Page 1

User Guide

020-102993-01

Mirage SST

Page 2

NOTICES

COPYRIGHT AND TRADEMARKS

yright © 2019 Christie Digital Systems USA Inc. All rights reserved.

Cop

All brand names and product names are trademarks, registered trademarks or trade names of their respective holders.

GENERAL

Every effort has been made to ensure accuracy, however in some cases changes in the products or availability could occur which may not be reflected in this

document. Christie reserves the right to make changes to specifications at any time without notice. Performance specifications are typical, but may vary

depending on conditions beyond Christie's control such as maintenance of the product in proper working conditions. Performance specifications are based on

information available at the time of printing. Christie makes no warranty of any kind with regard to this material, including, but not limited to, implied

warranties of fitness for a particular purpose. Christie will not be liable for errors contained herein or for incidental or consequential damages in connection

with the performance or use of this material. Manufacturing facilities in Canada and China are ISO 9001 certified. Manufacturing facilities in Canada are also

ISO 14001 certified.

WARRANTY

Products are warranted under Christie’s standard limited warranty, the complete details of which are available by contacting your Christie dealer or Christie. In

addition to the other limitations that may be specified in Christie’s standard limited warranty and, to the extent relevant or applicable to your product, the

warranty does not cover:

Problems or damage occurring during shipment, in either direction.

a.

Problems or damage caused by combination of a product with non-Christie equipment, such as distribution systems, cameras, DVD players, etc., or use

b.

of a product with any non-Christie interface device.

Problems or damage caused by misuse, improper power source, accident, fire, flood, lightning, earthquake, or other natural disaster.

c.

Problems or damage caused by improper installation/alignment, or by equipment modification, if by other than Christie service personnel or a Christie

d.

authorized repair service provider.

Use of third party product enclosures for environmental protection during outside use must be approved by Christie.

e.

Problems or damage caused by use of a product on a motion platform or other movable device where such product has not been designed, modified or

f.

approved by Christie for such use.

Except where the product is designed for outdoor use, problems or damage caused by use of the product outdoors unless such product is protected from

g.

precipitation or other adverse weather or environmental conditions and the ambient temperature is within the recommended ambient temperature set

forth in the specifications for such product.

Defects caused by normal wear and tear or otherwise due to normal aging of a product.

h.

The warranty does not apply to any product where the serial number has been removed or obliterated. The warranty also does not apply to any product sold

by a reseller to an end user outside of the country where the reseller is located unless (i) Christie has an office in the country where the end user is located or

(ii) the required international warranty fee has been paid.

The warranty does not obligate Christie to provide any on site warranty service at the product site location.

PREVENTATIVE MAINTENANCE

Preventative maintenance is an important part of the continued and proper operation of your product. Failure to perform maintenance as required, and in

accordance with the maintenance schedule specified by Christie, will void the warranty.

REGULATORY

The product has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the product is operated in a commercial environment. The product generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of the product in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at the user’s own expense. Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment

CAN ICES-3 (A) / NMB-3 (A)

이 기기는 업무용(A급)으로 전자파적합등록을 한 기기이오니 판매자 또는 사용자는 이점을 주의하시기 바라며, 가정 외의 지역에서 사용하는 것을 목적으로 합니다.

ENVIRONMENTAL

The product is designed and manufactured with high-quality materials and components that can be recycled and reused. This symbol

and electronic equipment, at their end-of

to local regulations. In the European Union, there are separate collection systems for used electrical and electronic products. Please help us to conserve the

environment we live in!

-life, should be disposed of separately from regular waste. Please dispose of the product appropriately and according

means that electrical

Page 3

Content

Introduction...................................................... 7

Third-part

Important safeguards.................................................7

Safety and warning guidelines......................................... 7

Installation safety and warning guidelines..................................8

AC power precautions...............................................9

Laser safety precautions.............................................9

Light intensity hazard distance........................................10

Product labels.....................................................12

General hazards................................................. 12

Mandatory action.................................................13

Electrical labels..................................................13

Laser labels....................................................13

Additional safety hazards............................................14

Product documentation...............................................14

Related documentation.............................................14

Projector overview..................................................15

Contact your dealer.................................................15

Key features......................................................15

How the projector works..............................................16

List of components..................................................16

Display panel components.............................................16

IR remote keypad..................................................18

y products................................................. 7

Operating the projector.............................................20

Performing initial system start-up........................................ 20

Turning on the system............................................. 22

Turning off the system............................................. 24

Projector LED status indicators........................................24

Projector LED shutter indicators....................................... 25

Adjusting the image............................................... 26

Selecting screen image orientation........................................26

Setting the image resize preset..........................................26

Mirage SST User Guide 3

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 4

Content

Adjusting lens settings...............................................26

Adjusting offset..................................................26

R

esetting the lens to home position.....................................27

Aligning the image with lens zoom and focus............................... 27

Locking the lens motor.............................................27

Determining what lens warnings are displayed.............................. 27

Adjusting primary colors..............................................28

DMD color correction................................................ 28

Adjusting color by precise chromaticity values...............................28

Adjusting color by saturation......................................... 29

Signal color correction............................................... 29

Adjusting the color space............................................29

Adjusting color by temperature........................................29

Selecting the color correction mode.....................................30

Correcting for ambient light..........................................30

Setting the frame delay...............................................30

Enabling film mode detect.............................................30

Adjusting the image sharpness..........................................31

Creating a seamless image with edge blending................................31

Adding edge blends to the projector.....................................31

Enabling basic edge blending.........................................31

Resetting edge blending............................................ 32

Geometry correction.................................................32

Enabling warping.................................................32

Correcting the shape of a keystoned image................................ 32

Configuring system settings.........................................35

Setting the date................................................... 35

Setting the time................................................... 35

Changing the splash screen............................................35

Determining the on-screen display position.................................. 35

Changing the language...............................................36

Changing the temperature units......................................... 36

Resuming projector operation after an AC power interruption.......................36

Keeping electronics on in standby mode.................................... 36

Enabling direct pass-through of HDMI, 3G, and DisplayPort input signals................37

Informing the source of signal preferences...................................37

Configuring the laser power settings.......................................37

Setting up 1D color uniformity.......................................... 38

Mirage SST User Guide 4

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 5

Content

Turning on the projector with low voltage....................................39

Configuring communications........................................40

Enabling projector communication........................................40

Setting the remote access lev

Communicating with Mirage SST through Art-Net...............................41

Art-Net channel listing............................................. 41

Index list for the input channel........................................43

Working with macros................................................45

Adding a macro..................................................45

Copying a macro.................................................45

Editing a macro..................................................46

Deleting a macro.................................................46

Configuring the GPIO................................................47

GPIO connector..................................................47

el..........................................40

Setting up projector profiles.........................................49

Creating a new projector profile......................................... 49

Importing a projector profile............................................49

Restoring settings from a profile.........................................49

Renaming a projector profile............................................50

Exporting a projector profile to an external device..............................50

Deleting a projector profile.............................................50

Backing up, restoring, and upgrading files..............................51

Upgrading the Mirage SST software.......................................51

Exporting backup settings to an external device............................... 51

Importing a file from an external device to restore settings........................ 52

Restoring projector default settings.......................................52

Diagnostic tools ..................................................53

Viewing Mirage SST information......................................... 53

Freezing an image..................................................53

Test patterns..................................................... 53

Selecting a test pattern.............................................53

Modifying grey level test pattern characteristics..............................54

Modifying ramp test pattern characteristics................................ 54

Modifying grid test pattern characteristics................................. 54

Enabling a specific test pattern color.....................................55

Mirage SST User Guide 5

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 6

Content

Selecting an engine test pattern....................................... 55

Viewing Mir

age SST status.............................................55

Running the Mirage SST interrogator...................................... 55

Identifying where alarm and trap messages are sent............................ 56

Setting the SNMP read community string..................................56

Configuring traps.................................................56

Defining a trap IP address...........................................56

Restoring factory default settings.........................................56

Regulatory...................................................... 58

Safety......................................................... 58

Electro-magnetic compatibility.......................................... 58

Emissions..................................................... 58

Immunity..................................................... 58

Environmental.................................................... 58

Mirage SST User Guide 6

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 7

Introduction

This manual is intended for professionally tr

systems.

Only Christie qualified technicians who are knowledgeable about the hazards associated with highvoltage, ultraviolet exposure, and the high temperatures generated by the projector are authorized to

assemble, install, and service the projector.

For complete Mirage SST product documentation and technical support, go to www.christiedigital.com.

ained operators of Christie high-brightness projection

Third-party products

This projector is certified to work only with certain specified third-party components. Use only Christie

approved third-party components with the projector. Using non-approved components with the

projector can lead to potential safety hazards and void the projector warranty.

For detailed safety information on third-party components, refer to the product documentation

provided by the manufacturer of the component.

Important safeguards

To prevent personal injury and to protect the device from damage, read and follow these safety

precautions.

Safety and warning guidelines

Read all safety and warning guidelines before installing or operating the projector.

This projector must be operated in an environment that meets the operating range specification. Use

only the attachments and/or accessories recommended by Christie. Use of others may result in the

risk of fire, shock, or personal injury.

