Page 1

Quick Start Guide

020-101941-01

M Series

Page 2

NOTICES

COPYRIGHT AND TRADEMARKS

Copyright ©2015 Christie Digital Systems USA Inc. All rights reserved.

All brand names and product names are trademarks, registered trademarks or trade names of their respective holders.

GENERAL

Every effort has been made to ensure accuracy, however in some cases changes in the products or availability could occur which may not be reflected in this

document. Christie reserves the right to make changes to specifications at any time without notice. Performance specifications are typical, but may vary

depending on conditions beyond Christie's control such as maintenance of the product in proper working conditions. Performance specifications are based

on information available at the time of printing. Christie makes no warranty of any kind with regard to this material, including, but not limited to, implied

warranties of fitness for a particular purpose. Christie will not be liable for errors contained herein or for incidental or consequential damages in connection

with the performance or use of this material. Canadian manufacturing facility is ISO 9001 and 14001 certified.

WARRANTY

Products are warranted under Christie’s standard limited warranty, the complete details of which are available by contacting your Christie dealer or Christie.

In addition to the other limitations that may be specified in Christie’s standard limited warranty and, to the extent relevant or applicable to your product, the

warranty does not cover:

a. Problems or damage occurring during shipment, in either direction.

b. Projector lamps (See Christie’s separate lamp program policy).

c. Problems or damage caused by use of a projector lamp beyond the recommended lamp life, or use of a lamp other than a Christie lamp supplied by

Christie or an authorized distributor of Christie lamps.

d. Problems or damage caused by combination of a product with non-Christie equipment, such as distribution systems, cameras, DVD players, etc., or

use of a product with any non-Christie interface device.

e. Problems or damage caused by the use of any lamp, replacement part or component purchased or obtained from an unauthorized distributor of

Christie lamps, replacement parts or components including, without limitation, any distributor offering Christie lamps, replacement parts or

components through the internet (confirmation of authorized distributors may be obtained from Christie).

f. Problems or damage caused by misuse, improper power source, accident, fire, flood, lightening, earthquake or other natural disaster.

g. Problems or damage caused by improper installation/alignment, or by equipment modification, if by other than Christie service personnel or a Christie

authorized repair service provider.

h. Problems or damage caused by use of a product on a motion platform or other movable device where such product has not been designed, modified

or approved by Christie for such use.

i. Problems or damage caused by use of a projector in the presence of an oil-based fog machine or laser-based lighting that is unrelated to the projector.

j. For LCD projectors, the warranty period specified in the warranty applies only where the LCD projector is in “normal use” which means the LCD

projector is not used more than 8 hours a day, 5 days a week.

k. Except where the product is designed for outdoor use, problems or damage caused by use of the product outdoors unless such product is protected

from precipitation or other adverse weather or environmental conditions and the ambient temperature is within the recommended ambient

temperature set forth in the specifications for such product.

l. Image retention on LCD flat panels.

m.Defects caused by normal wear and tear or otherwise due to normal aging of a product.

The warranty does not apply to any product where the serial number has been removed or obliterated. The warranty also does not apply to any product

sold by a reseller to an end user outside of the country where the reseller is located unless (i) Christie has an office in the country where the end user is

located or (ii) the required international warranty fee has been paid.

The warranty does not obligate Christie to provide any on site warranty service at the product site location.

PREVENTATIVE MAINTENANCE

Preventative maintenance is an important part of the continued and proper operation of your product. Please see the Maintenance section for specific

maintenance items as they relate to your product. Failure to perform maintenance as required, and in accordance with the maintenance schedule specified

by Christie, will void the warranty.

REGULATORY

The product has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the product is operated in a commercial environment. The product generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of the product in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at the user’s own expense.

CAN ICES-3 (A) / NMB-3 (A)

이 기기는 업무용 (A 급 ) 으로 전자파적합등록을 한 기기이오니 판매자 또는 사용자는 이점을 주의하시기 바라며 , 가정 외의 지역에서 사용하는 것을 목적

으로 합니다 .

Environmental

Theproductisdesignedandmanufacturedwithhigh‐qualitymaterialsandcomponentsthatcanberecycledandreused.

This symbol meansthatelectricaland

electronicequipment,attheirend‐of‐life,shouldbedisposedofseparatelyfromregularwaste.Pleasedisposeoftheproductappropriatelyandaccordingtolocal

regulations.IntheEuropeanUnion,thereareseparatecollectionsystemsforusedelectricalandelectronicproducts.Pleasehelpustoconservetheen

vironmentwe

livein!

