and releasing it

to return to normal operation.

The actual value of electronic short is dependent on the mode and range that are active when

the short is turned on. In CC mode it is equivalent to the programming of 110% or so

full-scale current about 30mS for the present current range, and then goes to rating current.

In CR mode it is equivalent to the programming of the minimum resistance for the present

resistance range. In CV mode it is equivalent to the programming of zero voltage. Turning

on the short circuit does not affect the programmed setting, and Load input will return to the

previously programmed values when the short circuit is turned off.

Note that turning on the short circuit may cause the Load to sink so much current to trig

protection circuit, and that will turn off the Load.

3.11 Load On/Off

A module’s input can be toggled on/off through the ON/OFF key on the front panel of

Mainframe, or the LOAD key on module, or the remote control. The on/off change of input

is done according to the slew rate.

Turning off the load does not affect the programmed setting. The load will return to the

previously programmed values when the Load is turned on again.

3.12 Protection Features

Each load module includes the following protection features: Overvoltage, Overcurrent,

Overpower, Overtemperature, and Reverse Voltage.

The appropriate bits in the Mainframe’s statue registers are set when any of the protection

features mentioned above is active. Besides, the Load’s buzzer will produce beep sound to

inform you till protection status is reset. When any protection occurs, it will cause the Load

input to be turned off.

• Overvoltage

The overvoltage protection circuit is set at a level slightly above the voltage range

specified in the specification of the Load. The overvoltage (OV) and voltage fault (VF)

status register bits are set when the OV condition occurs. They will remain set till they

are reset. The Load module will display ovP when overvoltage protection occurs.

• Overcurrent

When Load is operating in CR or CV mode, it is possible for a module to attempt to sink

current more than it is rated for. The limit level of current is set at a level slightly

above the current of the Load. The overcurrent (OC) and current error (CE) status

register bits are set when the OC condition occurs, and will remain set till they are reset.

The Load module will display oCP when overcurrent protection occurs.

3-11

Page 40

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

• Overpower

The overpower protection circuit is set at a level slightly above the power range

specified in the specifications of the Load. The overpower (OP) and power error (PE)

status register bits are set when the OP condition occurs, and will remain set till they are

reset. The Load module will display oPP when overpower protection occurs.

• Overtemperature

Each Load has an overtemperature protection circuit, which will turn off the load if

internal temperature exceeds safe limit. The overtemperature (OT) and temperature

error (TE) status register bits are set when the OT condition occurs, and will remain set

till they are reset. The Load module will display otP when overtemperature protection

occurs.

• Reverse Voltage

The Load conducts a reverse current when the polarity of UUT connection is not correct.

The maximum safe reverse current is the same as the rated current of Load. If the

reverse current of UUT is over the rated current of Load, the Load may be damaged. If

a reverse voltage condition is detected, you must turn off power to UUT immediately,

and make a correct connection. The reverse voltage (RV) and voltage fault (VF) status

register bits are set when the RV condition occurs, and will remain set till they are reset.

The Load module will display rEv when reverse voltage protection occurs.

All of the protection features will latch when they are tripped. When any protection occurs

the module will turn off the load input, and produce beep sound till you remove the condition

and reset protection by pressing

a CAUTION

To protect the electronic Load from possible damage, the input voltage must not exceed the

maximum input voltage rating specification. Besides, Load + terminal potential must be

more than − terminal potential.

LOAD key on the module.

3.13 Save/Recall Setting

The setting of the electronic Load for all channels can be saved and recalled for use in various

test setups. This simplifies the repetitive programming of different things. The present

setting of mode parameters (CC, CR, CV), programs and power on status (DEFAULT) can be

saved in the EEPROM using

file using RECALL key. The SAVE and RECALL keys affect all channels simultaneously.

SAVE key. Later you can recall the settings from the specified

3.14 Program

The program feature is so powerful. It allows you to simulate various test conditions.