Mirage SST User Guide 7

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 8

Introduction

Warning! If not a

• This product must be operated in an environment that meets the operating range as specified in

this document.

• Do not look directly into the lens when the light source is on. The extremely high brightness can

cause permanent eye damage.

• ELECTRICAL and BURN HAZARD! Use caution when accessing internal components.

• FIRE HAZARD! Keep hands, clothes, and all combustible material away from the concentrated

light beam of the projector.

• Keep fingers and other body parts away from the moving parts in the product. Tie back long

hair, and remove jewelry and loose clothing before manually adjusting the product.

• FIRE AND SHOCK HAZARD! Use only the attachments, accessories, tools, and replacement parts

specified by Christie.

• Do not operate the product without a lens installed.

• Always use a lens plug when installing or moving the product. This prevents contaminants from

entering the product.

• FIRE AND SHOCK HAZARD! Use only the attachments, accessories, tools, and replacement parts

specified by Christie.

Caution! If not a

• TRIP OR FIRE HAZARD! Position all cables where they cannot contact hot surfaces, be pulled, be

tripped over, or damaged by persons walking on or objects rolling over the cables.

voided, the following could result in death or serious injury.

voided, the following could result in minor or moderate injury.

Installation safety and warning guidelines

R

ead all safety and warning guidelines before installing the projector.

Warning! If not a

• Possible hazardous optical radiation emitted from this product. (Risk group 3)

• Christie products must be installed and serviced by Christie qualified technicians.

• Do not operate the product without all of its covers in place.

• A minimum of two people or appropriately rated lift equipment is required to safely lift, install,

or move the product.

• Always install safety straps when the frame and projector are installed overhead.

• Observe load ratings and applicable local safety codes.

• When installing the projector in portrait mode, the rigging device must have a sufficient load

rating, as identified in this manual.

• This product must be installed within a restricted access location not accessible by the general

public.

• Install the product so users and the audience cannot enter the restricted area at eye level.

• Only personnel who are trained on the precautions for the restricted access location can be

granted entry to the area.

• Only Christie qualified technicians are permitted to open product enclosures.

Caution! If not a

• ELECTRICAL and BURN HAZARD! Use caution when accessing internal components.

• Only Christie qualified technicians are authorized to use the tools provided in the toolbox.

voided, the following could result in death or serious injury.

voided, the following could result in minor or moderate injury.

Mirage SST User Guide 8

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 9

AC power precautions

R

ead all safety and warning guidelines before connecting to AC power.

Warning! If not a

• SHOCK HAZARD! Only use the AC power cord provided with the product or recommended by

Christie.

• FIRE AND SHOCK HAZARD! Do not attempt operation unless the power cord, power socket, and

power plug meet the appropriate local rating standards.

• SHOCK HAZARD! Do not attempt operation if the AC supply is not within the specified voltage

and current, as specified on the license label.

• SHOCK HAZARD! The AC power cord must be inserted into an outlet with grounding.

• SHOCK HAZARD! A dedicated, protected ground or earth wire must be installed on the product

by Christie qualified technicians or electricians before it can be connected to power.

• SHOCK HAZARD! Disconnect the product from AC before installing, moving, servicing, cleaning,

removing components, or opening any enclosure.

• Install the product near an easily accessible AC receptacle.

Caution! If not a

• FIRE HAZARD! Do not use a power cord, harness, or cable that appears damaged.

• FIRE OR SHOCK HAZARD! Do not overload power outlets and extension cords.

• SHOCK HAZARD! Power supply uses double pole/neutral fusing. Disconnect all power sources

before opening the product.

voided, the following could result in death or serious injury.

voided, the following could result in minor or moderate injury.

Introduction

Laser safety precautions

R

ead all safety and warning guidelines before operating the projector laser.

Warning! If not a

• LASER RADIATION HAZARD! This projector has an external Class 4 laser module. Never attempt

to disassemble or modify the laser module.

• Possible hazardous optical radiation emitted from this product. (Risk group 3)

• Only Christie qualified technicians who are knowledgeable about the hazards associated with

laser use, high-voltage, and high temperatures generated by the product are authorized to

assemble, install, and service the Christie Laser Projection System.

• RADIATION HAZARD! Use of controls or adjustments, or performing procedures other than those

specified may result in hazardous radiation exposure.

• Do not look directly into the lens when the light source is on. The extremely high brightness can

cause permanent eye damage.

• Do not operate the product without all of its covers in place.

• LASER RADIATION! Do not short the contact rings.

• Always keep a protective cap on disconnected fiber optic cables.

voided, the following could result in death or serious injury.

Mirage SST User Guide 9

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 10

Introduction

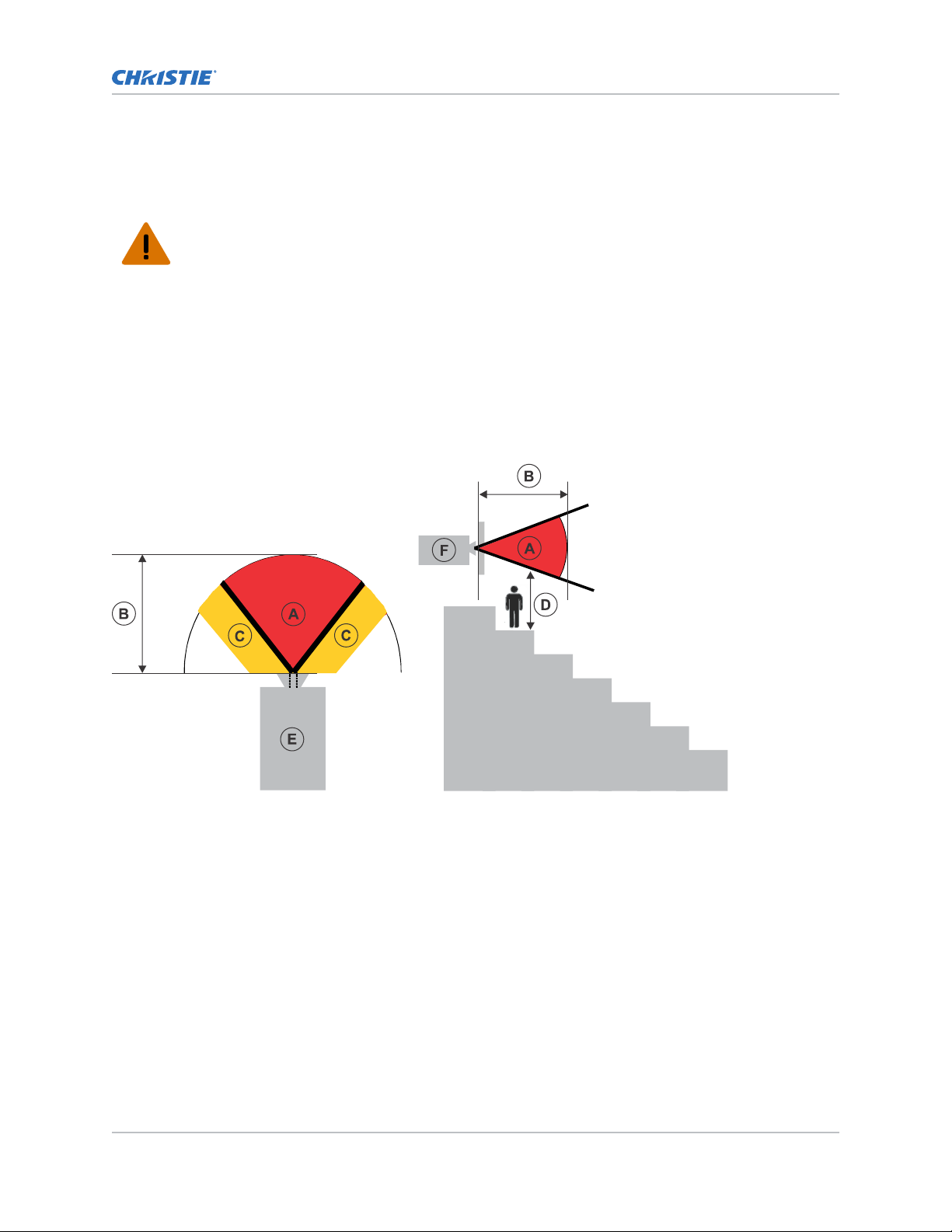

Light intensity hazard distance

This projector has been classified as Risk Group 3 as per the IEC 62471-5:2015 standard due to

possible hazardous optical and thermal r

Warning! If not a

• PERMANENT/TEMPORARY BLINDNESS HAZARD! No direct exposure to the beam must be

permitted. Class 1 Laser Product - Risk Group 3 according to IEC 60825-1:2014 and IEC

62471-5:2015.

• PERMANENT/TEMPORARY BLINDNESS HAZARD! Operators must control access to the beam

within the hazard distance or install the product at the height that prevents exposure of

spectators' eyes within the hazard distance. The hazard zone must be no lower than 2.5 meters

(US installations) or 2.0 meters (global installations) above any surface upon which any persons

are permitted to stand and the horizontal clearance to the hazard zone must be a minimum 1.0

meters.