Page 3

Content

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Purchase record and service contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Projector models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

How the projector works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

User interface overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

List of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Key features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safety warnings and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

AC/power precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Lamp precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Installation and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing a projection lens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Positioning the projector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connecting a source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Connecting the line cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Powering on the projector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Selecting a source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Adjusting the image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting the projector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Ceiling mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Special mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Stacking projectors in a frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stacking multiple projectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Stacking alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Aligning the image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Aligning boresight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Powering down the projector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Projector communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pixel Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

M Series Quick Start Guide 3

020-101941-01 Rev. 1 (07-2015)

Page 4

Gamma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Grayscale/Color Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Color Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Input (Source Signal) Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Analog (Only) Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Twin HDMI Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Dual Link DVI Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Video Decoder Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Dual 3G/HD/SD-SDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DisplayPort Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Temperature/Humidity/Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Regulatory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Electro-Magnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

M Series Quick Start Guide 4

020-101941-01 Rev. 1 (07-2015)

Page 5

Introduction

This manual is intended for trained users operating professional high-brightness projection

systems. Such users may also be trained to replace the lamp and air filter, but cannot install the

projector or perform any service functions on the M Series projector.

Only Christie accredited technicians knowledgeable about all potential hazards associated with high

voltage, ultraviolet exposure and high temperatures generated by the lamp and associated circuits

are authorized to assemble/install the projector and perform service functions inside the projector.

Purchase record and service contacts

Whether the projector is under warranty or the warranty has expired, Christie’s highly trained and

extensive factory and dealer service network is always available to quickly diagnose and correct

projector malfunctions. Complete service manuals and updates are available for all projectors.

Should a problem be encountered with any part of the projector , contact your dealer. In most cases,

servicing is performed on site. If you have purchased the projector, fill out the information below

and keep with your records.

Dealer:

Dealer or Christie Sales/Service Contact Phone Number:

Projector Serial Number*:

Purchase Date:

Installation Date:

* The serial number can be found on the license label located on the back of the projector.

Default Gateway:

DNS Server:

Projector DLP Address:

Projector Mgmt IP Address:

Subnet Mask:

M Series Quick Start Guide 5

020-101941-01 Rev. 1 (07-2015)