3-12

Page 41

Operation Overview

There are ten programs in the electronic Load. Each program has ten sequences. The

setting mapping of program sequence to file is one to one. It means that program 1,

sequence 1 maps to file 1, and program 3, sequence 4 maps to file 24. For setting and

running the program please refer to 4.2.3 and 4.2.4.

3-13

Page 42

Page 43

Local Operation

4. Local Operation

4.1 Introduction

This chapter describes how to operate the electronic load from the local panel in details.

The descriptions include: Mainframe panel control, Module panel control and indicators.

4.2 Local Operation of Load Mainframe

In order to use the front panel keys to control the electronic load, local operation must be in

effect. Immediately after power is applied, local operation will be in effect. When local

operation is in effect, you can select a channel, and use the display as well as keypad on the

front panel to control the Load. The display of Mainframe can be used to view the

programmed setting of a selected channel. The input voltage/current is displayed on

module’s display. The mainframe will scan module type at power-on, and memorize it for

channel setting.

LNotice

When you edit setting, the display will blink setting, and let you know that the active setting

is to be edited or selected.

In the remote state, the keys on the front panel will have no effect. Only the remote

controller can program the Load. The display of module will show the present input voltage

and current readings or the last display while the local state is in effect. The display of the

Mainframe will show REMOTE message.

LNotice

In the setting of load module level the resolution of current, voltage, resistance and slew rate

setting will be different from the entered values. The displayed or stored value of setting

will be the actual value of D/A programmed in the load module. The current, voltage and

slew rate setting will be degraded as low values are entered. The resistance setting will be

degraded as higher values are entered.