• EXTREME BRIGHTNESS! Do not place reflective objects in the product light path.

voided, the following could result in serious injury.

The following diagram and table show the zones for ocular and skin hazard distances:

adiation being emitted.

• A—Hazard zone. The region of space where the projection light from the laser-illuminated

projector is abo

ve emission limits for Risk Group 2. The light intensity may cause eye damage

after a momentary or brief exposure (before a person can avert his or her eyes away from the

light source). The light may cause skin burns to occur.

• B—Hazard distance. Operators must control access to the beam within the hazard distance or

install the product preventing potential exposure of the spectators' eyes from being in the

hazard distance.

• C—No access zone. Horizontal clearance of the no access zone must be a minimum of 1.0

meters.

• D—Vertical distance to hazard zone. The hazard zone must be no lower than 2.5 meters (US

installations) or 2.0 meters (global installations) above any surface upon which any persons

are permitted to stand.

• E—Represents the top view of the projector.

• F—Represents the side view of the projector.

Mirage SST User Guide 10

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 11

Introduction

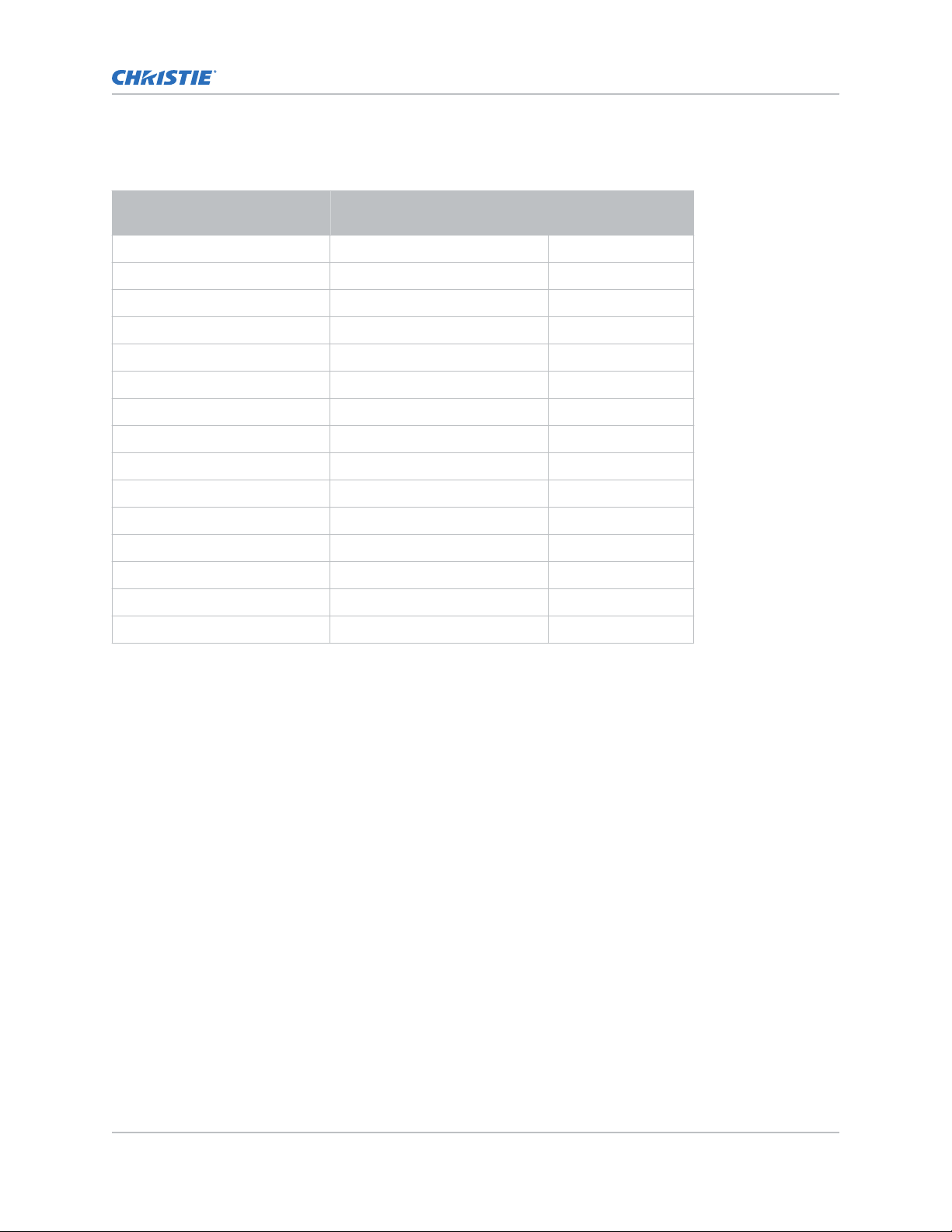

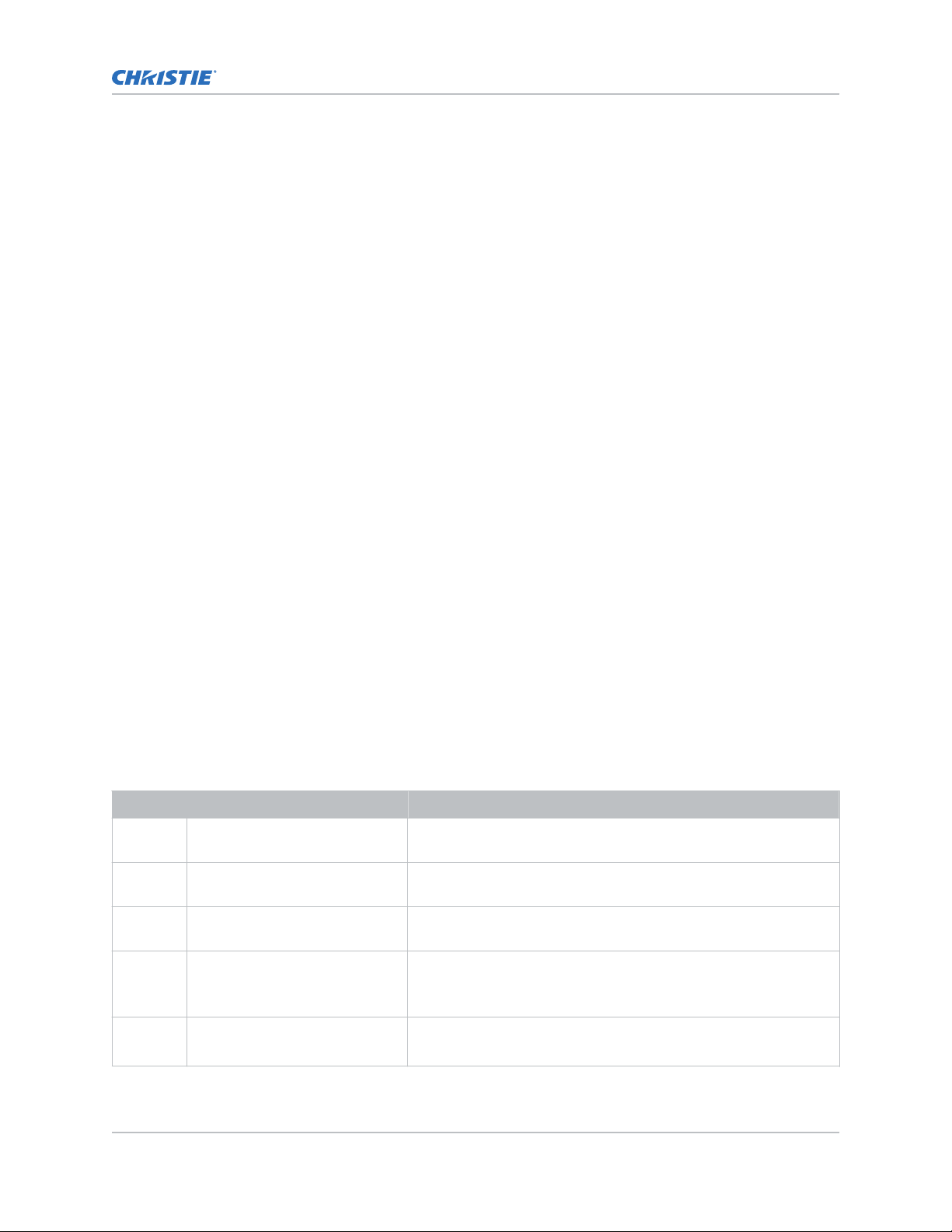

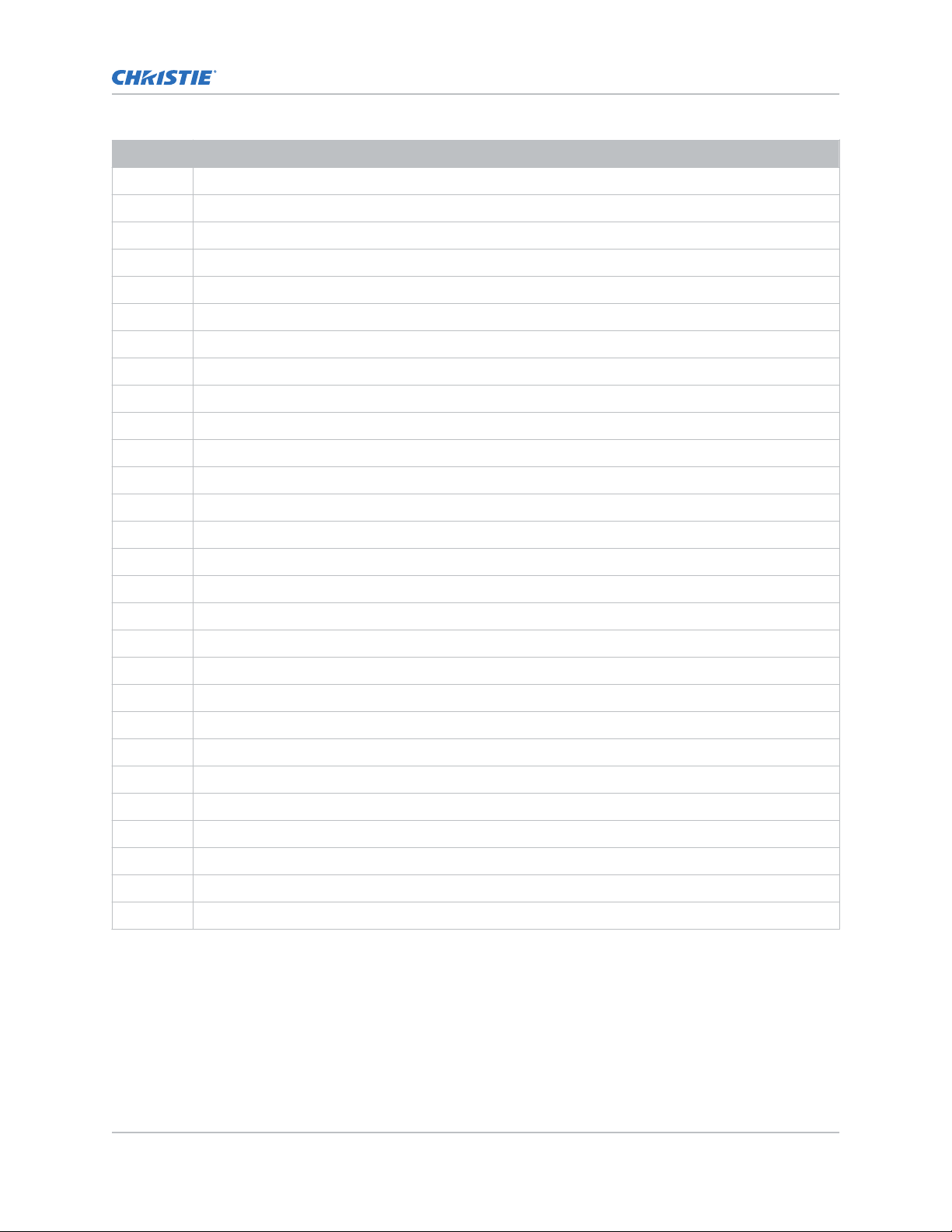

For US and international hazard distances based upon IEC 62471-5:2015, Photobiological Safety of

Lamps and Lamp Systems – Part 5: Image Projectors.

Projection lens Part number Hazard distance

(m)

0.72:1 HB fixed 144-110103-XX 1

0.9:1 fixed lens 144-111014-XX 1.2

1.13-1.31:1 HB zoom 144-103105-XX 1.5

1.13-1.66:1 HB zoom 144-129103-XX 2.1

1.31-1.63:1 HB zoom 144-104106-XX 2.1

1.45-2.17:1 HB zoom 144-130105-XX 2.6

1.63-2.17:1 HB zoom 144-105107-XX 2.6

1.95-3.26:1 HB zoom 144-131106-XX 3.8

1.99-2.71:1 HB zoom 144-106108-XX 3.2

2.71-3.89:1 HB zoom 144-107109-XX 4.4

3.89-5.43:1 HB zoom 144-108100-XX 6.1

4.96-7.69:1 HB zoom 144-109101-XX 8.7

1.13-1.66 UHC zoom 163-118101-XX 1.8

1.45-2.17 UHC zoom 163-119102-XX 2.1

1.95-3.26 UHC zoom 163-120103-XX 3.2

For Installations in the United States

The following must be in place for laser

• Permanent show installations containing Risk Group 3 laser-illuminated projectors must meet

the following conditions:

• Installed by Christie or by Christie-authorized and trained installers.

Refer to the Laser Illuminated Projector - Class 1 Risk Group 3 Installation training (Course

code: CF-LIPI-01) on the http://www.christieuniversity.com site.

• Performed according to instructions provided by Christie.

• Ensure the projection system is securely mounted or immobilized to prevent unintended

movement or misalignment of the projections.

• The projection room shall be clearly identified by the posting of laser warning and restricted

access signs. The projection room sign must display the warning "Class 1 Risk Group 3 Laser

Controlled Area No Direct Exposure to Beam Shall be Permitted".

• The Christie Laser Projection System Installation Checklist must be fully completed after the

installation and sent to lasercompliance@christiedigital.com. A copy can remain on-site. This

checklist can be found as a separate document in the accessory box with the manual.

• If installing in the US states of Arizona, Florida, Georgia, Illinois, and Massachusetts, go to

www.christiedigital.com for additional regulatory requirements.

-illuminated projector installations in the United States:

Mirage SST User Guide 11

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 12

Product labels

Introduction

Learn about the labels that ma

y be used on the product. Labels on your product may be yellow or

black and white.

General hazards

Hazard warnings also apply to accessories once they are installed in a Christie product that is

connected to power.

Fire and Shock Hazard