Page 6

Introduction

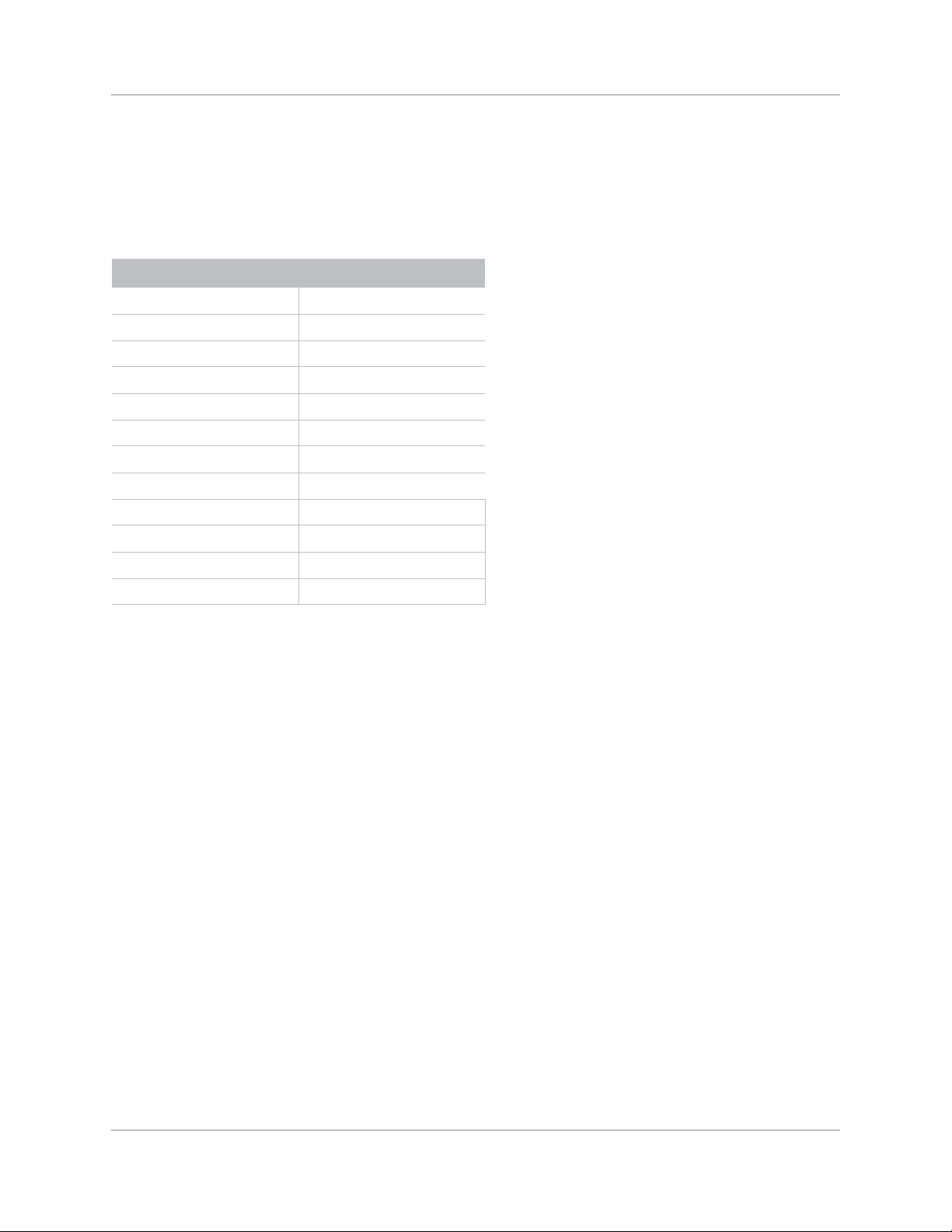

Projector models

The M Series is a family of high resolution video/graphics three chip 1080p HD, SXGA+, and

WUXGA projectors. These projectors are based on next generation DLP™ technology provided by

Texas Instruments.

Model name Part number

HD14K-M2 118-019101-xx

HD10K-M2 118-011103-xx

DS+14K-M2 118-010113-xx

DS+10K-M2 118-013105-xx

Roadster HD14K-M2 118-029102-XX

Roadster HD10K-M2 118-021104-XX

Roadster S+14K-M2 118-020114-XX

Roadster S+10K-M2 118-023106-XX

WU14K-M2 118-011114-XX

WU12K-M2 118-015107-XX

Roadster WU14K-M2 118-021115-XX

Roadster WU12K-M2 118-025108-XX

How the projector works

The projector accepts data/graphics and video input signals for projection onto front or rear

screens. Light is generated by dual mercury lamps, then modulated by three Digital Micro-mirror

Device (DMD) panels that provide digitized red, green or blue color information. Light from the

“ON” pixels of each panel is reflected, converged, and then projected to the screen through a single

front lens, where all pixels are perfectly superimposed as a sharp full-color image.

User interface overview

The projector is controlled through a menu system displayed on the image. The menu system is

controlled by an IR remote, wired remote, or through the built-in keypad. The LCD screen and

built-in keypad allow some functions to be controlled without the need of an OSD display, and

provide an accessible interface to view error reporting. The functions on the OSD can also be

controlled using the Christie Serial Protocol, through a serial or Ethernet connection to the

projector. The Web interface provides access to the menu system as a Virtual OSD (On-screen

display) and to features that maintain the software and settings.

List of components

Ensure the following components were received with the projector:

•IR remote keypad

M Series Quick Start Guide 6

020-101941-01 Rev. 1 (07-2015)

Page 7

•Line cord

• Lens Mount Security Screw (M6x10mm long, Qty. 2)

• Lens Mount Security Screw (5mm Hex, Qty. 1)

•Warranty Card

•Web Registration Form

Key features

• Up to 14,000 lumens

• HD (1080p), SXGA+, or WUXGA resolution

• Dual Mercury lamp illumination with 350W and 450W options

• Contrast aperture providing up to 10,000:1 contrast ratio (available on 350W models)

• Ultra-compact design and weighs less than 55lbs

• 10-bit image processor electronics with modular design

• Fully sealed optical system

Introduction

• Active fan control for minimum noise level

• Selectable, motorized Yellow Notch Filter for expanded color gamut

• User interchangeable projection lenses with no-tool mounting

• Picture-in-picture (PIP)

•LiteLOC for constant brightness maintenance

• Intelligent Lens System (ILS)

• Motorized lens mount for all models

• Auto-setup feature

•Integrated ChristieNET

• Networking ability through RS232 and RS422 connectors

• Status LED display on built-in keypad for easy projector status monitoring

• Control with remote keypad, wired remote, or built-in keypad

• Four input slots for Optional Input Modules

M Series Quick Start Guide 7

020-101941-01 Rev. 1 (07-2015)

Page 8

Safety warnings and guidelines

General Precautions

Danger! Failure to comply with the following results in death or serious injury.

• FIRE HAZARD. Keep hands, clothes and all combustible material away from the concentrated light

beam of the projector. Position all cables where they cannot contact hot surfaces or be pulled or

tripped over.

Warning! Failure to comply with the following could result in death or serious injury.

• All installation and maintenance procedures must be performed by a Christie qualified technician.

Warning! Failure to comply with the following could result in death or serious injury.

• Projector must be operated in an environment that meets operating specifications.

AC/power precautions

Warning! Failure to comply with the following could result in death or serious injury.

• Use only the AC power cord supplied. Do not attempt operation if the AC supply and cord are not

within the specified voltage and power r ange. See t he license label on the back of the projector

rated voltage and power.

Introduction

for

Warning! Failure to comply with the following could result in death or serious injury.

• The projector is equipped with a three-wire plug with a grounding pin. This is a safety feature. If

you are unable to insert the plug into t he outlet , contac t an elect rician to h ave the outle t replace d.

NEVER defeat the safety purpose of the grounding-type plug.

Warning! Failure to comply with the following could result in death or serious injury.