4-1

Page 44

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

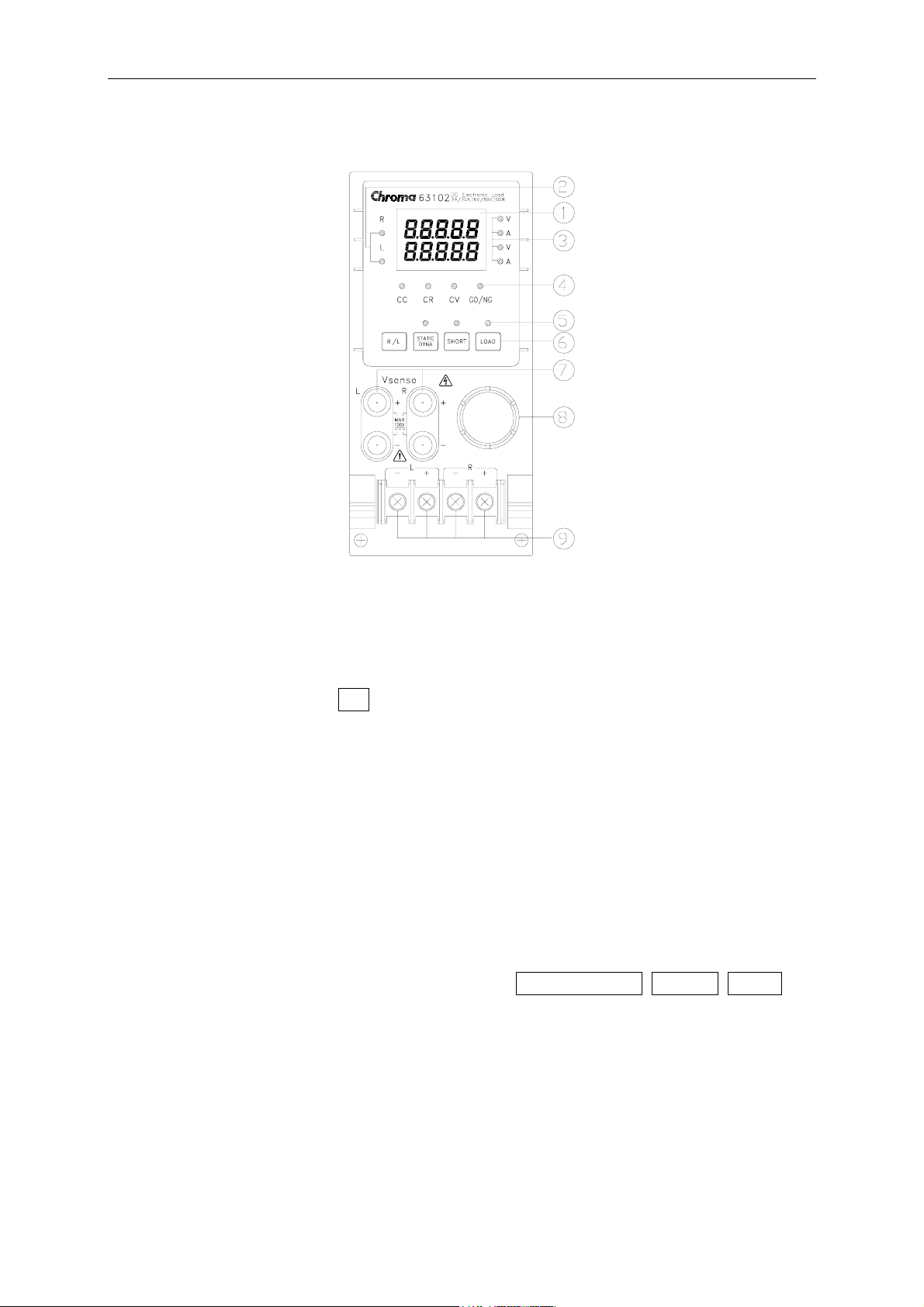

Figure 4-1 Front Panel of Mainframe

1. Line switch Turn the ac power on/off.

2. LCD display Display channel information normally.

3. Channel indicator Indicate the active channel settings.

4. Function keys

CHAN To select a channel for settings.

MODE To select a mode for settings.

PROG To select a program for settings or running.

CLEAR To clear the digit entered from keypad. This key lets you

correct wrong digits before they are entered.

RECALL To recall the saved settings from EEPROM, and all channel’s

settings from specified files (1 to 101). Recalling file 101

means to recall the factory default settings. Recalling program

is from PROG, number 1 to 10.

SAVE To save all of the present mode settings of all channels in the

specified files (1 to 100). Saving program is from 1 to 10.

Saving DEFAULT is to save the status of all channels for the

next time the electronic Load is turned on. All saved settings

are stored in EEPROM, and will not be lost when ac power is

cycled.

SPEC To select specification data for editing, or to enable SPEC

4-2

Page 45

Local Operation

function.

CONF To select configuration data for editing.

5. Entry keys

▲ ▼ They let you scroll through choices in a parameter list that is

applied to a specific command. Parameter lists are circular.

You can return to the starting position by pressing either of

the keys continuously.

ON/OFF It toggles the output of the electronic Load between on and

off states if channel SYNC. RUN is set at on.

ENTER It executes the entered value or the parameter of the presently

accessed command. The parameters you have entered with

other keys are displayed but not entered into the Load until you

press this key. Before pressing ENTER you can change or

abort anything previously entered into the display.

SHIFT It enables a shifted key to function (LOCK, SYS). When

in remote control state, this key acts as a local key.

0 – 9 They are used for entering numeric values.

. It is a decimal point.

4.2.1 Selecting the Channel

The CHAN key is used to select one of the channels for local control. See channel number in

2.3.1. To edit channel settings, you must select a channel first. If the channel does not exist, it

cannot be selected. If no module is installed in the mainframe, the display will show DUMMY

CHANNEL. When you press CHAN, the channel number you want to select will automatically

increase to the next existing channel. The mainframe will scan the module type at power-on,

and memorize it for channel editing.

4.2.2 Setting the Operation Mode

The MODE key and ▲ , ▼ keys are used to select modes of channels for local control.