To prevent fire or shock hazards, do not expose this product to rain or moisture.

Electrical Hazard

Do not alter the power plug, o

Do not remove the product enclosure.

Only Christie qualified technicians are authorized to service the product.

Risk of electric shock.

Do not remo

Only Christie qualified technicians are authorized to service the product.

General hazard.

ve the product enclosure.

verload the power outlet, or use it with extension cords.

Electric shock hazard. To avoid personal injury, disconnect all power sources before

performing maintenance or service.

Electrocution hazard. To avoid personal injury, always disconnect all power sources before

performing maintenance or service procedures.

Hot surface hazard. To avoid personal injury, allow the product to cool for the recommended

cool down time before performing maintenance or service.

Optical radiation hazard. To avoid personal injury, never look directly at the light source.

Moving parts hazard. To avoid personal injury, keep hands clear and loose clothing tied back.

Fan hazard. To avoid personal injury, keep hands clear and loose clothing tied back. Always

disconnect all power sources before performing maintenance or service procedures.

Laser hazard. To avoid personal injury, avoid eye or skin exposure to direct or scattered

adiations.

r

Mirage SST User Guide 12

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 13

Not for household use.

Mandatory action

Disconnect all power sources before performing maintenance or service procedures.

Consult the service manual.

Electrical labels

Indicates the presence of a protective earth ground.

Introduction

Laser labels

FDA laser variance (US projectors only)

Indicates a light hazard. Do not look directly into the lens. The

extreme high brightness can cause permanent ey

Laser Product - Risk Group 3 according to IEC 60825-1: 2014 and

IEC 62471-5:2015

Indicates the product is certified for use with IPG Photonics Model

-100-3P Part number 168-101103-XX laser.

RGB

e damage. Class 1

Mirage SST User Guide 13

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 14

Indicates a danger Class 4 laser radiation when open and interlocks

are defeated. A

radiation. Turn off power before removing the bracket.

Additional safety hazards

Do not look directly into the lens. The extremely high brightness

can cause permanent eye damage.

Indicates high leakage current. Earth connection essential before

connecting the power supply

Product documentation

Introduction

void eye or skin exposure to direct or scattered

.

F

or installation, setup, and user information, see the product documentation available on the Christie

website. Read all instructions before using or servicing this product.

1. Access the documentation from the Christie website:

• Go to this URL: http://bit.ly/2TI2aEW or

https://www.christiedigital.com/en-us/3d/products-and-solutions/projectors/mirage-sst.

• Scan the QR code using a QR code reader app on a smartphone or tablet.

2. On the product page, switch to the Downloads

tab.

Related documentation

Additional information on this product is available in the following documents.

• Mirage SST Product Safety Guide (P/N: 020-102992-XX)

• Mirage SST Installation and Setup Guide (P/N: 020-102956-XX)

• Mirage SST Projector Head Specifications Guide (P/N: 020-102994-XX)

• Mirage SST Status System Guide (P/N: 020-103007-XX)

• Mirage SST Serial Commands Guide (P/N: 020-103005-XX)

• Mirage SST Projector Head Service Guide (P/N: 020-103039-XX)

Mirage SST User Guide 14

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 15

Projector overview

Introduction

Learn about the

Mirage SST is a professional quality projector using Digital Light Processing (DLPTM) technology from

Texas Instruments. Mirage SST is engineered specifically for complex, high-end applications like

planetariums, dome theaters, and theme park attractions to offer stunning wide screen, high

resolution 4K images at 120 frames per second.