• Do not allow anything to rest on the power cord. Locate the power cord where persons walking on

it or objects rolling over it cannot damage the cord.

Lamp precautions

Warning! Failure to comply with the following could result in death or serious injury.

• Never attempt to access the lamp while th e lamp is ON. After turning the lamp OFF, it is crucial that

you wait at least 10 minutes before handling the lamp. This provides sufficient time for the lamp

cooling fans to properly cool the lamp.

M Series Quick Start Guide 8

020-101941-01 Rev. 1 (07-2015)

Page 9

Installation and Setup

LOCKING CLAMP

OPEN

This section explains how to install, connect, and optimize the projector for delivery of superior

image quality.

Installing a projection lens

The projection lens, shipped separately from the projector, must be installed prior to setting up the

projector.

Warning! Failure to comply with the following could result in death or serious injury.

• Remove the lens plug from the lens opening in the projector before installing the lens. Retain the

lens plug for projector transportation to protect the optical components from dust and debris.

Notice. Failure to comply with the following may result in property damage.

• The lens seals the projector, preventing contaminants from entering the interior of the projector.

Never operate a projector without a lens. Remove the rear lens cap from the lens. Keep the front

lens cap on the lens to protect it during installation.

• When installing the lens, ensure that the lens is not inserted at an angle, as this can cause

damage.

1. Rotate the lens clamp to the OPEN position, as shown.

2. Align the lens interface plate with the lens mount and align the lens electrical connector with

the mating connector on the lens mount.

M Series Quick Start Guide 9

020-101941-01 Rev. 1 (07-2015)

Page 10

Installation and Setup

3. Fully insert the assembly straight into the lens mount opening without turning and press with

your hand as shown.

4. While holding the lens flat against the lens mount, rotate the lens clamp clockwise to lock the

lens assembly in place.

5. Remove the front lens cap.

6. For added stability such as motion application, fasten the security screws provide with the lensmount.

7. Use a 5mm hex driver to fasten the red security screws provided with the lens mount, or hand

tighten the lens retaining screws attached to the lens. This is recommended for heaviest lenses

such as 0.73:1 and 1.2:1.

8. If the projector is hoisted or installed in an overhead position use the lens red security screws

or the lens retaining screws.

M Series Quick Start Guide 10

020-101941-01 Rev. 1 (07-2015)

Page 11

Installation and Setup

Positioning the projector

Warning! Failure to comply with the following could result in death or serious injury.

• Two people are required to safely lift and install the projector.

Place the projector on a sturdy, level surface and position it so that it is perpendicular to the screen

at a suitable distance. The further back the projector is positioned for the screen, the larger the

image will be.

To level the projector adjust its three feet. With the projector positioned perpendicular to the screen

the image will appear rectangular instead of keystoned.

Connecting a source

The input panel where all source connections are made, is located at the back of the projector . Each

input is clearly labeled for easy identification. Depending on the type of option card installed,

connect your source using the appropriate cable(s), as follows:

Option card Connection

Analog Input Card Connect three-, four-, or five-wire RGB source to Red/Pr, Green/Y, Blue/Pb, H/C

Dual 3G/HD/SD-SDI input card Connect the SDI (Serial Digital Interface) cable to one of the two i nputs, 1-IN or

Dual Link DVI input card Connect a single or dual DVI video signal to the DVI-I connector, an analog

Twin DHDMI input card Connect HDMI (High-Definition Multimedia Interface) cable to one of the two

Video Decoder input card Depending on the source you can apply the following;

DMX512 interface card Has two 5pin XLR connectors - one (input) male and one (output) female. If

TwinDisplay input card Accepts DisplayPort 1.1a inputs from one or two DisplayPort sources.

and V using three, four or five BNC connectors as required.

2-IN. Both standard-definition (SD) and high-definiti on (HD) signals are

accepted and automatically recognized on either input.

video signal to the DVI-I connector, or an analog video signal to the VGA

connector. The DVI signal may contain HDCP (High-Bandwidth Digital Content

Protection).

inputs, 1-IN or 2-IN.

• Composite video source to 1-CVBS, using a BNC Cable — the same signal can

be used on 4, 5, or 6 when input is selected as CVBS.

• A component signal on Inputs 4(Pr), 5(Y), 6(Pb) using BNC Connectors —

grouped as a component input, YPbPr,

• S-Video to one of the two, 2-SVID or three-SVID using S-Video cable.

• S-Video using two BNC cables, with Luma (Y) connected to 4 (Sy) and

Chroma (C) connected to 6 (Sc) — must be grouped as one S-Video + one

CVBS.

there is active communications on the DMX512 Interface card the power LED

will blink between low intensity and high intensity.

M Series Quick Start Guide 11

020-101941-01 Rev. 1 (07-2015)

Page 12

Installation and Setup

Connecting the line cord

Warning! Failure to comply with the following could result in death or serious injury.

