Christie Digital Systems XENON CONSOLE User Manual

DIGITAL SYSTEMS

INSTRUCTIONS

FOR

INSTALLATION AND OPERATION

OF

SLC SERIES

XENON CONSOLE

SLC 20/30,40,45,45R,70

TD-641 REV. 6.0

CHRISTIE DIGITAL SYSTEMS

10550 Camden Drive

Cypress, CA 90630

714-236-8610 Fax: 714-503-3385

Operator’s Manual

Xenon Console, Model SLC 20/30,40,45,45R,70

TD641, Rev. 6.0

Manufactured Under U.S. Patents 3,843,879 and 5,054,909

Other Patents Pending

The information in this document is subject to change without notice and does not represent a

commitment on the part of Christie Digital Systems (hereinafter referred to as Christie).

Christie does not assume responsibility for errors that may appear in this document. Christie

or its subsidiaries, designated representatives, and any other vendor of the SLC Xenon

Console are not responsible in any way for any liabilities or loss resulting from the use or

misuse of this document.

Copyright © 2003 by Christie Digital Systems

All Rights Reserved

All copyrights and trademarks are the property of their respective owners.

CHRISTIE DIGITAL SYSTEMS

10550 Camden Drive

Cypress, CA 90630

Telephone 714-236-8610

FAX 714-503-3385

TABLE OF CONTENTS

TABLE OF CONTENTS..............................................................................i

LIST OF FIGURES AND TABLES..............................................................iii

1. Introduction......................................................................................... 1-1

1.1. Contents of the Manual.................................................................................................. 1-1

1.2. Who Should Use This Manual?..................................................................................... 1-1

1.3. Special Notices .............................................................................................................. 1-2

1.3.1. Warning ..................................................................................................................1-2

1.3.2. Caution ................................................................................................................... 1-2

1.3.3. Note ........................................................................................................................1-2

2. Safety Precautions ............................................................................. 2-1

2.1. Wear Protective Clothing ..............................................................................................2-1

2.2. Allow Lamp to Cool ......................................................................................................2-2

2.3. Disconnect AC Lines Before Entering Console ............................................................ 2-2

2.4. Do Not Look Directly at Lamp...................................................................................... 2-2

2.5. Avoid Fire Hazards........................................................................................................2-3

3. General Description............................................................................ 3-1

3.1. The Xenon Lamp ........................................................................................................... 3-1

4. Installation Procedures ...................................................................... 4-1

4.1. Unpacking...................................................................................................................... 4-1

4.2. Installation ..................................................................................................................... 4-1

4.2.1. Leveling Feet ..........................................................................................................4-1

4.2.2. Door Panels ............................................................................................................ 4-4

4.2.3. Venting ................................................................................................................... 4-4

4.2.4. Mounting the Projector........................................................................................... 4-5

4.3. Electrical Connections...................................................................................................4-5

4.3.1. Verify Voltage ........................................................................................................4-5

4.3.2. Wiring Hook-Up..................................................................................................... 4-5

5. Alignment and Checkout Procedures............................................... 5-1

5.1. Mechanical Alignment................................................................................................... 5-1

5.2. Installation of Xenon Lamp ...........................................................................................5-1

6. Operating the SLC .............................................................................. 6-1

6.1. Safety Review................................................................................................................ 6-1

6.2. Starting and Operating the SLC..................................................................................... 6-1

6.3. Optical Alignment and Adjustment............................................................................... 6-4

6.4. Tilt Adjustment.............................................................................................................. 6-5

6.5. Replacing the Lamp....................................................................................................... 6-5

CHRISTIE DIGITAL SYSTEMS i

August 7, 2003

SLC Series Xenon Console

6.5.1. Removing the Lamp............................................................................................... 6-5

6.5.2. Installing a New Lamp ........................................................................................... 6-5

6.5.3. Defective Lamps .................................................................................................... 6-5

7. Maintenance and Adjustments .......................................................... 7-1

7.1. Before Opening the Console ......................................................................................... 7-1

7.2. Cleaning Optical Surfaces............................................................................................. 7-1

7.2.1. Cleaning Dust......................................................................................................... 7-2

7.2.2. Cleaning Grease ..................................................................................................... 7-2