Mirage SST provides several design and installation advantages. Its small form factor allows it to be

installed independently, or as part of a multi-projector array, into tight, challenging environments. The

remote light source also allows the chilling equipment to be located away from the projector head

where its noise will not impact the audience’s enjoyment of the show.

Mirage SST projector.

Contact your dealer

Record the information about your projector and keep this information with your records to assist with

the servicing of your projector. If you encounter a problem with your Christie projector, contact your

dealer.

Purchase record

Dealer:

Dealer or Christie Sales/Service contact phone number:

Projector serial number:

The serial number can be found on the license label located on the displa

Purchase date:

y panel

Installation date:

Ethernet settings

Default gateway

Projector IP address

Subnet mask

Key features

Understand the important features of the projector

• Built in warp and blend of projected images

• Improved lens mount with bayonet style insertion

• Single phase 100-240 V

• Side access to optical adjustments

• 4K resolution for flexibility and future proofing

• Omnidirectional operation

• TruLife electronics

.

Mirage SST User Guide 15

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 16

Introduction

• LCD display to provide information at-a-glance

How the projector works

The

Mirage SST accepts a variety of input signals for projection on front or rear projection screens,

typical in commercial or other large screen applications.

High-brightness light is generated by a laser illumination source, then fed to the projector through a

fiber optic cable, where it is modulated by three Digital Micromirror Device (DMD) panels responding

to incoming data streams of digitized red, green and blue color information. Based on digital signals

from the source, light from the responding on pixels of each panel is reflected, converged and then

projected to the screen through a projection lens, where all pixel reflections are superimposed into a

sharp full-color image.

The Mirage SST projector head provides all configuration and control for the laser illumination source.

Never connect a laptop to the laser illumination source unless directed by Technical Support.

List of components

Verify all components were received with the projector.

• Power cord

• IR remote keypad

• Network cable

• Tools

• Fiber optic support

• Laser illumination source interlock jumper for J33 harness (P/N: 001-114198-XX)

• Fiber connector safety cover

Display panel components

Identify the main components of the display panel (also known as the home page).

ID Component Description

A Projector Information Provides information about the projector such as the projector

name, serial number

B Projector and Component

Controls

C Power and Temperature Indicates the light source mode, power mode, and intake

D Status Contains information about the health of the projector including

E IP Settings Displays the IP address and subnet values.

Mirage SST User Guide 16

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Indicates the states of the projector and its components.

temperature.

the number of warnings and errors.

Provides access to the status system.

Provides access to changing the IP settings.

, software version, and projector ID.

Page 17

Introduction

ID Component Description

F Test Pattern Displays the currently selected test pattern. If no test pattern is

selected, Off is displa

Provides access to the list of test patterns.

G Input Displays the signal for the currently selected input.

Provides access to the list of input signals.

yed.

Mirage SST User Guide 17

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 18

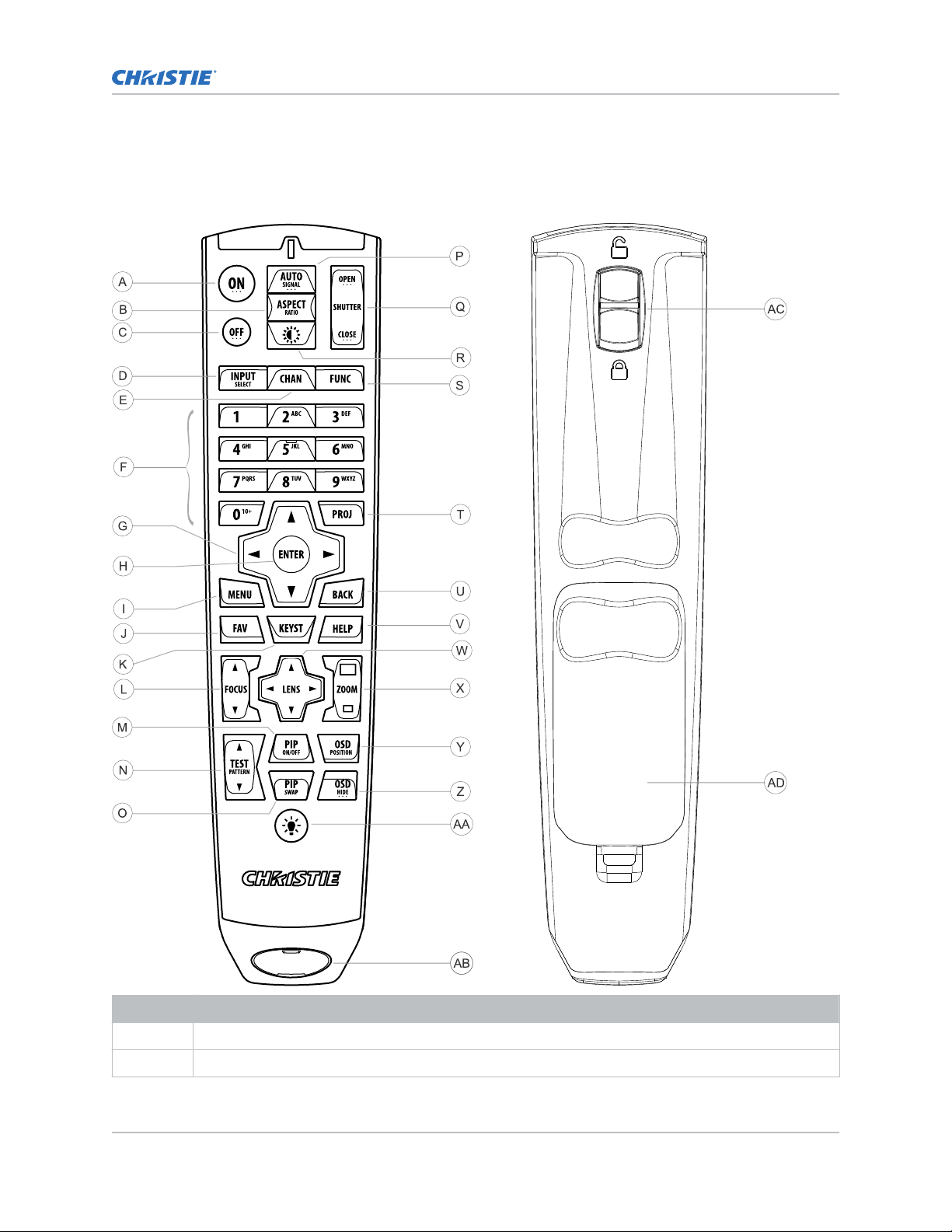

IR remote keypad

Introduction

The IR remote k

eypad controls the projector by way of wireless communications from a battery-

powered infrared (IR) transmitter.

Button Description

A Powers on the projector light source.

B Opens the aspect ratio dialog.

Mirage SST User Guide 18

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 19

Button Description

C Turns off the light source and puts the projector in standby.

D Selects an active or inactive input on any slot.

E Not supported.

F Enter a number, such as menu, item index or value.

G Use the arrows to navigate within a menu or to adjust settings.

H Selects a highlighted menu item and changes or accepts a value.

I Toggles the menus on/off.

J Not supported.

K Opens the keystone dialog.

L Adjusts the lens focus.

M Not supported.

N Displays a test pattern.

O Not supported.

P Optimizes the image automatically.

Introduction

Q Opens or closes the shutter.

R Not supported.

S Initiates a custom action when a number is selected.

T Selects a projector in multi-projector installations.

U Returns to the previous menu level or exits menus if at the top level.

V Displays context-sensitive help.

W Arrows adjust the lens offset.

X Adjust the lens zoom.

Y Opens the on-screen display position menu.

Z Shows or hides the on-screen display menus.

AA Turns the remote backlight on.

AB Male 3-pin XLR connector for wired option.

AC Lock/unlock the keypad.

AD Battery door.

Mirage SST User Guide 19

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 20

Operating the projector

Learn how to turn on and off the projector and the meaning of the status indicators.

Performing initial system start-up

Learn how to turn on all components of the

illumination source, and projector head.

Warning! If not a

• SHOCK HAZARD! Do not attempt operation if the AC supply is not within the specified voltage

and current, as specified on the license label.

Never run the laser illumination source without the cooling system already running. The chiller must

be the first item turned on before power is applied to the laser rack and kept operating until after the

AC lockout/switch is rotated to the off position.

1. Verify the coolant lines are connected correctly.

2. Fill the chiller reservoir with the required coolant (30% Propylene Glycol coolant).

3. Turn on the chiller, set the temperature to between 19°C (66°F) to 22°C (71.6°F).

For more information on how to turn on the chiller, refer to the chiller's product

documentation.

4. Check the coolant level in the reservoir and hoses and top up the coolant as required.

5. Check that no leaks exist in the system.

6. Allow the chiller to run until the system is operating with no new bubbles entering the

reservoir. Add additional coolant as necessary.

7. On the laser illumination source, rotate the main AC lockout/switch (A)to the on position and

rotate the Power key (B) clockwise to the on position.

The Interlock status indicator (C) on the laser illumination source turns yellow.

voided, the following could result in death or serious injury.

Mirage SST system for the first time: chiller, laser

Mirage SST User Guide 20

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 21

Operating the projector

8. On the projector beside the AC inlet, move the AC breaker/switch to the on position.

The projector boots into standb

y mode after approximately 30 seconds.