• Do not attempt operation if the AC suppl y an d cor d is not within the specified ratings . Us e t h e l ine

cord provided with the projector, or ensure you are using a line cord, power plug, and socket that

meet the appropriate rating standards. Voltage and current requirements are listed on the license

label, located at the back of the projector.

• On power down, wait 5-10 minutes for the fans to turn OFF before unplugging the projector.

Always switch off the projector before unplugging the AC line cord.

1. Connect the projector line cord to the AC receptacle at the AC inlet of the projector.

2. Push the wire clip over the plug to retain it. This prevents the line cord from inadvertent

disconnection.

3. Plug the three-pronged plug end into a suitably rated grounded AC receptacle.

4. Switch the projector ON. The switch is located just above the AC receptacle.

Powering on the projector

After the AC Power has been switched on, the LCD display above the keypad indicates “Please wait”

and the four LED status indicators on the top cover window switch on to amber. These indicate that

the projector is changing its state from powered down to standby. The message “Standby Mode”

appears in the display when the projector has completed its initialization and is ready for power up.

The two lamp status LEDs go off to indicate that the lamps are off. The Power status LED shows

amber, indicating that the projector is in standby mode. The shutter LED displays amber, indicating

the shutter is closed. For a full description of the status indicator, see Status LEDs on page 20.

1. Press and hold the power button on the keypad or remote for two seconds, or press twice

quickly. The lamps power on and the fans will come on.

The default settings for the projector are to perform a lens calibration after the insertion of a new

lens. If this is the first time the projector has been powered up with the lens, expect a short period

(about 15 seconds) where the lens will move slightly.

Selecting a source

1. To select and display the image for the connected source, press one of the input keys on the

remote, or on the built-in keypad.

Adjusting the image

Adjust the image settings, such as Brightness, Contrast, Gamma, Focus, Zoom etc. using the direct

keys on the remote, or on the built-in keypad.

M Series Quick Start Guide 12

020-101941-01 Rev. 1 (07-2015)

Page 13

Installation and Setup

Mounting the projector

There are several methods for mounting the projector. In typical front and rear screen installations

the projector can be mounted to a secure and level surface, such as a table or cart. Carts are useful

when the projector has to be moved often. To prevent accidental movement during a presentation,

lock the wheels on the cart.

Ceiling mount

The projector can be inverted and suspended from the ceiling using a specially designed ceiling

mount fixture 118-100108-XX. This mounting is recommended for installations that want the

projector out of plain view or have limited amount of space for the projector. For more information,

contact your dealer.

Warning! Failure to comply with the following could result in death or serious injury.

• Use only the Christie approved ceiling mount kit designed for your projector.

Special mounting

The projector can also be rotated (front-to-back) up to 360 degrees and fixed in a rotated position

without affecting performance. However, to ensure optimal performance of the projector the sideto-side tilt limit of the projector must not exceed +/-15 degrees.

Stacking projectors in a frame

The M Series projectors can be stacked up to a maximum of three projectors high using the Christie

stacking frame (118-100107-XX).

1. Turn the projector OFF and disconnect the AC power cord after the cooling fans have stopped.

2. Make sure the base plate is flat.

3. Place the projector into the stacking frame from the top or from the front.

4. Prior to placing the projector from the front make sure the pitch is to its maximum.

5. Make sure the bottom base plate of the frame is aligned with the projector.

M Series Quick Start Guide 13

020-101941-01 Rev. 1 (07-2015)

Page 14

Installation and Setup

6. Use a 6 mm Allen key to tighten the six M8 bolts securing the base plate to the bottom of the

projector.

7. When flying projectors overhead use the M8 safety point.

Stacking multiple projectors

The projectors can be stacked and hoisted in either an upright or inverted positions. Remove the

locking pin from each stacking leg prior to alignment and ensure the four stacking legs are fully seated

on the lower stacking frame.

1. With one person positioned on each side of the stacking

frame, lift the top stacking frame onto the bottom stacking

frame, aligning all four stacking legs between the frames.

Warning! Failure to comply with the following could

result in death or serious injury.

• Failure to engage the locking pin may cause the

projectors to separate.

2. Insert the locking pin through the holes in the stacking legs.

Make sure each pin is fully inserted.

M Series Quick Start Guide 14

020-101941-01 Rev. 1 (07-2015)

Page 15

Installation and Setup

The steel ball on the end of the pin keeps the pin from releasing inadvertently.

Table 1.1

3. When required, repeat steps 1 and 2 for the additional projectors in the stack.

Stacking alignment

Stacked projectors must be correctly aligned to one another so the resulting display is optimized. If

hoisting the stack, do so first and then align.

1. Prior to aligning the image, turn the locking nut to unlock then use the knob to adjust the

image.

2. To align the image, use pitch, yaw, or roll.

Pitch: Move the image up and down.

Roll: Rotates the image clockwise and counter-clockwise.

Yaw: Moves the image left and right.

If the projector is parallel to the screen, some keystone will be introduced with Pitch and Yaw

adjustment.