7.3. Maintaining Other Surfaces .......................................................................................... 7-2

7.3.1. Blower.................................................................................................................... 7-3

7.3.2. Igniter ..................................................................................................................... 7-3

7.3.3. Air Flow Interlocks ................................................................................................ 7-3

7.4. Aligning Lamphouse Without Alignment Tools........................................................... 7-3

7.5. Xenon Lamp Autofocus Adjustments (Option ABF) ................................................... 7-4

7.5.1. Autofocus Adjustment Procedures......................................................................... 7-4

7.6. Optimizer Reflector....................................................................................................... 7-6

7.7. Electrical Connections................................................................................................... 7-6

7.8. Airflow .......................................................................................................................... 7-6

7.9. Remote Lamp Adjustment Control (Option RBA) ....................................................... 7-6

8. Troubleshooting.................................................................................. 8-1

8.1. Malfunction: Power Supply Does Not Start.................................................................. 8-1

8.2. Malfunction: Lamp Does Not Ignite ............................................................................. 8-2

8.3. Power Supply Output Is Low Or Not Steady................................................................ 8-2

WARRANTY............................................................................................W-1

Appendix A: Assembly Diagrams and Parts Lists.............................. A-1

ii CHRISTIE DIGITAL SYSTEMS

August 7, 2003

Table of Contents

LIST OF FIGURES AND TABLES

Figure 2-1: Protective Clothing Safety Kit Contents.............................................................. 2-1

Figure 4-1: SLC Xenon Lamp Console (Front View) ............................................................ 4-2

Figure 4-2: SLC Xenon Lamp Console (Rear View) .............................................................4-3

Figure 4-3: Minimum and Maximum Exhaust Airflow Requirements for SLC Consoles..... 4-4

Figure 4-4: Minimum Wire Sizes for AC Connections ..........................................................4-6

Figure 4-5: Minimum Wire Sizes for DC Connections ..........................................................4-6

Figure 5-1: Plenum, Top View ...............................................................................................5-2

Figure 6-1: Control Panel........................................................................................................ 6-2

Figure 6-2: Optical Alignment of Xenon Lamp......................................................................6-4

Table 8-1: Troubleshooting for Power Supply Does Not Start ............................................. 8-1

Table 8-2: Troubleshooting for Lamp Does Not Ignite......................................................... 8-2

Table 8-3: Troubleshooting for Power Supply Output Low or Not Steady ..........................8-2

Figure A-1: Autofocus Assembly ........................................................................................... A-2

Table A-1: Parts List for Autofocus Assembly ..................................................................... A-3

Figure A-2: SLC Xenon Lamp Console (Front View) ........................................................... A-4

Table A-2: Parts List for SLC Xenon Lamp Console (Front View) .....................................A-5

Figure A-3: SLC Xenon Lamp Console (Rear View) ............................................................A-6

Table A-3: Parts List for SLC Xenon Lamp Console (Rear View) ...................................... A-7

Figure A-4: Control Panel.......................................................................................................A-8

Table A-4: Parts List for Control Panel................................................................................. A-9

Figure A-5: Manual Lamp Adjustment Assembly................................................................ A-10

Table A-5: Parts List for Manual Lamp Adjustment Assembly.......................................... A-11

Table A- 6: Parts List for Plenum, All Models (Top View)................................................. A-13

Figure A-7: Power Supply .................................................................................................... A-14

Table A-7: Power Supply .................................................................................................... A-15

CHRISTIE DIGITAL SYSTEMS iii

August 7, 2003

iii

1. INTRODUCTION

1.1. CONTENTS OF THE MANUAL

This manual contains installation, operation, and operator maintenance procedures for

Christie SLC Xenon Console. The material covered includes:

• General description

• Installation and assembly

• Alignment and checkout procedures

• Operating the SLC

• Troubleshooting.

1.2. WHO SHOULD U SE THIS M ANUAL?

This manual provides information suitable for various purposes.

All users should read Section 2: Safety Precautions.

1

Do not install, operate, maintain, or repair the SLC Xenon Lamp

Console unless you have read Section 2, are familiar with the safety

precautions, and have followed all warnings and instructions.