9. Once the projector is in standby, on the projector keypad or the projector remote, press and

hold the power button until you hear a beep.

The projector can also be turned on using the web user interface. After a few seconds, the

projector moves to the on state, causing the yellow light on the laser illumination source to

turn off. The laser is ready to be turned on but no illumination occurs until the green button is

pressed and the lasers have warmed up.

10. On the laser illumination source, press the green Start button (D).

The two Emission status indicators (E) turn red. When the lasers are warmed up and the

projector is ready, you can display an image (use test pattern if no source image is

connected).

On the projector, the Status > Laser Info > Laser Bank State menu displa

ys the message

"Warming Up". When that message disappears, the lasers are ready. It typically takes the

Mirage SST User Guide 21

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 22

Operating the projector

lasers approximately 10 to 15 minutes to warm up when turning on the first time from the off

position. This could be longer if the start

-up temperatures are approaching minimum or

maximum temperatures for operation. The projector will operate with the shutter closed until

the lasers are warmed up.

Turning on the system

After the system has been initiated for the first time, not all steps need to be performed when

subsequently turning on the system.

Warning! If not a

• SHOCK HAZARD! Do not attempt operation if the AC supply is not within the specified voltage

and current, as specified on the license label.

Never run the laser illumination source without the cooling system already running. The chiller must

be the first item turned on before power is applied to the laser r

AC lockout/switch is rotated to the off position.

1. Turn on the chiller.

For more information on how to turn on the chiller, refer to the chiller's product

documentation.

2. Check the coolant level. If the coolant level is low, add coolant and check for leaks.

3. On the laser illumination source, rotate the main AC lockout/switch (A) to the on position and

rotate the Power key (B) clockwise to the on position.

The Interlock status indicator (C) on the laser illumination source turns yellow.

voided, the following could result in death or serious injury.

ack and kept operating until after the

4. If the breaker is off, on the projector beside the AC inlet, move the AC breaker/switch to the

on position.

The projector boots into standb

Mirage SST User Guide 22

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

y mode after approximately 30 seconds.

Page 23

Operating the projector

5. Once the projector is in standby, on the projector keypad or the projector remote, press and

hold the power button until you hear a beep.

The projector can also be turned on using the web user interface. After a few seconds, the

projector moves to the on state, causing the yellow light on the laser illumination source to

turn off. The laser is ready to be turned on but no illumination occurs until the green button is

pressed and the lasers have warmed up.

6. On the laser illumination source, press the green Start button (D).

The two Emission status indicators (E) turn red. When the lasers are warmed up and the

projector is ready, you can display an image (use test pattern if no source image is

connected).

On the projector, the Status > Laser Info > Laser Bank State menu displa

ys the message

"Warming Up". When that message disappears, the lasers are ready. It typically takes the

lasers approximately 10 to 15 minutes to warm up when turning on the first time from the off

position. This could be longer if the start-up temperatures are approaching minimum or

Mirage SST User Guide 23

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 24

Operating the projector

maximum temperatures for operation. The projector will operate with the shutter closed until

the lasers are w

armed up.

Turning off the system

Learn how to turn off all components of the Mirage SST system: projector head, laser and chiller.

When powering off in preparation for inspection or maintenance, always disconnect from AC.

1. To turn the light source off using the projector keypad or remote, press and hold the

ou hear a beep.

until y

button

The projector can also be turned off with the web user interface. Always allow the projector to

complete the 10 minute cool down cycle before power is turned off at the breaker or

unplugged or projector damage could occur.

2. On the laser illumination source, rotate the main AC lockout/switch (A) to the off position and

rotate the Power key (B) counter clockwise to the off position.

3. Christie recommends, if possible, to keep the chiller operating for 10 minutes after laser AC

lock

out/switch A has been rotated to the off position.

For more information on the chiller operation, refer to the chiller's product documentation.

Projector LED status indicators

Identify the LED state colors and meaning.

LED State Description

Blue Solid Standby Light source is off. Video electronics are off.

Projector status is OK.

Flashing Cool down Projector is moving to one of the two standby

states:

•

Light source is off and video electronics are

booting up.

Mirage SST User Guide 24

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 25

Operating the projector

LED State Description

• Light source is off. Video electronics and light

source is cooling down.

Green Solid Light source on Light source is on. Projector status is OK.

Flashing Startup Projector is moving to light source on state. Light

source is w

initializing.

arming up. Video electronics are

Yellow Solid Warning in

standby

Flashing yellow/green Warning during

startup

Flashing Warning with

light source on

Flashing yellow/blue Warning during

cool down

Red Solid Error in

standby

Flashing Error An error with the projector exists during startup,

Off AC off The AC power is off.

Projector is in standby state. A problem exists with

the projector that does not prevent it from

operating.

Projector is in a startup state. A problem exists

with the projector that does not prevent it from

operating.

Light source is on. A problem exists with the

projector that will not cause it to shut down.

Projector is in a cool down state. Light source is off.

Video electronics and light source are cooling

down. A problem exists with the projector that

does not prevent it from operating.

Projector is in standby. An error exists that

prevents the projector from starting up.

cool down, or when the light source is off. Projector

will proceed to shut down.

Projector LED shutter indicators

Identif

y the shutter LED state colors and meaning.

LED State Description

Solid magenta Shutter closed The shutter is closed.

In standb

the magenta light is muted.

Off Shutter open The shutter is open.

Mirage SST User Guide 25

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

y, the shutter is always automatically closed and

Page 26

Adjusting the image

Adjust the projector image.

procedures as focus may change as the lens warms.

Christie recommends warming the lens before completing these

Selecting screen image orientation

Specify the orientation to use for the image. The projector supports front projection, rear projection,

front projection inverted, or rear projection inverted.

1. Select MENU > Image Settings > Image Orientation.

2. Select the required orientation from the list.

3. To confirm your selection, press Enter.

Setting the image resize preset

Set the image resize preset to determine if an image will display in its native resolution or will resize

by maximizing the height, width, both height and width, or to the maximum size while keeping the

original aspect ratio.

1. Select MENU > Image Settings > Size & Position > Resize Presets.

2. Select the appropriate resize preset:

• Auto—Maximize for current source.

• No Resizing—Display in native resolution.

• Full Size—Fill the screen, regardless of source.

• Full Width—Fill display width and keep aspect ratio.

• Full Height—Fill display height and keep aspect ratio.

3. Select Enter.

Adjusting lens settings

Adjust various lens settings including the offset, zoom, focus, and locking the lens motor.

Adjusting offset

Adjust the offset to align the image on the screen. Always adjust offset before adjusting boresight.

For the best optical performance and minimal keystone, use offsets instead of aiming at the center of

the image, in off

pattern indicate extreme offset that should be avoided using mechanical alignment.

1. Project an image with the primary lens.

Mirage SST User Guide 26

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

-axis installations. Avoid extreme tilts or offsets. Corner vignettes on a white test

Page 27

Adjusting the image

2. Select a framing test pattern.

3.

Select LENS OFFSET.

4. Use the arrows to adjust the offset to display a square image on the screen, with minimal

projector aiming error.

5. To exit to the home page, select Back.

Resetting the lens to home position

Set the lens offset back to the home position.

1. Select LENS OFFSET.

You can also select MENU > Configuration > Lens Settings > Lens Offset.

2. To reset the lens to the default home position, select Enter.

3. To confirm the reset, select OK.

Aligning the image with lens zoom and focus

Ensure that the image reflected from the digital micromirror device (DMD) is parallel and centered

with the lens and screen.

1. Display an image or test pattern that can be used to analyze image focus and geometry.

2. Select ZOOM.

You can also select the zoom function from MENU > Configuration > Lens Settings >

Zoom.

3. Use the up and down arrows to zoom in or out of the image.

4. To exit, select Back.

5. Select FOCUS.

You can also select the focus function from MENU > Configuration > Lens Settings >

Focus.

6. Use the up and down arrows to adjust the focus of the image.

7. To exit, select Back.

8. To refine your adjusts, repeat steps 2 to 7.

Locking the lens motor

Prevents all lens motors from moving. It disables the zoom, focus, and offset settings, locking out any

changes and overriding all other lens features. This feature prevents accidental lens position changes

in multi-projector installations.

1. Select MENU > Configuration > Lens Settings > Lock all Lens Motors.

2. To enable locking of all lens motors, select Enter.

Determining what lens warnings are displayed

Controls the level of lens warnings displayed.

1. Select MENU > Configuration > Lens Settings > Lens Warnings.

2. Select the appropriate lens warning level:

Mirage SST User Guide 27

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 28

Adjusting the image

• Show All Warnings—

• Hide Zoom Motor Warnings—Hides zoom motor warnings.

• Hide Detection Warnings—Hides lens detection warnings. Christie recommends

selecting this option when using a third-party lens.

3. Select Enter.

Shows all lens warnings.

Adjusting primary colors

Calibrate the accuracy of primary colors, which can change because of lighting and environmental

factors.