Press MODE to display the selected channel’s active mode. The active mode can be changed

by use of ▲ or ▼ key followed by the ENTER key. The sequence of mode selection

after pressing ▼ key is as follows:

CCL -> CCH -> CCDL -> CCDH -> CRL -> CRH -> CV go back to CCL.

Press ENTER key to select mode and confirm setting.

4-3

Page 46

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

LNotice

The eight operation modes of load module settings stored in the mainframe are independent.

Changing any mode setting won’t affect others. Storing the settings to EEPROM (1-100) will

store only one mode setting.

The load levels and slew rate are common to CC, CR modes. CV mode sets voltage level and

response speed. There are two level settings for single channel/module of CC, CR, and CV

modes. They can be switched by the module’s A/B key.

Setting CC Values

There are four modes for CC operation: CCL, CCH, CCDL, CCDH. The current levels are

programmed in Amps. The slew rate levels are programmed in milliamps/µS at low range and

in Amps/µS at high range. The timings are programmed in millisecond. The setting buffers of

four CC modes are independent. Changing the operation range doesn’t affect the settings of

other ranges. The following examples show how to set the CC values of Load module for

model number 63103. Before observing the examples, select channel first.

1. Select Range/Function

Press MODE, and use ▲ or ▼ key to select CCL followed by ENTER key.

CCL: static low range CCH: static high range

CCDL: dynamic low range CCDH: dynamic high range

MODE SELECT

CCL

2. Set Current Level

There are 4000 discrete steps from 0 to full scale in each range. Set level1 (A)

current level to 2 amps by pressing 2 , ENTER . Set level2 (B) current level to 1 amp

by pressing 1 , ENTER.

CCL1: 1.9995A

CCL2: 0.9990A

3. Set Slew Rate

There are 250 discrete steps in each range. Set the rise 50 mA/µS and fall slew rates

to 50 mA/µS by pressing 5 , 0 , ENTER for rise and 6 , 0 , ENTER for fall slew rate.

CCL : 50mA/µS

CCL : 60mA/µS

4. Set DYNAmic Function Periods

Dynamic function has period T1 and T2 to be set. Set dynamic period 1 to 0.1 mS,

period 2 to 0.2 mS by pressing 0 , . , 1 , ENTER and 0 , . , 2 , ENTER. The range

of Dynamic period is from 0.025 µS to 30 Sec.

CCDLT1: 0.100mS

4-4

Page 47

Local Operation

CCDLT2: 0.200mS

LNotice

If you press ENTER key, and the blinking data do not go to next, change configuration

setting Enter Data Next to YES.

Setting CR Values

The CR values for the selected channel are programmed by pressing MODE, ▲ and

ENTER keys. The resistance values can be programmed in low voltage (CRL) or high

voltage (CRH) range. The current is always in high range. ALL resistance levels are

programmed in ohms. The slew rate is in A/µS.

The following examples illustrate how to set CR values of Load module for model number

63103.

1. Select Range

Press MODE and use ▲ or ▼ key to select CRL followed by ENTER key.

MODE SELECT

CRL

2. Set Resistor Level

There are 4000 discrete steps from 0 to full scale in each range. Set the main resistor

level1 (A) to 2 ohms by pressing 2 , ENTER. Set the level2 (B) resistor level to 1 ohm

by pressing 1 , ENTER.

CCL1: 2.000Ω

CCL2: 1.000Ω

3. Set Slew Rate

There are 250 discrete steps in each range. Set the rise and fall slew rates to 0.1 A/µS

by pressing . , 1 , ENTER for rise slew rate and . , 2 , ENTER for fall slew rate.

CRL : 0.10A/µS

CRL : 0.20A/µS

Setting CV Values

The CV values for the selected channel are programmed by pressing MODE, ▲ and

ENTER keys. The voltage values can be programmed in one range. The voltage levels

are programmed in volts. And the response speed is programmed in fast/slow operations.

The following examples illustrate how to set CV values of Load module for model number

63103. Before observing the examples, select channel first.

4-5

Page 48

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

1. Select Range

Press MODE and use ▲ or ▼ key to select CR followed by ENTER key.