3. Ensure to lock the locking nut to maintain the image adjustment.

M Series Quick Start Guide 15

020-101941-01 Rev. 1 (07-2015)

Page 16

Installation and Setup

Aligning the image

Only perform image alignment once the projector is fully assembled and powered up in its final

location. Basic image alignment ensures the image reflected from the DMDs is parallel and wellcentered with the lens and screen. This initial optical alignment is the foundation for optimizing

images on the screen and must be completed before final boresight adjustments. Before beginning,

make sure the projector is properly positioned in relation to the screen.

1. To display a test pattern press the Test key on the remote keypad or use the built-in keypad

and press the soft key that displays Test on the LCD display.

2. Select a pattern appropriate for analyzing image focus and geometry, such as the Grid test

pattern showing the cross-hair centered across the image.

3. Do a quick preliminary focus and (if available) zoom adjustment with the primary lens.

Do not worry about consistency across the image at this point, just center focus. It is good

practice to have zoom adjustment color and focus adjustment color in the center of its range.

4. Holding a piece of paper at the lens surface, adjust offsets as necessary until the image is

centered within the lens perimeter. A full white field works best for this.

5. If the projector is mounted off center to the screen axis, offset the lens as much as required.

Aim the projector over slightly towards the center of the screen, but use caution when doing so,

as too much tilt will cause excessive keystone distortion.

6. With the framing pattern on screen, double-check projector leveling so the top edge of the

image is parallel to the top edge of the screen.

7. Ensure the projector is positioned in the throw distance range for the particular lens.

Folded optics

In rear screen applications where space behind the projector is limited, a mirror may be used to

fold the optical path. The position of the projector and mirror must be accurately set. If considering

this type of installation call your dealer for assistance.

M Series Quick Start Guide 16

020-101941-01 Rev. 1 (07-2015)

Page 17

Aligning boresight

1. Display the boresight test pattern.

a. Pressing the Test key on the remote keypad or use the built-in k eypad and press the soft

key that displays Test on the LCD display.

b. Press the Up Arrow key to cycle to Boresight.

c. Press Enter.

2. Focus the image on cross-hair image I.

Installation and Setup

3. Evaluate the focus on cross-hair image II and III.

If all three images are in focus, no further action is required.

If boresight is required, continue to step 3.

The adjustment screws on the lens mount affect the corresponding cross-hairs on the test

pattern. The cap screw (B) may be under a plastic cap. Remove and retain before adjusting.

M Series Quick Start Guide 17

020-101941-01 Rev. 1 (07-2015)

Page 18

Installation and Setup

A

B

A

B

Capscrew

Setscrew

A

B

A

B

4. Use a 5 mm hex driver to loosen three setscrews (A) on the lens mount. The setscrews must be

backed out several turns to avoid contact with the inner lens mount plate.

Cross-Hair Pattern Screw Locations

5. Fine tune the focus of cross-hair pattern I by adjusting the appropriate cap screw. Adjust until

the cross-hair image is in focus with minimal flare.

6. Adjust cross-hair pattern II, by adjusting the appropriate cap screw

image is in focus with minimal flare.

7. Adjust cross-hair pattern III, by adjusting the appropriate cap screw. Adjust until the crosshair image is in focus with minimal flare.

8. Repeat step 5, 6, and 7 as required until all three cross-hair patterns are in equal sharp focus.

If the boresight is acceptable, proceed with step 11.

If the boresight does not appear to be converging to an acceptable level of image quality, or if

the lens will not focus over the correct range of throw distances, proceed with step 9.

. Adjust until the cross-hair

M Series Quick Start Guide 18

020-101941-01 Rev. 1 (07-2015)

Page 19

Installation and Setup

9. The original factory boresight can be approximately recovered, by positioning the three

setscrews flush with the front face of the lens mount plate, and in contact with the inner lens

mount plate. This may require adjusting both setscrews and cap screws.

10. If further action is required. Repeat step 2.

11. Lock the setscrews, and re-check the boresight quality. Tighten the setscrew enough to ensure

they will not shift.

Powering down the projector

The projector can be powered down by using one of the following methods:

Remote keypad/built-in keypad

• Press and hold Power.

or

• Press Power twice.

or

• Press Power once, then immediately press the Down key.

If the second key is not pressed immediately, a confirmation window appears. The second key

must be pressed within one second of the window appearing.

After powering down, the Status LEDs will cycle, and the LCD displays the message “Cooling Down”

until cool down is complete.