All primary colors in the projector are precisely set to pre-established values to ensure overall color

performance is optimized and is as accurate as possible. Lighting and other environmental factors may

slightly change how these colors appear on your screen. While the change is negligible in most cases,

you may prefer to recover the originally intended color performance before trying to match colors from

several projectors.

To achieve consistency use a color meter to measure the native primary colors—red, green, blue, and

white—as they appear on the screen. On the basis of these new values, which are stored in memory,

each projector automatically calculates any necessary corrections to reproduce the original factory

colors under the current environmental conditions. This essentially calibrates a projector to its

surroundings, compensating for factors such as screen type, light source and/or ambient lighting, and

improves color accuracy and consistency in a group of projectors. It ensures a good starting point for

further customizing and matching; however, is not critical for all installations.

1. From the display panel, select MENU > Configuration.

2. Select Color Primary Settings.

3. To edit the primary colors, select Edit Primary Colors.

4. Adjust the slider or enter the measured color values of the primary color component you

selected.

5. To confirm your selection, select Enter.

6. Repeat steps 5 and 6 for each primary color component.

7. To view a specific color while adjusting, select Show Color Pattern.

8. Select the appropriate color and select Enter.

9. To reset the primary colors to their defaults, select Reset Color Primaries.

10. At the confirmation prompt, select OK.

DMD color correction

Adjust the DMD color values as required.

Adjusting color by precise chromaticity values

Change the values of the primary color components.

1. Select MENU > Configuration > Color Correction by x,y.

2. Adjust the slider or enter the measured color values of the primary color component you

selected.

Mirage SST User Guide 28

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 29

Adjusting the image

3. To confirm your selection, select Enter.

4.

Repeat steps 2 and 3 for each primary color component.

5. To view a specific color while adjusting, select Show Color Pattern.

6. Select the appropriate color and select Enter.

Adjusting color by saturation

Change the strength of the primary color in relation to the other primary colors.

1. Select MENU > Configuration > Color Saturation.

2. Adjust the value of the primary color you selected by using more or less of it in relation to the

other primary colors.

3. To confirm your selection, select Enter.

4. Repeat steps 2 and 3 for each primary color.

5. To view a specific color while adjusting, select Show Color Pattern.

6. Select the appropriate color and select Enter.

Signal color correction

Adjust the video signal color as required.

For best results, Christie recommends setting all color and gamma settings to Auto Detect.

Adjusting the color space

Determine how the color components are decoded for accur

1. Select MENU > Image Settings > Color & Gamma > Color Space.

2. Select the adjustment most suited to the input signal:

• Auto Detect

• RGB (Full Range)

• RGB (Limited Range)

• YCbCr HDTV (Expanded Range)

• YCbCr JPEG (Full Range)

• YCbCr UHDTV (ITU-R BT.2020) (Full Range)

3. Select Enter.

ate color in the display.

Adjusting color by temperature

Adjust the color temperature as expressed in degrees Kelvin.

1. Select MENU > Image Settings > Color & Gamma.

2. Select Color Temperature.

3. Adjust the slider to change the light to warmer or cooler and select Enter.

Mirage SST User Guide 29

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 30

Selecting the color correction mode

Select the color correction mode most suited to the input signal.

1.

Select MENU > Image Settings > Color & Gamma > Color Correction Mode.

2. Select the adjustment most suited to the input signal:

• Auto Detect—Automatically detect the appropriate color correction mode, where possible.

• Max Drives—All color adjustments are turned off, allowing the projector to run at

maximum brightness.

• Color Temperature—Specify a color temperature between 3200 and 9300, expressed in

degrees Kelvin.

• HD Video—Set the output color to a specific standard value. Adjusts the colors red,

green, blue, and white.

• DCI P3—Set the DCI P3 (cinema) colorimetry with DCI white point.

• DCI P3 (D65)—Set the DCI P3 colorimetry with D65 white point.

• Custom—Select a user defined set of color adjustments.

3. Select Enter.

Adjusting the image

Correcting for ambient light

Ambient light is the natural light that occurs in the environment where the projector is located.

1. Select MENU > Image Settings > Color & Gamma > Ambient Light Correction.

2. Select Enter.

3. Use the right and left arrows to adjust how the image displays in conditions with ambient light.

4. To confirm your selection, select Enter.

Setting the frame delay

Delay the output signal timing relative to the input signal timing by a fraction of a frame, and up to

several frames.

The minimum latency can vary based on the amount of scaling applied to the image. When using

keystone or warping, an additional latency is required, depending on the amount of warp.

1. Select MENU > Image Settings > Advanced Image Settings > Frame Delay.

2. To set the frame delay, select Set Delay.

3. Adjust the value and to confirm your selection, select Enter.

4. To set the achievable frame delay, select Actual Delay.

5. Adjust the value and to confirm your selection, select Enter.

Enabling film mode detect

Enables or disables the detection of film motion.

1. Select MENU > Image Settings > Advanced Image Settings > Film Mode Detect.

Mirage SST User Guide 30

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 31

Adjusting the image

2. To enable the detection of film motion, select Auto Detect.

3.

To disable the detection of film motion, select Disabled.

4. Select Enter.

Adjusting the image sharpness

Change the sharpness of the image.

Lower settings can improve a noisy signal. Setting the sharpness above the halfway point can

introduce noise in the image.

1. Select MENU > Image Settings > Advanced Image Settings > Sharpness.

2. Select Enter.

3. Use the right and left arrows to adjust the sharpness of the image.

4. To confirm your selection, select Enter.

Creating a seamless image with edge blending

Combine several projected images into one single, seamless image with edge blending.

Adding edge blends to the projector

Use Christie or to create edge blends and upload them to Mirage SST.

1. Create an edge blend file using the Christie or application.

To connect Mirage SST with Christie or , use port 3003.

Christie Twist Premium, Twist Pro, and offer advanced warping options. Refer to the Christie

website (www.christiedigital.com) for product information and documentation.

2. Upload the edge blend file to the projector.

3. On one projector, select MENU > Configuration > Edge Blending.

4. Select the appropriate edge blend setting and select Enter.

5. Repeat steps 2 to 4 for the remaining projectors.

6. To turn off edge blending, from MENU > Configuration > Edge Blending, select Off.

Enabling basic edge blending

Create basic edge blends directly on Mirage SST.

1. Start with two projectors and display the full white field test pattern from both.

2. On one projector, select MENU > Configuration > Edge Blending.

3. To enable basic edge blending, select Basic.

4. To edit blending adjustments, select Edge Blend Widths.

5. From the Basic Blending dialog, select a side to blend.

6. To make the blending adjustments, use the arrow keys to change either the vertical and

horizontal values as appropriate.

Mirage SST User Guide 31

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 32

Adjusting the image

7. To accept the selection, select Enter.

8.

Repeat steps 4 to 6 to blend the remaining sides.

9. When all adjustments are made, use the arrow keys to highlight Apply and select Enter.

10. Repeat steps 2 to 9 for the remaining projectors.

11. To turn off basic edge blending, from MENU > Configuration > Edge Blending, select Off.

Resetting edge blending

Reset the edge blending to revert any edge blends.

1. Select MENU > Configuration > Edge Blending.

2. Select Reset Edge Blends.

3. At the confirmation prompt, select Reset.

Geometry correction

Modify the geometry for all sources.

Enabling warping

Use warping to project images on any surface shape.

1. Create a warp file using the Mirage SST or application.

To connect Mirage SST with or , use port 3003.

Christie Twist Premium, Twist Pro, and offer advanced warping options. Refer to the Christie

website (www.christiedigital.com) for product information and documentation.

2. Upload the warp file to the projector.

3. Select MENU > Configuration > Geometry Correction > Geometry Correction Mode.

4. Select the appropriate warp setting and select Enter.

5. To turn off warping, from MENU > Configuration > Geometry Correction > Geometry

Correction Mode, select Off.

Pressing Func+Help on the IR remote keypad disables all geometry corrections (warping,

keystone, and black level blending) without changing the settings associated with them.

Correcting the shape of a keystoned image

Keystone effect occurs when you project an image onto the screen at an angle and the projector is not

centered on the screen. The image appears distorted and resembles a trapezoid.

To correct the shape of a keystoned image, use the keystone options available in the geometry

correction menu. Perform coarse keystone adjustments by using the horizontal or vertical settings. It

may not be possible to match the screen dimensions with the horizontal and vertical keystone controls

but you can refine these settings by adjusting the 2D keystone settings.

Enabling keystone adjustments

Enable keystone corrections to correct the shape of a keystoned image.

1. Select MENU > Configuration > Geometry Correction > Geometry Correction Mode.

Mirage SST User Guide 32

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 33

Adjusting the image

2. Select Keystone.

An

y keystone adjustments previously set are enabled.

To disable keystone adjustments, select MENU > Configuration > Geometry Correction >

Geometry Correction Mode > Off.

Adjusting the image with 2D keystone

2D keystone distorts the projected image both vertically and horizontally simultaneously and

resembles a trapezoid.

Adjusting horizontal or vertical keystone correction after 2D keystone erases the 2D keystone settings;

however, performing 2D keystone after horizontal or vertical correction retains the previous keystone

setting.

1. Select MENU > Configuration > Geometry Correction > Geometry correction Mode.

Select 2D Keystone Correction.