MODE SELECT

CV

2. Set Voltage Level

There are 4000 discrete steps from 0 to full scale in each range. Set the main voltage

level1 (A) to 5 volts by pressing 5 , ENTER. Set the level2 (B) voltage level to 6 volts

by pressing 6 , ENTER.

CV 1: 5.00V

CV 2: 6.00V

3. Set Response Speed

There are two response speeds for CV mode, fast and slow for different UUTs testing.

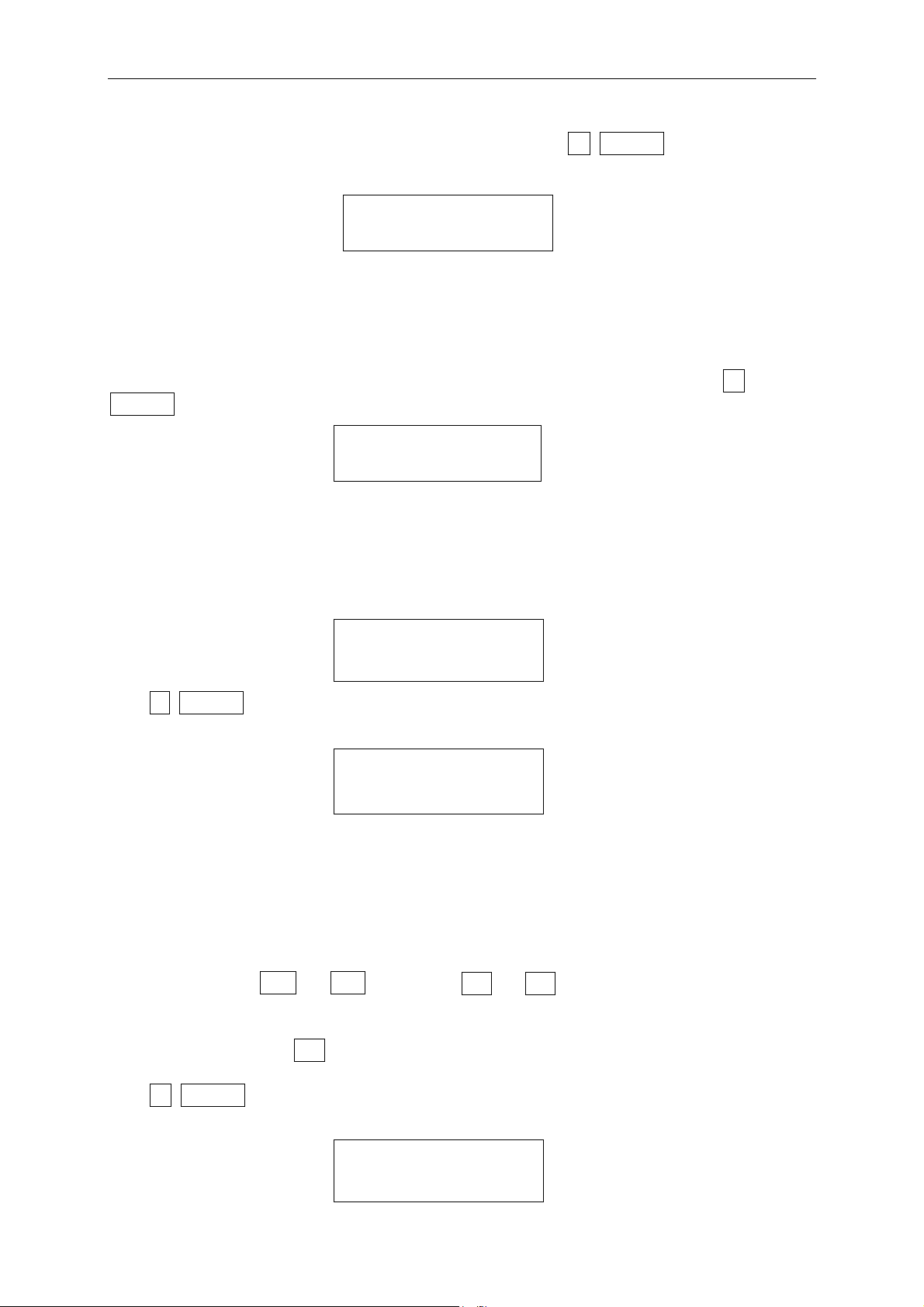

Refer to Figure 4-2 and 4-3 for transfer functions.