WARNING

For details on operating the projector and for general information, see:

• Section 3: General Description

• Section 4: Installation Procedures

• Section 5: Alignment and Checkout Procedures

• Section 6: Operating the SLC.

Before performing adjustments and periodic maintenance during normal operation, see:

• Section 4: Installation Procedures

• Section 5: Alignment and Checkout Procedures

• Section 7: Maintenance and Adjustments

• Section 8: Troubleshooting.

If a problem occurs, see:

• Section 8: Troubleshooting.

Additional reference information is contained in the appendices.

CHRISTIE DIGITAL SYSTEMS 1-1

August 7, 2003

SLC Series Xenon Console

1.3. SPECIAL NOTICES

Three kinds of specific notices are used within this manual to emphasize specific

information.

1.3.1. WARNING

WARNING: Indicates the presence of a hazard that can cause personal

injury if the hazard is not avoided.

WARNING

1.3.2. CAUTION

CAUTION: Indicates the presence of a hazard that could cause damage

to the system.

1.3.3. NOTE

NOTE: Provides additional information.

1-2 CHRISTIE DIGITAL SYSTEMS

August 7, 2003

2. SAFETY PRECAUTIONS

This section highlights the major dangers of working with the SLC Xenon Console.

Appropriate safety measures must be taken at all times.

2.1. WEAR PROTECTIVE C LOTHING

POSSIBLE EXPLOSION HAZARD!

WARNING

Xenon compact arc lamps are under high pressure. The lamps must be handled with great

care. They may explode if dropped or mishandled. Whenever the protective cover is

removed from the lamp, authorized protective clothing must be worn!

Protective clothing includes, but may not be limited to, rubberized cotton gloves, doublelayer 0.040-inch acetate face shield, and quilted ballistic nylon jacket. A Protective Clothing

Safety Kit (Part Number 598900-095) is available from Christie. Figure 2-1 lists the contents

of the Safety Kit.

2

Wear protective clothing when protective cover is removed from lamp.

WARNING

Instructions from Christie regarding protective clothing are subject to change. Any local or

federal specifications take precedence.

Part Number Item

598900-092 Safety Jacket

598900-093 Safety Mask

598900-094 Safety Gloves

Figure 2-1: Protective Clothing Safety Kit Contents

CHRISTIE DIGITAL SYSTEMS 2-1

August 7, 2003

SLC Series Xenon Console

2.2. ALLOW LAMP TO C OOL

If the lamp has been in use, wait at least ten minutes after shut-off

before opening the lamp housing.

WARNING

The ten-minute waiting period allows the internal lamp pressure to drop to a level at which it

is safe to work while wearing the authorized protective clothing. Again, always wear

protective clothing when the protective cover is removed from the lamp.

2.3. DISCONNECT AC LINES BEFORE E NTERING CONSOLE

Turn off the breaker at the building AC power distribution panel before

entering the console.

WARNING

Always turn off and disconnect power lines before entering the console. This protects

against accidental electrical shock.

2.4. DO NOT L OOK DIRECTLY AT LAMP

NEVER LOOK DIRECTLY AT THE LAMP!

WARNING

Serious and permanent eye damage can be caused by the ultraviolet radiation of the lamp.

Never attempt to open the console while the lamp is on. Always follow directions for

opening console and exposing the Xenon lamp. (See Section 5.2.)

2-2 CHRISTIE DIGITAL SYSTEMS

August 7, 2003

CHAPTER NUMBER: TITLE

2.5. AVOID FIRE H AZARDS

FIRE HAZARD: Keep hands, clothes, and combustible material away

from the concentrated light beam in front of the snood.

WARNING

Use extreme caution when working around the SLC Xenon Console. Fire danger may arise

from heat, electrical current, or the concentrated light beam emitted by the Xenon lamp.

CHRISTIE DIGITAL SYSTEMS 2-3

August 7, 2003

3. GENERAL DESCRIPTION

This SLC Xenon Console is a series of projection illumination systems that combine the

rectifier DC power supply and projector base with a Xenon lamphousing into a single,

integrated unit with a minimum of installation and wiring expense. These consoles are

designed for use with any standard 35-mm or 35/70-mm motion picture projector head.