Web user interface (UI)

1. From the Main tab, select Power > OFF.

2. Select Yes.

M Series Quick Start Guide 19

020-101941-01 Rev. 1 (07-2015)

Page 20

Installation and Setup

Projector communications

Status LEDs

Looking from the back of the projector, the LEDs represent, from left to right; Lamp 1, Lamp 2,

Power, and Status. The LEDs display the colors as shown below:

Projector states LEDS LED state

Hard Boot All All LEDs amber - means please wait

Standby Mode Lamps 1 and 2 Off—lamps are off

Power Amber—AC is present but projector is off or

standby

Shutter Green—shutter is open

Amber—shutter is closed

Warm-up (Powering ON from standby) All LEDs cycle green from left to right

Normal Operation Lamp 1 and 2 Amber—lamp time has expired and lamp

Power Green—projector is powered up and

Shutter Green—shutter is open

Cool-down All LEDS cycle from left to right

Error Lamp 1 and 2 Amber—lamp time has expired and lamp

Power Flashing Red—error has occurred. Details

Software Upgrade in progress All The pattern will alternate between:

Lamp Regeneration in progress Lamp 1 and 2 Flashing Green—the lamp is being switched

Power Green—on

Shutter Green—shutter is open

should be replace

operating normally

Amber—shutter is closed

should be replaced

Flashing Red—lamp has expired and lamp

should be replaced

are display on the status display.

Amber and Off

off for its regeneration period to extend lamp

life (typically 15 minutes every 24 hours)

Amber—standby

M Series Quick Start Guide 20

020-101941-01 Rev. 1 (07-2015)

Page 21

Installation and Setup

Projector states LEDS LED state

Note: A condition occurs on the first power on after a software upgrade, and is indicated by all the following:

• The Status LEDS are cycling green

• The LCD displays the warning Image Processor Upgrading

• The LED on the Image Processor card flashes green

• The web page shows a warning that the Image processor card is upgrading

• When this occurs, the projector should not be AC power cycled and the Image Processor card should not be

removed

M Series Quick Start Guide 21

020-101941-01 Rev. 1 (07-2015)

Page 22

Specifications

Specifications

This section provides detailed projector specifications. Due to continuing research, detailed features

are subject to change without notice.

Pixel Format

1080p (H x V square pixels) 1920 x 1080

SXGA+ (H x V square pixels) 1400 x 1050

WUXGA (H x V square pixels) 1920 x 1200

Contrast

ANSI: 16 pt. checker pattern on black screen 650:1 typical

Full field: 9 pt. average ON/OFF with background light

subtraction

2500:1 typical (full open aperture) 1080p

2100:1 typical (full open aperture) SXGA+

2100:1 typical (full open aperture) WUXGA

Gamma

Default Gamma (all points from 10 to 90 IRE) 2.2 + linear segment

Adjustable Gamma range 1.0 to 3.0

Grayscale/Color Resolution

Resolution 10 bits (non-linear) min. (Gamma encoded)

M Series Quick Start Guide 22

020-101941-01 Rev. 1 (07-2015)

Page 23

Color Temperature

White Default CCT (without YNF) 7700 K ±2000 K 350W, 450W Lamp

White YNF CCT (with YNF activation, electronically

corrected)

Range of Adjustment 3200 K - 9300 K

6500 K ±1000 K

Specifications

Tracking (deviation from normal over full range from 10

to 100 IRE)

Stability (during rated lamp life) ±500 K max

±500 K max

Input (Source Signal) Compatibility

Analog (Only) Input

Connectors five female BNC, 75 Ohm

R/Pr

G/Y

B/Pb

H/C

V

Color spaces/signal types RGB

YPbPr

A/D conversion 10 bits

Twin HDMI Input

Connectors Two independent HDMI inputs type A

Two loop-out connectors type A

Color spaces/signal types RGB

YCbCr (4:2:2)

YCbCr (4:4:4)

HDCP support

HDMI 1.3 supported (not including audio) except: 12-bit color dithered to 10

bits; 16 bit color not supported

M Series Quick Start Guide 23

020-101941-01 Rev. 1 (07-2015)

Page 24

Dual Link DVI Input

Connectors One dual link DVI-I

One analog 15-pin VGA

Color spaces/signal types HDCP support

A/D conversion 10 bits for single link DVI input

8 bits for dual link DVI inputs

Frequency 165 Megapixels/s analog

Video Decoder Input

Connectors Two S-Video 4-pin miniature DIN

Four BNC, 75 Ohm

Two independent decoder channels for PIP

Color spaces/signal types Composite video

Component video (SD and ED only)

S-video

A/D conversion 10 bits

Video Standards NTSC, NTSC 4.43, PAL, PAL M, PAL N, PAL 60, SECAM

Specifications

Dual 3G/HD/SD-SDI

Connectors BNC, 75 Ohm

Color spaces/signal types Dual HD input

SDI, HD-SDI, 3G-SDI

DisplayPort Input

Connectors Two independent DisplayPort inputs

Two loop-out DisplayPort connectors

Color spaces/signal types RGB

YCbCr (4:2:2)

YCbCr (4:4:4)

HDCP support on inputs

DisplayPort 1.1a supported (not including audio)

M Series Quick Start Guide 24

020-101941-01 Rev. 1 (07-2015)

Page 25

Power Requirements

Rated voltage 100 VAC – 240 VAC

Rated Current (dual lamp

operation)