CV RESPONSE

1:FAST 2:SLOW

4-6

Figure 4-2 CV Response Transfer Function (FAST)

Page 49

Local Operation

Figure 4-3 CV Response Transfer Function (SLOW)

4.2.3 Setting the Program

The electronic Load is able to select customized basic tests, and link them into a program test

for automatic execution.

The PROG key is used to select program, or recall program for local control. There are ten

programs (1-10). Each program has ten sequences to map files from 1 to 100. The

program 1 maps files from 1 to 10. Table 4-1 shows the relationship between the program

sequence and the corresponding file.

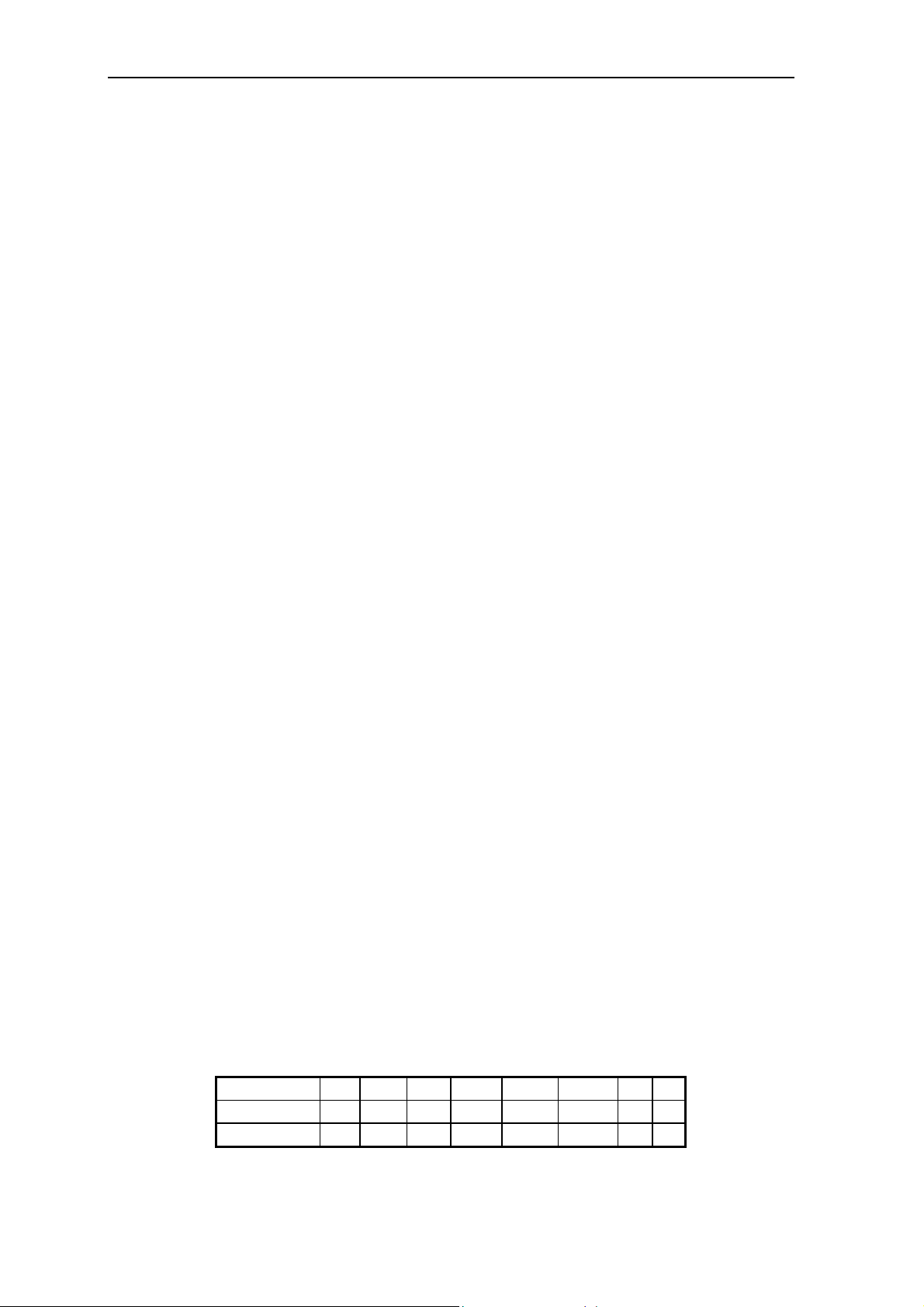

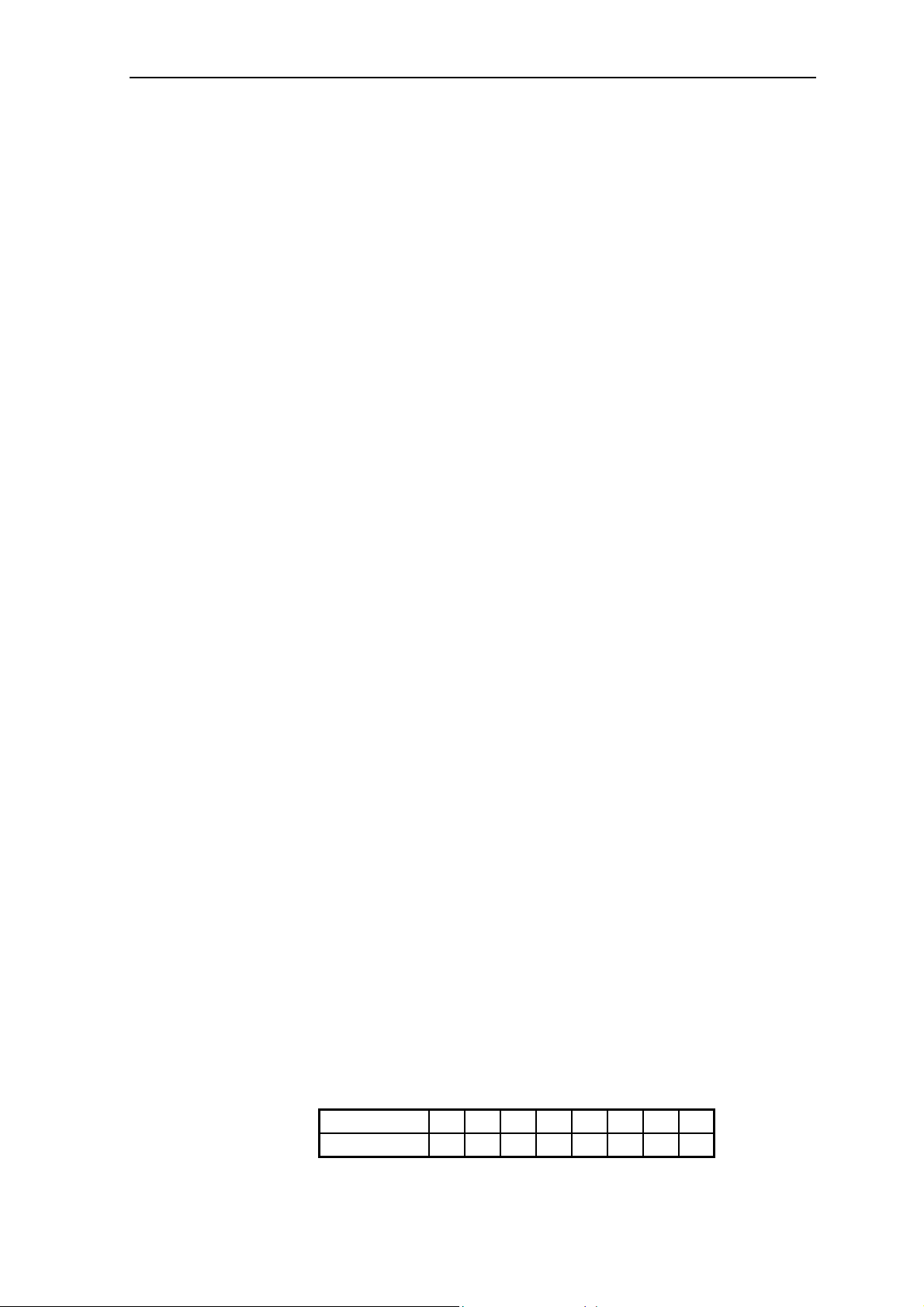

Program 1 Sequence No. 1 2 3 4 5 6 7 8 9 10

Corresponding File No. 1 2 3 4 5 6 7 8 9 10

Program 2 Sequence No. 1 2 3 4 5 6 7 8 9 10

Corresponding File No. 11 12 13 14 15 16 17 18 19 20

:

:

Program 10 Sequence No. 1 2 3 4 5 6 7 8 9 10

Corresponding File No. 91 92 93 94 95 96 97 98 99 100

Table 4-1 The Relationship of the Program Sequence and the Corresponding File.

In running a program you must set its corresponding file parameters first. If one program