3.1. THE XENON L AMP

The SLC Xenon Console utilizes a highly efficient optical system to obtain maximum light

output with extreme ease of operation and high reliability. This is accomplished by using a

horizontally operated Xenon lamp within a deep, explosion-proof reflector. For maximum

efficiency, the reflector has a computer-generated, aspheric shape. The high-voltage igniter

(Item 2 in Figure A-3), required for starting the Xenon lamps, is included within the

enclosure.

3

Authorized protective clothing must be worn when protective cover is

removed from lamp.

WARNING

For lamp description, recommendations, and warranty information, see the Christie (or

equivalent) lamp instructions.

SLC Consoles are equipped with a double interlock system on the lamp

access doors to extinguish the lamp if the enclosure is accidentally

opened. Keyed locks are provided on all access doors.

CHRISTIE DIGITAL SYSTEMS 3-1

August 7, 2003

4. INSTALLATION PROCEDURES

4.1. UNPACKING

Follow these instructions if the unit is crated.

Christie recommends that the unit be moved to the installation site before

uncrating.

1. Be sure container is upright.

2. Open crate and remove packing.

3. Carefully remove unit from crate.

4. Thoroughly inspect unpacked unit for damage that may have occurred during shipping.

4

Any damage discovered should be reported to the transportation company at

once for inspection and filing of claim.

4.2. INSTALLATION

Place console in intended operating location in projection booth.

4.2.1. LEVELING F EET

Install four (4) leveling feet by screwing one into each of the four corners underneath base

until about 1/2 inch of thread remains exposed. (See Item 8 in Figure 4-1.)

Christie recommends carefully tilting the console to one side to install the

first two feet, then tilting it to the other side to install the other two feet.

An assistant is required to do this safely.