2.

3. From the correction dialog, select the corner to adjust.

4. To make the keystone adjustments, use the arrow keys to change both the vertical and

horizontal values.

5. Select Apply Changes.

Adjusting vertical keystone

Use vertical keystone to correct a keystoned image shape in which the top and bottom borders of the

image are unequal in length, and both sides of the image are inclined toward the top or bottom edge.

If vertical keystone adjustments have been made, starting horizontal keystone adjustments erases the

vertical settings.

1. Select MENU > Configuration > Geometry Correction > Geometry Correction Mode.

Select Vertical Keystone Correction.

2.

3. From the correction dialog, adjust the vertical keystone by using the arrow keys.

4. Select Apply Changes.

Adjusting horizontal keystone

Use horizontal keystone to correct a keystoned image shape in which the left and right borders of the

image are unequal in length, and the top and bottom are slanted to one of the sides.

If horizontal keystone adjustments have been made, starting vertical keystone adjustments erases the

horizontal settings.

Mirage SST User Guide 33

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 34

Adjusting the image

1. Select MENU > Configuration > Geometry Correction > Geometry Correction Mode.

Select Horizontal Keystone Correction.

2.

3. From the correction dialog, adjust the horizontal keystone by using the arrow keys.

4. Select Apply Changes.

Resetting keystone correction

Reset keystone to revert the distorted image shape back to default values.

Pressing Func+Help on the IR remote keypad disables all geometry corrections (warping, keystone,

and black level blending) without changing the settings associated with them.

1. Select MENU > Configuration > Geometry Correction.

2. Select Reset Keystone Correction.

3. At the confirmation prompt, select Reset.

Mirage SST User Guide 34

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 35

Configuring system settings

Learn how to configure the system settings.

Setting the date

Configure the date on

1. Select Menu > System Settings.

2. Select Date.

3. Use the up and down keys to adjust the year (YYYY), month (MM), and day (DD).

Mirage SST.

Setting the time

Configure the time on Mirage SST.

1. Select Menu > System Settings.

2. Select Time.

3. Use the up and down keys to adjust the hour (HH), minutes (MM), and seconds (SS).

Changing the splash screen

Select the color displayed on the screen.

1. Select MENU > System Settings > Splash Screen Settings > Background Color.

2. Select a splash screen background color:

• Black

• Red

• Green

• Blue

3. Select Enter.

Determining the on-screen display position

Choose one of the pre-defined locations for the display of the on-screen menus.

1. Select MENU > System Settings > Menu Preferences > OSD Position.

Mirage SST User Guide 35

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 36

Configuring system settings

2. Select the location on the screen where you want the on-screen display menus to appear.

3.

Select Enter.

Changing the language

Choose the language you want displayed on projector display panel and on-screen display.

1. Select MENU > Languages.

You can also select the language from MENU > System Settings > Menu Preferences >

Languages.

2. Select Enter.

3. Select the appropriate language and select Enter.

The change takes effect immediately.

Changing the temperature units

Set if the temperature is measured in Celsius or Fahrenheit.

1. Select MENU > System Settings > Menu Preferences > Temperature Units.

2. Select the temperature unit: Celsius or Fahrenheit.

3. Select Enter.

Resuming projector operation after an AC power interruption

If an AC power interruption occurs while Auto Power Up is enabled, the projector will resume operation

in the same state it was prior to the loss of power.

1. Select MENU > System Settings > Power Settings.

2. Select Auto Power Up.

3. To enable automatically powering up the projector after an AC interruption, select Enter.

Keeping electronics on in standby mode

When the projector is placed in standby mode, the light source will be turned off but the electronics

will remain on.

1. Select MENU > System Settings > Power Settings.

2. Select Keep Electronics On In Standby.

3. To enable electronics remaining on in standby mode, select Enter.

Mirage SST User Guide 36

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 37

Configuring system settings

Enabling direct pass-through of HDMI, 3G, and DisplayPort input signals

Allow the signals from HDMI, 3G, and Displa

1. Select MENU > Configuration > Input Settings > Enable Video Loop Out.

2. To enable passing HDMI, 3G, and DisplayPort input signals through to another projector, select

Enter.

yPort inputs to pass through another projector.

Informing the source of signal preferences

Configure Mirage SST to automatically inform the video source of the preferred signal formats.

1. If you need a specific frame rate, from the display panel, select MENU > Configuration >

Input Settings > EDID Timing.

2. Select the required EDID timing and select Enter.

60 Hz is the default EDID timing.

Configuring the laser power settings

Projector profiles contain the power settings for the RGB laser light source.

1. To display the white test pattern, MENU > Test Pattern

2. Scroll through the list of test patterns and select White.

3. To confirm your selection, select Enter.

4. Select MENU > Image Settings > Color & Gamma > Color Correction Mode.

5. Select Max Drives and to confirm your selection, select Enter.

6. Select MENU > Configuration > Light & Output Settings.

7. To set the approximate red power level, select Red Laser Setpoint and use the slider to

increase and decrease the value required for your projection environment.

To turn off the red lasers but leave them in a ready state, select Red Laser Enable to clear

the checkbox.

8. To set the green (Green Laser Setpoint) and blue (Blue Laser Setpoint) power levels,

repeat step 7.

To turn off either the green or blue lasers but leave them in a ready state, select Green Laser

Enable or Blue Laser Enable to clear the checkbox.

9. If color is not at the target level, refine the red, green, and blue power settings to achieve the

target by repeating steps 7 and 8.

10. To control the brightness once the colors are set, select Maser Laser Power and use the

slider to increase or decrease the value.

To turn off all lasers but leave them in a ready state, select Maser Laser Enable to clear the

checkbox.

11. To save the new laser settings, save to a projector profile.

Mirage SST User Guide 37

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 38

Setting up 1D color uniformity

Configuring system settings

Learn how to set up 1D color uniformit

y on the projector after taking measurement of each of the

color primaries at points (15, 2, 5, 8, and 16).

1. Ensure the projector is running in representative ambient light.

2. Setup a spectroradiometer, such as the CR-250, on a tripod.

If not using the CR-250 or better, Christie recommends placing the meter perpendicular to the

screen to achieve accurate measurements.

Do not use the PR-655 spectroradiometer to perform color uniformity on a multi-projector

installation.

3. Power on the projector.

4. Allow the light source to stabilize.

5. Select MENU > Configuration > Horizontal 1D Color Uniformity.

6. To disable color uniformity, select Color Uniformity Mode.

7. Select Enter.

8. Select MENU > Image Settings > Color & Gamma > Color Correction Mode.

9. Select Max Drives and to confirm your selection, select Enter.

10. Select Show Color Pattern > Auto and to confirm your selection, select Enter.

11. From the side panel home page, use the arrows to select Test Pattern.

12. Select the 17 Point test pattern and to confirm your selection, select Enter.

13. Record the x, y, and RGB luminance values for the center point.

Point the spectroradiometer at point 5 (middle square).

a)

b) Click the X value.

c) Record the x value from the spectroradiometer.

d) Click the Y value.

e) Record the y value from the spectroradiometer.

f) Click on the Red luminance setting.

The display changes to the appropriate color.

g) Record the luminance value from the spectroradiometer.

h) Click on the Green luminance setting.

The display changes to the appropriate color.

i) Record the luminance value from the spectroradiometer.

j) Click on the Blue luminance setting.

Mirage SST User Guide 38

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 39

Configuring system settings

The display changes to the appropriate color.

k)

Record the luminance value from the spectroradiometer.

14. Record the luminance values for the remaining four points (2—inside left, middle square; 15—

far left, middle square; 8—inside right, middle square; and 16—far right, middle square)

a) Point the spectroradiometer at a point.

b) Click on the Red luminance setting.

The display changes to the appropriate color.

c) Record the luminance value from the spectroradiometer.

d) Click on the Green luminance setting.

The display changes to the appropriate color.

e) Record the luminance value from the spectroradiometer.

f) Click on the Blue luminance setting.

The display changes to the appropriate color.

g) Record the luminance value from the spectroradiometer.

h) For the remaining three points, repeat steps a to g.

15. Select MENU > Configuration > Horizontal 1D Color Uniformity.

16. To enable color uniformity, select Color Uniformity Mode.

17. Select Enter.

18. To verify 1D color uniformity is working, enable a flat white test pattern.

Turning on the projector with low voltage

Enable the projector to turn on even if the AC mains voltage is below specification.

1. From the display panel, select MENU > Admin > Service.

2. Enter the service password.

3. Select Ignore Low AC Input Voltage Error.

4. To ignore the Low AC Input Voltage error when turning on the projector, select Enter.

Mirage SST User Guide 39

020-102993-01 R

Copyright © 2019 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (06-2019)

Page 40

Configuring communications

Defines and controls how single or multiple projectors are link

device.

ed with each other and with a controlling

Enabling projector communication

Enable the receivers and the wired keypad to communicate with the projector from the remote.

The front and rear IR sensors receive transmissions from the IR remote. Keep the transmission path to

these sensors unobstructed for uninterrupted communications with the projector.

Alternatively, you can connect a wired version of the remote to the connector on the IMXB labeled

Wired Keypad.