sequence is not enough for you to test the UUT, you can use program chain function to get

more sequences.

Press PROG key, and the LCD will display as follows. Press number 1 -10 followed by

ENTER to recall program from EEPROM, or use ▲ , ▼ keys to edit program.

PROGRAM SELECT

No:

1. Setting the Active Channels

The LCD displays the active channels for the program to control. The LED channel

indicators will be active if the channel is active. The channel can be active only when it

exists and the mode of SYNC. RUN is ON. When the channel is not selected or does not

exist, the channel number will not be displayed. Press number 1 to 8 to enable or disable the

active channel.

ACTIVE CHANNEL

1 3 5

2. Setting the Program Chain

The chain function of program enables you to chain program so as to get more sequences for

testing. Set program chain number to 0 means no program chain. Program chain function

1

6 7 8

4-7

Page 50

Programmable DC Electronic Load 6310 Series Operation & Programming Manual

can chain itself for loop test, or chain other programs. Press 1 , ENTER to set chain itself

for loop test. The default setting is 0.

PROGRAM CHAIN

No:

1

3. Setting the Sequence P/F Delay Time

The sequence Pass/Failure delay time let you set the delay time for P/F checking when load

condition changes. The failure status of the sequence will latch when a program is executed.

It means that any failure will be memorized even when the UUT becomes stable within the

specifications later. The range of P/F delay time is from 0 to 60 seconds. Press 1 ,

ENTER to set the sequence P/F delay time 1 second. The default setting is 0 second.

SEQ.

P/F DELAY

TIME: 1.0Sec

4. Setting the Sequence ON/OFF Time

The sequence ON/OFF time controls the Load input ON/OFF when the program sequence is

executed. The range of ON/OFF time is from 0 to 60 seconds.

SEQ. ON TIME

TIME:

1.0Sec

Press 0 , ENTER keys to set OFF time 0 second. The default setting is 0 second for OFF

time.

SEQ. OFF TIME

TIME:

0.0Sec

5. Setting the Sequence Mode

There are three modes to control the method of sequence execution.

SKIP : Skip the sequence. Load will not change input status.

AUTO : Use ON/OFF time to control Load input on/off. When ON/OFF time