CHRISTIE DIGITAL SYSTEMS 4-1

August 7, 2003

SLC Series Xenon Console

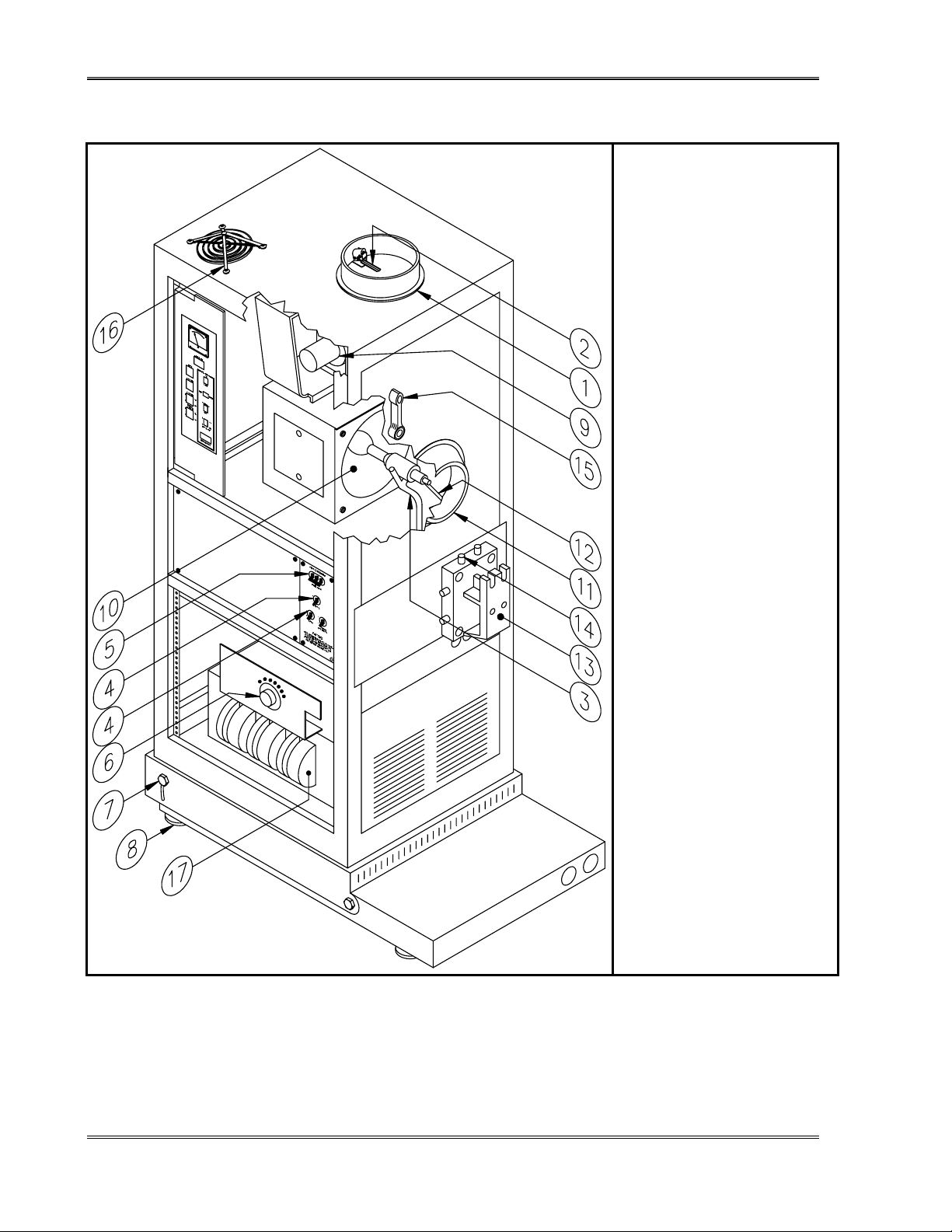

1: Exhaust Duct Connector (195713-001)

2: Air Switch Assembly (195557-002)

3: Lamp Support, Positive (193959-001)

4: Circuit Breaker, 30 A (573303-005)

Circuit Breaker ,20 A (573102-009)

Circuit Breaker, 15 A (573101-020)

5: Circuit Breaker, 40 A (573304-001)

Circuit Breaker, 30 A (573103-022)

Circuit Breaker, 20 A (573302-003)

6: Tap Switch (111972-002)

7: Tilt Adjust Bolt (515500-177)

8: Leveling Foot (520650-003)

9: Blower (SLC 20/30) (598931-548)

Blower (SLC 40,45,70) (598931-645)

10: Reflector (SLC 20/30) (195206-003)

Reflector (SLC 40/45) (195891-001)

Reflector (SLC 45R) (195710-001)

Reflector (SLC 70) (195572-002)

11: Snood (SLC 20, 30) (195954-001)

Snood (SLC 40/45/70) (195415-001)

12: Lamp Connector (+) (191925P001)

13: Projector Mnt. (20/30) (195955-001)

Projector Mnt. (40/45/70) (195738-001)

14: Alignment Adjust (515500-141)

15: Douser Handle (192121-001)

16: Guard Air Intake (195684-001)

17: Power Supply 3kW 208/230v (195463-010)

Power Supply 3kW 380/415v (195463-004)

Power Supply 4kW 208/230v (195464-010)

Power Supply 4kW 380/415v (195464-004)

Power Supply 7kW 208/230v (195556-010)

Power Supply 7kW 380/415v (195556-004)

Figure 4-1: SLC Xenon Lamp Console (Front View)

4-2 CHRISTIE DIGITAL SYSTEMS

August 7, 2003

4: Installation Procedures

1: Air Switch Assy. (195557-001)

2: Igniter, IGA-10 (116715-001)

IGA-15M (117124-001)

3: Door Interlock (578000-034)

4: Capacitor (SLC 20, 30) (530106-302)

(SLC 40, 45, 70) (530122-009)

5: Terminal Strip (586211-001)

6: Control Assy, 60 Hz (20, 30) (114173-002)

50 Hz (SLC 20) (114173-011)

50 Hz (30, 40, 45, 70) (114173-010)

60 Hz (40, 45, 70) (114173-001)

7: Power Input Terminal (586210-601)

8: Heat Sink Assembly (20) (114109-002)

(SLC 30) (114109-002)

(SLC 40, 45, 45R, 70) (195569-001)

9: Leveling Foot (520650-003)

10: Fan Guard (598931-496)

11: Transformer,60Hz(20/30)(195773-001)

50/60 Hz (SLC 20/30) (195773-001)