450W 1080p / SXGA+ / WUXGA 15 A @ 100 VAC

370W 1080p / SXGA+ / WUXGA 12 A @ 100 VAC

Line frequency 50/60 Hz

AC Input Coupler 15 A, 250 VAC

Type of connector IEC 320-C14 with wire cable clamp

Line Cord 14AWG type FT1 with plug, NEMA 5-15P, 15A

Inrush Current 60 A max

Specifications

Maximum Power Consumption Dual Lamp

1080p / SXGA+ / WUXGA 1500W (dual lamp) / 750W (single lamp)

1080p / SXGA+ / WUXGA 1320W (dual lamp) / 831W (single lamp)

1080p / SXGA+ / WUXGA 1267W (dual lamp) / 805W (single lamp)

1080p / SXGA+ / WUXGA 1135W (dual lamp) / 739W (single lamp)

1080p / SXGA+ / WUXGA 871W (dual lamp) / 607W (single lamp)

1080p / SXGA+ / WUXGA 739W (dual lamp) / 541W (single lamp)

Physical Specifications

Size

Maximum product dimensions (L x W x H)

(with lens removed)

Maximum shipping dimensions (L x W x H) 775 x 698.5 x 584 (mm)

561 x 500 x 247 (mm)

22.1 x 19.7 x 9.75 (inches)

30.5 x 27.5 x 23 (inches)

Weight

Maximum product weight

(with lens removed)

M Series Quick Start Guide 25

020-101941-01 Rev. 1 (07-2015)

25 kg (55 lb.)

Page 26

Specifications

Maximum shipping weight

(includes packaging)

40 kg (87 lb.)

Environment

Temperature/Humidity/Altitude

Operating temperature range 5 to 40ºC (41 to 104ºF)

Storage temperature range -40 to 70ºC

Humidity range 10% to 80%, non condensing

Operating Altitude 10,000 ft. maximum

Regulatory

Safety

• CAN/CSA C22.2 No. 60950-1

• UL 60950-1

• IEC 60950-1

• EN60950

Electro-Magnetic Compatibility

Emissions

• FCC CFR47, Part 15, Subpart B, Class A - Unintentional Radiators

• CISPR 22/EN55022 Class A - Information Technology Equipment

Immunity

• CISPR 24/EN55024 Class A - Information Technology Equipment

Environmental

The product must conform to:

• EU Directive (2011/65/EU) on the restriction of the use of certain hazardous substances (RoHS)

in electrical and electronic equipment and the applicable official amendment(s).

• EU Regulation (EC) No. 1907/2006 on the registration, evaluation, authorization and restriction

of chemicals (REACH) and the applicable official amendments.

M Series Quick Start Guide 26

020-101941-01 Rev. 1 (07-2015)

Page 27

Specifications

• EU Directive (2012/19/EU) on waste and electrical and electronic equipment (WEEE) and the

applicable official amendment(s).

• China Ministry of Information Industry Order No.39 (02/2006) on the control of pollution

caused by electronic information products, the hazardous substances concentration limits (SJ/

T11363-2006), and the applicable product marking requirement (SJ/T11364-2006).

Marking

This product shall conform to all relevant Canadian, US, and European directives, standards, safety,

health and environmental concerns and bare the following markings at product launch:

•UL

•CE

•RoHS

•WEEE

• Future International Certifications to include: CCC, KC, PSE, c-tick, CU, South Africa, Saudi

Arabia, and India

International packaging recycling mark requirements:

• EU Directive (2002/96/EC) on waste and electrical and electronic equipment (WEEE);

• EU Directive (94/62/EC) on packaging and packaging waste;

China packaging recycling mark standard (GB18455-2001).

M Series Quick Start Guide 27

020-101941-01 Rev. 1 (07-2015)

Page 28

For the most current technical documentation, please visit www.christiedigital.com

United Kingdom

ph: +44 (0) 118 977 8000

United Arab Emirates

ph: +971 4 3206688

Spain

ph: +34 91 633 9990

Singapore

ph: +65 6877-8737

Republic of South Africa

ph: +27 (0)11 510 0094

Korea (Seoul)

ph: +82 2 702 1601

Japan (Tokyo)

ph: 81 3 3599 7481

India

ph: +91 (080) 6708 9999

Germany

ph: +49 2161 664540

France

ph: +33 (0) 1 41 21 44 04

Eastern Europe and

Russian Federation

ph: +36 (0) 1 47 48 100

China (Shanghai)

ph: +86 21 6278 7708

China (Beijing)

ph: +86 10 6561 0240

Brazil

ph: +55 (11) 2548 4753

Australia

ph: +61 (0) 7 3624 4888

Worldwide offi ces

Italy

ph: +39 (0) 2 9902 1161

Consultant offi ces

Canada – Kitchener

ph: 519-744-8005

USA – Cypress

ph: 714-236-8610

Corporate offi ces

Loading...

Loading...