60 Hz (SLC 40) (195774-001)

50/60 Hz (SLC 40) (195774-004)

60 Hz (SLC45/70) (195775-001)

50/60Hz (SLC45/70) (195775-004)

60 Hz (45R/70R) (195775-001)

50/60 Hz (45R/70R) (195775-004)

12: Lamp Adjustment PCB

Automotorized (195315-001)

Motorized(195315-002)

13: Lamp Adj., Manual (195800-001)

Motorized (195800-002)

Au to f o c u s M o t . (195800-003)

Autofocus Man. (195800-004)

Motorized Man. (195800-005)

14: Tap Switch Assembly (111972-002)

15: Contactor

120v(SLC 20, 30) (571340-006)

120v,(SLC 40, 45, 70) (571340-008)

230v, (SLC 20, 30) (571340-007)

230v, (SLC 40, 45, 70) (571340-009)

16: Console Tilt Option (195535-001)

Figure 4-2: SLC Xenon Lamp Console (Rear View)

CHRISTIE DIGITAL SYSTEMS 4-3

August 7, 2003

SLC Series Xenon Console

4.2.2. DOOR P ANELS

All three door panels are removable for easier access to the interior of the console during

installation and maintenance.

To remove door panel:

1. Unlock key-lock.

2. Open door.

3. Push down on spring-loaded pin hinge.

4. Remove panel.

To install door panel, reverse the above procedure.

4.2.3. V

ENTING

It is necessary to vent hot exhaust air from console to the outside of the building.

1. Connect a eight-inch inner-diameter, flexible, fireproof ducting material to exhaust duct

(Item 1 in Figure A-2) on top of lamphouse.

2. Ensure that there are no obstructions in ducting, and that air intake openings of console

are unobstructed.

If ozone-free lamps are used, a short, vertical exhaust stack may be used, provided local

codes do not require the exhaust to be vented directly outside.

External exhaust air extraction is required. Minimum and maximum exhaust airflow

requirements for all SLC series models are shown in Figure 4-3.

Model Minimum Exhaust (ft3/min) Maximum Exhaust (ft3/min)

SLC 20 300 400

SLC 30 350 450

SLC 40 450 550

SLC 45, SLC 45R 550 750

SLC 70 750 900

Figure 4-3: Minimum and Maximum Exhaust Airflow Requirements for SLC Consoles

4-4 CHRISTIE DIGITAL SYSTEMS

August 7, 2003

4: Installation Procedures

4.2.4. MOUNTING THE P ROJECTOR

The SLC Console includes a standard projector mounting bracket for Christie P35 projectors.

If any other model projector is to be mounted, contact the Christie factory.

1. Mount projector on projector mounting bracket (Item 13 in Figure A-2).

2. Ensure that projector is level and in line with console before tightening mounting bolts.

3. Verify that all four (4) bolts are installed and securely tightened.

4.3. ELECTRICAL CONNECTIONS

SLC Consoles are factory wired and tested. All functions have been carefully tested and

calibrated to prevent problems during installation and operation.

Turn off all breakers at the building AC power distribution panel

before connecting the console.

WARNING

4.3.1. VERIFY V OLTAGE

Check the AC voltage shown on the console nameplates. Then measure the AC supply

voltages with a voltmeter. Verify that the measured voltages do not differ by more than 10%

from the rated nominal values of the unit.

4.3.2. WIRING H OOK-UP

1. Pull 3-phase wires and single-phase and ground wires through one of knock-out holes

located on front side on foot of console. Check charts in Figure 4-4 and Figure 4-5 for

correct wire size.

Grounding wire (green) must be at least as large in diameter as largest

wire used for AC power connections.

WARNING

2. Connect 3-phase wires to Terminal Board TB2–L1, TB2–L2, and TB2–L3.

3. Connect single-phase wires to TB2–L1, Neutral, marked 115V single-phase. Connect

ground wire to TB2–ground.

4. Check Schematic and/or Automation Manual for wiring hook-up to TB5. These

connections are for projector, sound, changeover douser, and auditorium functions.

5. Hook up all wires as required in above instructions.

CHRISTIE DIGITAL SYSTEMS 4-5

August 7, 2003